N

S

T

R

U

C

T

I

O

N

S

I

MODEL SWS40 WATER SUPPLY SYSTEM

SWS40 ML-110639

WORLD HEADQUARTERS

701 RIDGE AVENUE

TROY, OHIO 45374-0001

FORM 33716, Rev. A (11-96)

INSTALLATION INSTRUCTIONS

MODEL SWS40 WATER SUPPLY SYSTEM

SAVE THESE INSTRUCTIONS

Your Hobart SWS40 Water Supply System pumps water from the dishwasher prewash tank to the WS800 or

WS1000 waste equipment.

INSTALLATION

IMPORTANT: This system must be installed by qualified Hobart Service representatives only.

IMPORTANT: This system is recommended for use in Hobart Commercial Dishwashers only.

UNPACKING

Immediately after unpacking the SWS40 Water Supply System, check for possible shipping damage. If the

system is found to be damaged, save the packaging material and contact the carrier within 15 days of delivery.

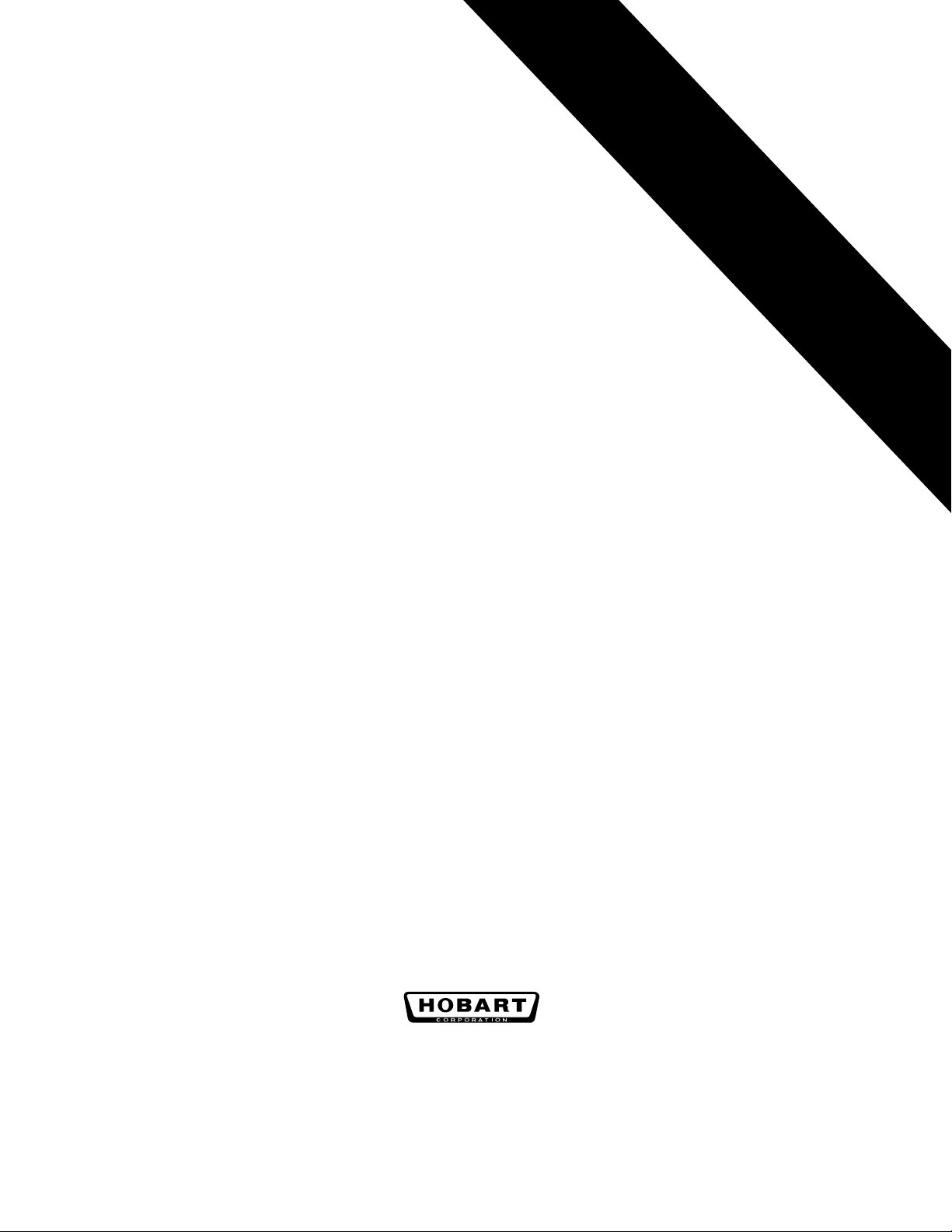

MODIFY THE DISHWASHER TANK (Fig's. 1-7)

Location of the SWS40 water supply system may not be the same on all models.

1. Drill two .625 diameter holes in the prewash tank for mounting the float switch box.

2. Drill four .750 diameter holes and one 2.25 diameter hole for mounting the pump.

.625 DIA.

(2 HOLES)

BACK SIDE OF

PREWASH TANK

2.000

45

5.000

11.000

TYP.

.750 DIA. 4 HOLES ON A

6.000 DIA. BOLT CIRCLE

2.250 DIA.

SWS-40 TO MOUNT

ON SIDE OF TANK

OPPOSITE PRE-WASH

PUMP

13.188

4.000

2.000

PL-52407

© HOBART CORPORATION, 1996

L-R SHOWN

R-L OPPOSITE

FT800 / FTM800

PRE-WASH TANK MODIFICATION

Fig. 1

– 2 –

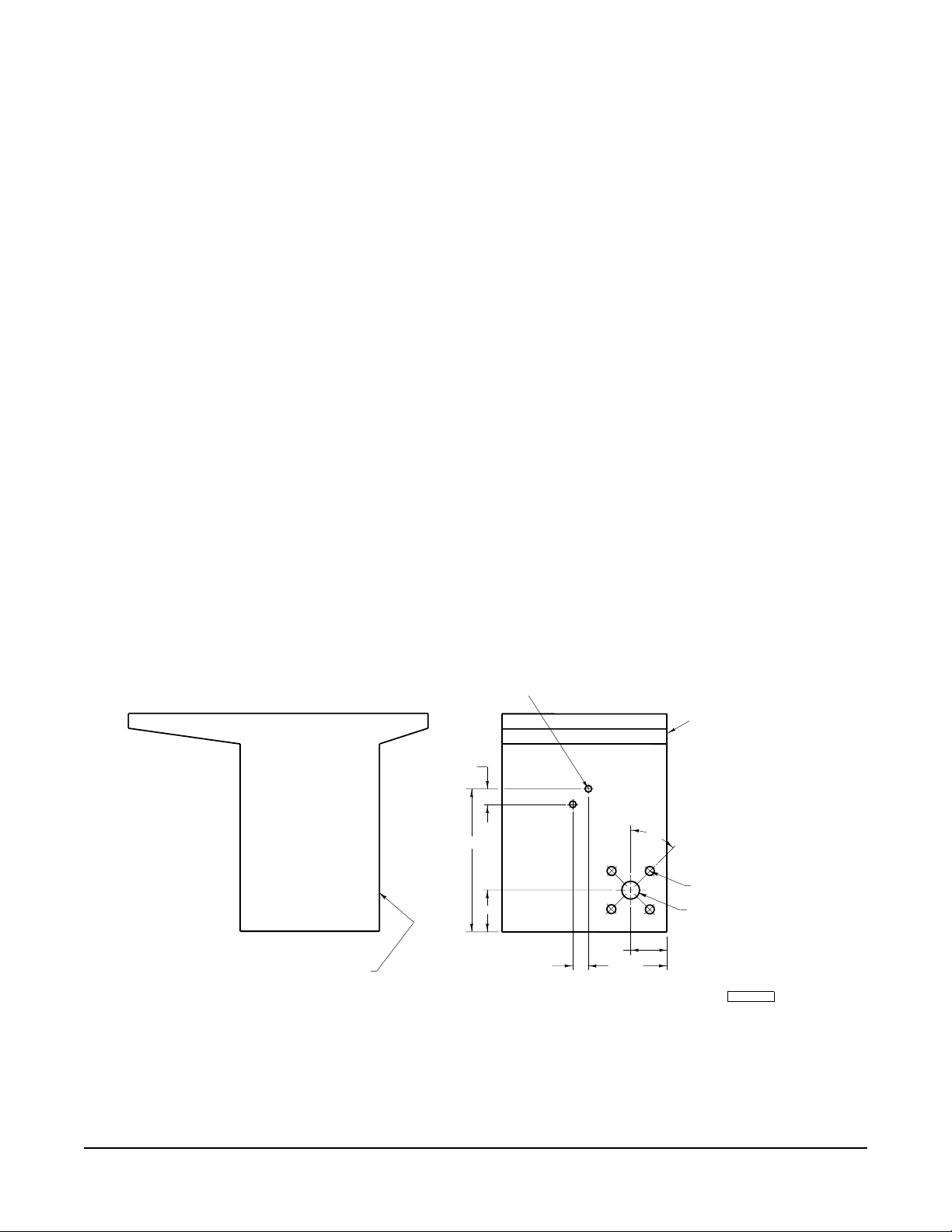

BACK SIDE OF

PREWASH TANK

.625 DIA.

(2 HOLES)

2.000

2.000

13.875

5.000

4.000

45

TYP.

.750 DIA. 4 HOLES ON A

6.000 DIA. BOLT CIRCLE

2.250 DIA.

L-R SHOWN

R-L OPPOSITE

RS-22A / RS-36A

PRE-WASH TANK MODIFICATION

Fig. 2

PL-52410

SWS-40 TO MOUNT

ON SIDE OF TANK

OPPOSITE PRE-WASH

PUMP

CW-INCCW-IN

CW-OUT

CCW-OUT

PL-52438

RS-22 ON CURVE

SCRAP BASKET INSIDE OR OUTSIDE

CLOCKWISE OR COUNTERCLOCKWISE LAYOUT

(See Pages 4 & 5 for Individual Tank Modifications)

Fig. 3

– 3 –

.625 DIA.

(2 HOLES)

BACK SIDE OF

PREWASH TANK

2.000

SWS-40 FLOAT SWITCHES

TO MOUNT ON SIDE OF TANK

OPPOSITE PRE-WASH PUMP

.750 DIA. 4 HOLES ON A

6.000 DIA. BOLT CIRCLE

12.188

5.000

2.000

2.250 DIA.

4.000

RS-22 ON CURVE

TANK MODIFICATION

(CLOCKWISE - SCRAP BASKET INSIDE)

Fig. 4

BACK SIDE OF

PREWASH TANK

45

TYP.

4.000

.625 DIA.

(2 HOLES)

PL-52408

.750 DIA. 4 HOLES ON A

6.000 DIA. BOLT CIRCLE

2.250 DIA.

2.000

45

TYP.

4.000

4.000

12.188

5.000

2.000

RS-22 ON CURVE

TANK MODIFICATION

(CLOCKWISE - SCRAP BASKET OUTSIDE)

Fig. 5

– 4 –

PL-52412

SWS-40 FLOAT SWITCHES

TO MOUNT ON SIDE OF TANK

OPPOSITE PRE-WASH PUMP

.625 DIA.

(2 HOLES)

BACK SIDE OF

PREWASH TANK

2.000

12.188

2.250 DIA.

4.000

45

TYP.

SWS-40 FLOAT SWITCHES

TO MOUNT ON SIDE OF TANK

OPPOSITE PRE-WASH PUMP

(COUNTERCLOCKWISE - SCRAP BASKET OUTSIDE)

45

TYP.

5.000

2.000

RS-22 ON CURVE

TANK MODIFICATION

Fig. 6

BACK SIDE OF

PREWASH TANK

2.000

12.188

4.000

.750 DIA. 4 HOLES ON A

6.000 DIA. BOLT CIRCLE

PL-52409

.625 DIA.

(2 HOLES)

.750 DIA. 4 HOLES ON A

6.000 DIA. BOLT CIRCLE

2.250 DIA.

4.000

4.000

5.000

2.000

SWS-40 FLOAT SWITCHES

TO MOUNT ON SIDE OF TANK

OPPOSITE PRE-WASH PUMP

RS-22 ON CURVE

TANK MODIFICATION

(COUNTERCLOCKWISE - SCRAP BASKET INSIDE)

Fig. 7

– 5 –

PL-52413

MOUNT FLOAT SWITCH BOX AND FLOAT SWITCHES (Fig. 8)

Assemble Float to Switch

1. Hook float into the float retainer.

2. Slide float over barrel of switch and retainer, along with the retainer ring, until it snaps into the groove of the

probe and switch assembly. The float must be assembled to the bottom side of the probe.

3. Place the O-ring over the threaded end of the probe and switch assembly.

4. Insert the probe and switch assembly through the prewash tank and float switch box. Secure with washer,

lockwasher and hex nut.

5. Repeat the above procedures for the second float switch.

Mount Float Switch Box

Location of the SWS40 water supply system may not be the same on all models.

Slide lid and gasket assembly over the mounting studs. Secure with locknuts.

10-24 ELASTIC

STOP NUT

RETAINING

RING

PROBE &

SWITCH ASSY.

"O" RING

FLOAT

RETAINER

FLOAT

PL-52405

WASHER

LOCKWASHER

HEX NUT

Fig. 8

– 6 –

PUMP ASSEMBLY (Fig. 9)

The pump assembly and motor are already assembled.

1. Install the leg on the pump. Attach with four bolts, lockwashers and nuts supplied.

2. Screw the 2" nipple into the pump.

3. Screw the elbow into the 2" nipple.

4. Screw the 6" nipple into the elbow.

5. Screw the flange into the 6" nipple. When tightening the flange, the mounting holes must align with the drilled

holes in the prewash tank.

REAR OF TANK

(OPP.OF SUMP)

6" NIPPLE

FLANGE

2" NIPPLE

COMPANION

FLANGE

TYPICAL SWS40 PUMP MOUNTING

RS ON CURVE SHOWN

Fig. 9

GASKET

PL-52406

Mount Pump Assembly to the Prewash Tank

1. Install two gaskets, one to the inside and one to the outside of the prewash tank wall.

2. Install the flange (Fig. 9) to the gasket inside the tank.

3. Apply sealer between tank and gasket (both sides).

4. Bolt pump, gaskets and inside flange to the prewash tank, using four bolts, lockwashers and nuts supplied.

– 7 –

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE APPLICABLE

PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH INDICATING THAT YOU ARE WORKING ON THE CIRCUIT.

WARNING: REPLACE FUSE ONLY WITH SAME TYPE AND RATING.

Wire the switch assemblies and motor to the terminals provided in the wall-mounted control box or waterpress

tower, using the wire nuts provided. Refer to the electrical wiring diagram located in the control box for wiring

SWS40 option.

PLUMBING

WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY, AND

PLUMBING CODES.

Install check valve, ball valve and piping (Fig. 10) between the dishwasher and pulper at the time of installation.

Use pipe sealant at every pipe joint.

1-1/2" NIPPLE

(BY OTHERS)

90 DEGREE

LONG RADIUS

ELBOW (TYP.)

(BY OTHERS)

SWS-40

PUMP

1-1/2" PIPING

(BY OTHERS)

1-1/2" CHECK VALVE

(SUPPLIED BY HOBART)

Fig. 10

TO

PULPER TANK

1-1/2" BALL VALVE

(SUPPLIED BY HOBART)

PL-52411

FORM 33716, Rev. A (11-96) PRINTED IN U.S.A.

– 8 –

Loading...

Loading...