Page 1

GETINGE DRYING CABINET S-363

USER MANUAL

6001300802

Page 2

The model name and serial number should always be provided when ordering

spare parts or during queries per telephone or written correspondence:

Serial number of the machine:

……………………………………………………

Machine model:

……………………………………………………

The manual, or parts thereof, are a part of the product. This manual must not be

modified, reproduced or copied without GETINGE’s written consent. The content

may not be reused by third parties or used for unauthorized purposes. Violators will

be prosecuted. Additional copies of this manual can be obtained from GETINGE

for a fee.

© Copyright 2013 GETINGE, Reprinting prohibited.

GETINGE DISINFECTION AB

Ljungadalsgatan 11

PO Box 1505

SE-351 15 Växjö, Sweden

Internet: www.getinge.com

2019-03-14

Page 3

Contents

1 INTRODUCTION........................................................................................................... 5

2 SAFETY INSTRUCTIONS............................................................................................ 6

3 TECHNICAL DATA....................................................................................................... 8

4 INSTALLATION........................................................................................................... 10

5 ELECTRICAL INSTALLATION.................................................................................... 12

6 DIRECTIONS FOR USE............................................................................................. 14

7 ERROR CODE 1......................................................................................................... 15

8 ADDRESSES.............................................................................................................. 18

Alphabetical index............................................................................................................ 21

Contents

1.1 Intended use....................................................................................................... 5

1.2 Product liability.................................................................................................... 5

1.2.1 Declaration of Conformity..................................................................... 5

1.2.2 Disclaimer............................................................................................. 5

1.2.3 Manufacturer......................................................................................... 5

1.2.4 Warranty............................................................................................... 5

2.1 General safety instructions.................................................................................. 6

2.2 Isolator switch..................................................................................................... 6

2.3 Warning symbols................................................................................................. 7

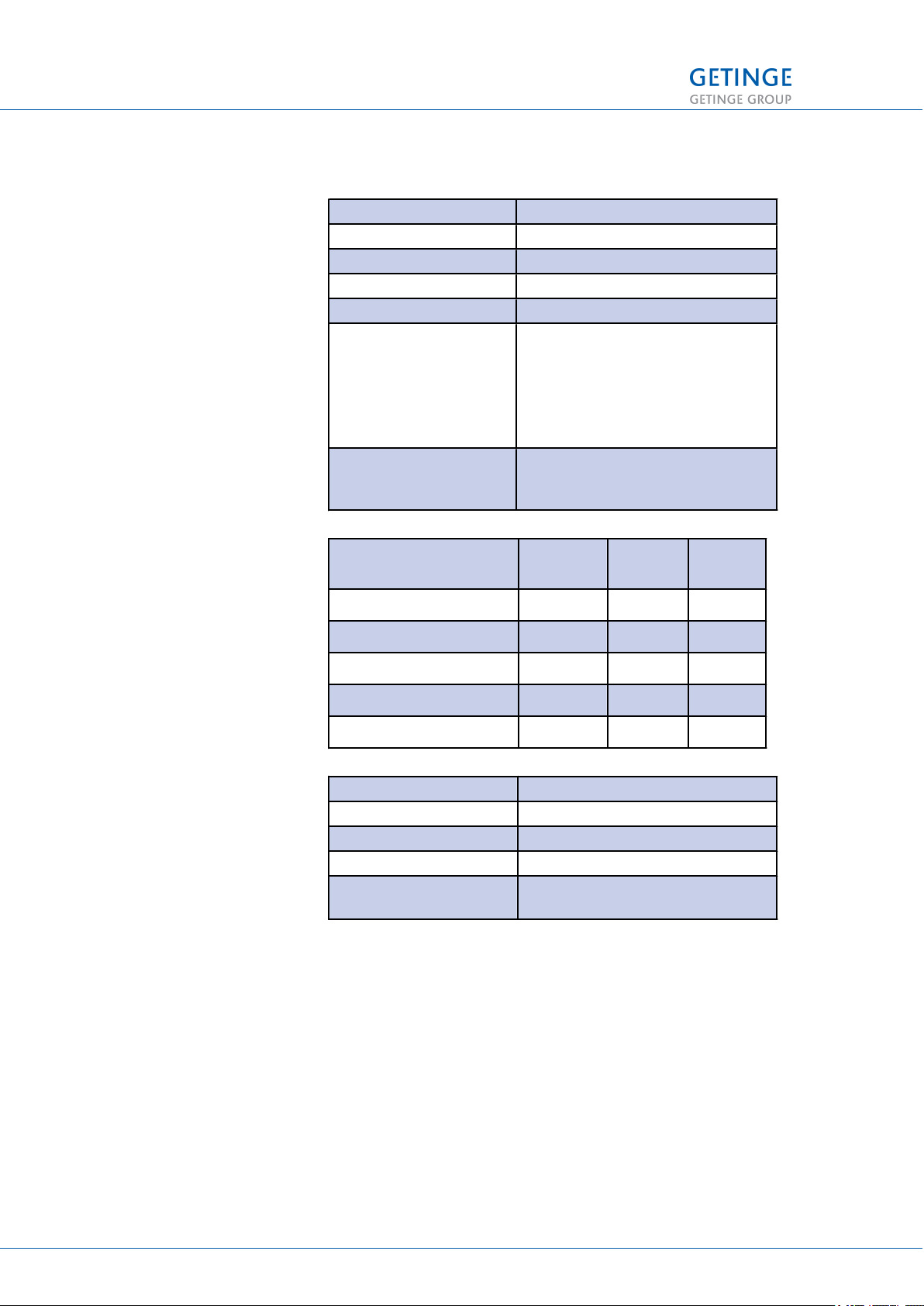

3.1 DRYING CABINET.............................................................................................. 9

3.1.1 Construction.......................................................................................... 9

3.1.2 Capacity................................................................................................ 9

4.1 Free-standing model......................................................................................... 10

4.2 Manual discharge damper................................................................................. 11

5.1 Electrical connections....................................................................................... 12

5.1.1 Connect electricity............................................................................... 12

5.1.2 Isolator switch..................................................................................... 12

5.1.3 Connection diagram............................................................................ 13

5.1.4 Pre fuse requirements......................................................................... 13

7.1 Drying anaesthetic and respiratory hoses and bellows..................................... 15

7.2 Maintenance when necessary........................................................................... 15

7.3 Cleaning the filter cassette................................................................................ 16

7.4 Overheating cut-out........................................................................................... 17

USER MANUAL GETINGE DRYING CABINET S-363 3 (24)

<Doc_6001300802><Rev.C><Lang_en>

Page 4

<Doc_6001300802><Rev.C><Lang_en>

4 (24) USER MANUAL GETINGE DRYING CABINET S-363

Page 5

1 INTRODUCTION

1.1 Intended use

The drying cabinet is designed for fast and sparing drying of

anesthetic tubing, such as hoses with smooth or corrugated

surfaces, bellows, breating masks and surgical instruments in

trays. All goods to be loaded must have passed an acknowledged

cleaning and disinfection process in a washer-disinfector.

The drying cabinet is designed for use in soiled and clean areas of

CSSDs, TSSUs and other departments where efficient drying of

equipment is important.

1.2 Product liability

1.2.1 Declaration of Conformity

The product compliance is stated in the Declaration of Conformity.

1.2.2 Disclaimer

1 INTRODUCTION

1.2.3

• The manufacturer cannot guarantee that the product will work

as intended if accessories or spare parts other than those

approved by the manufacturer are used.

• The product liability only applies when the instructions in this

manual have been followed in their entirety.

• The manufacturer accepts no responsibility for personal

injuries when the instructions in this manual have not been

followed in their entirety.

• The manufacturer reserves the right to change the

specification and design of the product without any prior

notice.

Manufacturer

This product was manufactured by:

GETINGE DISINFECTION AB

Ljungadalsgatan 11

PO Box 1505

SE-351 15 Växjö, Sweden

1.2.4 Warranty

The product warranty applies in accordance with the agreement

reached between the Getinge sales company and the customer.

USER MANUAL GETINGE DRYING CABINET S-363 5 (24)

<Doc_6001300802><Rev.C><Lang_en>

Page 6

2 SAFETY INSTRUCTIONS

2 SAFETY INSTRUCTIONS

This drying cabinet has been designed with a number of integral

safety devices. To avoid injury to the person it is essential that the

safety devices are not bypassed or in any other way put out of

action.

2.1 General safety instructions

• The drying cabinet should be connected according to the

instructions.

• The drying cabinet should be used according to the

instructions.

• The drying cabinet should not be used by minors.

• Installation work and servicing should only be undertaken by

staff qualified to do so.

• Staff involved should study up-to-date handbooks and service

manuals before undertaking any repairs or service work.

• All leads must be disconnected from all circuit boards of the

control system before commencing welding on or near the

drying cabinet.

• The drying cabinet should not be sprayed with water.

• Use safety gloves when performing service due to risk for

sharp edges.

• At least two persons should work together, due to weight

(100 kg) and high center of gravity.

2.2 Isolator switch

The drying cabinet should be provided with a separate main switch

in the power supply line, easily accessible on the wall. See section

5 ELECTRICAL INSTALLATION.

<Doc_6001300802><Rev.C><Lang_en>

6 (24) USER MANUAL GETINGE DRYING CABINET S-363

Page 7

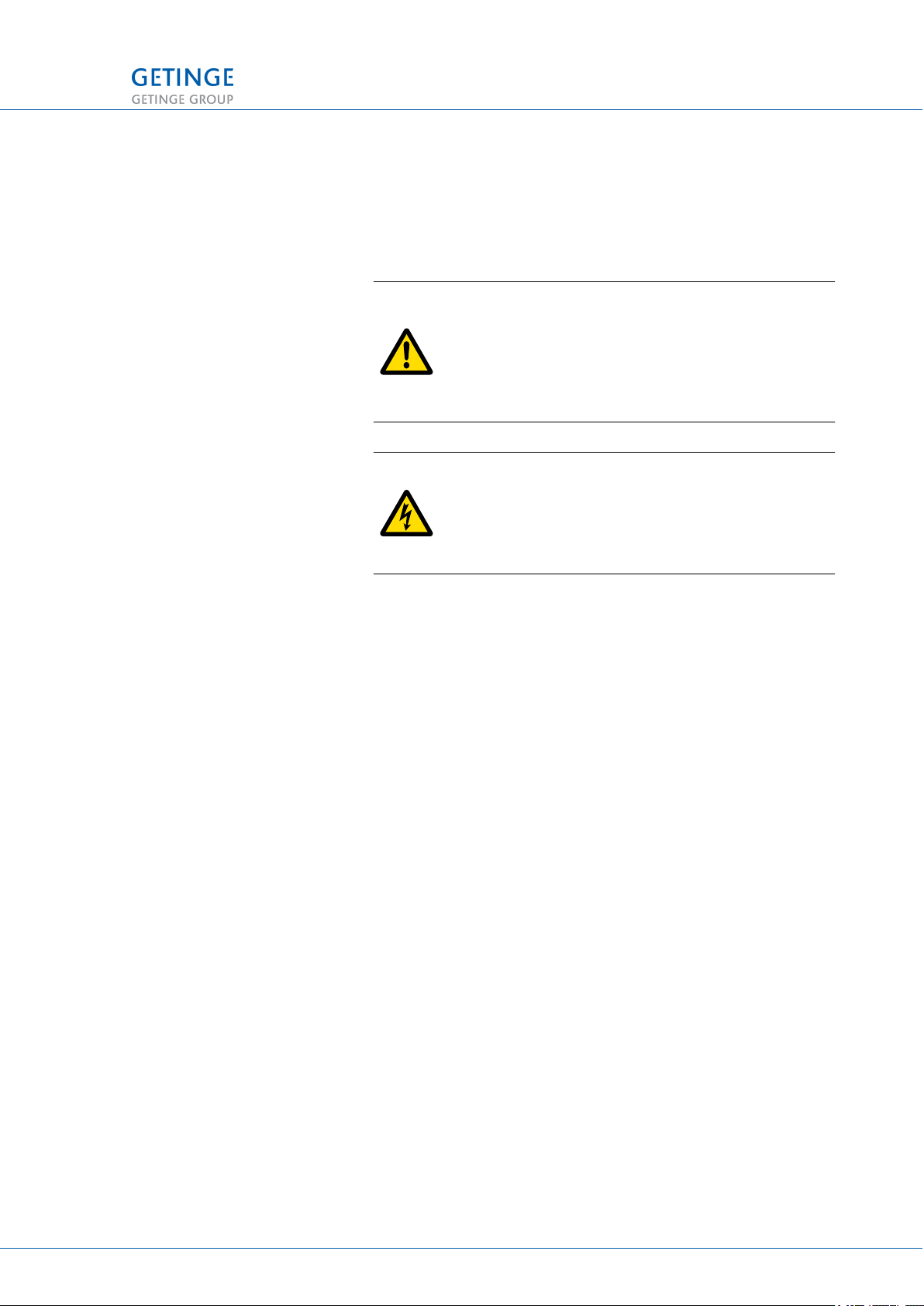

2.3 Warning symbols

2 SAFETY INSTRUCTIONS

This manual includes advice, and certain warnings and instructions

of such importance that they have been specially marked. The

configuration and use of the relevant symbols are as follows:

This symbol indicates a warning in the text. It

gives warning of dangers which could lead to

minor or major injury to the person and even to a

fatality.

It is also used in warnings to avoid damage to the

machine.

This symbol indicates a warning in the text

concerning high voltage (>2000 V). It gives

warning of dangers which could lead to

minor or major injury to the person and even to a

fatality.

USER MANUAL GETINGE DRYING CABINET S-363 7 (24)

<Doc_6001300802><Rev.C><Lang_en>

Page 8

3 TECHNICAL DATA

3 TECHNICAL DATA

Humidity Max 80 % at 31 °C

Room temperature 5–40 °C

Weight Approximately 100 kg

Internal dimensions 1600 x 495 x 375 (H x W x D)

Fan capacity 200 m³/h

Exhaust air Fully open exhaust valve:

approximately 75 m³/h, max 90 °C.

Fully closed exhaust valve:

approximately 40 m³/h, max 90 °C.

Exhaust stub pipe Ø 100 mm valve

regulated.

Heat dissipation into the

room

Approximately 500 W if the exhaust

stub pipe is connected to the

exhaust ventilation.

Electrical Max current

(A)

200 V, 3+PE, 50/60 Hz 11.6 A 2.6 kW C16 A

230 V, 3+PE, 50/60 Hz 13.3 A 3.4 kW C16 A

240 V, 3+PE, 50/60 Hz 13.8 A 3.7 kW C16 A

400 V, 3N+PE, 50/60 Hz 7.3 A 3.4 kW C10 A

415 V, 3N+PE, 50/60 Hz 7.8 A 3.7 kW C10 A

Pollution degree 2

Max altitude 2000 m

Indoor use only

Overvoltage category 2

Main supply voltage

fluctuations

+- 10% at nominal voltage short

term.

Power

(kW)

Max Pre

Fuse

<Doc_6001300802><Rev.C><Lang_en>

8 (24) USER MANUAL GETINGE DRYING CABINET S-363

Page 9

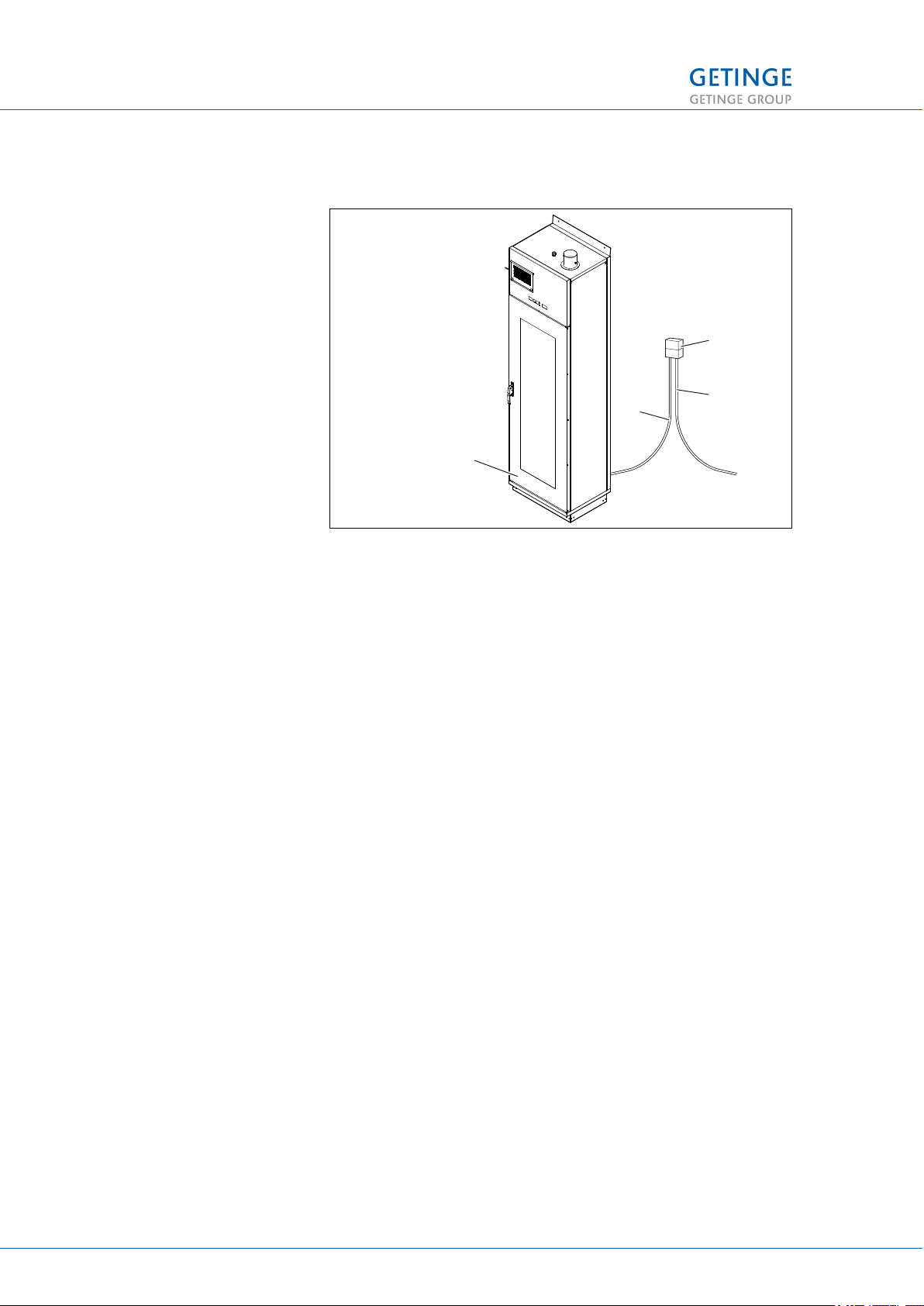

3.1 DRYING CABINET

3.1.1 Construction

3 TECHNICAL DATA

Made of stainless steel, SIS 2333, with a base and four adjustable

feet. Insulated with 20 mm mineral wool sheets.

The cabinet operates with recirculated hot air, approximately 80%

recirculation and 20% additional electrostatically-filtered air.

Automatic electronic controls with display of the drying time. The

drying time can be adjusted from 0-95 minutes. The time is

counted down in steps of 1 minute during the process so that the

display shows how much drying time is left. When the drying time

is complete, the fan runs for an additional 2 minutes with the heater

switched off so that the overheating cut-out does not trip.

There are two heater settings: 70° C for plastics and 90° C for

rubber hoses and instruments.

The display alternates between

filter needs cleaning.

The cabinet is available as a single configuration or a through-put

cabinet. The doors are fitted with a cremone bolt, either righthanded or left-handed.

and the drying time when the

3.1.2

Capacity

36 hoses or 9 DIN baskets or 9 shelves or SPRI I racks or 18

hoses and 8 shelves with SPRI II racks.

USER MANUAL GETINGE DRYING CABINET S-363 9 (24)

<Doc_6001300802><Rev.C><Lang_en>

Page 10

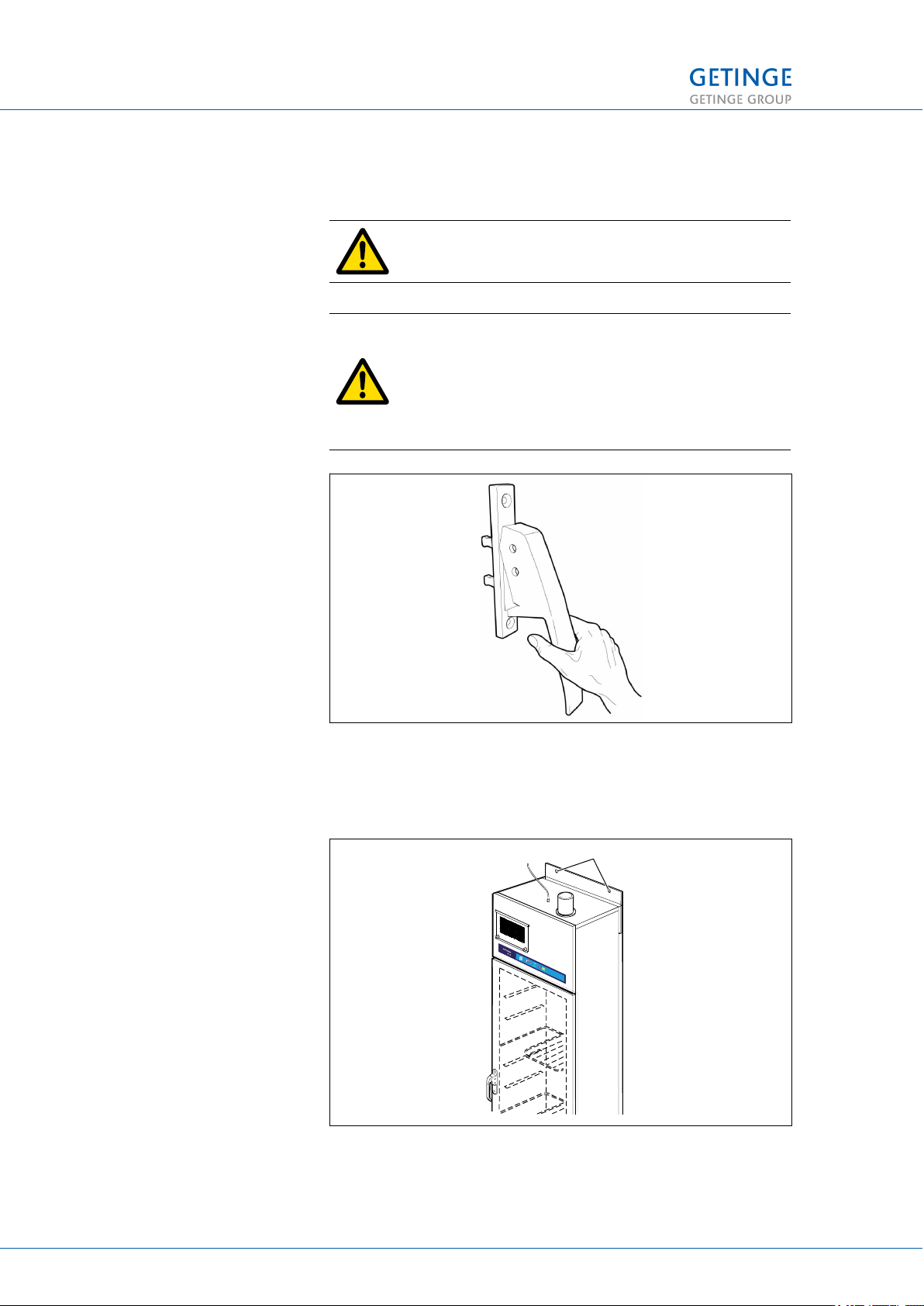

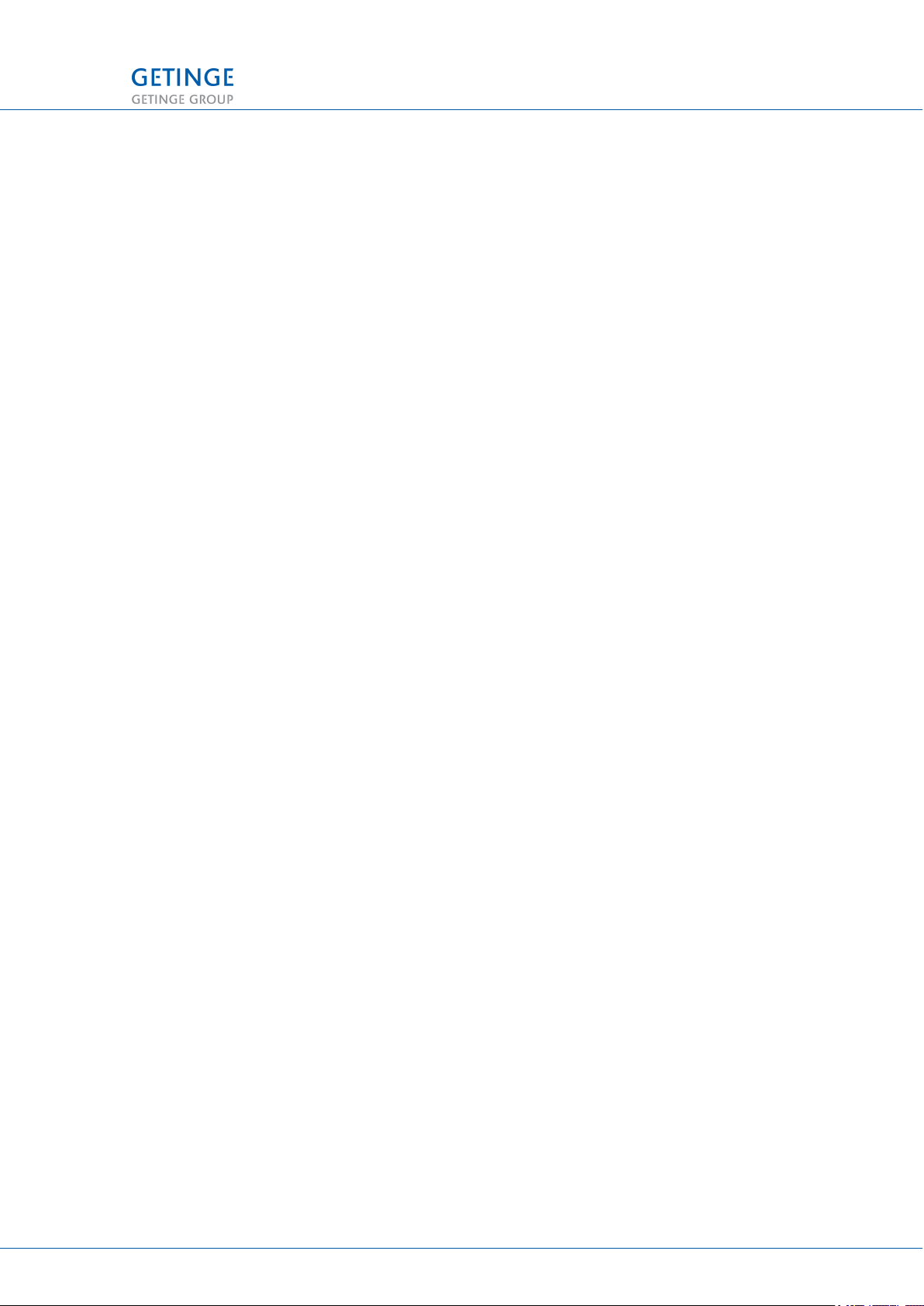

004832

004833

A

4 INSTALLATION

4 INSTALLATION

Installation should only be carried out by

authorised staff.

It is a risk to pinch a finger when opening and

closing the handle. This can be possible only if

you take the whole handle in your hand. If you

open and closed the handle by taking the lower

part of the handle it would not be possible to

pinch a finger.

4.1 Free-standing model

Secure the machine firmly to the wall with two screws through the

holes A at the top of the machine.

<Doc_6001300802><Rev.C><Lang_en>

10 (24) USER MANUAL GETINGE DRYING CABINET S-363

Page 11

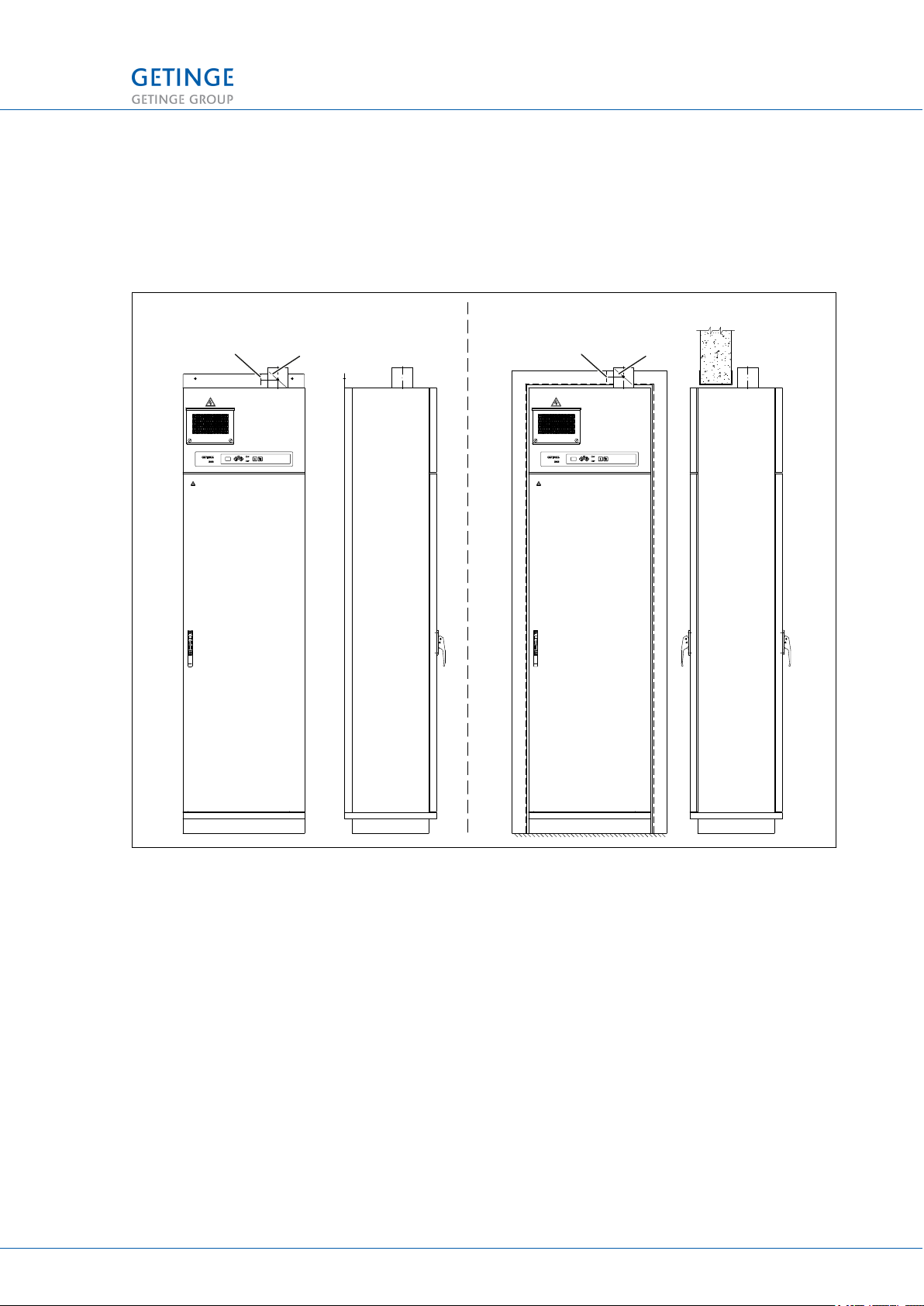

4.2 Manual discharge damper

004834

A B

1 2

1

2

There is a discharge damper which reduces the discharge in case

the ventilation in the installation is strong.

At installation, manually adjust the discharger

damper so it suits the ventilation capacity.

4 INSTALLATION

A. Wall hung singel door model, S-363E

1. Handle

2. Discharge damper

For ventilation requirements, see section 3 TECHNICAL DATA.

B. Recessed two door pass-through version, hole

in wall must be 615x2190

1. Handle

2. Discharge damper

USER MANUAL GETINGE DRYING CABINET S-363 11 (24)

<Doc_6001300802><Rev.C><Lang_en>

Page 12

1

2

3

4

005675

5 ELECTRICAL INSTALLATION

5 ELECTRICAL INSTALLATION

5.1 Electrical connections

5.1.1 Connect electricity

• Installation should only be carried out by authorized staff.

• Check the machine type plate.

• Install the machine in accordance with installation category

• Make sure the electrical connection is carried out in

5.1.2

Isolator switch

1. Isolator switch (not

included)

2. Supply cable

(not included). To be

sized by end user

according to local

conditions and

regulations

CAT II.

accordance with current local regulations and rules.

3. Supply cable

(3 m included)

4. Machine type

plate

• The machine must be preceded by a lockable isolator switch

for the electric power supply.

• The switch must be easily accessible on a wall close to the

machine.

• The installation must conform to and be marked in

accordance with local regulations.

<Doc_6001300802><Rev.C><Lang_en>

12 (24) USER MANUAL GETINGE DRYING CABINET S-363

Page 13

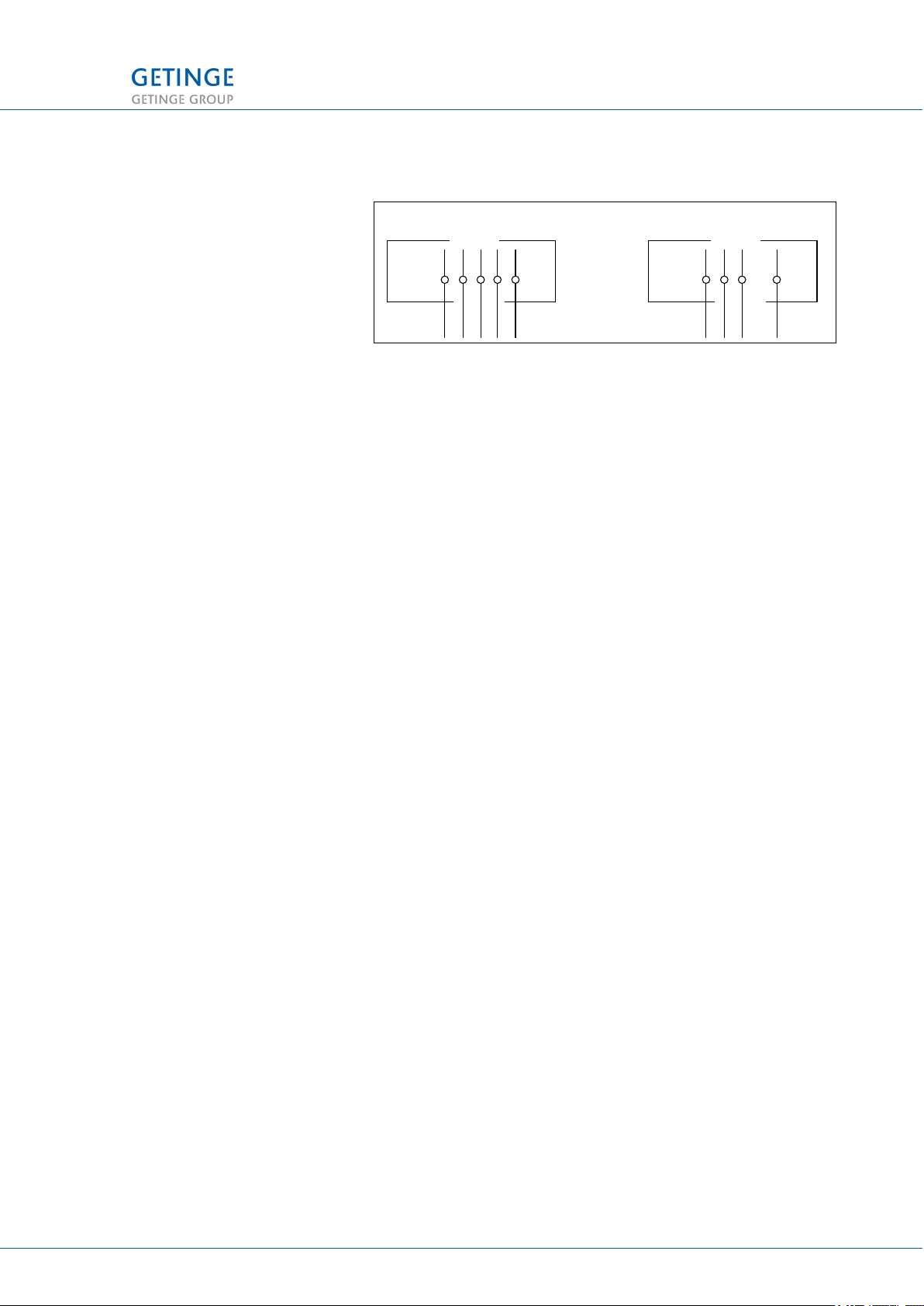

5.1.3 Connection diagram

004457

L1L2L3

N

PE

L1L2L3NPE

-X50

3N+PE

L1L2L3

PE

L1L2L3

PE

-X50

3+PE

5.1.4 Pre fuse requirements

5 ELECTRICAL INSTALLATION

See section 3 TECHNICAL DATA.

USER MANUAL GETINGE DRYING CABINET S-363 13 (24)

<Doc_6001300802><Rev.C><Lang_en>

Page 14

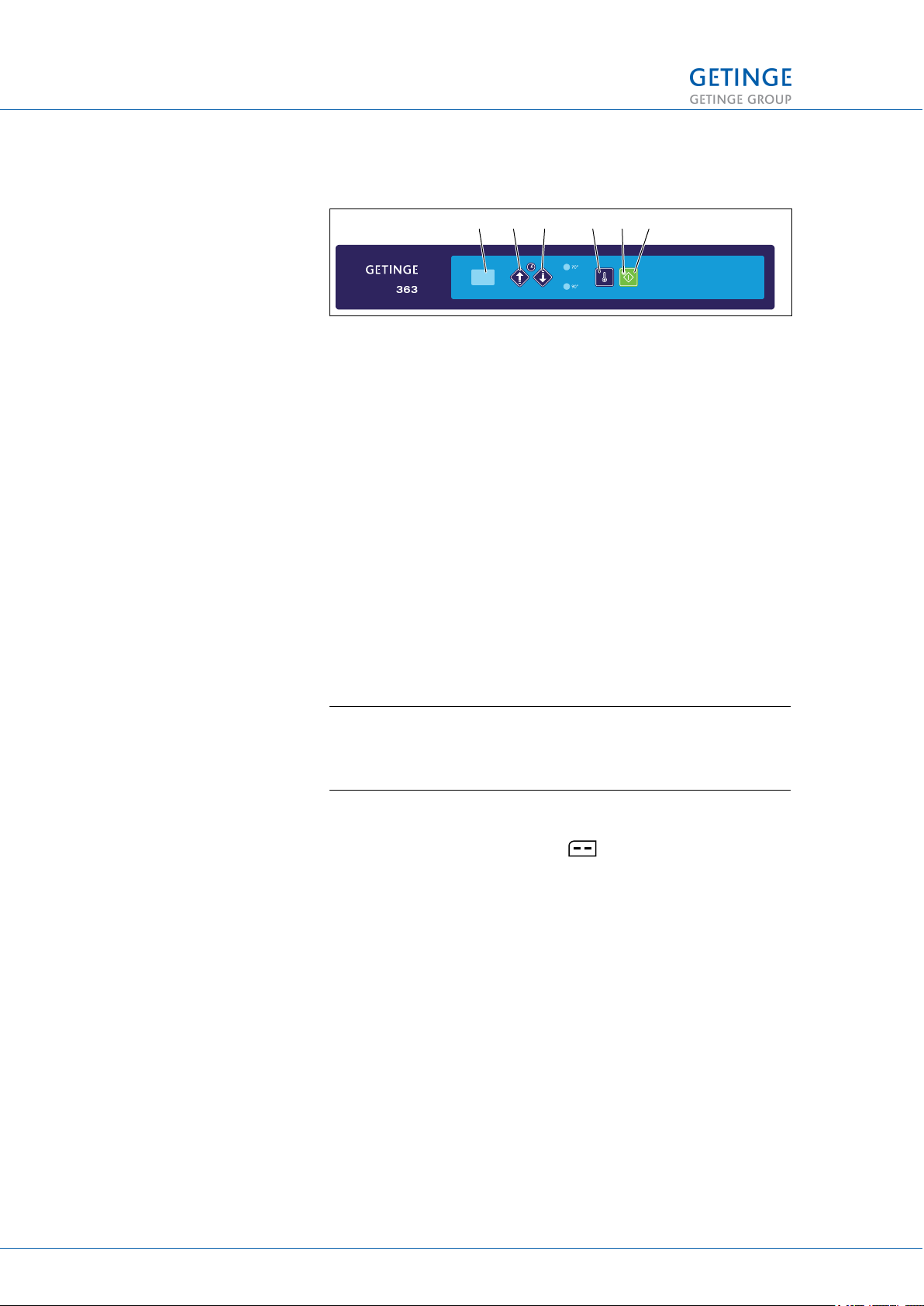

&=

004835

1 2 3 4 5 6

6 DIRECTIONS FOR USE

6 DIRECTIONS FOR USE

1. Display 4. Temperature selection

2. Increase 5. LED

3. Decrease 6. Start/stop

Cassettes together with moist hoses should be lifted directly into

the drying cabinet, where they are slid in on guides.

1. Respiratory bellows are placed in the cassette designed for

the purpose.

2. Racks for instruments etc. are placed on the rack shelves.

3. Select the required drying temperature, 70 °C or 90 °C by

pressing the temperature select button.

4. Set the required drying time on the display. Increase the time

by pressing A, decrease the time by pressing B.

5. Start the drying operation by pressing the start/stop button.

The LED comes on when the drying process starts.

Note!

Do not disconnect the power supply during the drying

process.

6. Drying is complete when the display shows 0.

Note! It is time to clean the filter cassette when the

display alternates between and the drying time.

7. Digital display of chamber temperature.

By pressing the two arrow keys and the temperature selection

button and the start/stop button simultaneously, the chamber

temperature will be indicated on the digital display. After

displaying the temperature for 2 minutes the display window

will revert to showing the count-down drying time.

<Doc_6001300802><Rev.C><Lang_en>

14 (24) USER MANUAL GETINGE DRYING CABINET S-363

Page 15

7 ERROR CODE 1

7 ERROR CODE 1

Error code 01 indicates that contact with the temperature gauge

has been broken.

7.1 Drying anaesthetic and respiratory hoses and bellows

The drying cabinet can be used for 6 cassettes at the same time.

To enable the drying air to be forced through the tubing, each

drying cabinet is also equipped with 4 loose blind flanges. If fewer

than 6 cassettes are used during the drying operation, these blind

flanges must be slid into the empty guides. If only a single cassette

is used, all 4 blind flanges must be slid in, leaving one guide

uncovered.

7.2 Maintenance when necessary

When necessary, the outside and the inside of the drying cabinet

can be cleaned and disinfected with an alcohol-based detergent,

surgical spirit, or normal detergent. The control panel can be

cleaned in the same way. Remove marks with ordinary stainremover for stainless steel.

USER MANUAL GETINGE DRYING CABINET S-363 15 (24)

<Doc_6001300802><Rev.C><Lang_en>

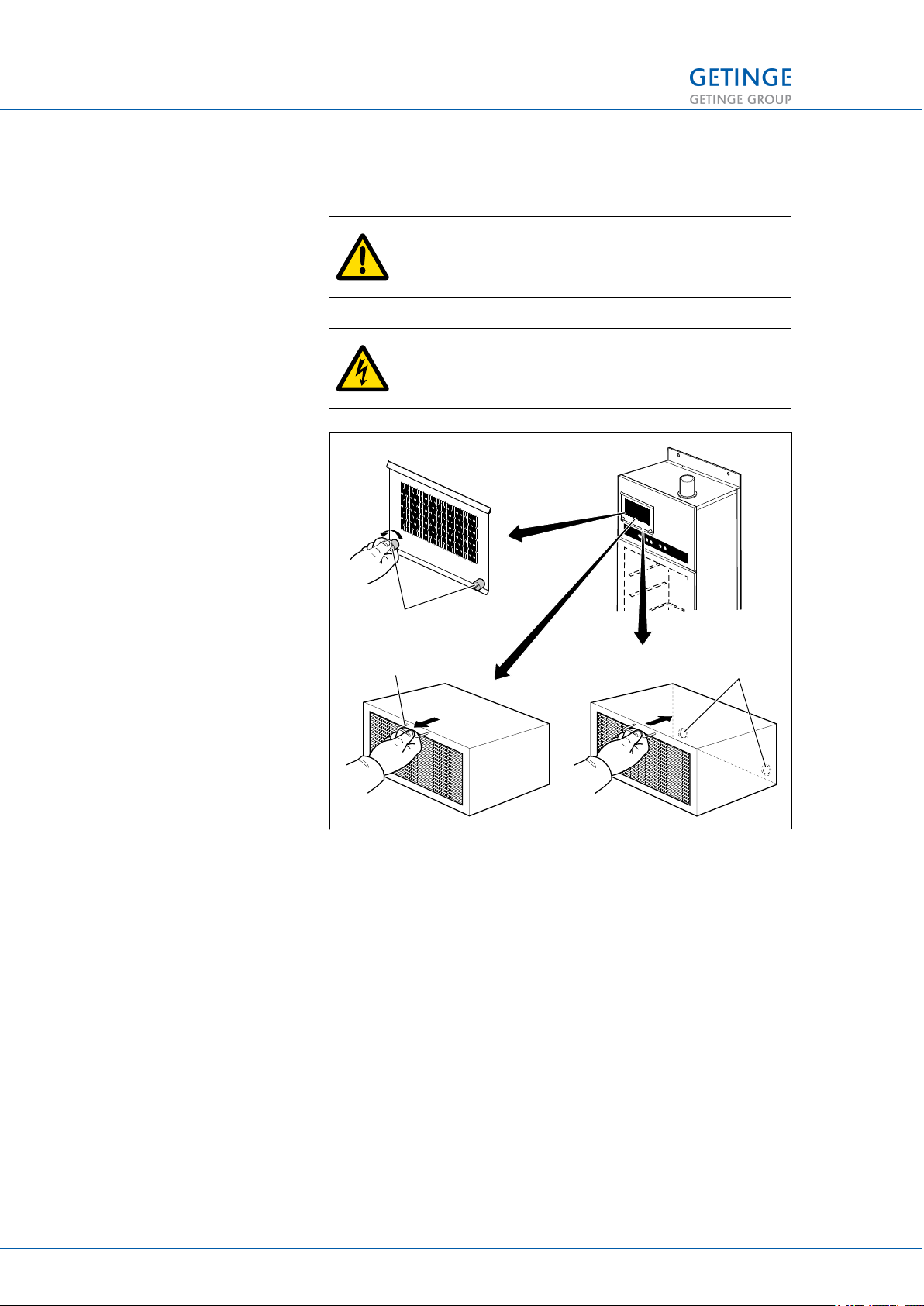

Page 16

1

004836

C

A

B

2

10

7 ERROR CODE 1

7.3 Cleaning the filter cassette

WARNING!

Maintenance must only be done by authorized

personnel.

WARNING!

Before starting work, make sure that the machine

is disconnected from the electric power supply.

<Doc_6001300802><Rev.C><Lang_en>

16 (24) USER MANUAL GETINGE DRYING CABINET S-363

Page 17

004837

A

B

7 ERROR CODE 1

1. Undo screws (A) and remove the cover.

2. Pull out the handle (B) and take out the cassette.

3. Take a suitable plastic wash basin in which the filter cassette

can be completely immersed.

4. Fill up with approx 60 °C hot water and add about 1% alkaline

detergent.

5. Stir the solution and carefully immerse the filter cassette.

6. Take out the filter after 15–30 minutes and rinse it on all sides

with clean water under a running water-tap.

7. Place the filter on water-absorbent paper or lint for 24 hours.

8. Do not use compressed air for cleaning or drying.

9. Check that the filter cassette has dried completely.

10. Put the cassette back into place after cleaning it. N.B. Make

sure the cassette is not turned upside down. The contacts (C)

at the back of the filter should face downwards.

7.4 Overheating cut-out

If the heating fails to work, or the fan fails to start, the over-heating

cut-out may have tripped. Remove front panel A. Reset the cut-out

by pressing red button B.

Do not use sharp implements when dismantling.

WARNING!

Only to be carried out by authorized staff.

WARNING!

Before starting work, make sure that the machine

is disconnected from the electric power supply.

<Doc_6001300802><Rev.C><Lang_en>

USER MANUAL GETINGE DRYING CABINET S-363 17 (24)

Page 18

8 ADDRESSES

8 ADDRESSES

Australia

Getinge Australia PTY Ltd

PO Box 50

Bulimba QLD 4171

Australia

Cust Support: 1300 155 500

Phone: +61 7 3399 3311

Fax: +61 7 3395 6712

E-mail:

info@getinge.com.au

China

Getinge (Suzhou) Co.Ltd

No.158, Fang Zhou Road,

Suzhou Industrial Park

215 021 Suzhou

Jiangsu Province P.R. China

Phone: +86-51 262 838 966

E-mail:

info@getinge.com.cn

Finland

Getinge Finland AB

Niittykatu 8

FI-02200 Espoo

Finland

Phone: +35-89 6824 120

E-mail:

getinge.finland@getinge.com

Belgium

Getinge NV

Vosveld 4 B-2

B-2110 Wijnegem

Belgium

Phone: +32-33 542 865

E-mail:

info@getinge.be

China

Getinge Shanghai Trading

Co.Ltd.

No.3, Lane 128, Lin Hong Road

Changing District

200335 Shanghai China

Phone: +86-21 6197 3999

E-mail:

info@getinge.com.cn

France

Getinge France SAS

BP 49, avenue du Canada

ZA de Courtaboeuf

Les Ulis, FR-91942

France

Phone: +33-1 64 86 89 00

E-mail:

getinge.france@getinge.fr

Canada

Getinge Canada Ltd

6685, Millcreek Drive

Unit 3-5

Mississauga, Ontario L5N5M5

Canada

Phone: +1-905-629-8777

E-mail:

customercare@getinge.ca

Denmark

Getinge Danmark A/S

Industriparken 44 B

DK-2750 Ballerup

Denmark

Phone: +45 45 93 27 27

Fax: +45 45 93 41 20

E-mail:

getinge.denmark@getinge.com

Germany

Getinge Vertrieb & Service

GmbH

Kehler Strasse 31

764 37 RASTATT

Germany

Phone: +49-7222 932 306

Fax: +49-7222 932 597

E-mail:

info.inco-de@getinge.com

Italy

Getinge S.p.A

via Poggio Verde, 34

00148 Rome

Italy

Phone: +39-06 656 631

E-mail:

info@getinge-it

<Doc_6001300802><Rev.C><Lang_en>

18 (24) USER MANUAL GETINGE DRYING CABINET S-363

Japan

Getinge Japan K.K.

3-9-2 Tatsumi,

Koto-ku, Tokyo

135-0053 JAPAN

Phone: +81-3-6758-2280

Netherlands

Getinge b.v.

Biezenwei 21

4004 MB Tiel

The Netherlands

Phone: +31 (0)344-809900

Fax: +31 (0)344-640885

E-mail:

info@getinge.nl

Page 19

8 ADDRESSES

Norway

Getinge Norge A/S

Strandveien 13

1366 Lysaker

Norway

Phone: +47-23 03 52 00

E-mail:

info@getinge.no

Spain

Getinge Iberica SL

C/ marie Curie, 5

Edificio Alfa, Planta 6a

28521 Rivas Vaciamadrid

Spain

Phone: +34-916 78 26 26

E-mail:

administracion@getinge.es

United Kingdom

Getinge UK Ltd

1 Pembroke Avenue,

Waterbeach

Cambridge, CB25 9QP

United Kingdom

Phone: +44 (0) 1223 861665

E-mail:

sales@getinge.co.uk

Poland

Getinge Poland sp. z o. o.

ul. Osmańska 14,

PL-02-823 Warsaw

Poland

Phone: +48-22 882 06 26

E-mail:

office@getinge.pl

Sweden

Getinge Sverige AB

P O Box 69

SE-310 44 Getinge

Sweden

Phone: +46 10 335 30 00

E-mail:

info@getinge.com

USA

Getinge USA Inc.

1777 East Henrietta Road

Rochester, NY 14623-3133

USA

Phone: +1-800-475-9040

E-mail:

info.northamerica@getinge.com

Singapore

Getinge International Far East

Pte. Ltd

20 Bendemeer Road,

#06-02, Cyberhub Building

Singapore, SG-339914

Phone: +65-6396 7298

E-mail:

info.sg@getinge.com

Switzerland

Getinge ALFA AG

Weidenweg 17

4310 Rheinfelden

Switzerland

www.getingealfa.ch

Phone: +41-61 836 15 15

E-mail:

info@alfo.ag

USER MANUAL GETINGE DRYING CABINET S-363 19 (24)

<Doc_6001300802><Rev.C><Lang_en>

Page 20

Page 21

Alphabetical index

ADDRESSES .................................................................................................................. 18

Capacity ............................................................................................................................ 9

Cleaning the filter cassette .............................................................................................. 16

Connect electricity ........................................................................................................... 12

Connection diagram ........................................................................................................ 13

Construction ...................................................................................................................... 9

Declaration of Conformity .................................................................................................. 5

DIRECTIONS FOR USE ................................................................................................. 14

Disclaimer .......................................................................................................................... 5

Drying anaesthetic and respiratory hoses and bellows ................................................... 15

DRYING CABINET ............................................................................................................ 9

Electrical connections ...................................................................................................... 12

ELECTRICAL INSTALLATION ........................................................................................ 12

ERROR CODE 1 ............................................................................................................. 15

Free-standing model ....................................................................................................... 10

General safety instructions ................................................................................................ 6

INSTALLATION ............................................................................................................... 10

Intended use ...................................................................................................................... 5

INTRODUCTION ............................................................................................................... 5

Isolator switch .............................................................................................................. 6, 12

Maintenance when necessary ......................................................................................... 15

Manual discharge damper ............................................................................................... 11

Manufacturer ..................................................................................................................... 5

Overheating cut-out ......................................................................................................... 17

Pre fuse requirements ..................................................................................................... 13

Product liability .................................................................................................................. 5

SAFETY INSTRUCTIONS ................................................................................................ 6

TECHNICAL DATA ........................................................................................................... 8

USER MANUAL ................................................................................................................ 1

Warning symbols ............................................................................................................... 7

Warranty ............................................................................................................................ 5

Alphabetical index

USER MANUAL GETINGE DRYING CABINET S-363 21 (24)

<Doc_6001300802><Rev.C><Lang_en>

Page 22

Page 23

Page 24

www.getinge.com

<Doc_6001300802><Rev.C><Lang_en>

Loading...

Loading...