Page 1

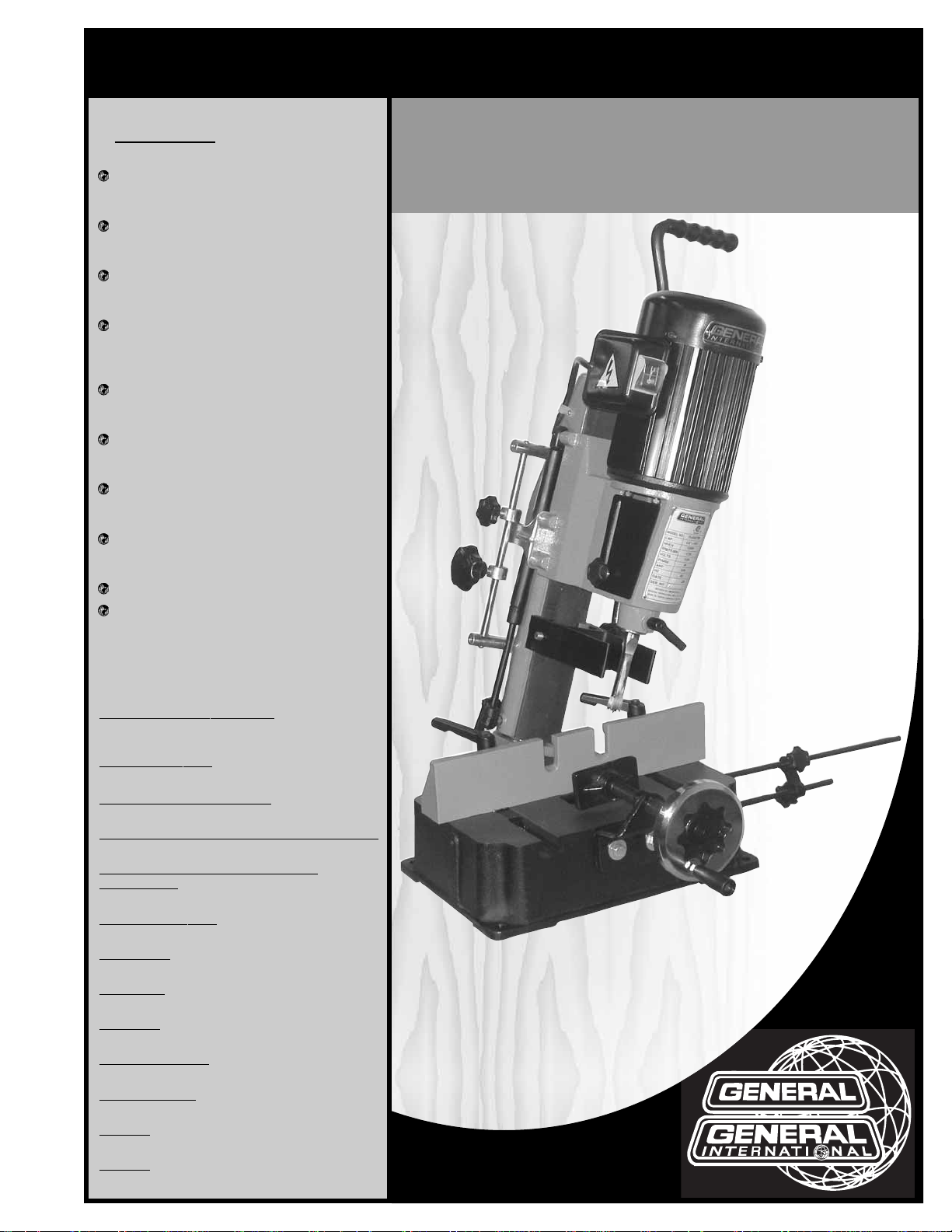

FEATURES

Heavy duty cast-iron head, column and

base built for steady vibration free performance.

Head slides on precision machined castiron dovetail ways - stroke is controlled by

a gas head-cylinder for smooth operation.

Head tilts up to 30° left or r ight for angled

mortising, and pivots up to 180° for off

table mortising.

Adjustable head height extends working

capacity by up to 3”(up to 9”under chisel), to accommodate work with taller workpieces.

Equipped with easy to adjust dual depth

stop for complete control of both down

stroke depth and upstroke travel.

Large feed handle with extra long, multiposition arm for better leverage and

increased feed control.

Includes an adjustable workpiece stop,

handwheel controlled clamp and a column mounted hold-down.

Totally enclosed fan cooled (T.E.F.C.) motor

with start capacitor for smooth star t-up

and longer running life.

Dust protected on/off switch.

Includes adapter bushings to accommo-

date both 5/8”and 3/4”sized chisel

shanks.

SPECIFICATIONS

CHISEL CAPACITY

1⁄4”TO 5⁄8”(6 TO 16 MM)

MAXIMUM CHISEL STROKE

9”(228 MM)

DIST

ANCE FROM FENCE TO CHISEL CENTER

4”(102 MM)

DIST

ANCE FROM CHISEL TO TABLE

(CHISEL 1/4”)

6”TO 9”(152 MM TO 228 MM)

CHUCK C

APACITY

1⁄2”(13 MM)

FENCE SIZE

14 1/8”X 2 7/8”

T

ABLE SIZE

13 1/2”X 9”(343 X 230 MM)

B

ASE SIZE

14 1/8”x 10 3⁄8”(360 x 265 MM)

O

VERALL HEIGHT

29”(736 MM)

SPINDLE SPEED

1720 RPM

MO

TOR

1/2 HP,110 V, 1 Ph, 3.8 A

WEIGHT

106 LBS (48 KG)

SETUP & OPERATION MANUAL

5/8” TILTING HEAD HOLLOW

VERSION 2_REVISION 2 - January 27/09

© Copyright General® International 01/2009

CHISEL MORTISER

MODEL

#75-050T M1

Page 2

THANK YOU

for choosing this General®International model 75-050T M1 5/8”

tilting head hollow chisel mortiser.This mortiser has been carefully tested and inspected before

shipment and if properly used and maintained, will provide you with years of reliable service.

To ensure optimum performance and trouble-free operation, and to get the most from your

investment, please take the time to read this manual before assembling, installing and operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic function, and features

of this mortiser as well as the set-up, maintenance and identification of its parts and components. This manual is not intended as a substitute for formal woodworking instruction, nor to

offer the user instruction in the craft of woodworking. If you are not sure about the safety of

performing a certain operation or procedure, do not proceed until you can confirm, from

knowledgeable and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

Disclaimer:

The information and specifications in this

manual pertain to the unit as it was supplied from the

factory at the time of printing. Because we are committed

to making constant improvements, General

®

International reserves the right to make changes to components,

parts or features of this unit as deemed necessary, without prior notice and without obligation to install any

such changes on previously delivered units.Reasonable

care is taken at the factory to ensure that the specifications and information in this manual corresponds with

that of the unit with which it was supplied. However, special orders and “after factory” modifications may render

some or all information in this manual inapplicable to

your machine. Further, as several generations of this model of mortiser and several versions of this manual may

be in circulation, if you own an earlier or later version of

this unit, this manual may not depict your machine

exactly. If you have any doubts or questions contact

your retailer or our support line with the model and serial number of your unit for clarification.

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

Page 3

GENERAL®& GENERAL®INTERNATIONAL WARRANTY

All component parts of General®, General® International and Excalibur by General

International ® products are carefully inspected during all stages of production and each unit

is thoroughly inspected upon completion of assembly.

Limited Lifetime

Warranty

Because of our commitment to quality and customer satisfaction, General® and General®

International agree to repair or replace any part or component which upon examination,

proves to be defective in either workmanship or material to the original purchaser for the life

of the tool.

However, the Limited Lifetime Warranty does not cover any product used for professionnal or commercial production purposes nor for industrial or educational applications.

Such cases are covered by our Standard 2-year Limited Warranty only. The Limited Lifetime

Warranty is also subject to the “Conditions and Exceptions” as listed below.

Standard 2-Year Limited Warranty

All products not covered by our lifetime warranty including products used in commercial,

industrial and educational applications are warranted for a period of 2 years (24 months) from

the date of purchase. General® and General® International agree to repair or replace any

part or component which upon examination, proves to be defective in either workmanship or

material to the original purchaser during this 2-year warranty period, subject to the “conditions

and exceptions” as listed below.

T

o file a Claim

To file a claim under our Standard 2-year Limited Warranty or under our Limited Lifetime

Warranty, all defective parts, components or machinery must be returned freight or postage

prepaid to General® International, or to a nearby distributor, repair center or other location

designated by General® International. For further details call our service department at 1-888949-1161 or your local distributor for assistance when filing your claim.

Along with the return of the product being claimed for warranty, a copy of the original proof

of purchase and a “letter of claim”must be included (a warranty claim form can also be used

and can be obtained, upon request, from General® International or an authorized distributor)

clearly stating the model and serial number of the unit (if applicable) and including an explanation of the complaint or presumed defect in material or workmanship.

CONDITIONS AND EXCEPTIONS:

This coverage is extended to the original purchaser only. Prior warranty registration is not

required but documented proof of purchase i.e. a copy of original sales invoice or receipt

showing the date and location of the purchase as well as the purchase price paid, must be

provided at the time of claim.

Warranty does not include failures, breakage or defects deemed after inspection by General®

or General® International to have been directly or indirectly caused by or resulting from;

improper use, or lack of or improper maintenance, misuse or abuse, negligence, accidents,

damage in handling or transport, or normal wear and tear of any generally considered consumable parts or components.

Repairs made without the written consent of General® Internationallwill void all warranty.

Page 4

TABLE OF CONTENTS

Rules for safe operation . . . . . . . . . . . . . . .5

Electrical requirements . . . . . . . . . . . . . . .6

Grounding instructions . . . . . . . . . . . . . . . . . . . . . . .6

Circuit capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Extension cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Identification of main parts

and components . . . . . . . . . . . . . . . . . . . .

7

Basic functions . . . . . . . . . . . . . . . . . . . . .8

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . .8

List of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Additional requirements for set up . . . . . . . . . . . . .8

Preparation and installation . . . . . . . . . . . .9

Clean up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Detach the mortiser from its shipping base . . . . . .9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Optional stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Mounting to a work surface . . . . . . . . . . . . . . . . . . .9

Assembly Instructions . . . . . . . . . . . . .10-12

Attach the workpiece clamp . . . . . . . . . . . . . . . . .10

Attach the workpiece hold down . . . . . . . . . . . . .10

Attach the workpiece stop . . . . . . . . . . . . . . . . . . .10

Install the down feed handle . . . . . . . . . . . . . . . . .10

Install a chisel and bit set . . . . . . . . . . . . . . . . . . . .11

To square the chisel to the fence . . . . . . . . . . . . .12

Basic adjustments & controls . . . . . . . .12-13

Connecting to a power source . . . . . . . . . . . . . . .12

On / off power switch . . . . . . . . . . . . . . . . . . . . . . .13

Setting the depth stop . . . . . . . . . . . . . . . . . . . . . . .13

Basic Operations . . . . . . . . . . . . . . . . .13-14

Additional Adjustments . . . . . . . . . . . . .15-16

Head height adjustment . . . . . . . . . . . . . . . . . . . . .15

Head tilt adjustment . . . . . . . . . . . . . . . . . . . . . . . .15

Head swivel adjustment . . . . . . . . . . . . . . . . . . . . .16

Maintenance . . . . . . . . . . . . . . . . . . . .16-17

Periodic maintenance . . . . . . . . . . . . . . . . . . . . . .16

Sharpening chisels and bits . . . . . . . . . . . . . . . . . .16

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Required maintenance . . . . . . . . . . . . . . . . . . . . .17

Tilt index stop adjustment . . . . . . . . . . . . . . . . . . . .17

Recommended optional accessories . . . . .18

Diagram . . . . . . . . . . . . . . . . . . . . . . . . . .19

Parts list . . . . . . . . . . . . . . . . . . . . . . . . .20

Contact info . . . . . . . . . . . . . . . . . . . . . . .22

Page 5

RULES FOR SAFE OPERATION

To help ensure safe operation, please take a moment to learn the machine’s applications and limitations, as well as potential hazards. General® International disclaims any real or implied warranty and holds itself harmless for any injury that

may result from improper use of its equipment.

1. Do not operate the mortiser when tired, distracted, or

under the effects of drugs, alcohol or any medication

that impairs reflexes or alertness.

2. The working area should be well lit, clean and free of

debris.

3. Keep children and visitors at a safe distance when the

mortiser is in operation; do not permit them to operate the mortiser.

4. Childproof and tamper proof your shop and all

machinery with locks, master electrical switches and

switch keys, to prevent unauthorized or unsupervised

use.

5. Stay alert! Give your work your undivided attention.

Even a momentary distraction can lead to serious

injury.

6. Fine particulate dust is a carcinogen that can be haz-

ardous to health. Work in a well-ventilated area and

whenever possible use a dust collector and wear eye,

ear and respiratory protection devices.

7. Do not wear loose clothing, gloves, bracelets, neck-

laces or other jewelry while the mortiser is in operation.

8. Be sure that adjusting wrenches, tools, drinks and

other clutter are removed from the machine and/or

the table surface before operating.

9. Keep hands well away from the mortising chisel, bit

and all moving parts. Use a hold-down or clamp to

secure the stock, and use a brush, not hands, to clear

away chips and dust.

10. Be sure that the mortising chisel and bit are securely

installed in the chuck before operation.

11. Be sure the mortising bit has gained full operating

speed before beginning to drill.

12. Always use a clean, properly sharpened chisel and

bit set. Dirty or dull chisels and bits are unsafe and can

lead to accidents.

13. Use suitable work piece support if the work piece does

not have a flat surface.

14. Do not push or force the chisel and bit into the stock.

The mortiser will perform better and more safely when

working at the rate feed for which it was designed.

15. Avoid working from awkward or off balance positions.

Do not overreach and keep both feet on floor.

16. Never leave the machine unattended while it is run-

ning or with the power on.

17. Use of parts and accessories NOT recommended by

GENERAL® INTERNATIONAL may result in equipment

malfunction or risk of injury.

18. Never stand on machinery. Serious injury could result

if the tool is tipped over or if the mortiser chisel and bit

are unintentionally contacted.

19. Always disconnect the tool from the power source

before servicing or changing accessories such as

chisel and bit sets, or before performing any maintenance, cleaning, or if the machine will be left unattended.

20. Make sure that the switch is in the “OFF”position before

plugging in the power cord.

21. Make sure the tool is properly grounded. If equipped

with a 3-prong plug, it should be used with a threepole receptacle. Never remove the third prong.

22. Do not use this mortiser for other than its intended

use. If used for other purposes, GENERAL® INTERNATIONAL disclaims any real implied warranty and holds

itself harmless for any injury, which may result from

that use.

5

Page 6

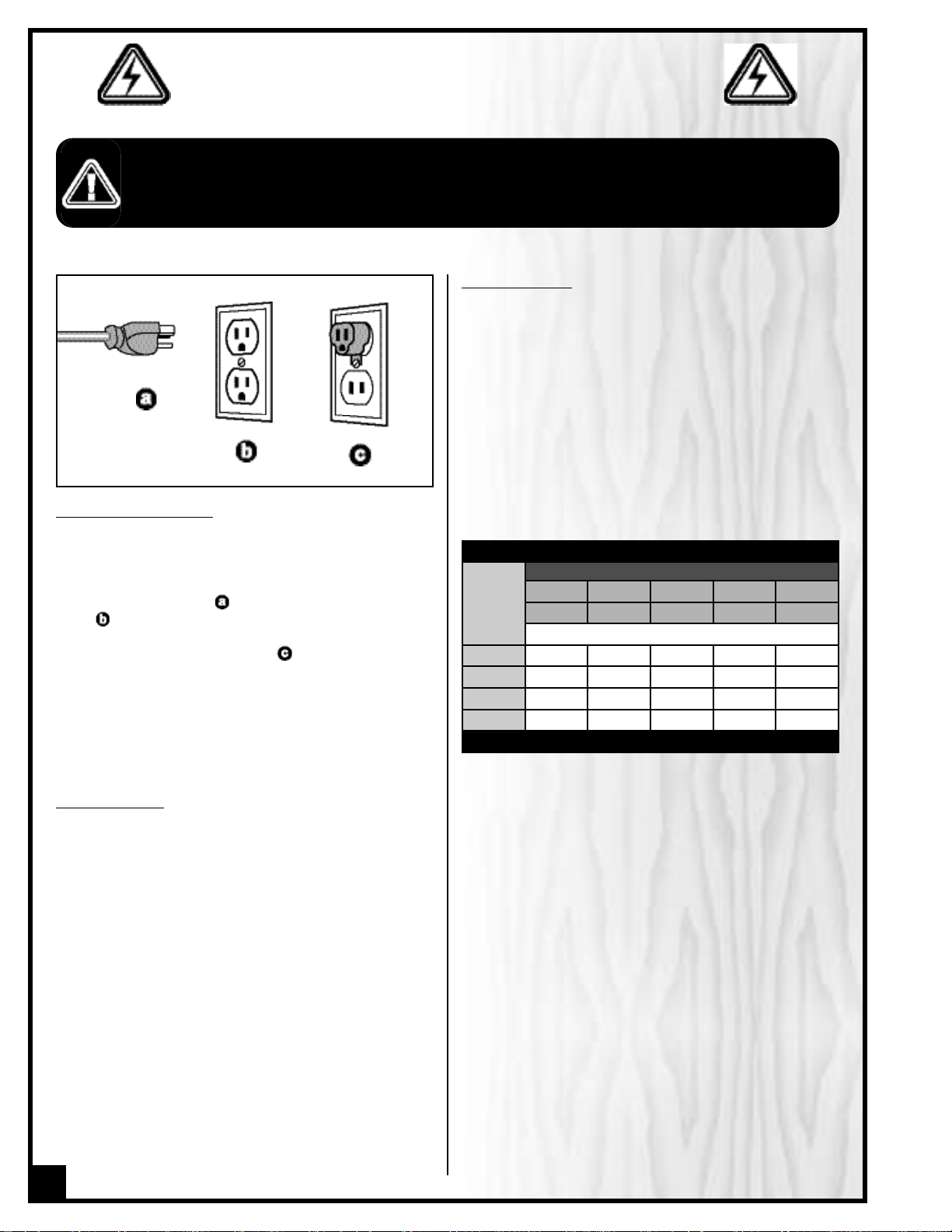

ELECTRICAL REQUIREMENTS

GROUNDING INSTRUCTIONS

In the event of an electrical malfunction or short circuit,

grounding reduces the risk of electric shock. The motor

of this machine is wired for 110V single phase operation

and is equipped with a 3-conductor cord and a 3prong grounding plug to fit a grounded type receptacle . Do not remove the 3rd prong (grounding pin)

to make it fit into an old 2-hole wall socket or extension

cord. If an adaptor plug is used , it must be attached

to the metal screw of the receptacle.

Note: The use of an adaptor plug is illegal in some

areas. Check your local codes. If you have any doubts

or if the supplied plug does not correspond to your electrical outlet, consult a qualified eletrician before proceeding.

CIRCUIT CAPACITY

Make sure that the wires in your circuit are capable of

handling the amperage draw from your machine, as

well as any other machines that could be operating on

the same circuit. If you are unsure, consult a qualified

electrician. If the circuit breaker trips or the fuse blows

regularly, your machine may be operating on a circuit

that is close to its amperage draw capacity. However, if

an unusual amperage draw does not exist and a

power failure still occurs, contact a qualified technician

or our service department.

BEFORE CONNECTING THE MACHINE TO THE POWER SOURCE,VERIFY THAT THE VOLTAGE OF YOUR POWER SUPPLY CORRESPONDS

WITH THE VOLTAGE SPECIFIED ON THE MOTOR I.D. NAMEPLATE. A POWER SOURCE WITH GREATER VOLTAGE THAN NEEDED CAN

RESULT IN SERIOUS INJURY TO THE USER AS WELL AS DAMAGE TO THE MACHINE. IF IN DOUBT, CONTACT A QUALIFIED ELECTRICIAN

BEFORE CONNECTING TO THE POWER SOURCE.

THIS TOOL IS FOR INDOOR USE ONLY. DO NOT EXPOSE TO RAIN OR USE IN WET OR DAMP LOCATIONS.

EXTENSION CORDS

If you find it necessary to use an extension cord with your

machine, use only 3-wire extension cords that have 3prong grounding plug and a matching 3-pole receptacle that accepts the tool’s plug. Repair or replace a

damaged extension cord or plug immediately.

Make sure the cord rating is suitable for the amperage

listed on the motor I.D. plate. An undersized cord will

cause a drop in line voltage resulting in loss of power

and overheating. The accompanying chart shows the

correct size extension cord to be used based on cord

length and motor I.D. plate amp rating. If in doubt, use

the next heavier gauge. The smaller the number, the

heavier the gauge.

TABLE - MINIMUM GAUGE FOR CORD

AMPERE

RATING

TOTAL LENGTH OF CORD IN FEET

110 VOLTS 25 FEET 50 FEET 100 FEET 150 FEET

220 VOLTS 50 FEET 100 FEET 200 FEET 300 FEET

AWG

< 5

------->

18 16 16 14

6 TO 10

------->

18 16 14 12

10 TO 12

------->

16 16 14 12

12 TO 16

------->

14 12 * NR * NR

* NR = Not Recommended

6

Page 7

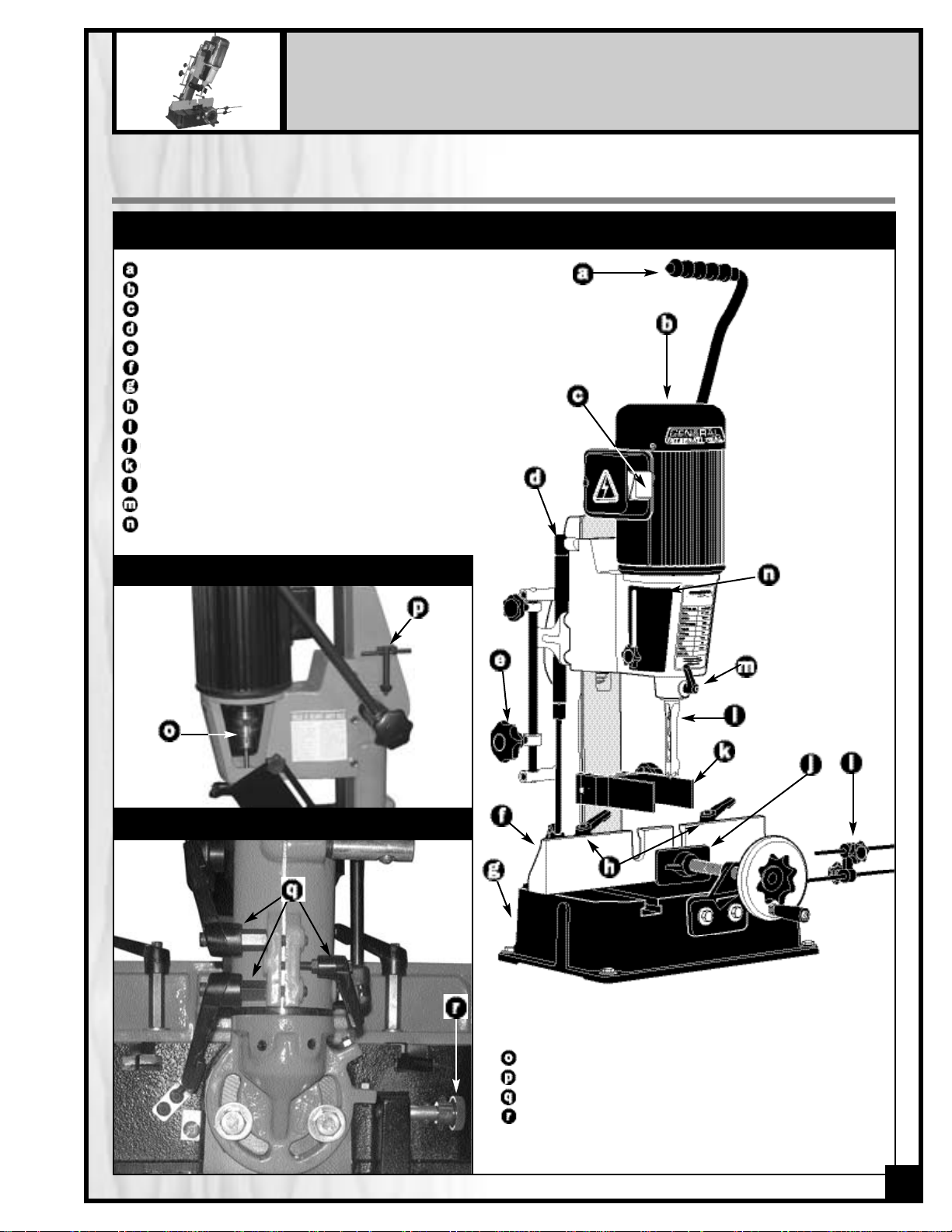

5/8” TILTING HEAD HOLLOW CHISEL MORTISER

75-050T M1

IDENTIFICATION OF MAIN PARTS AND COMPONENTS

LEFT SIDE VIEW

DOWNFEED HANDLE

MOTOR

ON/OFF SWITCH

GAS HEAD-CYLINDER

DEPTH STOP

FENCE

BASE

FENCE LOCKING LEVERS

WORKPIECE STOP

WORKPIECE CLAMP

WORKPIECE HOLD-DOWN

CHISEL AND BIT

CHISEL LOCKING LEVER

SLIDE PLATES

7

REAR VIEW

CHUCK

CHUCK KEY AND HOLDER

RATCHET LEVERS

STOP PIN

RIGHT SIDE VIEW

Page 8

UNPACKING

Carefully unpack and remove the mortiser and its components from the box and check for damaged or missing items as per the list of contents below.

NOTE: Please report any damaged or missing items to

your General International distributor immediately.

LIST OF CONTENTS QTY

MORTISER.......................................................................1

WORKPIECE HOLD-DOWN............................................1

WORKPIECE STOP..........................................................1

3/4” SHANK BUSHING ADAPTER....................................1

CHUCK KEY....................................................................1

3 MM ALLEN KEY ...........................................................1

4 MM ALLEN KEY ...........................................................1

5 MM ALLEN KEY ...........................................................1

WORKPIECE CLAMP......................................................1

1/4” - 6 MM CHISEL AND BIT.........................................1

5/16” - 8 MM CHISEL AND BIT.......................................1

3/8” - 10 MM CHISEL AND BIT.......................................1

1/2” - 13 MM CHISEL AND BIT.......................................1

HEX HEAD BOLT .............................................................2

FLAT WASHER..................................................................2

ADDITIONAL REQUIREMENTS FOR SET UP

• 13 & 17 mm socket or open end wrench

8

BASIC FUNCTIONS

This tilting head hollow chisel mortiser is designed to cut 90° and/or angled mortises in solid wood as well as other

wood based stock.With its tilting, pivoting and extendable height head, the 75-050TM1 is designed to tackle a wide

range of mortising applications suited to both hobbyist and professional users.

Ideal for use in any furniture making or cabinet making applications that require mortise and tenon joinery, the unit

is supplied with a set of 4 different sized chisel and bits to help the user cut mortises of varying widths to suit the application. The unit is also supplied with 2 different sized chisel bushings, allowing the user to install chisel and bit sets of

either 5/8" (4 supplied) or 3/4" (commonly available from other after-market sources) shank diameter.

This mortiser is designed to acommodate chisel and bit set sizes ranging from a minimum of 1/4" up to a maximum

of 5/8".

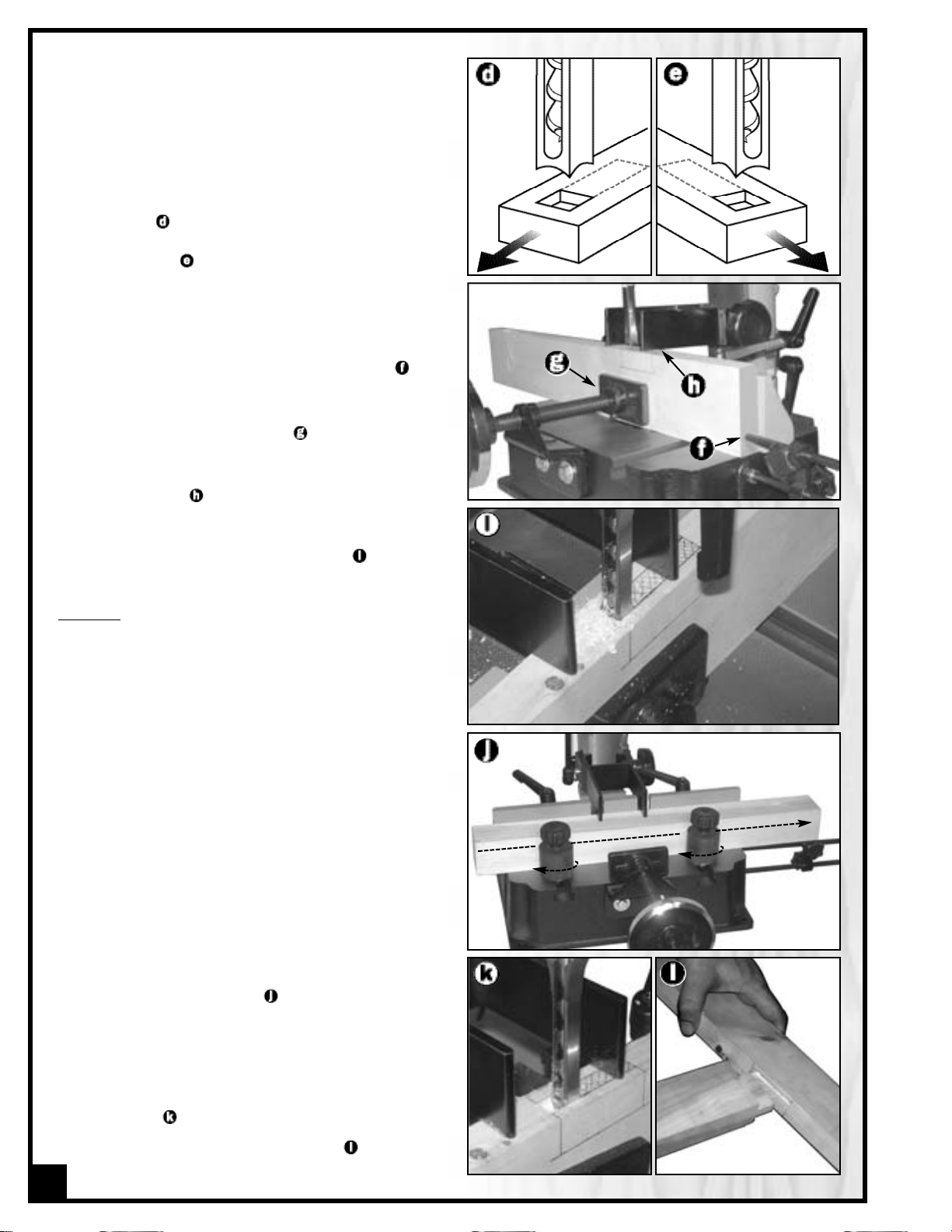

or

Page 9

CLEAN UP

Clean all rust protected surfaces by rubbing with a rag dipped in kerosene,mineral spirits or paint thinner. (Dispose

of potentially flammable solvent-soaked rags according to manufacturer’s safety recommendations.) Avoid rubbing any painted surfaces, as many solvent-based products will remove paint.

To prevent rust, apply a light coating of paste wax or use regular applications of any after-market surface protectant or rust inhibitor.

PREPARATION AND INSTALLATION

This machine should be installed and operated only

on a flat, sturdy and stable surface able to support the

weight of the machine (92 lbs - 42 kg) and the workpiece with ease.

NOTE: Never install the machine over the edge of a table

or workbench .

Unscrew the 4 shipping bolts using a 13 mm socket

or open end wrench, then remove the mortiser from

the protective plywood shipping base.

SERIOUS PERSONAL INJURY COULD OCCUR IF YOU CONNECT THE MACHINE TO THE POWER SOURCE BEFORE YOU HAVE COMPLETED THE INSTALLATION AND ASSEMBLY STEPS. DO NOT CONNECT THE MACHINE TO THE POWER SOURCE UNTIL INSTRUCTED

TO DO SO.

DETACH THE MORTISER FROM ITS SHIPPING BASE

INSTALL

ATION

If you prefer an optional stand, item 75-045 Heavy-duty

open stand is available from your local General

International dealer.

NOTE: For use with this machine, the use of a plywood (or

other) platform (not supplied) is required to cover the opening in the top of the stand. The platform must be bolted to

the stand through the mounting holes .

OPTIONAL STAND

MOUNTING TO A WORK SURFACE

If a permanent shop placement is practical, consider

drilling matching through holes in the mounting surface

of your workbench or stand’s platform to bolt the mortiser in place using hex bolts, flat washers, lock washers

and hex nuts (fasteners not included), in the assembly order shown in

.

HEX HEAD BOLT

FLAT WASHERS

LOCK WASHER

HEX NUT

FOR YOUR SAFETY IT IS ESSENTIAL THAT THE MORTISER DOES NOT ROCK OR TIP DURING OPERATION. MAKE SURE THAT THE

MORITSER IS FIRMLY SECURED TO THE WORK SURFACE OR STAND’S PLATFORM AND THAT THERE IS NO ROCKING, TIPPING OR

CHATTERING.

9

Page 10

ASSEMBLY INSTRUCTIONS

For your convenience this mortiser is shipped from the factory partially assembled and requires only minimal

assembly and set up before being put into service.

SERIOUS PERSONAL INJURY COULD OCCUR IF YOU CONNECT THE MACHINE TO THE POWER SOURCE BEFORE YOU HAVE COMPLETED THE ASSEMBLY STEPS. DO NOT CONNECT THE MACHINE TO THE POWER SOURCE UNTIL INSTRUCTED TO DO SO.

Attach the workpiece clamp assembly to the front of

the base with the two supplied hex bolts and flat washers as shown, using a 13 mm socket or open wrench.

A

TTACH THE WORKPIECE CLAMP

Separate the two parts of the workpiece hold down

assembly then re-assemble them on both sides of

the dovetail way as shown in .

A

TTACH THE WORKPIECE HOLD DOWN

The workpiece stop can be installed on either side of

the mortiser to suit your needs or personal work preferences.

1. Thread the workpiece stop into the threaded hole

in the base .

2. Secure with the lock nut .

ATTACH THE WORKPIECE STOP

The four holes in the down feed shaft allow you to

reposition the handle in the holes for better comfort

and convenience.

1. Loosen the lock knob .

2. Remove the handle and reposition it as needed,

choosing the hole that provides the most comfortable handle angle.

3. Re-tighten the lock knob to secure the down feed

handle in position .

INSTALL THE DOWN FEED HANDLE

10

CLOSE UP

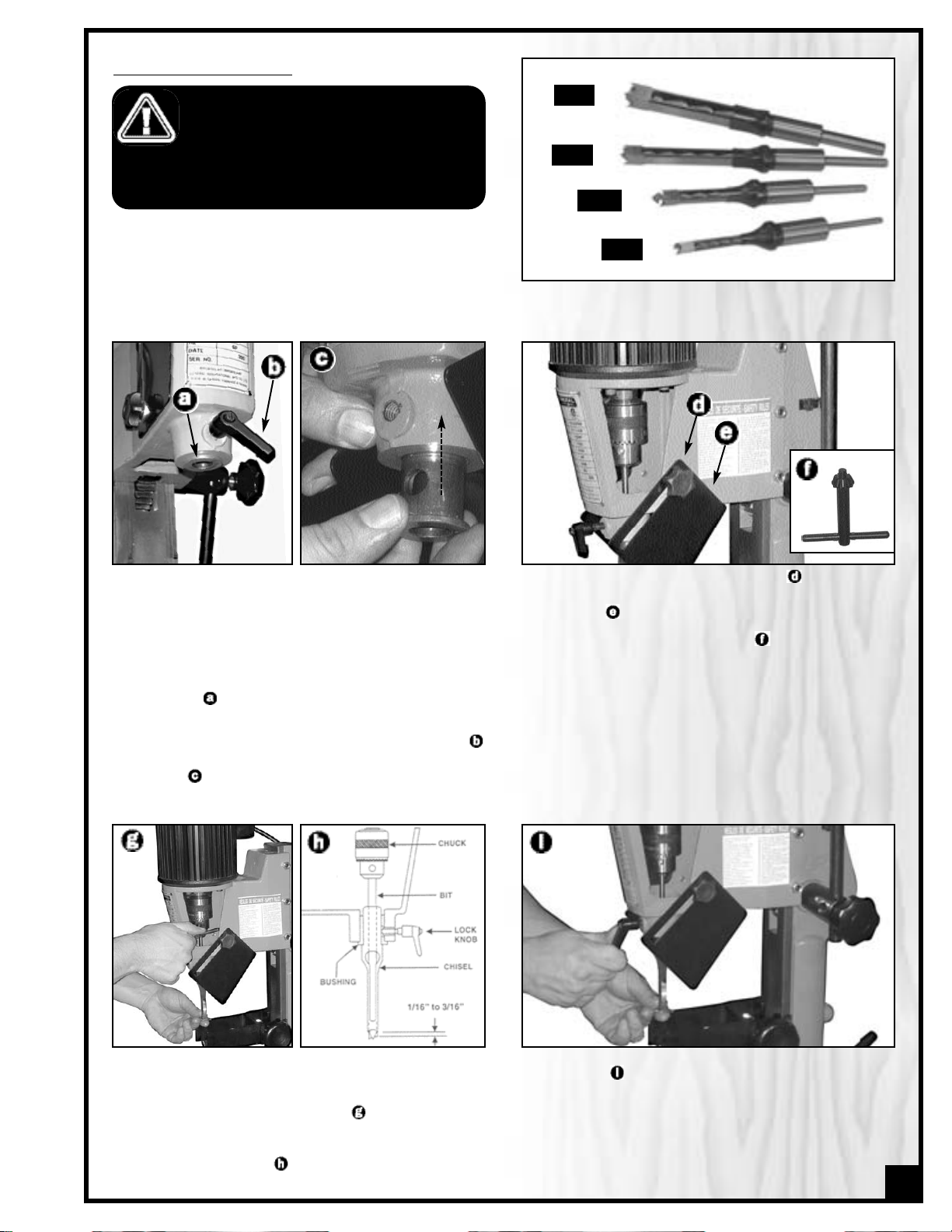

Page 11

1/2”

1/4”

5/16”

3/8”

11

The unit is also supplied with 2 different sized chisel

support bushing adapters allowing the user to install

chisel and bit sets of either 5/8" or 3/4" shank diameter, to accommodate bit sizes (some of which are

available as optional accessories) ranging from a minimum of 1/4" up to a maximum of 5/8”:

NOTE: The 5/8” shank diameter bushing is already intalled

at the factory .

2. Select the appropriate bushing and, if not already

installed, unscrew and remove the locking lever

then slip the bushing into the quill assembly as

shown, .

3. Loosen either of the two lock knobs on the chuck

cover and slide the corresponding slide plate out of

the way .

4. Insert the supplied chuck key and turn counter-

clockwise to open the chuck jaws and allow a drill

bit to fit in.

5. With a piece of plastic, carboard or wood held

between the tip of the bit and your finger,

install the chisel and bit with the chip clearing

slot facing either left or right and tighten the

bit in the chuck so that the tip of the bit juts out

approximately 1/16" to 3/16" (2 mm to 5 mm) from

the tip of the chisel .

6.

While still holding the chisel in place, tighten the locking lever to secure the chisel in the bushing.

NOTE: Do not overtighten the locking lever as this can damage your mortiser.

This unit is supplied with a set of four different sized chisel and bits to help the user cut mortises of varying

widths to suit the application.

1. Select the appropriate size of chisel and bit.

INSTALL A CHISEL AND BIT SET

TURN OFF AND UNPLUG THE MORTISER FROM THE

POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE, ADJUSTMENTS OR BIT CHANGES.

CHISEL AND BIT TIPS ARE VERY SHARP – HANDLE WITH

CARE. TO AVOID PERSONAL INJURY USE A PIECE OF

CARDBOARD, PLASTIC OR OTHER MATERIAL BETWEEN

YOUR FINGER AND THE TIP OF THE BIT WHENEVER HOLDING OR HANDLING THE CHISEL AND BIT BY THE TIP.

Page 12

12

1. Lower the head to its maximum .

2. Place a piece of taller stock (minimum 3”) against

the fence .

NOTE: Make sure you are using a piece of planed and

squared stock that has an even thickness.

3. Loosen the fence locking levers and slowly

advance the fence with the piece of wood towards

the chisel.

TO SQUARE THE CHISEL TO THE FENCE

If the face of the chisel sits flush against the stock the

chisel is square. Tighten the chisel locking lever and

proceed with normal operation.

If the chisel does not sit flush:

1. Loosen the chisel lock lever and manually turn

the chisel until its face sits flush against the stock.

2. Lock the lever to secure the chisel in position.

BASIC ADJUSTMENTS & CONTROLS

CONNECTING TO A POWER SOURCE

SWITCH OFF

TO REDUCE THE RISK OF SHOCK OR FIRE DO NOT OPERATE THE UNIT WITH A DAMAGED POWER CORD OR PLUG.

REPLACE DAMAGED CORD OR PLUG IMMEDIATELY.

TO AVOID UNEXPECTED OR UNINTENTIONAL START-UP, MAKE SURE THAT THE POWER SWITCH IS IN THE OFF POSITION BEFORE CONNECTING TO A POWER SOURCE.

Once the assembly steps have been completed and

the unit is safely secured to a work surface, uncoil the

power cord and plug the power cord into an appropriate outlet. Refer back to the section entitled “ELECTRICAL REQUIREMENTS” and make sure all requirements

and grounding instructions are followed. When mortising operations have been completed unplug the mortiser from the power source.

Page 13

The mortiser is equipped with a rocker style ON/OFF dust-proof switch located on the front left hand side of the mortiser head.

- To start the mortiser, push on the upper portion of the switch ;

- To stop the mortiser, push on the lower portion of the switch .

ON/OFF POWER SWITCH

VERIFY ALL FOLLOWING CHECK POINTS BEFORE

TURNING ON THE MORTISER. FAILURE TO COMPLY

CAN RESULT IN SERIOUS INJURIES.

BASIC OPERATIONS

1. Layout and mark workpieces for the mortises to be

cut.

2. Install the appropriate chisel and bit in the chuck.

3. Place the stock on the table against the fence .

4. Set the depth stop.

5. Loosen the fence locking levers and adjust the

fence until the workpiece is positioned with the

mortise to be cut centered on the chisel .

NOTE: If necessary, lower the chisel onto the workpiece to

make sure the layout lines of the mortise are aligned with

the bit.

Transfer a reference line showing the desired depth of cut onto the front face of the workpiece and then set the

depth stop as follows:

SETTING THE DEPTH STOP

1. Lower the chisel to the bottom of your depth refe-

rence line then adjust the depth stop

against the stop plate as shown to prevent the

chisel from lowering any further.

NOTE: As a time saving convenience, the upper stop

can be set to control the upward travel of the head. This

feature allows you to save time by raising the bit only

enough to clear the workpiece and allow you to reposition

the workpiece without having to raise the head to its maximum.

13

CLOSE UP

• MAKE SURE THE TWO SLIDE PLATES OF THE CHUCK COVER

ARE CLOSED AND THEIR LOCK KNOBS ARE TIGHTENED

SECURELY.

• MAKE SURE THE CHISEL AND BIT ARE PROPERLY INSTALLED

AND THAT THE BIT CHUCK AND CHISEL LOCK LEVER ARE

TIGHTENED SECURELY.

• WHEN THE MORTISER IS RUNNING CHECK TO SEE IF IT RUNS

WITHOUT VIBRATION OR SHAKING.

Page 14

6. With the fence now set to the correct front to back

position, tighten the two fence locking levers to

hold the fence in place.

7.

So that the chips are discharged into the part of

the mortise which is already cut, and that the part

to be cut remains well visible, set the workpiece on

the table with the bit aligned with either:

- The left end of the mortise if the chip clearing slot is

facing left ;

- The right end of the mortise if the chip clearing slot

is facing right ;

NOTE: To avoid overheating or damage to the chisel or bit,

do not position the slot against the blind end of the mortise

as this would prevent the chips from discharging from the

chisel.

8. If multiple workpieces are to be mortised in an

identical manner, adjust the workpiece stop to

allow to position the next workpiece at the exact

same location.

9. Tighten the workpiece clamp to hold the work-

piece securely against the fence.

10. Lower the workpiece hold down until slightly above

the workpiece and tighten.

11. Turn on the machine.

12. Lower the chisel into the workpiece using a

steady even pressure until it bottoms out on the

depth stop.

FEED RATE:

NOTE: To prevent burning of the tip of the bit, a steady feed

rate is required. The machine may stall or slow down if the

feed rate is too fast

TIP: To allow chips to discharge when cutting deeper mortises or through mortises, cut the mortise to its full depth in

several steps, by backing off periodically at roughly 3/8”

– 1/2” intervals. Raising the bit back out of the mortise

briefly, before plunging back in, allows the chips to discharge more easily and can contribute to longer chisel

and bit life and cleaner sharper mortises.

When cutting through mortises, place a piece of scrap

wood under the workpiece to help prevent tear-out as the

bit cuts its way through the opposite or exit face of the

workpiece.

13. Raise the chisel.

14. Loosen the workpiece clamp slightly, and reposi-

tion the workpiece against the fence to continue

the cut.

TIP: For added convenience and time savings when cutting longer mortises, optional rollers, item 75-055 (available from your General® International dealer) can be

used instead of the workpiece clamp, allowing you to

“roll” the workpiece left or right as needed to continue

the next cut for the mortise slot.

15. Re-tighten the workpiece clamp.

16. Continue cutting the mortise.

17. Repeat to complete the mortise overlapping each

cut slightly .

18. Test the fit of your tenon in the mortise . Re-adjust

if needed.

14

Page 15

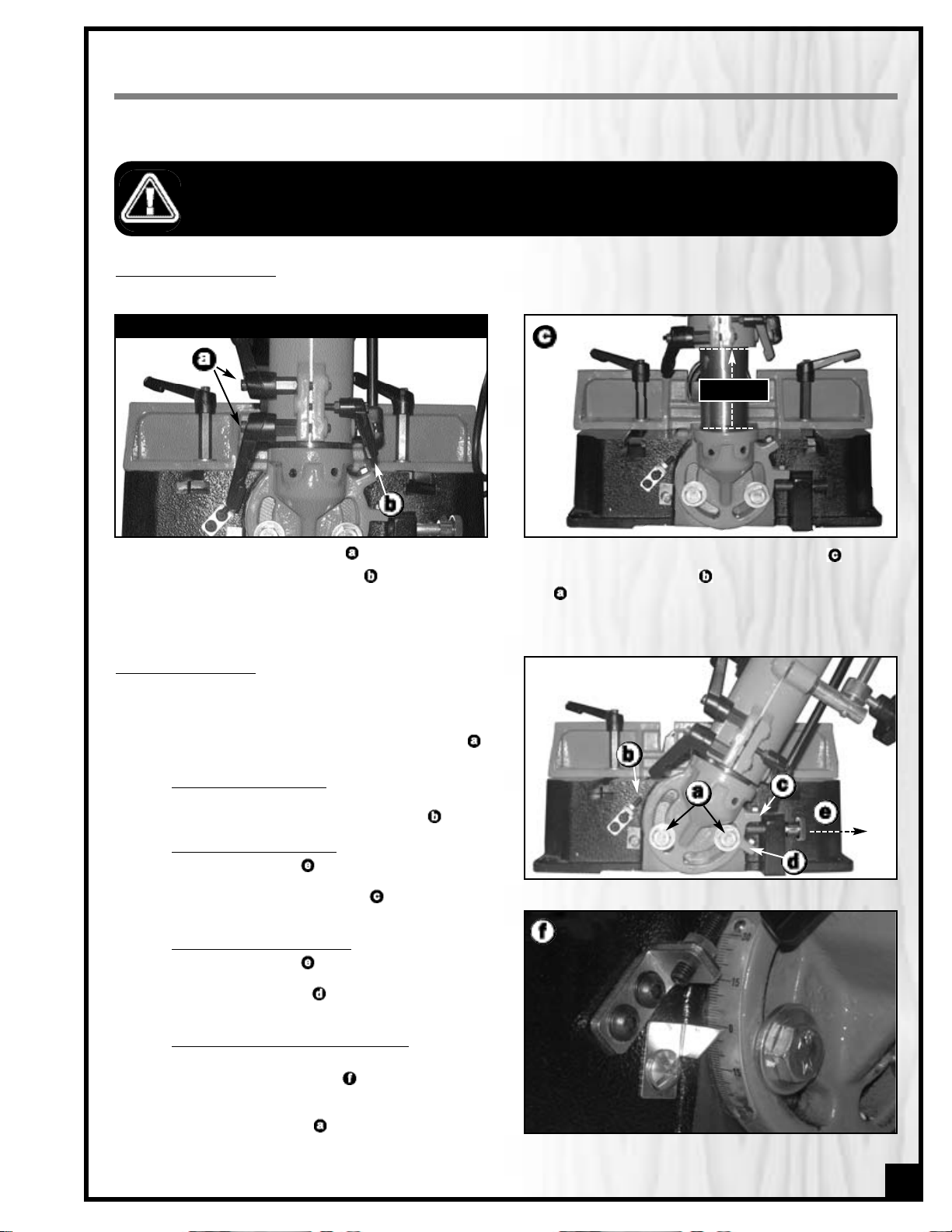

1. While holding the head, loosen the two bolts

,

using a 17 mm wrench

.

- T

o set the head 30° left:

Tilt the head towards the left until the tilting

bracket rests against the left 30° stop .

- T

o set the head 30° right:

Pull the stop pin out, then tilt the head

towards the right until the tilting bracket rests

against the 30° right stop , then release

the stop pin.

- T

o set the head back to 0°:

Pull the stop pin out, then tilt the head

towards the center until the tilting bracket rests

against the 0° stop , then release the stop

pin .

- T

o set the head to any other angle:

To use a setting other than 0° or 30°,refer to the

head tilt angle indicator to set the angle of

the head to the desired position.

2.

Re-tighten the two bolts to secure the head in

position.

HEAD TILT ADJUSTMENT

The head can be tilted to any angle from 0° to 30° to the

left or right, to allow for bevel (or angle) mortise cutting.

15

ADDITIONAL ADJUSTMENTS

For special applications such as taller workpieces (requiring off table mortising) or for angled mortises, the following machine adjustments can also be made.

1. Loosen the two ratchet levers .

2. Slightly tighten the ratchet lever .

HEAD HEIGHT ADJUSTMENT

REAR VIEW

3” max

MAKE SURE THE MORTISER HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY

ADJUSTMENTS.

3. Manually pull the head 3” up (approx.) .

4. Loosen ratchet lever and tighten ratchet levers

to secure the head in position.

To raise the height of the head and extend the working capacity of the mortiser (if needed) by up to 3”:

Page 16

MAINTENANCE

PERIODIC MAINTENANCE

• Keep the machine clean and free of dust, and woodchips. Vacuum or brush off any loose debris and wipe

down the machine and the table occasionally with a damp rag.

• An occasional light coating of paste wax can help protect the table surface and reduce workpiece friction.

Ask your local distributor for suggestions on aftermarket surface cleaners and protectants based

on what is readily available in your area. (Avoid using silicon based products that may affect wood finishing

products such as oil, solvent or water-based stains, varnishes and lacquers.)

• Periodically inspect the power cord and plug for damage. To minimize the risk of electric shock or fire, never

operate the mortiser with a damaged power cord or plug. Replace a damaged power cord or plug at the first

visible signs of damage.

• Periodically inspect chisel and bits for signs of visible damage. Replace a chipped or damaged chisel or bit

immediately.

MAKE SURE THE MORTISER HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY

MAINTENANCE.

For off-table work, for example with taller workpieces, the

entire head of the mortiser can be swivelled up to 180° left

or right. To swivel the head:

1. To avoid damaging the chisel and bit or the fence,

remove the chisel and bit and move the fence as far

as possible towards the front before swivelling the

head.

2. Loosen the two ratchet levers .

3. Tighten the ratchet lever then swivel the head to the

desired position.

4. Loosen ratchet lever and tighten ratchet levers

to secure the head in position.

HEAD SWIVEL ADJUSTMENT

SHARPENING CHISELS AND BITS

Working with properly sharpened chisel and bits sets will greatly increase the quality of your work and allow you to

obtain clean, crisply cut mortises with minimal effort. With use over time chisels and bits will need to be re-sharpened.

The frequency of use,type of workpiece material and the size and depth of the mortises you cut will affect how often

or infrequently re-sharpening will be required.

You will find there are a variety of aftermarket sharpening tools made by third party sources that are available on

the market for both the chisels and the bits for your mortiser. Your local distributor or tool retailer will be able to

advise you of any sharpening tool options based on what

is readily available in your area.

Take note that chisels should only be sharpened on their

inside edges as any material removed from the outside

edge will affect and change the overall dimensions of the

chisel. An example of a typical chisel sharpening cone is

shown in . Such cones are usually made available in

sets or individually by size and should be matched to the

size of the chisel – your local tool distributor or sharpening

supplies specialist will be able to advise you further. For

best results follow the instructions supplied with the sharpening tool or accessory being used.

16

Page 17

REQUIRED MAINTENANCE

LUBRICA

TION

Keep the column and both sides of the dovetail way

well lubricated and free of dust or debris. Clean and

remove dust, debris, and old lubricant as needed

depending on frequency of use. After cleaning, reapply

a verly light coating of lubricant.

NOTE: Use any all-purpose oil, available at any hardware store).

If the left 30° index stop needs to be adjusted:

1. Loosen the lock nut using a 10 mm wrench.

2. Using the supplied 3 mm Allen key, adjust the set

screw in or out until the indicator points toward

30° on the angle scale, then re-tighten the lock nut.

TILT INDEX STOP ADJUSTMENT

The 0°, 30° right and 30° left index stops are factory set. However, with use and vibration over time, they eventually

may need minor adjustments.

If the right 30° stop or 0° stop needs to be adjusted:

1. Loosen the lock nut using a 10 mm wrench.

2. Using the supplied 3 mm Allen key, adjust the set

screw in or out until the indicator points to 30° or

0°, respectively, then re-tighten the lock nut.

17

REAR VIEW

With use and normal wear over time,the motor assembly may loosen slightly. If you notice abnormal noise

or vibrations, tighten the cap screws (accessible

behind the slide plates on both sides of the chuck),

using the supplied 5 mm allen key.

With use over time, some slight play may develop in

head on the dovetail way due to wear. To eliminate play

between the head and the dovetail way, loosen the lock

nuts , and adjust the individual set screws as needed.

Re-tighten the lock nut(s) once the adjustment has been

completed.

NOTE: Adjust only enough to eliminate play – do not over

tighten as this can stiffen or restrict head travel, requiring

more effort to complete the feed stroke and cause premature wear of the dovetail way.

Page 18

RECOMMENDED OPTIONAL ACCESSORIES

Here are some of the optional accessories available from your local General International dealer.

For more information about our products, please visit our website at www.general.ca

HEAVY

-DUTY OPEN STAND

ITEM # 75-045

Heavy duty adjustable height, flared steel stand. Wide stance

design with sturdy cross-bracing for stable vibration-free

operation.

- Height: 30 5/8” (778 mm)

- Dimensions at top: 13 1/4” x 18 1/2” (336 x 470 mm)

- Dimensions at feet: 26 1/2” x 33 1/4” (673 x 845 mm)

NOTE: Top opening measures are 9 1/4” x 12 3/4”. For use with

this machine, the use of a plywood (or other) platform (not supplied) is required to cover the opening in the top of the stand.

MORTISING TABLE ROLLERS (2)

ITEM # 75-055

For added convenience and time savings when cutting

longer mortises. Use rollers instead of the workpiece clamp.

No more clamp ing and unclamping after each cut! Simply

butt the rollers up against the workpiece keeping it tight to

the fence; after completing a cut,“roll”the workpiece left or

right as needed to continue the next cut for the mortise slot.

REPLA

CEMENT/OPTIONAL CHISEL & BIT SETS

ITEM # 70-910

1⁄4” (6 mm) mortising chisel & bit set, 5⁄8” (16 mm) shank

ITEM # 70-920

5/16” (8 mm) mortising chisel & bit set, 5⁄8” (16 mm) shank

ITEM # 70-930

3/8” (10 mm) mortising chisel & bit set, 5⁄8” (16 mm) shank

ITEM # 70-940

1/2” (13 mm) mortising chisel & bit set, 5⁄8” (16 mm) shank

ITEM # 70-950

5/8” (16 mm) mortising chisel & bit set, 5⁄8” (16 mm) shank

18

Page 19

19

DIAGRAM

12-1

11

10

09

12

33

13

37

05

14

15

06

36

64

62

38

53

61

39

17-1

05

03

16

06

40

58

41

52

34

46

17

43

25

44

35N

22

42

59

63

52

60

24

18

23

55

03

04

53

19

21

26N

20

81

12

82

46-1

83

80

71

65

66

67

72

43

70

79

78

68

54

69

75

76

74

77

26-1N

70-1N

43

73

45N

28

29

07

01N

08

30

56

50

48

31

49

27

51

02

32

56

57

Page 20

PARTS LIST

75-050T M1

PART N0.

75050T-01N

75050T-02

75050T-03

75050T-04

75050T-05

75050T-06

75050T-07

75050T-08

75050T-09

75050T-10

75050T-11

75050T-12

75050T- 12-1

75050T-13

75050T-14

75050T-15

75050T-16

75050T-17

75050T -17-1

75050T-18

75050T-19

75050T-20

75050T-21

75050T-22

75050T-23

75050T-24

75050T-25

75050T-26N

75050T-26-1N

75050T-27

75050T-28

75050T-29

75050T-30N

75050T-31

75050T-32

75050T-33

75050T-34

75050T-35N

75050T-36

75050T-37

75050T-38

75050T-39

75050T-40

75050T-41

75050T-42

75050T-43

DESCRIPTION

BASE

SET SCREW 5/16 X 3/8

WASHER 1/4

RATCHET LEVER M8

SCREW M8

LOCK WASHER 3/8

WASHER 5/16

HEX HEAD BOLT 5/16 X 1

DEPTH STOP BAR

LOCK KNOB 5/16 X 3/4

ADJUSTING SLEEVE

LOCK KNOB 5/16

SET SCREW 5/16 X 3/8

STOP BAR SUPPORT POST

SCREW 3/16

CORD CLAMP 1/4

COLUMN

"C" RING 15

"C" RING 20

HANDLE GRIP

DOWNFEED HANDLE

DOWNFEED SHAFT

KEY

GEAR

LOCK KNOB 3/8 X 90

HOLD DOWN CLAMP ARM

HOLD DOWN CLAMP ARM

FENCE

SLIDE BAR

STOP BAR BLOCK

SCREW 1/4 X 5/8

VISE PLATE

VISE MOUNT BRACKET

THREADED ROD

HANDWHEEL

GAS SPRING

CAP SCREW 1/4 X 1

MACHINE HEAD

STOP PLATE

CAP SCREW 1/4 X 3/4

CAP SCREW 1/4 X 5/8

RACK

SLIDE PLATE

MOTOR

SET SCREW 5/16 X 3/4

HEX NUT 5/16

PART N0.

75050T-44

75050T-45N

75050T-46

75050T-46-1

75050T-48

75050T-49

75050T-50

75050T-51

75050T-52

75050T-53

75050T-54

75050T-55

75050T-56

75050T-57

75050T-58

75050T-59

75050T-60

75050T-61

75050T-62

75050T-63

75050T-64

75050T-65

75050T-66

75050T-67

75050T-68

75050T-69

75050T-70

75050T-70-1N

75050T-71

75050T-72

75050T-73

75050T-74

75050T-75

75050T-76

75050T-77

75050T-78

75050T-79

75050T-80

75050T-81

75050T-82

75050T-83

70-910

70-920

70-930

70-940

DESCRIPTION

CHUCK X 13 MM

SCALE

CHISEL BUSHING

(5/8 SHANK)

CHISEL BUSHING

(3/4 SHANK)

STOP BAR (SHORT)

STOP BAR (LONG)

LOCK KNOB

LOCK KNOB

SLIDE PLATE (CHUCK COVER)

LOCK KNOB 1/4

BOLT M 8

RATCHET LEVER

NUT 5/16

HANDLE

SWITCH

CHUCK KEY HOLDER

SCREW 3/16

GEAR COVER

SCREW

RATCHET LEVER 5/16

RATCHET LEVER M6

COLUMN EXTENSION POST

COLUMN MOUNT BRACKET

SET SCREW

LABEL

ANGLE SCALE

SET SCREW

SET SCREW M6X25

HEX HEAD BOLT

FLAT WASHER

TILT STOP BRACKET

FLAT WASHER

HEX HEAD BOLT

SCREW

POINTER

STOP PIN

NUT

CHUCK KEY

3 MM ALLEN KEY

4 MM ALLEN KEY

5 MM ALLEN KEY

1/4” - 6 MM CHISEL AND BIT

(NOT SHOWN)

5/16” - 8 MM CHISEL AND BIT

(NOT SHOWN)

3/8” - 10 MM CHISEL AND BIT

(NOT SHOWN)

1/2” - 13MM CHISEL AND BIT

(NOT SHOWN)

QTY

1

1

2

2

2

2

2

2

1

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

2

2

1

1

1

3

3

QTY

1

1

1

1

1

1

1

1

2

2

2

1

2

1

1

1

1

1

2

2

1

1

1

2

2

1

2

1

2

4

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

NOTES

20

Page 21

21

Notes

Page 22

IMPORTANT

When ordering replacement parts, always give the model number, serial number of the machine and

part number. Also a brief description of each item and quantity desired.

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Tel.: (514) 326-1161

Fax: (514) 326-5565 - Parts & Service / Fax: (514) 326-5555 - Order Desk

orderdesk@general.ca

www.general.ca

MODEL 75-050T M1

Loading...

Loading...