Page 1

KONFORMITÄTSERKLÄRUNG

DECLARATION OF CONFORMITY

Standard references: DIN EN 166: 2002-04, DIN EN 170: 2003-01 · 89 / 686 / EEC

KOMPERNASS HANDELS GMBH · BURGSTRASSE 21 · 44867 BOCHUM · GERMANY

Semi Uguzlu (Qualitätsmanager), erklärt folgende Konformität gemäß EU-Richtlinie und Normen für Artikel:

Schutzbrille QB1207

Semi Uguzlu (Quality Manager), declares the following

conformity in accordance with the EU directive and

standards for products: Protective glasses QB1207

Semi Uguzlu (Responsable qualité), explique la conformité

suivante selon la directive européenne et les normes pour

l‘article: Paire de lunettes de protection QB1207

Semi Uguzlu (Vodja kakovosti), vsebuje navedbe o naslednji skladnosti v skladu z direktivo EU in standardi, ki

veljajo za ta izdelek: Zaščitna očala QB1207

Semi Uguzlu (Manager jakosti), prohlašuje následující shodu podle směrnice EU a příslušných norem pro výrobek:

Ochranné brýle QB1207

Semi Uguzlu (manažér kvality), vyhlasuje nasledujúcu

zhodu podľa smernice EU a noriem pre výrobok:

Ochranné okuliare QB1207

Semi Uguzlu (Direttore del Reparto Qualità), dichiara la

seguente conformità secondo direttiva EU e le norme per

l‘articolo: Occhiali protettivi QB1207

Semi Uguzlu (Kwaliteitsmanager), verklaart de volgende

conformiteit conform de EU-richtijn en normen voor artikel:

Beschermingsbril QB1207

Semi Uguzlu (Laadunvalvoja), saa tietoa EU-direktiivien ja

normien mukaisesta tuotteiden vaatimustenmukaisuudesta:

Suojalasit QB1207

Semi Uguzlu (Kvalitetsansvarig), förklarar följande konformitet enligt EU-direktiv och normer för artikeln:

Skyddsglasögon QB1207

Semi Uguzlu (Kvalitetsmanager), erklærer følgende

overensstemmelse iht. EU-direktiv og standarder for artikel:

Beskyttelsesbrille QB1207

Semi Uguzlu (Responsable de calidad), se declara la siguiente

conformidad de acuerdo con las directivas y normativas europeas para el artículo: Gafas protectoras QB1207

Semi Uguzlu (Gestor de qualidade), declara a seguinte

conformidade com as directiva EU e normas para o

artigo: Óculos de protecção QB1207

Semi Uguzlu (manager za kvalitetu), izjavljuje slijedeću

sukladnost prema EU-smjernicama i normama za artikl:

zaštitne naočale QB1207

Semi Uguzlu (Manager de calitate), se declară următoarea

conformitate cu directivele şi standardele EU pentru articolul:

Pereche ochelari de protecţie QB1207

Semi Uguzlu (Мениджър по качеството), разяснява

следното съответствие с директивите и стандартите

на ЕU за артикула: Предпазни очила QB1207

Semi Uguzlu (Menadżer jakości), oświadczamy, iż

niniejszy artykuł jest zgodny ze stosownymi dyrektywami

i normami EU: Okulary ochronne QB1207

Semi Uguzlu (minőségellenőr) kijelenti az EU-irányelv

és a termékszabványok szerinti megfelelőséget:

Védőszemüveg QB1207

Semi Uguzlu (Διαχειριστής ποιότητας), δηλώνει την

ακόλουθη συμμόρφωση σύμφωνα με την Οδηγία της ΕU

και τα πρότυπα για το προϊόν:

Ζευγάρι προστατευτικά γυαλιά QB1207

Bochum, 11.03.2015

Page 2

4-IN-1 PETROL MULTI-TOOL FBK 4 A1

4-IN-1 PETROL MULTI-TOOL

Translation of original operation manual

Read carefully before using machine!

BENZINE-COMBIAPPARAAT 4-IN-1

Vertaling van de originele gebruiksaanwijzing

Voor gebruik van de machine zorgvuldig lezen!

IAN 110011

OUTIL MODULABLE À ESSENCE 4 EN 1

Traduction du mode d'emploi d'origine

Lire consciencieusement avant d'utiliser a machine !

BENZIN-KOMBIGERÄT 4 IN 1

Originalbetriebsanleitung

Vor dem Gebrauch der Maschine sorgfältig lesen!

Page 3

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the device.

Avant de lire le mode d'emploi, ouvrez les deux pages contenant les illustrations et familiarisez-vous ensuite

avec toutes les fonctions de l'appareil.

Vouw vóór het lezen de beide pagina‘s met de afbeeldingen open en maak u vertrouwd met alle functies

van het apparaat.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

GB / IE Translation of original operation manual Page 1

FR / BE Traduction du mode d'emploi d'origine Page 19

NL / BE Vertaling van de originele gebruiksaanwijzing Pagina 37

DE / AT / CH Originalbetriebsanleitung Seite 55

Page 4

5a

5b

5%

6!

5@

5#5$

5^ 5&

5*

5(6)

Page 5

6&

6* 6( 7) 7!

7@

1a

1e

7#

2c

5@

7^

6(

7^

6@

6$6# 6%

6^

7#

7$ 7% 7^

1b 1c 1d

7$

2b

1f

7%

2a

7!

6(

3a 3b 3c

3d

3h

3e 3f

3i

3g

4

H1

H2

Page 6

5a 5b

5e 5f

5@

5c

5d

6a 6b

A

6c 6d 6e

Page 7

Contents

GB

IE

Introduction .................................2

Intended use ........................................2

Features............................................2

Package contents.....................................3

Technical data.......................................3

Safety information ...........................5

Operational safety instructions for hedge trimmers ...........5

Complementary safety instructions for hedge trimmers ........6

Operational safety instructions for the pole pruner ...........7

Precautions against kickback............................7

Operational safety instructions for the strimmer .............8

Operational safety instructions for the cutting blade..........8

Safety equipment.....................................9

Before use .................................. 9

Attaching the round handle.............................9

Fitting the quick release mechanism ......................9

Fixing/attaching the carrying harness.....................9

Fitting the hedge trimmer ..............................10

Removing the hedge trimmer...........................10

Swivelling the hedge trimmer...........................10

Mounting the saw chain and blade .....................10

Removing the saw chain ..............................10

Tightening and checking the saw chain ..................10

Lubricating the chain .................................10

Sharpening the saw chain.............................10

Attaching the extension attachment......................10

Fitting/removing the protective guard ....................11

Installing/replacing the cutting blade ....................11

Installing/replacing the strimmer ........................11

Putting on the carrying harness .........................11

Setting the cutting height ..............................11

Fuel and oil ........................................11

Before use .................................12

Starting when the engine is cold ........................12

Starting when the engine is hot .........................12

Working with the hedge trimmer........................13

Cutting techniques ...................................13

Working with the pole pruner ..........................13

Sawing techniques ..................................13

Working safely .....................................13

Transport ..................................13

Cleaning ...................................13

Maintenance ...............................14

Storage and transportation ...................14

Troubleshooting.............................15

Motor unit .........................................15

Pole pruner ........................................15

Hedge trimmer......................................15

Maintenance interval ........................15

Pole pruner ........................................15

Hedge trimmer......................................15

Spare part orders ...........................15

Disposal ...................................16

Appendix ..................................16

Warranty..........................................16

Service............................................16

Importer...........................................16

Translation of the original Conformity Declaration ..........17

FBK 4 A1

1

Page 8

4-IN-1 PETROL MULTI-TOOL FBK 4 A1

GB

IE

Introduction

Congratulations on the purchase of your new appliance. You have selected

a high-quality product. The operating instructions are a part of this product.

They contain important information on safety, usage and disposal.

Before using the product, familiarise yourself with all handling and safety

guidelines. Use the product only as described and for the range of applications specified. Please also pass these operating instructions on to any

future owner(s).

Intended use

Long-handled hedge trimmer

This appliance is intended for the cutting and trimming of hedges, bushes

and flowering shrubs in the home environment. This is a hand-held appliance with an integrated motor unit with linear reciprocating cutting blades.

WARNING!

► Hedge trimmers are not suitable for use by children.

Pole pruner

This appliance is intended for trimming branches in trees.

3-section cutting blade/strimmer

Use with 3-section cutting blade: for cutting high grass, undergrowth and

light scrub.

Use with strimmer: for cutting grass and small weeds.

Extension attachment

CAUTION!

■ Do not use the extension attachment/boom

the 3-section cutting blade/strimmer attachment!

Any other use which is not expressly permitted in these operating instructions may damage the appliance and represents a serious risk for the user.

Please make sure that you pay attention to the restrictions in the safety

instructions Pay attention to the national regulations which may restrict the

use of the machine. Any other uses of or modifications to the appliance are

deemed to be improper usage and may result in serious physical injury.

Not intended for commercial use.

PROHIBITED APPLICATIONS!

Due to the physical risk posed to the user, the appliance may not be used

to perform the following activities: cleaning footpaths and as a shredder

for shredding tree and hedge sections. Furthermore, the appliance may not

be used to level ground elevations such as molehills. For safety reasons,

the appliance may not be used as a drive unit for any other devices. The

user, not the manufacturer, is liable for any resulting damage or injuries of

any kind.

in combination with

5^

Features

Motor unit

Safety lock-out

On/Off switch

Carrying lug

4 x fixing bolts (with snap ring, washer and nut)

Round handle

5a

Rubber ring

5b

Pin

Barrier bar

Cover

Screw grip

Safety lever

Boom

Throttle control

Spark plug connector

Choke lever

Starter pull cord

Fuel tank

Filler cap

Fuel pump (primer)

Air filter housing cover

Hedge trimmer attachment FBK 4 A1-1

Handle

Lock/release

Transmission case

Cutter bar

Base plate (hedge shears)

Control lever

Front boom (hedge trimmer)

Locking hole

Drive shaft

Pole pruner attachment FBK 4 A1-2

Front boom (pole pruner)

Safety ring

Oil filler cap

Oil tank

Blade

Saw chain

Grinder support

Stop

Locking hole

Drive shaft

Nut

Thread

Sprocket cover

Blade guide

Blade hole

Guide rail

Oil dispenser

Chain sprocket

Oil adjusting screw

Chain tensioner pin

Chain-tensioner screw

2

FBK 4 A1

Page 9

Strimmer/cutting blade attachment FBK 4 A1

4 x bolts (with snap ring, washer and nut)

Blade guard

3-section cutting blade

Strimmer with cutting filament

5@

Front boom (strimmer/3-section cutting blade)

5#

Locking hole

5$

Drive shaft

5%

Extension attachment

Boom

5^

Screw grip

5&

Safety lever

5*

Cover

5(

Locking hole

6)

Drive shaft

6!

Accessories

Carrying harness

6@

Blade guard

6#

Chain guard

6$

Organic chain oil

6%

Oil/petrol mixing canister

6^

Safety goggles

6&

M4 Allen key

6*

M5 Allen key

6(

SW 8/10 open-ended spanner

7)

Spark plug wrench/flat-blade screwdriver

7!

Tool bag

7@

M10 nut (left-hand thread)

7#

Pressure plate cover

7$

Pressure plate

7%

Drive plate

7^

Package contents

1 Motor unit

1 Hedge trimmer attachment FBK 4 A1-1 (hereinafter hedge trimmer)

1 Pole pruner attachment FBK 4 A1-2 (hereinafter pole pruner)

1 Strimmer/cutting blade attachment FBK 4 A1

1 Extension attachment

1 Handle with barrier bar

1 Strimmer with cutting filament

1 3-section cutting blade

1 Carrying harness

1 Protective cover for chain

1 Protective cover for blade

1 Oil/petrol mixing canister

1 100 ml organic chain oil

1 Tool bag

1 M4 Allen key

1 M5 Allen key

1 Spark plug wrench/flat-blade screwdriver

1 SW 8/10 open-ended spanner

1 Safety goggles

1 Operating manual

Technical data

Motor unit

Engine type: 2-stroke engine, air-cooled,

chrome cylinder

Engine output (max.): 1.35 kW/1.85 hp

Cylinder capacity: 42.7 cm³

Engine idle speed: 3000 min

Max. engine speed

with 3-section cutting blade: 9200 min

with strimmer: 8700 min

with chainsaw: 9200 min

with hedge trimmer: 9200 min

Max. cutting speed

with 3-section cutting blade: 6900 min

with strimmer: 6525 min

with chainsaw: 20 m/s

with hedge trimmer: 1550 min

Ignition: Electronic

Drive Centrifugal clutch

Weight:

(empty tank): approx. 5.6 kg

Tank size: 1200 cm

Spark plug: TORCH L7RTC

Fuel consumption at

max. engine performance: 0.6 kg/h

Specific

fuel consumption

at max. engine performance: 446 g/kWh

Hedge trimmer FBK 4 A1-1

Cut length: 425 mm

Cutting capacity: 20 mm

Weight

(ready for use): approx. 2.24 kg

Pole pruner: FBK 4 A1-2

Weight (ready for use): approx. 1.6 kg

Recommended fill level (oil tank): 140 cm

Cut length: approx. 260 mm

Blade: Oregon Type 100SDEA318

Saw chain Oregon 91P040X

Oregon 91P040E

Strimmer/

cutting blade attachment: FBK 4 A1

Strimmer with cutting filament (IAN 110011)

Filament cutting circle Ø: 43 cm

Filament length: 8.0 m

Filament Ø: 2.0 mm

3-section cutting blade (IAN 110011):

Cutting blade cutting diameter Ø: 25.5 cm

-1

-1

-1

-1

-1

-1

-1

-1

3

3

GB

IE

FBK 4 A1

3

Page 10

Noise and vibration data:

GB

Noise measurement value determined in accordance with ISO 22868,

IE

EN ISO 10517. The A-rated noise level is typically as follows:

Hedge trimmer

Sound pressure level L

Uncertainty K

WA

Sound power level L

Guaranteed sound power level L

Uncertainty K

WA

: 98.79 dB(A)

pA

: 2.5 dB

: 109.53 dB(A)

WA

: 114 dB(A)

WA

: 2.5 dB

Pole pruner:

Sound pressure level L

Uncertainty K

WA

: 97.06 dB(A)

pA

: 2.5 dB

Sound power level: 110.87 dB(A)

Uncertainty K

: 2.5 dB

WA

Strimmer/3-section cutting blade:

Sound pressure level L

Uncertainty K

pA

Sound power level L

Uncertainty K

WA

: 97.64 dB(A)

pA

: 2.5 dB

: 111.27 dB(A)

WA

: 2.5 dB

Wear ear protection to prevent hearing damage!

NOTE

The vibration level specified in these instructions has been measured

►

in accordance with the standardised measuring procedure specified

in EN ISO 11806-1, EN ISO 10517, EN ISO 11680-1 and can be

used to make equipment comparisons. The specified vibration emission value can also be used to make an initial exposure estimate.

WARNING!

► The vibration level varies in accordance with use and may be higher

than the value specified in these instructions in some cases. There is

a risk of underestimation of the vibration load if the appliance is used

regularly in this manner. For an accurate estimate of the vibration

load during a specific working period, the periods during which the

appliance is switched off or is running but not actually being used

must also be taken into consideration. This can significantly reduce

the vibration load over the total working period.

WARNING!

■ You can reduce the vibration risk, for example, the risk of Raynaud's

phenomenon, by taking regular breaks during which you rub your

hands together.

Explanation of the symbols on the motor unit:

Vibration values (vector total of three directions) determined in accordance

with EN ISO 11806-1, EN ISO 10517, EN ISO 11680-1 :

Hedge trimmer

Vibration at the front handle: Vibration emission value

= 4.182 m/s

a

h,D

Uncertainty K = 1.5 m/s

2

2

Vibration at the rear handle: Vibration emission value

= 9.695 m/s

a

h,D

Uncertainty K = 1.5 m/s

2

2

Pole pruner:

Vibration on the front handle: Vibration emission value

= 3.855 m/s

a

h,D

Uncertainty K = 1.5 m/s

2

2

Vibration on the rear handle: Vibration emission value

= 7.590 m/s

a

h,D

Uncertainty K = 1.5 m/s

2

2

Strimmer:

Vibration on the front handle: Vibration emission value

= 4.864 m/s

a

h,D

Uncertainty K = 1.5 m/s

2

2

Vibration on the rear handle: Vibration emission value

= 9.750 m/s

a

h,D

Uncertainty K = 1.5 m/s

2

2

3-section cutting blade:

Vibration on the front handle: Vibration emission value

= 4.622 m/s

a

h,D

Uncertainty K = 1.5 m/s

2

2

Vibration on the rear handle: Vibration emission value

= 7.708 m/s

a

h,D

Uncertainty K = 1.5 m/s

2

2

Warning! Read the operating instructions before use!

Wear protective gloves!

Wear safety shoes!

Wear ear protection!

Wear a hard hat!

Wear safety goggles!

Important, hot parts. Keep a safe distance away!

Explanation of the symbols on the hedge trimmer:

Risk of fatal electrical shock! Keep at least 10m away from

overhead power lines!

Caution! Falling objects.

Especially when cutting above head height.

Caution! Risk of injury due to running blades!

Keep a safe distance away!

4

FBK 4 A1

Page 11

Explanation of the symbols on the pole pruner!

Risk of fatal electrical shock! Keep at least 10m away from

overhead power lines!

Protect the appliance from rain and moisture!

Caution! Falling objects.

Especially when cutting above head height.

Caution! Risk of injury due to running blades!

Explanation of the symbols on the strimmer/cutting blade

attachment!

Caution! Left-hand thread.

Protect the appliance from rain and moisture!

Beware of flung objects!

Beware of recoil!

Attention! Risk of injury from rotating cutting blade!

Keep hands and feet away!

Attention – petrol is highly flammable!

Risk of explosion! Do not spill fuel!

Turn the appliance off and disconnect the spark plug before

performing any maintenance work!

Caution! Risk of suffocation!

Attention! Poisonous CO vapours (carbon monoxide vapours)!

Do not use the appliance in closed rooms!

Warning! Do not use circular saw blades for the cutting

blade function.

20 h

Add a little grease after every 20 hours of operation

(gear grease)

A distance of 15 metres must be maintained between the

machine and third parties!

The cutting tool continues running after it is turned off

(cutting blade/cutting filament)!

Important, hot parts. Keep a safe distance away!

Sound power level LWA data in dB.

Fire, naked flames and smoking are prohibited!

Safety information

IMPORTANT! READ CAREFULLY BEFORE USE! KEEP FOR YOUR

RECORDS.

Operational safety instructions for hedge trimmers

NOTE

► The hedge trimmer is supplied completely assembled.

► Instructions and pictorial representations regarding the settings and use

of the hedge trimmer and/or its controls, maintenance, lubrication by

the user can be found in these instructions and on the fold-out page.

► Notes on the working position (see fold-out page)

► Notes on the operating controls (see fold-out page)

► Note on the safe handling of fuel (see section "Preparation", point f).

► Notes on the recommended replacement or repair of parts or the

Customer Service and specification of spare parts to be used,

inasmuch as these affect the health and safety of the user, can be

found in these instructions.

► The explanation of all graphical symbols, information, features and

technical data as well as the procedure in the event of accidents and

faults can be found in these instructions.

► Blocked tool: remove any blockages from the cutter bar

WARNING!

■ Children may never use the hedge trimmer.

■ Stay alert, watch what you are doing and use common sense

when operating the appliance. Do not use the appliance while

you are ill, tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating the appliance may

result in serious personal injury.

■ Avoid improper use. Use the machine only as described under

"Intended use".

.

Familiarise yourself with the operating instructions before you

operate the appliance.

Preparation

a) THE HEDGE TRIMMER CAN CAUSE SERIOUS INJURIES! Read the

instructions on correct handling, preparation, maintenance, starting and

stopping the hedge trimmer very carefully. Familiarise yourself with all

manual controls and the proper use of the hedge trimmer.

b) Children may never use the hedge trimmer.

c) Beware of overhead power lines.

d) Do not use the hedge trimmer while anyone, especially children, is in

the vicinity.

e) Wear appropriate clothing! Do not wear loose clothing or jewellery

which could get caught in moving parts. We recommend wearing

heavy-duty gloves, non-slip footwear and goggles.

f) Handle fuel carefully. It is highly flammable and the vapours are

explosive. The following points should be followed:

– Use only specially-designed containers.

– Never open the tank filler cap or top up the petrol tank while the motor

is running or hot. Allow the motor and the exhaust components to cool

down before refuelling.

– Do not smoke.

– Refuel outside only.

– Never store the hedge trimmer or the fuel tank in a room where there is

an open flame, for example in a hot water boiler.

GB

IE

FBK 4 A1

5

Page 12

GB

IE

– If the petrol has overflowed, do not attempt to start the engine. Remove

the machine from the fuel-contaminated area before restarting.

– Always replace the filler cap after refuelling and close it securely.

– If the tank is empty, this should be done in the open.

g) If the cutting unit comes in contact with a foreign object or if the operating

noise increases or the hedge trimmer starts to vibrate abnormally, stop

the engine and allow the hedge trimmer to come to a standstill. Pull the

spark plug connector off the spark plug and take the following action:

– check for damage;

– check for loose parts and secure all the loose parts;

– replace damaged parts with equivalent parts or have them repaired.

Wear ear protection!

Wear safety goggles!

■ Familiarise yourself with the operation of the hedge trimmer so that you

know how to stop immediately in an emergency.

Operation

a) The engine is to be immobilised before:

– cleaning or removal of a blockage;

– inspection, maintenance or work on the hedge trimmer;

– setting the working position of the cutting unit;

– if the hedge trimmer is to be left unattended.

b) Always make sure that the hedge trimmer is in the proper working posi-

tion before the engine is started.

c) During operation of the hedge trimmer, always ensure that you have firm

footing, especially when using a ladder.

d) Do not use the hedge trimmer if it has a defective or badly worn cutting

unit.

e) To minimise the risk of fire, ensure that the engine and the silencer are

free of residues, leaves or leaked lubricant.

f) Ensure that all supplied handles and safety guards are mounted when

operating the hedge trimmer. Never attempt to operate an incompletely

assembled hedge trimmer or a hedge trimmer with non-approved modifications.

g) Always use both hands if the hedge trimmer is equipped with two

handles.

h) Always familiarise yourself with your environment and be aware of potential

dangers that you may not be able to hear because of the noise of the

hedge trimmer.

Maintenance and storage

a) If the hedge trimmer is shut down for maintenance, inspection or storage,

switch off the engine, pull the spark plug connector off the spark plug

and ensure that all rotating parts have come to a standstill. Allow the

machine to cool down before carrying out an inspection, settings, etc.

b) Store the hedge trimmer where the petrol vapours cannot come into

contact with flames or sparks. Always allow the hedge trimmer to cool

down before storage.

c) When transporting or storing the hedge trimmer, cover the cutting unit

with the protective cover for the cutting unit.

Complementary safety instructions for hedge

trimmers

Environmental safety

■ Only operate the hedge trimmer in daylight or good artificial light.

■ While trimming, ensure that you do not come into contact with objects

such as fence wire or plant supports. They could cause damage to the

cutter bar

wires or other foreign bodies.

■ Be aware of your environment and all possible hazards that you may

be unable to hear while cutting the hedge.

DANGER!

► In the event of imminent danger or an emergency, switch off the

engine immediately.

Electrical safety

■ Hold the power tool only by the insulated grips as the cutting blades

could come into contact with hidden power lines. Contact between

the blades and a live wire may make exposed metal parts of the power

tool live and could give the operator an electric shock.

Personal safety

■ During operation, no other person or animal may be within a radius

of 15 metres. The operator is responsible for third parties within the

working area.

■ During operation, ensure that you have proper footing and balance at

all times, especially when used on steps or ladders.

■ Never grasp the hedge trimmer by the cutter bar

■ Keep your hands away from the cutting blades. Do not attempt to

clear cuttings or hold onto the material to be cut while the blades

are still in motion. Remove any jammed clippings only when the

appliance has been switched off. A moment of inattention while oper-

ating the hedge trimmer may result in serious personal injury.

■ Wait until the tool has come to a standstill before putting it down.

Use and handling

CAUTION!

► Between tasks or after completion of a task, do not set the cutter bar

down on its tip as this could cause damage to the cutter bar .

■ Before use, always check that the blades, the blade screws and other

parts of the cutting tool are not worn or damaged. Never work with a

damaged or heavily worn blade.

■ After making settings to the working angle, check whether both setting

levers are clicked firmly into place. If one of the setting levers remains

open, the second could be unintentionally be released by a branch

and the cutter bar

■ Never use the hedge trimmer with defective or missing safety guards.

■ Never grasp the hedge trimmer by the safety guards.

■ Carry the hedge trimmer by the front handle when switched off, and

with the cutter bar facing away from your body. When transporting

or storing the trimmer, always put on the protective cover. Careful

handling of the appliance reduces the likelihood of accidental contact

with the moving blades.

■ Store the hedge trimmer in a dry, high or closed space out of the reach

of children.

■ Do not attempt to repair the equipment unless you have received the

necessary training.

■ For safety's sake, change worn or damaged parts.

DANGER!

► In the event of imminent danger or an emergency, switch off the

engine immediately.

. Inspect the hedge to be cut carefully and remove any

.

could swing down.

6

FBK 4 A1

Page 13

Operational safety instructions for the pole pruner

CAUTION! RISK OF INJURY!

► To prevent injuries, never touch the appliance above the safety ring

while it is running.

Preparation

■ Always wear a hard hat, hearing protection and safety gloves. Also

wear eye protection to prevent splashes of oil or sawdust from falling

into your eyes. Wear a dust mask to protect yourself from dust.

■ Wear sturdy, non-slip boots.

■ Do not use the appliance in the rain.

■ Before use, check the appliance's safety condition, especially the blade

and the saw chain.

■ Do not use the appliance near overhead power lines. Maintain a

minimum distance of 10 m to overhead power lines.

Electrical safety

■ Do not use the appliance in a potentially explosive environment con-

taining flammable liquids, gases or dusts. The sparks generated by the

machine could ignite the vapours or gases.

■ Appliances with defective switches must be repaired immediately to

avoid damage or injuries.

Personal safety

■ Never use the appliance while standing on a ladder.

■ Do not lean too far forwards while using the appliance. Ensure you are

standing firmly and keep your balance at all times. Use the supplied

carrying harness to spread the weight evenly on the body.

■ To avoid injuries due to falling branches, do not stand under the branches

that you want to cut off. Be aware of branches that may spring back

and cause injuries. Work at an angle of approximately 60°.

■ Be aware that the appliance can kick back.

■ Keep an eye not only on the branches being cut, but also on falling

material, to avoid tripping.

■ Cover the guide rail and the chain during transport during transport

and storage using the cover.

■ Avoid unintentional starting of the appliance.

■ Store the appliance outside the reach of children. Only those who are

fully acquainted with the operating instructions and the appliance itself

may operate the appliance.

Use and handling

■ Never start the appliance before the blade, saw chain and sprocket

covers have been fitted correctly.

■ Do not cut any wood that is lying on the ground and do not attempt to

saw roots that are protruding from the soil. Avoid immersing the saw

chain in the soil at all costs, as this could blunt the saw chain.

■ If the appliance accidentally comes into contact with a solid object, turn

off the engine immediately and inspect the appliance for damage.

■ After 30 minutes' work, take a break of at least one hour.

■ If the pole pruner is shut down for maintenance, inspection or storage,

switch off the engine, pull the spark plug connector off the spark plug

and ensure that all rotating parts have come to a standstill. Allow the

machine to cool down before carrying out an inspection, settings, etc.

■ Service the appliance carefully. Check for misalignment or binding

of moving parts, breakage of parts and any other damage that may

impair the tool’s operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly-maintained tools.

■ Keep cutting tools sharp and clean. Properly maintained cutting tools

with sharp cutting edges are less likely to jam and are easier to control.

■ Therefore, have the appliance checked by qualified specialists. Use

only the replacement parts recommended by the manufacturer.

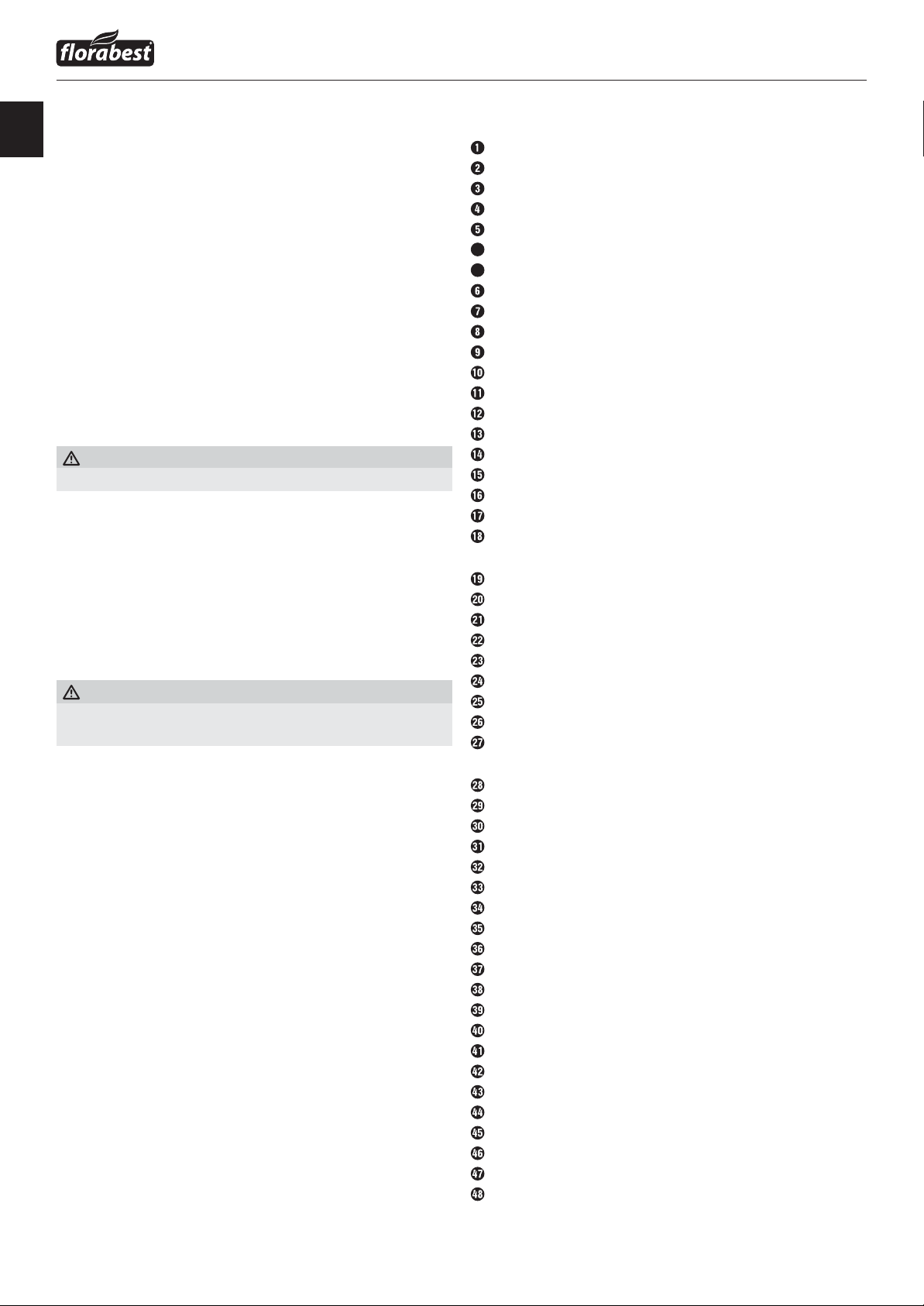

Precautions against kickback

CAUTION KICKBACK!

► Be aware of the danger of kickback when working with the appliance.

There is a risk of personal injury. You can avoid kickbacks by being

careful and using the correct sawing technique.

■ Contact with the tip of the rail can, in some cases, lead to an unexpected

rearwards reaction resulting in the guide rail flying upwards towards

the operator (see Fig. A).

Bild 1

Fig. A

■ Kickbacks can occur if the tip of the guide rail touches an object or if

the wood bends and the saw chain gets caught in the cut (see Fig. B).

Fig. B

■ If the saw chain jams in the upper edge of the guide rail, the rail can

kick back violently towards the operator.

■ Any such reaction can lead to you losing control over the saw and

possibly injuring yourself. Do not rely solely on the chainsaw's built-in

safety devices. As the user of a chainsaw, you can take a number

of measures to avoid accidents and injury. A kickback is caused by

incorrect use or misuse. It can be avoided by taking proper precautions

as given below.

■ Hold the saw firmly with both hands, with your thumb and fingers

around the handles of the chainsaw. Hold your body and arms in

a position in which you can withstand kickback forces. If suitable

measures are taken, the operator can control the recoil forces. Never

let go of the chainsaw.

■ Avoid an abnormal posture and do not saw above shoulder height.

This will prevent inadvertent contact with the tip of the rail and allows a

better control of the chainsaw in unexpected situations.

■ Always use the replacement rails and saw chains specified by the

manufacturer. Incorrect replacement rails and saw chains can lead to

a tearing of the saw chain and/or kickback.

■ Follow the manufacturer's instructions for sharpening and mainten-

ance of the saw chain. Setting the depth stop too low can increase the

risk of kickback.

■ Do not saw with the tip of the blade. This can lead to kickback.

■ Ensure that there are no objects on the ground that you can trip

over.

GB

IE

FBK 4 A1

7

Page 14

Operational safety instructions for the strimmer

GB

Preparation

IE

■ Wear close-fitting clothes that offer good protection, such as long

trousers, sturdy work shoes, heavy-duty protective gloves, a hard hat,

a protective mask for your face or safety goggles to protect your eyes

and good ear plugs or some other hearing protection against noise.

■ Always use the enclosed shoulder strap.

■ Always ensure that the handles are dry and clean and that no petrol

mixture is present.

■ Before working, check the area for objects such as pieces of metal,

bottles, stones, etc, which could get thrown up and cause injuries to the

user.

■ Before starting the engine, make sure that the strimmer is not in contact

with any obstacles.

■ Do not use the appliance until you have familiarised yourself with its

use.

Electrical safety

■ Never use the appliance near highly flammable liquids or gases, either

in closed rooms or in the open. This may result in explosions and/or

fire.

■ Do not work with a damaged or incomplete appliance or an appli-

ance that has been modified without the consent of the manufacturer.

Never use the unit with defective protective equipment. Do not use the

appliance if it has a defective on/off switch. If the appliance has been

dropped, check for significant damage or defects.

Personal safety

■ This appliance may only be operated, adjusted and maintained by

appropriately trained individuals and adults.

■ If you are not familiar with the appliance, practice handling the appliance

while the engine is off.

■ Do not touch the exhaust.

■ Do not operate the appliance under the influence of alcohol or drugs.

■ Always hold the appliance with both hands. Your thumbs and fingers

should encircle the handles.

■ Work posture: Do not operate the appliance in an uncomfortable

position, when you are unbalanced, with arms fully stretched or with

only one hand.

■ Always ensure that you have a solid and firm stance.

■ Do not use the appliance if spectators or animals are in the direct vicin-

ity. Maintain a minimum distance of 15 metres between the operator

and other people or animals when trimming. Maintain a minimum distance of 30 metres between the operator and other persons or animals

when mowing down to the ground.

■ When mowing on a slope, always stand at a lower level than the

cutting tool. Never cut or trim on an icy, slippery hill or slope.

■ Any modifications to the product may risk personal safety and void the

manufacturer's warranty.

■ Children should be supervised to ensure that they do not play with the

appliance.

■ Do not use the appliance if it is damaged or if there are visible defects.

Use and handling

■ Use the appliance only for its intended purpose: cutting grass, mowing,

pruning branches, cutting and trimming hedges and bushes.

■ Do not use the appliance for extended periods; take regular breaks.

■ Ensure that screws and connecting elements are firmly tightened. Never

operate the appliance if it is not correctly adjusted, incomplete or if it is

not properly assembled.

■ Open the fuel tank slowly in order to allow any pressure which may have

built up in the tank to dissipate. To prevent the risk of fire, move at least 3

metres away from the refuelling area before starting the appliance.

■ Guide the strimmer to the desired height. Avoid contact with small

objects (e.g. stones) when using the strimmer.

■ Always hold the strimmer on the ground when the appliance is in

operation.

■ Do not use the appliance unless the appropriate protective guard has

been installed and is in good condition.

■ Do not use any other cutting tools. For your safety, only use the

accessories and additional devices that are indicated in the operating

instructions. The use of parts other than those recommended in the

operating instructions, or other accessories, can put you at risk of injury.

■ Always trim and cut using the high speed range. Do not let the engine

run at a low speed when starting to mow or trim.

■ When starting and operating the appliance, ensure that it does not

come into contact with the ground, stones, wire or other foreign material. Switch off the appliance before you put it down.

■ Switch off the appliance before you put it away.

■ Always turn the engine off before working on the cutting tool.

Operational safety instructions for the cutting

blade

Preparation

■ The cutting blade flings objects and soil with great force. These can

blind or cause other injuries. Wear eye, face and leg protection. Always

remove objects from the work area before using the cutting blade.

■ The cutting blade continues running after the throttle lever has been

released. A running-down cutting blade can inflict cuts to yourself or

other people standing nearby. Turn the engine off and make sure that

the cutting blade has come to a complete stop before performing any

work on the cutting blade.

Personal safety

■ The appliance can blind and cause injuries to bystanders. Maintain a

minimum distance of 15 metres in all directions between the appliance

and other people or animals.

Use and handling

■ Do not use the appliance if any of the cutting blade accessories have

not been properly installed.

■ The cutting blade can kick back from objects with force. This can cause

injuries to your arms and legs. If the appliance comes into contact with

a foreign body, immediately shut down the engine and wait until the

cutting blade has come to a complete stop. Check the cutting blade for

damage. Always replace the cutting blade if it is bent or cracked.

8

FBK 4 A1

Page 15

Safety equipment

The relevant plastic protective guard for the cutting blade or filament

operation must be installed when working with the appliance in order to

prevent objects from being flung away.

WARNING!

■ Never mow/trim while other individuals, especially children or animals,

are in the vicinity.

■ Maintain a safety distance of 15 m. Turn off the appliance immedi-

ately if this distance is not maintained.

CAUTION! RISK OF POISONING!

■ Exhaust gases, fuels and lubricants are toxic. Exhaust gases must

never be inhaled.

WARNING!

■ Petrol is highly flammable. Store petrol only in the containers

provided.

■ Refuel only outdoors and do not smoke.

■ The filler cap must not be opened and refuelling must not take place

while the engine is running or when the appliance is hot.

■ Do not attempt to start the engine if the petrol has overflowed. In-

stead, remove the appliance from the area polluted by petrol. Do not

attempt to restart the appliance until the petrol fumes have dissipated.

■ For safety reasons, the petrol tank and filler cap must be replaced if

they are damaged.

Limit the noise development and vibrations to a minimum!

■ Only use appliances that are in good condition.

■ Maintain and clean the appliance on a regular basis.

■ Adapt your working method to the appliance.

■ Do not overload the appliance.

■ Have the appliance inspected if necessary.

■ Switch the appliance off when not in use.

■ Wear protective gloves!

Before use

CAUTION!

■ Always wear non-slip footwear and appropriate safety clothing

such as protective gloves, a hard hat, a protective mask and safety

goggles as well as hearing protection.

■ Check the area in which the appliance is to be used and remove any

objects that may be caught and slung away.

■ Before use and after dropping or other impacts, always visually in-

spect the appliance to check whether the cutting tool, mounting bolts

and the entire cutting unit are damaged. Worn or damaged cutting

tools and mounting bolts must be replaced.

■ Always carry out a visual inspection before use to check whether the

cutting tools are worn or damaged. To prevent imbalance, worn or

damaged cutting tools and mounting bolts should be replaced only

as complete sets.

Attaching the round handle

♦ Start by fitting the rubber ring 5a on the boom .

♦ Attach the barrier bar

♦ The pin

♦ Push the round handle

♦ Insert the 4 mounting bolts

♦ Tighten the bolts

5b

on the barrier bar must be pushed into one of the two

holes on the boom to lock it into place.

boom .

and secure them with the 4 nuts in the barrier bar

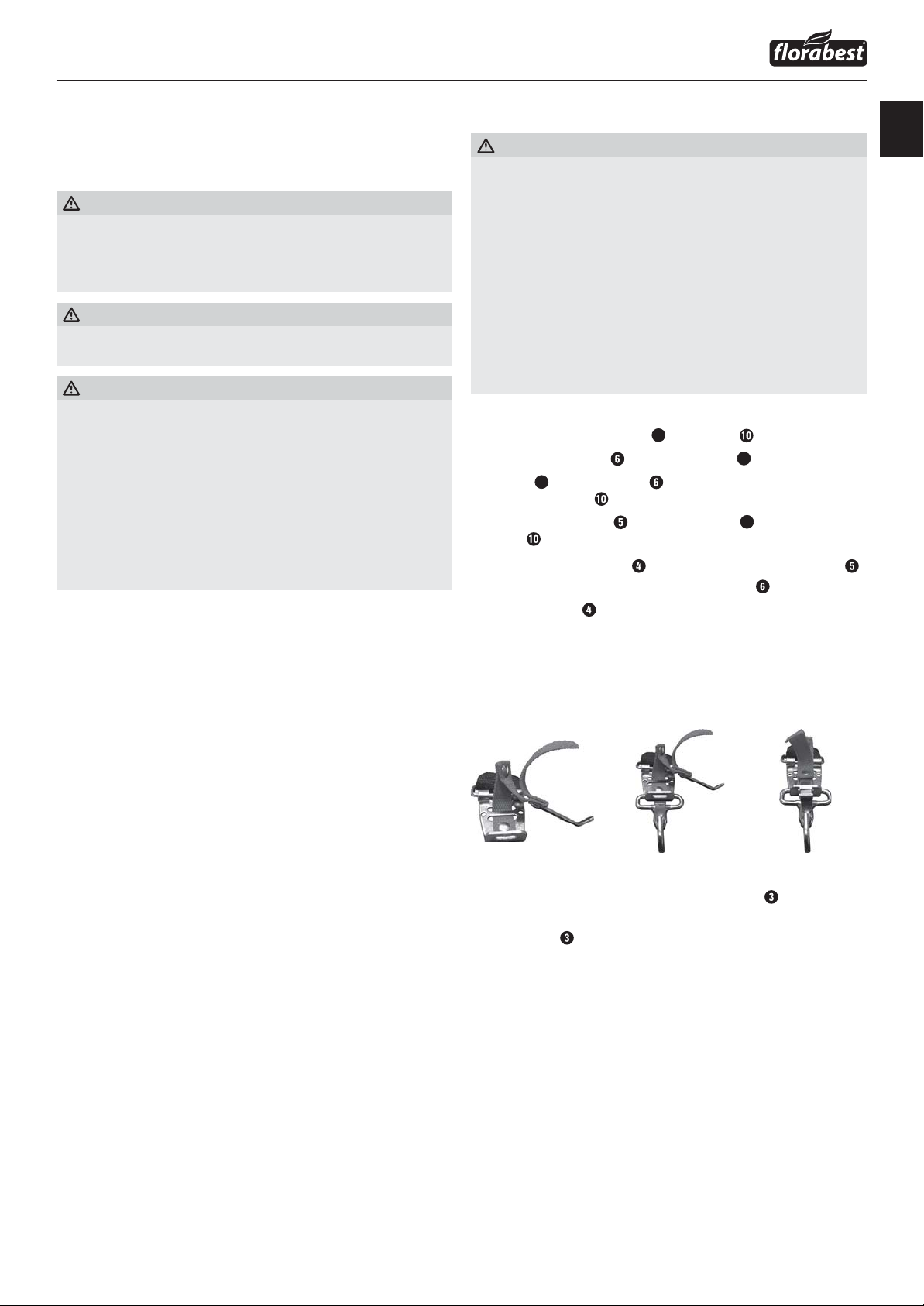

Fitting the quick release mechanism

♦ Hook in the carabiner and secure it with the red strap on the quick

release mechanism (see figures). Pull on the red strap if you have to

release the appliance quickly.

onto the rubber ring 5a from below.

onto the rubber ring 5a provided on the

from above through the round handle

.

.

GB

IE

FBK 4 A1

Fixing/attaching the carrying harness

♦ Hook the carrying harness 6@ into the carrying lug .

♦ Adjust the length of the carrying harness

carrying lug

is at hip height when hooked in place.

to your size so that the

6@

9

Page 16

Fitting the hedge trimmer

GB

IE

♦ Start by undoing the screw grip on the boom of the motor unit.

♦ Push the front boom

motor unit.

♦ The safety lever

♦ Press the cover

hold it down.

♦ Tighten the screw grip

NOTE

► The assembly of the pole pruner/strimmer/3-section cutting blade/

extension attachment is carried out in the same order.

of the hedge trimmer onto the boom of the

must click into the locking hole .

that protects the safety lever downwards and

.

Tightening and checking the saw chain

WARNING!

► Wear protective gloves! There is a danger of injury from the sharp

cutting teeth.

♦ Turn the chain-tensioner screw

flat-blade screwdriver

♦ The saw chain

whether the saw chain

NOTE

► A new saw chain

7!

must lie against the underside of the blade. Check

stretches and must be tightened more regularly.

in a clockwise direction using the

to increase the tension.

can be drawn by hand over the blade .

Removing the hedge trimmer

♦ Undo the screw grip .

♦ Press the safety lever

trimmer out of the boom

NOTE

► Disassembly of the pole pruner/strimmer/3-section cutting blade/

extension attachment is carried out in the same order.

and pull the front boom on the hedge

on the motor unit.

Swivelling the hedge trimmer

♦ Release the lock/release .

♦ Press the control lever

desired position.

♦ Allow the control lever

(hedge trimmer)

and swivel the hedge trimmer into the

to click into the recess in the base plate

.

Mounting the saw chain and blade

WARNING!

► Wear protective gloves! There is a danger of injury from the sharp

cutting teeth.

NOTE

► Pay close attention to the running direction of the saw chain

the blade

► Depending on wear, the blade

♦ Undo the nut

♦ Remove the sprocket cover

♦ Lay the saw chain

♦ Now fit the blade

♦ Lay the guide rail

tensioner pin

chain

♦ Now you can tighten the saw chain

checking the saw chain").

♦ Replace the sprocket cover

and at the base plate (pole pruner) .

can be turned.

using the open-ended spanner 7).

.

over the blade starting at the tip.

and saw chain .

over the blade guide while inserting the chain

in the blade hole . At the same time, lay the saw

over the chain sprocket .

(see section "Tightening and

and tighten the nut gently.

Removing the saw chain

♦ You may have to loosen the saw chain to remove the blade

and the saw chain

chain"). Follow these instructions in reverse order.

(see section "Tightening and checking the saw

on

Lubricating the chain

♦ Remove the oil filler cap .

♦ Fill the oil tank

♦ The chain lubrication can be increased or decreased using the oil

adjusting screw

♦ Press and then turn the oil adjusting screw

the chain lubrication.

♦ Press and then turn the oil adjusting screw

the chain lubrication.

WARNING!

► Never work without chain lubrication!

If the saw chain runs dry, the cutting equipment may become irreparably damaged in a short time. Always check chain lubrication and

oil level in the tank before starting work.

NOTE

► Use only saw chain oil. Preferably biodegradable. Do not use waste

oil, motor oil, etc.

► While working, check whether the chain lubrication is working

correctly.

with approx. 100ml of organic chain oil 6%.

.

clockwise to decrease

anticlockwise to increase

Sharpening the saw chain

NOTE

A grinder can be attached to the grinder support

►

during grinding.

► You will find detailed information on sharpening in the sharpening

set, e.g. from Oregon.

► Alternatively, you can use an electrical saw chain sharpening device

and follow the manufacturer's instructions .

► If you have any doubts about carrying out the work, the saw chain

should be replaced.

for a secure grip

Attaching the extension attachment

CAUTION!

■ Do not use the extension attachment/boom

the 3-section cutting blade/strimmer attachment!

NOTE

► Use the extension attachment/boom

heights.

5^

in combination with

5^

for working at greater

10

♦ Fit the extension attachment/boom

hedge trimmer/pole pruner. The assembly is carried out in the same

manner as for the attachments described previously.

between the motor unit and the

5^

FBK 4 A1

Page 17

Fitting/removing the protective guard

WARNING!

■ When working with the 3-section cutting blade, the protective guard

must be fitted. Fold the metal sheet of the front boom 5# down

slightly. The protective cover

and the boom

attached to the front boom

Allen key

mounting arm. The protective guard

5#

and the open-ended spanner 7).

6*

is positioned between the metal sheet

is now

with 4 screws . Use the supplied

5#

Cutting equipment Protective equipment

3-section cutting blade

Strimmer with cutting filament

5@

WARNING!

■ Do not use any other cutting equipment apart from that which is

supplied with the product. The use of any other cutting equipment

or protective equipment is deemed to be improper and carries a

significant risk of accidents.

Protective cover

Protective cover + cutting filament

protective guard

C

Installing/replacing the cutting blade

■ Fit/remove the 3-section cutting blade as shown in Figures 1a–1f.

■ Find the hole in the drive plate

block it with the supplied Allen key

■ Place the 3-section cutting blade

■ Fit the pressure plate

■ Fit the pressure plate cover

■ Now tighten the nut

■ The 3-section cutting blade is fitted with a plastic cover on delivery. This

must be removed before use and refitted during periods when not in use.

■ The plastic cover can now be removed.

CAUTION! Left-hand thread!

CAUTION! SHARP EDGES, WEAR PROTECTIVE GLOVES

■ Fit the cutting filament protective guard

■ The cutting filament protective guard C must be fitted when working

with the cutting filament. The cutting filament protective guard

(pre-fitted on delivery) is fitted as shown in Figure 2a.

■ Ensure that the cutting filament protective guard

into place. There is a blade A on the inside of the cutting filament protective guard C. This is covered with a safety cover B (see Fig. 2a.).

■ Remove the safety cover

finishing work.

CAUTION! SHARP EDGES, WEAR PROTECTIVE GLOVES

■ To remove the cutting filament protective guard C from the protective

guard

three mounting pins. CAUTION! RISK OF INJURY!

, take a tool, such as a screwdriver, to carefully remove the

over the thread on the splined shaft (see Fig. 1c).

7%

with the spark plug wrench 7! (see Fig. 1f).

7#

, align it with the opposite hole and

7^

.

6(

on the drive plate 7^ (see Fig. 1b).

(see Fig. 1d).

7$

C

on the protective guard .

C

C

is correctly clicked

B

before starting work and replace it after

Installing/replacing the strimmer

■ Fit/remove the strimmer 5@ as shown in Figure 2c.

■ Find the hole in the drive plate

block it with the supplied Allen key

■ Place the pressure plate

plate elevation

■ Now screw the strimmer

CAUTION! Left-hand thread!

7%

7%

on the drive plate elevation 7^.

5@

, align it with the opposite hole and

7^

.

6(

on the drive plate 7^. Place the pressure

onto the thread.

Putting on the carrying harness

NOTE

The following adjustments can be made to make sure that you can

■

work without becoming fatigued. The settings may vary depending

on your body size.

■ Before starting work, adjust the carrying harness

size.

■ Balance the appliance with the fitted cutting tool so that the cutting

tool swings just over the ground without the need to move the appliance with your hands.

1.) Put on the carrying harness

into place (see Fig. 3a).

2.) As shown in Figure 3b, pull on the belt

harness

3.) To tighten the two shoulder straps, pull on the two shoulder straps as

shown in Figure 3c.

4.) To ensure to the correct position of the appliance on the carrying

harness, pull the belt as shown in Figure 3d.

5.) Hook in the carabiner

quick release mechanism (see Figures 3e–3g).

6.) Now take the appliance and hang it, as shown in Figure 3h, so that the

carrying lug

also be moved by loosening the screw

optimum orientation of the appliance.

centrally on your body and adjust the upper body size.

6@

clicks into the carabiner . The carrying lug can

and close the clasps so that they click

6@

to position the carrying

6@

and secure it with the red strap on the

and sliding it to achieve the

to suit your body

6@

Setting the cutting height

■ Put on the carrying harness 6@ and hook in the appliance (see section

"Putting on the carrying harness").

■ Use the various belt straps on the carrying harness

optimum working and cutting position (see section "Putting on the

carrying harness").

■ Perform a few circular movements without starting the engine in order to

find the ideal shoulder strap length (see fig. 6a).

■ The carrying harness

anism. Pull on the red strap

quickly (see Fig. 3i).

CAUTION!

■ Always use the carrying harness

the appliance. Put on the carrying harness

started the engine and it is ticking over. Switch off the engine before

removing the carrying harness

is equipped with a quick-release locking mech-

6@

if you have to release the appliance

when you are working with

6@

6@

.

6@

to adjust the

6@

as soon as you have

Fuel and oil

■ Only use a mixture of unleaded petrol and special 2-stroke engine oil.

Mix the fuel mixture in accordance with the fuel mix table.

■ Add the respective correct amounts of unleaded petrol and 2-stroke

oil to the supplied oil/petrol mixing canister

Then shake the canister well.

Fuel mix table

Mixing process: 40 parts petrol to 1 part oil

(see "Fuel mix table").

6^

Petrol 2-stroke oil

0.5 litre 12.5 ml

GB

IE

FBK 4 A1

11

Page 18

Before use

GB

IE

CAUTION!

■ Please pay attention to the statutory provisions in the relevant noise

protection regulations.

Before starting the appliance, always check that:

■ The fuel system is not leaking.

■ The protective equipment and cutting equipment is complete and in

perfect working order.

■ All screw connections are firmly tightened.

■ All moving parts can move smoothly and freely.

Starting when the engine is cold

CAUTION!

■ Never allow the starter pull cord to whip back This could cause

damage.

1.) Fill the fuel tank

2.) Press the primer

3.) Switch the on/off switch

4.) Pull the choke lever

5.) Hold the appliance firmly and pull out the starter pull cord

point of first resistance. Now pull hard on the starter pull cord

The appliance starts.

6.) If the engine does not start, repeat steps 4–5.

7.) As soon as the engine is running, press the safety lock-out

press the throttle

If the engine does not start after several attempts, read the "Troubleshooting guide" section.

CAUTION!

■ Always pull the starter pull cord

the starter pull cord firmly when the starter pull cord retracts.

Do not allow the starter pull cord to whip back.

NOTE

■ At very high ambient temperatures it is possible that even a cold

engine has to be started without using the choke!

(see also the section "Fuel and oil").

6 times.

to "I".

into position " ".

to activate the automatic choke.

straight out. Hold the handle of

Starting when the engine is hot

(The appliance has been turned off for less than 15–20

minutes)

1.) Switch the on/off switch

2.) The choke lever

motor.

3.) Hold the appliance firmly and pull out the starter pull cord

point of first resistance. Now pull hard on the starter pull cord

The appliance should start after 1–2 pulls. If the appliance still hasn't

started after 6 pulls, repeat steps 1–7 under "Starting when the engine

is cold".

Turning the engine off

Emergency stop sequence

If you need to stop the appliance immediately, switch the on/off switch

to "0".

Normal sequence

■ Release the throttle lever

to its idling speed. Then switch the on/off switch to "0".

to "I".

does not need to be pulled out to start a warm

and wait until the engine has slowed down

to the

.

and then

to the

.

Optimal working procedures

Before using the appliance, practice all working techniques (see Figs.

6a–6c) with the engine stopped.

Extending the cutting filament

To lengthen the cutting filament, rev the engine to full throttle and tap

the strimmer

knife A on the cutting filament protective guard C cuts the thread to the

permissible length (see Fig. 6d).

CAUTION!

Grass/weed residues can get caught under the protective guard

■ Remove the remains using a scraper or similar item when the engine

is switched off.

Various cutting methods

Trimming/mowing (3-section cutting blade or strimmer)

■ Swing the appliance in a scything motion (see Fig. 6a).

■ Hold the cutting tool parallel to the ground and set the desired cutting

height.

Low trimming (with strimmer)

■ Hold the appliance with a slight incline to the ground (see Fig. 6b). Al-

ways cut away from your body. Never pull the appliance towards you.

Short mowing (with strimmer)

■ Short mowing removes all the vegetation right down to the ground.

Angle the strimmer 30° to the right. Set the handle to the desired

position (see Fig. 6c).

Cutting against trees/fences/foundations (with strimmer)

NOTE

■ The filament will wear or fray quickly if it comes into contact with

trees, rocks, walls or foundations. The filament will break off if it

strikes fence mesh.

CAUTION!

■ Do not use the appliance to remove any objects from footpaths, etc.!

The appliance is powerful and can fling small stones or other objects

15 metres or more and may cause injuries or damage to cars,

houses and windows.

Jamming

Immediately turn off the engine if the cutting tool becomes blocked.

Remove all grass and scrub from the appliance before restarting the

appliance.

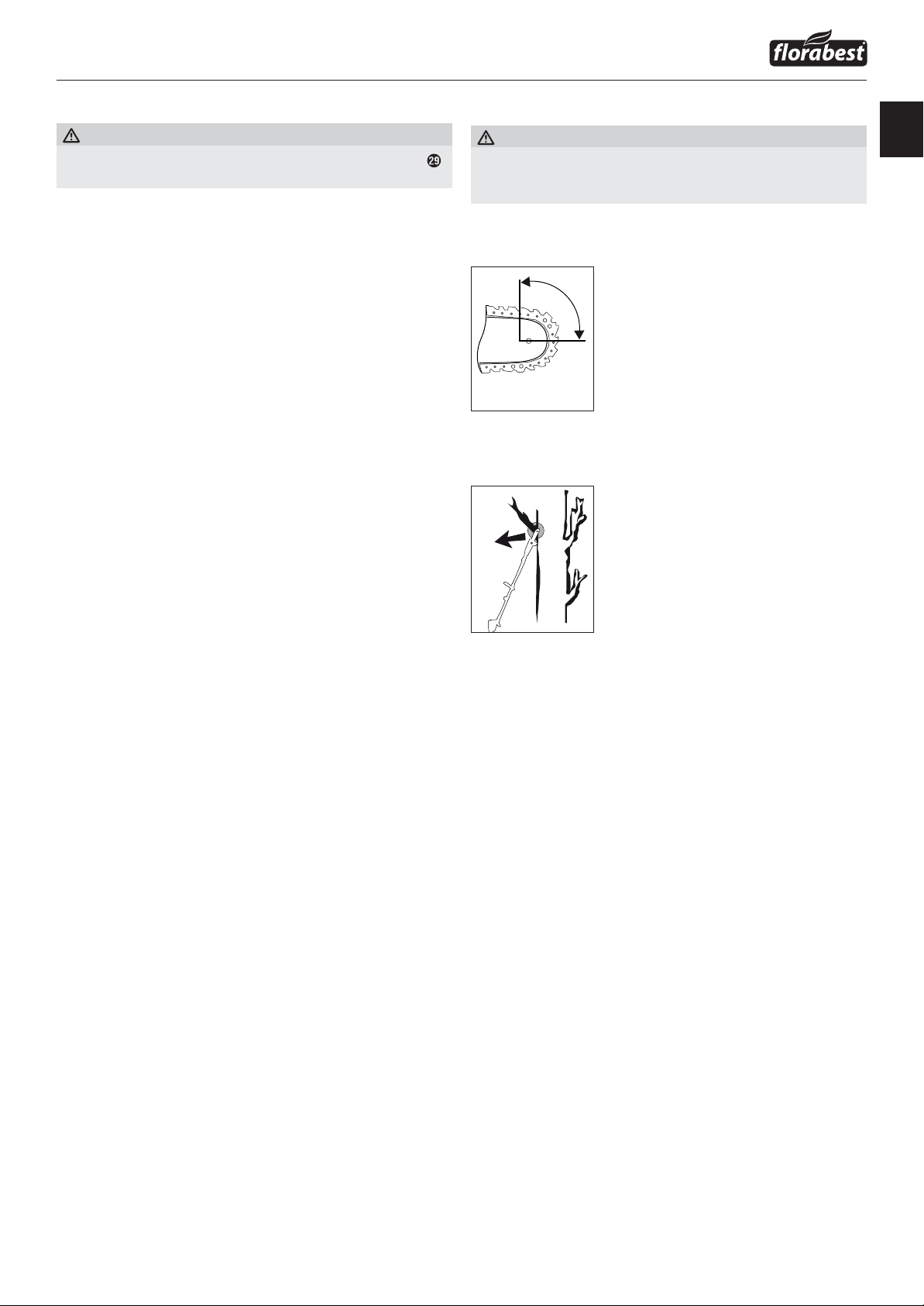

Preventing kickback

When working with the cutting blade there is a risk of kickback if the blade

strikes against solid obstacles (tree trunks, branches, tree stumps, rocks or

similar). This will result in the cutting tool being catapulted back against the

direction of rotation. This can lead to the loss of control of the appliance.

Do not use the cutting blade near fences, metal posts, boundary stones or

foundations. To cut weak shrubs, position the appliance as shown in Fig.

6e to avoid kickbacks.

on the ground. The filament extends automatically. The

5@

Wear safety goggles!

.

CAUTION!

■ The 3-section cutting blade must be stationary when the engine is

idling. If the 3-section cutting blade is rotating adjust the carburettor!

12

FBK 4 A1

Page 19

Working with the hedge trimmer

Cutting techniques

■ The double-sided cutter bar allows cutting in both directions or by using

swinging movements from one side to the other.

■ For a vertical cut, move the hedge trimmer evenly forwards or up and

down in an arc.

■ For a horizontal cut, move the hedge trimmer in a scything motion

along the edge of the hedge so that cut branches fall to the ground.

■ See fold-out page (Figure A).

NOTE

► Remove thicker branches with a branch cutter.

Working with the pole pruner

Sawing techniques

Working safely

■ Keep the appliance, the cutting mechanism and the chain guard 6$ in

good condition to prevent injury.

■ If the appliance has been dropped, check for significant damage or

defects.

■ Observe the specified working angle max. 60°±10° to ensure safe

working (see figure).

max. 60°±10°

GB

IE

WARNING!

► Pay attention to falling clippings.

► Be aware of the danger of branches flying back.

NOTE

►

Place the stop

and quietly.

► Now you can begin sawing.

Sawing off small branches

♦ Saw small branches (Ø 0–8 cm) from the top down (see figure).

Sawing off larger branches

♦ When sawing larger branches (Ø 8–25 cm), first make a relief cut A

(see figure). A relief cut also prevents peeling of the bark on the main

trunk.

♦ Saw from the top

on the branch. This will help you work more safely

B

to the bottom A.

■ Do not use the appliance while standing on a ladder or with unsteady

footing.

■ Do not be tempted into making a poorly considered cut.

You could endanger yourself and others.

■ Children should be supervised to ensure that they do not play with the

appliance.

■ Change your working position regularly. Using the appliance for a long

time can lead to vibration-related circulation disorders of the hands.

You can extend the usage duration by means of appropriate gloves or

by taking regular breaks. Note that any personal predisposition to poor

blood circulation, low external temperatures or large prehensile forces

can reduce the usage period.

Transport

■ Use the protective guards 6# 6$ when transporting the appliance.

■ Ensure that the appliance cannot switch on during transport (see

figure).

B

A

Saw in sections.

Trim long or thick branches before you make the final cut (see figure).

C A B

cb a

2

1

FBK 4 A1

Cleaning

Cleaning the engine unit

NOTE

■

Clean the appliance thoroughly after every use.

■ Always switch off the appliance before cleaning and then disconnect

the spark plug connector

■ Clean the appliance regularly with a damp cloth and a mild detergent.

Make sure that no water can penetrate into the interior of the appliance.

Cleaning the pole pruner

■ The pole pruner must be cleaned of sawdust at regular intervals.

♦ Remove the sprocket cover

♦ Remove the saw chain

♦ Keep the saw chain

and the oil supply.

.

.

from the blade and clean the guide rail .

sharp and check the tension; check the oil level

13

Page 20

Cleaning the hedge trimmer

GB

IE

♦ Check the hedge trimmer for loose screws on the cutter bar

tighten these if necessary.

♦ Remove stuck cuttings.

♦ Maintain the cutter bar

Cleaning the strimmer/3-section cutting blade attachment

♦ Remove stuck cuttings.

♦ Keep the 3-section cutting blade

using an oil spray or an oil can.

sharp to facilitate your work.

and

Spark plug maintenance

1.) Pull off the spark plug connector

2.) Unscrew the spark plug using the spark plug wrench

3.) Assembly takes place in the reverse order.

Electrode gap = 0.6 mm (distance between the electrodes between which

the ignition spark is generated). Check the spark plug for contamination

after the first 10 hours of operation and clean it with a copper wire brush

if required.

Afterwards, service the spark plug after every 50 hours of operation.

.

supplied.

7!

Maintenance

Replacing the strimmer/cutting filament

1.) The strimmer

replacing the strimmer. Press the marking (see Fig. 5a), turn the cover

and remove one half of the casing (see Fig. 5b).

2.) Remove the spool bobbin

3.) Remove any remaining cutting filament.

4.) Double the new cutting filament in the middle and hook the loop that

you have made into the recess on the spool bobbin (see Fig. 5d).

5.) Wind the filament tightly in an anticlockwise direction. The spool bobbin

6.) Hook the last 15cm of the two ends of the filament into the opposite

filament holders

7.) Guide the two ends of the filament through the metal lugs in the strimmer

housing (see Fig. 5e).

8.) Press the spool bobbin

9.) Reconnect the two halves of the housing.

10.) Pull hard on the two ends of the filament to free them from the filament

holders (see Fig. 5f).

11.) Cut any excess filament back to about 13 cm. This reduces the load

on the engine when starting and warming up.

12.) Refit the strimmer (see section "Installing/replacing the strimmer").

Skip points 3–6 if you are replacing the entire strimmer.

Air filter maintenance

Contaminated air filters reduce the engine performance due to low air

supply to the carburettor.

Regular inspection is essential. The air filter

every 25 hours of operation and cleaned if necessary.

The air filter must be checked more frequently if the air is dusty.

1.) Remove the cover of the air filter housing

2.) Remove the air filter

3.) Clean the air filter

air).

4.) Assembly takes place in the reverse order.

CAUTION!

■ Never clean the air filter with petrol or flammable solvents.

is removed as described in the section Installing/

5@

from the strimmer housing (see Fig. 5c).

separates the two halves of the cutting filament (see Fig. 5d).

(see Fig. 5e).

into the strimmer housing (see Fig. 5e).

must be inspected after

.

.

by tapping or blowing it out (with compressed

Grinding the protective guard blade

A

The blade

to be the case, undo the 2 screws that hold the blade

filament protective guard

blade

of the cutting edge.

Adjusting the carburettor

Remove the cover of the air filter housing

Adjusting the throttle cable

If the appliance no longer reaches maximum speed after a while and all

other causes as described in the "Troubleshooting" section have been ruled

out, this may mean that the throttle cable needs to be adjusted. To adjust

the throttle cable, screw in the screw

as the lock nut H2 correctly (see Fig. 4).

Lubricating the gears

■ Add liquid gear grease after every 20 hours of operation (approx. 10 g)

to lubricate the angle gear.

♦ To do this, undo the screw (see Fig. 2c) to press the gear grease

into the gear housing.

♦ After filling the gearbox, close the lubrication hole with the screw

(see Fig. 2a) can become blunt over time. If you find this

A

onto the cutting

C

. Clamp the blade A in a vice. Grind the

A

with a sharpening stone and make sure you maintain the angle

.

or the adjusting screw H1 as well

Storage and transportation

■ Store the appliance in a safe location.

■ Store the appliance and accessories in a safe location which is

protected against naked flames and sources of heat/sparks, such as

gas-powered water heaters, dryers, oil stoves or mobile heaters, etc.

■ Ensure that the protective guard

free of cutting residue when storing.

■ The plastic cover for the 3-section cutting blade must be refitted for

transport and storage.

■ Always turn the appliance off before performing any maintenance work

and remove the spark plug connector .

Storing the appliance

The appliance must be prepared for storage if it is to be stored for longer

than 30 days. Otherwise the residual fuel in the carburettor will evaporate

and leave a gooey sediment. This may make starting the appliance more

difficult and result in expensive repair work.

1.) Remove the filler cap

Carefully empty the fuel tank

2.) To remove all fuel from the carburettor, start the engine and leave it to

run until it stops.

3.) Allow the engine to cool for about 10 minutes.

4.) Remove the spark plug (see section "Spark plug maintenance").

to relieve any pressure in the fuel tank .

, the strimmer 5@ and the engine are

.

.

14

FBK 4 A1

Page 21

5.) Add 1 teaspoon of 2-stroke oil to the combustion chamber. Pull the

starter pull cord

with oil. Replace the spark plug.

NOTE

■ Store the appliance in a dry place and away from possible ignition

sources.

Start-up after storage

1.) Remove the spark plug (see section "Spark plug maintenance").

2.) Pull the starter pull cord

from the combustion chamber.

3.) Clean the spark plug and observe the correct electrode gap on the

spark plug.

4.) Fill the fuel tank

Transporting

■ If you are planning to transport the appliance, empty the fuel tank

as explained in the section "Storage".

several times in order to wet all mechanical parts

quickly in order to remove any excess oil

. See the section "Fuel and oil".

Troubleshooting

Motor unit

Problem Possible cause Remedy

The engine does

not start.

The engine starts

but does not run

at full power.

The engine does

not run smoothly.

Soot deposits or

wetness on the

spark plug.

Incorrect start-up process. Follow the instructions

regarding starting.

Incorrect adjustment of the

choke lever

Contaminated air filter. Clean air filter.

Incorrect spark plug gap. Clean the spark plug

Incorrect carburettor adjustment.

.

Set the choke lever

".

to "

and adjust the spark

plug gap or replace

the spark plug.

Clean spark plug or

replace it with a new

spark plug.

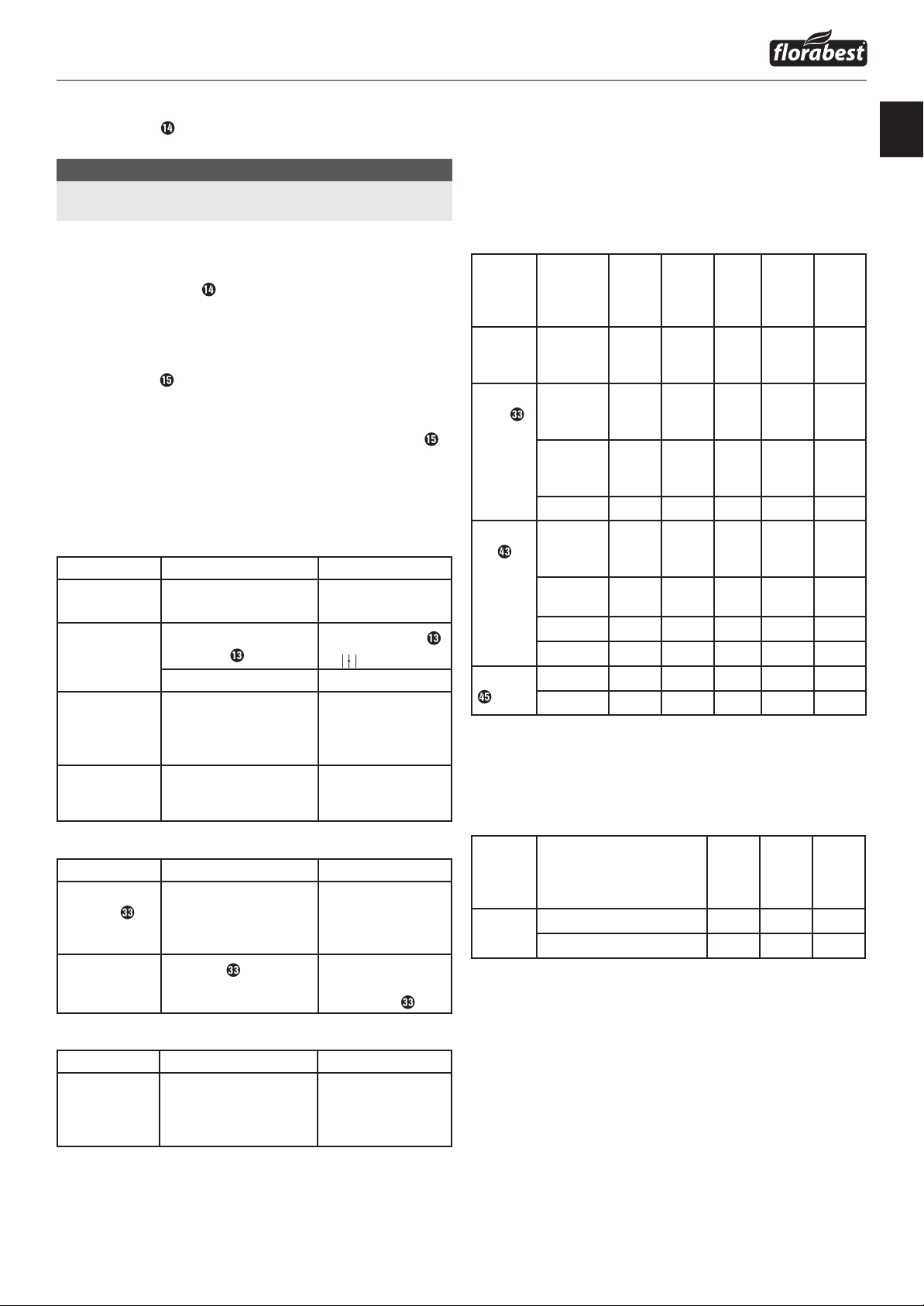

Maintenance interval

Pole pruner

The figures given here are based on normal operating conditions. In the

event of more difficult conditions, such as strong dust generation and

longer daily working hours, the given intervals are to be reduced correspondingly.

Appliance part

Lubricating the

chain

Saw

chain

Guide

rail

Sprocket

Hedge trimmer

The figures given here are based on normal operating conditions. In the

event of more difficult conditions, such as strong dust generation and longer

daily working hours, the given intervals are to be reduced correspondingly.

Action Before

check

check and

note sharpness

check

chain

tension

sharpen

check

(wear,

damage)

clean and

turn

deburr

replace

check

replace

starting

work

X

X

X

X

Weekly In the

event

of

faults

XX

X

X

In the

event

of damage

XX

GB

IE

As required

X

X

Pole pruner

Problem Possible cause Remedy

Motor is running,

saw chain

does not move.

No work progress.

Hedge trimmer attachment

or pole pruner attachment

is not connected properly

to the motor unit.

Saw chain

heating or is sagging.

dry/over-

Check assembly.

Top up the oil or regrind, replace or tighten

the saw chain

Hedge trimmer

Problem Possible cause Remedy

Motor is running,

blades do not

move.

Hedge trimmer attachment

or pole pruner attachment

is not connected properly

to the motor unit.

Check assembly.

FBK 4 A1

.

Appliance part

Cutting

blades

Action Before

starting

work

visual inspection

clean

X

After

completion

of work

As required

XX

Spare part orders

Ordering spare parts

The following information should be provided when ordering spare parts:

■ Type of appliance

■ Item number of the appliance

■ Device ID number

Current prices and information are available at

www.kompernass.com

15

Page 22

Disposal

GB

IE

The packaging is made from environmentally friendly material and

can be disposed of at your local recycling plant. The appliance

and its accessories are made from various materials, such as

metal and plastic.

Your local community or municipal authorities can provide information on

how to dispose of the worn-out appliance.

Environmental protection

■ Carefully empty the petrol and oil tank and dispose of your appliance

at a recycling plant. The plastic and metal parts used can be separated

and recycled.

■ Dispose of waste oil and petrol at a waste collection centre, do not

dump these into the sewerage or drainage system.

■ Dispose of contaminated maintenance material and working materials

at a collection point provided for this purpose.

Appendix

Service

WARNING!

■ Have your appliance repaired by qualified specialists only. Always

use genuine spare parts. This will ensure the ongoing safety of the

appliance.

Service Great Britain

Tel.: 0871 5000 720 (£ 0.10/Min.)

E-Mail: kompernass@lidl.co.uk

IAN 110011

Service Ireland

Tel.: 1890 930 034

(0,08 EUR/Min., (peak))

(0,06 EUR/Min., (off peak))

E-Mail: kompernass@lidl.ie

IAN 110011

Hotline availability:

Monday to Friday from 8:00 a.m. to 8:00 p.m. (CET)

Warranty

You are provided a 3-year warranty on this appliance, valid from the

date of purchase. This appliance has been manufactured with care

and inspected meticulously prior to delivery. Please retain your receipt

as proof of purchase. In the event of a warranty claim, please contact

your Customer Service unit by telephone. This is the only way to guarantee free return of your goods.

The warranty only covers claims for material and manufacturing defects,

not for damage sustained during carriage, components subject to wear

and tear or damage to fragile components such as switches or batteries.

This appliance is intended solely for domestic, not commercial, use.

The warranty shall be deemed void in cases of misuse or improper handling,

use of force and modifications/repairs which have not been carried out

by one of our authorised Service centres. Your statutory rights are not

restricted by this warranty.

The warranty period is not prolonged by repairs effected under the warranty.

This also applies to replaced and repaired components. Any damage and

defects present at the time of purchase must be reported immediately after

unpacking, but no later than two days after the date of purchase. Repairs

carried out after expiry of the warranty period shall be subject to charge.

Importer

KOMPERNASS HANDELS GMBH