Page 1

SERVICE MANUAL

VS 60/90/130

Page 2

TABLE OF CONTENTS

INTRODUCTION

CONTROL PANEL

PERIODIC MAINTENANCE

START TROUBLE SHOOTING

COMPONENT CHECK

ADVANCED TROUBLE SHO OTING

COMPONENT PLACEMENT

MENU NAVIGATION

WIRING DIAGRAM

INSTALLATION

TECHNICAL DATA

FEEDBACK

SPARE PARTS LIST

Rev D TABLE OF CONTENTS

Page 3

INTRODUCTION

WARNING!

• As the sterilizer works with

steam under pressure, some

parts of it may become warm.

You should therefore exercise

the greatest caution whenever

working on the sterilizer.

• Hot steam may flow out of the

sterilizer when the door is opened.

• When handling materials and

loading the sterilizer, bear in

mind that the chamber and the

area close to the chamber entrance is very warm.

• Liquids must be sterilised in

special programs intended for

liquids. The sterilizer's liquid

program is solely intended for

the sterilisation of liquids in

open vessels.

General

The VS-series consists of vertical sterilizers with preprogrammed sterilisation programs. The sterilizer

works with steam produced in a chamber, fed with water from an external connection.

WARNING TEXTS IN THI S MANUAL

There are 4 di fferent admonitory levels in the manual:

• WARNING!

Factor, circumstance or state that can give rise to

the risk of personal injury.

• CAUTION!

Factor, circumstance or state that can give rise to

the risk of damage to machinery or the process.

• IMPORTANT!

Clarification that facilitates the understanding of

that described in this manual.

• TIP!

Factor, circumstance or state that can facilitate

execution or the process.

The following warning symbols is placed on the outside of the sterilizer (symbol acc. to ISO 3864)

If national requirements do not accept this symbol, the

symbol must be replaced by a suitable symbol valid in

the country were the sterilizer is used.

The warning symbol indicates that the person, responsible for the sterilizer must be fully conversant

with all requirements mentioned in the documents for

the sterilizer.

INTRODUCTION

Page 4

Warranty

IMPORTANT!

The warranty on the delivered

product is invalidated by faulty

installation or an overlooked/

incorrect service interval/maintenance It must be possible to verify

service/maintenance.

A 2 year warranty is provided. However, not on those

components considered to be consumables, for example, door gaskets. For service work, reference

should be made to agreements with the supplier.

The Product Liability Act only applies when the instructions in this manual have been followed in their

entirety.

Copyright

Copyright © 2005 Getinge Skärhamn AB. All rights reserved.

All technical documentation provided by Getinge

Skärhamn AB is copyright protected and the property

of Getinge Skärhamn AB.

This publication may be downloaded from Getinge

Skärhamn's official website:

www.skarhamn.getinge.com.

The technical documentation is supplied as is. The

documentation can contain printing errors, technical

errors or other errors. Getinge Skärhamn AB reserves

the right to make alterations without prior notice.

No part of this publication may be copied without the

expressed permission of Getinge Skärhamn AB.

Manufacturer

Getinge Skärhamn AB Industrivägen 5

SE-47131 Skärhamn Sweden

Disposal

This product consists of (percentage by weight)

76 % Stainless steel

4 % Plastic

9 % Aluminium

5 % Brass

2 % Copper

4 % Electronics

When disposing of the sterilizer, it must be sorted at

source in accordance with the requirements set out in

the WEEE directive (2002(96/EC).

Contact your dealer when disposing of the sterilizer.

INTRODUCTION

Page 5

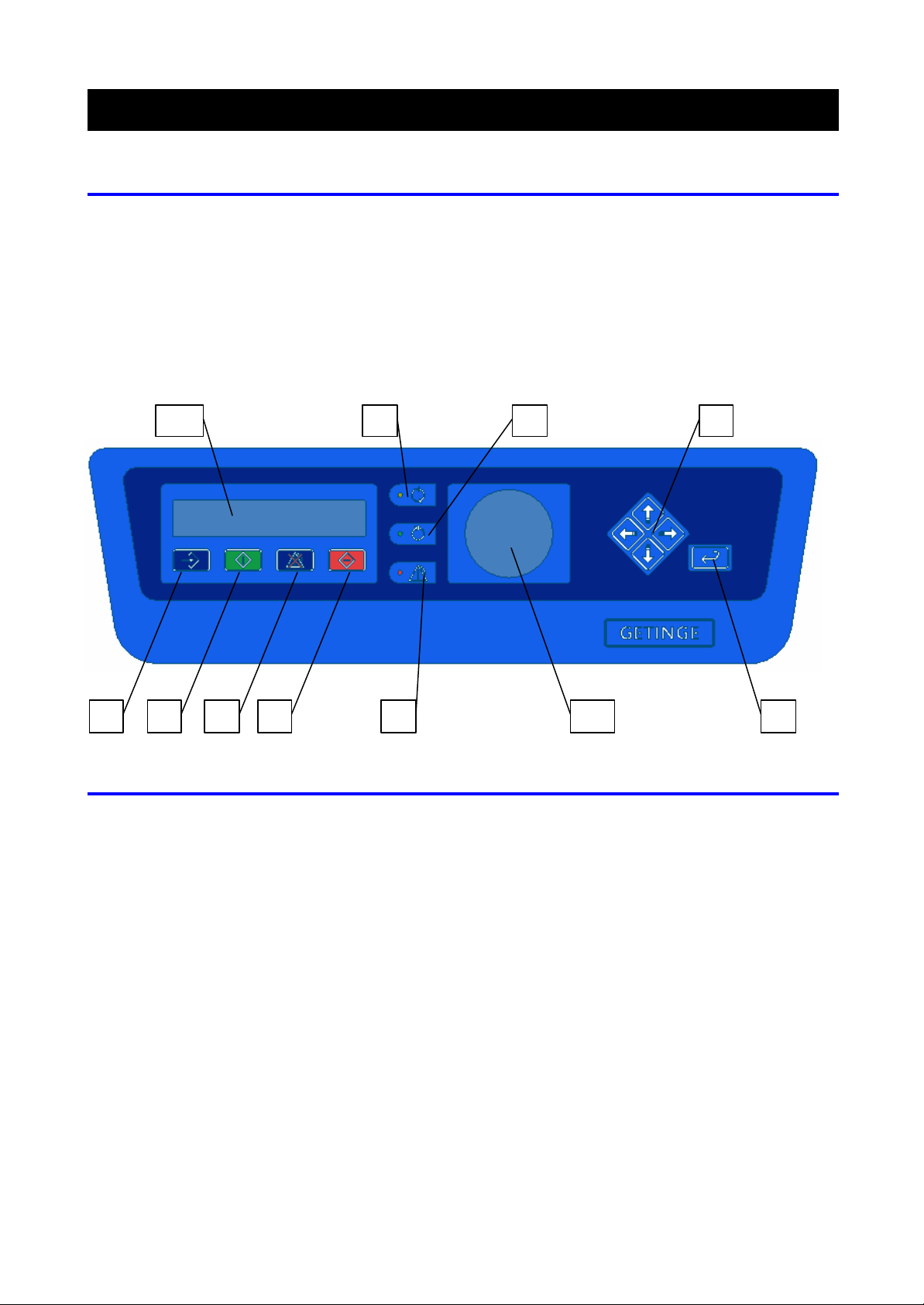

CONTROL PANEL

2 3 4 5 6 7 8 9 10 11

Layout of the control panel

1. PROGRAM SELECTOR button –

selection of the program

2. START button – start of the program

3. RESET button – reset a fault

4. STOP button – emergency stop

5. Yellow status lamp – program in progress

6. Green status lamp – program finished

7. Red status lamp – alarm

8. ENTER button – select items from the menu

9. Arrow keys – navigate through menus/lists

10. Pressure gauge – shows the chamber pressure

11. Display unit

1

Display unit

Shows the current status, program progres s, number of minutes after program start, number of completed

cycles and error codes.

IN STANDBY MODE SHOW S:

• Process name (program)

• Sterile time/temperature

Menu

Press the DOWN arrow to CYCLE COUNTER (twice)

and then press the ENTER button now press the

DOWN arrow to read the pressure and load sensor temperature (when the sterilizer features a

liquid program).

SHOWN DURING THE PRO CESS:

• Process name

• Process time

Home position:

Press the LEFT arrow for at least 4 seconds

To specifically read the load sensor temperature

(when the sterilizer features a liquid program),

press the ENTER button at the process name.

Page 6

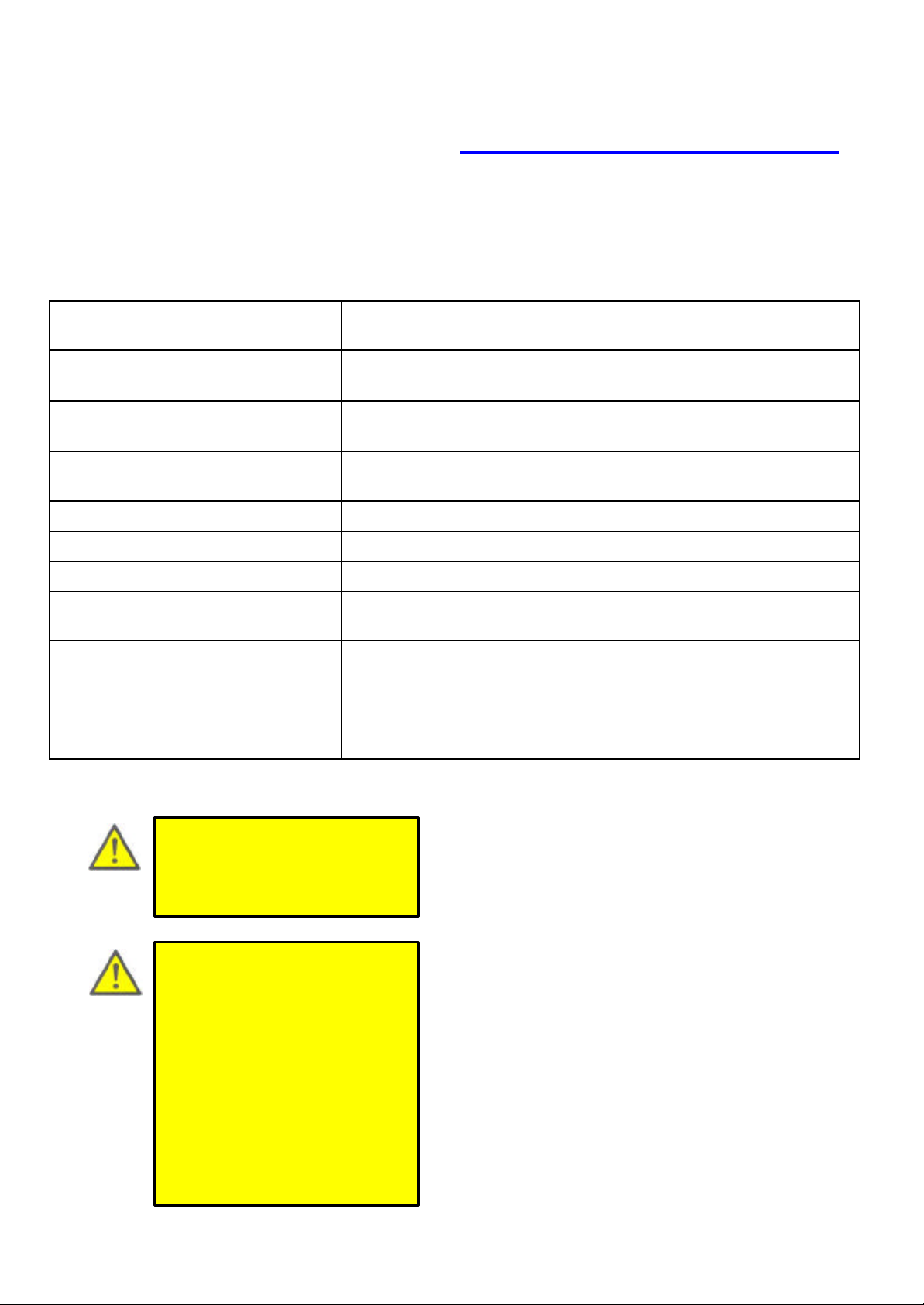

Operation, check

as not been locked before the start button has been pressed. Read

INCORRECT OPERATION, CHECKLIST

The table below lists the most common operating

faults that result in an alarm (error code) or that certain symptoms are experienced.

Check that usage was correct.

ALARM (ERROR CODE) REASON

Close door Door h

the text below the table, Correct operation, checklist .

Sterile error The sterilizer may have been overloaded. Read the Technical data se c-

tion.

Door open The handle has been activated befo re the finished signal has been dis-

played. Read the text below the table, Correct operation, checklist .

Process stopped The stop button has been pressed by the operator.

Heating error Can be due to items caught in the door.

No water Perhaps the water supply tap has not been opened

SYMPTOM REASON

Process abnormally long Can be due to:

• no water on the incoming supply.

• sterilizer overloaded. Read the Technical data section.

• leakage.

WARNING!

Consider the risk of burns when

loading the sterilizer.

CAUTION!

Only sterilise items intended for

sterilisation with steam and that

can withstand at least 121 degrees.

Only use loading equipment especially designed for the VS series.

Each standard basket may be

loaded with max. 12 kg of goods.

To ensure optimal ergonomics use

a lifting device when processing

heavy loads.

CORRECT OPERATION, CHECKLIST

1 Placing items in the sterilising chamber. Only use

loading equipment especially designed for the

VS series. Carefully check that nothing is caught

between the door and chamber.

Place moisture -sensitive items and low-mass

items at the top of the chamber.

Place heavy items at the bottom of the sterilis-

ing chamber.

Place dish-shaped items dish side down.

Place empty containers (bottles, test tubes,

etc.) with their opening downwards.

2 Close the door and pull the handle clockwise to

lock.

3 Press the START button, the cycle starts and will

be completed automatically.

OPERATION, CHECK

Page 7

Recommended accessories

Basket, part no. 566687401

Solid, stainless steel container

48325031

4 When the display shows FINISH, the green status

lamp comes on and when the pressure gauge

shows zero the process is completed.

5 The display never shows FINISH and the green

status lamp for process finished never comes on if

the process is interrupted.

6 As soon as the door is opened FINISH is no

longer shown on the display, this provides information that if FINISH is not shown on the display,

then the goods in the chamber may have been

loaded by “someone else”, but not sterilised.

7 If the red status lamp for an alarm is on after a

sterilising process, the goods should be considered as unsterilised and must then be sterilised

again.

When the door is opened FINISH is no longer dis-

played. The display now shows:

INSTRUMENT 1340C (last selected program)

00.05.00_1340C

WARNING!

Remember the goods are hot after

sterilising.

Never attempt to open the door

until the pressure gauge has returned completely to zero.

LIQUID STERILISATION

• A special liquid program and a load sensor in the

chamber are required to sterilise liquids. The liquid process is solely intended for liquid sterilisation in open receptacles.

• Bottles should be filled to max. 80 % of their vol-

ume.

• Place the load sensor in the largest container.

When there is no space in the liquid for the load

sensor, use a control receptacle where the load

sensor can be placed. The volume of the liquid in

the control receptacle should be as great or greater than the liquid intended for sterilisation. Boiling

point for the liquid in the control vessel must be

the same as for the liquid to be sterilised.

• Use a receptacle with the smallest possible vol-

ume for the fastest processing.

OPERATION, CHECK

Page 8

IMPORTANT!

If the process must be cancelled

for one reason or another press

the STOP button; the red status

lamp will come on and an audio

signal with sound.

Now press the RESET button and

wait for the pressure gauge to

drop to zero.

When the red status lamp indicating an alarm has gone out, press

the RESET button.

Open the door.

IMPORTANT!

When a process is interrupted,

there is a risk of steam streaming

out of the chamber when the door

is opened.

INTERRUPTED PROCESS

If the sterilizer stops the process:

1 Press the RESET button; the audio signal stops.

2 Wait until the pressure indication shows zero.

3 When the red status lamp has gone out:

4 Press the RESET button; the alarm text is no

longer displayed

If a process in progress has to be interrupted:

1 Press the STOP button; the text PROCESS

STOPPED is shown on the display. The audio sig-

nal sounds and the red status light comes on.

2 Press the RESET button; the audio signal stops.

3 Wait until the pressure indication shows zero.

4 When the red status lamp has gone out, press the

RESET button; the alarm text is no longer displayed.

OPERATION, CHECK

Page 9

PERIODIC MAINTENANCE

General

WARNING!

The outer casing may only be

removed by technicians with documented experience.

WARNING!

Bear in mind when cleaning that

the chamber and the area close to

the chamber entrance is very

warm.

TIP!

The following Service kits are

available:

• Disks for solenoid valves

• Grease for door gaskets

WARNING!

The electrical power supply must

always be disconnected with all

types of maintenance work.

The manufacturer recommends at full utilization of capacity that at least the following maintenance operations should be performed at the specified intervals

with by service technicians. Monthly and weekly maintenance is carried out by the operator as set out in the

user manual.

Annual maintenance

ANNUALLY OR AT LEAST EVERY 400 CYCLES

UNLESS OTHERWISE STATED.

• Replace the filter where appropriate (accessory).

Check that the filter is not wet.

• Replace the plunger and O-ring on MV-1,MV-2,

MV-6 and MV-8. Refer to the section Component

check, 3. Solenoid valves.

• Check the door and its flange. Lubricate the mov-

ing parts by the door gasket. Use a grease suitable for use in the food industry.

• Replace the door gasket. At least every 3rd year

or 1200 cycles. See the section Component

check, 20. Door, Door gasket.

• Measure the pressure using a calibrated absolute

test pressure gauge, use the intended flange

marked VT on the sterilizer. See the section

Component check, 12. Absolute pressure sensor.

• Inspect and rectify any leakage from pipe cou-

plings and instrument connections. See the section Advanced trouble shooting, Trouble

shooting leakage .

• Check and clean the water outlet in the chamber.

At least every 800 cycles.

• Check that the monthly and daily maintenance

have been carried out correctly.

PERIODIC MAINTENANCE

Page 10

• Perform a functional check of the electrical com-

ponents. See the section Component check. At

least every 1200 cycles or every 3rd year.

• Reset the service alarm from the Service mes-

sages men u. (situated under SE-

TUP/SYSTEM/SERVICE in the menu tree)

SAFETY CHECKS

• Check that the door seals against the steam pres-

sure during the sterilising process. See the section Component check, 20. Door.

• Check that the sterilizer can not be started when

the door has not been closed. See the section

Component check, 20. Door.

• Check that the door's counter-hold spring works

and prevents crush injuries. See the section

Component check, 20. Door, check the door

spring

• Inform the customer about the significance of the

warning signs.

• Inform the customer of the risks involved with the

program for sterilising liquids, if installed. Particularly the information that it is only permitted to

sterilise liquids inopen vessels.

PERIODIC MAINTENANCE

Page 11

Monthly maintenance

MONTHLY, OR AS REQUI RED

• Clean the bottom filter. See the section Component check, 1. Chamber.

• Clean the chamber. See the section Component

check, 1. Chamber.

• Clean the door gasket and lubricate with the gre-

ase recommended by Getinge.

Daily maintenance

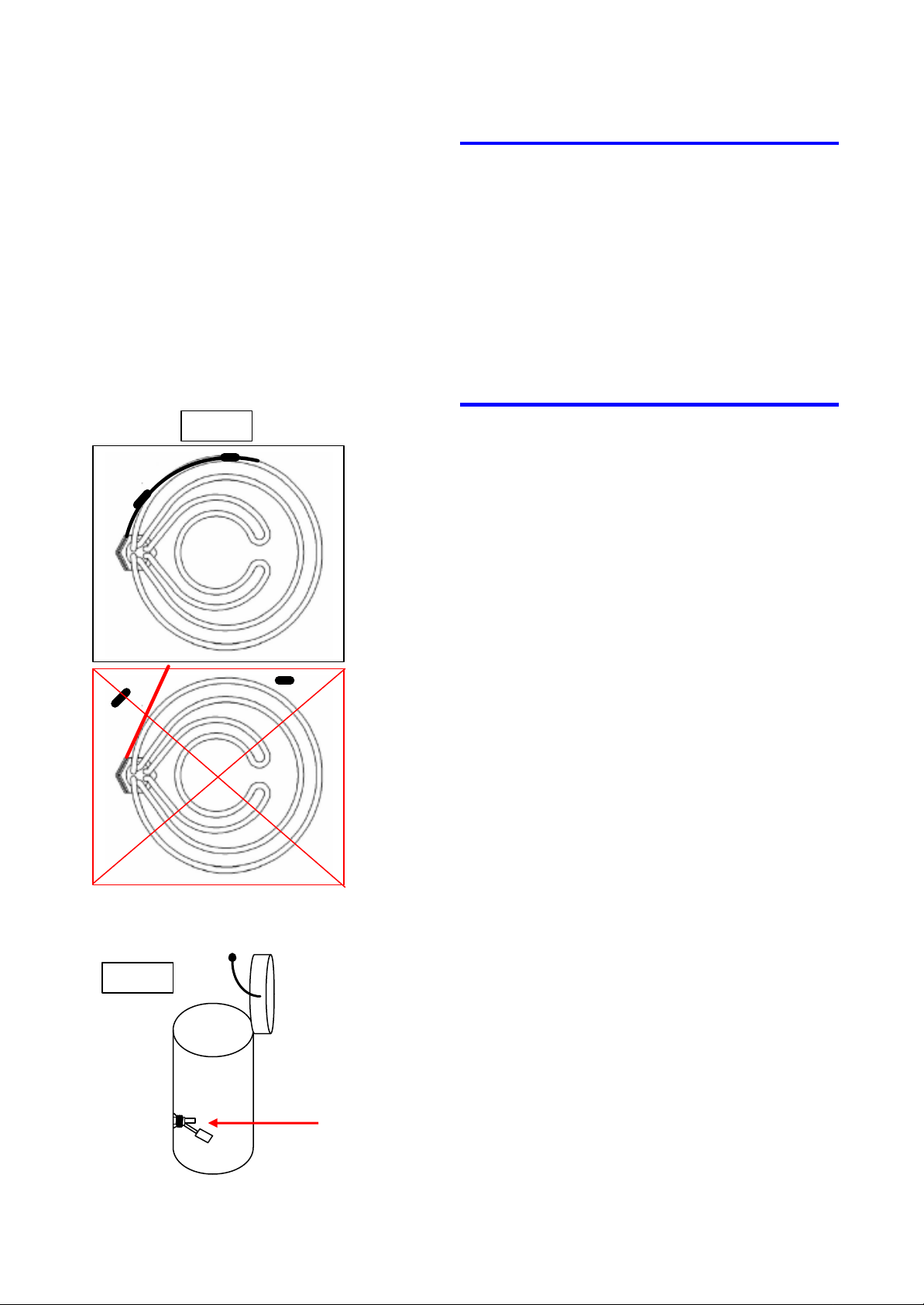

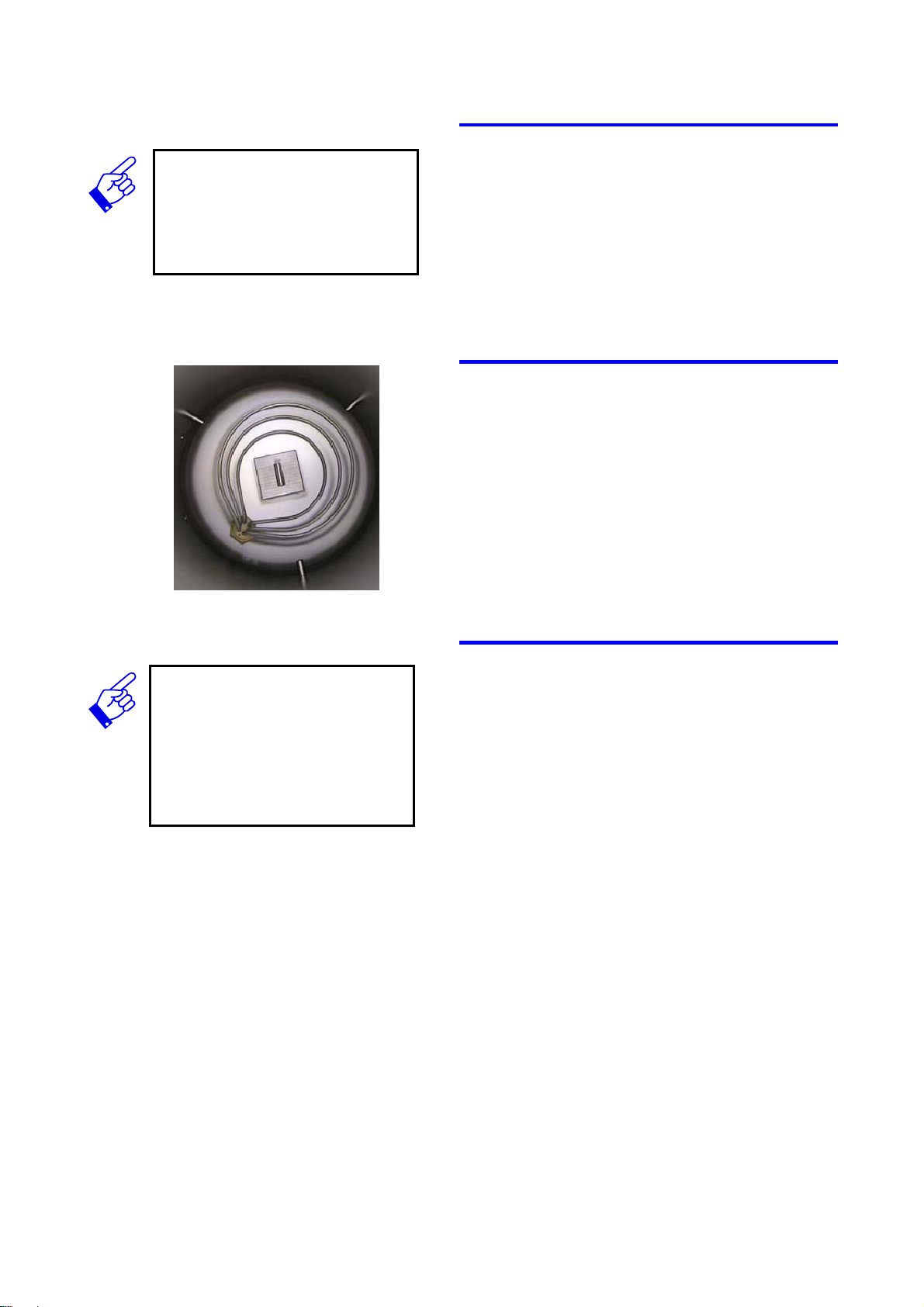

Fig. 1

• Check that the overheating protection sensor is fi t-

ted on the heating element, see fig 1. See the

section Component check, 6. Overheating pro-

tection.

• Check that the level guard in the bottom of the

chamber is clean, fig. 2.

See the section Component check, 1. Chamber.

Fig. 2

PERIODIC MAINTENANCE

Page 12

START TROUBLE SHOOTING

4 Final

3 Verify the

1 Start

Trouble shooting orientation

START TROUBLE SHOOTING HERE

Choose the error code/codes displayed and the symptom experienced in the table below. Carry out the pr e-

verification

Choose the

error code

symptom

scribed actions in the stated order, until the fault has

been identifie d and corrected.

CHECK PROCEDURE

1 START

Select the alarm (error code) or symptom in the

tables below.

2 Action

action

IMPORTANT!

The actions stated in the tables

are usually specific checks on the

components. However, the actions

can also represent advanced

trouble shooting and indicate the

specific component to be checked.

IMPORTANT!

After the action (for example,

component replacement) the action must be verified (e.g. manual activation).

In addition, it must be verified that

the error code/customer's experienced symptom has been corrected.

Several actions may be needed

with subsequent action verification, remember to always end

with verification against the

error code/symptom.

2 ACTION

Carry out the actions set out in the table. Carry

out the actions in the stated order, continue until

the fault has been corrected.

a. Check the components. In the event of a

component fault, repair or replace it. Instructions are enclosed with the spare part or are

set out after each check.

b. Should the check indicate that the component

is OK, return to the table in this section and

continue with next action as per point 2.

3 VERIFY ACTION

After repair/replacement the action must be verified. Instructions concerning verification are enclosed with the spare part or are set out after

each check.

4 FINAL VERIFICATION

(ERROR CODE/SYMPTOM VERIFICATION)

After ac tion verification it must be verified that the

displayed error code is not displayed again and

the experienced symptom no longer remains. This

is done by running a program and checking that

no error codes are displayed or the symptoms are

experienced.

START TROUBLE SHOOTING

Page 13

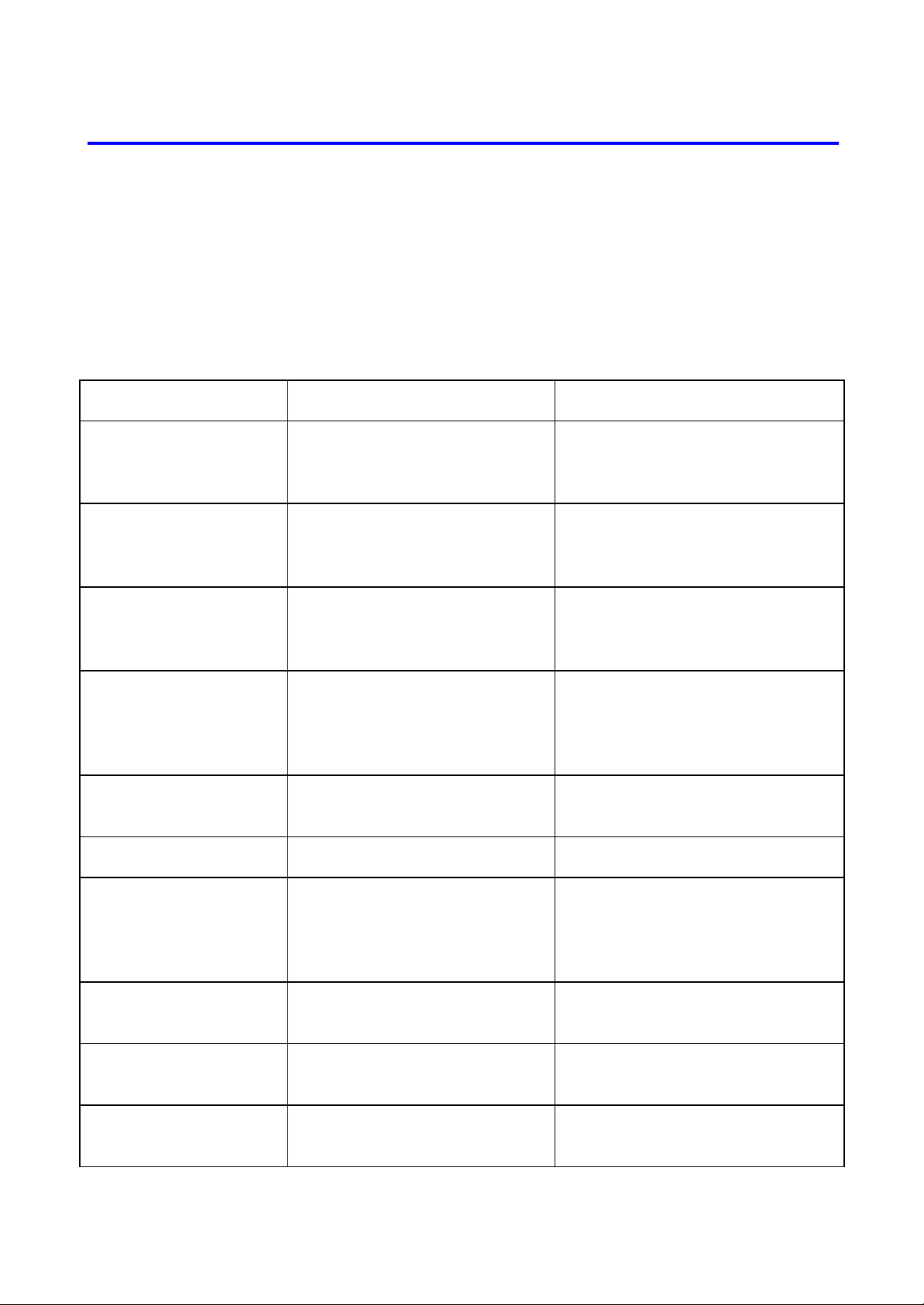

Alarm (error codes visible on the display)

EXPLANATIONS

Explanations to references to sections stated in the

tables below:

CC : chapter Component check

Advanced chapter Advanced trouble

trouble shooting: shooting

Other references are given in plain text.

ERROR CODE EXPLANATION ACTIONS IN ORDER OF PRIORITY

GETINGE PACS 300

GETINGE PACS 300 DISPLAY

CLOSE THE DOOR Door unlocked at point of start 1. Operation, check

DOOR OPEN Door open during process 1. Operation, check

POWER FAILURE Power failure during process 1. Check external fuses.

PT-100 ERROR Error on load sensor during process 1. CC, 15. Load temperature sensor

SERVICE Service indicator. 1. Contact the service technician

Process does not start, frozen process

1. CC, 19. Software PACS cold start

2. CC, 18. Display

3. CC, 17. Circuit board

2. CC, 20. Door, (micro-switch)

3. CC, 17. Circuit board

2. CC, 20. Door, (micro-switch)

3. CC, 17. Circuit board

2. CC, 6. Overheating protection

3. CC, 17. Circuit board (Fuse)

4. CC, 17. Circuit board

2. CC, 17. Circuit board AI

STERILE ERROR Incorrect pressure/steam tempera-

ture in the sterile phase

PROCESS STOPPED The process has been stopped with

the STOP button

PRESSURE SENSOR

ERROR

UPDATE Battery replacement or circuit board

Pressure sensor incorrectly calibrated

fault

1. Operation, check

2. CC, 15. Load temperature sensor

3. CC, 12. Absolute pressure sensor,

4. CC, 17. Circuit board

1. Operation, check

2. CC, 18. Display

1. Advanced trouble shooting, Checks

with error code

1. CC, 17. Circuit board

START TROUBLE SHOOTING

Page 14

ERROR CODE EXPLANATION ACTIONS IN ORDER OF PRIORITY

NO WATER Timeout level guard 1. Operation, check

2. CC, 10. Level guard

3. CC, 3. Solenoid valve MV-3

HEATING ERROR Timeout heater 1. CC, 6. Overheating protection

2. CC, 5. Relay

3. CC, 4. Heater

4. CC, 17. Circuit board

HEATING ERROR Leakage Trouble shoot according to the section

Trouble shooting leakage

MANUAL MODE Component manually ac tivated 1. Operation, check

2. An output on the circuit board has

been set to manual mode. ( menu

tree Diagnostic)

POST TREATMENT E RROR

POST TREATMENT E RROR

Outlet valve clogged CC, 3. Solenoid valve, MV-1

Screen in the chamber clogged CC, 3. Strainer

START TROUBLE SHOOTING

Page 15

Symptom (experienced by user)

EXPLANATIONS

Explanations to references to sections stated in the

tables below:

CC: chapter Component check

Advanced chapter Advanced trouble

trouble shooting: shooting

Other references are given in plain text.

SYMPTOM ACTIONS IN ORDER OF PRIORITY

No ready signal 1. CC, 12. Absolute pressure sensor

2. CC, 3. Solenoid valve MV-2

3. CC, 11. Air filter

Instruments rust in the sterilizer 1. Poor quality instruments

2. Water cleaning filter – type de -ionization, check

(see documentation supplie d with the water filter)

Process time abnormally long 1. See the section installation. Electricity, Water

requirement

2. Advanced trouble shooting, Leakage test, check

3. Operation, check

4. CC, 22. Strainer

Humming noise in standby mode 1. CC, 3. Solenoid valves

Door hard to open/cannot be opened 1. CC, 3. Solenoid valve MV-8

2. CC, 20. Door, (lock)

Pressure gauge shows pressure with the door open 1. CC, 14. Pressure gauge

Steam leaks from the door 1. CC, 20. Door, door gasket

2. CC, 3. Solenoid valve MV-5

3. CC, 21 Pressure relief valve door gasket

Black background on the display 1. CC, 23 Fan.

2. CC, 18 Display

Unstable measurement value and text on display 1. CC, 23 Fan.

2. CC, 18 Display

3. CC 17 Circuit board

4. Check the power supply (Fluctuations?)

START TROUBLE SHOOTING

Page 16

COMPONENT CHECK

TABLE OF CONTENTS

1. General ............................................................ 2

2. Chamber .......................................................... 2

3. Pipe/pipe couplings.......................................... 2

4. Solenoid valves................................................ 3

5. Heater............................................................... 5

6. Relay................................................................ 6

7. Overheating protection, resetting.....................6

8. Non return valve BV-1...................................... 7

9. Non return valve BV-2...................................... 7

10. Non return valve BV-3...................................... 7

10. Non return valve BV-3...................................... 7

11. Level guard ...................................................... 8

12. Air filter (accessory) ......................................... 8

13. Absolute pressure sensor ................................ 8

14. Ejector.............................................................. 9

15. Pressure gauge................................................9

16. Load temperature sensor (accessory)........... 10

17. Pressure relief valve....................................... 10

18. Circuit board...................................................11

19. Display............................................................ 12

20. PACS software...............................................12

21. Door................................................................ 14

22. Pressure relief valve, door gasket.................. 16

23. Screen............................................................ 16

24. Fan................................................................. 16

COMPONENT CHECK

page 1

Page 17

1. General

IMPORTANT!

Only use Teflon tape that is intended for sealing pipe couplings

against steam pressure.

It is extremely important for safe functionality that all

nipples are tightened so that air, which can jeopardize

the sterilisation result, can not enter the chamber. If

pipe couplings must be removed while performing

checks, think about the following when assembling:

• Use ample Teflon tape, so that the tape partly

forms a seal and partly seals the threads.

2. Chamber

The chamber walls are cleaned using a mild lime dissolving agent. Rinse well. Drain by closing the door,

the bottom valve then opens automatically.

BOTTOM FILTER (ALSO SEE 23. SCREEN)

Lift out the filter. Clean

LEVEL GUARD (ALSO SEE 11. LEVEL GUARD)

Check that the rocker moves up and down easily.

TIP!

Check whether steam is let out

with an overpressure.

• Use soapy water on cold components

• Use a mirror on hot components

3. Pipe/pipe couplings

Check:

Start a 134 °C program. Trouble shoot when the sterilizer is in “Sterilisation” mode.

Check whether steam is let out.

Action:

Check according to respective component checks.

Also see 1. General.

Verification:

Check all pipes/pipe couplings again.

COMPONENT CHECK

page 2

Page 18

IMPORTANT!

All valves open in an energised

state.

4. Solenoid valves

Pay attention to solenoid valves that hum! The noise

may be a forewarning about the coil starting to overheat due to it not working in a closed iron circuit. This

can occur when the moving core is influenced by the

magnetic forces from the winding and dirt prevents the

coil from reaching the end position. An air gap is then

formed in the magnetic circuit, which lowers the inductance in the coil resulting in increased current.

MV-1

Is fitted in the bottom of the sterilizer and has the task

of evacuating any remaining water in the sterilizer at

the end of the process.

Check:

Check that both the plunger and the area it runs in are

clean. Always change the O-ring that seals between

the coil and housing after removing the coil. Activate

MV-3 and fill the chamber. Activate MV-1 and MV4

(ejector). Check that the water runs out of the chamber again. Measure the voltage across the coil.

Action:

Clean and replace the plunger and O-ring. Replace

the entire valve if necessary.

Verification:

Check that the water level in the chamber is maintained for a long period (about 15 minutes).

MV-2

Is fitted at the rear, top edge of the sterilizer. Takes

care of pressure equalization after the post-vacuum

phase by releasing air into the chamber. The valve is

open when the sterilizer is in standby mode if the door

is locked. It becomes de-energised as soon as the

door is opened.

Check:

Check that both the plunger and the area it runs in are

clean. Always change the O-ring that seals between

the coil and housing after removing the coil. Activate

MV-4 and MV-2 on the diagnostic menu. The pressure

should not drop appreciably below atmospheric presssure. Measure the voltage across the coil.

Check for leakage: Dismantle BV-2. Activate MV-3

and the heater. No steam should come out of MV-2.

Action:

Clean and replace the plunger and O-ring. Replace

the entire valve if necessary.

Verification:

Run a sterilisation program. Check for leakage ac-

COMPONENT CHECK

page 3

Page 19

cording to Check and that pressure equalization takes

place at the end of the program.

MV-3

Is fitted directly on the inlet. Loads the chamber with

water at the start of the process.

Check the opening function:

Activate MV-3 in the diagnostic menu; water should

then flow into the chamber.

Check the closing function:

In standby mode, check that the water level in the

chamber does not rise once the valve to the chamber

has been closed.

Action:

Clean and replace the plunger and O-ring. Replace

the entire valve if necessary.

Verification:

Run a sterilisation program. Check that no water enters the chamber after the process has ended and the

door is open.

IMPORTANT!

Minor steam leakage can be due

to a leaking gasket and has nothing to do with the MV-5 function

MV-4

Opens the water flow to the ejector to produce a vacuum

Check:

Check that water does not run out of the drain hose in

standby mode

Action:

Clean and replace the plunger and O-ring. Replace

the entire valve if necessary.

Verification:

Run a process and check again that water does not

run out of the drain hose in standby mode.

MV-5

Pressurises the door gasket before a program.

Check:

During the process, check that the door seals against

steam.

Action:

Clean and replace the plunger and O-ring. Replace

the entire valve if necessary.

Verification:

Check the door for steam leakage.

MV-6

Vents the chamber while the program is running.

Opens at the given time interval. Also simplifies eva-

COMPONENT CHECK

page 4

Page 20

evacuation of the chamber pressure after sterilisation

is completed.

Check:

Build up a pressure in the chamber. Open MV-6. The

chamber pressure should drop. Check that the chamber pressure is maintained when MV-6 is closed. Pipes on the outlet side should be cooler than on the

pressurised side.

Action:

Clean and replace the plunger and O-ring. Replace

the entire valve if necessary.

Verification:

Run a program. Now verify according to Check, see

above.

MV-8

Evacuates the door gasket pressure after the completed process.

IMPORTANT!

A symptom of poor opening function in the valve is difficult door

opening.

TIP!

Ensure the heater is de-energised

before you measure the resistance.

Check:

Close and lock the door. Open MV-5 and open MV-8.

Water should flow out of the drain.

Action:

Clean and replace the plunger and O-ring. Replace

the entire valve if necessary.

Verification:

Run a process. The door should be easy to unlock after the completed process.

5. Heater

Is fitted in the bottom of the chamber and has the task

of heating the water dosed for the process.

Check:

Activate the heater. Measure with a clamp-on ammeter, this should show about 8 A/coil. The heater output

is 2000 W x3 coils, which gives a resistance of about

27 Ω/coil. Check the resistance.

Action:

Replace the heater with incorrect resistance.

If the clamp-on ammeter shows 0 A, and the relay and

circuit board are OK. Replace the heater.

Verification:

Verify by measuring the resistance.

COMPONENT CHECK

page 5

Page 21

IMPORTANT!

Note that if overheating protection

trips due to a temperature outside

of the working range (0 - 300 °C),

the sterilizer must cool for a period so that the resetting button

shall remain pressed in. Wait until

the sterilizer is within the working

range again.

Note that it may also require a

great deal of force to press in the

overheating protection.

6. Relay

Is fitted in the distribution box. Its task is to connect

the heater to the power supply.

Check:

Activate the heater, measure the coil on the relay using a voltmeter. The coil is across A1-A2. Measure the

voltage on the outgoing connection 2 - 4 - 6

7. Overheating protection, resetting

Protects the heater against overheating, the protection

trips at approx. 300 °C. Requires manual resetting.

The sensor is positioned on the heater coil. The resetting button is positioned on the protection. A symptom

that the overheating protection has tripped is the timeout alarm, heating error.

Possible causes:

• That the sterilizer has been transported in tem-

peratures below freezing.

• That a fault has occurred in the temperature regu-

lation of the heater.

• That leakage results in the water being consumed

during the process.

The unit should always be de-energised when resetting.

CAUTION!

Check that the overheating protection sensor is fitted correctly on

the heater. Otherwise the sensor

has no function.

Check:

Check that the manual resetting button is pressed in.

Measure the voltage on the incoming and outgoing

pins on the protection. Voltage on the incoming but

not on the outgoing, means that the protection has

tripped or is faulty.

Action:

Replace the overheating protection. Make sure that

the sensor is correctly fitted on the heater. Also see

daily maintenance

Verification:

Check that the sterilizer display is lit.

COMPONENT CHECK

page 6

Page 22

8. Non return valve

BV-1

Is fitted between MV-1 and the chamber and has the

purpose of preventing return flow through MV-3

Check:

Fill the chamber with an open door by opening MV-3.

Shut the main tap and let MV-3 remain energised and

open MV-4. Check whether water is running out from

the drain or that the level in the chamber drops over a

long period of time, at least 15 minutes.

Action:

Replace BV-1.

Verification:

As Check, see above.

9. Non return valve

BV-2

Is fitted between the air filter and MV-2. Its task is to

prevent steam, with a fault on MV-2 being forced through the filter.

Check:

Close and lock the door. Remove the air filter. Build

up a pressure; open MV5 and MV1, close MV1, activate the heater, open MV2. The pressure should rise

to 1 bar according to the front pressure gauge. Check

that no steam comes out of the air filter holder.

Action:

Replace BV-2. Check that the air filter is not wet.

Verification:

As Check, see above.

10. Non return valve

BV-3

Is fitted after MV-1 and has the task of preventing water from the ejector returning up into the chamber

Check:

Open MV-4 and MV-1. Check that no water enters the

chamber.

Action:

Replace BV-3

Verification:

As Check, see above.

COMPONENT CHECK

page 7

Page 23

11. Level guard

Is fitted in the lower part of the chamber above the

heater. The task is to check the filling of the chamber.

Check:

Move the rocker arm up and down so the digital input

(Service, Diagnostic, Digital input) should switch between 1 and 0.

12. Air filter (accessory)

Its task is to supply the sterilizer with sterile filtered air

after the post vacuum phase.

Check:

The air filter must be dry. Check that pressure equalization takes place after the post vacuum phase in the

program.

Action:

Replace the filter.

Verification:

Run a program. Also see section BV-2, check.

CAUTION!

Connect the pressure gauge for

the absolute pressure to the outlet

on the lead-through at the rear of

the chamber.

TIP!

Start a program and stop it by

using the “Pause” switch in the

vacuum and sterile phase. Then

adjust the A-value (sterile phase)

and the B-value (vacuum)

TIP!

Use the program CS1000 (for PC),

for a basic calibration procedure.

13. Absolute pressure

sensor

Its task is to monitor and control the process.

Check:

Carried out with an independently, calibrated pressure

gauge for the absolute pressure, whose values are

compared with the values shown on the display. Area:

0 - 4 bar absolute pressure corresponds to 4 – 20 mA,

output signal with an open lid approx. 8 mA

Action:

When the deviation is significant, replace the sensor

and calibrate. With minor deviation, calibrate. Calibration is carried out via the menu tree. Step using the

UP arrow and the ENTER button through SETUP/

SYSTEM/ (password)/ CALIBRATION/ MANUAL CALIBRATION. Select the sensor and adjust index A or

B up or down depending on the type of fault indication. B with vacuum and A with a sterile pressure.

Verification:

Run a sterilisation program. Perform with an independently, calibrated pressure gauge for the absolute

pressure whose pressure values are compared with

the values shown on the display.

COMPONENT CHECK

page 8

Page 24

14. Ejector

The ejector is mounted on the pipe from the water inlet to the drain. The ejector's function is to create an

underpressure in the chamber.

Check:

Activate MV-1 and MV-4 through the diagnostic menu.

The pressure shall, under the condition that BV-3 is

problem free and the water pressure is above 1.5 Bar,

reach a vacuum greater than 800 mBar within 15 minutes.

Action:

Clean the ejector. Any dirt or leakage in the ejector

connections cause impaired vacuum capacity.

Verification:

Check the depth of vacuum according to the check

section above.

15. Pressure gauge

CAUTION!

The pressure gauge only gives an

indication of the pressure and

should not be used during calibration.

Is placed on the front of the sterilizer. Shows the

chamber pressure even if the power is switched off.

Check:

When the door is open the pressure should show 0

±0.1 bar. Check that the pointer indicates a pressure

higher and lower than zero during a cycle.

Action:

Calibrate the pressure gauge according to the section

Pressure gauge adjustment. If it is not possible, replace the pressure gauge.

Verification:

Run a program. Compare the pressure gauge with the

pressure indication on the display.

PRESSURE GAUGE ADJUSTMENT

• Make sure the door is open.

• Open the front.

• Loosen the brass nipple at the rear of the pres-

sure gauge and lift out the pressure gauge.

• Pry loose the pressure gauge glass by inserting a

screwdriver in the notch at the top of the pressure

gauge glass.

• Insert narrow tipped pliers under the pointer and

lift it off.

• Adjust and press back the pointer in the right posi-

tion.

COMPONENT CHECK

page 9

Page 25

16. Load temperature

sensor (accessory)

TEMPERATURE SENSOR

The sensor is placed in the lead-through to the chamber and is connected to contact piece X2 on the circuit

board. It monitors the sterile process and provides the

display with information about the temperature of the

liquid that sterilises and controls that the liquid is under 95°C before the door can be opened.

Check:

Loosen the connection on the circuit board and measure the resistance on the sensor with an ohmmeter.

The sensor's resistance should at 20 ° be about 120

ohm. The higher the temperature, the higher the resistance.

Action:

With a resistance above 150 ohm or 0 ohm. Replace

the sensor.

Check for leakage:

Check that there is no steam leakage from the sensor's lead-through – silicone seal.

WARNING!

Adjustments or actions that alter

the opening pressure on the

pressure relief valve may only be

performed by persons with documented experience.

Action:

With leakage – replace the silicone seal.

17. Pressure relief valve

The function of the pressure relief valve is to relieve

the pressure in the chamber, should this rise uncontrolledly.

Check:

Start a process. When “sterilisation” is reached, close

MV-1 and MV-6 as well as start the heater. Check using an independently calibrated pressure gauge for

absolute pressure that the opening pressure is 3.7

±0.14 bar (absolute pressure). Check that the pressure relief valve does not leak water or steam at normal sterilisation pressure – max 3.15 bar.

Action:

Clean the valve. Replace the valve if necessary.

Verification:

Run up the chamber pressure, activate the heater and

close MV1 and MV6. Read when the pressure relief

valve trips. Check that the valve does not leak during

a program

COMPONENT CHECK

page 10

Page 26

CAUTION!

The display unit and the circuit

board unit must always be kept in

shielded bags until the components are to be installed in the

sterilizer. Make sure not to be

electro statically charged when

these parts are handled, by e.g.

touching an earthed heater or by

WARNING!

Lithium battery. Explosion risk.

Replace the battery with the same

type as recommended by Getinge.

TIP!

Battery

When battery replacement is necessary and no battery is available,

the sterilizer can temporarily be

run with jumper (see section 25

Software PACS, Cold start) in

cold start mode.

The calendar and process counter

do not work in cold start mode.

18. Circuit board

Is located in the casing to the right. Its function is to

bridge all input and output signals with the software

PACS. The circuit board houses, among others, the

flash memory that holds the PACS software and the

battery.

Check the circuit board:

• Incoming voltage on X23.

• That PT100/PT1000 jumpers are located cor-

rectly: PT 100 position

• Fuse 315 mA.

• Voltage on the battery, 3.6 V.

• Connect the cables and connectors.

Check the relays:

To check the function of a relay, activate each output,

connect a voltmeter between Line N (X23) and each

output. The voltmeter should show approx. 230 VAC.

On connection COM 1 ( X32) the board is equipped

with a serial communication port (RS232) for connection e.g. to a computer.

Action:

Replacing the battery.

Make a backup of the software according to the section 25 Software PACS, if possible.

Cut off the battery solder tags as close to the battery

as possible.

Do not solder on the circuit board!

Solder in the new battery on the old solder tags.

Check that the new battery's voltage is 3.7 V

Perform a cold start according to 25 Software PACS,

Cold start.

Action:

If the above does not correspond, correct or replace

the board.

Verification:

Run a prepacked program.

Replacing the circuit board

Move over the flashmemory circuit from the old board.

Check the circuit board according to the section

above.

Perform a cold start according to 25 Software PACS,

Cold start.

Set the time and date and the language version

Go to the menu TOOLS-PACS and select SAVE RAM

TO FLASH.

COMPONENT CHECK

page 11

Page 27

19. Display

Is placed on the front of the sterilizer. Its task is to

show values and act as the interface to the PACS

software. The display board is connected to X26 on

the circuit board. The keypad in the decal is connected to contacts J1 and J3 on the display card.

Check:

Check the cables including connection X26. Check

jumper JP1. Should be fitted between pins 1 and 2.

Action:

Replace the display card.

Verification:

Run a program and make sure the display communicates without interference.

20. PACS software

Is installed in the flash memory on the circuit board.

Its function is to monitor and govern the entire sterilizer and the processes run on it. PACS also logs

events and alarms.

Action:

MAKE A BACKUP.

Follow the following when the sterilizer's program version is to be saved on a PC:

NOTE. The calibration settings will not be saved on

this back up.

X24

Connect your PC to contact X32 on the sterilizer use

the communications cable.

Start the CS 100 program. State the service password

Go to the menu TOOLS-PACS to RAM/

UPLOAD TO FILE.

Now save the backup file on the hard drive

in the PC.

LOAD A NEW BACKUP

Connect your PC to contact X32 on the sterilizer use

the communications cable.

Start the CS 100 program. State the password

Go to the menu TOOLS-PACS and select SAVE RAM

TO FLASH.

Go to the same menu and select RAM/ DOWNLOAD

FROM FILE.

Set the time and date and the language version

Go to the menu TOOLS-PACS and select SAVE RAM

TO FLASH.

COMPONENT CHECK

page 12

Page 28

Verification:

connect an external pressure gauge intended for absolute pressure. Run a process and check the calibration against the display.

BACK UP THROUGH A NEW FLASH MEMORY

Connect your PC to contact X32 on the sterilizer use

the communications cable.

Start the CS 100 program. State the password

Go to the menu TOOLS-PACS and select SAVE RAM

TO FLASH

Switch off the power and change FLASH circuit

Make a “cold start” see below

Set the time and date and the language version

Go to the menu TOOLS-PACS and select SAVE RAM

TO FLASH

COLD START

Switch off the power and place the jumper (marked

with an arrow in picture) to position Cold start.

Switch on the power again, wait a few seconds.

Place the jumper in the Normal position

POST VACUUM ADJUSTMENT

How to navigate through the menus, see the section

Main menus. Password. Step as set out in the section Menu navigation. The post vacuum time is adjustable up to 30 minutes. A value lower than the factory setting can not be made.

COMPONENT CHECK

page 13

Page 29

21. Door

Door is locked mechanically by a bayonet mount and

10 flanges. The door gasket seals through the gasket

groove being pressurised at the start of the process

which then presses against the door.

Open and close the sterilizer door several times in a

row and check that there is no play on the door and

hinge. Also check that the door spring has not become too weak or has broken.

Check:

Check that a process can not be started if the door is

not closed correctly. Check the hinge joints, microswitch and door lock.

Action:

• Clean and lubricate the door's moving parts.

• Check the wear to the hinge joint, change if nec-

essary.

IMPORTANT!

The door must be fully open (110°)

to carry out the action.

• Check the micro-switch by activating it manually

and read the display (switches between the program parameter and “

• Check the door lock moves easily and does not

jam. Check especially that it reaches all the way in

the deactivated position.

Verification:

Open and close the door. The door's movement

should not be more resistant than it can be closed using normal force. In general as in Action.

Check the door spring:

Check that the door spring has not become too weak

or has broken by opening the door. The door spring

shall prevent the door from shutting.

Action:

• Remove the door's plastic cover

• Open the door as far as possible

• Loosen the nut (6)

START OK” on the display)

7 6 8

• Loosen the index screw (7). Remove the door

• Remove both clasps holding the spring axle. Se-

cured with six nuts under the axle

• Remove the circlip (8) located at the end of the

spring axle.

• Pull off the axle

COMPONENT CHECK

page 14

Page 30

• Change the spring. Press the spring leg in the

door holder.

• Refit in the reverse order

• Centre the door with the help of the screw (7)

Verification:

Open the door and check that the door spring prevents the door from shutting.

DOOR GASKET

Door is locked mechanically by a bayonet mount and

10 flanges. The door gasket seals through the gasket

groove being pressurised at the start of the process

which then presses against the door.

Check:

Check that the gasket is in one piece and that the

contact surfaces are clean and lubricated with a food

industry grease.

Action:

The door gasket should be replaced after max 1200

cycles/once every 3rd year. Close the water connection before replacing the door gasket.

Open the door

Remove the gasket using a blunt tool

Check that the gasket groove is clean

Clean the groove if necessary

Grease the new gasket

Press the new gasket in the groove fully

IMPORTANT!

Check that steam does not blow

out around the door when the

pressure is built up.

Verification:

Close the door and run a program 134 °C check for

leakage. Also see section Component check, 4. So-

lenoid valves, MV-5 and MV-8.

COMPONENT CHECK

page 15

Page 31

22. Pressure relief val-

ve, door gasket

Used to release the water pressure in the door gasket

groove if the pressure exceeds 4.8 bar

Check:

Check that the pipe after the pressure relief valve is

not hot during “sterilisation”.

Action:

Replace the pressure relief valve

Verification:

Run a new process and check whether the pipe is hot

23. Screen

Is positioned in the bottom of the chamber to prevent

a stoppage in the outlet.

Check:

Remove the screen, by lifting it straight up from the

chamber

Action:

Clean the screen

Verification:

Make a visual inspection that the screen is clean.

24. Fan

The fan is positioned behind the casing and is connected to contact piece X16 on the circuit board. Its

task is to lower the temperature under the casing

when the process is run.

Check:

Loosen the casing and check that the fan rotates

when a process is run. Check that the fan is voltage

fed.

Action:

Replace the fan

COMPONENT CHECK

page 16

Page 32

ADVANCED TROUBLE SHOOTING

Flow chart

This section concerns advanced trouble shooting. The

different sub -sections below follow on from the previous sectionSTART TROUBLE SHOOTING. This means that all trouble shooting starts there.

ADVANCED TROUBLE SHOOTING, PROCESS DESCRIPTION

Page 33

Process description

Steam is generated in the sterilizer through an exter-

5.

6. 7.

8.

3.

nal water feed that may be preceded by a softening fi lter.

Condensation is led off to the drain.

1. The door gasket is pressurized by MV-5 opening

and releasing water into the gasket groove.

2. The sterilizer is filled with water until the level guard cuts in.

3. The heater heats the water and the pressure rises.

1. 2.

4.

9.

10.

4. The steam pressure is monitored by the pressure

sensor which, via a PID -regulator, controls the

heater.

5. The temperature of the steam is monitored by the

pressure sensor (through a theoretical calculation).

6. The solenoid valve MV-1 is used to empty the water from the chamber.

7. The steam pressure is released via MV1 and MV6

8. The water pressure powers an ejector, which creates an underpressure in order to lowe r the

chamber pressure below atmospheric pressure.

MV4 releases the water pressure on the ejector.

9. MV-2 is used to release the air in the chamber.

10. MV-8 releases the door gasket's water pressure.

The door can now be opened.

ADVANCED TROUBLE SHOOTING, PROCESS DESCRIPTION

Page 34

13.

11. 12.

14.

15.

16.

17.

18.

LIQUID LOAD

11. The door gasket is pressurised.

12. The sterilizer is filled with water until the level guard cuts in.

13. The heater heats the water and the pressure rises.

14. The steam pressure is monitored by the pressure

sensor which, via a PID -regulator, controls the

heater.

15. The load sensor monitors the temperature of the

liquid to be sterilised. The load sensor temper ature determines when the sterilizer switches to

sterilisation.

16. The solenoid valve MV-1 is used to empty the water from the chamber.

17. The steam pressure is released via MV1 and MV6

through ramping to prevent decoction.

18. When the liquid reaches a temperature below

95°C (controlled by the load sensor) MV-8 releases the gasket pressure and the door can be

opened. The process is complete.

PRE-TREATMENT

The purpose of pre-treatment is to remove air from the

chamber and from the goods. Air prevents the requisite contact between the steam and micro -organisms

to be killed.

Pre-treatment consists of steam injection and evacuation pulses in different processes depending on the

program selected. In addition, the humidification essential to killing mainly takes place during the pretreatment stage.

Pre-treatment process:

• Blow through (1)

MV-1 opens, the chamber is filled with water and

the heater then heats the water. MV-6 opens during the preset time.

• Pressure increases (2)

MV-6 closes and the heater heats. The pressure

rises to a preset level. The sterilisation pressure

should be reached during the final increase in

pressure. Sterilisation begins when the sterilisation pressure is reached.

ADVANCED TROUBLE SHOOTING, PROCESS DESCRIPTION

Page 35

STERILISATION

Sterilisation takes place by maintaining the saturated

steam's relation (boiling point at a specific pressure).

The sterilisation phase is in progress during a pre programmed number of minutes at the preselected

temperature/pressure.

Sterilisation process:

• MV-6 opens during the preset time intervals.

• The pressure is controlled by means of the heater,

which heats as required.

POST TREATMENT

The purpose of post treatment is to reduce the moisture content in the goods. During post treatment the

pressure drops to atmospheric pressure or lower –

depending on the selected program. Post treatment is

completed by air being drawn in until the chamber is

at atmospheric pressure.

Post treatment process:

• MV-1 opens and releases the remaining water.

• MV-4 opens and the ejector starts.

• MV-6 opens after an additional few of minutes.

• When the right vacuum is reached (800 mBar)

time metering starts.

• When the time elapses MV-1, MV-4 and MV-6

close. MV-2 opens and air is drawn in and the

pressure rises towards atmos pheric pressure.

MV-8 opens and the door gasket pressure is released. The process is finished.

ADVANCED TROUBLE SHOOTING, PROCESS DESCRIPTION

Page 36

PROCESS DESCRIPTION - LIQUID LOAD

PRE-TREATMENT

The purpose of pre-treatment is to remove air from the

chamber and from the goods. Air prevents the requisite contact between the steam and micro-organisms

to be killed.

Pre-treatment consists of steam injection and evacuation pulses in different processes depending on the

program selected. In addition, the humidification essential to killing mainly takes place du ring the pretreatment stage.

Pre-treatment process:

• Blow through (1)

MV-1 opens, the chamber is filled with water and

the heater then heats the water. MV-6 opens during the preset time.

• Pressure increases

MV-6 closes and the heater heats. The pressure

rises to a preset level just above the sterilisation

pressure to accelerate the heating of the liquid.

When the load sensor temperature approaches

the sterilisation temperature, the steam pressure

drops to the sterilisation pressure. Sterilisation

starts.

ADVANCED TROUBLE SHOOTING, PROCESS DESCRIPTION

Page 37

STERILISATION

Sterilisation takes place by maintaining the saturated

steam's relation (boiling point at a specific pressure).

The sterilisation phase is in progress during a pre programmed number of minutes at the preselected

temperature/pressure. The load sensor monitors the

temperature of the liquid.

Sterilisation process:

• MV-6 opens during the preset time intervals.

• The pressure is controlled by means of the heater,

which heats as required.

POST TREATMENT

The purpose of post treatment is to lower the temperature of the liquid below boiling point at atmospheric pressure.

Post treatment process:

• MV-4 opens and the ejector starts.

• MV-1 opens at the preset time intervals to ensure

a slow pressure decrease and prevent decoction

of the liquid. The remainin g process water is released in connection with ramping.

• When atmospheric pressure is reached and the

temperature of the liquid (controlled by the load

sensor) is below 95°C, MV-1 and MV-4 close.

MV-2 opens and the atmosphere in the chamber

and the atmosph ere is the room are kept at the

same level. MV-8 opens and the door gasket

pressure is released. The process is finished.

ADVANCED TROUBLE SHOOTING, PROCESS DESCRIPTION

Page 38

Trouble shooting leakage

IMPORTANT!

Trouble shooting takes place:

• At overpressure

Follow the method prescribed in

Check component, 2. Pipe/pipe

couplings.

TIP!

Check whether steam is let out

with an overpressure.

• On cold components:

use soapy water

• On hot components

use a mirror

1 Check for door leakage as set out in the section

Check component, 20. Door.

2 Check for leakage from the pressure relief valve

as set out in the section Check component, 16.

Pressure relief valve.

3 Check for leakage from the solenoi d valves as set

out in the section Check component, 3. Sole-

noid valves.

4 Check for leakage from the pipe couplings as set

out in the section Check component 2.

Pipe/pipe couplings.

5 Check for leakage on the temperature sensor's

lead-throughs as set out in the section Check

component, 15. Load temperature sensor.

6 Check for leakage from the ejector as set out in

the section Check component, 13. Ejector.

Calibration instruction

1 Connect a calibrated test pressure gauge to the

connection labelled PT on the sterilizer.

2 Start a 134 °C program.

3 Let the program run to post treatment

4 When the vacuum has stabilized, calibrate the B

parameter for the pressure sensor.

5 Check that the external pressure gauge shows

the same pressure as on the sterilizer's display.

6 Allow the sterilizer to finish.

7 Start a new 134 °C program. Let the program run

to “sterilisation”. Calibrate the A parameter for the

load sensor. Check that the external pressure

gauge shows the same pressure as on the steri-

lizer's display.

8 The sterilizer will calculate the theoretical sterile

temperature, based on the calibrated pressure va-

lues.

9 Allow the program to finish. Check the vacuum

setting during the post vacuum phase.

ADVANCED TROUBLE SHOOTING, TROUBLE SHOOTING LEAKAGE

Page 39

MENU NAVIGATION

Orientation

Navigation through the menus is done using the four

arrow keys UP arrow, DOWN arrow, LEFT arrow,

RIGHT arrow and the ENTER key.

Navigate to your choice using the UP arrow and

DOWN arrow . The selection is indicated on the display by a cursor below the value to be changed.

To return to the previous level, press the left arrow

when the menu position is not selectable.

Press the ENTER key to activate your menu selec-

tion.

When a menu selection has been activated, one of

two actions can be performed.

• When the selection is a new menu position, a fur-

ther selection can be made.

TIP!

You can return at anytime to the

main menu by pressing the left

key and holding it down for 4 seconds.

• When the value can be edited, use the arrow keys

as set out above.

The selection can either be shown on one or two

rows. When one row is shown, this means the row

can be selected and activated using the ENTER key.

When two rows are shown, the first row shows the selected name and the second row the value linked to

the selection.

MENU NAVIGATION

Page 40

Edit values

Press the ENTER key to set the display in edit mode,

i.e. make the selected value editable. The cursor is

positioned to the far left below the first character when

the value is selectable.

EDIT PRESET VALUES

Use the UP arrow and DOWN arrow to change a value. Different values are shown each time the arrow

key is pressed.

Save the value by pressing the ENTER key.

EDITING NUMERICAL VALUES

TIP!

When adjusting the sterile or post

vacuum times, the value can not

be set below the preset value.

The value can consist of several characters. The character with the cursor below can be edited.

The highlighted character can be increased or decreased by using the UP arrow or DOWN arrow.

Use the RIGHT arrow or LEFT arrow to select the

next editable character to the right respective left.

When you have finished, save the values by pressing

the ENTER key.

MENU NAVIGATION

Page 41

THE MENU TREE

Main menus

Main selection: Program name, Program version,

Phase, Cycle counter and Setup menu.

Password service 120416

Navigate to your choice using the UP arrow and

DOWN arrow. The selection is indicated on the dis-

play by a cursor below the value to be changed.

To return to the previous level, press the LEFT arrow

when the menu position is not selectable.

Press the ENTER key to activate your menu selec-

tion.

1. PROGRAM NAME

Program name: Selected program

Params 1 Params 2: Sterilisation time & temp (or

Heating up)

Select program: Sub-menu to selected program.

Important, the sterilizer has a PROGRAM SELEC-

TOR button for this on the front.

Change parameter: Possibility to change the sterile

time and post vacuum time. Password 558

2. PROGRAM VERSION

E.g.

050121

3. PHASE

E.g.

PRE-TREATMENT

4. CYCLE COUNTER

Possibility to read the sterilizer's counter, pressure

and temperatures. E.g.

0210

Setup menu

5. SETUP MENU

Print Last Cycle: Not used.

System: To access the System menu.

Password: State

System menu: See the section System menu.

About: Software version

MENU TREE, MAIN MENUS

Page 42

System menu

Navigate to your choice using the UP arrow and

DOWN arrow . The selection is indicated on the

display by a cursor below the value to be changed.

To return to the previous level, press the LEFT arrow

when the menu position is not selectable.

Press the ENTER key to activate your menu

selection.

The sterilizer's menu for installation specific

settings and unique machine settings.

Main selection: Calendar, Calibration,

configuration, Dipswitch, Service and Flash

memory.

1. CALENDAR MENU

Time and date settings

2. CALIBRATION MENU

Only possible with manual calibration

See separate section Calibration menu

3. CONFIGURATION MENU

See separate section Configuration menu

4. DIPSWITCH MENU

Not used.

5. SERVICE MENU

See separate section Service menu

6. FLASH MEMORY MENU

Save adjustments and changes to the flash memory.

Should always be done once adjustments and

calibrations have been made.

MENU TREE, SYSTEM MENU, ETC

Page 43

Calibration menu

Main selection: Manual calibration, Automatic calibration and Compensation table.

Navigate to your choice using the UP arrow and

DOWN arrow . The selection is indicated on the dis-

play by a cursor below the value to be changed.

To return to the previous level, press the LEFT arrow

when the menu position is not selectable.

Press the ENTER key to activate your menu selec-

tion.

1. MANUAL CALIBRATION

Always use MANUAL CALIBRATION. To calibrate,

see the section Advanced trouble shooting, Cali-

bration

00 Not used

01 Not used

02 Not used

03 Pressure : Step the cursor to each value to be

changed. Verify with Enter

04 Not used

05 Not used

06 Not used

07 Load sensor: Step the cursor to each value to be

changed. Verify with Enter

2. AUTOMATIC CALIBRATION

Not used

MENU TREE, CALIBRATION MENU

Page 44

Configuration menu

Main selection: Calendar, Calibration, configuration, Dipswitch, Service and Flash memory.

Navigate to your choice using the UP arrow and

DOWN arrow . The selection is indicated on the dis-

play by a cursor below the value to be changed.

To return to the previous level, press the LEFT arrow

when the menu position is not selectable.

Press the ENTER key to activate your menu selec-

tion.

1. LANGUAGE DATE UNI T

Settings related to countries

Language setting: Display language

Date format

Pressure format: NOTE! Must not be changed! The

sterilizer is calibrated based on bar.

Temperature format: NOTE! Must not be changed!

The sterilizer is calibrated base don degrees Celsius.

2. PRINTER

Printing Mode: Not used.

Logging interval low: Logging interval for the total

process excluding the sterilisation phase.

Logging interval high: Logging interval for the sterili-

sation phase only.

3. ALARM CLOCK

Not used

4. PACS ADDRESS

Possibility to give the sterilizer an Id. When there is

more than on sterilizer with the printer in the same location. 1-99

5. COMMUNICATION

Settings for the Com-ports (3) RS232 or RS485

Set for communication with the service software.

Must not be changed!

MENU TREE, CONFIGURATION MENU

Page 45

Service menu

Main selection: Error log, Service messages and

Diagnostics.

Navigate to your choice using the UP arrow and

DOWN arrow . The selection is indicated on the dis-

play by a cursor below the value to be changed.

To return to the previous level, pres s the LEFT arrow

when the menu position is not selectable.

Press the ENTER key to activate your menu selec-

tion.

1. ERROR LOG

20 most recent error codes

The type of error code, in which phase of the program

and when.

2. SERVICE MESSAGES

Resetting of the service alarm (alarm every 400 process)

3. DIAGNOSTICS

Manual test of components. Set the value under MAN

and control with S:1 or S:0

Analog input: Shows the water, pressure and temperature values

Analog output: Not used.

Digital input: Shows the door switch and an external

level switch

Digital output: Check of all components

Test User Flag: Not used

Test System Flag: Not used

Test Printer: Not used

Test LED/buzzer: Functional check of the sterilizer's

audio signal and LEDs.

MENU TREE, SERVICE MENU

Page 46

Component placement,

internal

1 Circuit board

2

3 Ejector

4 Solenoid valve MV-3

5 Non return valve BV-1

6 Solenoid valve MV-4

7 Solenoid valve MV-5

8 Solenoid valve MV-6

9 Solenoid valve MV-8

10 Heater

11 Relay

12 Overheating protection, ÖV300

13 Chamber

14 Level guard

15 Solenoid valve MV-1

16 Absolute pressure sensor

17 Pressure relief valve (Chamber)

18 VT/PT-outlet

19 Pressure relief valve (Door gasket)

20 Solenoid valve MV-2

21 BV-2

22 BV-3

COMPONENT PLACEMENT, INTERNAL

Page 47

23

24

COMPONENT PLACEMENT, INTERNAL

Page 48

COMPONENT PLACEMENT

Component placement,

outside

1. Water supply

2. Water connection

3. Water outlet

4. Handle

5. Control panel

6. Reset button, overheating protection

7. Printer port RS232 (accessory)

8. Mains supply

9. Door lock

COMPONENT PLACEMENT, OUTSIDE

Page 49

CIRCUIT BOARD DIAGRAM

X1 Absolute pressure sensor

X2 Temperature sensor

X3

X9

X10:A1 Switch (Door)

X10:A3 Level guard water

X16:2 L1 (Phase)

X16:3 Fan

X16:4 MV-1

X16:5 MV-2

X17:3 MV-5

X17:4 MV-4

X17:5 MV-3

X18:3 MV-6

X18:4 Relay (Heater)

X18:5 MV-8

X19:4 Recorder

X20

X21

X23

X23:1 L1 (Phase)

X23:2 Neutral

X24 PC communication

X25

X26 Display

X27

X32

CIRCUIT BOARD DIAGRAM

Page 50

WIRING DIAGRAM

KRETSKORTSCHEMA

Page 51

INSTALLATION

CAUTION!

Installation must be carried by

technicians with documented

experience.

WARNING!

Make sure that the area where the

sterilizer is to be located can

withstand a load of at least 250 kg.

INTERNAL TRANSPORT

The easiest method to move the sterilizer is using a

pallet truck or a barrow with a minimum lifting limit of

120 kg.

UNPACKING

Check that the packaging is intact.

Check that the supplied goods correspond with the

order.

Check that the sterilizer is free from defects.

Transport damage must be reported immediately to the

carrier.

Setup

PREPARATIONS

Setup ought to be carried out by technicians with

documented experience.

The sterilizer must be located indoors with a maximum

ambient temperature of 35 °C and a relative, no

condensing, humidity of maximum 95 %.

CAUTION!

Ambient temperature, max 35 °C.

Ambient humidity, max 95 %.

PLACEMENT

The sterilizer is a floor model and must stand free, it

must not be enclosed. It should be positioned so that

loading and unloading can be performed without risk. It

must be possible to open the door fully. See the

recommended distances in the picture

Follow local safety regulations.

Once the placement of the sterilizer has been

established, anchor the sterilizer to the floor by each of

the three feet. This prevents the sterilizer from tipping. A

13 mm hole has been drilled in each foot. Use a screw

and plug intended for the surface in question. Make sure

there is a slight backward incline, i.e. the side of the door

should be slightly lower than the front, about 2 - 3 mm.

This is accomplished by placing a washer under each of

the front feet.

INSTALLATION

Page 52

VS 90/60 1550mm

VS130 1750mm

130mm

INSTALLATION

Page 53

Electrical connection

IMPORTANT!

The electrical connection of the

unit must be carried out by trained

personnel

Prior to carrying out any connection work, ensure that

the characteristics stated on the nameplate correspon d

to the mains supply to which it is to be connected. In

case of uncertainty as to the unit supply voltage,

VOLTAGE FLUCTUATION:

The electrical components tolerate a supply voltage

fluctuation of between -10 and +10 %. For larger

fluctuations, it is necessary to use a voltage stabilisation

system placed between the circuit-breaker and the

processor unit transformer. In this case, contact the

sales office.

POWER-SURGE PROTECTION:

A power-surge protection device (over current

protection) must be placed on the sterilizer’s AC power

supply. This protection is the responsibility of the

customer.

CIRCUIT-BREAKER:

A device enabling the sterilizer to be electrically isolated

must be inserted on all the live conductors (including

neutral). This switch or circuit-breaker must be part of

the building’s electrical equipment, positioned near the

unit, and must be easily accessible and marked as the

power switch for the unit, while stating its function.

CAUTION!

The sterilizer must be declared to

your electricity supplier in case of

a 230 single phase connection.

If the unit is connected in polyphase. Its characteristics

are as follows:

• Breaking power 63 A breaking the 3 phases as well as

neutral

Earth terminal making it possible to connect the isolating

device to the earth conductor without braking it.

The on and off positions must be marked: I on and O off

• Box IP 54

TYPE- Power (kW) Voltage (V) Current (A)

VS 60 - 130 6.1KW 230V Single phase 30A

VS 60 - 130 6.1KW 230X3V 20A

VS 60 - 130 6.1KW 400X3V + N 16A

Connect the sterilizer to the earth and according to the

specification of the manual. The installation must be

protected in accordance with the regulations in force.

Failure to comply with this instruction may result in

electrocution of the user and damage to the unit.

CONNECTION POWER SUPPLY

Open the front box.

INSTALLATION

Page 54

WARNING!

Never work with energized

equipment.

The sterilizer must be earthed.

400V 3 phases connection

5-wire cable (3 phase + Neutral + earth)

No jumper

230V 3 phases connection

4-wire for 230V (3 phase (3 phase + earth)

Jumper between L2-N

230V single phase connection

3 wire (1phase + Neutral + earth).

Jumper between L1-L2-L3

With appropriate section to 60227 and 60245.

Pass the power cable through the rear housing provided

for this purpose.

Connect the power cable earth connector to the terminal

marked with the earth symbol

Connect the other end of the cable to the circuit-

breaker/cut-off device located on the outside.

Change of voltage:

This adaptation requires certain parts to be changed;

use the “Jumper kit” furnished with the machine to

perform this change. For further information see the

electrical diagram, or get in touch with the selling

company.

Terminal connection:

Also see “Wiring diagram X1”

400 V 3 Phases Jumper between E-G-H

230 V 3 Phases Jumper between A-G, B-E, C-H

230 V Mono Phase Jumper between N-A-B-C

INSTALLATION

Page 55

CAUTION!

The water supply must be fitted

with a shutoff tap, as the sterilizer

must not be left without

supervision with the water

pressurized.

WARNING!

Risk of hot water from the drain

hose, exercise the greatest

possible caution.

Water connection

The incoming water must have a pressure between 1.5

bar and 6 bar with a temperature of about 15 °C.

Water quality <4 dH

The sterilizer is connected to a ½" water connection with

a shutoff tap. The sterilizer must not be connected with

hoses less than 12 mm. The hoses supplied with the

sterilizer are fitted with Gaz ½" G connections. The

hoses (two) are labelled “Inlet” and “Drain”.

The drain should be connected to a 6" cesspool, with a

capacity of 10 litres/min that can withstand 100° C.

Condensation can occur.

The drain hose must end at least 3 cm above the water

surface in the well.

The drain hose must not go higher than to the lower

edge of the chamber.

Diverse

Should the sterilizer be transported in temperatures

below -5 °C, the overheating protection on the sterilizer

may need to be reset. The error code Heating error

when a process is started indicates a symptom for this.

Keep all instructions and description of operation close

to the sterilizer.

Make sure the operator has read the User manual.

All other documentation supplied with the sterilizer must

be looked after by the operator. The documentation shall

be kept with the sterilizer until its service life comes to an

end.

INSTALLATION

Page 56

TECHNICAL DATA

Dimensions/weight

Width/Depth 570/700 mm

Height VS60/VS90/VS130 1030/1030/1230 mm

Load height VS60/VS90/VS130 940/940/1140 mm

Weight VS60/VS90/VS130 100/106/115 kg

Operating weight VS60/VS90/VS130 107/113/122 kg

Capacity

Chamber, diameter 444 mm

Chamber, depth VS60/VS90/VS130 384/590/858 mm

Chamber, volume VS60/VS90/VS130 60/90/130 L

Instrument load VS60/VS90/VS130 12/24/36 kg

Electrical specifications

Electrical connection according to rating plate

Control voltage according to rating plate

Total output 6 kW (3 x 2 kW)

Power consumption 5 A (3 x 400 V), 9 A (3 x 230 V)

Heat emission while operational, closed door about 615 W

Heat emission in standby, open door 0 W

Other data

Chamber, calculation pressure 3.0 bar

Chamber, provisions AFS 1999:4 (ÅKN 71), Isbest PED 97/23 EEC)

Chamber/door, material EN 1.4404, AISI 316L

Water quality Max 4dH

Water pressure 1.5 - 6 bar

Water and drainage connections ½”

Water consumption during steam phase 7 litres

Water consumption per process 75 - 100 litres

Sound level less than 53 dB

Not intended for the USA market

TECHNICAL DATA

Page 57

Type designations, select

• ? VS60

• ? VS90

• ? VS130

Serial number:

_______________________________

Points of view, tips or criticism:

_______________________________

_______________________________

_______________________________

_______________________________