Page 1

FANUC Series 16/160/18/180 –Model B

CONNECTION MANUAL

(Hardware)

B-62443E/02

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The export of this product is subject to the authorization of the government of the country

from where the product is exported.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by or in the main body.

Page 3

H2443E/O2

Table of Contents . .

IPREFACE ............................

.....................

........

2. CONFIGURATION . ..e..*...m.**..o~*.*.~**~.~a~mmm~a~~.*...o~~.~~..*..*...~.

3.1

3.2

3.3 POWERCAPACITY

3.4 DESIGN

3.5 THERMAL DESIGN OF THE CABINET

3.6 INSTALLING THE HEAT EXCHANGER

3.7

3.8 CONTROLUNIT .................................................................

3.9 C~LELEAD-INDIAGRAM

ENVIRONMENTAL REQUIREMENTS OF CNC

INSTALLATION CONDITION OF SERVO UNIT

................................................................

........................................

........................................

AND INSTALLATION CONDITIONS OF THE MACHINE TOOL

MAGNETICCABINET

3.5.1 Temperature Rise within the Cabinet

3.5.2 Coolingby HeatExchanger

3.5.3 HeatLossofEachUnit

3.6.1 CoolingFinA/B/C ............................................................

3.6.2

3.6.3

3.7.1

3.7.2

3.7.3 Connecting the Signal Ground (SG) of the Control Unit

3.7.4

3.7.5

3.8.1 Configuration and Installation of the Control Unit

3.8.2 Battery for Memory Backup

Heat Exchanger for CRT/MD1 Unit

The Heat Pipe Type Heat Exchanger

3.6.3.1 Installation

ACTIONAGAINSTNOISE

Separating Signal Lines

Ground .....................................................................

NoiseSuppressor .............................................................

Cable Clamp and Shield Processing

.............................................................

...............................................

...............................................

......................................................

..........................................................

.............................................

................................................

..............................................

..............................................................

.........................................................

........................................................

...............................................

....................................

.....................................................

.......................................................

...............................

.........

1

3

5

5

5

6

8

8

8

9

10

10

15

18

18

22

22

24

25

26

27

30

30

34

36

TOTAL CONNECTION

4.

4.1 CONTROLUNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1 POWER SUPPLY UNIT PANEL LAYOUT

5.2 POWER SUPPLY UNIT CONNECTION

5.3

5.4

CONNECTION OF I/O UNITS TO MACHINE INTERFACE . l l . . . . l l . l l l l l l l a l l l l l

6.

6.1

6.2

24V INPUT POWER SOURCE

5.3.1

5.3.2

5.3.3 Procedure for Turning off the Power

Power Supply for the Control Unit

Procedure for Turning on the Power

CABLE FOR POWER SUPPLY TO CONTROL UNIT

GENERAL....................................................................... 76

CONNECTION OF THE FANUC I/O Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

*m*~mm*m*~~*mmom~~m~~mo*~mo*~m*~~*~o~*mm~mmm**o*m~mmo*

.............................................

...............................................

......................................................

................................................

...............................................

..............................................

...................................

c-l

50

67

69

71

71

73

73

74

75

Page 4

TABLE OF COIVTENTS

B-624436/02

.

6.2.1 General .....................................................................

6.2.2

6.2.3

6.3

6.3.1 Structure of FANUC I/O Unit-MODEL A

6.3.2

6.3.3

Connection of FANUC I/O Link by Electric Cable ...................................

ConnectionofFANUCI/OLinkOpticalFiberCabIe

................................. 79

CONNECTIONOFTHEFANUCI,‘OUnit-MODELA ...................................

..........................................

OuterDimensions.. ...........................................................

Mounting and Dismounting Modules ..............................................

6.3.4 ConnectionDiagram ...........................................................

6.35 Connecting Input Power Source ..................................................

6.3.6 Grouding ....................................................................

6.3.7 ConnectingSignaIcabIes .......................................................

6.3.8 Connecting with I/O Modules ....................................................

6.3.9

DigitalInput/OutputModule

6.3.10 Correspondence between I/O Signals and Addresses in a Module

6.3.11 Number of Points for I/O Unit-MODEL A

6.4

CONNECTION OF MACHINE OPERATOR’S PANEL INTERFACE UNIT ..................

6.4.1

6.4.2

6.4.3

6.4.4

6.4.5

6.4.6

6.4.7

6.4.8

6.4.9

FunctionOverview ............................................................

System Configuration ..........................................................

SignalAssignment ............................................................

Interface ....................................................................

PMCAddresses ..............................................................

Major Connection Precautions ..................................................

State of the LEDs on the Machine Operator’s Panel Interface Unit

Connector (on the Cable Side) Specifications ......................................

Machine Operator’s Panel Interface Unit Dimension Diagram

.................................................... 90

........................ 92

.........................................

...................... 110

(Including Connector Locations) ................................................

6.4.10

6.4.11

6.5 CONNECTION OF OPERATOR’S PANEL CONNECIION UNIT

6.5.1 Input Signal Regulations for Operator’s Panel Connection Unit

Machine Operator’s Panel Interface Unit Mounting Dimension Diagram

Fuse Mounting Position .......................................................

......................... 116

........................ 117

6.5.2 Output Signal Regulations for Operator’s Panel Connection Unit .......................

6.5.3 Connector Layout for Operator’s Panel Connection Unit

............................. 119

6.5.4 External View of Operator’s Panel Connection Unit .................................

6.6

CONNECTIONOFI/OCARD ......................................................

6.6.1 I/O Card Input Signal Regulation

................................................

6.6.2 Specifications of the Output Signals of the I/O Card (Sink Type) .......................

6.6.3

6.6.4

6.6.5

6.6.6 Address Mapping of I/O Card (Sink Type)

Connector Layout of I/O Card (Output on the Sink Side) .............................

Connector Pin Layout of I/O Card (Sink Type) (Input Signals) .........................

Connector Pin Layout of I/O Card (Sink type) (Output Signals)

........................ 130

.........................................

6.7 SOURCEOUTPUTI/OCARD.. ....................................................

6.7.1 Input Signal Specifications .....................................................

6.7.2 Output Signal Specifications

....................................................

6.7.3 ConnectorLocations ..........................................................

6.7.4

6.7.5

Pin Assignment of the Input Connectors on the Source Type I/O Card

Pin Assignment of the Output Connectors on the Source Type I/O Card

................... 143

6.7.6 AddressMap.. ..............................................................

77

78

81

81

81

82

83

84

85

86

89

93

94

94

96

97

99

109

110

110

112

................. 113

115

118

121

122

123

124

125

126

133

138

138

140

142

................. 145

146

c-2

Page 5

8_62443E/o2

TA8LE OF CONTENT-S

6.8

USEOFTWOVOCARDS..

6.8.1

6.8.2

6.8.3

Specifications of Input and Output Signals

VOCardAddressMap

Addresses Assigned to Each I/O Card

.......................................................

........................................................

7. CONNECTION TO CNC PERIPHERALS

7.1

7.2

7.3 MANUAL PULSE GENERATOR INTERFACE

7.4

7.5

7.6

7.7

7.8 HIGH SPEED DI SIGNAL INTERFACE

7.9

7.10

CRT/MD1 UNIT INTERFACE

7.1.1

7.1.2

Outline .....................................................................

CRT or PDP Display Interface

......................................................

7.1.2.1 CRT or PDP display interface

7.1.2.2 9” PDP display interface for CE marking

7.1.2.3 14” CRT/MD1 unit interface for CE marking (14” analog CRT unit)

7.1.3

7.1.4

7.1.5

7.2.1

7.2.2

7.2.3

7.2.4

7.2.5

7.2.6

LCD Dispiay Interface

Adjusting the Flat Display

Keyboard Interface

I/ODEVICEINTERFACE

RS-232-CSerialPort

PPRConnection

........................................................

.....................................................

...........................................................

.........................................................

.........................................................

.............................................................

Portable Tape Reader Connection

FANUC FLOPPY CASSETTE Connection

Connection of Tape Reader without Reels

Connection of Tape Reader with Reels

REMOTE BUFFER INTERFACE (RS-232-C)

REMOTE BUFFER INTERFACE (R-22)

DNClINTERFACE

7.6.1

7.6.2

Multi-points Connection

1tolConnection ............................................................

DNC2INTERFACE(RS-232-C)

SPINDLE INTERFACE

7.9.1

7.9.2

7.9.3

7.9.4

Serial Spindle Interface

Analog Spindle Interface

a Series Spindle Amplifier Interface

Position Coder Interface

SERVOINTERFACE

7.10.1

Outline

.....................................................................

7.10.2 Servo Amplifier Interface

..............................................................

......................................................

....................................................

...........................................................

........................................................

......................................................

.......................................................

.............................................................

......................................................

7.10.2.1 S series servo amplifier (Series 16 MAIN-A SPEC.)

7.10.2.2 C series servo amplifier a series servo amplifier

(Series 16/160 MAIN-A SPEC.)

7.10.2.3 C series semo amplifier (Series 16/160 MAIN-B SPEC. and Series 18/180)

7.10.3 Serial Pulse Coder Interface

7.10.3.1

7.10.3.2

Serial pulse coder A and B (Series 16 MAIN-A SPEC.)

Serial pulse coder C (for OS or subsequent models)

....................................................

(Series 16/160 MAIN-A SPEC.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.3.3

Serial pulse coder C (for models MS to O-OSP

(Regardless of incremental or absolute command))

(Series 16/160 MAIN-A SPEC.) . . . . . . . . . e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

........................................

............................................

. mm~mmmmmmmm*~mmmoa~mmm~mmmm~mmm~

..................................................

..............................................

.....................................

................................................

........................................

.........................................

............................................

........................................

.........................................

...........................................

..............................................

.............................................

............................

............................................

....

................

.......... 187

. . . . . . . . . . . . . . . . . . . . . . . . .

152

152

152

153

154

155

155

156

156

157

158

159

160

161

162

162

163

164

165

166

167

168

170

172

174

174

175

176

177

178

179

180

181

183

184

184

185

185

186

188

188

189

190

c-3

Page 6

TABLE OF COi’JTENTS

B=62443E/o2

7.1034 Serial cz pulse coder interface

7.10.3.5 a3/30OOto

a40/2000,aC3/2000 to aC22/1500.. ...............................

...............................................

7.10.3.6 Cable connection for the incremental pulse coder ...............................

7.10.3.7 Cable connection for the absolute pulse coder

7.10.4 Separate Type Detector Interface

7.10.4-l Linear scale interface

................................................

.....................................................

..................................

7.10.4.2 Separate type pulse coder interface ..........................................

7.11

7.10.4.3 Input signal requirements

7.10.4.4 Time requirements

7.10.4.5 Receiver circuit

7.10.5

APC Battery Interface

ANALOG SIGNAL INTERFACE

..........................................................

.........................................................

..................................................

.......................................................

...................................................

APPENDIX

A. EXTERNAL DIMENSIONS OF EACH UNIT.. . . . . . . . . . . l ~mmmmomomommmoomommmmm

B. EXTERNAL DIMENSIONS OF EACH CONNECTOR . . . . . .

Cm Z&PIN INTERFACE CONNECTORS AND CABLES

m

l mmmmm~mmmm~mmmmmmmm 243

l l m l l l l l l l l l m l l l l a l l l l l l l 266

191

193

195

196

197

197

198

200

201

201

202

204

207

D. LIST OF UNIT FOR CE MARKING

l a~~~om~mmom~~~~mmmm~~omam~m~~~mmommmoooao

275

Page 7

B=62443E/o2

::.:.:.:.:.:.::.:.:.:.::.:.:.:,:.:,,.’.):.:.:.’::.

1. PREFACE

1

PREFACE

:.:.:.‘.~~:.:.‘.:.:.:.:.~.,.: :.:.:...:. ..,...:,. . . . . . . . . . . . . . . . . . . ..,.. .:.*. . . . . . . . . . . . -.....- . . ,.,. .: . .

.,....... . . . . .:.:. .,

....I. ‘.‘.‘.‘.‘.‘.‘.‘.‘.~,.:. :.::,::..: ._., . ,... :;;.... ., :........,.:. ,. ,,.,., :,:, ,,

. . . . . .:....;.... . . . .

: .‘.‘,:,~:::~‘:‘:::‘:::~~:::::,:,::: : :. ..:_

:::::::‘.:::::.:j::::::::::.~~:::~.~ ~:;;;. . . . .

:::::; i:i::‘:“‘:‘:‘:‘:::::;:‘:::.:.:.:.

. : .:. . . . .

. . . . . . . . . . . . . . . . . ..~............

. . . ..‘.......‘..........

‘..,.. ~...v,.:,_.:,.

::::::‘:::::.:::‘:::::::~~:..: . : ..?. . . ,j: ,.,.: .;:..,.. . . ,..., ;;. . . ..:. : .::

. . . . . . ~.,.,‘,‘,.,.~~~) ~ :.,. :::I :.:.:,::

:.:.:.:.:q.:.:.: .,.......

. . . . . . . . ..~.........:.:.:.~.:.:.: ..,. :.:.‘2.~.~.~.~.~,.~ ..,. >>:.. ,... :.:.:+:.y,- ..,.... . . . . . . . ..i.... ~... ..L. ‘I. . . . . . * . . . . . . . . . . . . . . . . . . . ..,.............i..............................,... . . . . . . . . . .

.* . . . . . . . . . . . . . . . . . . ..+.. . . . ..‘.....‘.....‘...............................~..~~~.........,.......,.....,......... :.~:::.~:.:.:.~.~~:..:...‘.‘.‘...’. . . . . . . . . . . . . . . . . . ..5....... . . . . . . . . ..,.. . . . . . . . . . . . . . . . . . . . . . . . 5

. . . ,:,:.,,. .,,,,,: :,.. .:. : . ,‘.~,..~.~,..~.~ ‘...‘....,..

::. . . ...‘.‘.‘. .‘:::::‘::.: . . . . . :.:.:.:.:.,. . . .

. .

. : ::. .,:;: ...’ ‘1 :.

. . ...‘.‘. ,L....

. ..‘. . . . . . . . . . . .

.,.‘.‘.‘.‘.

..::;:

.,.,.,.,.,.,.

.,...,..,..... .,...,...,

.,

. ..,.. . . . . ..-.. . . . . . . . . . . . . . . . . . .

,.

. . . . . . ..,., :. .: .:

.,,~,~.,,~.,,I.:.:,~ .,+:.:.,.:.:. > :+::.:,., :.I :.;:: ‘.’ ‘.‘.>: +:.:.:.>:.:.:.:.:.:...:.>..:.; y.‘.‘.‘.‘.“:. . . . . . . . . . . . . . . . . . . . . . :.::.:., . . . . . . . ..,...,.,.. . . .‘.L.... .

”

‘.’ ....’ ~.‘.‘.‘...‘.‘.‘.‘.‘.‘.:.:.:.:.~.~~.:.:.:.:.~. . . ..+ :,: .:...:,:, .:. i..,...,... . . . . . . . ‘.,.:.~:.~:.‘.:.:.:.:.:.~ :.,.:.: . . .: :.,..

. ‘.’ . “‘:‘:““‘:“.::::::.::.,:: 2.: :.: :.:.:,:.:.:.:.: ,.,.~.,.~,~,~.,.,.2~.,.~.,,., . . .

‘:.,:::,:::.‘.:.‘.:.:o . . . . . . . . . . . . .

. . . . . . I . . . . . . . . . . . . . . . . . . . . . . . . . . . . r ..*.,..._.*.......,. :...:.:.:.:.:...:.:.,.~ :.

. ..: ..,.. ,........., . . . ..,.... . . . . . . . . . . . . . .:, .i...,........,.. . . :: .:...:.::.:. . . . . ., ,.,.,.:. ,.: . .

:.:.:.:.:.:.:.:...... . . . . . . . . ..h’...

. . . . . . . . . . . . . ‘.~:.:.:.:.:.:.:,:.:...~.~.!.~,~.:.... .,..

.

. . . ::.. .‘.‘.:.:‘:.:. x::::::: :,.. >:.x,. . . . . . . . . . . . . ..-...-. . . ,.. .:,:,;:.:,:,,.:,> .>: ~.~.~,Y.~.~~

: ‘.:.:.:...‘,‘: >:, . .

:.:,. ,...: ,.,:. ,,,: ,.,:..,.,,,

,. . . . . ,. .,. .,... :.:.,.: ‘.:.:.: ‘.‘.:I :.:.:.:.‘.:.:.:‘.:.:.:.~:,:..,.,... S........... ..;, . .

: . . “...‘.‘... .‘...‘...’ .‘.‘.’ .‘..‘.‘.‘.‘. ..‘i..,‘... :. , .

_. . . . . . . . . . . . . . . . . _... . . . ._... . . . .._...,. .,.......,... . . . . . . .

. .?i.‘.‘.. ~.~.‘.‘.~.~.~.~.~.‘,~.~.~.~.. . . . . . . . . . . . . . . ..l.......-....‘. .:::. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .

.: . .

. . . . . . . .,. . . , . .., .. . ... . . . .,. ..,._. ...,’ . . _ . . .

This manual describes the electrical and structural specifications required

for connecting the CNC control unit to a machine tool. The manual

outlines the components commonly used for FANUC CNC control units,

as shown in the configuration diagram in Chapter 2, and supplies

additional information on using these components. Refer to individual

manuals for the detailed specifications of each model.

The models covered by this manual, and their abbreviations, are :

\

. . . . . . . . . . . . . .

. . . .

.

.,,__,._, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . >:...>:l: ,... ..y.: : ..: ..:.: ; ::::: :.:.: y+$:::. . . . . . . . .::,.. . . . . . . . .,.,. ._.,. .F.> .:..,.v ..v...,.>>: ‘. .,... ._

.‘.S.......,............. ~.~.L~...~.~,~.~.~.~ . . .

. .

. . . . . :.y.: :.:.:.:.: I:.‘.: ;. . . .‘...‘...‘...... “““:.y$$:::::::: ‘.‘.‘.‘.‘.‘.: ‘.:.‘.: 1, ;;:

. . .,.*...,..... .,.,.;.. .~‘~.,‘,.,‘,‘,‘,‘~.~.~,~‘.~ .:.:,:.:. . ..z.:.:‘:‘.,:,. >: .,.,

. ..::::... .*. . . . .., . . . . .

Product Name Abbreviations

FANUC Series 16-TB

FANUC Series 16-MB

FANUC Series 18-TB

FANUC Sen’es

FANUC Series 160-TB

FANUC Series 160-MB

.,.,....

. . . . . . .;::... . . ..i......... .;;

.

::, . . . . ...“.‘.

. .:.:.:.:.~,:.:.:.:‘.:.:,:,~.:.~.:.:.::.’.’,’”.’. .*.‘..+:.L* ‘,‘.‘.‘.‘.‘.:.:.:..:.:.~.:.:,:.~:.:.~~:.:.’.~...‘.‘...‘. . . t

.

.

. .:.:.: : : ,..

.

. . .,.. .,. . . . . . . . . . . . . .. ,... . . .

. . . . . . . .

. . . . . . . . . . . . . .

. . . . ..‘.‘.‘.~.~.~.‘.“.“.“. ..‘.

*...-..... . . . . ..‘.......... :.:.: ,.

:+>:.:.>>:.: ..,.:

.‘.1.‘.‘...‘.‘.’ ‘.‘. . . .I..,.,.,...,.,._...,. . . . . . . . .

. . . . . . . . ::

::

1 &-MB

. . . . . . . . . . . . .

,, ::::.:~:~:::#:i:i::::::::::::::;:.:.:.:.:.~:.~.:.:.:.:.~::~!~:~, y: :.,. .,

_...,... .;....,.,... ~..~..:.:.~:...:...~..:...~.,.:.:. . . .: .:. .:. ._ :.:.:.: :. . .:.:., . . . .,.. ..:....,.. ..,...;. ,.. ,+:. ~..: :.:.:> 1.1.: :. ,: ,:::. ..:.: :,, ,.. .:

._ . . . ..,.

. . . . . . . ..,....... . . . . . ..:: : >:...;.;:‘: ::::.:;‘::‘:.:., . ..,., ‘. .‘.‘I :::..:. . . . .T’ . :. :.:..:. .::. .‘.‘.‘. . . . . . . . ..., . . ._

. . . . . . . . ; . . . . . .

. . . . . . . . . . . . . . .>:.:.:.:.:.y . . . . .

:,:.:.:,:.:

. . . . . . . . . . . . . . . . . . . . ..~.....~. :.:.:.:.:.:.:.:.:.:.~...‘.‘.....:.:~ ‘..

. . . . . . . . .*..... . . . . . . ..‘.\’ ::

. . . . . . . ..‘. . ., :.:.:.:.:.‘.....,.,...,., ,..., ,.. ..,.....,. ._ ..,.

‘Q’.‘. .,.:.: >:.>:.:.: . . . . ..,....... .,...,...;: . .._ :.:.:,‘.~,:,~. : .:,. cc.::

::, . .~i.~.i’.‘..~.~.‘.~.~.~.‘.~.~.‘.’.’~.’ ...i..,.,...,. :., ;:.:. .,.:. ., ::.:.:.:: ::::::::::::.,.:.‘.:.‘.~:., .., ;, _. .,., ,... >: .,...,...,._. . . . . ,.,....... ,. . ,.. ., ,, .,,;,, ,, .,,. .

. . . . . . . . . ...‘.’ ‘. . . . . . :.:.:>,.:.: ; .:: .y:. ‘.

‘... :::, . . :.:‘::.‘:~::.p .:+:.:-: :.:.‘.:x.: :.:.;.:.:...:.:.:...‘.:.‘.:.:.~.:.:.: :.:.: :..:y+.:. q:;,::i : :_i; .,,,,,,... .;,,,. ..:,:, ~:

., ,.,. . .,. .,. ._ ,. . . . . . . . .;,...,.,... . . . . *.. .,...,...,

. ., . . . : . ‘.‘.++. .:.:,.,.., : . . . . . .

:.: . . .’ .:.:.:.: . .

.’ :j :::. :, :.:..,. .‘.. . . . . .:.,.:.:. ..:,

.i:... . . ,.::.; .,.:

,.,.....,.,..... :.,.:.:. . . . . .,..., .

16-TB

l&MB

18-l-0

18-M%

160-TB

160-MB

,.>:.v.~....,.,... ....v .

c+ .:-;:. ,. .:::. .:.: ~:.:.:.:..‘.‘.‘.‘.‘.‘. ::::,.:.. .

., ,... .: :.y.: :,:.>:.:.:.‘.:.: ‘...:.:.:.:.:.:.:.:... ,, y. .,

,’ y.:. ‘,:.:.:.:. : .::: ‘: . . . . . ..,.. ‘.. . . . . . . ..:...... . . . . . . . . . .*

:. . . ...‘.... . . . . . . . . . . . . . . . . . . . . . . . ..-.......... . . . .

.> ._, .

:: ‘.‘_.’ .: ‘.‘.‘.‘.‘.‘. : .::::,. .,.. . . ., _,,, 1.1,. ,,,.. ._.. . ., ,,,. ,.

.:, ..‘...“.‘. .: :.:.,

. .

. . . .,. . . . .,. . ._. . . . . . . . . . . . . . . , . . . . . .,. . .

;. . . . . . . . . . . . . . . . . . . : . . . _.:..;.. ._.:.._.;.. . . . .

..,..., _.;: ..:.: ‘.: .,.,

. _.;

. . . .I..:+ . . . .:.:.:.... ;..:

,.:, ..: ;z.:: ,.

:;:,... ‘.‘.:.:.‘.,. .,. .;,

,.

; . . .,

:.:.:. ..,.., .., . . ,:,:g:;: .+f.i:g:.:.: ;: :_:.:. :. .,. .:.

.,..,,..: . . . . . . . . . .

. 9 .

. . . . ::.> .,:,.,:,,: . . . . . . . . :: ..,. ..:.,:::

:, :.::.:

,.

. . . :.:.>,.:.: ,,, ;, . .:. .;.:: :,:.:.:.:,:.: :~‘p:.:. .,. .

. _. ,., . .

.._, :‘,‘:..:‘..‘.“.‘.:.‘:.‘.“:.‘,

. . . . . .,. . . . . . . .,. .,. . . ., . . . . . . . . . . . . ...+ . . . . ..,. . .,...... . . . . . . . . .,, . _ .,. .,,_. ..,..: . . . . . . . . . . . . . . . .:..:y.y.:.::.~: :.:.: .:, .:: ,.... _.... . . . . . . . . .‘.‘..‘-’ ‘. . . . . . . . . ..‘.‘...‘....I..‘..‘.‘.‘...‘...‘. .‘. . . . . .T.‘. . . . ..‘.....‘.....‘i. .,.,., ,.. ..,.

Series 16

Series 18

Series 160

.::.., . :.:. :.l.~: :.::, ;,i, 1::

*

. . . . . ... ::::;:.>:.:., ::::+,:: >:::::

.,.,. ., ,,. ,.,.; . . . . .

::,: .:“i:.: ::‘,...: ::

_‘, ;;~:;~: .,: :..,::

Related manuals

FANUC Series 180-TB

FANUC Series 180-MB

The table below lists manuals related to MODEL B of Series 16, Series

18, Series 160 and Series 180.

In the table, this manual is marked with an asterisk(*).

Table 1 Manuals Related

Manual name

DESCRIPTIONS

I

CONNECTION MANUAL (HARDWARE)

I

CONNECTION MANUAL (FUNCTION)

I

OPERATOR’S MANUAL (For LATHE)

I

1 OPERATOR’S MANUAL (FOR MACHINING CENTER) (&-62454E

MAINTENANCE MANUAL

I

PARAMETER MANUAL

I

PROGRAMMING MANUAL

(Macro Compiler / Macro Executer)

180-TB

180-MB

Series 180

Specification

Number

H2442E

I

B-62443E *

1w2443E-1

B-62444E

I

8-62445E

B-62450E

B+1803E-1

I I

I I

I I

1 1

I I

1 1

I I

FAPT MACRO COMPILER PROGRAMMING MANUAL

- l-

B-661 02E

Page 8

I. PREFACE

B42443Elo2

Table 1 Manuals Related

Manual name

FANUC Super CAP T OPERATOR’S MANUAL

FANUC Super CAP M OPERATOR’S MANUAL

FANUC Super CAP M PROGRAMMING MANUAL

CONVERSATIONAL AUTOMATIC PROGRAMMING

FUNCTION

MANUAL

CONVERSATIONAL AUTOMATh PROGRAMMING

FUNCTION FOR LATHE (Series ISMODEL B, Series

16 CAP II ) OPERATOR’S MANUAL

I FOR LATHE (Series I&-TB) OPERATOR’S

Specification

Number

8_62444E-E-1

I

2z-f

B-61 804E-1

s-61 804E-2

- 2 -

Page 9

&62443EJo2

:.:.:.:.:.:.:.:.:.~,:.~:~:.:.:.:...:.:.:.:.~:.:.:.~:.:

::.‘.:.:.:.:.:.:.‘.~.~.~.~....,‘,.,..:.,.:.~.:.~.~.~..~,~.:.~:.:.:.:.:‘.~:.:.:.:.:

‘.L’i.~.‘.‘.~.‘..,~.~.....~.‘.~.~,

.,.~.~.,.~.~.,.,‘,.~.,.~.,.,.,.~.~.,.~.~.~.

:.:.:.?:.:.:.:.~,:.:.:.:.:.:.:

.:.:.~:.:.~:,:.:.:.~.~.~~.:.~.:...~...:.~:.....:.~~:.~,..~::::~:.~.:;::~::.~.:.~.......~.~...~...............~.~...

~,~.‘..,~,-.‘.‘.‘.‘.‘.‘.‘.‘.~.~.~.~.~.~.~.’.~.’.

2

CONFIGURATION

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .:.:.:.:‘:‘:..‘:.:,.:.:,:...~;.: : : : . . . . . . . .

.:.:*..:.:.:.:.: :: ,.~:.“:~.:.,.:.:.‘.‘.‘.‘.‘. ,‘.“‘.:.:.~~:.,.~:,:, ..,.;.. ‘.‘.‘,‘.‘.‘.‘,‘,‘.‘:.:.:,‘,,

:+x>.+.:~.~: cc.:.: ::.:.. . . . . . . . . . . ,.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~.... :.>:.:.y. . . . . . . . . :.:.: ~.~,~,..~,~,‘....,‘,...,...........,. .,..., . . . . . . . . . . . . . . . . . . ..‘....*...* .

.‘.‘.‘.‘.‘.‘...‘.‘.‘.:.:.:.~:.:.~: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. ..‘. :. . . . ‘...

.:.:.:.p...:. . . . . . :.:.:.:.:.:.:.:.:.:.:,:.~:.~:,:.~.:.:...:.:..,..:..,...~~:.: :v... . .

. . ..v. . ...‘:.:.:.:.‘.‘.‘!‘:‘:‘:‘:‘:‘:.,’: :‘:‘:‘: :’

:.:.: . . . . . . . . . . . . . . . . . .:: : : : : : :: : : :: : :

.>;.:.: :.:.:.: :.: : :c.:.:.:.:.:.:.:.:.:.:.:.:.: :,:,:.:.:.‘.’ :,: :,..:...: :...:.:.

:.:.>: :.:.:.:.:.:.:.:.::.:.:.:.:.:.~:.:.’.:,:.:.:.:,;.:.:.:.:.:.:,:.:.:.:.... ..,.. . . ..‘.....‘.......‘........... . . .,.

. . . . . . . . . . . . . . .

. . . ._. . . . . . . . . . . . 1 . . . . .,. . . . .,.,. , . . . . . . . .,. . .,. . .,. . .

. . . . . . . . . . .

. . . . . . . . . :.:.:.:.: :.; ,...... . ..i. . . . ..~......... ,. . . . . . ..‘...‘.‘.‘..i.‘.. . . . . . . . ‘.. .,.....,. ::_.:.:,:.:. .,.,. . .,.,.,.,...,..,

.

,. . . . . . . .

. _. . .

.I.,.: ,..,.: :::..... . . . . . .

> ,...,,, ,,,.,.,. :.: . . . . ‘.‘.:,:.:.:.~,:.:.~~~,.:

. . . . . . . . . * . . . . .‘.‘.‘...‘.~.‘.‘.‘... ..a’.‘.. . . . .’

. ...:,.... ;.. . . . . . . . .* . . . . . . . . . . . . . . . . . . . . *. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..S.............................. . . . . . . . . . . . . . . ,.........,........ ..,.... . . . . . . . . . . . . . . . . . . . . . . ... .... . .

. . . . . .,.. ., . . . . ,. .

,: . ::::‘:::::: ::::::::::::::: :::,y . . . . . . :.:.~.:.:.~:.:.:.:.‘.~~:.:.:.:.~:.~.~.:.:::::,~:.~: :.:.:.:::.: :.> ,..... . . . . . . . . . . . . . . . . . . . . . . . . . . .

.: :.:.: :.: . . .: %:.:...>,._ . . . . . .,,,.,...,. .,. .,:,: ::::::::::::::::::::.::,:: :::ij:.:.:.:.: .,.. . ._. . .., . . . . , ._. .,. . . . . . . . . . . . . . . .5.... . . . . . . . . . . . . . .‘.‘.:.:.;. .:...:::‘::::,::::.:.:.:.:.:.:.~.:.,.:.~.:.,.:,. . . . . . :,..::.:.:.:.: :+::~::+:+:.: :.:.:.: :.::::+:x.: :.:.:.::.:.~.:.‘................. . . . . . . .: .. +: :.:.:.:.‘.:.:‘.:.:.:.:.:.:.::.,:,:..

..;.... . . . . . . . .

. ;....:;. . . .::; . . ;, :. :... . .

.;

. . . .+ :. :, . ,. .,...

..,.... .;.., ;. . . .

.‘.‘...‘...... ‘i.‘.. ‘.‘.:.:.:.:.:.:.‘.:.;~ .,.;. ,.... ,... . . . . . . . . . . . . . . . . . ..i......... . . . . .

..‘.‘.~.‘.:*: . . . . . , . . . . . . ,.,.,., ..,.,...,.,...................,.......,.: y.:.: :.,.:.:..:. .

.5’.................... ‘...... “.‘.:,:,:.:.: :.:.:.:,:.:.:.:.:.:.:.~ ..,. :,:.: ..: . . . . . . .

._

. . . . ._. .,. . . . . . . . .,a,.. .,. . .,. . .,

. . . . . . . , . . . . . . . . . . . . . . :,:.?:.:.:.~f..‘.‘... .._ . . . . . . . . . . . . . . ..‘.‘..‘...‘.*.‘.“.‘...:.:.~:.:.:.~:.:.:.:.: ,....... . . . . . . . . . ,.,../..._... .;,.

_.:,... . . . . . ..: ,.....,. .~.~.,.........,.,.,...~.~~,. .,:,: :.:.:,:, :.:.:‘:~:.:.:.:.:.~~~. .:.:.y.: :.:.:.:.:.>:.: .,.I... ,...,. .,.....,.. s.: :.:.I.: :.,.:.:.:.:.:.:,~:.:.:.. ..,..., :.:,::::::::::,:..:. :.:,:. .~.:.;.:.:,:.‘.‘........, . . . . I . . . . . . . . . . . . .,..I.. . . . . . . . . .

. . . ...‘.

‘.‘.:.:...:.:.:.:.:.:.~.:.:.:.:.:.~:.:.:.:.~:.:,~:.:.:.~ ,.., :. . . . . . . ..,....... . . . . . . . . . . . . . . . . . . ..i.....‘....‘...‘.‘.‘............. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .,

. . . . . . .,...,.,.....,. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .‘.“.>>~:.: :.:.:.:.~~:.:.:.:‘~:.: : ~.:.:.:.~)~:.::.:.:.~:.:.:.:.~~:.~: :.:.>: :.‘.:.:.:.:.:.:.~:...~ .,.. ,.,.........,.,.,. ::.:.

. .i’*.. .‘.....‘.... . . . . . * . . . . . . . . . . . . . . . . . . .

:: ._.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..,...*...

‘...... . . .._ . . . . . . . . . . . . . . . . ..,.......... . . . . . . . . . . . . . ..,.......... . . . . . . . . . . . . . . . . . . . *.... . . . . . . . . . . ..:.._.... I..

. .

.

.

.

.

. . . . . . . . . . . . . . . . . . . , . ,.,.....,.,.. . . . . . . . .

. : . ...:;. ..,..‘.‘.. ‘.‘.L......‘...........‘.. ..‘.‘.‘...‘.:.:.:.~:.~. ., ..,.,..... . .,.,.

. . . .,. ._. .,...,. . . . . . . . . . . . .,. . ., .

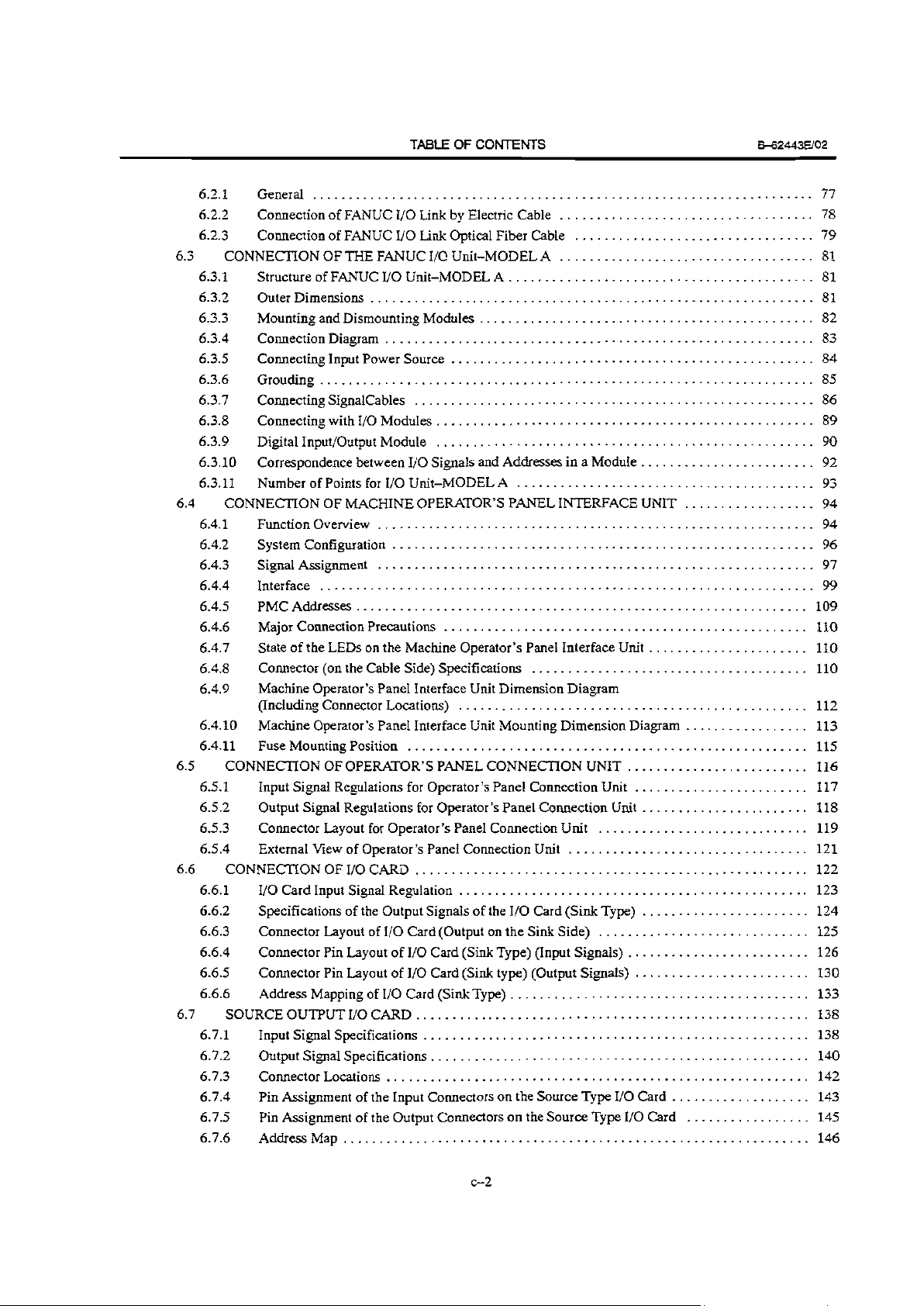

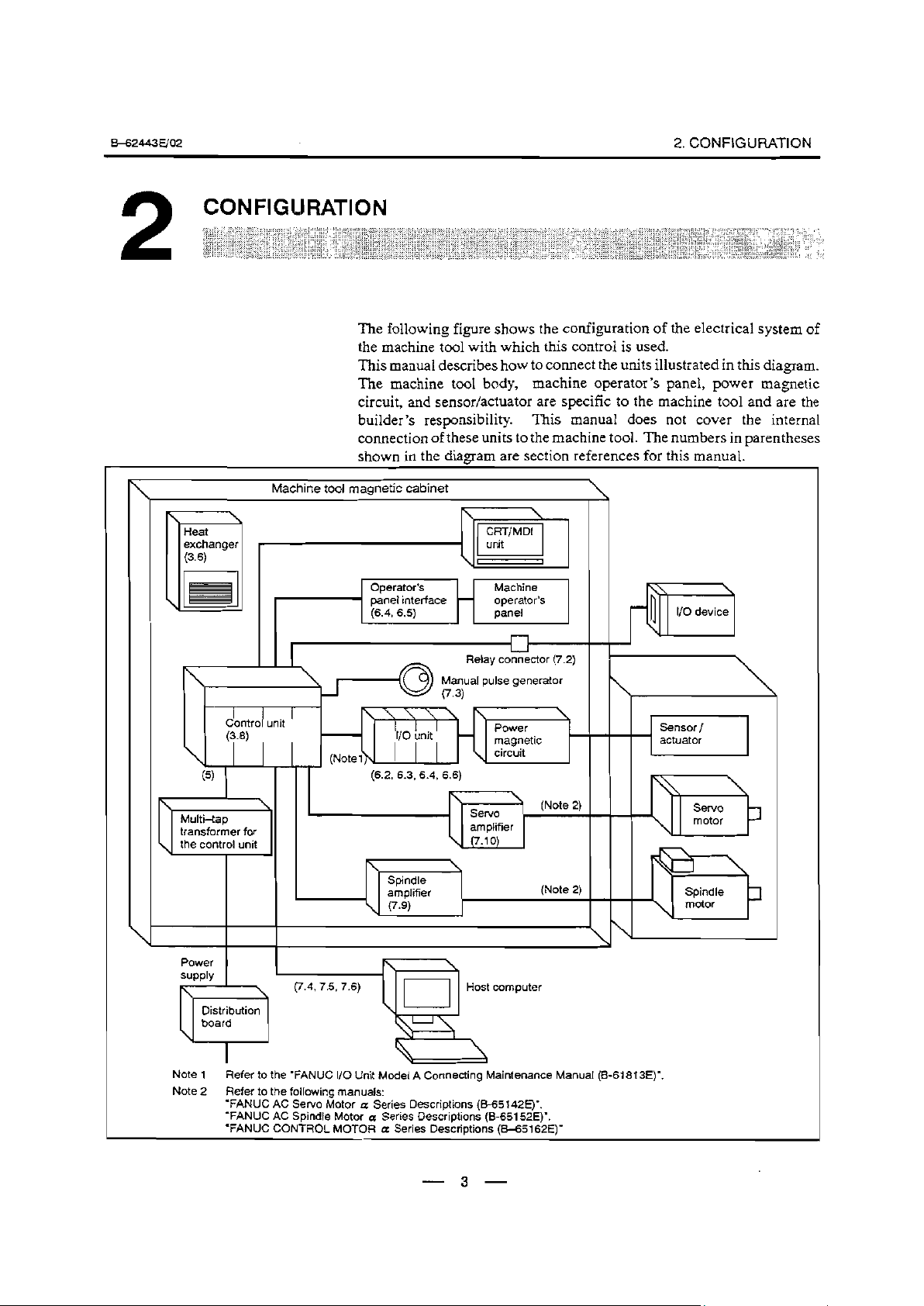

The following figure shows the configuration of the electrical system of

the machine tool with which this control is used.

This manual describes how to connect the units illustrated in this diagram.

The machine tool body, machine operator’s panel, power magnetic

circuit, and sensor/actuator are specific to the machine tool and are the

builder’s responsibility. This manual does not cover the internal

connection of these units to the machine tool. The numbers in Darentheses

shown in the

. . . . . ..‘*‘.‘.‘.:.: .,....... .;.. ._...,. :.:.: ‘:.:.:.:.~~:.“.‘.‘.‘.......‘.:.:.~.:’.: . . . . . . . _. . . . _

, .

.:.:.:... ‘......,.,. . . . . . . . . . .

. .

.

.:.~~,~:.~.:.:.:.~.~.~.~.~~.~.~,~.~.~,~.~.~.~.~,,.~~.~. +:.:.:.:,:.‘.‘.‘.’ .:... .‘.‘.‘.‘.‘,‘.‘.‘.‘.‘...‘.~.~.~...’.:.: :.:.:.:.~:.:.:.:.:.‘.‘....,..........’,.,... . . . . . . . . ..,......‘......................,..’. . . . . . . . . . . . . . .?. . .

. . . . .

.

,.,...,, .,.....,.,.,.*...... y:.:.:.:.

. . . . . . . .,., . . . . . . . . . . . . . ,*, ,.,... ., .

:: :::*: ::::::““‘“.“‘~.“‘~.‘...~..‘.:::::,:::::::::::::‘:i:i:: :..::: ~~‘:~,:i:.:l,‘:

. . . . t.. . f

. . . . *. . . . . . . ..L....... . . . . . . . . v.:.:.:.y.:.:. .: . . . . . . . . . . . .;,.,.;, . . .

. . . . . . .~. . . .,,. .

diagram are section references for this manual.’

. .

” ..:_:.:c.:.:.: :-:::.:.:.:.......::. . . . .

. . . . . :.I.>

. .,.,.,. . . .,. . . .

. . . . . .

. . . . . . . . . . . . . .,. . . . . ._.

.,,,.:,,....,.....,.........,

. . . 9 ,.,. ._. . . . .,..,.,. . .,* . .

. . . . . . . . . . . . . . . . . . . . . .

r:..:.: :.:.:.:.:.:.:.:.:.s: . . . . . . . ‘.‘.‘.:+.x...... ..‘..........................,...,.., . _.

. . .,.,.;.. ‘.: :.. >:.:.: .(.,. :.:.:.:.:.:.‘.:.:.:.‘.:.:.....~~’.~.~:.:.:.~.,.:.. ..‘...‘.....‘.‘.....‘.~.~,~,; ~:,:,: :,:.:,: :.~:,. .:.:.:.:‘: :::::,:::::::::::::j::: ._ _. ._

.,... ..‘.‘........’ . . . . ..‘~‘.

. .,,~: :::‘:‘::s >: . . . . . . . . .._. ..,.... . . . . . . , . . . . . . . . . . . .

. . . ..,.. . . . . . . ..~.~.~.~.~.....~.. .‘... ~.5....~.~.~,.,.,~......,. ..:. . .:.. . . . . . . . ..I,. . .,..., . . . .

. . . . _.

. . . . . . . . . . ~,~,~,~...5~.~, .

. . . . . . . . . . . . . . . . . . . . . .:.:.:+:.: . . . . . ..I... . . . . . . . . . . . . . . . . . . . . . . . . ..,.i... ., ..,..

.:.::.:q..

. . . . * . . . ...‘...‘.‘.‘.’ ‘.‘..Z....... . .

. , . . . . . . . .._......... ;,.*..:,.*..:. . . . .

2. CONFIGURATION

‘. . -*.*. . . . . * . . . 5............. .:........:. .:

. . ‘...‘. . .‘.‘.‘...L..... ‘.. ‘.‘.:‘:.:.~:.:,:,:,:., :,. ,..,, . . ..,..,

. . . . . . . . . . . . ...‘.....‘.‘.‘.. ‘... .

.

. . . ..*....... ..,..*.._...:..

. . . . . . . . . . . . . ..,.. ‘,‘,‘.‘.‘.‘,‘.‘.‘.:.~

. . . . . . . . ,....::..,.......;.. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .

. . . . . . .

* . . . . . . .

.

. . . . . . . . . . . . . . . . . . . .

.

““““‘::::y .,...,.....,.l.,.,..,.~. ,.;.... ..,.,,::.‘.:~ ,:,..:,: ,.,.:,:.::,...

:.. :‘.+.:.:.:.: . . . . . . . . . . . . . . . . . ‘+..

. . . ..,..‘. .

‘...‘..,..‘.............. . 7.::. ...:i:::::::~.~:,:.:.:.:. . . . .., . .

:. :.........-..,.....,.. .‘.‘.‘.,.: 1. .+.....,...,,........,...,, > :. . ..,. . . . ., ,.

.‘.‘_‘.‘.‘...~...... . . . . . . . 1.‘. .,...~.~....,,.,..,,.,. .,, .:.::.: : : : :. .:

. . . . . :.:i,... .:..:......:

.:+ . . . . . ..i...... . . . . . . . . . . . . . ,.... . . . .

,....,...,.,.,., . _.;;;.. .._ ..,...............,.....,.

.‘.... ,._. .,...,... . . . . . . .., . . .

. . . . . . . . . . . . . * ..,.... . . ..a . . . . . . . . . . . . . . . . . . . .._....... . . ._. ._. . .,

:.: . .,.. ..,.. . . . . . .,. ‘.‘.T ,. .:,

.‘.‘.‘.‘. :::. .‘. . ..‘.. .;. . . . . .,..

,.: 1.1 : >I.,.: I.‘.‘. :. ,c; .:; ..‘.,.;,.

.: :::. . . , . . , . . :.. . . :;.

.

. . ..*+. . . . . . . . . . . . ..:.

. :..:.. . . . . . . .

. . :.-:: .‘... . ...*..... . . . . . . . . .: .: . .

:.:.:.:,:. .:,:,,, ,:,: _:,:.:. .:

,. _.

:,.. ,,,,_ .:

._ ‘.: :.

:., T.1 : :.:.:,:.,_:: :.:+

. . . .‘.>,.:.:.: ,.:: ..;,:

I Inl I

1

Contro unit

.

(3 8)

(5)

1 Multi-tap

Machine tool magnetic cabinet

Operator’s Machine

Panel interface - operator’s

(6.4, 6.5)

, \ I

-

I

I II

I I Sninflle

-r- l -*-

amplifier

\ (7.9)

panel

Relay connector (7.2)

A_. .,I ,..I-- ------*--

Manual purse gewrarur

.

(7 3)

magnetic ’

circuit

(Note 2)

L

\

(Note 2)

\

.

\

1

I I\

sor /

1

actuator

J

\

b

Power

supply

I

I

Note 1 Refer to the “FANUC I/O Unit Model A Connecting Maintenance Manual (B-61 813E)“.

Note 2

Refer to the following manuals:

‘FANUC AC Servo Motor a Series Descriptions (R65142E)“.

l FANUC AC Spindle Motor a Series Descriptions (B-651 52E)“.

‘FANUC CONTROL MOTOR a Series Descriptions (B-651 62E)”

‘“gi y m puter

1

!

- 3 -

Page 10

3. INSTALLATION .

“‘..“.:.:‘:.:.‘.~:.:.~::,~:.~.~:,~~~~~~~,~,~~.~.~..

:.:.~.:.:.‘.:.:.:.:.:.:.:.::.:.:.:

..5..‘.....5...................

“‘.:,:‘:‘:‘:.~:.:,:,~~.~~~..

..‘...‘...‘...‘...i........‘.....’.’.....

~.‘.~.~.~.‘.‘.~.‘.‘.~.~.~.~.~.~.’.~.’.~.~.~,~.

“:.‘::.~~:.~:,~:.‘.:.~:,:.~,~~,,~,~~.~~.~.

:.:s.:.:.:.j:.~.:.::.:.~.~.~.~.:.:.~:,:,:,:.:,:

~.~.~.~.~~.‘.~.~.~.~.~.~.~.~.‘.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.~.‘.‘.~.~.’.~,~.~.~,~,.

~.~.~.~...~,....

.5’.‘..‘.~.‘.‘.“.‘.‘.‘.‘.‘...“..,’.’.....~.:.:.~.:.:.:.:.:.~.:.:.~:.:.~‘....

.-..‘.‘..‘.................L....’........

&62443E/o2

3

INSTALLATION

.’ * . . . . . .f * . . . . . . v... . . . . . . . . . ..I....

..‘.‘.....‘................,~..... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._....... . . . . . . ~.~.‘,~.~.~..,....~,~.~.~.~,~.~.~.~...’..,~.~. .:,:.:...:

..\.... ..,., . . . . . . . . . . . . .

. . . . ..-........i . . . . . . . . ...‘.‘.. . . . . . . . . 55. . . . .

. . . . i::::::::::::,::::::.:.~:.... . . . . . . . ..r..+.....

.*......:...... . . . * ..,.. .,..‘...f...,. .,. . .,.:... . ..: . .:.:.:.:.‘.:.:.:*:i.>‘.::.:.‘.: :...:.~.~:.f.:.:.:.~~.. .,....... ..:, :.:.~~ :,:, ::+:.: ~ ,.,...,.,.,..... .,.,.,. . . . .

.~.~.‘.‘.‘.‘,~.‘.‘.~.~......,~. .‘.‘i...‘.‘. .

. . . . . . . , . . . . . . . . . . . . . . . .._. . . . . . . . . . . . . . . . . . . . . . . . ...+... . . . . . . . . . . . . . . . . . ..,. .+...,. ~ .,.,.

‘.‘.‘.’ . . ..‘.‘..~‘...5..‘.‘............

f:.:.:.:.:.:.:.: :.~f:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.~.:.:.: :

.~~:.:...:,~:,:.::::::::::::::::~:::~:::~:::.:.:.:.:.:...:.:.:.:.:.:.:.:.~:.:.:.~:.:.:.~:.:.:.:.:.:.~

. . . . . . . . . ...*...

.,.,...,.,., . . . . . ..._...+.. . . . ,...Z_.~.,‘~.,.,.~ 5 .._....... . . . . . . . . . . . . . . . . . . . . . . .,.......:....

:::::::::::j.:::j:::::::::‘::~~::::i::::’::.:. .

f.............,.,.. * . . . . . . . . . . . . . . . . . . . . . . . . . . -: ,.....I..... . . . . . . . . . . . . ‘s’,., . . . . . . . . . . . *....,* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..,...:.

.,. . . .,. . . . .,., . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . * . . . . ..‘.......‘.5..‘......‘...‘... ..:.-...........- . . . . . .,.,. ..‘.., . . . . . . . . . . . ..,.:..........,.:;.. ,...:. . . . . . . . . , . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . :.:.:.:.~:.:.:.:.:.~.:.~.~:.~...’...........’...‘.‘..‘.‘. .

. . . . . . .

. . . . . . . . .. . . . . . . . . * . . . . . . . . . . ,.... . . . ...* * . . . . . . . ..I....... . ..,.......,.. :.:

. . ..*.........

..‘.......S....‘.i....‘...‘..........

*

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ,.,.i~.~.,.,...~.,...,.~.,.

:.:*:.:.:.:.: . . . . . . . .

,.. ,...... ,.,.. ,... . . . . . . . . . . . .

.; ..,.......,..., ..,.....,.....,.,.. , ,.,.,...,. . . . . . . . . . ..,...

. . . .

. . . . . . . . . . . . . . . ;.:2.:.: : ..:.:.> . . ,.. . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . ..,..,..,.......................,......,,..

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . .

. ..‘.‘. . . . ..‘.L..‘. : ‘...... . . ‘.‘.‘...’ ‘..::.-.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . I . .~...,...,.,.~.,.,.~.,.~ . . ..,..,, .,,,.,.,.,.l. . . .., ,.... . . . . ...*......... . ..v...‘...‘.

:

: : :. :

:: ::: : : : 1.1 ..,.

. . . . . . . . . . .

. . . . . . . . . . ,...,.,..._. .;,. . ..., :,:,:,:.: :::::::::‘.:::::.:.~~~~.....‘.‘..’.’.’.’...*...:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , .,...,.,...,.,... .,.,.....,.,.....,...,... . . . . . . .

. ,.,.,.,.,..., ._..... :,:_:.: .:,:_:,: ,:.:,..::,,..,.,. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ,..... .I...... . . . . *. . . . . . . . . . . . . . . .

. .

,~:....;;: :...., -.. . . . . . . . .:: . . . ..L...... . . ..* . . . . . . . . :‘:.:.:.:.I::.:.~:.:.:.:.: :.I~:.:.:.:.:.:.:.:.: :.:.:.~~:.:.:.:.:.:.:.:.~.:.:.:.~.:

.

. . a.. . . . . . . . . . . . . . . . . . . . . . . . . . .:,..:. ~ ..,... . . . .

. . . ,.... t ,.,.,.......,.,.,.......

.:.:,:.‘.:.:.:.:.:,:.~:..,... ..Z. . . . . .

. . . . . . .,.,. ‘.“:.‘.:3:.:.:.:.:.:.‘.:.:.:.:.~~. . . . . . . .: : ::: : :::

:.:.:,: :,:,:,:,: . . . . . . . . . . . . ,.,.,...... ,‘......I..........,. . . . . . . . . . . ..‘.‘.‘.‘...’ . .’ -. . .

.‘... : . ..‘.....‘.‘.‘........‘.‘.. ‘.‘...’ ..‘...... L....

. . .

. . . . . . . . . . . . . . I . . . . . . . . . . . . . . . . . . . . . . ..‘..........

., ;.,,., ;. . . . . . . . . . . . . . . . . . . .

.,.~.,.,...,.,.~.~.,.~.,.~.,.,.,.~ ..,

..: .:;:.:

. . .

. .

. . . ..,...,.............,. _ .............,.,...r.,...

..‘.........‘...,. ..,..f .,... . ..‘. .:...... . . . . . . . . . . . . . .

‘...i.

.

. ..,.,.

.2.::.:.:.~.:,::‘:::‘:.:.:.:.:.:.:.~,~.~..~.:.:~.:.~~.:.:.:.:.:.~~.,~..

. . . . . . . %... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . * . . . . . . . . . . . :.‘.:.:.f:.~.~. .:.:.I~:.:.:.:.:.:.:.:.~ ..,.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . ,.,.......,.I........,............ .

. . . . .‘..‘.’

.‘...’ .:: ‘.‘...‘...‘.f:.:.:.:.:.~:,:.:.:.:

. . . . . . . . . ..r..............................

.

. . . . . . . . .

, ,

. . . . , .

.a.... . . . . . *:.. . . . . . :.:.:.~:,:i,:.:,:,:,~,:.~ . . . . . . ..I... * . . .._.... . . . . . . . . . . ..::,...... I ,.(.. . . . ...* . . . . . . . . . . . . . . . . . . . . . . . ‘.:,:.:.:.:,:.~~:,:...:.:.:.:.:.:, . . . ..‘........... , ,.... . . . . _..-, .:.:.>:.:

.:.>:

:.:.:.‘.:.:.~:.:.:.:.~:.:.~.~:.:.:.:.: . . . . . .

. . ,.......

. . . . . . . . . . . . ..,.. . . . . . . . . . . .,... ,........ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._........ . ..> . . . . . . . . . . . . . . . . . ..f .,...:............ .,...................,.......,.. ..,.,.

. . . ..f... . . . . . . . . . . . . . . . . . . . . . ..*................

. . . . . . . .~.,.,.~.~.~.,.~.,.,.~.~.~.. . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . , . . . . , . . . ..i............... . . . ..,...,., . . . . . . . . ..,.......:............... . . . ,.......;. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . :.:.:.:.: :: :.:: : : : : :: :

. . . . . . . .._ . ..,... . . . . . . . . . . . . . . .

:......... . . . . . . . .<...:,:.:.: .:.:. :.> :.:.:. ~ :.~.~.:......,., * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . ,.,‘..,.... . . . . . . . . ..L.. . . . . . . _...... ..,.f.. ..:..;... . . . ..::,.. . . . . . . . . . . . . . . . .:..::: . . . . . . . . . . . . . ..;:. . . . . . . . . . . . :,.......,. >:.:.>..>

. . * . . . . . . ._. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .,. . . . . . . . . . . . . . . . . . . . . . . ._. . . . .,. . . . . . . . . . . . . .‘.‘.‘.‘.‘.~.~.~.~.~.~~.~ . . . . . ‘i.‘...‘...‘.‘.:...~.:.

.. . . ..,...,...,.....,.... . . . . . . . . . . . .

. . . . . . . ( . ,

..L.........,......... . . . . . . . . . . . . . .._

.:::... . . . . . . . . . . . . .P.‘.‘.‘~..‘..‘.~.‘...~.~,~ . . . . . .

. . . . . . . . . . .

.I,.*.. . . . . . ..I . . . . ..L.....

. . . . . . . . . .

. . . . . . . . . . . . . . . :.:.:.:.:.~.‘.“.‘.......~...~.‘.~

..,.....,.,.......,.....,.......,.....,.... . . . . . ..f.....................

. . . . . . . . . . . . . . . . * .

. . . . . . . . . . . *. . . . . . . . . . . . . . . . . . . .‘i.‘. .‘...........5....5..‘. . . . . , . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. .* ..‘.‘.’ ‘.............. . ...-...‘.‘...*.- -.....-........... . . . . . ‘. . . . . . . . . . . . . . :.:.i!.:.:.:.:.:.:.~:.~. :.‘:.‘.‘. . . . . . . . f .;_

..,.:,:. y: .:,., >; +:,‘*‘,....” . . . . . . . . . . ,.,.;,... :: . .

..i......; . . . . . .

<.... . . . . . .x. .Y+,..... Z...

. .

,+:.:, ~.

..,, ~~~~: ~ :.:, :z . . . . . . . . . . . . ., . . . . . . . . . . . . . . . .:.::

>:.>>:.>:.:.: . . . . . . . . . . . .

,.I..,.,...,._.,.Z.... .:.:.~:.:.:.:3:,:...‘.......‘.‘.

. . . .

. .

:.;.:.:.:.

:.:z.>>:. :.y.:.>:

.

. . . . . . . . . . . . . . . . ..,...,.....,

,.,.,...,. . . . . . . . . .. .. .....,.............,. . . . . . es..:...*...

,. .,. . . . . . . . . . . . . . . . . . . . . . . .

. . .‘...........‘.. ....’ ‘...‘.. ..’ . . . . . . . . . . . . . . . . . . . . .,.,.,.,.i,., . . . . . . . .

..,........ * . . . . . . . . . . . . .,. ;..

. . . . :.:...:.:.: :.:.:.: ::.: :.:.:.:.:.:.:.:.:.;.:.:.:..

.

. . . . . .,.,........... .~.,.,.,.~.,.,.,.,.~

. . . . . .

. . . . . . . . . .

. . . . . .

:.:.:.~:.:.:.:.:.:.:.:...’

. .

,...,. ::.,.:, :. .:...>:.:

: :.>:.:.:.:. . . . ::

.>>>?:.:...:.:.:.

.,._ * . . . . . . . .‘.’

.

._ ,. .

‘. .‘...., ;, . . . . .

.‘.:.:.:.‘.>:.:.:..

. . .

. . . . . . ..‘......................

>.“.‘.‘. ..‘.‘..... .‘....

.‘.‘.:.:.‘.:.:.:.:.~.‘.: y.>:.:.>>:.:.>>: .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..I 2:. Q.....,‘.‘... . . . . . . .

..:.: ‘.:.,.:,:.:.:.: :,: ,., ,.,._ ._,.,.,., ..,

:.:.

. . ,..... ,.......,. .:.:r.,.:‘::.:

. .

. . . . 9 . . . . . .’ . . . *...,.a %v..:..::.:

. . . . . a,. . . . . . . .,. . . . . . . . .,.,... . . . . .

. . . . . . .

,‘.‘,‘.,.:.:.:.,, . . . . . .

:.y .:.. .

. :: . . . . . . . . . . .

.,...,., ;...

- . . . . . . . . . . . * .

. . . . .

.>>

. .,.

- 4 -

Page 11

G62443E102

3. INSTALLATION

l

31

ENVIRONMENTAL

The peripheral units, such as the control unit and CRT/MIX, have been

designed on the assumption that they are housed in closed cabinets. In

this manual “cabinet” refers to the following:

REQUIREMENTS OF l

CNC

0

The environmental conditions when installing these cabinets shall

conform to the following table. Section 3.4 describes the installation and

design conditions of a cabinet satisfying these conditions.

Change in

temperature

Vibration

Cabinet manufactured by the machine tool builder for housing

the control unit or peripheral units;

Cabinet for housing the flexible turnkey system provided by

FANUC ;

Operation pendant, manufactured by the machine tool builder,

for housing the CRT/MD1 unit or operator’s panel.

Equivalent to the above.

45O

Room temperature 1

Relative humidity L

1 In operation:

1 Normal machine shoe environment

Environment

I

1 and/or organic solvent is relatively high.)

In operation

In storage or

lYC/minute max.

Normal

Temporary (within 1 month)

uhe environment must be considered if the cabinets

are in a location where the density of dust, coolant,

transportation

0.5G or less

0” to

-20" to 60"

I 75% or less

of less

95%

32

IiSTALLATlON

CONDITION OF

SERVO UNIT

33

PbWER CAPACITY

?

Room temperature

Relative humidity

Vibration

Environment

In operation

In storage or transportation

95% RH or less (no condensation)

I

0.5 G or less

The unit shall not

bricant or cutting chips.

be exposed direct to cutting oil, lu-

o”c to +55”C

-20°C to +6O”C

The power capacity of the CNC control unit, which in this section means

the specification required for the power supply, is obtained by adding the

power capacity of the control section and the power capacity of the servo

section.

The power capacity of the control section includes the power capacity of

the control unit, CRT/MDI, I/O unit, and operator’s panel interface.

Power capacity of

the control section

Power capacity

the servo

of

section

When

power supply Al is used and AC out-

put terminals CP2 and CP3 are not used.

When power supply Al is used and AC out-

put terminals CP2 and CP3 are

When power supply BI is used and AC out-

put terminals CP2 and CP3 are not used.

When power supply BI is used and AC out-

put terminals CP2 and CP3 are

Depends on seNo motor type.

used.

used.

0.3kVA

0.8kVA

0.5kVA

I I

1 .OkVA

I I

1

,

5

Page 12

3. INSTALLATION . 842443uo2

3.4

DESIGN AND

INSTALLATION

CONDITIONS OF THE

MACHINE TOOL MAGNETIC CABINET

When a cabinet is designed, it must satisfy the environmental conditions

described in Section 3.1. In addition, the magnetic interference on the

CRT screen, noise resistance, and maintenance requirements must be

considered. The cabinet design must meet the following conditions :

.

The cabinet must be fully closed.

The cabinet must be designed to prevent the entry of airborne

dust,coolant,and organic solvent.

Cabinets that let in air may be designed for the servo amplifier and

servo transformer provided that they :

0

Use an air filter on the air inlet ;

0

Place the ventilating fan so that it does not blow air directly toward

the unit;

0 Control the air flow so that no dust or coolant enters the air outlet

The cabinet must be designed to maintain a difference in temperature

of 10°C or less between the air in the cabinet and the outside air when

the temperature in the cabinet increases.

See Section 3.5 for the details on thermal design of the cabinet.

A closed cabinet must be equipped with a fan to circulate the air

within.

The fan must be adjusted so that the air moves at 0.5 m/set along the

surface of each installed unit.

CAUTION : If the air blows directly from the fan to the unit, dust

easily adheres to the unit. This may cause the unit to fail.

For the air to move easily, a clearance of 100 mm is required between

each unit and the wall of the cabinet.

Packing materials must be used for the cable port and the door in order

to seal the cabinet.

Because the CRT unit uses a voltage of approximately 11 kV, airborne

dust gathers easily. If the cabinet is insufficiently sealed, dust passes

through the gap and adheres to the unit. This may cause the insulation

of the unit to deteriorate.

The CRT/MIX unit must be installed in a location where coolant

cannot be poured directly on it. The unit does have a dust-proof front

panel.

Noise must be minimized.

As the machine and the CNC unit are reduced in size, the parts that

generate noise may be placed near noise-sensitive parts in the

magnet& cabinet.

The CNC unit is built to protect it from external noise. Cabinet design

to minimize noise generation and to prevent it from being transmitted

to the CNC unit is necessary. See section 3.7 for details of noise

elimination/management.

0

The units must be installed or arranged in the cabinet so that they are

easy to inspect and maintain.

- 6 -

Page 13

&-62443E/o2 3. INSTALlATlON

The CRT screen can be distorted by magnetic interference.

Arranging magnetic sources must be done with care.

If magnetic sources (such as transformers, fan motors,

electromagnetic contactors, solenoids, and relays) are located near the

CRT display, they frequently distort the display screen. To prevent

this, the CRT display and the magnetic sources generally must be kept

300 mm apart. If the CRT display and the magnetic sources are not

300 mm apart, the screen distortion may be suppressed by changing

the direction in which the magnetic sources are installed.

The magnetic intensity is not constant, and it is often increased by

magnetic interference from multiple magnetic sources interacting

with each other. As a result, simply keeping the CRT and the magnetic

sources 300 mm apart may not be enough to prevent the distortion.

If they cannot be kept apart, or if the CRT screen remains distorted

despite the distance, cover the screen with a magnetic shield.

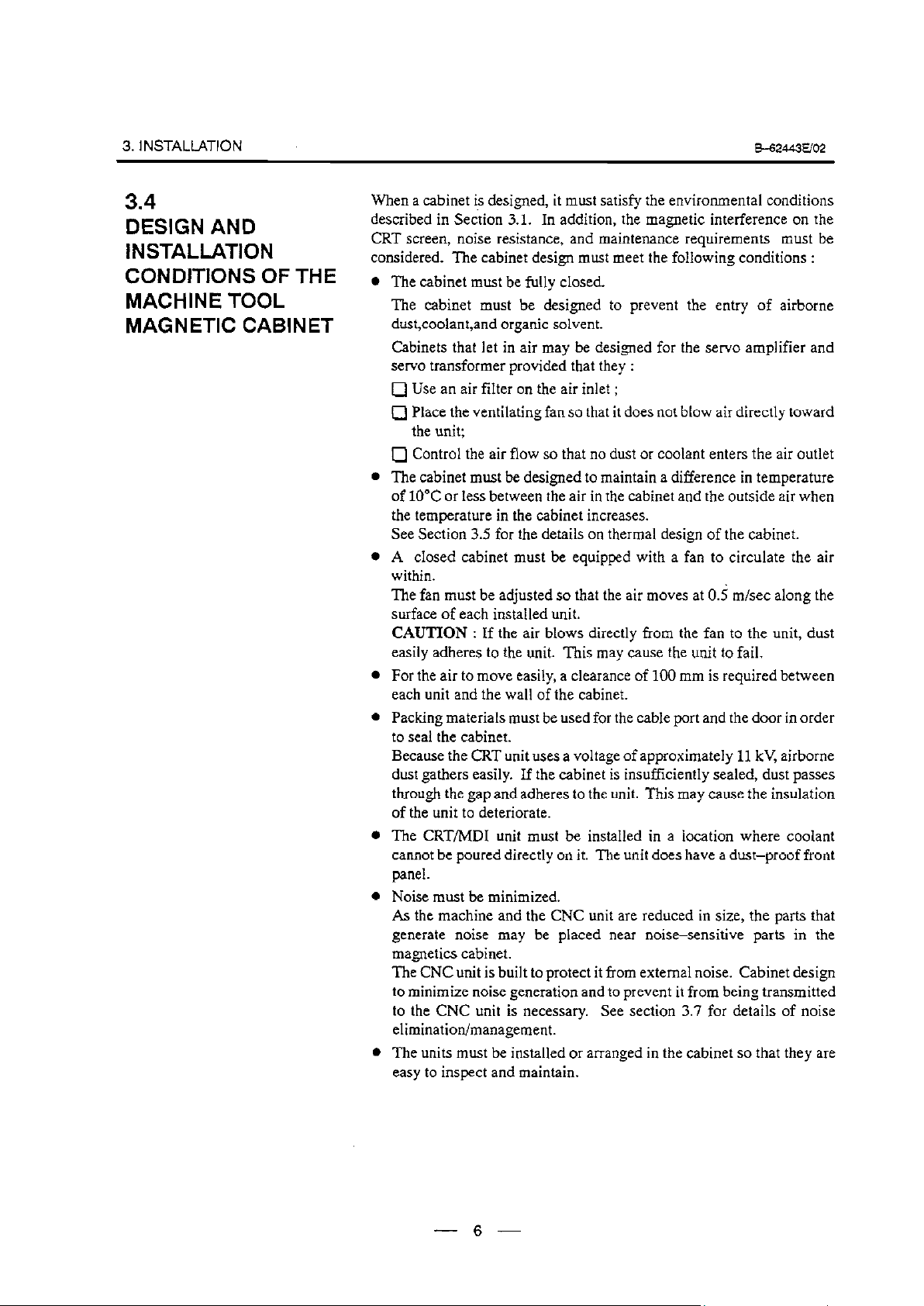

The installation conditions of the I/O unit must be satisfied.

To obtain good ventilation in the module, the I/O unit must be installed

in the direction shown in the following figure. Clearances of 100 mm

or more both above and below the I/O unit are required for wiring and

ventilation.

Equipment radiating too much heat must not be put below the I/O unit.

6ottom

l/O base unit

H (No screws or

extend from the bottom of this

unit.)

protrusions shall

7

Page 14

3. INSTALLATION .

3.5

THERMALDESIGN

OFTHECABINET

3.5.1

Temperature Rise

within the Cabinet

&-62443E/O2

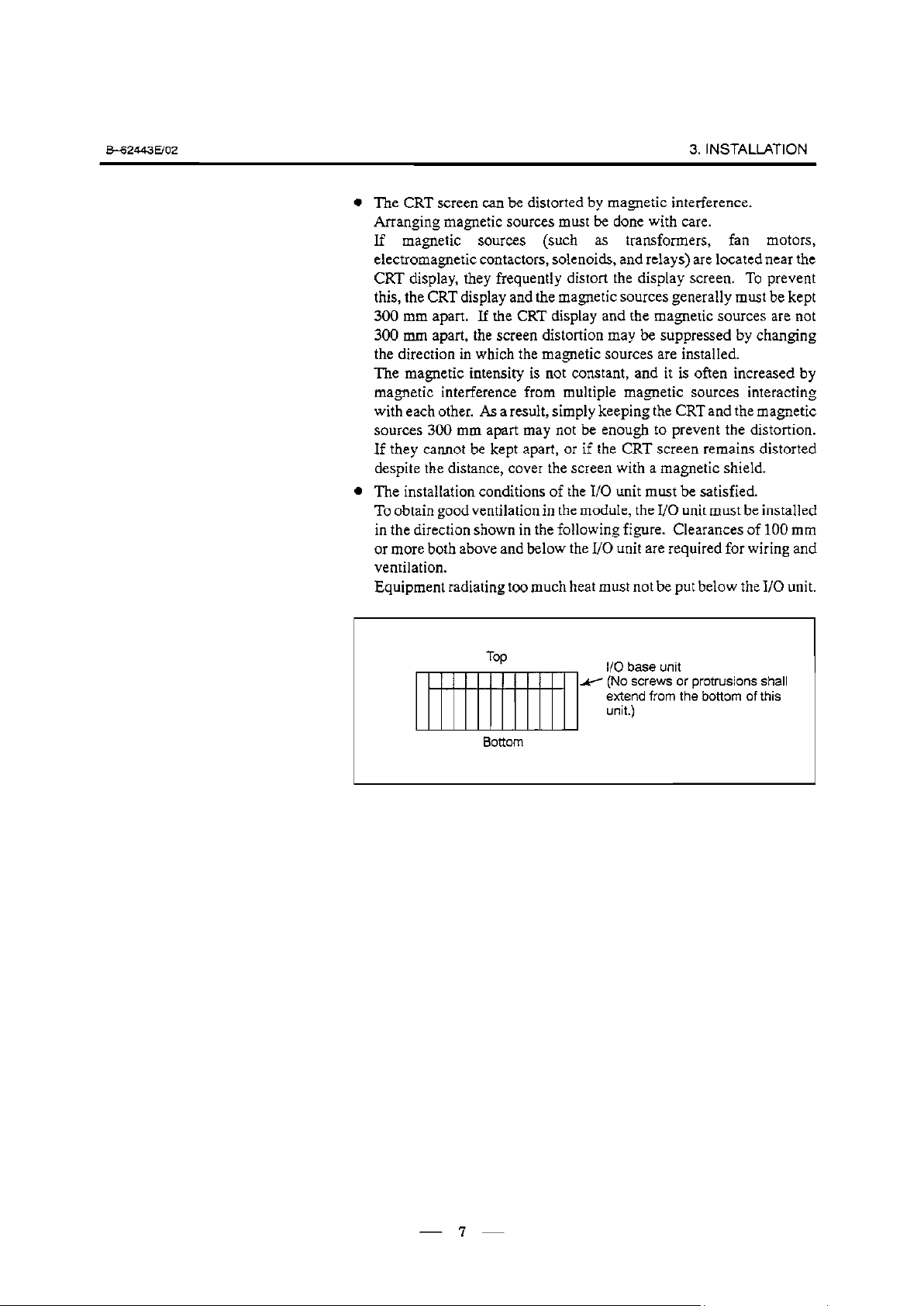

purpose of the thermal design of the cabinet is to limit the difference

The

in temperature between the air in the cabinet and the outside air to 10°C

or less .when the temperature in the cabinet increases.

The internal air temperature of the cabinet increases when the units and

parts installed in the cabinet generate heat. Since the generated heat is

radiated from the surface of the cabinet, the temperature of the air in the

cabinet and the outside air balance at certain heat levels. If the amount

of heat.generated is constant, the larger the surface area of the cabinet, the

less the internal temperature rises. The thermal design of the cabinet

refers to calculating the heat generated in the cabinet, evaluating the

surface area of the cabinet, and enlarging that surface area by installing

heat exchangers in the cabinet, if necessary. Such a design method is

described in the following subsections.

The

cooling capacity of a cabinet made of sheet metal is generally 6 W/“C

per lm2 surface area, that is, when the 6W heat source is contained in a

cabinet having a surface area of 1 mz, the temperature of the air in the

cabinet rises by l°C. In this case the surface area of the cabinet refers to

the area useful in cooling, that is, the area obtained by subtracting the area

of the cabinet touching the floor from the total surface area of the cabinet.

There are two preconditions : The air in the cabinet must be circuited by

the fun, and the temperature of the air in the cabinet must be almost

constantThe following expression must then be satisfied to limit the

difference in temperature between the air in the cabinet and the outside air

to 10°C or less when the temperature in the cabinet rises:

Internal heat loss P m (

6w/m2 l

For example, a cabinet having a surface area of 4m2 has a cooling capacity

of 24W/“C. To limit the internal temperature increase to 10°C under these

conditions, the internal heat must not exceed 240W. If the actual internal

heat is 32OW, however, the temperature in the cabinet rises by 13’C or

more. When this happens, the cooling capacity of the cabinet must be

improved using the heat exchanger described next.

“C] X surface area S[m2] X lO[OC] of rise in temperature

3.5.2

Exchanger

If the temperature rise cannot be limited to 10°C by the cooling capacity

Heat Cooling by

of the cabinet, a heat exchanger must be added. The heat exchanger

forcibly applies the air from both the inside and outside of the cabinet to

the cooling fin to obtain effective cooling. The heat exchanger enlarges

the surface area. Section 3.7 explains five heat exchangers supplied by

FANUC. Select one of these according to the application.

If cooling fin A is used for the cabinet, the total cooling capacity of a

cabinet having a surface area of 4 rn? in the example above is improved

as follows :

6W/m* l “C X 4m2 + 9.1WI°C= 33.1Wl°C

The calculated value verifies that even if the internal heat is 320 W, the

temperature rise can be limited to less than 10°C.

See Section 3.6 for installing the heat exchanger.

Page 15

562443Em2

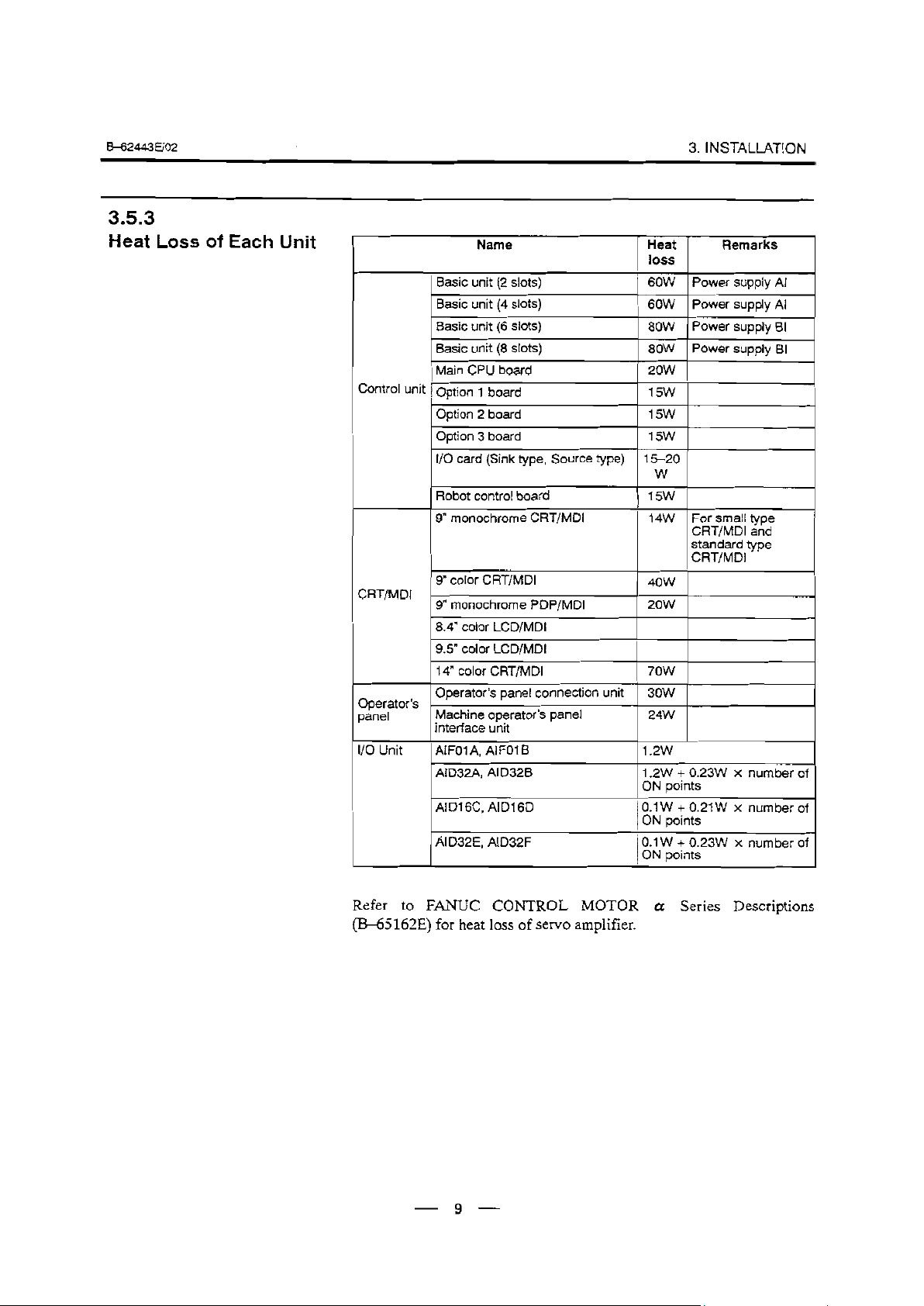

3.53

Heat Loss of Each Unit

Name Heat

Basic unit (2 slots)

Basic unit (4 slots)

Basic unit (6 slots)

Basic unit (8 slots)

Main CPU board

Contfol unit Option 1 board

Option 2 board

Option 3 board

I/O card (Sink type, Source type) 15-20

control board

Robot

monochrome CRT/MD1

9”

CRT/MD1 ’

Operator’s

panel

l/O Unit

9” color CRT/MD1

9” monochrome PDP/MDi 2ow

8.4” color LCD/MD1

9.5” color LCD/MD1

14” color CRT/MD1 7ow

Operator’s panel connection unit

I

Machine operator’s panel 24W

interface unit

AIFOIA, AIFOI B

AID32A, AID328

AID1 6C, AID1 60

AlD32E, AlD32F

3. INSTAUATION

loss

60W

60W Power supply Al

80W Power supply BI

80W Power supply BI

2ow

15w

l5W

Remarks

Power supply Al

15w

W

15w

14W For small type

CRT/MD1 and

standard type

CRT/MD1

4ow

3ow

1.2w

1.2W + 0.23W x number of

points

ON

0.1 W + 0.21 W x number of

ON points

0.1 W + 0.23W x number of

ON points

Refer to FANUC CONTROL MOTOR a Series Descriptions

(E345162E) for heat loss of servo amplifier.

- 9 -

Page 16

3. INSTALLATION .

562443uo2

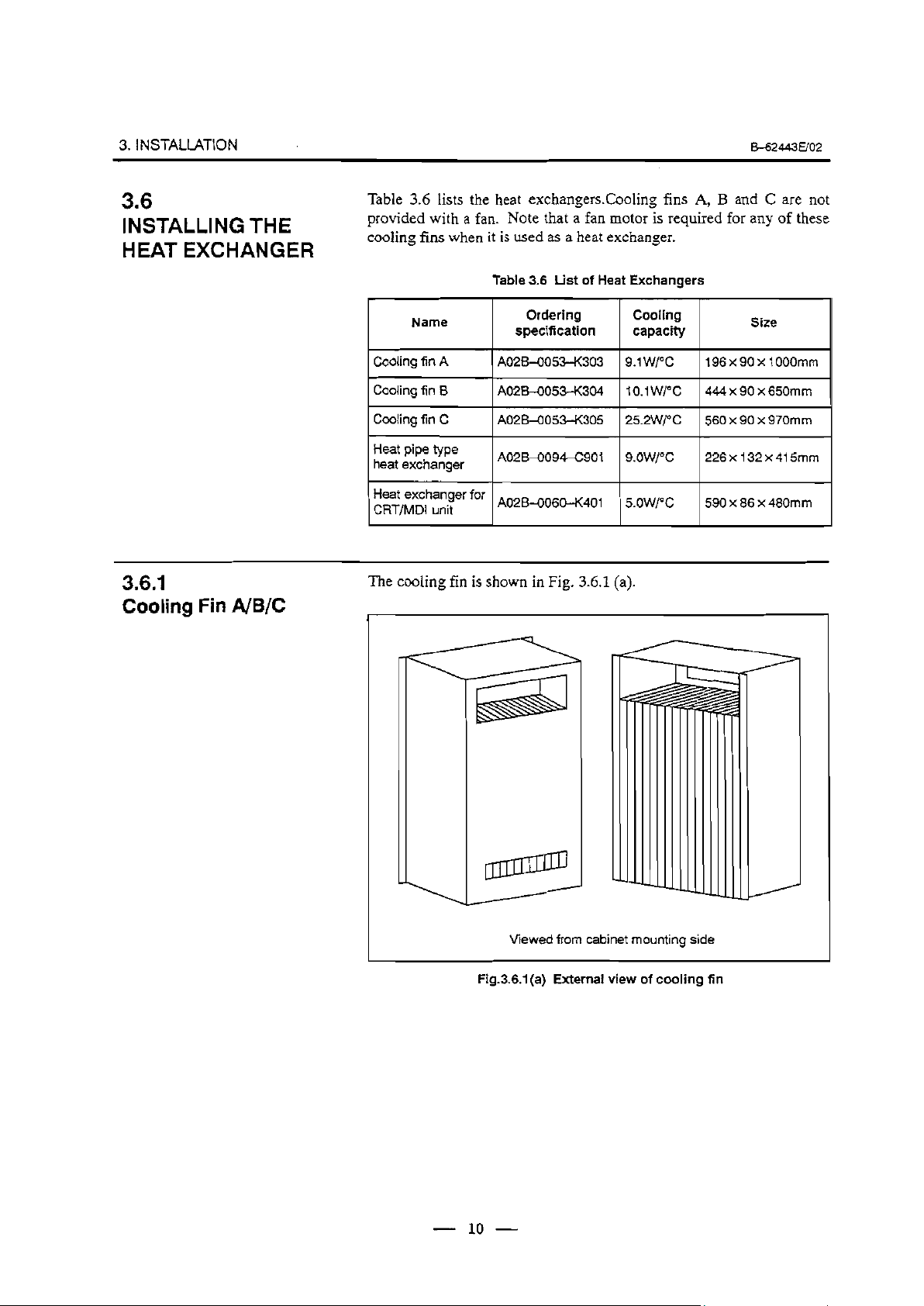

36

iSTALLING THE

HEAT EXCHANGER

3.6.1

Cooling Fin A/B/C

Table 3.6 lists the heat exchangers.Cooling fins A, B and C are not

provided with a fan. Note that a fan motor is required for any of these

cooling fins when it is used as a heat exchanger.

Table 3.6 List of Heat Exchangers

Name

Cooling fin A

Cooling fin B A02B-O053-K304

Cooling fin C A02B-O0533<305

Heat pipe type

heat exchanger

I Heat exchanger for

CRT/MD1 unit

The

cooling fin is shown in Fig. 3.6.1 (a).

Ordering

specification

A02B-0053-K303 9.1 W/“C

A02B-0094-C901

AO2BqO603<401

Cooling

capacity

196x90x1OOOmm

1o.1w/oc

25.2W/“C

9.OW/OC 226xl32x415mm

5.OWl”C

444 x 90 x 650mm

560 x 90 x 970mm

590 x 86 x 480mm

Size

Viewed from cabinet mounting side

Fig.3.6.l(a) External view of cooling fin

10

Page 17

B-62443WO2

3. INSTALlATlON

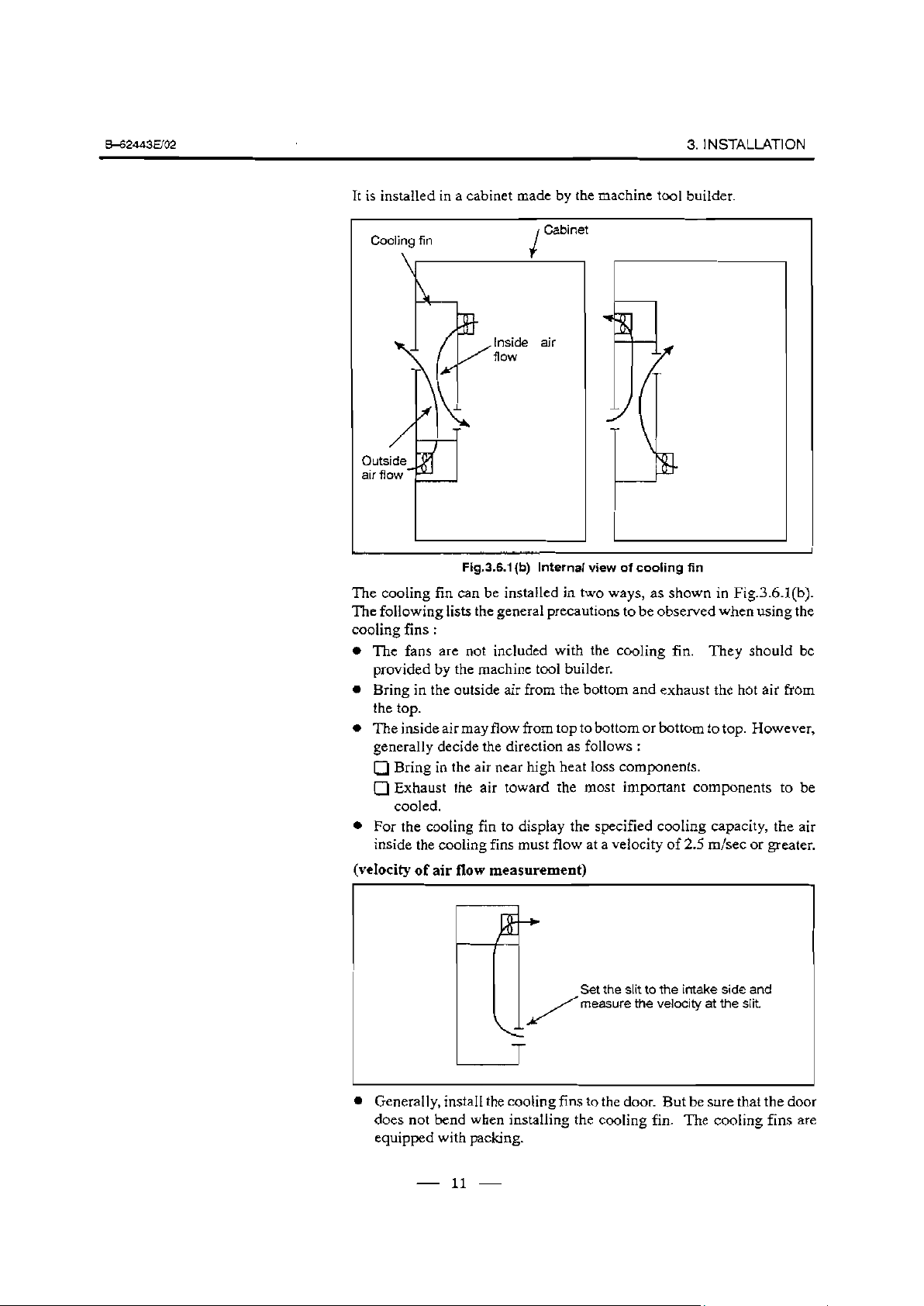

It is installed in a cabinet made by the machine tool builder.

Cooling fin

Inside

fiow

Cabinet

ou

air

Fig.3.6.1 (b) Internal view of cooling fin

The cooling fin can be installed in two ways, as shown in Fig.3.6.l(b).

The following lists the general precautions to be observed when using the

cooling fins :

The fans are not included with the cooling fin. They should be

provided by the machine tool builder.

Bring in the outside air from the bottom and exhaust the hot air from

the top.

The inside air may flow from top to bottom or bottom to top. However,

generally decide the direction as follows :

0

Bring in the air near high heat loss components.

0 Exhaust the air toward the most important components to be

cooled.

For the cooling fin to display the specified cooling capacity, the air

inside the cooling fins must flow at a velocity of 2.5 m/set or greater.

(velocity of air flow measurement)

Set the slit to the intake side and

measure the velocity at the slit.

l Generally, install the cooling fins to the door. But be sure that the door

does not bend when installing the cooling fin. The cooling fins are

equipped with packing.

- 11 -

Page 18

3. INSTALLATION .

562443uo2

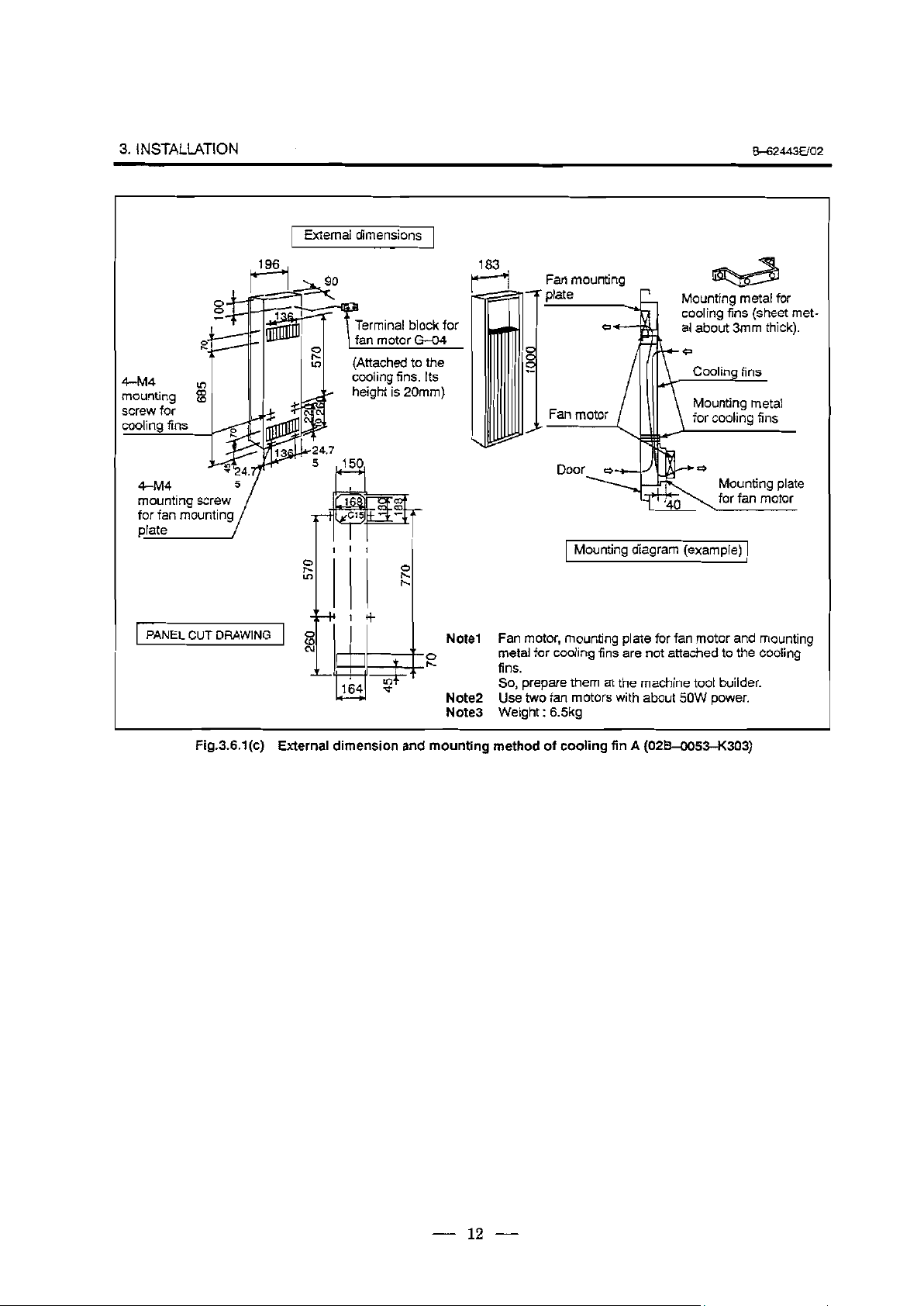

1 External dimensions 1

Fan mounting

Mounting metal for

cooling fins (sheet met-

al about 3mm thick).

AM4

mounting

screw

cooling fins

4

PANEL CUT DRAWING

;

for

Fig.3.6.l(c)

II I I I

0

s;

cooling fins. Its

height is 20mm)

(Mounting diagram (example)

0

k

/l/l I

I I+

g

cv

:

ILuLl :I

164 %

w

External dimension and mounting method of cooling fin A (0254053-K303)

Note1

E

Note2

Note3 Weight

Fan motor, mounting plate for fan motor and mounting

metal for cooling fins are not attached to the cooling

fins.

So, prepare them at the machine tool builder.

Use two fan motors with about 5OW power.

: 6.5kg

1

- 12 -

Page 19

B42443uo2

3. INSTALLATION

(Make a hole 5 dia. for

fan motor)

t

Panel cut drawing

c

External dimensions

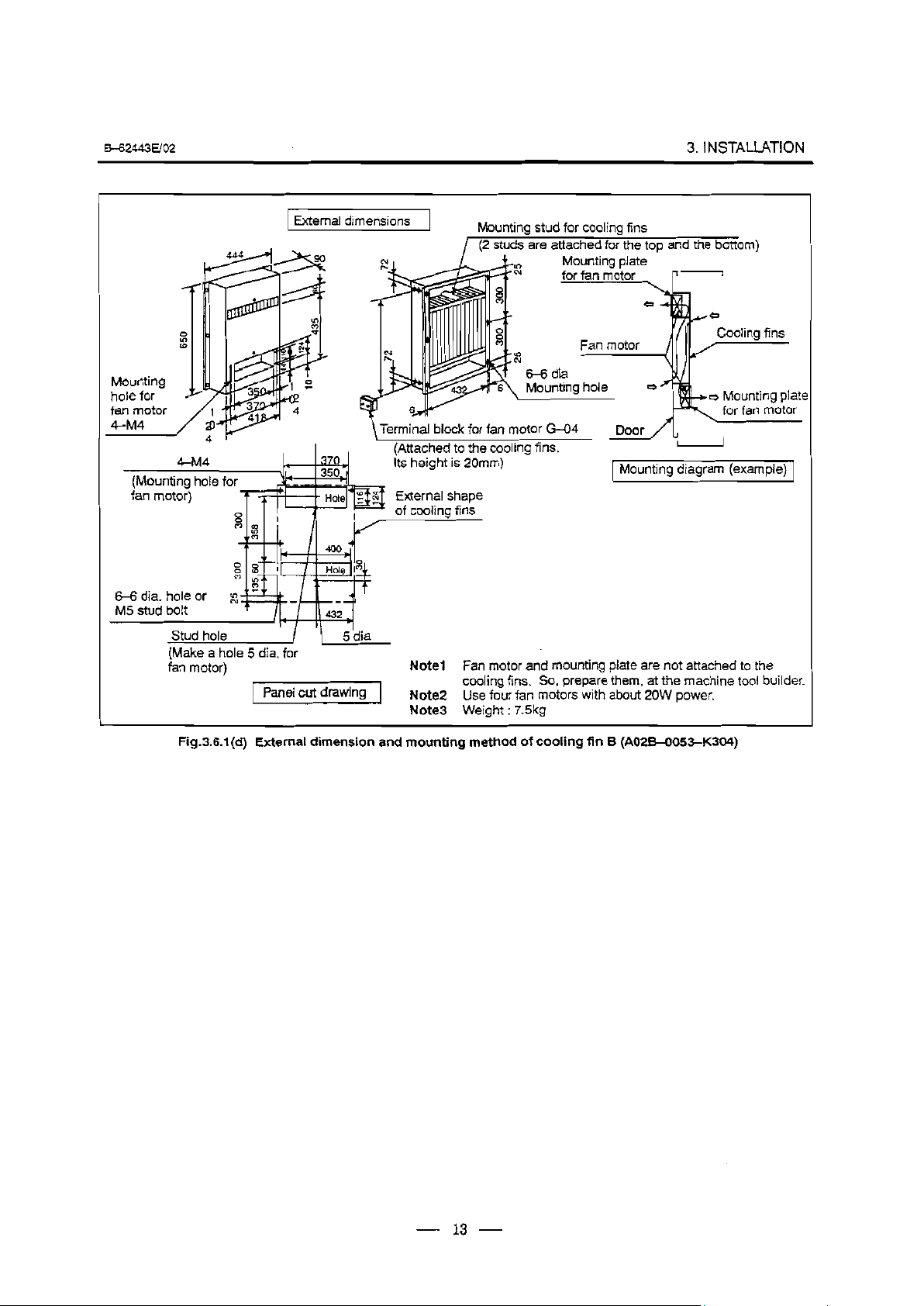

Mounting stud for cooling fins

Note1

Note2

Note3 Weight

Fan motor and mounting plate are not attached to the

cooling fins. So, prepare them, at the machine tool builder.

Use four fan motors with about 20W power.

: 7.5kg

Mounting diagram (example)

.

Fig.3.6.l(d) External dimension and mounting method of cooling fin 6 (A02B405WC304)

- 13 -

Page 20

3. INSTALLATION .

BG2443E/O2

0

H

P

&M4

Mounti--

m olor

6-6 dia. hole or M5

stud bolt

Panel cut drawing 1

I

I

c

External dimensions

.

P

Terminal block

for fan motor

HE-04

(Attached to the

__

._

cooling fins. Its

height is 20mm)

548 I

.

External shape of

cooling fins

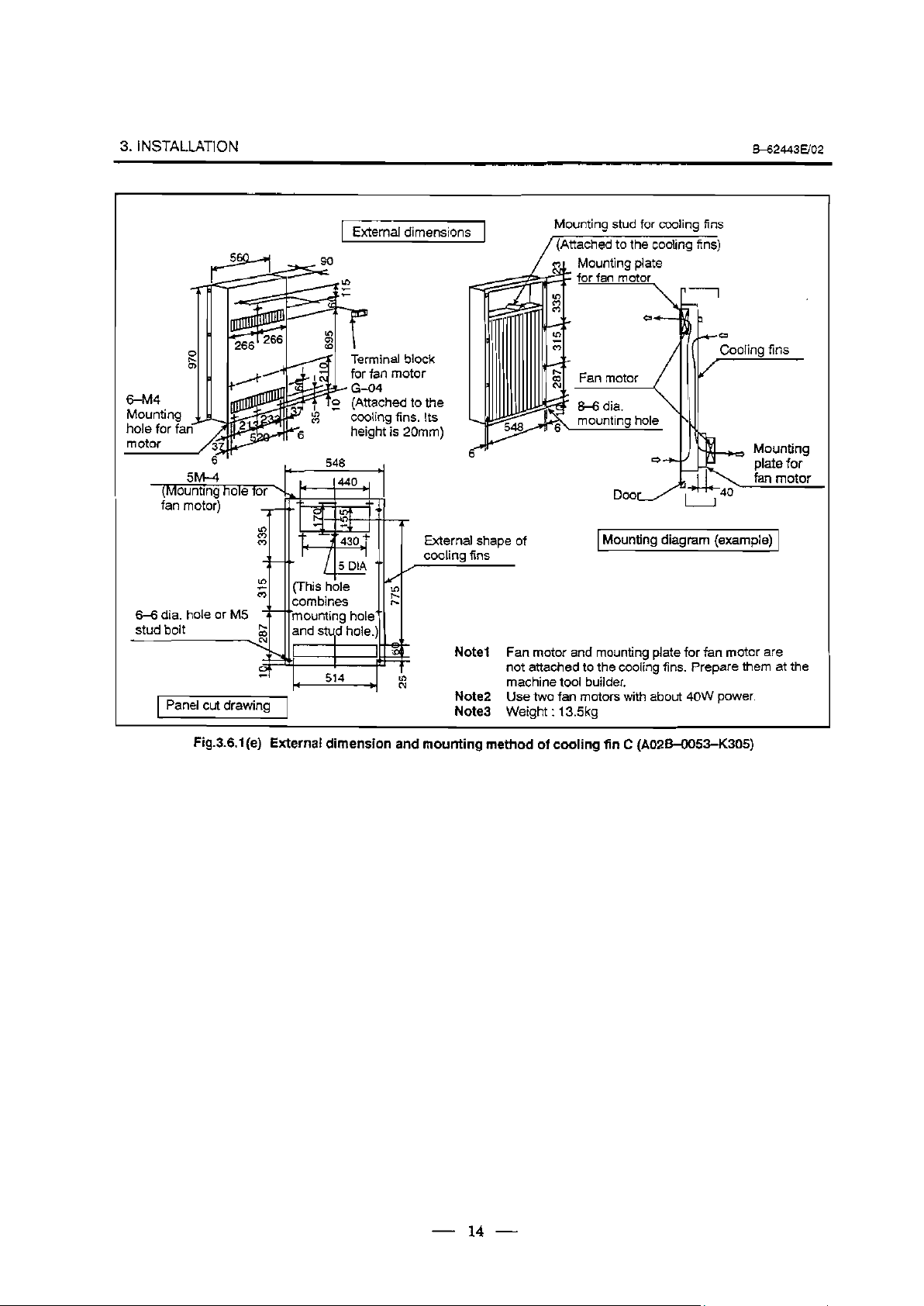

Note1 Fan motor ar Id mounting plate for fan motor ar

not attached

machine tool

Note2 Use two fan

Note3 Weight

unting stud for cooling

MO

/(Attached

to the cooling fins)

Mounting plate

for fan motor

an motor /

F

Ezkg hole

1 Mounting diagram (example)

to the cooling fins. Prepare them

bl uilder.

motors‘ with about 40W power.

: 13.5kg

fins

1

+-a

Cooling fin

S

1

l e

at the

Fig.3.6.l(e) External dimension and mounting method of cooling fin C (A02B4053-K305)

- 14 -

Page 21

b62443uo2

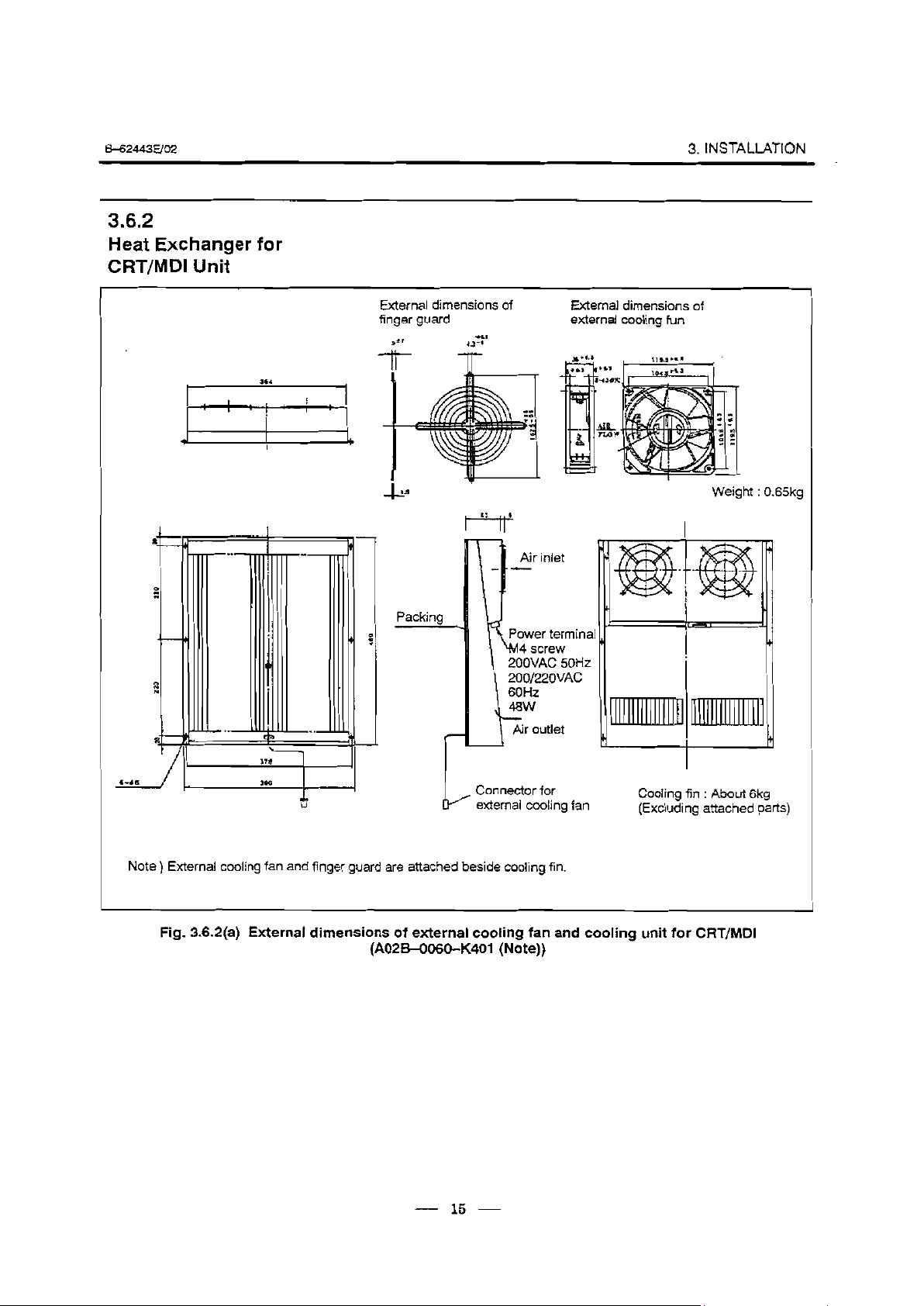

3.6.2

Heat Exchanger for

CRT/MD1 Unit

3. INSTALLATION

External dimensions of

finger guard

s*’

+rl

43”

-It-

External dimensions of

external cooling fun

Weight : 0.65kg

37a

I

396

Note

) External cooling fan and finger guard are attached beside cooling fin.

Fig. 3.6.2(a) External dimensions of external cooling fan and cooling unit for CRT/MD1

(A02B-O060-K401 (Note))

Connector for

k

external cooling fan

Cooling fin

(Excluding attached parts)

: About 6kg

15

Page 22

3. INSTALDWON .

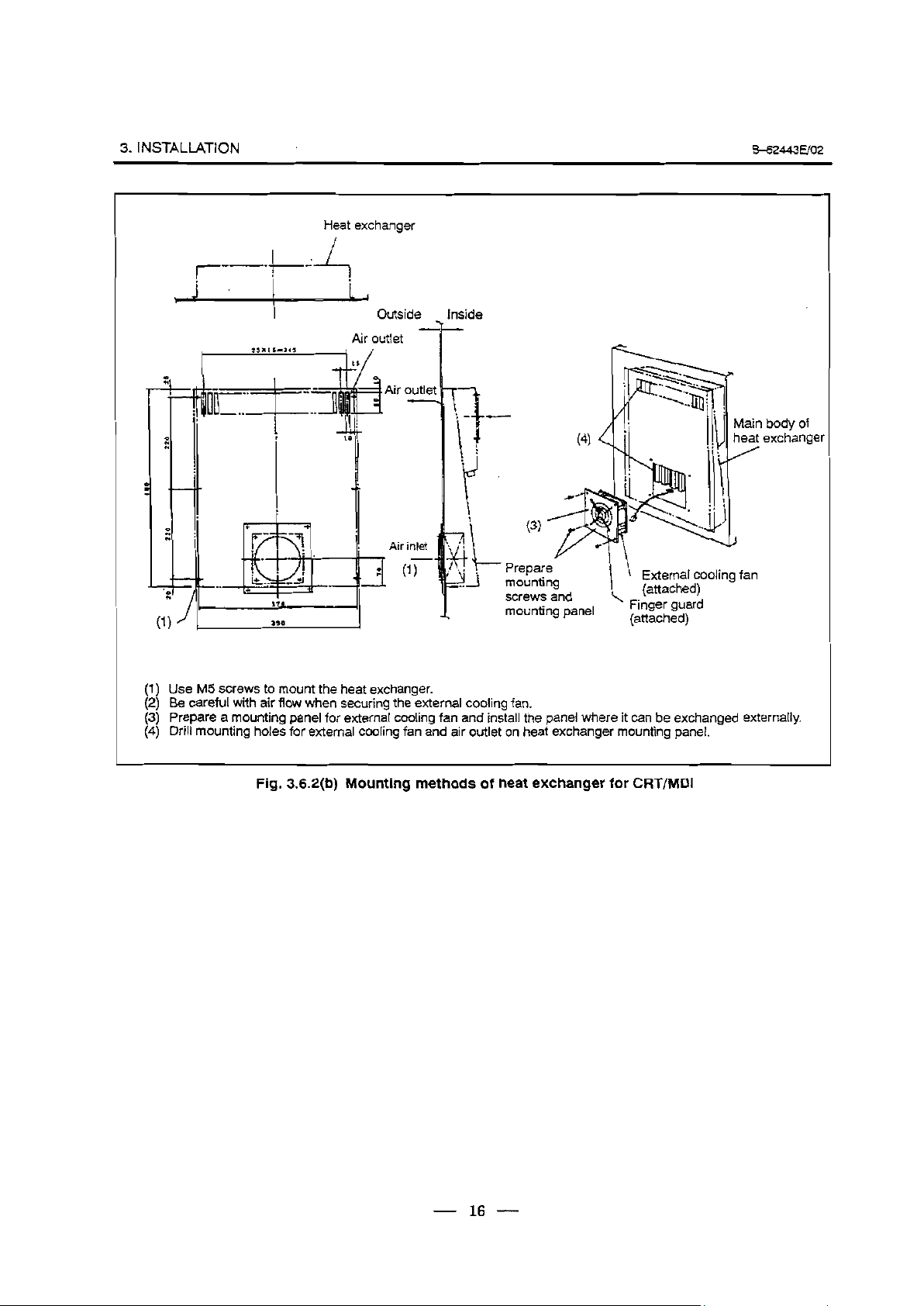

8 Outside Inside

Heat exchanger

Air outlet -

&624436/02

I-

body of

exchanger

Prepare

mounting

screws and

mounting panel

(1)

Use M5 screws to mount the heat exchanger.

(2)

Be careful with air flow when securing the external cooling fan.

Prepare a mounting panel for external cooling fan and install the panel where it can be exchanged externally.

(3)

(4)

Drill mounting holes for external cooling fan and air outlet on heat exchanger mounting panel.

Fig. 3.6.2(b) Mounting methods of heat exchanger for CRT/MD1

. 1

t External cooling fan

I

\ (attached)

Finger guard

(attached)

- 16 -

Page 23

B42443EiO2

3. INSTALLATION

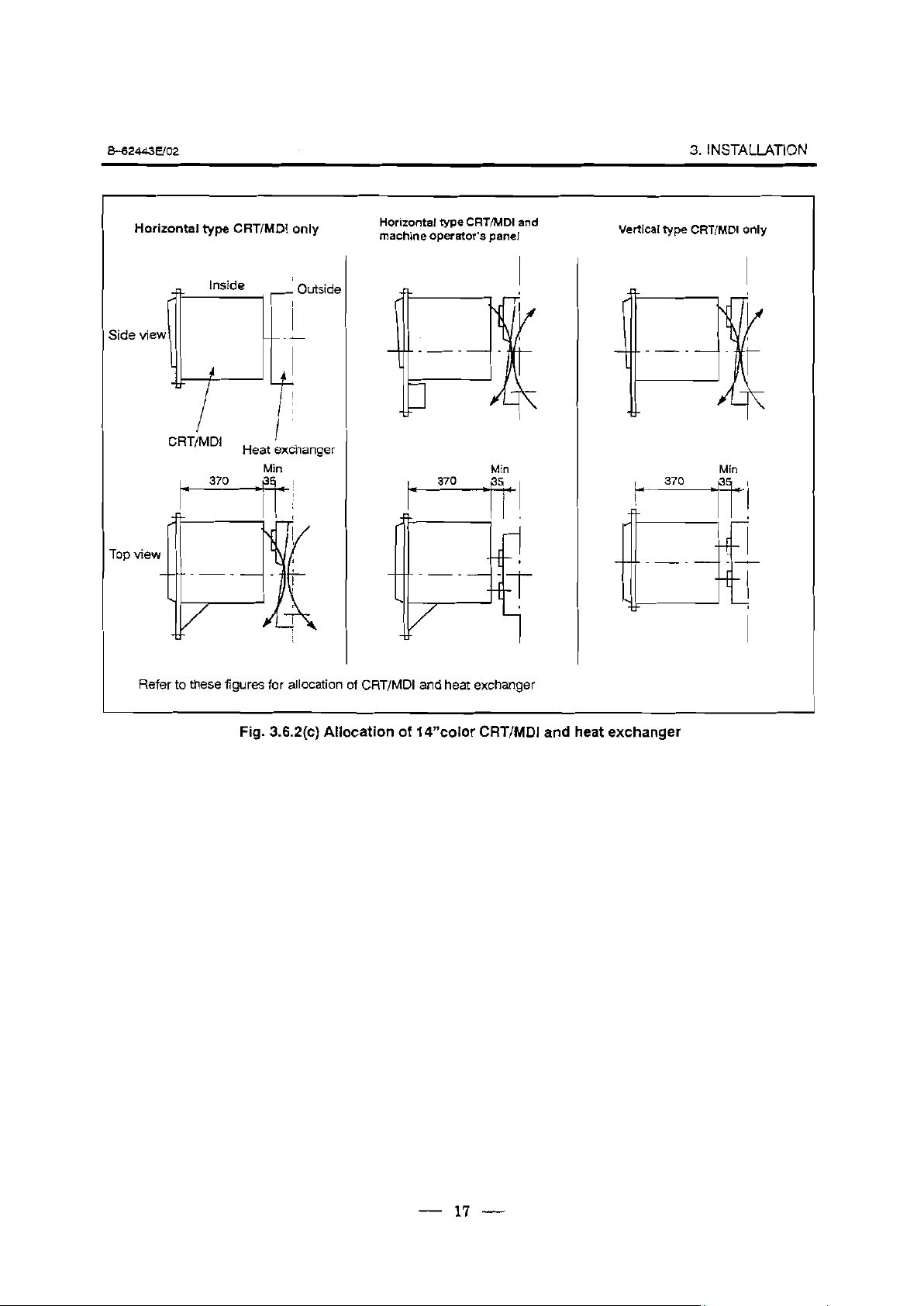

Horizontal type CRT/MD1 only

L Inside

f’ -

f

,.L outs

1

‘ide

Horizontal type CRT/MDI and

machine operator’s panel

Side view

CRT/MD1

I

Heat exchanger

Min

t-7

Top view

-tt

I

I

I

Refer to these figures for allocation of CRT/MD1 and heat exchanger

Min

Vertical type CRT/MD1 only

Min

Fig. 3.6.2(c) Allocation of 14”color CRT/MDl and heat exchanger

- 17 -

Page 24

3. INSTALLATION .

3.6.3

The Heat Pipe Type Heat

Exchanger

B-62443uoz

3.6.3.1

Installation

Specifications

The heat pipe type heat exchanger is used for cooling the airtight cabinet

of small sized electronic devices.

It is a compact, lightweight, and

heat-efficient unit. Because the fan is built-in, it is used simply by

installing it, performing the “panel cut’ operation.

I

Fan

specifications

Weight (kg)

Color

Installation format

Cooling ability (w/“C)

L

Voltage (V)

Frequency (Hz)

1 Rating current (A)

Rating input (W)

1 Installation type in board

9 (50Hz when operating)

200VAC

50

0.28

28

4

Munsell signal N 1.5

60

0.24

26

Order specifications 1 Heat exchanger A02B-O094-C901 1

Remarks

A filter is installed on the outside air inhalation side.

The installation board thickness is the standard 1.6 t.

When a fan motor and filter are necessary for maintenance, prepare

them separately.

Fan motor specifications

A90L=0001”219#A

Filter specifications

A250-0689-X004

If the heat exchanger is installed near the CRT, screen distortion may

occur due to magnetic flux leakage from the fan motor.

18

Page 25

8-62443EJo2

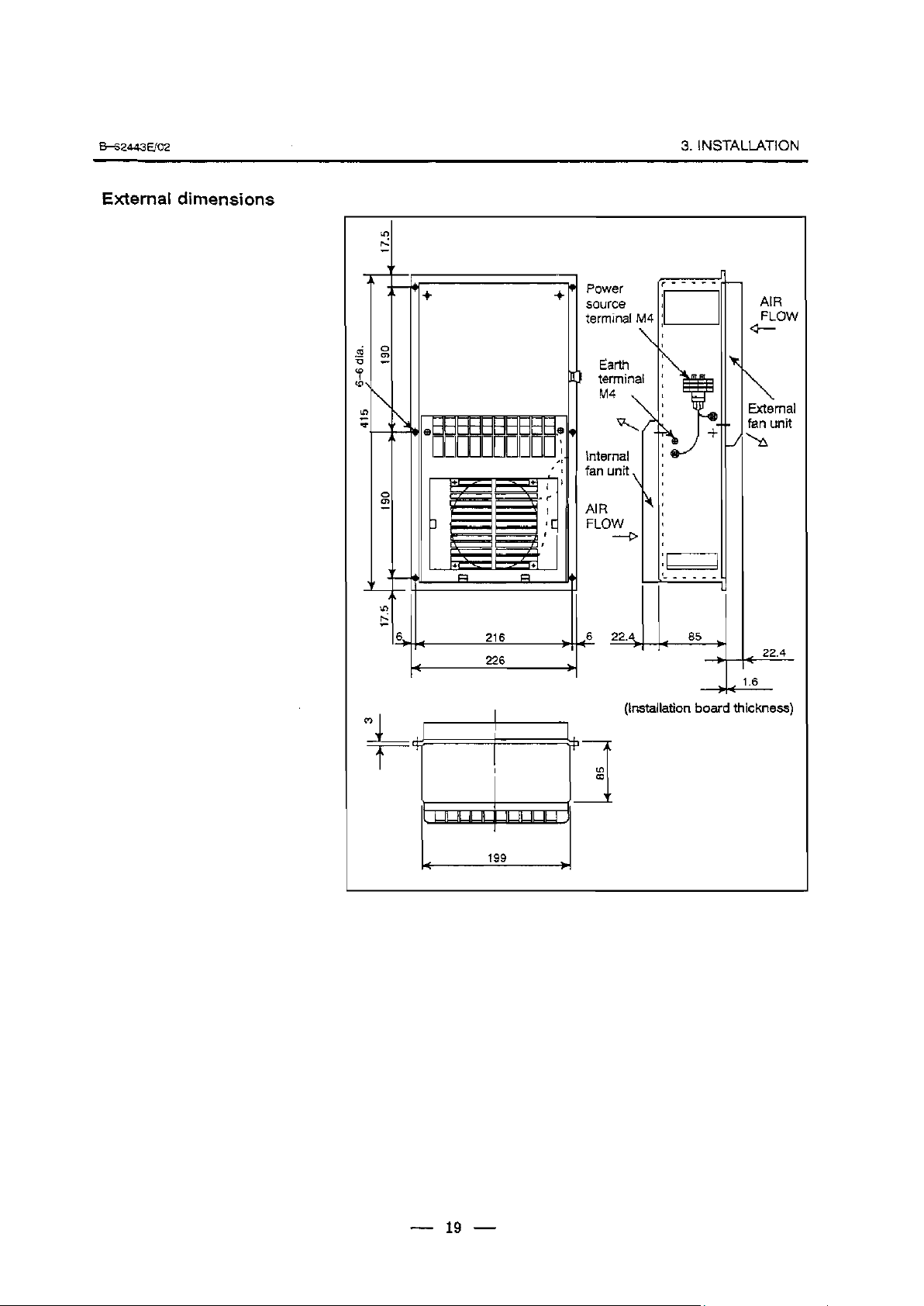

External dimensions

-

-

L

-

Power

source

terminal M4

Earth

: terminal

M4

Internal

fan unit

3.iNSTALLATION

AIR

FLOW

\

\

External

Fan unit

b

AIR

FLOW

,

-

-

226

P

PI

1

__----

L

22.

-A-

(Installation board thickness)

85

-4

4 1.6

22.4

- 19 -

Page 26

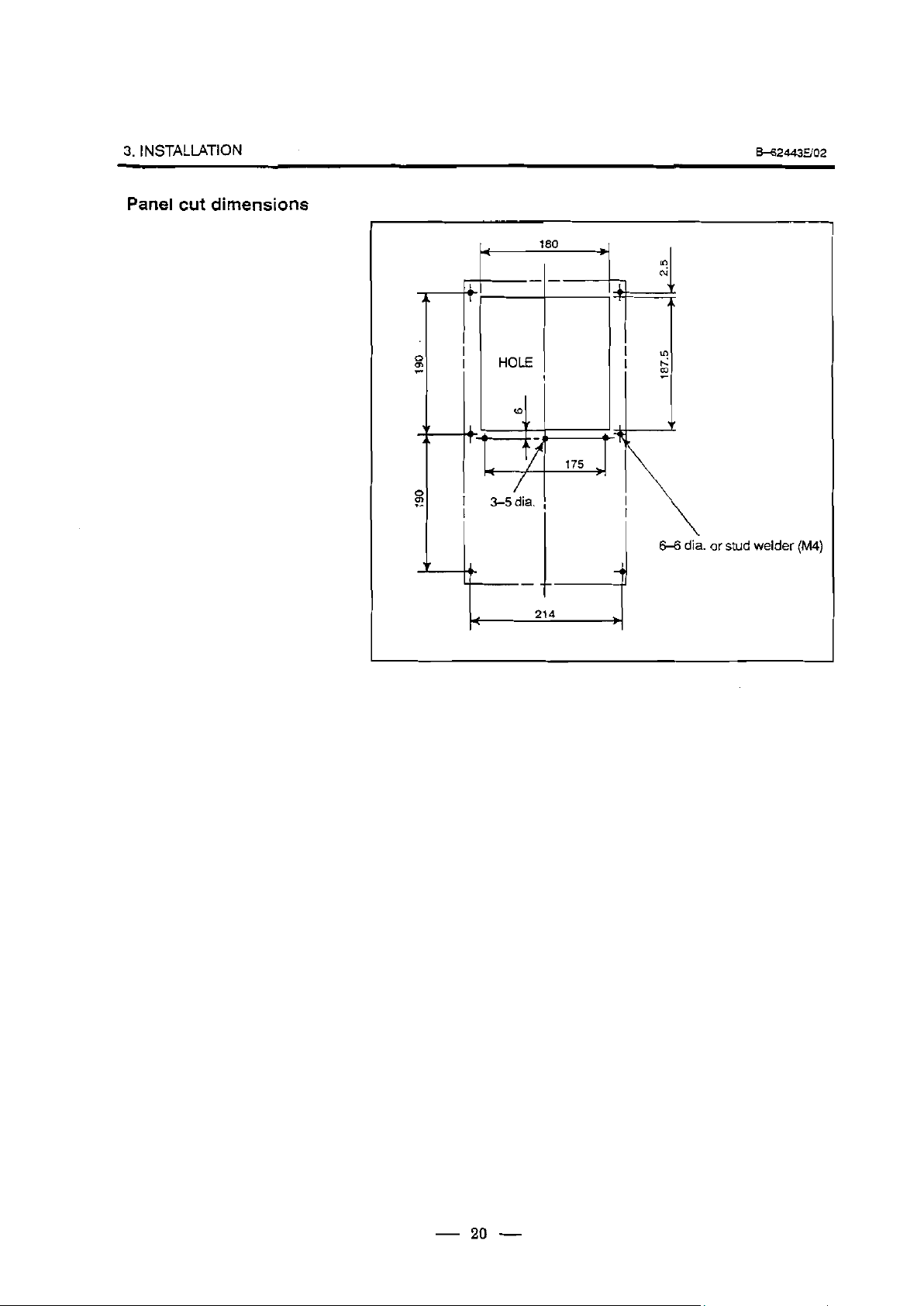

3. INSTALLATION .

Panel cut dimensions

&-62443E/o2

180

I

. or stud

welder

uw

- 20 -

Page 27

&62443u02

3.lNSTALlATiON

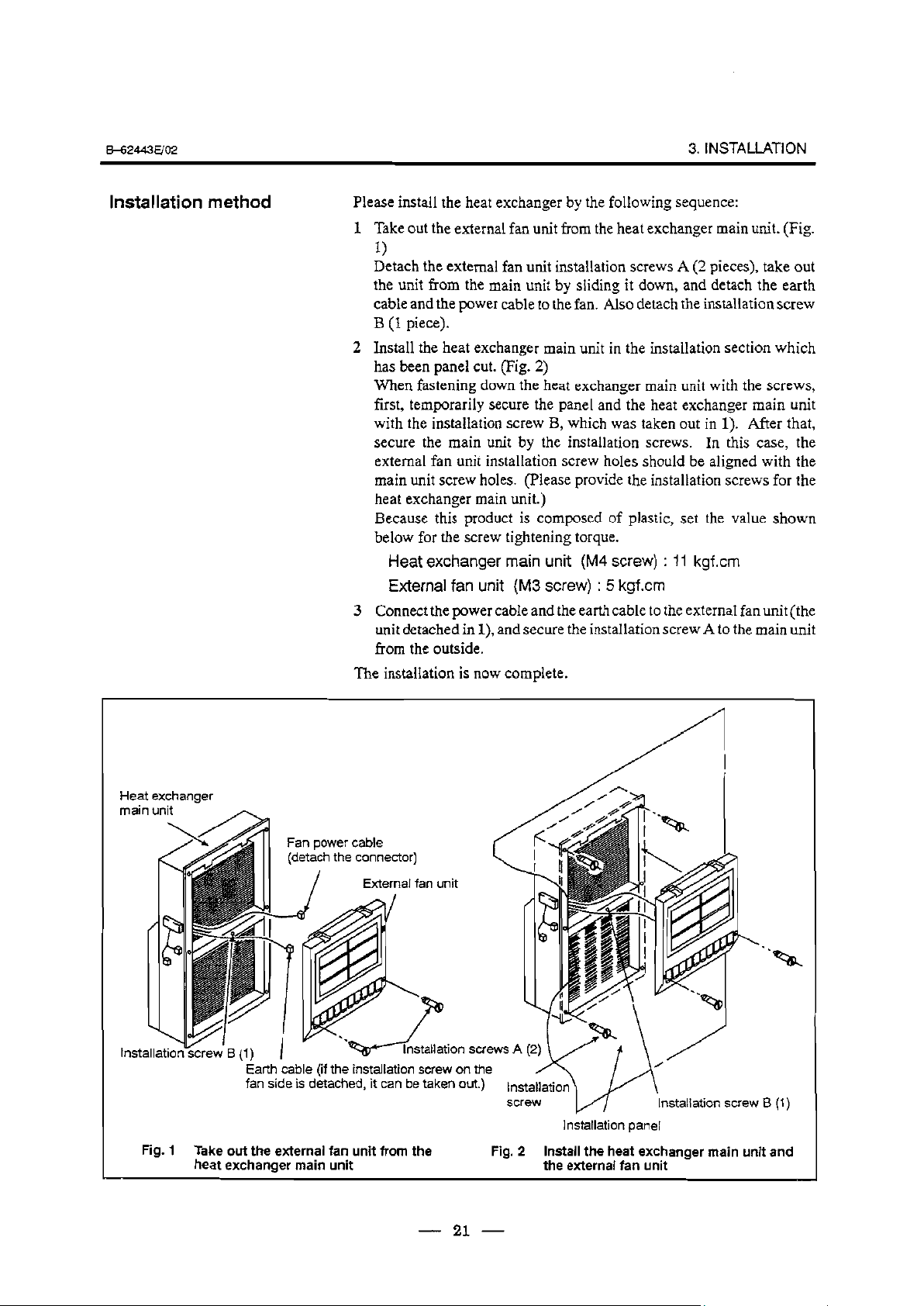

Installation method

Please install the heat exchanger by the following sequence:

1 Take out the external fan unit from the heat exchanger main unit. (Fig.

1)

Detach the external fan unit installation screws A (2 pieces), take out

the unit from the main unit by sliding it down, and detach the earth

cable and the power cable to the fan. Also detach the installation screw

B (1 piece).

2 Install the heat exchanger main unit in the installation section which

has been panel cut. (Fig. 2)

When fastening down the heat exchanger main unit with the screws,

first, temporarily secure the panel and the heat exchanger main unit

with the installation screw B, which was taken out in 1). After that,

secure the main unit by the installation screws. In this case, the

external fan unit installation screw holes should be aligned with the

main unit screw holes. (Please provide the installation screws for the

heat exchanger main unit.)

Because this product is composed of plastic, set the value shown

below for the screw tightening torque.

Heat exchanger main unit (M4 screw) : 11 kgf.cm

External fan unit (M3 screw) : 5 kgf.cm

3 Connect the power cable and the earth cable to the external fan unit (the

unit detached in l), and secure the installation screw A to the main unit

from the outside.

The installation is now complete.

Fig. 1

Fan power cable

(detach the connector)

Earth cable (if the installation screw on the

fan side is detached, it can be taken out.)

Take out the external fan unit from the

heat exchanger main unit

- 21 -

Installation screw B (1)

1 nstallation panel

Fig. 2 Install the heat exchanger main unit and

the external fan unit

Page 28

3. INSTALLATION .

37

A’CTION AGAINST

NOISE

3.7.1

Separating Signal

Lines

B-62443uo2

The

CNC has been steadily reduced in size using surface-mount and

custom LSI technologies for electronic components. The CNC also is

designed to be protected from external noise. However, it is difficult to

measure the level and frequency of noise quantitatively, and noise has

many uncertain factors. It is important to prevent both noise from being

generated and generated noise from being introduced into the CNC. This

precaution improves the stability of the CNC machine tool system.

The CNC component units are often installed close to the parts generating

noise in the power magnetics cabinet. Possible noise sources into the

CNC are capacitive

couplin

g,

electromagnetic induction, and ground

loops.

When designing the power magnetics cabinet, guard against noise in the

machine as described in the following section.

-~

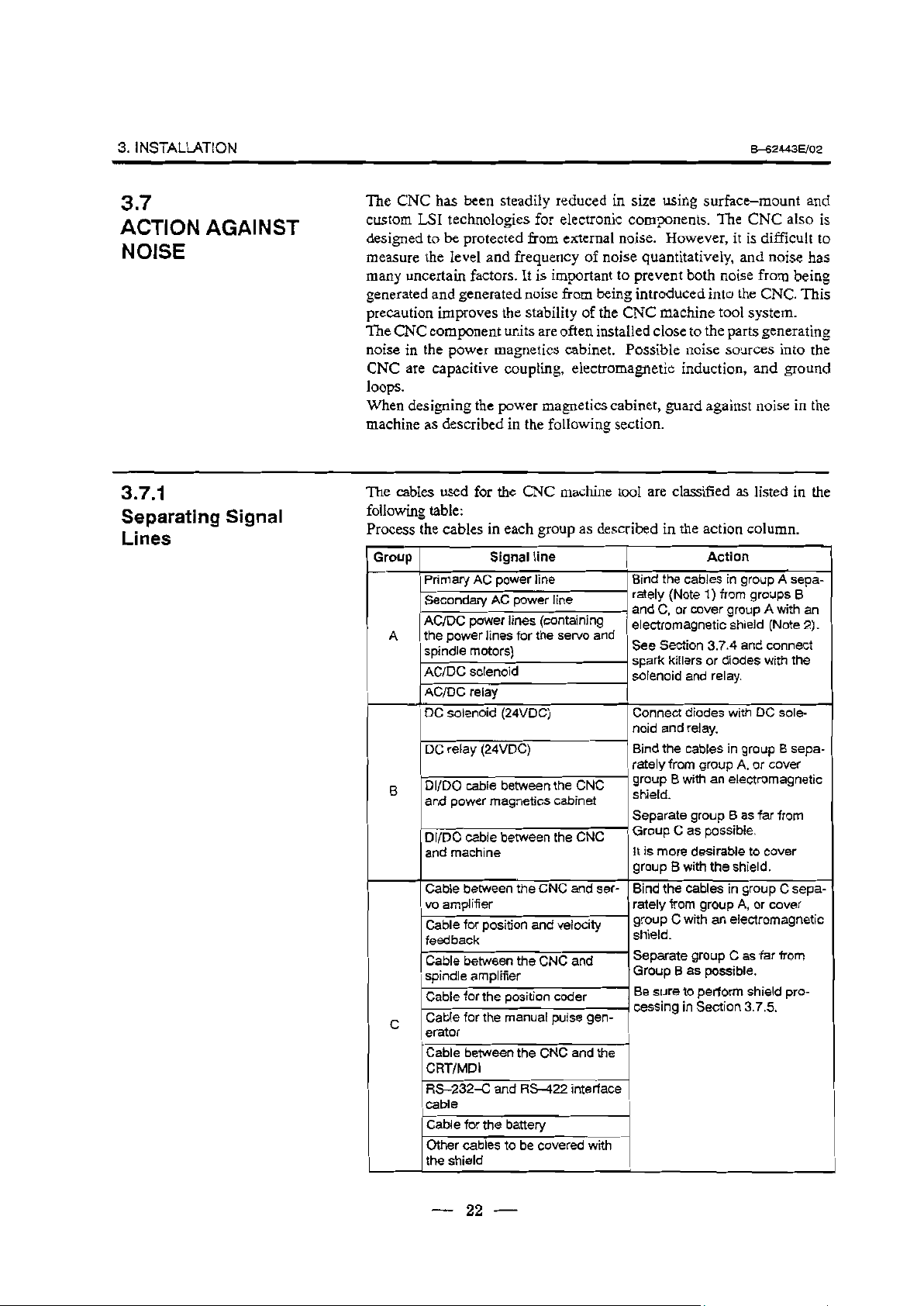

The cables used for the CNC machine tool are classified as listed in the

following table:

Process the cables in each group as described in the action column.

‘0°F) 1

I

Primary AC power line

Secondary AC power line

AC/DC power lines (containing

A the power lines for the sewo and

spindle motors)

AC/DC solenoid

AC/DC relay

DC solenoid (24VDC)

DC relay (24VDC)

Dl/DO cable between the CNC

B

and power magnet& cabinet

Dl/DO cable

and machine

Cable between the CNC and ser-

Signal line

between the CNC

vo amplifier

Cable for position and velocity

feedback

Cable between the CNC and

spindle amplifier

Cable for the position coder

Cable for the manual

C

erator

Cable between the CNC and the

CRT/MD1

RS-232-C and RS-422 interface

cable

Cable for the

Other cables to be covered with

the shield

battery

pulse gen-

I

Bind

rately (Note 1) from groups B

Action

the cables in group A sepa-

. and C, or cover group A with an

electromagnetic shield (Note 2).

See Section 3.7.4 and connect

l spark killers or diodes with the

solenoid and relay.

Connect diodes with DC sole-

noid and relay.

Bind the cables in group B

rately from group A, or cover

1 group B with an electromagnetic

shield.

Separate group B as far from

’ Group C as possible.

It is more desirable to cover

group B with the shield.

Bind the cables in

rately from group A, or cover

group C sepa-

’ group C with an electromagnetic

shield.

Separate group C as far from

Group B as possible.

Be sure to perform shield pro-

cessing in Section 3.7.5.

_

sepa-

22

Page 29

&62443E/o2

3. INSTALLATION

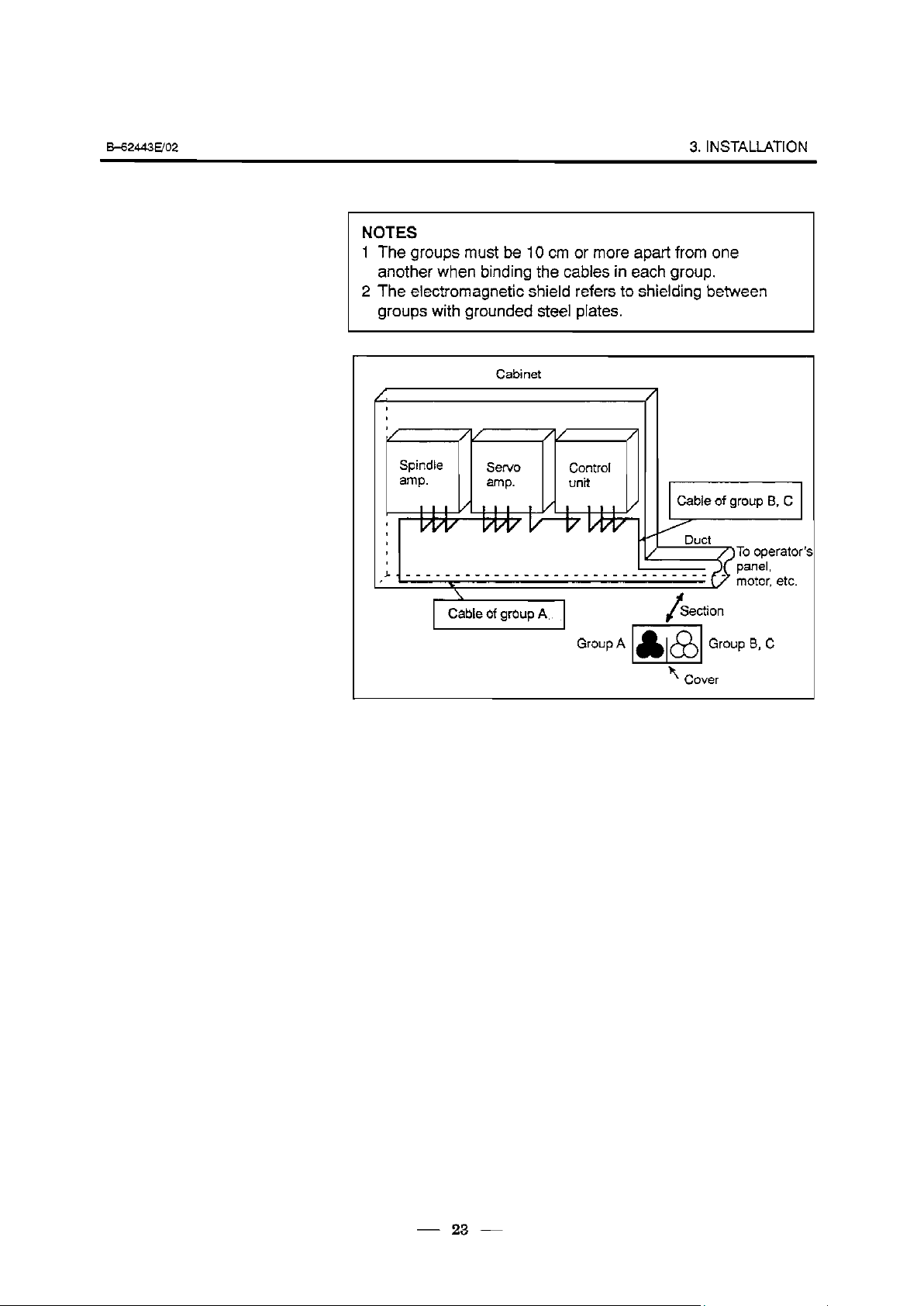

NOTES

1 The groups must be 10 cm or more apart from one

another when binding the cables in each group.

2 The electromagnetic shield refers to shielding between

groups with grounded steel plates.

Cabinet

amp.

I

I

I

I

~.~~_~_~~_~_____~____~__~_~__~___ _

/ /

amp.

unit

C&e of group B, C

Duct

ATo operator

(vl &pan&l

b

‘\ Cover

I

mot& etc.

- 23 -

Page 30

3. INSTALLATION .

8_62443E/o2

3.7.2

Ground

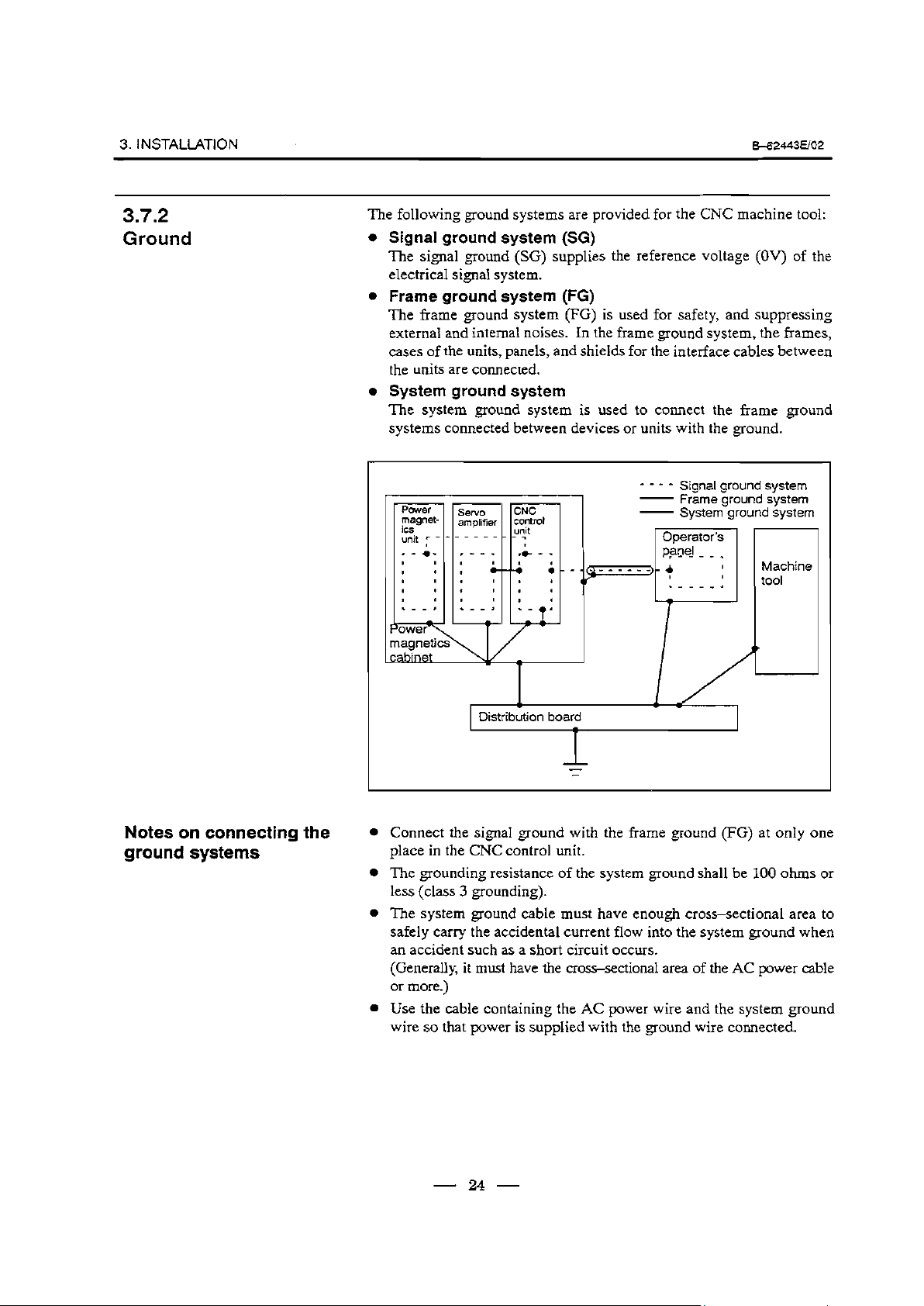

The following ground systems are provided for the CNC machine tool:

l Signal ground system (SG)

The signal ground (SG) supplies the reference voltage (OV) of the

electrical signal system.

l Frame ground system (FG)

The frame ground system (FG) is used for safety, and suppressing

external and internal noises. In the frame ground system, the frames,

cases of the units, panels, and shields for the interface cables between

the units are connected.

l System ground system

The system ground system is used to connect the frame ground

systems connected between devices or units with the ground.

----

Signal ground system

POWM

magnet-

its

unit r -

- Frame

- System ground system

Operator’s

PFCe_l_ _ _

.rr--4

ground system

.

I

Machine

I

tool

Notes on connecting the

ground systems

D&rib&on board

I

l Connect the signal ground with the frame ground (FG) at only one

place in the CNC control unit.

The grounding resistance of the system ground shall be 100 ohms or

l

less (class 3 grounding).

l The system ground cable must have enough cross-sectional area to

safely carry the accidental current flow into the system ground when

an accident such as a short circuit occurs.

(Generally, it must have the cross-sectional area of the AC power cable

or more.)

Use the cable containing the AC power wire and the system ground

l

wire so that power is supplied with the ground wire connected.

- 24 -

Page 31

6-62443ED2

3. INSTALlATlON

3.7.3

Connecting the

Ground (SG) of

Control Unit

Signal

the

Connect the 0 V line of the

ground plate of the cabinet

The SG terminal is located

control unit.

Control unit

electronic circuit in the contro1 unit with the

via the signal ground (SG) terminal.

on the printed circuit board at the rear of the

Ground cable

\

- 25 -

Page 32

3. INSTALLATION .

8-62443uo2

3.7.4

Noise Suppressor

Notes on selecting the

spark killer

The AC/DC solenoid and relay are used in the power magnetics cabinet.

A high pulse voltage is caused by coil inductance when these devices are

turned on or off.