Process Indicator Type DAS 72.1 Mark III

MANUAL

Firmware Version 72.181.v.4.28 or higher

Hardware Version 72.101.5.v.3.0x

Document No G128 Rev6 GB

www.flintec.com

Manual DAS 72.1 Page 1

A GENERAL

A.1 INTRODUCTION AND SPECIFICATION

The model DAS 72.1 Mark III is a high precision, high speed digital amplifier for weighing and force

measurements with strain gauge (SG) sensors. The device can be controlled either by the front keys or via RS

485 port. 3 Logic inputsand outputs makecomplex control functionseasy.The 3 logic outputs canbe controlled

external too.

With the available as standard analogue output 4…20 mA the DAS 72.1 fulfills industrial requirements. The

device features full multi-drop communications capability and can be programmed via a straightforward ASCII

command set. The LDU xx.x series and the amplifier DAS 72.1 with on-board digital display, use the same

command set. You can connect up to 32 SG amplifiers of either the LDU XX.X series or DAS 72.1 type onto a

single RS485 bus.

The DAS 72.1 with its high precision 18-bit A to D converter and internal sample rate of up to 2400 measure

ments / second, is particularly suitable for high dynamic measurements and control purposes.

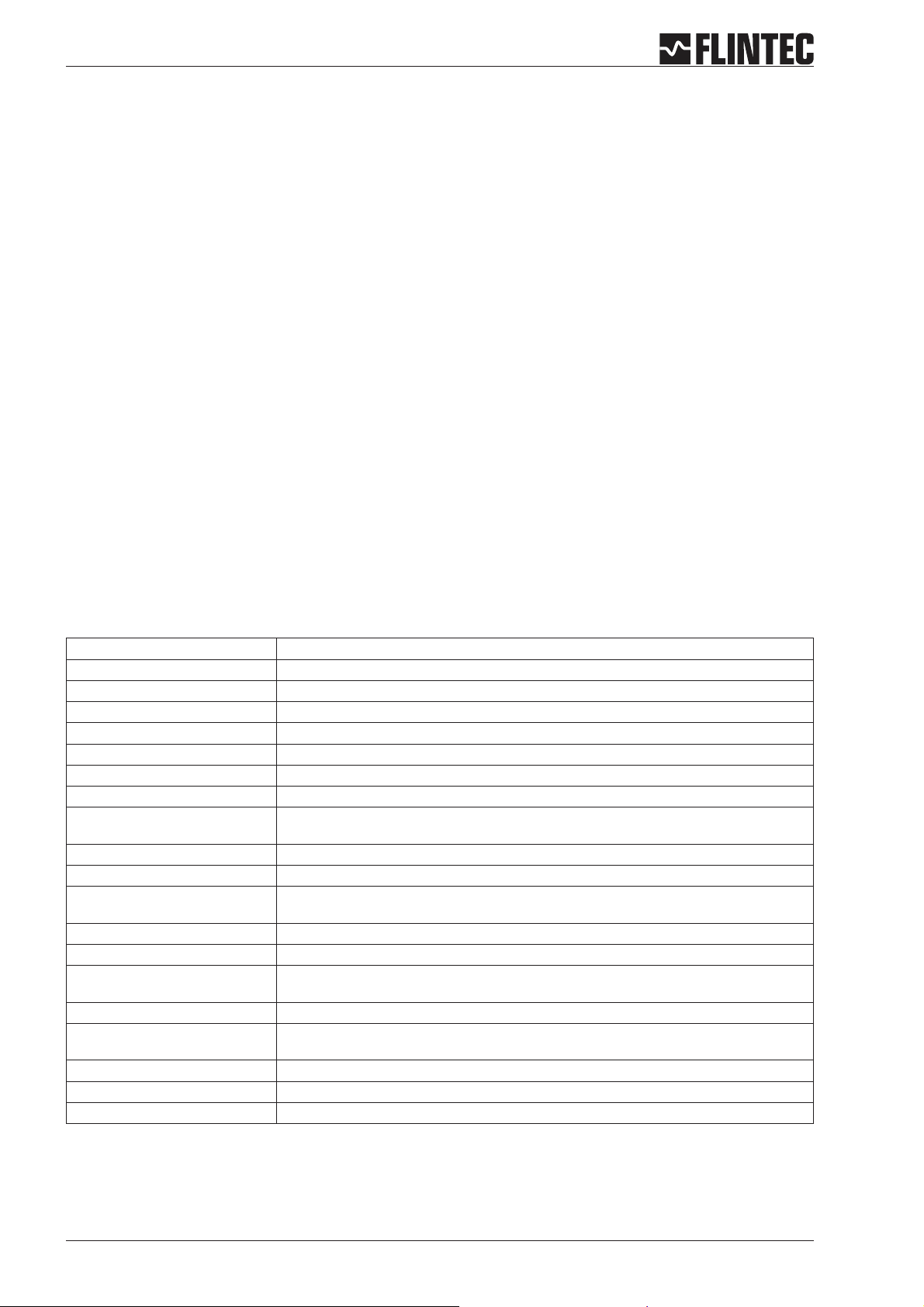

DAS 72.1 Mark II / III Specifications

Linearity < 0.002 %

Excitation 5 V DC, load cells 80-2000 Ohm, 6 wire technique

Analogue input range ±3.2 mV/V (bipolar, for weighing applications and force measurements)

Minimum input per vsi 0.05 μV/d

Resolution Internal ±260000 counts, ±18-Bit-A/D convertor; display max. ±99999 counts

Conversion rate Internal 2400 measurements per second; external up to 600 measurements per second

Digital filter FIR Filter 2.5 ... 19.7 Hz or IIR Filter 0.25 ... 18 Hz; programmable in 8 steps each

Calibration Software calibration and set up

Computer interface RS485 or RS422, full duplex, 9600 ... 115200 Baud; bus capability up to 32 devices

(RS485)

Weighing functions zero, gross, tare, net, filter etc.

Analogue output 0/4...20 mA, 14-Bit resolution

Display 10.2 mm LED, green, 5 digits, 3 status LED for nett/motion/sign,

6 status LED for logic inputs and outputs

Logic inputs 3 opto-isolated inputs, 10 ... 30 V DC, max. 3.5 mA

Logic outputs 3 opto-isolated outputs, < 45 V DC / AC, 1 A

Temperature effects on zero 5 ppm/°K typ.; max. <10 ppm/°K

on span 4 ppm/°K typ.; max. <8 ppm/°K

Temperature range –10 °C to +50 °C (operating); –20 °C to +60 °C (storage)

Enclosure tinned steel enclosure, protection IP 40; for 35 mm DIN-rail mounting.

Special housing IP 65 on request.

Dimensions 135 x 66 x 19 mm, weight ca. 180 g

Power supply 11 ... 25 V DC ±10 %, < 3 W, galvanically isolated

EMC CE 73/23/EEC; 93/98/EEC and 89/336/EEC

All dimensions in mm. Dimensions and specifications are subject to change without notice.

-

Page 2 Manual DAS 72.1

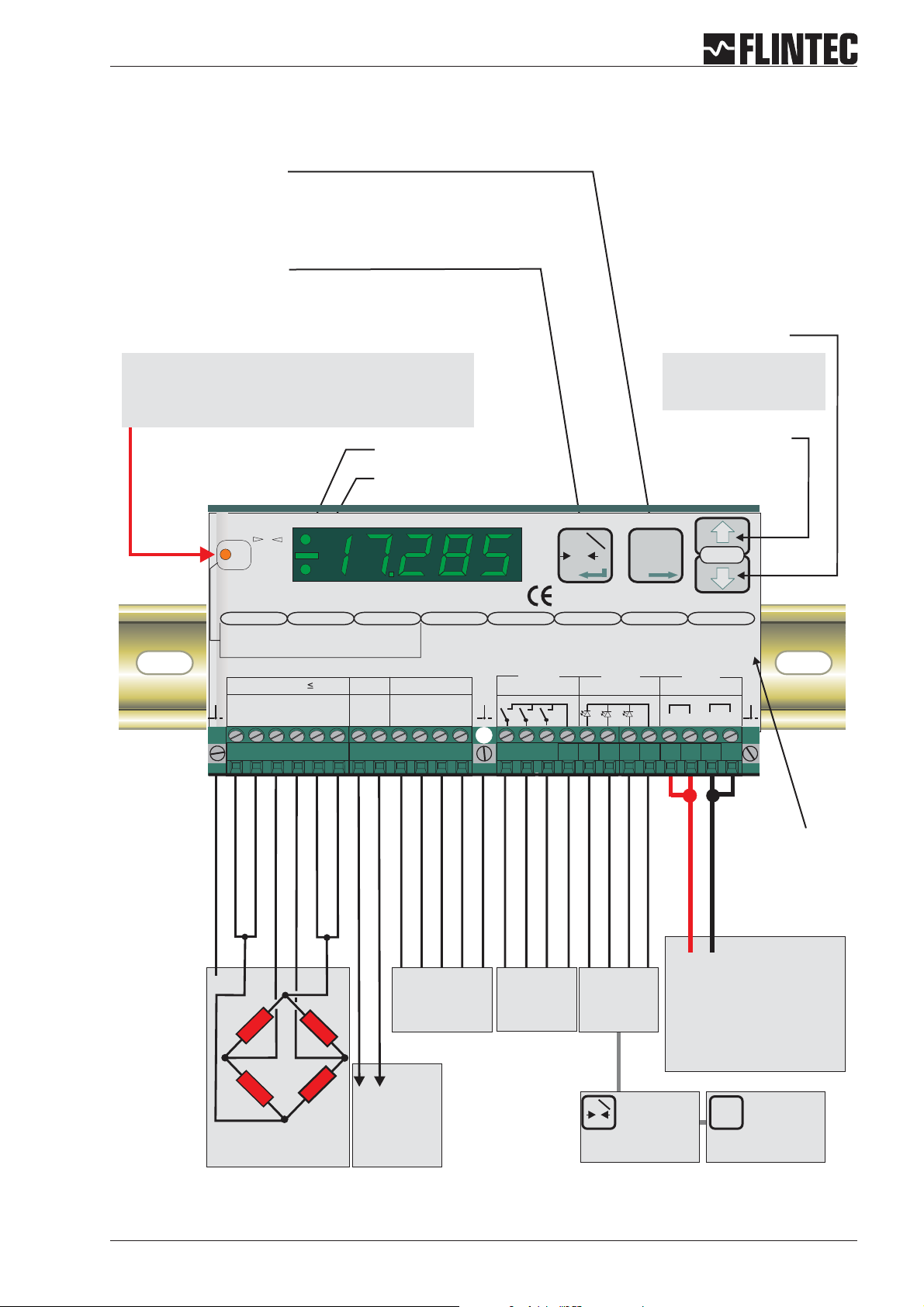

A.2 KEY FUNCTIONS

Tare Key

Puts unit into ‘Net’ mode.When inside

‘Set-up’ Menu this key moves the menu

back one step. Also moves‘Digit Selected’

to the right inside sub menus.

Zero Key

Sets new zero (if enabled). Reverts to calibrated zero

if the button is held down for more than 3 seconds.

Switches unit back to ‘Gross’ mode if a tare has been

set. Acts as the‘Enter’ key in the ‘Set-up’ Mode.

Down key

Recessed Enable Switch

(Enables changes to be made to important parameters.

Must be pressed before attempting to change

parameters 1.1 to 1.3, 2.1 to 2.3 and 3.1 to 3.3)

No motion LED

Net mode LED

Logic input 1 2 3

0

Depress

To

Change

Net

Logic output

1.Zero

1.0/allow>0<

2.Calibrate

3.Set mV/V

Load cell 5Vdc 80mA

Exc Sen Sig Sig Sen Exc Rx Rx Tx Tx

+++ +

2 3 4 5 6 7 8 9 10 111213

1

2.Span

1.Set cal. ´n´

2.Calibrate

3.Set mV/V

4.Disp.mV/V

--- -

123

3.Display

1.o/u limits´n´

2.Step * ´n´

3.Dec.point

4.Logic stats

0-20mA

Io Gnd

4.Filter

1.f Hz

cut

2.Algorithm

3.Update rate

4.

Motion´n´

RS422/485CL out

+

to enter the set up mode

7.Outp. 1/2/3

1.SPoint ´n´

2.Hyst. ´n´

3.Base

4.Test

Isolated

Mark III

T

T

T0

±

Isolated

Power 11 -25Vdc

+

+

SET UP

8.Datacom.

1.Baud rate

2.422/485

3.Address

4.Auto trnsm.

Digital Amplifier + Setpoint DAS 72.1

Inp.1 Inp.2

T

Isolated

6.Input 1/2/3

1.Assign key

2.

3.

4.Test

Logic Inputs

12 3com

5.CLout

1.4mA=´n´

2.20mA=´n´

3.Base

4.TestImA

Logic Outputs

12 3com

-

14 27

Press either key for

more than 3 seconds

Up key

0

0

261516 17 2324 25181920 2122

SHIELD

+ EXCITATION

+ SENSE

+SIGNAL

- SENSE

- SIGNAL

- EXCITATION

Receive -

Receive +

Ground

Transmit -

Transmit +

Logic Input 1 (+)

Logic Input 2 (+)

Logic Input 3 (+)

Commmon

“Set up”

menu structure

+0

RS422/485

COM port

Logic

outputs

+0

0 4-20mA

/

Load cell

connections

Manual DAS 72.1 Page 3

analogue

output

Logic

inputs

Input 1

Inp.1

T

(Functions as

0

Zero button,

Tare off, Set zero,

see paragraph B.3.6)

Power supply

12-25 V DC

Inp.2

Input 2

(Functions as

T

T

T

Tare button,

Display net mode,

see paragraph B.3.6)

B KEYBOARD SET UP

A GENERAL 2

A.1 INTRODUCTION AND SPECIFICATION 2

A.2 KEYFUNCTIONS 3

B KEYBOARDSET UP 4

B.1 SHORTMANUAL OF KEYBOARD SETUP 5

B.2 SETUPTABLE 6

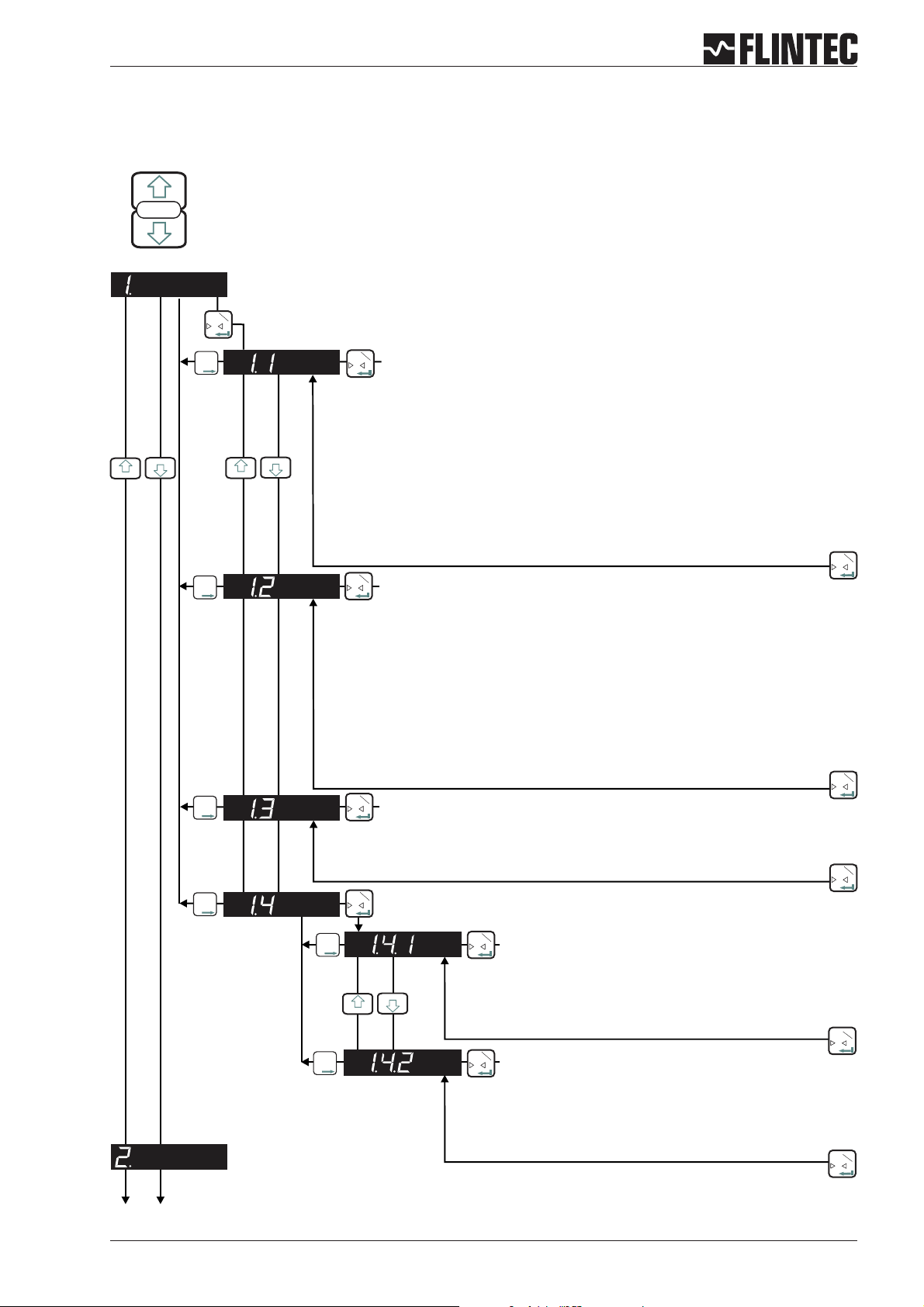

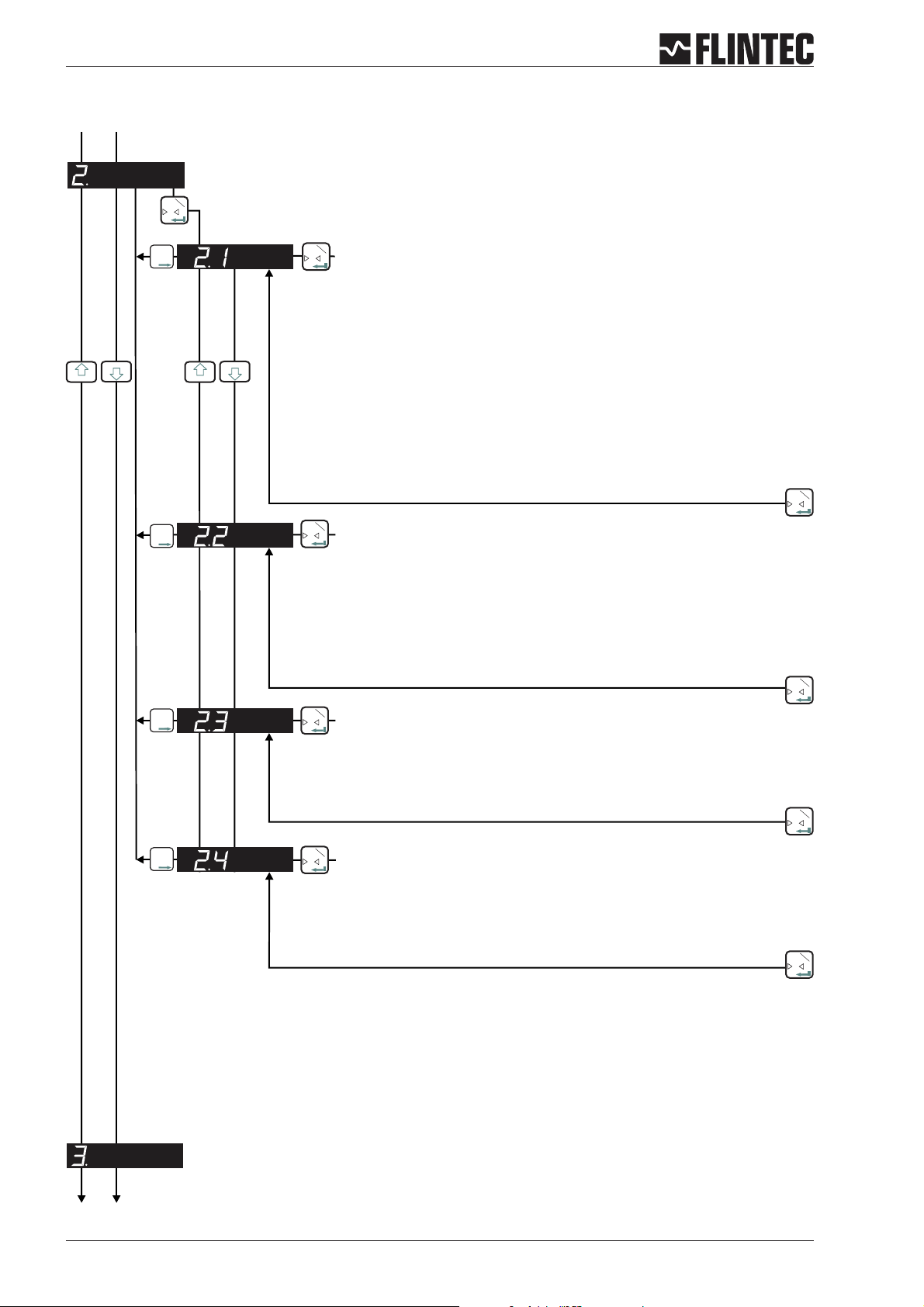

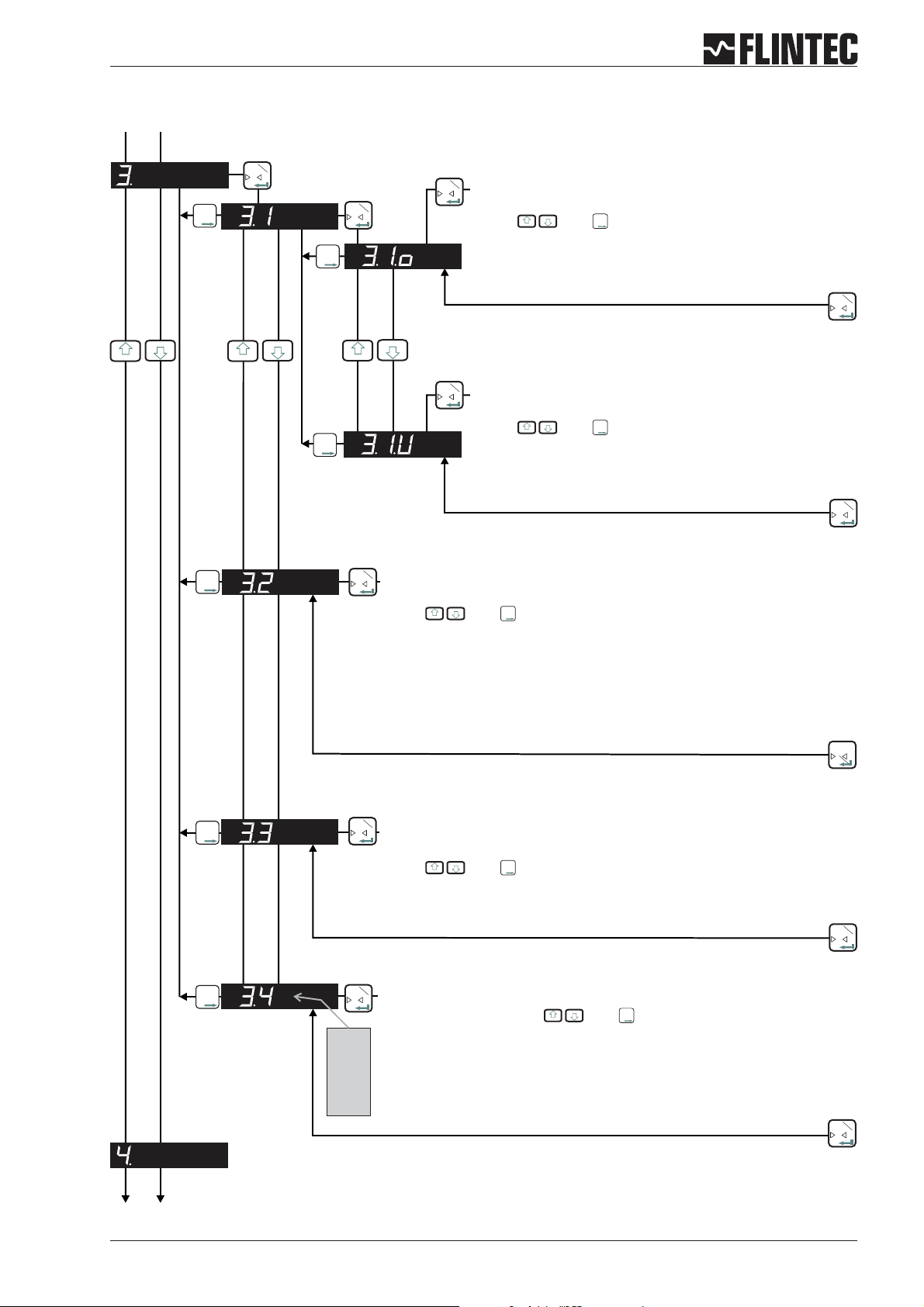

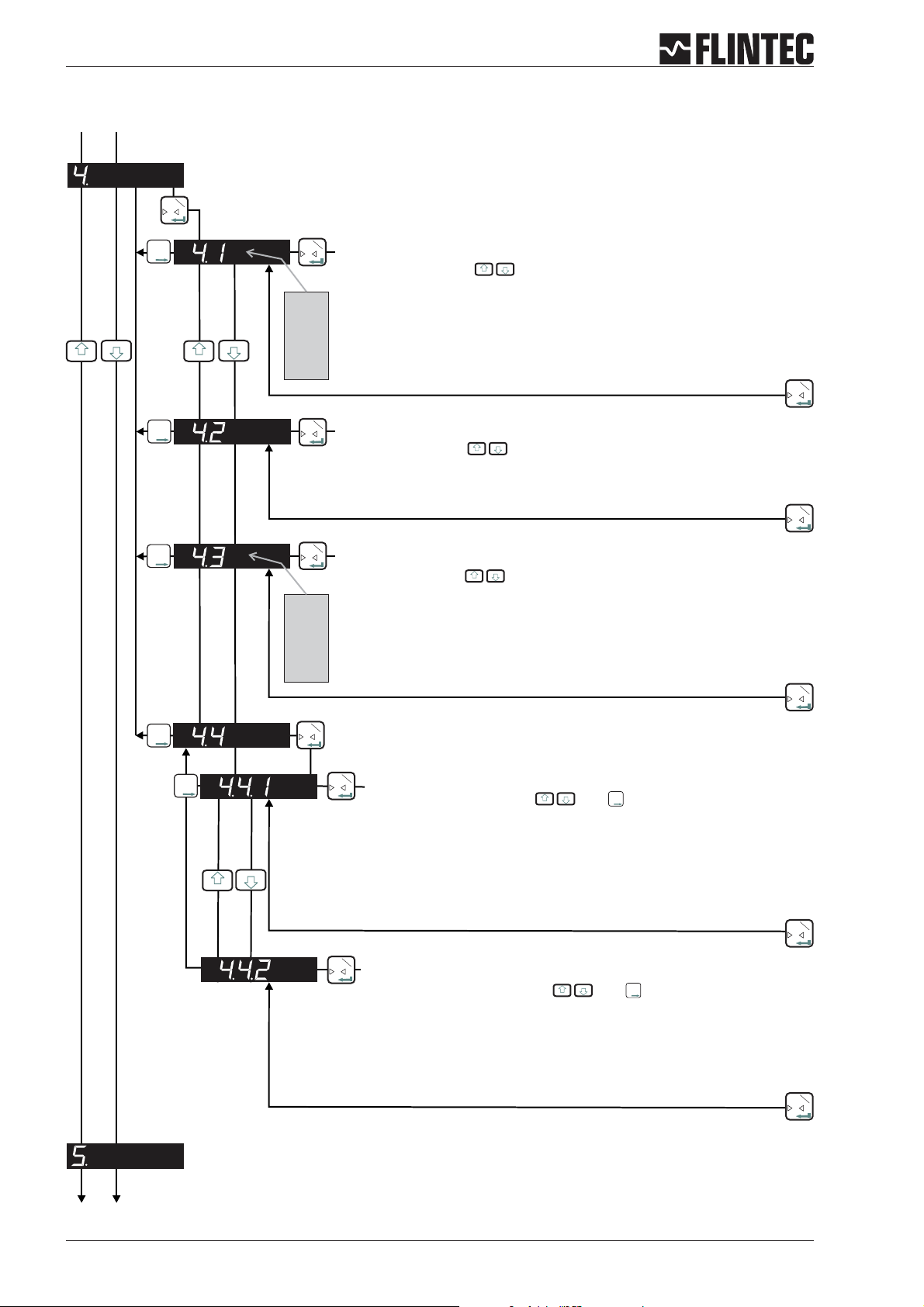

B.3 SETUP FLOWCHARTS 7

B.3.1 Zeroset up,Menu 1.1 - 1.4 7

B.3.2 Spanset up,Menu 2.1 -2.4 8

B.3.3 Displayset up,Menu 3.1 - 3.4 9

B.3.4 Filter / no motion setup, Menu 4.1- 4.4 10

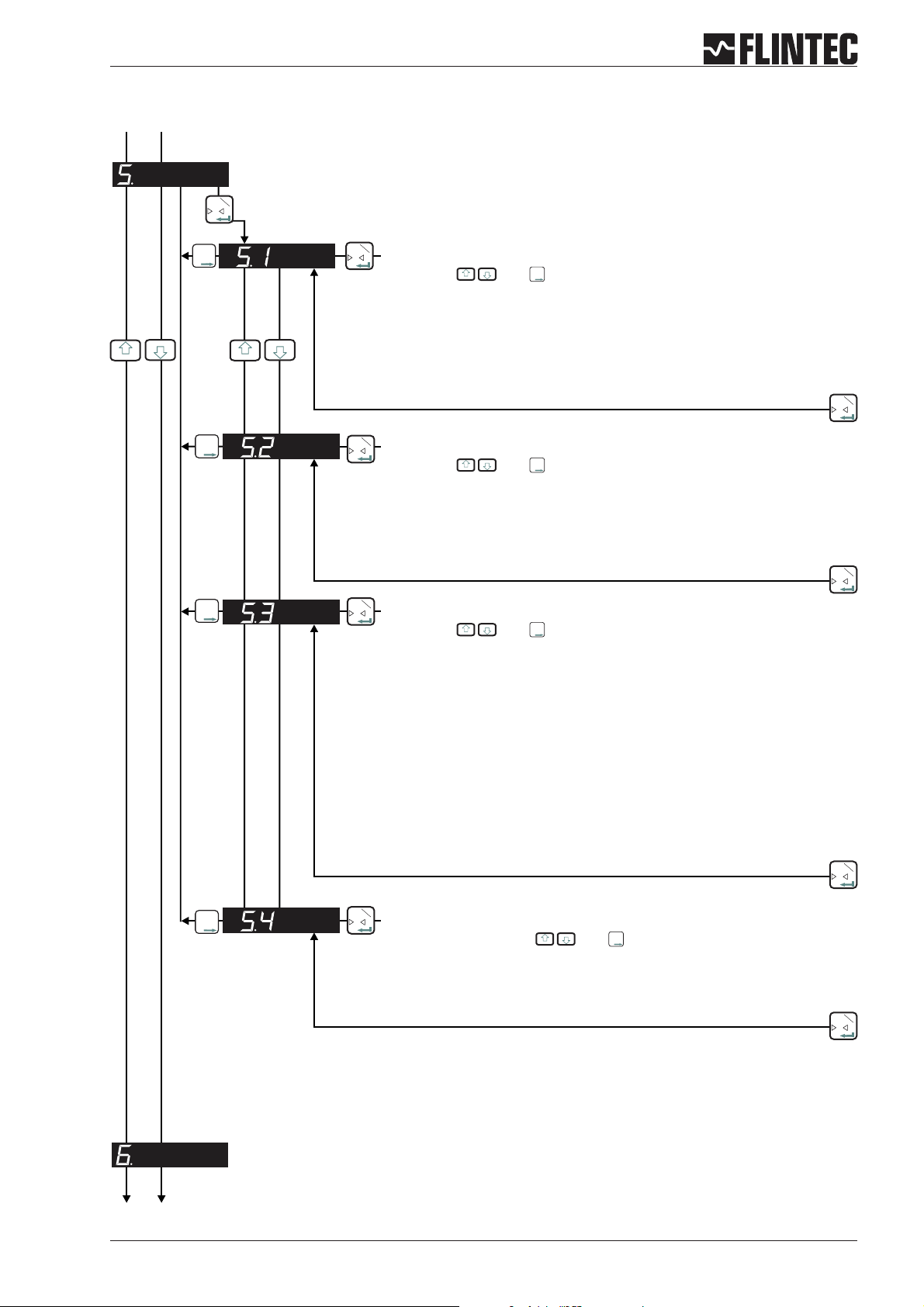

B.3.5 Analogueoutput set up, Menu 5.1- 5.4 11

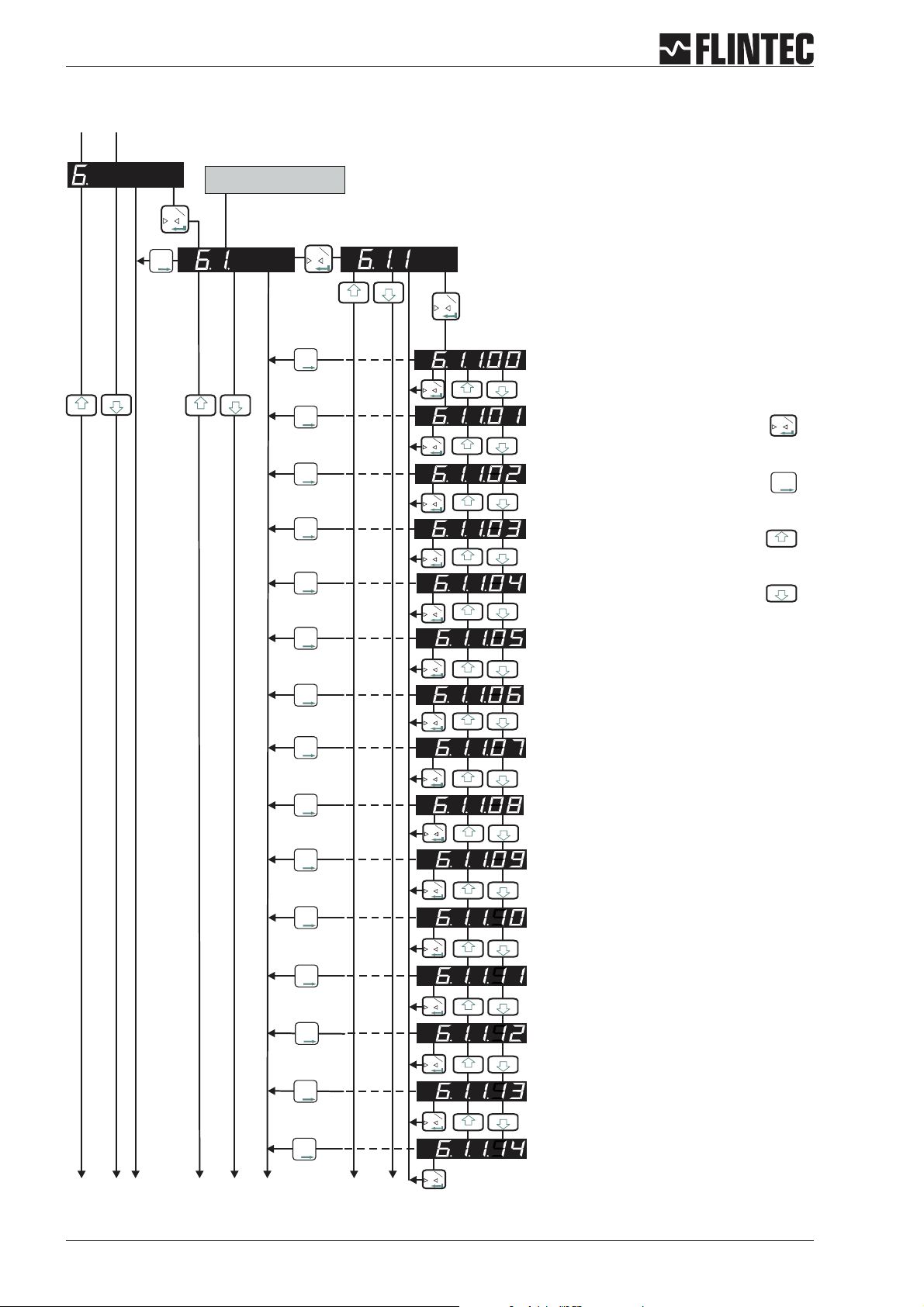

B.3.6 Logicinput setup, Menu 6.1.3- 6.3.4 12

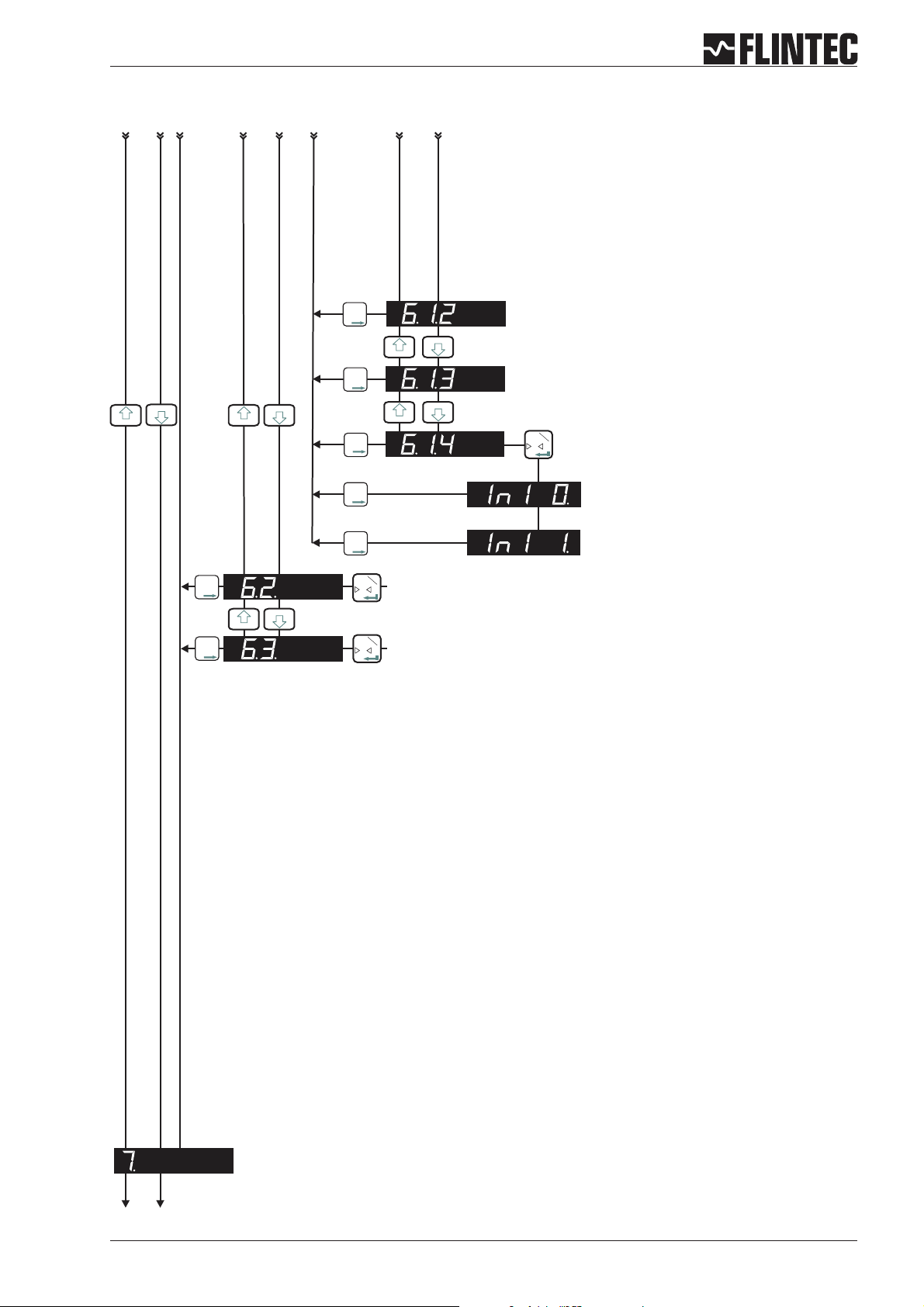

B.3.7 Logicoutput setup, Menu 7.1- 7.3 14

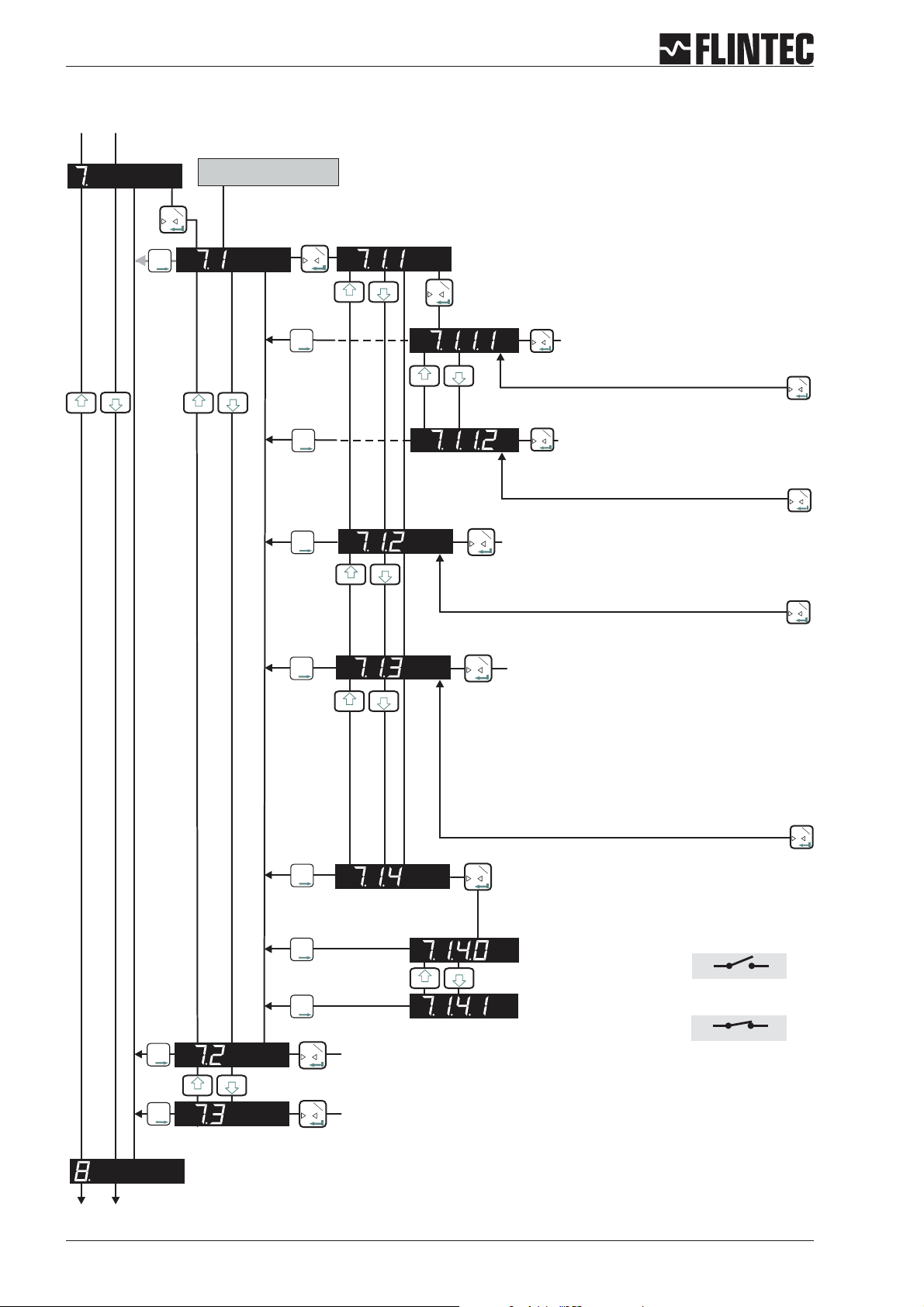

B.3.8 Datacommunication set up,menu 8.1 - 8.4 15

B.3.9 Errorcodes 16

B.4 EXAMPLES 17

B.4.1 Example1, calibration procedureusing weights 17

B.4.2 Example2, calibration procedureusing loadcell mV/V sensitivity and

B.4.3 Example3, calibration procedureusing loadcell mV/V sensitivity 21

D CE KONFORMITÄTSERKLÄRUNG 57

zero offset 19

Page 4 Manual DAS 72.1

B.1 SHORT MANUAL OF KEYBOARD SETUP

9600...115,2 k Baud

1. Setup Baudrate:

Setup setpoints

for outputs 1/2/3

1.1

• (00) not used

1. External Key control :

output of 4 mA

1. Setup value for an

• (01) Zero

Example:

2. Setup Mode for Com.

1.2 Setup switch logic

• (02) Tare

0.0 (g) @ 4 mA

ports

for:

Valid addresses

0...255

Address "0" device is

always active on bus

Address enable via

• RS-422 full duplex

• RS-485 Network

•

"open"

3. Setup Port Address

•

Example:

2. Setup Hysteresis of

• (06) Get average

• (07) Display Peak

1000 (g) @ 20 mA

setpoints

• (08) Delete Peak

• (09) Display Hold

output:

3. Base of analogue

• (0) Gross

3. Base of Outputs:

• (10) Peak to Peak

• Gross value

• (1) Net

• (11) Display Valley

• Nett value

• (12) Key lock

• Average valuet

• on

• off

• (03) Move up

• (04) Move down

• (05) External trigger

output of 20 mA

2. Setup value for an

• (2) Peak

• (3) Average

• (13) Store Weight

• Hold valuet

4. Auto Transmit of

• (14) Tare and delete

• Peak to Peak valuet

data:

• (4) Hold

• Valley valuet

• Gross

• (5) Peak to Peak

• Display value

2. not used

• Net

• (6) Valley

• Swiched off

• All (Data string)

• (7) Error 4 or 5

3. not used

• Sap (A/D value)

• (8) Swiched of

• Aver (Average

4. Test of Logic inputs

output signal

4. Simulate an analogue

value)

• Pea (Peak value

• Hold (Hold value)

The display shows

the signal status of

logic outputs

4. Test of Logic outputs

The display shows

the signal status of

logic inputs

Setup 12.345 for

getting an output

current of 12,345 mA

value)

• Vall (Valley value)

• Pp (Peak to Peak

• Off (switched off)

Standard display is

switched off!

Standard display is

switched off!

Setup menu : To enter, press one of the arrow keys for 3 seconds. To change calibration data, also press recessed switch (to the left of the display) once.

1. ZERO 2. Span 3. Display 4. Filter 5. CL out 6. Input 1/2/3 7. Output 1/2/3 8. Data Com

1. 0 / allow >O< 1. Set cal.”n” 1. o/u limits ‘n’ 1. f-cut Hz 1. 4 mA=’n’ 1. Assign key 1. SPoint ‘n’ 1. Baud rate

2. Calibrate 2. Calibrate 2. Step*’n’ 2. Algorithm 2. 20 mA=’n’ 2. 2. Hyst +/- ‘n’ 2. 422/485

3. Set mV/V 3. Set mV/V 3. Dec.point 3. Update rates 3. Base 3. 3. Base 3. Address

4. Tare Memory 4. Disp. mV/V 4. Logic stats 4. Motion ‘n’ 4. Test I mA 4. Test 4. Test 4. Auto trnsm.

adjustable from

1=18Hzto

1. Cut off frequency

at which the display

shows an overload (o)

1. Measured value

actual measured

signal after 2.2 or

1. Calibration value for

Zero lock / unlock

1. Zero Tracking or Set

8 = 0.25 Hz

or an underload (u)

with internal mV/V

2. Calibrate Zero with

Typical setup:

signal after 2.3

should be displayed

actual or external

"4"=3 Hz

2. Display step size as

simulated input

signal changes

• FIR-Filter for quick

dampening

• IIR-Filter for high

2. Select Filter Type:

1, 2, 5, 10, 20 etc

point of the display

Example:

000.00 @ 100.00(g)

3. Position decimal

Example: 10 000 (g)

cell(s) connected or

will be simulated by a

simulator

This signal refers to

2. Input signal of load

signal

display "Zero” with

manual setup of

mV/V signal

3. Calibrate Zero to

This setup has

additional influence

•

on filters

3. Update rate

status

• No Status I/O

(approx 1,5 s)

• Short display of

for in motion band

(Tare, Zero and

Zero Tracking are

only allowed at

4.1 No Motion Range

4.2 Stabilisation time

I/O

• Permenant status

"No Motion")

4. Display I/O:

calibrate value of

setup 2.1

4.1 Tare "ON":= Tare

value stred

3. Input signal in mV/

non-volatile

Tare "OFF": Tare

setupwiththefront

panel keys

This signal refers to

calibrate value of

setup 2.1

1,6500 mV/V @ 1000

(g)

input signal in mV/V

For test purposes

4. Display of actual

value deleted at

power off

"ON" Load cells

connected with

Zener barriers

"OFF" Load cells

connected without

Zener barriers

4.2 EX-Modus

Manual DAS 72.1 Page 5

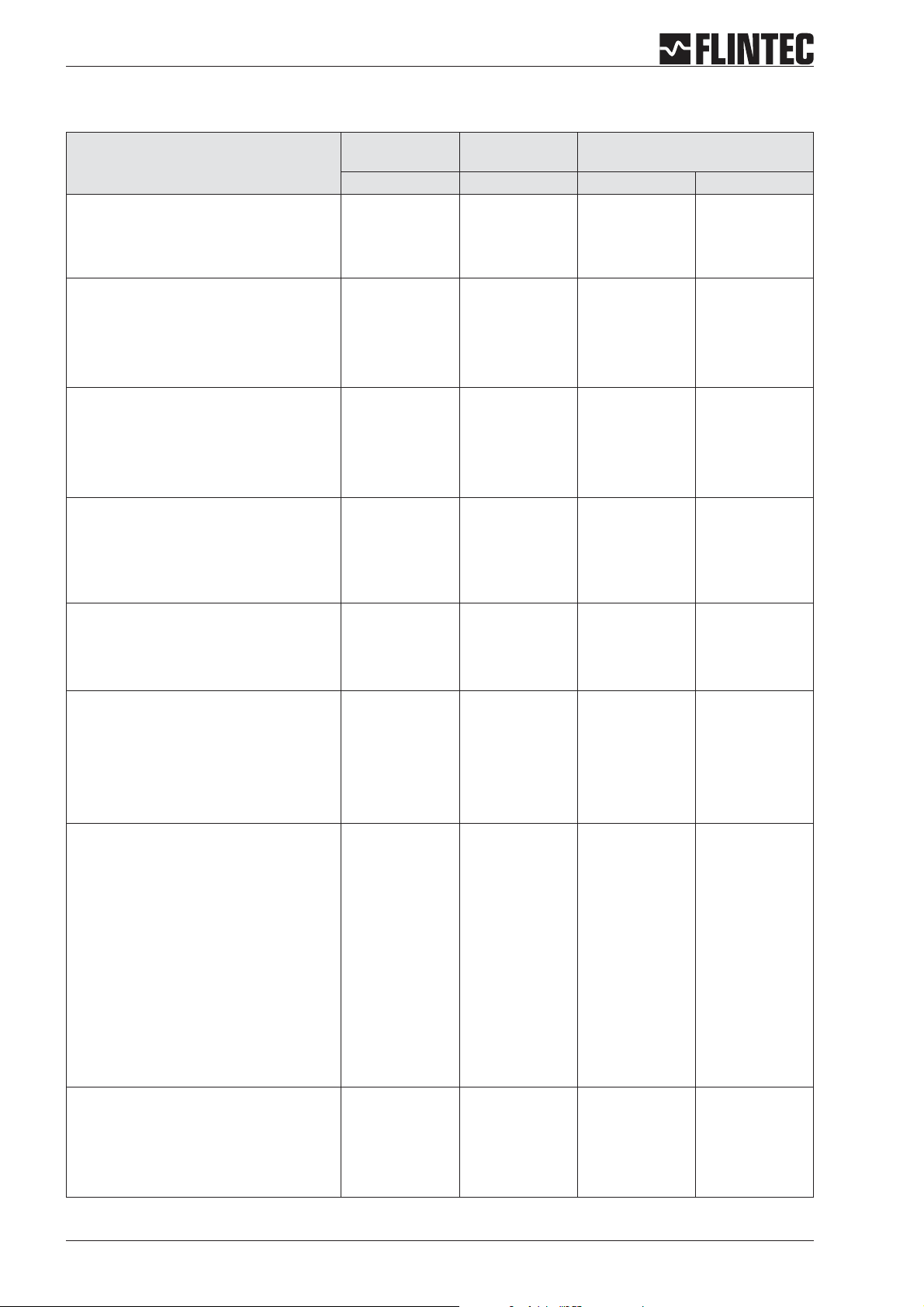

B.2 SETUP TABLE

Description

Function Zero key (on/off))

Zero Calibration / Weight

Zero Calibration / mV/V

Span / Weight or mV/V

Span / Weight

Span / mV/V

Displays Actual mV/V Signal

Maximum Display Value

Maximum Display Value

Display Step Size

Decimal Point Position

Display Status I/O

Cut Off Filter Frequency

Filter Type

Update Rate per second (filtered)

No Motion Range

Set Analogue Output @ 4 mA

Set Analogue Output @ 20 mA

Base of Analogue Output

Simulate Analogue Output Signal

Input 1 for External Key Control

Input 2 for External Key Control

Input 3 for External Key Control

Read Iinput Status

Base of Digital Inputs

Test Logic Inputs

Output Setpoint 1

Output Setpoint 2

Output Setpoint 3

Hysteresis & Logic Setpoint 1

Hysteresis & Logic Setpoint 2

Hysteresis & Logic Setpoint 2

Base Setpoint 1

Base Setpoint 2

Base Setpoint 3

Function Test Output 1

Function Test Output 2

Function Test Output 3

Baudrate RS-422/485 Port

Port Mode (422 or 485)

Device Address Com Port

Auto Transmit Data

LED Display Pre Setup Example: 3000 kg scale

with 0.5 kg step

Menu Point Value Value Result

<1.1>

<1.2>

<1.3>

<2.1>

<2.2>

<2.3>

<2.4>

< 3.1.o >

< 3.1.u >

<3.2>

<3.3>

<3.4>

<4.1>

<4.2>

<4.3>

<4.4>

<5.1>

<5.2>

<5.3>

<5.4>

< 6.1.1 >

< 6.2.1 >

< 6.3.1 >

<6.2>

<6.3>

<6.4>

< 7.1.1 >

< 7.2.1 >

< 7.3.1 >

< 7.1.2 >

< 7.2.2 >

< 7.3.2 >

< 7.1.3 >

< 7.2.3 >

< 7.3.3 >

< 7.1.4 >

< 7.2.4 >

< 7.3.4 >

<8.1>

<8.2>

<8.3>

<8.4>

0-oFF

0.000

0.000

20000

0.000

2.000

--

99999

-9999

1

0

1

33.3

FIR

3

1

00000

20000

gross

--

--

--

--

--

--

-99999

00000

oFF

--

--

--

--

--

--

--

--

--

9600

422

0

oFF

0-oFF

0.000

0.400

a)3000.0 or

b)750.0

0.9

2.000

--

3100.0

-200.0

5

0.0

1

3.0

FIR

3

1

0.0

3000.0

gross

--

--

--

--

--

--

--

0000.0

1000.0

3000.0

0000.0

0000.0

0000.0

net

net

net

--

--

--

9600

422

0

nEt

Set zero not

possible

kg

mV/V

Cal. with mV/V

Cal. with 750 kg

mV/V

mV/V

-kg

kg

0,5 kg

0000.0

Status for 1 s

Hz

for quick signal

changes

measurements/s

kg

kg

gross

--

--

--

--

--

--

-kg

kg

kg

kg

kg

kg

net

net

net

--

--

--

Baud

422-Port

Device No.

auto transmit

net weight

Page 6 Manual DAS 72.1

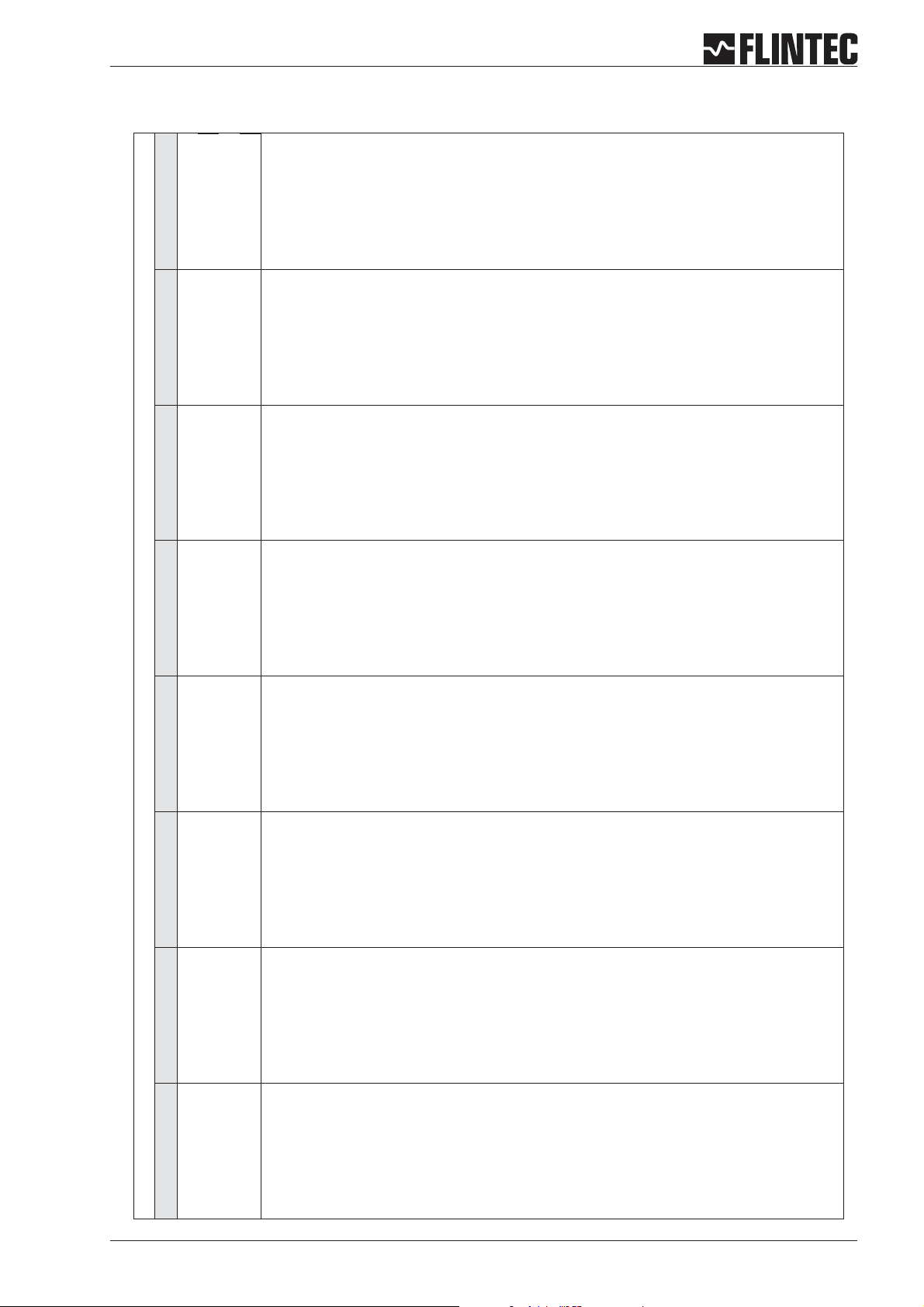

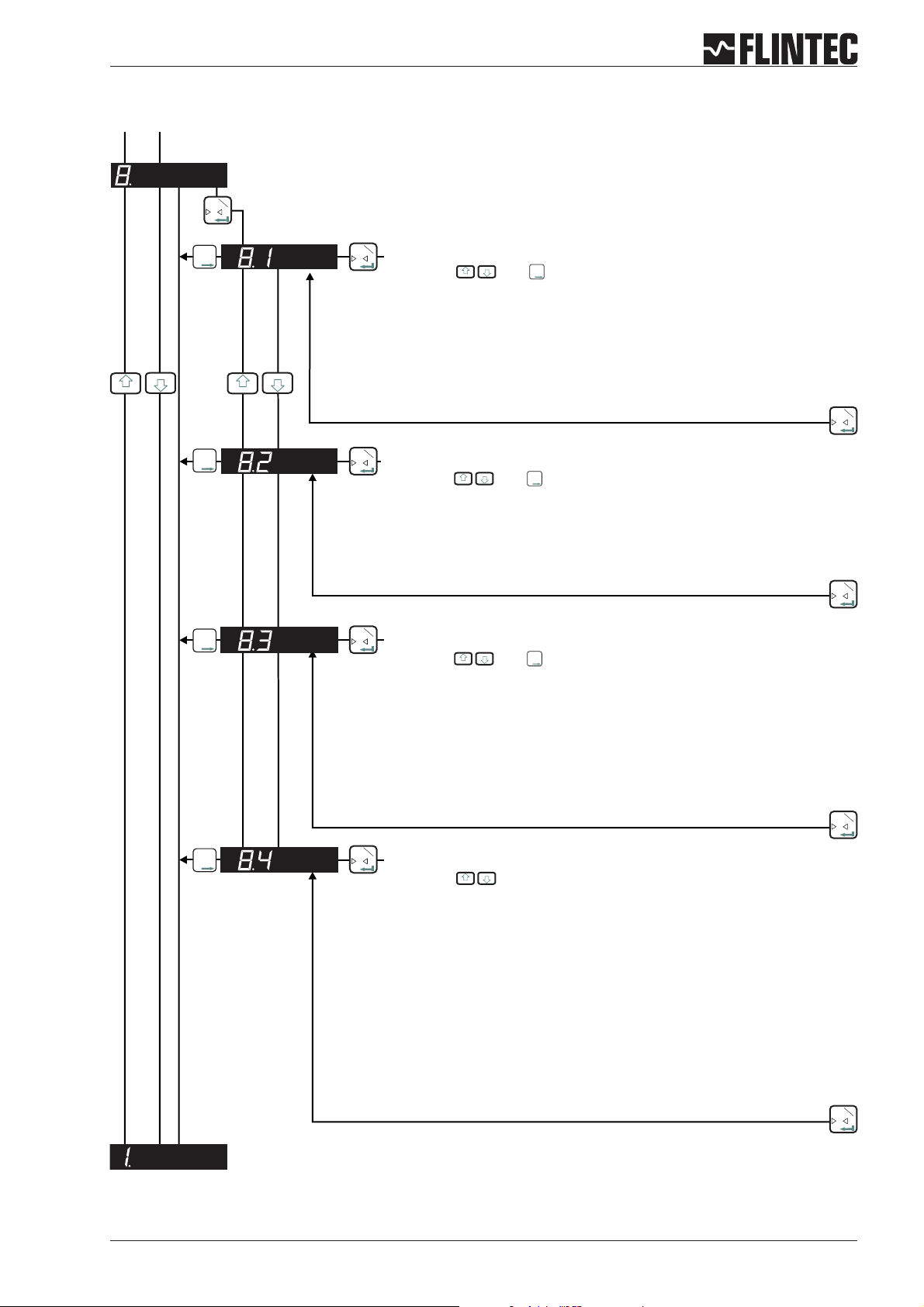

B.3 SET UP FLOWCHARTS

B.3.1 Zero set up, Menu 1.1 - 1.4

SET UP

Press the UP or DOWN key

for more than 3 seconds to enter the Set-up Menu

Inp.1

T

0

Inp.2

T

T

T

Inp.1

T

Automatic Zero Tracking

0

Settings: 0 ... 255 d

Function is swiched off at setting 00 000.

Zero Setting with zero key or by external signal is not possible (Menu 6).

Function is swiched on at setting 00 001 or higher, (max 00 255).

Zero Setting with zero key or by external signal (Menu 6).

Setting 00 001 sets a zero range of +/-2%ofUpper Display Limit (Menu 3.1),

setting 00 002 up to 00 255 sets a range of2dupto255d(independant of

decimal point setting).

Inp.2

T

T

T

Inp.1

T

0

CALIBRATE OR ADJUST THE ZERO POINT

(CONVENTIONAL WEIGHING SYSTEM)

Display shows the actual input signal in mV/V.

Press the Enter key to store the zero.

Note:

Recessed Enable Switch

(Enables changes to be made

to important parameters.

Must be pressed before

attempting to change parameters

1.1 to 1.3, 2.1 to 2.3 and 3.1 to 3.3)

Inp.1

T

0

Remark:

Inp.2

T

T

T

Inp.1

T

0

CALIBRATE THE ZERO POINT FROM THE LOAD CELL mV/V READING

scale should be unloaded.

Inp.1

T

0

Use the UP/DOWN & MOVE RIGHT keys to set the mV/V reading at which the

unit should read zero.

Inp.2

T

T

T

Inp.1

T

0

Inp.2

T

T

T

Inp.1

T

0

Store Tare value, setting ON or OFF

Inp.1

T

0

OFF: Tare value deleted at power off

ON: Tare value stored non-volatile (max. 1 000 000 times)

Inp.1

T

Inp.2

T

T

T

Inp.1

T

0

EX-Modus, setting ON or OFF

0

OFF:Load cell connection without Zener barrieres

ON: Load cell connection with Zener barrieres,

extended error band for ERR 5

Inp.1

T

0

Manual DAS 72.1 Page 7

B.3.2 Span set up, Menu 2.1 - 2.4

Inp.1

T

0

Inp.2

T

T

T

Inp.1

T

SET THE SPAN CALIBRATION VALUE

0

Twopossibilities areavailable:

A. Setthe displayvalue equivalent to thecalibration weight,continue withstep 2.2

or

B. Use the mV/Vsignal derivedfrom the load cell(s)test data,continue withstep 2.3.

Inp.1

T

0

Inp.2

T

T

T

Inp.1

T

0

CALIBRATE THE SPAN (CONVENTIONAL WEIGHING SYSTEM)

Display shows the actual input signal in mV/V.

Apply test weights equivalent to the calibration value set in section 2.1. Press the Enter

key to store the new span value.

Inp.1

T

Inp.2

T

T

T

Inp.1

T

CALIBRATE THE SPAN FROM THE LOAD CELL mV/V READING

0

0

Use the UP/DOWN & MOVE RIGHT keys to set the mV/V reading at which the unit should

read the value set in section 2.1.

Inp.1

0

Inp.2

T

T

T

Inp.1

T

0

DISPLAY THE INPUT SIGNAL IN mV/V

This function allows you to view the input signal in mV/V.

Inp.1

0

Page 8 Manual DAS 72.1

T

T

B.3.3 Display set up, Menu 3.1 - 3.4

Inp.1

T

0

Inp.2

T

T

T

Inp.1

T

0

Inp.2

T

T

T

Inp.2

T

T

T

Inp.1

T

SET THE DISPLAY OVER RANGE LIMIT

0

(MAXIMUM VALUE +99 999)

Use the and keys to set the maximum display value

Inp.2

T

T

T

above which the display shows over range (all dashes in the top of the

display).

Inp.1

T

SET THE DISPLAY UNDER RANGE LIMIT

0

(MINIMUM VALUE -99 999)

Use the and keys to set the minimum display value

Inp.2

T

T

T

below which the display shows under range (all dashes in the bottom

of the display).

Inp.1

T

0

Inp.1

T

0

Inp.2

T

T

T

Inp.2

T

T

T

Inp.1

T

SET THE DISPLAY DIVISION OR STEP SIZE

0

(1, 2, 5, 10, 20, 50, 100, 200, 500)

Use the and keys to set the required display division or step size.

Inp.1

T

0

SET THE DECIMAL POINT POSITION ON THE DISPLAY

(0, 0.0, 0.00, 0.000, 0.0000)

Use the and keys to set the required decimal point position on the

Inp.2

T

T

T

Inp.2

T

T

T

Inp.1

T

0

display.

Inp.1

T

0

Inp.2

T

T

T

Inp.1

3.4.0

T

LOGIC I-O STATUS

0

Select setting 0, 1 or 2 with and .

Inp.2

T

T

T

Setting 0 = Continious indication of Weight, no input/output status.

Setting 1 = Indication of Weight, short indication input/output status (ca. 1,5 sec)

3.4.1

Setting 2 = Continious indication of input/output status.

3.4.2

Inp.1

T

0

Manual DAS 72.1 Page 9

B.3.4 Filter / no motion set up, Menu 4.1 - 4.4

Inp.1

T

0

Inp.2

T

T

T

Inp.2

T

T

T

Inp.2

T

T

T

Inp.2

T

T

T

Inp.1

0

4.1.0

:

:

:

4.1.8

Inp.1

0

Inp.1

0

4.3.0

:

:

:

4.3.7

Inp.1

0

T

Set the low pass filter cut off frequency

Set Range: 0 - 8 with

Filter setting 18 Hz (4.1.1) to 0.25 Hz (4.1.8) with Filter type IIR.

Filter setting 19.7 Hz (4.1.1) to 2.5 Hz (4.1.8) with Filter type FIR.

Attention

See Paragraph C.4.5 for more information.

T

Set the type of low pass filter required

: FIR or IIR

Setting with

Type IIR should be used where heavy damping is required.

Type FIR should be used where high speed is required.

T

Defines the number of filtered readings averaged

Set Range: 0-7mit

This Parameter defines the number of Readings from the IIR or FIR filter that

will be averaged.

Selection between “0” (1 Reading) and “7” (128 Readings).

Attention:

T

: Setting

“0” (4.1.0) deactivates the Filter.

See Paragraph C.4.5 for more information.

Inp.1

T

0

Inp.1

T

0

Inp.1

T

0

Inp.2

T

T

T

Inp.1

T

Set the No Motion Range

0

Set Range: 0 - 30 000 steps and

Inp.2

T

T

T

Fluctuations in weight values inside this range will be considered as

‘stable’.

Attention:

See also 4.4.2 for the Stabilisation Time

If the condition of the No Motion Range is fullfilled within the Stabilistion

Time the “No Motion” status bit will be set to allow zero setting, taring as

well as calibrating zero and span.

Inp.1

T

0

Inp.1

T

0

Set the Stabilisation Time

Set Range: 0 - 30 000 mS with and

Inp.2

T

T

T

Sets the Stabilisation Time in milliseconds within which the weight value

displayed has to remain within the No Motion Range, for the weigh to be

considered ‘stable’.

Inp.1

T

0

Page 10 Manual DAS 72.1

B.3.5 Analogue output set up, Menu 5.1 - 5.4

Inp.1

T

0

Inp.2

T

T

T

Inp.1

T

Set the weight value at which 4 mA is send

0

Setting with and

Inp.2

T

T

T

Set the weight value at which 4 mA is send.

Examples:

Weighing range 3 000 kg and 3 000 d with 0/4...20 mA.

Analogue output 4...20 mA: for 0 kg=4mAmake setting 00 000.

Analogue output 0...20 mA: for 600 kg=4mAmake setting 00 600.

Inp.1

T

0

Inp.2

T

T

T

Inp.1

T

Set the weight value at which 20 mA is send

0

Setting with and

Inp.2

T

T

T

Set the weight value at which 20 mA is send.

Examples:

Weighing range 3 000 kg and 3 000 d with 0/4...20 mA.

Analogue output 4...20 mA: for 3 000 kg = 20 mA make seting 03 000.

Analogue output 0...20 mA: for 3 000 kg = 20 mA make seting 03 000.

Inp.2

T

T

T

Inp.1

T

Set the analogue output base

0

Setting with and for the following values:

GROS Gross

NET Net

PEA Peak

AVER Average

HOLD Hold

PP Peak÷Peak

VALL Valley

DISP Display

OFF OFF

= Analogue output follows value

= Analogue output follows value

= Analogue output follows value (maximum)

= Analogue output follows value

= Analogue output follows value

= Analogue output follows value

= Analogue output follows value (minimum)

= Analogue output follows value

= Analogue output is switched

Inp.2

T

T

T

Inp.1

T

0

Inp.1

0

Inp.2

T

T

T

Inp.1

T

0

Test the current output

Set Range 0...20 mA with . And

Inp.2

T

T

T

Set a current value in mA, which will be sent down the analogue output,

independent of the load applied to the weighing system.

Inp.1

0

Manual DAS 72.1 Page 11

T

T

B.3.6 Logic input set up, Menu 6.1.3 - 6.3.4

The second digit coresponds

with the input number

1

T

0

2

T

T

T

1

T

0

Set the function for Logic Input “1”

Possible settings: 00, 01 ,02 ,03 ,04 ,05 ,06 ,07, 08, 09,

10, 11, 12, 13, 14.

1

T

0

12

3

56

4

Fortsetzung nächste Seite

2

T

T

T

1

T

0

2

T

T

T

1

T

0

2

T

T

T

1

T

2

T

T

T

2

T

T

T

2

T

T

T

2

T

T

T

2

T

T

T

2

T

T

T

2

T

T

T

2

T

T

T

2

T

T

T

2

T

T

T

2

T

T

T

2

T

T

T

7

0

1

T

0

1

T

0

1

T

0

1

T

0

1

T

0

1

T

0

1

T

0

1

T

0

1

T

0

1

T

0

1

T

0

8

1

T

0

Input “1” no function

Input “1” acts as Zero button

Input “1” acts as Tare button

1

T

0

2

T

T

T

Input “1” acts as Up arrow button

Input “1” acts as Down arrow button

Input “1” starts the Trigger function

Input “1” displays the Average value

Input “1” displays the Peak value (maximum)

Input “1” deletes the Peak value

Input “1” displays the Hold value

Input “1” displays the Peak to Peak value

Input “1” displays the Valley value (minimum)

Input “1” disables the keyboard

Input “1” stores the actual weight (Hold value)

Input “1” tares the display and deletes all other

values like 6.1.1.08

Page 12 Manual DAS 72.1

Logic input set up, Menu 6.1.3 - 6.3.4 (continued)

12

3

56

4

2

T

T

T

2

T

T

T

2

T

T

T

2

T

T

T

2

T

T

T

2

T

T

T

1

T

0

8

7

No function

No function

1

T

0

Check Logic Input “1”

(6.1.1. must be set to “0” => 6.1.1.0)

“In1 0.” Input is ”low”

“In1 1.” Input is ”high”

As per section 6.1 but for Logic Input “2”

2

T

T

T

1

T

As per section 6.1 but for Logic Input “3”

0

Manual DAS 72.1 Page 13

B.3.7 Logic output set up, Menu 7.1 - 7.3

The second digit coresponds

with the output number

1

T

0

2

T

T

T

1

T

0

2

T

T

T

2

T

T

T

2

T

T

T

Set the function for Logic Output “1”

1

T

0

Set weight value at which Logic

1

T

Output “1” switches

0

Permitted values +/- 99 999

1

T

0

Set whether Logic Output “1”

1

switches ON or OFF

T

0

Use the UP/DOWN keys to set whether

logic output 1 switches ON or OFF at the

1

T

0

Set the hysteresis value on the setpoint for

1

T

0

Logic Output “1”

Permitted values +/- 99 999.

1

T

0

Set base for Logic Output “1”

2

T

T

T

2

T

T

T

2

T

T

T

2

T

T

T

2

T

T

T

1

T

0

As per section 7.1 but for Logic Output “2”

1

T

0

GROS Gross

NET Net

PEA Peak

AVER Average

HOLD Hold

PP Peak to Peak

VALL Valley

ERR Error

OFF OFF

Check Logic Output “1”

1

T

Use the UP/DOWN keys to switch.

0

= value

= value

= value (maximum)

= value

= value

= value

= value (minimum)

= 4 or 5

= Sets output

The output is “off”.

The output is “on”.

out 1

out 1

com

com

1

T

0

2

T

T

T

1

T

As per section 7.1 but for Logic Output “3”

0

Page 14 Manual DAS 72.1

B.3.8 Data communication set up, menu 8.1 - 8.4

Inp.1

T

0

Inp.2

T

T

T

Inp.1

T

Set the Baud Rate for COMPORT (RS-422/485)

0

Setting with and

Inp.2

T

T

T

9 600 Baud

19 200 Baud

38 400 Baud

57 600 Baud

115 200 Baud

Inp.1

T

0

Inp.2

T

T

T

Inp.1

T

Select either RS-422 or RS-485

0

Setting with and

Inp.2

T

T

T

422 = RS-422-Interface (use for single DAS application)

485 = RS-485-Interface (use for multiple DAS application in BUS)

Inp.1

T

0

Inp.2

T

T

T

Inp.1

T

0

Set the Device Address Comport (RS-422/485)

Setting with and

Inp.2

T

T

T

Set the device address for multi-drop to 001 ... 255.

Set to 000 for single point to point applications.

Inp.1

0

Inp.2

T

T

T

Inp.1

T

0

Select the Autotransmit Mode

Setting with

GROS

NET

ALL

SAP

AVER

PEA

HOLD

VALL

PP

OFF

= Gross value

= Net value

= Data string with Gross, Net and Status

= A/D value

= Average value

= Peak value (maximum)

= Hold value

= Valley value (minimum)

= Peak to Peak value

= Autotransmit OFF

Inp.1

0

Manual DAS 72.1 Page 15

T

T

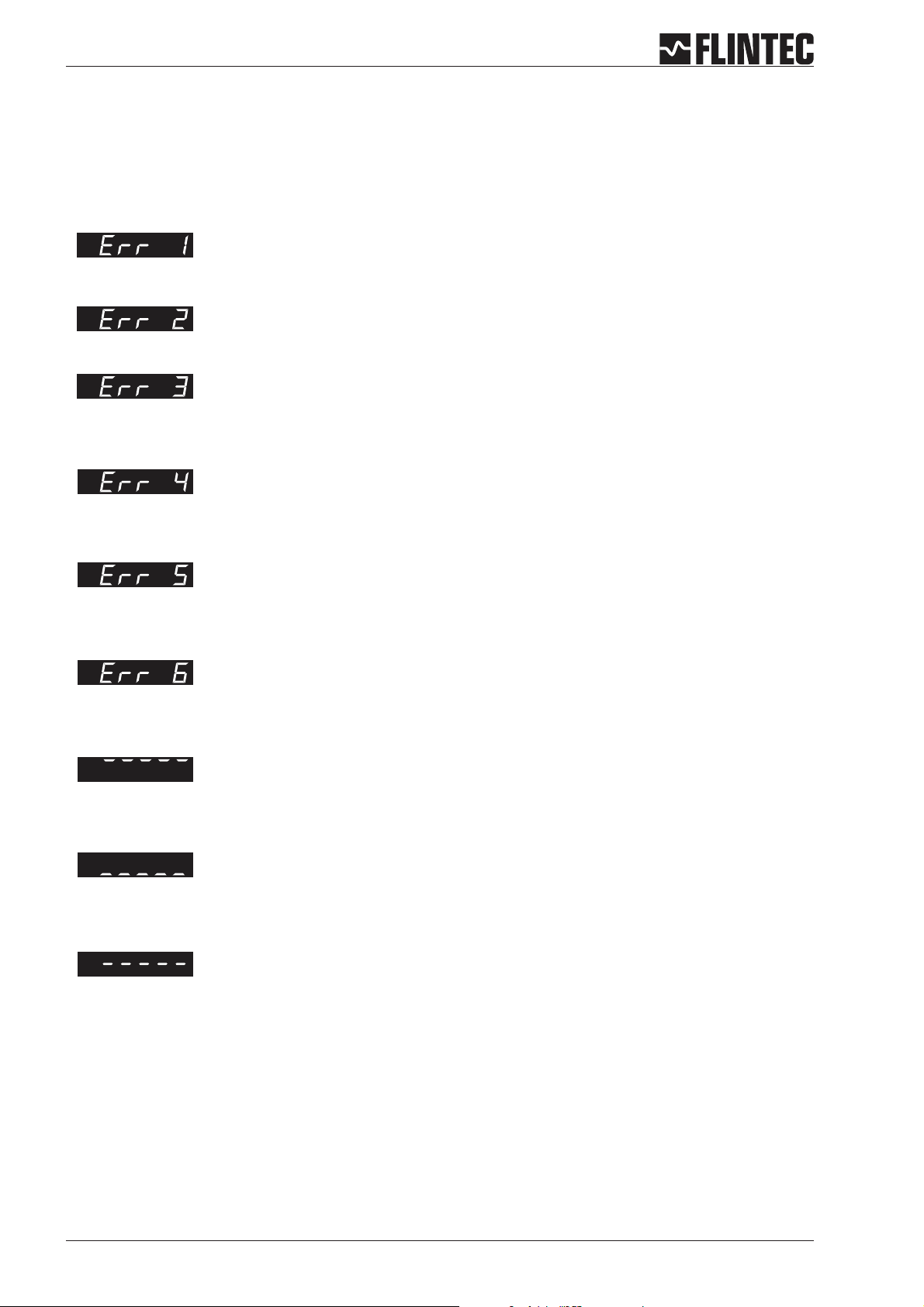

B.3.9 Error codes

The zero key is not enabled (See menu 1.1)

Set final zero out of range.

(You are trying to set a zero which is greater than ±2% of the Upper Display Limit)

Excessive sensitivity requested.

(The input signal is being divided into too many divisions i.e the size of each division is < 0.5 V)m

The input signal is in excess of ± 2.6 mV/V

Faulty load cell connection (Open circuit / Short Circuit / Wire disconnected)

You are trying to enter a value which is not valid (Outside the acceptable parameter range)

Display overload (Display value exceeds the upper limit set in Menu 3.1.o)

Display underload (Display value is more negative than the lower limit set in Menu 3.1.U)

The Zero or Tare motion limit has been exceeded. Set Zero or Tare function disallowed.

Review Zero and Tare motion limits set in menu 4.4

Remark

If you need to return the DAS72.1 Mark III to the factory settings simply press and hold the recessed enable switch whilst

powering up the unit. All parameters will then revert to the factory settings

Page 16 Manual DAS 72.1

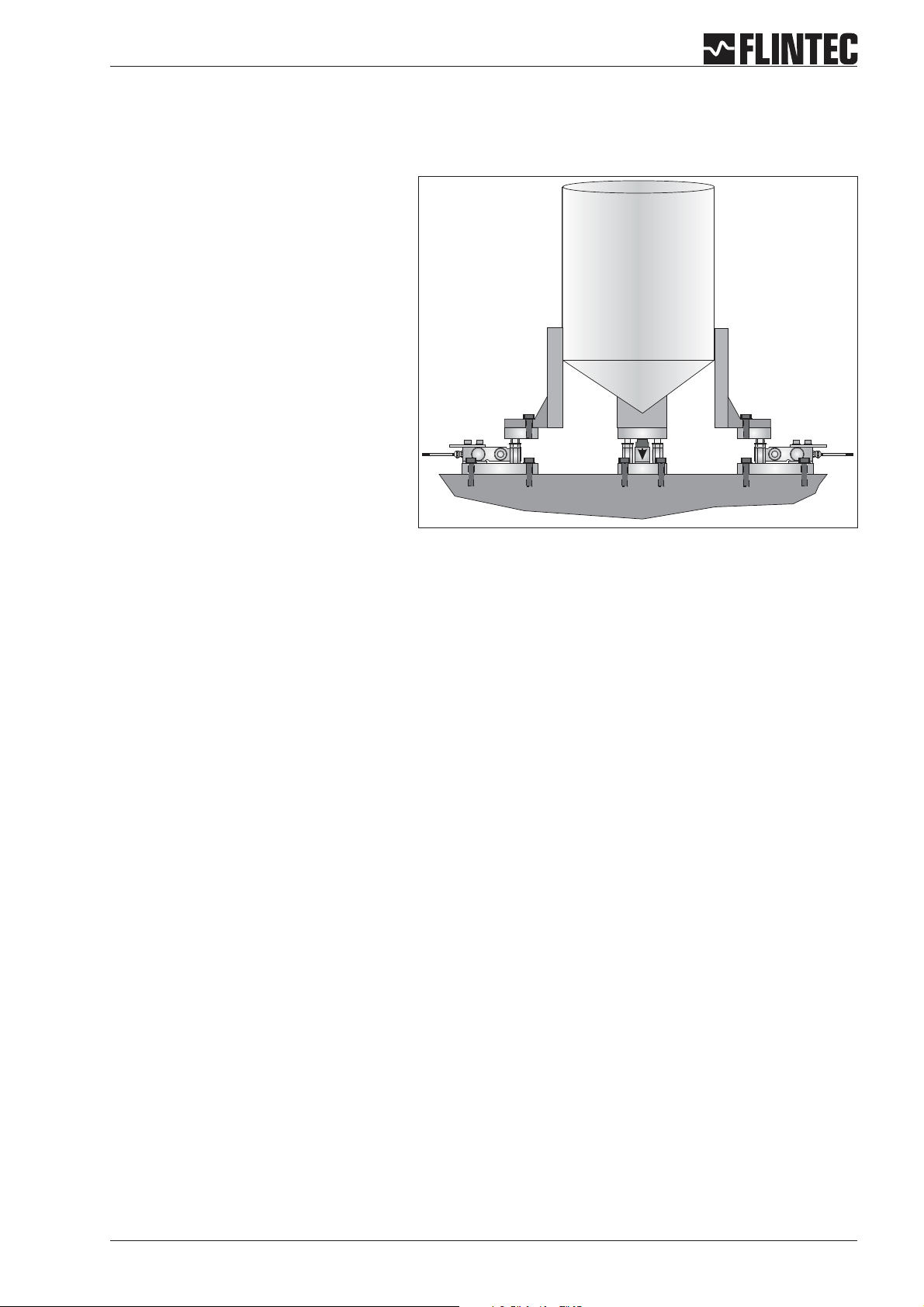

B.4 EXAMPLES

B.4.1 Example 1, calibration procedure using weights

3 Leg tank or silo fitted with 3 off 1000 kg

@ 2 mV/V load cells.

Dead load 600 kg.

Live range 2000 kg in 0.5 kg steps.

It is assumed that the load cell system is

connected to the DAS72.1 and the power

is on. The maximum and minimum display

values, display increment size and decimal

point position should be defined prior to

carrying out the calibration (See Menu 3).

For this example the display maximum is

defined as 2100.0, the display minimum is

-200.0, the display step size is 0.5 kg.

Remember that all parameters under

sections 1.1 - 1.3, 2.1 - 2.3 and 3.1 - 3.3 can only be accessed or changed after the Recessed Enable

Switch has been pressed.

Go to Menu 1.2 and using the UP/DOWN and RIGHT keys set the display to read 0000.0. Make sure that the

a

weighing system is empty or at the point where you want the display to read zero. Press the 0 [Enter] key.

This defines the actual zero calibration point.

b

Go to Menu 2.1 and using the UP/DOWN and RIGHT keys set the display to read the value of the calibration

weight(s) applied. For this example if the calibration load applied is 750 kg set the display to read 750.0.

Press the 0 [Enter] key. This defines the calibration weight.

c

Go to Menu 2.2.Apply the calibration weight(s) to the weighing system. Press the 0 [Enter] key. The display

will show the actual input signal in mV/V. Press the 0 [Enter] key. This defines the actual span calibration

point.The displaywill show 2.2. Press the rightarrow keytwice and the DAS willbe back in weighing mode.

Calibration is now completed.

Manual DAS 72.1 Page 17

Flowchart Example 1

Enter the

Set-up menu

Set the decimal

point position

Set the

display

step size

Set the Display

Upper Limit

(Overload)

Set the Display

Lower Limit

SET UP

1. Press the UP or DOWN key for more than

3 seconds to enter the Set-up Menu

2. Press the recessed enable switch

SET THE DECIMAL POINT POSITION (0, 0.0, 0.00, 0.000, 0.0000)

Use the UP or DOWN key to set the required decimal point position.

Choose 0.0

SET THE DISPLAY STEP SIZE. (1, 2, 5, 10, 20, 50, 100, 200, 500)

Use the UP or DOWN key to set the required display step size.

SET THE DISPLAY OVER RANGE LIMIT. (MAX. VALUE +99999)

Use the UP/DOWN & MOVE RIGHT keys to set the maximum display value

above which the display shows over range

(all dashes in the top of the display).

SET THE DISPLAY UNDER RANGE LIMIT. (MIN. VALUE -99999)

Use the UP/DOWN & MOVE RIGHT keys to set the minimum display value

below which the display shows under range

(all dashes in the bottom of the display).

Calibrate the

Zero point

Set the Display value

equal to the

Calibration weight

Calibrate

the Span

Calibration

completed

CALIBRATE THE ZERO POINT. (CONVENTIONAL WEIGHING SYSTEM)

Display shows the actual input signal in mV/V.

SET THE SPAN CALIBRATION VALUE.

Use the UP/DOWN & MOVE RIGHT keys to set the display value equivalent

to the calibration weight, e.g. 750 kg.

CALIBRATE THE SPAN. (CONVENTIONAL WEIGHING SYSTEM)

Display shows the actual input signal in mV/V. Apply test weights equivalent

to the calibration value set in section 2.1.

Press the Enter key to store the new Span value

Note:

Choose Filter type IIR (menu 4.2), Low Pass Filter 6 ... 8 (menu 4.1)

and wait for ‘No Motion’ in the calibration routine.

Page 18 Manual DAS 72.1

B.4.2 Example 2, calibration procedure using load cell mV/V sensitivity and zero offset

3 Leg tank or silo fitted with 3 off

1000 kg @ 2mV/V load cells

Dead load 600 kg.

Live range 2000 kg in 0.5 kg steps.

It is assumed that the load cell system is

connected to the DAS72.1 and the power is

on. The maximum and minimum display

values, display increment size and decimal

point position should be defined prior to

carrying out the calibration (See Menu 3).

For this example the display maximum is

defined as 2100.0, the display minimum is

-200.0, the display step size is 0.5 kg.

Remember that allparameters undersections 1.1 - 1.3, 2.1 - 2.3 and3.1 -3.3 can only be accessed or changed

after the Recessed Enable Switch has been pressed.

Go to Menu 1.3. and using the UP/DOWN and RIGHT keys to set the zero point of the 3 load cells to 0.0000

a

mV/V. Press the 0 [Enter] key. This defines the theoretical zero calibration.

b

Go to Menu 2.1 and using the UP/DOWN and RIGHT keys set the display to read the capacity of the load cell

system or the weight value at which the sensitivity is known. For this example the load cell capacity is 3 x

1000 kg = 3000 kg @ 2 mV/V. Set the display to read 3000.0. Press the 0 [Enter] key. This defines the

theoretical calibration weight (equivalent to 2mV/V in this example).

c

Go to Menu 2.3. Press the 0 [Enter] key. Use the UP/DOWN and RIGHT keys set the display to read the mV/V

sensitivity of the load cell system you are using.For this example the load cell sensitivity or Output at Rated

Load is 2.000 mV/V. In multiple load cell installations (load cells wired in parallel) the sensitivity is the

average of all the load cells connected. Press the 0 [Enter] key. This defines the theoretical span calibration

point.

d

If required the zero can be re-calibrated without affecting the span. To do this make sure that the weighing

system is empty or at the point where you want the display to read zero. Goto Menu 1.2. Press the 0 [Enter]

key. The display shows the actual input signal in mV/V. Press the 0 [Enter] key. Press the right arrow key

twice and the DAS will be back in weighting mode.

Calibration is now completed.

Manual DAS 72.1 Page 19

Flowchart Example 2

Enter the

Set-up menu

Set the decimal

point position

Set the

display

step size

Set the Display

Upper Limit

(Overload)

Set the Display

Lower Limit

Set Zero of load cells

mV/V sensitivity

for Zero point

SET UP

1. Press the UP or DOWN key for more than

3 seconds to enter the Set-up Menu

2. Press the recessed enable switch

SET THE DECIMAL POINT POSITION (0, 0.0, 0.00, 0.000, 0.0000)

Use the UP or DOWN key to set the required decimal point position.

Choose 0.0

SET THE DISPLAY STEP SIZE. (1, 2, 5, 10, 20, 50, 100, 200, 500)

Use the UP or DOWN key to set the required display step size.

Choose 5 = 0,5 kg display resolution

SET THE DISPLAY OVER RANGE LIMIT. (MAX. VALUE +99999)

Use the UP/DOWN & MOVE RIGHT keys to set the maximum display value

above which the display shows over range (all dashes in the top of the

display).

Choose 3100.0 = Over Range Limit at 3100 kg

SET THE DISPLAY UNDER RANGE LIMIT. (MIN. VALUE -99999)

Use the UP/DOWN & MOVE RIGHT keys to set the minimum display value

below which the display shows under range (all dashes in the bottom of the

display).

Choose -200.0 = Under Range Limit at -200 kg

CALIBRATE THE ZERO POINT IN mV/V.

Use the UP/DOWN & MOVE RIGHT keys to set the load cell summary mV/V

value, e.g. 0.000 mV/V.

Choose 0.0000 for Zero Point of Scale

Set the Display value

equal to

mV/V sensitivity

Set mV/V equivalent

to

Span Calibration Value

Set Zero point

Shift for Display

gross or net

Calibration

completed

SET THE SPAN CALIBRATION VALUE.

Use the UP/DOWN & MOVE RIGHT keys to set the display value equivalent

to the load cell summary nominal load, e.g. 3000 kg.

Choose 3000.0 for load cell summary nominal load 3000 kg

CALIBRATE THE SPAN FROM mV/V LOAD CELL SENSITIVITIES

Use the UP/DOWN & MOVE RIGHT keys to set the mV/V reading equivalent

to the span calibration value set in section 2.1.

Choose 2.0000 Sensitivity for summary nominal load 3000 kg

Note:

Choose Filter type IIR (menu 4.2), Low Pass Filter 6 ... 8 (menu 4.1) and

wait for ‘No Motion’ in the calibration routine.

SHIFT ZERO POINT of empty Silo.

Display reading is the actual mV/V value. Set the new Zero Point by

pressing the ENTER key.

Choose the Zero Shift to display gross (Silo weight) and net weight

Page 20 Manual DAS 72.1

B.4.3 Example 3, calibration procedure using load cell mV/V sensitivity

3 Leg tank or silo fitted with 3 off

1000 kg @ 2 mV/V load cells.

Dead load 600 kg.

Live range 2000 kg in 0.5 kg steps.

It is assumed that the load cell system is

connected to the DAS 72.1 and the power is

on. The maximum and minimum display

values, display increment size and decimal

point position should be defined prior to

carrying out the calibration (See Menu 3).

For this example the display maximum is

defined as 2100.0, the display minimum is

-200.0, the display step size is 0.5 kg.

Remember that allparameters undersections 1.1 - 1.3, 2.1 - 2.3 and3.1 -3.3 can only be accessed or changed

after the Recessed Enable Switch has been pressed.

Situation: The silo is partly filled, a zero point shift (menu 1.2) is not possible. Tare of the silo and load cell

a

sensitivity are known.

Example:Tare is600 kg,load cellsensitivity is 2.0000mV/V.In this casewe have to usealso 2.0000 mV/V for

3000 kg. This means at tare the signal is 0.4000 mV/V.

Go to Menu 1.3.using the UP/DOWN and RIGHT keysto set the zero pointof the 3 load cells to 0.4000mV/V.

b

Go to Menu 2.1 and using the UP/DOWN and RIGHT keys set the display to read the capacity of the load cell

system or the weight value at which the sensitivity is known. For this example the load cell capacity is 3 x

1000 kg = 3000 kg @ 2 mV/V. Set the display to read 3000.0. Press the 0 [Enter] key. This defines the

theoretical calibration weight (equivalent to 2 mV/V in this example).

c

Go to Menu 2.3. Press the 0 [Enter] key. Use the UP/DOWN and RIGHT keys set the display to read the mV/V

sensitivity of the load cell system you are using.For this example the load cell sensitivity or Output at Rated

Load is 2.000 mV/V. In multiple load cell installations (load cells wired in parallel) the sensitivity is the

average of all the load cells connected. Press the 0 [Enter] key. This defines the theoretical span calibration

point.

Calibration is now completed.

Manual DAS 72.1 Page 21

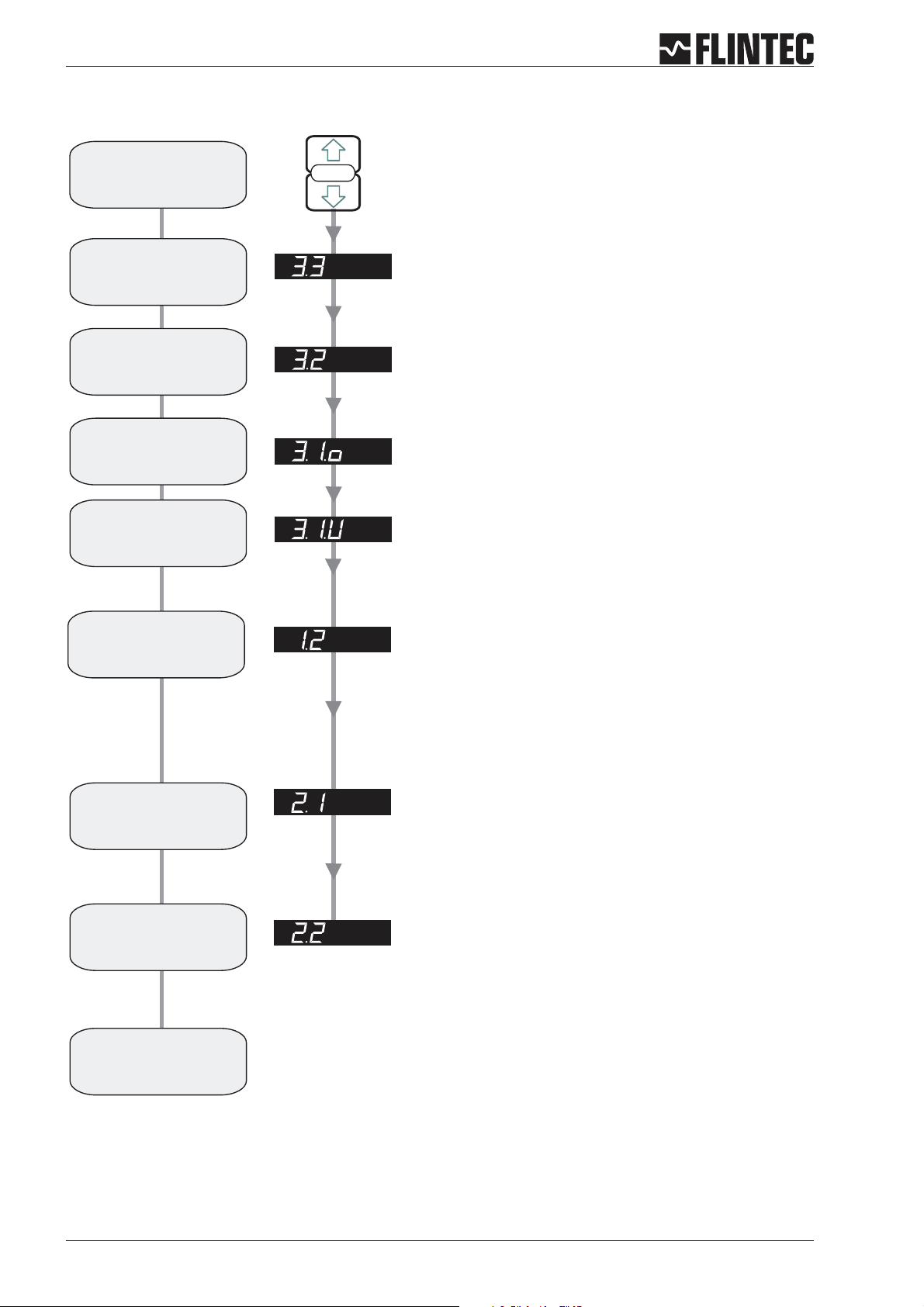

Flowchart Example 3

Enter the

Set-up menu

Set the decimal

point position

Set the

display

step size

Set the Display

Upper Limit

(Overload)

Set the Display

Lower Limit

SET UP

1. Press the UP or DOWN key for more than

3 seconds to enter the Set-up Menu

2. Press the recessed enable switch

SET THE DECIMAL POINT POSITION (0, 0.0, 0.00, 0.000, 0.0000)

Use the UP or DOWN key to set the required decimal point position.

Choose 0.0

SET THE DISPLAY STEP SIZE. (1, 2, 5, 10, 20, 50, 100, 200, 500)

Use the UP or DOWN key to set the required display step size.

SET THE DISPLAY OVER RANGE LIMIT. (MAX. VALUE +99999)

Use the UP/DOWN & MOVE RIGHT keys to set the maximum display value

above which the display shows over range

(all dashes in the top of the display).

SET THE DISPLAY UNDER RANGE LIMIT. (MIN. VALUE -99999)

Use the UP/DOWN & MOVE RIGHT keys to set the minimum display value

below which the display shows under range

(all dashes in the bottom of the display).

Calibrate the

Zero point

Set the Display value

equal to

mV/V sensitivity

Set mV/V equivalent

to

Span Calibration Value

Calibration

completed

CALIBRATE THE ZERO POINT IN mV/V.

Use the UP/DOWN & MOVE RIGHT keys to set the load cell summary mV/V

value, e.g. 0.000 mV/V.

SET THE SPAN CALIBRATION VALUE.

Use the UP/DOWN & MOVE RIGHT keys to set the display value equivalent to

the load cell summary nominal load, e.g. 3,000 kg.

Choose 3000.0 for load cell summary nominal load 3000 kg

CALIBRATE THE SPAN FROM mV/V LOAD CELL SENSITIVITIES

Use the UP/DOWN & MOVE RIGHT keys to set the mV/V reading equivalent

to the span calibration value set in section 2.1.

Choose 2.0000 Sensitivity for summary nominal load 3000 kg

Note:

Choose Filter type IIR (menu 4.2), Low Pass Filter 6 ... 8 (menu 4.1) and

wait for ‘No Motion’ in the calibration routine.

Page 22 Manual DAS 72.1

C SETUP VIA SERIAL PORT

C SETUP VIASERIAL PORT 23

C.1 COMMUNICATIONS& GETTING STARTED 24

C.1.1 Serial interface 24

C.1.2 Command Language 24

C.1.3 Setup baud rate/ deviceaddress 25

C.1.4 Getting Started 25

C.2 WIRING DIAGRAM 26

C.3 COMMANDS SUMMARY 27

C.4 COMMANDS 29

C.5 CALIBRATIONPROCEDURE. 54

C.6 USE IN “APPROVED”APPLICATIONS(only as information) 55

C.7 SOFTWARE (FIRMWARE) DOWNLOAD 56

Manual DAS 72.1 Page 23

C.1 COMMUNICATIONS & GETTING STARTED

C.1.1 Serial interface

Communicating with the DAS 72.1 digitizer is carried out via the RS422/RS485 port.

The data format is the familiar 8/N/1 structure (8 data bits, no parity, 1 stop bit).

Available baud rates via the RS422/RS485 port are as follows:

9.600, 19.200, 38.400, 57.600 or 115.200 baud.

RS422

Connection using a 4 wire technique.

•

Point-to-Point connection, i.e. no bus communication possible.

•

Half duplex setup (DX=0).

•

RS485

Connection using 2- or 4-wire techniques.

•

Multi-drop connection possible, up to 32 DAS 72.1.

•

Half or Full Duplex (DX=0 or DX=1) possible.

•

(RS232)

Select a RS485/RS232 converter.

•

C.1.2 Command Language

The command set of the DAS 72.1 series is based on a simple ASCII format (2 capital letters). This enables

the user to setup the device, get results or check parameters.

Example:

DAS 72.1 with the address or channel number 1 is connected via the RS 485 port to a bus system. You want

to get the net weight.

In this manual “_“ means space & “¿“ means enter (CR/LF)

Master (PC / PLC) sends Slave (DAS 72.1) responds Status

OP_1¿

OK

GN¿

N+123.45

open device #1

device #1 ready

get Net weigh

Net weight with algebraic

sign / comma

The command OP_2 opens the communication channel to DAS 72.1 device #2. Now device #2

acknowledges that it is active and responds to any commands on the bus. Communication with device #2

will be closed by another OP command (for another device on the bus e.g. OP_5) or by the command CL_2.

Each OP_X command implies a CL command to all other devices on the bus except device #X. This makes

the address structures easier and the system performance improves.

Page 24 Manual DAS 72.1

C.1.3 Setup baud rate / device address

Baud rate

Factory default: 9600 baud

Address settings

It is possible to set the network address of the device using the AD command. (Address range between 0

and 255). Setting the device address to 0 will set the continuously active mode, where the device becomes

permanently active, and will listen and respond to any command on the bus, without the need for an OP xxx

command.

Factory default: Address 0

C.1.4 Getting Started

You will require a:

PC or PLC with either a RS422 or RS485 communication port.

•

If using a PC/PLC with RS232 port, an RS422/485 to RS232 converter will be required.

•

Interconnecting cabling - confirm that all relevant pins used – See the wiring diagram at the end of this

•

section.

A load cell / scale with test weights or a load cell simulator.

•

A 12-25 V DC power supply capable of delivering approximately 150 mA for each DAS 72.1 and load cell.

•

One or more DAS 72.1.

•

• A suitable ASCII communication software *.

Refer to the wiring diagram on page 26.

* You can easily communicate between a PC and a DAS 72.1 using programs such as Procomm, Telemate,

Kermit or HyperTerminal (included in Windows).

Also, the DOP software with graphical user interface and oscilloscope function is now available on request

(Windows 98/2000/XP).

Manual DAS 72.1 Page 25

C.2 WIRING DIAGRAM

Logic input 1 2 3

0

Depress

To

Change

Net

Logic output

1.Zero

1.0/allow>0<

2.Calibrate

3.Set mV/V

Load cell 5Vdc 80mA

Exc Sen Inp Inp Sen Exc Rx Rx Tx Tx

+++ +

2 3 4 5 6 7 8 9 10 1112 13

1

SHIELD

2.Span

1.Set cal. ´n´

2.Calibrate

3.Set mV/V

4.Disp.mV/V

--- -

+ SENSE

- SIGNAL

+ SIGNAL

+ EXCITATION

123

3.Display

1.o/u limits´n´

2.Step * ´n´

3.Dec.point

4.Logic stats

0-20mA

Io Gnd

Relaisausgang 2 aktiv

- SENSE

- EXCITATION

RS422/485CL out

Receive +

4.Filter

1.f Hz

cut

2.Algorithm

3.Update rate

4.

Motion´n´

-

+

Receive -

Transmit -

Transmit +

7.Outp. 1/2/3

1.SPoint ´n´

2.Hyst. ´n´

3.Base

4.Test

Isolated

Mark III

T

T

T0

±

Isolated

Power 11 -25Vdc

+

+

SET UP

8.Datacom.

1.Baud rate

2.422/485

3.Address

4.Auto trnsm.

0

Digital Amplifier + Setpoint DAS 72.1

Inp.1 Inp.2

T

Isolated

6.Input 1/2/3

1.Assign key

2.

3.

4.Test

Logic Inputs

12 3com

5.CLout

1.4mA=´n´

2.20mA=´n´

3.Base

4.TestImA

Logic Outputs

12 3com

14 27

Ground

Commmon

Logic input 3 (+)

Logic input 1 (+)

Logic input 2 (+)

0

261516 17 232425181920 2122

Load cell

connections

+0

4-20mA

analogue

output

RS422/485

COM port

Logic

outputs

Logic

inputs

Input 1

Inp.1

T

(Functions as

0

Zero button,

Tare off, Set zero,

see description)

+0

Attention:

For load cells with 4-wire connection “Exc +” / “Sen +” and “Exc -” / “Sen -” should be shortened.

+ Excitation

+ Signal

– Excitation

– Signal

Shield

(green)

(white)

(black)

(red)

(yellow)

Flintec load cell; 4-wire

Flintec load cell; 6-wire

+ Excitation

+ Sense

+ Signal

– Sense

– Excitation

– Signal

Shield

Power supply

12-25 V DC

Inp.2

Output 2

(Funktions as

T

T

T

Tare button,

Display net mode,

see description)

(green)

(blue)

(white)

(brown)

(black)

(red)

(yellow)

Page 26 Manual DAS 72.1

C.3 COMMANDS SUMMARY

Get/set analog action Analog action 0 through 8 A+00000/OK/ERR

Network address Read/modify Network address 0 through 255 A:014/OK/ERR

Absolute gain calibrate (TAC protected) Cailbrate gain using absolute sensitivity in mV/V (without dp) +/-32000; 0 through 99999 G+2.0000/OK/ERR

Get/set analog high Analog calibration point 20 mA (high) -99999 through 9999 H+10000/OK/ERR

Action input n Function of logic input 1, 2 or 3 0 through 14 In:+00006

Get/set analog low Analog calibration point 4 mA (low) -99999 through 99999 L+00000/OK/ERR

Get/set setpoint n action Setpoint action 1, 2 or 3 0 through 8 An:+00000/OK/ERR

Save analog output parameters Save AL, AH, AA to EEPROM none OK/ERRAZAbsolute zero calibrate (TAC protected) Calbrate zero using absolute zero in mV/V (without decimal point) -32000 through 32000 Z+0.000/OK/ERR

Baudrate Read/modify baudrate setting 9600 through 115200 B 9600CECalibrate enable Open legal parameters (CE 'TAC') 0 through 65535 E+00001/OK/ERR

Calibrate gain (TAC protected) Calibrate gain at some load >> zero 0 through 99999 G+20000/OK/ERR

Calibrate min (TAC protected) Read/modify min 0 through -99999 I+09000/OK/ERR

Close all connections Close all devices (OP XXX implies CL) none noneCMCalibrate max (TAC protected) Read/modify max 0 through 99999 M+30000/OK/ERR

Calibrate save (TAC protected) Save CM, CZ, AZ, CG, AG, DS, DP, ZT to EEPROM none OK/ERCZCalibrate zero (TAC protected) Calibrate zero - no load on platform none OK/ERDPDecimal point (TAC protected) Read/modify decimal point position 0 through 5 P+00005/OK/ERR

Command Short Description Usage Parameter Values Typical Answer

AA

AD

AG

AH

AIn

AL

An

AS

BR

CG

CI

CL

CS

Manual DAS 72.1 Page 27

Display step size (TAC protected) Read/modify the display step size 1, 2.5, 10, 20, 50, 100, 200, 500 S+00001/OK/ERR

Duplex Select half (0) or full (1) duplex 0 oder 1 X+000/OK/ERR

Factory default (TAC protected) Load factory defaults into EEPROM none OK/ERFLFilter setting Read/modify filter setting 0 through 8 F+00008/OK/ERR

Filter mode Read/modify filter mode setting 0 oder 1 M+00001/OK/ERR

DS

DX

FD

FM

Get Average weight Returns the current average value none A+00000

Get Gross value Returns the gross value none G+01100GHGet Hold value Returns the hold value none H+01000/OK/ERR

Get Peak value (maximum) Returns the peak value none M+00100GNGet Net value Returns the net value none N+00000GOGet Peak to Peak value Returns the Peak to Peak value none O+01000/OK/ERR

GA

GG

GM

Get sample Returns the A/D value none S+000000

Get Tare value Returns the tare value none T+00000GVGet Valley value (minimum) Returns the valley value none V+01000/OK/ERR

Get long Weight information Get long weight information none W+00100+01100010F

Get/set setpoint n hysteresis Setpoint hysteresis 1, 2 or 3 -99999 through 99999 Hn:+00000/OK/ERR

GS

GT

GW

Hn

Inform. device ID Information - device identification none D:7210INRead input status Read input status none IN:0011IORead/Modify output status Read/Modify output status 0000 through 0111 IO:0011ISInform. on device status Information - no motion, zero and tare status none S:000000IVInform. version number Information - software version number none V:0428LIList settings Information - list settings as ASCII lines none List of settingsMTMeasuring Time The time over which the average value is derived 0 through 500 ms M+00100/OK/ERR

Command Short Description Usage Parameter Values Typical Answer

ID

No-motion range No-motion range 0 through 65535 R+00010/OK/ERR

No-motion time No-motion time in milliseconds 0 through 65535 T+00500/OK/ERR

Output mask Disable setpoint outputs 0000 through 0111 OM:0000/OK/ERR

Open connection Open device XXX 0 through 255 O:O02/OK

Get/set logic setpoint / hysteresis Logic hysteresis 1, 2 or 3 0 oder 1 Pn:+00000/OK/ERR

NR

NT

OM

OP

Pn

Reset peak weight value Clears the current peak weight value to zero none OK/ERRRTReset tare Restores current zero point none OK/ERRRZReset system zero Restores the calibration zero point none OK/ERRSDStart Delay Start delay between trigger and start of measurement 0 through 500 ms S+00100/OK/ERR

RM

Start auto-transmit gross Start auto-transmitting gross value none G+01100/OK/ERR

Auto-transmit hold value Start auto-transmitting hold value none H+01000/OK/ERR

Auto-transmit peak weight value Start auto-transmitting peak value none M+00100/OK/ERR

Start auto-transmit net Start auto-transmitting net value none N+00000/OK/ERR

SG

SH

SM

SN

Auto-transmit peak to peak value Start auto-transmitting peak to peak value none O+01000/OK/ERR

Get/set setpoint n Setpoint 1, 2 or 3 -99999 through 99999 Sn:+00000/OK/ERR

Software reset Restart the DAS none OKSSSave setpoint parameters Save S1, S2, S3, H1, H2, H3, A1, A2, A3 to EEPROM none OK/ERRSTSet tare Set tare point none OK/ERRSVAuto-transmit valley value Start auto-transmitting valley value none V+01000/OK/ERR

SO

Sn

SR

Start auto-transmit weight Start auto-transmitting long weight result none W+0750+750061F4

Set system zero Set system zero point none OK/ERRTETrigger Edge Selects trigger on a falling (0) or rising (1) edge 0 oder 1 E:000/OK/ERR

Software-Hold Store hold value none OK/ERRTLTrigger Level Set value of the rising or falling trigger edge 0 through 99999 T+00100/OK/ERR

Trigger Software trigger to start measuring cycle none OK/ERRURUpdate rate Read/modify update rate setting 0 through 7 U+00000/OK/ERR

SW

SZ

TH

TR

Save set-up parameters Save FL, FM, UR, NR, NT, AD, BR, DX to EEPROM none OK/ERRZTZerotrack (TAC protected) Zerotrack off (0) or zerotrack on (1) 0 bis 255 Z:001/OK/ERR

WP

Page 28 Manual DAS 72.1

C.4 COMMANDS

For better clarity, all commands are divided into groups as described on the following pages.

C.4.1 System diagnosis Commands – ID,IV,IS,SR 30

C.4.2 Set up Commands– SD,MT,GA,TE, TR, TL, AI 31

C.4.3 Calibration Commands – CE, CI,CM,DS,DP,CZ,CG, AZ, AG, ZT, FD,CS 33

C.4.4 Motion detection Commands – NR,NT 37

C.4.5 Filter setting Commands – FM, FL, UR 38

C.4.6 Set Zero/Tareand Reset Zero/Tare Commands –SZ, RZ, ST, RT 40

C.4.7 Output Commands – GG,GN, GT,GS,GM, RM, GH, GO,GV,GW 42

C.4.8 Auto-transmit Commands –SG, SN, SW, SM, SH,SO,SV 44

C.4.9 Commands for externalI/O control– IN,IO,OM, AI 46

C.4.10 Setpoint Commands- Sn,Hn,Pn,An 48

C.4.11 Communication setup Commands – AD, CL, BR, DX,OP, LI 50

C.4.12 Commands Analogue Output 4 – 20 mA- AL, AH, AA 52

C.4.13 Save parameters Commands –CS, WP, SS, AS, TH 53

Manual DAS 72.1 Page 29

C.4.1 System diagnosis Commands – ID, IV, IS, SR

Use these commands you get the DAS 72.1 type, firmware version or device status. These commands are

sent without parameters.

ID Request of device identify

Master ( PC / PLC ) sends DAS 72.1 responds

ID

¿

D:7210

The response to this request gives the actual identity of the active device. This is particularly useful when

trying to identify different device types on a bus.

IV Request of firmware version

Master ( PC / PLC ) sends DAS 72.1 responds

IV

¿

V:0210

The response to this request gives the firmware version of the active device.

IS Request device status

Master ( PC / PLC ) sends DAS 72.1 responds

IS¿

S:067000

The response to this request comprises of two 3-digit decimal values, which can be decoded according to

the table below:

Leftmost 3-digit value : R ightmost 3-digit value:

1 Signal stable 1 (not used)

2 Zero action performed 2 (not used)

4 Tare active 4 (not used)

8 (not used) 8 (not used)

16 (not used) 16 (not used)

32 Output 1 active 32 (not used)

64 Output 2 active 64 (not used)

128 Output 3 active 128 (not used)

The example decodes the result S:067000 (binary 01000011) as follows:

0

Signal stable (no-motion) [2

Zero action [2

Output 2 active [2

= 1, LSB ]

1

=2]

6

=64]

Note: the bits that are not used are set to zero.

SR Reset DAS 72.1 firmware

Master ( PC / PLC ) sends DAS 72.1 responds

SR¿

OK

This command will respond with ‘OK’ and after maximum 400 ms perform a complete reset of the DAS

72.1. It has the same functionality as power off and on again.

Page 30 Manual DAS 72.1

C.4.2 Set up Commands – SD, MT, GA, TE, TR, TL, AI

Note: All setups should be stored with the WP command before power off.

SD Start Delay 0 … 500 ms

Set the delay between falling/rising edge of trigger pulse and start of measurement. Permitted values are 0

… 500 ms.

Master ( PC / PLC ) sends DAS 72.1 responds Result

SD¿

SD_200¿

S+00100

OK

Request: SD=100 ms

Setting: SD=200 ms

Factory default: 0 [= 0 ms]

See time diagram of check weighing page 32

MT Measuring Time, range 0…500 milliseconds

Set the time over which the average value will be built. Permitted values are 0 … 500 ms.

Master ( PC / PLC ) sends DAS 72.1 responds Result

MT¿

MT_500

M+00100

¿

OK

Request: MT=100 ms

Setting: MT=500 ms

Note: MT = 0 means disabled trigger and average function.

Factory default: 0

See time diagram of check weighing page 32

GA Get Average

Issuing the GA command the DAS 72.1 returns the current average weight value by using the MT setup.

Master ( PC / PLC ) sends DAS 72.1 responds Result

GA¿

A+01100

Answer: GA=1100 g

Note: During the time between the trigger condition being accepted and the average value being updated,

the GA command will return the value 99 999.

TE Trigger Edge

Issuing the TE command selects rising or falling edge trigger. Parameter = 0 select falling edge and

parameter = 1 select rising edge.

Master ( PC / PLC ) sends DAS 72.1 responds Result

TE

TE_0

¿

¿

E:001

OK

Request: TE=1

Setting: TE=0

Factory default: 0 [falling edge]

See time diagram of check weighing page 32

Manual DAS 72.1 Page 31

TR Trigger

This command will start the measuring cycle in the same way as the hardware trigger input.

Master ( PC / PLC ) sends DAS 72.1 responds Result

TR¿

OK

Trigger started

TL Trigger Level

Set the trigger level for rising edge start of measurement. Permitted values are in the range 0 … 99 999.

Master ( PC / PLC ) sends DAS 72.1 responds Result

TL¿

TL_1000

T+99999

¿

OK

Request: TL=99 999

Setting: TL=1 000

With regard to all the trigger commands (SD, TR, TE, TL), a check weighing will automatically restart when

the weight falls below or overshoots by 1000 d (increment), e.g. 100,0 g.

Factory default: 99 999

The Timing Diagram for Check Weighing

M

(g)

Trigger point

choose 1 of 3:

1. Light barrier or

2. TR command or

3. TL Trigger Level

Typical Checkweigher Signal

SD

Start Delay

MT

Measuring Time

t

Page 32 Manual DAS 72.1

C.4.3 Calibration Commands – CE, CI, CM, DS, DP, CZ, CG, AZ, AG, ZT, FD, CS

Note: TAC represents Traceable Access Code (calibration counter).

CE TAC counter reading

With this command you get the TAC counter reading or you can enable a calibration sequence.

Master ( PC / PLC ) sends DAS 72.1 responds Result

CE¿

CE_17¿

E+00017 (example)

OK

Request: TAC-counter CE17

Calibration sequence active

This command must be issued PRIOR to any attempt to set the calibration parameters CZ, CG etc. In legal

for trade applications the TAC counter can be used to check if critical parameters have been changed

without re-verification. After each calibration the TAC counter increases by 1.

CI Set minimum output value

This command is used for setup minimum allowable output value. Permitted values are 0 ... -99 999

Master ( PC / PLC ) sends DAS 72.1 responds Result

CI¿

CE¿

CE_17¿

CI_-10000¿

I-00300

E+00017 (example)

OK

OK

Request: CI = -300

Request: TAC-counter CE17

Calibration sequence active

Setting: CI = -10 000

This value will determine the point at which the output will change to “uuuuuu”, signifying under-range.

Factory default setting: -9 000.

CM Set maximum output value

This command is used for setup the maximum output value. Permitted values are between 1 … 99 999.

Master ( PC / PLC ) sends DAS 72.1 responds Result

CM

¿

CE

¿

CE_17

¿

CM_50000

M+30000

E+00017 (example)

OK

¿

OK

Request: CM = 30 000

Request: TAC-counter CE17

Calibration sequence active

Setting: CM = 50 000

This value will determine the point at which the output will change to “oooooo”, signifying over-range.

Note: The range, in which a scale can be set to zero (SZ) or automatic zero tracking (ZT) is active, is +/- 2%

of CM value.

Factory default: CM = 99 999.

Manual DAS 72.1 Page 33

DS Display step size

This command allows the output to step up or down by a unit other than 1. Permitted values are 1, 2, 5, 10,

20, 50, 100 and 200.

Master ( PC / PLC ) sends DAS 72.1 responds Result

DS¿

CE¿

CE_17¿

DS_50¿

S+00002

E+00017 (example)

OK

OK

Request: display step size 2

Request: TAC-counter CE17

Calibration sequence active

Setting: step size 50

DP Set decimal point position

This command allows the decimal point to be positioned anywhere between leftmost and rightmost digits of

the 5-digit output result. Position 0 means no decimal point.

Master ( PC / PLC ) sends DAS 72.1 responds Result

DP¿

CE¿

CE_17¿

DP_0¿

P+00002

E+00017 (example)

OK

OK

Request: position of decimal point

Request: TAC-counter CE17

Calibration sequence active

Setting: no decimal point

CZ Set calibration zero point

This is the reference point for all weight calculations, and is subject to TAC control.

Master ( PC / PLC ) sends DAS 72.1 responds Result

CE¿

CE_17¿

CZ¿

E+00017 (example)

OK

OK

Request: TAC-counter CE17

Calibration sequence active

Zero point saved

Factory default: approx. 0 mV/V input signal

CG Set calibration gain (span) value

This is the reference point for calibration under load, and is subject to TAC control.

Permitted values are 1 … 99 999.

Master ( PC / PLC ) sends DAS 72.1 responds Result

CG¿

CE¿

CE_17¿

CG_15000¿

G+10000

E+00017 (example)

OK

OK

Request: measuring range 10 000 d

Request: TAC-counter CE17

Calibration sequence active

Setting: span 15 000 d

For calibration an input signal near the display maximum (CM) will give the best system performance. The

minimum calibration load of at least 20% is recommended.

Factory default: 20 000 = 2,000 mV/V input signal

Page 34 Manual DAS 72.1

AZ Absolute zero point calibration

The command AZ is used as reference point for all weight calculations and will setup in mV/V. Permitted values

are ± 32 000 (= ± 3.2000 mV/V).

Master ( PC / PLC ) sends DAS 72.1 responds Result

AZ¿

CE¿

CE_17¿

AZ_00500¿

Z+0.0005

E+00017 (example)

OK

OK

Request: Zero point @ 0.0005 mV/V

Request: TAC-counter CE17

Calibration sequence active

new: Zero point @ 0.0500 mV/V

Factory default: 00 000 @ 0.0000 mV/V input signal.

AG Absolute gain calibration

The command AG is used as absolute gain (or measuring range) for all weight calculations and will setup in

mV/V. Permitted values are ± 32 000 (= ± 3.2000 mV/V).

Master ( PC / PLC ) sends DAS 72.1 responds Result

AG¿

CE¿

CE_17¿

AG_17500_10000¿

G+2.0000

E+00017 (example)

OK

OK

Request: Meas. range 2.000 mV/V

Request: TAC-counter CE17

Calibration sequence active

new: Measuring range

1.750 mV/V @ 10 000 d

Factory default: 10 000 @ 2.0000 mV/V input signal.

ZT Zero tracking

This command enables or disables the zero tracking. Parameter = 0 disables the zero tracking and

parameter = 1 enables the zero tracking. Issuing the command without any parameter returns the current

ZT value.

Master ( PC / PLC ) sends DAS 72.1 responds Result

ZT¿

CE¿

CE_17¿

ZT 0¿

Z: 001

E+00017 (example)

OK

OK

Request: ZT-Status

Request: TAC-counter CE17

Calibration sequence active

Setting: ZT = OFF

Zero tracking will be performed only on results less than +/-0.5 d at a rate of 0.4 d/sec, where d = display

step size (see DS command).

The zero can only be tracked to +/- 2% of maximum (see CM command).

Factory default: ZT=0

Manual DAS 72.1 Page 35

FD Factory default settings

This command puts the DAS 72.1 back to a known state. The data will be written to the EEPROM and the

TAC will be incremented by 1.

Note: All calibration and setup information will be lost by issuing this command!

Master ( PC / PLC ) sends DAS 72.1 responds Result

CE¿

CE_17¿

FD¿

E+00017 (example)

OK

OK

Request: TAC-counter CE17

Calibration sequence active

Factory default setting

CS Save the calibration values

This command results in the calibration values being saved to EEPROM, and causes the TAC to be

incremented by 1.

Master ( PC / PLC ) sends DAS 72.1 responds Result

CE¿

CE_17¿

CS¿

E+00017 (example)

OK

OK

Request: TAC-counter CE17

Calibration sequence active

Calibration values saved

The CS command saves all of the calibration group values, as set by CZ, CG, CM, DS, DP and ZT. The

command returns ERR and has no updating action unless it is preceded by the CE_XXXXX.

Page 36 Manual DAS 72.1

C.4.4 Motion detection Commands – NR, NT

The motion detection facility provides a means of disabling certain functions whenever a condition of

instability, or “motion”, is detected. The “no-motion” or “stable” condition is achieved whenever the signal

is steady for the period of time set by NT, during which it cannot fluctuate by more than NR increments.The

stable condition activates the relevant bit of responses to “Info Status” (IS).

ATTENTION:

The following functions are disabled if motion is detected: “Calibrate Zero” (CZ)

“Calibrate Gain” (CG) “Set Zero” (SZ) and “Set Tare” (ST).

NR No Motion range

This is the range within which the weighing signal is allowed to fluctuate and still be considered as “stable”.

Permitted values are between 1 and 65 000.

Master ( PC / PLC ) sends DAS 72.1 responds Result

NR¿

NR_2¿

WP¿

R+00010

OK

OK

Request: NR = 10 d

Setting: NR = 2 d

Setting saved

NR = 2 i.e. fluctuations within a maximum of±2d,intheperiod NT, will be considered “stable”.

Factory default: NR = 1.

NT Stabilisation time for in motion band

This sets the time (in milliseconds) over which the weight signal is checked to see if it is “stable” or has

“no-motion“. The weight signal has to vary by less than NR divisions over the time period NT to be

considered ‘stable’. Permitted range 1 ... 65 535 milliseconds.

Master ( PC / PLC ) sends DAS 72.1 responds Result

NT¿

NT_500¿

WP¿

T+01000

OK

OK

Request: NT = 1 000 ms

Setting: NT = 500 ms

Setting saved

If the value of NT =500 milliseconds, the output must not fluctuate more than NR increments within 500

milliseconds in order to be considered “stable”.

Factory default: NT = 1 000 [=1000 ms].

Manual DAS 72.1 Page 37

C.4.5 Filter setting Commands – FM, FL, UR

Using the commands FM and FL, a digital filter type and strength can be set which will eliminate most of the

unwanted disturbances. Please note that these filters are positioned immediately after the A/D Converter

and therefore affect all aspects of the weighing operation.

FM Filter Mode FIR / IIR

Choose filter mode, permitted values are “0” for IIR and “1” for FIR.

Master ( PC / PLC ) sends DAS 72.1 responds Result

FM¿

FM_0¿

WP¿

M+00001

OK

OK

Request: FM = 1 (FIR)

Setting: FM = 0 (IIR)

Setting saved

The digital IIR filter works as a low-pass filter of 2nd order with Gaussian characteristic, damping is 40

dB/decade; see table mode 0.

The digital FIR filter works as a low-pass filter with quick response; damping see table mode 1.

Factory default: 0

FL Setup filters

Command for setup cut off frequency, permitted values are 0 … 8.

Master ( PC / PLC ) sends DAS 72.1 responds Result

FL¿

FL_1¿

WP¿

F+00003

OK

OK

Request: FL = 3

Setting: FL = 1

Setting saved

Filter values can be choosen between 0 and 8, see table below.

FL= 0 means no filter in mode 0 or 1 (command FM).

Factory default: 3

Mode 0 Characteristic (IIR-Filter)

FL Settling time to 0.1%

(ms)

0 no filtering ** 600

1551857600

2 122 8 78 600

3 242 4 96 600

4 322 3 104 600

5 482 2 114 600

6 963 1 132 600

7 1923 0.5 149 600

8 3847 0.25 164 600

3dB Cut-off frequency

(Hz)

* Output-rate = 600/2URsamples/s

** Antialiasing filter 17 Hz @ 60 dB/decade

Damping @300Hz

(dB)

Output-rate*

(samples/s)

Page 38 Manual DAS 72.1

Mode 1 Characteristic (FIR-Filter)

FL Settling time to

0.1%

(ms)

0 no filtering ** 600

1 47 19.7 48 64 >90 >80 600

2 93 9.8 24 32 >90 >40 300

3 140 6.5 16 21 >90 >26 200

4 187 4.9 12 16 >90 >20 150

5 233 3.9 10 13 >90 >16 120

6 280 3.2 8 11 >90 >13 100

7 327 2.8 7 9 >90 >11 85.7

8 373 2.5 6 8 >90 >10 75

3dBCut-off

(Hz)

20 dB damping

at frequency

(Hz)

40 dB damping

at frequency

(Hz)

Dampinginthe

stopband

(dB)

Stopband

(Hz)

Output rate

max.

(samples/s)

** Antialiasing filter 17 Hz @ 60 dB/decade

Attention:

In mode 1 the output rate is dependant on the selected filter level (FL).

UR Set the update rate (average building)

This command will define over how many measurements, from the preceeding IIR or FIR filter, an average

will be calculated. The average will be calculated over 2

UR

samples. Permitted values 0...7 (see table below)

UR 01234567

numberofsamples1248163264128

Check / adjustment update rate:

Master ( PC / PLC ) sends LDU XX.X responds Result

UR¿

UR_4¿

U+0001

OK

Request: average over 2 samples

Setting: average over 16 samples

Factory default: 0 [no average, = 600 samples/s]

Remark to Mode 1

Dependency Output Rate - averaging UR - Filter FL

UR Output Rate samples/s

FL 0 FL 1

19.7 Hz

0 600 600 300 200 150 120 100 85.7 75

1 300 300 150 100 75 60 50 42.85 37.5

2 150 150 75 50 37,5 30 25 21.42 18.75

3 75 75 37.5 25 18.75 15 12.5 10.71 9.38

4 37.5 37.5 18.75 12.5 9.38 7.5 6.25 5.36 4.69

5 18.75 18.75 9.38 6.25 4.69 3.75 3.13 2.68 2.34

6 9.38 9.38 4.69 3.13 2.34 1.88 1.56 1.34 1.17

7 4.69 4.69 2.34 1.56 1.17 0.94 0.78 0.67 0.59

FL 2

9.8 Hz

FL 3

6.5 Hz

FL 4

4.9 Hz

FL 5

3.9 Hz

FL 6

3.2 Hz

FL 7

2.8 Hz

FL 8

2.5 Hz

Manual DAS 72.1 Page 39

C.4.6 Set Zero/Tare and Reset Zero/Tare Commands – SZ, RZ, ST, RT

The following commands allow you to set and reset zero and tare values. The zero set during calibration

remains the ‘true zero’ but new ‘current zero’ can be set using the SZ command. If the SZ command is

issued and accepted then all weight values will then be based on the new ‘current zero’. Please remember

that zero value will be subject to the Zero tracking function if enabled.

If the weight signal is not stable (as defined by the No motion range NR and the No motion time NT) then

both the set zero SZ and set tare ST commands will be disabled.

Also the Set Zero SZ command is not allowed if the new zero value required and the ‘calibration zero’ differ

by more than2%oftheCMvalue (maximum allowable value).

See chapter 8 “Legal for trade” applications.

SZ Set Zero

This command sets a new “current zero” which is then the basis of all weight values until further updated