Page 1

SCB Super

Char Broiler with piezo ignition.

INSTALLATION OPERATION

This appliance shall be installed in conformity with the current regulations and

only used in a well-ventilated location. Consult these instructions before

installing and using this appliance.

PLE200513 – C 08-07 EU8079

PLEASE KEEP THIS MANUAL IN A SAFE PLACE FOR FUTURE REFERENCE.

CONTENTS.

Page 2

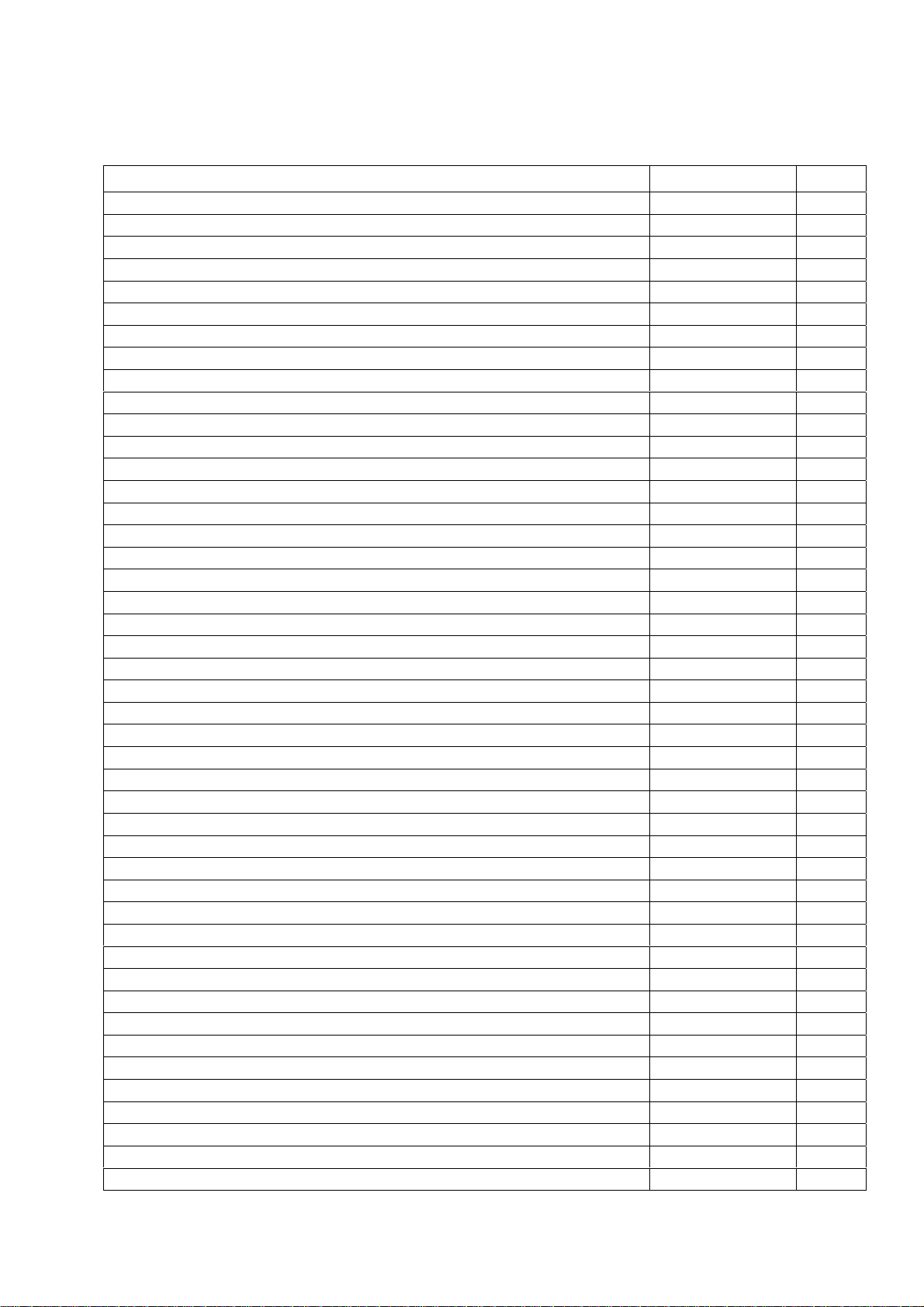

SECTION PAGE

SAFETY AND GENERAL INFORMATION

Safety information 1 3

Safety guidelines 1.1 3

Warning symbols 1.2 4

Liability 1.3 4

Definitions 1.4 5

Environmental responsibility 1.5 5

Packing material 1.5.1 5

Disposal of your old appliance 1.5.2 5

Foreword 2 5

General information 3 5

SCB Super Char Broiler component identification. Photograph 1. 6

Features and benefits 3.1 7

Safety instructions 4 7

Never 4.1 7

Always 4.2 8

INFORMATION FOR OPERATORS AND USERS

Operating the SCB Super Char Broiler 5 9

Lighting instructions-piezo ignition 5.1 9

Using the SCB Super Char Broiler 5.2 10

Reversing the grates 5.3 11

Using the grate removal tool 5.4 12

Cleaning 6 12

Cleaning the grates 6.1 12

Cleaning the radiants 6.2 12

Cleaning external surfaces 6.3 12

INFORMATION FOR INSTALLATION AND COMMISSIONING.

Design and construction data 7 13

Technical information. Part 1. Table 1 13

Technical information. Part 2. Table 2 15

Burner and pilot orifice dimensions. Table 3. 15

Gas categories and pressures. Table 4. 16

Gas consumption and energy usage Table 5. 16

Installation dimensions. Figure 1. 17

Installing the SCB Super Char Broiler 8 17

Unpacking and handling 8.1 17

Location 8.2 18

General installation guidelines 8.3 18

Mounting of the appliance 8.4 19

Gas pipe work 8.5 19

Ventilation 8.6 20

Gas installation 8.7 21

Fitting the gas regulator 8.8 21

Electrical earth bonding 8.9 21

Gas burner securing tape removal 8.10 22

1

Page 3

Commissioning 9 22

Check the manifold gas pressures 9.1 22

Operator training 9.2 23

INFORMATION FOR MAINTENANACE AND REGULAR

SERVICING

Maintenance 10 23

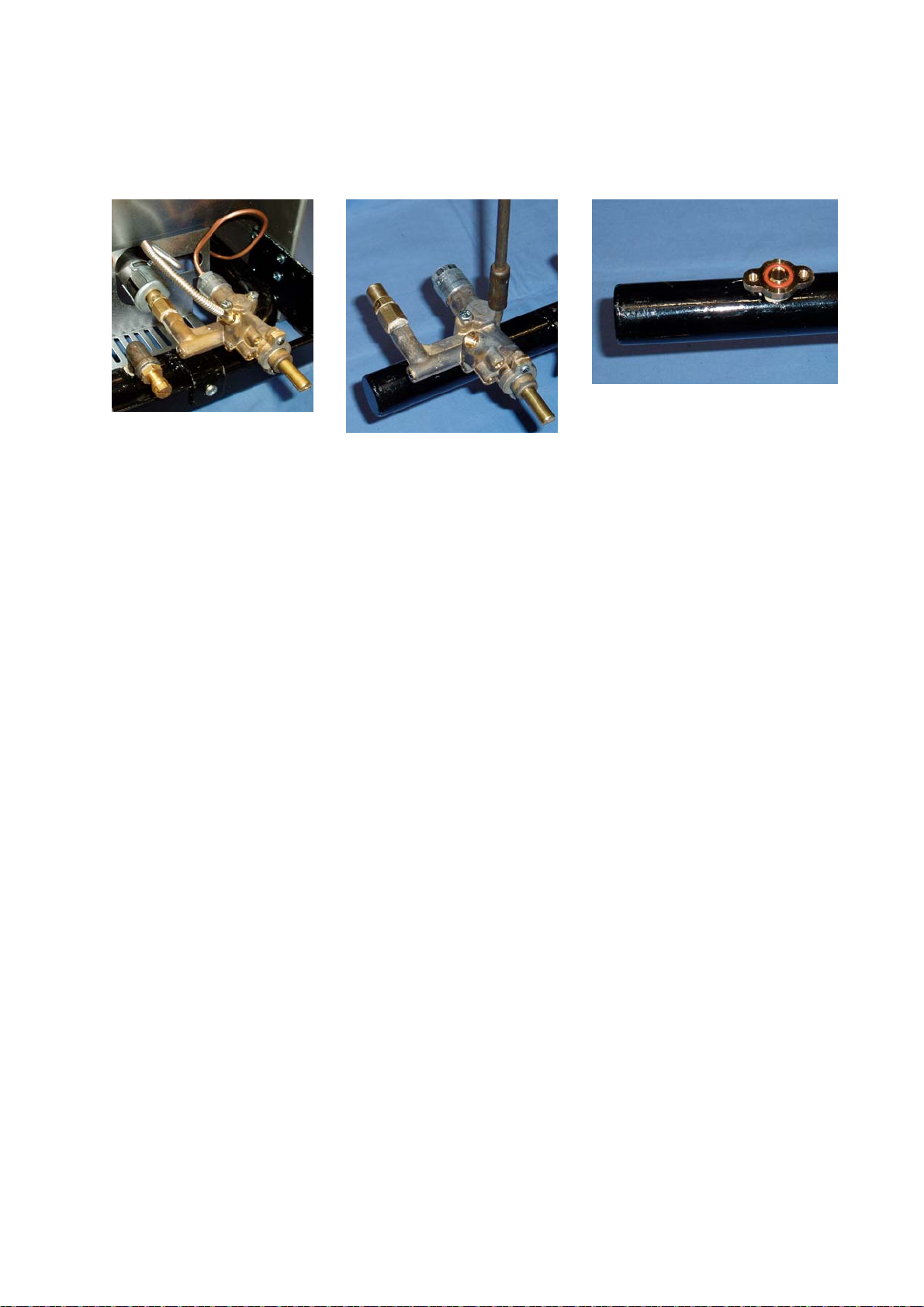

Gas control system component identification. Photograph 15. 23

Cleaning the burner baffle 10.1 24

Adjusting the pilot burner flame 10.2 24

Replacing the pilot burner 10.3 25

Replacing the thermocouple 10.4 26

Replacing the main burner 10.5 26

Replacing the burner nozzle 10.6 27

Replacing the gas control valve 10.7 28

Fault finding 11 29

Fault summary 11.1 29

Servicing 12 30

Service interval Table 6 31

Recommended spare parts 13 32

Service contacts 14 33

2

Page 4

1.0 SAFETY INFORMATION.

The procedures and precautions contained in this manual apply to SCB Super Char

Broiler only when used in the prescribed manner.

If the SCB Char Broiler is used other than in the recommended manner, the operator

will be responsible for his/her own safety and for the safety of the other persons who

may be involved.

The information in this manual has been prepared to assist the operator to

understand, maintain, and operate the Char Broiler. In order to prevent accidents,

read, understand and follow all the precautions and warnings contained in this

manual before installation or operating for the first time. This manual must be studied

to obtain a clear understanding of the SCB Super Char Broiler and its capabilities.

Hot surfaces and gas are dangerous and may cause injury if sufficient precautions

are not taken prior to operating or servicing the SCB Super Char Broiler.

The SCB Super Char Broiler must only be serviced by Qualified Service

Personnel. Ensure the gas supply has been isolated and all hot surfaces are

allowed to cool to an acceptable temperature before attempting to service the unit. In

certain fault finding situations it may be necessary to operate the machine whilst still

hot; in which case extreme caution must be used.

These instructions are only valid for the countries listed in table 4 section 8.

This appliance shall be installed by a competent, trained and qualified person in

conformity with the current local gas regulations. The appliance must only be used in

a well-ventilated location. Consult the instructions before installing and using this

appliance.

The SCB Super Char Broiler is only intended for professional use by qualified

people.

1.1 SAFETY GUIDELINES.

Ensure sufficient precautions are observed during manually handling of the SCB

Super Char Broiler particularly when moving into position on installation. Reference

must be made to manual handling regulations. The SCB Super Char Broiler weights

are given in table 2, section 8. Refer to section 5 for installation and operating safety

instructions.

• Do not hose or pressure clean this appliance. It is vital to adhere to the

cleaning instructions detailed in this manual.

• Do not remove any covers or loosen any fittings whilst the appliance is

operating.

• Ensure this manual is kept in an easily accessible place near the SCB Super

Char Broiler for future reference.

3

Page 5

• All operators must be trained in the safe use and operation of the appliance.

• This appliance is not intended for use by persons if their physical, sensory or

mental capabilities prevent them from using it safely.

• This SCB Super Char Broiler is not intended for use by children.

• Ensure the gas supply has been isolated before attempting to service or move

the appliance.

• The appliance must be disconnected from the gas supply before withdrawing.

• Instructions must be placed in a prominent position within the kitchen that will

advise operators of this equipment of the procedure in the event a gas leak is

detected by smell or other means.

• Hot surfaces and gas are potentially hazardous and may cause injury if

sufficient precautions are not taken prior to operating or servicing the

machine.

• Always have your gas appliance regularly serviced; at least once a year,

depending on frequency of use (refer to table 6, section 12). For information

on service contracts please contact your local Hobart sales office.

• Prior to connecting the appliance check the gas type and rating on the data

plate corresponds with the gas supply.

• The area around the SCB Super Char Broiler must always be kept free and

clear of combustibles such as solvents, cleaning fluids, mops, rags, brooms,

etc.

• Do not obstruct any vents or openings on the appliance.

1.2 WARNING SYMBOLS.

To identify the safety messages in this manual, the following symbol has been used

The "Warning" symbol is found primarily where the corresponding

information is important for the safe use of the machinery.

1.3 LIABILITY.

Installations and repairs which are not carried out by Authorised technicians or the

use of other than original spare parts, and any technical alterations to the

appliance, may affect the warranty set out in the standard conditions of sale.

4

Page 6

1.4 DEFINITIONS.

Qualified operators. The SCB Super Char Broiler is only intended for professional

use by qualified operators. Qualified operators are those personnel who have

received training in the operation of the appliance from a suitable qualified person

and have carefully read the information in this manual and are familiar with the

equipment’s function or had previous experience with the operation of this SCB

Super Char Broiler.

Qualified installation personnel. Any ‘work’ performed within the UK on the

appliance including installation that is within the scope of the Gas Safety (Installation

and Use) Regulations shall be carried out by a business that is CORGI approved

(Council for Registered Gas Installers) and approved by the Health and Safety

Executive (HSE). For countries outside the UK qualified installation personnel must

be experienced and familiar with precautions required, have complied with all

requirements of state and local authorities having jurisdiction. In the EU installation

must comply with national or local requirements of the country of destination of the

appliance.

Qualified Service Personnel: Those who are familiar with Wolf equipment,

competent, trained and approved by Hobart UK. All service personnel are required to

be equipped with a complete set of manuals and original service parts.

1.5 ENVIRONMENTAL RESPONSIBILITY.

1.5.1 PACKING MATERIAL.

The pallet and protective polyethylene packing film have been selected

from materials that are environmentally friendly for disposal or can

normally be recycled. Instead of throwing them away, please ensure they

are recycled.

1.5.2 DISPOSAL OF YOUR OLD APPLIANCE.

Old appliances contain materials that can be recycled. Please contact your local

waste collection centre; scrap merchant or local Hobart office about potential

recycling schemes.

2.0 FOREWORD.

Hobart reserves the right to alter the design of their products without prior notice.

Whilst every effort is made to ensure this publication reflects the latest design, the

Company cannot guarantee full compliance.

Take pride in your SCB series Char Broiler - keep it clean and in good mechanical

condition. Refer to the cleaning and maintenance sections in this manual.

3.0 GENERAL INFORMATION

The information and instructions contained in this manual may not cover all details or

variations in the equipment, nor provide for every eventuality to arise with

5

Page 7

installation, operation, or maintenance. If additional information is required please

contact your local Hobart office.

The SCB series Char Broiler is a commercial gas cooker intended for the cooking of

meat, seafood, pita bread and stockpot heating. The SCB features ‘flame arrestor’

broiling grates that control fat flare-up and ensure uniform broiling temperatures. The

specially designed cast iron grates have an angled grease trough to ensure all food

waste and fat runs off to enable the equipment to operate at its optimum

performance. The grates are removable to allow the radiants to be quickly and easily

cleaned. The broiling grates are reversible so they can be either flat or angled

depending on the food product being cooked. Steel baffles positioned under each

burner reflect heat up to the radiants and ensure the grease drawer and drip pan

area remains at a relatively lower temperature. The finned heat radiants situated

under the grates control cross draughts within the SCB Char Broiler to maintain a

constant cooking temperature for maximum efficiency and optimum cooking results.

The piezo ignition system enables the appliance to be lit without removing the grates

and radiants. The piezo igniter lights the pilot burner. One piezo igniter is used for

two pilot burners.

The SCB Char Broiler is supplied with adjustable stainless steel legs for bench

mounting

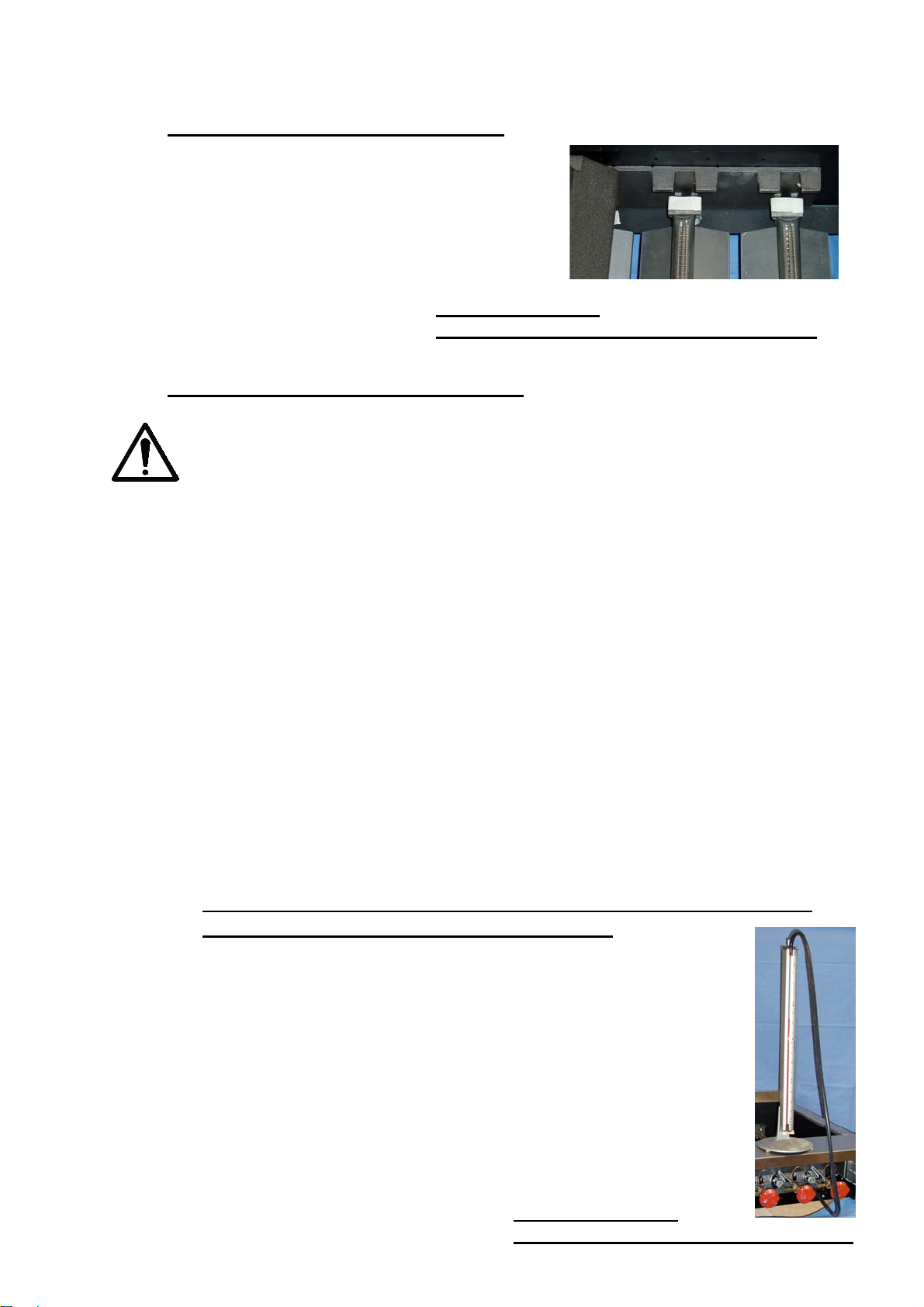

REVERSIBLE

BROILING

GRATES

(ANGLED).

PILOT

BURNER

VIEWING

WINDOW

100 mm

HIGH

LEGS

SLIDING

DRIP TRAY.

SPLASH

BACK

FRY

PLATE

REVERSIBLE

BROILING

GRATES

(FLAT).

PIEZO

IGNITER

GAS

CONTROL

KNOB

MOBILE

STAND

SCB SUPER CHAR BROILER COMPONENT

IDENTIFICATION. PHOTOGRAPH 1.

6

Page 8

3.1 FEATURES AND BENEFITS.

• Robust and strong design.

• Reversible grates flat or angled.

• Cast iron radiants to provide an even cooking temperature over the entire grate.

• Heat deflector to ensure improved cooking efficiency and create a lower

temperature zone in the drip tray area.

• Flame failure protection.

• Removable front grease channel for easy cleaning.

• Full or half flame burner control.

• Finned heat radiants to control cross draughts within the Char broiler and

maintain a constant cooking temperature.

• Effective guard to protect the pilot burner from food debris.

• Removable grates and radiants to ensure daily cleaning in quick and easy.

• Slanted cast iron grates with fat gully.

• High power burners each rated at 4.2 kW.

• Straight cast iron grates available.

• Stainless steel drip trays to collect fat and food waste.

• Individually controlled burners.

• Piezo ignition of pilot burners.

• Easy clean stainless steel exterior surfaces.

• Tap stem guard

• Insulated side and rear panels.

• Optional stainless steel fry plate for fish, eggs, bacon etc.

• Optional splash-back 100mm and 250 mm high easily removed for cleaning.

• Optional grate removal tool.

• Mobile or static stand options available.

4.0 SAFETY INSTRUCTIONS.

ONLY A FULLY TRAINED AND COMPETENT PERSON MUST USE THE

SCB SUPER CHAR BROILER

The following instructions must be observed when using the appliance.

Note: The SCB Super Char Broiler must only be used for the purpose it was design

and inline with the supplied operating instructions.

GRILL.

4.1 NEVER

• Allow children, infirm persons or unqualified personnel to operate the grill.

• Operate the SCB Super Char Broiler if a fault develops or is unsafe.

• Wear loose clothing.

• Wear flammable clothing such as silks, polyester, etc that are highly flammable

when using this appliance.

• Use bleach, hypochlorite or chlorine compounds to clean the SCB Super Char

Broiler internally or externally.

7

Page 9

• Use excessive force when operating which could affect the stability of the

appliance.

• Operate the SCB Super Char Broiler if parts are disassembled.

• Use the appliance in an unsafe condition.

• Clean the SCB Super Char Broiler with scouring powder or a scouring pad.

• Dry tea towels and cloths on the appliance.

• Obstruct openings or heat vents

• Tamper or change any sealed devices on the appliance.

• Use wax tapers to ignite the pilot light.

• Allow debris to accumulate on the grates.

4.2 ALWAYS

• Use the appliance in a well-lit area.

• Use the SCB Super Char Broiler as intended and inline with the operating

instructions.

• Be aware of hot surfaces on the appliance.

• Wear safety glasses whilst cooking.

• Apply cooking oil to the grates before use.

8

Page 10

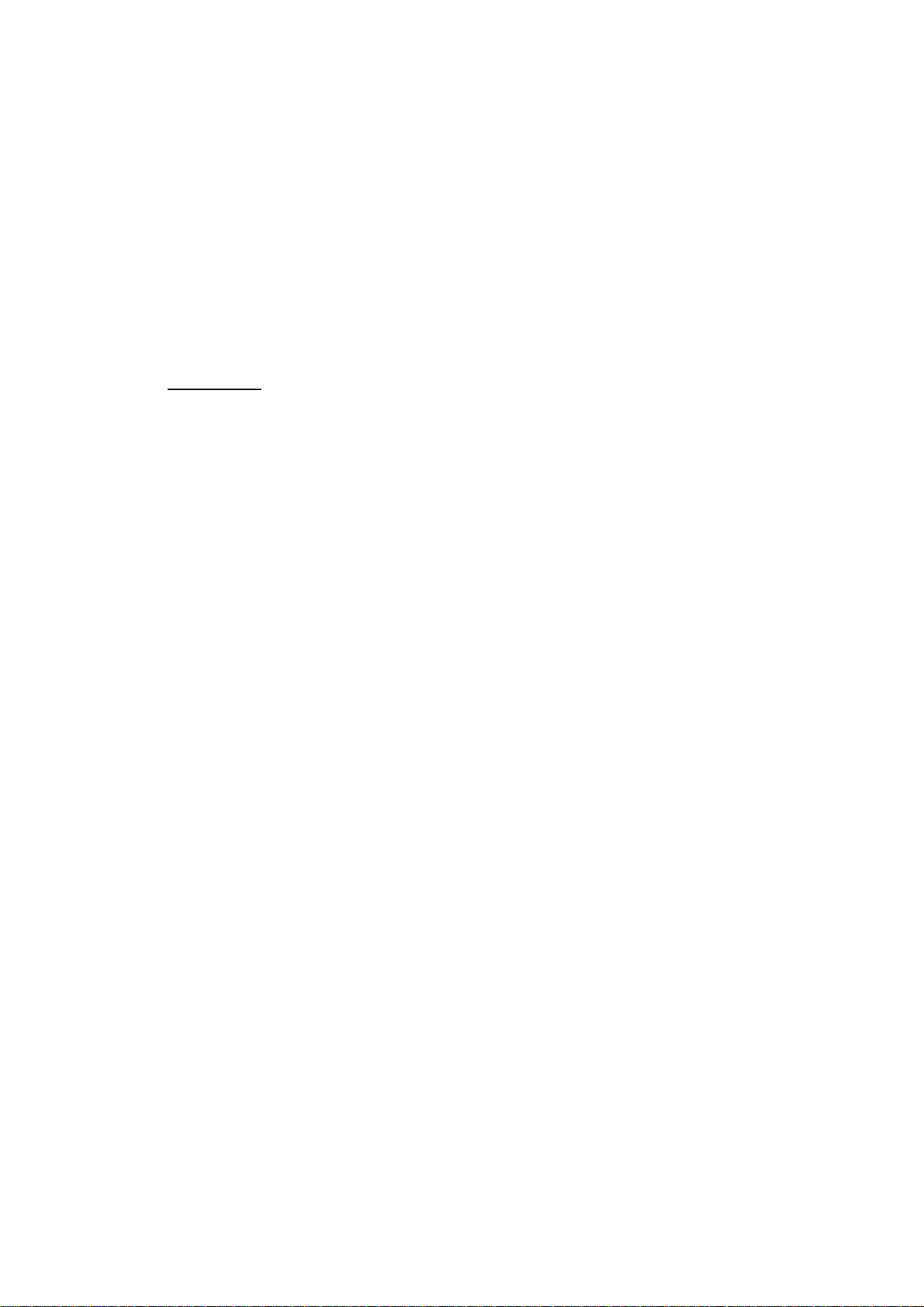

5.0 OPERATING THE SCB SUPER CHAR BROILER.

5.1 LIGHTING INSTRUCTIONS –PIEZO IGNITION.

It is not necessary to remove the grates and radiants when using the piezo ignition

system. However in certain instances the grates and radiants may be removed.

WARNING! Before attempting to remove the grate and radiants ensure

they are at an acceptable temperature to touch and handle. This will

normally take approximately 3 hours after turning off the main burner.

1. Ensure the gas supply to the SCB is turned

‘on’.

2. Push in and turn the

control knob approximately 30

degrees anti-clockwise to the

ignition point indicated by the

star (*) symbol as shown in

photograph 3.

IGNITION POSITION PILOT

GRATES AND RADIANTS.

PHOTOGRAPH 2.

3. Push and hold the control knob in for approximately 5 seconds to release gas

from the pilot burner jet and then press the piezo igniter. Normally only 2 or 3

‘clicks’ are required to ignite each pilot burner.

Hold the control knob in for 10 to 15 seconds

before releasing. This allows the flame failure

control system to heat up to its normal

operating temperature. If the pilot burner does

not remain illuminated wait three minutes and

try again. This ignition position (*) allows the

pilot light to burn continuously. In a cold kitchen

the heat up time may be longer, up to

20 seconds.

Piezo igniter

positioned

between 2

gas valves.

4. If the grates and radiants have

been removed replace them but only

with the pilot jet illuminated. Place the

radiant on the backrest first and then

lower the front.

5. To ignite the main burner, turn the

LIGHT ‘ON’ POSITION.

PHOTOGRAPH 3.

PIEZO IGNITER POSITION

BETWEEN GAS VALVES.

PHOTOGRAPH 4.

REPLACING THE RADIANTS.

PHOTOGRAPH 5.

knob to the ‘flame’ position. Allow

9

Page 11

approximately 30 minutes for the appliance to heat up to temperature before starting

to cook.

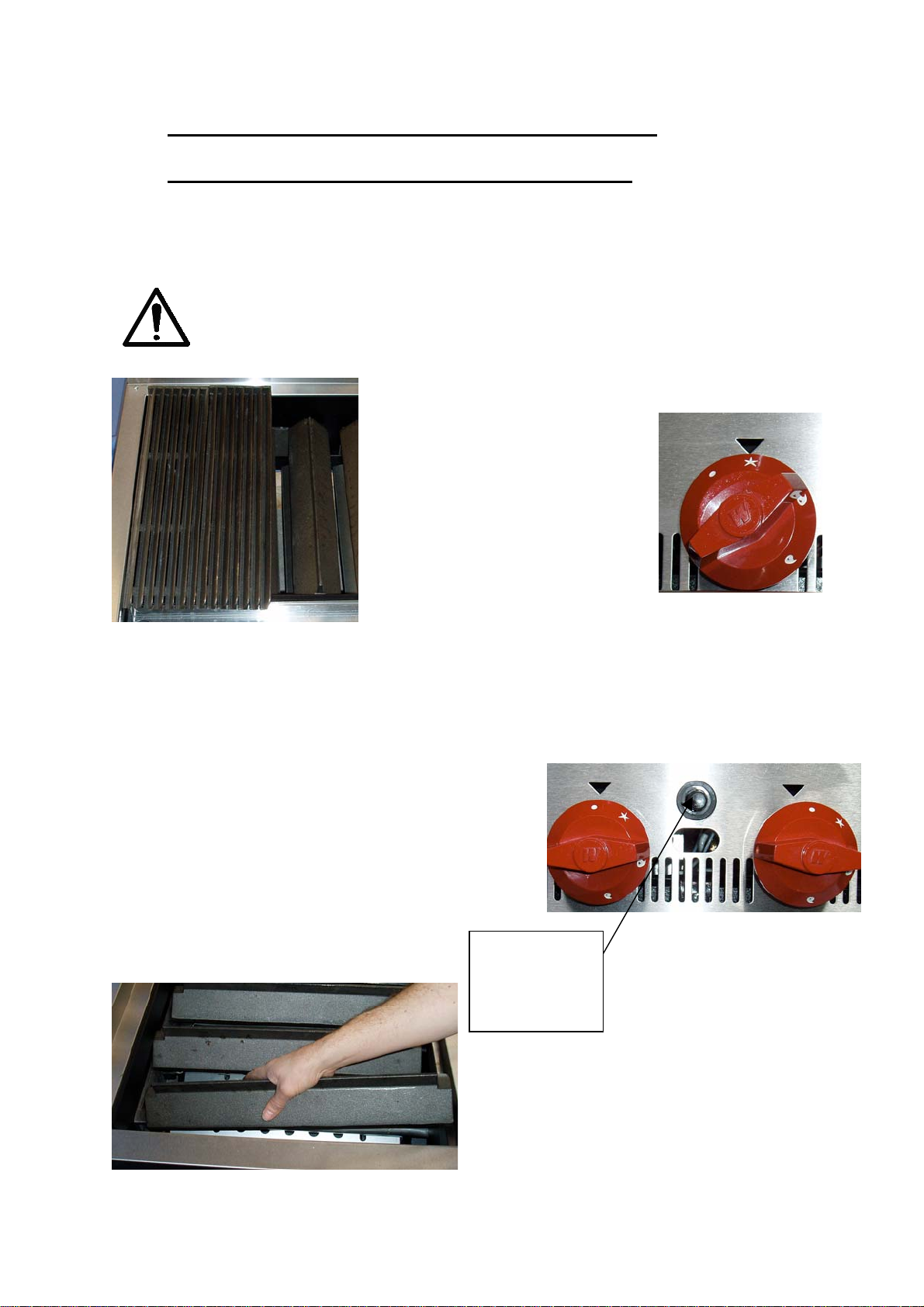

MAIN BURNER ‘ON’

HALF FLAME POSITION.

PHOTOGRAPH 6.

6. To extinguish the main burner and leave the pilot flame

burning turn the control knob clockwise to the star position

shown in photograph 8.

PILOT BURNER

‘ON’ POSITION.

PHOTOGRAPH 8.

7. To turn off the SCB char broiler main burner and pilot flame, rotate the control

knob to the 'OFF' position indicated by the white dot.

MAIN BURNER ‘ON’

FULL FLAME POSITION.

PHOTOGRAPH 7.

‘OFF’ POSITION.

PHOTOGRAPH 9.

5.2 USING THE SCB CHAR BROILER.

The following notes provide general guidance on the operation of the SCB Char

Broiler.

• Apply cooking oil to the grates before use. Excess grease will run forward and

drip onto the front grease trough.

10

Page 12

• When the SCB Char Broiler is loaded with food product adjust the gas valves to a

lower setting to prevent overheating causing the food to char.

• The grates must be scraped with a wire brush to keep them clean. Do not allow

debris to accumulate on the grates.

• Adjust the flame to the low setting or pilot burner during slack periods to conserve

energy.

• The SCB Char Broiler is a free venting appliance. All the products of combustion

and heat generated during cooking pass through the grates. When food product

is placed on the grates the ventilation is partially blocked causing a temperature

build-up. The appliance will operate more efficiently in these circumstances with

the gas valves adjusted down one third to one half.

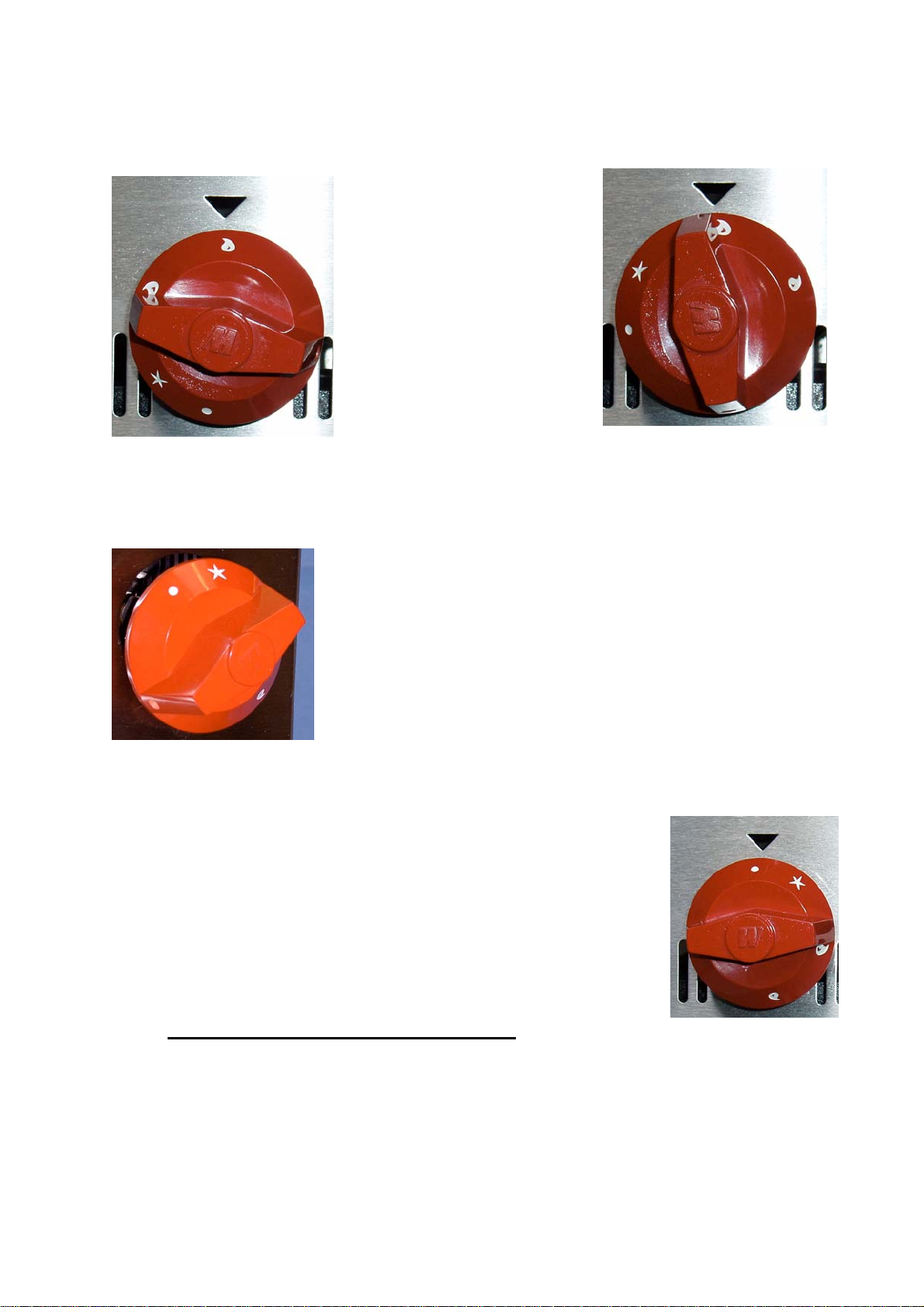

5.3 REVERSING THE GRATES.

The slope of the grates can be altered to suit the type of product being cooked. The

shape of the casting at the far end allows the grates to be positioned either with a

slope to the front trough of the appliance or flat, as shown below. The angled

position is used for the cooking of meat and fish products where any oil or fat must

run into the trough situated at the front of the appliance. The flat position enables

pans to be heated on the top of the unit.

WARNING! Before attempting to alter the grate positions ensure they are

at an acceptable temperature to touch and handle. This will normally take

approximately 3 hours after turning off the main burner.

ANGLED

GRATES

GRATES SHOWN FLAT AND

SLOPING. PHOTOGRAPH 10.

FLAT

GRATES

11

Page 13

5.4 USING THE GRATE REMOVAL TOOL (OPTIONAL).

The following sequence describes the procedure to remove or reverse a grate.

4

12

5

7 8

3

6

9

12

10

Caution! Wear suitable protective clothing when handling hot grates.

11

12

Page 14

6.0 CLEANING.

DO NOT HOSE OR PRESSURE CLEAN THIS SCB CHAR BROILER.

INDIVIDUAL PARTS MAY BE PRESSURE CLEANED. REFER TO THE

FOLLOWING SECTION.

DO NOT USE ANY ABRASIVE CLEANERS

REFER TO THE RELEVANT COSHH DATA SHEETS PRIOR TO USING ANY

CLEANING PRODUCTS.

WEAR APPROPRIATE PERSONAL PROTECTIVE EQUIPMENT.

Prior to cleaning the appliance extinguish the main and pilot burner flames, isolate

the gas supply using the locally fitted isolating valve and ensure the appliance is at

an acceptable temperature to handle prior to cleaning.

6.1 CLEANING THE GRATES.

WARNING! Before attempting to remove the grates ensure they are at an

acceptable temperature to touch. This will normally take approximately 3

hours after using with the main burner.

1. Scrape the grease trough cast into the grates so the grease flows uninhibited

into the gutter and drawer. This will reduce the risk of flare-up.

2. The grates may be laid in the flat position and the burners then turned on full

to burn off excessive fat and carbon. When the grates have cooled off, clean

thoroughly with a wire brush.

3. The grates may be immersed in a strong commercial non-toxic cleaning

solution over night. In the morning flush with hot water and steam clean to

remove any debris.

4. To clean the front gutter, remove the grates and lift out the gutter. Wash

thoroughly with a hot detergent solution.

6.2 CLEANING THE RADIANTS.

Occasionally the cast iron radiant situated under the grates may require cleaning.

WARNING! Before attempting to remove the grates and radiants ensure

they are at an acceptable temperature to touch. This will normally take

approximately 3 hours after using with the main burner.

1. The radiants may be cleaned thoroughly using a wire brush or by immersing

in a strong commercial non-toxic cleaning solution over night. In the morning

flush with hot water and steam clean to remove any debris.

6.3 CLEANING THE EXTERIOR SURFACES.

When the appliance is cool, the gas control knobs and stainless steel surfaces may

be cleaned with a mild soap and water solution applied with a damp cloth. Rinse

the surface with clean water and dry with a soft cloth. Do not use an abrasive or

strong liquid cleaner on the stainless surface since they may damage the finish.

Page 15

CAUTION ABOUT USING "SPRAY-ON" CLEANERS

Be careful when using spray cleaners. Read the safety data sheet prior to use and

follow the instruction label on the container. Wear appropriate protective clothing.

Some cleaners may contain caustics.

7.0 DESIGN AND CONSTRUCTION DATA.

The data listed in table 1 applies to all of the natural gas and LPG versions of the

SCB Super Char Broiler.

TABLE 1. TECHNICAL INFORMATION, PART 1.

Parameter Units Model

#

SCBXXCE-1

#

SCBXXCE-2

Type of gas Natural (G20) LPG (G31)

Appliance category I

2H

I

3P

Nominal heat input per burner kW (Btu/hour) 4.2 (14,300) 4.2 (14,300)

Gas supply pressure

m bar 20 37

(nominal)

Gas supply pressure

m bar 17 30

(minimum)

Gas supply pressure

m bar 25 45

(maximum)

Gas operating pressure

(standard orifice)

m bar (inches

water gauge)

12.5 (5) 25.0 (10)

Pressure tap nozzle size mm (inch) 9.0 (0.354) 9.0 (0.354)

Minimum gas supply pipe

mm (inch) 22 (7/8) 22 (7/8)

internal diameter

Burner orifice diameter (no

mm 1.70 1.10

adjustment)

Burner orifice identification #051 #057

Pilot orifice diameter mm 0.533 0.356

Pilot orifice identification 1.8N 1.0P

Thermocouple hold on time

Seconds 15 15

(nominal)

Flame out time (nominal) Seconds 30 30

Type of appliance A A

Recommended hood air flow

m/s 0.4 0.4

velocity

Minimum clearance dimensions

Combustible material, rear,

mm (inch) 305 (12) 305 (12)

above grid level

Combustible material, rear,

mm (inch) 75 (3) 76 (3)

below grid level

Combustible, material sides,

mm (inch) 225 (9) 225 (9)

above grid level

Combustible, material sides,

mm (inch) 75 (3) 75 (3)

below grid level

13

Page 16

Parameter Units Model

#

SCBXXCE-1

#

SCBXXCE-2

Combustible, material below mm (inch) 100 (4) 100 (4)

Non combustible, material

mm (inch) 150 (6) 150 (6)

below

Non combustible material,

mm (inch) 75 (3) 75 (3)

rear, above and below grid

level

Non combustible material,

mm (inch) 0 (0) 0 (0)

sides, above and below grid

level

Adjustable leg thread size 3/8” UNC 3/8” UNC

Gas connection (to BS2779) BSP G3/4A (3/4”

parallel male

G3/4A (3/4” parallel

male thread).

thread).

Initial heat up time on

Minutes 30 30

maximum burner setting

Time for grates and radiants

Hours 3 3

to cool to a safe handling

temperature.

Grate weight each kg 6.3 6.3

Radiant weight each kg 5.1 5.1

Noise level dB (A)

Storage conditions.

Temperature and humidity.

o

C,

% RH

##

less than 60

+5 to +55,

85

##

less than 60

+5 to +55,

85

#

Refer to table 2 for specific model data.

##

In accordance with EN-ISO 11202.

14

Page 17

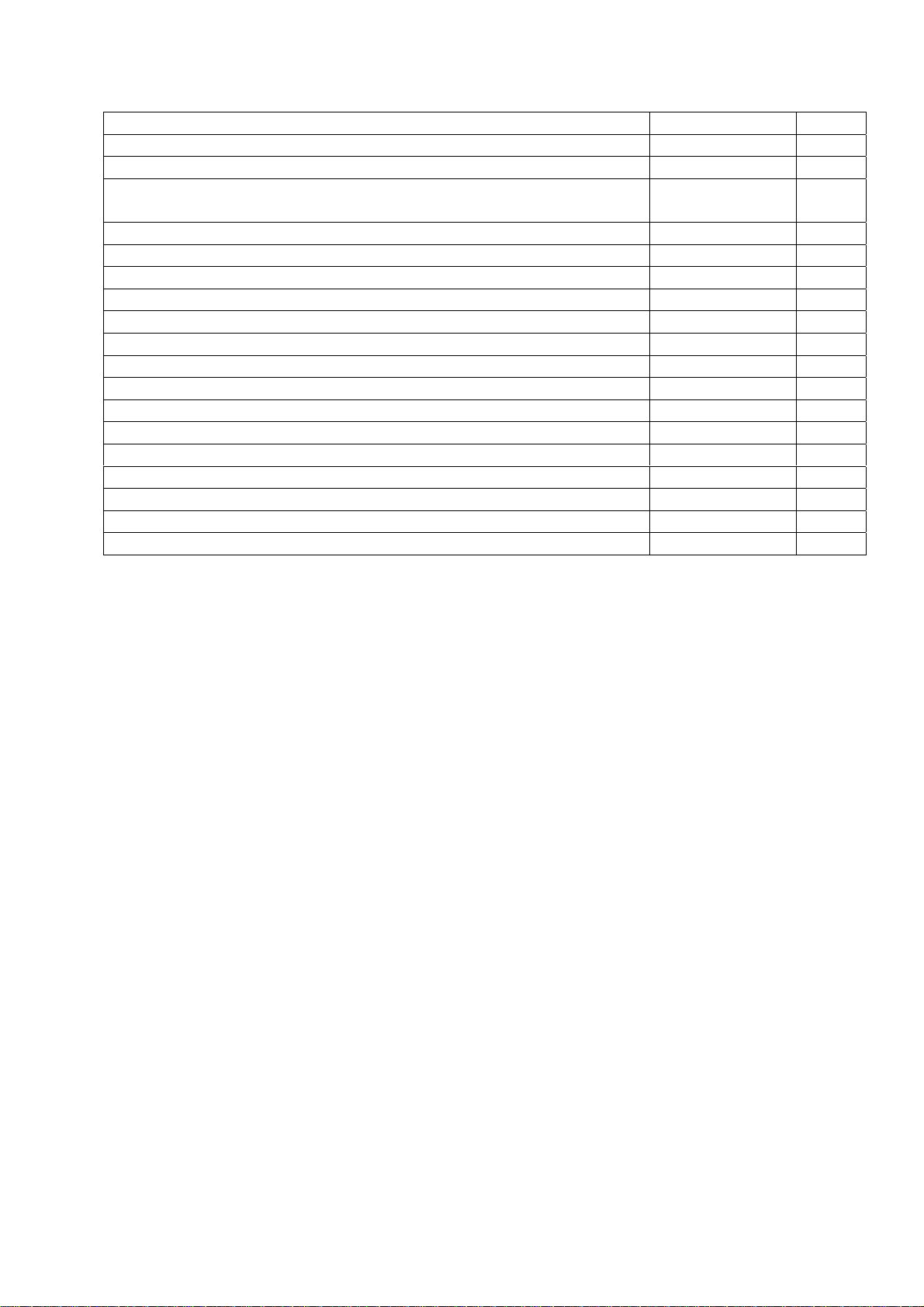

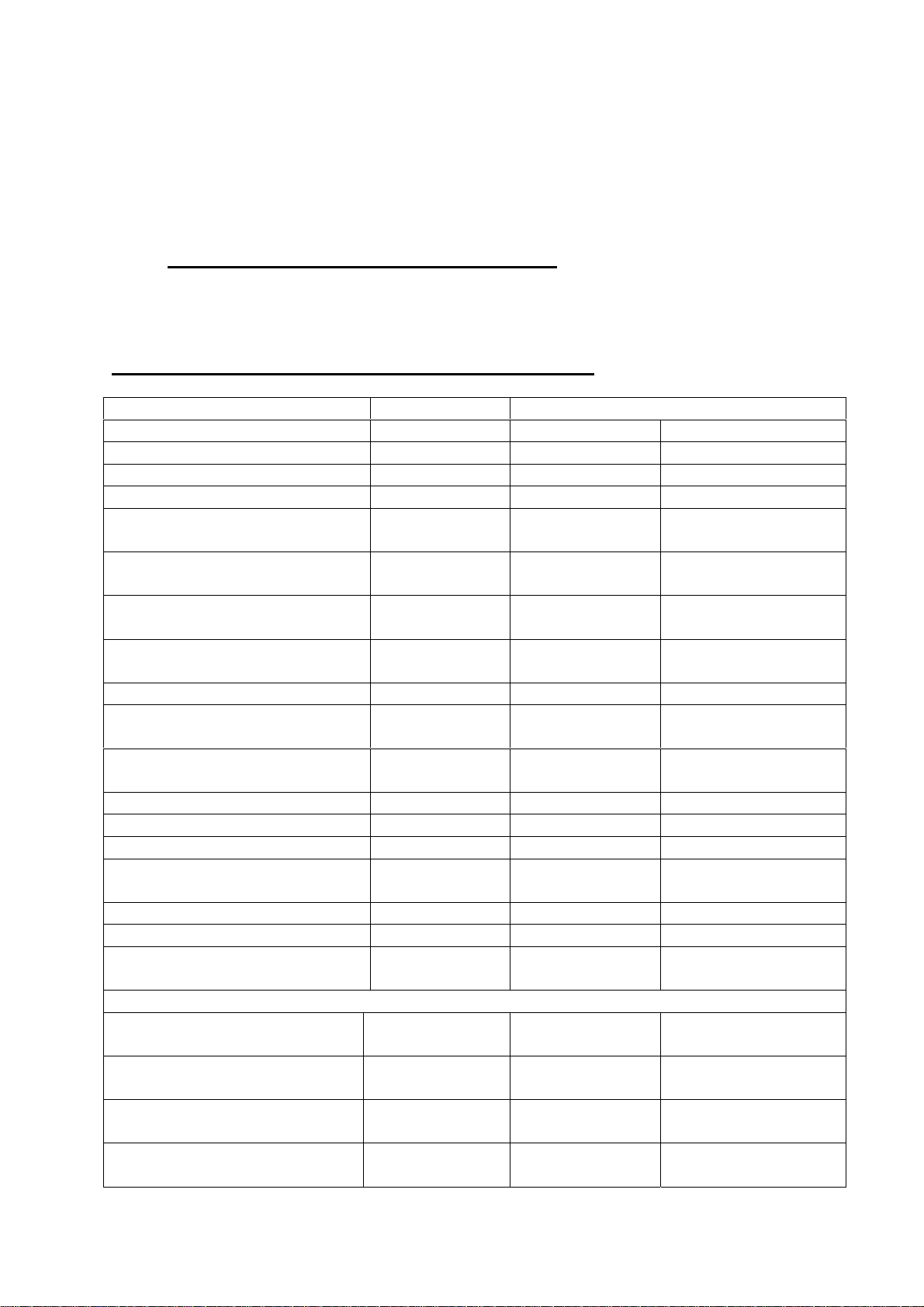

TABLE 2. TECHNICAL INFORMATION, PART 2.

Parameter Units SCB25CE SCB36CE SCB47CE SCB60CE SCB72CE

Net weight kg 86.5 127 169.5 211 260

External

dimensions

Shipping

weight

Shipping

dimensions

(including

pallet)

Number of

burners

Total burner

rating

Nominal gas

consumption

(natural gas)

Nominal gas

consumption

(LPG)

Typical rate of

ventilation

based on

54m3/minute

per m2 of

appliance.

W x D x H

mm

kg 107 152 196 251.5 308

W x D x H

mm

kW

(Btu/hour)

m3/h 1.78 2.67 3.56 4.90 5.79

m3/h 0.69 1.03 1.37 1.89 2.23

m3/minute2840526780

635 x 810

x 380

745 x 920

x 500

4681113

16.8

(57200)

914 x 810

x 380

1025 x

920 x 500

25.2

(85800)

1194 x

810 x 380

1305 x

920 x 500

33.6

(114400)

1524 x

810 x 380

1635 x

920 x 560

46.2

(157300)

1829 x

810 x 380

1940 x

920 x 560

54.6

(185900)

TABLE 3. BURNER AND PILOT ORIFICE SIZES.

Gas P mbar Jet description Size

G20 20 12.5 Burner Orifice 1.70 mm (0.067”)

Pilot Orifice 1 off 0.533 mm

(0.021”)

G31 29 25 Burner Orifice 1.10 mm (0.043”)

G31 37 25 Pilot Orifice 1 off 0.22 mm (1 off

0.0087”)

G31 50 25

15

Page 18

TABLE 4. GAS CATEGORY AND PRESSURES.

P mbarCountry Category Gas

Inlet Manifold

AT I2H G20 20 12.5

DK

IE

PT

ES

IT

SE

FI

GR

CH

GB

DE I2E G20 20 12.5

LU

FR I2Er G20 20 12.5

NL I3P G31 30 25

FR I3P G31 37 25

GB

BE

IE

GR

NL I3P G31 50 25

GB

BE

ES

DE

GR

FR

TABLE 5. GAS CONSUMPTION AND ENERGY USAGE.

The following table is based on actual test results.

Pilot burner Half flame main

burner

Model Number of

burners

SCB25 4.00 0.06 0.68 0.54 5.83 1.65 17.86

SCB36 6.00 0.09 1.02 0.81 8.75 2.47 26.79

SCB47 8.00 0.13 1.36 1.08 11.67 3.29 35.72

SCB60 11.00 0.17 1.88 1.48 16.04 4.53 49.12

SCB72 13.00 0.20 2.22 1.75 18.96 5.35 58.05

Gas

consumption

M3/hr kWh M3/hr kWh M3/hr kWh

Energy

usage

Gas

consumption

16

Energy

usage

Full flame main burner

Gas

consumption

Energy

usage

Page 19

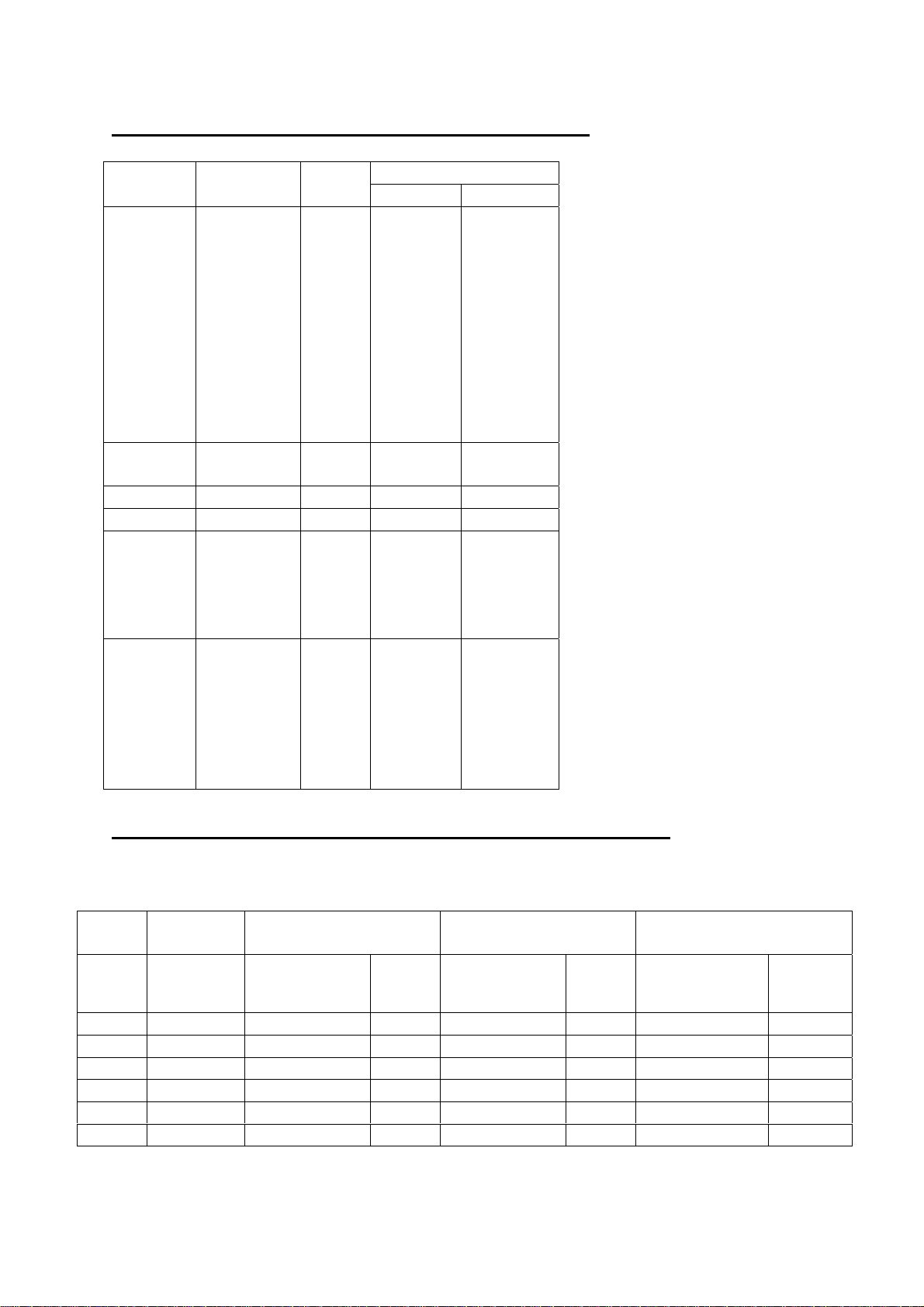

FIGURE 1. INSTALLATION DIMENSIONS (example is for an

SCB47CE refer to table 2 for all models).

8.0 INSTALLING THE SCB SUPER CHAR BROILER.

In order to ensure a safe and satisfactory installation it is important that discussions

take place between those involved with the kitchen design, selection of the grill,

layout and installation of the equipment. The SCB must be installed by a competent

person to ensure safe and hygienic operation. Consideration must be given to

catering and food hygiene.

8.1 UNPACKING AND HANDLING.

Wherever possible the appliance should be transported to the

installation position in the packaging provided to avoid damage.

Do not use a sharp knife to cut into the packaging as damage to

the machine may occur. Check for possible shipping damage. If

the unit is found to be damaged, save the packaging material

and contact your nearest Hobart sales office.

17

Page 20

Caution: The SCB Char Broiler is a heavy object and must be correctly

handled and lifted to avoid personal injury. Refer to table 2 for weights and

dimensions. For UK installations refer to the ‘Manual Handling Operations

Regulations 1992 and HSE guidance notes for manual handling.

With the appliance in the vicinity of its final position remove the shrink wrap film and

lift the unit from the transportation pallet.

Care must be taken during this operation to ensure: -

a) All required safety measures are taken to ensure correct lifting and handling to

avoid risk of injury through dropping, falling and tilting.

b) No damage occurs to the machine, that could impair the normal operation.

8.2 LOCATION.

The SCB Char Broiler is not suitable for outdoor installation and must not be installed

where a water jet could be used for cleaning. The appliance must only be operated

by trained staff and must be installed in an area where the use and maintenance is

restricted to trained personnel.

This appliance shall be installed in conformity with the current regulations (BS6173)

and used only in a well-ventilated location. Consult the instructions before installing

and using this appliance.

The LPG version of the SCB must not be installed in a room having no means of low

level natural ventilation direct to outside (for example in a basement or cellar).

Important! Ensure there is sufficient space around the SCB to enable safe

operation. Servicing may be more difficult because of reduced clearances and you

should always check that equipment specifications permit the close proximity of

other equipment. Refer to table 1 for minimum clearances. Service access is

required to the front, bottom, sides and top of the appliance. It is suggested that at

least 600 mm of free area be provided to the front of the unit.

8.3 GENERAL INSTALLATION GUIDELINES.

The SCB Char broiler should not be located adjacent to customer services where hot

surfaces may cause burns.

The SCB Char Broiler must not be installed next to open burners or fryers. Other

types of gas fired appliances can be positioned adjacent to the SCB Char Broiler

however there must not be any obstruction to the front.

Before proceeding with the installation, remove the protective plastic film from all

panels. Use an appropriate cleaning product to remove any adhesive residues from

the stainless steel.

18

Page 21

When installing never enclose the unit’s lower area in any way that would obstruct

the flow of air into the appliance.

Crevices need to be avoided between and behind the appliance, and pipe work

where any spillage may lodge.

All supports shelves and wall finishes must be capable of withstanding a minimum

temperature of 65°C and be non-combustible.

The SCB must be secured in position to prevent any movement. Restraints must not

be fixed to the gas supply pipes or points not sufficiently anchored.

For any ‘work’ performed in the UK on the appliance including installation that is

within the scope of the Gas Safety (Installation and Use) Regulations shall be carried

out by a business that is CORGI approved (Council for Registered Gas Installers)

and approved by the Health and Safety Executive (HSE).

The SCB Char Broiler shall have a single manual isolating valve to be used when

servicing or cleaning.

A manual operation valve must be fitted to the gas supply to the catering area to

enable it to be isolated in an emergency. Ideally this valve should be located outside

the catering area or near an exit in a readily accessible position.

On completion of the installation a leak test must be performed. CAUTION!

A naked flame must not be used for this purpose. Leak test solutions may

cause corrosion therefore thorough rinsing with water is required after

testing.

8.4 MOUNTING OF THE APPLIANCE.

The SCB Char Broiler must be mounted on a flat surface. The appliance is supplied

with 4 off legs 100 mm high (4”) to ease cleaning underneath. This appliance is not

suitable for building in to other appliances.

Select a suitable flat level surface that can support the weight of the SCB Char

Broiler and food product (refer to table 2 for weights and dimensions). The unit must

be installed on a horizontal flat surface. Once the appliance is in position adjust the

feet to ensure the unit is level to within 1mm in 1 metre side to side and front to back.

The SCB Char Broiler must be adequately secured and restrained in position.

8.5 GAS PIPE WORK.

The installation of the gas pipe work in the UK must be in accordance with latest

revision of standard BS6173.

• Gas pipe work must be installed in a sound and workman-like manner and be

constructed of materials suitable for its purpose.

• Pipes conveying gas must be adequately identified.

19

Page 22

• For rigidly fixed pipe work a union or similar method of disconnection must be

provided between the isolation valve and appliance.

• The clearance between the gas pipe and wall must be at least 25mm to ease

cleaning.

• Semi-rigid pipe must conform to BS7838 and only be installed in a ventilated area

where it cannot be damaged.

• If a flexible connection is installed it must not touch the floor or be exposed to

excessive heat.

• The gas outlet to which the connection is made must be located in the same

room as the appliance.

• If a flexible connection is used it must not be concealed within or routed through

any wall or partition.

• Flexible gas connections must not come into contact with sharp edges or wiring.

8.6 VENTILLATION.

Provision is required for adequate dispersal of combustion and cooking fume

products, supply of combustion air and ventilation for the appliance and cooking

processes. Adequate fresh air is required in kitchens to provide air for combustion to

limit the effects of heat and humidity (reference must be made to HVCA DW/171 to

ensure there is adequate ventilation for the appliance). Refer to table 2 for the typical

ventilation rate. Consideration must be made for other gas appliance that may be in

the same area as the SCB Char Broiler.

This type ‘A’ appliance is not designed to be connected to a flue or other device for

evacuating the combustion products to the outside of the room where it is installed.

The appliance must be installed in a suitably ventilated room in accordance with

current regulations (BS6173).

It is advisable that a hood is fitted above the appliance to ensure effective extraction

of combustion fumes and cooking odours. The plan dimension of the canopy should

exceed the plan area of the SCB Char Broiler by an overhang of 250mm at the front

and 150mm at the ends. The hood and ductwork must be constructed from noncombustible material. Table 2 specifies the ventilation airflow requirement.

For new installations the gas supply to the appliance must be interlocked with any

mechanical ventilation system fitted to ensure safe operation of the appliance.

The SCB must not be installed in a catering area where the ventilation system could

adversely affect its safe operation.

Broiling produces greasy cooking odours and vapours that require filtration. The

filters must be reviewed frequently and cleaned on a regular basis (at least every

month).

The SCB Char Broiler must be supported on a suitably designed surface that will

withstand the weight of the appliance and food product. The appliance must be

restrained to prevent any movement during use.

20

Page 23

Low level ventilation is always required for appliances using a gas (LPG) heavier

than air.

It is strongly recommended that a flammable gas and CO detector is fitted that is

suitable for catering environments.

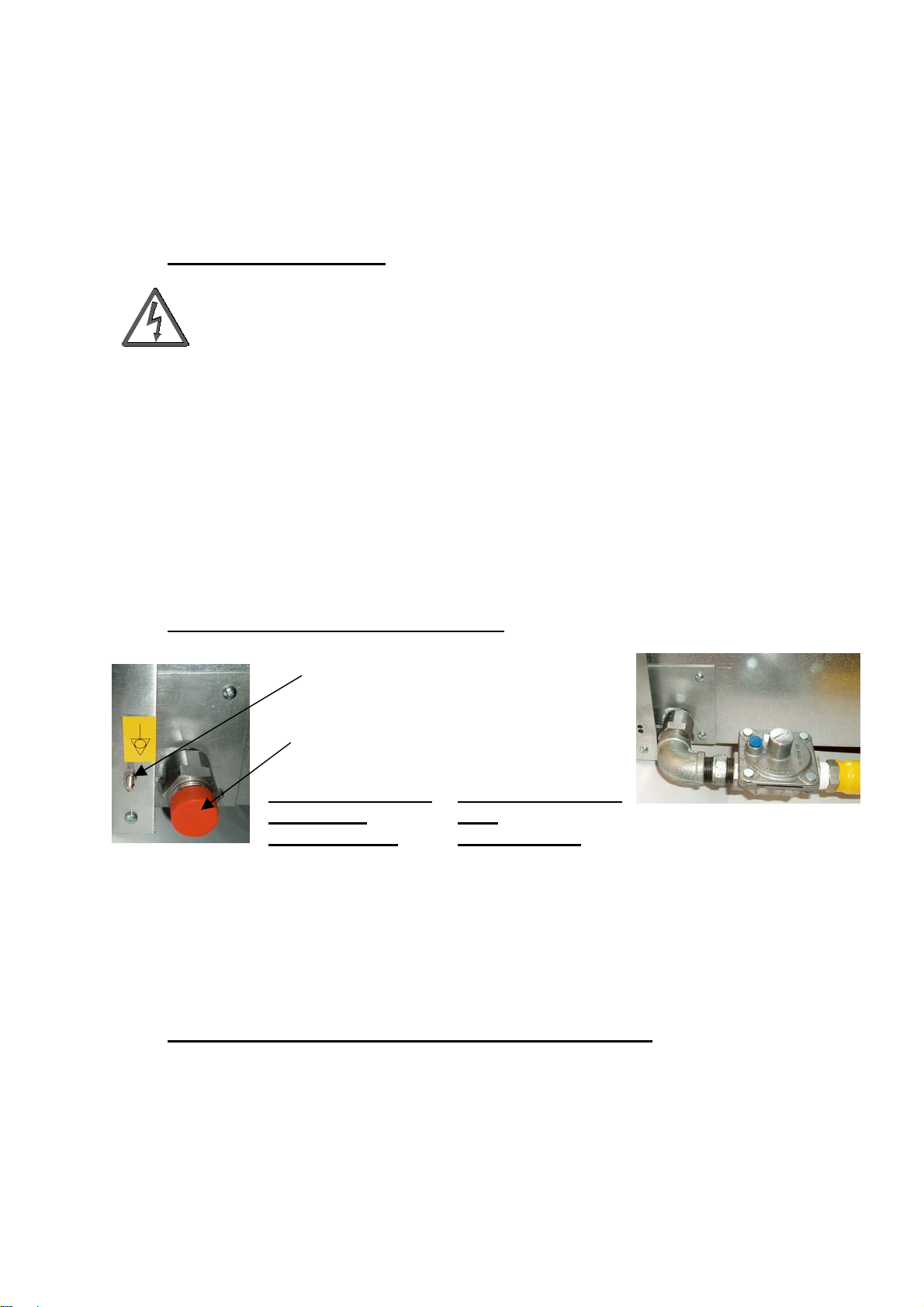

8.7 GAS INSTALLATION.

When installed in the United Kingdom the installation must conform to

the Gas Safety (Installation and Use) Regulations. This appliance must

be earthed as shown in section 9.9.

It is strongly recommended that a flexible connection be used for the gas supply to

the appliance.

Refer to table 2 and the appliance data plate to ensure there is an adequate supply

of gas. Check that the gas type and gas pressure is consistent with the gas supply of

the SCB. If the appliance is not suitable for the gas being supplied it shall not be

installed or connected to the gas supply.

Conversion of the appliance from one gas to another must be carried out strictly in

accordance with Hobart instruction’s by a competent person.

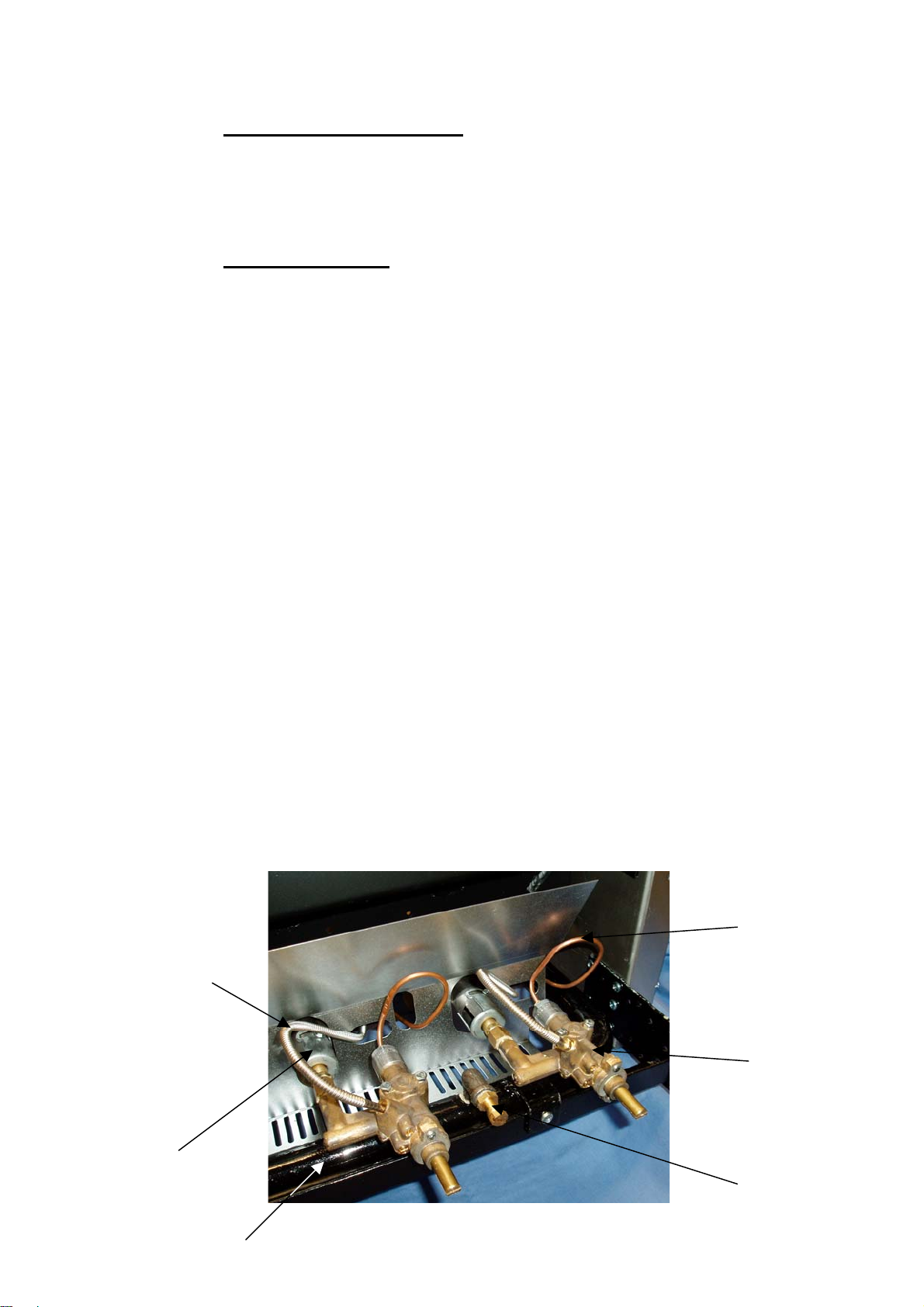

8.8 FITTING THE GAS REGULATOR.

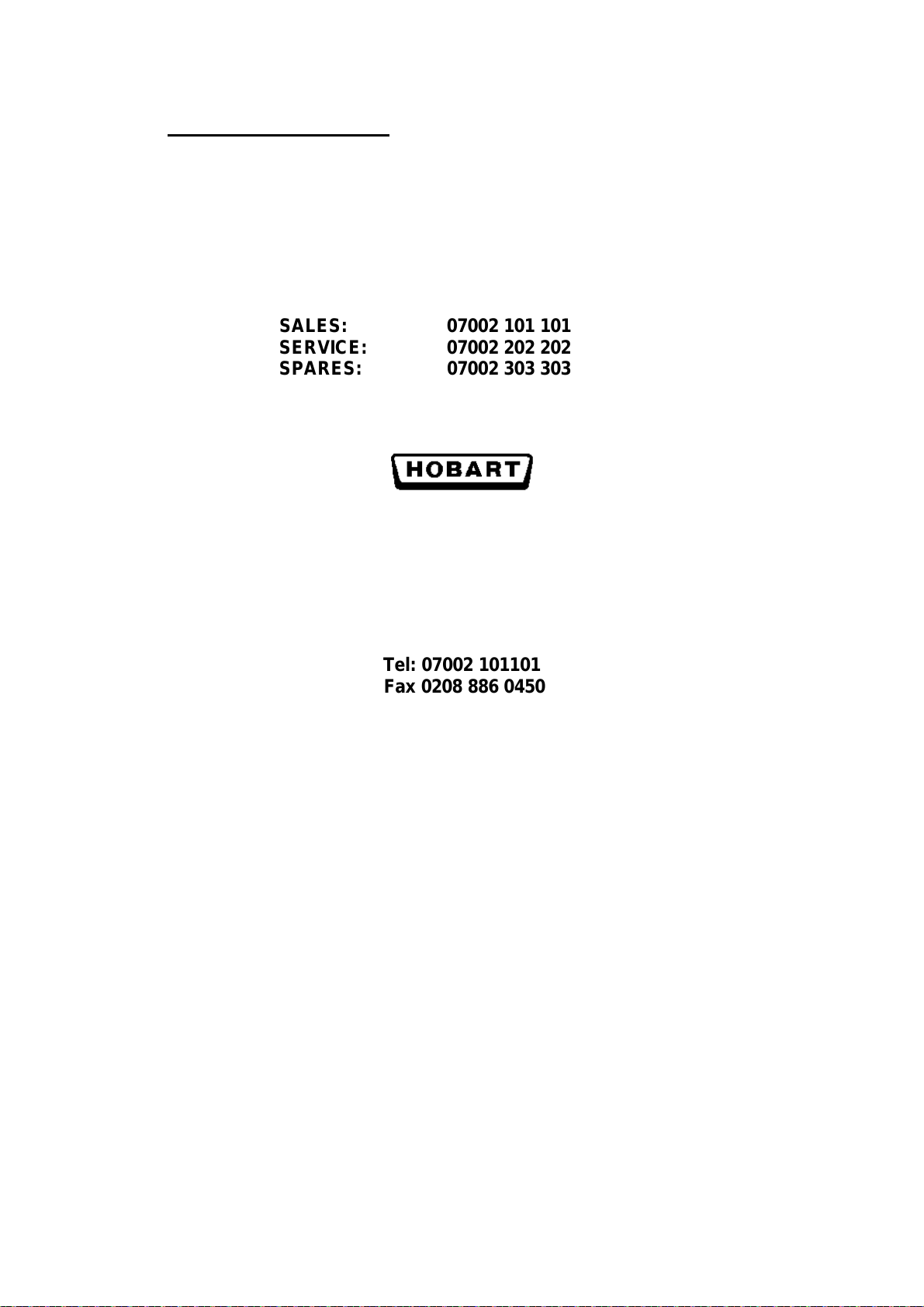

Earth bonding

screw.

Gas inlet

connection.

PHOTOGRAPH 11.

GAS INLET

CONNECTION.

The gas regulator is supplied loose with the appliance. Fit the regulator as follows:

1. The SCB Char Broiler gas inlet pipe connection is ¾” BSP male. Apply

suitably approved jointing compound to the threads.

2. Using a spanner tighten the gas regulator on to the appliance. Note the

direction of gas flow arrow.

PHOTOGRAPH 12.

GAS

REGULATOR.

8.9 ELECTRICAL EARTH BONDING CONNECTION.

Where necessary for electrical safety the SCB Char Broiler should be fitted with an

earth bonding screw as shown in photograph 11. Check the earth bonding resistance

is less than 0.1Ω.

21

Page 24

8.10 GAS BURNER SECURING TAPE.

The gas burners are secured in place during transit

with masking tape as shown in photograph 13.

Carefully lift off the grates and radiants as detailed in

section 6.1 and remove the masking tape before use.

PHOTOGRAPH 13.

GAS BURNER SECURING MASKING TAPE.

9.0 COMMISSIONING INSTRUCTIONS.

This SCB Char Broiler is only intended for professional use by suitably

trained people. Ensure operators have read and understood this manual

and have received adequate training.

The installation of the appliance must be commissioned by a competent person

using the following instructions. In the UK the installation must be in accordance with

BS6173.

All new gas pipes upstream of the appliance must be tested for soundness and

purged of air before igniting the pilot burners. This can take several minutes

depending on the length of gas pipe to the appliance gas regulator. Hold several gas

burners in the priming position and allow the gas to flow through the pipe work.

Commissioning shall check the correct operation of the flame failure valve,

thermocouple and the burner pressure is adjusted to the value given in the technical

information table 1 and on the data plate.

All pipe work between the isolating valve and SCB Char Broiler must be tested for

leaks with no perceptible drop in water pressure gauge over a period of two minutes

at a pressure at least the operating pressure and not more than 1.5 times the

operating pressure. Following pressure testing the pipe work must be purged of air.

9.1 TO CHECK THE MANIFOLD GAS INLET PRESSURE

(DOWNSTREAM OF THE REGULATOR).

1. The gas inlet pressure to the appliance must be checked using a 0.80 m

bar WG manometer with an accuracy of at least 0.1 m bar WG.

2. Remove the screw from the 9mm-diameter pressure test nipple. The

pressure test nipple is situated on the front of the appliance (see

photograph 15).

3. Connect a silicone rubber tube to the manometer and test nipple. Ignite

the pilot and main burner and check the operating inlet pressure. Refer

to table 1 for the correct pressure.

4. Adjust the gas regulator to achieve the required pressure if necessary.

5. Replace the screw into the pressure test nipple and check for soundness

with a gas leak detector solution.

22

PHOTOGRAPH 14.

GAS INLET PRESSURE MANOMETER.

Page 25

9. 2 OPERATOR TRAINING.

Take time to explain the correct operation and cleaning of the SCB Char Broiler to

the users referring to this manual. Leave this manual with the operator and explain

that it is important to use it for further reference.

10.0. MAINTENANCE.

The frequency of service maintenance will depend on customer usage. Refer to table

5, section 13 for recommended service intervals.

The SCB Char Broiler must not be modified other than as specified by Hobart UK. A

competent person shall carry out all servicing and maintenance work.

If the appliance restraints are disconnected in order to remove it for servicing a

notice must be fixed near the restraint reminding the operator to reconnect the

restraint and any electrical earth bonding.

1. All moving parts must be checked for wear and lubricated, if necessary.

Replace if excessively worn.

2. The burner ports and throats should be thoroughly cleaned. The burner

orifice must be free from grease and lint. When cleaning DO NOT insert a

pick in the burner porthole.

3. SCB Char Broilers equipped with appliance restraints should be checked by a

competent person to ensure proper installation.

4. All places where oil, grease, or food can accumulate must be kept clean at all

times.

5. Pilot lights are to be kept clean and adjusted to the correct flame height to

assure constant ignition and to prevent fire flash-outs caused by delayed

ignition.

6. At the first sign of sticking all valves and controls, should be lubricated by a

trained person using high temperature grease.

7. At the slightest odour of gas, all fittings, pipes, tubing and controls should be

tested with a gas leak detector solution.

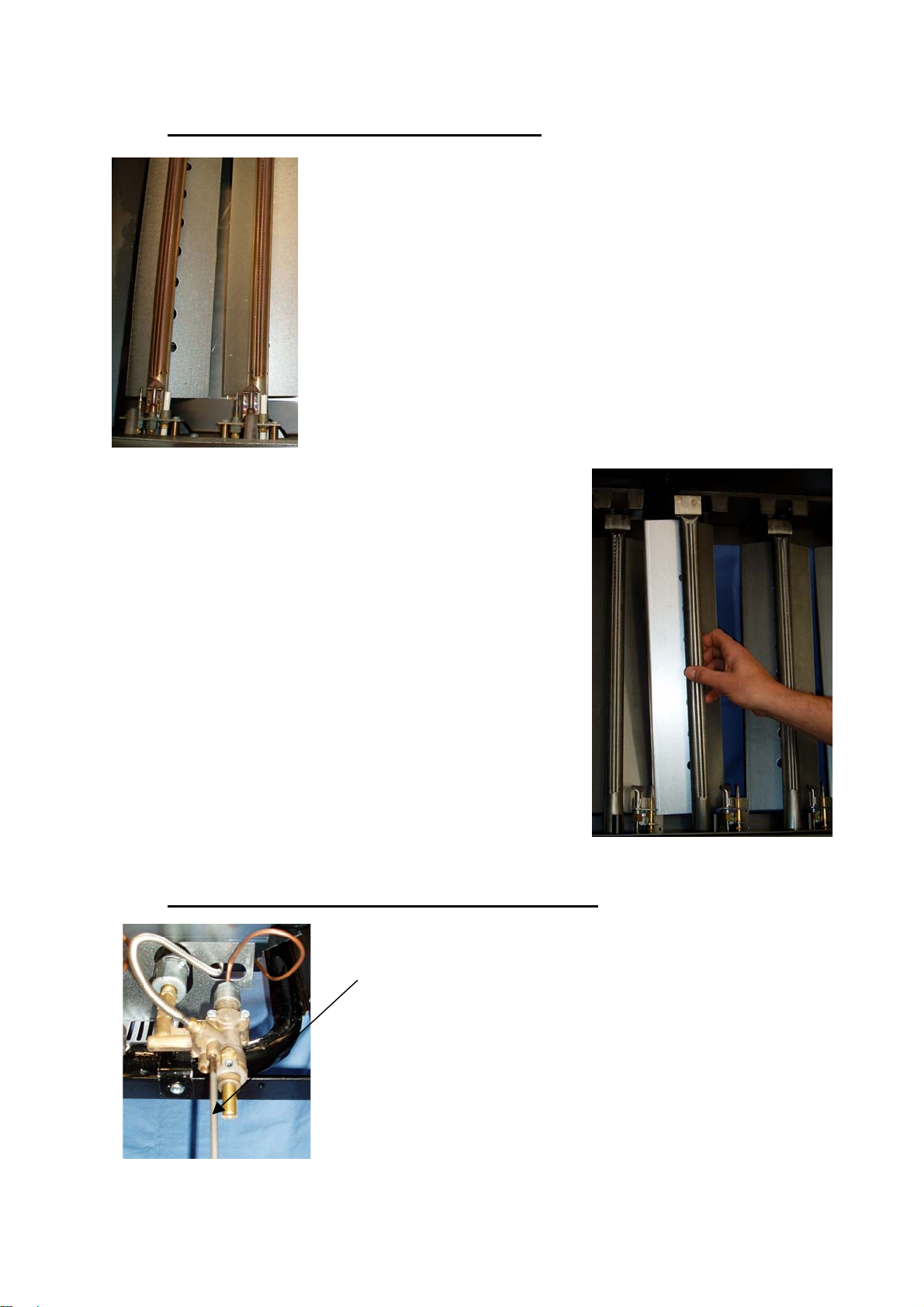

Pilot valve

gas supply

pipe.

Main

gas

burner

Gas supply

manifold.

23

Thermo

couple

Gas

control

valve.

Gas test

nipple

GAS CONTROL SYSTEM COMPONENT

IDENTIFICATION. PHOTOGRAPH 15.

Page 26

10.1 CLEANING THE BURNER BAFFLES.

The burner baffles are situated underneath the main

burners. Occasionally the baffles may need to be removed

for cleaning with a wire brush. The baffles are removed as

follows.

WARNING! Before attempting to remove the grates ensure

they are at an acceptable temperature to touch. This will

normally take approximately 3 hours after using with the

main burner.

NOTE! THE BURNERS MUST ONLY BE ADJUSTED BY A

COMPETENT AND AUTHORISED PERSON.

BURNER BAFFLES.

PHOTOGRAPH 16.

1. Carefully remove the grates and radiants.

2. To lift out the burner and baffle raise the rear of

the burner and withdraw to one side of the radiant

support.

3. Place the baffle on a flat surface a clean with a

wire brush.

4. Replacement of the burner and baffle is the

reverse of the above procedure.

5. Ensure the open end of the burner locates

correctly onto the gas nozzle.

WITHDRAWING THE

BURNER AND BAFFLE.

PHOTOGRAPH 17.

10.2 ADJUSTING THE PILOT BURNER FLAME.

PILOT BURNER FLAME

ADJUSTMENT SCREW.

TURN ANTI-CLOCKWISE TO

INCREASE FLAME SIZE.

PILOT BURNER FLAME

ADJUSTMENT SCREW.

PHOTOGRAPH 18.

24

NOTE! THE PILOT

BURNER FLAME MUST

ONLY BE ADJUSTED BY A

COMPETENT AND

AUTHORISED PERSON.

Page 27

The pilot burner flame must be stable and have an even and adequate coverage on

the thermocouple without flame lifting. The flame height range should be between 10

to 15 mm.

Air shutters situated on the main burners can be individually adjusted to provide a

blue flame.

To adjust the pilot burner flame, ignite the pilot jet as detailed in section 6.

Using a 4 mm wide slotted screw driver adjust the pilot burner screw anti-clockwise

to increase the flame height or clockwise to reduce the flame height. Ensure the

flame does not lift off the thermocouple when adjusted. This is particularly important

if the appliance is located directly above a strong ventilation system.

10.3 REPLACING THE PILOT BURNER.

NOTE! THE PILOT BURNER MUST ONLY BE REPLACED BY A COMPETENT AND

AUTHORISED PERSON.

WARNING! Before attempting to remove the grates ensure they are at an

acceptable temperature to touch. This will normally take approximately 3

hours after using with the main burner.

To replace the pilot burner assembly follow the instructions detailed below.

1. Isolate the gas supply to the appliance.

2. Carefully remove the grates and radiants

3. The pilot burner cover is secured using keyhole slots and two screws. Lift the

cover up and away from the locating screws (refer to photograph 19).

4. Partially pull open the drip tray(s).

5. Remove the gas control knobs, front cover securing screws and support the

front cover on the drip tray.

6. Pull off the relevant electrode wire from the piezo igniter.

7. Unscrew the thermocouple brass retaining nut and the pilot burner gas pipe

brass nut (refer to photograph 20).

8. Remove the screw securing the pilot burner assembly to the bracket.

9. Replacement is the reverse of the above procedure. After assembly check for

gas leaks with a suitable leak detection fluid.

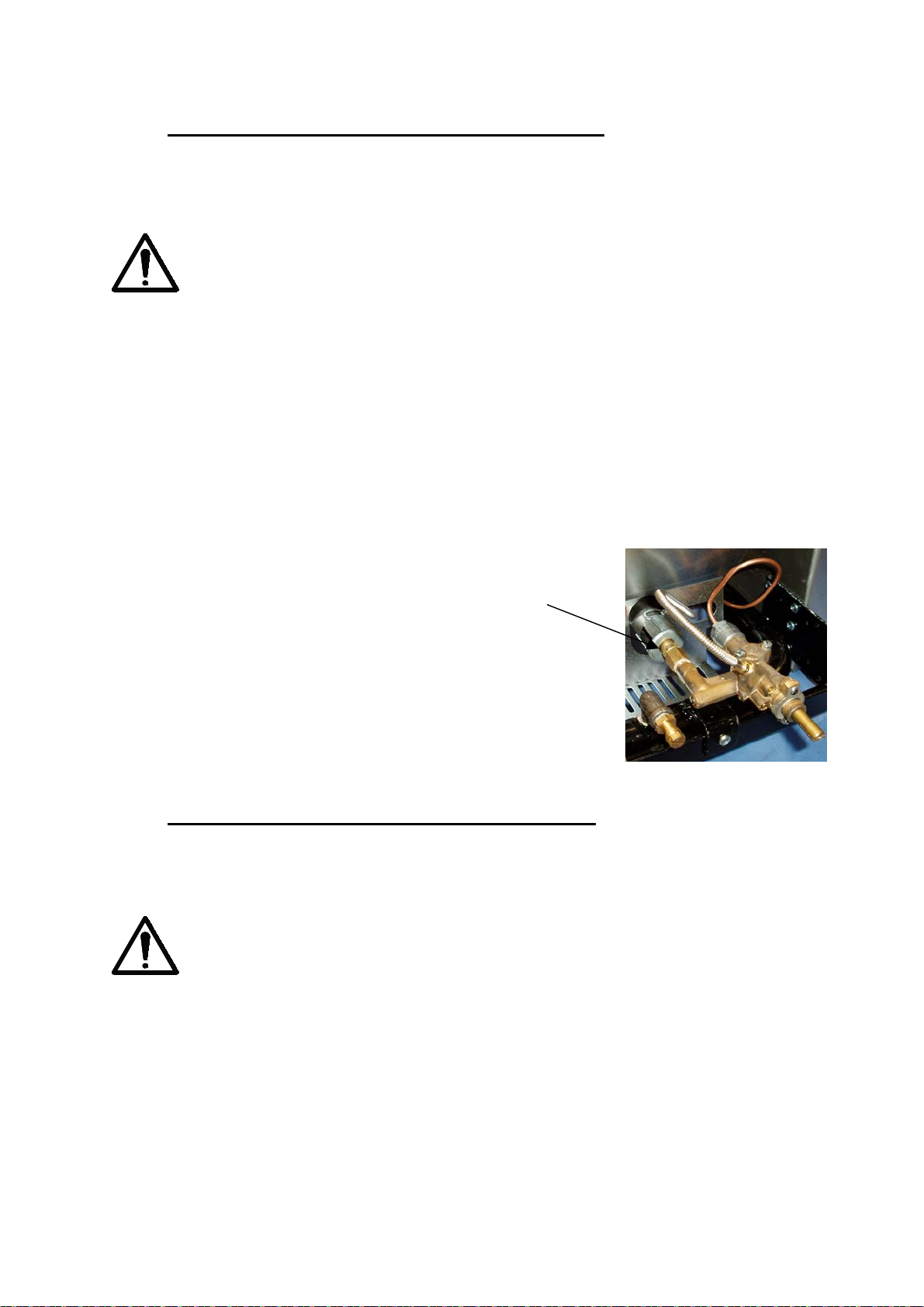

Pilot burner

cover.

‘Key hole’

slots.

25

PILOT BURNER DEFLECTOR

COVER. PHOTOGRAPH 19.

Page 28

Electrode

cable

termination.

Piezo

igniter.

Pilot

assembly-

Thermocouple

back nut.

mounting

PILOT BURNER AND

THERMOCOUPLE.

PHOTOGRAPH 20.

Pilot jet

nut.

10.4 REPLACING THE THERMOCOUPLE.

NOTE! THE PILOT BURNER MUST ONLY BE REPLACED BY A COMPETENT AND

AUTHORISED PERSON.

Gas

control

knob.

Front panelretaining screws.

FRONT PANEL RETAINING SCREWS

(SCB60 SHOWN). PHOTOGRAPH 21.

WARNING! Before attempting to remove the grates ensure they are at an

acceptable temperature to touch. This will normally take approximately 3

hours after using with the main burner.

Access to the thermocouple is from underneath the grates.

1. Isolate the gas supply to the appliance.

26

Page 29

2. Carefully remove the grates and radiants

3. The pilot burner cover is secured using keyhole slots and two screws. Lift the

cover up and away from the locating screws (refer to photograph 19).

4. Partially pull open the drip tray(s).

5. Remove the gas control knobs, front cover securing screws and support the front

cover on the drip tray.

6. Unscrew the thermocouple brass retaining nut (refer to photograph 22).

7. Un-screw the retaining nut and withdraw the

thermocouple through the front of the appliance.

8. Replacement is the reverse of the above procedure.

After assembly check for gas leaks with a suitable leak

detection fluid.

Thermocouple

retaining nut.

THERMOCOUPLE RETAINING

NUT. PHOTOGRAPH 22.

10.5 REPLACING THE MAIN BURNER.

NOTE! THE PILOT BURNER MUST ONLY BE REPLACED BY A COMPETENT AND

AUTHORISED PERSON.

WARNING! Before attempting to remove the

grates ensure they are at an acceptable

temperature to touch. This will normally take

approximately 3 hours after using with the main

burner.

Access to the main burner is from underneath the grates.

1 Ensure the unit is cool to the touch before

commencing any work.

2 Isolate the gas supply to the appliance.

3 Carefully remove the grates and radiants

4 The pilot burner cover is secured using keyhole slots

and two screws. Lift the cover up and away from the

locating screws.

5 To remove the main burner and deflector by lifting the

rear end and moving to the left to enable the unit to

be withdrawn.

6 Replacement is the reverse procedure.

7 Ensure the open end of the burner locates correctly

onto the gas nozzle.

MAIN BURNER AND

DEFLECTOR.

PHOTOGRAPH 23.

27

Page 30

10.6 REPLACING THE MAIN BURNER NOZZLE.

NOTE! THE MAIN BURNER NOZZLE MUST ONLY BE REPLACED BY A COMPETENT

AND AUTHORISED PERSON.

WARNING! Before attempting to remove the grates ensure they are at an

acceptable temperature to touch. This will normally take approximately 3

hours after using with the main burner.

1. Ensure the unit is cool to the touch before commencing any work.

2. Isolate the gas supply to the appliance.

3. Carefully remove the grates and radiants

4. Remove the main burner and deflector as detailed in section 11.5

5. Partially pull open the drip tray(s).

6. Remove the gas control knobs, front cover securing screws and support the

front cover on the drip tray.

7. Un-screw the burner nozzle from the gas valve.

8. Replacement is the reverse procedure. Ensure the open end of the burner

locates correctly onto the gas nozzle. After assembly check for gas leaks with

a suitable leak detection fluid.

9. Check the main burner flame pattern and adjust the

air shutter if necessary.

Main burner

nozzle.

MAIN BURNER NOZZLE.

PHOTOGRAPH 24.

10.7 REPLACING THE GAS CONTROL VALVE.

NOTE! THE GAS CONTROL VALVE MUST ONLY BE REPLACED BY A COMPETENT

AND AUTHORISED PERSON.

WARNING! Before attempting to replace the gas control valve ensure the

appliance is at an acceptable temperature to touch.

1. Isolate the gas supply to the appliance.

2. Remove the gas control knobs, 4 off front cover securing screws and front

cover.

3. Unscrew the pilot burner gas supply pipe nut

4. Unscrew the thermocouple retaining nut.

5. Remove the two screws securing the gas valve to the manifold and carefully

lift off the valve assembly.

6. Check the condition of the sealing O ring and replace if necessary.

28

Page 31

7. Replacement of the gas valve is the reverse of the above procedure. After

assembly check for gas leaks with a suitable leak detection fluid.

GAS CONTROL VALVE

SEAT AND O RING.

PHOTOGRAPH 27.

GAS CONTROL

VALVE ASSEMBLY.

PHOTOGRAPH 25.

GAS CONTROL VALVE.

PHOTOGRAPH 26.

29

Page 32

11.0 FAULT FINDING AND REMEDIAL ACTION.

NOTE! ONLY A FULLY TRAINED AND COMPETENT PERSON MUST

USE, INSTALL, MAINTAIN AND SERVICE THE SCB SUPER CHAR

BROILER.

11.1 FAULT FINDING SUMMARY.

Fault Possible cause Remedy

Pilot flame

fails to ignite.

the

electrode.

Pilot flame

fails to

remain

ignited

Main burner

fails to ignite.

Smell of gas Leak from pipe or joint. Isolate gas supply, ventilate room

Gas supply isolated to appliance Check gas isolation valve and open

if necessary.

Gas supply pipe requires purging Purge gas supply pipe.

Blocked pilot jet Remove pilot jet and clean

Failed regulator Check regulator and replace as

necessary.

Incorrect gas regulator pressure

setting.

Gas control knob not set to correct

position.

Failed gas control valve. Check and replace as necessary.

Piezo igniter failure. Replace the piezo igniter.No spark at

Poor electrical connection to the

piezo igniter

Thermocouple not heated sufficiently. Wait 3 minutes and ignite pilot

Pilot flame too small Check flame height and adjust as

Incorrect gas regulator pressure

setting.

Failed thermocouple. Check and replace as necessary.

Failed gas control valve. Check and replace as necessary.

Gas supply isolated to appliance Check gas isolation valve and open

Incorrect gas regulator pressure

setting.

Failed gas control valve. Check and replace as necessary.

Appliance still fails to operate Call local Hobart service centre.

Pressure regulator requires

adjustment.

Re-adjust control knob to pilot

flame position.

Check cable connection to the

piezo igniter.

burner, hold the control knob in for

20 seconds to heat the

thermocouple.

necessary.

Pressure regulator requires

adjustment.

if necessary.

Pressure regulator requires

adjustment.

and call Hobart Service.

30

Page 33

12.0 COMPLETE SCB SUPPER CHAR BROILER MAINTENANCE

SERVICING

A HOBART TRAINED AND COMPETENT PERSON SHOULD CARRY

OUT SERVICING.

Do not remove any covers or loosen any fittings while the SCB Char broiler is

operating. Ensure the gas supply has been isolated before attempting to service or

move the appliance.

It is recommended that the appliance be serviced regularly depending on the

customer usage as summarised in the table below. Refer to section 11 for more

detailed maintenance information. It is recommended that servicing is only carried

out by Hobart trained service personnel. For further information on Hobart service

contracts contact our service division on 07002 202 202.

Table 6. RECOMMENDED SERVICE INTERVALS.

Hours of use per day Service interval

10 to 12 hours per day, 7 days per week Every 30 to 60 days

4 to 6 hours per day, 5 days per week Every 3 months

Limited daily usage Every 6 months

31

Page 34

13.0. RECOMMENDED SPARE PARTS.

Part number Description SCB25CE SCB36CE SCB47CE SCB60CE SCB72CE

Qty per

appliance

00-722131 Grate, angled 6 rib 3 1

00-710424 Grate, angled 7 rib 4 6 8 8 12

00-710423-1 Grate, straight 6 rib 3 1

00-710423 Grate, straight 7 rib 4 6 8 8 12

00-710453-1 Burner, natural gas 4 6 8 11 13

00-700871 Burner, LPG 4 6 8 11 13

00-739029-1 Regulator, natural

gas

00-739029-2 Regulator, LPG 1 1 1 1 1

00-739456 Heat deflector 4 6 8 11 13

00-739164 Grease channel 1

00-739280 Grease channel 1

00-739083 Grease channel 1

00-739285 Grease channel 1

00-739288 Grease channel 1

00-710407 Radiant 4 6 8 11 13

00-719255-3 Knob, control red 4 6 8 11 13

00-719260 Leg, adjustable 4 4 4 4 4

00-738986-1 Thermocouple 4 6 8 11 13

00-739299-1 Piezo ignitor c/w

earth strip single

spark

00-739299-2 Piezo ignitor twin

spark

00-739491 Pilot burner c/w

electrode, natural

gas

00-711339-NPilot orifice, natural

gas

00-711339-PPilot orifice LPG 4 6 8 11 13

11111

23456

4681113

4681113

Qty per

appliance

Qty per

appliance

Qty per

appliance

11

Qty per

appliance

GE-E-1-38 Magnet unit flame

failure

00-719951-51Orifice, main burner

#51, natural gas

00-719951-57Orifice, main burner

#57, LPG

00-720516-4 Gas control valve,

natural gas

24132421 Tap, test nipple 1 1 1 1 1

00-739265-1 Drip pan 1

00-739265-2 Drip pan 1

00-739265-3 Drip pan 2

00-739265-4 Drip pan 2

00-739265-5 Drip pan 2

00-739037 Grate lifting tool (Optional extra)

00-739397 Fry plate kit (Optional extra)

4681113

4681113

4681113

4681113

32

Page 35

14.0 SERVICE CONTACTS

Hobart trained service technicians strategically located at the listed Hobart branches

are prepared to give you fast, efficient and reliable service. Protect your investment

by having a Hobart inspection contract, which assures the continued, efficient

operation of your Hobart machines, spares and accessories.

For further detail contact: -

SALES: 07002 101 101

SERVICE: 07002 202 202

SPARES: 07002 303 303

Continued product improvement is a Hobart policy, specifications may change without notice.

Hobart UK.

Hobart House,

51 The Bourne,

Southgate,

London

N14 6RT

Tel: 07002 101101

Fax 0208 886 0450

PLE200513 – C 08-08 EU8079

33

Loading...

Loading...