Henny Penny PFG-600 Installation Manual

Henny Penny

Pressure Fryers

Model 500

Model 561

Model 600

OPERATOR’S MANUAL

REGISTER WARRANTYONLINEATWWW.HENNYPENNY.COM

Model 500/561/600

LIMITED WARRANTY FOR HENNY PENNY EQUIPMENT

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT: Any part of a new appliance, except baskets, lamps, and fuses, which proves to be defective in material or workmanship within two (2) years from date of original installation, will be repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. Baskets will be repaired or replaced for ninety (90) days from date of original installation. Lamps and fuses are not covered under this Limited Warranty. To validate this warranty, the registration card for the appliance must be mailed to Henny Penny within ten (10) days after installation.

FILTER SYSTEM: Failure of any parts within a fryer filter system caused by the use of the non-OEM filters or other unapproved filters is not covered under this Limited Warranty.

REPLACEMENT PARTS: Any appliance replacement part, except lamps and fuses, which proves to be defective in material or workmanship within ninety (90) days from date of original installation will be repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment covers the repair or replacement of the defective part and includes labor charges and maximum mileage charges of 200 miles round trip for a period of one (1) year from the date of original installation.

The warranty for replacement parts covers only the repair or replacement of the defective part and does not include any labor charges for the removal and installation of any parts, travel, or other expenses incidental to the repair or replacement of a part.

EXTENDED FRYPOTWARRANTY: Henny Penny will replace any frypot that fails due to manufacturing or workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a new frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to install the new frypot as well as the cost of any other parts replaced, such as insulation, thermal sensors, high limits, fittings, and hardware, will be the responsibility of the owner.

Any claim must be presented to either Henny Penny or the distributor from whom the appliance was purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written consent. If damage occurs during shipping, notify the sender at once so that a claim may be filed.

THEABOVELIMITEDWARRANTYSETSFORTHTHESOLEREMEDYAGAINSTHENNYPENNYFORANYBREACH OFWARRANTYOR OTHER TERM. BUYERAGREES THATNO OTHER REMEDY(INCLUDINGCLAIMS FORANY INCIDENTALORCONSEQUENTIALDAMAGES)SHALLBEAVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE LIMITED WARRANTY IS EXPRESSLYINLIEUOFALLOTHERWARRANTIES,EXPRESSORIMPLIED,INCLUDINGMERCHANTABILITYAND FITNESS,ANDALLOTHERWARRANTIESAREEXCLUDED. HENNYPENNYNEITHERASSUMESNORAUTHORIZES ANYPERSONTOASSUMEFORITANYOTHEROBLIGATIONORLIABILITY.

Revised 01/01/07

FM05-011-M

Revised 01-17-13

Model 500/561/600

This manual should be retained in a convenient location for future reference.

A wiring diagram for this appliance is located on the rear shroud cover of the control panel.

Post in a prominent location, instructions to be followed if user smells gas. This information should be obtained by consulting the local gas supplier.

Do not obstruct the flow of combustion and ventilation air.Adequate clearance must be left all around appliance for sufficient air to the combustion chamber.

The Model 600 Fryer is equipped with a continuous pilot. But Fryer can not be operated without electric power. Fryer will automatically return to normal operation when power is restored.

Keep appliance area free and clear from combustibles.

Improper installation, adjustment, alteration, service, or maintenance can cause property damage, injury, or death. Read the installation, operating, and maintenance

instructions thoroughly before installing or servicing this equipment.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS ORANY OTHER APPLIANCE. FIRE OR EXPLOSION COULD RESULT.

803

Model 500/561/600

|

Technical Data for CE/AGA Marked Products |

||

Nominal Heat Input: |

Natural (I2H) = 21.1 KW (72,000 Btu/h) |

||

(Net) |

Natural (I2E) = 21.1 KW (72,000 Btu/h) |

||

|

Natural (I2E+) = 21.1 KW (72,000 Btu/h) |

||

|

Natural (I2L) = 21.1 KW (72,000 Btu/h) |

||

|

Liquid Propane (I3P) = 21.1 KW (72,000 Btu/h) |

||

Nominal Heat Input: |

Natural (I2H) = 23.4 KW (80,000 Btu/h) |

||

(Gross) |

Natural (I2E) = 23.4 KW (80,000 Btu/h) |

||

|

Natural (I2E+) = 23.4 KW (80,000 Btu/h) |

||

|

Natural (I2L) = 23.4 KW (80,000 Btu/h) |

||

|

Liquid Propane (I3P) = 22.9 KW (78,000 Btu/h) |

||

Supply Pressure: |

Natural (I2H) = 20 mbar (2.0 kPa) |

||

|

Natural (I |

) = 20 mbar |

|

|

Natural (I2E |

|

) = 20/25 mbar |

|

2E+ |

||

|

Natural (I2L) = 25 mbar |

||

|

Liquid Propane (I3P) = 30 mbar (3.0 kPa) |

||

|

Liquid Propane (I3P) = 37 mbar (3.7 kPa) |

||

|

Liquid Propane (I3P) = 50 mbar (5.0 kPa) |

||

Test Point Pressure: |

Natural (I2H) = 8.7 mbar (0.87 kPa) |

||

|

Natural (I |

) = 8.7 mbar |

|

|

Natural (I2E |

|

) = 8.7/10 mbar |

|

2E+ |

||

|

Natural (I2L) = 10 mbar |

||

|

Liquid Propane (I3P) = 25 mbar (2.5 kPa) |

||

Injector Size: |

Natural (I2H) = 1.04 mm |

||

|

Natural (I ) = 1.04 mm |

||

|

Natural (I2E |

|

) = 1.04 mm |

|

2E+ |

|

|

|

Natural (I2L) = 1.04 mm |

||

|

Liquid Propane (I3P) = 0.66 mm |

||

Restrictor Size: |

Natural (I2E+) = 4.1 mm |

||

This appliance must be installed in accordance with the manufacturer’s instructions and the regulations in force and only used in a suitably ventilated location. Read the instructions fully before installing or using the appliance.

|

|

Model 500/561/600 |

Section |

TABLE OF CONTENTS |

Page |

|

||

Section 1. INTRODUCTION ....................................................................................................... |

1-1 |

|

1-1. |

Pressure Fryer..................................................................................................... |

1-1 |

1-2. |

Proper Care ........................................................................................................ |

1-1 |

1-3. |

Assistance ........................................................................................................... |

1-1 |

1-4. |

Model Variations ................................................................................................. |

1-1 |

1-5. |

Safety ................................................................................................................. |

1-2 |

Section 2. INSTALLATION ......................................................................................................... |

2-1 |

|

2-1. |

Introduction......................................................................................................... |

2-1 |

2-2. |

Unpacking Instructions ........................................................................................ |

2-1 |

2-3. |

Selecting the Fryer Location ................................................................................ |

2-3 |

2-4 |

Leveling the Fryer................................................................................................ |

2-3 |

2-5. |

Ventilation of Fryer .............................................................................................. |

2-4 |

2-6. |

Gas Supply ......................................................................................................... |

2-5 |

2-7. |

Gas Piping........................................................................................................... |

2-6 |

2-8. |

Gas Leak Test ..................................................................................................... |

2-9 |

2-9. |

Gas Pressure Regulator Setting ............................................................................ |

2-9 |

2-10. |

Gas Pilot & Burner Lighting and Shutdown Procedure.......................................... |

2-9 |

2-11. |

Pilot FlameAdjustment (Gas Only) ...................................................................... |

2-10 |

2-12. |

Pressure RegulatorAdjustment (Gas Only)........................................................... |

2-10 |

2-13. |

Electrical Requirements (Electric Fryer)................................................................ |

2-11 |

2-14. |

Electrical Requirements (Gas Fryer) ..................................................................... |

2-12 |

2-15. |

Testing the Fryer.................................................................................................. |

2-12 |

2-16. |

Motor Bearings ................................................................................................... |

2-12 |

Section 3. OPERATING INSTRUCTIONS .................................................................................. |

3-1 |

|

3-1. |

Operating Components........................................................................................ |

3-1 |

3-2. |

Filling orAdding Shortening ................................................................................. |

3-9 |

3-3. |

Care of the Shortening ......................................................................................... |

3-10 |

3-4. |

Product Cooking Guidelines ................................................................................ |

3-11 |

3-5. |

Chicken Frying Procedures.................................................................................. |

3-12 |

3-6. |

C1000 Programming Instructions ......................................................................... |

3-17 |

3-7. |

C1000 Special Programming ............................................................................... |

3-17 |

708 |

i |

|

|

Model 500/561/600 |

Section |

TABLE OF CONTENTS (Continued) |

Page |

|

||

Section 3. OPERATING INSTRUCTIONS (Continued) |

|

|

3-8. |

Regular Maintenance Schedule ............................................................................ |

3-19 |

3-9. |

Filter Pump Motor Protector - Manual Reset ....................................................... |

3-19 |

3-10. |

Filtering of Shortening .......................................................................................... |

3-20 |

3-11. |

Cleaning the Optional Crumb Pan ........................................................................ |

3-24 |

3-12. |

Filter Pump Problem Prevention........................................................................... |

3-25 |

3-13. |

Changing the Filter Envelope................................................................................ |

3-25 |

3-14. |

Changing the Charcoal Filter ................................................................................ |

3-28 |

3-15. |

Cleaning the Frypot ............................................................................................. |

3-29 |

3-16. |

Cleaning the DeadweightAssembly ...................................................................... |

3-32 |

3-17. |

Night Closing Procedures .................................................................................... |

3-33 |

3-18. |

Operating Instructions for Optional Direct-Connect Shortening System ................. |

3-34 |

3-19. |

Reversing the Lid Gasket ..................................................................................... |

3-35 |

3-20. |

Lid Lubrication .................................................................................................... |

3-36 |

3-21. |

Limit StopAdjustment ......................................................................................... |

3-37 |

3-22. |

Cleaning the Safety ReliefValve ........................................................................... |

3-38 |

3-23. |

Check & Tighten Element Spreader Bars (Models 500 & 561 only) ..................... |

3-39 |

3-24. |

Seasonal Shutdown ............................................................................................. |

3-40 |

3-25. |

Cut-Up Fried Chicken......................................................................................... |

3-40 |

3-26. |

Chicken Quarters ................................................................................................ |

3-41 |

3-27. |

Barbecued Chicken ............................................................................................. |

3-41 |

3-28. |

Fried Pork Chops/Veal Cutlets ............................................................................ |

3-41 |

3-29. |

Barbecued Pork Chops ....................................................................................... |

3-41 |

3-30. |

Barbecued Ribs................................................................................................... |

3-41 |

3-31. |

Top Sirloin Steak and Filet Mignon ...................................................................... |

3-42 |

3-32. |

Fish Filets............................................................................................................ |

3-42 |

3-33. |

Frog Legs ........................................................................................................... |

3-42 |

3-34. |

Oysters ............................................................................................................... |

3-42 |

3-35. |

Shrimp ................................................................................................................ |

3-42 |

3-36. |

Rock Lobster Tail................................................................................................ |

3-43 |

3-37. |

Potatoes.............................................................................................................. |

3-43 |

3-38. |

Corn on the Cob ................................................................................................. |

3-43 |

3-39. |

Cauliflower.......................................................................................................... |

3-43 |

Section 4. TROUBLESHOOTING ............................................................................................... |

4-1 |

|

4-1. |

Troubleshooting Guide ......................................................................................... |

4-1 |

4-2. |

Error Codes ........................................................................................................ |

4-2 |

GLOSSARY ................................................................................................................ |

G-1 |

|

Distributors List - Domestic and International |

|

|

ii |

|

708 |

Model 500/561/600

SECTION 1. INTRODUCTION

1-1. PRESSURE FRYER

P-H-T

Pressure

Heat

Time

1-2. PROPER CARE

1-3. ASSISTANCE

1-4. MODEL VARIATIONS

207

The Henny Penny Pressure Fryer is a basic unit of food processing equipment. It has found wide application in institutional and commercial food service operations.

A combination of pressure, heat, and time is automatically controlled to produce the optimum in a tasty, appealing product.

Pressure is basic to this method of food preparation. This pressure is developed from the natural moisture of the food. The patented lid traps this moisture and uses it as steam. Because the steam builds rapidly, the greater part of the natural juices are retained within the food. An exclusive deadweight assembly vents excess steam from the pot and maintains constant low, live steam pressure.

Heat generated is another important factor of the pressure fryer. The normal suggested frying operation is between 315 and 325°F. This results in energy savings and extends the frying life of the shortening. Energy savings is realized due to the unit’s short frying time, low temperature, and heat retention of the stainless steel frypot.

Time is important because the shorter the time involved in frying foods results in additional economies for the user. Foods are table ready in less time than it would take to fry them in a conventional open-type fryer.

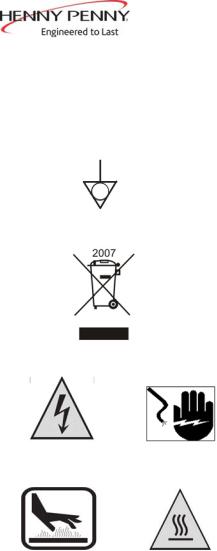

As of August 16, 2005, the Waste Electrical and Electronic Equipment directive went into effect for the European Union. Our products have been evaluated to the WEEE directive. We have also reviewed our products to determine if they comply with the Restriction of Hazardous Substances directive (RoHS) and have redesigned our products as needed in order to comply. To continue compliance with these directives, this unit must not be disposed as unsorted municipal waste. For proper disposal, please contact your nearest Henny Penny distributor.

As in any unit of food service equipment, the Henny Penny Pressure Fryer does require care and maintenance. Requirements for the maintenance and cleaning are contained in this manual and must become a regular part of the operation of the unit at all times.

Should you require outside assistance, just call your local Henny Penny distributor in your area, call Henny Penny Corp. 1-800-417-8405 toll free or 1-937-456-8405, or go online to the Henny Penny Web site at www.hennypenny.com.

This manual covers both gas and electric models, as well as, various options and major accessories. Where information pertains to only one model, it is so noted.

1-1

1-5. SAFETY

1-2

Model 500/561/600

The Henny Penny Pressure Fryer has may safety features incorporated. However, the only way to ensure a safe operation is to fully understand the proper installation, operation, and maintenance procedures. The instructions in this manual have been prepared to aid you in learning the proper procedures. Where information is of particular importance or safety related,

the words DANGER, WARNING, CAUTION, and NOTICE are used. Their usage is described below.

SAFETYALERT SYMBOL is used with DANGER, WARNING, or CAUTION which indicates a personal injury type hazard.

NOTICE is used to highlight especially important information.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may result in property damage.

CAUTION used with the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

DANGER INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN DEATH OR SERIOUS INJURY.

703

Model 500/561/600

1-5. SAFETY (Continued)

Equipotential Ground Symbol

Waste Electrical and Electronic Equipment (WEEE) Symbol

Shock Hazard Symbols

OR

Hot Surface Symbols

OR

908 |

1-3 |

Model 500/561/600

Model 500/561/600

SECTION 2. INSTALLATION

2-1. INTRODUCTION

2-2. UNPACKING INSTRUCTIONS

710

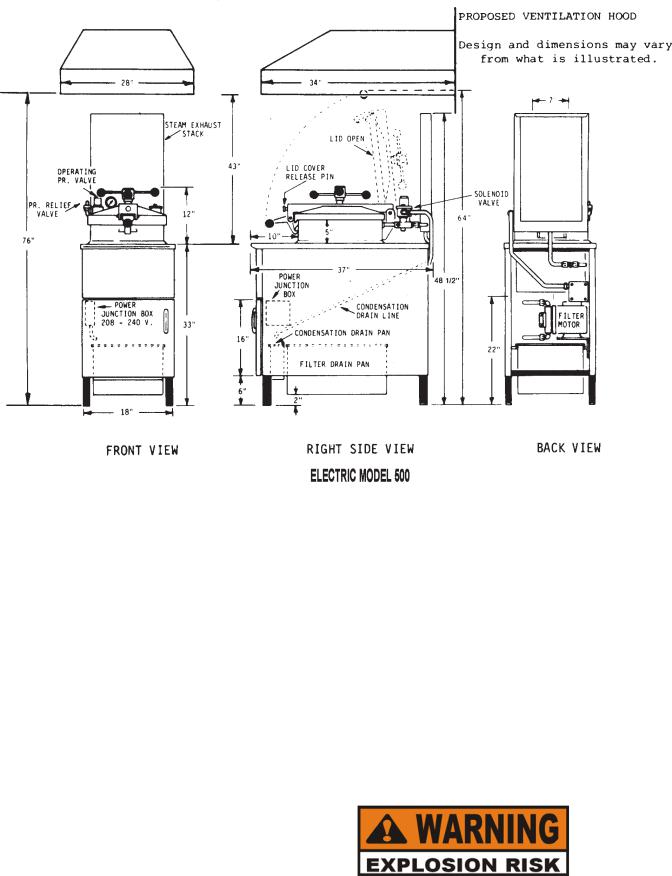

This section provides the installation instructions for the electric and gas models of Henny Penny Pressure Fryers.

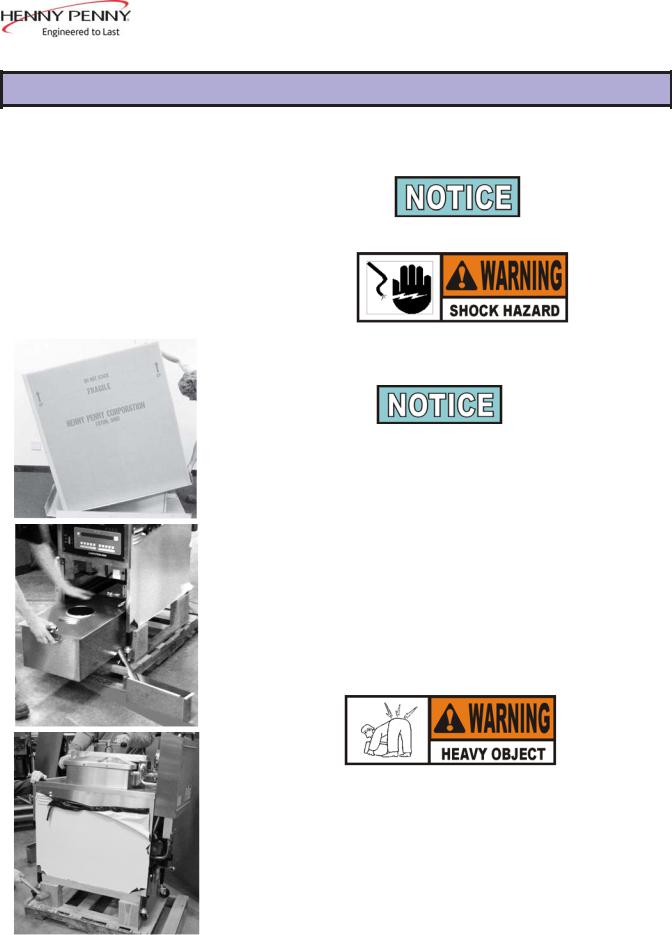

Installation of this unit should be performed only by a qualified service technician.

Do not puncture the fryer with any objects such as drills or screws as electrical shock or component damage could result.

1. Cut the bands from around the carton.

Any shipping damage should be noted in the presence of the delivery agent and signed prior to his or her departure.

2.Lift the carton from the fryer.

3.Remove the inside packing from the fryer.

4.Open fryer lid and remove the basket plus all accessories.

5.Open the front door and remove the condensation drain pan.

6.Unscrew the filter union and remove the filter drain pan.

7.Close the door.

Take care when moving the fryer to prevent personal injury. The fryer weighs approximately 300 lbs. (136 kgs).

8.Tilt fryer to one side so one side of fryer frame is raised up off skid.

9.While one person holds unit up, another person hits the vertical wood supports with a hammer pushing them under the fryer.

10.Return the fryer to fully upright.

.

2-1

2-2. UNPACKING INSTRUC-

TIONS (Continued)

Cap

2-2

Model 500/561/600

11.Open front door, remove two vertical supports and a horizontal support and close the front door.

12.Unlock all four casters.

13.Lift fryer up so casters are above the skid, move the fryer off the skid, and set the fryer on the floor.

14.Prepare the deadweight assembly for operation:

A metal shipping support is installed inside the deadweight valve assembly and must be removed prior to installation and startup, or unit will NOT build pressure.

a.Unscrew the deadweight cap.

b.Remove the round deadweight.

c.Remove and discard the shipping support.

d.Clean the deadweight orifice with a dry cloth.

e.Replace the deadweight and secure the deadweight cap.

15.Remove the protective paper from the fryer cabinet and clean the surfaces with a cloth, soap, and water.

710

2-3. SELECTING THE FRYER LOCATION

2-4. LEVELING THE FRYER

408

Model 500/561/600

The proper location of the fryer is very important for operation, speed, and convenience. Choose a location which will provide easy loading and unloading without interfering with the final assembly of food orders. Operators have found that frying from raw to finish, and holding the product in a warmer provides fast continuous service. Landing or dumping tables should be provided next to at least one side of the fryer. Keep in mind the best efficiency will be obtained by a straight line operation, i.e., raw in one side and finish out the other side. Order assembly can be moved away with only a slight loss of efficiency. To properly service the fryer, 24 inches (60.96 cm) of clearance is needed on all sides of the fryer. Access for servicing can be attained by removing a side panel. Also, at least 6 inches (15.24 cm) around the base of the gas units is needed for proper air supply to the combustion chamber.

To avoid a fire, install the gas fryer with minimum clearance from all combustible and noncombustible materials, 6 inches (15.24 cm) from side and 6 inches (15.24 cm) from back. If installed properly, the gas fryer is designed for operation on combustible floors and adjacent to combustible walls.

To avoid fire and ruined supplies, the area under the fryer should not be used to store supplies.

Do not spray aerosols in the vicinity of this appliance while it is in operation.

To prevent severe burns from splashing hot shortening, position and install fryer to prevent tipping or movement. Restraining ties may be used for stabilization.

For proper operation, level the fryer from side to side and front to back, using level on the flat areas around the frypot collar.

FAILURE TO FOLLOW THESE LEVELING INSTRUCTIONS CAN RESULT IN SHORTENING OVERFLOWINGTHE FRYPOTWHICH COULD CAUSE SERIOUS BURNS, PERSONAL INJURY, FIRE,AND/OR PROPERTY DAMAGE.

2-3

Model 500/561/600

2-5. VENTILATION OF FRYER The fryer must be located with provision for venting into adequate exhaust hood or ventilation system. This is essential to permit efficient removal of the flue gases and frying odors. Special precaution must be taken in designing an exhaust canopy to avoid interference with the operation of the fryer.

We recommend you consult a local ventilation or heating company to help in designing an adequate system.

Ventilation must conform to local, state, and national codes.

Consult your local fire department or building authorities.

When installing the gas fryer do not attach an extension to the gas flue exhaust stack. This may impair proper operation of the burner, causing malfunctions and possible

negative backdraft.

2-4 |

703 |

Model 500/561/600

2-6. GAS SUPPLY |

The gas fryer is factory available for either natural or propane gas. |

|

Check the data plate on the right side panel of the cabinet to deter- |

|

mine the proper gas supply requirements. The minimum supply for |

|

natural gas is 7 inches water column (1.7 kPa), and 10 inches water |

|

column (2.49 kPa) for propane. Maximum gas supply is 14 inches |

|

water column (3.49 kPa, or .5 psi.) |

|

ForAGAmarked gas fryers, the gas supply pressure must meet the |

|

followingminimumvalues: |

|

Natural Gas: 1.13 kPa |

|

Propane (LPG): 2.75 kPa |

Do not attempt to use any gas other than that specified on the data plate. Conversion kits can be installed by your distributor if required. Incorrect gas supply could cause an explosion or fire resulting in severe injuries and/or property damage.

113 |

2-5 |

|

Model 500/561/600 |

2-7. GAS PIPING |

Please refer below for the recommended hookup of the fryer to |

|

main gas line supply. |

To avoid possible serious personal injury:

•Installation must conform withAmerican National Standard Z223.1-Latest Edition National Fuel Gas Code and the local municipal building codes.

In Canada, installation must be in accordance with Canadian GasAuthority Standard CSAB149-& 2, Installation Codes - Gas Burning Appliances and in accordance withAustralian GasAssociation current edition of AS5601 Gas Installations.

•The fryer and its manual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of 1/2 psig (3.45 kPa)

(34.47 mbar).

•The fryer must be isolated from the gas supply piping system by closing its manual shutoff

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig. (3.45 kPa) (34.47 mbar).

•A standard 1/2 inch, black steel pipe and malleable fittingsshould be used for gas service connections.

•Do not use cast iron fittings.

•Although 1/2 inch size pipe is recommended, piping should be of adequate size and installed to provide a supply of gas sufficient to meet the maximum demand without undue loss of pressure between the meter and the fryer. The pressure loss in the piping system should not exceed 0.3 inch water column

(0.747 mbar).

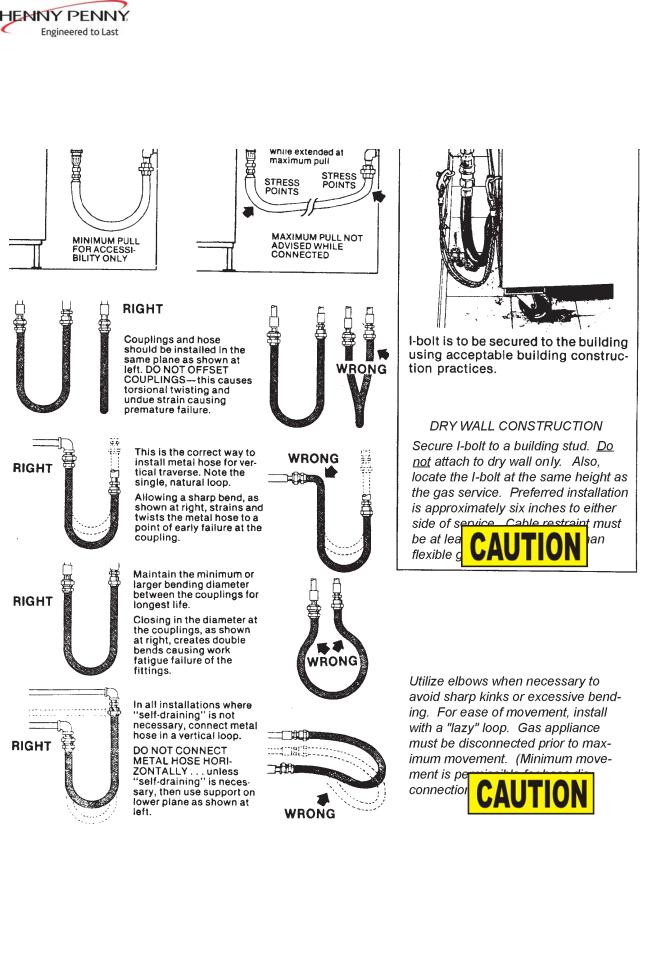

Provisions should be made for moving the fryer for cleaning and servicing. This may be accomplished by:

1.Installing a manual gas shutoff valve and a disconnect union, or

2.Installing a heavy duty design A.G.A. certified connector which complies with the Standard for Connectors for Moveable GasAppliances,ANSI Z21.6, or CAN/CSA 6.16 with a quick disconnect coupling

2-6 |

408 |

|

Model 500/561/600 |

2-7. GAS PIPING |

(Henny Penny Part No. 19921), which complies with |

(Continued) |

ANSI standard Z21.41, or CAN 1-6.9. Also adequate |

|

means must be provided to limit the movement of the |

|

fryer without depending on the connector and quick- |

|

disconnect device or its associated piping to limit the |

|

fryer movement. |

|

3. See the illustration on following page for the proper connec- |

|

tions of the flexible gas line and cable restraint. |

The cable restraint limits the distance the fryer can be pulled from the wall. For cleaning and servicing the fryer, the cable must be unsnapped from the unit and the flexible gas line disconnected. This will allow better access to all sides of the fryer. The gas line and cable restraint must be reconnected once the cleaning and servicing is complete.

703 |

2-7 |

2-7. GAS PIPING (Continued)

Model 500/561/600

ForAustralia or New Zealand: Where a model is supplied with casters and is to be connected to a fixed gas supply via a flexible hose connection, a restraining chain or wire of adequate strength shall be fixed to the appliance and be suitable to be fixed to the wall within 50 mm of each connection point. The length of the chain or wire shall not exceed 80% of the length of

the hose assembly.

2-8 |

113 |

Model 500/561/600

2.8 GAS LEAK TEST

Prior to turning the gas supply on, move “ON/OFF” selector on gas control valve to the OFF position.

After the piping and fittings have been installed, check for gas leaks.A simple checking method is to turn on the gas and brush all connections with a soap solution. If bubbles occur, it indicates escaping gas. In this event, the piping connection must be redone.

2-9. GAS PRESSURE REGULATOR SETTING

2-10. GAS PILOT & BURNER

LIGHTINGAND SHUTDOWN PROCEDURE

Gas Control Valve “ON/OFF” Selector

710

To avoid fire or explosion, never use a lighted match or open flame to test for gas leaks. Ignited gas could result in severe personal injury and/or property damage.

The gas pressure regulator on the automatic gas valve is factory set as follows:

Natural: 3.5 inches water column (0.87 kPa) Propane: 10.0 inches water column (2.49 kPa)

The gas pressure regulator has been set by Henny Penny and is not to be adjusted by the user.

Lighting Procedure - Solid State Ignition

1.Turn main power switch to OFF position.

2.Move “ON/OFF” selector on gas control valve to OFF position.

3.Wait a sufficient length of time (at least 5 minutes) to allow any gas which may have accumulated in burner compartment to escape.

4.Move “ON/OFF” selector on gas control valve to ON position.

5.Turn main power switch to ON position.

6.Wait about 45 seconds for the burner to light.

7.Listen for the gas burner ignition.

•It will be an audible sound due to the gas igniting at the gas jets within the burner.

2-9

|

Model 500/561/600 |

2-10. GAS PILOT & BURNER |

8. The burner lights and operates until the shortening temperature |

LIGHTINGAND |

reaches a preset temperature, and when tempearture light goes |

SHUTDOWN |

out, set controls for desired length of time. |

PROCEDURE (Continued) |

|

2-11. PILOT FLAME ADJUSTMENT (GAS ONLY)

2-12. PRESSURE REGULATOR ADJUSTMENT (GAS ONLY)

Do not leave burner on for more than 10 seconds

without shortening in the frypot or damage to the frypot may result.

9.The frypot should be cleaned per the instructions in Section 3.

10.The frypot must be filled to the proper level with shortening. Refer to Filling orAdding Shortening Section.

Shutdown Procedure

1.Move “ON/OFF” selector on gas control valve to OFF position.

2.Turn main power switch to ON position.

The pilot flame is preset at the factory. If adjustment is necessary, contact your local independent Henny Penny distributor.

The gas regulator is preset at the factory at 3.5 inch water column (0.87 kPa) for natural gas (10.0 inch (2.49 kPa) for propane). If adjustment is necessary, contact your local independent Henny Penny distributor.

2-10 |

710 |

2-13. ELECTRICAL REQUIREMENTS (ELECTRIC FRYER)

DRYWALL CONSTRUCTION Secure I-bolt to a building stud. Do not attach to drywall only. Preferred installation is approximately six inches to either side of service. Cable restraint must be at least six inches shorter than flexible conduit.

908

Model 500/561/600

The electric fryer is available from the factory wired for 208, 220/240, or 440/480 volts, single or three phase, 60 Hertz service. The proper power service cable must be ordered as an accessory or provided at installation. Check the data plate on the inside of the fryer door to determine the correct power supply.

This fryer must be adequately and safely grounded (earthed) or electrical shock could result. Refer to local electrical codes for correct grounding (earthing) procedures or in absence of local codes, with The National Electrical Code, ANSI/NFPA No. 70-(the current edition). In Canada, all electrical connections are to be made in accordance with CSA C22.1, Canadian Electrical Code Part 1, and/or local codes.

To avoid electrical shock, this appliance must be equipped with an external circuit breaker which will disconnect all ungrounded (unearthed) conductors. The main power switch on this appliance does not disconnect all line conductors.

The field supply wiring to the fryer should be of the size indicated in the data table. It should be an insulated copper conductor rated for 600 volts and 90°C. For runs longer than 50 feet (15.24 m), use the next larger size wire.

Permanently connected electric fryers with casters must be installed with flexible conduit and a cable restraint, when installed in the United States. See illustration at left. Holes are available in the rear fryer frame for securing the cable restraint to the fryer. The cable restraint does not prevent the fryer from tipping.

Electrical Specifications Table |

|

||

Volts |

Phase |

KW |

Amps |

208 |

Single |

11.25 |

54 |

208 |

Single |

13.50 |

65 |

208 |

Three |

11.25 |

31 |

208 |

Three |

13.50 |

38 |

240 |

Single |

11.25 |

47 |

240 |

Single |

13.50 |

56 |

240 |

Three |

11.25 |

27 |

240 |

Three |

13.50 |

33 |

480 |

Three |

11.25 |

14 |

480 |

Three |

13.50 |

16 |

2-11

2-13. ELECTRICAL REQUIREMENTS (ELECTRIC FRYER) (Continued)

Model 500/561/600

Additional CE Electrical Statements:

The supply power cords shall be oil-resistant, sheathed flexible cable, no lighter than ordinary polychloroprene or other equivalent synthetic elastomer-sheathed cord, and must be HO7RN type.

It is recommended that a 30 mA rated protective device such as a residual current circuit breaker (RCCB), or ground fault circuit interrupter (GFCI), be used on the fryer circuit.

(FOR EQUIPMENT WITH CE MARK ONLY!)

To prevent electric shock hazard this appliance must be bonded to other appliances or touchable metal surfaces in close proximity to this appliance with an equipotential bonding conductor. This appliance is equipped with an equipotential lug for this purpose. The equipotential lug is marked with the following symbol  .

.

2-12 |

908 |

Loading...

Loading...