Page 1

Rebuild Kit Instructions

REBUILD KIT

CHECK VALVE

LOW PRESSURE STEAM SERVICE

3/4 OR 1 NPT Ċ 1I ORIFICE

MAINTENANCE

WARNING: To prevent the possibility of death,

serious injury or property damage, depressurize

valve and vent fluid to a safe area before servicing

the valve

Note: It is not necessary to remove the valve from the pipeline for

repairs.

INSTALLATION OF REBUILD KIT

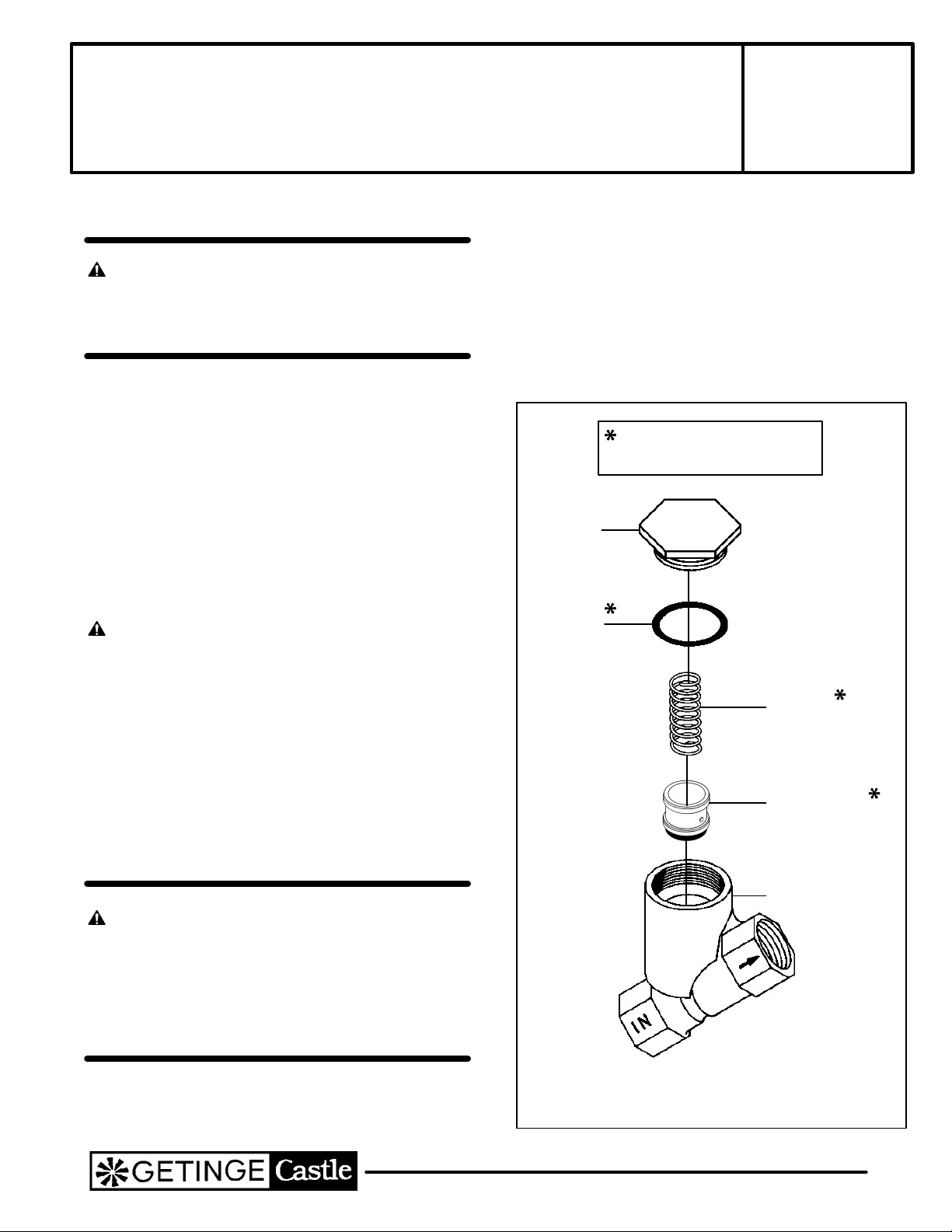

Valve Disassembly (Refer to Figure 1)

1. Disassemble valve in an orderly fashion using exploded view for

identification and placement of parts.

2. Unscrew end cap from valve body.

3. Remove end cap gasket, return spring and disc holder

assembly from valve body.

4. All parts are now accessible for cleaning or replacement. If

parts are worn or damaged, install a complete rebuild kit.

CAUTION: To ensure proper valve operation,

install all parts supplied in rebuild kit. Do not mix old

and new parts.

No. 513700

Form No.V7440

ORDERING INFORMATION

FOR REBUILD KITS

Parts marked with an asterisk (*) in the exploded view are supplied in

Rebuild Kits. When Ordering Rebuild Kits for valves, order the

Rebuild Kit number stamped on the valve nameplate. If the number

of the kit is not visible, order by indicating the number of kits

required, and the Catalog Number and Serial Number of the valve(s)

for which they are intended.

Indicates Parts Supplied

In Rebuild Kit

end cap

end cap

gasket

Valve Reassembly

1. Reassemble valve using exploded view for identification and

placement of parts.

2. Lubricate end cap gasket with DOW CORNINGr 200 Fluid

lubricant or an equivalent high-grade silicone fluid.

3. Install new disc holder assembly and return spring in valve body.

4. Position end cap gasket on end cap.

5. Hand thread end cap with gasket onto valve body as far as

possible, then torque to 175$25 in-lbs [19,8$2,8Nm].

WARNING: To prevent the possibility of

death, serious injury or property damage,

check valve for proper operation before

returning to service. Also perform internal

seat and external leakage tests with a

nonhazardous, noncombustible fluid.

6. Restore line pressure valve.

7. After maintenance is completed, operate the valve a few times

to be sure of proper operation.

return

spring

disc holder

assembly

valve body

Figure 1. Check valve.

MM

1777 East Henrietta Road, Rochester New York 14623-3133 Tel:716-475-1400 Fax:716-272-5297

Printed in U.S.A.

Page 1 of 1

Loading...

Loading...