Henny Penny PFG-600 Service Manual

44--HHeeaadd GGaass

PPrreessssuurree FFrryyeerrss

SERVICE

MANUAL

MODEL 600

FM06-009D

Table of Contents

Safety and Compliance................................................................................................ ix

Chapter 1 Troubleshooting..............................................................................................1

1.1 Introduction ...........................................................................................................1

1.2 Diagnostics............................................................................................................1

Chapter 2 Maintenance ................................................................................................13

2.1 Introduction .........................................................................................................13

2.2 Maintenance Hints ...............................................................................................13

2.3 Preventative Maintenance Schedule......................................................................13

2.4 Lower the Control.................................................................................................14

2.4.1 Raise the Control ........................................................................................... 14

2.4.2 Replace the Control ....................................................................................... 14

2.4.3 Configure the Serial Number...........................................................................15

2.4.3.1 Verify the Serial Number ............................................................................. 15

2.4.3.2 Adding or Correcting a 9 Character Serial Number........................................ 16

2.4.3.3 Adding or Correcting a 7 Character Serial Number........................................ 17

2.5 Transformer Replacement ....................................................................................17

2.6 Temperature Probe Replacement ..........................................................................18

2.7 Temperature Regulation (Single Stage) .................................................................20

2.7.1 Front Panel Thermostat..................................................................................20

2.7.2 Internal Operation ..........................................................................................20

2.7.3 Drain Microswitch ..........................................................................................21

2.7.4 High Limit Temperature Control .......................................................................21

2.8 Calibrating The Standard Single Stage Thermostat.................................................21

2.9 Testing The Thermostat ........................................................................................ 21

2.9.1 Procedure .....................................................................................................21

2.10 Thermostat Replacement....................................................................................22

2.11 High Temperature Limit Control ...........................................................................25

2.11.1 Description ..................................................................................................25

2.11.2 Checkout ..................................................................................................... 26

2.11.3 Replacement ...............................................................................................26

2.12 Gas Burner Assembly.........................................................................................28

2.12.1 Description ..................................................................................................28

2.12.2 Safety Precautions ....................................................................................... 29

2.12.3 Replacement ...............................................................................................29

2.13 Thermocouple.................................................................................................... 31

2.13.1 Description ..................................................................................................31

2.13.2 Safety Precautions ....................................................................................... 32

2.13.3 Replacement ...............................................................................................32

2.14 Gas Control Valve .............................................................................................. 33

2.14.1 Description ..................................................................................................33

2.14.2 Safety Precautions ....................................................................................... 33

2.14.3 Operator Replacement .................................................................................33

2.14.4 Regulator Spring Replacement ..................................................................... 35

2.14.5 Adjusting Pilot Burner ................................................................................... 35

2.14.6 Adjusting Regulator......................................................................................36

Contents

i

2.15 Electrical Components........................................................................................37

2.16 Timing Control ...................................................................................................42

2.17 Pressure Regulation/Exhaust..............................................................................45

2.18 Filtering System ................................................................................................. 68

Contents

2.15.1 Fan .............................................................................................................38

2.15.2 Drain Switch ................................................................................................ 38

2.15.2.1 Gas Models..............................................................................................38

2.15.3 Main Power Switch....................................................................................... 39

2.15.4 Continuity Check Procedure..........................................................................40

2.15.5 Replacement ...............................................................................................40

2.15.6 Indicator Lights ............................................................................................41

2.15.7 Fuse Holder.................................................................................................41

2.15.8 Checking Procedure For Fuses ..................................................................... 41

2.15.9 Cord & Plug Check.......................................................................................41

2.15.10 Wall Receptacle (Voltage Check)................................................................. 41

2.15.10.1 Gas Models............................................................................................41

2.16.1 Description ..................................................................................................42

2.16.2 Checking Procedure..................................................................................... 42

2.16.3 Replacement ...............................................................................................43

2.16.4 Timer Light ..................................................................................................44

2.16.5 Buzzer Coil..................................................................................................44

2.16.6 Timer Switch ................................................................................................ 45

2.17.1 Solenoid Valve .............................................................................................45

2.17.2 Coil Check Procedure................................................................................... 45

2.17.3 Replacement ...............................................................................................46

2.17.4 Deadweight Valve ........................................................................................51

2.17.5 Cleaning Steps ............................................................................................51

2.17.6 Removal & Cleaning of Safety Relief Valve ....................................................52

2.17.7 Pressure Gauge........................................................................................... 52

2.17.7.1 Calibration Steps ......................................................................................52

2.17.7.2 Cleaning Steps.........................................................................................53

2.17.8 Condensation Box Assembly ........................................................................53

2.17.9 Condensation Box Bottom Removal .............................................................. 54

2.17.10 Lid Cover Assembly.................................................................................... 55

2.17.10.1 Description.............................................................................................55

2.17.10.2 Lid Cover Removal .................................................................................55

2.17.10.3 Lid Cover Installation .............................................................................. 56

2.17.11 Lid Hinge Spring......................................................................................... 56

2.17.12 Latch Spring Installation.............................................................................. 57

2.17.13 Lid Liner .................................................................................................... 60

2.17.14 Reversing The Lid Gasket...........................................................................60

2.17.14.1 Purpose .................................................................................................60

2.17.14.2 Process .................................................................................................61

2.17.15 Lid Limit Stop Adjustment ...........................................................................62

2.17.16 Spindle Screw Assembly ............................................................................63

2.18.1 Filter Rinse Hose .........................................................................................68

2.18.2 Removal......................................................................................................69

2.18.3 Installation ...................................................................................................69

2.18.4 Filter Valve Description .................................................................................69

2.18.5 Removal......................................................................................................70

2.18.6 Filter Pump Repair ....................................................................................... 70

2.18.7 Cover Removal ............................................................................................ 70

ii

2.18.8 Pump Removal ............................................................................................ 71

2.18.9 Filter Pump Motor Protector - Manual Reset ................................................... 73

2.19 Gas Conversion ................................................................................................. 73

2.19.1 Service Hints ............................................................................................... 73

2.19.2 Maintenance................................................................................................74

2.20 Wiring Diagrams ................................................................................................ 75

2.21 Caster Replacement Procedure.......................................................................... 75

2.22 Solenoid Valve ................................................................................................... 75

2.22.1 Replace Solenoid Valve Assembly................................................................. 76

Chapter 3 Parts Information ..........................................................................................79

3.1 Introduction .........................................................................................................79

3.2 Genuine Parts...................................................................................................... 79

3.3 How To Find Parts ................................................................................................ 79

3.4 Sub-Assemblies................................................................................................... 80

3.5 How To Order Parts ..............................................................................................81

3.6 Prices..................................................................................................................81

3.7 Delivery...............................................................................................................82

3.8 Warranty ............................................................................................................. 82

3.9 Recommended Spare Parts For Distributors ..........................................................82

3.10 Parts and Illustrations ......................................................................................... 83

Chapter 4 C8000 Replacement Parts ........................................................................... 175

4.1 Controls and Decals ........................................................................................... 175

4.2 600 Series Gas Control Valve ............................................................................. 177

4.3 600 Series Gas Components ..............................................................................178

4.4 Rear Panel Wiring Connection Decal ................................................................... 180

4.5 600 230v 50/60Hz. 1PH...................................................................................... 181

4.6 600 208-240v 50/60Hz. 1PH ............................................................................... 182

4.7 600 120v 50/60Hz. 1PH...................................................................................... 183

4.8 600 120v 50/60Hz. 1PH...................................................................................... 184

4.9 600 208-240v 50/60Hz. 1PH ............................................................................... 185

Chapter 5 Pressure Assist Features and Function ......................................................... 187

5.1 Software............................................................................................................ 187

5.1.1 C8000 Controller.......................................................................................... 187

Chapter 6 Programming ............................................................................................. 189

Chapter 7 Wiring Diagrams.......................................................................................... 197

7.1 600 GF, 120v, 60Hz, 1P, STD IGN (63240H) ........................................................197

7.2 600 GF, 240v, 50Hz, 1P, SI (55318A) ................................................................... 198

7.3 600 GF, 120v, 60Hz, 1P, EI (34389C)................................................................... 199

7.4 600 GF, 120-240v, 50/60Hz, 1P, STD IGN (63694L) (Before AN0702112)............... 200

7.5 600 GF, 120-240v, 50/60Hz, 1P, ESI (75555B) (AN0703021-11029-Shaw) ............. 201

7.6 600 GF, 120-240v, 50/60Hz, 1P, ESI (75555E) (After AN0703021-Fenwal) ............. 202

7.7 600 GF, 120v, 50/60Hz, 1P, ESI (67152C) (After AN0703021 use 75555) ............... 203

7.8 600 GF, 208-240v, 50/60Hz, 1P, ESI (69076C) (After AN0703021 use

75555) ..............................................................................................................204

7.9 600 GF, 230v, 50Hz, 1P (34807K) (Before AN0702112) ........................................ 205

7.10 600 GF, 230v, 50Hz, 1P, SSI (75556B) (AN0703021-711029-Shaw)..................... 206

7.11 600 GF, 230v, 50Hz, 1P, SSI (75556D) (After AN0711030-Fenwal).......................207

7.12 600 GF, C1000 & 2000, 100/120v, 50/60Hz, 1P, 24v, SSI (78558D)...................... 208

7.13 600 GF, C1000 & 2000, 230v, 50Hz, 1P, 24v, 24v SSI (80221B) ........................... 209

7.14 600 EF, LVC, 120v, 50/60Hz, 1P (68598B) ......................................................... 210

Contents

iii

7.16 600 C/C EF, 120v, 50/60Hz, 1P, ESI (67199J) (After AN0711030-Fenwal) ............212

7.17 600 C/C EF, 208-240v, 50/60Hz, 1P (32759G) .................................................... 213

7.18 600 C/C EF, 208-240v, 50/60Hz, 1P, ESI (67204E) .............................................214

7.19 600 C/C EF, LVC, 208-240v, 50/60Hz, 1P (68614B) ............................................ 215

7.20 600 C/C EF, LVC, 230v, 50/60Hz, 1P (68615B) ................................................... 216

7.21 600 GF, 100-240v 50/60 Hz, 1P (63357N) (Before AN0702112)...........................217

7.23 600 GF, 100-240v, 50/60Hz, 1P, SSI (75510) (After AN0711030-Fenwal).............. 219

7.24 600 EF, 230v, 50/60Hz, 1P (63358N) (Before AN0702112) .................................. 220

7.25 600 EF, 230v, 50/60Hz, 1P, SSI (75511C) (AN0703021-0711029-Shaw)...............221

7.26 600 EF, 230v, 50/60Hz, 1P, SSI (75511F) (After AN0711030-Fenwal)................... 222

7.27 600 EF, 120v, 50/60Hz, 1P (23457F) (After AN0703021 use 75510)..................... 223

7.28 600 SC GF, 120v, 60Hz, 1P, Dual Thermostat (17353F) ...................................... 224

7.29 600 SMS EF, 100-240v, 50/60Hz, 1P, SMS, SSI (75190D)................................... 225

Chapter 8 Annual Inspection........................................................................................ 229

8.1 Henny Penny Start-Up Provider Information......................................................... 229

8.2 Store Information ...............................................................................................229

8.3 Equipment Information ....................................................................................... 229

8.4 Signatures......................................................................................................... 229

8.5 Checklist ........................................................................................................... 229

8.6 Inspect the Fry Pot ............................................................................................. 234

8.7 Inspect the Casters and Frame ........................................................................... 235

8.8 Inspect the Power Cord ...................................................................................... 235

8.9 Inspect the Gas Hose and Connection ................................................................. 236

8.10 Inspect the Flue ............................................................................................... 236

8.11 Inspect the Condensation Box ........................................................................... 237

8.12 Inspect the Solenoid and Deadweight Plumbing .................................................238

8.13 Inspect the Drain Switch ...................................................................................240

8.14 Test the Filtration System .................................................................................. 240

8.15 Inspect the Drain Pan ....................................................................................... 241

8.16 Inspect the High Limit ....................................................................................... 241

8.17 Inspect the Temperature Probe ......................................................................... 242

8.18 Inspect the Burner............................................................................................ 243

8.19 Inspect for Oil Leaks......................................................................................... 245

8.20 Test Pressure Regulator ...................................................................................246

8.21 Inspect Deadweight.......................................................................................... 247

8.22 Inspect Latch, Catch and Spring........................................................................ 248

Contents

8.23 Inspect Cross Arm Component.......................................................................... 250

8.24 Lubricate Cross Arm Components ..................................................................... 253

7.15 600 C/C EF, 120v, 50/60Hz, 1P, Wendy’s FPS, ESI (67199G) (AN0703021-

711029-Shaw) ................................................................................................... 211

7.22 600 GF, 100-240v 50/60 Hz, 1P, SSI (75510C) (AN0703021-0711029-

Shaw) ...............................................................................................................218

7.30 600 SMS EF, 230v, 50Hz, 1P, SMS, SSI (75512B) (AN0703021-711029-

Shaw) ...............................................................................................................226

7.31 600 SMS EF, 230v, 50Hz, 1P, SMS, SSI (75512F) (After AN0711030-

Fenwal)............................................................................................................. 227

8.12.1 Clean the Dead Weight Plumbing ................................................................ 238

8.12.2 Clean the Solenoid Plumbing ...................................................................... 239

8.18.1 Clean the Burner Jets................................................................................. 243

8.18.2 Clean the Pilot Assembly ............................................................................ 244

8.19.1 Plumbing Leaks in Filtration ........................................................................ 245

8.19.2 Plumbing Leaks During Cooking .................................................................246

iv

8.25 Pressure Regulation and Exhaust System.......................................................... 254

8.25.1 Clean the Lid Liner .....................................................................................254

8.25.2 Reverse the Lid Gasket ..............................................................................255

8.25.3 Adjust the Lid Limit Stop ............................................................................. 255

8.25.4 Removal and Cleaning of Safety Relief Valve ............................................... 256

8.25.5 Pressure Gauge Calibration ........................................................................ 257

8.25.6 Coil Check Procedure................................................................................. 258

8.25.7 Locking Pin Test Procedure ........................................................................ 258

Contents

v

List of Tables

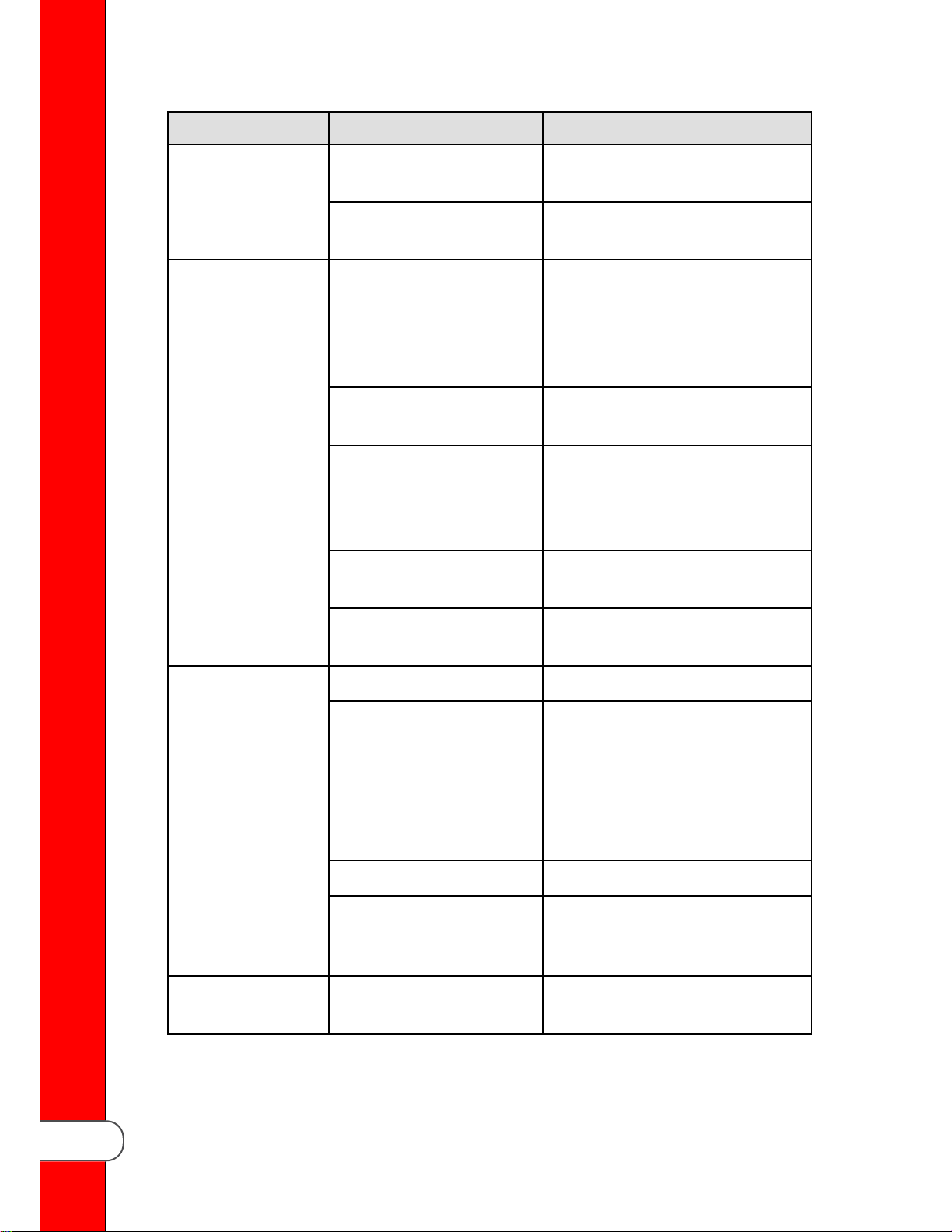

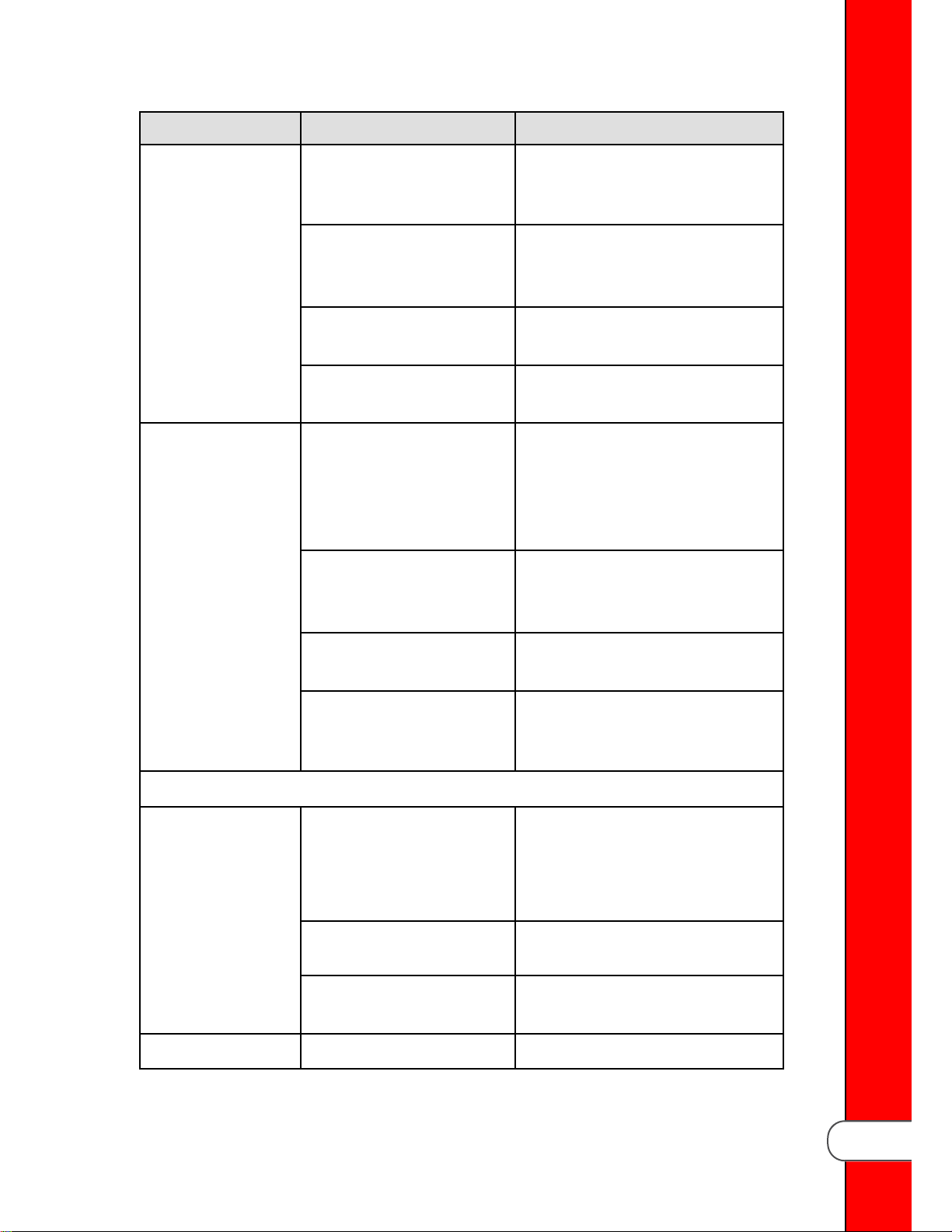

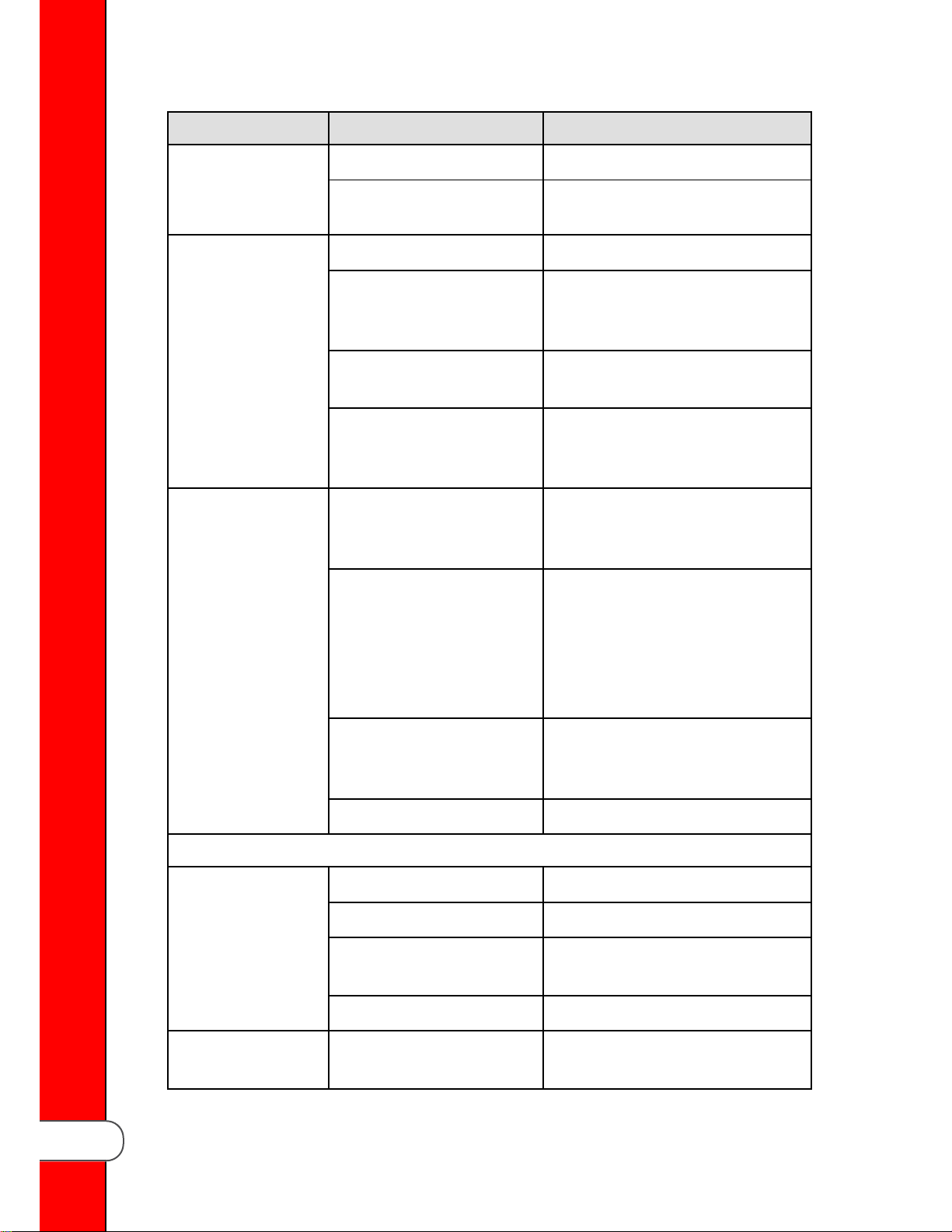

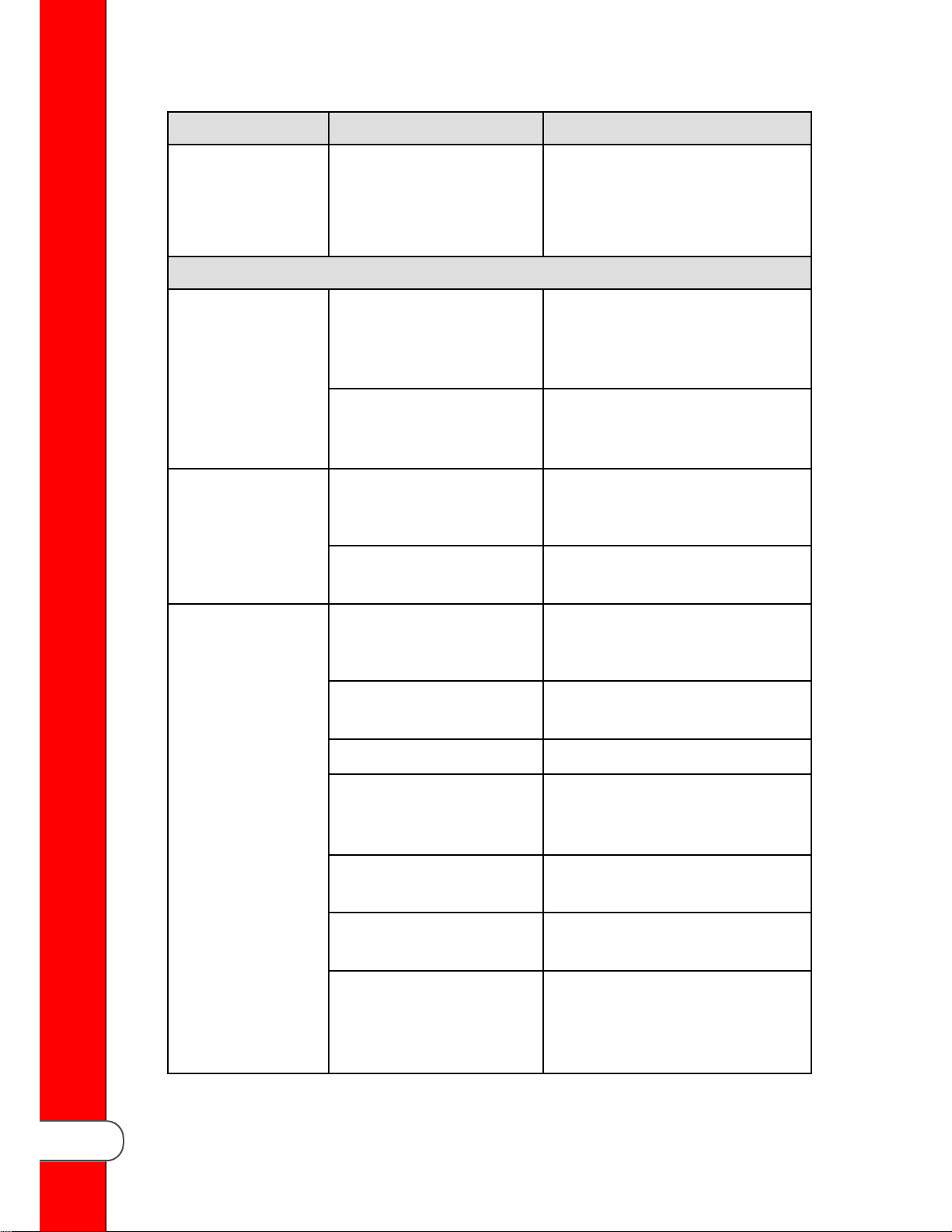

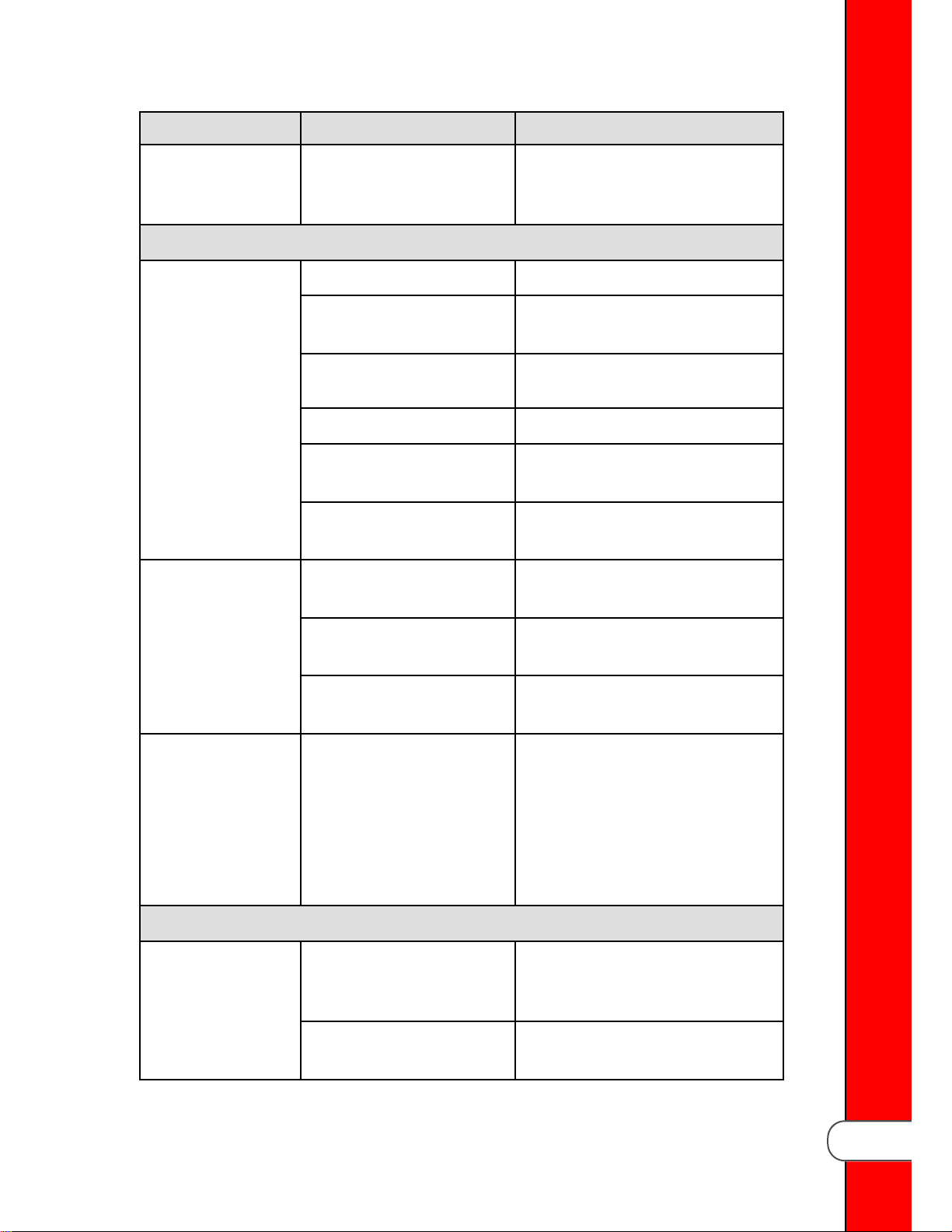

Table 1-1 Troubleshooting..................................................................................................1

Table 2-1 Preventative Maintenance Schedule .................................................................. 13

Table 2-2 Gas Control Valve Check Procedures .................................................................34

Table 2-3 Continuity Check Procedure - Off Position .......................................................... 40

Table 2-4 Continuity Check Procedure - Power Position ..................................................... 40

Table 2-5 Continuity Check Procedure - Pump Position ......................................................40

Table 2-6 Checking Procedure - ON/OFF Switch ...............................................................42

Table 2-7 Checking Procedure - Buzzer Coil ......................................................................43

Table 2-8 Checking Procedure - Microswitch ..................................................................... 43

Table 2-9 Checking Procedure - Motor ..............................................................................43

Table 2-10 Checking Procedure - Reset Coil......................................................................43

Table 2-11 Coil Check Procedure ......................................................................................46

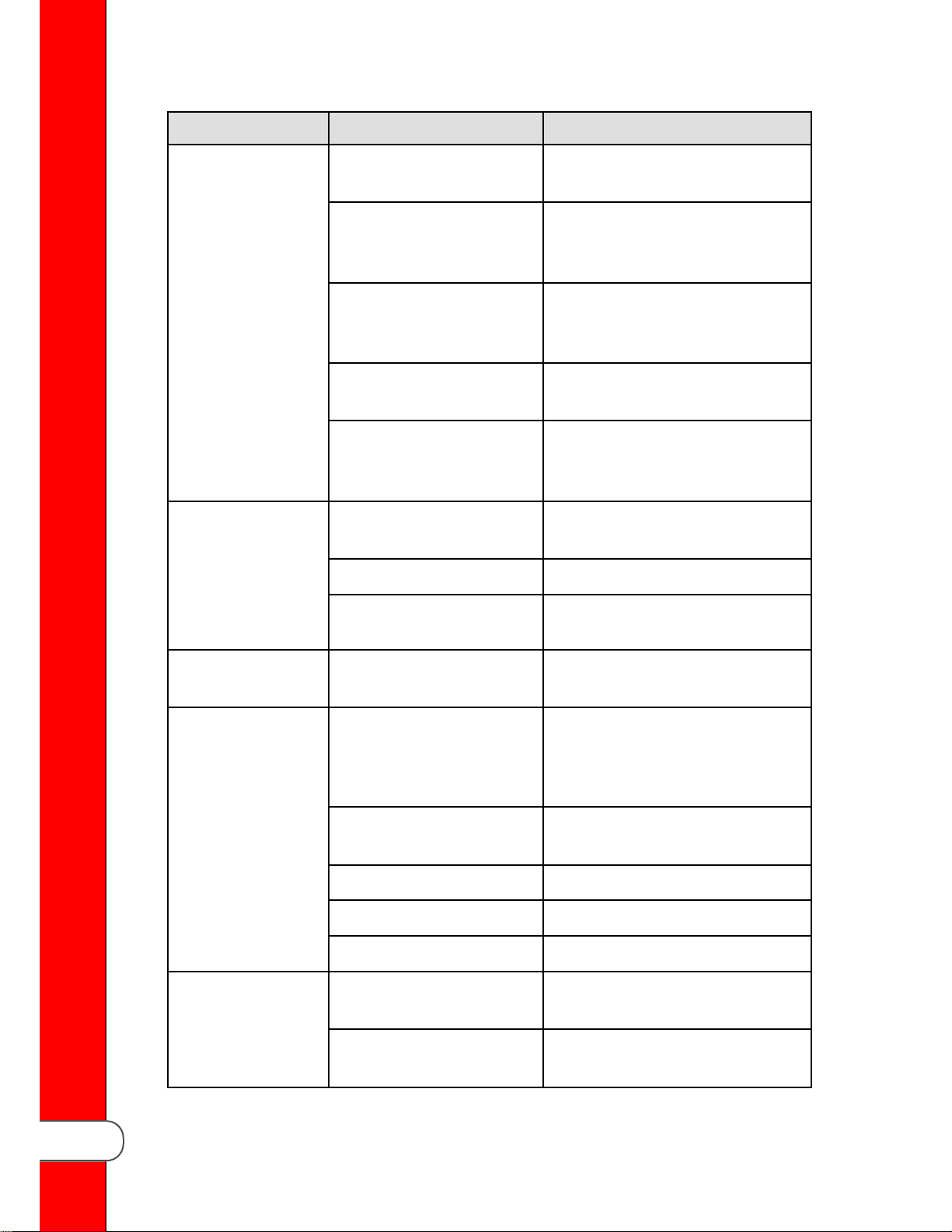

Table 3-1 KFC SMS-20 Controls & Spare Parts .................................................................87

Table 3-2 Fast Control Panel ............................................................................................ 95

Table 3-3 Hybrid Control Panel .........................................................................................96

Table 3-4 Filter Screen Kits ............................................................................................ 144

Table 3-5 Table 1 ........................................................................................................... 167

Table 3-6 Table 2 ........................................................................................................... 167

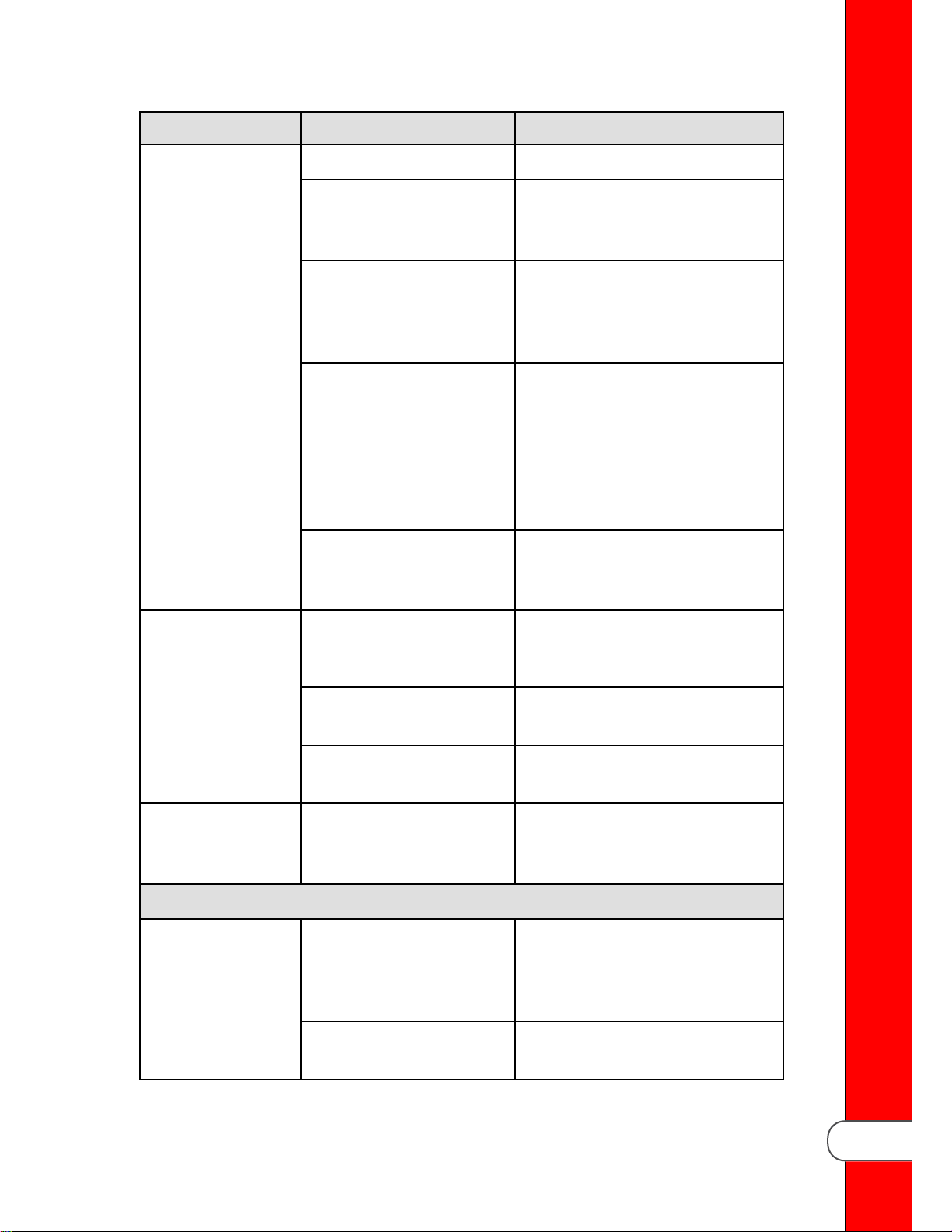

Table 6-1 Programming.................................................................................................. 189

Figure 2-1 Thermostat Test Points .................................................................................... 22

Figure 2-2 Thermostat Sensing Bulb - Gas ........................................................................ 22

Figure 2-3 Thermostat & Control Panel Diagram ................................................................23

Figure 2-4 Screw Nut Assembly........................................................................................ 24

Figure 2-5 High Limit Reset Button - Gas........................................................................... 25

Figure 2-6 High Limit Capillary Tube - Gas ........................................................................27

Figure 2-7 Gas Burner Assembly ......................................................................................28

Figure 2-8 Gas Supply Connection ...................................................................................30

Figure 2-9 Heat Shield Deflector Assembly........................................................................30

Figure 2-10 Pilot & Thermocouple Assembly .....................................................................32

Figure 2-11 Gas Control Valve ..........................................................................................33

Figure 2-12 Regulator Spring Replacement .......................................................................35

Figure 2-13 Pilot Burner ...................................................................................................35

Figure 2-14 Pressure Tap ................................................................................................. 36

Figure 2-15 Adjusting Regulator .......................................................................................37

Figure 2-16 Continuity Check Test Points ..........................................................................40

Figure 2-17 Solenoid Valve Assembly ............................................................................... 46

Figure 2-18 Exhaust Fitting ..............................................................................................49

Figure 2-19 Conduit Fitting ...............................................................................................50

Contents

Figure 2-20 Solenoid Valve Diagram .................................................................................50

List of Figures

vi

Figure 2-21 Latch Spring Assembly ..................................................................................58

Figure 2-22 Lid Cover Screws ..........................................................................................61

Figure 3-1 Computron C1000 Control ............................................................................... 83

Figure 3-2 Wendy’s Computron C2000 Control .................................................................. 85

Figure 3-3 KFC SMS-20 Control .......................................................................................87

Figure 3-4 Fast Control Panel...........................................................................................89

Figure 3-5 Standard Control Panel....................................................................................92

Figure 3-6 Automatic Reset Timer Assembly ..................................................................... 97

Figure 3-7 CFA Original Panel .......................................................................................... 98

Figure 3-8 Electric Conduit Assembly.............................................................................. 100

Figure 3-9 Frame & Cabinet Assembly............................................................................103

Figure 3-10 Lid Components .......................................................................................... 107

Figure 3-11 Complete Lid w/ Crossbar Assembly (with Language Specific Labels) ............. 110

Figure 3-12 Fry Basket .................................................................................................. 112

Figure 3-13 3 Tier Wire Basket ....................................................................................... 114

Figure 3-14 CFA Half-Quarter Size Funnels..................................................................... 116

Figure 3-15 CFA Double Hinged Basket .......................................................................... 117

Figure 3-16 Exhaust Stack Assembly.............................................................................. 118

Figure 3-17 Deadweight Valve Assembly ........................................................................ 122

Figure 3-18 Solenoid Valve Assembly ............................................................................. 124

Figure 3-19 Drain Valve Assembly .................................................................................. 127

Figure 3-20 Lower Filter Plumbing Components............................................................... 129

Figure 3-21 Upper Filter Plumbing Components............................................................... 133

Figure 3-22 Rinse Hose ................................................................................................. 136

Figure 3-23 Filter Motor & Pump ..................................................................................... 137

Figure 3-24 Direct-Connect Assembly - Model 600........................................................... 139

Figure 3-25 Filter Drain Pan & Filter Screen Assembly .....................................................141

Figure 3-26 Supersorb Filter Assembly (Before 3–1–02)................................................... 145

Figure 3-27 Supersorb Filter Assembly (3–1–02 & After) ..................................................148

Figure 3-28 Contactor & Frame Assembly (Single Phase Electric Model)...........................150

Figure 3-29 Contactor & Frame Assembly (Three Phase Electric Model) ........................... 152

Figure 3-30 Fan & High Temperature Limit Control ........................................................... 154

Figure 3-31 Electronic Ignition Assembly......................................................................... 156

Figure 3-32 Vat (frypot) & Gas Burner Assy - Non-CE, Domestic, & Electric Ignition............ 158

Figure 3-33 Gas Line & Burner Assembly - CE, International, & Electronic Ignition .............161

Figure 3-34 Gas Control Valve........................................................................................ 165

Figure 3-35 Countertop Insulation Assembly (Gas Model) ................................................ 168

Figure 3-36 Firebox & Flue Assembly (Gas Model) .......................................................... 170

Figure 3-37 Firebox Insulation Assembly (Gas Model)...................................................... 172

Figure 8-1 PFG 600 Weld Locations ............................................................................... 234

Contents

vii

Contents

viii

SSaaffeettyy aanndd CCoommpplliiaannccee

Henny Penny fryers have many safety features incorporated. However, the only way

to ensure safe operation is to fully understand the proper installation, operation, and

maintenance procedures. The instructions in this manual have been prepared to aid

you in learning the proper procedures. Where information is of particular importance

or is safety related, the words DANGER, WARNING, CAUTION, or NOTICE are used.

Their usage is described as follows:

DDAANNGGEERR!! indicates hazardous situation which, if not

avoided, will result in death or serious injury.

DDAANNGGEERR!!

WWAARRNNIINNGG!!

CCAAUUTTIIOONN!!

NOTICE

WWAARRNNIINNGG!! indicates hazardous situation which, if not

avoided, could result in death or serious injury.

CCAAUUTTIIOONN!! indicates hazardous situation which, if not

avoided, could result in moderate or minor injury.

NOTICE

regarding property damage.

is used for information considered important

Preface

ix

These are the original version controlled Henny Penny instructions for Pressure Fryer

Gas (PFG) model 600 (PFG 600).

This manual is available on the Henny Penny Public website (www.hennypenny.com).

Read these instructions completely prior to installation and operation of this appliance

to ensure compliance to all required installation, operation and safety standards. Read

and obey all safety messages to avoid damage to the appliance and personal injury.

• TThhiiss ffrryyeerr mmuusstt bbee iinnssttaalllleedd aanndd uusseedd iinn aa wwaayy tthhaatt

wwaatteerr ddooeess nnoott ccoonnttaacctt tthhee ooiill wwhhiicchh ccaann ccaauussee

ssppllaasshhiinngg aanndd bbooiilliinngg oovveerr ooff ooiill aanndd sstteeaamm lleeaaddiinngg

ttoo ppeerrssoonnaall iinnjjuurryy;; eexxcclluuddeess nnoorrmmaall pprroodduucctt

mmooiissttuurree..

• BBuurrnn rriisskk!! DDoo nnoott mmoovvee tthhee ffrryyeerr oorr ffiilltteerr ddrraaiinn ppaann

wwhhiillee ccoonnttaaiinniinngg hhoott ooiill.. PPeerrssoonnaall iinnjjuurryy oorr sseerriioouuss

bbuurrnnss ccaann rreessuulltt ffrroomm ssppllaasshhiinngg hhoott ooiill..

This appliance is intended for commercial use in kitchens of restaurants, bakeries,

hospitals, etc. but not for the continuous mass production of food such as in a factory

setting. During use the units airborne A-weighted emission sound pressure is below

70 db(A). All repairs must be performed by the manufacturer, its service agent or

similarly qualified persons in order to avoid a hazard.

Always use strain relief. The provided power cord must be installed with a strain relief

in a way that if the strain relief fails, wires L1, L2, L3 and N must draw taunt and fail

first. If the supplied power cord or an existing one becomes damaged, do not use it;

rather, replace it with a known good power cord. The power cord must be replaced by

the manufacturer, its service agent or similarly qualified persons in order to avoid a

hazard.

Proper daily, weekly, monthly, quarterly and yearly maintenance must be performed

on this appliance to ensure safe and continuous operation. This appliance must never

be cleaned with a water jet or steam cleaning tool. Cleaning brushes are shipped with

the appliance and proper cleaning instructions are included in this manual.

Proper maintenance also increases the usable life of the appliance and oil, which

reduces lifetime operating costs. Additionally, old oil increases the possibility of surge

boiling and fire due to the reduced flash point of the oil. The oil temperature must

never exceed 450⁰ F (230⁰ C).

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

Preface

x

person responsible for their safety. Children should be supervised to ensure that they

do not play with the appliance.

This appliance is not intended to be operated by means of an external timer or a

separate remote control system.

This appliance must be installed in accordance with the manufacturer’s instructions

and the regulations in force and only used in suitably ventilated location. Read the

instructions fully before installing or using the appliance.

This appliance must be installed with suitable ventilation in accordance with the

manufacturer’s instructions and the regulations in force to prevent the occurrence of

unacceptable concentrations of substances harmful to health. Proper air flow is

essential to permit efficient removal of the steam exhaust and frying odors. Air flow for

this model is 33.3 cfm (56.6 m3/h) of air flow.

For gas appliance installations in South Africa, the installation shall be carried out by a

registered installer, and the installation shall comply with requirements of SANS

10087-1 or SANS827 as applicable.

WWAASSTTEE EELLEECCTTRRIICCAALL AANNDD EELLEECCTTRROONNIICC EEQQUUIIPPMMEENNTT ((WWEEEEEE)) As of August

16, 2005, the Waste Electrical and Electronic Equipment directive went into effect for

the European Union. Our products have been evaluated to the WEEE directive. We

have also reviewed our products to determine if they comply with the Restriction of

Hazardous Substances directive (RoHS) and have redesigned our products as

needed in order to comply. To continue compliance with these directives, this unit

must not be disposed as unsorted municipal waste. For proper disposal, please

contact your nearest Henny Penny distributor.

Technical Data For CE Marker Products

Nominal Heat Input (Net): Natural (I

Natural (I

Natural (I

Natural (I

Natural (I

(72,000 Btu/h)

Liquid Propane (I

h)

) = 21.1 kW (72,000 Btu/h)

2H

) = 21.1 kW (72,000 Btu/h)

2E

) = 21.1 kW (72,000 Btu/h)

2E+

) = 21.1 kW (85,000 Btu/h)

2L

2(43.46-45.3 MJ/m3(0°C))

) = 21.1 kW (72,000 Btu/

3P

) = 21.1 kW

Preface

xi

Technical Data For CE Marker Products

Nominal Heat Input (Gross): Natural (I

Natural (I

Natural (I

Natural (I

Liquid Propane (I

h)

Supply Pressure: Natural (I

Natural (I

Natural (I

Natural (I

Liquid Propane (I

Liquid Propane (I

Liquid Propane (I

) = 23.4 kW (80,000 Btu/h)

2H

) = 23.4 kW (80,000 Btu/h)

2E

) = 23.4 kW (80,000 Btu/h)

2E+

) = 23.4 kW (80,000 Btu/h)

2L

) = 22.9 kW (78,000 Btu/

3P

) = 20 mbar (2.0 kPa)

2H

) = 20 mbar

2E

) = 20/25 mbar

2E+

) = 25 mbar

2L

) = 30 mbar

3P

) = 37 mbar

3P

) = 50 mbar

3P

Preface

Test Point Pressure: Natural (I

Natural (I

Natural (I

Natural (I

Liquid Propane (I

Injector Size: Natural (I

Natural (I

Natural (I

Natural (I

Liquid Propane (I

Restrictor Size: Natural (I

) = 8.7 mbar (0.87 kPa)

2H

) = 8.7 mbar

2E

) = 8.7/10 mbar

2E+

) = 10 mbar

2L

) = 25 mbar

3P

) = 1.04 mm

2H

) = 1.04 mm

2E

) = 1.04 mm

2E+

) = 1.04 mm

2L

) = 0.66 mm

3P

) = 4.1 mm

2E+

xii

CChhaapptteerr 11 TTrroouubblleesshhoooottiinngg

11..11 IInnttrroodduuccttiioonn

This section provides troubleshooting information in the form of an easy to read table.

If a problem occurs during the first operation of a new fryer, recheck the installation

per Section 2 Unpacking/Installation of the Operator’s Manual. Before

troubleshooting, always recheck the operating procedure per Section 3 Operating

Instructions of the Operator’s Manual.

11..22 DDiiaaggnnoossttiiccss

To isolate a malfunction, proceed as follows:

11.. Clearly define the problem (or symptom) and when it occurs.

22.. Locate the problem in the troubleshooting table.

33.. Review all possible causes. Then, one-at-a-time, work through the list of

corrections until the problem is solved.

RReeffeerr ttoo tthhee mmaaiinntteennaannccee pprroocceedduurreess iinn CChhaapptteerr 22

WWAARRNNIINNGG!!

MMaaiinntteennaannccee

aarree nnoott ffoolllloowweedd ccoorrrreeccttllyy iinnjjuurriieess aanndd//oorr pprrooppeerrttyy

ddaammaaggee ccaann rreessuulltt..

,, ppaaggee 1133.. IIff mmaaiinntteennaannccee pprroocceedduurreess

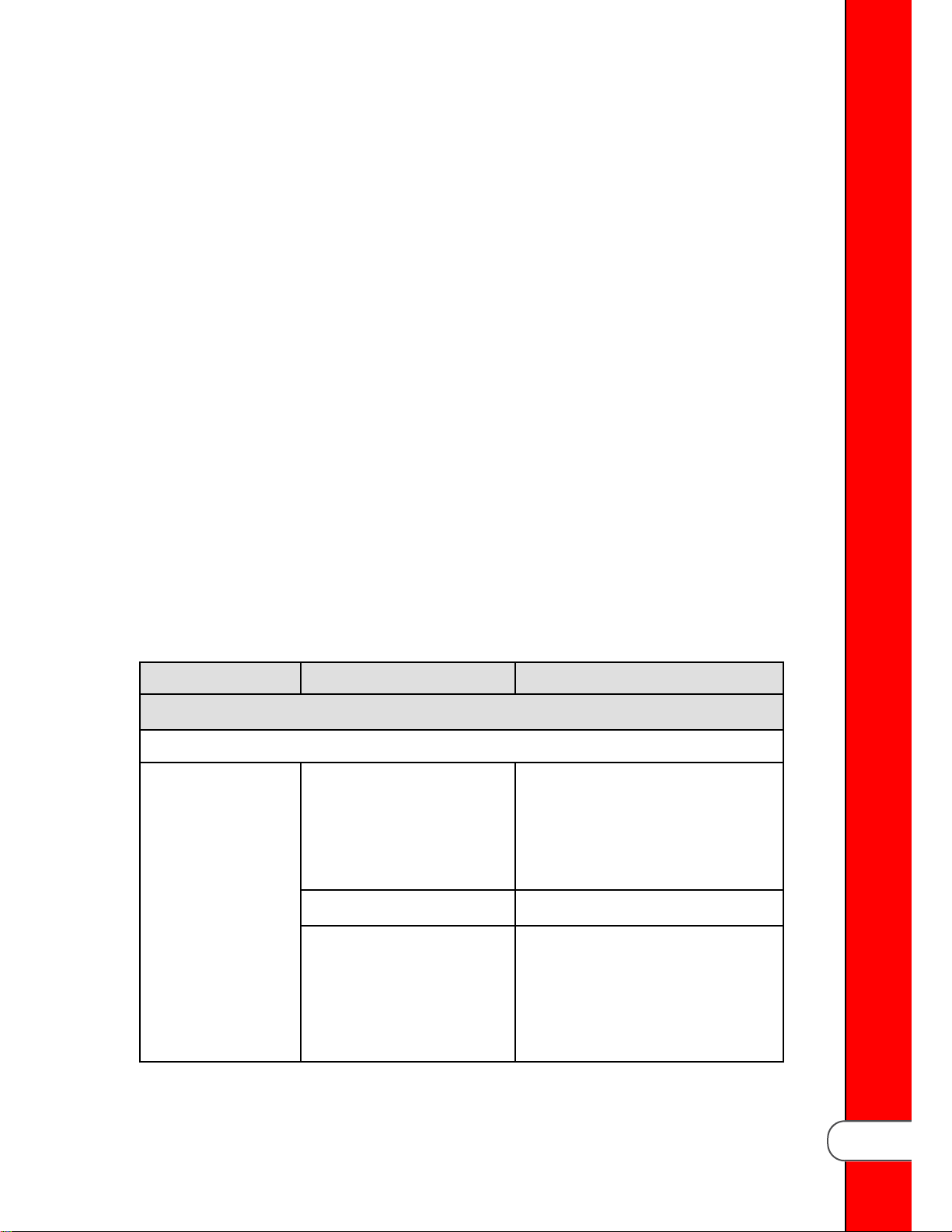

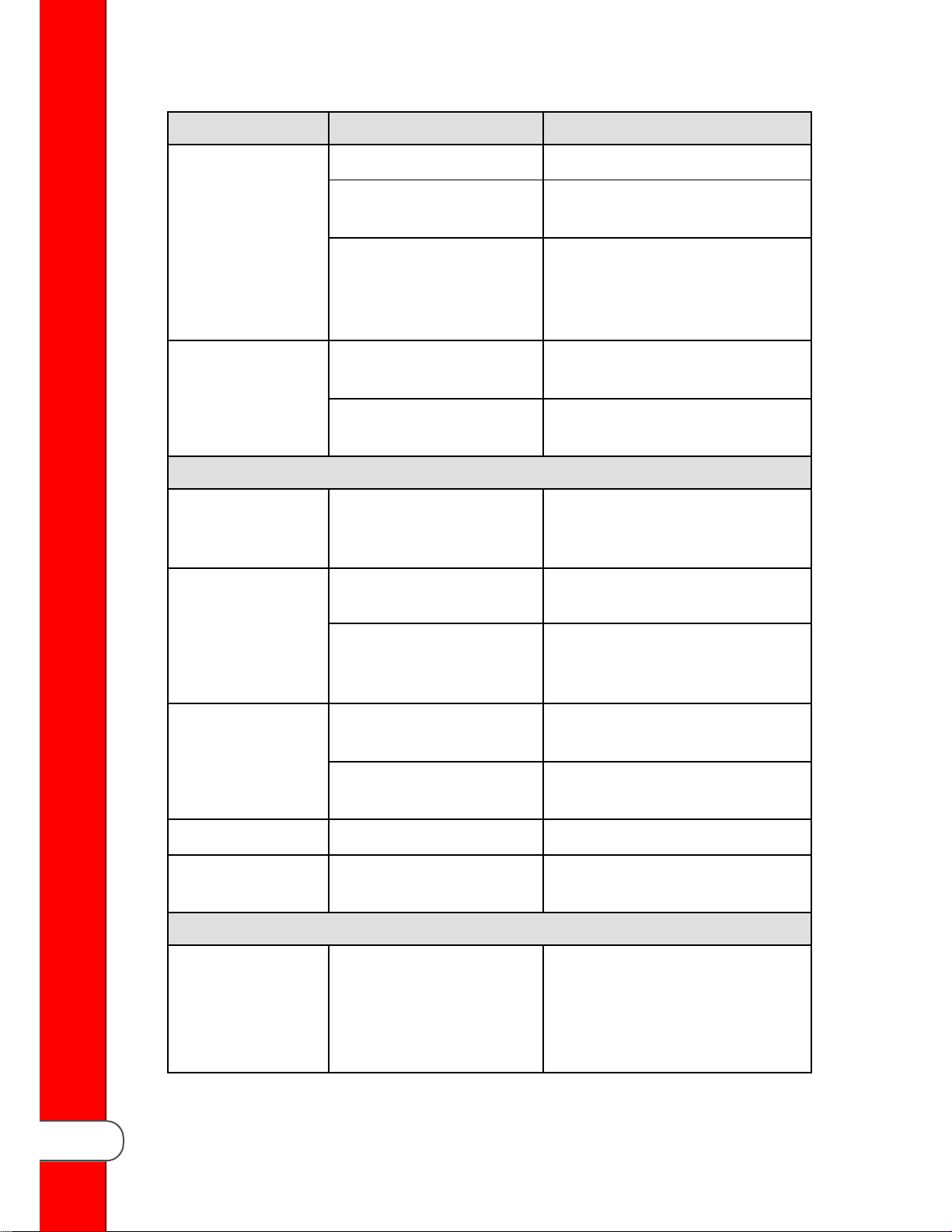

TTaabbllee 11--11 TTrroouubblleesshhoooottiinngg

Problem Cause Correction

CCooookkiinngg SSeeccttiioonn

Product Color Not Correct:

A. Too dark. Temperature too high.

• Reduce thermostat setting.

• Remove and replace defective

thermostat per 2.10

Replacement

Shortening too old. Change shortening.

Shortening too dark.

• Filter shortening.

• Shortening taste test, see the

Operator’s Manual.

• Change Shortening.

Thermostat

, page 22.

Troubleshooting

1

Problem Cause Correction

Dip solution too strong for

product.

Breading product too far in

advance.

B. Too light. Temperature too low.

Dip solution too weak for

product.

Incorrect preheat

procedures.

Vat (frypot) overloaded with

product.

Use correct dip solution or shorten

product immersion time.

Bread product closer to actual frying

period.

• Increase temperature.

• Remove and replace defective

thermostat per 2.10

Replacement

Correct dip solution.

• Allow proper preheat time.

• Stir shortening prior to dropping

product into vat (frypot).

Reduce cooking load.

Thermostat

, page 22.

C. Product greasy. Shortening old. Replace shortening.

D. Spotted product. Improper separation of the

Troubleshooting

Slow fryer heat-up/recovery. Refer to burner or heating elements

in Chapter 2

Temperature too low.

Vat (frypot) overloaded. Reduce cooking load.

Product not removed from

vat (frypot) immediately after

depressurization.

product.

• Increase thermostat settings.

• Temperature not recovered when

product was dropped in vat

(frypot) basket.

• Replace thermostat if needed.

Remove product immediately after

depressurization of the vat (frypot).

Refer to Operator’s Manual.

Maintenance

, page 13.

2

Problem Cause Correction

E. Dryness of

product.

Product was incorrectly

dipped in water before

breading.

Breading not uniform on

product.

Burned breading particles on

product.

Product sticking together. Separate product prior to pressure

Moisture loss prior to

cooking.

Over cooking the product.

Agitate product during the dipping

procedure.

• Sift breading during breading.

• Refer to Operator’s Manual.

Filter the shortening more frequently.

cooking, see the Operator’s Manual.

• Use fresh products.

• Keep product covered with a

moist cloth to reduce

evaporation.

• Reduce cooking time.

• Reduce cooking temperature.

Low operating pressure. Check pressure gauge reading;

check for pressure leaks.

Product load too small. Increase quantity to obtain correct

operating pressure and product

quality.

Product Flavor (Taste):

A. Salty taste. Breading mixture is too salty.

Marination mixture too

concentrated.

Incorrect choice of breading. Use breading designed for the de-

B. Burned taste. Burned shortening flavor. Replace shortening.

• Sift breading after each use.

• Incorrect breading mixture.

• Discard old breading.

Reduce the concentration of the

marination mixture.

sired product.

Troubleshooting

3

Problem Cause Correction

Shortening needs filtering. Filter shortening more frequently.

Vat (frypot) not properly

cleaned.

C. Bland taste. Raw product not fresh. Use fresh raw products.

Breading mixture incorrect

for product (spice content too

low).

Cooking temperature too

high (spice flavor lost).

Breading does not adhere to

product.

D. Rancid taste. Shortening too old. Replace shortening, and follow rec-

Non-compatible products

cooked within the same

shortening.

Drain and clean vat (frypot).

Use breading designed for desired

product.

Use correct temperature for breading

used.

Use correct dip and breading, and

use correct procedure for the

product.

ommended care and use of shortening, see the Operator’s Manual.

• Replace shortening.

• Use compatible products, and

follow recommended care and

use of shortening; refer to

Operator’s Manual.

General:

A. Meat separation

from bone.

B. Bone color not

Troubleshooting

proper.

4

Infrequent filtering. Replace shortening and follow rec-

ommended care and use of shortening; refer to Operator’s Manual.

Raw product not fresh. Use fresh product.

Incorrect meat cut. Use correct meat cutting procedures.

Overcooking. Reduce cooking time.

Raw product contains too

much water.

Product not fresh. Use fresh product.

Using frozen product (black

bone).

Allow product to drain after

marinating.

Use fresh product.

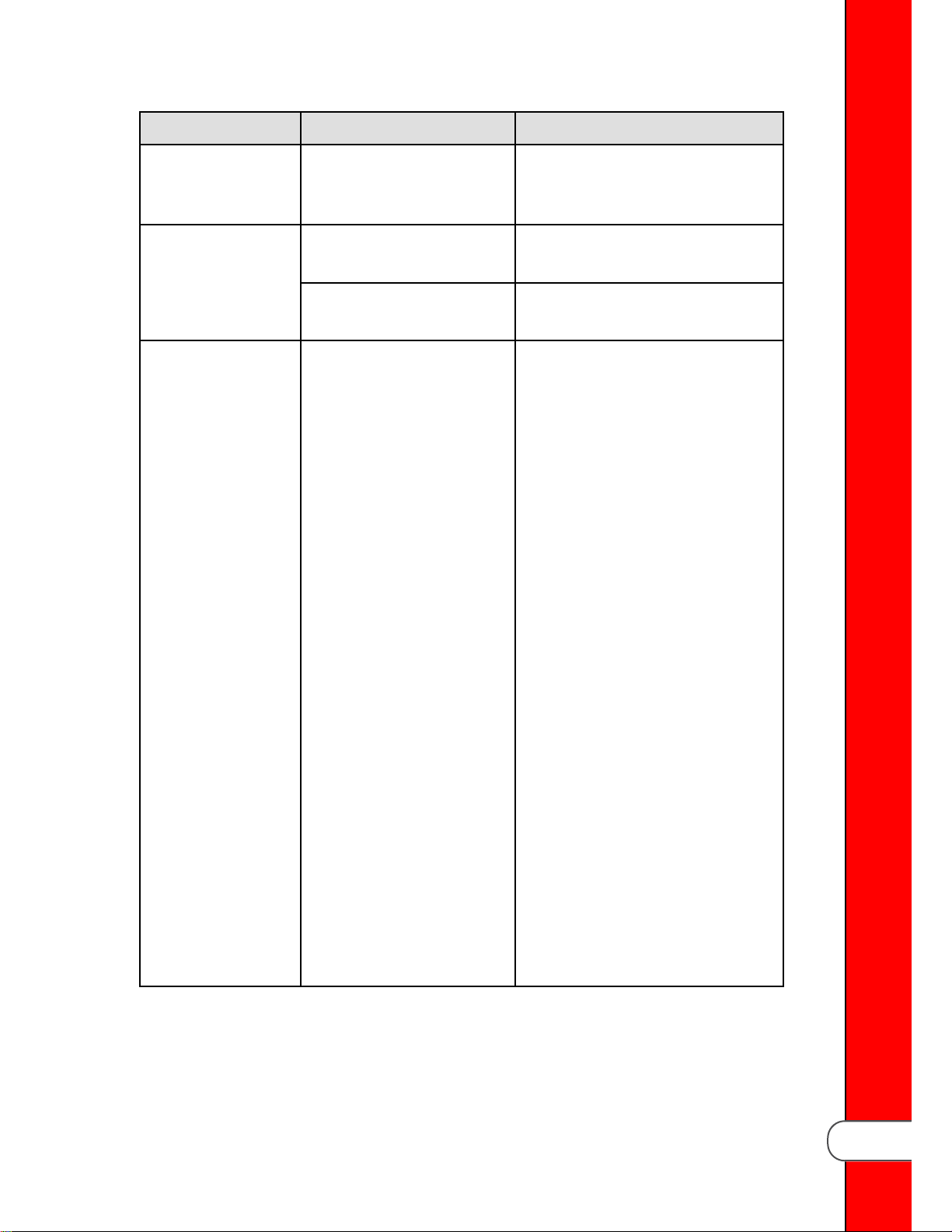

Problem Cause Correction

Improper handling of product

(black bone).

Product not thoroughly

cooked (red bone).

C. Breading falls off. Incorrect breading

procedures.

Product partially frozen during breading.

Improper handling of cooked

product.

Excessive stirring of product

prior to closing the lid.

D. Product sticking

together.

Product breaded too long prior to cooking.

Improper separation procedures prior to closing the lid.

Use proper handling procedures for

product.

Increase cooking time.

Use correct breading procedure, see

the Operator’s Manual.

Thoroughly thaw the product before

breading.

Handle cooked product carefully.

Separate the product, see the Operator’s Manual.

Refer to breading & frying

instructions.

Separate the product, see the Operator’s Manual.

With switch in

POWER position,

the fryer is completely inoperative

(NO POWER).

Vat (frypot)) overloaded with

product.

Improper loading procedure. Load product properly into vat (fry-

PPoowweerr SSeeccttiioonn

Open circuit.

Reduce the cooking load.

pot), see the Operator’s Manual.

• Check to see that unit is plugged

in.

• Check breaker or fuse at supply

box.

• Check control panel fuses per

2.15

Electrical Components

page 37 section (electric module

only).

• Check voltage at wall receptacle.

• Check MAIN POWER switch per

2.15

Electrical Components

page 37; replace if defective.

,

,

Troubleshooting

5

Problem Cause Correction

• Check cord and plug per 2.15

Electrical Components

• Check circuit breaker on single

phase fryers.

PPrreessssuurree SSeeccttiioonn

, page 37.

Pressure will not exhaust at end of cook

cycle.

Operating pressure

too high.

Pressure does not

build.

Exhaust line from solenoid

valve to expansion tank

clogged.

Solenoid valve clogged. Check and clean solenoid valve per

Deadweight clogged. Place proper quantity of moist prod-

Exhaust line to stack

clogged.

Not enough product in fryer

or product not moist.

Metal shipping spacer not removed from deadweight.

Lid open or not latched. Close and latch lid.

Release pressure from vat (frypot);

clean all pressure lines, exhaust

stacks, and expansion tank on gas

model.

2.17

Pressure Regulation/Exhaust

page 45.

uct within vat (frypot) to generate

steam.

Clean exhaust line to stack.

Place proper quantity of moist product within vat (frypot) to generate

steam.

Remove shipping spacer per Operator’s Manual.

,

Troubleshooting

6

Solenoid valve leaking or not

closing.

Deadweight valve leaking. Repair per 2.17

Main timer not closing

solenoid.

Lid gasket leaking. Adjust lid limit stop; if this does not

Check and clean solenoid valve per

2.17

Pressure Regulation/Exhaust

page 45.

Pressure Regula-

tion/Exhaust

Check main timer per 2.16

Control

correct the problem, reverse the lid

gasket; if this fails to correct the

problem, replace the lid gasket.

, page 45.

Timing

, page 42.

,

Problem Cause Correction

Safety relief valve leaking. Check and replace, if necessary, per

2.17

Pressure Regulation/Exhaust

page 45.

FFiilltteerr SSyysstteemm SSeeccttiioonn

,

Filter motor runs but

pumps shortening

slowly.

Pump switch ON,

motor does not run.

Filter valve not open. Open filter valve.

Pump clogged. Remove and clean pump per 2.18

Filtering System

Filter frame not properly

assembled.

Filter line connections loose. Tighten all filter line connections.

Solidified shortening in lines. Clear all filter lines of solidified

Charcoal filter clogged (if

applicable).

Defective switch. Check/replace switch per 2.15

Defective motor. Check/replace motor per 2.18

Motor thermal protector

tripped.

Handles must put pressure on filter.

shortening.

Change charcoal filter (if applicable).

trical Components

ing System

Reset thermal switch per 2.18

ing System

, page 68.

Elec-

, page 37.

Filter-

, page 68.

Filter-

, page 68.

Motor hums but will

not pump.

Shortening will not

heat.

Clogged lines or pump.

HHeeaattiinngg ooff SShhoorrtteenniinngg SSeeccttiioonn

Blown fuse or tripped circuit

breaker at supply box or control panel.

Blown fuse at control panel. Check fuse per 2.15

• Remove and clean pump and

lines per 2.18

page 68.

• Replace pump seal, rotor and

rollers per 2.18

page 68.

Reset breaker or replace fuse.

ponents

, page 37.

Filtering System

Filtering System

Electrical Com-

,

,

Troubleshooting

7

Problem Cause Correction

Heating of shortening too slow.

Faulty main switch. Check main switch per 2.15

cal Components

No power. Check cord and plug and power at

wall receptacle per 2.15

Components

High limit control switch

open.

Faulty thermostat. Check thermostat per 2.10

Faulty high limit control

switch.

Low or improper voltage. Use a meter and check the recep-

Wire(s) loose. Tighten.

Burnt or charred wire

connection.

Press red high limit reset per 2.11

High Temperature Limit Control

page 25.

stat Replacement

Check high limit control switch per

2.11

High Temperature Limit Control

page 25.

tacle against data plate.

Replace wire and clean connectors.

, page 37.

, page 37.

, page 22.

Electri-

Electrical

,

Thermo-

,

Shortening

overheating.

Pilot will not light. Pilot not lit. Light pilot per Section 2-10 Gas Pilot

Pilot will not stay lit. Faulty thermocouple. Replace thermocouple per 2.13

Troubleshooting

Check thermostat. Check faulty thermostat per 2.10

Thermostat Replacement

Lightning & Burner Lighting and

Shutdown Procedure of Operator’s

manual.

Plugged pilot orifice, and/or

pilot supply tube.

Gas supply off. Turn ON gas supply.

Faulty gas control valve. Replace gas control valve.

Air in gas supply line. Bleed air from supply line.

Pilot magnetic plug. Replace gas control valve per 2.14

Unplug pilot orifice and/or pilot supply tube.

Thermocouple

Gas Control Valve

, page 31.

, page 33.

, page 22.

8

Problem Cause Correction

Burner will not light,

pilot lit (gas model)

Drain valve open. Close drain valve.

High limit control switch. Press red high limit reset per 2.11

High Temperature Limit Control

page 25.

Faulty high limit control

switch.

Possible faulty gas control

valve.

Possible faulty thermostat. Check thermostat per 2.10

With power removed from fryer,

check across high limit switch terminals with ohmmeter; replace if no

reading is indicated on meter.

With power removed from fryer,

check across electrical leads of gas

control valve with ohmmeter, and

gas control valve in ON position;

Ohm reading should be 350 ohms

resistance; replace the control valve

if not within 10%.

stat Replacement

thermostat if found to be faulty.

, page 22; replace

,

Thermo-

Heating of Shortening Too Slow (gas

model).

Shortening overheating (gas model).

Foaming or boiling

over of shortening

(gas/electric

models).

Supply line too small - low

gas volume.

Incorrect jet size. Replace with proper size jet for type

Improper ventilation system. Refer to Section 2-5 Ventilation of

Possible faulty thermostat. Check thermostat per 2.10

SShhoorrtteenniinngg FFooaammiinngg//DDrraaiinniinngg

Water in shortening. At end of cook cycle, drain shorten-

Condensation line stopped

up.

Increase supply line size, see Section 2 Unpacking/Installation of Operator’s manual.

of gas, and altitude (contact factory).

Fryer in Operator’s Manual.

Thermo-

stat Replacement

thermostat if found to be faulty.

ing and clean vat (frypot), add fresh

shortening, and check procedure for

raising lid.

Condensation line stopped up.

, page 22; replace

Troubleshooting

9

Problem Cause Correction

Improper or bad shortening. Use recommended shortening.

Improper filtering. Refer to the procedure covering fil-

tering the shortening.

Improper rinsing after cleaning the fryer.

Shortening will not

drain from vat

(frypot).

Timer fails to run. No power input.

Buzzer continues to

buzz.

Drain valve clogged with

crumbs.

Drain valve will not open by

turning handle.

MMaaiinn TTiimmeerr SSeeccttiioonn

Timer set at zero. Set timer indicator to a setting other

Faulty microswitch. Check and replace faulty micro-

Clean and neutralize the vat (frypot);

rinse with vinegar to remove alkaline

then rinse with hot water, and dry vat

(frypot).

Open valve - force cleaning brush

through drain opening.

Replace cotter pins in valve

coupling.

• Check timer switch.

• Check timer motor.

than zero.

switch per 2.15

nents

, page 37.

Electrical Compo-

Buzzer will not buzz. Possible faulty buzzer. Check buzzer per 2.16

Timer will not reset. Faulty timer. Replace timer.

Timer light out. Faulty lamp. Replace lamp per 2.16

Gasket coming out of

lid liner.

Troubleshooting

10

Timer indicator not returning

to zero.

LLiidd SSeeccttiioonn

Crumbs under gasket.

Timing Con-

trol

, page 42.

Replace timer per 2.16

trol

, page 42.

trol

, page 42.

• Remove gasket and clean per

2.17

Pressure Regulation/

Exhaust

• Clean top rim of vat (frypot).

, page 45.

Timing Con-

Timing Con-

Problem Cause Correction

• Replace worn or damaged

gasket per 2.17

Regulation/Exhaust

Pressure

, page 45.

Lid spindle will not

turn or turns hard

with lid open.

Lid will not unlatch

from closed position.

Spindle dry. Lubricate spindle per 2.17

Regulation/Exhaust

Worn acme nut. Replace acme nut per 2.17

Regulation/Exhaust

Lid gasket not seated properly or idle nut not adjusted.

To check the problem, perform

the following procedures:

11.. Remove pressure from vat

(frypot).

22.. Turn main switch to off position.

33.. Drain shortening from vat

(frypot).WWAARRNNIINNGG!! TThhee nneexxtt

pprroocceedduurree mmuusstt bbee ppeerrffoorrmmeedd

wwhhiillee hhoollddiinngg tthhee lliidd cclloosseedd

uunnttiill tthhee lliidd llaattcchh iiss ffrreeee ffrroomm

tthhee ccrroossss--aarrmm.. ffaaiilluurree ttoo hhoolldd

ddoowwnn tthhee lliidd wwiillll rreessuulltt iinn tthhee lliidd

sspprriinnggiinngg bbaacckk ttoo aa ffuullll ooppeenn

ppoossiittiioonn.. ppeerrssoonnaall iinnjjuurryy,, oorr

ddaammaaggee ttoo tthhee hhiinnggee mmaayy

rreessuulltt..

, page 45.

, page 45.

Pressure

Pressure

44.. Remove Tru-Arc ring. Drive latch

pin out. Lid will open.

55.. Raise lid slowly.

66.. Reinstall latch.

77.. Adjust limit stop, per 2.17

Pressure Regulation/Exhaust

page 45.

88.. Lid gasket should be properly

seated in lid liner.

,

Troubleshooting

11

Troubleshooting

12

CChhaapptteerr 22 MMaaiinntteennaannccee

22..11 IInnttrroodduuccttiioonn

This section provides procedures for the checkout and replacement of the various

parts used within the fryer. Before replacing any parts, see Chapter 1

Troubleshooting

22..22 MMaaiinntteennaannccee HHiinnttss

• You may use two test instruments to check electric components:

– A continuity light

– An ohmmeter

• When the manual refers to the circuit being closed, the continuity light will be illuminated or

the ohmmeter should read zero unless otherwise noted.

• When the manual refers to the circuit being open, the continuity light will not be illuminated

or the ohmmeter will read 1 (one).

, page 1. It will aid you in determining the cause of the malfunction.

NOTICE:

A continuity tester cannot be used to check coils or motors.

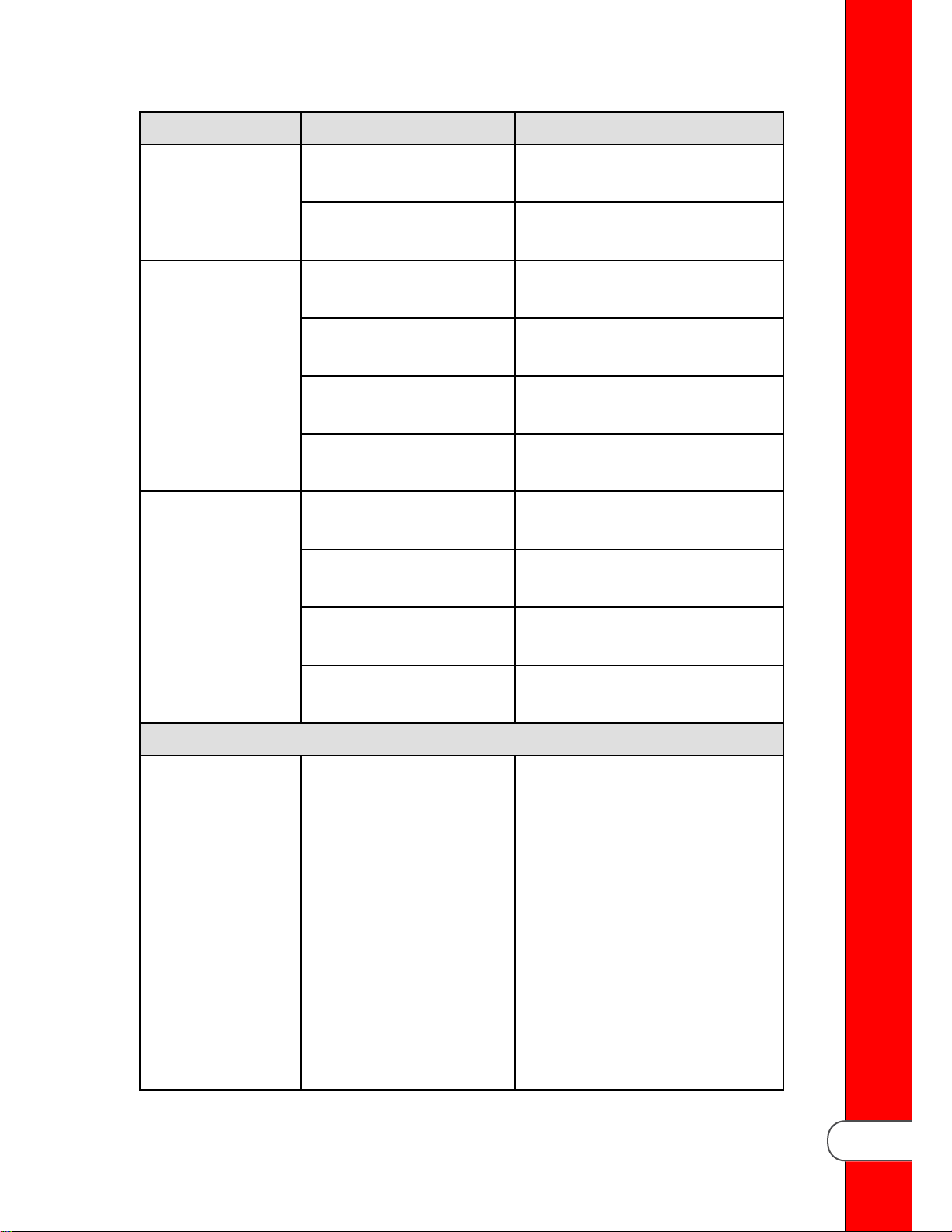

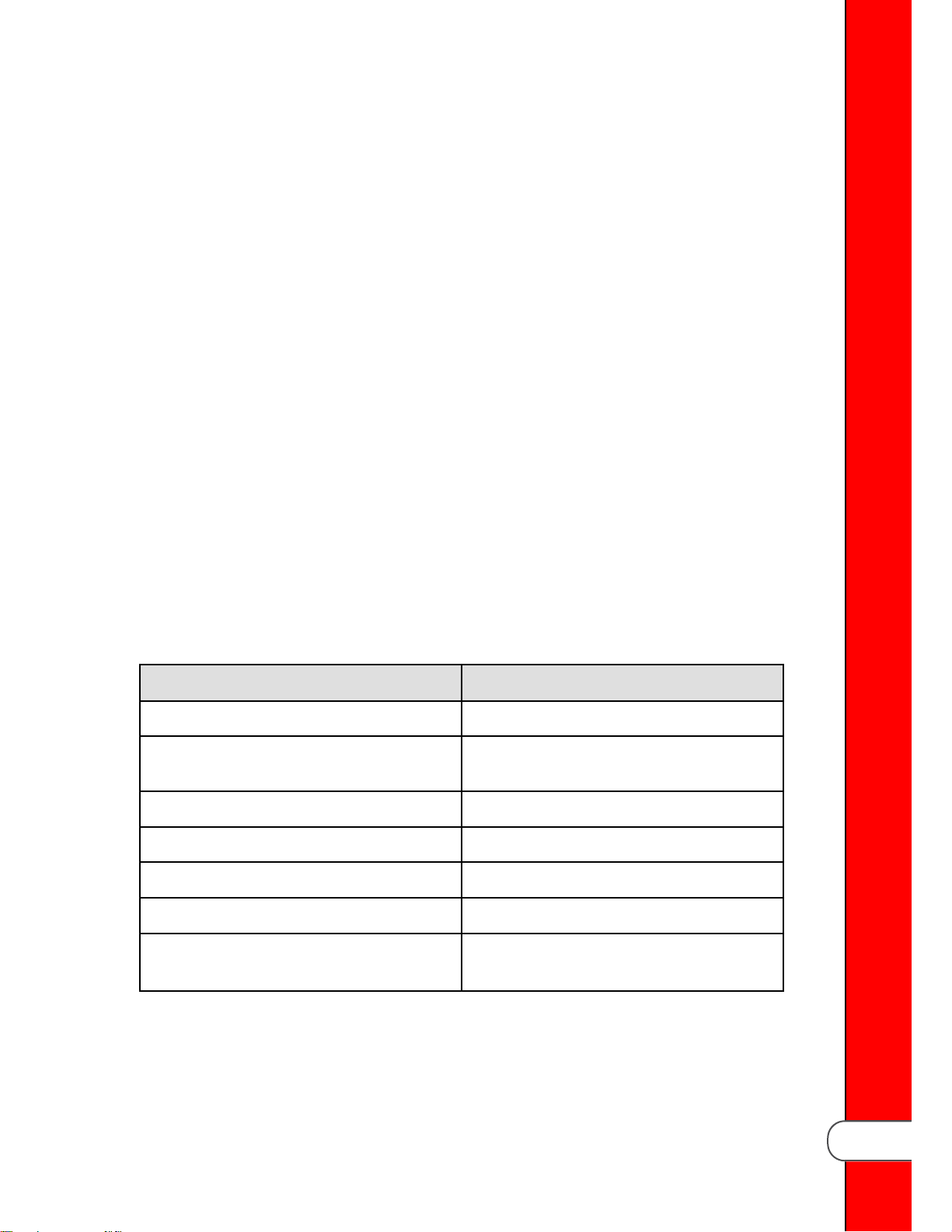

22..33 PPrreevveennttaattiivvee MMaaiinntteennaannccee SScchheedduullee

To ensure a long life of the fryers and their components, regular maintenance should

be performed, see the chart below.

TTaabbllee 22--11 PPrreevveennttaattiivvee MMaaiinntteennaannccee SScchheedduullee

Frequency Action

Daily (3-4 loads) Filter shortening.

Daily Clean deadweight valve cap, weight, and

orifice.

30 Days Lubricate spindle threads and ball seat.

90 Days Reverse lid gasket.

90 Days Check limit stop adjustment.

90 Days Check and tighten element spreader bars.

Once A Year Annual preventative maintenance, see Ap-

pendix A.

Maintenance

13

22..44 LLoowweerr tthhee CCoonnttrrooll

TToo aavvooiidd eelleeccttrriiccaall sshhoocckk oorr pprrooppeerrttyy ddaammaaggee,, mmoovvee tthhee

ppoowweerr sswwiittcchh ttoo ooffff aanndd ddiissccoonnnneecctt mmaaiinn cciirrccuuiitt bbrreeaakkeerr,, oorr

uunnpplluugg ccoorrdd aatt wwaallll rreecceeppttaaccllee..

To replace parts inside the fryer, lower the control by doing the following:

11)) Place the main power switch to the off position. The switch is labeled POWER/

OFF/PUMP.

22)) Remove the two screws from the bottom of the control.

33)) Carefully slide the control upward until it lifts off the metal hangers.

44)) With the fryer door closed, place the lower edge of the control in the slot

between the door and the frame of the fryer.

22..44..11 RRaaiissee tthhee CCoonnttrrooll

11)) Raise the control, and then hook it on the metal hangers that hold the top of the

control in place.

22)) Install the two screws in the bottom of the control.

33)) Reconnect power to the fryer.

22..44..22 RReeppllaaccee tthhee CCoonnttrrooll

Follow the steps outlined in 2.4

Control

, page 14.

Lower the Control

, page 14 and 2.4.1

Raise the

11)) Note the locations of the connectors on the back of the control

Maintenance

22)) Remove the connectors, and then swap out the old control for the new.

14

33)) Reconnect the connectors on the back of the control.

22..44..33 CCoonnffiigguurree tthhee SSeerriiaall NNuummbbeerr

NOTICE

module cannot receive or transmit data, including automated software updates.

22..44..33..11 VVeerriiffyy tthhee SSeerriiaall NNuummbbeerr

: The serial number must be added correctly in to the control or the WiFi

11)) Set the power switch to the OFF position.

22)) Locate the machine data plate on the inside of the filter pan door, and then

record the serial number displayed on it.

NNOOTTEE: Serial numbers may be one of two formats:

• AAXXXXXXX (AA followed by seven digits)

• BCXXXDE (Two letters followed by three digits followed by two more letters)

The serial number may also be etched in to the rear top left corner of the pot

(see image below).

33)) Press and hold for 7-8 seconds until L-2 LEVEL 2 displays. CFA PROG /

ENTER CODE displays.

44)) Press twice. SETUP / ENTER CODE displays.

55)) Using the left product buttons, press 1,2,3. - SETUP MODE - briefly displays.

66)) Compare the serial number displayed in SM-1 with the number you recorded.

77)) Perform one of the two actions:

•

If the serial number matches, press and hold

control resumes normal operation.

•

If the serial number is missing or does not match, follow either the 9 or 7

character serial number correction procedure.

until - OFF - displays. The

Maintenance

15

22..44..33..22 AAddddiinngg oorr CCoorrrreeccttiinngg aa 99 CChhaarraacctteerr SSeerriiaall NNuummbbeerr

NNOOTTEE: You only need to enter the first four and last three digits; the “AA” is already

populated.

11)) Press the left-side button.

22)) Press the right-side for standard (STD).

33)) Press the product keys to enter the first four digits of the serial number you

recorded.

NNOOTTEE: The value of each product key is represented by the number below the

product key (see above image).

44)) Press to continue.

55)) Press the product keys to enter the last three digits of the serial number

recorded in 2.4.3.1

66)) Press . SAVE ? YES NO displays.

77)) Do one of the following:

- If the serial number is correct, press the right-side

- If the serial number is incorrect, press the right-side

repeat steps 2-6 of this procedure.

Verify the Serial Number

, page 15.

for YES.

for NO, and then

88)) Press and hold until - OFF - displays. The control resumes normal

Maintenance

16

operation.

Loading...

Loading...