Page 1

Security Label Applier

Operator Manual

Model

SLA-1, SLA-2 ML-44180

SLA-2A ML-44197

SLA-3 ML-44192

701 S. RIDGE AVENUE

TROY, OHIO 45374

937 332-3000

www.hobartcorp.com

© HOBART 2006 F33995 (Rev. A, 6/06)

Page 2

Security Label Applier (SLA)

SAVE THESE INSTRUCTIONS

Note

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential

area is likely to cause harmful interference; in which case, the

user will be required to correct the interference at his own

expense.

CAUTION — Look At This

To provide continued protection against risk of electric shock,

connect to properly grounded outlets only.

F33995 (Rev. A, 6/06) Page 2 of 12 © HOBART 2006

Page 3

Security Label Applier

The Security Label Applier (SLA) is designed to apply an

Electronic Article Surveillance (EAS) label to a standard Ultima

scale label. The SLA works in conjunction with an Ultima (with

remote keypad) and an Ultima Wrapping System (UWS),

Compact Label Applier (CLA) or Indexing Label Applier (ILA).

As a label is printed and expelled from the Ultima Printer, the

SLA attaches a security label to the adhesive side of the

merchandising label. The UWS, CLA or ILA then places the

label on the package. As the label’s barcode is scanned, the

security label is deactivated by the security provider’s

(Checkpoint or Sensormatic) equipment and will not be

detected by the store security system.

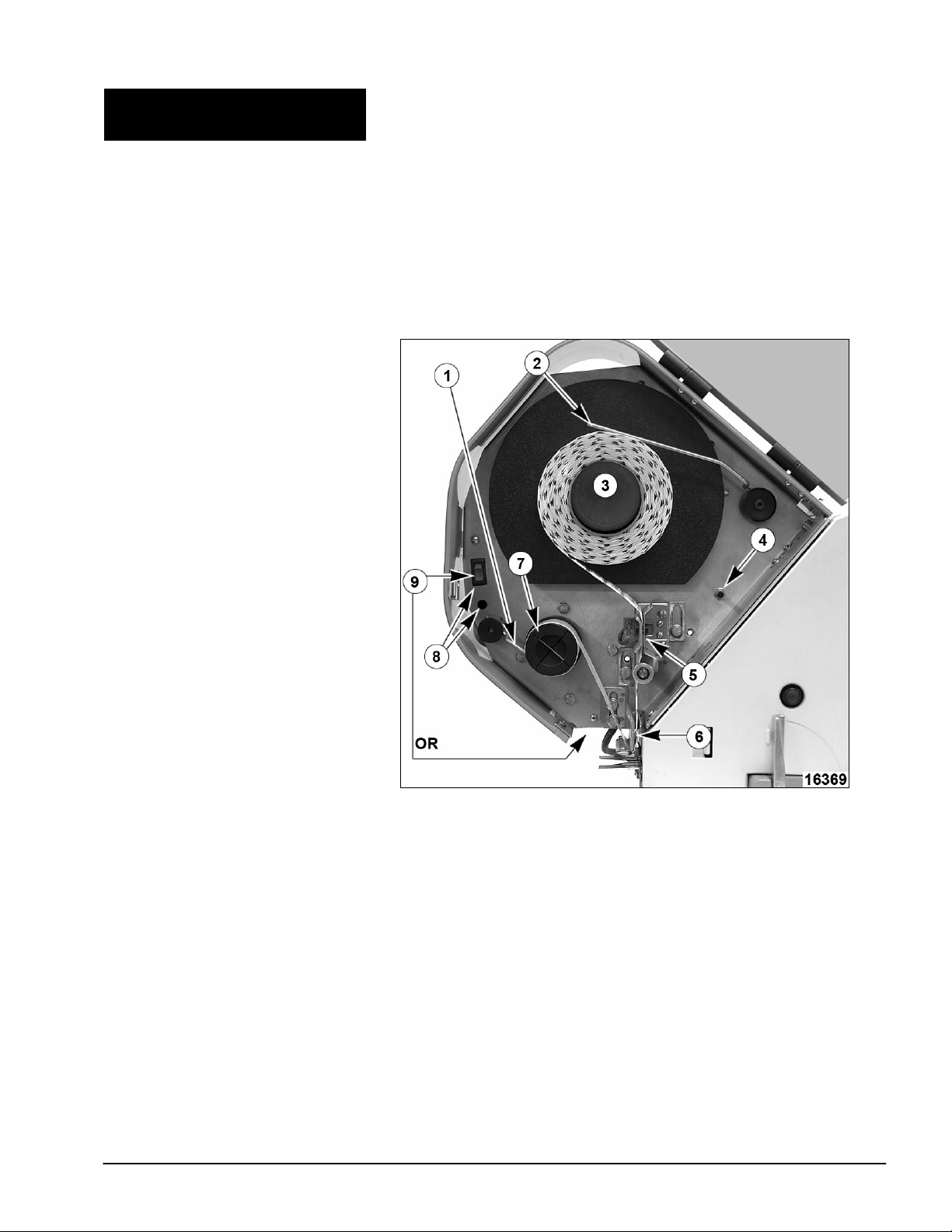

1. Dwell arm 6. Peel bar

2. Tension arm 7. Take up spool

3. Label hub 8. Power on indicator

4. Label eject switch 9. ON/OFF power switch

5. Label sensor assembly

© HOBART 2006 Page 3 of 12 F33995 (Rev. A, 6/06)

Page 4

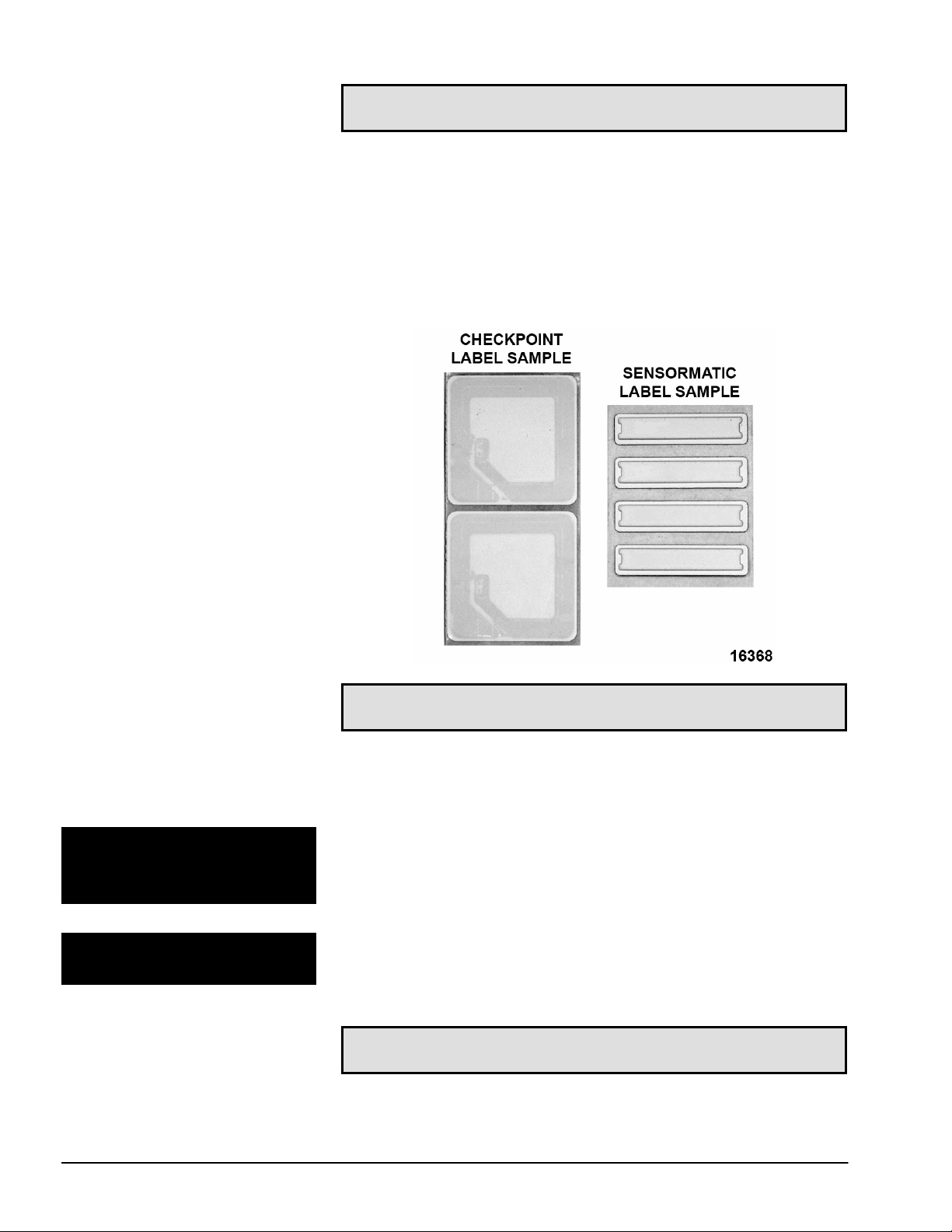

Note

There are two types of security labels available. Depending on

If used with an HWS or NSW Semi Automatic System, the

security label is automatically placed on the Ultima scale label.

The Operator then hand applies the labels to the package.

your store security system, you will either use the Checkpoint

label (similar in size to the safe handling label) or the

Sensormatic label (similar to what is used with audio CDs).

Note

Powering Up/Powering Down

Setting Up the SLA

F33995 (Rev. A, 6/06) Page 4 of 12 © HOBART 2006

For label ordering information, contact your security system

provider.

Power runs to the SLA through a standard 110 VAC electrical

connection. Flip the switch located inside the unit or lower front

to power up/down.

The SLA can determine which packages receive a security label

by Minimum Unit Price, Minimum Total Price and/or PLU

number.

Note

Early model SLA was only configurable for minimum Unit Price.

Page 5

1. At the Ultima Keypad, PRESS [SUPER MENU ON/OFF]. If

applicable, enter your Secret ID. The Supervisor Menu

displays.

2. PRESS [F5] to select Scale Setup Menu.

3. PRESS [F3] to select Labels Menu.

4. PRESS [F6] to select Security Labels.

© HOBART 2006 Page 5 of 12 F33995 (Rev. A, 6/06)

Page 6

5. From the Security Labels screen, enter the minimum Unit

Price and/or the minimum Total Price. A security label will be

applied to any package with a Unit Price and/or Total Price

that is the same as or higher than the amounts entered. If

the Unit Price and Total Price are lower than the entered

prices, the security label will not be applied.

6. PRESS [ESC] to return to the Start a Run screen.

To set up the SLA to apply a label by PLU:

1. At the Ultima Keypad, PRESS [SUPER MENU ON/OFF]. If

applicable, enter your Secret ID. The Supervisor Menu

displays.

2. Use the numeric keypad to enter 10 in the Function code

box and PRESS [ENTER].

F33995 (Rev. A, 6/06) Page 6 of 12 © HOBART 2006

Page 7

3. Use the numeric keypad to enter PLU number in the Product

number and PRESS [ENTER].

4. PRESS [F2] to select Apply Security Label.

5. PRESS [ESC] to return to the Start a Run screen.

Once set up, the SLA runs with minimal operator intervention.

Operating the SLA

The labels are automatically generated, combined and placed

on the appropriate package.

The SLA contains a label sensor to alert the operator when out

of labels or when labels are not advancing. When the sensor

does not find a label edge in 5 seconds, the message Out of

Security Labels displays on the Ultima console and a beep

sounds to alert the operator.

Note

If used with an HSW or NSW Semi Automatic System, the

security label is automatically placed on the scale label, but the

Operator must hand apply the labels to the package.

© HOBART 2006 Page 7 of 12 F33995 (Rev. A, 6/06)

Page 8

Loading Labels

The SLA contains a label sensor to alert the operator when out

of labels or when labels are not advancing. When applicable,

the message Out of Security Labels displays on the Ultima

console and a beep sounds to alert the operator. Although,

when out of security labels, the Ultima merchandising labels

continue to print. You may also receive this message if the SLA

is turned off, but you are still operating the Ultima printer.

Refer to the following procedures and diagrams to correctly load

labels. Be sure the SLA is powered off when loading labels.

Note

If applicable, remove the backing paper from the take-up spool

and label core from the label hub before you begin loading.

To load labels:

1. Open the SLA label supply door.

2. Turn off power at ON/OFF power switch.

3. Place the roll of labels on the label hub.

4. If the label roll does not have a leader, strip approximately

12” of labels off the backing paper to create a leader.

5. Thread the leader between the label sensor guide and the

label guide as shown in Fig 1 and 2. On the early model

SLA, thread the leader between the label sensor guide and

the 2 guide pins as shown in Fig 3 and 4.

6. Continue threading the leader past the label guide pin as

shown in Fig 1-4.

7. For Sensormatic labels, the leader should be threaded

between the stripper plate and the stripper guide plate. Loop

the end of the leader and thread through the slit in the

stripper plate as shown in Fig 2 or Fig 4. For Checkpoint

labels, the leader should be threaded around the stripper

plate as shown in Fig 1 or Fig 3.

8. Thread the leader thru the slots of the take-up spool. Wrap

the leader counterclockwise around the take-up spool as

shown in Fig 1-4.

9. Turn the take-up spool counterclockwise a few times to be

sure the backing paper winds securely.

10. Turn on power at ON/OFF power switch.

11. Press label eject switch to position the label so that it is

visible below the edge of the stripper plate. This may require

the label eject switch to be pressed several times.

12. Close the SLA label supply door.

F33995 (Rev. A, 6/06) Page 8 of 12 © HOBART 2006

Page 9

Fig 1 Fig 2

Fig 3 Fig 4

© HOBART 2006 Page 9 of 12 F33995 (Rev. A, 6/06)

Page 10

Cleaning and Maintaining

Maintain the SLA by regularly cleaning the paper dust from

inside the unit. Clean the SLA exterior surfaces with a cloth and

warm water/detergent solution. When cleaning, be sure to

protect the unit from direct water entry.

To clean the SLA:

1. Dampen a soft cloth with mild detergent and water.

2. Wipe the exterior surfaces.

Note

Remove any adhered labels with an alcohol soaked cloth. Do

not use metal to scrape the labels or adhesive off of the unit.

Troubleshooting

DISPLAY PROMPTS POSSIBLE CAUSES/REMIDIES

1. Out of security labels. Load security

labels or press escape to continue.

2. Verify labels threaded correctly.

3. SLA power switch is OFF.

4. Check power cord and power source.

5. Call local Hobart Office.

SYMPTOMS POSSIBLE CAUSES/REMIDIES

Power ON indicator is not illuminated and unit will

not function.

1. SLA power switch is OFF.

2. Check power cord and power source.

3. Call local Hobart Office.

Power ON indicator is illuminated and will not

issue label (motor does not run).

Issue label only when manual eject button is

pressed.

1. Call local Hobart Office.

1. Minimum Unit Price or minimum Total

Price is set too high in the Security label

setup and/or apply by PLU is not

configured correctly in Change Product

screen in Supervisor.

2. Call local Hobart office.

Label does not peel off of backing paper.

1. Verify labels threaded correctly.

2. Call local Hobart office.

F33995 (Rev. A, 6/06) Page 10 of 12 © HOBART 2006

Page 11

SYMPTOMS POSSIBLE CAUSES/REMIDIES

Multiple labels are issued followed by an

audible beeping sound.

No label is issued followed by an audible

beeping sound

.

1. Verify labels threaded correctly.

2. Call local Hobart office.

1. Out of security labels.

2. Missing security labels on backing paper.

3. Verify labels threaded correctly.

4. Call local Hobart Office.

Security label placement on Ultima label is

incorrect.

1. Verify that dwell control lever is resting

against the backing paper on the take-up

spool.

2. Verify labels threaded correctly.

3. Call local Hobart office.

© HOBART 2006 Page 11 of 12 F33995 (Rev. A, 6/06)

Page 12

© HOBART 2006 F33995 (Rev. A, 6/06)

Loading...

Loading...