Henny Penny EEG-163 Operators Manual

TECHNICAL

M A N U A L

Evolution Elite™

MODEL

EEG-163

EEG-164

R E G I S T E R WA R R A N T Y O N L I N E AT W W W. H E N N Y P E N N Y. C O M

Section 1: introduction

1-1 SAFETY

The instructions in this manual have been prepared to aid you in learning the proper procedures for your equipment. Where information is of particular importance or is safety related, the words NOTICE, CAUTION, or WARNING are used. Their usage is described below.

If a problem occurs during the first operation of a new unit, recheck the Installation Section of the Operator’s Manual.

Before troubleshooting, always recheck the Operation Section of the Operator’s Manual.

Where information is of particular importance or is safety related, the words DANGER, WARNING, CAUTION, or NOTICE are

used. Their usage is described as follows:

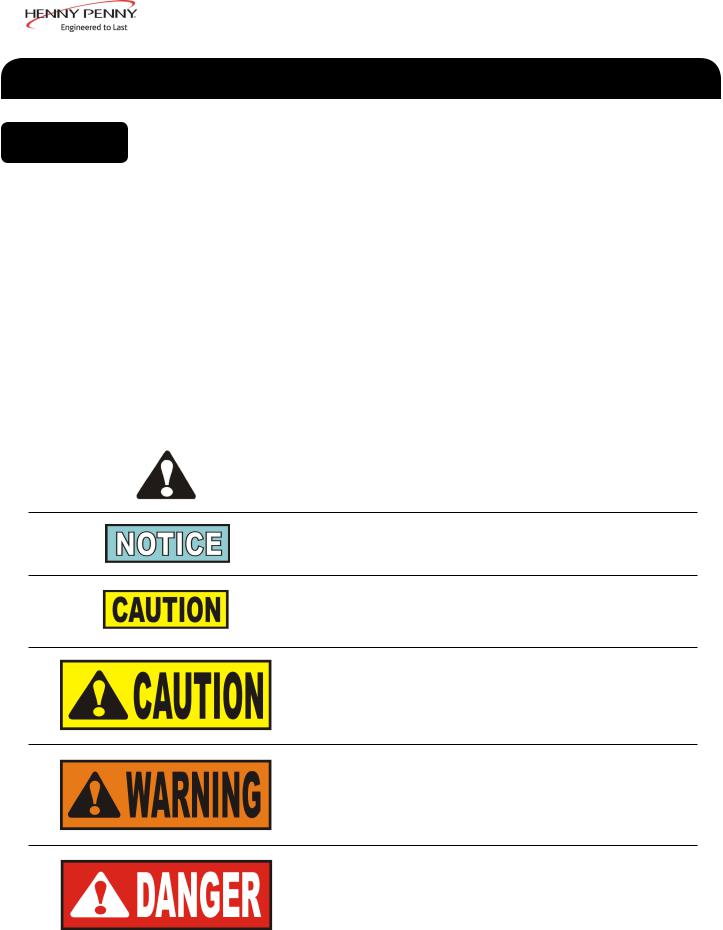

SAFETY ALERT SYMBOL is used with DANGER, WARNING or CAUTION which indicates a personal injury type hazard.

NOTICE is used to highlight especially important information.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may result in property damage.

CAUTION used with the safety alert symbol indicates a potentially hazardous situation which, if not avoided, could result in minor or moderate injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

DANGER INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN DEATH OR SERIOUS INJURY.

Sept. 2013 |

2 |

1-2. SAFETY (Cont.)

Equipotential Ground Symbol

Waste Electrical and Electronic Equipment (WEEE) Symbol

OR |

Shock Hazard Symbols |

OR |

Hot Surface Symbols |

Sept. 2013 |

3 |

Section 2: troubleshooting

2-1. TROUBLE SHOOTING GUIDE

Problem |

|

Cause |

Correction |

POWER switch ON |

• |

Open circuit |

• Plug fryer in |

but fryer completely |

|

|

• Check breaker or fuse at supply |

inoperative |

|

|

box |

Control error code “E- |

• |

Oil temperature too |

• Let unit cool down (15-20 |

10” |

|

high |

minutes), push up on metal reset |

|

|

|

button under right side of the |

|

|

|

controls; if high limit does not |

|

|

|

reset, high limit must be replaced |

Vat is under-filled |

• |

JIB is low or empty |

• |

Fill the JIB |

|

• JIB oil line is clogged |

• |

Check JIB line |

|

|

|

or collapsed |

• Clean filter pan and change |

|

|

• |

Filter pan needs |

|

paper or pad |

|

|

cleaned |

|

|

Sept. 2013 |

4 |

2-1. TROUBLE SHOOTING GUIDE (cont.)

Problem |

|

Cause |

|

Correction |

Oil foaming or boiling |

• |

Water in oil |

• Drain and clean oil |

|

over top of vat |

• |

Improper or bad oil |

• |

Use recommended oil |

|

• |

Improper filtering |

• Refer to filtering procedures |

|

|

• |

Improper rinsing after |

• Clean and rinse vat and then dry thor- |

|

|

|

cleaning the vat |

|

oughly |

Oil will not drain from vat |

• |

Drain valve clogged with |

• Open valve, force cleaning brush |

|

|

|

crumbs |

|

through drain |

|

• |

Drain trough clogged |

• Remove right side panel and remove |

|

|

|

|

|

plug from end of trough and clean trough |

Filter motor runs but |

• |

Filter line connections |

• Tighten all filter line connections |

|

pumps oil slowly |

|

loose |

• Change filter paper or pad |

|

|

• Filter paper or pad |

• Refer to assembly instructions on inside |

||

|

|

clogged |

|

door |

|

• |

Filter not reassembled |

|

|

|

|

correctly |

|

|

Bubbles in oil during en- |

• |

Filter pan not completely |

• Make sure filter pan return line is pushed |

|

tire filtering process |

|

engaged |

|

completely into the receiver on the fryer |

|

• |

Filter pan clogged |

• Clean pan and change paper or pad |

|

|

• Damaged O-ring on filter |

• |

Change O-ring |

|

|

|

line receiver on fryer |

|

|

Filter motor will not run |

• |

The thermal reset button |

• Remove the right side panel and |

|

|

|

on the rear of the pump |

|

allow time for the motor to cool and |

|

|

motor is tripped |

|

then, using a screwdriver, press hard |

|

|

|

|

against the button until it clicks |

To prevent burns caused by splashing shortening, turn the unit’s POWER switch to the OFF position before resetting the filter pump motor’s manual reset

protection device.

Sept. 2013 |

5 |

2-2. ERROR CODES

In the event of a control system failure, the digital display shows an error message. The message codes are shown in the DISPLAY column below. A constant tone is heard when an error code is displayed, and to silence this tone, press any button.

DISPLAY |

|

CAUSE |

CORRECTION |

|

• |

Control board |

Turn switch to OFF position, then turn switch back to ON; if |

“E-4” |

|

overheating |

display shows “E-4”, the control board is getting too hot; check |

|

|

the louvers on each side of the unit for obstructions |

|

|

|

|

|

|

|

|

|

|

• |

Oil overheating |

Turn switch to OFF position, then turn switch back to ON; if |

“E-5” |

|

|

display shows “E-5”, the heating circuits and temperature probe |

|

|

should be checked |

|

|

|

|

|

|

|

|

|

|

• |

Temperature probe |

Turn switch to OFF position, then turn switch back to ON; if |

“E-6A” |

|

open |

display shows “E-6A”, the temperature probe should be checked |

|

|

|

|

“E-6B” |

• |

Temperature probe |

Turn switch to OFF position, then turn switch back to ON; if |

|

shorted |

display shows “E-6B”, the temperature probe should be checked |

|

|

|

||

|

• |

Hight limit |

Let unit cool down (15-20 minutes), push up on metal reset |

|

|

|

button under right side of the controls; if high limit does not |

|

|

|

reset, high limit must be replaced |

“E-10”

“E-15” |

• |

Drain switch |

Make sure drain knob is completely pushed-in; if E-15 persists, |

|

|

|

have drain switch checked |

||

|

|

|

||

“E-18-A” |

• LH level sensor open |

Turn switch to OFF position, then turn switch back to ON; |

||

• RH level sensor open |

if display still indicates a failed sensor, have the connectors |

|||

“E-18-B” |

||||

• |

Both sensors open |

checked at the control board; have sensor checked & replace if |

||

“E-18-C” |

||||

|

|

necessary |

||

|

|

|

||

Sept. 2013 |

6 |

Loading...

Loading...