QE, EQE, QEH, & PEQ SERIES

N

S

T

R

U

C

T

I

O

N

S

I

ROLL-IN, ROLL-THROUGH

FOOD STORAGE CABINETS

AND PROOFERS

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 18529 Rev. E (Jan. 2000)

QE Series Roll-In Food Storage Cabinets

– 2 –

Installation, Operation, and Care of

PL-50949

DOOR

BOLT

SCREW

ASSEMBLY

MOUNTING

SCREW

HANDLE ASSEMBLY

KEY

MOUNTING SCREW

PLUG

BUTTON

QE, EQE, QEH, & PEQ SERIES

ROLL-IN FOOD STORAGE CABINETS & PROOFERS

SAVE THESE INSTRUCTIONS

GENERAL

The QE and EQE Series Roll-in Food Storage Cabinets are available as medium temperature (38°F)

or frozen food (0°F) storage cabinets. The QEH Series is available as a hot food (180°F) storage

cabinet. QE, EQE, and QEH Series may be ordered as one-, two-, or three-section, roll-in or rollthrough cabinets. The PEQ Series may be ordered as one-, two-, or three -section roll-in or roll-through

proofer cabinets for the baking industry. Proofer cabinets control temperature, humidity, and time.

Thaw Proofer cabinets have a two-stage control, an initial Thaw stage is automatically followed by a

Proof stage; each stage independently controls temperature, humidity, and time.

INSTALLATION

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the cabinet is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, test the electrical service to verify that it agrees with the data plate located in the

upper left corner inside the cabinet.

ASSEMBLY

Some components can be removed to allow the cabinet

to pass through short or narrow doorways.

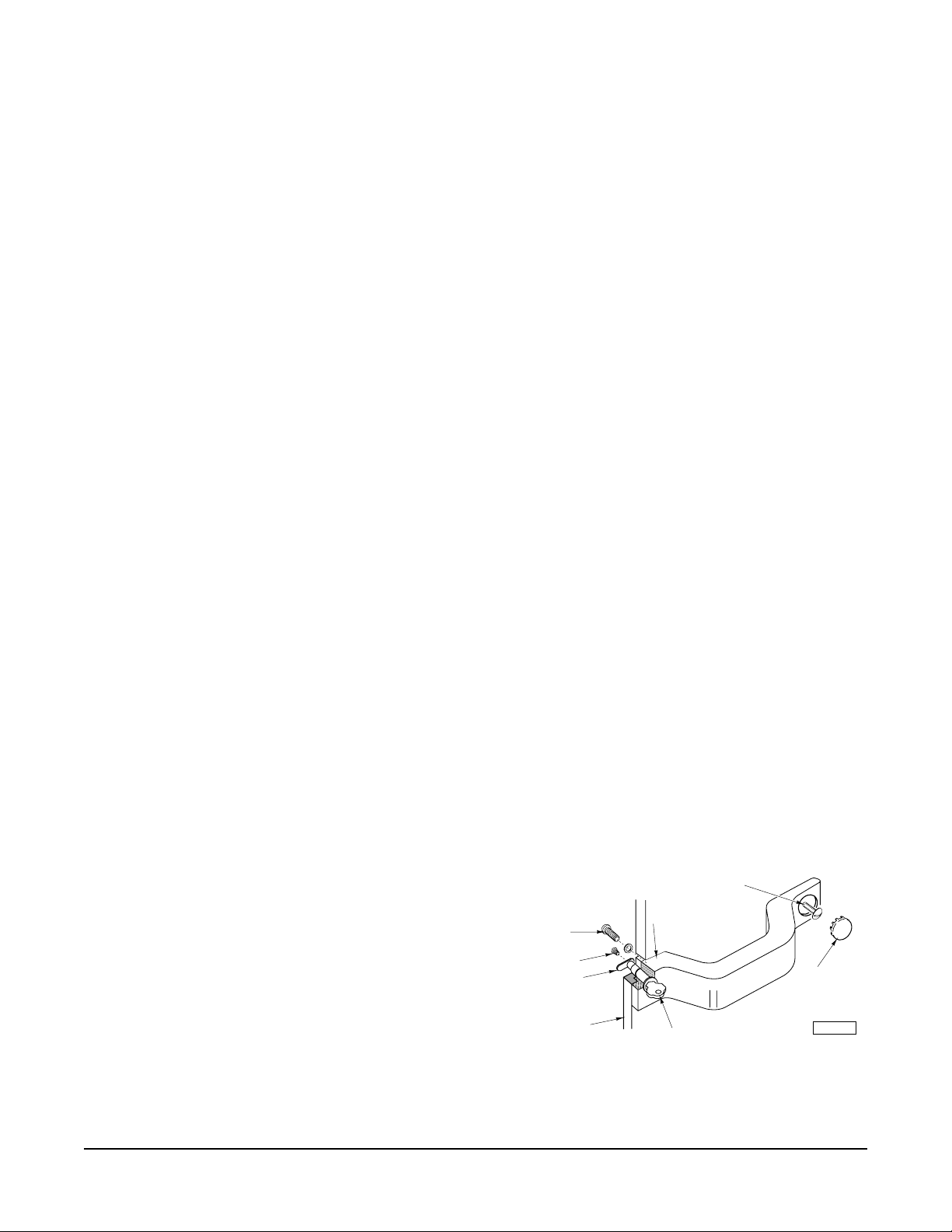

The door handle can be removed, as follows:

1. Remove the screw and bolt from the tumbler.

2. Remove the two mounting screws and the handle

assembly (Fig. 1).

3. Replace in reverse order of disassembly.

NOTE: Proofers do not have locks.

Fig. 1

© HOBART CORPORATION, 1992

– 3 –

Door(s) and hinges can be removed, as follows:

PL-53452

UPPER

HINGE

SCREWS

(3)

LOWER

HINGE

SCREWS

(6)

NUT

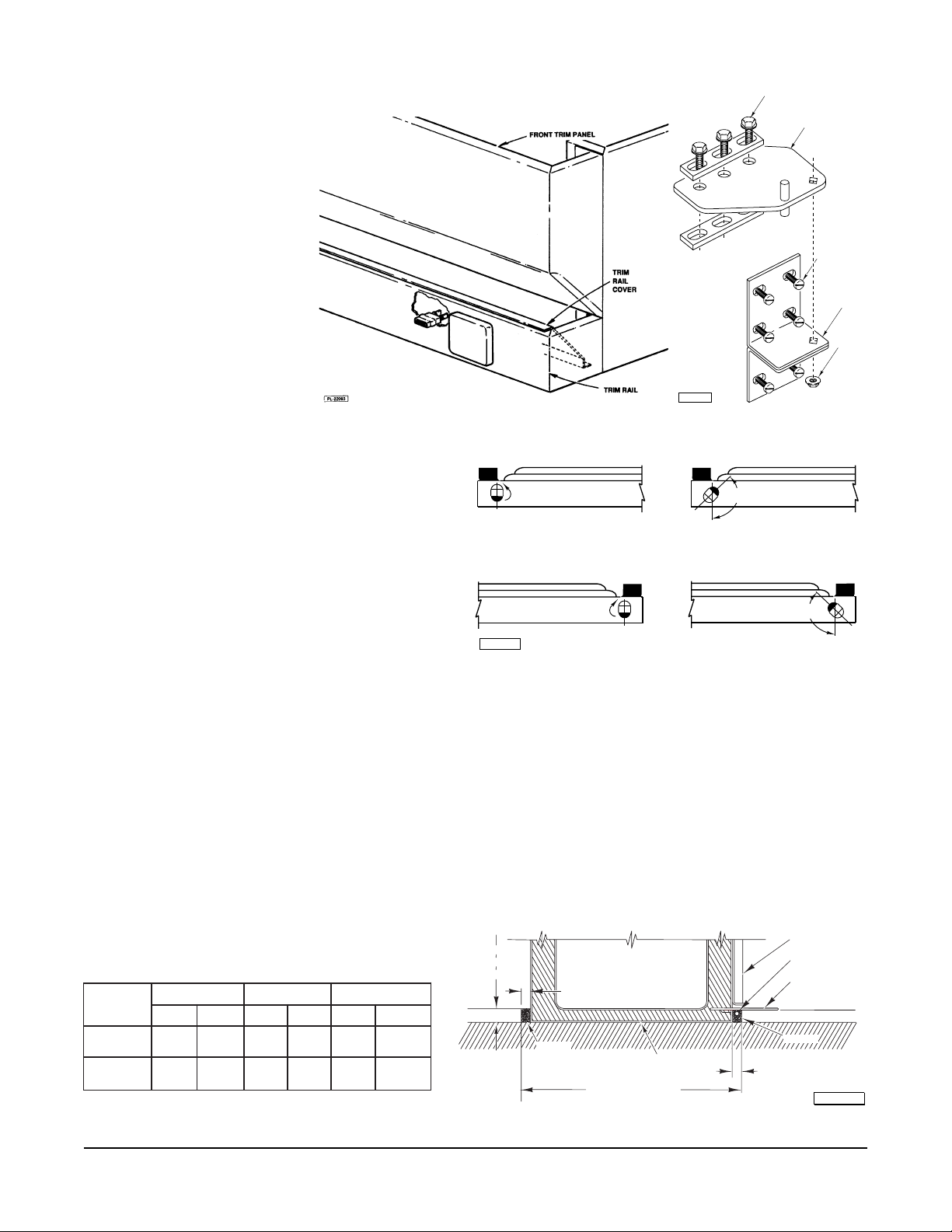

1. Lift up and remove the

front trim panel (Fig. 2).

2. Remove the screws

which secure the trim

rail cover (Fig. 2),

unplug the door switch

lead wires and remove

the screws which secure

the trim rail (Fig. 2).

Carefully lay the trim rail

on top of the cabinet —

avoid damaging or

kinking the thermometer

capillary tube.

3. Remove the three screws which secure the

upper hinge plate to the cabinet (Fig. 3).

This will remove hinge tension. Remove

the nut underneath the lower hinge plate

which secures the bottom hinge. Remove

door. Remove lower hinge plate (Fig. 3).

4. If the hinge mechanism should become

uncocked while changing the door, it will

be necessary to recock the hinge

mechanism. To do this, remove the door

from the cabinet and position the door face

5

down on a work table. Using a

/16" open

end or adjustable wrench, turn the hinge

mechanism shaft 135° (Fig. 4).

Fig. 2

Fig. 3

UNCOCKED POSITION

TURN 135º

– POSITION 1 – (LEFT-HAND HINGED DOOR)

UNCOCKED POSITION COCKED POSITION

TURN 135º

PL-50961

– POSITION 2 – (RIGHT-HAND HINGED DOOR)

POSITION DOOR IN ONE OF THE TWO POSITIONS SHOWN.

COCKED POSITION

135º

Fig. 4

135º

5. Replace the hinge plates and door(s) in the reverse order of disassembly.

If cabinets are too tall, the refrigeration system may need to be removed in order to pass through short

openings. Contact your dealer or authorized servicer if this becomes necessary.

Once the cabinet is in its final position, replace any components that may have been removed (door

handle, etc.) and then level the cabinet front-to-back and side-to-side using shims as required.

Before installing the ramp or flat threshold, seal between the bottom of the cabinet perimeter and the

floor by applying a bead of NSF-approved sealant, such as Dow Corning 732 or GE RTV108.

Cabinets equipped with flat threshold(s) must have a recessed floor (Fig. 5). The recessed floor should

3

/8" deep. This allows 1/4" for leveling shims.

be 1

tenibaC

epyT

tnorF

"73431/4""73761/2""730013/4"

gninepO

urhTssaP

733/4"431/4"733/4"761/2"733/4"0013/4"

noitceS-enOnoitceS-owTnoitceS-eerhT

htpeDhtdiWhtpeDhtdiWhtpeDhtdiW

snoisnemiDroolFdesseceR

CABINET

83-7/8"

APPROX.

– 4 –

1-3/8"

GROUT

1-1/2" (F.O.)

2-1/4" (P.T.)

1/4" SHIM

2-1/4"

RECESSED FLOOR

Fig. 5

FRONT

DOOR

HEATER

FLAT

THRESHOLD

FLOOR

GROUT

SUB-FLOOR

PL-53453

On pass thru models, the recessed floor dimension allows 21/4" clearance at both front and rear and

1

/2" on both sides. On a front opening cabinet, the recessed floor dimension allows 21/4" clearance at

the front, 1

1

/2" clearance at the rear, and 1/2" on both sides (Fig. 5). The plug for the heater under the

flat threshold must be connected to the receptacle, provided, before installing grout.

The space between the cabinet base and the recessed opening must be filled with grout for sanitary

purposes. DO NOT fill the area below or above the hinge plate with grout, as the fastener on the bottom

of the hinge plate must remain accessible to remove the door for service. Place a piece of cardboard

around the hinge plate to make sure this area is free of any grout. Keep grout away from heater plug.

Ramp (Equipped as an Alternate to Flat Threshold)

Install ramp(s) and ramp heater(s) as follows:

The heater is secured to the bottom of the ramp

(Fig. 6). Connect the heater plug into the receptacle

provided at the bottom of the door opening (Fig. 6).

Position the ramp by placing the lip of the ramp

inside the door opening. Hook the ramp on the clips

provided at the bottom of the door opening (Fig. 6).

Ramp heaters are not used on QEH or PEQ models.

Fig. 6

Shelves (Fig. 7)

The shelves and shelf clips are provided only if specially

PILASTER

ordered. Insert shelf clips in pilaster slots and install the shelves.

Index holes are provided in the pilaster to help in leveling the

shelves.

COLD AIR

DUCT

Bonus shelves are provided to fill the space between the

standard shelves. These are positioned and supported by the

standard shelves.

NOTE: Loosen all thumb screws which secure shelf pilasters

BONUS

SHELF

INDEX

HOLE

SHELF

CLIP

SHELF

and light cover(s) prior to placing product in cabinet. Thumb

screws should be loose enough to remove with your fingers so

parts can be readily removed for cleaning without the use of

tools. Failure to comply with this request will invalidate the NSF

PL-50910

listing.

Fig. 7

Miscellaneous

Some models have the compressor specially mounted to help prevent damage during shipment. If the

compressor is mounted on shipping blocks, they must be removed prior to operation. If the compressor

is mounted on springs, refer to the tag attached to the compressor.

On cabinets with remote refrigeration systems, place the condensate dish heater in the condensate

dish and connect it to the outlet provided.

– 5 –

PLUMBING CONNECTIONS (PEQ Series Proofer only)

WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY,

AND PLUMBING CODES.

Make sure the water supply has proper hardness and pH. The recommended water hardness range

is 4 – 6 grains per gallon. The recommended pH range is 6.5 to 8.0. Consult your local water company

and/or water conditioner dealer before installing a PEQ Series Proofer.

ELECTRICAL CONNECTIONS (Cord-Connected Roll-Ins) 120 Volts / 60 Hertz / 1 Phase Only

WARNING: THIS MACHINE IS PROVIDED WITH A THREE-PRONG GROUNDING PLUG. THE

OUTLET TO WHICH THIS PLUG IS CONNECTED MUST BE PROPERLY GROUNDED. IF THE

RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN.

ELECTRICAL CONNECTIONS (Permanently Connected Roll-Ins)

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH APPLICABLE

PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL ELECTRICAL

CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT.

Refer to the wiring diagram supplied with the cabinet.

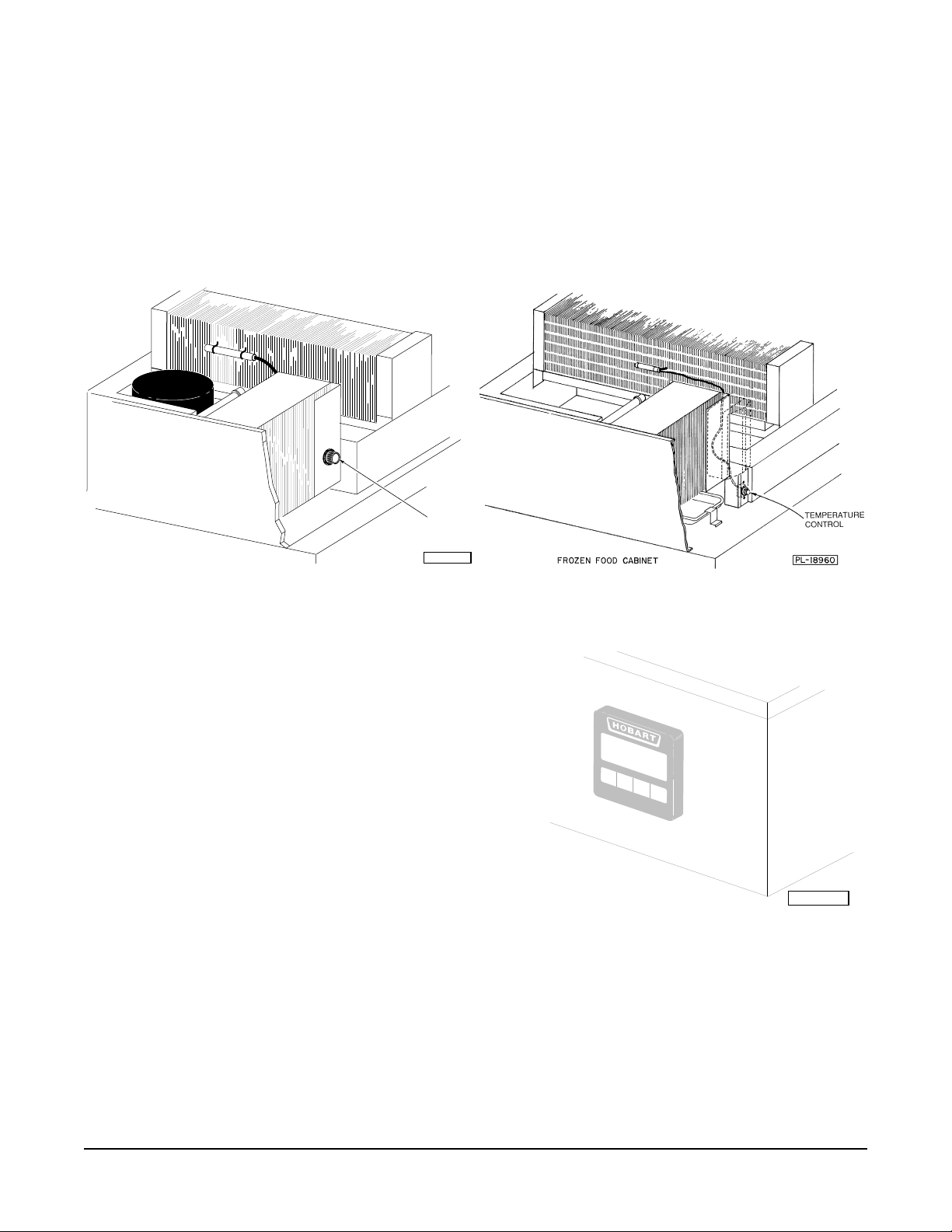

PRESTART CHECKS (Refrigeration Cabinets Only)

REFRIGERANT LINES — Check for tubing shifts due to shipping that would cause operating noise,

wear, or leaks.

DEFROST TIMER (Low Temperature Units and Convertible Models in Low Temperature Mode) —

When power is initially applied to the cabinet, the exterior dial of the defrost time clock (Fig. 5) must

be set to the correct time of day.

To access the defrost timer, remove the front

TIME-OF-DAY POINTER

EXTERIOR DIAL (24 HOUR)

trim panel (Fig. 4) by lifting up and out. Open

door on the defrost timer box. Turn the inside

knob counterclockwise until the exterior dial is

TURN KNOB

COUNTERCLOCKWISE

positioned so the correct time of day is at the

time of day pointer. Replace the front trim

DEFROST CYCLE PINS

panel when done.

The defrost timer (Fig. 5) is set at the factory

for four 26-minute defrost cycles per day (2

AM, 2 PM, and 8 PM). Depending on local

8

AM,

conditions, it may be necessary to change the

frequency or duration of defrost cycles.

END DEFROST

(26 MINUTES)

If the power supply is interrupted, the defrost

timer must be reset to the correct time of day.

BEGIN DEFROST

PL-41397-1

Fig. 8

– 6 –

OPERATION

CONTROLS (Refrigeration)

TEMPERATURE CONTROL — The temperature control is set at the factory, but local conditions may

necessitate slight adjustment. To adjust the temperature control, lift up and remove the front trim panel (see

Fig. 2) and turn the control knob (Fig. 9 or 10) a small amount at a time. Turning the control knob in the direction

of the arrow lowers the temperature. The control knob has a marked "OFF" position which interrupts power to

the compressor and condenser fan only, not the entire roll-in.

TEMPERATURE

CONTROL

ONE SECTION REFRIGERATOR CABINET

PL-50544

Fig. 9 Fig. 10

STANDARD THERMOMETER (Fig. 11) — The standard

digital thermometer is calibrated at the factory and does

not permit recalibration.

OPTIONAL DIAL THERMOMETER — The optional dial

thermometer can be recalibrated. Compare the cabinet

thermometer with an accurate test thermometer. If there is

any variation, contact a Hobart-authorized Refrigeration

Service Company.

OPERATIONAL CHECK — The refrigeration and defrost

cycles should be checked for proper operation and the

thermometer(s) should also be checked for correct

temperature indication — before product is stored in the

cabinet.

Refrigerator

PL-50767

Fig. 11

– 7 –

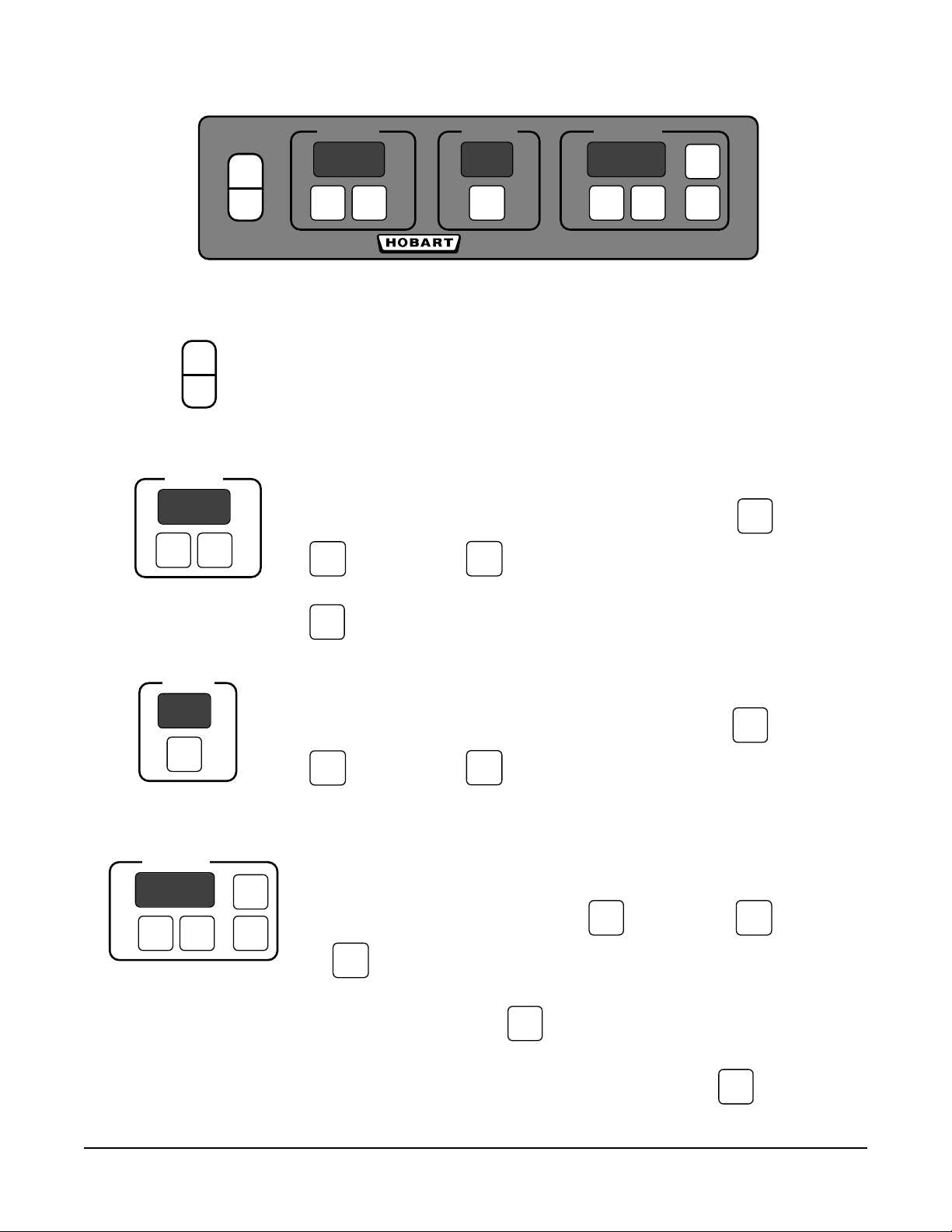

CONTROLS — Proofer and Thaw Proofer (Figs. 12 & 13)

T

ON

OFF

TEMP

SET VIEW

• F

HUM

%

SET

•

TIMER

SET

START

▲

▼

Proof Box

Fig. 12

On-Off Switch Turns the Proofer Control On or Off. The On-Off switch is not a

ON

disconnect switch —

TO SERVICE THE CABINET.

ALWAYS DISCONNECT POWER AT THE SOURCE

OFF

TEMP

SET

• F

VIEW

TEMP normally displays the Set-Point Temperature.

To adjust the Set-Point Temperature, press and hold

to Increase or

▲

to Decrease.

▼

while using

SET

•

TIMER

SET

HUM

SET

START

%

▲

▼

displays the Actual Temperature.

VIEW

HUM displays the Humidity Set-Point.

To adjust the Humidity Set-Point, press and hold

to Increase or

▲

to Decrease.

▼

while using

SET

TIMER displays the minutes remaining [zero (0) indicates not in use].

To s et the Time, press and hold

or

To start the Timer, press

to Decrease.

▼

. The Time (minutes) displays and begins

STA R

while using

SET

to Increase

▲

flashing as it counts down. When the Timer reaches zero (0), a beeper

sounds for 30 seconds. To stop the beeper, press

– 8 –

SET

.

CONTROLS — Thaw Proofer (Fig. 13)

T

T

SET THA W

•

PROOF

•

AUTOMATIC

•

MODE

ON

OFF

TEMP

SET VIEW

Press

MODE

• F

and

HUM TIMER

%

SET

Fig. 13

or

▲

▼

The mode lights indicate control function

SET THA W

PROOF

•

AUTOMATIC

MANUAL PROOF mode allows you to set Temperature, Humidity, and

Time values for manual or automatic proofing operations. To start

a manual (non-timed) proofing operation, press

Proofer values, refer to page 8.

SET THA W

•

PROOF

AUTOMATIC

ET THAW mode allows you to set Temperature, Humidity, and Time

S

values for the Preheat and Thaw portions of an Automatic cycle

without disturbing an ongoing proofing operation. Thaw values are

set the same as Proofer values — refer to page 8. Control returns

to manual Proof mode if no buttons are pressed in 30 seconds. To

enter Set Thaw mode, the timer must not be running.

SET THA W

•

PROOF

•

AUTOMATIC

•

MODE

•

START

SET

▲

▼

Thaw Proofer

to select Proof, Set Thaw, or Automatic mode.

:

. To set

STAR

UTOMATIC PREHEAT — displays Thaw Temperature and Thaw

SET THA W

PROOF

•

AUTOM ATIC

A

Humidity. Thaw Temperature flashes when reached, indicating

ready-to-load. Load the product and press

to begin an

STAR

Automatic Thaw and Proof cycle.

UTOMATIC THAW — maintains the Thaw Temperature and Thaw

SET THA W

•

PROOF

•

AUTOMATIC

SET THA W

PROOF

•

•

AUTOM ATIC

A

Humidity while the Thaw Time counts down. After the Timer counts

down to zero, the control immediately goes into Automatic Proof.

AUTOMATIC PROOF — maintains the Proof Temperature and Proof

Humidity while the Proof Time counts down. After the Timer counts

down to zero, the control beeps and the display flashes indicating

that the product is ready to be unloaded from the proofer and moved

to an oven for baking. The control returns to manual Proof mode.

During Automatic mode —

To cancel the Thaw portion of an Automatic cycle, press Timer Set and advance to the Proof portion.

To cancel the entire Automatic Thaw and Proof cycle, press the Mode button and return to manual Proof.

– 9 –

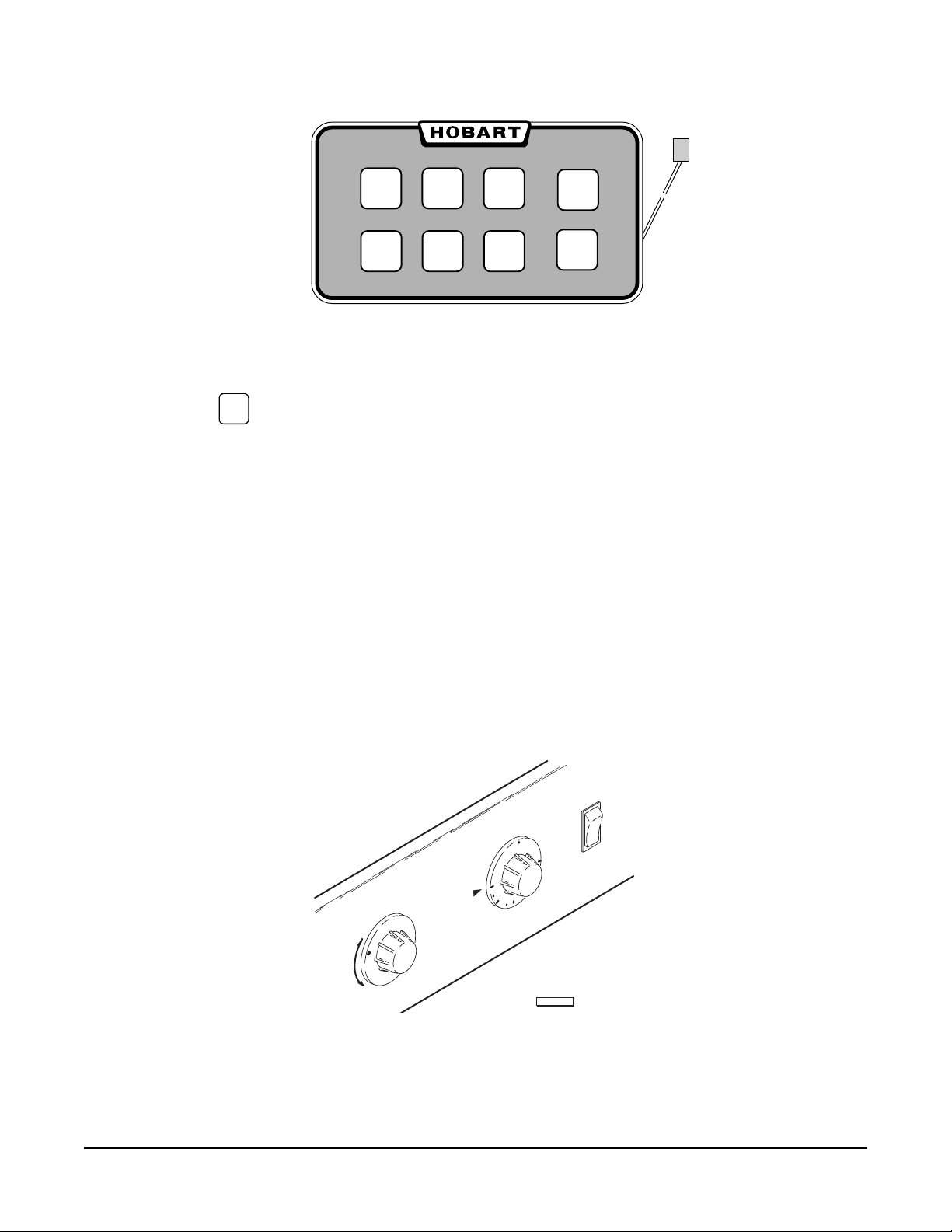

REMOTE CONTROL — Proofer and Thaw Proofer (When Equipped)

SET

TEMP

SET

HUM

SET

TIMER

▼

Connect Remote Control

'Phone Jack' to Terminal

on Electrical Box on Top

VIEW

TEMP

MODE

START

TIMER

▼

of Unit

Fig. 14

The Remote Control is used in conjunction with either Proofer Controls or Thaw Proofer Controls described on

pages 8 – 9. The

MODE

key is used only on Thaw Proofer models.

CONTROLS — Hot Food Storage Cabinets (Fig. 15)

The ON-OFF switch controls power to the fan motors and the thermostat / heater circuit. Turn the switch OFF

whenever the cabinet is not in use. The ON-OFF switch is not a disconnect switch — ALWAYS DISCONNECT

POWER AT THE SOURCE TO SERVICE THE CABINET. The temperature control dial, which has a marked OFF

position (no heat), is used to select the temperature at which the food will be held. When this dial is OFF, the

air circulating fans continue to run.

The HUMIDITY control dial is used to regulate the humidity level inside the cabinet. Three-section cabinets have

two HUMIDITY control dials.

ON

TEMPERATURE

F

F

HI

LO

HUMIDITY

O

0

0

1

1

0

2

OFF

PL-53471

Fig. 15

– 10 –

MAINTENANCE

CLEANING

Cabinet

Clean the inside of the cabinet and the doors weekly with a warm water solution of mild household liquid

dishwashing detergent (such as Palmolive green or Ivory). Do not use anything containing grit,

abrasive materials, bleach or harsh chemicals. Be cautious with new or improved formulas; use only

after being well tested. Rinse thoroughly and dry with a clean soft cloth. Do not use steel wool to clean

surfaces.

NOTE: Failure to follow use, care and maintenance instructions may void your Hobart warranty.

Gaskets

Door gaskets should be cleaned weekly using a warm water solution of mild household liquid

dishwashing detergent (such as Palmolive green or Ivory). Never allow gaskets to contact concentrated

cleaners or disinfectants. This can cause premature failure of the gasket material.

Condenser Coil

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING THE CONDENSING UNIT.

Check the condenser coil weekly. This surface must be kept free of dirt and grease for proper system

operation. Remove the front trim panel and carefully vacuum or brush dirt and lint from the condenser

coil. Replace the trim panel.

Evaporator Coil, Drain Pan, Condensate Loop, and Condensate Dish

When needed, flush these components with fresh water. This should be a part of any routine

maintenance program and can prolong the life of the equipment.

Light Bulb Replacement

Replace light bulb(s) with 40 watt incandescent appliance type bulb(s) ONLY. The protective cover

can easily be removed and replaced.

For additional information or to discuss a maintenance program, contact your local authorized

refrigeration servicer.

– 11 –

— NOTES —

FORM 18529 Rev. E (Jan. 2000) PRINTED IN U.S.A.

– 12 –

Loading...

Loading...