Page 1

6-ChannelDigitalProportionalR/CSystem

TM

TM

INSTRUCTION MANUAL

1M23N30302

Page 2

Technical updates and additional programming examples available at: http://www.futaba-rc.com/faq

Entire Contents © 2015

Page 3

TABLE OF CONTENTS

Introduction ............................................6

●Support and Service ..................................6

●Application, Export, and Modication ....7

●Denitions of Symbols ...............................9

●Precautions (do not operate without

reading) .......................................................9

Before use ..............................................14

●Features ...................................................14

●Contents and technical specications ....15

●System compatibilty ................................15

●Accessories ................................................16

●Transmitter controls ................................17

●Battery ......................................................19

●How to turn transmitter power ON/OFF .23

●Adjusting display contrast .....................23

●Transmitter displays & buttons .............24

●Keys lock ..................................................25

●Stick control ............................................25

Stick control : Airplane example ................. 26

Stick control : Helicopter example .............. 27

Stick control : Multicopter example ............ 28

INTRODUCTION

BEFORE USE

COMMON

AIRPLANE

HELICOPTER

●Digital trims ............................................29

●Connector/Plug ........................................30

●Switch assignment table ..........................31

●Receiver and servo connections ..............32

●Adjusting the length of the control sticks ..35

●Stick lever tension adjustment................35

●Warning & error displays .......................36

●Link procedure ........................................37

●Receiver nomenclature ............................38

●R3006SB CH mode ..................................39

●Receiver's antenna installation ...............40

●Mounting the servo ..................................41

●Mounting the power switch ....................41

GLIDER

MULTICOPTER

TX SETTING

3

Page 4

●Range check the radio .............................42

●S.BUS/S.BUS2 Installation .....................43

●S.BUS Wiring example ............................44

●S.BUS2 System .........................................45

●S.BUS/S.BUS2 Device setting .................46

●Telemetry System .....................................47

Common function.................................48

●Model select ..............................................50

Model select .................................................... 51

RX type ............................................................ 51

Link ................................................................. 51

Date reset ......................................................... 52

Model copy ...................................................... 52

●Model type ................................................53

Model type ...................................................... 54

Wing type ........................................................ 54

Tail type ........................................................... 54

Swash type ...................................................... 54

Speech volume ................................................ 67

Stick position alarm ....................................... 67

●Program mixing .......................................68

●AUX channel ............................................71

●Servo monitor/Servo test ....................72

●Telemetry ..................................................73

Telemetry:Rx-batt .......................................... 73

Telemetry:Ext-volt ......................................... 77

Optional telemetry sensors ............................ 81

Telemetry:temp............................................... 82

Telemetry:rpm ................................................ 83

Telemetry:altitude .......................................... 84

Telemetry:vario .............................................. 85

●Sensor ........................................................86

Sensor:register ................................................ 87

●S.BUS servo link ......................................88

●Model transfer..........................................91

●Timer .........................................................92

●Trainer ......................................................94

●Model name ..............................................55

Model name .................................................... 55

User name ....................................................... 56

●Fail safe .....................................................57

●End point ..................................................59

●Trim...........................................................60

●Sub trim ....................................................61

●Servo reverse ............................................62

●Parameter .................................................63

LCD contrast .................................................. 64

Back light ........................................................ 65

Light time ........................................................ 65

Light adjustment ............................................ 65

Battery alarm voltage ................................... 65

Battery alarm voltage vibration ................... 65

Buzzer tone ..................................................... 65

Home display .................................................. 66

Telemetry mode .............................................. 66

Telemetry unit ................................................. 66

Speech language ............................................. 66

Airplane function .................................96

●Throttle cut ...............................................98

●Dual rate/EXPO ................................100

●Throttle curve ........................................102

●Idle down ................................................103

●Gyro sensor ............................................104

●Aileron Differential ................................105

●V-Tail .......................................................106

●Camber ...................................................107

●Air brake ................................................108

●Elevator→Flap mixing .......................... 110

●Flap→Elevator mixing .......................... 111

●Elevon .....................................................112

Helicopter function ............................113

●Condition ................................................ 115

●Throttle cut .............................................116

4

Page 5

●Dual rate /EXPO ................................ 118

●Stick-mode ..............................................159

●Trim offset ..............................................120

●Delay .......................................................121

●Gyro sensor ............................................122

●Swash AFR .............................................123

●Swash mixing .........................................124

●Throttle curve ........................................126

●Pitch curve ..............................................128

●Revolution mixing (PIT to RUD) .........130

●Throttle hold ..........................................132

●Hovering throttle ...................................133

●Hovering pitch .......................................134

Glider function ...................................135

●Condition ................................................137

●Dual rate /EXPO ................................138

●Motor switch ..........................................140

●Gyro sensor ............................................141

●Stick-adjustment ....................................159

●Throttle stick reverse .............................160

●Language ................................................160

●Aileron Differential ................................142

●V-tail ........................................................143

●Buttery mixing .....................................144

●Trim mix .................................................145

●Elevator→Camber mixing ....................146

●Camber mixing ......................................148

●Aileron→Camber mixing ......................149

Multicopter function ..........................150

●Flight mode .............................................152

●Center alarm ..........................................153

●Dual rate/EXPO ................................154

●Throttle curve ........................................156

●Throttle delay .........................................157

●Gyro sensor ............................................158

TX setting ............................................159

5

Page 6

INTRODUCTION

Thank you for purchasing a Futaba

system. This system is extremely versatile and may be used by beginners and pros alike. In order

for you to make the best use of your system and to y safely, please read this manual carefully.

If you have any difficulties while using your system, please consult the manual, our online

Frequently Asked Questions (on the web pages referenced below), your hobby dealer, or the

Futaba Service Center.

®

T-FHSS Air-2.4GHz 6K series digital proportional R/C

Introduction

Due to unforeseen changes in production procedures, the information contained in this manual is

subject to change without notice.

Support and Service: It is recommended to have your Futaba equipment serviced annually during

your hobby’s “off season” to ensure safe operation.

IN NORTH AMERICA

Please feel free to contact the Futaba Service Center for assistance in operation, use and

programming. Please be sure to regularly visit the 6K Frequently Asked Questions web site

at www.futaba-rc.com/faq/. This page includes extensive programming, use, set up and safety

information on the 6K radio system and is updated regularly. Any technical updates and US

manual corrections will be available on this web page. If you do not nd the answers to your

questions there, please see the end of our F.A.Q. area for information on contacting us via email

for the most rapid and convenient response.

Don’t have Internet access? Internet access is available at no charge at most public libraries,

schools, and other public resources. We nd internet support to be a fabulous reference for many

modelers as items can be printed and saved for future reference, and can be accessed at any hour

of the day, night, weekend or holiday. If you do not wish to access the internet for information,

however, don’t worry. Our support teams are available Monday through Friday 8-5 Central time

to assist you.

FOR SERVICE ONLY:

Futaba Service Center

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

Phone: 217-398-0007

www.futaba-rc.com/service.html

Email: futabaservice@hobbico.com

OUTSIDE NORTH AMERICA

Please contact your Futaba importer in your region of the world to assist you with any questions,

problems or service needs.

Please recognize that all information in this manual, and all support availability, is based upon

the systems sold in North America only. Products purchased elsewhere may vary. Always contact

your region’s support center for assistance.

(PROGRAMMING AND USER

Please start here for answers to most questions:

FOR SUPPORT :

QUESTIONS)

www.futaba-rc.com/faq/

Fax: 217-398-7721

Phone: 217-398-8970 option 2

6

Page 7

Application, Export, and Modication

1. This product may be used for model airplane or surface (boat, car, robot) use. It is not intended

for use in any application other than the control of models for hobby and recreational purposes.

The product is subject to regulations of the Ministry of Radio/Telecommunications and is

restricted under Japanese law to such purposes.

2. Exportation precautions:

(a) When this product is exported from the country of manufacture, its use is to be approved by

the laws governing the country of destination which govern devices that emit radio frequencies. If

this product is then re-exported to other countries, it may be subject to restrictions on such export.

Prior approval of the appropriate government authorities may be required. If you have purchased

this product from an exporter outside your country, and not the authorized Futaba distributor in

your country, please contact the seller immediately to determine if such export regulations have

been met.

(b) Use of this product with other than models may be restricted by Export and Trade Control

Regulations, and an application for export approval must be submitted. This equipment must not

be utilized to operate equipment other than radio controlled models.

3. Modication, adjustment, and replacement of parts: Futaba is not responsible for unauthorized

modication, adjustment, and replacement of parts on this product. Any such changes may void

the warranty.

Compliance Information Statement (for U.S.A.)

This device, trade name Futaba Corporation, complies with part 15 of the FCC Rules. Operation

is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause

undesired operation.

(3) This module meets the requirements for a mobile device that may be used at separation

distances of more than 20cm from human body.

To meet the RF exposure requirements of the FCC this device shall not be co-located with another

transmitting device.

The responsible party of this device compliance is:

Futaba Service Center

3002 N Apollo Drive Suite 1, Champaign, IL 61822 U.S.A.

TEL (217)398-8970 or E-mail: support@hobbico.com (Support)

TEL (217)398-0007 or E-mail: futabaservice@hobbico.com (Service)

Introduction

The RBRC. SEAL on the nickel-cadmium battery contained in Futaba products

indicates that Futaba Corporation is voluntarily participating in an industry-wide

program to collect and recycle these batteries at the end of their useful lives, when

taken out of service within the United States. The RBRC. program provides a

convenient alternative to placing used nickel-cadmium batteries into the trash or

municipal waste system, which is illegal in some areas.

(for USA)

You may contact your local recycling center for information on where to return the spent battery.

Please call 1-800-8BATTERY for information on NiCd battery recycling in your area. Futaba

Corporation involvement in this program is part of its commitment to protecting our environment

and conserving natural resources.

*RBRC is a trademark of the Rechargeable Battery Recycling Corporation.

7

Page 8

Federal Communications Commission Interference Statement (for U.S.A.)

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception,

Introduction

which can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

--Reorient or relocate the receiving antenna.

--Increase the separation between the equipment and receiver.

--Consult the dealer or your Futaba Serivce center for help.

CAUTION:

To assure continued FCC compliance:

Any changes or modications not expressly approved by the grantee of this device could void the

user's authority to operate the equipment.

Exposure to Radio Frequency Radiation

To comply with FCC RF exposure compliance requirements, a separation distance of at least

20cm must be maintained between the antenna of this device and all persons.

This device must not be co-located or operating in conjunction with any other antenna or

transmitter.

Where to Fly

We recommend that you y at a recognized model airplane ying eld. You can nd model

clubs and elds by asking your nearest hobby dealer, or in the US by contacting the Academy

of Model Aeronautics.

You can also contact the national Academy of Model Aeronautics (AMA), which has more

than 2,500 chartered clubs across the country. Through any one of them, instructor training

programs and insured newcomer training are available. Contact the AMA at the address or toll-

free phone number below.

Academy of Model Aeronautics

5161 East Memorial Drive

Muncie, IN 47302

Tele. (800) 435-9262

Fax (765) 289-4248

or via the Internet at http:\\www.

modelaircraft.org

Always pay particular attention to the ying eld’s rules, as well as the presence and

location of spectators, the wind direction, and any obstacles on the eld. Be very careful

ying in areas near power lines, tall buildings, or communication facilities as there may be

radio interference in their vicinity.

8

Page 9

Precautions

Application, Export, and Modification Precautions.

1. This product is only designed for use with radio control models. Use of the product described in this instruction

manual is limited to radio control models.

2. Export precautions:

a) When this product is exported, it cannot be used where prohibited by the laws governing radio waves of the

destination country.

b) Use of this product with other than models may be restricted by Export and Trade Control Regulations.

3. Modification, adjustment, and parts replacement

Futaba is not responsible for unauthorized modification, adjustment, or replacement of parts on this product.

■ No part of this manual may be reproduced in any form without prior permission.

■ The contents of this manual are subject to change without prior notice.

■ The contents of this manual should be complete, but if there are any unclear or missing parts please contact a

Futaba Service Center.

■ Futaba is not responsible for the use of this product by the customer.

■ Company and product names in this manual are trademarks or registered trademarks of the respective company.

For safe use

Please observe the following precautions to ensure safe use of this product at all times.

Meaning of Special Markings:

The parts of this manual indicated by the following marks require special attention from the standpoint of safety.

Introduction

DANGER - Procedures which may lead to dangerous conditions and cause death/serious injury if not carried out

WARNING - Procedures which may lead to a dangerous condition or cause death or serious injury to the user if not

CAUTION - Procedures where the possibility of serious injury to the user is small, but there is a danger of injury, or

WARNING:

properly.

carried out properly, or procedures where the probability of supercial injury or physical damage is high.

physical damage, if not carried out properly.

= Prohibited

Always keep electrical components away from small children.

= Mandatory

Flying Precautions

WARNING

Never grasp the transmitter built-in antenna

part while ying.

■ The transmitter output may drop drastically.

Always make sure that all transmitter stick

movements operate all servos properly in the

model prior to flight. Also, make sure that all

switches, etc. function properly as well. If there

are any diculties, do not use the system until all

inputs are functioning properly.

Never y in the range check mode.

■ In the dedicated range test range check mode, the

transmitter output range is reduced and may cause a

crash.

While operating, never touch the transmitter

with, or bring the transmitter near, another

transmitter, a cellphone, or other wireless devices.

■ Doing so may cause erroneous operation.

9

Page 10

Never fly on a rainy day, when the wind is

strong, and at night.

■ Water could lead to failure or improper functionality

and poor control of the aircraft which could lead to a

crash.

Never turn the power switch on and o during

ight or while the engine or motor is running.

■ Operation will become impossible and the aircraft will

Introduction

crash. Even if the power switch is turned on, operation

will not begin until transmitter and receiver internal

processing is complete.

Do not start the engine or motor while wearing

the neck strap.

■ The neck strap may become entangled with the

rotating propeller, rotor, etc. and cause a serious injury.

Do not y when you are physically impaired as

it could pose a safety hazard to yourself or others.

Do not y at the following places:

■ Near another radio control ying eld.

■ Near or above people.

■ Near homes, schools, hospitals or other places where

people congregate.

■ Near high voltage lines, high structures, or

communication facilities.

When setting the transmitter on the ground

during ight preparations, do not stand it upright.

■ The transmitter may tip over, the sticks may move and

the propeller or rotor may rotate unexpectedly and cause

injury.

Do not touch the engine, motor, or FET amp

during and immediately after use.

■ These items may become hot during use.

For safety, y so that the aircraft is visible at all

times.

■ Flying behind buildings or other large structures

will not only cause you to lose sight of the aircraft, but

also degrade the RF link performance and cause loss of

control.

From the standpoint of safety, always set the

fail safe function.

■ In particular, normally set the throttle channel to idle.

For a helicopter, set the throttle channel to maintain a

hover.

When flying, always return the transmitter

setup screen to the Home screen.

■ Erroneous input during ight is extremely dangerous.

Always check the remaining capacity of the

transmitter and receiver batteries before each

ying session prior to ight.

■ Low battery capacity will cause loss of control and a

crash.

Always check operation of each control surface

and perform a range test before each flying

session. Also, when using the trainer function,

check the operation of both the teacher and

student transmitter.

■ Even one transmitter setting or aircraft abnormality

cause a crash.

Before turning on the transmitter:

1. Always move the transmitter throttle stick position to

the minimum (idle) position.

2. Turn on the transmitter rst and then the receiver.

When turning off the transmitter's power

switch. After the engine or motor has stopped

(state in which it will not rotate again):

1. Turn o the receiver power switch.

2. Then turn o the transmitter power switch.

■ If the power switch is turned on/off in the opposite

order, the propeller may rotate unexpectedly and cause a

serious injury.

■ Also always observe the above order when setting the

fail safe function.

■ Maximum low throttle: Direction in which the engine

or motor runs at the slowest speed or stops.

When adjusting the transmitter, stop the

engine except when necessary. In the case of

a motor, disconnect the wiring and to allow it

to continue operation. When doing so, please

exercise extreme caution. Ensure that the aircraft

is secured and that it will not come into contact

with anything or anyone. Ensure that the motor

will not rotate prior to making any adjustments.

■ Unexpected high speed rotation of the engine may

cause a serious injury.

10

Page 11

Battery and Charger Handling Precautions

DANGER

Do not recharge a battery that is damaged,

deteriorated, leaking electrolyte, or wet.

Do not use the charger in applications other

than as intended.

Do not allow the charger or battery to become

wet.

■ Do not use the charger, when it or your hands, are wet.

Do not use the charger in humid places.

Do not short circuit the battery.

Do not solder or repair, deform, modify, or

disassemble the battery and/or battery charger.

Do not drop the battery into a fire or bring it

near a re.

Do not charge and store the battery in direct

sunlight or other hot places.

Do not charge the battery if it is covered with

any object as it may become very hot.

Do not use the battery in a combustible

environment.

■ The gas ignite and cause an explosion or re.

Always charge the battery before each flying

session.

■ If the battery goes dead during ight, the aircraft will

crash.

Charge the nickel-hydride battery with the

dedicated charger supplied with the set.

■ Charging the battery past the specified value may

cause a re, combustion, rupture, or liquid leakage. When

quick charging, do not charge the battery above 1C.

■ Do not charge the battery while riding in a vehicle.

Vibration will prevent normal charging.

When using the optional Li-Fe battery,

disconnect the battery from the transmitter and

charge it with the special LBC-4E5 Li-Fe Battery

Charger sold separately.

When using the optional Li-Fe battery, do

not connect the charger to the balance charge

connector and the power connector at the same

time.

■ Doing so cause a re, combustion, generation of heat,

rupture, or liquid leakage.

Insert the power cord plug firmly into the

receptacle up to its base.

Always use the charger with the specified

power supply voltage.

■ Use the special charger by connecting it to a proper

power outlet.

If the battery should get in your eyes, do not

rub your eyes, but immediately wash them with

tap water or other clean water and get treated by

a doctor.

■ The liquid can cause blindness.

Introduction

WARNING

Do not touch the charger and battery for any

length of time during charging.

■ Doing so may result burns.

Do not use a charger or battery that has been

damaged.

Do not touch any of the internal components

of the charger.

■ Doing so may cause electric shock or a burn.

If any abnormalities such as smoke or

discoloration are noted with either the charger

or the battery, remove the battery from the

transmitter or charger and disconnect the power

cord plug and do not use the charger.

■ Continued use may cause re, combustion, generation

of heat, or rupture.

Do not subject the batteries to impact.

■ Doing so may cause fire, combustion, generation of

heat, rupture, or liquid leakage.

Do not repeatedly charge a nickel-hydrogen

battery in the shallow discharge state.

■ The battery memory effect will substantially shorten

the battery life even if it is recharged.

Use and store the battery and battery charger

in a secure location away from children.

■ Doing so may cause electric shock or injury.

If the battery leaks liquid or generates an

abnormal odor, immediately move it to a safe

place for disposal.

■ Not doing so may cause combustion.

If the battery liquid gets on your skin or

clothing, immediately flush the area with tap

water or other clean water.

■ Consult a doctor. The liquid can cause skin damage.

After the specied charging time has elapsed,

end charging and disconnect the charger from the

receptacle.

When recycling or disposing of the battery,

isolate the terminals by covering them with

cellophane tape.

■ Short circuit of the terminals may cause combustion,

generation of heat or rupture.

11

Page 12

CAUTION

Do not use the nickel-hydride battery with

devices other than the corresponding transmitter.

Do not place heavy objects on top of the

battery or charger. Also, do not place the battery

or charger in any location where it fall.

■ Doing so may cause damage or injury.

Introduction

Do not store or use the battery and charger

where it is dusty or humid.

■ Insert the power cord plug into the receptacle only

after eliminating the dust.

After the transmitter has been used for a long

time, the battery may become hot. Immediately

remove from the transmitter.

■ Not doing so may cause a burn.

Storage and Disposal Precautions

WARNING

Keep wireless equipment, batteries, aircraft,

etc. away from children.

CAUTION

Do not store wireless devices in the following

places:

・ Where it is extremely hot (40℃ [104F] or higher)

or cold (-10℃ [14F] or lower)

・ Where the equipment will be exposed to direct

sunlight

・ Where the humidity is high

・ Where vibration is prevalent

・ Where it is very dusty

・ Where the device may be exposed to steam and

heat

Do not charge the battery in extreme

temperatures.

■ Doing so will degrade the battery performance. An

ambient temperature of 10℃ to 30℃ (50F to 86F) is ideal

for charging.

Unplug the charger when not in use.

Do not bend or pull the cord unreasonably and

do not place heavy objects on the cord.

■ The power cord may be damaged and cause

combustion, generation of heat, or electric shock.

When the device will not be used for a long

time, remove the battery from the transmitter

and aircraft and store them in a dry place where

the temperature is between 0 and 30℃ [32F and

86F].

■ Left standing 'as is' may will cause battery deterioration,

liquid leakage, etc.

Other Precautions

CAUTION

Do not directly expose plastic parts to fuel, oil,

exhaust gas, etc.

■ If left in such an environment, the plastic may be

attacked and damaged.

■ Since the metal parts of the case may corrode, always

keep them clean.

Join the Academy of Model Aeronautics.

■ The Academy of Model Aeronautics (AMA) provides

guidelines and liability protection should the need arise.

Always use genuine Futaba products such as

transmitter, receiver, servo, FET amplier, battery,

etc.

12

■ Futaba is not responsible for damage sustained by

combination with other than Futaba Genuine Parts. Use

the parts specied in the instruction manual and catalog.

Page 13

Introduction

13

Page 14

BEFORE USE

FEATURES

●T-FHSS Air-2.4G multi-function 6-channel transmitter

The Futaba 2.4GHz T-FHSS Air system is employed.

●Telemetry system

A T-FHSS Air bidirectional communication system is used. The voltage of the battery mounted in the

fuselage can be displayed at the transmitter during ight. Altitude, temperature and R.P.M data can be

displayed at the transmitter by installing various optional telemetry sensors in the fuselage.

●Speech function

Telemetry data can be listened to by plugging commercial earphones into the transmitter.

●Built-in antenna

Before use

Antenna built into the transmitter provides a simple appearance and improves handling ease.

●S.BUS/S.BUS2 servo setting function

S.BUS/S.BUS2 servo channel and various functions can be set by connecting the servo to the

transmitter.

●Power-saving type transmitter

Four AA's alkaline batteries can be used. The optional HT5F1800B (NiMH 6.0V, 1800mA) or

FT2F2100BV2 (lithium-ferrite 6.6V, 2100mA) battery can also be used.

●Vibration

A function that noties the operator of various alarms by vibrating the transmitter can be selected.

●Unique model memory system

The transmitter body contains a 30 model memory.

●Mixing type selection

Fixed wing, helicopter, and glider mixing type can be selected to match the fuselage. In addition, 6

swash plate types can also be selected for helicopters. Multi-copter selection is also possible.

●Digital trim

Rapid trimming during ight is possible. The sound changes at the center of trim. The step size can be

arbitrarily changed. The trim position is displayed on the LCD.

●Lever head length adjustment

The lever head length can be adjusted. Lever head shape that reduces slip during operation has been

adopted.

●Switch/VR position change and AUX channel function change

Mixing and other switches and VR can be selected. Since the function of the AUX channels (5ch

6ch) can also be changed, original mixing, in addition to existing mixing, can be created by using the

programmable mixing function.

●Model data transfer function

Model data can be wirelessly transferred between 6K.

R3006SB receiver

●T-FHSS Air system S.BUS compatible

S.BUS output and conventional channel output are provided. S.BUS and conventional system sharing is

possible.

,

●Battery fail safe function

14

Page 15

CONTENTS AND TECHNICAL SPECIFICATIONS

(Specications and ratings are subject to change without notice.)

Your 6K includes the following components:

• T6K transmitter for airplanes or helicopters

• R3006SB Receiver

• Switch harness

*The set contents depend on the type of set.

Transmitter T6K

(2-stick, 6-channel, T-FHSS Air-2.4G system)

Transmitting frequency: 2.4GHz band

System: T-FHSS Air, S-FHSS, switchable

Power supply: 6.0V Dry battery

Receiver R3006SB

(T-FHSS Air-2.4G system, dual antenna diversity, S.BUS, S.BUS2 system)

Power requirement: 4.8V~7.4V battery or regulated output from ESC, etc. (*1)

Size: 1.7 x 0.98 x 0.35 in. (43.1 x 25.0 x 8.8 mm)

Weight: 0.3 oz. (8.5g)

Battery F/S Voltage: It sets up with a transmitter

(*1) When using ESC's make sure that the regulated output capacity meets your usage application.

Before use

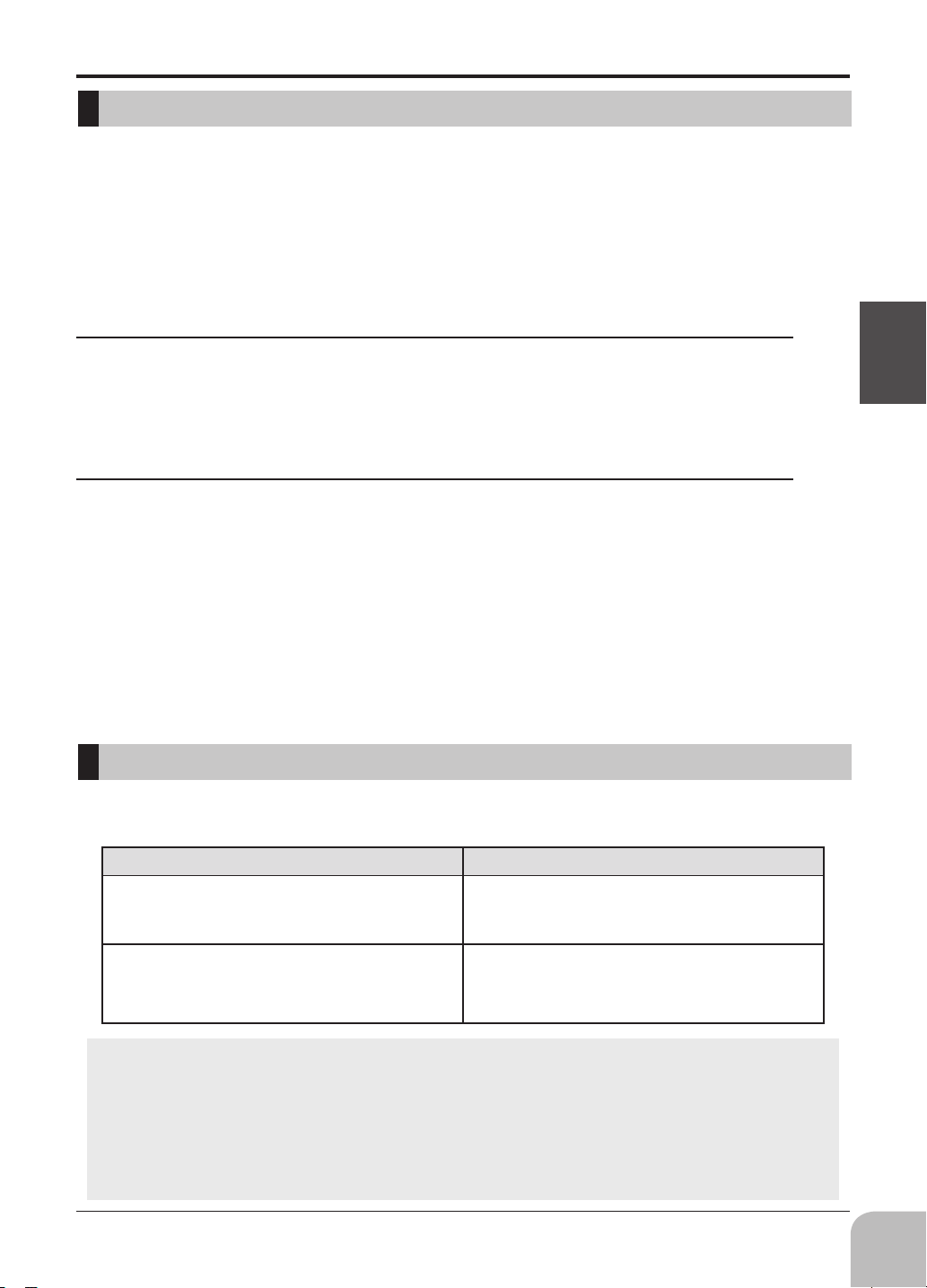

SYSTEM COMPATIBILITY

The 6K is a

system cannot be used with S-FHSS.) The usable receivers are shown below.

2.4GHz T-FHSS Air system

Communications System

T-FHSS Air

(Default)

S-FHSS

(Change is possible)

NOTE:

*The Futaba

it with a

be used with an

cannot be used.

*The

T-FHSS Air system

R304SB, R304SB-E

T-FHSS Air

T-FHSS Air

S-FHSS

system cannot be used with Futaba

system transmitter and receiver. The

receiver by switching to

and

or

T-FHSS

. The transmitter can also be switched to

R3006SB, R3008SB

*R304SB, R304SB-E, T-FHSS surface system

receivers do not operate.

R2008SB

R2006GS

R2106GF

S-FHSS/FASST/FASSTest

T6K

S-FHSS

T-FHSS

surface system are different. The

surface system receivers.

. However, in this case the telemetry system

is a

. (However, the telemetry

S-FHSS

Usable Receivers

T-FHSS Air system

cannot be used with the

T6K

systems. Use

, but can also

15

Page 16

The following additional accessories are available from your dealer. Refer to a Futaba catalog for

more information:

• HT5F1800B Transmitter battery pack - the (1800mAh) transmitter NiMH battery pack may be easily

exchanged with a fresh one to provide enough capacity for extended ying sessions.

• FT2F2100BV2 Transmitter LiFe battery pack can also be used. However, charge with the charger only for

LiFe.

• Trainer cord - the optional training cord may be used to help a beginning pilot learn to fly easily by

placing the instructor on a separate transmitter. Note that the T6K transmitter may be connected to another

T6K system, as well as to any other models of Futaba transmitters. The T6K transmitter uses one of the

three cord plug types according to the transmitter connected. (Refer to the description at the TRAINER

Before use

function instructions). The part number of this cord is: FUTM4405.

• Servos - there are various kinds of servos. Please choose the Futaba servos best suited for the model and

purpose you are using them for. If you utilize a S.BUS system, you should choose a S.BUS servo.

• Telemetry sensor - please purchase an optional sensor, in order to utilize bidirectional communication

system and to acquire the information from a model high up in the sky.

Temperature sensor : SBS-01T/TE] [Altitude sensor : SBS-01A] [RPM sensor magnet type : SBS-

[

01RM][RPM sensor optical type : SBS-01RO] [RPM sensor brushless motor type : SBS-01RB]

• Neckstrap - a neckstrap can be connected to your T6K system to make it easier to handle and improve

your ying precision since your hands won’t need to support the transmitter’s weight.

• Y-harnesses, servo extensions, hub,etc - Genuine Futaba extensions and Y-harnesses, including a heavyduty version with heavier wire, are available to aid in your larger model and other installations.

• Gyros - a variety of genuine Futaba gyros is available for your aircraft or helicopter needs.

• Receivers - various models of Futaba receivers may be purchased for use in other models. (Receivers for

T-FHSS Air, S-FHSS types are available.)

16

Page 17

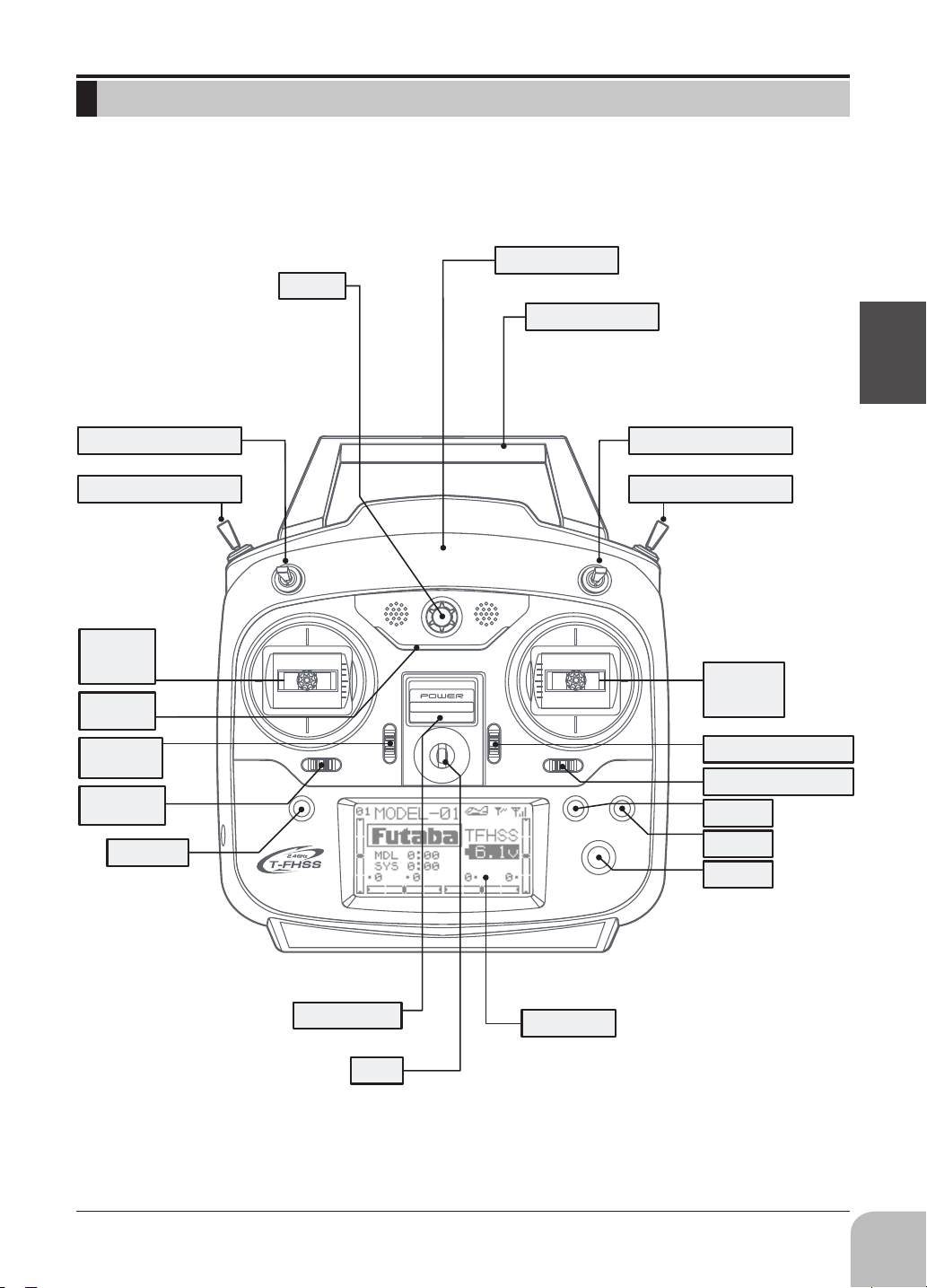

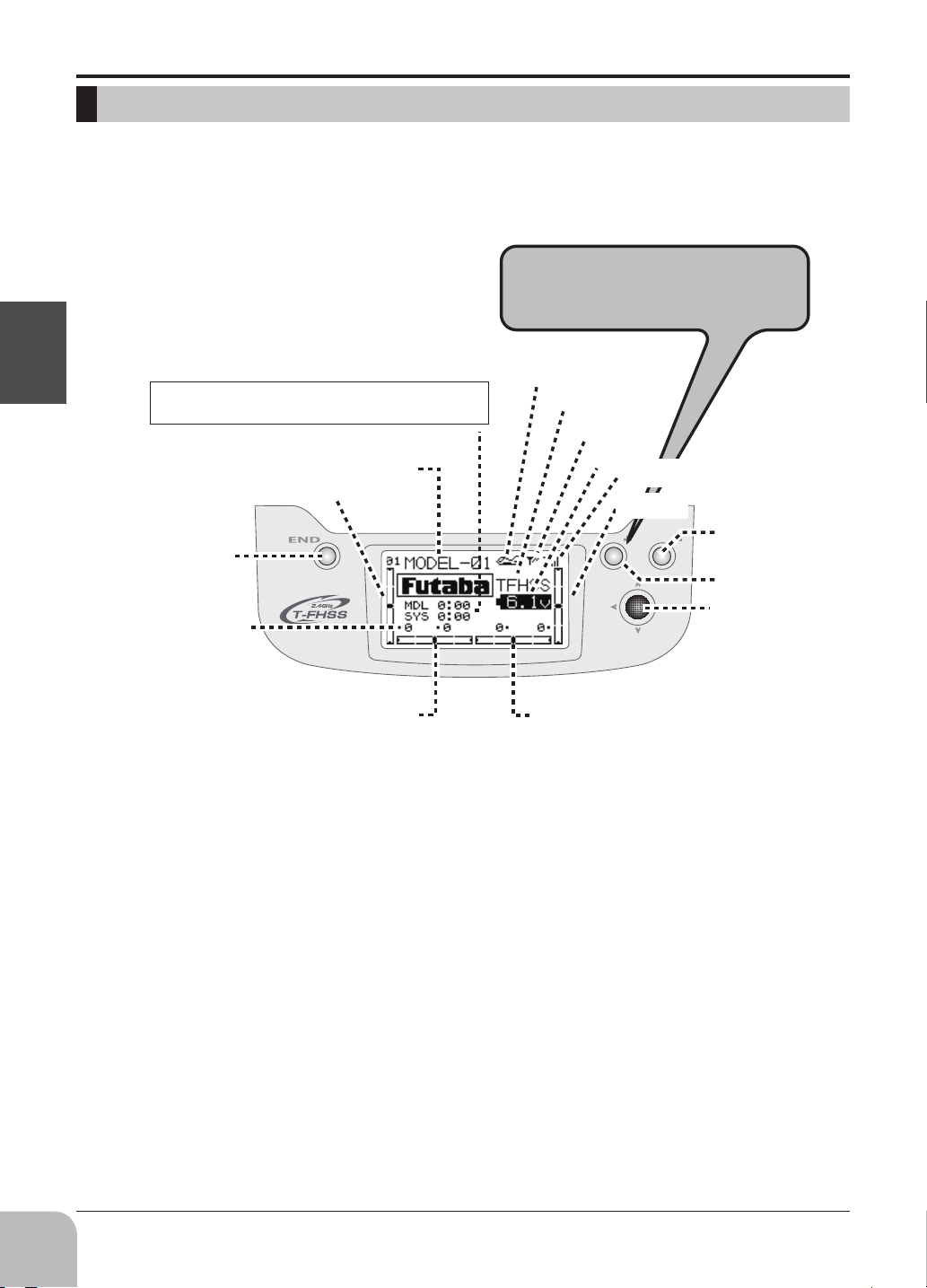

TRANSMITTER CONTROLS - T6K

Built-in Antenna

Volume

Carrying Handle

Before use

3 Position Switch (A)

3 Position Switch (C)

Rudder

/Throttle

Stick

Power

LED

Throttle

Trim Lever

Rudder

Trim Lever

END Key

3 Position Switch (B)

2 Position Switch (D)

Elevator

/Aileron

Stick

Elevator Trim Lever

Aileron Trim Lever

+ Key

- Key

Jog Key

Power Switch

(Up position: ON)

Hook

(for optional neckstrap)

LCD Panel

17

Page 18

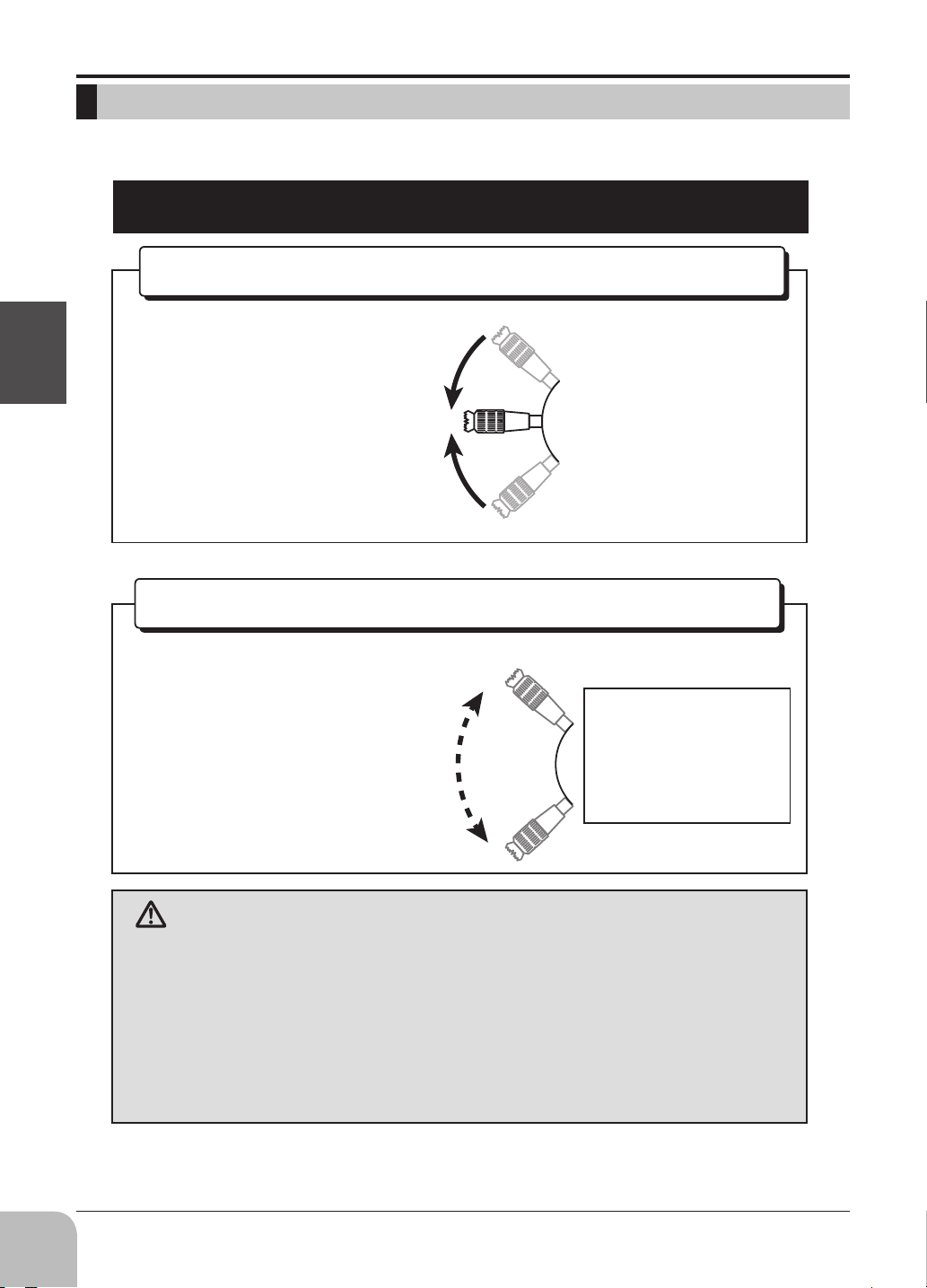

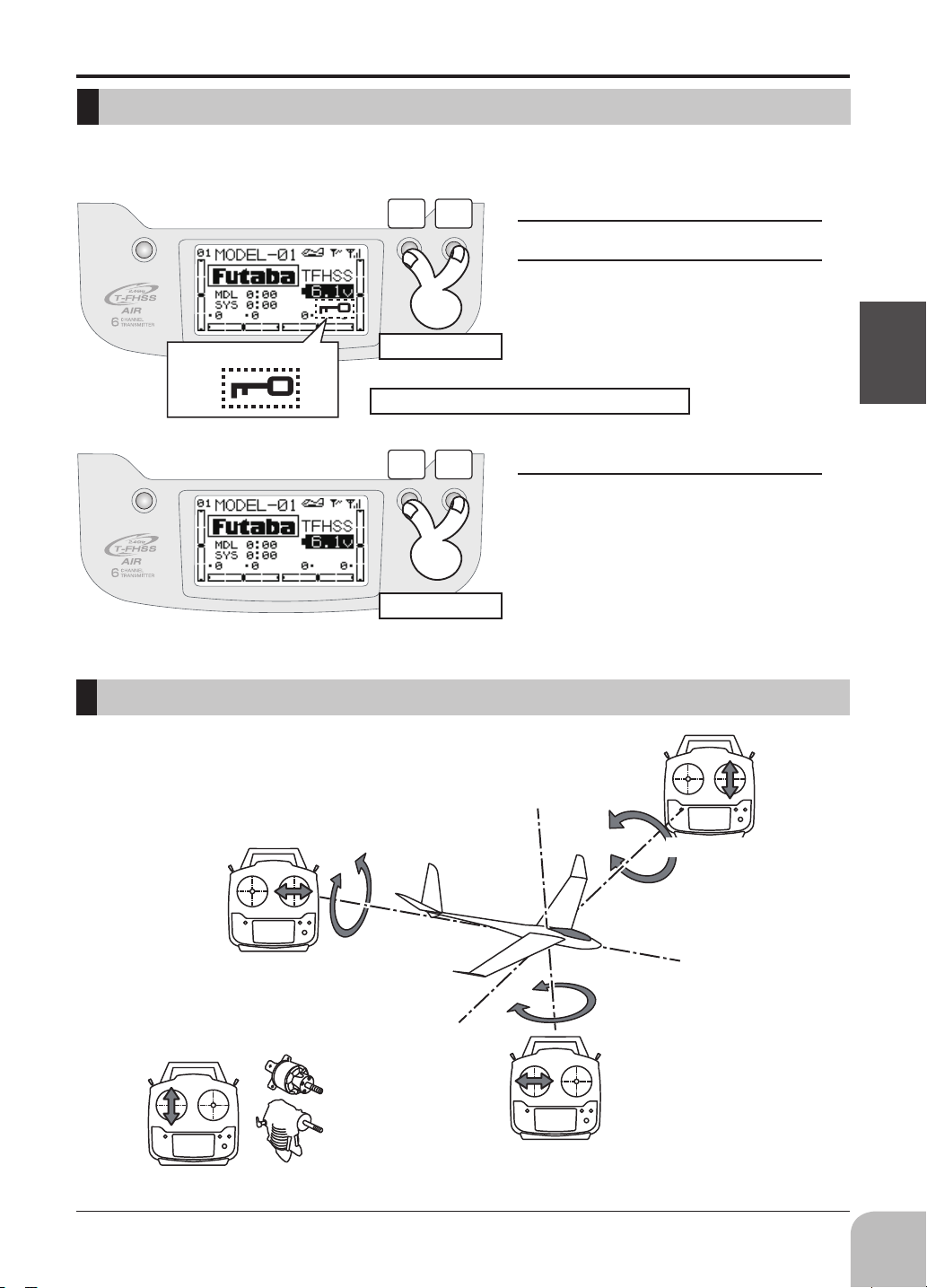

Multicopter/Robot specication

Throttle stick warning

Before use

Self neutral type

A throttle stick returns

neutrally by a spring.

Ratchet type(General transmitter)

A throttle stick doesn't return

neutrally.

(Multicopter/Robot specication)

Throttle stick:

Motor or engine

power is controlled.

18

WARNING

You cannot use the throttle stick of self-neutral type for RC

airplane, RC helicopter, and certain multi-copter.

It's very dangerous if Engine / Motor becomes middle-speed

by self-return.

It's necessary to change the stick to the ratchet type if using it for

RC airplane and RC helicopter.

Page 19

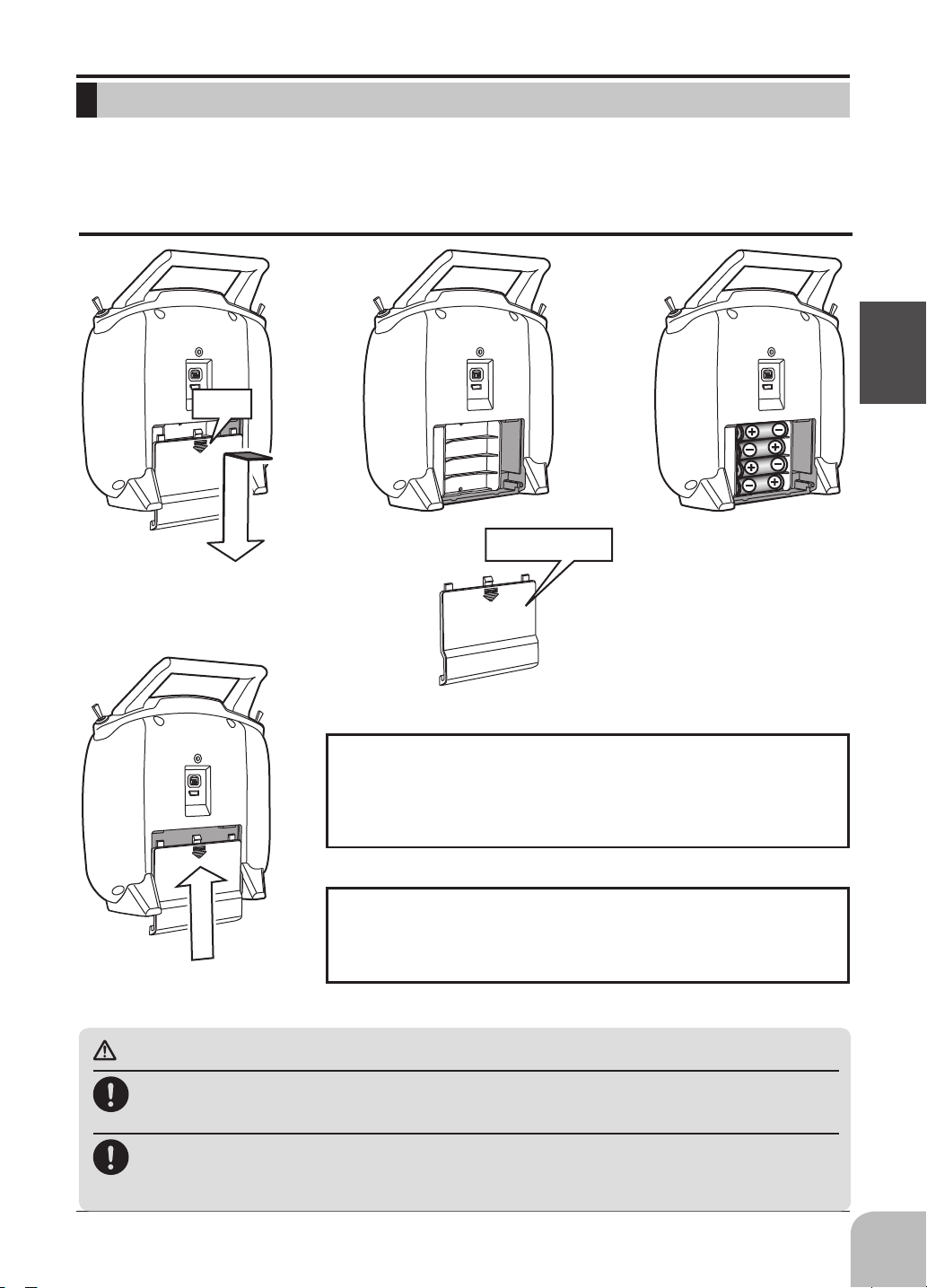

INSTALLATION AND REMOVAL OF THE T6K BATTERY

The T6K transmitter is designed to work with either four (4) AA alkaline dry cell batteries, or

HT5F1800B battery pack, both available separately. The transmitter batteries used are a matter of personal

preference. AA Alkaline batteries are available at any local hobby shop, grocery store, etc. A battery pack

will need to be purchased from a hobby shop.

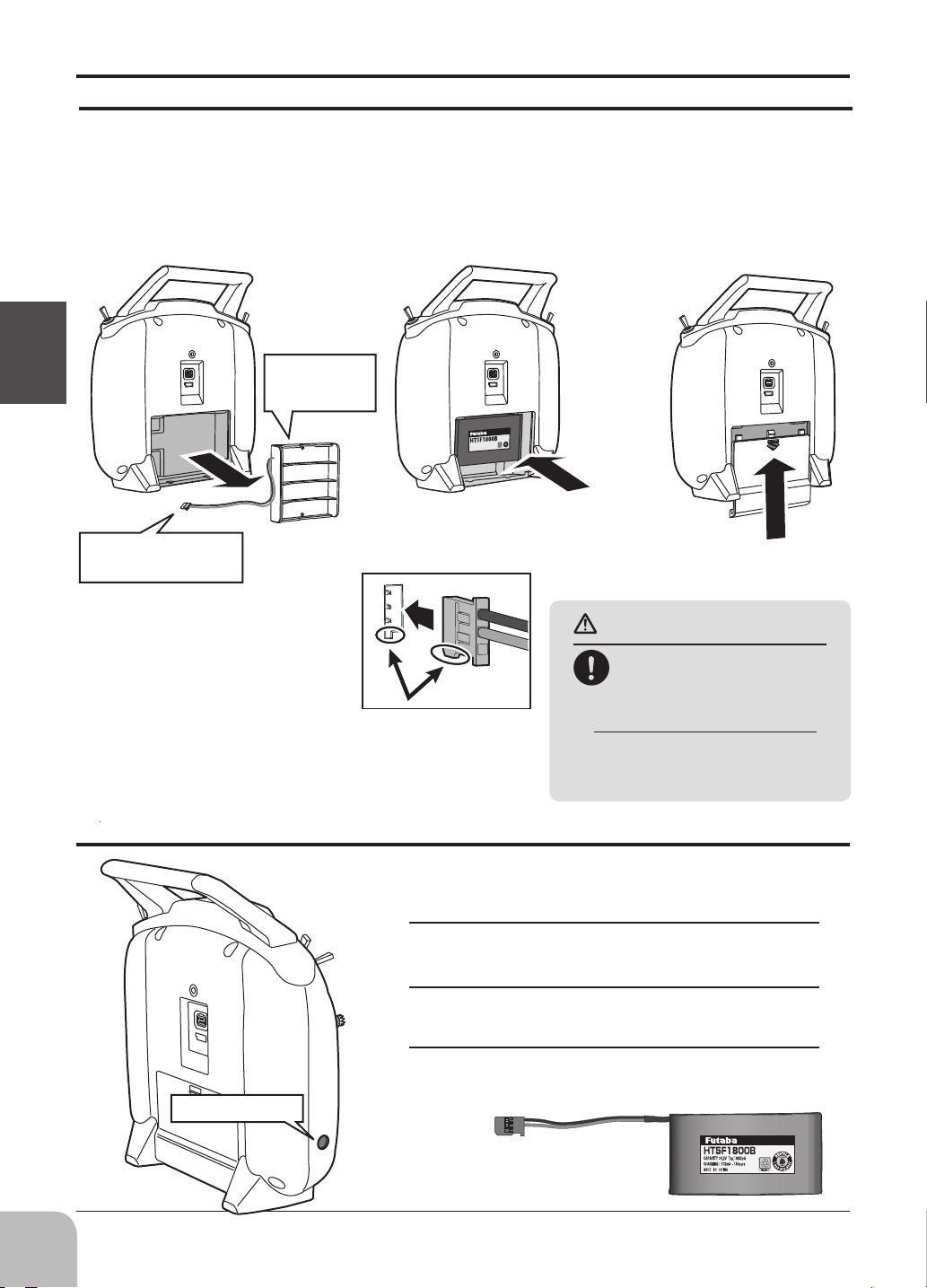

Battery Replacement Method

Push

Slide the battery cover o the

transmitter in the direction of

the arrow in the gure.

Slide the battery cover

back onto the case.

Battery Cover

Check:

Load the new AA size

batteries. Pay very close

attention to the polarity

markings and reinsert

accordingly.

Turn the power switch on the transmitter to the ON position.

Check the battery voltage display on the LCD screen. If the

voltage is low, check the batteries for insufcient contact in

the case or incorrect battery polarity.

Disposal of the Dry Cell Batteries:

The method to dispose of used dry cell batteries depends on

the area in which you reside. Dispose of the batteries in ac

cordance with the regulations for your area.

Before use

-

CAUTION

Always be sure you reinsert the batteries in the correct polarity order.

If the batteries are loaded incorrectly, the transmitter may be damaged.

When the transmitter will not be used for any short or long period of time, always remove the

batteries.

oughly. Make sure the contacts are free of corrosion.

If the batteries do happen to leak, clean the battery case and contacts thor-

19

Page 20

When Using The Optional Battery HT5F1800B

When using an optional rechargeable battery, replace the battery as described below.

-Always use the optional HT5F1800B rechargeable battery.

-The type of power source used must be set by system setting.

-When the transmitter will not be used for a long time, remove the battery.

Dry cell

Before use

Disconnect the

connector

Refer to the previous

description and remove the

transmitter battery cover.

After removing the dry

cell battery box from the

transmitter, disconnect the

connector.

battery BOX

Insert the connector of the

new battery and load the new

battery into the transmitter.

Connect the battery

connector.

Finish by installing the

battery cover.

CAUTION

When closing the battery

cover, be careful that the

battery cover does not pinch

the battery lead wires.

Shorting of the battery lead wires may

lead to fire and abnormal heating and

cause burns or fire disaster.

When Charging the Optional Battery HT5F1800B

(Example: When using the HT5F1800B with the special charger)

Charging jack

20

Charging a NiMH Battery

Plug the transmitter cord of the special charger into

1

the charging jack on the rear of the transmitter.

Plug the charger into an AC outlet.

2

Check that the charging LED lights.

3

NiMH battery HT5F1800B

(not included)

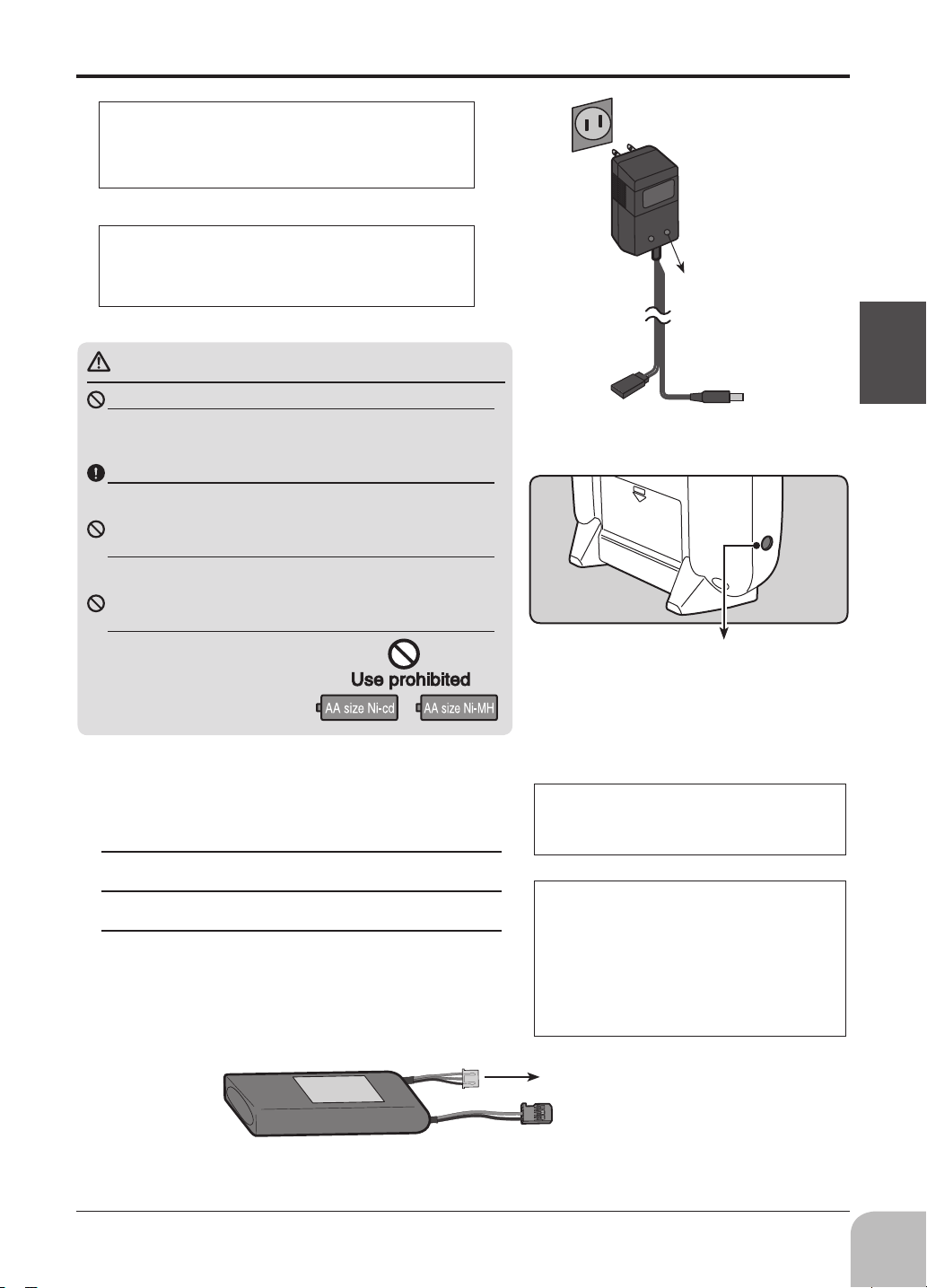

Page 21

The charging time when charging the HT5F1800B battery

with the optional special charger is approximately 15 hours.

However, when the battery has not been used for some time,

repeat charging 2 or 3 times to activate the battery.

Over current protection

The transmitter charging circuit is equipped with an over cur-

rent protection circuit (1.0A). If the battery is charged with a

quick charger for other than digital proportional R/C sets, it

may not be fully charged.

CAUTION

AC outlet

Charger

Transmitter

charging LED

Never try to recharge a dry cell battery.

The transmitter may be damaged or the battery electrolyte may

leak or the battery may break.

Insert the batteries in the correct polarity.

If the polarity is incorrect, the transmitter may be damaged.

When the transmitter is not in use, remove the batter-

ies.

If the battery electrolyte leaks, wipe off the case and contacts.

Do not use commercial AA size NiCd and NiMH batter-

ies.

Quick charging may cause the

battery contacts to overheat and

damage the battery holder.

Charging A LiFe Battery

(Example: When using the FT2F1700BV2/2100BV2 with the special

charger)

Remove the battery cover.

1

Disconnect the battery from the T6K.

2

Balance charging cannot be done through the

3

transmitter, you must remove the LiFe battery to do

this charge.

To receiver

Ni-Cd battery

To transmitter

charging jack

Charging jack

Cannot be used for

charge of LiFe.

Charg e the opti on al FT2F1700BV2/2100B V2

(LiFe) battery with the special charger in accor-

dance with the instruction manual supplied.

When the battery will not be used for a long time,

to prevent it from deteriorating we recommend

that it be kept in about the half capacity state instead of fully charged. Also be careful that the battery does not enter the over-discharged state due

to self-discharge.

Periodically (about every 3 months) charge the

battery.

Before use

LiFe battery is removed

from transmitter.

Balance charging connector for

LiFe battery charger.

21

Page 22

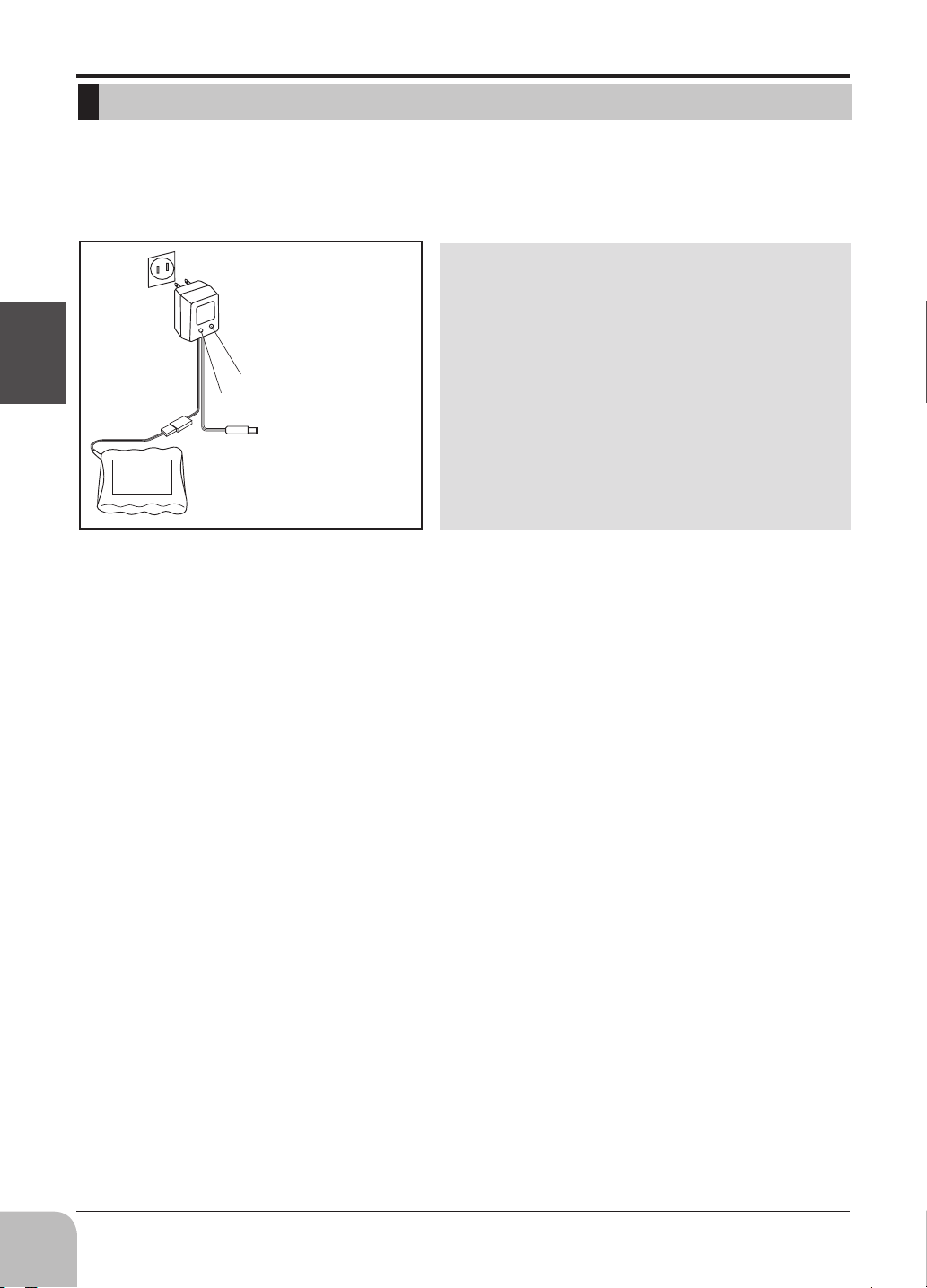

CHARGING THE BATTERIES

r

(When the rechargeable battery option is used)

Charging Your System’s Batteries

1. Connect the transmitter charging jack and batteries to the transmitter and receiver connectors

of the charger.

2. Plug the charger into a wall socket.

3. Check that the charger LED lights.

According to the description of the battery to be used

and its exclusive charger, please use it after carrying

out full charge.

We recommend charging the batteries with the

charger supplied with your system. Note that the

use of a fast charger may damage the batteries by

overheating and dramatically reduce their lifetime.

When HT5F1800B is chosen, HBC-3A (4) is

recommended.

When charging FT2F2100BV2, please make sure

to remove the battery from the system to charge it.

Charger for this battery is recommended to use LBC-

4E5.

Before use

Charger

TX: Transmitter charging indicato

RX: Receiver charging indicator

To transmitter charging jack

Receiver battery

Battery Care and Precautions

Below you will find some general rules and guidelines which should be adhered to when

charging transmitter and/or receiver battery packs. These are included to serve only as general

guidelines, and are not intended to replace or supersede the information provided by the battery

and/or charger manufacturer. For complete information, please refer to the instructions that are

included with the battery pack(s) and/or chargers that accompany the products purchased.

• Do not allow children to charge battery packs without adult supervision.

• Do not charge battery packs that have been damaged in any way. We strongly suggest frequent

inspection of the battery packs to ensure that no damage has occurred.

• Do not to allow batteries to overheat! If overheated, disconnect the battery from the charger

immediately and allow to cool.

• Do not mix cells- all cells should be of the same material, conguration, etc.

• Do not deep cycle NiMH batteries as permanent damage could result.

• Never charge batteries on a surface that may become hot, or may be impacted by the heat.

• Immediately end the charging procedure if either the batteries or charger itself become overly hot.

• NiMH cells do not exhibit the “memory effect” like NiCd cells, so little cycling is needed. Store

NiMH packs with some voltage remaining on the cells (refer to battery supplier).

• NiMH cells have a self-discharge rate of approximately 20-25% (compared to 15% for NiCd

batteries). It is important to recharge NiMH batteries immediately prior to use.

• Never connect the battery in reverse. Reverse connection will cause the battery to overheat or

will damage the inside of the charger.

• Do not add an additional charge after charging.

• Never charge with a current exceeding the nominal capacity (lC) of the rechargeable battery.

• If a battery is charged with a current exceeding 1C, the battery will overheat and deteriorate.

• Do not connect two battery packs or more to one output terminal.

• Avoid extremely cold and hot places and the direct sunlight when you charge batteries.

• It is recommended to perform charging within the 10 ~ 30°C (50-86°F) range. Otherwise, it may

cause abnormal charging and overheat.

22

Page 23

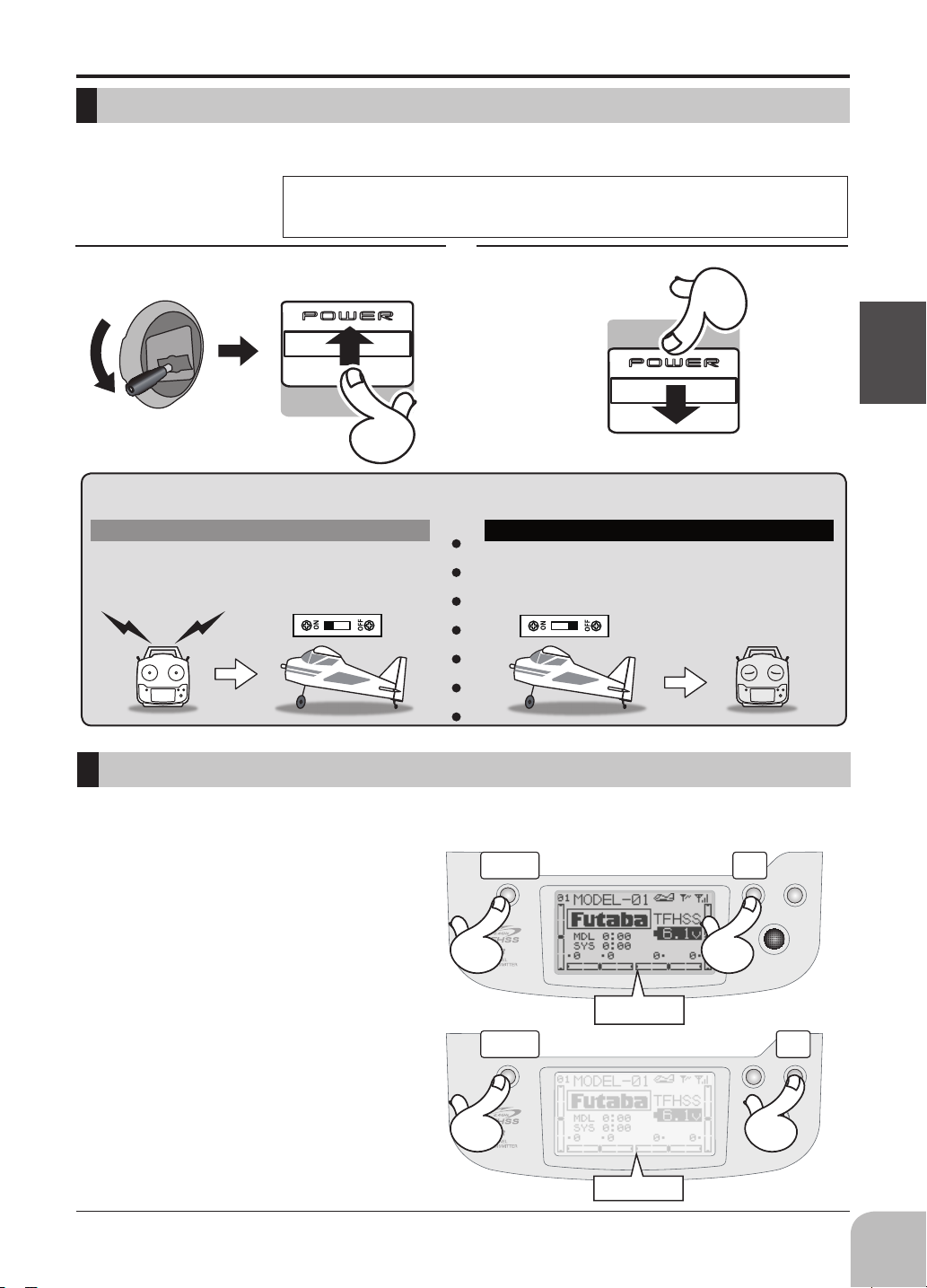

How to turn transmitter power ON/OFF

When turning on the power, the T6K transmitter will begin emitting RF automatically after it conrms

the surrounding RF conditions. The status of the transmitter is displayed by LED at the upper part of the

front of a T6K.

Throttle Stick Slow

If the power switches are turned o in the opposite order the model may unexpectedly run out of control and

cause a very dangerous situation.

Turning on the power switches

1. Turn on the transmitter power switch.

2. Turn on the receiver or speed control power switch.

*If THR stick is high, the next WARNING screen will come out. Moreover, if a power supply

is switched on while SW set by WARNING setup has been ON, it will be indicated by

WARNING.(In the case of Multicopter mode, throttle position alarm does not occur. )

Power OFFPower ON

Power Switch

Power Switch

Turning o the power switches

Always be sure the motor/engine is stopped.

1. Turn o the receiver or speed control power switch.

2. Then turn o the transmitter power switch.

Before use

ON

ON

OFF

OFF

ADJUSTING DISPLAY CONTRAST

To adjust the display contrast, from the home menu press and hold the END BUTTON.

Push the

KEY while still holding the END BUTTON:

+-

KEY to brighten

+

KEY to darken the display

-

END +

Brighten

END -

Darken

23

Page 24

TRANSMITTER DISPLAYS & BUTTONS

When you rst turn on your transmitter, a conrmation double beep sounds, and the screen shown

below appears. Before ying, or even starting the engine, be sure that the model type and name

appearing on the display matches the model that you are about to y! If you are in the wrong model

memory, servos may be reversed, and travels and trims will be wrong, potentially leading to a crash.

Press and hold + KEY for one

second to open programming

menus.

Model type

"T-FHSS" "S-FHSS"

Output display

System

Battery

voltage

Receiving accuracy

Elevator trim

Telemetry

display

-key

+key

Jog key

Before use

Model timer display <MDL>

Shows the cumulated ON time for each model. (hours:minutes)

System timer display <SYS>

Shows the cumulated ON time. (hours:minutes)

Resetting timers:

Select the desired timer with JOG KEY. The timer display

flashes. To reset the timer, press JOG KEY.

Model number

and name

display

END

Key

Each trim

value

Throttle trim

Rudder trim

display

Aileron trim

display

Edit buttons and Start-up Screen (appears when system is rst turned on):

JOG KEY:

Control JOG KEY to scroll up/scroll down/scroll left/scroll right and select the option to edit within a

function. When the menu has multiple pages, move the JOG KEY horizontally (left or right).

Press JOG KEY to select the actual function you wish to edit from the menu.

Press JOG KEY and hold one second to confirm major decisions, such as the decision to: select

a different model from memory, copy one model memory over another, trim reset, store channel

position in FailSafe, change model type, reset entire model, condition of a helicopter setup is changed.

An on screen inquiry will ask if you are sure.

Press JOG KEY again to accept the change.

KEY:

+

Press and hold + KEY for one second to open programming menus. It is used for changing a setup,

or a numerical increase. Changing the menus pages can also be performed.

KEY:

-

It is used for change of a setup, or reduction of a number. Change of the page of a menu can also be

performed.

END KEY:

Press END KEY to return to previous screen, close functions back to menus, and close menus to start-

up screen.

24

Page 25

Keys Lock

To prevent the data from being changed by erroneous touching of the keys during flight, a

function which makes are keys impossible temporarily.

Keys Lock Display

Stick control

+ -

Press 1 second

Lock : Jog key, + key, - key, END key

+ -

Press 1 second

How to lock

The home screen is displayed.

1

Press the +key a nd -key simul-

2

taneously for about 1 second. "Key

mark" is displayed and the keys dis-

abled.

How to unlock

Press the +key a nd -key simul-

1

taneously for about 1 second in the

touch sensor locked state. The keys

enabled again.

Before use

Aileron stick

Engine/motor

Power

Throttle stick

Elevator Stick

Pitching axis

Roll axis

Yawing axis

Rudder stick

*Example Stick Mode2

25

Page 26

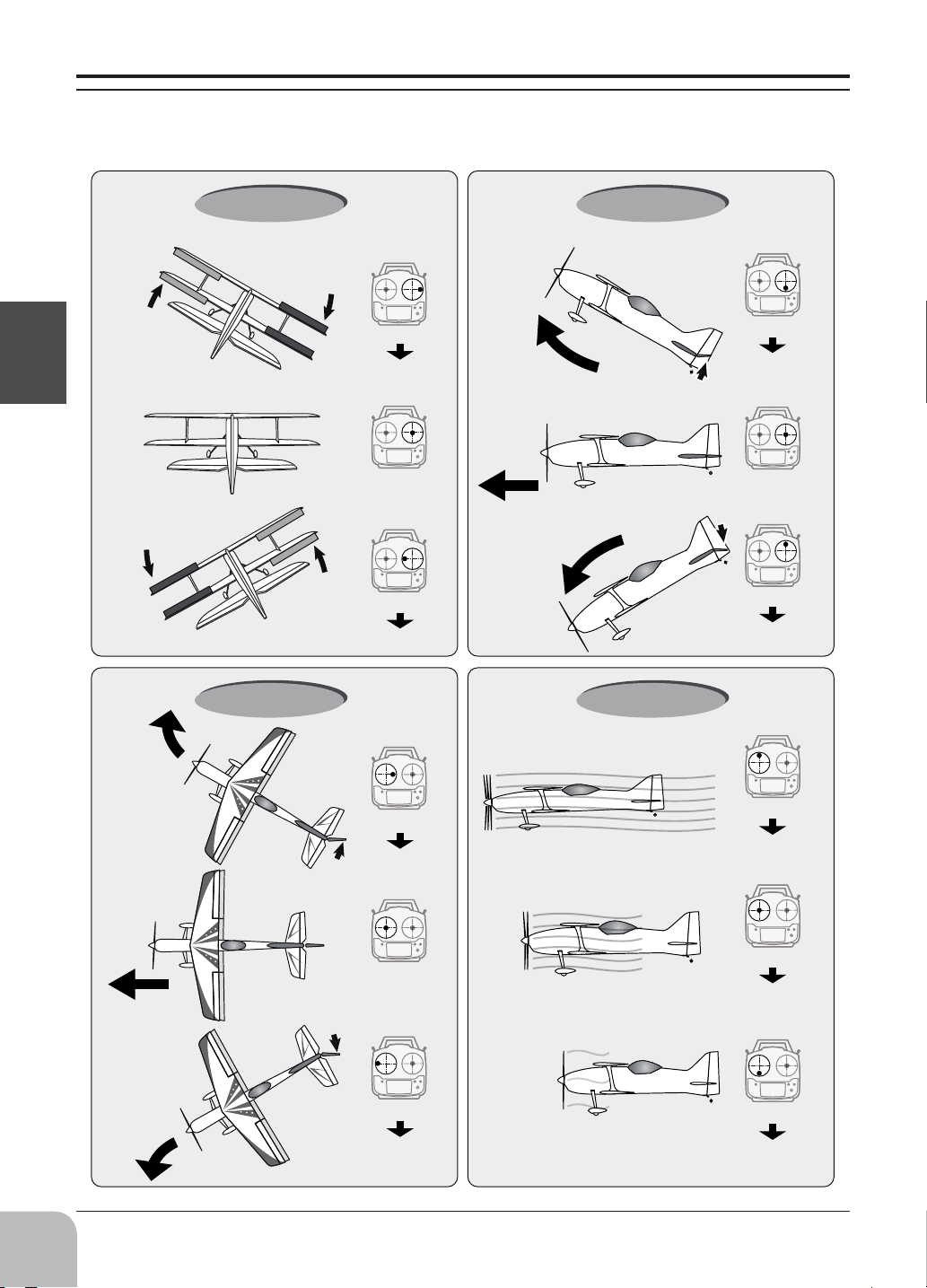

Stick control : Airplane Example

A general model example. (There is also a dierent operational model.)

*Example Stick Mode2

The left aileron

is in the down.

Before use

The left aileron

is in the up.

Roll axis Control

Pitch axis Control

Right roll

The right aileron

is to the up.

Nose Up

Aileron stick

To the right

Level flight

Level flight

Neutral

Left roll

The right

aileron is to

the down.

Aileron stick

To the left

Nose Down

Yaw axis Control Throttle Control

Elevator is a

up.

Elevator is a

down.

Elevator stick

UP

(moved to the bottom)

Neutral

Elevator stick

DOWN

(moved to the top)

26

Nose Right

Straight

Nose Left

A rudder is to

the right.

A rudder is to

the left.

Rudder stick

To the right

Neutral

Rudder stick

To the left

Hight

Middle

Slow

Throttle stick

HIGHT

(moved to the top)

Throttle stick

MIDDLE

(neutral)

Throttle stick

SLOW

(moved to the bottom)

Page 27

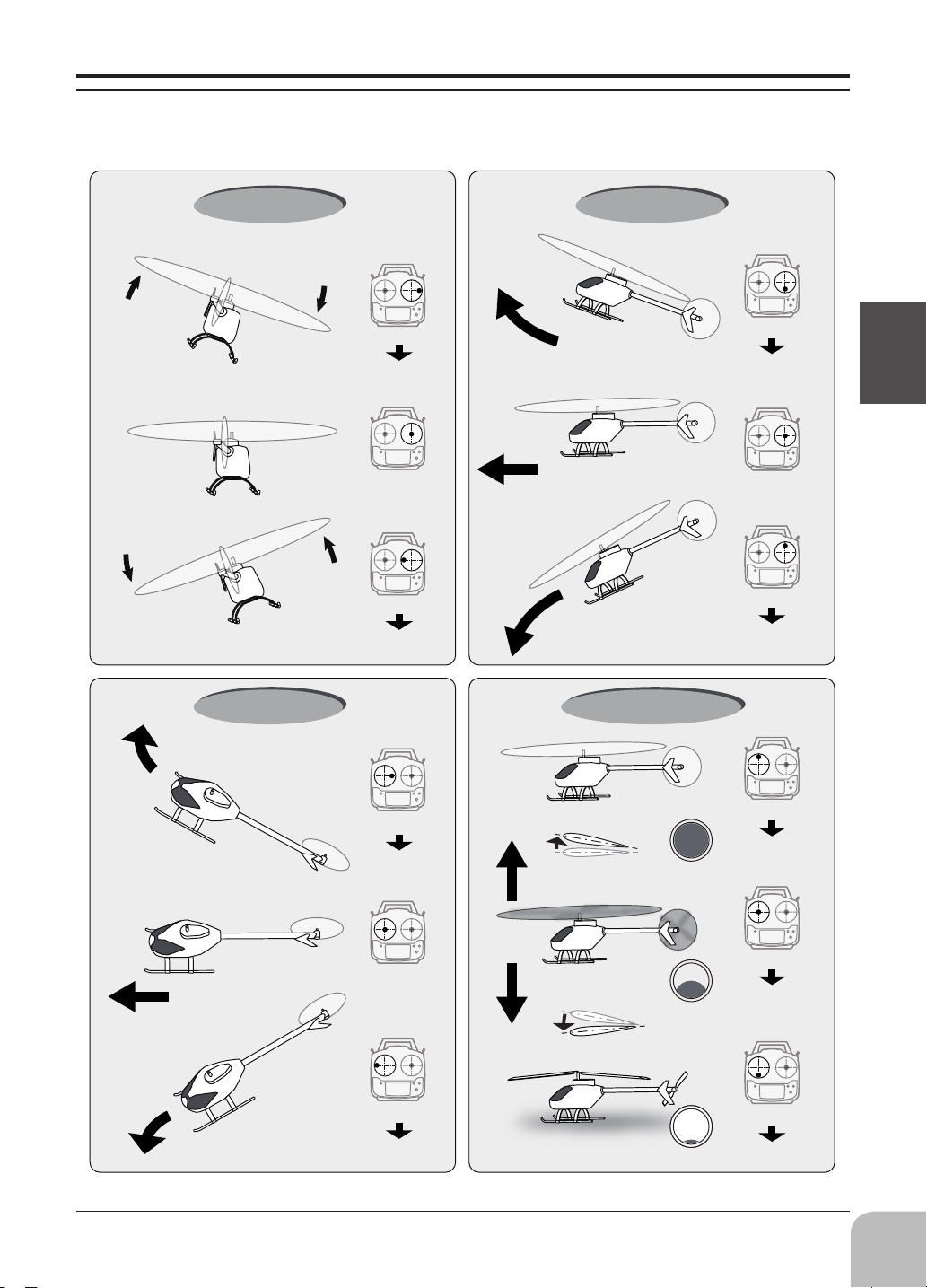

Stick control : Helicopter Example

A general model example. (There is also a dierent operational model.)

*Example Stick Mode2

Nose Right

Roll axis Control

Level flight

Left roll

Right roll

Nose Up

Aileron stick

To the right

Level flight

Neutral

Aileron stick

To the left

Pitch axis Control

Nose Down

Yaw axis Control Throttle /Pitch Control

Elevator stick

UP

(moved to the bottom)

Neutral

Elevator stick

DOWN

(moved to the top)

Before use

Straight

Nose Left

Rudder stick

To the right

Neutral

Rudder stick

To the left

Rise

Hovering

Descent

Pitch Down

HightPitch Up

Middle

Slow

(moved to the bottom)

Throttle stick

HIGHT

(moved to the top)

Throttle stick

MIDDLE

(neutral)

Throttle stick

SLOW

27

Page 28

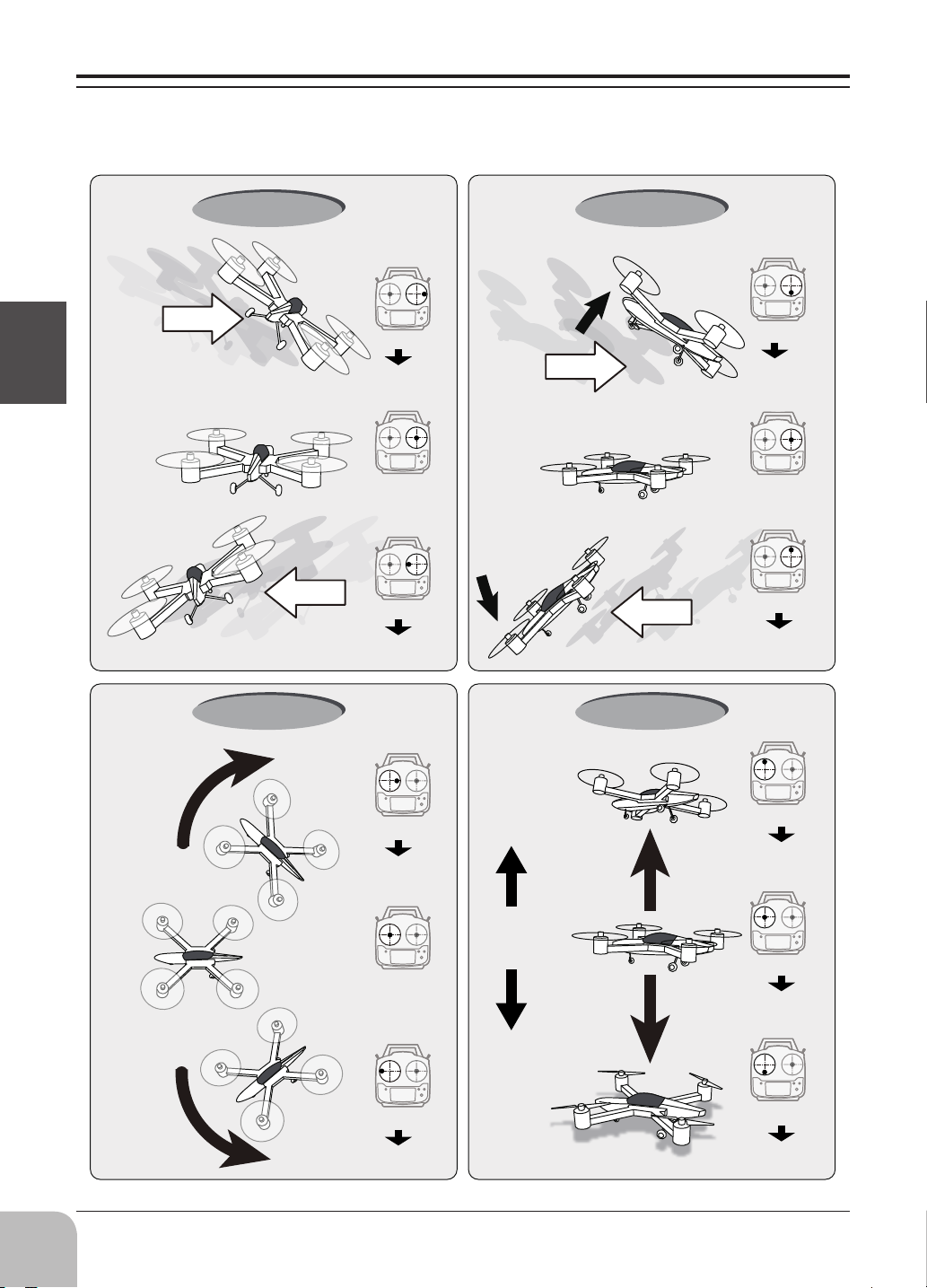

Stick control : Multicopter Example

A general model example. (There is also a dierent operational model.)

*Example Stick Mode2

Before use

Right slide

Left roll

Roll axis Control

Right roll

Hovering

Level flight

Left slide

Nose Up

Aileron stick

To the right

Hovering

Level flight

Neutral

Nose Down

Aileron stick

To the left

Pitch axis Control

Back slide

Front slide

Yaw axis Control Throttle Control

Elevator stick

UP

(moved to the bottom)

Neutral

Elevator stick

DOWN

(moved to the top)

28

Nose Right

Nose Left

Hovering

Level flight

Rudder stick

To the right

Neutral

Rudder stick

To the left

Rise

Hovering

Descent

Stop

Throttle stick

HIGHT

(moved to the top)

Throttle stick

MIDDLE

(neutral)

Throttle stick

SLOW

(moved to the bottom)

Page 29

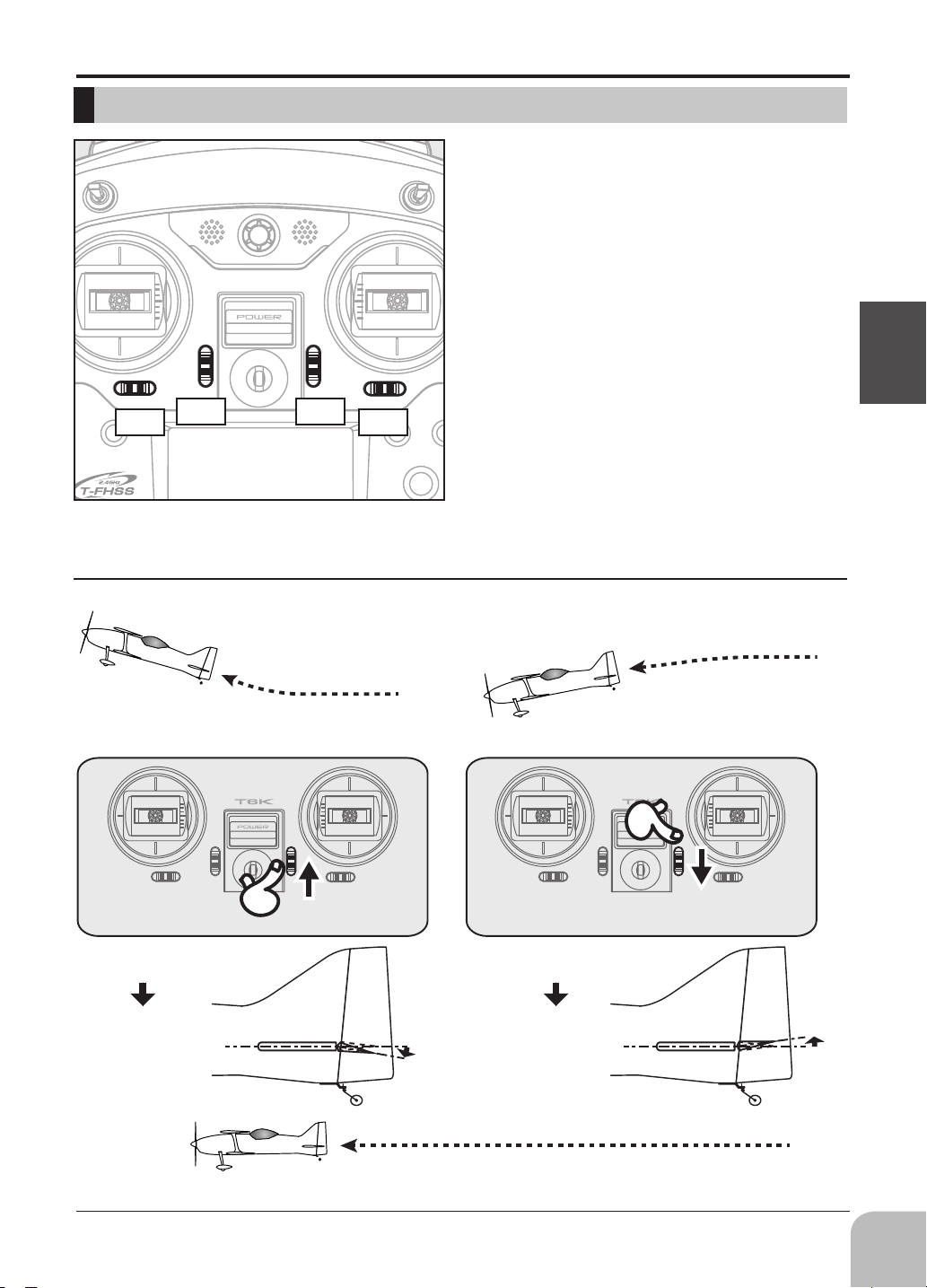

Digital Trims T1-T4

T3 T2

Digital trim operational example

This transmitter is equipped with 4 digital trims.

Each time you press a trim button, the trim position

moves one step. If you continue pressing it, the trim

position starts to move faster. In addition, when

the trim position returns to the center, the tone will

change. You can always monitor trim positions by

referencing the LCD screen.

*You can select the trim step amount and the display unit

on the home screen on the T1-T4 setting screen within the

linkage menu.

Note: The trim positions you have set will be stored in the

non-volatile memory and will remain there.

Before use

T1T4

*Example Stick Mode2

◆When an airplane nose up though an

elevator stick is neutral.

◆Elevator trim to down

Elevator neutral

Down

◆When an airplane nose down though

an elevator stick is neutral.

◆Elevator trim to up

Elevator neutral

Up

◆It's adjusted so that it may fly levelly.

29

Page 30

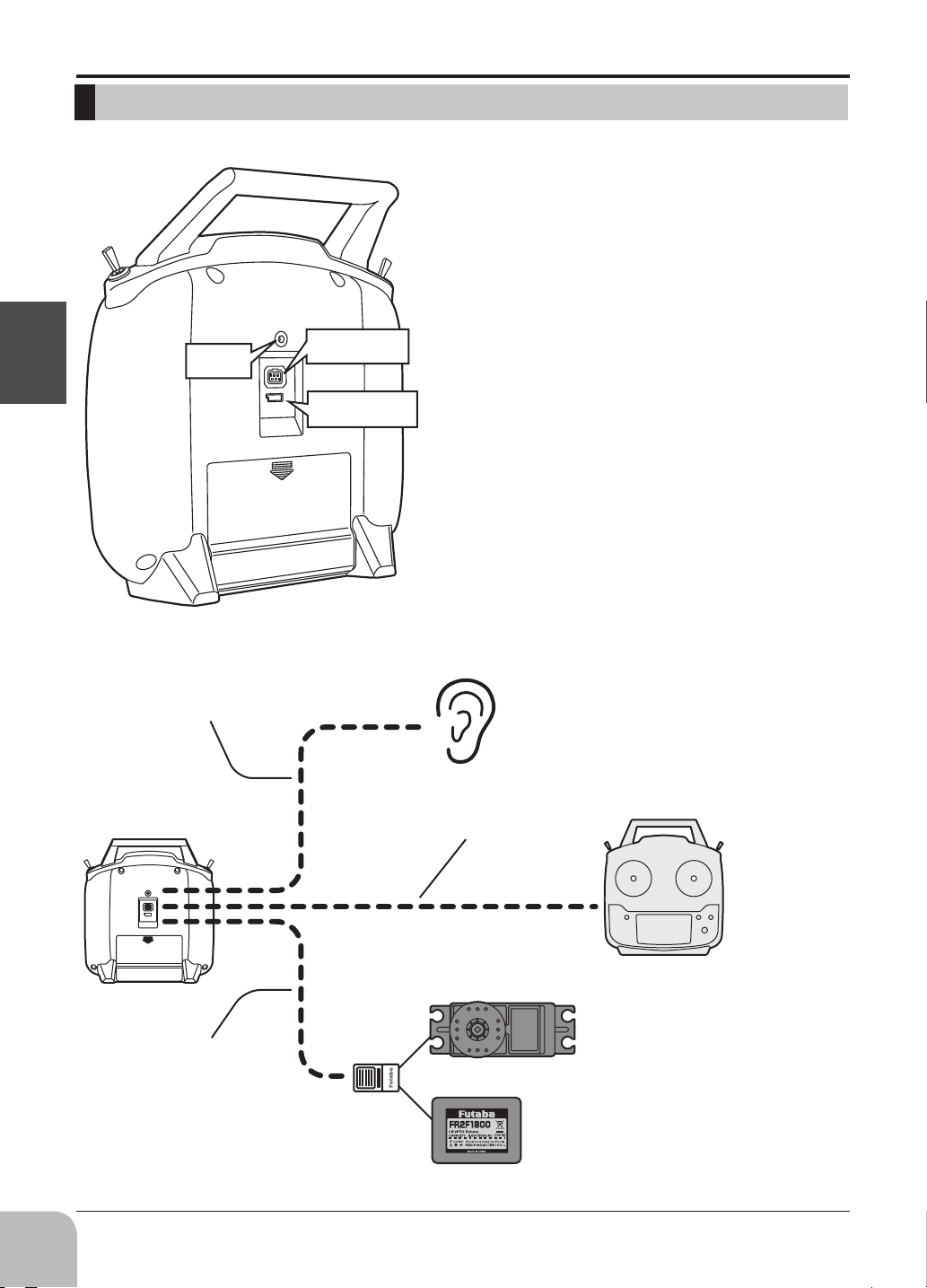

CONNECTOR / PLUG

Before use

Earphone

plug

Trainer function

connector

S.BUS

connector (S.I/F)

Earphone plug

The telemetry data can be listened to by plugging

in commercial 3.5mm earphones. (See the

telemetry item for the detailed setting.)

Trainer function connector

When you use the trainer function, connect the

optional trainer cable between the transmitters

for teacher and student.

*You can set the trainer function on the Trainer Function

screen.

S.BUS connector (S.I/F)

When setting an S.BUS servo and telemetry

sensor, connect them both here.

(Supply power by 3-way hub or 2-way cord.)

Earphone cable

3-way hub or

2-way cord

Telemetry data is heard

Trainer cable

Trainer system

S.BUS servo setting

30

Page 31

SWITCH ASSIGNMENT TABLE

• The factory default functions activated by the switches and VR for an 6K transmitter are shown

below.

• Most 6K functions may be reassigned to non-default positions quickly and easily.

• Basic control assignments of channels 5-6 are quickly adjustable in AUX-CH.

• Note that most functions need to be activated in the programming to operate.

AIRPLANE

Switch/VR 1AIL 1AIL1FLP 2AIL 2AIL1FLP ELEVON

Switch A --- --- --- --- ---

Switch B CH6 CH6 --- --- CH6

Switch C CH5 CH5 CH5 CH5 CH5

Switch D --- --- --- --- ---

VR --- --- --- --- ---

GLIDER

Switch/VR 1AIL 1AIL1FLP 2AIL 2AIL1FLP 2AIL2FLP

Switch A --- --- --- --- ---

SwitchB CH6 --- --- --- ---

SwitchC --- --- --- --- ---

SwitchD --- --- --- --- ---

VR CH5 Flap CH5 Flap Flap

Before use

HELICOPTER MULTI COPT

Switch/VR HELICOPTER

Switch A ---

SwitchB CH5

SwitchC IDLE-UP1/2

SwitchD THR-HOLD

VR ---

Remember that if you

assign primary control of a

channel to a switch which you

later use for other functions

(like dual/triple rates or

airbrakes), every time you use

that other function you will

also be moving the auxiliary

channel.

Don't assign the function

it inuences each other to the

same switch.

*When idle-up 1/2

and a throttle hold

were used.

Switch/VR MULTI COPT

Switch A ---

SwitchB ---

SwitchC ---

SwitchD CH5

VR ---

31

Page 32

RECEIVER AND SERVO CONNECTIONS

Aircraft

1AIL1FLP

1Aileron

1Flap

2AIL

2Aileron

CH

1AIL

1Aileron

1 Aileron Aileron Aileron1 Aileron Elevon1

2 Elevator Elevator Elevator Elevator Elevon2

3 Throttle Throttle Throttle Throttle Throttle

4 Rudder Rudder Rudder Rudder Rudder

5 --- Flap --- Flap Flap

2AIL1FLP

2Aileron

1Flap

ELEVON

Before use

6 --- --- Aileron6 Aileron6 ---

1AIL

Aileron1Servo

(CH1)

(WING TYPE)

Flap1Servo

(CH5)

Aileron 1

(CH1)

Aileron1Servo

(CH1)

2AIL+1FLP ELEVON

Flap1Servo

(CH5)

Elevon 1

(CH1)

(TAIL TYPE)

Elevon 2

(CH2)

2AIL 1AIL+1FLP

Aileron 6

(CH6)

32

Rudder

(CH4)

NORMAL V-TAIL

Elevator

Elevator

(CH2)

+Rudder

(CH2)

Elevator

+Rudder

(CH4)

Page 33

Helicopter

PIT

:Pitch Servo

CH HELICOPTER

(Swash Type)

1 Aileron (cyclic roll)

2 Elevator (cyclic roll)

3 Throttle

4 Rudder

5 Gyro

6 Pitch (collective pitch)

Multicopter

(Normal linkage type)

H-1: each servo linked

to the swashplate

independently.

AIL

:Aileron Servo

ELE

:Elevator Servo

Before use

CH MULTI COPTER

1 Aileron

2 Elevator

3 Throttle

4 Rudder

5 AUX

Mode

6

for Multicopter

controller

[ Connection example ]

Receiver

CH1 ←

CH2 ←

CH3 ←

CH4 ←

CH6 ←

When using an accessary (e.g,

shutter of a camera), use 5CH.

Motor

ESC

Motor

ESC

CH1 AIL

CH2 ELE

CH3 THR

CH4 RUD

MODE

(e.g, U

Multicopter

Controller

-port)

Motor

ESC

Motor

ESC

Battery

33

Page 34

Glider

CH

1 Aileron Aileron Aileron1 Aileron1 Aileron1

2 Elevator Elevator Elevator Elevator Elevator

3 Motor Motor Motor Motor Flap3

4 Rudder Rudder Rudder Rudder Rudder

5 --- Flap --- Flap Flap5

Before use

6 --- --- Aileron6 Aileron6 Aileron6

1Aileron

1AIL

1AIL

Aileron1Servo

(CH1)

1A+1F

1Aileron

1Flap

Flap1Servo

(CH5)

2AIL

2Aileron

(WING TYPE)

1AIL+1FLP

Aileron1Servo

(CH1)

2A+1F

2Aileron

1Flap

Aileron 1

(CH1)

2AIL

2A+2F

2Aileron

2Flap

Aileron 6

(CH6)

34

2AIL+1FLP 2AIL+2FLP

Aileron 1

(CH1)

Aileron 6

(CH6)

Flap1Servo

(CH5)

Aileron 1

(CH1)

Flap 5

(CH5)

*2AIL+2FLP type can't be used for a

motor glider.

(TAIL TYPE)

Rudder

(CH4)

NORMAL V-TAIL

Elevator

Elevator

(CH2)

+Rudder

(CH2)

Flap 3

(CH3)

Elevator

+Rudder

(CH4)

Aileron 6

(CH6)

Page 35

ADJUSTING THE LENGTH OF THE CONTROL STICKS

You may change the length of the control sticks to make

your transmitter more comfortable to hold and operate. To

Stick tip A Locking piece B

lengthen or shorten your transmitter’s sticks, first unlock

the stick tip by holding locking piece B and turning stick

tip A counterclockwise. Next, move the locking piece B

up or down (to lengthen or shorten). When the length feels

comfortable, lock the position by turning locking piece B

counterclockwise.

STICK LEVER TENSION ADJUSTMENT

You may adjust the tension of your sticks to provide the feel that you prefer for ying. To adjust

your springs, you’ll have to remove the rear case of the transmitter. First, remove the battery

cover on the rear of the transmitter. Next, unplug the battery wire, and remove the battery from

the transmitter. Next, using a screwdriver, remove the four screws that hold the transmitter’s rear

cover in position, and put them in a safe place. Gently ease off the transmitter’s rear cover. Now

you’ll see the view shown in the gure above.

Using a small Phillips screwdriver, rotate the adjusting screw for each stick for the desired spring

tension. The tension increases when the adjusting screw is turned clockwise. When you are

satised with the spring tensions, reattach the transmitter's rear cover. When the cover is properly

in place, reinstall and tighten the four screws. Reinstall the battery and cover.

Before use

Four screws are

removed and rear

case is removed.

+ screw is clockwise.

Stick tension maximum Stick tension minimum

+ screw is counter-clockwise.

Elevator

Aileron

StickStick

Mode 2 transmitter with rear case removed.

Do not loosen

the screw past

the top of the

frame, as this

will cause the

screw to rub on

the back case.

A screw touches a case.

※

Rudder

35

Page 36

WARNING & ERROR DISPLAYS

An alarm or error indication may appear on the display of your transmitter for a number of

reasons, including when the transmitter power switch is turned on, when the battery voltage is

low, and several others. Each display has a unique sound associated with it, as described below.

LOW BATTERY ERROR:

The

LOW BATTERY

LOW BATT

Before use

MIXING ALARM WARNING:

overridden.

will be issued at power-up are listed below. Throttle cut, idle-down, airbrake, motor SW,

ight MD, throttle-stick and condition. If turning a switch OFF does not stop the mixing

warning: The functions described previously probably use the same switch and the OFF

direction setting is reversed. In short, one of the mixings described above is not in the OFF

state. In this case, reset the warning display by pressing both +/-KEY at the same time.

Next, change one of the switch settings of the duplicated mixings.

*If "ESC mode" is chosen by "THR.CUT", a THR CUT will not start warning.

BACKUP ERROR:

The

BACKUP ERROR

occurs, all of the data will be reset when the power is turned on again.

Warning sound: Continuous beep until transmitter is powered off.

warning is displayed when the transmitter battery voltage drops below 4.1V.

Land your model as soon as possible before loss of control

due to a dead battery.

Warning sound: Several beeps repeated until problem resolved or

The

MIXING ALARM

whenever you turn on the transmitter with any of the mixing

switches active. This warning will disappear when the offending

switch or control is deactivated. Switches for which warnings

Warning sound: Several beeps (repeated continuously)

warning occurs when the transmitter memory is lost for any reason. If this

warning is displayed to ALARM you

Do not y when this message is displayed: all programming

has been erased and is not available. Return your transmitter to

Futaba for service.

A setup of warning of each sensor can be performed in

TLM

36

TELEMETRY

"TLM" mark is shown about

warning of TELEMETRY.

.

Page 37

LINK PROCEDURE (T6K/R3006SB)

Each transmitter has an individually assigned, unique ID code. In order to start operation, the

receiver must be linked with the ID code of the transmitter with which it is being paired. Once the

link is made, the ID code is stored in the receiver and no further linking is necessary unless the

receiver is to be used with another transmitter. When you purchase additional R3006SB receivers,

this procedure is necessary; otherwise the receiver will not work.

Link procedure

1. Place the transmitter and the receiver

close to each other within 20 inches(half

meter).

Less than 20 inches

2. Turn on the transmitter.

3. Select [MDL-SEL] and access the setup

screen shown below by press the jog key .

4. Use the jog key to select (NO LINK) or the

ID number next to LINK in the [MDL-SEL]

menu.

XXXXXXXXX

8. If the receiver ID is displayed in the

transmitter and the LED changed from red

blinking to a steady green light, linking is

complete. (The receiver linking wait state

ends in about 3 seconds.)

9. Check system operation. If the transmitter

and receiver are not linked, try linking

again.

* If there are many T-FHSS Air systems turned on in close

proximity, your receiver might have difculty establishing

a link to your transmitter. This is a rare occurrence.

However, should another T-FHSS Air transmitter/receiver

be linking at the same time, your receiver could link to

the wrong transmitter. This is very dangerous if you do

not notice this situation. In order to avoid the problem,we

strongly recommend you to double check whether your

receiver is really under control by your transmitter.

*When the linked transmitter power is turned on,

communications begins.

*When using 2 receivers, perform the linking operation the

same as the 1st receiver. (However, when 2 receivers are

used, the telemetry system cannot be used.)

*Link is required when a new model is made from a model

selection.

Before use

5. Hold down the jog key to enter the link

mode.

6. A chime from the transmitter notifies the

operator that the transmitter has entered

the link mode.

“Beep beep beep”

(Enters the link mode for 20 seconds)

In "Link" Mode

Receiver ON

7. Immediately turn on the receiver power.

The receiver will enter the linking state

(LED blinks red) about 3 seconds after the

receiver power is turned on.

WARNING

After the linking is done, please cycle receiver

power and check that the receiver to be linked

is really under the control of the transmitter.

Don't perform the linking procedure with

motor's main wire connected or with the

engine operating as it may result in serious

injury.

*Link is required when a new

model is made from a model

selection.

*When telemetry can't be used, try

a relink once again.

37

Page 38

RECEIVER NOMENCLATURE

DANGER

Before using the receiver, be sure to read the precautions listed in the following pages.

(Typical installation)

Mode Switch

Use the small plastic screw

driver that was included with your

receiver.

Switch is also used for the CH

Before use

mode selection. (CH6⇔S.BUS)

Mode switch

Antenna

R3006SB

LED Indication

Green Red Status

Off Solid No signal reception

Solid Off Receiving signals

Alternate blink Unrecoverable error (EEPROM, etc.)

LED

S.BUS2 port

(SB2/B)

1:Aileron servo

2:Elevator servo

3:Throttle servo (engine)

3:Motor controller (electric)

4:Rudder servo

5:Gear servo (airplane)

5:Gyro gain(Helicopter)

6:Flap servo (airplane)

6:Pitch servo(Helicopter)

Battery

Switch

HUB

Telemetry Sensor

Telemetry Sensor

HUB

Telemetry Sensor

38

DANGER

Don't connect a connector, as shown in a

before figure.

*It will short-circuit, if connected in this way. A short circuit

AIRPLANEss the battery terminals may cause abnormal

heating, re and burns.

Don't connect servo for conventional system

to S.BUS2 port.

*Digital servo for conventional system→ It does not operate.

*Analog servo → It may cause abnormal heat, re and burning.

WARNING

S.BUS2 connectors

Don't connect an S.BUS servo / gyro to

S.BUS2 connector.

Receiver

Do not insert either a switch

or battery in this manner.

Page 39

R3006SB CH MODE

The R3006SB receiver is a very versatile unit. It has 6 PWM outputs and S.BUS2 outputs. Additionally

the SB/6 outputs can be changed from channels PWM 6 channel to S.BUS.

How to change the R3006SB Channel mode

(S.BUS⇔6CH )

The R3006SB is capable of changing its channel

allocations as described in the table below.

1 Turn on the receiver. (At this moment, the

transmitter should be off.) Then, LED blinks

RED in about 3 seconds. Next, wait until it

becomes solid RED.

2 Press and hold the Mode switch more than 5

seconds.

3 Release the button when the LED blinks RED

and GREEN simultaneously.

4 The receiver is now in the "Operation CH Set"

mode. At this moment, the LED indicates

current set status through ashing a pattern

that corresponds to the CH mode.

*Cannot exit this CH setting mode before the operation mode is

xed.

**See the below table that shows correspondence between "CH

mode" and way of ashing LED.

***Default CH mode is "Mode A (6CH)".

5 By pressing the Mode switch, the operation

CH is switched sequentially as " Mode A"

"Mode B" "Mode A"....

6 The operation mode will be set by pressing

the Mode switch more than 2 seconds at the

desired CH mode.

7 Release the button when the LED blinks

RED and GREEN simultaneously. Then, the

operation CH is xed.

6 After confirming the operation CH mode is

changed, turn off and back on the receiver

power.

*The “Operation CH Set” mode cannot be changed during the

receiver communicates to the transmitter.

Before use

R3006SB CH Mode table

Mode A Mode B

6/SB 6CH S.BUS

Red LED blink 1 time 2 time

Default CH mode

PWM 6ch

WARNING

S.BUS2 connectors

Don't connect servo for

conventional system to S.BUS

port.

*Digital servo for conventional system→

It does not operate.

*Analog servo → It may cause abnormal

heat, re and burning.

S.BUS

39

Page 40

RECEIVER's ANTENNA INSTALLATION

The R3006SB has two antennas. In order to maximize signal reception and promote safe

modeling Futaba has adopted a diversity antenna system. This allows the receiver to obtain RF

signals on both antennas and y problem-free.

*Must be kept as straight as possible.

Antenna

Coaxial cable

To obtain the best results of the diversity

function, please refer to the following

Before use

instructions:

1. The two antennas must be kept as straight

as possible. Otherwise it will reduce the

effective range.

2. The two antennas should be placed at 90

degrees to each other.

Antenna

This is not a critical figure, but the most

important thing is to keep the antennas

away from each other as much as possible.

Larger models can have large metal

objects that can attenuate the RF signal. In

this case the antennas should be placed

at both sides of the model. Then the best

RF signal condition is obtained at any ying

attitude.

3. The antennas must be kept away from

conductive materials, such as metal,

carbon and fuel tank by at least a half

inch. The coaxial part of the antennas does

not need to follow these guidelines, but do

not bend it in a tight radius.

4. Keep the antennas away from the motor,

ESC, and other noise sources as much as

possible.

Antenna

40

*The two antennas should be placed at 90 degrees to each other.

*The Illustration demonstrates how the antenna should be placed.

*Receiver Vibration and Waterproofing: The receiver contains precision electronic parts. Be sure to avoid vibration,

shock, and temperature extremes. For protection, wrap the receiver in foam rubber or other vibration-absorbing