Page 1

Heavy-duty enclosed stand for

reater stability.

g

Sanding belt operates at any angle

from horizontal to vertical.

ccurate belt tension and tracking

A

djustment.

a

Cast-iron table can be adjusted up

or down for full belt use.

Conveniently mounted motor

controls.

Cast-iron miter gauge can be locked

in position for quick and easy setup.

Adjustable, removable front table

fence.

Graphite covered steel plate for

reduced friction and extended

belt life.

LENGTH OF OSCILLA

TION

UP: 1/8’’ (3.2 mm)

DOWN: 1/8’’ (3.2 mm)

TOTAL: 1/4’’ (6.4 mm)

T SIZE

BEL

6’’ x 89’’ (152 x 2260 mm)

T SPEED

BEL

3900 LIN. FPM (1279 LIN. MPM)

AREA

LENGTH OF

W

ORK

33 3⁄4” (857 mm)

DUST CHUTE OUTLET

(102 mm)

4”

FRONT

TABLE SIZE

9 7⁄8” x 29 5⁄8” (250 x 751 mm)

UXILIARY/END TABLE SIZE

A

9 7⁄8” x 11 7⁄8” (250 x 300 mm)

ASE DIMENSIONS (L x W)

B

21 1/2” x 17” (546 x 432 mm)

VERALL DIMENSIONS (L x W x H)

O

50” x 21” x 49” (1270 x 533 x 1245 mm)

MO

TOR - PRE-WIRED 220V

110/220

,

2 HP

⁄

1 1

V

18/9

,

A

WEIGHT

277 LBS (126 kg)

REVISION 1 - OCTOBER 26/07

© COPYRIGHT GENERAL INTERNA

TIONAL 10/2007

Page 2

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

THANK YOU for choosing this General® International model 15-005S 6” x 89”

oscilla

ment and if pr

ting edge belt sander. This sander has been car

operly used and maintained,

will provide you with years of reliable service. To

ensure optimum performance and trouble-free operation, and to get the most from your

tment, please tak

inves

e the time to r

ead this manual befor

ating the unit.

efully tested and inspected before ship-

e assembling, installing and oper-

The man

ual’s purpose is to familiarize you with the safe operation, basic function, and features

of this edge belt sander as well as the set-up, maintenance and identification of its parts and

components. This manual is not intended as a substitute for formal woodworking instruction,

nor to offer the user ins

uction in the craft of w

tr

oodworking. If you are not sure about the safety of performing a certain operation or procedure, do not proceed until you can confirm, from

knowledgeable and qualified sources, that it is safe to do so.

ve read through these instructions, keep this manual handy for future reference.

Once y

ou’

GENERAL ® INTERNATIONAL WARRANTY

All component par

production, and each machine is thoroughly inspected upon completion of assembly. Because of our commitment to quality and customer satisfaction, General® International agrees to repair or replace, within a period of 24

months from da

manship or material. In order to obtain this warranty, all defective parts must be returned freight pre-paid to

General® International Mfg. Co., Ltd. Repairs attempted without our written authorization will void this warranty.

Disclaimer: The inf

the unit as it was supplied from the factory at the time of printing.

Because we are committed to making constant improvements, General

International reserves the right to make changes to components, parts

or features of this unit as deemed necessary, without prior notice and

without obligation to install any such changes on previously delivered

Reasona

.

units

cations and information in this manual corresponds with that of the unit

with which it was supplied. However, special orders and “after factory”

ble car

ts of General® Inter

te of purchase, any genuine part or parts which, upon examination, prove to be defective in work-

tion and specifications in this manual pertain to

ma

or

actory to ensure that the specifi-

t the f

en a

e is tak

national machiner

y are car

modif

inapplicable to your machine. Further, as several generations of this

model of sander and several versions of this manual may be in circulation, if you own an earlier or later version of this unit, this manual may not

depict your machine exactly. If you have any doubts or questions

contact your retailer or our support line with the model and serial number of y

efully tested and inspected during all stages of

tions may r

ica

our unit f

ender some or all information in this manual

tion.

ica

if

or clar

Page 3

Rules for Safe Operation

To help ensure safe operation, please take a moment to learn the machine’s applications and limita-

ions, as well as potential hazards. General® International disclaims any real or implied warranty and

t

olds itself harmless for any injury that may result from improper use of its equipment.

h

1. Do not operate the sander when tired, distracted, or

under the effects of drugs, alcohol or any medica-

ion that impairs reflexes or alertness.

t

2. The working area should be well lit, clean and free

of debris.

3. Keep children and visitors at a safe distance when

the sander is in operation; do not permit them to

operate the sander.

4. Childproof and tamper proof your shop and all

machinery with locks, master electrical switches

and switch keys, to prevent unauthorized or unsupervised use.

5. Stay alert! Give your work your undivided attention.

Even a momentary distraction can lead to serious

injury.

6. Fine particulate dust is a carcinogen that can be

hazardous to health. Work in a well-ventilated area

and whenever possible use a dust collector and

wear eye, ear and respiratory protection devices.

7. Do not wear loose clothing, gloves, bracelets, neck-

hile the sander is in opera-

y w

laces or other jew

tion.

8. Be sure that adjusting wrenches, tools, drinks and

other clutter are removed from the machine and/or

the table surface before operating.

elr

12. Do not push or force the work piece into the sander.

The machine will perform better and more safely

hen working at the feed rate for which it was

w

designed.

13. Avoid working from awkward or off balance positions. Do not overreach and keep both feet on floor.

14. Keep guards in place and in working order. If a

guard must be removed for maintenance or cleaning, be sure it is properly re-attached before using

the tool again.

15. Never leave the machine unattended while it is running or with the power on.

16. Use of parts and accessories NOT recommended

by General

ment malfunction or risk of injury.

17. Never stand on tool.Serious injury could occur if the

tool is tipped over or if the sanding belt is unintentionally contacted.

18. Always disconnect the tool from the power source

before servicing, changing accessories or the

sanding belt, or bef

nance or cleaning, or if the machine will be left

unattended.

19. Make sure that switch is in "OFF" position before

plugging in the power cord.

® International may result in equip-

e performing any mainte-

or

9. Keep hands well away from the sanding belt and

all moving parts. Use a brush, not hands, to clear

away chips and dust.

10. Be sure sanding belts are securely installed in the

machine.

11. Do not operate the sander if the sand paper is

damaged or badly worn.

20. Make sure the tool is properly grounded. If

equipped with a 3-prong plug it should be used

with a three-pole receptacle. Never remove the

third prong.

21. Do not use this sander for other than its intended

use. If used for other purposes, General

International disclaims any real implied warranty

and holds itself harmless for any injury, which may

result from that use.

®

Page 4

ELECTRICAL REQUIREMENTS

SERIOUS PERSONAL INJURY COULD OCCUR IF YOU CONNECT THE MACHINE TO THE POWER SOURCE BEFORE

COMPLETING THE SET-UP AND ASSEMBLY PROCESS. DO NOT PLUG THE MACHINE INTO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO.

Plug the sander into a proper receptacle. Your power tools should be connected to a dedicated electrical circuit

of not less than #14 wire and should be protected with a 15 amp time lag fuse. If an extension cord is needed use

only 3 wire cords with 3-prong grounded type plugs and 3-pole receptacles. Consult the chart below for details on

electing an extension cord.

s

TABLE - MINIMUM GAUGE FOR CORD

AMPERE

RA

ORE

M

THAN

0

6

10

12

TING

NOT

M

ORE

THAN

6

10

12

16

BEFORE CONNECTING THE SANDER TO A POWER SOURCE, MAKE SURE THAT THE ELECTRICAL CURRENT IS OF THE

SAME TYPE AS THAT STAMPED ON THE MOTOR NAMEPLATE. ALL ELECTRICAL CONNECTIONS SHOULD HAVE A PROPER CONTACT. NEVER CONNECT THE MACHINE TO A POWER SOURCE OF GREATER OR LOWER VOLTAGE THAN NEEDED. FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY TO THE USER AND/OR DAMAGE TO THE MACHINE. IF IN

DOUBT, CONTACT A QUALIFIED ELECTRICIAN BEFORE CONNECTING TO THE POWER SOURCE.

VOLTS

110 V

220 V

2

5 ft.

50 ft.

18

18

16

14

TOTAL LENGTH OF CORD IN FEET

5

0 ft.

100 ft.

AWG

16

16

16

12

GROUNDING

This sander must be grounded to protect the operator from electrical shock. The

supplied motor for this sander is pre-wired for 220V, single phase operation and has

a 3-conductor cord and 3-prong grounded plug to fit a grounded-type recepta-

.

cle

1

00 ft.

200 ft.

16

14

14

-

1

50 ft.

300 ft.

14

12

12

-

CONVERTING THE MOTOR TO 110V

Should y

the inside of the motor cover plate. Unless you are a qualified electrician, we do not recommend attempting this conversion on your own. If you choose to do so, you may risk serious personal injury, damage to the motor and voiding the warranty of your machine.

We suggest you ask your local General International distributor to recommend qualified electricians in your area

(or perhaps one of their own technicians) who can make this conversion properly and safely.

ou need to convert your machine’s motor from 220V to 110V power, there is an electrical schematic drawing on

4

Page 5

6” X 89” OSCILLATING EDGE BELT SANDER

15-005S

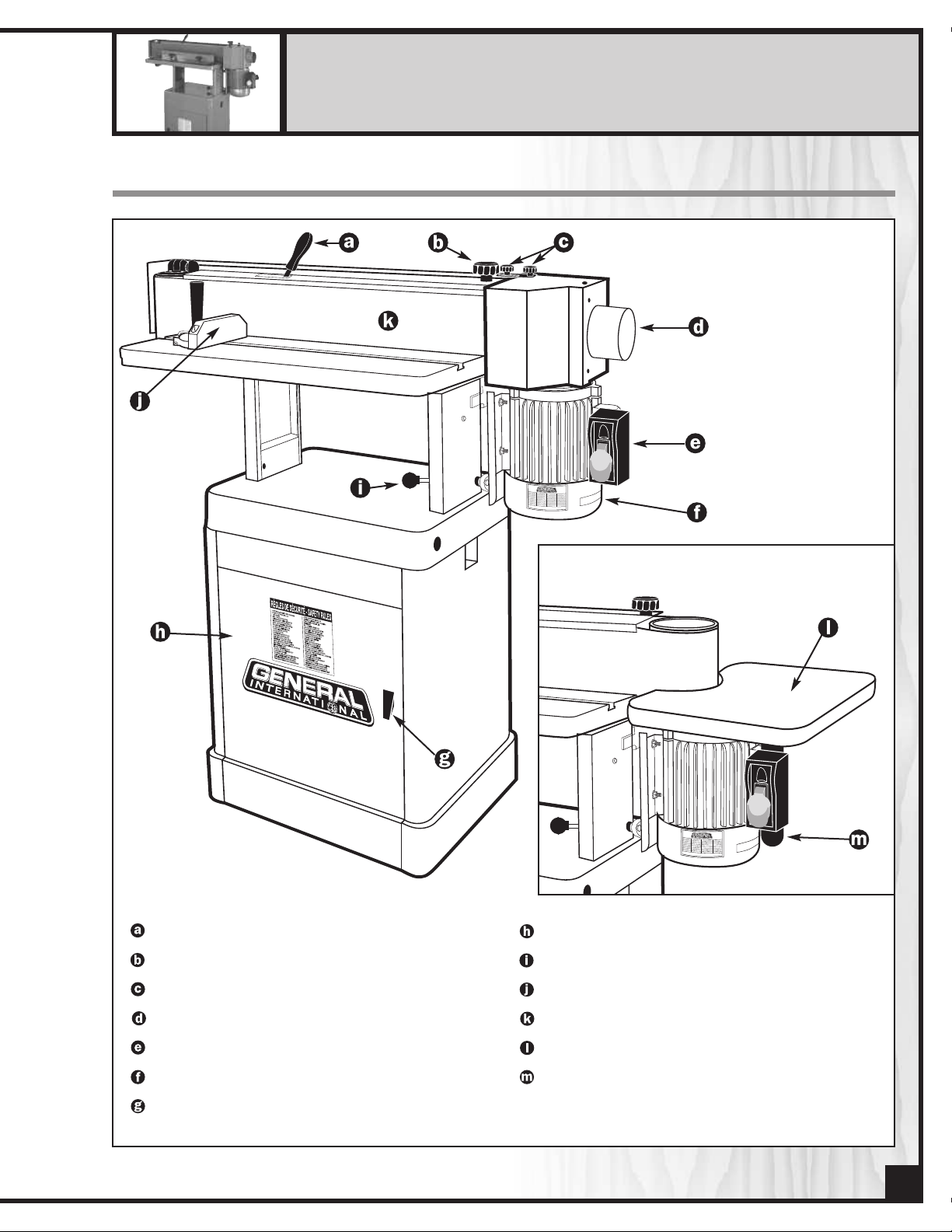

IDENTIFICATION OF MAIN PARTS AND COMPONENTS

BELT TENSION LEVER

LOCK KNOB

DUST HOOD LOCK KNOB

DUST OUTLET

SAFETY

MOTOR

ASE

B

SWITCH

DOOR HANDLE

ASSEMBLY

DOOR

ADJUSTMENT LEVER

T

SANDING HEAD

MITER GAUGE

SANDING BELT

UXILIAR

A

AUXILIARY/END TABLE SUPPORT ROD

Y/END TABLE

TIL

5

Page 6

UNPACKING

arefully unpack and remove the unit and its components from its shipping container and check for missing or

C

damaged items as per the list of contents below.

NOTE: Please report any damaged or missing items to your GENERAL® INTERNATIONAL distributor immediately.

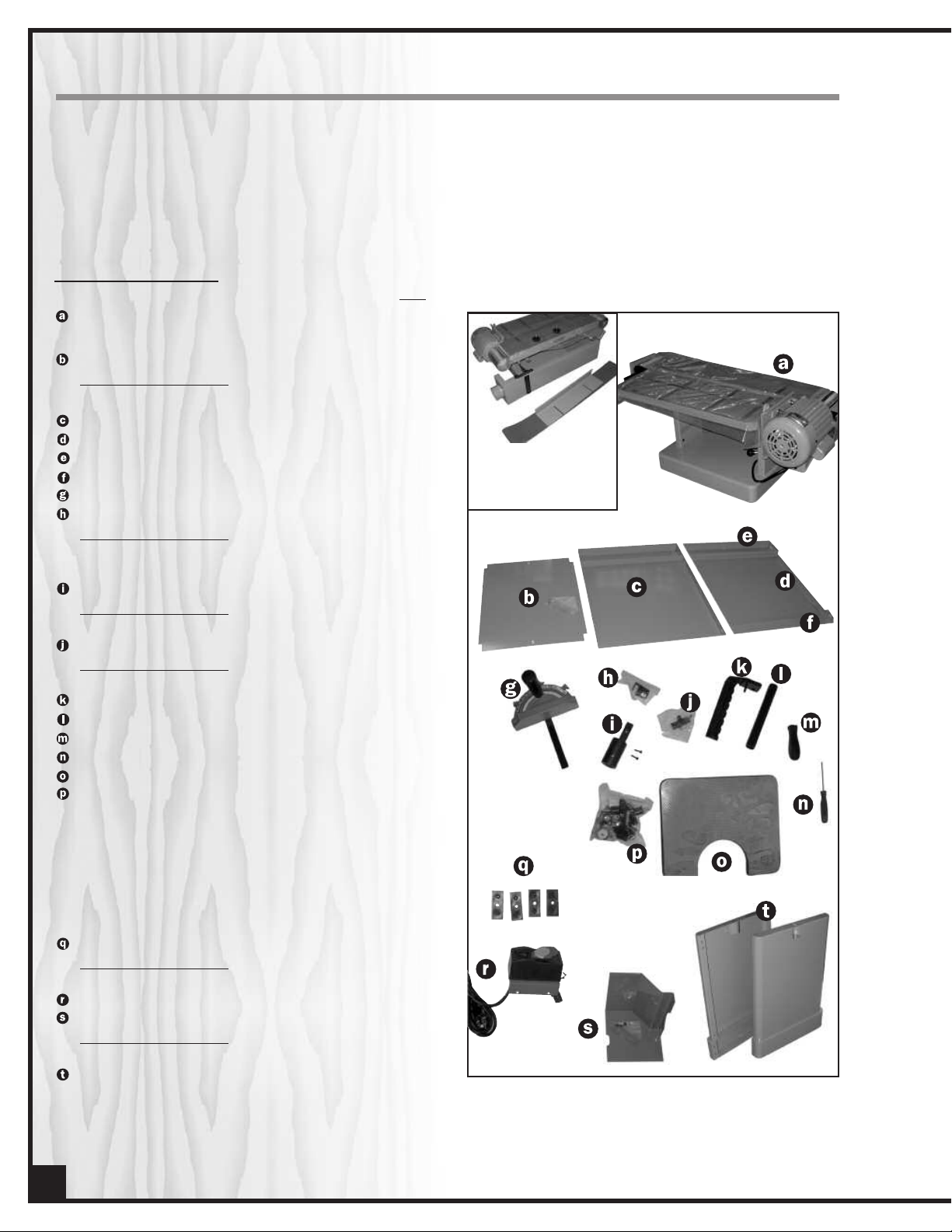

LIST OF CONTENTS

QTY

SANDING HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

-FENCE*, 6” X 89” 100 GRIT SANDING BELT* . . . . . . . . . . . . . .1

SHELF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

HARDWARE BAG INCLUDING:

— PHILLIPS SCREW, FLAT WASHER , LOCK WASHER . . . . . . . . . . . . . . .2

BACK PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

DOOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

UPPER DOOR SUPPORT RAIL . . . . . . . . . . . . . . . . . . . . . .1

LOWER DOOR SUPPORT RAIL . . . . . . . . . . . . . . . . . . . . .1

MITER GAUGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

DOOR STOPPER

HARDWARE BAG INCLUDING:

— STOPPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

— PHILLIPS SCREW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

TABLE SUPPORT BRACKET . . . . . . . . . . . . . . . . . . . . . . . . .1

HARDWARE BAG INCLUDING:

— SCREW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

DOOR HANDLE

HARDWARE BAG INCLUDING:

— HANDLE, RUBBER STOPPER, FLAT WASHER, LOCK NUT . . . . . . . . . .1

WORKPIECE STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

TABLE ROD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

TENSION LEVER HANDLE . . . . . . . . . . . . . . . . . . . . . . . . . .1

DRUM ADJUSTMENT TOOL . . . . . . . . . . . . . . . . . . . . . . .1

AUXILIARY/END TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . .1

WARE BAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

HARD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

HANDLE

—

-LOCK KNOB (SHORT TOGGLE SCREW) . . . . . . . . . . . . . .2

LOCK KNOB (MEDIUM & LONG TOGGLE SCREW) . . . . . .1

-

ASHER (LARGE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

W

T

FLA

—

— FLAT WASHER (MEDIUM), LOCK WASHER . . . . . . . . . . . . . . . . . .14

— CARRIAGE BOLT, HEX NUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

HEX BOL

—

T (LONG)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RUBBER FEET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

HARDWARE BAG INCLUDING:

BOLT, NUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

ASHER,

W

T

— FLA

SAFETY SWITCH ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . .1

RIGHT DRUM GUARD . . . . . . . . . . . . . . . . . . . . . . . . . . .1

AG INCLUDING:

WARE B

HARD

— FLANGE SCREW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SIDE PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2

*The sanding belt and the

ence are stored inside the

f

sanding head to prevent

damage in shipping.

6

Page 7

PREPARATION AND PLACEMENT WITHIN THE SHOP

50”

21 1/2”

17”

21”

49”

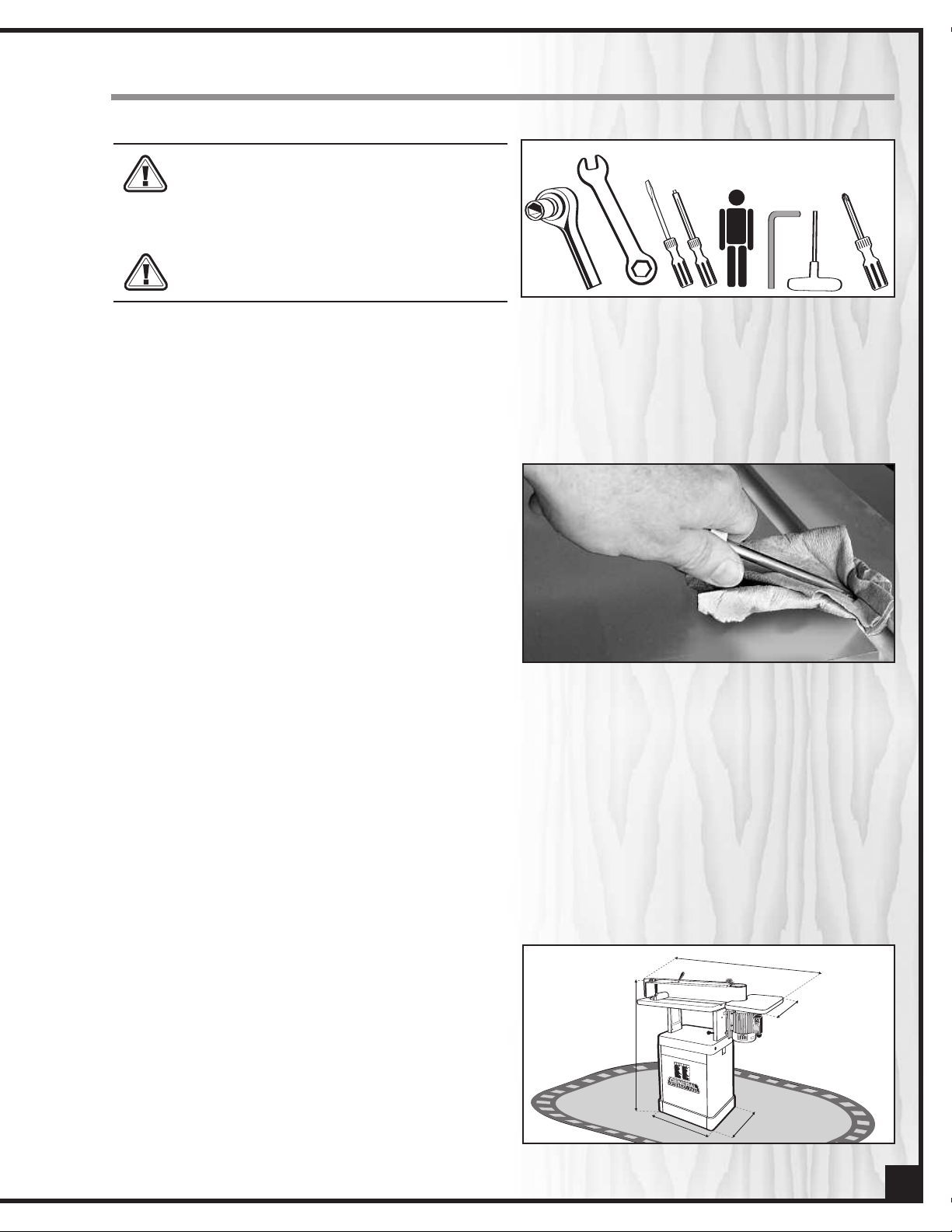

SET UP SAFETY

Serious personal injury could occur if you connect

the machine to the power source before you have

completed the set up process. DO NOT connect

the machine to the power source until instructed to

do so.

The MODEL 15-005S is a heavy machine (277 LBS 126 kg). Do not over-exert. Arrange to have help

nearby and ready for unpacking and set- up.

CLEAN UP

The unpainted cast-iron surface of the tables are covered

with a protective coating that helps prevent rust from

forming during shipping and storage. Remove this protective coating by rubbing with a rag dipped in kerosene,

mineral spirits or paint thinner.

tially flammable solvent soaked rags according to manufacturers’ safety recommendations.) A putty knife, held flat to avoid

scratching the surface, may also be used to scrape off the

coating followed by clean-up with solvent. Avoid rubbing

the painted surfaces, as many solvent based products will

remove paint.

To prevent rust, apply a light coating of paste wax or use

regular applications of any after-market surface protectant or rust inhibitor such as General International “Top

Saver” item #GC-010.

(Handle and dispose of poten-

ADDITIONAL REQUIREMENTS FOR SET UP

OROR

• 12 mm Hex socket or 12 mm Open end wrench

• Flat head screwdriver

• Small square head screwdriver

• Extra person for help with lifting

• 4 mm Allen key or 4 mm T-handle hex wrench

• Phillips screwdriver

Tip/Hint: With a screw driver, push a solvent-saturated rag into the

T-slot to remove the grease so the miter gauge will slide freely.

PLACEMENT WITHIN THE SHOP

This model 10-005S MI should be installed and operated only on a solid, flat and stable floor that is able to support

the weight of the sander (277 LBS -126 kg) and the operator. Using the dimensions shown as a guideline, plan for

placement within y

(either passing shop visitors or other shop workers) or other tools or machinery.

our shop that will allo

w the operator to w

k unencumbered and unobs

or

tructed by foot traffic

ESTABLISHING A SAFETY ZONE

For shops with fr

advisable to establish a Safety Zone around shop

machinery. A clearly defined “no-go” zone on the floor

around each machine can help avoid accidents that

could cause injury to either the operator or the shop visitor. It is advisable to take a few moments to either paint

(using non-slip paint) or using tape, define on the floor the

limits or perimeter of each machines safety zone. Take

teps to ensur

s

e that these areas are off limits whenever a machine

ar

aw

is running for everyone but the individual operating the

unit.

equent visitor

e tha

t all opera

s or multiple operators, it is

s and shop visitors are

tor

7

Page 8

ASSEMBLY INSTRUCTIONS

ASSEMBLE THE BASE

b

w

n

olt

asher

ut

rubber

f

oot

1. Using a bolt, washer, and a nut, attach 2 rubber

feet to the side panels (2) according to

order of assembly . Tighten nuts with either a 12

mm hex socket or 12 mm Allen key.

DOOR

stopper

w

asher

ut

n

3. Install the door handle on the door by following the order illustrated in figure .Install the door

between both door supports, first by inserting the

rod into the hole of the lower door support ,

then, by pulling down on the spring lever , and

placing it in the hole of the upper door support.

2. Attach the upper and lower door supports to

the side panels , shown above, using the carriage bolts, medium flat washers, lock washers and

nuts.

Note: Make sure the hole in the upper door support

faces downward , and the hole in the lower door

support faces upward (so that the table rod can be

inserted into the lower door support and the spring

lever can be inserted into the upper door support.)

4. Install the door stopper with 2 screws , using a

small square head screwdriver.

tall the back panel using 2 carriage bolts,

Ins

5.

medium flat washers, lock washers and nuts ,

one on each side.

8

6. Place the shelf in the base and secure using 2

, medium flat washers and lock washers.

ws

e

scr

Page 9

INSTALL THE SANDING HEAD ONTO THE BASE

To Loosen

To Lock

The sanding head is heavy. Do not over-exert. The

help of an assistant will be needed for the following

step.

Note: Position the sanding head onto the base so that

the motor is on the right side of the front of the base.

1. With the help of an assistant, place the sanding head on to the base and a

with a hex bolt,

washer .

lock washer and a medium flat

ttach each end

INSTALL THE SWITCH

Screw the switch assembly and the table support

bracket into the mounting holes on the end of the

wn above, using a 4 mm T-handle hex

as sho

,

motor

wrench or a 4 mm Allen key. Then, connect the power

d from the motor to the inlet plug on the switch

cor

2. To facilitate the upcoming assembly steps, reposition the sanding head from the horizontal (180º) to

the vertical (90º) position. To reposition the head,

push back the sanding head tilting adjustment

lever (under the sanding head) and swivel the

head into the vertical position.

Note: Make sure to pull the lever back to lock the head

in position.

INSTALL THE SANDING BELT

Note: The sanding belt and the fence are stored inside

the sanding head to prevent damage in shipping

To access the sanding belt and fence, remove the belt

guard , left drum guard (side opposite the motor)

.

and dust hood , which are already installed on the

sanding head

.

1. Unscrew the lock knob that retains the left drum

d. Then remove the guard and put it aside for

guar

now.

2. Unscrew the lock knob that retains the belt

guard and the dust hood, then remove the guards

.

w

and put them aside f

or no

9

Page 10

. Remove the sanding belt and the fence that

3

are stored in the sanding head. Put the fence aside

for now.

Tight - Loose

. Install the handle onto the belt tension lever . To

4

install or change the sanding belt, simply pull the

belt tension lever to the “loose” position . Then

install the sanding belt and reposition the belt

tension lever back to the “tight” position.

5. Install the sanding belt guard between the 2

rear supports – secure the left side only for now,

using a short lock knob and a large flat washer, as

shown above .

Note: Raise the guar

tightened at the top of the rear supports, to facilitate

the upcoming assembly s

will not rub or bump against the motor).

ds so tha

t the loc

teps (so tha

k knobs can be

t the dust hood

6. Fit the left drum guard between the support

and the belt guard just installed, using another

large flat washer and short lock knob .

7. Attach the right drum guard on the dust hood

with 3 flange screws .

10

Page 11

INSTALL THE WORKPIECE STOP

The workpiece stop acts as a fence to assist in maintaining control over the workpiece making it easier

and safer to hold the workpiece flat to the belt for an

even, more uniform sanding job. It also acts as a stopper to prevent the workpiece from being carried away

or flung from the machine by the rotation of the sanding belt.

2. Insert the rod of the workpiece stop into the first

hole on top of the belt.

3. Replace the dust hood in position, sliding the right

drum guard under the head of the workpiece

stop.

1. Loosen the small knob and move the dust

hood towards the back , then re-tighten the

knob to prevent the piece from moving.

4. Using a medium flat washer and a long lock knob,

attach the workpiece stop, as well as the right

drum guard, to the sanding head, as show above.

OPERATING INSTRUCTIONS

TO REDUCE THE RISK OF DAMAGE TO THE SANDER OR THE WORKPIECE, AS WELL AS THE POTENTIAL FOR PERSONAL

INJURY

AND

MACHINE.

AFTER INITIAL SET

,

THAT ALL FASTENERS AND MOVING PARTS ON THIS SANDER ARE LOCKED IN PLACE BEFORE STARTING THE

CONNECT TO A DUST COLLECTOR

DEPENDING UPON THE TYPE OF SANDING, WHENEVER POSSIBLE, CONNECT YOUR MACHINE TO A DUST COLLECTOR.

ALWAYS TURN ON THE DUST COLLECTOR BEFORE STARTING THE SANDER AND ALWAYS STOP THE SANDER BEFORE

TURNING OFF THE DUST COLLECTOR.

AS WELL AS BEFORE EACH USE, MAKE SURE THAT EVERYTHING IS SECURELY INSTALLED

-UP

11

Page 12

• There is a 4” diameter dust outlet on the right side

of the machine allowing for the connection to a

dust collector (not included).

• Be sure to use appropriate sized hose and fittings

(not included) and check that all connections are

ealed tightly to minimize airborne dust.

s

• If you do not already own a dust collection system

consider contacting your General® International

istributor for information on our complete line

d

of dust collection systems or visit our Web Site at:

www.general.ca

CONNECTING TO A POWER SOURCE

TO AVOID RISK OF SHOCK OR FIRE, DO NOT OPERATE THE UNIT WITH A DAMAGED POWER CORD OR PLUG.

REPLACE DAMAGED CORD OR PLUG IMMEDIATELY.

Plug the machine into a proper receptacle – before connecting to the power source make sure that the switch is in

the “off” position and that the power supply is of the same type as that stamped on the I.D. nameplate of the motor.

Running on low voltage will damage the motor.

ON/OFF SWITCH & SAFETY KEY

MAKE SURE THE SWITCH IS IN THE “OFF” POSITION BEFORE PLUGGING IN THE POWER CORD. REMOVE THE SWITCH

KEY WHENEVER THE SANDER IS NOT IN USE. PLACE IT IN A SAFE PLACE AND OUT OF THE REACH OF CHILDREN.

The model 15-005S M1 is equipped with a simple “rocker style” On/Off switch featuring a removable lock out safety

key.

To prevent unauthorized use or unintentional start-up, remove the safety key and store it in a safe place whenever

the sander is not in use.

To start the sander insert the safety key and pull the switch toward you. To stop the machine, push the switch in.

SAFETY KEY

POWER ON

WER OFF

PO

(PREVENTS START-UP

WHEN REMOVED)

BASIC FUNCTIONS OF THIS MACHINE

This machine has been designed f

such as chair legs or cabinet doors.

The sanding belt can be tilted at any angle between 90º and 180º for bevelled pieces. Flat sanding, with belt in

hoizontal position (180º), is easier and safer for longer workpieces.

The auxiliary/end table can be installed on the right side of the sanding head and used for sanding round or

.

aces

ed surf

v

cur

ws f

e allo

surf

tur

Another advantage of the oscillating action of the belt is to help dissipate surface heat build-

ace.

The oscilla

lation (vertical travel) of the belt optimizes sanding efficiency and extends sanding belt life by using a larger area

of the belts’

up – as heat build-up can cause premature belt wear.

ting fea

or sanding or polishing (removing kerf or pencil marks) on small workpieces,

or faster more efficient sanding. The cross grain sanding action caused by the oscil-

12

Page 13

RECOMMENDED ADJUSTMENTS

INSTALL THE AUXILIARY/END TABLE

Install the auxiliary/end table on the right side of

machine when you need support for sanding rounded

or curved workpieces.

Tip: The dust hood cannot be properly closed or fully

used when the auxiliary table is installed, therefore

whenever the table is not required remove it and set it

aside in order to maximize dust collection efficiency by

allowing you to close and make full use of the dust

hood. The auxiliary/end table is very easy to install or

remove when needed by simply loosening (or tightening) the lock knob holding it in place on the bracket

and then removing it from (or installing onto) the

bracket.

1. To install the table in its bracket, the dust hood must

be moved by unscrewing both the large and

small knobs and moving the dust hood towards

the back . Screw the small knob back in to

prevent the piece from moving.

2. Insert the table rod in the opening under the

table and tighten using the bolt and nut, which

are already mounted

.

3. Place the table rod assembly into the table bracket . Insert a medium lock knob into the hole in the

table bracket to keep it in place

.

Tip: Align the flat surface of the table rod with the hole

in the table bracket,a flat surface offering a better grip

for the toggle screw than a rounded one.

ADJUST THE HEIGHT OF THE MAIN TABLE

Adjusting the height of the table allows an even wearing of the sanding belt surface.

Loosen the two lock knobs , which are under the

sanding head, then adjust the table height and tighten

the knobs to lock the table in position.

Tip: To maximize belt usage when working with shorter

work pieces, periodically adjust the table height to systematically make use of various portions of the belt. For

example; a series of 2” tall workpieces can be separated into 3 smaller batches with each batch being sanded with the table set at different heights to use in

sequence the lower, middle or upper portion of the belt.

13

Page 14

INSTALL THE FENCE

1. The fence allows easier and safer sanding, providing support for long workpieces. The fence can

also be positioned diagonal to the belt, allowing

you to sand bevelled workpieces.

2. Align both blocks , which are inside the slot in the

t

able, with both holes in the fence, then lock them

with medium flat washers and short lock knobs .

ADJUST THE MITER GAUGE (IF NEEDED)

The miter gauge allows for easier and safer sanding by providing workpiece support when sanding straight (90°)

or angled ends (30° to 90°). The miter gauge supplied with your sander is adjustable from 30° to 90° right to left,

and has adjustable index stops at 90° and 45° to the right and left.

To use a setting other than 90°, loosen the lock knob

by turning it counter-clockwise, pull the stop-lock

pin , rotate the miter head to the required angle,

shown on the angle indicator. Turn the lock knob

clockwise to tighten it.

To check the accuracy of the miter gauge’s factory

settings, set it at 90° and check it with an L-square or Tsquare. Repeat adjustment if necessary.

If the miter gauge needs adjusting, manually turn the

head so the pointer is where you think it ought to be,

tighten the lock knob and loosen the nut . Turn the

adjusting screw until it touches the stop-lock pin

and tighten down the nut again. Recheck the angle.

Repeat, if necessary, until a true 90° is achieved.

ADJUST THE ANGLE OF THE SANDING HEAD

Depending upon y

adjusted to any angle from 90º to 180º.

Push back the sanding head tilting adjustment lever

(under the sanding head) to unlock the head, then tilt

the head to the required angle on the angle indicator

scale . Make sure to pull the lever back to lock the

head in position.

our needs, the sanding head can be

14

Note: Bef

position, always lock the dust hood so that the sanding

head can be easily tilted, and so it will not scratch the

base of the sander.

ore tilting the sanding head in the horizontal

Page 15

INSTALLATION/REPLACEMENT OF THE SANDING BELT

Standard size (6” by 89”) replacement belts can be purchased in a variety of grits from your General® International

dealer under the following parts numbers:

• 15-006 - 80 Grit

• 15-007 - 100 Grit

• 15-008 - 120 Grit

• 15-009 - 150 Grit

or (depending on availability) from your local tool,abrasives or sharpening supply dealer. These are standard sizes

that should be readily available in most areas. The use of any other size is not recommended and can lead to serious injury and/or damage to the machine.

Note: For best unobstructed access remove the belt guards, workpiece stop and dust hood, whenever changing

anding belts.

s

Tip: To extend belt life and avoid premature breakage,

take note of the direction arrows printed on the inside of

the sanding belt to make sure you install the belt in the

correct direction.

1. Place the sanding head in the vertical position.

2. Pull the belt tension lever to the "loose" position

and remove the sanding belt (if there is already

one installed).

3. Install a new sanding belt onto the drums .

4. Reposition the belt tension lever back to the “tight”

position .

TIGHT - LOOSE

BELT TRACKING ADJUSTMENT

Note: Belt tracking adjustments may be necessary after

changing or replacing a sanding belt, to counterbalance for unevennesses between sanding belts.

Though not essential, proper belt tracking (having the

belt running straight and oscillating as evenly on the

drums as possible) can prolong belt life and avoid having the belt slip off during operation. This is done by tilting the left drum (opposite side to motor) slightly

towards the front or rear, so that the belt does not get

uncentered, as a result of its oscillating movement, but

tays on the middle of the drums

s

urn on the machine on for 5-10 seconds to visually con-

T

firm the belt tracking.

If the belt is tracking straight and oscillating evenly

up and do

piece stop and dust hood and proceed with normal operations.

If the belt is not tracking straight, follow the instructions below before proceeding with normal sanding operations.

1. Turn off the machine.

2. With the supplied drum adjustment tool , turn the

adjustment knob clockwise or counter clockwise,

T

3.

confirm the belt tracking.

4. As needed, turn off the machine and repeat this

adjus

on the drums.

5. Re-install the belt guards, workpiece stop and dust

hood and proceed with normal operations.

wn on the drums on the middle of the rollers , you are ready to sand - Reinstall the belt guards, work-

as needed,

n on the machine f

ur

tment pr

to adjus

ocess until the belt is trac

.

t the belt tracking.

or 5-10 seconds to visually

king evenly

15

Page 16

MAINTENANCE

MAKE SURE THE SWITCH IS IN THE OFF POSITION AND UNPLUG THE UNIT FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE.

UBRICATION

L

Use an all purpose grease. Keep the belt tilting mechanism and belt tension mechanism well greased. Regrease every year as needed. Lubricate the drum oscillating mechanism . Unscrew and remove the cover of the

black box , located under the left drum, with a 4 mm Allen key.

ll motor and drum bearings are sealed and permanently lubricated. No further lubrication is needed.

A

PERIODIC MAINTENANCE

1. Work area, and machine should be cleaned after every finished project.

2. Keep the machine CLEAN and FREE OF DUST to help dissipate heat and avoid motor overheating.

3. Drums must always be kept clean. Dirt on drums will cause poor tracking and belt slippage

4. Periodically inspect the ON/OFF switch, power cord, plug and other parts for damage.

DO NOT OPERATE THE SANDER WITH A DAMAGED SWITCH, POWER CORD, PLUG, OR OTHER PARTS. REPLACE A DAMAGED PART IMMEDIATELY.

REQUIRED MAINTENANCE

1. Sanding belt should be replaced when worn out.

2. Replace any damaged or missing parts before

operating.

3. The graphite coating on the platen will wear and

ery 3 years

eplacement.

er time requir

v

o

(approx) in small shop settings and up to 10 years in

home shop settings,

to show visible signs of wear and will need to be

peeled of

removed. A replacement graphite coated paper

strip should be glued (with contact cement) onto

the platen in it’s place. Most retail outlets that sell

s

tationary power tools and abrasives products do

toc

s

sizes of sanders.

f (using a solvent based s

k graphite replacement strips for most popular

e r

the graphite coa

Ev

ting will begin

tripper ) and

16

NEVER

TTEMPT

A

AIR MOTOR YOURSELF. CONTACT A QUALIFIED TECHNICIAN.

O REP

T

Page 17

RECOMMENDED OPTIONAL ACCESSORIES FOR YOUR SANDER

W

e offer a large variety of products to help you increase productivity, accuracy and safety

when using your sander. Here’s a small sampling of accessories available from your local

General International dealer. For a complete list, visit our website at www.general.ca.

Sanding Belts

Standard size (6” by 89”)

15-006 - 80 Grit

15-007 - 100 Grit

15-008 - 120 Grit

15-009 - 150 Grit

Mobile base

item 50-025

Easily roll your sander anywhere in your shop. Load

capacity: 500 lbs. Wheels lock

when equipment is in use.

Dust Collector

We have a wide selection of

dust collectors to suit all your

shop needs. Dust

collectors contribute to a

cleaner and more healthful

workshop environment.

“TOP SAVER”

item #GC-010

All in one, table top rust

remover and lubricant. /

Reduces friction and prevents

binding. / Removes and

inhibits rust and corrosion. /

Repels dust and moisture.

cleaner

NOTES

17

Page 18

18

Page 19

P

ARTS LIST

15-005S

PART N0. REF. NO. DESCRIPTION SPECIFICATION QTY

0101001BG

15005-01 BASE 1

15005-02 SWITCH 1

15005-08 THREADED ROD 1

15005-09 NUT 1

15005-10 ECCENTRIC CAM 1

15005-10A NUT 1

15005-11 PIN 1

15005-12 LOCK HANDLE 1

15005-13 HANDLE KNOB 1

15005-14 KEY 1

15005-15 HEX HEAD. SCREW 1

15005-16 WASHER 1

15005-17 MAIN TABLE 1

15005-17A CAP SCREW 4

15005-18 MACHINIST BOLT 2

15005-19 HEX NUT 2

15005-19A LOCK WASHER 2

15005-20 GUIDE BLOCK 2

15005-21 FENCE 1

15005-22 LOCK KNOB 4

15005-23 MOTOR DRUM 1

15005-24 MITER GUIDE BAR 1

15005-25 PIN 1

15005-26 SET SCREW 1

15005-27 LOCATING PLATE 1

15005-28 POINTER 1

15005-28A GUIDE WASHER 1

15005-29 SANDING BELT 1

15005-30 MITER GAUGE BODY 1

15005-30A WASHER 1

15005-31 SCREW 3

15005-32 HEX NUT 3

15005-33 HANDLE 1

15005-34 PLATEN 1

15005S-34B SANDING HEAD TOP COVER 1

15005S-35

15005-36 LOCK KNOB M8X1.25X35 1

15005-37A PIN 1

15005S-38 SPRING 1

15005-39 SP

15005S-40 KEY 4X4X15 1

15005S-41 ROLLER ARM 1

15005S-42 BEARING 6011ZZ 2

15005-43 PHILLIPS HEAD SCREW 2

15005-44 FLAT WASHER 2

15005S-45 LOCK WASHER 2

15005S-49 SCREW 3/16"-24UNCX1/4" 4

15005-50

15005-51

15005S-52 RETENTION PLATE 1

15005-53

15005-54

2

W2010002

20101005

S0120380

20101007

S0110600

S0310525

10102024

10102023

S0410525

S0020416

S0210404

20101011A

S0020510

20101065

S0111000M

S0230308

20101013

20101014

20101015

20101016

20101022

21700001

21700002

21700037

20101039

S0310640

21700004

20101055

S0400415

21700005G

C1106011ZZ

S0030510M

S0210401

S0230400

S0030304

S0220300

20101031

21600041

S0060510

20101032a

TENSION B

CER 1

A

SPROCKET WASHER 12

T TENSION LEVER 1

BEL

ARRIA

C

T

BEL

AR 1

GE BOL

TENSION LEVER HANDLE

T12

1

19

Page 20

PARTS LIST

15-005S

PART N0. REF NO. DESCRIPTION SPECIFICATION QTY

15005-55 HEX HEAD BOLT 5/16"-18UNCX1-3/4" 1

15005-56 LOCK NUT 5/16"-18UNC 5

15005-57 TILT SCALE 1

15005-58 SCREW 1

15005-59 POINTER 1

15005-60 SCREW 1

15005-61 MOTOR 1

15005-62 HEX HEAD BOLT 5/16"-18UNCX1-1/4" 5

15005S-63 FLAT WASHER 40

15005S-65 HINGE PIN 2

15005-67 MOTOR TO SWITCH POWER CORD 1

15005-69A LEFT DRUM GUARD 1

15005S-69B BELT COVER 1

15005S-69N REAR BELT GUARD 1

15005-70 SLIDE PANEL 2

15005-71 LOCK KNOB M8-1.25X12 3

15005-72 WORKPIECE STOP 1

15005-73 SIDE PANEL 2

15005-74 BACK PANEL 1

15005-75 DOOR 1

15005S-78 LOCK WASHER 22

15005-79 HEX NUT 5/16"-18UNC 26

15005S-80 HINGE BRACKET 2

15005-81 DRUM ADJUSTMENT TOOL 1

15005-82 SCREW M5X0.8X12 8

15005S-83 SCREW M4X20 8

15005-88 RUBBER FOOT 4

15005-89 HEX HEAD BOLT 5/16"-18UNCX5/8" 4

15005S-90 HINGE 2

15005-94 AUXILIARY/END TABLE 1

15005S-95 LOCK WASHER 10

15005-96 TABLE ROD 1

15005-100 ANGLE INDICATOR STICKER 1

15005-101 I.D. STICKER 1

15005-102 BELT TENSION LEVER STICKER 1

15005-103 DUST HOOD 1

15005-104 PHILLIPS HEAD SCREW 3/16"-24UNCX1/4"L 3

15005S-105 WORM GEAR COVER 1

15005S-106 WORM GEAR HOUSING 1

15005S-107 CAM SHAFT 1

15005S-108 CAM 1

15005S-109 MOUNTING BRACKET 1

15005S-110 BRACKET 1

15005S-111 CAP SCREW 2

15005-112 NAME PLATE 1

15005-114 UPPER DOOR SUPPORT 1

15005-115 LOWER DOOR SUPPORT 1

15005-116 SHELF 1

15005-117 DOOR STOPPER 1

15005-118 GRAPHITE COATED PAPER 1

15005-119 SCREW M3X0.5 2

15005-120 DOOR HANDLE 1

20

S0020530

S0120201

20101033

S0040301c

10102022

S0040300

M2142211

S0020520

S0210500c

90100064

L0000111-1P

20101038a

21700014

21700013G

20101002

20101024

20101040

20104054G

20104053G

20104060G

S0230506

S0110500

90100063

20103044

S0040512M

S0040420M

10401029

S0090512

90100062

20101051

S0230300

20101050

J0000102

J2091001

I2000009

20104044G

S0030304

21700023

21700024

21700030

21700022

21700028

21700027A

S0010420

JG000004

20104058G

20104059G

20104051G

20104061G

20101048A

S0040404

12100038

Page 21

P

ARTS LIST

15-005S

PART N0. REF. NO DESCRIPTION SPECIFICATION QTY

15005-121 DOOR HANDLE SCREW 1

5005-122 SPRING PIN 1

1

15005-123 NYLON NUT M4 1

5005S-124 WASHER 7

1

5005-125 RUBBER STOPPER 1

1

15005-126 STRAIN RELIEF 1

15005-127 SWITCH BRACKET 1

15005-128 SWITCH INLET CORD 1

15005-132 MAIN POWER CORD 1

15005-133 SWITCH BOX 1

15005-134 SCREW 3/16"-24UNCX3/4" 2

15005-135 SCREW 3/16"-24UNCX1/4" L 2

15005S-136 TABLE SUPPORT BRACKET 1

15005S-137 CAP SCREW 2

15005S-146 SUPPORT RING 2

15005S-147 CAP SCREW M5X0.8PX20L 4

15005S-148 BEARING COVER 1

15005S-149 CAP SCREW 5/16"-18UNCX1X1" L 1

15005S-150 SCREW 3

15005S-151 BEARING SEAT 1

15005S-152 BEARING 6202 1

15005S-154 BEARING COVER 1

15005S-155 BEARING 6003 1

15005S-158 CAP SCREW 2

15005-159 WARNING STICKER 1

15005S-160 BELT DIRECTION STICKER 1

15005-161 POWER CORD LABEL 1

15005S-164 SPACER 2

15005S-165 BEARING 6800 2

15005S-167 WORM GEAR 1

15005S-168 CAP SCREW 5/16"X1-1/4" 2

15005S-169

15005S-183 IDLER DRUM 1

15005S-184 SET SCREW 2

15005S-185 ROLLER SHAFT 1

15005S-186 KEY 1

15005S-188 WORM GEAR SHAFT 1

15005S-191 KEY 1

15005S-194

15005S-203 KNOB 1/4"-20UNC 1

15005S-204

15005S-205 SHAFT 1

15005S-206 WORM GEAR HOUSING GASKET 1

15005S-207 CAP SCREW 2

12100039

0310318

S

S0120600M

0210401

S

12100040

7w-2

20101044

L0000112-2

L0000132

12100038

S0030340

S0070302

21700018

S0010308

21700025

S0010520M

20900049

S0020501

S0040412M

21700017

C1206202

20900049

C1106003

S0010409

JG00001

I2000010

JG00001

21700031

C1106800

21700010

S0010510

50203004

21700008

S0050606M

21700051G

S0400540

21700009

S0400425

21700032

11108024

S0520028

21700056

21700054G

S0010530M

LOCK KNOB M6X P1.0 2

CONNECTION PLATE 1

C RING

2

21

Page 22

15-005S

8360, Champ-d’Eau, Montreal (Quebec)

Canada H1P 1Y3

el.: (514) 326-1161

T

ax : (514) 326-5565

F

ax : (514) 326-5555

F

desk@general.ca

der

or

www.general.ca

ar

P

Or

ts & Ser

vice

der Desk

IMPORTANT: When ordering replacement parts, always give the model number, serial number of

the machine and par

ed.

desir

t number

. Also a brief description of each item and quantity

Loading...

Loading...