Page 1

Installation Flusher disinfector S-406

INSTALLATION

9904

Flusher

disinfector

S-406

Serial No. 203.238 -

4996959-01

0301

1

Produced: 1998

Page 2

Flusher disinfector S-406 Installation

Contents

Safety rules _______________________________________________3

General safety rules _______________________________________ 3

Power cut-off device ______________________________________3

Caution symbols _________________________________________3

Installation ________________________________________________ 4

Free-standing position _____________________________________ 4

Fixation in wall __________________________________________4

Connection of electricity, water, drain, and possibly steam ________6

Goods arrangement chart __________________________________ 7

Detergent container _______________________________________8

Settings and functional check ________________________________ 9

Checking and changing preset parameters _____________________ 9

Setting the amount of cleaning and deliming agents on

pumps by means of adjusting screw _________________________10

Checking and adjusting the door turning mechanism ____________11

Final inspection _________________________________________12

9904

2

Page 3

Installation Flusher disinfector S-406

Safety rules

This machine is designed with a number of integrated safety devices. To avoid

personal injury it is essential that the safety devices are not bypassed or in any

other way put out of action.

General safety rules

• The machine should be connected in accordance with the installation

instructions.

• The machine may not by used by juveniles.

• Installation and servicing should be carried out by staff with experience of

this machine.

• The lid lock of the machine may not be bypassed under any circumstances.

• Leakage in the system, eg, due to worn lid gasket, must be repaired

immediately.

• Personnel concerned must study valid handbooks and service manuals prior to

any repairs or service work.

• The machine may not be sprayed with water.

• Caution must be observed when using corrosive detergents.

• Safety precautions must be observed when using hot water or steam.

Power cut-off device

The machine must always be provided with a separate power cut-off device in

the power supply line, easily accessible on the wall.

Caution symbols

This manual contains certain warnings, instructions and advice of such

importance that they are particularly emphasized. The configuration and use of

the appertaining symbols are as follows:

This symbol indicates a warning in text included in the manual.

Such warnings refer to hazards that can result in more or less

serious injury and in some cases fatal injury.

It is also used in warnings to avoid damage to the machine.

9904

3

Page 4

Flusher disinfector S-406 Installation

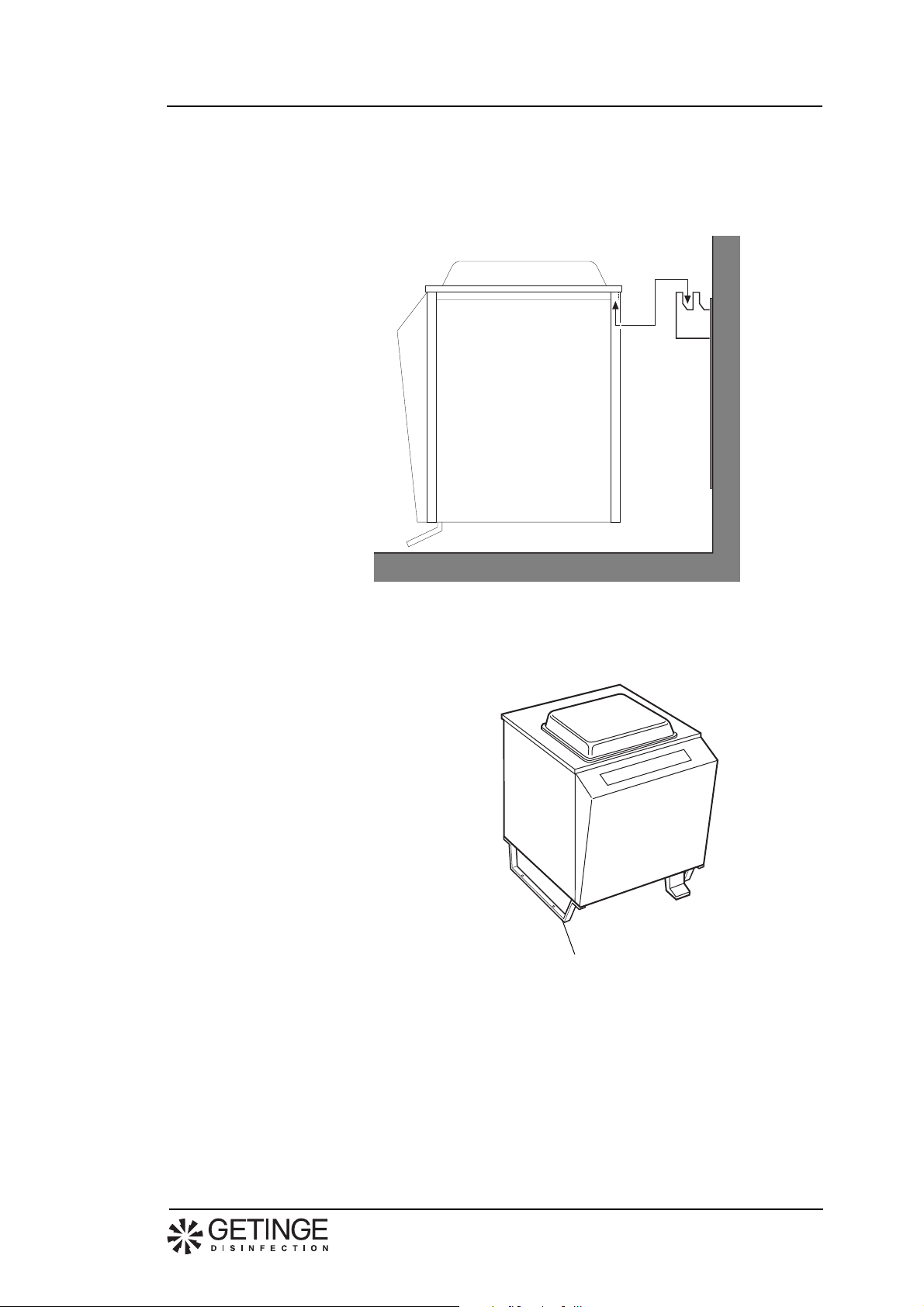

Installation

The disinfector may be placed in a free-standing position on four legs or mounted

on a wall in a special wall bracket.

To facilitate cleaning, a lateral distance of 100 mm to an adjacent wall or other

equipment is recommended. If the disinfector is installed next to a sink unit or

worktop, a lateral distance of 40 mm is recommended.

Wall-mounted models have a transport stay which should be removed.

Free-standing position

Screw the legs securely into the four corners of the support frame. Adjust with the

adjusting screws until the disinfector stands level and firm.

V060

Adjusting

screw

Leg

Fixation in wall

V116

Fig. 1. Fitting the support legs

• Fix the disinfector on the wall bracket supplied with the machine. If the wall

does not provide good support, use a wall fixture or support legs (both of

which can be ordered from Växjö Rostfritt). Ensure that the machine is in

level.

N.B.

If a wall fixture is used, this must be put into position when the

wall is being built up.

• Drill holes for the securing screws for the wall bracket as per figure 2.

235,5

179,5

235,5

179,5

350

Wall fixture

4685140-00

900

Wall bracket

9904

4

470

806

Wall

V061

Fig. 2. Hole pattern for wall bracket.

Page 5

Installation Flusher disinfector S-406

• If support legs are to be used: remove the transport stay and attach the legs

before fixing the disinfector in position.

• Make sure that the disinfector hooks properly into the bracket when it is

mounted on the wall fitting.

Fig 3. Mounting the wall bracket.

• Remove the transport stays.

V300

V644

Transport stay

9904

5

Page 6

Flusher disinfector S-406 Installation

Connection of electricity, water, drain, and possibly steam

May only be performed by authorized personnel.

• The electrical installation must include a cut-off device in the power supply

line to the machine to facilitate maintenance and servicing. The device shall

be located within easy reach on the wall.

• The terminals for electric installation are located under the cover of the

terminal block.

• Connect the disinfector to protective earth and to the voltage supply stated on

the type data plate. Check that the correct fuse is fitted. The recommended

fuse value is stated on the type plate.

• The mounting bracket for the terminal box can be unscrewed and pulled

forward to facilitate installation.

Electrical

connection

V116

Mounting

bracket

V296

Fig. 4. Electrical connection (see electric circuit diagram in Service

instructions).

• To prevent clogging of filters and valves, flush the water pipes clean, and any

steam pipes too, that are to be connected to the machine.

• Connect the disinfector to the cold and hot water supply, and to steam supply

if used. The water and steam connections must conform to the following

requirements:

Connection (mm) Pressure (kPa) Flow (l/s) Consumption (l/process)

Normal Glassware

Cold water 15 50-500 0,2 15 8

Hot water 15 50-500 0,2 18 16

Steam 15 60-300 0,5 kg/process

9904

6

• Drill out the steam jets if necesssary as per the table below:

Steam pressure

kPa

Hole diameters

mm

60-80 80-125 125-200 200-250 250-300

5 4 3.5 3 2,5

• Teflon tape is recommended for sealing the connections.

Page 7

Installation Flusher disinfector S-406

590

295

900

V313

250

150

180

Hot water

Cold water

255 255

180

Fig. 5. Connection of water and steam supply.

Electricity

Steam

• Connect the disinfector to drain outlet. The drain outlet can be connected

either to the rear or downwards as shown in figure 6. Pipe diameter: 110 mm.

600

470

V314

110

Fig. 6. Connection of drain outlet.

Goods arrangement chart

Place the notice with user’s instruction on the wall above the disinfector. Make

sure that the lid does not obscure the chart.

9904

7

Page 8

Flusher disinfector S-406 Installation

Detergent container

• For machines fitted with a dosing system, a tray is provided for the detergent

container, which is fitted on the left-hand or right-hand side of the disinfector

(Fig. 7).

• Fit the tray with the screws in the two cage nuts.

Wear protective gloves. The media in the cans can be corrosive.

• The container may also be placed on the floor or on the lower shelf of an

adjacent sink unit, up to a distance of about 70 cm from the disinfector. The

bottom of the container should not be higher than the lower edge of the side

plates on the disinfector.

• The suction line that is inserted into the detergent container is placed inside

the front panel on delivery. Som option kan Spoldesinfektorn förses med

nivågivare för medel.

Cage nut

Shelf

Screw

V119

Fig. 7. Tray for detergent container.

9904

8

Page 9

Installation Flusher disinfector S-406

Settings and functional check

• Check to make sure that the disinfector is connected to the correct voltage as

indicated on the type data plate.

• Open the water valves, and steam valve if relevant, and turn on the main

switch.

To adapt the machine to the prevailing operating conditions, a number of

parameters must be checked and possibly reset when installing.

The following parameters are to be checked when installing:

• Amount of cleaning agent, see page 10.

• Amount of deliming agent, see page 10.

Checking and changing preset parameters

V310

12 3 45

To check the parameters for the above items, you should enter the service

program as follows:

• Simultaneously press 4 and 5 for 10 seconds.

The machine is then reset to the Service mode (see also under the heading

’Service program’). The push buttons 1 - 5 will have the following

functions:

1 Up 4 Abort

2 Down 5 Completed

3 ON/OFF

• Press 1 and 2 until you arrive at the desired line number as shown in

the table below:

Parameter Line number Basic setting Setting range

Amount of cleaning agent * 42 25 0 - 99

Amount of deliming agent * 48 13 0 - 99

* See further under the heading Setting the amount of detergent and descaling compound.

• Press 5 to enter the line. You can then read the set value and check it against

the table above.

9904

N.B.

To change the contents of a line you must first key in your authority

code (1992) on line 00.

• Use 1 and 2 to change the contents of a line to the desired value as per

the above table.

9

Page 10

Flusher disinfector S-406 Installation

• Press 5 when you have finished. The display window will then go ’OFF’

for a short period (the new value is stored in the machine memory) and then

the new value will be displayed with a steady light.

If you change your mind before pressing ’Completed’, you can press4. The

old value will then be reset again.

• Press 5 once again to quit the line and enter the line number. Go to the

next line that is to be changed.

• Press 4 for three seconds to quit the service program.

The machine is now ready for operation.

Setting the amount of cleaning and deliming agents on pumps by means of adjusting screw

The disinfector may be supplied with three different dosage systems: two for

detergent dosage and one for descaling compound. For descaling and spray

dosage the amount of compound can be set in the service program (see

Illustration 8).

May only be performed by authorized personnel.

This machine is connected to mains power supply and some

components are live.

Set by the service program

V071

Detergent pump

50 ml

V304

Detergent pump

(spray)

40 ml

Deliming pump

6 - 10 dH° 1,5 ml

10 - 15 dH° 3,0 ml

15 - 20 dH° 4,5 ml

V583

Fig. 8. Dosage pumps

• Measure out 100 ml of detergent into a measuring glass. Check that the

suction pipe and pump are full of detergent before carrying out the check.

• Insert the suction pipe into the measuring glass and run a washing program.

Remove the suction pipe and read off consumption. Adjust if necessary in the

service program and repeat measurement until the amount is correct

according to manufacturer’s recommendations.

9904

10

Page 11

Installation Flusher disinfector S-406

Checking and adjusting the door turning mechanism

May only be performed by authorized personnel.

This machine is connected to mains power supply and some

components are live.

If a program starts and the lid is obstructed by an object between the lid and the

top of the disinfector, the lid shall open again. The limit for this safety

precaution is between 6 and 12 mm as shown in figure 9.

Use the accompanying spacer bar to check this function.

• Stand the bar on edge (so that it is 12 mm high).

• Insert it between the top of the machine and the lid.

• Close the lid.

The lid must change direction and open again.

• Then turn the bar so that it is 6 mm high.

• Check to ensure that the lid closes.

Adjustment of the lid reversing function is described in the Service instructions.

V601

Fig. 9. Closing the lid.

6-12 mm

9904

11

Page 12

Flusher disinfector S-406 Installation

Final inspection

• If the machine has dosing of cleaning agent: Press S and check to make

sure the lamp in the push button lights.

• Check to make sure the incoming hot water has the correct temperature. It

should be between 45 and 60°C.

• Start the ’Normal’ program with empty machine and check that:

- The PROCESS IN OPERATION lamp is ON.

- The temperature rises continuously until its cooling phase begins.

- Any pause for heating is not longer than about 10 minutes (applies to

apparatus connected to steam and apparatus with steam generator).

- The final temperature is higher than 90°C.

- The PROCESS COMPLETE lamp lights when the program is over.

Fig. 10. Indicating lamps

L M K

Process in operation

• If the machine has a system for cleaning or deliming agent, or both:

Pour a sufficient amount of agent into a measuring glass. Make sure that the

suction hose is full of agent. Start a ’normal’ program and check that the

disinfector uses the correct amount. For cleaning agent, the amount per

program is normally about 30 ml, and for deliming agent about 1,5 to 4,5 ml

(follow the supplier’s recommendations).

N.B.

When taking the reading, the suction pipe should not be in the

measuring glass.

• Check that there are no leaks. Tighten if necessary.

Process completed

9904

12

Page 13

Installation Flusher disinfector S-406

Technical data

Weight 70 kg

Width 590 mm

Depth600 mm

Height 900 mm

Ambient requirements:

Relative humidity maximum 80% at 31°C

Room temperature 5 - 40 °C

Cold water

Connection 15 (1/2") mm

Pressure 50-500 kPa

Flow 0,2 l/s

Consumption 13 l/process

Hot water

Temperature 45-60 °C

Connection 15 (1/2") mm

Pressure 50-500 kPa

Flow 0,2 l/s

Consumption 22 l/process

Steam (V version only)

Connection 15 (1/2") mm

Pressure 60-300 kPa

Consumption 0,3 kg/process

Drain outlet dia. 110 mm

Max. external temperature 50 °C

Noise level ca 59 dB(A)

Power

Model Electrical connection Fuse requirement

L1 230 V, 1N+PE 50 Hz (TN) 1x16 A 2,94 kW

L2 230 V, 3+PE 50 Hz 3x16 A 3,91 kW

L3 400 V, 3N+PE 50 Hz (TN) 3x10 A 3,91 kW

L5 240 V, 2+PE 60 Hz (TN) 2x15 A 3,29 kW

L6 240 V, 3N+PE 60 Hz (TN) 3x15 A 4,26 kW

L9 208 V, 2+PE 60 Hz (TN) 2x15 A 3,29 kW

L10 208 V, 3N+PE 60 Hz (TN) 3x15 A 4,26 kW

L14 200 V, 2+PE 50 Hz (TN) 2x16 A 2,94 kW

L15 200 V, 3+PE 50 Hz (TN) 3x16 A 2,94 kW

L18 200 V, 2+PE 60 Hz (TN) 2x16 A 3,29 kW

L19 200 V, 3+PE 60 Hz (TN) 3x16 A 3,29 kW

L22 230 V, 1N+PE 60 Hz (TN) 1x16 A 3,29 kW

L24 400 V, 3N+PE 60 Hz (TN )3x10 A 4,26 kW

V2 230 V, 1N+PE 50Hz (TN) 1x10 A 1,01 kW

V3 240 V, 2+PE 60 Hz (TN) 2x15 A 1,36 kW

V4 208 V, 2+PE 60 Hz (TN) 2x15 A 1,36 kW

9904

V7 230 V, 1N+PE 60Hz (TN) 1x10 A 1,36 kW

13

Page 14

Flusher disinfector S-406 Installation

Diameter of nozzle orifice at various steam pressures

If no steam pressure is specified, the disinfector nozzle is delivered with an

orifice diameter of 1.8 mm. If the pressure used is less than 300 kPa, the nozzle

orifice should be made larger as shown in the table below.

Steam pressure

kPa

Orifice diameter

60-80 80-125 125-200 200-250 250-300

5 4 3.5 3 2,5

9904

14

Page 15

Installation Flusher disinfector S-406

9904

15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

This product is manufactur ed b y:

GETINGE DISINFECTION AB, Ljungadalsgatan 11, Box 1505, 351 15 Växjö, Sweden

Loading...

Loading...