Page 1

USER MANUAL

350545 Rev. F

MP–129 Series

Water-Saver

Page 2

Page 3

USER MANUAL

350545 Rev. F

MP–129 SERIES

WATER-SAVER

Getinge USA, Inc.

1777 East Henrietta Road

Rochester, New York 14623-3133 USA

Phone: (800) 950-9912

Facsimile: (800) 950-2570

Page 4

USER MANUAL 350545

Rev. A (9/09/94) Graphics revised, pgs 11 & 22

Rev. B (11/22/96) General revision; combined with Parts Catalog (350575)

Rev. C (01/31/97) Company name changed to Getinge/Castle, Inc.

Rev. D (10/26/99) Redesign to fit Series x00 sterilizers

Rev. E (10/05/01) Update to reflect design changes—BOMs removed

Rev. F (4/30/03) General Revision; MP-129F added

DESCRIPTION OF SYMBOLS & NOTES IN MANUAL

The following symbols with related notes appear in this manual.

DANGER

WARNING

CAUTION

NOTE

NOTES

“Danger” notes alert the user to the possibility of serious injury or death.

“Warning” notes alert the user to the possibility of personal injury.

“Caution” notes alert the user to the possibility of damage to the equipment.

“Notes” alert the user to pertinent facts and conditions.

• This manual contains proprietary information of Getinge USA, Inc. It shall

not be reproduced in whole or in part without the written permission of

Getinge USA, Inc.

• This manual is intended for qualified technicians with specialized training.

If you require additional help, contact the company service representative.

is a registered trademark.

Copyright © 2003 by Getinge USA, Inc.

ii

Page 5

Section 1 Introduction

GENERAL DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . 1–1

TECHNICAL DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . 1–5

BYPASS SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

MANUAL DRAIN VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

Section 2 MP-129 Installation

PACKAGE CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

MP-129 INSTALLATION SEQUENCE. . . . . . . . . . . . . . . . 2–4

LOCATING, MOUNTING, AND ANCHORING. . . . . . . . . . 2–5

CONNECTING THE PIPING COMPONENTS . . . . . . . . . . 2–6

CONNECTING THE ELECTRICAL CABLES

CONNECTING THE ELECTRICAL CABLES

Table of Contents

MP-129 Water-Saver . . . . . . . . . . . . . . . . . . . . . . . . . .1–2

MP-129F Water-Saver . . . . . . . . . . . . . . . . . . . . . . . . .1–3

MP-129 Water-Saver . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

MP-129F Water-Saver . . . . . . . . . . . . . . . . . . . . . . . . .1–6

All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–7

MP-129 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

MP-129F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

MP-129A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

MP-129B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

MP-129C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

MP-129D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

220V Conversion Packages . . . . . . . . . . . . . . . . . . . . . 2–3

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

Mounting and Anchoring . . . . . . . . . . . . . . . . . . . . . . . 2–5

Water-Saver I/F Box . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

Pressure Switch 1PS . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

Solenoid Valve 20SV and Check Valve 9CV . . . . . . . . 2–6

Cold Water Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

Overflow Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

(MP-129 A & B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

Pump Motor 2–9

Pressure Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

Solenoid Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

Water-Saver I/F Box . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

(MP-129 C & D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–11

iii

Page 6

CHECKING THE ROTATION OF THE PUMP MOTOR . . 2–14

Section 3 MP-129F Installation

PACKAGE CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

MP-129F INSTALLATION SEQUENCE . . . . . . . . . . . . . . . 3–3

LOCATING, MOUNTING, AND ANCHORING . . . . . . . . . . 3–4

CONNECTING THE PIPING . . . . . . . . . . . . . . . . . . . . . . . 3–5

CONNECTING THE ELECTRICAL CABLES . . . . . . . . . . 3–7

CHECKING THE ROTATION OF THE PUMP MOTOR . . . 3–9

CHECKING THE OVERLOAD RELAY. . . . . . . . . . . . . . . 3–10

Pump Motor Connection . . . . . . . . . . . . . . . . . . . . . . 2–12

Pressure Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

Solenoid Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

Motor Start Relay (11A). . . . . . . . . . . . . . . . . . . . . . . 2–13

MP-129F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

220V Conversion Package . . . . . . . . . . . . . . . . . . . . . 3–2

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Mounting and Anchoring . . . . . . . . . . . . . . . . . . . . . . . 3–4

Solenoid Valve 15SV and Check Valve 9CV . . . . . . . . 3–5

Cold Water Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Overflow Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Pump Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Water-Saver I/F Box . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Solenoid Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Section 4 Maintenance and Troubleshooting

PERIODIC MAINTENANCE SCHEDULE . . . . . . . . . . . . . 4–1

CLEANING AND SANITIZING THE TANK . . . . . . . . . . . . 4–2

TEMPERATURE SWITCH ADJUSTMENT . . . . . . . . . . . . 4–3

PRESSURE SWITCH ADJUSTMENT. . . . . . . . . . . . . . . . 4–4

100 and 200 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

M/C 3500 and 3600 . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

M/C 4200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–6

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–7

RECOMMENDED SPARE PARTS . . . . . . . . . . . . . . . . . . 4–8

MP-129 (A&B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–8

MP-129 (C&D). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–8

MP-129F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–9

Ordering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–9

Section 5 Reference Drawings

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

iv

Page 7

GENERAL DESCRIPTION

Section 1 Introduction

The water-saver is an add-on system that incorporates a water ejector with

a pump and a water reservoir to recirculate the water that creates the

vacuum necessary for part of the sterilization cycle. The water-saver can

typically save 70% of the total water used during a cycle.

Compatible sterilizer models are listed in Table 1–1.

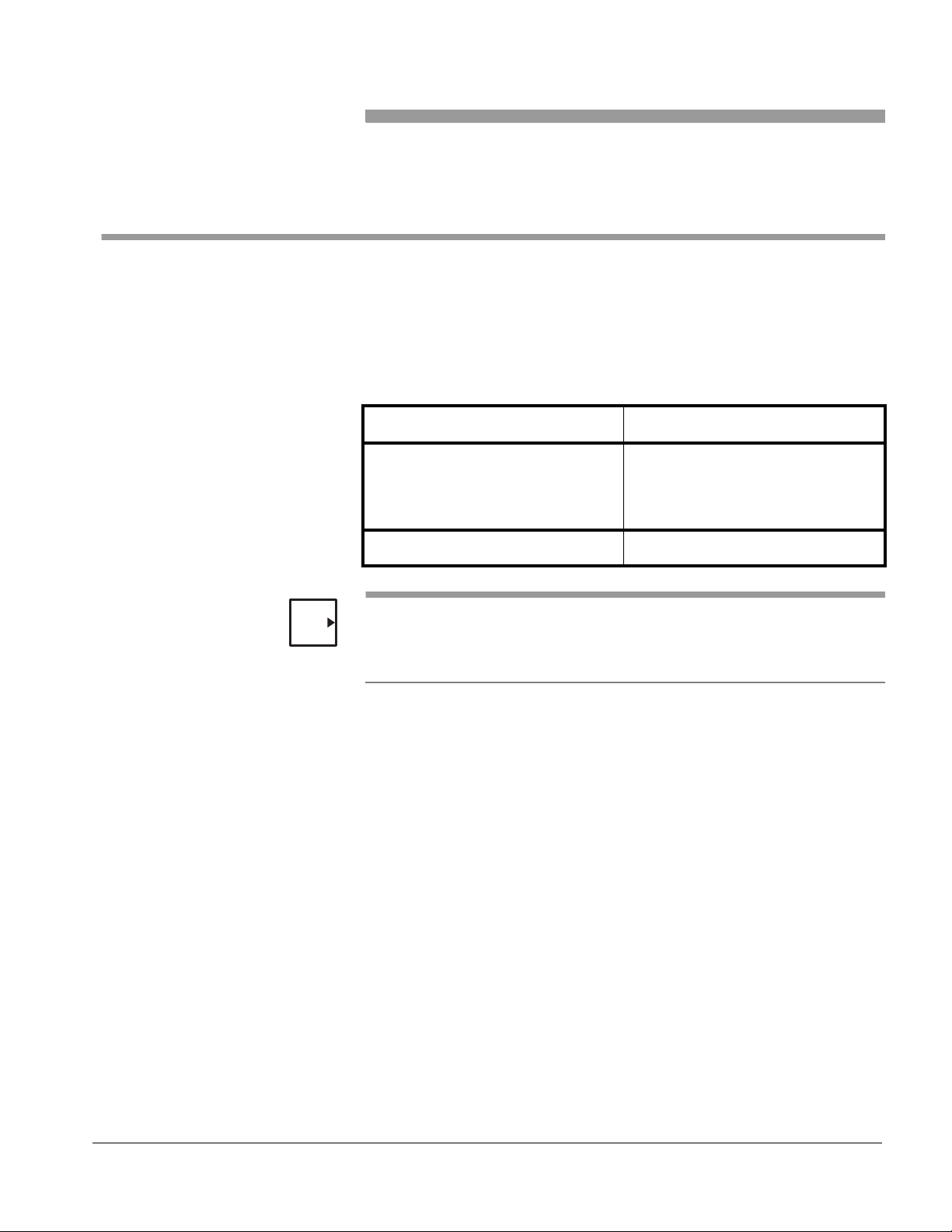

Table 1–1. Water-Saver Models

Water-Saver Model Sterilizer Model

NOTES

MP-129A

MP-129B

MP-129C

MP-129D

MP-129F 400/500, 700 and 800 Series

• In this manual, "MP-129 Water-Saver" refers to MP-129A, B, C, and D.

• The MP-129A can be installed on the 400/500 Series sterilizers, but the

MP129F is preferred because it does not require a pressure switch.

M/C 3500 and 100 Series (see Note)

M/C 3600 and 200 Series

M/C 4233 (42")

M/C 4233 (76")

350545 1–1

Page 8

Introduction

Click Here To View Parts List & Wiring Rev A thru E

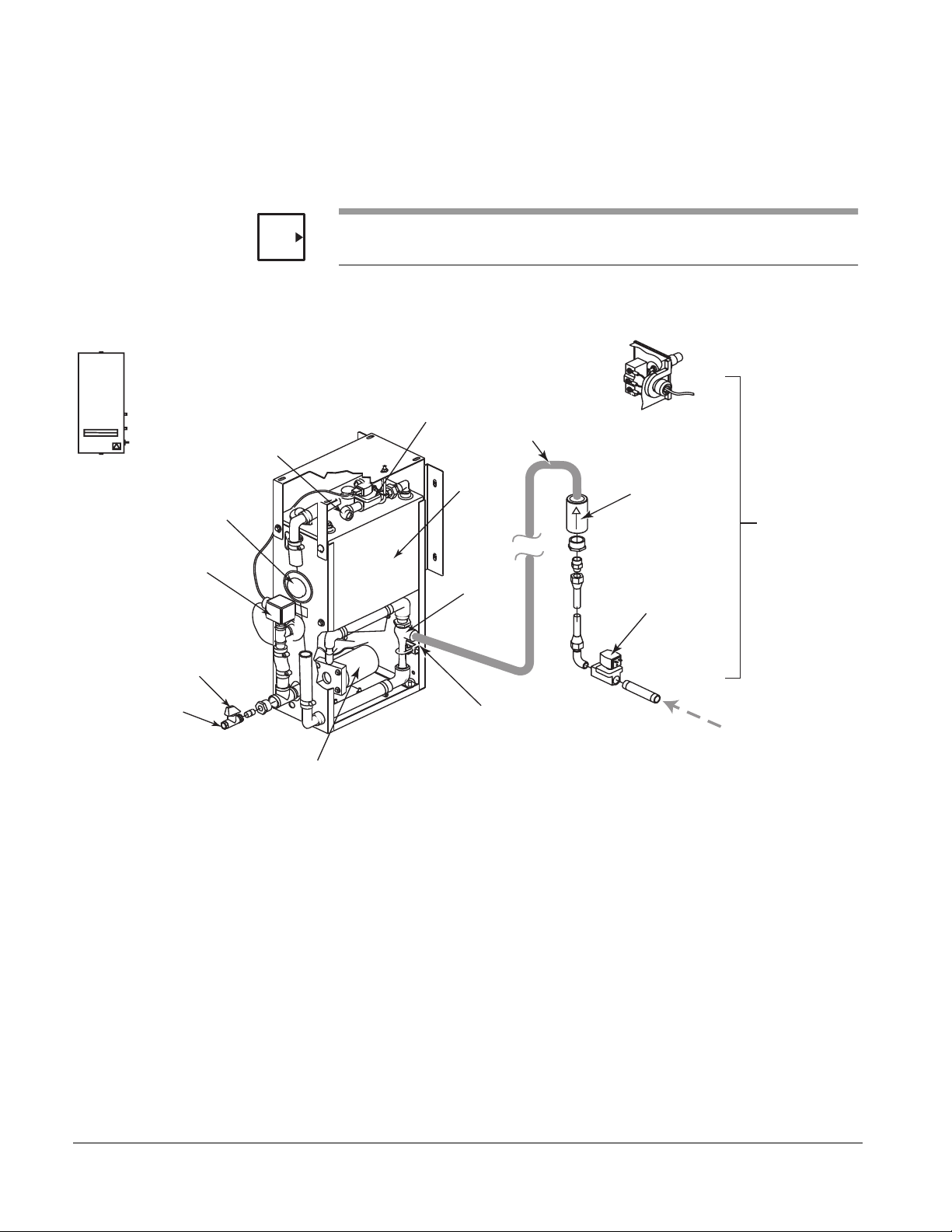

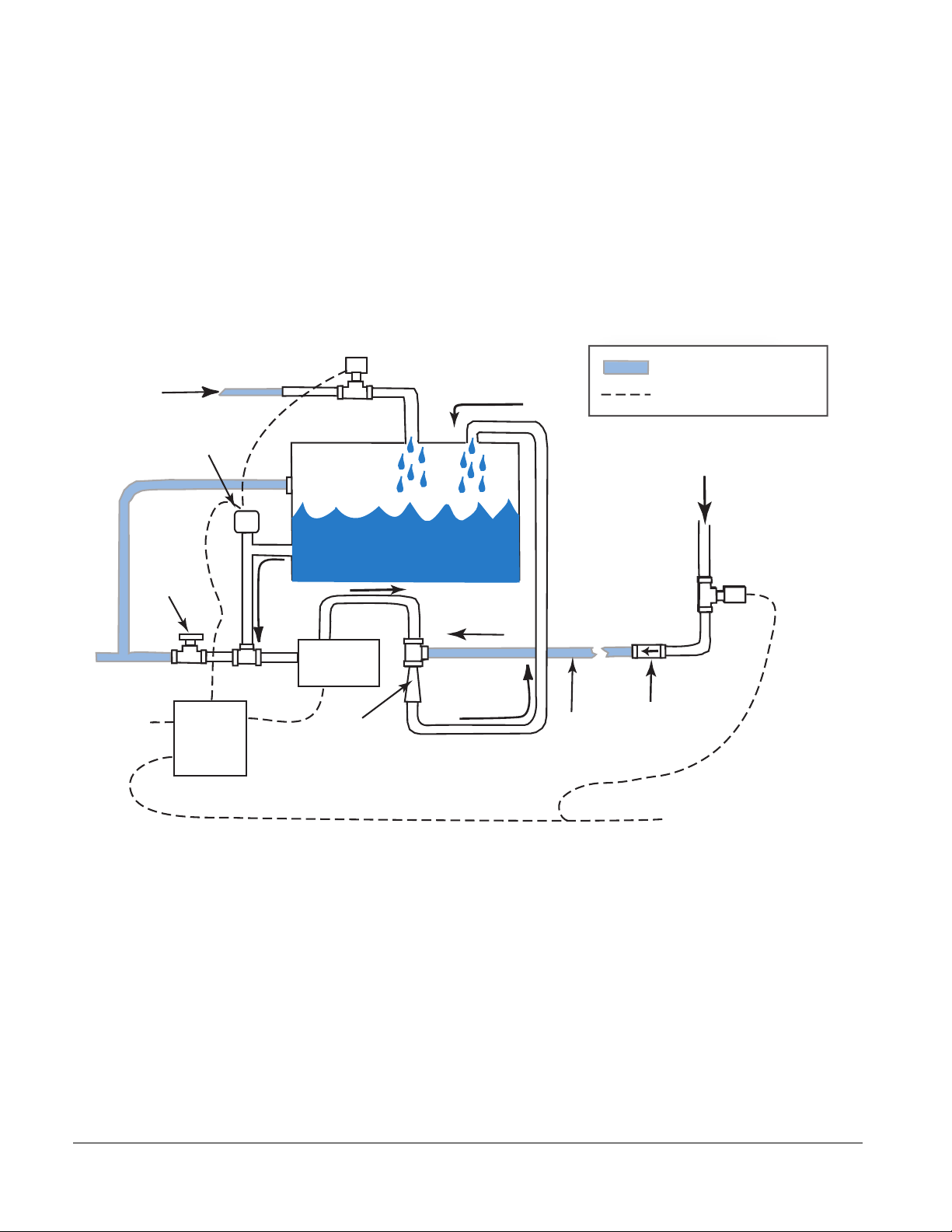

MP-129 Water-Saver The operation of the MP-129 Water-Saver (see Figure 1–1) is controlled by

an electromechanical pressure switch (1PS) that monitors the pressure in

the sterilizer chamber. See Theory of Operation — “MP-129 Water-Saver”

on page 1–5 for a detailed description.

Water-Saver

I/F Box

47A

Overflow

Drain Outlet

Temperature

Control Switch

1S

Manual

Drain Valve

NOTE

Water Supply

Inlet

Water-Saver I/F Box 47A can be mounted at any convenient location near the water-saver.

Figure 1–1. MP-129 WATER-SAVER PACKAGE

Water to Tank

Solenoid Valve

1SV

Copper Tubing

(by customer)

Reservoir

Ejector

Pressure

Switch 1PS

Check Valve

9CV

Parts Mounted

on Sterilizer

Solenoid Valve

20SV

Water Saver

Drain Outlet

Recirculating

Pump

Ejector

Vacuum Inlet

Exhaust from

Sterilizer

350545-AB

1–2

Page 9

MP-129 Series Water-Saver

Click Here To Open Parts List & Wiring Rev F

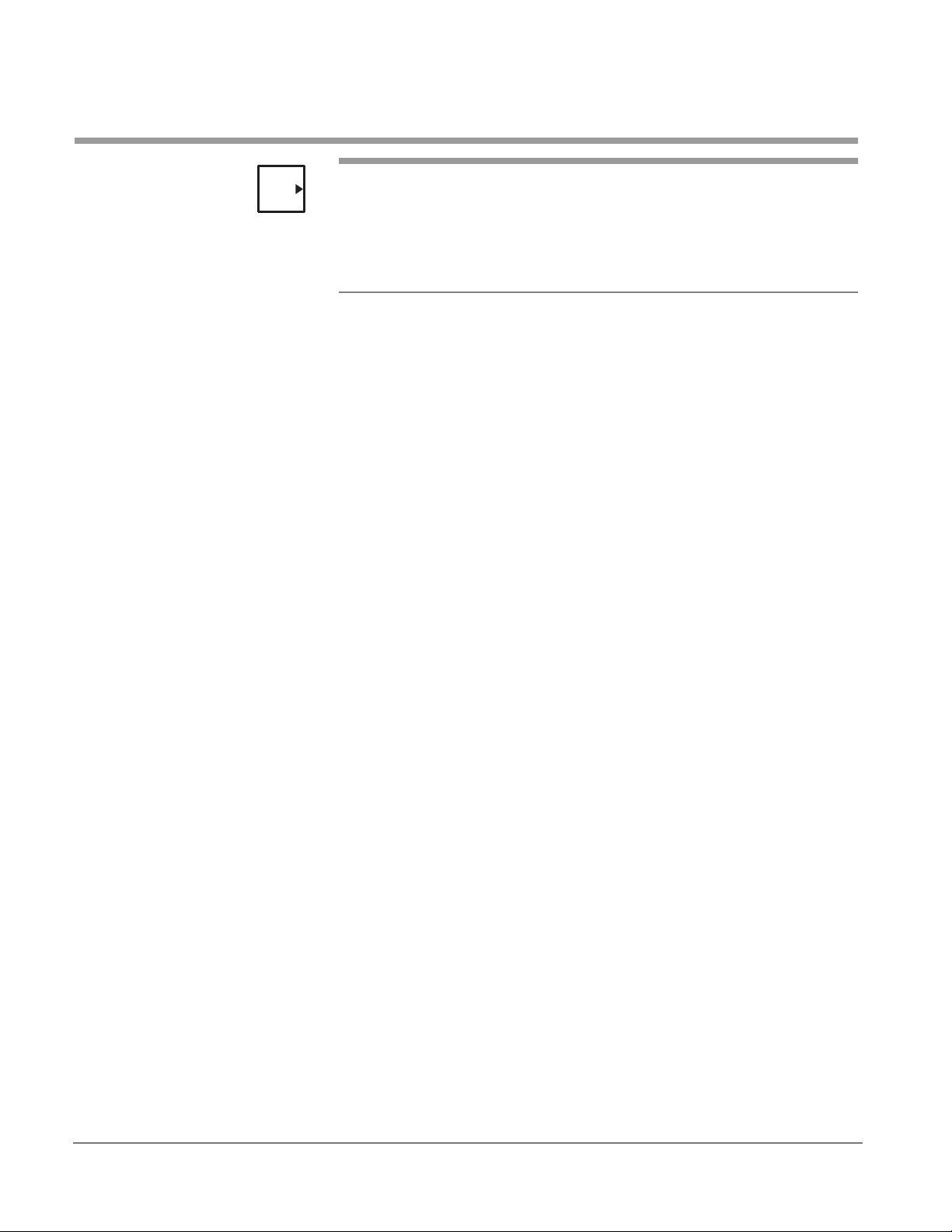

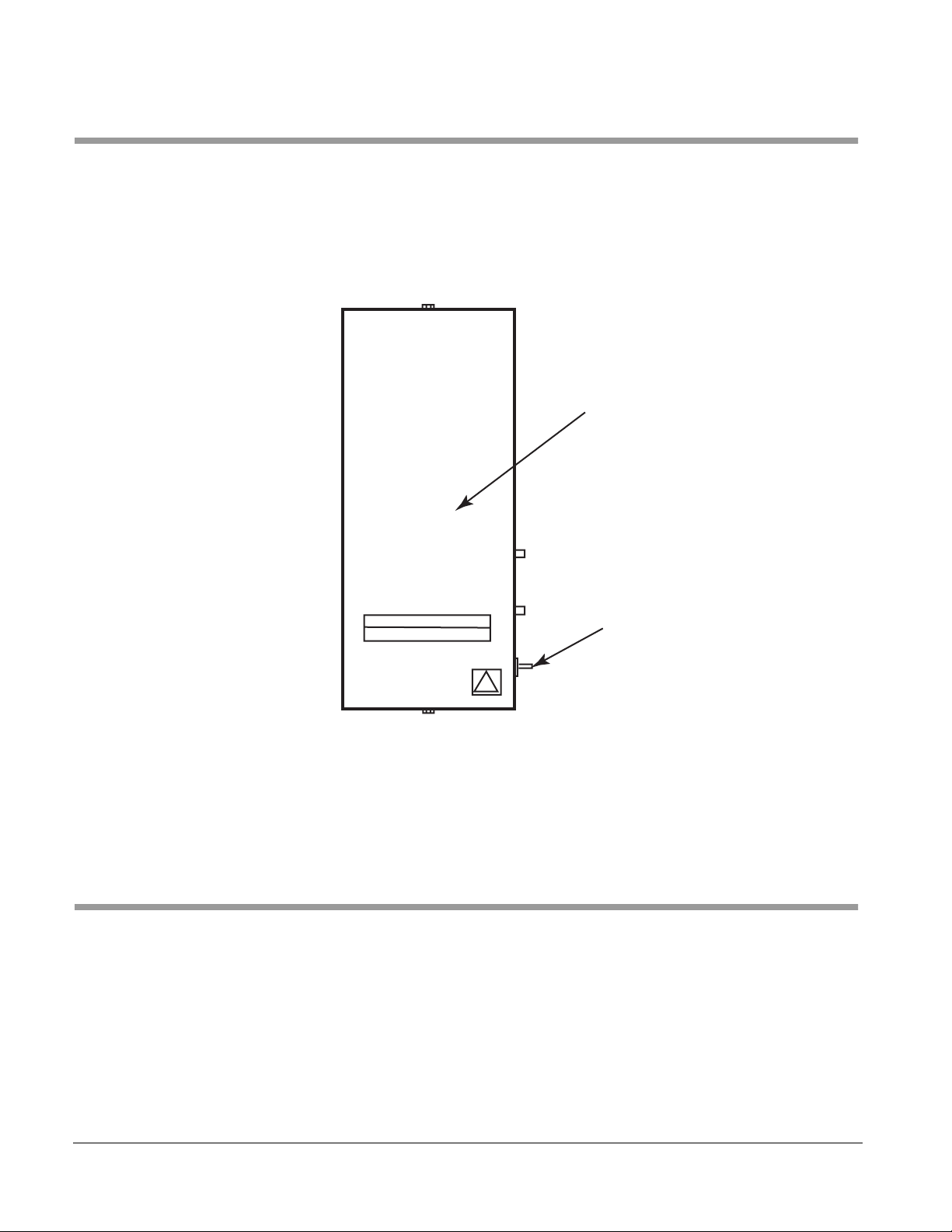

MP-129F Water-Saver The operation of the MP-129F Water-Saver (see Figure 1–2) is controlled by

the sterilizer software. See Theory of Operation — “MP-129F Water-Saver”

on page 1–6 for a detailed description.

Overflow

Drain Outlet

Temperature

Control Switch

1S

Manual

Drain Valve

NOTE

Water-Saver

I/F Box

11A

Water Supply

Inlet

Water-Saver I/F Box 11A is mounted on the water-saver unit. Water to

Ejector solenoid valve 6SV and Water-Saver ON solenoid valve 15SV are

connected directly to sterilizer Control Box 2A.

Figure 1–2. MP-129F WATER-SAVER PACKAGE

Water to Tank

Solenoid Valve

1SV

Reservoir

Ejector

Copper Tubing

(by customer)

Check Valve

Water-Saver ON

Solenoid Valve 15SV

9CV

Parts Mounted

on Sterilizer

Water Saver

Drain Outlet

Recirculating

Pump

Ejector

Vacuum Inlet

Exhaust from

Sterilizer

350545-AC

350545 1–3

Page 10

Introduction

TECHNICAL DATA

NOTE

The water-saver should not be used with a sterilizer with Sealing Flange—

for example, those installed in an area that may process Bio Hazard

material or Bio-contaminated waste. If installed in a sterilizer of this type, the

water-saver could become a breeding ground for bioburden, which would

then be constantly recirculated through the system. Additionally,

decontaminating the components would be difficult at best.

The dimensions and weight, utilities requirements, and electrical supply for

the water-saver are listed on installation drawing HS3472, included in the

water-saver package.

The capacity of the reservoir tank is approximately 6 gallons (22.7 liters).

1–4

Page 11

MP-129 Series Water-Saver

st

g

l

Click Here To View Parts List & Wiring Rev A thru E

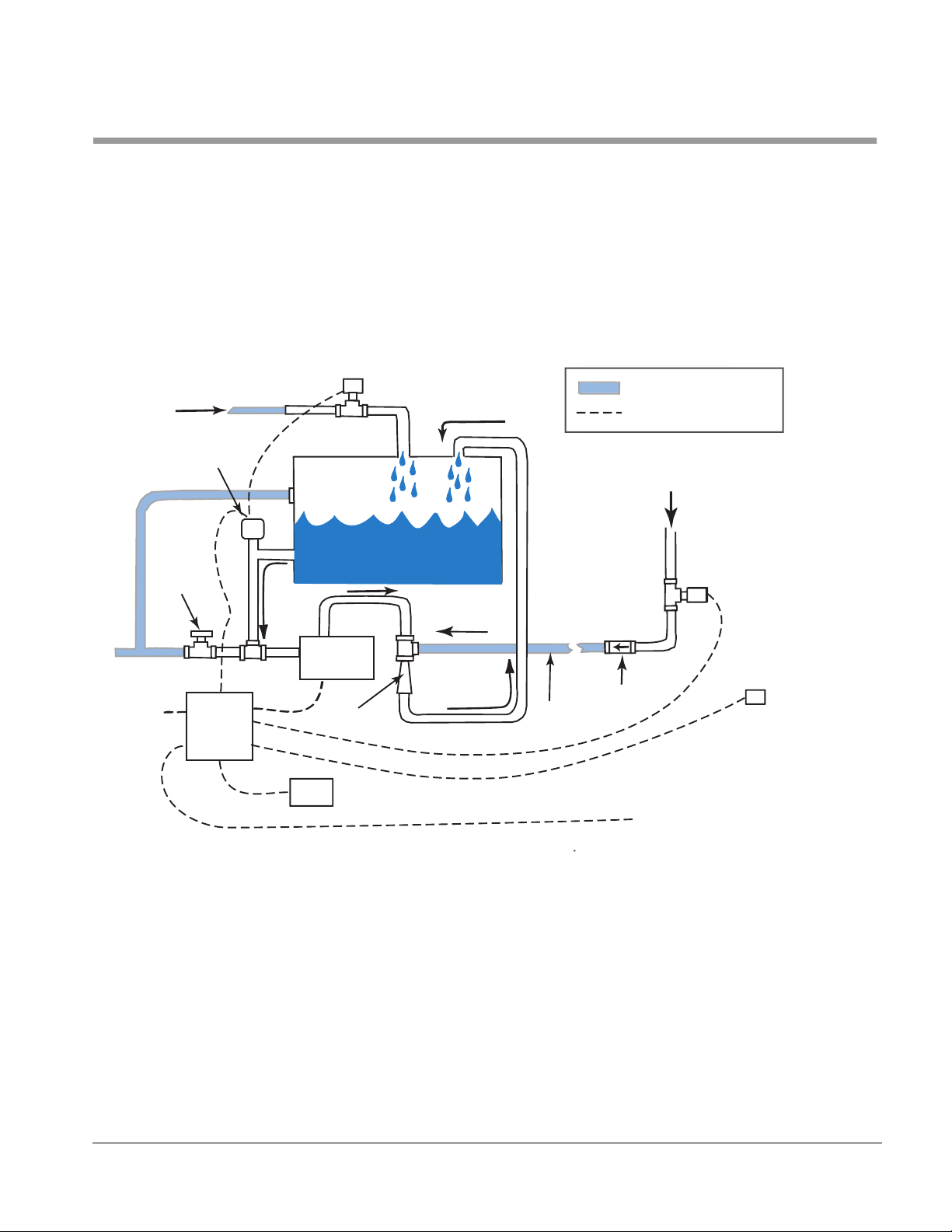

THEORY OF OPERATION

MP-129 Water-Saver Water-saver Pressure Switch 1PS determines whether the water-saver or

the standard ejector in the sterilizer provides the vacuum. While the

pressure in the sterilizer chamber is above 1 PSIG, Pressure Switch 1PS

selects the standard ejector. But when the sterilizer chamber pressure drops

to 1 PSIG or lower, Pressure Switch 1PS instead turns on the recirculating

pump to activate the ejector in the water-saver system.

Figure 1–3. MP-129 WATER-SAVER SYSTEM

1SV

Customer Pipin

Cold Water

Temperature

Switch

Electrica

Exhau

from Sterilizer

115 VAC

Manual

Drain

Valve

I/F Box

47A

1S

Water Saver ON

20SV

Pump

Water to Ejector

6SV

350545-AD

Ejector

Pressure Switch

1PS

Copper

Tubing

Check

Valve

Water to Ejector

Output from Sterilizer

350545 1–5

Page 12

Introduction

st

g

l

Click Here To Open Parts List & Wiring Rev F

MP-129F Water-Saver Pressure values are evaluated by the sterilizer software to determine

whether the water-saver or the standard ejector in the sterilizer provides the

vacuum. The water-saver configuration dipswitch (DS14 on the sterilizer’s

DISPSWITCHES menu) must be set to 1 in order for the water-saver to

operate. While the pressure in the chamber is above -5 psig for vacuum

cycles, or above atmospheric pressure for gravity cycles, the sterilizer

software selects the standard ejector. When below these values, the

software turns on the water saver.

Figure 1–4. MP-129F WATER-SAVER SYSTEM

1SV

Customer Pipin

Cold Water

Temperature

Switch

Electrica

Exhau

from Sterilizer

115 VAC

Manual

Drain

Valve

I/F Box

11A

1S

Pump

Ejector

Copper

Tubing

Water-Saver ON

15SV

Check

Valve

Water-Saver ON

Output DO14

from Sterilzer

350545-AE

1–6

Page 13

MP-129 Series Water-Saver

All Models Solenoid valve 6SV, which supplies water to activate the standard ejector, is

still active in the sterilizer piping system. However, 6SV is only energized

during negative pulses and during the purge above the water-saver pressure setpoint.

The cooler the water used for the ejector, the more efficiently the ejector

operates. To keep the water in the reservoir below 120°F (49°C), temperature control switch 1S controls the flow of cold water through solenoid valve

1SV.

When the water temperature rises above 115°F (46°C), temperature control

switch 1S signals solenoid valve 1SV to open, allowing cold water to enter

the reservoir and cool the stored water. Temperature control valve 1S continually monitors the water temperature within the reservoir. When the reservoir water cools (temperature is below 96°F [36°C]), temperature control

switch 1S outputs signals to solenoid valve 1SV and the solenoid valve

closes. This maintains the desired water temperature.

Any excess water, such as when cooling water is added to the reservoir,

drains through the overflow drain port.

When the pump motor turns on, it draws water from the bottom of the reservoir into the pump. The pump forces the water through the ejector and then

recirculates it to the reservoir. This creates the required vacuum.

350545 1–7

Page 14

Introduction

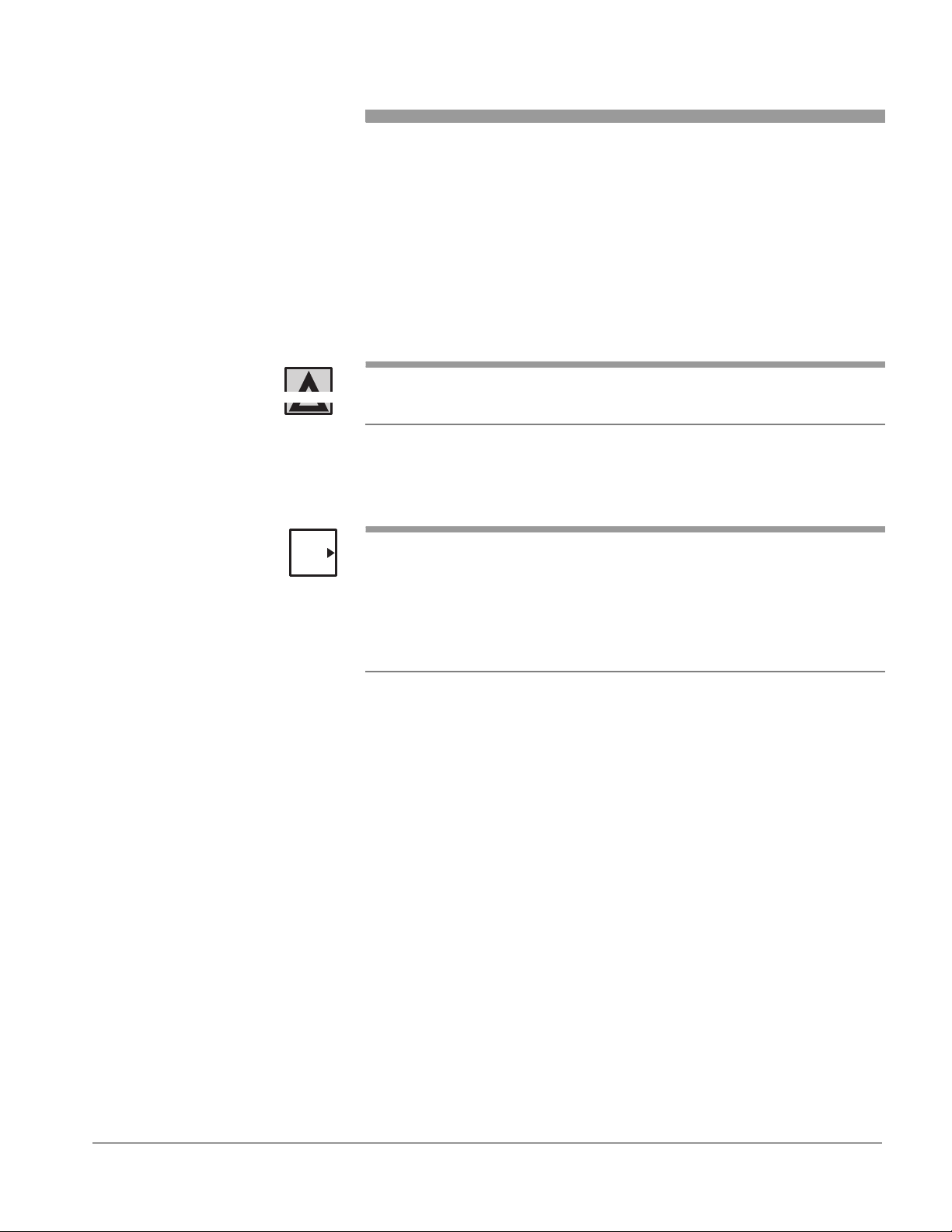

BYPASS SWITCH

MP-129 The toggle switch on Water-Saver I/F Box 47A permits hospital

maintenance or Getinge USA service personnel to switch off the watersaver as a vacuum source and use the sterilizer’s standard ejector with

external water supply.

Figure 1–5. BYPASS SWITCH (MP-129 Only)

Water Saver

I/F Box 41A

Bypass

Switch

MP-129F The water-saver can be turned off from the display panel on the sterilizer.

The Water Saver configuration switch (DS14) is located on the

DIPSWITCHES branch of the SERVICE menu tree. Refer to the sterilizer

Service Manual for instructions on how to navigate the menu tree.

MANUAL DRAIN VALVE

Located in the feed water line to the pump, this manual valve permits easy

draining of the water-saver reservoir when required.

1–8

Page 15

Section 2 MP-129 Installation

Follow the instructions in this user manual when installing an MP-129

Water-Saver to any of the following sterilizers:

• 100 and M/C 3500 Series (MP-129A)

• 200 and M/C 3600 Series (MP-129B)

• M/C 4233 (42") (MP-129C)

• M/C 4233 (76") (MP-129D)

CAUTION

NOTES

If you are installing a MP-129F Water-Saver to a 400/500, 700

or 800 Series sterilizer, follow the instructions in Section 3.

High-vacuum sterilizers (x33 or xx33 models) benefit most from the use of

the water-saver. However, the water-saver can be installed on any Getinge

USA sterilizer that uses a water ejector as its vacuum source.

Bills of Materials (BOMs) and drawings necessary for assembling this kit are

included with the parts.

• Use the BOMs as a checklist to verify receipt of all parts.

• Use the BOMs and the drawings to assemble the parts per these

instructions.

• Retain all BOMs and drawings with the unit for future reference

350545 2–1

Page 16

MP-129 Installation

Click Here To View Parts List & Wiring Rev A thru E

PACKAGE CONTENTS

MP-129A Assembly 61301602997 (Rev. C)

Item Description Part Number Qty

1 MANUAL(U)-WATER SAVER 350545

2 CASTLE,WATER SAVER SYS HS03472

3 WATER SAVER PKG,1.25ID,120V 531167

4 PIPING PKG,100/MC3500,WTR SVR 61301603246

5 SCH,PIPING,SPCL OPTION P1925

6 CONT PKG,WTR SVR,PACS/MC,120V 61301603222

7 DIAG,WIRING,WTR SVR,PACS/MC W1297

MP-129B Assembly 61301602998 (Rev. A)

Item Description Part Number Qty

1 MANUAL(U)-WATER SAVER 350545

2 CASTLE,WATER SAVER SYS HS03472

3 WATER SAVER PKG,1.25ID,120V 531167

4 PIPING PKG,233/MC3633,WTR SVR 61301603247

5 SCH,PIPING,SPCL OPTION P1925

6 CONT PKG,WTR SVR,PACS/MC,120V 61301603222

7 DIAG,WIRING,WTR SVR,PACS/MC W1297

MP-129A,3500/100,WATER SAVER

1

1

1

1

1

1

1

MP-129B,3600/200,WATER SAVER

1

1

1

1

1

1

1

MP-129C Assembly 531185 (Rev. D )

Item Description Part Number Qty

1 MANUAL(U)-WATER SAVER

2 CASTLE,WATER SAVER SYS

3 WATER SAVER PKG,1.25ID,120V

4 PIPING PKG,MC4233(76"") WTR SVR

5 SCH,PIPING,MC4233,W/WTR SAVER

6 CONT PKG,WATER SAVER,120V

7 DIAG,WIRING,WATER SAVER,MC----

MP-129D Assembly 531186 (Rev. C)

Item Description Part Number Qty

1 MANUAL(U)-WATER SAVER 350545

2 CASTLE,WATER SAVER SYS HS03472

3 WATER SAVER PKG,1.25ID,120V 531167

4 PIPING PKG,MC4233(76"") WTR SVR 531174

5 SCH,PIPING,MC4233,W/WTR SAVER P1781

6 CONT PKG,WATER SAVER,120V 531175

7 DIAG,WIRING,WATER SAVER,MC---- 531181

MP-129C,4200(42),WATER SAVER

350545 1

HS03472 1

531167 1

531174 1

P1781 1

531175 1

531181 1

MP-129D,4200(76),WATER SAVER

1

1

1

1

1

1

1

2–2

Page 17

220V Conversion Packages 100 SERIES

Click Here To Open Parts List & Wiring Rev A thru E

Assembly 61301603000 (Rev. A)

Item Description Part Number Qty

1 CONTACTOR,18AMPS,24 VAC COIL 61301602111

2 RELAY,OVERLOAD,12.0-18.0AMPS 61301602113

3 VALVE,SOL,MLD,2WAY,NC,.750,24V 61301601701

200 SERIES

Assembly 61301603259 (Rev. B)

Item Description Part Number Qty

1 CONTACTOR,18AMPS,24 VAC COIL 61301602111

2 RELAY,OVERLOAD,12.0-18.0AMPS 61301602113

3 VALVE,SOL,2WAY,NC,1.00,24V,AFL 61301604082

M/C 3500/3600 SERIES

Assembly 61301603260 (Rev. A)

Item Description Part Number Qty

1 "CONTACTOR,18 AMPS,110VAC" 61301603258

2 "RELAY,OVERLOAD,12.0-18.0AMPS" 61301602113

MP–129 Water-Saver

MP129 CONV PKG 100,220V

1

1

1

MP129 200/220V

1

1

1

MP129,3500/3600,220V

1

1

350545 2–3

Page 18

MP-129 Installation

MP-129 INSTALLATION SEQUENCE

BURN HAZARD/SHOCK HAZARD: Turn OFF all electricity,

WARNING

water, and steam to the sterilizer before starting the watersaver installation. Touching live electrical connections and/or

exposure to live steam could cause serious injury.

Installation of the water-saver consists of:

1. Locating, mounting, and anchoring (page 2-5).

2. Installing the pressure switch (page 2-6).

3. Modifying the sterilizer piping (page 2-6).

4. Connecting the cold water supply (page 2-7).

5. Connecting the overflow drain (page 2-7).

6. Connecting the electrical cables:

a. MP-129 A & B (page 2-8).

b. MP-129 C & D (page 2-11).

7. Checking the rotation of the pump motor (page 2-14).

Refer to the engineering drawings listed in Table 2–1 during

installation of the MP-129 Water-Saver.

Table 2–1. MP-129 Water-Saver Drawings

Water-Saver Sterilizer Model Piping Package Piping Schematic Wiring Diagram

MP-129A 100 Series

M/C 3500 Series

MP-129B 200 Series

M/C 3600 Series

MP-129C M/C 4233 (42") 531173 P1781 531181

MP-129D M/C 4233 (76") 531174

NOTE

If an MP-129A is installed on a 400/500 Series sterilizer, refer to drawing

SK48835 for piping and wiring detail.

61301603246 P1925 W1297

61301603247

2–4

Page 19

MP–129 Water-Saver

LOCATING, MOUNTING, AND ANCHORING

Location Refer to installation drawing HS3472 (included in water-saver package).

The water-saver can be placed on the floor or mounted to the ceiling in any

convenient location adjacent to the sterilizer. A 20-foot length of copper tubing, with connection fittings is supplied for connecting the water-saver to the

sterilizer.

Locating the water-saver within the connected reach of the copper tubing

limits the positioning to approximately 15 feet from the sterilizer. If the watersaver is to be located on the side of the sterilizer opposite the connection

piping, the distance may be somewhat reduced.

When mounting to an overhead structure, positioning the vacuum port of the

water ejector on the water-saver 10 feet above the floor is about the maximum height that permits the 20-foot copper tubing to reach the sterilizer.

Mounting and Anchoring Mounting brackets are provided to secure the unit to a wall or to mount it to

the ceiling. Mounting holes in the bottom plate are provided for securing the

unit to the floor.

Structures for ceiling-mounted units must be able to support a minimum of

250 lbs. (113 Kg) (150 lbs. [68 Kg] plus water, hardware, and safety margin).

Use 3/8" diameter bolts with appropriate anchoring devices to secure the

water-saver.

For seismic anchoring requirements, worst case center of gravity location,

and weight, refer to drawing No. 531199 (located in Section 5).

The water-saver can stand stationary of its own weight if anchoring is not

required or in areas where accidental tipping is not a possibility.

All mounting hardware other than the mounting brackets provided on the

water-saver is the responsibility of the customer installer.

Water-Saver I/F Box Mount the Water-Saver I/F Box (47A) supplied with the water-saver at any

convenient location that allows easy electrical connections to the motor on

the water-saver and to the sterilizer control box.

350545 2–5

Page 20

MP-129 Installation

CONNECTING THE PIPING COMPONENTS

Each sterilizer being fitted with the water-saver must be modified by

installing pressure switch 1PS, solenoid valve 20SV, check valve 9CV, and

the copper tubing to connect into the water-saver.

Pressure Switch 1PS Pressure switch 1PS can be mounted in any convenient location, on or near

the sterilizer or water-saver, so that it can be piped into the chamber

pressure transducer line and wired to the sterilizer and water-saver.

Connect a ¼" OD copper tubing (supplied by customer) from the pressure

switch to the chamber pressure line.

A convenient location is to tap into the ¼" OD coiled copper tubing from the

sterilizer pressure transducer.

Figure 2–1. PRESSURE SWITCH CONNECTION

Solenoid Valve 20SV and Check Valve 9CV

NOTE

NOTE

2–6

Separate packages of fittings and components for the various sterilizer

models are listed in Table 2–1 on page 2-4. Refer to the piping assembly

drawing and piping schematic included with the water-saver when installing

the piping modification package.

Water to Ejector valve 6SV remains in the sterilizer piping, but its cable is

disconnected from the sterilizer control box and connected to the watersaver I/F box.

Apply pipe thread sealant compound or pipe sealant tape to all pipe fitting threads.

Page 21

MP–129 Water-Saver

Cold Water Supply Connect the 3/4” NPT water supply piping to the water supply elbow on the

top of the reservoir (labeled CWI on installation drawing HS3472).

Figure 2–2. COLD WATER CONNECTION

3/4" NPT

350545-Y

Overflow Drain Connect a drain line to the 1¼" female pipe thread fitting on the overflow

drain port on the side of the water-saver reservoir. Connect the manual

drain valve to the same drain line.

Figure 2–3. DRAIN CONNECTIONS

Overflow

Drain Outlet

Manual

Drain Valve

Water Saver

Drain Outlet

350545-AF

350545 2–7

Page 22

MP-129 Installation

Click Here To Open Parts List & Wiring Rev A thru E

CONNECTING THE ELECTRICAL CABLES (MP-129 A & B)

Refer to Figure 2–4 and wiring diagram W1297, included in the water-saver

package.

Figure 2–4. CABLE CONNECTIONS (MP-129 A & B)

M/C 3500 and 100 Series (MP-129A)

M/C 3600 and 200 Series (MP-129B)

120 VAC

Power Supply

Water-Saver

I/F Box

47A

Pump Motor

1B

Sterilizer

Control Box

2A

Sterilizer

Power Box

1A

3500/3600

ONLY

Pressure Switch

1PS

Temperature

Control Switch

1S

Drain to Water-Saver

15SV (20SV)

Cold Water

1SV

Water to Ejector

6SV

2–8

350545-W

Page 23

MP–129 Water-Saver

Pump Motor 1. Remove the cover plate from the junction box on the side of

pump motor 1B.

2. Pull the wires out and connect these wires for the proper

voltage as shown on the connection diagram on the wiring

diagram.

230VAC CONVERSION PACKAGE

If the water-saver will be connected to 230 VAC power:

1. All Units: Replace the contactor and the overload relay

inside Water-Saver I/F Box 47A with the components

supplied in the conversion pacakge (see bill of materials).

2. 100 and 200 Series only: Replace solenoid valve 20SV

with the 24 VAC solenoid valve in the conversion package.

3. Replace the cover plate.

4. Route the wires from pump motor 1B to Water-Saver I/F

Box 47A and connect as shown on the wiring diagram.

Pressure Switch 1. Connect pressure switch 1PS to Water-Saver I/F Box 47A

as shown on the wiring diagram.

2. Adjust the pressure switch:

100 and 200 Series: See "PRESSURE SWITCH ADJUSTMENT

— 100 and 200 Series" on page 4-4.

M/C 3500 and 3600: See "PRESSURE SWITCH ADJUSTMENT

— M/C 3500 and 3600" on page 4-5.

Solenoid Valves 1. Connect Water Saver ON valve 15SV (20SV) to jack 1J on

Water-Saver I/F Box 47A.

2. Disconnect Water to Ejector valve 6SV from sterilizer Control Box 2A.

3. Connect Water to Ejector valve 6SV to jack 2J on WaterSaver I/F Box 47A.

Water-Saver I/F Box 1. Route a 120VAC, 60Hz, 30AMP (or 230VAC, 60Hz,

15AMP) power source to Water-Saver I/F Box 47A and

connect the wires to relay 1K as shown on the wiring

diagram.

2. Connect the water-saver to the sterilizer as shown on the wiring diagram:

100 and 200 Series: Connect Water-Saver I/F Box 47A to

sterilizer Control Box 2A.

350545 2–9

Page 24

MP-129 Installation

M/C 3500 and 3600: Connect Water-Saver I/F Box 47A to

sterilizer Control Box 2A and Power Box 1A.

3. Check the pump motor for proper rotation when electrical

power is supplied to Water-Saver I/F Box 47A.

See CHECKING THE ROTATION OF THE PUMP MOTOR on page 2-

.

14

2–10

Page 25

CONNECTING THE ELECTRICAL CABLES (MP-129 C & D)

Click Here To Open Parts List & Wiring Rev A thru E

Refer to Figure 2–5 and wiring diagram 531181 (included in the water-saver

package).

Figure 2–5. CABLE CONNECTIONS (MP-129 C & D)

M/C 4233 – 42" (MP-129C)

M/C 4233 – 76" (MP-129D)

Sterilizer

Control Box

2A

MP–129 Water-Saver

Motor Start

Relay

11A

Pump Motor

120 VAC

Power Supply

Temperature

Switch

1S

Sterilizer

Power Box

1A

Solenoid Valve

20SOL

Pressure

Switch

1PS

Solenoid Valve

6SOL

350545-AA

Solenoid Valve

1SV

350545 2–11

Page 26

MP-129 Installation

NOTE

18-gauge industrial-grade wire is required for the low voltage wiring of the

pressure switch and solenoid valve.

Pump Motor Connection 1. Remove the cover plate from the junction box on the side of

the pump motor.

2. Pull the wires out and connect these wires in the

appropriate combinations as shown on the wiring diagram.

NOTE

If the pump is wired for High Voltage, you must also replace the overload

heaters (see Figure 2–6 on page 2-13).

3. Replace the cover plate.

4. Route the brown, blue, and green/yellow wires from the

pump motor to motor start relay 2K and connect as shown

on wiring diagram 531181.

Pressure Switch 1. Connect the black wire from the “NC” terminal on tpressure

switch 1PS to the No. 9 terminal on motor start relay 2K.

2. Connect the white wire from the common wire nut in the

pressure switch box to the No. 3 terminal on the motor start

relay.

3. Connect a black wire from the “C” terminal on pressure

switch 1PS to the No. 12 terminal on terminal block 2TB in

sterilizer Control Box 2A.

4. Connect a white wire from the No. 2 terminal on terminal

block 1TB in sterilizer Power Box 1A to the common wire

nut inside the pressure switch box.

5. Adjust the pressure switch to 2 psi above atmospheric.

See "PRESSURE SWITCH ADJUSTMENT — M/C 4200" on page 4-6.

Solenoid Valves 1. Connect a black wire between solenoid valve 20SOL to

terminal No. 9 on motor start relay 2K.

2. Connect a white wire between solenoid valve 20SOL to terminal No. 3 on the motor start relay 2K.

3. Connect a black wire from solenoid valve 6SOL to the “NO” terminal on pressure switch 1PS.

4. Connect a white wire from solenoid valve 6SOL to the

common wire nut inside the pressure switch box.

2–12

Page 27

MP–129 Water-Saver

Motor Start Relay (11A) 1. Route a 120VAC, 60Hz, 30AMP power source to motor

start relay 2K and connect to terminals L1, L2, and GRN.

2. The connections from the motor start relay to the watersaver motor should be factory assembled. If the wiring

should be disconnected, refer to the wiring diagram when

replacing wires.

NOTE

Be sure the overload heaters are in place at terminals T1 and T2 in the

motor start interface box (see Figure 2–6).

Figure 2–6. OVERLOAD HEATERS

350545-K

OVERLOAD

HEATERS

T1 T2

3. Check the pump motor for proper rotation when electrical

power is supplied to motor start relay 2K.

See "CHECKING THE ROTATION OF THE PUMP MOTOR" on page

2-14.

350545 2–13

Page 28

MP-129 Installation

CHECKING THE ROTATION OF THE PUMP MOTOR

To check the pump motor for proper rotation:

1. Turn on the motor momentarily and visually observe the rotation of the motor shaft.

2. If the shaft is not rotating in the same direction as the

indicator arrow embossed on the pump housing,

interchange the No. 5 and No. 8 wires.

3. Recheck the rotation.

2–14

Page 29

Section 3 MP-129F Installation

Follow the instructions in this user manual when installing the water-saver to

any of the following sterilizers:

• 400/500 Series

• 700 Series

• 800 Series

NOTES

Bills of Materials (BOMs) and drawings necessary for assembling this kit are

included with the parts.

• Use the BOMs as a checklist to verify receipt of all parts.

• Use the BOMs and the drawings to assemble the parts per these

instructions.

• Retain all BOMs and drawings with the unit for future reference.

350545 3–1

Page 30

MP-129F Installation

Click Here To Open Parts List & Wiring Rev F

PACKAGE CONTENTS

MP-129F Assembly 61301609267 (Rev. A)

Item

1 CASTLE,WATER SAVER SYS HS03472

2 WATERSAVER PKG,WS700/800 61301609272

3 PIPING PKG,WS700/800,WATERSVR 61301609273

4 ID,WS700/800 WATERSAVER PI0022

5 DIAG,WIRING,11A,WATERSAVER,WS W1320

7 MANUAL(U)-WATER SAVER 350545

220V Conversion Package Assembly 61301609274 (Rev. A)

Item Description Part Number Qty

1 RELAY,OVERLOAD,12.0-18.0AMPS 61301602113

Description

MP129F-WS700/800 WATERSAVER

Par t Number Qty

1

1

1

1

1

1

MP129F-WS700/800 WATERSVR,220V

1

3–2

Page 31

MP-129F INSTALLATION SEQUENCE

Turn off all electricity, water, and steam to the sterilizer before

WARNING

starting the water-saver installation. Touching live electrical

connections and/or exposure to live steam could cause serious

injury.

Installation of the water-saver consists of:

1. Locating, mounting, and anchoring (page 3-4).

2. Modifying the sterilizer piping (page 3-5).

3. Connecting the cold water supply (page 3-5).

4. Connecting the overflow drain line (page 3-6).

5. Connecting the electrical cables (page 3-7).

6. Checking the rotation of the pump motor (page 3-9).

MP–129F Water-Saver

Refer to the engineering drawings listed in Table 3–1 during

installation of the MP-129F Water-Saver.

Table 3–1. MP-129F Water Saver Drawings

Sterilizer Model Piping Package Piping Schematic Wiring Diagram

400/500 Series

700 Series

800 Series

61301609273 PI0022 W1320

350545 3–3

Page 32

MP-129F Installation

LOCATING, MOUNTING, AND ANCHORING

Location Refer to installation drawing HS3472 (included in water-saver package).

The water-saver can be placed on the floor or mounted to the ceiling in any

convenient location adjacent to the sterilizer. A 20-foot length of copper tubing, with connection fittings is supplied for connecting the water-saver to the

sterilizer.

Locating the water-saver within the connected reach of the copper tubing

limits the positioning to approximately 15 feet from the sterilizer. If the watersaver is to be located on the side of the sterilizer opposite the connection

piping, the distance may be somewhat reduced.

When mounting to an overhead structure, positioning the vacuum port of the

water ejector on the water-saver 10 feet above the floor is about the maximum height that permits the 20-foot copper tubing to reach the sterilizer.

Mounting and Anchoring Mounting brackets are provided to secure the unit to a wall or to mount it to

the ceiling. Mounting holes in the bottom plate are provided for securing the

unit to the floor.

Structures for ceiling-mounted units must be able to support a minimum of

250 lbs. (113 Kg) (150 lbs. [68 Kg] plus water, hardware, and safety margin).

Use 3/8" diameter bolts with appropriate anchoring devices to secure the

water-saver.

For seismic anchoring requirements, worst case center of gravity location,

and weight, refer to drawing No. 531199 (located in Section 5).

The water-saver can stand stationary of its own weight if anchoring is not

required or in areas where accidental tipping is not a possibility.

All mounting hardware other than the mounting brackets provided on the

water-saver is the responsibility of the customer installer.

3–4

Page 33

CONNECTING THE PIPING

MP–129F Water-Saver

Each sterilizer being fitted with the water-saver must be modified by

installing solenoid valve 15SV, check valve 9CV, and the copper tubing to

connect into the water-saver.

Solenoid Valve 15SV and Check Valve 9CV

NOTE

Refer to the piping assembly drawing and piping schematic included with

the water-saver when installing the piping modification package.

Apply pipe thread sealant compound or pipe sealant tape to all pipe fitting threads.

Cold Water Supply Connect the 3/4” NPT water supply piping to the water supply elbow on the

top of the reservoir (labeled CWI on installation drawing HS3472).

Figure 3–1. COLD WATER CONNECTION

3/4" NPT

350545-Y

350545 3–5

Page 34

MP-129F Installation

Overflow Drain Connect a drain line to the 1¼" female pipe thread fitting on the overflow

drain port on the side of the water-saver reservoir. Connect the manual

drain valve to the same drain line.

Figure 3–2. DRAIN CONNECTIONS

Overflow

Drain Outlet

Manual

Drain Valve

Water Saver

Drain Outlet

350545-AF

3–6

Page 35

CONNECTING THE ELECTRICAL CABLES

Z

Click Here To Open Parts List & Wiring Rev F

Refer to Figure 3–3 and wiring diagram W1320, included in the water-saver

package.

Figure 3–3. CABLE CONNECTIONS (MP-129F)

MP-129F (400/500, 700 and 800 Series Sterilizers)

120 VAC

Power Supply

Water-Saver

I/F Box

11A

MP–129F Water-Saver

Sterilizer

Control Box

2A

Pump Motor

1B

Temperature

Control Switch

Cold Water

1SV

1S

Water-Saver ON

15SV

350545-

350545 3–7

Page 36

MP-129F Installation

Pump Motor 1. Remove the cover plate from the junction box on the side of

pump motor 1B.

2. Verify the pump is wired for 120 VAC as shown on the

wiring diagram.

230 VAC CONVERSION PACKAGE

If the water-saver will be connected to 230 VAC power:

1. Replace the overload relay.

2. Replace the cover plate.

3. Route the wires from pump motor 1B to Water-Saver I/F

Box 11A and connect as shown on the wiring diagram.

Water-Saver I/F Box 1. Route a 120VAC, 60Hz, 30AMP (or 230VAC, 60Hz,

15AMP) power source to Water-Saver I/F Box 11A and

connect to terminals 1, 3, and GRN on 1K.

2. Check the pump motor for proper rotation when electrical

power is supplied to Water Saver I/F Box 11A.

See "CHECKING THE ROTATION OF THE PUMP MOTOR" on

page 3-9.

Solenoid Valve Connect Water-Saver ON valve 15SV to 15JO on Control Box

2A.

3–8

Page 37

CHECKING THE ROTATION OF THE PUMP MOTOR

To check the pump motor for proper rotation:

1. Turn on the motor momentarily and visually observe the rotation of the motor shaft.

2. If the shaft is not rotating in the same direction as the

indicator arrow embossed on the pump housing,

interchange the No. 5 and No. 8 wires.

3. Recheck the rotation.

MP–129F Water-Saver

350545 3–9

Page 38

MP-129F Installation

CHECKING THE OVERLOAD RELAY

To check the overload relay:

1. Remove the cover from Water-Saver I/F Box 11A.

2. Verify the overload current selector as set as follows:

• 115 VAC – set to 26 AMPS

• 230 VAC – set to 13 AMPS

3. Manually turn ON the Water Saver ON (DO14) output on

the sterilizer. Verify the water-saver turns ON.

4. Press the test button. Verify the pump motor stops running.

5. Reset the overload relay.

6. Manually turn OFF the Water Saver ON (DO14) output.

7. Reinstall the I/F box cover.

Figure 3–4. OVERLOAD RELAY

Overload Current

Selector

115 VAC – 26 AMPS

230 VAC – 13 AMPS

NO

98 97 96 95

246

T1 T2 T3

NC

350545-AG

Test Button

Reset Switch

3–10

Page 39

PERIODIC MAINTENANCE SCHEDULE

Section 4 Maintenance and

Troubleshooting

WARNING

PERFORMANCE

ASSURANCE PLAN

Preventive maintenance

performed by factory-trained

service representatives, using

authorized parts and service

techniques, is recommended.

Recognizing symptoms of

potential trouble and making

corrections immediately is less

costly and time consuming

than repairing damaged

equipment. Our Performance

Assurance Plan offers scientific

maintenance, not merely repair

service.

For quality service on this

equipment and information on

our Performance Assurance

Plan, contact Getinge USA,

Inc. 1777 East Henrietta Road,

Rochester, NY 14623-3133 or

call

1-800-950-9912.

Maintenance should be performed by qualified personnel

ONLY.

Provide preventive maintenance for the water-saver at the intervals

specified.

Table 4–1. Periodic Maintenance Schedule

MAINTENANCE ITEM

Check the operation of water-saver

components as part of the periodic

maintenance of the sterilizer.

Clean and sanitize the tank. WHEN REQUIRED 4-2

Check the operation of the

temperature switch

Check the operation of the

pressure switch. To adjust, use the

proper procedure for your model

sterilizer:

RECOMMENDED

INTERVAL

WHEN REQUIRED Refer to the

EVERY

THREE MONTHS

EVERY

THREE MONTHS

FOR DETAILS,

SEE PAGE

Periodic

Maintenance

Schedule in the

Service Manual

for your

sterilizer.

4-3

See Note below.

NOTE

• 100 and 200 Series

• M/C 3500 and 3600

• M/C 4233

If an MP-129A Water-Saver is installed on a 400 /500 Series sterilizer, follow

4-4

4-5

4-6

the pressure switch adjustment procedure on drawing SK48835.

350545 4–1

Page 40

Maintenance and Troubleshooting

CLEANING AND SANITIZING THE TANK

To clean and sanitize the water-saver tank:

1. Disable the water-saver:

a. Turn OFF the bypass switch S1.

b. Disconnect the high-voltage power supply to the pump.

NOTE

NOTE

On MP-129F units, disable the water-saver by setting configuration switch

DS14 to 0. Refer to the sterilizer service manual for procedure.

2. Remove the large plug in the top of the tank.

3. Add sanitizing agent to the tank water.

Use an off-the-shelf, non-toxic, non-caustic water tank

sanitizer and cleaner.

4. Agitate the water solution. Use a long-handled brush if necessary for proper cleaning.

5. Drain the tank.

6. Enable the water-saver:

a. Connect the high-voltage power supply to the pump.

b. Turn ON the bypass switch S1.

On MP-129F units, enable the water-saver by setting configuration switch DS14 to 1.

7. Verify that the tank refills.

4–2

8. Replace the large plug.

Page 41

TEMPERATURE SWITCH ADJUSTMENT

TOOLS REQUIRED

• Digital Thermometer

CHECK

1. Turn on the hot and cold water lines. Using the digital

thermometer set for °F, place the thermocouple probe in

the stream of the incoming water.

The temperature should read 120°F or greater.

2. Adjust the thermocouple to be approximately halfway down into the tank.

3. When the tank is approximately three-fourths (3/4) full, the

solenoid valve (cold water supply) should also be admitting

water into the tank. Observe the water flow in the tank from

the valve.

MP–129 Series Water-Saver

4. Turn off the hot water supply to the tank.

As the water is cooled, the solenoid valve should be deenergized (check with screwdriver).

5. Using the digital thermometer set for °F, take the

temperature of the water in the tank and record it on the

line in the left margin.

The water temperature should be less than 115°F.

ADJUST

6. If the water in the tank is not less than 115°F, r e m o v e t h e

cover of the temperature switch.

7. Using a 1/4” open end wrench, turn the stem counterclockwise to lower the temperature setting.

8. Turn on the hot water and retest until the water solenoid is

energized whenever the water temperature rises above

115°F. Verify the solenoid valve turns off the cold water

supply when the tank temperature is lowered to

approximately 96°F.

9. Use the ball valve at the circulating pump inlet to drain the

tank then refill the tank as described above.

10. After the correct temperature is attained, replace the temperature switch cover.

350545 4–3

Page 42

Maintenance and Troubleshooting

PRESSURE SWITCH ADJUSTMENT

100 and 200 Series TOOLS REQUIRED

• 0 to 50 psia pressure meter accurate to ±0.05 psia. (Must be an absolute

pressure meter.) See Appendix B in the sterilizer Service Manual.

• 120VAC volt meter or test lamp.

WARNING

SHOCK HAZARD: AC line voltage is present on the pressure

switch terminals. Turn OFF power to the sterilizer when

connecting the test lamp and adjusting the pressure switch.

PROCEDURE

1. Remove the cover from the pressure switch.

2. Connect a 120VAC test lamp between the normally closed

contact of the pressure switch and ground.

Figure 4–1. PRESSURE SWITCH ADJUSTMENT (MP-129 A&B)

ADJUSTMENT

SCREW

BK

COMMON

NORM

OPEN

NORM

CLOSED

R

4–4

TEST LAMP

GRND

350545-S

3. Close and seal the chamber.

4. Using manual mode, pressurize the chamber by turning

ON digital output DO00 (steam to chamber). See the

sterilizer service manual.

5. When the test lamp turns OFF, turn OFF output DO00.

Chamber pressure should read 2 psi above atmospheric.

6. Adjust the pressure switch and recheck the trip point.

Page 43

M/C 3500 and 3600 TOOLS REQUIRED

• 0 to 50 psia pressure meter accurate to ±0.05 psia. (Must be an absolute

pressure meter.) Refer to Appendix B in the Sterilizer Service Manual.

• 120VAC volt meter or test lamp.

MP–129 Series Water-Saver

WARNING

SHOCK HAZARD: AC line voltage is present on the pressure

switch terminals. Turn OFF power to the sterilizer when

connecting the test lamp and adjusting the pressure switch.

PROCEDURE

1. Connect the pressure meter to the pressure meter

connection on the sterilizer control box.

Air should be used to pressurize the chamber when

making the pressure switch adjustment.

2. Raise the sterilizer control bezel and open the control box.

Switch the controls switch on the control PC board from

AUTO to MANual. Using the necessary dip switch,

pressurize the sterilizer chamber to 2 psi above

atmospheric.

3. Connect the voltmeter or the test lamp between the

common (C) and the normally closed (NC) terminals on the

water-saver pressure switch (see Figure 4–1on page 4-4).

4. Using the adjustment screw on the pressure switch, adjust

the pressure switch so the voltmeter reads no continuity (or

the test lamp goes OFF) when the pressure gauge reads 2

psi above atmospheric.

350545 4–5

Page 44

Maintenance and Troubleshooting

M/C 4200 The pressure switch is factory set and should not need adjustment.

However, if the switch should be out of adjustment the switch can be reset

as follows:

TOOLS REQUIRED

• 0 to 50 psia pressure meter accurate to ±0.05 psia. (Must be an absolute

pressure meter.) Refer to Appendix B in the Sterilizer Service Manual.

• 120VAC volt meter or test lamp.

WARNING

SHOCK HAZARD: AC line voltage is present on the pressure

switch terminals. Turn OFF power to the sterilizer when

connecting the test lamp and adjusting the pressure switch.

PROCEDURE

1. Connect the pressure meter to the pressure meter

connection on the sterilizer control box.

Air should be used to pressurize the chamber when

making the pressure switch adjustment.

2. Raise the sterilizer control bezel and open the control box.

Switch the controls switch on the control p.c. board from

AUTO to MANual. Using the necessary dip switch,

pressurize the sterilizer chamber to 2 psi above

atmospheric.

3. Connect the voltmeter or the test lamp between the

common (C) and the normally closed (NC) terminals on the

water-saver pressure switch.

Figure 4–2. PRESSURE SWITCH ADJUSTMENT (MP-129 C&D)

ADJUSTMENT

WHEEL

4–6

2 x 2 x4

OUTLET BOX

350545-L

4. Using the adjustment wheel on the pressure switch (see

Figure 4–2), adjust the wheel so the voltmeter reads no

continuity (or the test lamp goes OFF) when the pressure

gauge reads 2 psi above atmospheric.

Page 45

MP–129 Series Water-Saver

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSES REMEDY

Little or no vacuum

(motor running).

Motor does not run. 1. Electrical Supply off.

Water overflows

continuously from

reservoir.

Overflow water too hot

(steam).

1. Chamber Drain Screen clogged.

2. Solenoid Valve 15SV (20SV) not opening.

3. Solenoid Valve 2SV not opening properly.

4. Solenoid Valve 4SV not opening properly.

5. Clogged Ejector or Vacuum Line.

6. Water Supply off or restricted.

7. Temperature Switch.

8. Check Valve 9CV.

9. Pump defective.

10. Piping leaks.

2. Motor defective.

3. Pump seizes.

Temperature Switch activated. Repair or readjust.

Temperature Switch set too high. Adjust Temperature Switch.

1. Clean Drain Screen.

2. Clean or repair.

3. Clean or repair.

4. Clean or repair.

5. Clean or replace.

6. Restore Water Supply.

7. Readjust or replace.

8. Clean or replace.

9. Repair or replace.

10. Repair or replace.

1. Restore Electrical Supply.

2. Repair or replace.

3. Repair or replace.

(Refer to Sterilizer Service Manual — “Trouble Analysis.”)

350545 4–7

Page 46

Maintenance and Troubleshooting

RECOMMENDED SPARE PARTS

MP-129 (A&B) To ensure that parts are immediately available when needed, keep in stock

the parts listed below.

Table 4–2. MP-129 (A&B) Replacement Parts

Qty

Description Part Number 100 3500 200 3600

115V 230V 115V 230V 115V 230V 115V 230V

COIL,SOL REPL,VLV#517345 517303 1 1 1

COIL,SOL,24V,238-812-005,10.1W 61301600157 1

KIT,SOL,541581 61301600443 1 1 1 1

COIL,SOL REPL,VLV#517350 517304 1 1 1

COIL,SOL,24V,206-089-004,15.4W 61301600429 1

REPAIR PKG,ASCO SOL VAL,HV200- 61301604084 1 1 1

PKG,REBUILD FOR 61301601702 61301601744 1

SWITCH,PRESS,2-4 PSI,W/COVER 530931 1 1 1 1 1 1 1 1

RELAY,24VAC,DPDT,20A/240VAC 61301601073 1 1

RELAY,OVERLOAD,23-32AMPS 61301603224 1 1 1 1

RELAY,OVERLOAD,12.0-18.0AMPS 61301602113 1 1 1 1

MP-129 (C&D) To ensure that parts are immediately available when needed, keep in stock

the parts listed below.

Table 4–3. MP-129 (C&D) Replacement Parts

Description Part Number Qty

REPLACEMENT COIL, SOLENOID VALVE 517345 517303 1

SERVICE KPACKAGE, SOLENOID VALVE 517345 54190 1

REPLACEMENT COIL, SOLENOID VALVE 517346 517304 1

SERVICE PACKAGE, SOLENOID VALVE 517346 61301604084 1

HEATER, OVERLOAD 37963 1

RELAY, MOTOR START 37956 1

SWITCH, PRESSURE 89444 1

4–8

Page 47

MP–129 Series Water-Saver

Click Here To Open Parts List & Wiring Rev F

MP-129F To ensure that parts are immediately available when needed, keep in stock

the parts listed below.

Table 4–4. MP-129F Replacement Parts

Qty

Description Part Number 115V 230V

COIL,SOL,24V,238-812-005,10.1W 61301600157 1 1

KIT,SOL,541581 61301600443 1 1

RELAY,OVERLOAD,23-32AMPS 61301603224 1

RELAY,OVERLOAD,12.0-18.0AMPS 61301602113 1

Ordering For ordering information concerning parts listed in this manual, call the

company’s Customer Service line at (800) 950–9912.

350545 4–9

Page 48

Maintenance and Troubleshooting

4–10

Page 49

INTRODUCTION

Section 5 Reference Drawings

This section includes the rough-in drawing for the MP-129 Series WaterSaver. Contact Getinge USA technical service to confirm the latest revision.

Piping assembly drawings, piping schematics, and electrical schematics are

included in the water-saver parts package.

• MP-129: See Table 2–1 on page 2-4.

• MP-129F: See Table 3–1 on page 3-3.

For water-saver anchoring information, contact Getinge USA technical

services at (800) 950-9912.

350545 5–1

Page 50

Reference Drawings

Figure 5–1. WATER SAVER SYSTEM (sheet 1 of 2)

5–2

Page 51

MP–129 Series Water-Saver

Figure 5–1. WATER SAVER SYSTEM (sheet 2 of 2)

350545 5–3

Page 52

Reference Drawings

5–4

Page 53

MP-129 Series Water-Saver

Numerics

230 VAC conversion package 2–9, 3–8

A

anchoring the water-saver 2–5, 3–4, 5–1

B

bypass switch (MP-129) 1–8

C

checking the pump motor rotation 2–14, 3–9

cleaning the water-saver tank 4–2

cold water supply 2–7, 3–5

compatible sterilizer models 1–5

configuration switch (DS14) 1–6, 1–8, 4–2

D

L

locating the water-saver 2–5, 3–4

M

manual drain valve 1–8

motor start relay (M/C 4200) 2–13

mounting the water-saver 2–5, 3–4

MP-129

compatible sterilizer models 1–5

water-saver components 1–2

MP-129F

compatible sterilizer models 1–5

water-saver components 1–3

O

overflow drain 3–6

overload heaters (M/C 4200) 2–13

P

dimensions 1–4

E

electrical cables

connecting (100 and 200 series) 2–8

connecting (400 and 500 series) 2–8

connecting (M/C 3500 and 3600) 2–8

connecting (M/C 4200) 2–11

connecting (MP-129F) 3–7

electrical supply 1–4

engineering drawings

installation (roughing-in) 2–5, 3–4

piping assembly (MP-129) 2–4

piping package (MP-129F) 3–3

piping schematic (MP-129) 2–4

piping schematic (MP-129F) 3–3

roughing-in 2–5, 3–4

seismic anchorage 5–1

wiring diagram (MP-129) 2–4

wiring diagram (MP-129F) 3–3

I

installation drawing 2–5, 3–4

installation sequence

MP-129 2–4

MP-129F 3–3

piping assemblies

MP-129 2–4

MP-129F 3–3

piping connections

check valve 2–6, 3–5

cold water supply 2–7, 3–5

overflow drain 3–6

pressure switch 2–6

solenoid valves 2–6, 3–5

piping modifications

MP-129 2–6

MP-129F 3–5

piping schematics

MP-129 2–4

MP-129F 3–3

pressure switch

adjusting 4–4, 4–5, 4–6

connecting 2–9

connecting (M/C 4200) 2–12

installing 2–6

pressure switch adjustment

100 and 200 Series 4–4

M/C 3500 and 3600 4–5

M/C 4200 4–6

required tools 4–5, 4–6

tools required 4–4

350545 I–1

Page 54

pump motor

checking rotation 2–14, 3–9

wiring 2–9, 2–12, 3–8

R

recommended spare parts

MP-129 4–8

MP-129F 4–9

reservoir capacity 1–4

roughing-in drawing 2–5, 3–4

S

sanitizing agent 4–2

sanitizing the water-saver tank 4–2

sealing flange units (do not use with) 1–4

seismic anchorage drawing 5–1

solenoid valves

connecting 2–9

connecting (M/C 4200) 2–12

spare parts

MP-129 4–8

MP-129F 4–9

ordering 4–9

T

temperature switch

adjustment 4–3

check 4–3

theory of operation

MP-129 Water-Saver 1–5

MP-129F Water-Saver 1–6

troubleshooting chart 4–7

U

utilities requirements 1–4

W

water-saver

anchoring 2–5, 3–4, 5–1

locating 2–5, 3–4

mounting 2–5, 3–4

water-saver drawings

MP-129 2–4

MP-129F 3–3

water-saver I/F box

installing 2–5

location (MP-129) 1–2

location (MP-129F) 1–3

water-saver package

MP-129 1–2

MP-129F 1–3

water-saver tank

cleaning 4–2

sanitizing 4–2

weight 1–4

wiring diagrams

MP-129 2–4

MP-129F 3–3

I–2

Page 55

Page 56

Getinge USA, Inc.

1777 East Henrietta Road

Telephone (800) 950–9912 Rochester, New York 14623–3133 USA Facsimile (800) 950–2570

Loading...

Loading...