Page 1

FANUC Series 16/160/18/180 –Model B

PARAMETER MANUAL

B-62450E/02

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The export of this product is subject to the authorization of the government of the country

from where the product is exported.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by or in the main body.

Page 3

PREFACE .

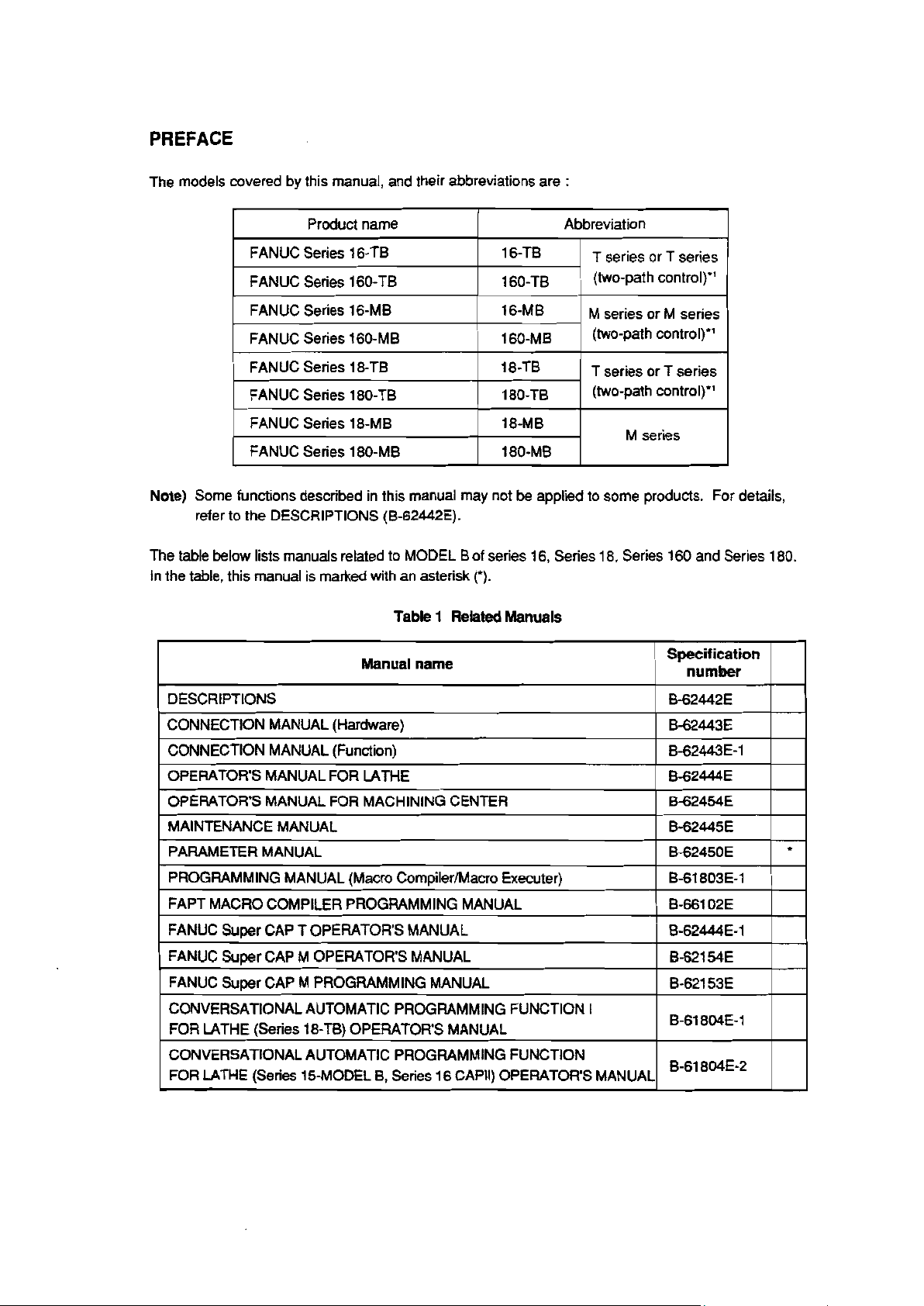

The models covered by this manual, and their abbreviations are :

1

FANUC Series 16.TB

FANUC Series 160.TB

I

FANUC Series 16.MB

I

FANUC Series 160.MB

I

FANUC Series 18-TB 180TB

FANUC Series 180-TB 180-TB

FANUC Series 18.MB 180MB

I

FANUC Series 180.MB 1800MB

Note) Some functions described in this manual may not be applied to some products. For details,

refer to the DESCRIPTIONS (B-62442E).

The table below lists manuals related to MODEL B of series 16, Series 18, Series 160 and Series 180.

In the table, this manual is marked with an asterisk (‘).

DESCRIPTIONS

I

1 CONNECTION MANUAL (Hardware)

1 CONNECTION MANUAL (Function)

OPERATOR’S MANUAL FOR LATHE

OPERATOR’S MANUAL FOR MACHINING CENTER

MAINTENANCE MANUAL

I

PARAMETER MANUAL

PROGRAMMING MANUAL (Macro Compiler/Macro Executer)

Product name 0 Abbreviation

I

I

I

Table 1 Related Manuals

Manual name

160TB

1600TB

160MB

1600MB

T series or T series

two-path control)”

I (

M series or M series

1 (two-path control)*’

T series or T series

(two-path control)‘l

M series

Specification

number

B62442E

I

B-62443E

I

1 B-62443E-I -11

B-62444E

B-62454E

B-62445E

I

B-62450E

B-61 803E-1

I I

I I

I I

I I

l

FAPT MACRO COMPILER PROGRAMMING MANUAL

FANUC Super CAP T OPERATOR’S MANUAL

FANUC Super CAP M OPERATOR’S MANUAL

1 FANUC Super CAP M PROGRAMMING MANUAL

CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION I

FOR LATHE (Series 18.TB) OPERATOR’S MANUAL

CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION

FOR LATHE (Series 15MODEL B, Series 16 CAPII) OPERATOR’S MANUAL

B-661 02E ~~ 7-1

I

’ B-62444EE-1

B-621 54E

B-621 53E

I

B-61 804E-1

B-61 804E2

-11

I I

I1

Page 4

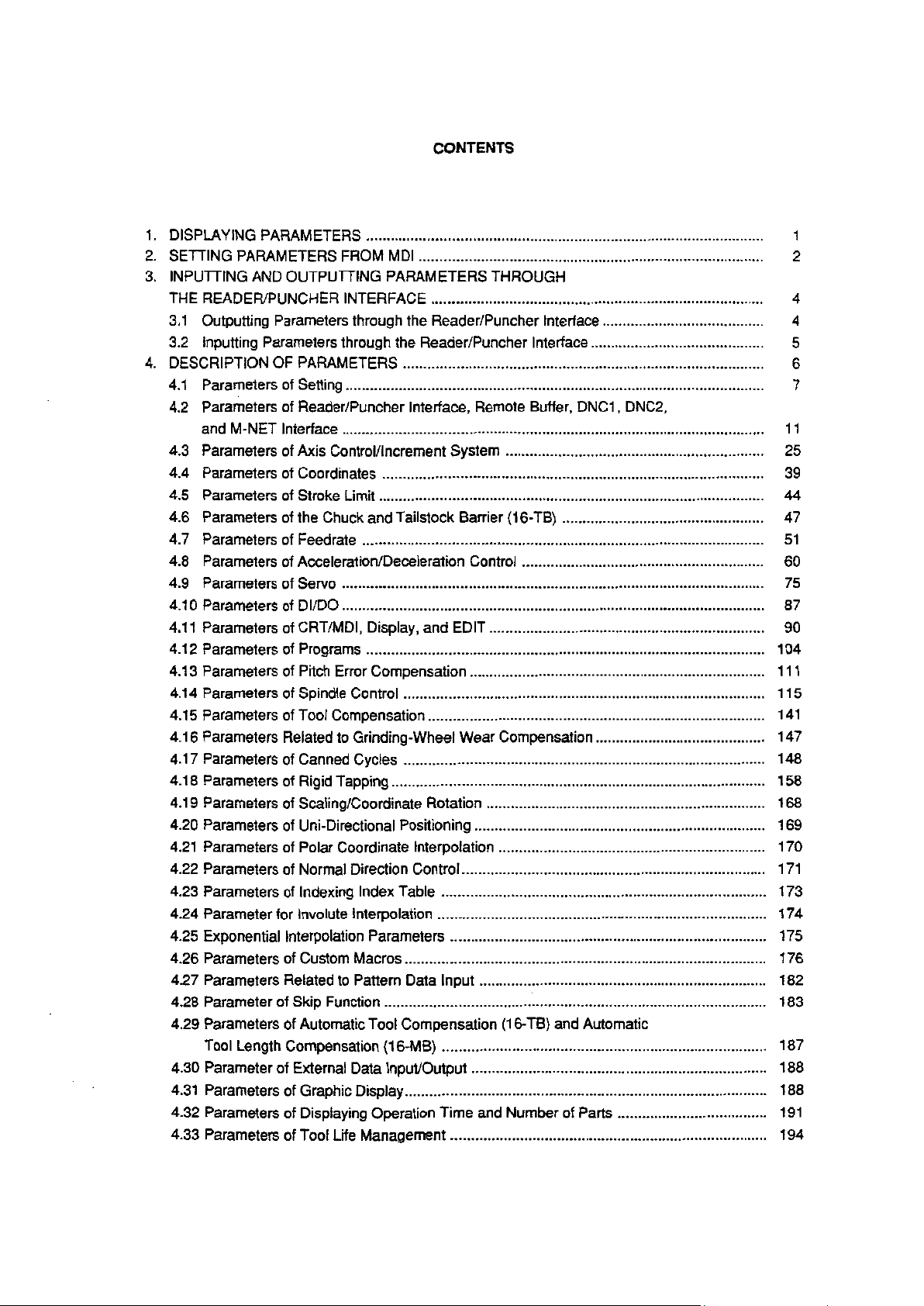

CONTENTS

DISPLAYING PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..*...**...........................

1.

.

2

SETTING PARAMETERS FROM MDI

.

3

INPUTTING AND OUTPUTTING PARAMETERS THROUGH

THE READER/PUNCHER INTERFACE

3.1 Outputting Parameters through the Reader/Puncher Interface

Inputting Parameters through the Reader/Puncher Interface

3.2

.

DESCRIPTION OF PARAMETERS

4

4.1 Parameters of Setting

.......................................................................................................

.....................................................................................

..................................................................................

........................................

...........................................

.........................................................................................

4.2 Parameters of Reader/Puncher Interface, Remote Buffer, DNCl, DNC2,

and M-NET Interface

Parameters of Axis Control/increment System

4.3

........................................................................................................

................................................................

4.4 Parameters of Coordinates ..............................................................................................

4.5 Parameters of Stroke Limit ...............................................................................................

Parameters of the Chuck and Tailstock Barrier (16.TB) ..................................................

4.6

4.7 Parameters of Feedrate

4.8 Parameters of Acceleration/Deceleration Control

4.9 Parameters of Servo

4.10 Parameters of Dl/DO

4.11 Parameters of CRT/MDI, Display, and EDIT

4.12 Parameters of Programs

4.13 Parameters of Pitch Error Compensation

4.14 Parameters of Spindle Control

4.15 Parameters of Tool Compensation

4.16 Parameters Related to Grinding-Wheel Wear Compensation

4.17 Parameters of Canned Cycles

4.18 Parameters of Rigid Tapping

4.19 Parameters of Scaling/Coordinate Rotation

4.20 Parameters of Uni-Directional Positioning

4.21 Parameters of Polar Coordinate Interpolation

4.22 Parameters of Normal Direction Control

4.23 Parameters of Indexing Index Table

4.24 Parameter for Involute Interpolation

4.25 Exponential Interpolation Parameters

4.26 Parameters of Custom Macros

4.27 Parameters Related to Pattern Data Input

4.28 Parameter of Skip Function

...................................................................................................

............................................................

........................................................................................................

........................................................................................................

....................................................................

..................................................................................................

.........................................................................

.........................................................................................

...................................................................................

..........................................

.........................................................................................

............................................................................................

.....................................................................

........................................................................

..................................................................

...........................................................................

................................................................................

.................................................................................

..............................................................................

.........................................................................................

.......................................................................

..............................................................................................

4.29 Parameters of Automatic Tool Compensation (16-TB) and Automatic

Tool Length Compensation (16.MB)

4.30 Parameter of External Data Input/Output

4.31 Parameters of

Graphic Display

4.32 Parameters of Displaying Operation Time and Number of Parts

4.33 Parameters of

Tool Life Management

................................................................................

.........................................................................

.........................................................................................

.....................................

..............................................................................

1

2

11

25

39

44

47

51

60

75

87

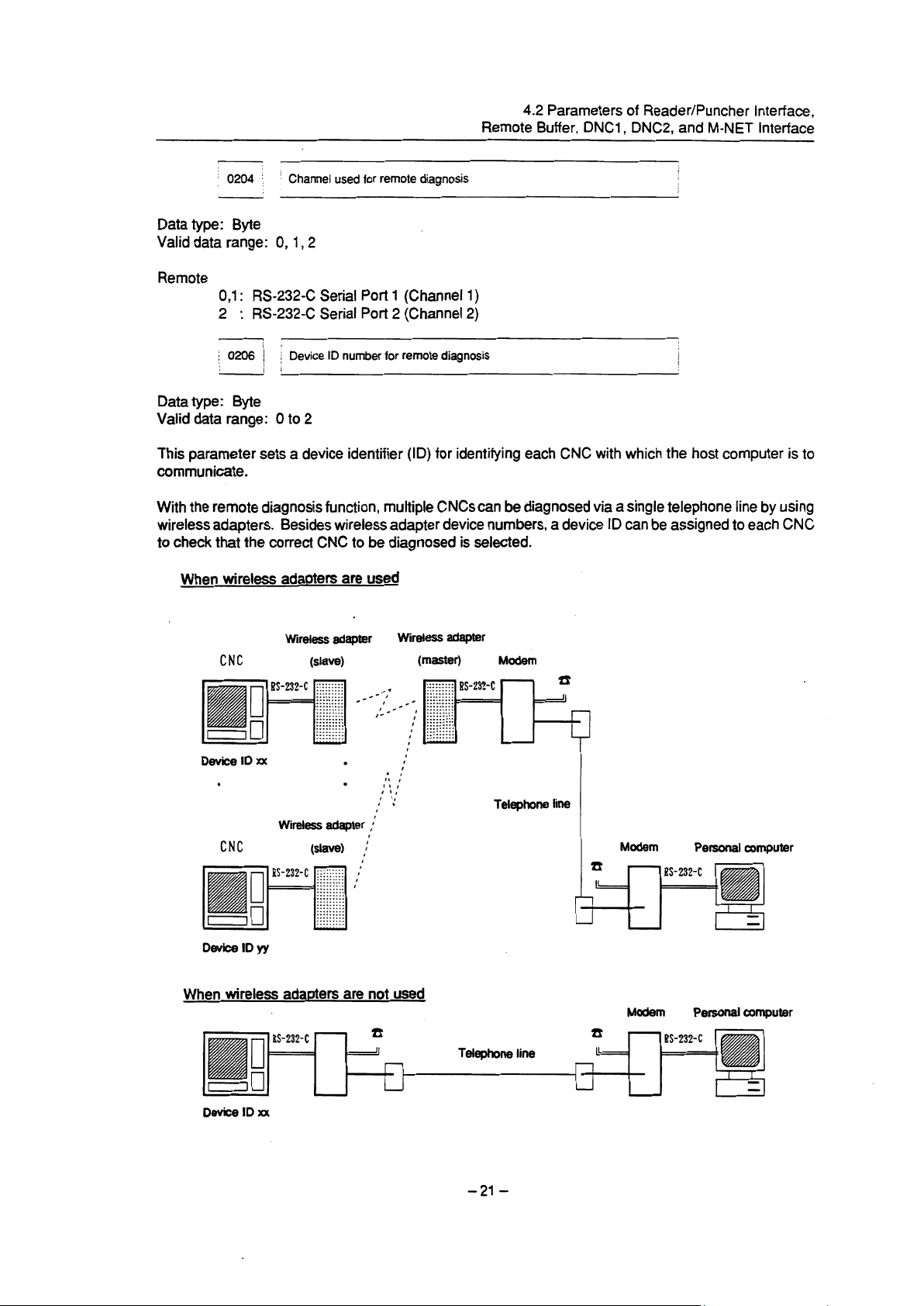

90

104

111

115

141

147

148

158

168

169

170

171

173

174

175

176

182

183

187

188

188

191

194

Page 5

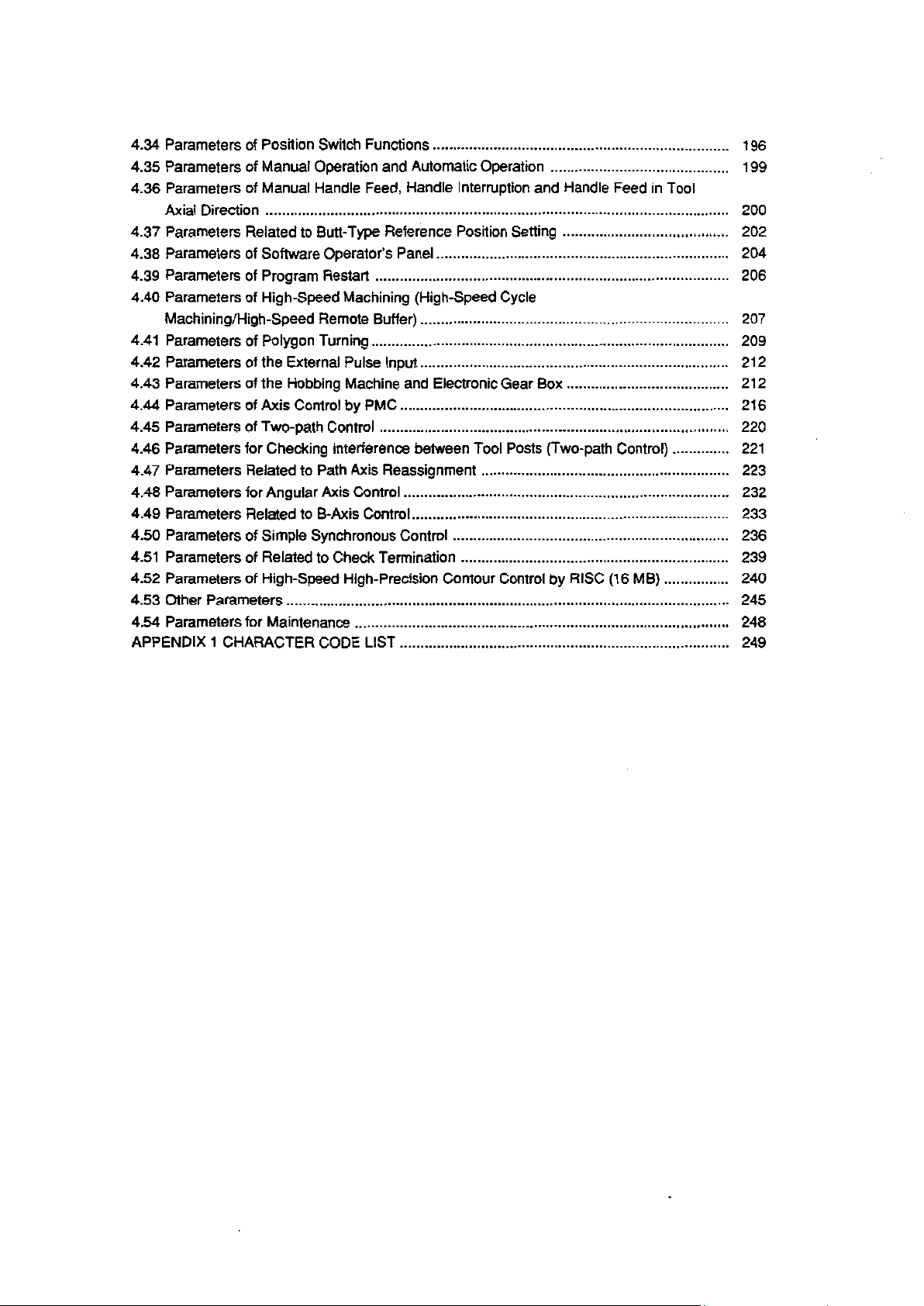

4.34

Parameters of Position Switch Functions

Parameters of Manual Operation and Automatic Operation

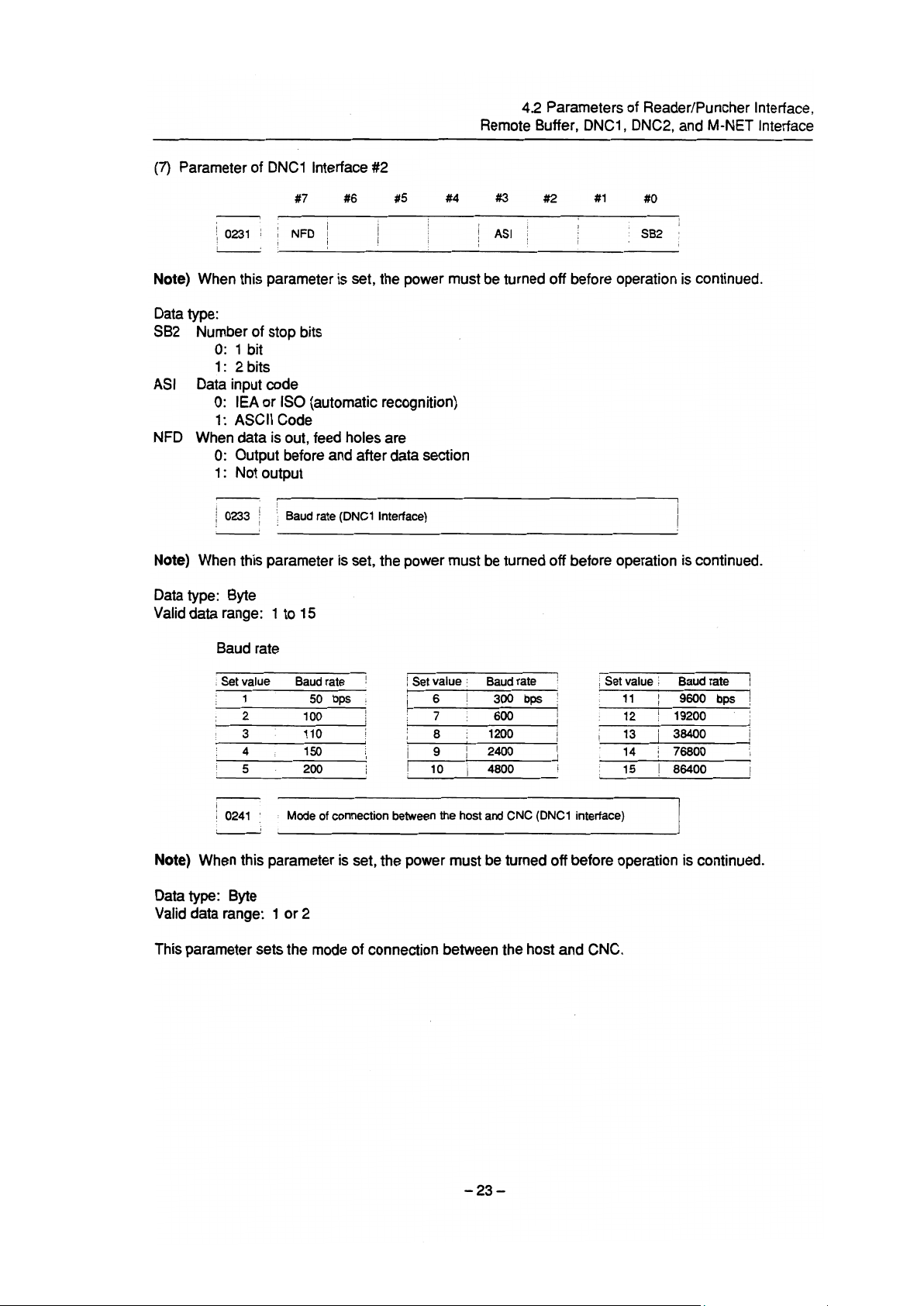

4.35

Parameters of Manual Handle Feed, Handle Interruption and Handle Feed in Tool

4.36

Axial Direction

4.37

Parameters Related to Butt-Type Reference Position Setting .........................................

4.38

Parameters of Software Operator’s Panel

4.39

Parameters of Program Restart

4.40

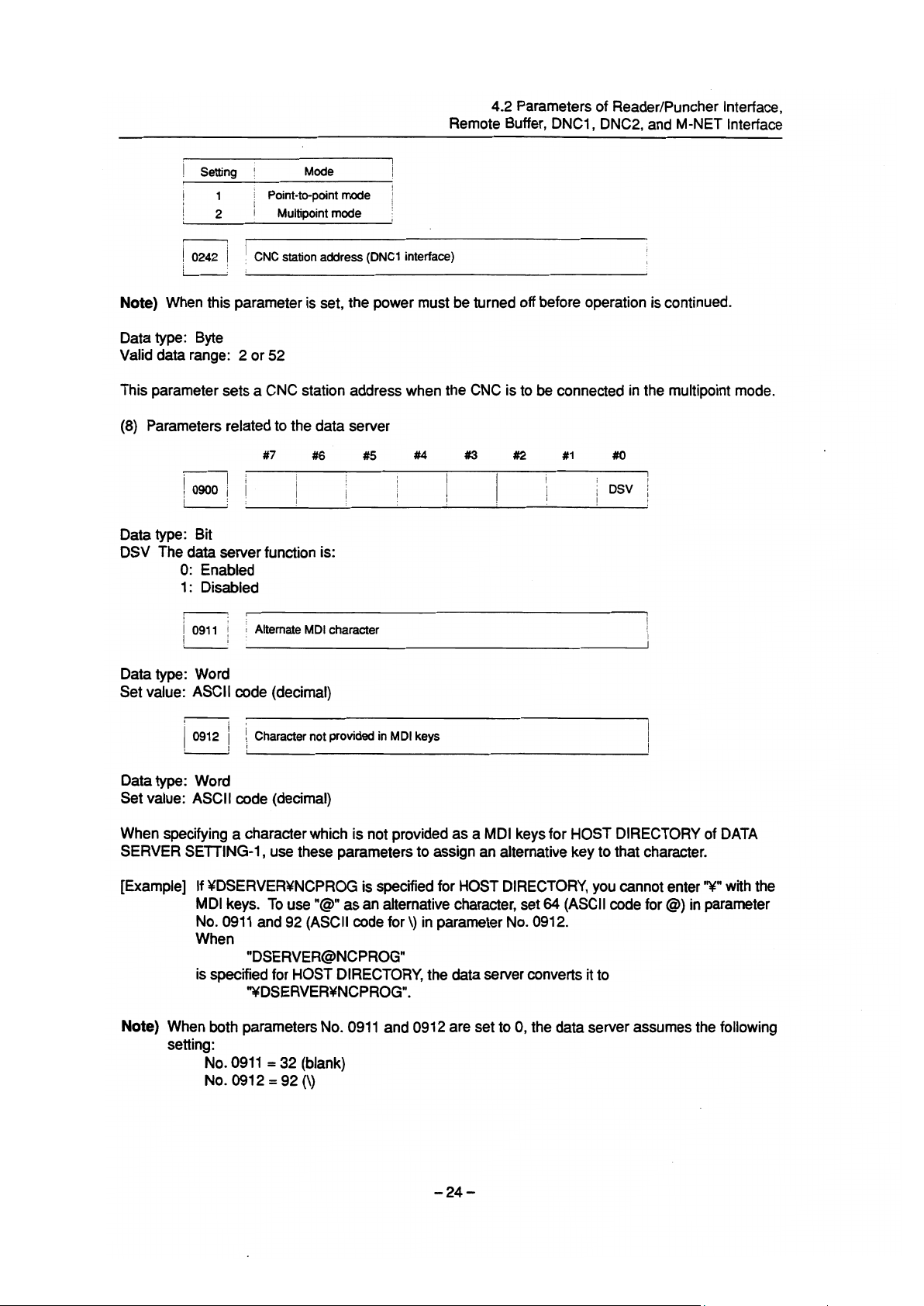

Parameters of High-Speed Machining (High-Speed Cycle

Machining/High-Speed Remote Buffer) ............................................................................

4.41

Parameters of Polygon Turning ........................................................................................

4.42

Parameters of the External Pulse Input ............................................................................

4.43

Parameters of the Hobbing Machine and Electronic Gear Box

4.44

Parameters of Axis Control by PMC .................................................................................

4.45

Parameters of Two-path Control

4.46

Parameters for Checking Interference between Tool Posts (Two-path Control)

4.47

Parameters Related to Path Axis Reassignment

4.48

Parameters for Angular Axis Control ................................................................................

4.49

Parameters Related to B-Axis Control ..............................................................................

4.50

Parameters of Simple Synchronous Control ....................................................................

4.51

Parameters of Related to Check Termination ..................................................................

4.52

Parameters of High-Speed High-Precision Contour Control by RISC (16 MB)

Other Parameters

4.53

4.54

Parameters for Maintenance

APPENDIX 1 CHARACTER CODE LIST

..................................................................................................................

.......................................................................................

......................................................................................

.............................................................................................................

............................................................................................

.........................................................................

............................................

........................................................................

........................................

.............................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..............

................

196

199

200

202

204

206

207

209

212

212

216

220

221

223

232

233

236

239

240

245

248

249

Page 6

I.

DISPLAYING PARAMETERS

1 l DISPLAYING PARAMETERS

Follow the procedure below to display parameters.

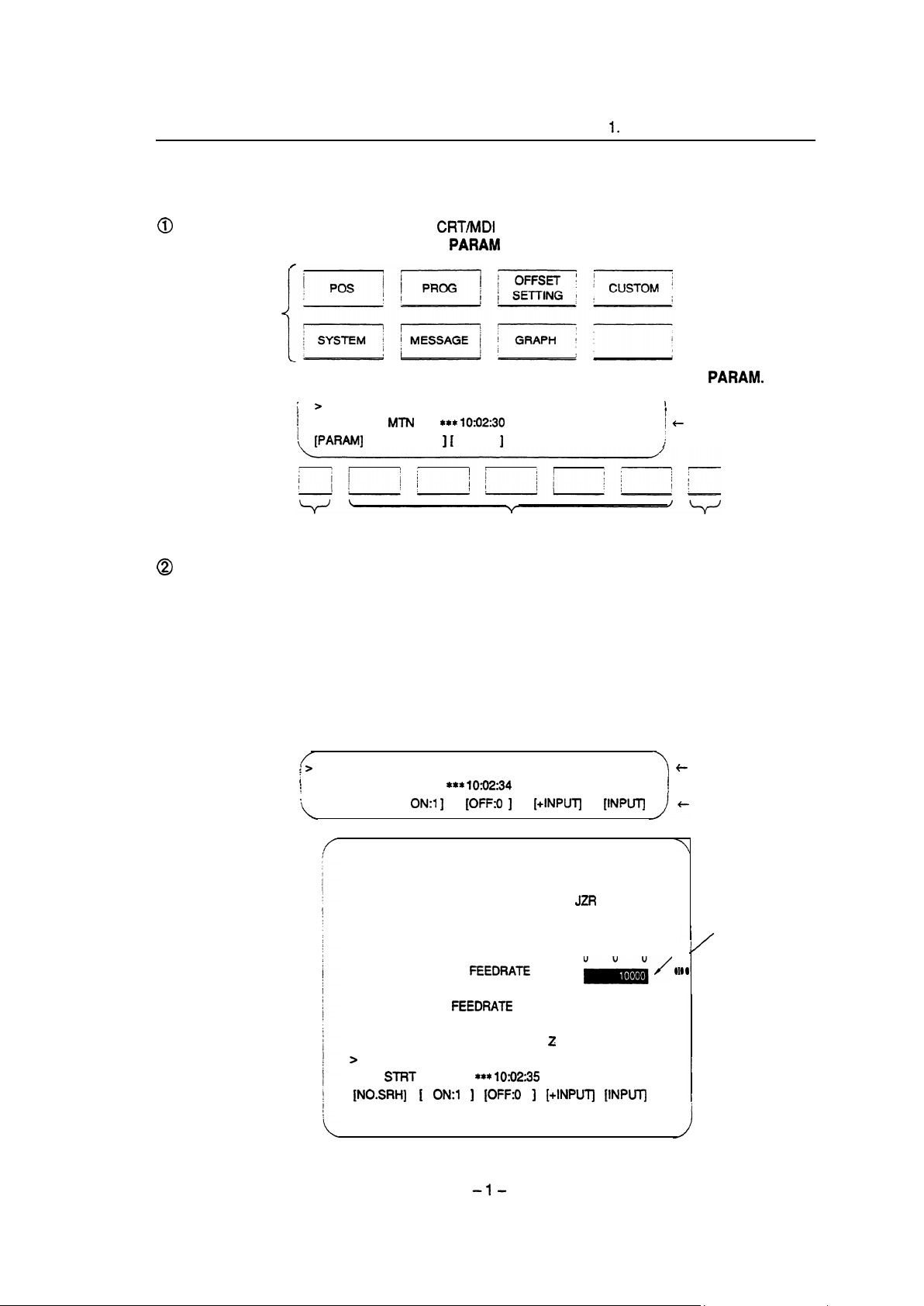

@

Press the SYSTEM function key on the

the SYSTEM function key once, then the

then selected.

Function keys

Note)

Pressing the SYSTEM function key displays section select soft keys including

CRT/MD1

PARAM

as many times as required, or alternatively, press

section select soft key. The parameter screen is

PARAM.

: >

I

i

MEM STRT

[PARAM]

Return menu key Soft keys Continuous menu key

@

The parameter screen consists of multiple pages. Use step (a) or (b) to display the page that contains

Ml-N

FIN

*** lOzO2:30

[ DGNOS ] [ PMC ][SYSTEM] [(OPRT)]

I

Soft

/t

(section select)

j

key display

the parameter you want to display.

Use the page select key or the cursor move keys to display the desired page.

(a)

(b)

Enter the data number of the parameter you want to display from the keyboard, then press the

NO.SRH soft

key. The parameter page containing the specified data number appears with the

cursor positioned at the data number. (The data is displayed in reverse video.)

Note)

If key entry is started with the section select soft keys displayed, they are replaced automatically

by operation select soft keys including

NO.SRH.

Pressing the (OPRT) soft key can also cause the

operation select keys to be displayed.

/

i >

1410

i

i

MEM STRT MTN FIN

\

[NO. SRH][ ON:1 ]

*** lOzO2:34

[OFF:0 ]

[+INPUTJ [INPUTJ

Data

f-

\

the keyboard

1

Soft key display

(operation select)

entered from

PARAMETER (FEEDRATE) 00001 NO0010

1401

1402

1410 DRY

1412

1420 RAPID

>

MEM

STRT

[NOSRH] [

RDR

0 0 0 0

JRV

0 0 0 0

RUN

FEEDRATE

FEEDRATE X

MTN FIN

*** 10102:35

ON:1 ] [OFF:0 ] [+INPUTJ [INPUT)

JZR

0

0

Y

z

0 0 0

0 0 0

-/

RPD

09

0

15000

15000

15000

Cursor

/

0

Page 7

2. SETTING PARAMETERS FROM MDI

Follow the procedure below to set parameters.

2.

SETTING PARAMETERS FROM MDI

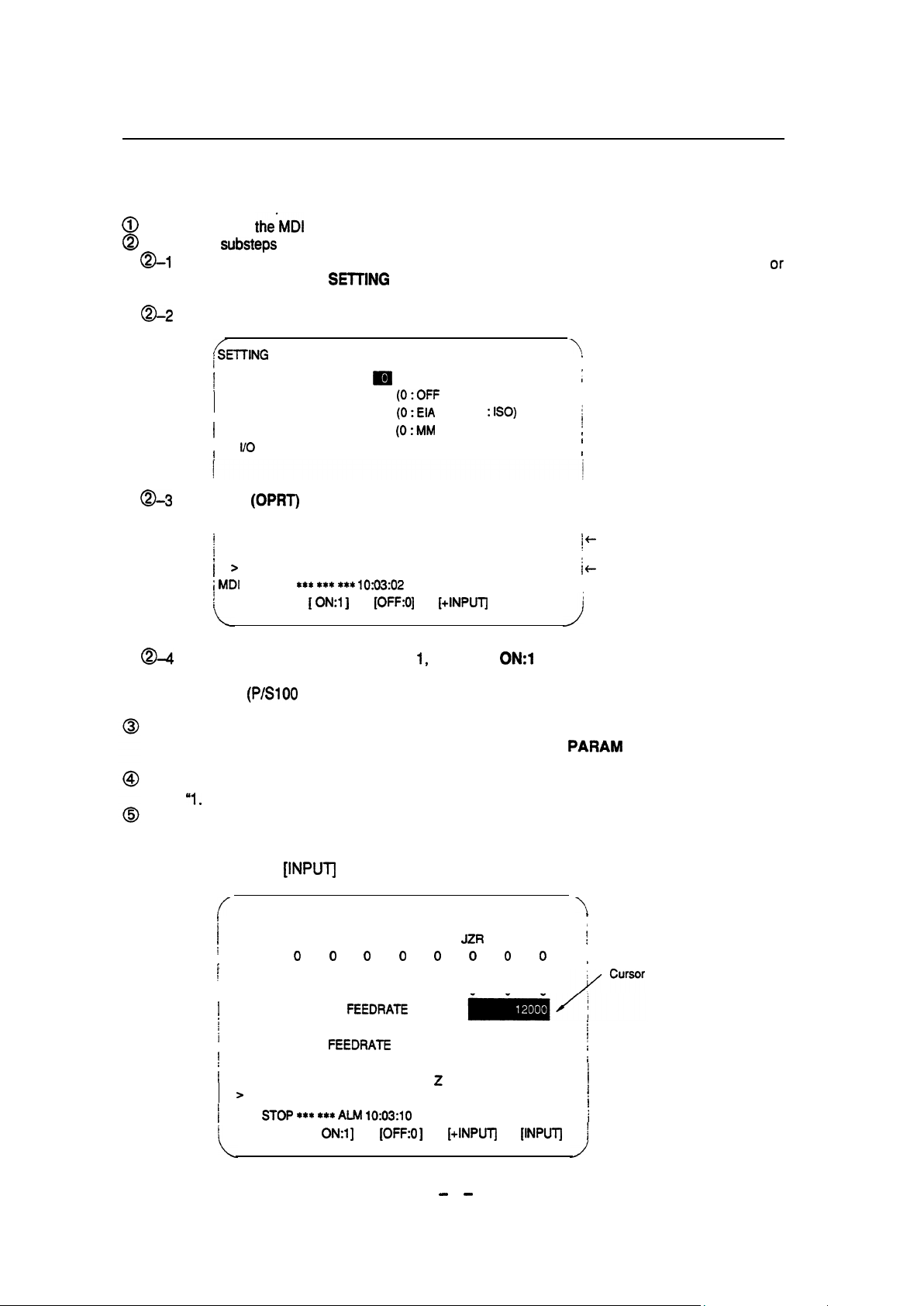

@@Place the NC in

Follow the

@I

substeps

To display the setting screen, press the SETTING function key as many times

alternatively press the

The first page of the setting screen appears.

Position the cursor on “PARAMETER WRITE” using the cursor move keys.

B-2

f

I

SElTlNG (HANDY)

I

PARAMETER WRITE = m (0 : DISABLE 1 : ENABLE)

’

/

TV CHECK

PUNCH CODE

I

INPUT UNIT

I

i

l/O

I

a-3

Press the

i

i

>

1410

I

i

MDI

STOP

i

[NO. SRH]\[ ON:1 ]

Q-4

To set “PARAMETER WRITE=” to I, press the

press the INPUT soft key. From now on, the parameters can be set. At the same time an alarm

condition

(P/S100

the’MDI

mode or the emergency stop state.

below to enable writing of parameters.

CHANNEL

(OPRT)

***

SETTING

soft key to display operation select soft keys.

*s*

*** 10:03:02

function key once, then the SETTING section select soft key.

00001 NO0010

[+lNPUT]

1 :ON)

1

: ISO)

1 : INCH)

[INPUTJ

ON:1

soft key, or alternatively enter 1 and

= 0

(0:OFF

= 0

(0:ElA

= 0 (0:MM

= 0 (O-3 : CHANNEL NO.)

[OFF:01

PARAMETER WRITE ENABLE) occurs in the CNC.

as required,

\

s

;

I

,

1

1

I

I

1 +

Data entered from the keyboard

i +

Soft key display (operation select)

or

To display the parameter screen, press the

SYSTEM

function key as many times as required, or

alternatively press the SYSTEM function key once, then the

(See “I. Displaying Parameters.“)

Display the page containing the parameter you

(See

“I.

Displaying Parameters.“)

Enter data, then press the

INPUT soft

key. The parameter indicated by the cursor is set to the entered

want

to set, and position the cursor on the parameter.

data.

[Example] 12000

f

I

PARAMETER (FEEDRATE)

I

I

i

;

i

I

I

i

I

i

i

i

f

I

>

1

MDI

[NO. SRH][ ON:1 ]

[INPUTJ

1401

0

1402

0

1410

DRY RUN

1412

1420 RAPID

SVOP

*** **= ALM 10:03:10

RDR

0 0 0 0

JRV

0 0

FEEDRATE

FEEDRATE

0 0

[OFF:0 ]

00001 NO0010

JZR

0

0

X

Y

2

[+INPUTj [INPUTJ j

RPD

0 0

0 0

0

15000

15000

15000

PARAM

\

’

I

j

I

f

/

i

I

i

I

1

8

t

i

I

section select soft key.

- -

2

Page 8

2.

SETTING PARAMETERS FROM MDI

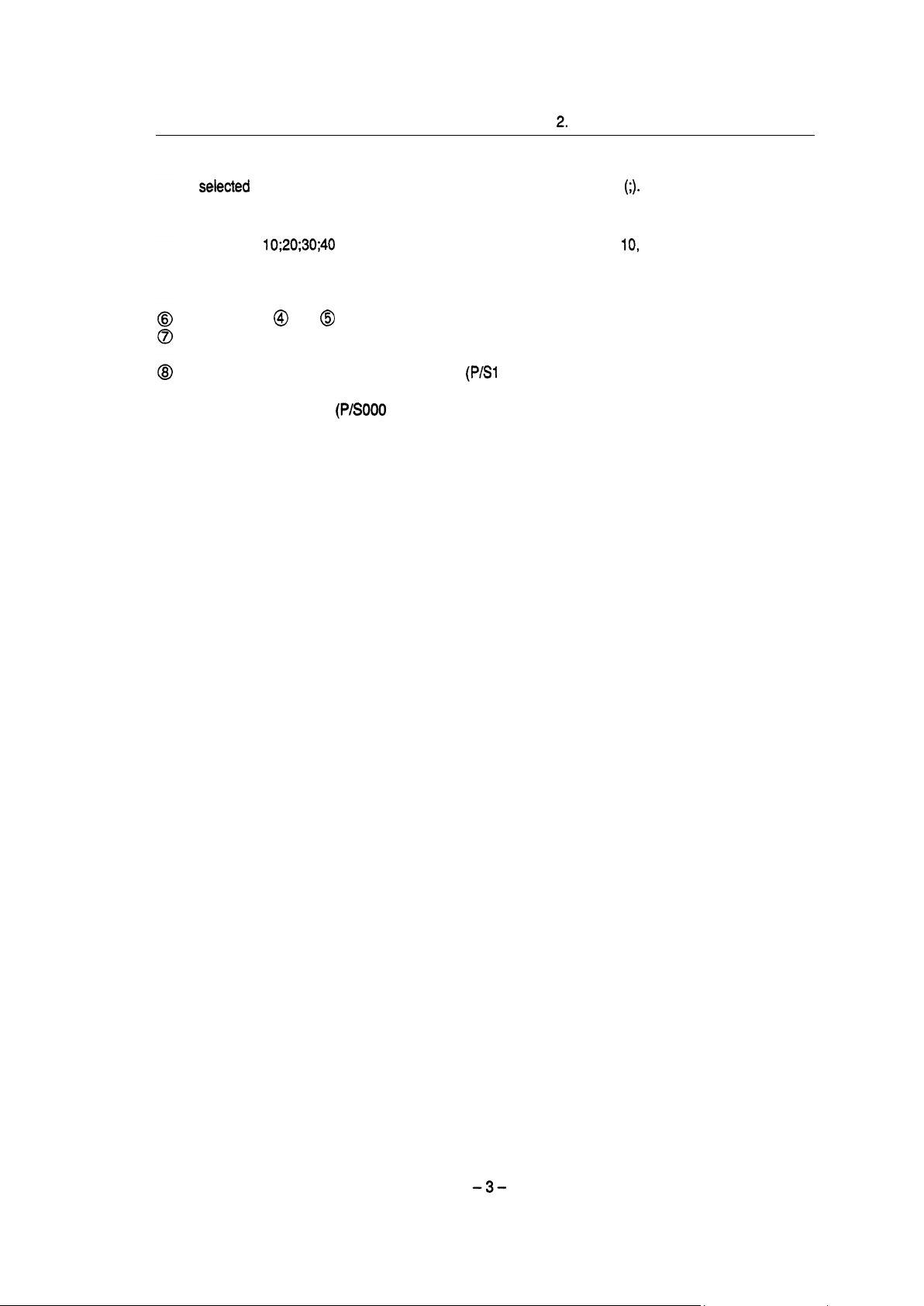

Data can be entered continuously for parameters, starting at the

seiected

parameter, by separating each data

item

with a semicolon

(;).

[Example]

Entering

20, 30, and 40 to parameters in order starting at the parameter

indicated by the

Repeat steps @ and @ as required.

If parameter setting is complete, set

further

Reset

10;20;30;40

and

pressing the INPUT key assigns values

cursor.

“PARAMETER

parameter setting.

the NC to release the alarm condition

(P/S1

IO,

WRITE=” to 0 on the setting screen to disable

00).

If an alarm condition

continuing operation.

Note) The bits left blank in4. DESCRIPTION OF PARAMETERS and the parameter numbers that appear

on the CRT screen but are not found in the parameter list are resewed for future expansion. They

must always be 0.

(P/SO00

PLEASE TURN OFF

POWER)

occurs in the NC, turn it off before

Page 9

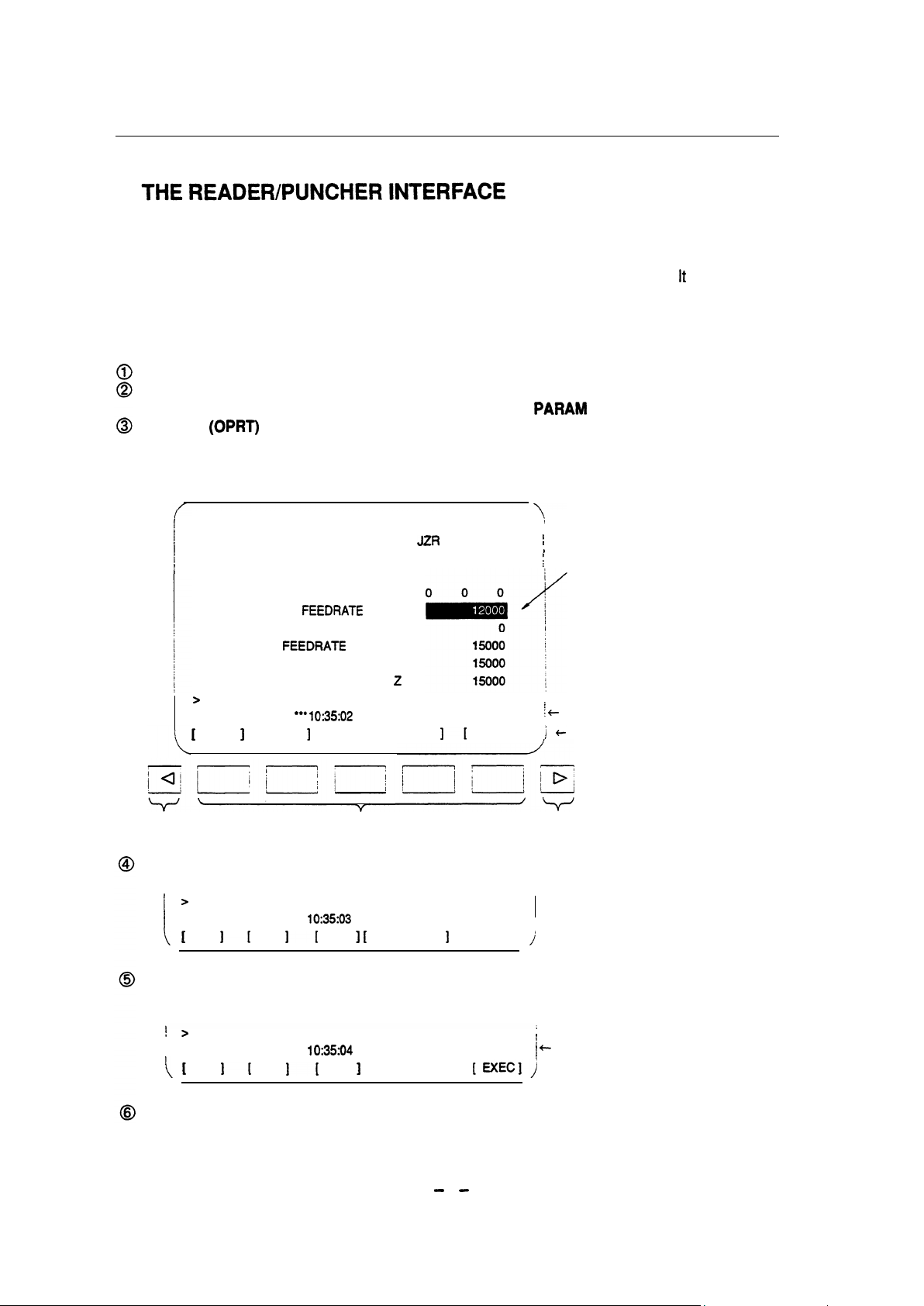

3. INPUTTING AND OUTPUTTING PARAMETERS THROUGH

THE READER/PUNCHER INTERFACE

3. INPUTTING AND OUTPUTTING PARAMETERS THROUGH

This section explains the parameter input/output procedures for input/output devices connected to the

reader/puncher interface.

It

The following description assumes the input/output devices are ready for input/output.

parameters peculiar to the input/output devices, such as the baud rate and the number of stop bits, have

been set in advance.

3.1 Outputting Parameters through the Reader/Puncher Interface

Select the EDIT mode.

To select the parameter screen, press the SYSTEM function key as many times as required, or

alternatively press the SYSTEM function key once, then the PARAM section select soft key.

Press the

located at the right-hand side of the soft keys to display another set of operation select keys including

PUNCH.

(OPRT)

soft key to display operation select soft keys, then press the forward menu key

also assumes

PARAMETER (FEEDRATE)

1401

1402 JRV

1410 DRY RUN

1412

1420 RAPID

RDR

0 0

0 0

FEEDRATE

FEEDRATE X

0

0

0 0

0 0

Y

z

00001 NO0010

JtR

0 0 0

RPD

\

I

0

;

Cursor

>

! t

EDIT STOP l ** l -*

[

Return menu key

*-+ lo:3502

]

[READ ] [PUNCH] [

Soft keys

I[

1

Continuous menu key

State display

c- Soft key display (operation select)

Pressing the PUNCH soft key changes the soft key display as shown below:

>

I

1

EDIT STOP l ** l ** l **

II

\ [

I[

lo:3503

] [

CANCEL

]

[ EXEC]

/

Press the EXEC soft key to start parameter output. When parameters are being output, “OUTPUT”

blinks in the state display field on the lower part of the screen.

!

>

EDIT STOPl *+ l +* l **

I

I[

i

11

t 0:35:04

OUTPUT

]

[CANCEL]

[EXEC],j

t

1 +

OUTPUT blinking

When parameter output terminates, “OUTPUT” stops blinking. Press the RESET key to interrupt

parameter output.

- -

4

Page 10

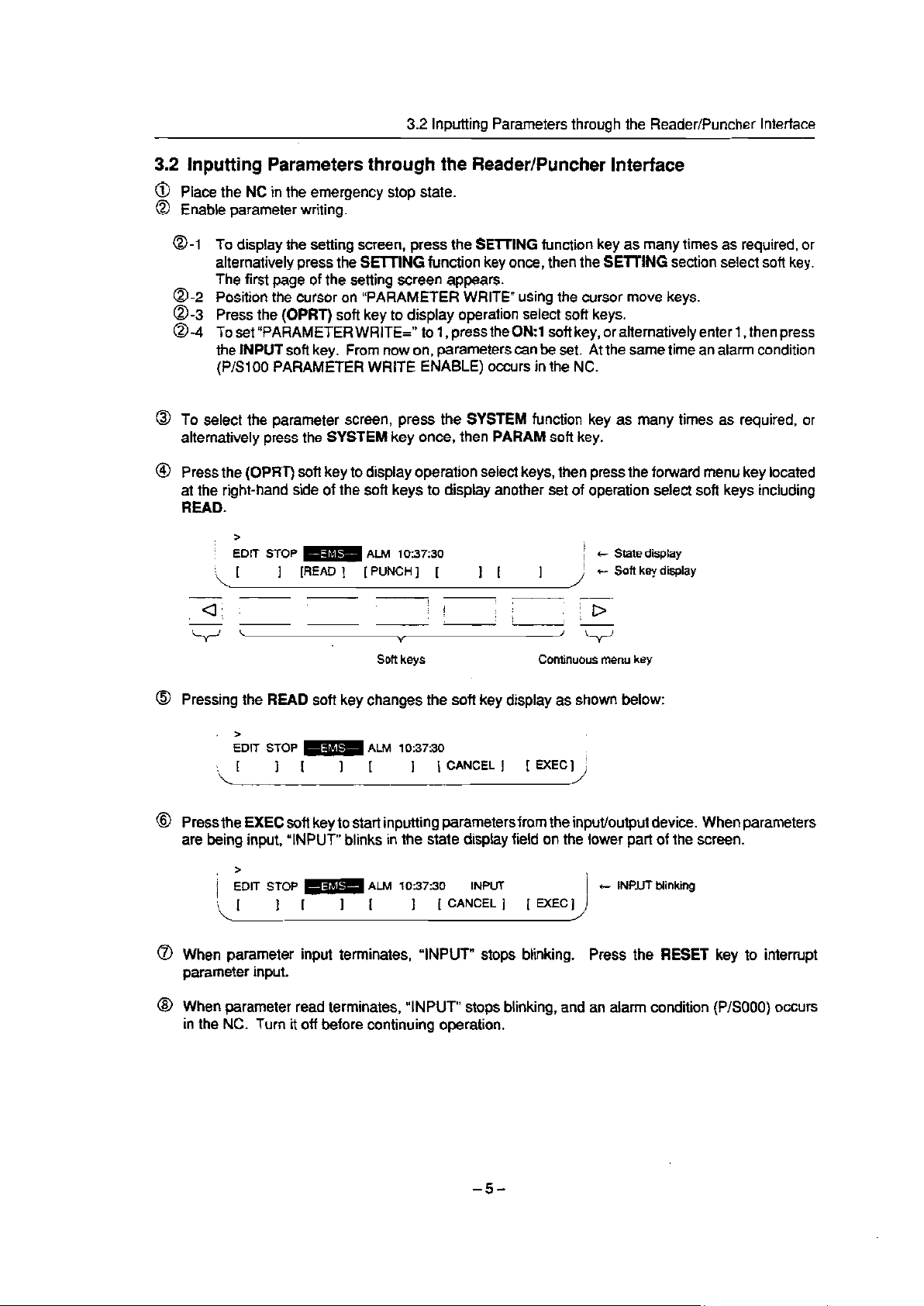

3.2 Inputting Parameters through the Reader/Puncher interface

3.2 Inputting Parameters through the Reader/Puncher Interface

Place the NC in the emergency stop state.

@

0 Enable parameter writing.

To display the setting screen, press the SETTING function key as many times as required, or

alternatively press the SElTlNG function key once, then the SETTING section select soft key.

The first page of the setting screen appears.

Position the cursor on “PARAMETER WRITE” using the cursor move keys.

Press the (OPRT) soft key to display operation select soft keys.

To set “PARAMETER WRITE=” to 1, press the ON:1 soft key, or alternatively enter 1, then press

the INPUT soft key. From now on, parameters can be set. At the same time an alarm condition

(P/S100 PARAMETER WRITE ENABLE) occurs in the NC.

To select the parameter screen, press the SYSTEM function key as many times as required, or

alternatively press the SYSTEM key once, then PARAM soft key.

Press the (OPRT) soft key to display operation select keys, then press the forward menu key located

at the right-hand side of the soft keys to display another set of operation select soft keys including

READ.

>

j

, EDIT STOP m A!Jvl 10:37:30

i

1 [READ I [PUNCH1 [ I 1

[

Soft keys

i

I c- State display

I

Soft key display

1

Continuous menu key

t

Pressing the READ soft key changes the soft key display as shown below:

I

: EDIT STOP - Altv’l 10:37:30

11 3 1

] [ CANCEL

[

EXEC]

]

I

/

Press the EXEC soft key to start inputting parameters from the input/output device. When parameters

are being input, “INPUT” blinks in the state display field on the lower part of the screen.

>

j EDIT STOP - Al&l 10:37:30

II II

]

INPUT

[CANCEL] [EXEC])

When parameter input terminates, “INPUT” stops blinking.

I

1 t INPUT blinking

Press the RESET key to interrupt

parameter input.

When parameter read terminates, “INPUT” stops blinking, and an alarm condition (P/SOOO) occurs

in the NC. Turn it off before continuing operation.

Page 11

4. DESCRIPTION OF PARAMETERS

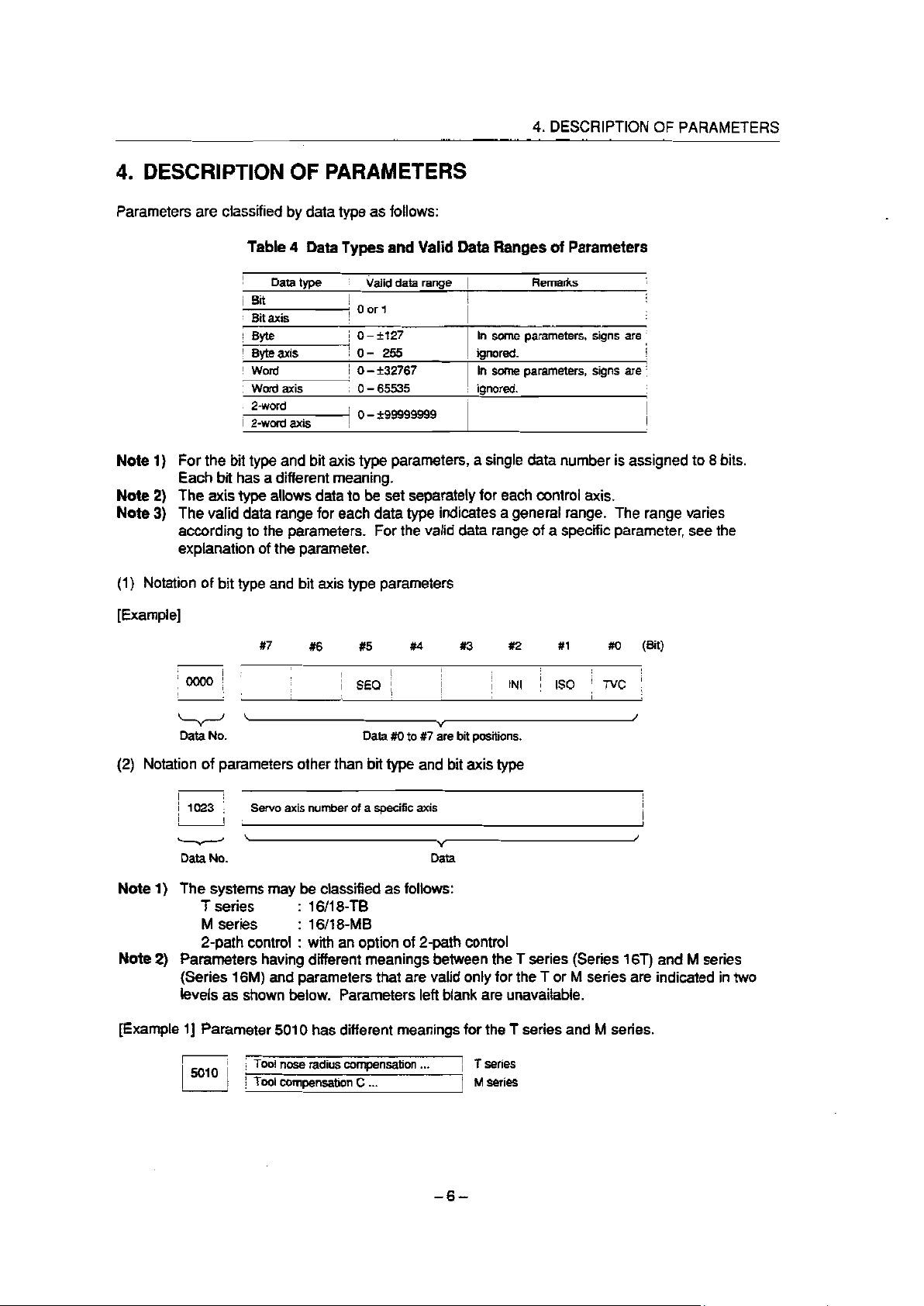

Parameters are classified by data type as follows:

Table 4 Data Types and Valid Data Ranges of Parameters

!

4

Data type

1 Bit

: Bit axis

iv*

b

(

Byteaxis

I

I word

I

:

Word axis

l 2-word

i 2-word axis

i

hddata range [

I

1 Oorl

t

i O-+127

! o- 255

1 0 - k32767

i 0 - 65535

I

1 0 -299999999

I

4. DESCRIPTION OF PARAMETERS

Remarks

1

I

In some parameters, signs are

ignored.

In some parameters, signs are !

ignored.

;

I

0

:

I

1

j

1

4

8

i

I

Note 1)

For the bit type and bit axis type parameters, a single data number is assigned to 8 bits.

Each bit has a different meaning.

Note 2)

Note 3)

The axis type allows data to be set separately for each control axis.

The valid data range for each data type indicates a general range. The range varies

according to the parameters. For the valid data range of a specific parameter, see the

explanation of the parameter.

(1) Notation of bit type and bit axis type parameters

[Example]

l

(W

I

1

j i

I

IoooOi :

; 1.

#7

#6

I

,

t I

#5

I

i SEQ ;

##4 ##3 #2 #1

I

I

/

I

I

i

1 IN1

/

##O

/

i IS0 / Tvc ;

I I

I

\

Data No. Data ##0 to #y7 are bit positions.

(2) Notation of parameters other than bit type and bit axis type

;

I :

I

1

1023 ; ; Servo axis number of a specific axis

I

I i

Data No. Data

t

!

I

Note 1) The systems may be classified as follows:

T series : 16/l 8-TB

M series : 16/l 8-MB

2-path control : with an option of 2-path control

Note 2) Parameters having different meanings between the T series (Series 16T) and M series

(Series 16M) and parameters that are valid only for the T or M series are indicated in two

levels as shown below. Parameters left blank are unavailable.

[Example l] Parameter 5010 has different meanings for the T series and M series.

I

5010 I

8

i Tool nose radius compensation ..;

! Tool compensation C . . .

)

- -

1 T

1 M series

6

series

Page 12

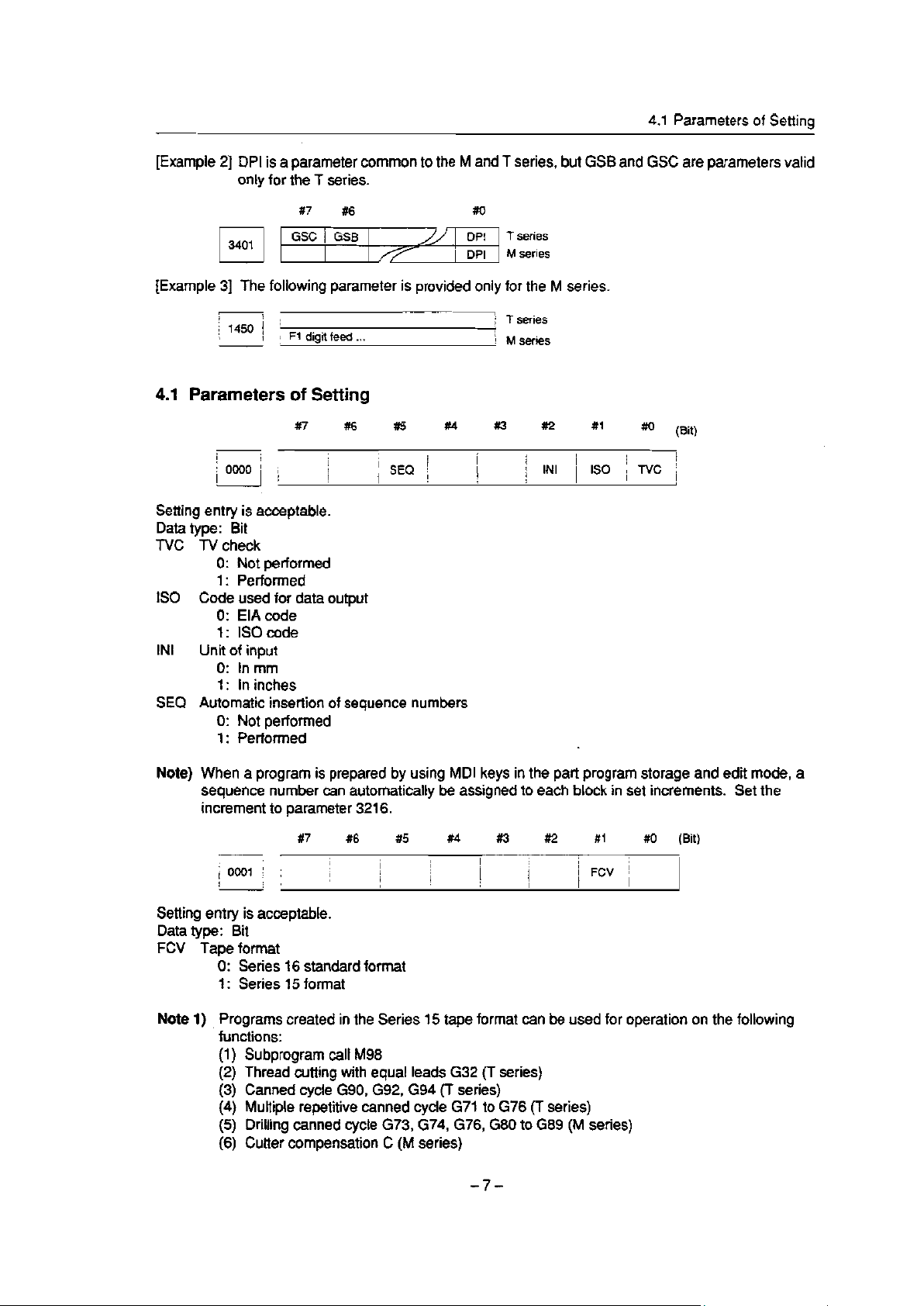

4.1 Parameters of Setting

[Example 21 DPI is a parameter common to the M and T series, but GSB and GSC are parameters valid

only for the T series.

157 #6

GSC GSB

#O

T series

M series

[Example 31 The following parameter is provided only for the M series.

,

i ’

I

’ ;

;14501 :

-

; Fl digit feed . . .

I

i T series

i M series

4.1 Parameters of Setting

#?

#6

Setting entry is acceptable.

Data type: Bit

TVC

TV check

0: Not performed

1: Performed

IS0

Code used for data output

0: EIA code

1: IS0 code

INI

Unit of input

0: In mm

1: In inches

Automatic insertion of sequence numbers

SEQ

0: Not performed

1: Performed

#5

##4 #3 #2 #I

.

#O i

(W

When a program is prepared by using MDI keys in the part program storage and edit mode, a

Note)

sequence number can automatically be assigned to each block in set increments. Set the

increment to parameter 3216.

#l #O i

I

FCV !

I

!

I

i

I

(W

j 0001 ; ;

: 8

I

L

#7 #6 I#5

6

j

I

I

/

#4

I

j

#3 #2

!

j

I

I

I

Setting entry is acceptable.

Data type: Bit

FCV Tape format

0: Series 16 standard format

1: Series 15 format

Note I)

Programs created in the Series 15 tape format can be used for operation on the following

functions:

Subprogram call M98

(1)

Thread cutting with equal leads G32 (T series)

(2)

Canned cycle G90, G92, G94 (T series)

(3)

Multiple repetitive canned cycle G71 to G76 (T series)

(4)

Drilling canned cycle G73, G74, G76, G80 to G89 (M series)

(5)

Cutter compensation C (M series)

(6)

Page 13

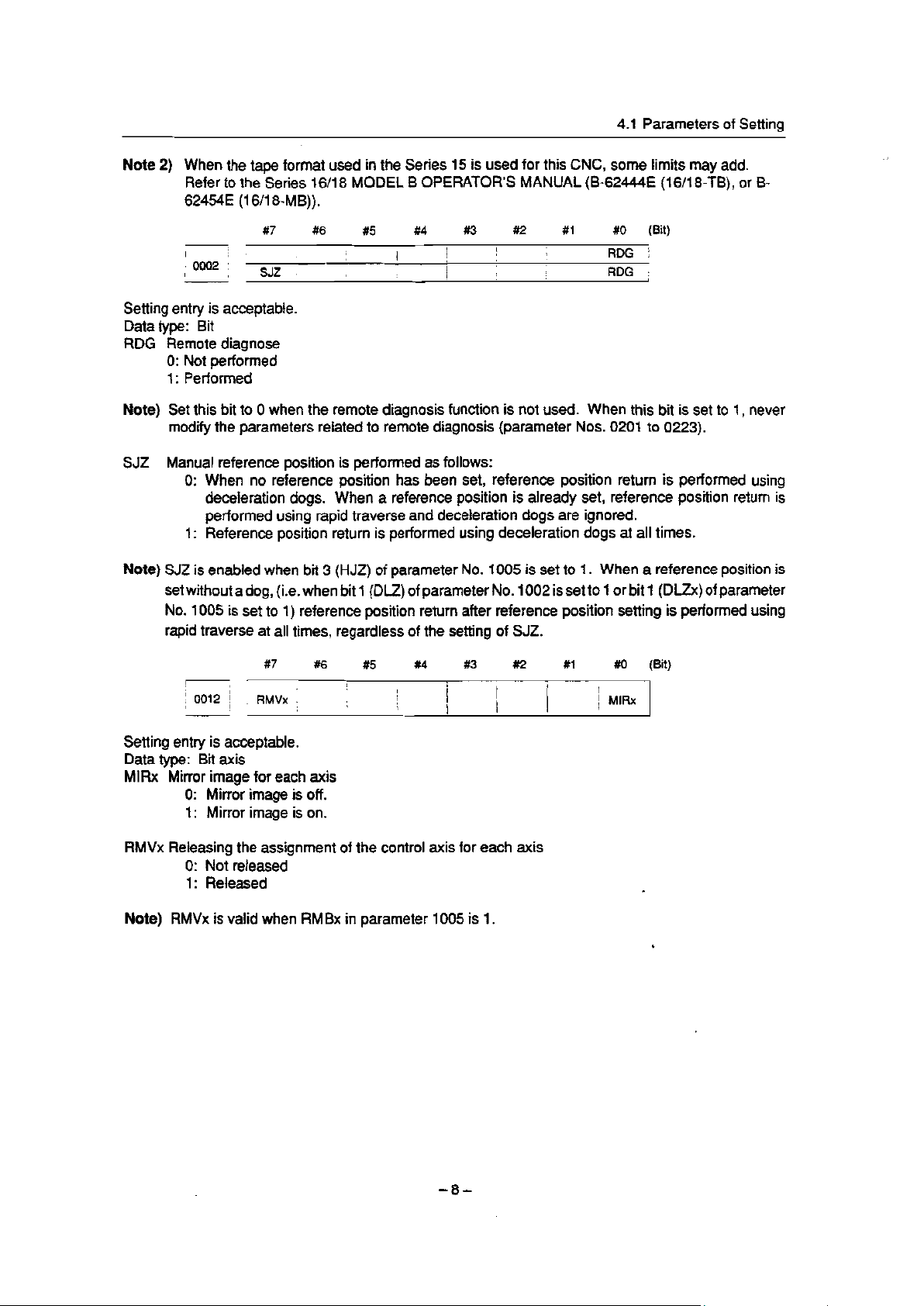

4.1 Parameters of Setting

Note 2) When the tape format used in the Series 15 is used for this CNC, some limits may add.

Refer to the Series 16/l 8 MODEL B OPERATOR’S MANUAL (B-62444E (16/l 8-TB), or B-

62454E (16/l 8-MB)).

RDG :

(Bit)

,

I

I

’ 0002 i , sJz f

I

#7

i :

!

#6

#5 #4

i

I

#3 #2

1

,

I ! j

I

I

1

,

#l #O

I

I

’ RDG j

Setting entry is acceptable.

Data type: Bit

RDG Remote diagnose

0: Not performed

1: Performed

Note) Set this bit to 0 when the remote diagnosis function is not used. When this bit is set to 1, never

modify the parameters reiated to remote diagnosis (parameter Nos. 0201 to 0223).

SJZ Manual reference position is performed as follows:

0: When no reference position has been set, reference position return is performed using

deceleration dogs. When a reference position is already set, reference position return is

performed using rapid traverse and deceleration dogs are ignored.

1: Reference position return is performed using deceleration dogs at all times.

Note) SJZ is enabled when bit 3

(HJZ) of parameter No. 1005 is set to 1. When a reference position is

set without a dog, (i.e. when bit 1 (DLZ) of parameter No. 1002 is set to 1 or bit 1 (DLZx) of parameter

No. 1005 is set to 1) reference position return after reference position setting is performed using

rapid traverse at all times, regardless of the setting of SJZ.

#7 #6 #5

I

/ 0012 ! ; RMVx j

:

/

!

I

I

I

i

\

##4 #3 #I2 #l #0 i

I

1

I

,

I

I

I

I

!

1 MRx

(B t)

Setting entry is acceptable.

Data type: Bit axis

MlFIx Mirror image for each axis

0: Mirror image is off.

1: Mirror image is on.

RMVx Releasing the assignment of the control axis for each axis

0: Not released

1: Released

Note) RMVx is valid when RMBx in parameter 1005 is 1.

- -

8

Page 14

4.1 Parameters of Setting

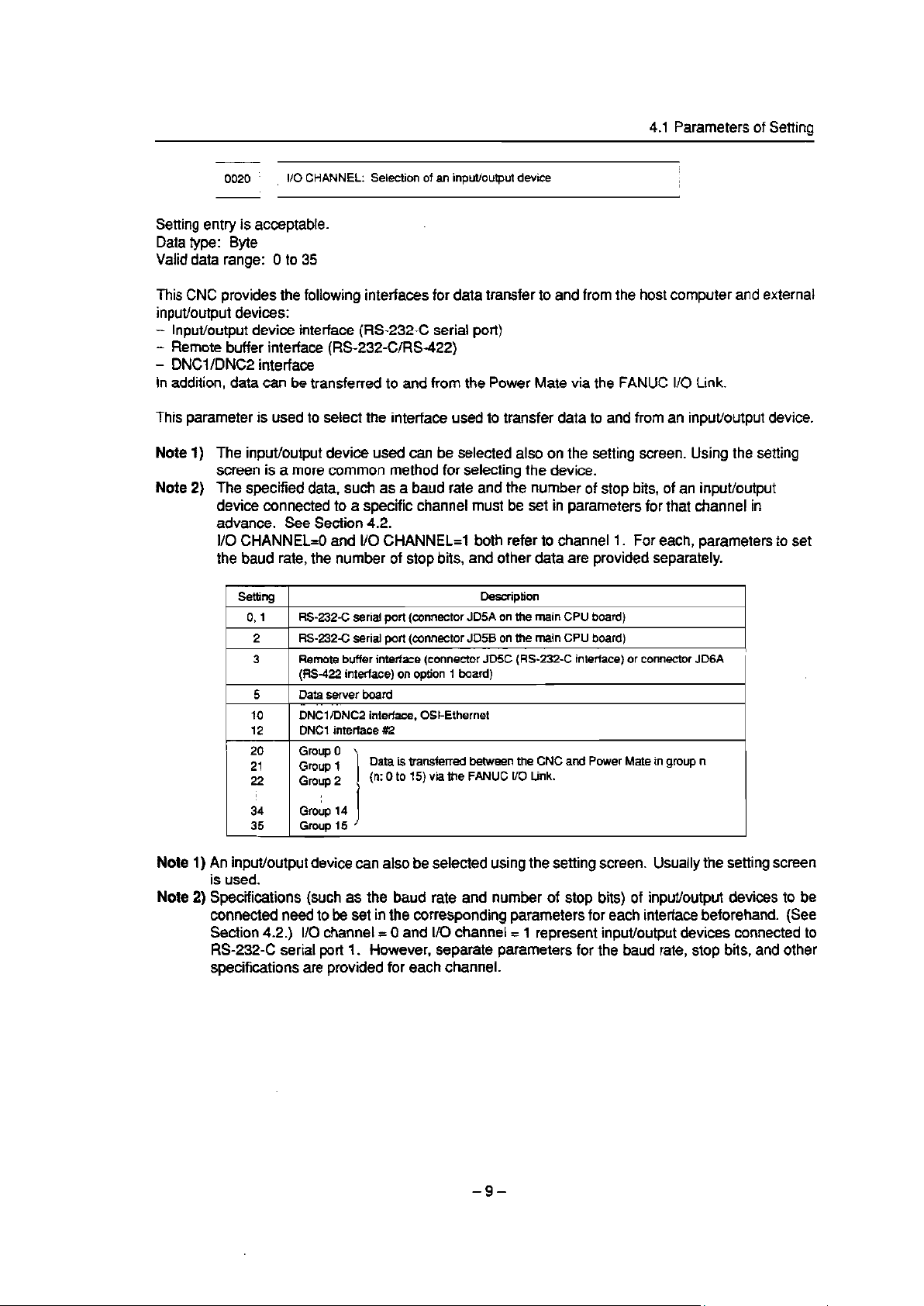

0020 !

l/O CHANNEL: Selection of an input/output device

I

i

Setting entry is acceptable.

Data type: Byte

Valid data range: 0 to 35

This CNC provides the following interfaces for data transfer to and from the host computer and external

input/output devices:

- Input/output device interface (RS-232-C serial port)

- Remote buffer interface (RS-232.CYRS-422)

- DNCl /DNC2 interface

In addition, data can be transferred to and from the Power Mate via the FANUC I/O Link.

This parameter is used to select the interface used to transfer data to and from an input/output device.

Note 1)

The input/output device used can be selected also on the setting screen. Using the setting

screen is a more common method for selecting the device.

Note 2)

The specified data, such as a baud rate and the number of stop bits, of an input/output

device connected to a specific channel must be set in parameters for that channel in

advance. See Section 4.2.

I/O CHANNEL=0 and l/O CHANNEL=1 both refer to channel I. For each, parameters to set

the baud rate, the number of stop bits, and other data are provided separately.

[

Setting r

1 k-232-C serial port (connector JD5A on the main CPU board)

091

I ~~~ ~~~

2 I RS-232-C serial port (connector JD5B on the main CPU board)

I

Remote buffer interface (connector JDSC (RS-232-C interface) or connector JDGA

I 3 I

1 5 1 Dataserver board

20

21

22

(RS-422 interface) on option 1 board)

DNWDNC2 interface, OSI-Ethernet

DNCl interface #2

Group 0

Group 1

Group 2

Data is transferred between the CNC and Power Mate in group n

(n: 0 to 15) via the FANUC l/O Link.

Description

I

I

I

I

I

34

35

GroLp 14

Group 15

I

Note 1) An input/output device can also be selected using the setting screen. Usually the setting screen

is used.

Note 2) Specifications (such as the baud rate and number of stop bits) of input/output devices to be

connected need to be set in the corresponding parameters for each interface beforehand. (See

Section 4.2.) I/O channel = 0 and l/O channel =

1 represent input/output devices connected to

RS-232-C serial port I. However, separate parameters for the baud rate, stop bits, and other

specifications are provided for each channel.

- -

9

Page 15

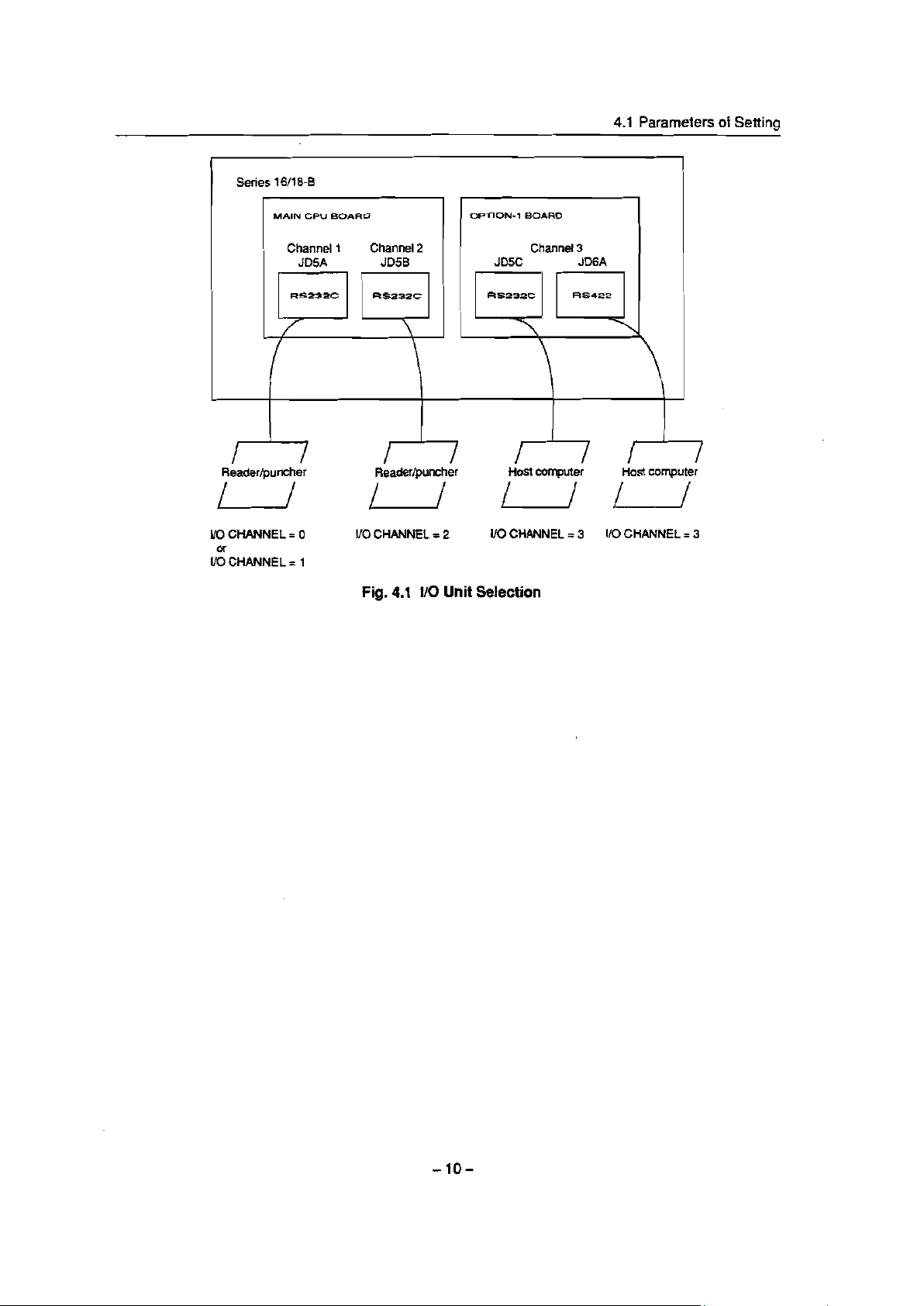

Series 16/l 8-B

4.1 Parameters of Seth

Reader/puncher

l/O CHANNEL = 0

l/&HANNEL = 1

Reader/puncher Host computer

Host computer

u uu

l/O CHANNEL = 2 VO CHANNEL = 3 I/O CHANNEL = 3

Fig. 4.1 l/O Unit Selection

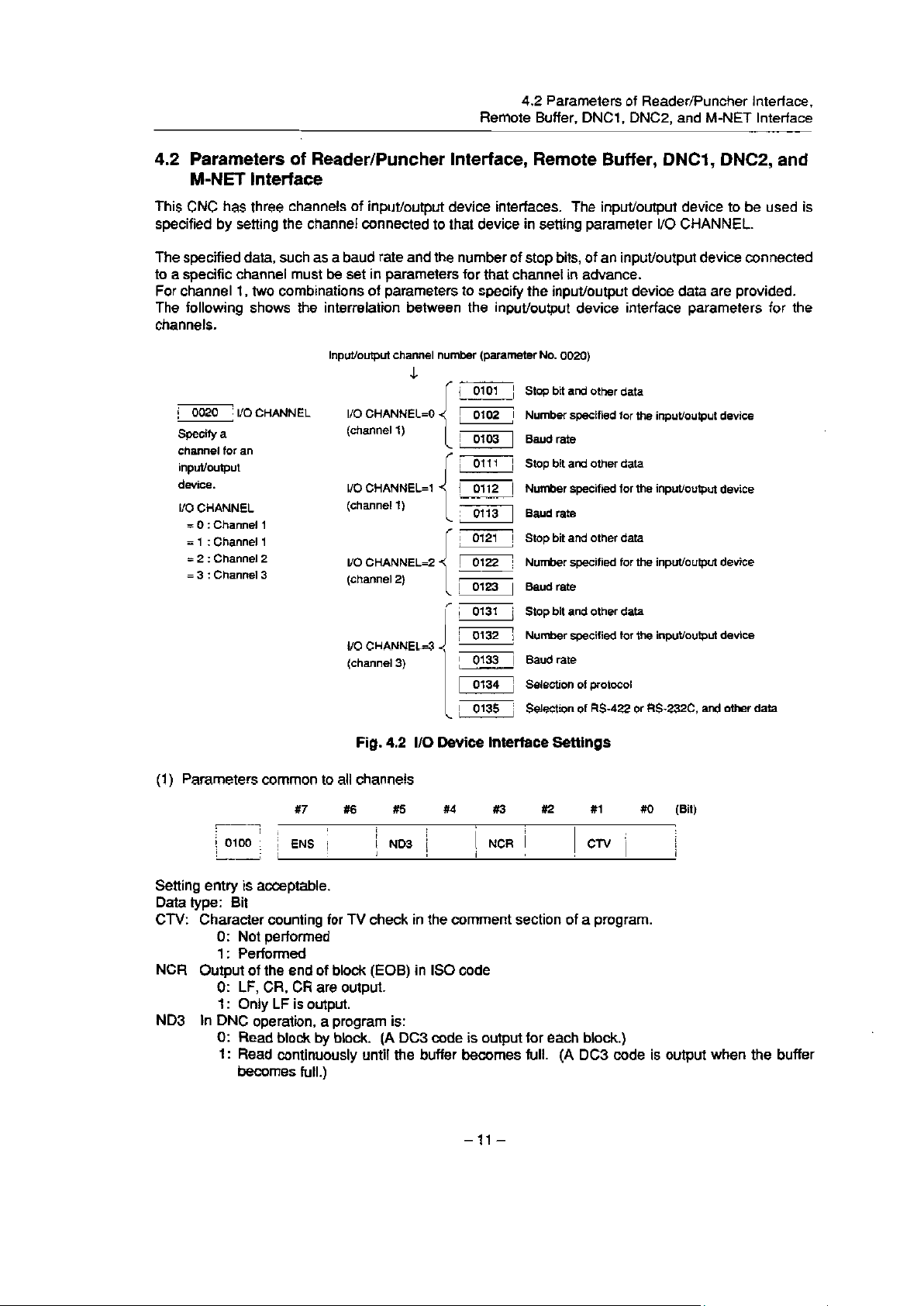

Page 16

4.2 Parameters of Reader/Puncher Interface,

Remote Buffer, DNCl, DNCZ, and M-NET Interface

4.2 Parameters of Reader/Puncher Interface, Remote Buffer, DNCl, DNC2, and

M-NET interface

This CNC has three channels of input/output device interfaces. The input/output device to be used is

specified by setting the channel connected to that device in setting parameter 110 CHANNEL.

The specified data, such as a baud rate and the number of stop bits, of an input/output device connected

to a specific channel must be set in parameters for that channel in advance.

For channel 1, two combinations of parameters to specify the input/output device data are provided.

The following shows the interrelation between the input/output device interface parameters for the

channels.

Input/output channel number (parameter No. 0020)

Stop bit and other data

! 0020 i I/O CHANNEL

Specify a

channel for an

input/output

device.

I/O CHANNEL

= 0 : Channel

= 1 :

Channel

: Channel

= 2

: Channel 3

3

=

1

1

2

I/O CHANNEL=0

(channel 1)

l/O CHANNEL=1

(channel 1)

l/O CHANNEL=2

j

iT/

I

Number specified for the input/output device

Baud rate

Stop bit and other data

Number specified for the input/output device

Baud rate

Stop bit and other data

Number specified for the input/output device

Baud rate

Stop bit and other data

Number specified for the input/output device

Baud rate

Selection of protocol

Selection of M-422 or RS232C, and other data

Fig. 4.2 I/O Device Interface Settings

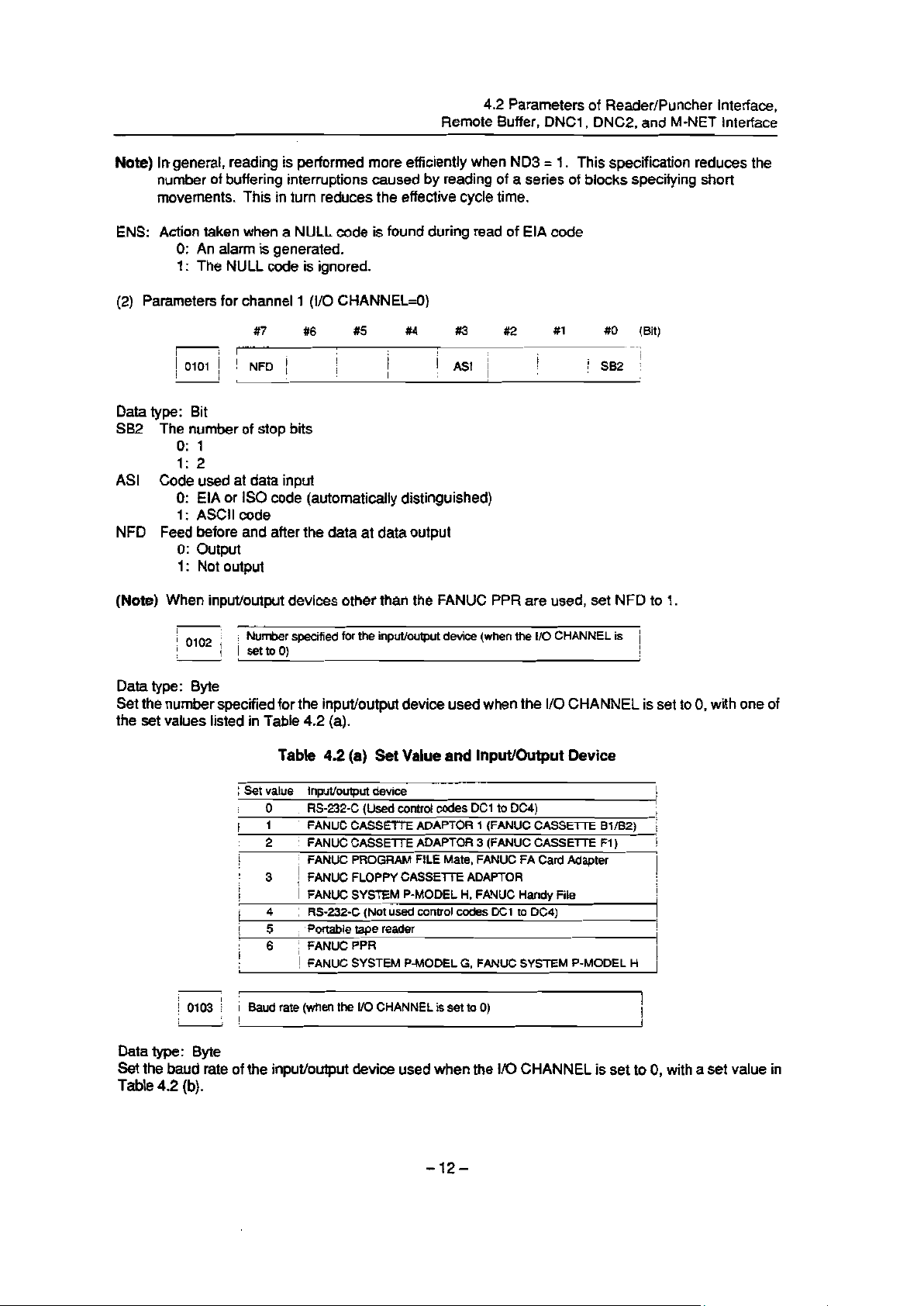

(1) Parameters common to all channels

, 1

9

/ 0100 ;

!A

I

I

j

#7 #6

I

ENS /

#5

i

/ ND3 /

##4 #3 #2 81

I

I

I

/ NCR 1

i

I i

Setting entry is acceptable.

Data type: Bit

Character counting for W check in the comment section of a program.

CTV:

0: Not performed

1: Performed

NCR Output of the end of block (EOB) in IS0 code

0: LF, CR, CR are output.

1: Only LF is output.

In DNC operation, a program is:

ND3

0: Read block by block. (A DC3 code is output for each block.)

1: Read continuously until the buffer becomes full. (A DC3 code is output when the buffer

becomes full .)

\

clv :

#O i

WI

,

/

i

i

Page 17

4.2 Parameters of Reader/Puncher Interface,

Remote Buffer, DNCI, DNC2, and M-NET interface

Note) in general, reading is performed more efficiently when ND3 = 1. This specification reduces the

number of buffering interruptions caused by reading of a series of blocks specifying short

movements. This in turn reduces the effective cycle time.

ENS: Action taken when a NULL code is found during read of EIA code

0: An aiarm is generated.

1: The NULL code is ignored.

(2) Parameters for channel 1 (I/O CHANNEL=O)

#I #O

1

,

j

SB2 i

(Bit)

1

1

/

m

0101 j

1,

#7

1

NFD

#6 #5

i j

I

I

I

I

#4 #3 #Q

i

i

I

) AS!

I

/

1

Data type: Bit

The number of stop bits

SB2

0: 1

1: 2

Code used at data input

ASI

0: EIA or IS0 code (automatically distinguished)

1: ASCH code

Feed before and after the data at data output

NFD

0: output

I : Not output

(Note) When input/output devices other than the FANUC PPR are used, set NFD to 1.

I

j 0102 j

I

! L

Data type: Byte

Set the number specified for the input/output device used when the I/O CHANNEL is set to 0, with one of

the set values listed in Table 4.2 (a).

i Number specified for the input/output device (when the l/O CHANNEL is

!

set to 0)

1

/

!

,

Table 4.2 (a) Set Value and Input/Output Device

I

!

I

I

j

i

i

I

,

I

I

I

I

I

1

/

I ,

I

i :

i 0103 i

I

I

I

:

i Set value : Input/output device

! 0 ; RS-232-C (Used control codes DC1 to DC4)

i

:

I

i

f 3 j FANUC FLOPPY CASSETTE ADAPTOR

I

!

j 4

i

; 6

i

I

!

Baud rate (when the I/O CHANNEL is set to 0)

FANUC CASSETTE ADAPTOR 1 (FANUC CASSElTE Bl/B2)

1

2 i

FANUC CASSE-ITE ADAPTOR 3 (FANUC CASSEI-I-E Fl)

i

FANUC PROGRAM FILE Mate, FANUC FA Card Adapter

i

FANUC SYSTEM P-MODEL H, FANUC Handy File

j RS-232-C (Not used control codes DC1 to DC4) 1

5 ; ‘Portable tape reader

j FANUC PPR

FANUC SYSTEM P-MODEL G, FANUC SYSTEM P-MODEL H

[

Data type: Byte

Set the baud rate of the input/output device used when the I/o CHANNEL is set to 0, with a set value in

Table 4.2 (b).

-12-

Page 18

4.2 Parameters of Reader/Puncher interface,

Remote Buffer, DNCI , DNC2, and M-NET Interface

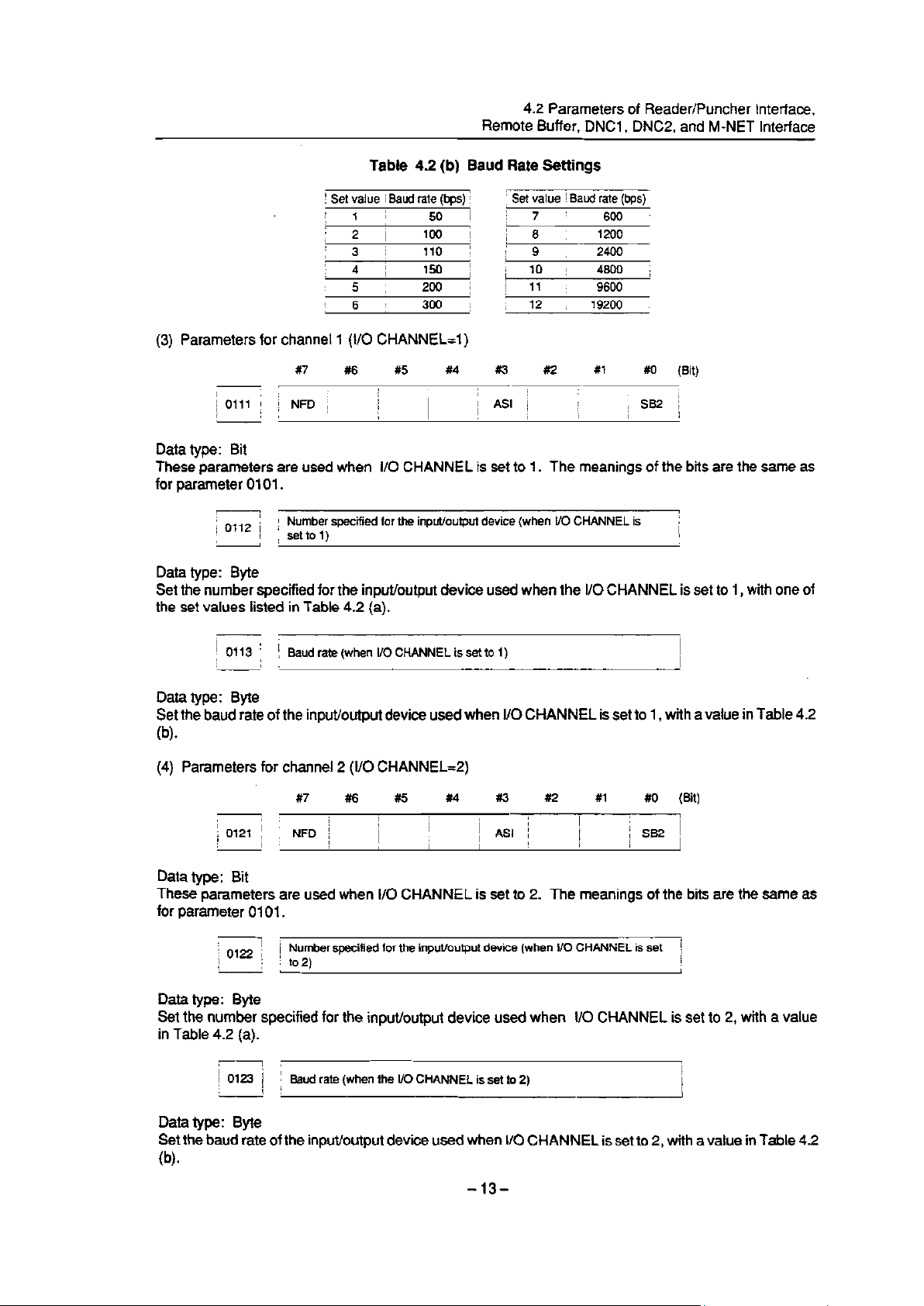

Table 4.2

1 set value f Baud rate (bps) !

r --2-- I

f 3 i 110 I I , 9 ; 2400

1 i 4

i 4 i 1% ! :

1 5 j

* 1

j 6

j 300 i 1 12 j 19200 !

(b) Baud Rate Settings

] Set value ! Baud rate (bps)

I

;

loo

I

200 j 11 i 9600

8 j 1200

10 j 4800 i

I

(3) Parameters for channel 1 (I/O CHANNEL=1 )

i

1 0111 i

I

c

I

j NFD i

I I

#I7

#6 #5

i

1 .

i

i I

#4

#3 #2

1

ASI 1

1

!

#l

I

I

,

I

1

##o

1 SB2 j

I

i

w

i

Data type: Bit

These parameters are used when I/O CHANNEL is set to 1. The meanings of the bits are the same as

for parameter 0101.

I

/

,

0112

i

; Number specified for the input/output device (when l/O CHANNEL is

i

settol)

: ;

Data type: Byte

Set the number specified for the input/output device used when the l/O CHANNEL is set to 1, with one of

the set vaiues listed in Table 4.2 (a).

.

I

I

;0113! ,

i

Baud rate (when I/O CHANNEL is set to 1)

I 1

Data type: Byte

Set the baud rate of the input/output device used when I/O CHANNEL is set to 1, with a value in Table 4.2

.

(b)

(4) Parameters for channel 2 (I/O CHANNEL=2)

#5 #4 #3 #2 a1 80 i

I

I

I

i

I

I

I

! ASI 1

I

I

I

I

j SB2

I

(W

’ .

I .

0

/ 0121 j ;

!:

I

#7 #6

I

NFD j

Data type: Bit

These parameters are used when I/O CHANNEL is set to 2. The meanings of the bits are the same as

for parameter 0101.

:

0122 i

i

I ,

, to2)

I

- L

/

Number specified for the input/ou@ut device (when l/O CHANNEL is set

!

--

/

Data type: Byte

Set the number specified for the input/output device used when I/O CHANNEL is set to 2, with a value

in Table 4.2 (a).

r

i

0123 i

i

*

,

,

i (

1 Baud rate (when the l/O CHANNEL is set to 2)

! !

9

-- I

Data type: Byte

Set the baud rate of the input/output device used when I/O CHANNEL is set to 2, with a value in Table 4.2

.

(b)

-13-

Page 19

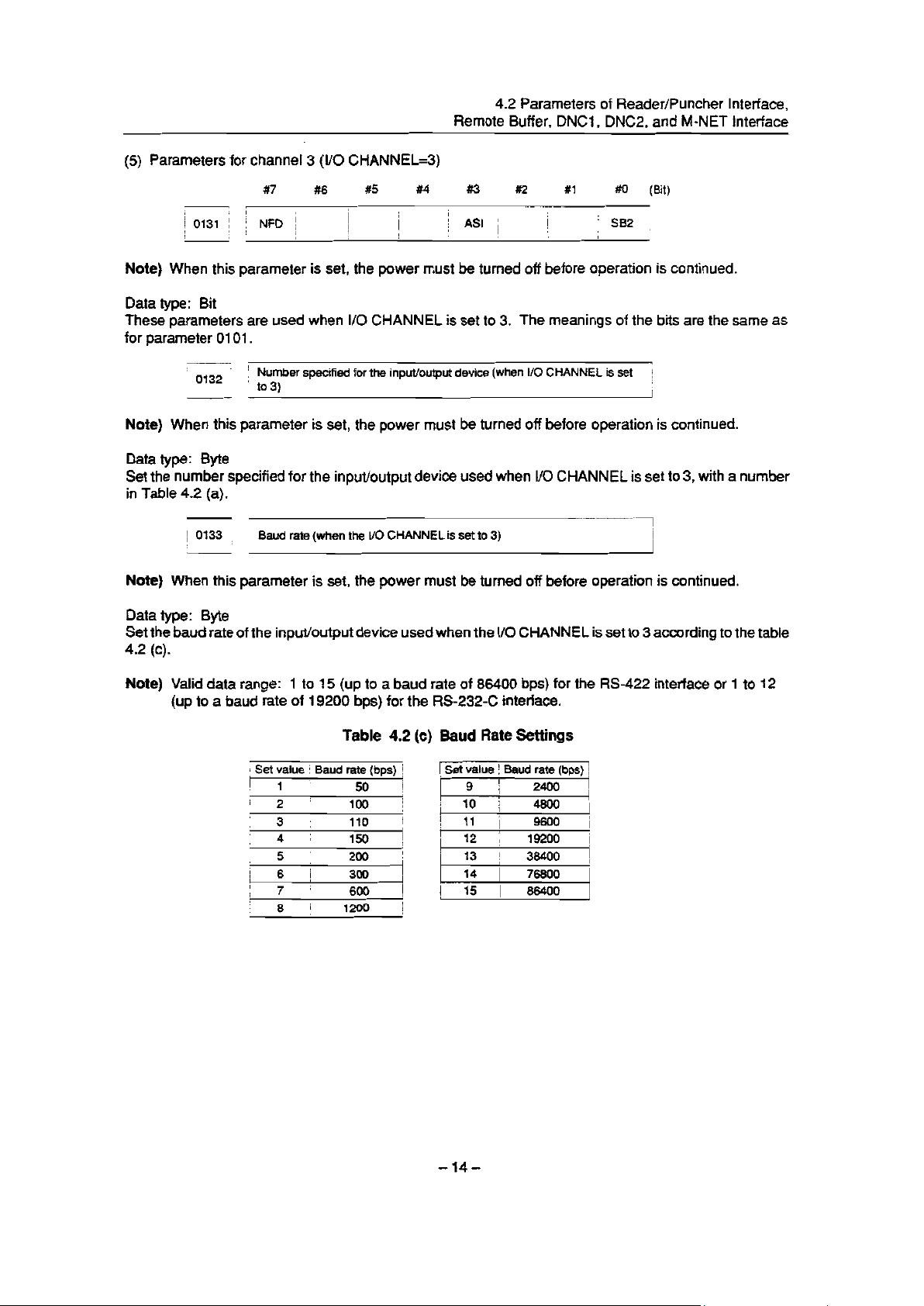

(5) Parameters for channel 3 (I/O CHANNEL=3)

4.2 Parameters of Reader/Puncher Interface,

Remote Buffer, DNCI, DNC2, and M-NET Interface

1 c

/ 0131 f j

I I

I

A.

#7

I

NFD ;

#6 #5 #4

,

1

I

1

j

9

I

/

!

I

#a #2 #1

I

j ASI /

#O (Bit)

[

: SB2 :

,

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Bit

These parameters are used when I/O CHANNEL is set to 3. The meanings of the bits are the same as

for parameter 0101.

0132 !

I

u

j Number specified for the input/output device (when I/O CHANNEL is set :

D to3)

I

I

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Byte

Set the number specified for the input/output device used when I/O CHANNEL is set to 3, with a number

in Table 4.2 (a).

!

/

0133 :

,

:

Baud rate (when the I/O CHANNEL is set to 3)

I

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Byte

Set the baud rate of the input/output device used when the I/O CHANNEL is set to 3 according to the table

4.2 (c).

Note) Valid data range: 1 to 15 (up to a baud rate of 86400 bps) for the RS-422 interface or 1 to 12

(up to a baud rate of 19200 bps) for the RS-232-C interface.

Table 4.2

: Set value ! Baud rate (bps) !

I 1 ;

2 i 100 i

i

3 # t

1 4

/ 5 t

6 1

I

7

1 :

i 8 i

50 1

110

150 /

j

200 ;

300 I

j 600

1200 f

1

Baud Rate Settings

(cl

1 Set value

1 9 1 2400 I

i

’ 10 i

I

i

1

11 ‘i

I

1 12 j

i

13 I 38400

I 14 I

! 15 1 86400

,

! Baud rate (bps) !

4800 /

9600 /

19200 1

!

76800 I

-14-

Page 20

4.2 Parameters of Reader/Puncher Interface,

Remote Buffer, DNCl, DNC2, and M-NET Interface

.

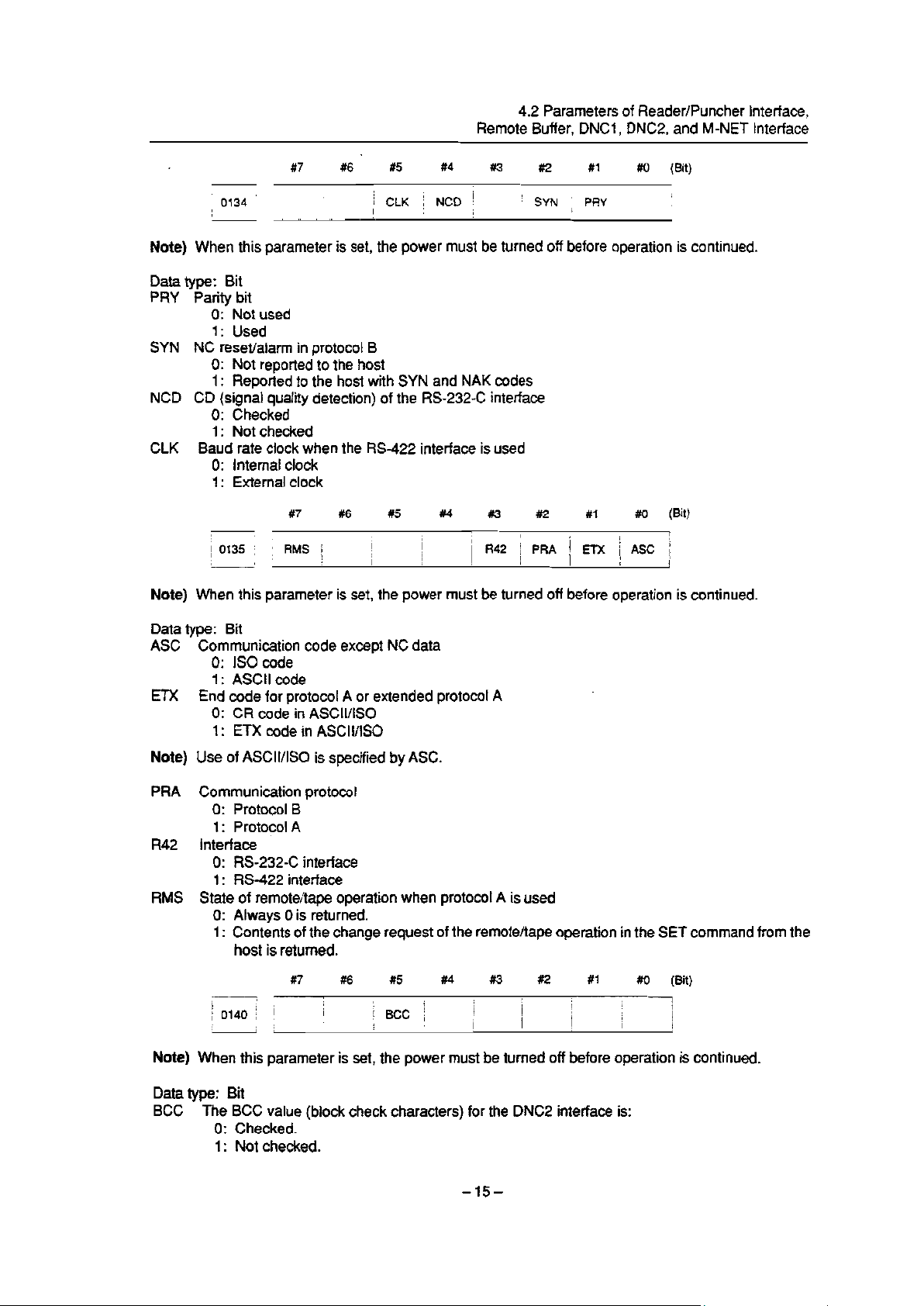

!0134! j

I

I

#7

#6

t5

1 CLK j NCD !

I

X4 #3 #2

I

’ SYN ; PRY

#l

,

#O (Bit)

:

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Bit

PRY Parity bit

0: Not used

1: Used

SYN NC reset/alarm in protocol B

0: Not reported to the host

1: Reported to the host with SYN and NAK codes

NCD CD (signal quality detection) of the RS-232-C interface

0: Checked

1: Not checked

CLK

Baud rate clock when the RS-422 interface is used

0: Internal clock

1: External clock

i

#7 #6

.

/

0135 ; i RMS j

I ;

I

#5

i

i

#4 #3 ##2

i

1

/ R42 [ PRA j ETX 1 ASC ;

i I

#l

#0

(B t)

1

t

I

1

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Bit

ASC Communication code except NC data

0: IS0 code

1: ASCII code

ETX End code for protocol A or extended protocol A

0: CR code in ASCII/IS0

1: ETX code in ASCII/IS0

Note) Use of ASCII/IS0 is specified by ASC.

PRA Communication protocol

0: Protocol B

1: Protocol A

R42 Interface

0: RS-232-C interface

1: RS-422 interface

RMS State of remote/tape operation when protocol A is used

0: Always 0 is returned.

1: Contents of the change request of the remote/tape operation in the SET command from the

host is returned.

#2 #1 #O (Bit)

1

i

I

I

I

)

i

1

!

1

1

I

!

I

i

1 0140 j I

I ,

I

I 1

#7

I I

#6

\

I

I

#5

8

j BCC j

##4 #3

i

I

!

j

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Bit

BCC

The BCC value (block check characters) for the DNC2 interface is:

0: Checked.

1: Not checked.

-15-

Page 21

4.2 Parameters of Reader/Puncher interface,

Remote Buffer, DNCI , DNC2, and M-NET Interface

i

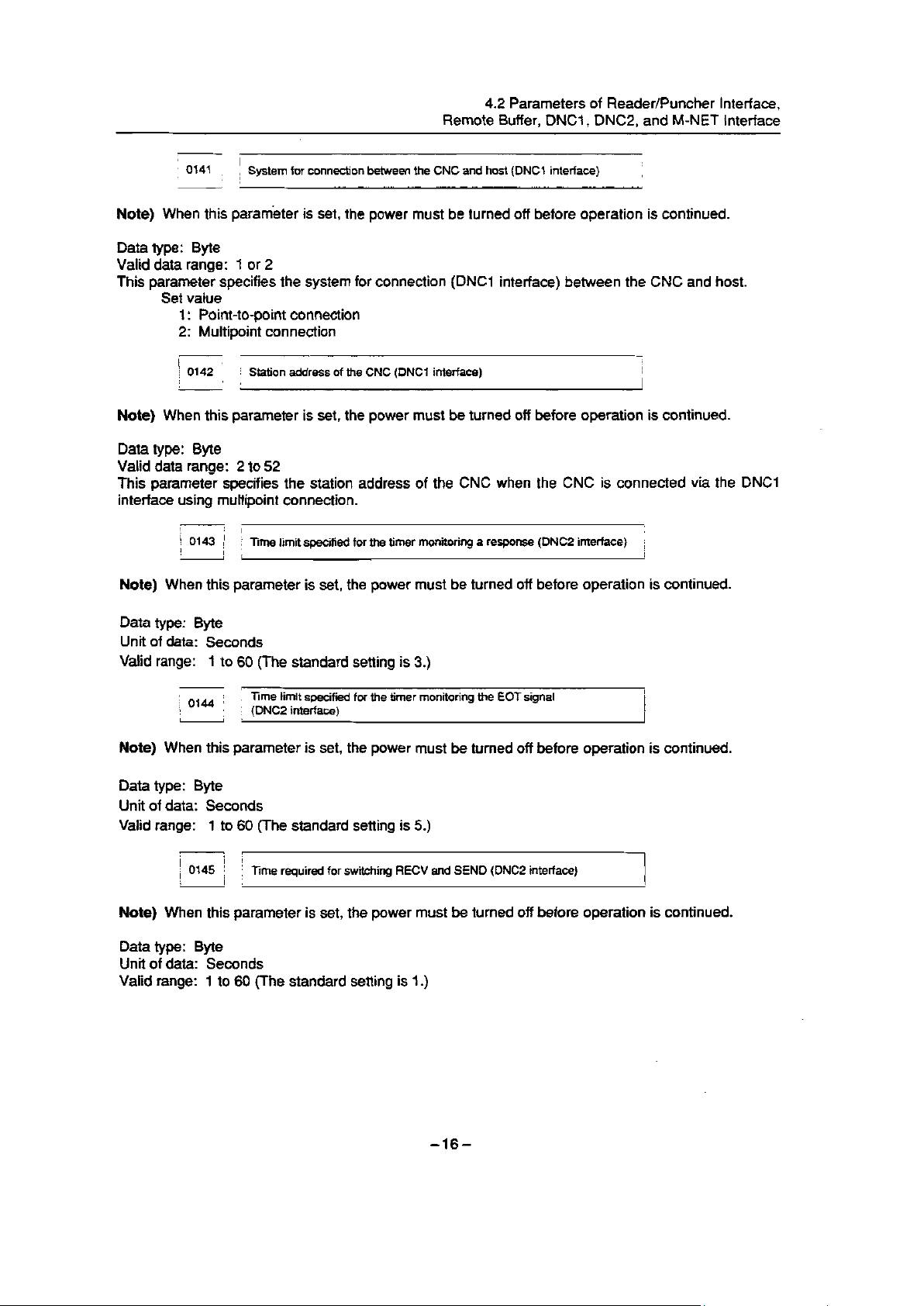

; 0141 ;

L

/ System for connection between the CNC and host (DNCl interface)

I

I

I

I

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Byte

Valid data range: 1 or 2

This parameter specifies the system for connection (DNCI interface) between the CNC and host.

Set value

I : Point-to-point connection

2: Multipoint connection

I i

I

i 0142 i ; Station address of the CNC (DNCl interface)

, I!

Note) When this parameter is set, the power must be turned off

before operation is continued.

Data type: Byte

Valid data range: 2 to 52

This parameter specifies the station address of the CNC when

the CNC is connected via the DNCI

interface using multipoint connection.

I

0143 ; 1 j

/

I

I

3me limit specified for the timer monitoring a response (DNC2 interface)

ji

I

/

i

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Byte

Unit of data: Seconds

Valid range:

Note) When this

1 to 60 (The standard setting is 3.)

j ;

i 0144 ;

j Time limit specified for the timer monitoring the EOT signal

: (DNC2 interface)

parameter is set, the power must be turned off before operation is continued.

Data type: Byte

Unit of data: Seconds

Valid range:

1 to 60 (The standard setting is 5.)

d r

,

i i

i

i 0145 i

i

(

lime required for switching RECV and SEND (DNC2 interface)

] ;

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Byte

Unit of data: Seconds

Valid range: 1 to 60 (The standard setting is 1.)

-16-

Page 22

4.2 Parameters of Reader/Puncher Interface,

Remote Buffer, DNCI, DNC2, and M-NET Interface

io,&: j

i

I

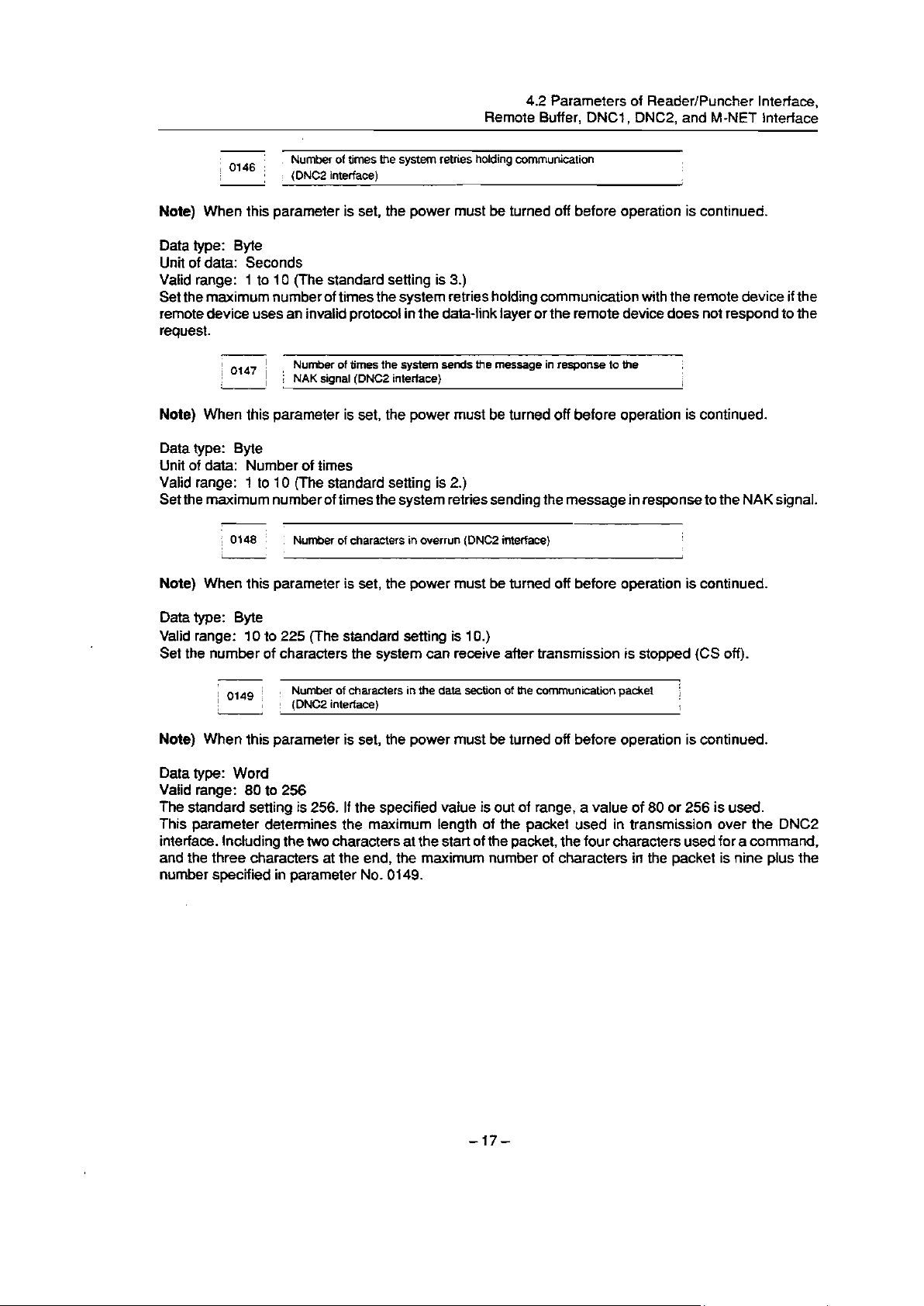

Number of times the system retries holding communication

(DNC2 interface)

1 :

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Byte

Unit of data: Seconds

Valid range: 1 to 10 (The standard setting is 3.)

Set the maximum number of times the system retries holding communication with the remote device if the

remote device uses an invaiid protocol in the data-link layer or the remote device does not respond to the

request.

-

0147 j

/

I

; I!

: ! Number of times the system sends the message in response to the

NAK signal (DNC2 interface)

i

]

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Byte

Unit of data: Number of times

Valid range: 1 to IO (The standard setting is 2.)

Set the maximum number of times the system retries sending the message in response to the NAK signal.

1

;

I

,

: Number of characters in overrun (DNC2 interface)

1

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Byte

Valid range: 10 to 225 (The standard setting is IO.)

Set the number of characters the system can receive after transmission is stopped (CS off).

I

0149 /

i

1 1 ;

j

Number of characters in the data section of the communication packet

(DNC2 interface)

‘

1

i

.

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Word

Valid range: 80 to 256

The standard setting is 256. If the specified value is out of range, a value of 80 or 256 is used.

This parameter determines the maximum length of the packet used in transmission over the DNC2

interface. including the two characters at the start of the packet, the four characters used for a command,

and the three characters at the end, the maximum number of characters in the packet is nine plus the

number specified in parameter No. 0149.

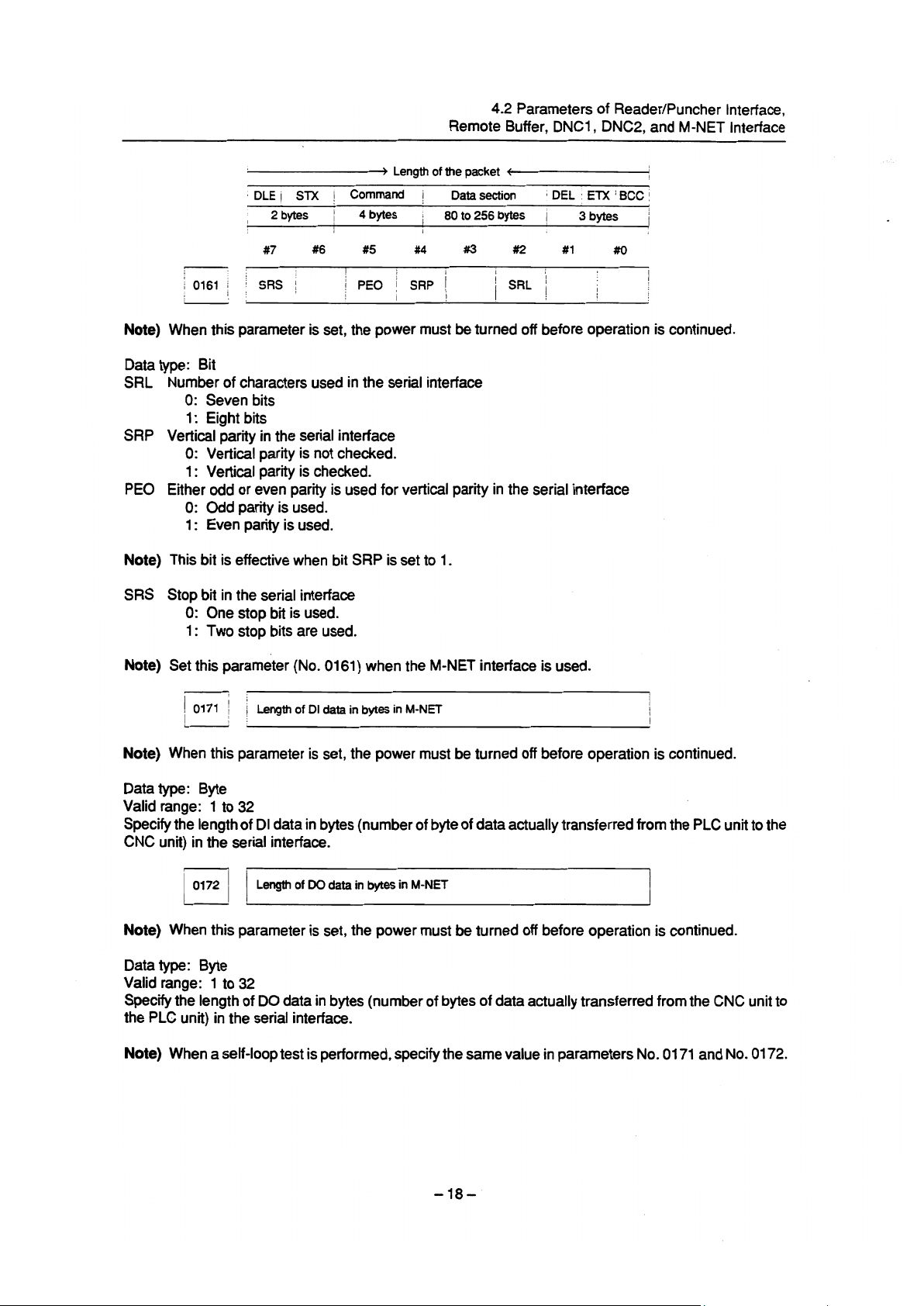

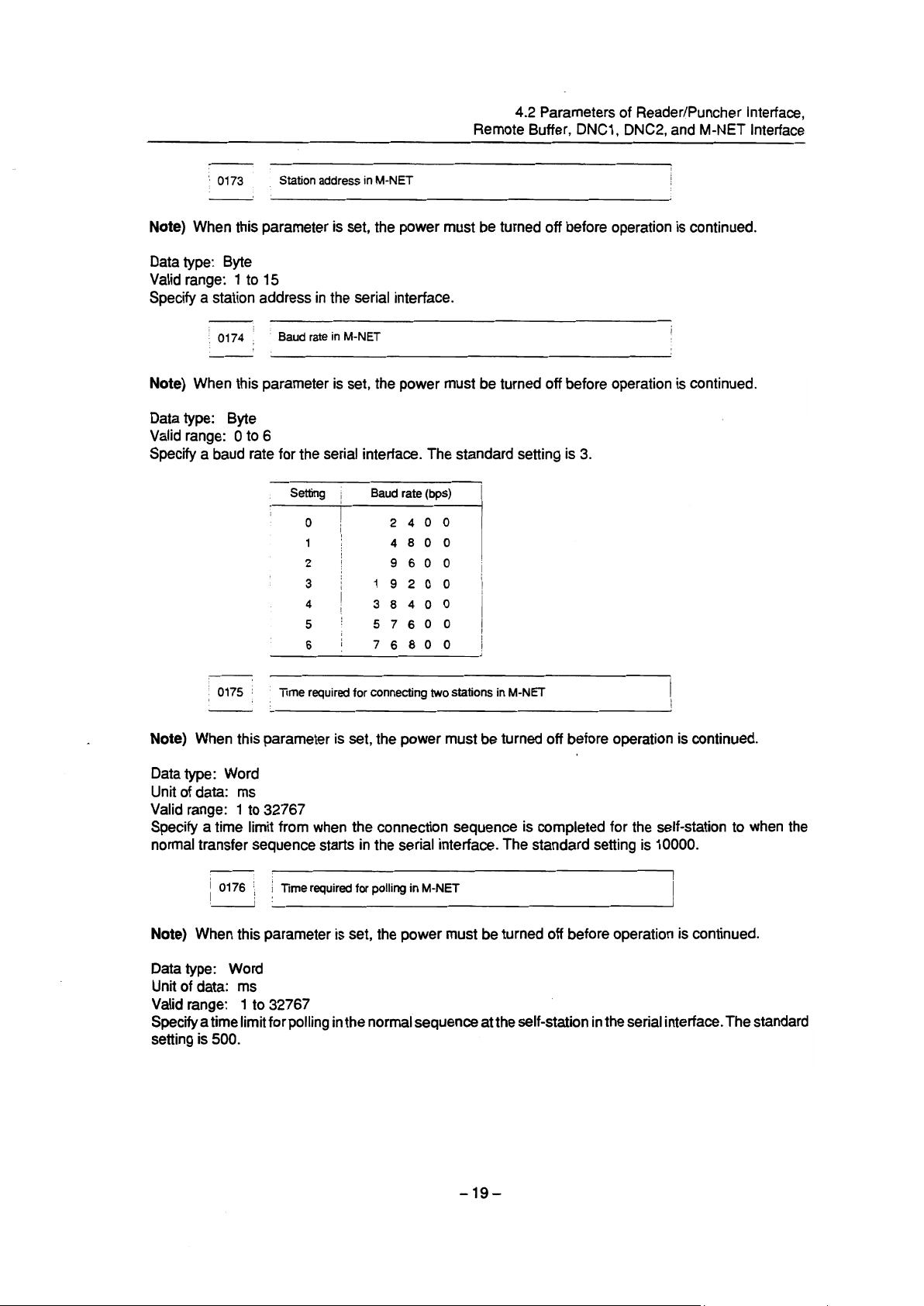

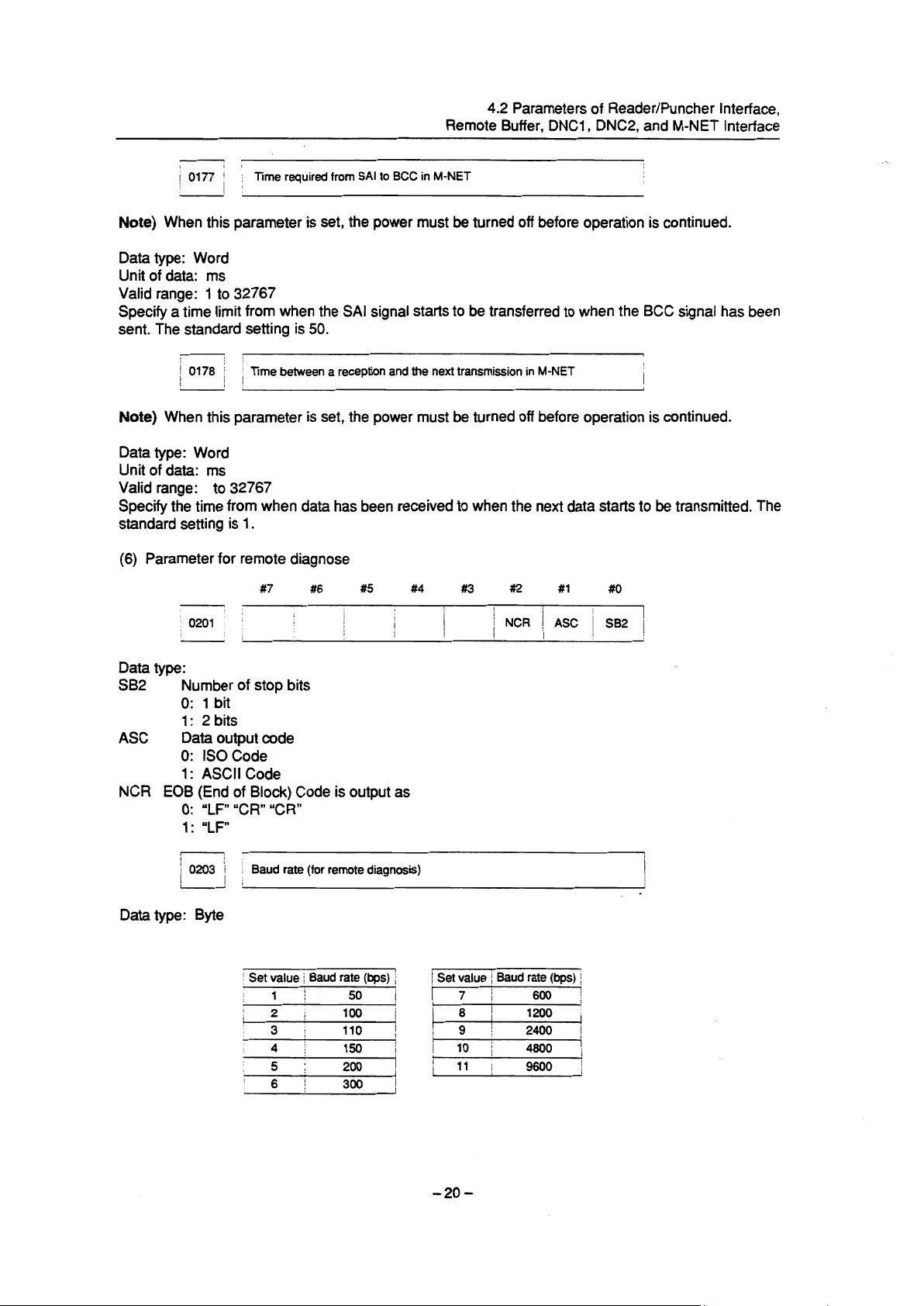

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

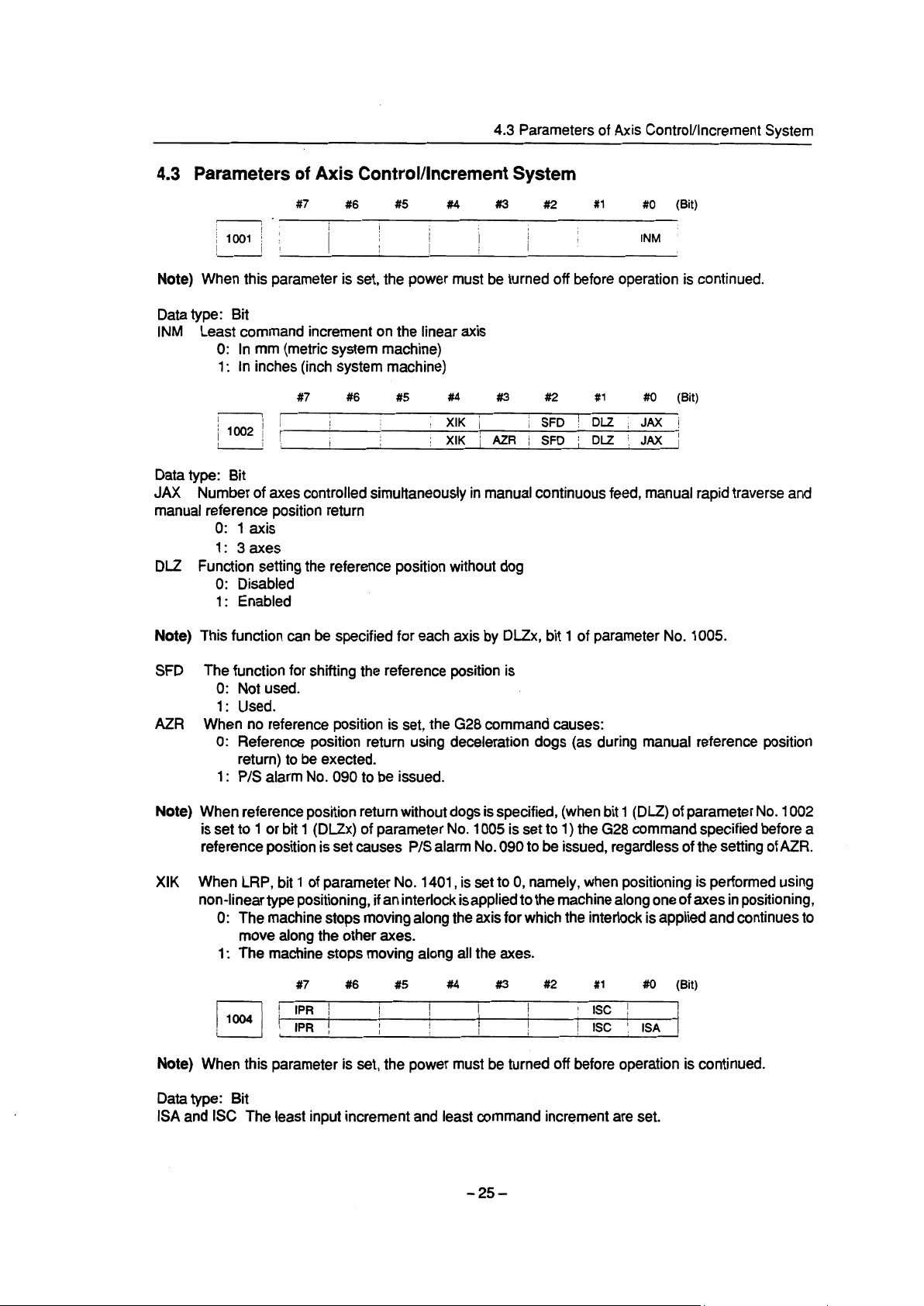

4.3 Parameters of Axis Control/increment System

DIAx Either a diameter or radius is set to be used for specifying the amount of travel on each axis.

0: Radius

1: Diameter

ZMIx The direction of reference position return and the direction of initial backlash at power-on

0: Positive direction

1: Negative direction

#7

#6 #5

#4 #3 ##2 #1

Data type: Bit axis

RAAx When an absolute command is specified for a rotation axis:

0: The end point coordinates and direction of rotation conform to bit 1 (RABx) of parameter No.

1008.

1: The end point coordinates conform to the absolute value of the value specifed in the command.

The rotational direction conforms to the sign of the value specified

Note) This parameter is valid when the rotary axis control function is provided and the rotation axis

rollover function is applied (bit 0 (ROAx) of parameter No. 1008 is set to 1).

#?

#6

#5

##4 #3 ##2

#O

in the command.

#1 #O

,-

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Bit axis

The roll-over function of a rotation axis is

ROAX

0: Invalid

1: Valid

Note)

ROAx specifies the function only for a rotation axis (for which ROTx, #0 of parameter No. 1006,

issettol)

In the absolute commands, the axis rotates

RABx

in the direction

0: In which the distance to the target is shorter.

1: Specified by the sign of command value.

RABx is valid only when ROAx is 1.

Note)

Relative coordinates are

RRLx

0: Not rounded by the amount of the shift per one rotation

1: Rounded by the amount of the shift per one rotation

Note 1) RRLx is valid only when ROAx is 1.

Note 2) Assign the amount of the shift per one rotation in parameter No. 1260.

I

I

10091 j

i

’ I

,

#7

#6

I n

I I 1

#5

#4

1

I

RAAx The rotation direction of a rotation axis and end point coordinates in the absolute command mode:

0: Agree with the setting of bit 1 (RABx) of parameter No. 1008.

1: Agree with the absolute value of the specified value for the end point coordinates and the sign

of the specified value for the rotation direction.

#I3 #2 #1 #o

I

RAAx !

i *

I

I

i

Note) This parameter is enabled when the rotary axis control function is provided and the rotation axis

roll-over function is used (with bit

0 (ROAx) of parameter No. 1008 set to 1).

-280

Page 34

4.3 Parameters of Axis Control/Increment System

i

1010 /

Number of CNC-controlled axes

j

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Byte

Valid data range:

1,2,3, . . . . the number of controlled axes

Set the maximum number of axes that can be controlled by the CNC.

[Example] Suppose that the first axis is the X axis, and the second and subsequent axes are the Y, Z,

A, B, and C axes in that order, and that they are controlled as follows:

X, Y, Z, and A axes: Controlled by the CNC and PMC

B and C axes: Controlled by the PMC

Then set this parameter to 4 (the 4th axis: A axis).

v

f

i 1020 *

I

I

! Name of the axis used for programming for each axis

1.

Data type: Byte axis

Set the name of the program axis for each control axis, with one of the values listed in the following table:

Note 1)

I Axis name 1 Set value

,

I

x i

Y 89 j V i 86 i

,

L

2 : 90

j Axis name / Set value i Axisname

88 ; u i 85 i A 65 1

j W ; 87 1 C 67

In the T series, when G code system A is used, neither U, V, nor W can be used as an axis name.

B

Set value

66 1

1

1

Only when G code system B or C is used, U, V, and W can be used as axis names.

Note 2)

Note 3)

The same axis name cannot be assigned to more than one axis.

When the secondary miscellaneous function is provided, address B cannot be used as an axis

name. In the T series, when CCR, ##4 of parameter 3405, is set to 1, addresses A and C may

not be used with functions, chamfering, corner R, and direct input of drawing dimensions.

Y I

I 1

I

j1022i :

I

I :

I

Setting of each axis in the basic coordinate system

I

!

1

Note) When this parameter is set, the power must be turned off before operation is continued.

Data type: Byte axis

To determine the following planes

used for circular interpolation, cutter compensation C (for the M series),

tool nose radius compensation (for the T series), etc., each control axis is set to one of the basic three axes

X, Y, and Z, or an axis parallel to the X, Y, or Z axis.

G17: Plane Xp-Yp

Gi 8: Plane Zp-Xp

G19: Plane Yp-Zp

Only one axis can be set for each of the three basic axes X, Y, and Z, but two or more parallel axes can

be set.

-290

Page 35

4.3 Parameters of Axis Control/Increment System

Meaning

axes nor a parallel axis

1

I

I

1

I

I

i

/

T I

j

i 1023

,

I ’

*

Set value i

j Neither the basic three

0

1 ! X axis of the basic three axes

i

2 ! Y axis of the basic three axes

I

3

5

6 I 1 Axis parallel to the Y axis

7

I

1

Number of the servo axis for each axis

axis of the basic three axes

! 2

Axis parallel to the X axis

i

j Axis paraDeI to the 2 axis

Note) When this parameter is set, power must be turned off before operation is continued.

Data type: Byte axis

Valid data range: 1,2,3, . . . . number of control axes

Set the servo axis number for each control axis.

Usually set the same number as the control axis number.

The control axis number is the order number that is used for setting the axis-type parameters or axis-type

machine signals.

-3o-

Page 36

(Example 1) In case of 1 path control

(a) Main CPU board max. 4 axes + Additional board

(I) Parameter No. 1023 X 1

Y 2

z 3

C 4

U 5

V

W

6

7

A 8

Main CPU board

Control axis

number

ProgElMXiSWYE

(Set by parameter No. 1020) (Set by parameter No. 1023)

4.3 Parameters of Axis ControUncrement System

Servo axis

number

1

1

2 Y

3

4

- Additional axis board

5

6

7

8 A

I

X

Z

C

U

v -

W

L

’ JVI/JSl

1

>

JVUJS2

>

1

2

.

v JV3/JS3

3

>

motor

7

t

I

-X

*

-Y

-Z

I .

I

JV4/JS4 4

>

1 .

-C

I

I .

v

JVI /JV5/JSl 5

?

>

I

l JVUJVGjJS2 6

c

*

-U

-V

4

I

JV3/JV7/JS3 7

>

c

I

I

JV4/JV8/JS4 8 A

>

I

I

-W

A

-A

-31.

Page 37

4.3 Parameters of Axis Control/Increment System

(II) Parameter No. 1023

- Main CPU board ~-1

Control axis

number

1

I

Program axis name

(Set by parameter No. 1020)

1

X

X

Y

Z

C

U

V

W

A

(Set by parameter No. 1023)

7 ’

\

*

.

JVl /JSl 1

I ,

JV2/JS2

I

I

t JV3IJS3

1 ’

l JV4WS4 4

’

L

Sewo axis number

2

3

motor

w

1

+

.

1

-X

-U

.

-Y

f

-Z

- Additional axis board

W

V

A

X

’ - JVINVSIJSI 5

l

I

JV2lJV6/JS2 6

I

I

’ - JV3IJV7IJS3 7

I

’ ’ JV4NV8/JS4 8

I

I ’

,

&

w

.

-C

,

-V

.

-A

-W

-320

Page 38

4.3 Parameters of Axis Control/increment System

(b) Main CPU board max. 6 axes + Additional board

(I) Parameter No. 1023 X

- Main

ControI axis

number

I

X

Y

z

C

U

V

Additional axis board

7 W

8

A

Y ) 2

z 3

C

U 5

V 6

>

>

>

>

l

1

4

(Set by parameter No. 1023)

I JS1

h

4

I

JS2 2 .

4

I

JS3 3

I

JS4

I

I

I ’ JS6 6

I

I

,

L .

JVI /JV5/JSl 7

’

l JV2lJV6/JS2 8

I

Sew0 axis number

1

4

motor

*

L *

t

-X

-Y

-2

‘- c

U

-V

.

l

-W

I

-A

-330

Page 39

4.3 Parameters of Axis Control/Increment System

(II) Parameter No. 1023 X

- Main CPU board

Contrul axis

number

I

1 X

2

3

4

5 U

6

(Set by parameter No. 1020)

1

Y

Z

C

V

Y

Z

C 5

U

V 6

W

A

1

3

4

2

8

7

Servo axis number

(Set by parameter No. 1023)

motor

.

1

I

.

4

-X

-U

-Y

-Z

-C

-V

>

>

I

I 4

v

I ,

v

I

L

I

’ ’ JS6

I

JSI

JS2

I

I

JS3

v JS4

JS5

.

i

A

1

2

3

4

5

6

Page 40

4.3 Parameters of Axis Control/increment System

(Example 2) In case of 2 path control

(a) Main CPU board max. 4 axes + Sub CPU board max. 4 axes

(I) Parameter No. 1023

Xl 1

Yl

Zl

Cl

- Main CPU board

Control axis Programaxisname

number

I

1

2

(Set by parameter No. 1020)

I

X

Y

3 Z

4 C

- Sub CPU board

X

Y -

3

Z

4 C

Path

1

2

3 22

4

1

JVI /JSl

>

I

I

JWJS2

>

+

. JV3/JS3

>

I

I

.

9 JV4lJS4

>

1 ,

?

>

*

I

c

>

&

l

JVl /JV5/JSl 5

I ,

JWJS6/JS2 6

A .

I

JV3IJWJS3 7

l t

’ 4 JV4lJS8fJS4 8

Path 2

x2

Y2

c2

Servo axis number

5

6

7

8

(Set by parameter No. 1023)

-1

1

motor

c

.

2

.

3

4

.

l

l

- Xl

1

- YI

- Zl

*

1

-

TX2

*

-

$

-Z2

- c2

Cl

Y2

-35-

Page 41

4.3 Parameters of Axis ControVincrement System

(II) Parameter No. 1023

- Main CPU board

Control axis

number (Set by pararwter No. 1020)

1

2

3

4

-

Sub CPU board g61

Path 1 Path 2

Xl

YI 3

Zl

Cl

X

Y

Z

C

X

Y

1 x2

2 22

4

>

.

’ 4 JWJS2 2

x ; ’ :I

I

>

I

1

I

t

Y2 7

c2

Serva axis number

(Set by parameter No. 1023)

JVllJSl

.

JV3/JS3

JV4/JS4

JWJV5lJSl 5

JWJS6IJS2 6

r

5

6

a

4

1

3

4

motor

L

1

t

.

!

\

.

*

*

-

- Zl

,

- Yl

.

- Cl

-

*

-22

Xl

x2

Z

C

x

JV3/JS?lJS3 7

-

Y2

?

JV4/JS8/JS4 8

I

c

- c2

-360

Page 42

4.3 Parameters of Axis Control/Increment System

(b) Main CPU board max. 6 axes + Sub CPU board max. 6 axes

(I) Parameter

No. 1023 Path 1

.

- Main CPU board

Control axis

number

1

2

3

4

(Set by parameter No. 1020)

X

Y

z

C

5 U

6

V

- Sub CPU board ‘1

1

X

2 Y

3

4

z

C

Xl 1

Yl 2

21 3

Cl 4

Ul 5

Vl

Path 2

X2 7

Y2

22

8

9

c2 IO

u2

6

v2 12

Servo axis number

(Set by parameter No. 1023)

11

4

’ 8 JSl 1

\

I

JS2

1

’ 4 JS3 3

I )

\

JS4

L

v

I

JS5

l

v

’ JS6 6

I

I

JSI

*

c

, A

JS2 8

JS3

+

.

I

JS4 10

2

4

5

7

9

motor

c .

, .

t

c

t

h

-

Xl

- Yl

+

- 21

.

- Cl

- Ul

- VI

-X2

-

Y2

-22

.

-

c2

71e.

5

U

6 V

I 1 JS5

I

I

-370

.

1 JS6

11

12

c

4

u2

-

.

,

v2

-

.

Page 43

Page 44

Page 45

4.4 Parameters of Coordinates

G50 When the CNC has commands G54 to G59 specifying workpiece coordinate systems (optional

function), if the G50 command for setting a coordinate system (or the G92 command in G command

system B or C) is specified,

0: The G50 (dr G92) command is executed without an alarm.

1: P/S alarm No. 010 is issued and the G50 (or G92) command is not executed.

Local coordinate system is

RLC

0: Not cancelled by reset

1: Canceled by reset

112201 I

; 11

External workpiece zero point offset value

A

Data type: 2-word axis

Unit of data:

input increment

j Linear axis (input in mm)

i Linear axis (input in inches)

Rotation axis

j IS-A i IS-B j IS-C j Unit j

j 0.01 j 0.001 i 0.0001 i mm i

f 0.001 i 0.0001 1 0.09001 i inch

1 0.01 j 0.001 : 0.0~1 : da !

j

Valid data range: -7999 to 7999

This is one of the parameters that give the position of the origin of workpiece coordinate system (G54 to

G59). It gives an offset of the workpiece origin common to ail workpiece coordinate systems.

In general,

the offset varies depending on the workpiece coordinate systems. The value can be set from the PMC

using the external data input function.

_i

t

i

I

I

I

I

,

;

I

,

I

)

m ’

i 1221 ;

I

:

/

lzzz I

t L

r

1

1223 j

;

1 PP ---I

,

1 I’

P24! !(G57)

; 1

; ’

/ 1225 [

I

I

1 1226 /

I

Workpiece zero point offset value in workpiece coordinate system 1

; WV

I

8

1

Workpiece zero point offset value in workpiece coordinate system 2 I

i 1 (G55)

,

j Workpiece zero point offset value in workpiece coordinate system 3 i

--

; ] GW

Workpiece zero point offset value in workpiece coordinate system 4

)

---

1

I

Workpiece zero point offset value in workpiece coordinate system?

] (GW

!

_-

I

I

I

1 Workpiece zero point offset value in workpiece coordinate system 6

: 1 (G59)

;- ---

--

--P-P

--e---. -- ._- _ ____

----_ --_ _-J

_-.,.-w-J

--

--..__-- ___.

Data type: 2-word axis

Unit of data:

Input increment

i Linear axis (input in mm)

--

! Linear axis (input in inches)

rEotation axis

--

i IS-A : IS-B ;

0.01 i 0.001 i 0.9001 j mm i

/

t 0.001 :

j

0.01

-_---__ -- ----

O.oool I o.oooo1~ xii-j

-----_-i

: 0.001 1 0.0091 f deg i

.--------

IS-C

: Unit ;

_ ---

Valid data range: -99999999 to 99999999

The workpiece zero point offset values in workpiece coordinate systems 1 to 6 (G54 to G59) are set.

-40s

Page 46

Workpiece coordinate

system 1 (G54)

>

\

Zero position of a machine cwrdiiate system

Fig. 4.4 Workpiece Zero Point Offset

4.4 Parameters of Coordinates

A

Workpiece coordinate

system 2 (G55)

>

i

t

I

/

i

1

i

0

1241 ’

1242 ’

_

i 1243 ;

Coordinate value of the reference position on each axis in the machine

:

coordinate system

I

Coordinate value of the second reference position on each axis in the 1

machine coordinate system

’

Coordinate value of the third reference position on each axis in the machine )

:

coordinate system

Coordinate value of the fourth reference position on each axis in the ;

machine coordinate system

Data type: 2-word axis

Unit of data

Increment system I

Millimeter machine

e Inch machine

I Rotation axis

&A I IS-8 f IS-C ;

~ -I----

: 0.01

i 0.001

i 0.01

i 0.001

! 0.0001 1 0~00001~ inch 1

1 0.001 i 0.0001 \ deg i

i 0.0001 ! mm i

1

Unit j

Valid data range: -99999999 to 99999999

Set the coordinate values of the reference positions in the machine coordinate system.

,

i :

p2444 i ;

I

:

Coodinates of the floating reference position for each axis

1

1

I

Data type: 2-word axis

Unit of data:

-41.

Page 47

4.4 Parameters of Coordinates

Increment svstem

I Millimeter machine

’ inch machine f 0.001 I 0.0001 i 0.00001 ! inch !

i Rotation

axis

1 IS-A 1 IS-B i IS-C I Unit !

i 0.01

j 0.01

0.001 j 0.0001 mm i

i

i 0.001 i 0.0001 ! dw 7

Valid data range: -99999999 to 99999999

This parameter specifies the coordinates of the floating reference position for each axis. The parameter

is automatically set when the floating reference position is specified using soft keys on the current position

display screen.

j

11250i i

I

1

i

Coordinate value of the reference position used when automatic coordinate

l system setting is performed

(

Data type: 2-word axis

Unit of data

I

Increment system

/ Linear axis (input in mm)

! Linear axis (input in inches)

Rotation axis

f

1

IS-A / IS-B i IS-C ! Unit i

;

0.01 j 0.001 1 0.0001 j mm

! 0.001 [ 0.0001 1 0.000011 inch

i 0.01

1 0.001 / 0.0001 ; deg ]

Valid data range: -99999999 to 99999999

Set the coordinate value of the reference position on each axis to be used for setting a coordinate system

automatically.

1

I

i

1251 j

!

i Coordinate

value of the reference position on each axis used for setting a

[ coordinate system automatically when input is performed in inches

i

i

Data type: 2-word axis

Unit of data .

Increment system

! Linear axis (input in inches)

j IS-A i IS-B 1 IS-C i Unit i

1 0.001 i 0.0001 j 0.00001 i inch 1

Valid data range: -99999999 to 99999999

Set the coordinate value of the reference position on each axis to be used for setting a coordinate system

automatically when input is performed in inches.

Note) This parameter is valid when ZPI in parameter 1201 #I is set to I.

Amount of a shift per one rotation of a rotation axis

Note) After setting the parameter, turn off the power once and turn it on again to operate the machine.

Data type: 2-word axis

Unit of data

-420

Page 48

4.4 Parameters of Coordinates

i Standard value i

: 36000

j 360000

1 3600000

Valid data range:

Set the amount of

i

increment system ! Unit of data

I

i

1

1000

IS-A i 0.01 deg

IS-B j 0.001 deg

IS-C : 0.0001 deg

to 9999999

a shift per one rotation of a rotation axis.

j Distance between two oooosite tool posts in mirror image

Data type: 2-word

Unit of data:

Increment system / IS-A ! IS-B j IS-C ’

f Miliimeter machine

1 Inch machine

j 0.01 ) 0.001 i

I

:

0.001 1 0.0001

Valid data range: 0 to 99999999

Set the distance between two opposite tool posts in mirror image.

1

I

:

0.0001

o.00001 i

f

Unit

1 mm i

inch I

1

i

j

-439

Page 49

Parameters of Stroke Limit

4.5

4.5 Parameters of Stroke Limit

#7

#6 #5

I

BFA ’ LZR 1 RL3

I

#4 #3 #2 #1

I

1 LMS j

I

I

##O i

i

i OUT 1

I

(B t)

I

I

J

Data type: Bit

OUT The area inside or outside of the stored stroke limit 2 is set as an inhibition area.

0: Inside

1: Outside

LMS The EXLM signal for switching stored stroke limit 1

0: Disabled

1:

Enabled

RL

Stored stroke limit 3 release signal RLSOT3 is

0: Disabled

1: Enabled

LZR Checking of stored stroke limit 1 during the time from power-on to the manual position

reference return

0: The stroke limit 1 is checked.

1: The stroke limit 1 is not checked

BFA When a command that exceeds a stored stroke limit is issued

,

0: An alarm is generated after the stroke limit is exceeded.

1: An alarm is generated before the stroke limit is exceeded.

Note) When an absolute position detector is used and a reference position is already set upon power-

up, stored stroke limit check I is started immediately after power-up, regardless of the setting.

(Bit)

3

,

I

/ 1301

L

, 1

1

I ’

i

#7 #6

1

PLC 1

#5

i

#4 #I3 #2 #l 80

NPC (

I

,

I

I

I

I

I

1

I

I

I

!

Data type: Bit

NPC As part of the stroke limit check performed before movement, the movement specified in G31 (skip)

and G37 (automatic tool length measurement (for M series) or automatic tool compensation (for

T series)) blocks is:

0: Checked

1: Not checked

PLC Stroke limit check before movement is:

0: Not performed

1: Performed

#7 #6 #5

I

I

I

!

#4 ##3 #2 #I

I

!

i

]

I

i oT3x i onx

I

I

#IO i

OT2x

i

(BV

Data type: Bit axis

OT2x Whether stored stroke limit 2 is checked for each axis is set.

0: Stored stroke limit 2 is not checked.

1: Stored stroke limit 2 is checked.

OT3x Whether stored stroke limit 3 is checked for each axis is set.

0: Stored stroke limit 3 is not checked.

1: Stored stroke limit 3 is checked.

Page 50

4.5 Parameters of Stroke Limit

1

i 13201

i

1

I

1 1321 i

I

,-

Coordinate value

;=is

,L

j

’

i Coordinate value

each axis

I of stored stroke limit 1 in the positive direction on each

1 of stored stroke limit 1 in the negative direction on

i

[

I *

Data type: 2-word axis

Unit of data:

I

Increment svstem

I Millimeter machine i 0.01

!

; Inch machine i 0.001

Rotation axis ’ 0.01

I

f 0.001 ! 0.0001 : mm 1

I

j 0.0001 ; 0.00001

0.001 j 0.ooo1 ’ deg i

/

Unit 1

inch /

+

Valid data range: -99999999 to 99999999

The coordinate values of stored stroke limits I in the positive and negative directions are set for each axis

in the machine coordinate system. The outside area of the two limits set in the parameters is inhibited.

Note 1)

Note 2)

For axes with diameter specification, a diameter value must be set.

When the parameters are set as follows, the stroke becomes infinite:

parameter 1320. < parameter 1321

For movement along the axis for which infinite stroke is set, only incremental commands are

available.

If an absolute command is issued for this axis, the absolute register may overflow,

and normal movement will not result.

7

I

: .

/ 1322 i

1

;

/-) Ls

Coordinate value of stored stroke limit 2 in the positive direction on each

axis

Coordinate value of stored stroke limit 2 in the negative direction on each

’

A

7

’

1 ,

Data type: 2-word axis

Unit of data:

Increment system

i Millimeter machine

I Inch machine

; Rotation axis

/ IS-A 1 IS-B j IS-C f Unit 1

1

i 0.01

! O-001 / 0.00Ol j 0.00001 : inch i

; 0.01 i 0.001 [

f 0.001 j 0.0001 i mm i

0.0001 ; &g i

‘(

I

Valid data range: -99999999 to 99999999

Set the coordinate values of stored stroke limits 2 in the positive and negative directions for each axis in

the machine coordinate system. OUT, #O of parameter 1300, sets either the area outside or the area

inside specified by two limits as the inhibition area.

Note) For axes with diameter specification, a diameter value must be set.

I

/ 1324 i

I

i

i 1325 j i Coordinate value of stored stroke limit 3 in the negative direction on each axis

L I I

I

I

Coordinate value of stored stroke limit 3 in the positive direction on each axis

1

I

I

I *

J

,

I

Data type: 2-word axis

Unit of data:

-45-

Page 51

4.5 Parameters of Stroke Limit

I

Increment system

j Millimeter machine

! Inch machine i 0.001 1 0.0001 i 0.00001 j inch 1

I

Rotation axis

i

i IS-A ; IS-B i IS-C i Unit !

! 0.01

I

/ 0.001 0.0001 j mm

I

I 0.01 I i 0.001 i 0.0001 ! deg :

j

Valid data range: -99999999 to 99999999

Set the coordinate values of stored stroke limits 3 in the positive and negative directions for each axis in

the machine coordinate system. The area inside the limits set in the parameters is inhibited.