Page 1

© Copyright General International 08/2007

REVISION 2 - NOVEMBER 15/07

Page 2

THANK YOU

for choosing this General® International model 50-195/50-295

Router Extension Wing/Router Fence.This router extension wing/router fence has been carefully

tested and inspected before shipment and if properly used and maintained, will provide you

with years of reliable service. To ensure optimum performance and trouble-free operation, and

to get the most from your investment, please take the time to read this manual before assembling, installing and operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic function, and features

of this router extension wing/router fence as well as the setup, maintenance and identification

of its parts and components. This manual is not intended as a substitute for formal woodworking instruction, nor to offer the user instruction in the craft of woodworking. If you are not sure

about the safety of performing a certain operation or procedure, do not proceed until you

can confirm, from knowledgeable and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

All component parts of General® International machinery are carefully tested and inspected during all stages of

production, and each machine is thoroughly inspected upon completion of assembly. Because of our commitment to quality and customer satisfaction, General® International agrees to repair or replace, within a period of 24

months from date of purchase, any genuine part or parts which, upon examination, prove to be defective in workmanship or material. In order to obtain this warranty, all defective parts must be returned freight pre-paid to

General® International Mfg. Co., Ltd. Repairs attempted without our written authorization will void this warranty.

GENERAL ® INTERNATIONAL WARRANTY

Disclaimer:

The information and specifications in this manual pertain to

the unit as it was supplied from the factory at the time of printing.

Because we are committed to making constant improvements, General

International reserves the right to make changes to components, parts

or features of this/these unit(s) as deemed necessary, without prior

notice and without obligation to install any such changes on previously

delivered units. Reasonable care is taken at the factory to ensure that

the specifications and information in this manual corresponds with that

of the unit with which it was supplied. However, special orders and “after

factory” modifications may render some or all information in this manual inapplicable to your extension wing/fence. Further, as several generations of this model of router extension wing/router fence and several

versions of this manual may be in circulation, if you own an earlier or

later version of this/these unit(s), this manual may not depict your unit(s)

exactly.If you have any doubts or questions contact your retailer or our

support line with the model and serial number of your unit for clarification.

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

Page 3

Rules for Safe Operation

To help ensure safe operation, please take a moment to learn the machine’s applications and limitations, as well as potential hazards. General® International disclaims any real or implied warranty and

holds itself harmless for any injury that may result from improper use of its equipment.

1. Make sure that the operator has been properly trained

and has read and understands the Owner’s Manual

before operating any machinery.

2. Be sure to read, understand,and follow all instructions,

warnings, and safety guidelines supplied with your

table saw and router.

3. Keep the work area well lit, clean, and free of debris.

4. STAY ALERT! Give your work you undivided attention.

Even a momentary distraction can lead to serious

injury.

5. Do not wear loose clothing, gloves, bracelets, neck-

laces, or other jewelry. Wear protective hair covering

to contain long hair and wear non-slip footwear.

6. Keep hands and other body parts well away from bits

or cutting tools. When working close to the cutting tool,

always use a feather board or push-stick to hold or

guide the workpiece. Do not clear chips and sawdust

away with hands; use a brush.

7. Fine particulate dust is a carcinogen that can be haz-

ardous to health. Always work in a well ventilated area

and whenever possible use a dust collector.

8. Be sure the router bit and/or saw blade has gained full

operating speed before feeding the workpiece.

9. Keep children and visitors at a safe distance when the

table saw is in operation – do not permit them to operate the table saw.

10. Childproof and taper proof your shop and all machin-

ery with locks, mater electrical switches and switch

keys, to prevent unauthorized or unsupervised use.

11. Never stand or lean on your table saw. Serious injury

can occur if the table saw is tipped or if unintentional

contact is made with the spinning saw blade or router

bit.

12. Keep all guards and safety devices in place and in

good working order. If a guard must be removed for

maintenance or cleaning make sure it is properly reinstalled before using the machine again.

13. Hold the workpiece firmly against the table and use

suitable support if the workpiece does not have a flat

surface.

14. Feed the stock into the bit against the rotation direc-

tion of the bit. Never run the stock between the fence

and the bit.

15. Do not operate the router with a damaged bit and/or

the table saw with a damaged blade.

16. Always disconnect the router and/or the table saw

from the power source before changing accessories

or before performing any maintenance and adjustments or if the machine will be left unattended.

17. Be sure that all adjustment tools, wrenches, or other

clutter are removed from the table surface and safely

stored before sawing or routing.

18. Make sure the router and/or table saw switch(es) is

(are) in the “OFF” position before plugging in to a power source.

19. Avoid working from awkward or off-balance positions.

Do not overreach and always keep both feet firmly on

the floor.

20. Never leave the table saw and/or router unattended

while running or with the power “ON”.

21. Do not use this router extension wing/router fence for

any purposes other than its intended use. If used for

other purposes, General® International disclaims any

real or implied warranty and holds itself harmless for

any injury which may result from such use.

Page 4

4

ROUTER EXTENSION WING / ROUTER FENCE

50-195 / 50-295 / 50-295CT

UNPACKING & SETUP

ROUTING MAY PRESENT SERIOUS INJURY HAZARDS TO UNTRAINED USERS. BE SURE TO READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS AND SAFETY RULES SUPPLIED WITH YOUR ROUTER.

The router extension wing (Model #50-195) and router fence (Model #50-295) may be purchased either separately

or together as a kit (Model #50-295CT). Contact your General® International distributor for more information.

This manual contains instructions for both the router extension wing (Model #50-195) and the router fence (Model

#50-295). Depending on your purchase, some of the information in this manual may not apply.

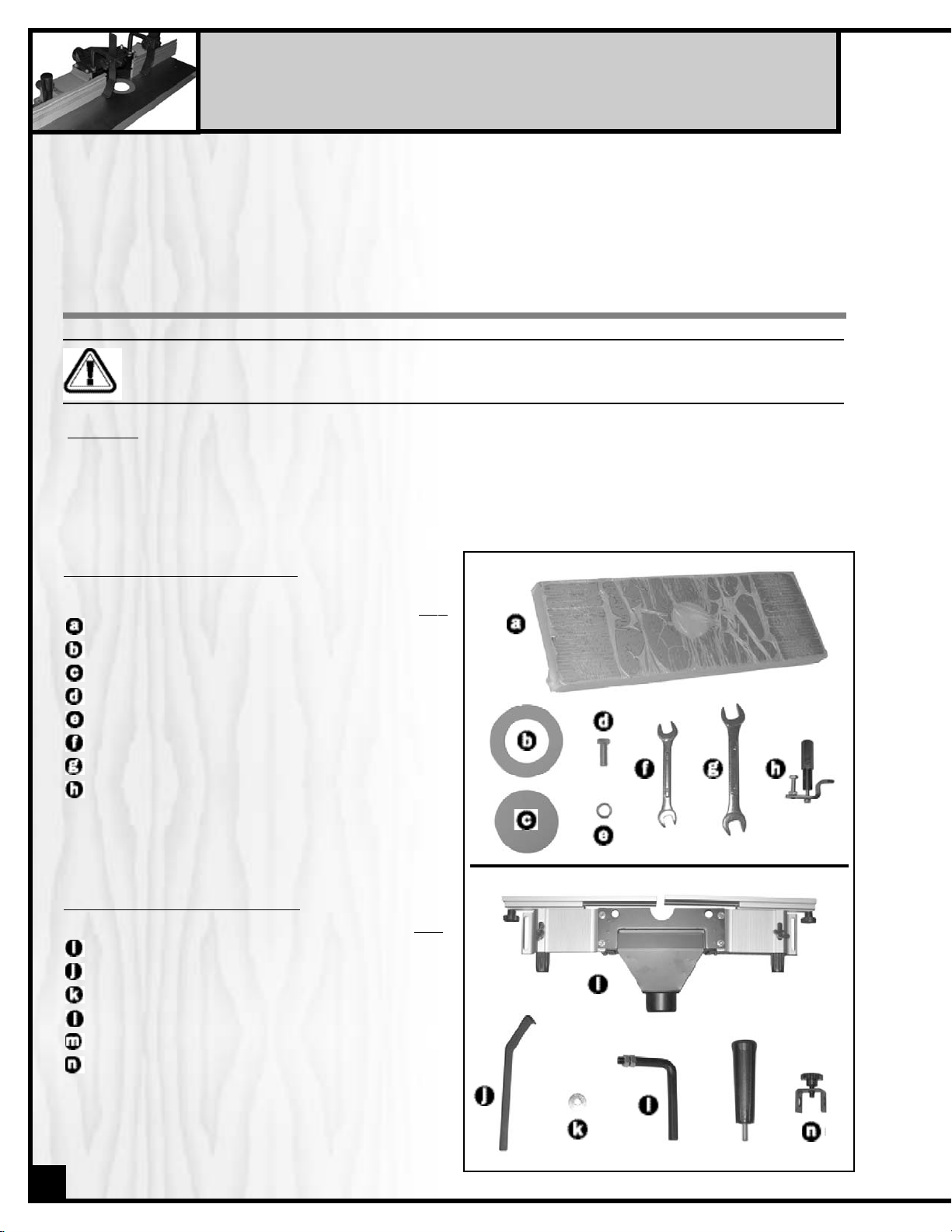

UNPACKING

Carefully unpack and remove the unit and its components from the box and check for missing or damaged items

as per the list of contents below.

Note: Report any missing or damaged items to your General® International distributor immediately.

LIST

OF CONTENTS

50-195

QTY

ROUTER EXTENSION WING

. . . . . . . . . . . . . . . . . .1

TABLE INSERT (60 MM)

. . . . . . . . . . . . . . . . . . . . .1

TABLE INSERT (29 MM)

. . . . . . . . . . . . . . . . . . . . .1

MOUNTING BOLTS

. . . . . . . . . . . . . . . . . . . . . . . . .3

LOCK WASHER

. . . . . . . . . . . . . . . . . . . . . . . . . . . .3

COMBINATION WRENCH (10 / 12 MM)

. . . . . . .1

COMBINATION WRENCH (14 / 17 MM)

. . . . . . .1

MOUNTING CLIP ASSEMBLY

. . . . . . . . . . . . . . . . .4

LIST OF CONTENTS 50-295

QTY

FENCE ASSEMBLY

. . . . . . . . . . . . . . . . . . . . . . . . .1

HOLD-DOWN PLATE

. . . . . . . . . . . . . . . . . . . . . . . .2

WASHER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

HOLD-DOWN SUPPORT ARM

. . . . . . . . . . . . . . . .2

HANDLE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

HOLD-DOWN BRACKET

. . . . . . . . . . . . . . . . . . . . .2

INCLUDED IN 50-195 PACKAGE

INCLUDED IN 50-295 PACKAGE

Page 5

TABLE TOP CLEAN UP

All unpainted surfaces are covered with a protective coating

that helps prevent rust from forming during shipping and storage. Remove the protective coating by rubbing with a rag

dipped in kerosene, mineral spirits, or paint thinner (Dispose of

potentially flammable solvent soaked rags according to manufacturer’s safety recommendations). A putty knife, held flat to

avoid scratching the surface, may also be used to scrape off

the coating followed by clean up with solvent.

Note: Avoid rubbing the painted surfaces, as many solventbased products will remove paint.

Fig. 1

INSTALLING THE ROUTER EXTENSION WING (50-195)

The router extension is designed to replace either of the existing

27” long wings (left or right) on your table saw. It is designed to

fit on General® International models 50-175/185 and 50-250/260

table saws without further modification. Deciding whether to

install the wing to the left or right end of the saw is entirely a matter of personal preference, and should be determined by your

own work habits and/or shop space considerations. Whichever

side you choose, make sure to leave adequate room to work.

(Fig. 2)

Note: Some cabinet style saws have motor cover doors that

extend underneath beyond the main table, thus preventing the

router from being hung from that side of the saw. In such cases

the model 50-195 router table must be installed on the side

opposite to the motor cover door.

Fig. 2

The unit can fit other models or brands of table saws with 27”

tables. It can also be added to the end of either existing wing

(see note below for further details), but additional mounting

hardware (not included) may be required. Should the predrilled

holes in the extension wing not line up with the existing holes in

the main table of your saw, clamp the extension wing in place

on the saw.Level the wing with the main table and line it up flush

with the front edge of the saw and with the clamps holding it

securely in place, drill matching holes into the main table

through the mounting holes in the wing (Fig. 3).

Note: When adding the 50-195 router extension wing to the end

of an existing table extension (rather than in place of the existing wing) keep in mind that the added weight of the wing will

affect the center of gravity of the saw making the saw heavier

on the side that the wing is installed on. This could increase the

possibility of a tip-over should a heavier piece of stock or sheet

goods be placed on the saw. (Fig. 4)

To reduce the possibility of a tip over, install support legs under

the router extension. A simple 2” x 4” cut to length from the floor

the underside of the table will provide the support need to help

prevent a tip over. (Fig. 4.1)

Attach the extension wing using the 3 hex head bolts and lock

washers finger tight at first (Fig. 5). Use a straightedge to ensure

that wing is level with table from front to back. Gently tap the

wing up or down, then tighten the bolts with the supplied

wrench, leaving the center bolt to be tightened last. Be sure that

the extension wing is flush with the front edge of the table.

Fig. 3

Fig. 4

Fig. 5

Fig. 4.1

5

Page 6

6

MOUNTING A ROUTER

Fig. 6 Fig. 7

Fig. 8

Fig. 9

4. Fit the router between the clips and the underside

of the table. Holding the router in place, tighten

one shoulder bolt and its diagonal opposite to

raise the clip to grip and tighten the router plate

to the table.

Fig. 10

Fig. 11

3. Continue adjusting until the space between the

clips and the underside of the table is slightly

wider then the thickness of your router base.

Note: In some cases, if the router base is too thin for

the clips to secure it, flat wooden shims or spacers

can be used between clips and the router base to

facilitate installation.

1. Slide the T-head bolts into the T-slots allowing them

to loosely hang from the underside of the table.

Line the mounting clips up straight with the slots so

that the rear bolt can fit in the slot when tightened.

Note: Use the inner slots for smaller diameter router

bases or the outer slots for larger bases.

5. Loosen, adjust, and retighten as needed until the

router is centered in the table opening.

6. With the router centered in the table opening,

tighten down all 4-shoulder bolts, , and make

sure all 4 mounting clips, , are securely holding the router to the underside of the table. Tighten the 4 stop nuts, , on the rear bolts to lock

down the clip system.

2. Adjust the rear bolts, , on the mounting clips

until they bottom out in the slots and tilt the front

edge of the clips forward.

Inner slots

Outer slots

Wooden shim or

spacer (may be

required)

Page 7

TABLE INSERT RINGS

The router extension wing (Model #50-195) comes with 2 removable insert rings allowing the opening on the extension wing to

be changed to suit the most common sizes of router bits.

The supplied rings come in two sizes: 1 1/8” (29 mm), 2 3/8”

(60 mm), allowing for three different table opening sizes.

The smallest opening is 1 1/8” (29 mm), the largest opening is

2 3/8”(60 mm) and with no insert ring installed the opening in the

wing measures 3 7/8”(98.5 mm).

Fig. 12

ASSEMBLING AND INSTALLING THE ROUTER FENCE (50-295)

Fig. 13

Fig. 14

Fig. 15

Fig. 16

1. Secure the router fence to the table at each end

by threading a washer and a handle into the

holes located closest to the edge of the table.

2. Remove one hex nut from each of the hold-down

support arms .

Note: You may have to loosen the horizontal fence

adjustment knobs and slide the fences apart to give

you enough clearance to easily complete the following steps (See section Fence Adjustments on

page 8 for instructions on moving the fence).

3. Fit the threaded ends of the hold-down support

arms through the holes on the dust hood secure

the support arms in place using the hex nut, ,

removed in step 2.

4. Slide a hold-down bracket into each of the holddown support arms. Slide a hold-down into the

hold-down bracket (make sure the legs of the

hold-downs are pointing against the rotation of

the router bit, see section “Using the workpiece

hold-downs”on page 8) and tighten using the

lock knob on the hold-down bracket.

Precise placement and postioning, of the holddown brackets or the hold-downs can be adjusted later and will vary depending on the height

and width of the workpiece.

7

1 1/8”(29 mm)

2 3/8”(60 mm)

Page 8

FENCE ADJUSTMENTS

The fences can be moved and adjusted both left and right and

are completely independent of one another.

Left/Right

Adjustment

Loosen the knob, , to manually move the fence left or right.

Once you have the fence at the desired position, retighten the

knob.

Front to Bac

k

Adjustment

Loosen the thumb screw, , on the top of the fence frame and

adjust the fence front to back using the adjustment knob, ,

Once you have the fence at the desired position remember to

lock the fence by tightening the thumb screw before use.

Note: For safety considerations, the two fences should be adjusted as close to the router bit as possible (without

touching the bit).

Fig. 17

CONNECTING A DUST COLLECTOR

There is a 2 1/2” dust outlet on the rear of the fence assembly allowing for the connection of a dust collector (not

included).

Be sure to use an appropriate size hose and fittings (not included) and check that all connections are sealed tightly to minimize airborne dust.

If you do not already own a dust collection system, consider contacting your General® International distributor for

information on our complete line of dust collection systems or visit our website at: www.general.ca

BEFORE ROUTING CONNECT THE UNIT TO A DUST COLLECTION SYSTEM.

ALWAYS TURN ON THE DUST COLLECTOR BEFORE STARTING THE ROUTER AND ALWAYS STOP THE ROUTER BEFORE

TURNING OFF THE DUST COLLECTOR.

OPERATING INSTRUCTIONS

MAKE SURE TO READ, UNDERSTAND, AND FOLLOW ALL OPERATING INSTRUCTIONS AND SAFETY GUIDELINES THAT

CAME WITH YOUR ROUTER – FAILURE TO DO SO MAY LEAD TO SERIOUS INJURY AND/OR DAMAGE TO THE ROUTER,

ROUTER TABLE, OR WORKPIECE.

BEFORE ST

ARTING:

• Install the required bit in your router according to the instructions supplied with your router.

• Make sure that the router is firmly attached to the router extension table and that the appropiate table insert ring

is properly fitted and level in the table opening.

• When jointing, and/or profile cutting always perform a test cut on a scrap piece of wood before routing your final

piece.

USING THE WORKPIECE HOLD-DOWNS

The 50-295 router fence comes with a pair of hold-downs to help

reduce the likelihood of kickback.

Install the hold-downs with its legs pointing against the rotation of

the router bit.

It’s important to remember the stock must

always be fed against the rotation of the router bit.

Make the hold-downs as tight as possible to the stock being fed

while still allowing it to move smoothly.

8

Fig. 18

Feed direction

Bit rotation

Loosen knobs

to adjust height

Page 9

JOINTING AN EDGE

Jointing the edge of a board involves using a straight cutting

router bit to remove wood from the edge face of a board. The

result is a perfectly flat and square edge.

1. Install a straight cutting router bit into your router according to

the manufacturer’s instructions.

2. Snap the smallest table insert into the recessed hole that still

allows the router bit to rotate freely.

3. Loosen the locking lever and using the fence adjustment

knob adjust the out-feed fence lever so that it is flush with

the edge of the router bit, for precision use a straightedge

(Fig. 19).

4. Loosen the knobs and adjust the opening between the fences to allow the bit to clear the edge of both fences.

5. Raise or lower the bit slightly so that the bit is higher than the board’s thickness.

6. Adjust the in-feed fence to the router bit center, so that the distance is equal to the desired depth of the cut.

Fig. 19

PROFILE CUTTING

Profile cutting is usually performed using a bit with a guide bearing. The guide bearing controls the depth of cut into the edge

face of a board. A good example would be a chamfer bit

(Fig. 21).

The bearing rides along the uncut edge of the board while the

cutter removes the wood.

1. Mount a router bit into your router according to the manufac-

turer’s instructions.

2. Snap the smallest table insert into the recessed hole that still

allows the router bit to freely rotate.

3. Raise or lower the router bit to the desired height.

4. Loosen the knobs and adjust the opening between the

fences to allow the bit to clear the edge of both fences.

5. Adjust the fence back and away from the bit only enough to

allow the guide bearing to control the depth of cut.

6. Adjust the fence as close as possible to the bearing. The

fence will serve as a backup support, reducing the chance of

an accident.

Fig. 20

Fig. 22

Fig. 21

NOTES

9

Page 10

10

PARTS LIST

50-195

REF. DIAG. PART N0. DESCRIPTION SPECIFICATION QTY

1 50195-01 ROUTER EXTENSION WING 1

2 50195-02 TABLE INSERT 1 1/4” (29 MM) 1

3 50195-03 LOCK WASHER 3

4 50195-04 MOUNTING BOLT 7/16” X 1 3/4” 3

5 50195-05 MOUNTING CLIP 4

6 50195-06 HEX. HEAD BOLT 1/4” X 1 3/4” 4

7 50195-07 HEX NUT 4

8 50195-08 T-HEAD BOLT 4

9 50195-09 SHOULDER BOLT 4

10 50195-10 COMBINATION WRENCH 10-12 MM 1

11 50195-11 COMBINATION WRENCH 14-17 MM 1

12 50195-12 TABLE INSERT 2 5/8” (60 MM) 1

ROUTER EXTENSION WING

Page 11

11

PARTS LIST

50-295

REF. DIAG. PART N0. DESCRIPTION SPECIFICATION QTY

1 50295-01 FENCE FACE 2

2 50295-02 FENCE MOUNTING PLATE 2

3 50295-03 WASHER 2

4 50295-04 MOUNTING HANDLE 2

5 50295-05 MICRO ADJUSTMENT SLEEVE 2

6 50295-06 FENCE BODY 2

7 50295-07 THUMB SCREW 3/8” X 3/4” 2

8 50295-08 FENCE BODY BACKER PLATE 2

9 50295-09 MICRO ADJUSTMENT KNOB 2

10 50295-10 HEX. HEAD BOLT 3/8” X 1 1/2” 2

11 50295-11 HOLD-DOWN 2

12 50295-12 HOLD-DOWN BRACKET 2

13 50295-13 HOLD-DOWN SUPPORT ARM 2

14 50295-14 LOCK KNOB 5/16” X 5/8” 2

15 50295-15 HEX. NUT 1/2” 4

16 50295-16 DUST COVER 1

16A 50295-16A DUST COVER BODY 1

17 50295-17 HEX. NUT 1/4” 4

18 50295-18 FLAT WASHER 4

19 50295-19 LOCK KNOB 1/4” 2

20 50295-20 T-BOLT 1/4” X 1” 4

21 50295-21 HEX.HEAD BOLT 3/8” X 5/8” 2

22 50295-22 LOCK NUT 1/4” 2

23 50295-23 HEX. HEAD BOLT 1/4” X 1/2” 4

24 50295-24 PHILLIPS HEAD METAL SCREW 3/16” X 3/8” 6

ROUTER FENCE

Page 12

IMPORTANT: When ordering replacement parts, always give the model number, serial number of

the machine and part number. Also a brief description of each item and quantity

desired.

8360, Champ-d’Eau, Montreal (Quebec)

Canada H1P 1Y3

Tel.: (514) 326-1161

Fax : (514) 326-5565

Parts & Service

Fax : (514) 326-5555 Order Desk

orderdesk@general.ca

www.general.ca

50-195/295

Loading...

Loading...