Hoshizaki IM-500SAA User Manual

AM SERVICE TRAINING

Featuring the

IM-500SAA

80047 |

9/10/13 |

2

All IM models have similar sequence of operation. This manual is designed as a generic IM Training manual.

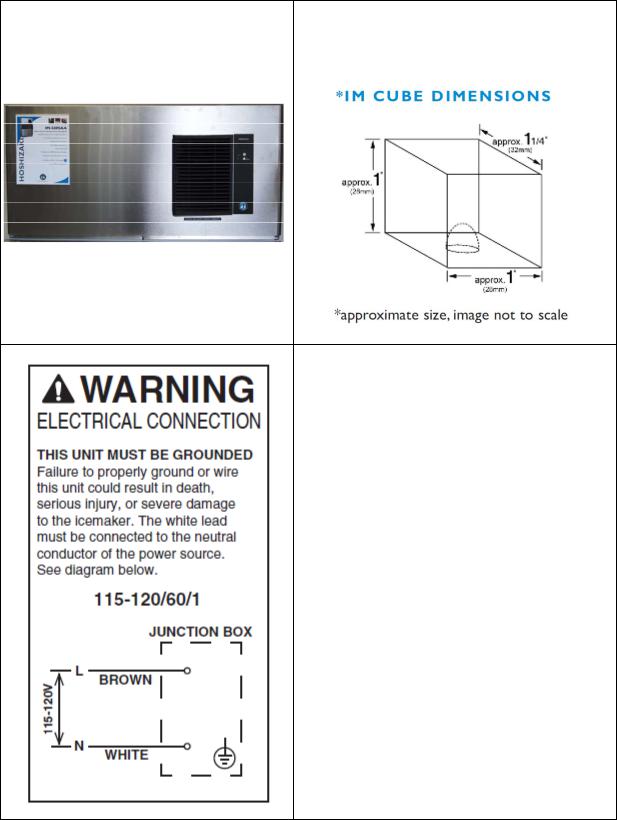

The Hoshizaki IM series ice machine uses a horizontal evaporator design which forms a square cube shape with a small dimple. 20mm

A standard 120-volt power cord (field supplied) provides the electrical connection. The unit is designed to operate on a separate 20-amp circuit.

The water supply connection is 1/2” FPT fitting and is located at the top right side of the unit. A minimum 1/4” water line is required for proper operation.

The drain connection is 3/4” FPT fitting located on the right rear of the unit. A standard 3/4” MPT fitting can be used to connect this drain.

3

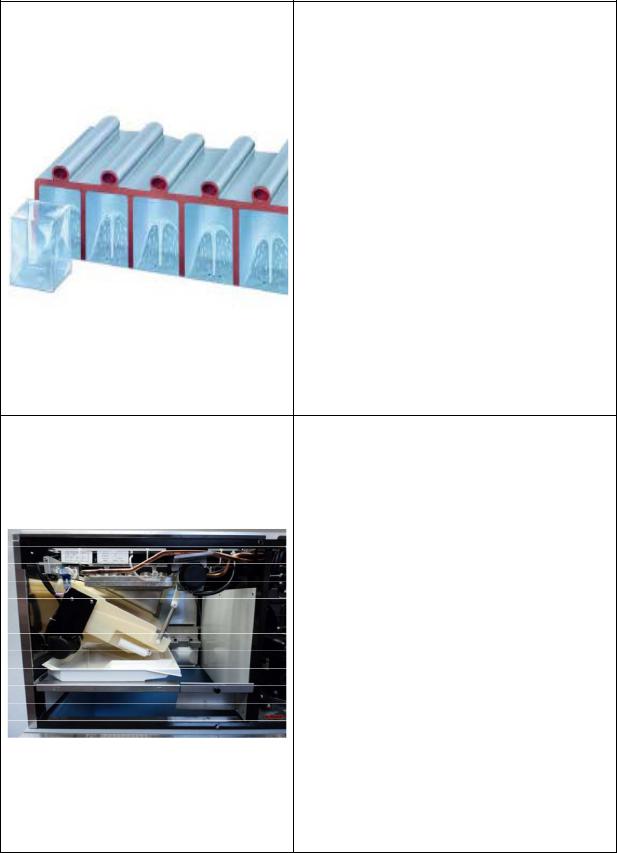

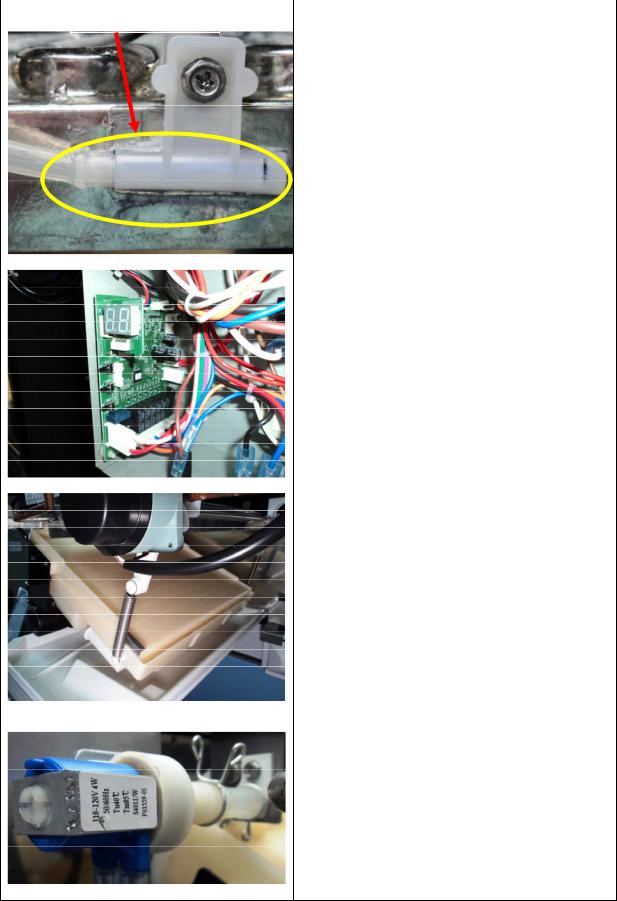

The ABS water plate sprays water up into the evaporator cells to form the square IM cube.

The moveable water pan assembly includes the water plate, reservoir pan, and pump motor assembly.

Tension springs connect two cam arms to the water plate assembly. An actuator motor rotates the cam arms to raise and lower the water pan during the ice making cycle.

4

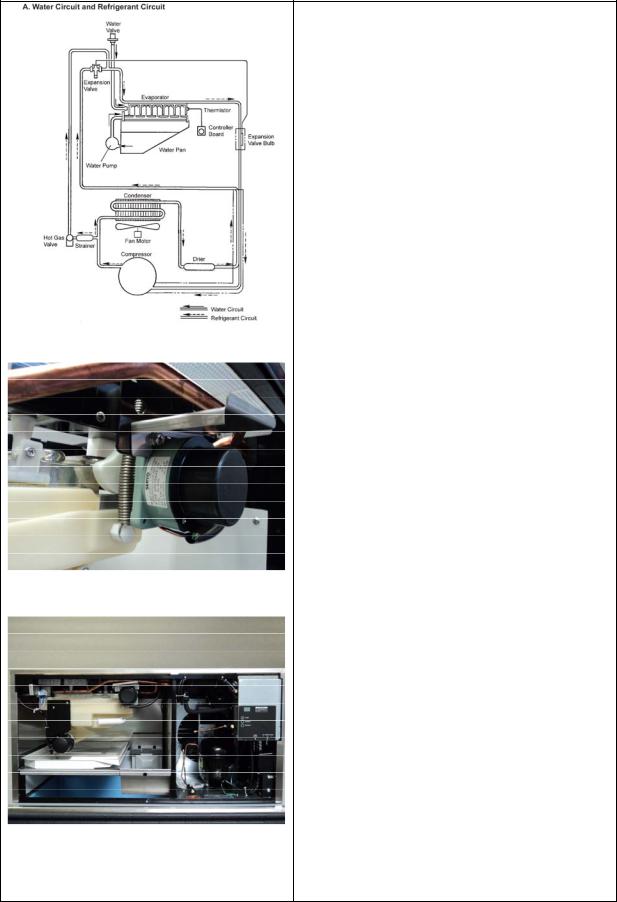

The horizontal evaporator and water distribution system are unique to the Hoshizaki IM series. The IM-500 makes ice on a horizontal evaporator and uses R-404a refrigerant.

The IM-500SSA sequence of operation will be explained in the following pages.

5

|

|

The |

IM-500SAA |

unit |

uses |

a |

|

|

Thermistor |

||||||

|

combination thermistor and |

control |

|||||

|

|

||||||

|

|

board to control the sequence of |

|||||

|

|

operation. |

|

|

|

|

|

|

|

SOFT START: |

|

|

|

|

|

|

|

When the toggle switch is placed in the |

|||||

|

|

“ON” position and the bin control calls |

|||||

|

|

for ice, the unit will begin in the soft |

|||||

|

|

start the display will say “on” and the |

|||||

|

|

hot gas valve will open after 30 seconds |

|||||

|

|

the initial harvest cycle begins,(if the |

|||||

|

|

reset switch is pressed during the 30 sec. |

|||||

|

|

standby time the unit will skip soft start |

|||||

|

|

and immediately starts operation). |

|||||

|

|

Starting the unit in harvest allows the |

|||||

|

|

compressor to start up in basically an |

|||||

|

|

unloaded condition, |

greatly |

extending |

|||

|

|

the life of the compressor. |

|

This |

|||

|

|

operation is common among all |

|||||

|

|

Hoshizaki cube icemakers. |

|

|

|

||

WATER PAN OPENS/HARVEST:

During the initial harvest, the compressor, hot gas valve and the actuator motor starts to open, after 20 seconds the water valve will energize to supply defrosting water for a specified time. (The time varies depending on the incoming water temperature above or below 48ºF(9ºC) also in initial cycle the water temp. is not detected and assumed to be below 48ºF (9ºC) resulting in a longer defrosting water supply time.

The opening backup timer starts counting when the water pan starts to open if the hall IC (magnetic switch) does not turn on within 3 min. the display will show “EE” and the unit stops for 60 minutes, if it reoccurs after the unit resumes display will show “EE” and the unit shuts down and (records as “E3” in the error history.

6

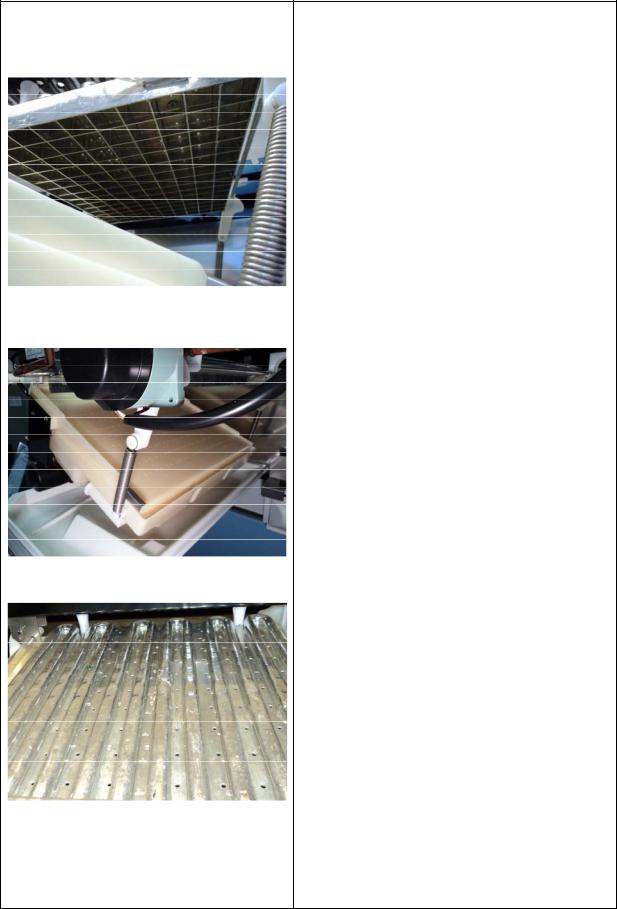

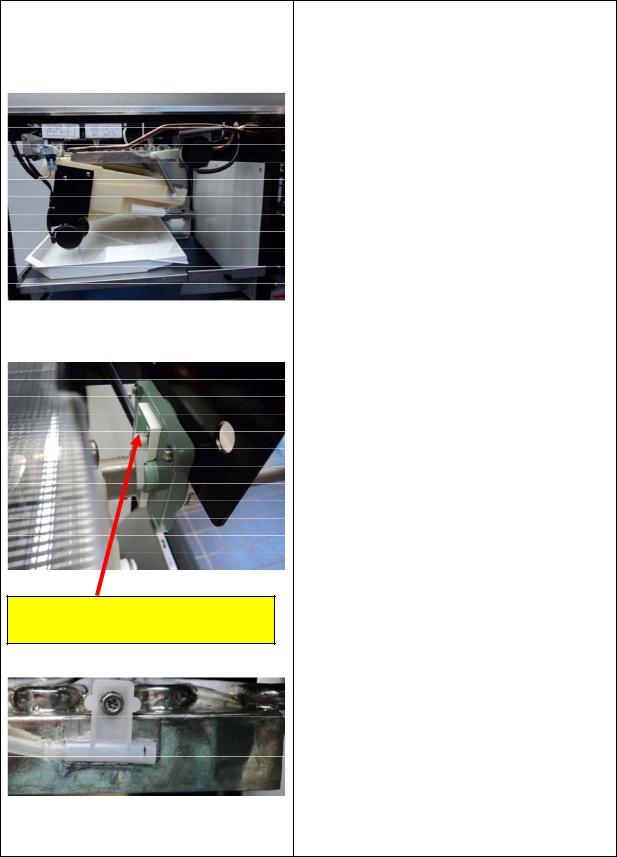

Hall IC Switch is located on the motor backside. (Magnetic Switch)

As soon as the pan starts to open the defrost backup timer starts, if the thermistor mounted on the evaporator does not reach the defrost completion temperature before the timer times out at 30 min. the display will show “E2” and the unit stops. (if the HGV does not open this could also give you an “E2” error)

The harvest cycle is controlled by thermistor when the defrost completion temperature of 18.5º C or more is reached the HGV closes, the fan motor starts, and the water pan starts closing.

As before there is a timer that starts as soon as the water pan starts to close. If the hall IC (magnetic Switch) does not turn on within 3 min. the machine will stop and give a “EE” error and the machine shuts down for 60 minutes if the error reoccurs after restart the unit will shut down again and again shows “EE” (recorded as ‘E4” in the error history).

NOTE: in the initial cycle or when the water is below 48º F (9ºC), the water valve will open to supply defrosting water for 10 second after the water pan starts to close.

To check the resistance between thermistor leads, follow the steps below.

1)Disconnect the connector CN13 on the board.

2)Remove the screw and the thermistor holder on the evaporator.

3)Immerse the sensor part in a glass containing ice and water for 2 or 3 minutes.

4)Check the resistance between thermistor leads. Normal reading is within 5 to 7 kΩ

Replace the thermistor if it is outside the normal reading.

7

WATER PAN CLOSES/FREEZE:

When the water pan closes and the hall IC turns on the water valve opens to supply ice making water for a specific time. The supply time varies between startup, reset, and end of bin control cycle between partial flush and full drain.

NOTE Full drain flush: After a freeze cycle ends the unit drains all remaining water out of the tank and refills for the next freeze cycle.

Partial drain flush: (default setting)

After a freeze cycle ends, the unit leaves remaining water in tank and adds water for the next cycle.

After water has been supplied the pump motor starts, after 30 seconds the thermistor senses the temperature that will be added with a predetermined offset value and used as the water temperature for the freeze cycle, pan opening, defrost, and pan closing cycle. The freeze cycle is considered to be 100% complete when the predetermined target and the integrated values are reached. To reduce ice forming on the water pan when the freeze completion rate reaches 100% with an ambient temperature below 86º F (30ºC), the hot gas valve opens and closes two times to raise the water pan temperature and the actuator motor starts to open the water pan. The freeze cycle is not considered complete and the pump motor and fan motor continue. The unit will continue to cycle between freeze and harvest until the bin control opens, signaling a full bin or until power is interrupted

8

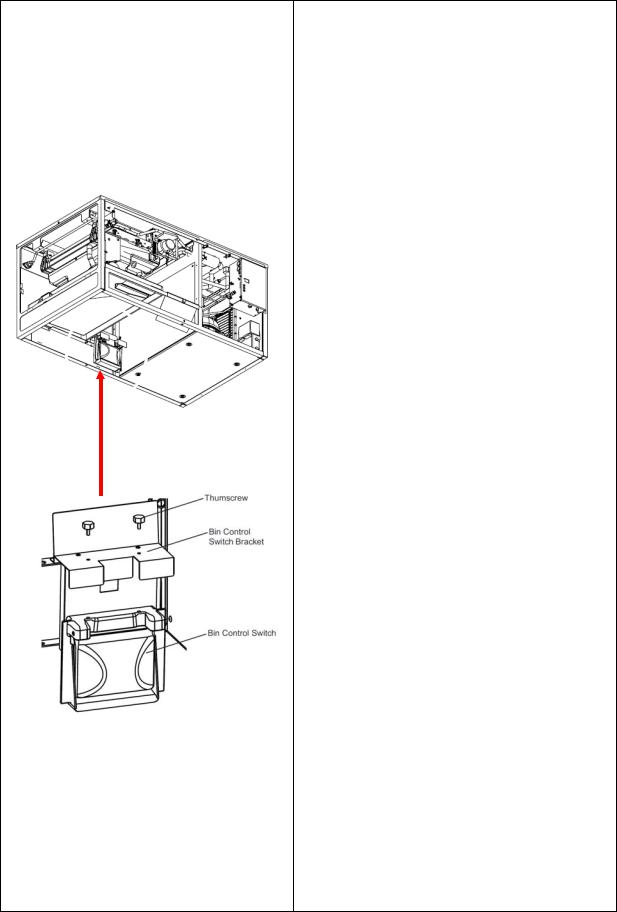

The IM-500SAA uses a mechanical bin control located on the right rear side of the ice drop zone. This control will open when ice pushes against the switch, if the switch stays open for more than 10 seconds the machine will start the bin control cycle, starts and the machine will shut down after the next defrost cycle.

After the bin control stays closed for more than 80 seconds the bin control cycle will end and the machine will restart.(the hot gas valve opens 30 seconds before the icemaker restarts)

After the bin control cycle ends (or when the power supply is turned on), the water pan starts to open.

When the water pan opens and the hall IC turns on, the bin control cycle starts after 10 seconds and the ice maker stops.

.

Loading...

Loading...