Page 1

PARAMETER MANUAL

B-63790EN/01

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The export of this product is subject to the authorization of the government of the country

from where the product is exported.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by or in the main body.

Page 3

B-63790EN/01 DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine.

Precautions are classified into Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly

before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved

procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and

Caution.

- Read this manual carefully, and store it in a safe place.

s-1

Page 4

Page 5

B-63790EN/01 PREFACE

PREFACE

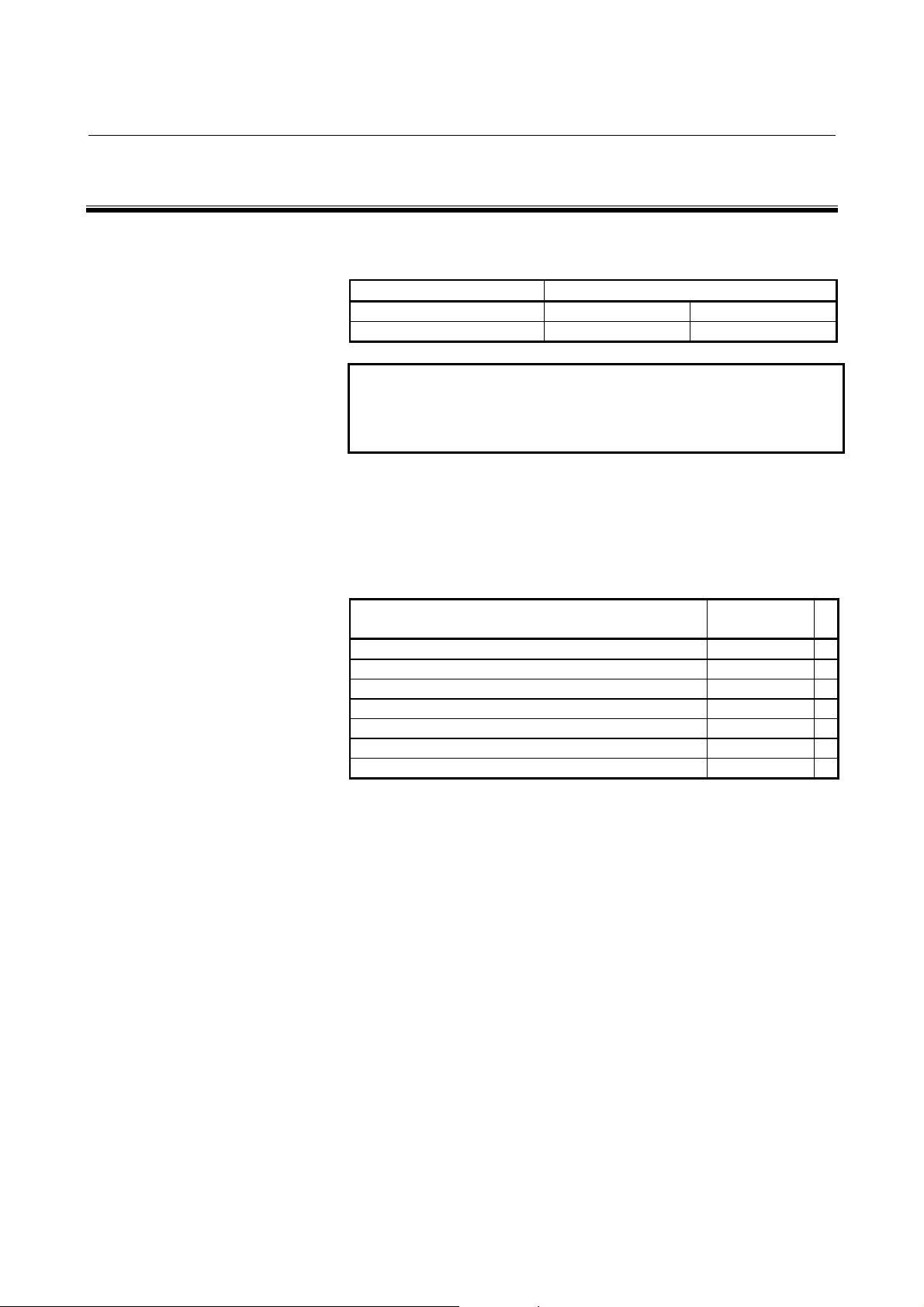

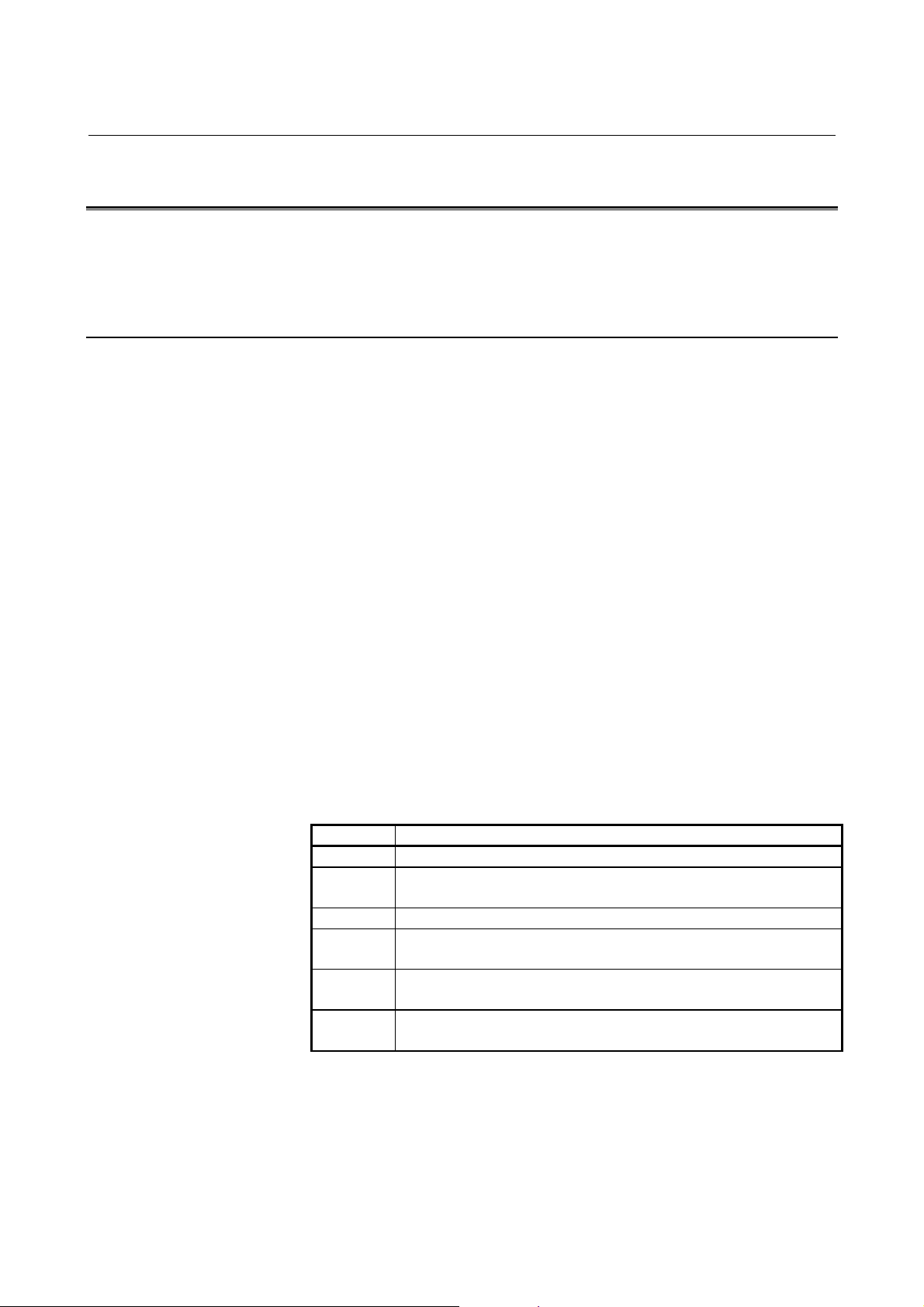

Applicable product name

The models covered by this manual, and their abbreviations are:

Product name Abbreviations

FANUC Series 15i-MB 15i-MB Series 15i

FANUC Series 150i-MB 150i-MB Series 150i

NOTE

Some functions described in this manual may not be

applied to some products. For detail, refer to the

DESCRIPTIONS manual (B-63782EN).

Related manuals

The table below lists manuals related to MODEL B of Series 15i, and

Series 150i. In the table, this manual is marked with an asterisk (*).

Table 1 (a) Related Manuals

Manual name

DESCRIPTIONS B-63782EN

CONNECTION MANUAL (HARDWARE) B-63783EN

CONNECTION MANUAL (FUNCTION) B-63783EN-1

OPERATOR'S MANUAL (PROGRAMMING) B-63784EN

OPERATOR'S MANUAL (OPERATION) B-63784EN-1

MAINTENANCE MANUAL B-63785EN

PARAMETER MANUAL B-63790EN *

Specification

number

p-1

Page 6

Page 7

B-63790EN/01 TABLE OF CONTENTS

TABLE OF CONTENTS

DEFINITION OF WARNING, CAUTION, AND NOTE................................ s-1

PREFACE.................................................................................................. p-1

1 DISPLAYING PARAMETERS AND PITCH ERROR

COMPENSATION DATA........................................................................1

1.1 DISPLAYING PARAMETERS........................................................................2

1.2 DISPLAYING PITCH ERROR COMPENSATION DATA ...............................5

2 SETTING PARAMETERS AND PITCH ERROR

COMPENSATION DATA........................................................................7

2.1 SETTING PARAMETERS..............................................................................8

2.2 SETTING PITCH ERROR COMPENSATION DATA ...................................10

3 INPUTTING AND OUTPUTTING PARAMETERS USING

EXTERNAL INPUT/OUTPUT DEVICES...............................................12

3.1 INPUTTING AND OUTPUTTING PARAMETERS

ON THE PARAMETER SCREEN ................................................................13

3.2 INPUTTING AND OUTPUTTING PARAMETERS

ON THE FLOPPY DIRECTORY SCREEN ..................................................16

3.3 INPUTTING AND OUTPUTTING PARAMETERS

ON THE MEMORY CARD SCREEN ...........................................................18

3.4 INPUT/OUTPUT FORMATS........................................................................20

3.4.1 Input/Output Formats for Parameters .................................................................... 20

3.4.2 Input/Output Format for Pitch Error Compensation Data..................................... 26

4 DESCRIPTION OF PARAMETERS......................................................27

4.1 DATA TYPES ..............................................................................................27

4.2 REPRESENTATION OF PARAMETERS ....................................................28

4.3 STANDARD PARAMETER SETTING TABLES ..........................................29

4.4 SETTING PARAMETERS (DATA NO. 0000 AND LATER) .........................31

4.5 TIMER PARAMETERS (DATA NO. 0100 AND LATER)..............................41

4.6 AXIS CONTROL PARAMETERS (DATA NO. 1000 AND LATER)..............44

4.7 CHOPPING PARAMETERS (DATA NO. 1181 AND LATER)......................69

4.8 COORDINATE SYSTEM PARAMETERS (DATA NO. 1200 AND LATER) .72

4.9 FEEDRATE PARAMETERS (DATA NO. 1400 AND LATER)......................80

c-1

Page 8

TABLE OF CONTENTS B-63790EN/01

4.10 ACCELERATION/DECELERATION CONTROL PARAMETERS

(DATA NO. 1600 AND LATER) .................................................................107

4.11 SERVO PARAMETER

(DATA NO. 1700 TO 1999 AND 2600 AND LATER).................................122

4.12 DI/DO PARAMETERS (DATA NO. 2000 AND LATER).............................151

4.13 DISPLAY/MDI AND EDIT PARAMETERS

(DATA NO. 2200 AND LATER) .................................................................165

4.14 PROGRAM PARAMETERS (DATA NO. 2400 AND LATER) ....................185

4.15 SPINDLE SERIIAL OUTPUT AND CS CONTOUR CONTROL

FUNCTION PARAMETERS (DATA NO. 3000 AND LATER) ....................198

4.16 WAVEFORM DIAGNOSIS FUNCTION PARAMETERS

(DATA NO. 4600 AND LATER) .................................................................199

4.17 DRAWING PARAMETERS (DATA NO. 4820 AND LATER) .....................210

4.18 DATA I/O PARAMETERS (DATA NO. 5000 AND LATER) .......................213

4.19 STROKE LIMIT PARAMETERS (DATA NO. 5200 AND LATER)..............221

4.20 PITCH ERROR COMPENSATION PARAMETERS

(DATA NO. 5420 AND LATER) .................................................................229

4.21 SPINDLE CONTROL PARAMETERS (DATA NO. 5602 AND LATER).....245

4.22 TOOL COMPENSATION PARAMETERS

(DATA NO. 6000 AND LATER) .................................................................287

4.23 CANNED CYCLE PARAMETERS (DATA NO. 6200 AND LATER)...........328

4.24 SCALING AND COORDINATE SYSTEM ROTATION PARAMETERS

(DATA NO. 6400 AND LATER) .................................................................333

4.25 CUSTOM MACRO PARAMETERS (DATA NO. 7000 AND LATER) .........342

4.26 PROGRAM RESTART, BLOCK RESTART, AND TOOL RETRACTION

AND RETURN PARAMETERS (DATA NO. 7110 AND LATER) ...............358

4.27 SKIP FUNCTION PARAMETERS (DATA NO. 7200 AND LATER) ...........359

4.28 TOOL LIFE MANAGEMENT PARAMETERS

(DATA NO. 7400 AND LATER) .................................................................368

4.29 FIVE-AXIS CONTROL FUNCTION PARAMETERS

(DATA NO. 7514 AND LATER) .................................................................373

4.30 OTHER PARAMETERS (1 OF 2) ..............................................................383

4.31 SERVICE PARAMETERS (DATA NO. 8000 AND LATER).......................413

4.32 OTHER PARAMETERS (2 OF 2) ..............................................................414

4.33 MACRO EXECUTOR PARAMETERS (DATA NO. 8500 AND LATER).....415

4.34 C LANGUAGE EXECUTOR PARAMETERS

(DATA NO. 8649 AND LATER) .................................................................416

c-2

Page 9

B-63790EN/01 TABLE OF CONTENTS

APPENDIX

A CHARACTER CODE LIST .................................................................423

B LIST OF COMPATIBLE PARAMETERS FOR SERIES 15-MB..........424

c-3

Page 10

Page 11

B-63790EN/01 1.DISPLAYING PARAMETERS AND PITCH ERROR COMPENSATION DATA

1 DISPLAYING PARAMETERS AND PITCH

ERROR COMPENSATION DATA

This chapter explains how to display parameters and pitch error

compensation data.

- 1 -

Page 12

1.DISPLAYING PARAMETERS AND PITCH ERROR COMPENSATION DATA B-63790EN/01

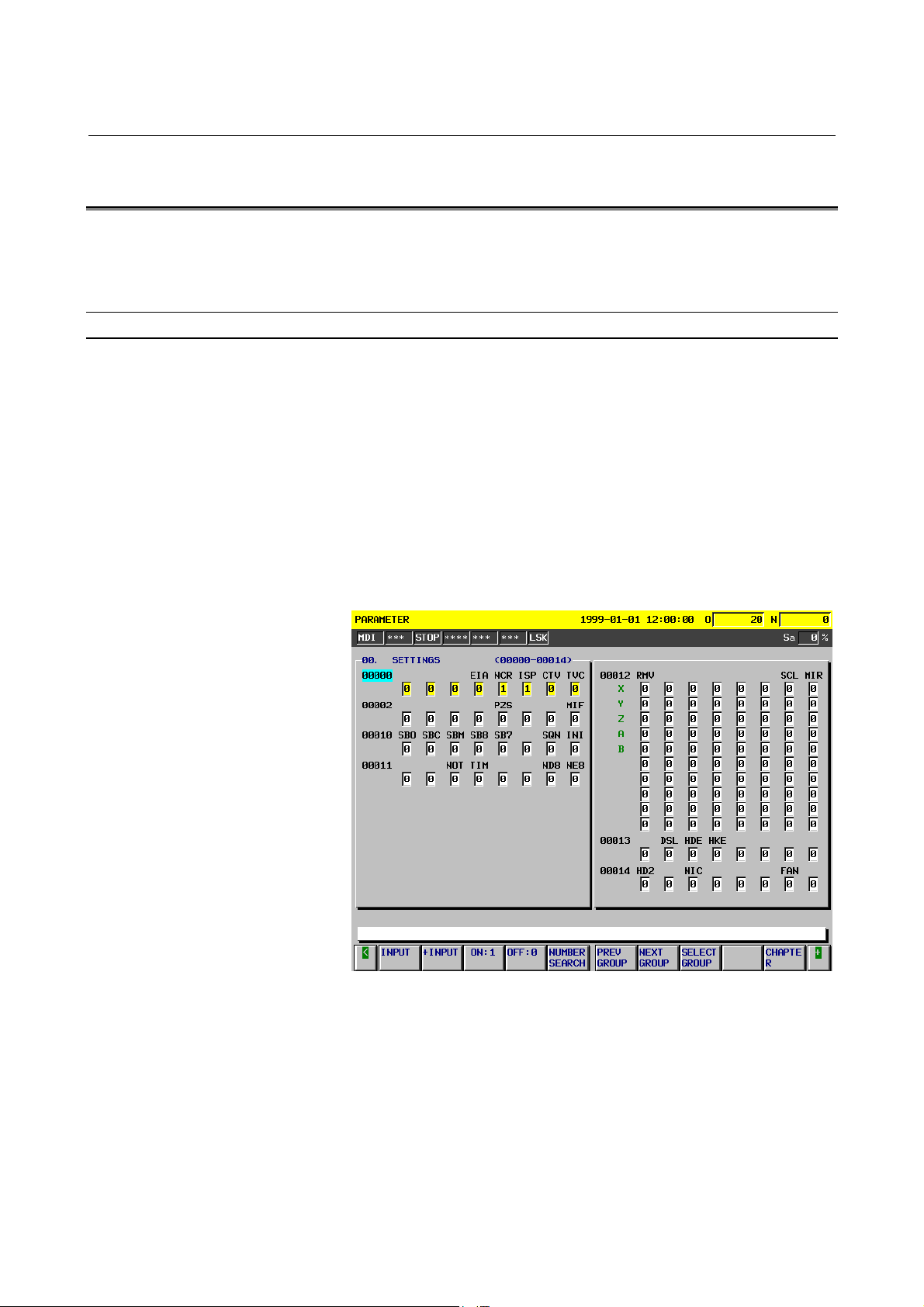

1.1 DISPLAYING PARAMETERS

The Parameter screen displays the values specified for CNC

parameters.

Parameter screen

Displaying the Parameter screen

Follow either of the procedures described below to display the

Parameter screen.

Method 1

Press the <SYSTEM> function key several times, until the

Parameter screen appears.

Method 2

(1) Press the <SYSTEM> function key.

(2) Click the [PARAMETER] soft key.

Fig. 1.1 (a) Parameter Screen

- 2 -

Page 13

B-63790EN/01 1.DISPLAYING PARAMETERS AND PITCH ERROR COMPENSATION DATA

Displaying specified parameters

The Parameter screen consists of multiple pages.

Follow one of the procedures described below to display the specified

parameter.

Method 1

Using the <PAGE ↑> <PAGE ↓> page keys, and the <↑> <↓>

<←> <→> cursor keys, move the cursor to display the desired

parameter.

Method 2

(1) Click the [NO. SEARCH] soft key.

(2) Key in the number of the parameter to be displayed.

(3) Click the [EXEC] soft key.

Method 3

(1) Key in the number of the parameter to be displayed.

(2) Click the [NO. SEARCH] soft key.

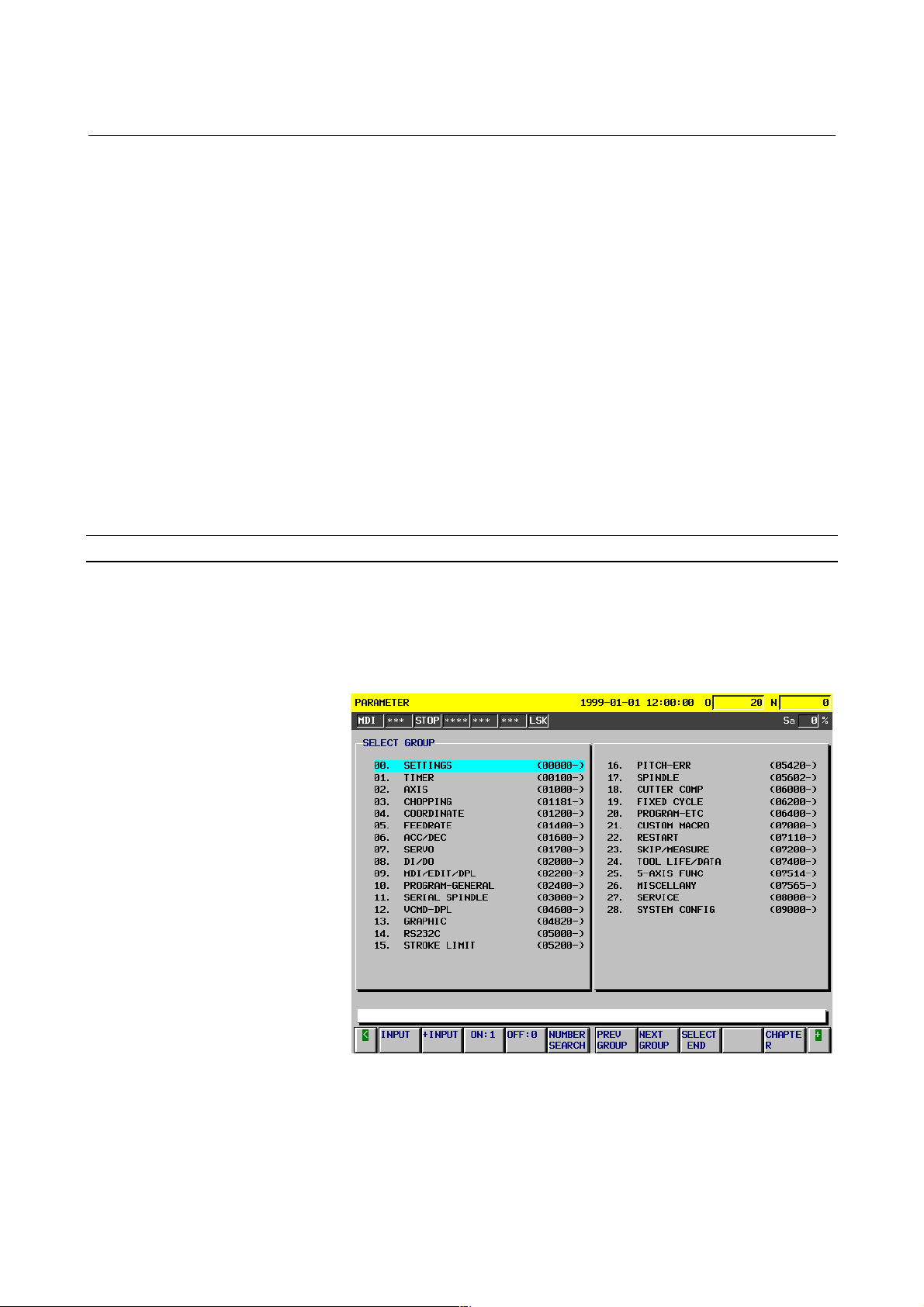

Select Group screen

The Select Group screen can be used to display a selected group of

parameters.

Displaying the Select Group screen

On the Parameter screen, select the [SELECTGROUP] soft key.

Fig. 1.1 (b) Select Group Screen

- 3 -

Page 14

1.DISPLAYING PARAMETERS AND PITCH ERROR COMPENSATION DATA B-63790EN/01

Selecting a group

Move the cursor to the group to be displayed.

Method 1

Use the <↑> <↓> <←> <→> cursor keys, move the cursor.

Method 2

(1) Click the [NO. SEARCH] soft key.

(2) Key in the number of the group to be displayed.

(3) Click the [EXEC] soft key.

Method 3

(1) Key in the number of the group to be displayed.

(2) Click the [NO. SEARCH] soft key.

Ending group selection

Click the [SELECTEND] soft key to exit from the Select Group

screen and return to the Parameter screen. The selected group of

parameters is displayed, starting with the first parameter.

- 4 -

Page 15

B-63790EN/01 1.DISPLAYING PARAMETERS AND PITCH ERROR COMPENSATION DATA

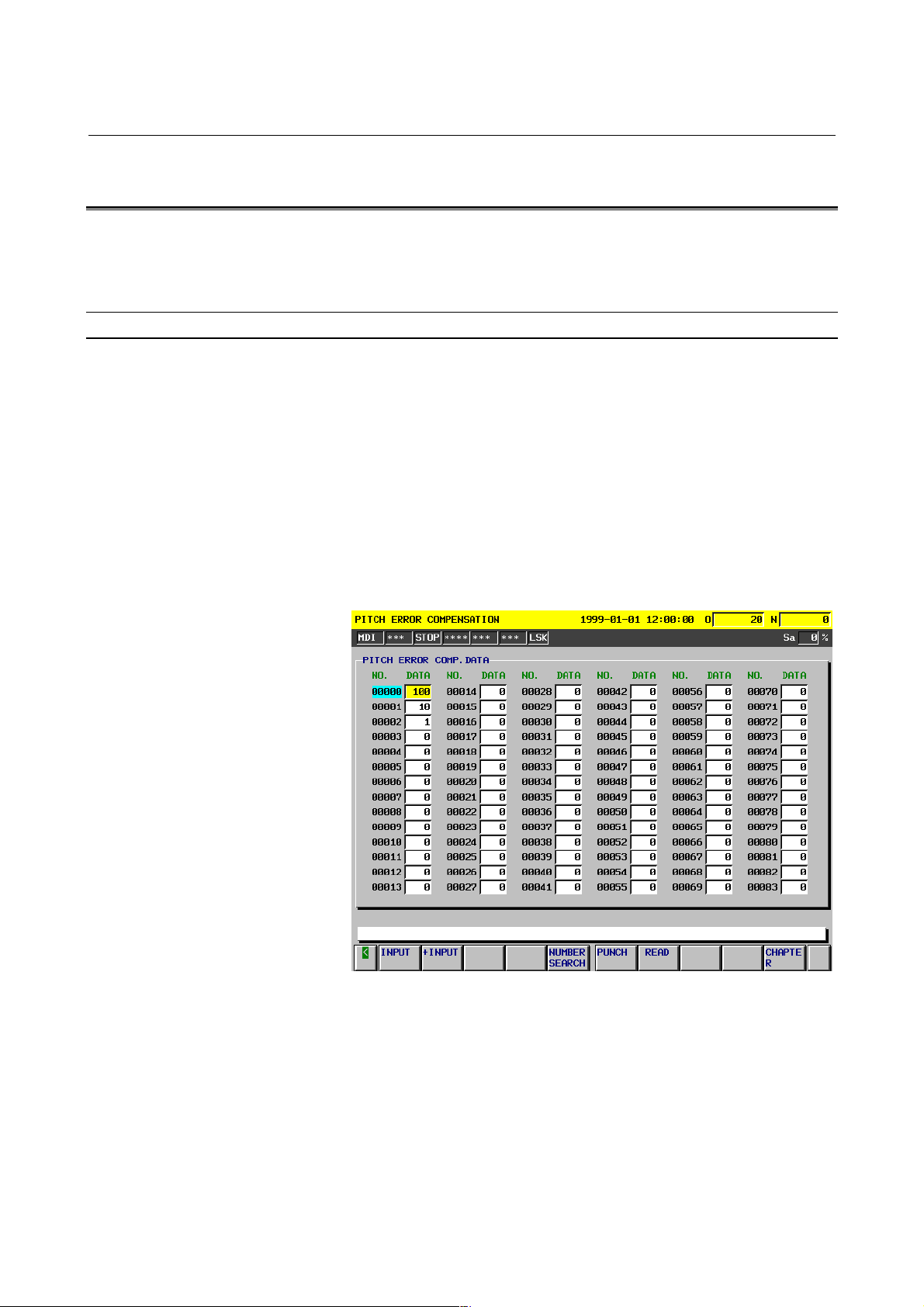

1.2 DISPLAYING PITCH ERROR COMPENSATION DATA

The Pitch Error Compensation screen displays the values specified for

pitch error compensation data.

Pitch Error Compensation screen

Displaying the Pitch Error Compensation screen

Follow either of the procedures described below to display the Pitch

Error Compensation screen.

Method 1

Press the <SYSTEM> function key several times, until the Pitch

Error Compensation screen appears.

Method 2

(1) Press the <SYSTEM> function key.

(2) Click the [PITCH ERROR] soft key.

Fig. 1.2 (a) Pitch Error Compensation Screen

- 5 -

Page 16

1.DISPLAYING PARAMETERS AND PITCH ERROR COMPENSATION DATA B-63790EN/01

Displaying specified pitch error compensation data

The Pitch Error Compensation screen consists of multiple pages.

Follow one of the procedures described below to display specified

pitch error compensation data.

Method 1

Using the <PAGE ↑> <PAGE ↓> page keys, and the <↑> <↓>

<←> <→> cursor keys, move the cursor to display the desired

pitch error compensation data.

Method 2

(1) Click the [NO. SEARCH] soft key.

(2) Key in the number of the pitch error compensation data to be

displayed.

(3) Click the [EXEC] soft key.

Method 3

(1) Key in the number of the pitch error compensation data to

be displayed.

(2) Click the [NO. SEARCH] soft key.

- 6 -

Page 17

B-63790EN/01 2.SETTING PARAMETERS AND PITCH ERROR COMPENSATION DATA

2 SETTING PARAMETERS AND PITCH

ERROR COMPENSATION DATA

This chapter explains how to set parameters and pitch error

compensation data from the MDI.

- 7 -

Page 18

2.SETTING PARAMETERS AND PITCH ERROR COMPENSATION DATA B-63790EN/01

2.1 SETTING PARAMETERS

The Parameter screen is used to set parameters from the MDI.

For an explanation of how to display the Parameter screen, see

Section 1.1, "Displaying Parameters."

Procedure for setting parameters

- Entering the mode

Enter MDI mode. Alternatively, press the emergency stop button to

enter the emergency stop status.

- Setting parameter PWE

On the Setting Parameter screen, set bit 0 of the setting/input-enabled

parameter PWE (No. 8000) to 1.

For the setting procedure, refer to Section II-9.3, "Displaying and

Setting Setting Parameters" in the "FANUC Series 15i/150i-MB

OPERATOR'S MANUAL (Operation) (B-63784EN-1)."

- Moving the cursor

Move the cursor to the parameter to be set.

Method 1

Using the <PAGE ↑> <PAGE ↓> page keys, and the <↑> <↓>

<←> <→> cursor keys, to move the cursor.

Method 2

(1) Click the [NO. SEARCH] soft key.

(2) Key in the parameter number.

(3) Click the [EXEC] soft key.

Method 3

(1) Key in the parameter number.

(2) Click the [NO. SEARCH] soft key.

- Entering a setting (absolute input)

Method 1

(1) Click the [INPUT] soft key.

(2) Key in the desired setting.

(3) Click the [EXEC] soft key.

Method 2

(1) Key in the desired setting.

(2) Click the [INPUT] soft key.

Method 3

(1) Key in the desired setting.

(2) Click the [INPUT] soft key.

- 8 -

Page 19

B-63790EN/01 2.SETTING PARAMETERS AND PITCH ERROR COMPENSATION DATA

- Entering a setting (incremental input)

Method 1

(1) Click the [+INPUT] soft key.

(2) Key in the value to be added to the current setting.

(3) Click the [EXEC] soft key.

Method 2

(1) Key in the value to be added to the current setting.

(2) Click the [+INPUT] soft key.

NOTE

For bit/bit axis/bit spindle type parameters,

incremental input is not possible. Even if the

[+INPUT] soft key is clicked, absolute input is

assumed.

- Bit ON:1

By clicking the [ON:1] soft key, the bit of a bit/bit axis/bit spindle

type parameter on which the cursor is displayed is set to 1.

If the cursor is displayed on all bits, all the bits are set to 1.

- Bit OFF:0

- Ending the setting

By clicking the [OFF:0] soft key, the bit of a bit/bit axis/bit spindle

type parameter on which the cursor is displayed is set to 0.

If the cursor is displayed on all bits, all the bits are set to 0.

When parameters have been set, set bit 0 of the setting/input-enabled

parameter PWE (No. 8000) to 0.

NOTE

The blank bits in the parameter list (Chapter 4,

"DESCRIPTION OF PARAMETERS") and the

parameters displayed on the Parameter screen but

not shown on the list are either reserved for future

expansion or used internally in the CNC. Do not

change the values of these parameter bits.

- 9 -

Page 20

2.SETTING PARAMETERS AND PITCH ERROR COMPENSATION DATA B-63790EN/01

2.2 SETTING PITCH ERROR COMPENSATION DATA

For an explanation of how to display the Pitch Error Compensation

screen, see Section 1.2, "Displaying Pitch Error Compensation Data."

The Pitch Error Compensation screen is used to set pitch error

compensation data.

Procedure for setting pitch error compensation data

- Entering the mode

Enter MDI mode. Alternatively, press the emergency stop button to

enter the emergency stop status.

- Setting parameter PWE

On the Setting Parameter screen, set bit 0 of the setting/input-enabled

parameter PWE (No. 8000) to 1.

For the setting procedure, refer to Section II-9.3, "Displaying and

Setting Setting Parameters" in the "FANUC Series 15i/150i-MA

OPERATOR'S MANUAL (Operation)."

- Moving the cursor

Move the cursor to the pitch error compensation data to be set.

Method 1

Using the <PAGE ↑> <PAGE ↓> page keys, and the <↑> <↓>

<←> <→> cursor keys, to move the cursor.

Method 2

(1) Click the [NO. SEARCH] soft key.

(2) Key in the pitch error compensation data number.

(3) Click the [EXEC] soft key.

Method 3

(1) Key in the pitch error compensation data number.

(2) Click the [NO. SEARCH] soft key.

- Entering a setting (absolute input)

Method 1

(1) Click the [INPUT] soft key.

(2) Key in the desired setting.

(3) Click the [EXEC] soft key.

Method 2

(1) Key in the desired setting.

(2) Click the [INPUT] soft key.

Method 3

(1) Key in the desired setting.

(2) Click the [INPUT] soft key.

- 10 -

Page 21

B-63790EN/01 2.SETTING PARAMETERS AND PITCH ERROR COMPENSATION DATA

- Entering a setting (incremental input)

Method 1

(1) Click the [+INPUT] soft key.

(2) Key in the value to be added to the current setting.

(3) Click the [EXEC] soft key.

Method 2

(1) Key in the value to be added to the current setting.

(2) Click the [+INPUT] soft key.

- 11 -

Page 22

3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES B-63790EN/01

3 INPUTTING AND OUTPUTTING

PARAMETERS USING EXTERNAL

INPUT/OUTPUT DEVICES

This chapter explains the procedures for inputting and outputting

parameters using the input/output device connected to the

reader/punch interface or using a memory card, as well as

input/output formats.

- 12 -

Page 23

B-63790EN/01 3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES

3.1 INPUTTING AND OUTPUTTING PARAMETERS ON THE

PARAMETER SCREEN

This section explains the procedures for inputting and outputting

parameters on the Parameter screen.

Before parameters can be input and output, the parameters related to

the input/output device must be set.

Displaying the Parameter screen

Follow either of the procedures described below to display the

Parameter screen.

Method 1

Press the <SYSTEM> function key several times, until the

Parameter screen appears.

Method 2

(1) Press the <SYSTEM> function key.

(2) Click the [PARAMETER] soft key.

Outputting parameters

Method 1 (neither the output file name nor number need be specified)

(1) Enter MDI mode.

(2) Click the [PUNCH] soft key.

(3) Click the [PARAMETER] soft key.

Method 2 (the output file name is specified)

(1) Enter MDI mode.

(2) Click the [PUNCH] soft key.

(3) Click the ["FILE NAME] soft key.

(4) Key in the file name.

(5) Click the [FILE NAME"] soft key.

(6) Click the [PARAMETER] soft key.

Method 3 (the file number is specified, one of three methods)

(1) Enter MDI mode.

(2) Click the [PUNCH] soft key.

(3) Click the [(FILE#)] soft key.

(4) Key in the file number.

(5) Click the [PARAMETER] soft key.

Method 4 (the file number is specified, one of three methods)

(1) Enter MDI mode.

(2) Click the [PUNCH] soft key.

(3) Click the <N> address key.

(4) Key in the file number.

(5) Click the [PARAMETER] soft key.

Method 5 (the file number is specified, one of three methods)

(1) Enter MDI mode.

(2) Click the <N> address key.

(3) Key in the file number.

(4) Click the [PUNCH] soft key.

- 13 -

Page 24

3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES B-63790EN/01

Inputting parameters

Method 1 (neither the input file name nor number need be specified)

(1) Enter MDI mode.

(2) Enter the emergency stop status.

(3) Click the [READ] soft key.

(4) Click the [PARAMETER] soft key.

Method 2 (the input file is specified with its file name)

(1) Enter MDI mode.

(2) Enter the emergency stop status.

(3) Click the [READ] soft key.

(4) Click the ["FILE NAME] soft key.

(5) Key in the file name.

(6) Click the [FILE NAME"] soft key.

(7) Click the [PARAMETER] soft key.

Method 3 (the input file is specified with its file number, one of three

methods)

(1) Enter MDI mode.

(2) Enter the emergency stop status.

(3) Click the [READ] soft key.

(4) Click the [(FILE#)] soft key.

(5) Key in the file number.

(6) Click the [PARAMETER] soft key.

Method 4 (the input file is specified with its file number, one of three

methods)

(1) Enter MDI mode.

(2) Enter the emergency stop status.

(3) Click the [READ] soft key.

(4) Click the <N> address key.

(5) Key in the file number.

(6) Click the [PARAMETER] soft key.

Method 5 (the input file is specified with its file number, one of three

methods)

(1) Enter MDI mode.

(2) Enter the emergency stop status.

(3) Click the <N> address key.

(4) Key in the file number.

(5) Click the [READ] soft key.

- 14 -

Page 25

B-63790EN/01 3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES

NOTE

1 When outputting and inputting parameters to and

from a FANUC Floppy Cassette, FANUC FA Card,

and FANUC Handy File, you can specify the

input/output file with its file name or number.

2 When outputting and inputting parameters to and

from a memory card, you can specify the

input/output file with its file name.

3 When method 1 (in which neither the output file

name nor number need be specified), described in

"Outputting parameters," is used to output

parameters to a FANUC Floppy Cassette, FANUC

FA Card, FANUC Handy File, and memory card,

the file name will be CNC-PARA.TXT.

- 15 -

Page 26

3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES B-63790EN/01

3.2 INPUTTING AND OUTPUTTING PARAMETERS ON THE

FLOPPY DIRECTORY SCREEN

This section explains the procedures for inputting and outputting

parameters on the Floppy Directory screen, using the FANUC Floppy

Cassette, FANUC FA Card, FANUC Handy File, or FANUC

PROGRAM FILE Mate connected to the serial interface (RS-232-C

or RS-422).

Before parameters can be input and output, the parameters related to

the input/output device must be set.

Displaying the Floppy Directory screen

Follow either of the procedures described below to display the Floppy

Directory screen.

Method 1

Press the <OFFSET/SETTING> function key several times, until

the Floppy Directory screen appears.

Method 2

(1) Press the <OFFSET/SETTING> function key.

(2) Click the [RS232C] soft key.

Outputting parameters

(1) Click the [DATA SELECT] soft key.

(2) Click the [PARAMETER] soft key.

"PARAMETER" appears in IN/OUT DATA.

(3) Follow either of the procedures described below to set the output

file name

Method 1 (the file name is entered using MDI keys)

(1) Click the [NAME INPUT] soft key.

(2) Click the ["FILE NAME] soft key.

(3) Enter the file name with MDI keys.

(4) Click the [FILE NAME"] soft key.

(5) Click the [EXEC] soft key.

Method 2 (the file name is selected from a file list)

(1) Click the [DIR. VIEW] soft key.

A list of files contained in the input/output device is

displayed. If the list cannot be displayed on a single page,

"Prev Page" and "Next Page" are displayed in PAGE

SELECT to indicate that there are multiple pages.

Press the <PAGE ↑> <PAGE ↓> key to display the

specified page.

(2) Move the cursor to the desired output file name.

(3) Click the [NAME GET] soft key.

(4) Enter MDI mode.

(5) Click the [DATA PUNCH] soft key.

(6) Click the [EXEC] soft key.

- 16 -

Page 27

B-63790EN/01 3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES

Inputting parameters

(1) Click the [DATA SELECT] soft key.

(2) Click the [PARAMETER] soft key.

"PARAMETER" appears in IN/OUT DATA.

(3) Click the [DIR. VIEW] soft key.

A list of files contained in the input/output device is displayed. If

the list cannot be displayed on a single page, "Prev Page" and

"Next Page" are displayed in PAGE SELECT to indicate that

there are multiple pages.

Press the <PAGE ↑> <PAGE ↓> key to display the specified

page.

(4) Move the cursor to the desired input file name.

(5) Enter MDI mode.

(6) Enter the emergency stop status.

(7) Click the [DATA READ] soft key.

(8) Click the [EXEC] soft key.

- 17 -

Page 28

3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES B-63790EN/01

3.3 INPUTTING AND OUTPUTTING PARAMETERS ON THE

MEMORY CARD SCREEN

This section explains the procedures for inputting and outputting

parameters on the Memory Card screen.

Before parameters can be input and output, the parameters related to

the input/output device must be set.

Displaying the Memory Card screen

Follow either of the procedures described below to display the

Memory Card screen.

Method 1

Press the <OFFSET/SETTING> function key several times, until

the Memory Card screen appears.

Method 2

(1) Press the <OFFSET/SETTING> function key.

(2) Click the [MEMCARD] soft key.

Outputting parameters

(1) Click the [DATA SELECT] soft key.

(2) Click the [PARAMETER] soft key.

"PARAMETER" appears in IN/OUT DATA.

(3) Follow either of the procedures described below to set the output

file name.

Method 1 (the file name is entered using MDI keys)

(1) Click the [NAME INPUT] soft key.

(2) Click the ["FILE NAME] soft key.

(3) Enter the file name with MDI keys.

(4) Click the [FILE NAME"] soft key.

(5) Click the [EXEC] soft key.

Method 2 (the file name is selected from a file list)

(1) Click the [DIR. VIEW] soft key.

A list of files contained in the input/output device is

displayed. If the list cannot be displayed on a single

page, "Prev Page" and "Next Page" are displayed in

PAGE SELECT to indicate that there are multiple

pages.

Press the <PAGE ↑> <PAGE ↓> key to display the

specified page.

(2) Move the cursor to the desired output file name.

(3) Click the [NAME GET] soft key.

(4) Enter MDI mode.

(5) Click the [DATA PUNCH] soft key.

(6) Click the [EXEC] soft key.

- 18 -

Page 29

B-63790EN/01 3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES

Inputting parameters

(1) Click the [DATA SELECT] soft key.

(2) Click the [PARAMETER] soft key.

"PARAMETER" appears in IN/OUT DATA.

(3) Click the [DIR. VIEW] soft key.

A list of files contained in the input/output device is displayed. If

the list cannot be displayed on a single page, "Prev Page" and

"Next Page" are displayed in PAGE SELECT to indicate that

there are multiple pages.

Press the <PAGE ↑> <PAGE ↓> key to display the specified

page.

(4) Move the cursor to the desired input file name.

(5) Enter MDI mode.

(6) Enter the emergency stop status.

(7) Click the [DATA READ] soft key.

(8) Click the [EXEC] soft key.

- 19 -

Page 30

3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES B-63790EN/01

3.4 INPUT/OUTPUT FORMATS

This section explains the input/output formats for parameters and

pitch error compensation data.

3.4.1 Input/Output Formats for Parameters

Parameters are classified according to data types, as follows.

- Bit type

- Bit axis type

- Bit spindle type

- Integer type

- Integer axis type

- Integer spindle type

- Real type

- Real axis type

- Real spindle type

- Keywords

Bit/bit axis/bit spindle type parameters are represented by 8-digit

binary numbers, with each digit occupying a single bit.

The valid value ranges of the individual integer/integer axis/integer

spindle/real/real axis/real spindle type parameters differ. For details,

see the description of each parameter.

The following alphabetic characters are used as keywords.

The numeric values following the keywords have the meanings

described below.

Keyword Description of the numeric value following the keyword

N

A

S

P

M

I

Parameter number

Controlled axis number of an axis type parameter (1 or

above)

Spindle number of a spindle type parameter (1 or above)

Value of a parameter that does not depend on

inch/metric switching

Metric-input-time value of a parameter dependent on

inch/metric switching

Inch-input-time value of a parameter dependent on

inch/metric switching

- 20 -

Page 31

B-63790EN/01 3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES

- Inch/metric switching

The data specified for parameters dependent on inch/metric switching,

such as length and feedrate parameters, is determined to be in either

inch or metric mode depending on the mode assumed at input time for

input from the MDI and depending on whether the keyword preceding

the data is I or M for input from an external input/output device.

These I and M keywords are added to data as appropriate when that

data is output from an external input/output device.

If the mode assumed at input time or the keyword does not match the

mode assumed when the data is to be used, for example, the data input

in inch mode is to be used in metric mode, the CNC automatically

converts the data before use, eliminating the need to change the data

according to the mode change. In addition, in the display of parameter

data, data is converted according to the mode assumed at display time,

before the data is displayed. When the data is to be output from the

external input/output device, it is converted back to the original data

according to the keyword or mode.

- Bit type format

N ***** P ******** ;

- Bit axis type format

The 8-digit binary number following P represents the values (0 or 1)

of the bits of the parameter, with the first digit corresponding to bit 0

and the eighth digit to bit 7. Leading zeros cannot be omitted.

; is an end of block character (LF for ISO code and CR for EIA code).

Example

N00010P00000001;

Parameter number 10

Parameter value Bit 0 is 1 and the others are 0.

N ***** A ** P ******** A ** P ******** . . . . ;

The numeric value following N represents the parameter number.

The numeric value following A represents the controlled axis number

(1 or above).

The 8-digit binary number following P represents the values (0 or 1)

of the bits of the parameter for that controlled axis, with the first digit

corresponding to bit 0 and the eighth digit to bit 7. Leading zeros

cannot be omitted.

; is an end of block character (LF for ISO code and CR for EIA code).

Example

N0005A1P10000001A2P10000001A3P10000001A4P00001001....;

Parameter number 1005

Parameter values

First axis: Bits 0 and 7 are 1 and the others are 0.

Second axis: Bits 0 and 7 are 1 and the others are 0.

Third axis: Bits 0 and 7 are 1 and the others are 0.

Fourth axis: Bits 0 and 3 are 1 and the others are 0.

- 21 -

Page 32

3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES B-63790EN/01

- Bit spindle type format

N ***** S * P ******** S * P ******** . . . . ;

The numeric value following N represents the parameter number.

The numeric value following S represents the spindle number (1 or

above).

The 8-digit binary number following P represents the values (0 or 1)

of the bits of the parameter for that spindle, with the first digit

corresponding to bit 0 and the eighth digit to bit 7. Leading zeros

cannot be omitted.

; is an end of block character (LF for ISO code and CR for EIA code).

Example

N05603S1P00001000S2P00001000S3P00000000S4P000000000;

Parameter number 5603

Parameter values

First spindle: Bit 3 is 1 and the others are 0.

Second spindle: Bit 3 is 1 and the others are 0.

Third spindle: All bits are 0.

Fourth spindle: All bits are 0.

- Integer type format

N ***** P ****** ;

The numeric value following N represents the parameter number.

The numeric value following P represents the value (integer) of the

parameter.

; is an end of block character (LF for ISO code and CR for EIA code).

Example

N00100P31515;

Parameter number 100

Parameter value 31515

- 22 -

Page 33

B-63790EN/01 3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES

- Integer axis type format

N ***** A ** P ****** A ** P ****** . . . . ;

The numeric value following N represents the parameter number.

The numeric value following A represents the controlled axis number

(1 or above).

The numeric value following P represents the value (integer) of the

parameter.

; is an end of block character (LF for ISO code and CR for EIA code).

Example

N01020A1P88A2P89A3P90A4P66......;

Parameter number 1020

Parameter values

First axis: 88

Second axis: 89

Third axis: 90

Fourth axis: 66

- Integer spindle type format

N ***** S * P ****** S * P ****** . . . . ;

The numeric value following N represents the parameter number.

The numeric value following S represents the controlled axis number

(1 or above).

The numeric value following P represents the value (integer) of the

parameter.

; is an end of block character (LF for ISO code and CR for EIA code).

Example

N05680S1P19S2P19S3P0S4P0;

Parameter number 5680

Parameter values

First spindle: 19

Second spindle: 19

Third spindle: 0

Fourth spindle: 0

- 23 -

Page 34

3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES B-63790EN/01

- Real type format

N ***** P ****** ;

N ***** M ****** ;

N ***** I ****** ;

The numeric value following N represents the parameter number.

The numeric value following P, M, or I represents the value (real) of

the parameter.

; is an end of block character (LF for ISO code and CR for EIA code).

Example

N01451P5000.0;

Parameter number 1451

Parameter number 000.0

- Real axis type format

N ***** A ** P ****** A ** P ****** . . . . ;

N ***** A ** M ****** A ** M ****** . . . . ;

N ***** A ** I ****** A ** I ****** . . . . ;

The numeric value following N represents the parameter number.

The numeric value following A represents the controlled axis number

(1 or above).

The numeric value following P, M, or I represents the value (real) of

the parameter.

; is an end of block character (LF for ISO code and CR for EIA code).

Example

N01220A1M50.0A2M60.0A3M70.0A4M0.0A5M0.0 ........;

Parameter number 1220

Parameter values

First axis: 50.0

Second axis: 60.0

Third axis: 70.0

Fourth axis: 0.0

Fifth axis: 0.0

- 24 -

Page 35

B-63790EN/01 3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES

- Real spindle type format

N ***** S * P ****** S * P ****** . . . . ;

N ***** S * M ****** S * M ****** . . . . ;

N ***** S * I ****** S * I ****** . . . . ;

The numeric value following N represents the parameter number.

The numeric value following S represents the controlled axis number

(1 or above).

The numeric value following P, M, or I represents the value (real) of

the parameter.

; is an end of block character (LF for ISO code and CR for EIA code).

Example

N05898S1P30.0S2P30.0S3P0.0S4P0.0;

Parameter number 5898

Parameter values

First spindle: 30.0

Second spindle: 30.0

Third spindle: 0.0

Fourth spindle: 0.0

- Beginning and end of a record

A record of parameters begins with "%" and ends with "%."

When parameters and pitch error compensation data are collected into

a single file, the file begins and ends with "%."

Example

%; ................................ Beginning of a record

N00000P00001100;

N00002P00000000;

:

N09162P00000000;

N09163P00000000;

% ................................ End of the record

- 25 -

Page 36

3.INPUTTING AND OUTPUTTING PARAMETERS USING EXTERNAL INPUT/OUTPUT DEVICES B-63790EN/01

3.4.2 Input/Output Format for Pitch Error Compensation Data

- Keywords

The following alphabetic characters are used as keywords.

The numeric values following the keywords have the meanings

described below.

Keyword Description of the numeric value following the keyword

N

P

- Format

Pitch error compensation data is output in the following format.

N ***** P **** ;

The 5-digit numeric value following N represents the pitch error

compensation data number. Note that this number is equal to the

actual pitch error compensation data number plus 10000.

The numeric value following P represents the value (integer) of the

pitch error compensation data, which is in the range of -128 to 127.

; is an end of block character (LF for ISO code and CR for EIA code).

Pitch error compensation data number

Pitch error compensation data value

- Beginning and end of a record

A record of pitch error compensation data begins with "%" and ends

with "%."

When parameters and pitch error compensation data are collected into

a single file, the file begins and ends with "%."

Example

N10001P100;

Pitch error compensation data number

Pitch error compensation data value

Example

% ; .................................... Beginning of a record

N10000P10;

N10001P100;

:

N11279P0;

% .................................... End of the record

- 26 -

Page 37

B-63790EN/01 4.DESCRIPTION OF PARAMETERS

4 DESCRIPTION OF PARAMETERS

4.1 DATA TYPES

Parameters are classified according to data types, as follows:

Data type Valid data range Remarks

Bit type

Bit axis type

Bit spindle type

Integer type

Integer axis type

Integer spindle type

Real type

Real axis type

Real spindle type

0 or 1

0 to ±999999999

See the Standard

Parameter Setting

Tables.

Some parameters are handled as

unsigned data.

NOTE

1 Each of bit, bit axis, and bit spindle type parameters

contains eight bits (eight different meanings) for a

single data number.

2 The axis type means that independent data can be

set for each controlled axis.

3 The spindle type means that independent data can

be set for each spindle.

4 The valid data ranges are general ones. The valid

data range differs from one parameter to another.

For details, see the explanation of each parameter.

- 27 -

Page 38

4.DESCRIPTION OF PARAMETERS B-63790EN/01

4.2 REPRESENTATION OF PARAMETERS

Bit, bit axis, and bit spindle types

#7 #6 #5 #4 #3 #2 #1 #0

0000 EIA NCR ISP CTV TVC

Data

number

Data (#0 to #7 indicate bit positions.)

Types other than bit, bit axis, and bit spindle types

1023 Servo axis number of each axis

Data

number

NOTE

The blank bits in the parameter list (Chapter 4,

"DESCRIPTION OF PARAMETERS") and the

parameters displayed on the Parameter screen but

not shown on the list are reserved for future

expansion. Be sure to set these parameter bits to 0.

Data

- 28 -

Page 39

B-63790EN/01 4.DESCRIPTION OF PARAMETERS

4.3 STANDARD PARAMETER SETTING TABLES

Overview

This section specifies the standard minimum data units and standard

valid data ranges of real, real axis, and real spindle type CNC

parameters. The data type of each parameter and its unit of data

conform to the specifications of each function.

Explanations

(A) Length and angle parameters (type 1)

Unit of data

mm

deg.

inch

Increment

system

IS-A 0.01 -999999.99 to +999999.99

IS-B 0.001 -999999.999 to +999999.999

IS-C 0.0001 -99999.9999 to +99999.9999

IS-D 0.00001 -9999.99999 to +9999.99999

IS-E 0.000001 -999.999999 to +999.999999

IS-A 0.001 -99999.999 to +99999.999

IS-B 0.0001 -99999.9999 to +99999.9999

IS-C 0.00001 -9999.99999 to +9999.99999

IS-D 0.000001 -999.999999 to +999.999999

IS-E 0.0000001 -99.9999999 to +99.9999999

Minimum data unit Valid data range

(B) Length and angle parameters (type 2)

Unit of data

mm

deg.

inch

Increment

system

IS-A 0.01 0.00 to +999999.99

IS-B 0.001 0.000 to +999999.999

IS-C 0.0001 0.0000 to +99999.9999

IS-D 0.00001 0.00000 to +9999.99999

IS-E 0.000001 0.000000 to +999.999999

IS-A 0.001 0.000 to +99999.999

IS-B 0.0001 0.0000 to +99999.9999

IS-C 0.00001 0.00000 to +9999.99999

IS-D 0.000001 0.000000 to +999.999999

IS-E 0.0000001 0.0000000 to +99.9999999

Minimum data unit Valid data range

- 29 -

Page 40

4.DESCRIPTION OF PARAMETERS B-63790EN/01

(C) Velocity and angular velocity parameters

Unit of data

mm/min

deg./min

inch/min

Increment

system

IS-A 0.01 0.0 to +2400000.0

IS-B 0.001 0.0 to +240000.0

IS-C 0.0001 0.0 to +99999.9999

IS-D 0.00001 0.0 to +9999.99999

IS-E 0.000001 0.0 to +999.999999

IS-A 0.001 0.0 to +96000.000

IS-B 0.0001 0.0 to +9600.0000

IS-C 0.00001 0.0 to +4000.00000

IS-D 0.000001 0.0 to +400.000000

IS-E 0.0000001 0.0 to +40.0000000

Minimum data unit Valid data range

(D) Acceleration and angular acceleration parameters

Unit of data

mm/sec

deg./sec

inch/sec

2

2

2

Increment

system

IS-A 0.01 0.00 to +999999.99

IS-B 0.001 0.000 to +999999.999

IS-C 0.0001 0.0000 to +99999.9999

IS-D 0.00001 0.00000 to +9999.99999

IS-E 0.000001 0.000000 to +999.999999

IS-A 0.001 0.000 to +999999.999

IS-B 0.0001 0.0000 to +99999.9999

IS-C 0.00001 0.00000 to +9999.99999

IS-D 0.000001 0.000000 to +999.999999

IS-E 0.0000001 0.0000000 to +99.9999999

Minimum data unit Valid data range

Notes

(1) Values are rounded up or down to the nearest multiples of the

minimum data unit.

(2) A valid data range means the range of CNC performance.

Therefore, set data within this range. This range may differ from

the performance of an actual machine.

(3) For information on the ranges of commands to the CNC, refer to

Appendix, "List of Command Ranges," in the "FANUC Series

15i/150i-MB OPERATOR'S MANUAL (Programming)" (B-

63784EN).

- 30 -

Page 41

B-63790EN/01 4.DESCRIPTION OF PARAMETERS

ANCR

4.4 SETTING PARAMETERS (DATA NO. 0000 AND LATER)

#7 #6 #5 #4 #3 #2 #1 #0

0000 RDN EI

[Input type] Setting input

[Data type] Bit

#0 TVC Specifies whether TV check is performed.

0: Do not perform.

1: Perform.

#1 CTV Specifies whether characters are counted for TV check during control

out.

0: Count.

1: Do not count.

#2 ISP Specifies whether ISO codes contain a parity bit.

0: Contain parity bit.

1: Do not contain parity bit.

A parity bit is located at channel 8 in a punched tape in the ISO code.

#3 NCR Specifies how to punch an EOB (end-of-block) code when using ISO

codes.

0: Punch LF CR CR.

1: Punch LF.

NOTE

This bit is disabled, when bit 2 (CRF) of parameter

No.0002 is set to 1.

ISP CTV TVC

#4 EIA Specifies the code system to use for punch codes.

0: ISO code

1: EIA code

#6 RDN Specifies whether the Remote Diagnostic Function is used

0: Disable

1: Enable

The device setting for Remote Diagnostic Function is used current

setting when this bit is set to 1. After all device parameters are set,

this bit should be set to 1. When the device parameters are changed,

this bit must be set to 0.

NOTE

During this bit is set to 1, the communication device is

occupied by Remote Diagnostic Function. So, while

this bit is 1, don't read data and don't punch data from

CNC side.

- 31 -

Page 42

4.DESCRIPTION OF PARAMETERS B-63790EN/01

#7 #6 #5 #4 #3 #2 #1 #0

0002 SJZ PZS CRF

[Input type] Setting input

[Data type] Bit

#2 CRF Specifies how to punch an EOB (end-of-block) code when using ISO

codes.

0: Use parameter NCR (No.0#3).

1: Punch CR LF.

#3 PZS

0: Do not suppress the zeros of O numbers during the punching of a

part program.

1: Suppress the zeros of O numbers during the punching of a part

program.

#7 SJZ Manual reference position return:

0: Performs reference position return using deceleration dogs if the

reference position has not been established and performs

positioning to the reference position with rapid traverse

irrespective of deceleration dogs if the reference position has

already been established.

1: Always performs reference position return using deceleration

dogs.

SJZ is effective to those axes for which HJZ, bit 4 of parameter No.

1013, is 1. After the reference position has been established using

the function for setting the reference position without dogs (DOG, bit

7 of parameter No. 1007 = 1), however, manual reference position

return always performs positioning to the reference position with

rapid traverse irrespective of the setting of SJZ.

#7 #6 #5 #4 #3 #2 #1 #0

0009 SPI SVI IDW

[Input type] Setting input

[Data type] Bit

# 0 IDW Specifies whether to permit editing of the servo or spindle

information screen.

0: Do not permit editing.

1: Permit editing.

# 1 SVI Specifies whether to display the servo information screen.

0: Display the servo information screen.

1: Do not display the servo information screen.

NOTE

After this parameter has been set, the power must be

off turned off then back on for the setting to become

effective.

# 2 SPI Specifies whether to display the spindle information screen.

0: Display the servo information screen.

1: Do not display the servo information screen.

- 32 -

Page 43

B-63790EN/01 4.DESCRIPTION OF PARAMETERS

#7 #6 #5 #4 #3 #2 #1 #0

0010 SBO SBC SBM SB8 SB7 SQN INI

[Input type] Setting input

[Data type] Bit

#0 INI Specifies whether the increment system is metric or in inches.

0: Metric input

1: Inch input

#1 SQN Specifies whether sequence numbers are automatically inserted.

0: Do not insert.

1: Insert.

#3 SB7 Specifies whether to stop after each block of custom macro statements

in programs O7000 to O7999.

0: Do not stop after each block.

1: Stop after each block.

This bit is used to check programs O7000 to O7999 containing

custom macro statements.

#4 SB8 Specifies whether to stop after each block of custom macro statements

in programs O8000 to O8999.

0: Do not stop after each block.

1: Stop after each block.

This bit is used to check programs O8000 to O8999 containing

custom macro statements.

#5 SBM Specifies whether to stop after each block of custom macro statements

in any program.

0: Do not stop after each block. However, when stopping is

specified in SB7 or SB8, stopping will occur in programs

affected by these parameters.

1: Stop after each block.

This bit is used to check programs containing custom macro

statements.

#6 SBC Specifies whether to stop after each block in hole-machining canned

cycles.

0: Do not stop after each block.

1: Stop after each block.

This bit is used to check programs containing canned cycles.

#7 SBO Specifies whether to stop after each block automatically generated in

the NC for cutter or tool tip radius compensation.

0: Do not stop after each block.

1: Stop after each block.

This bit is used to check programs containing cutter or tool tip radius

compensation.

- 33 -

Page 44

4.DESCRIPTION OF PARAMETERS B-63790EN/01

R

#7 #6 #5 #4 #3 #2 #1 #0

0011 NOT TIM ND8 NE8

[Input type] Setting input

[Data type] Bit

#0 NE8 Specifies whether to permit editing of O8000 to O8999 programs.

0: Permit editing.

1: Do not permit editing.

#1 ND8 Specifies whether to display the program being executed on the

screen for programs O8000 to O8999.

0: Display program being executed.

1: Do not display program being executed.

When there is no need to display custom macros or other programs

being executed, set this parameter to 1.

#4 TIM Specifies the information displayed on the screen for the program No.

and name directory.

0: Display program No., name, and memory used.

1: Display program No., name, and processing time.

#5 NOT Specifies whether to use Tool Nos. to specify output of tool pot Nos.

and tool offsets.

0: Use tool Nos. (H/D codes cannot be used to specify tool length

compensation and cutter compensation.)

1: Do not use tool Nos. (H/D codes can be used to specify tool

length compensation and cutter compensation.)

#7 #6 #5 #4 #3 #2 #1 #0

0012 RMV SCL MI

[Input type] Setting input

[Data type] Bit axis

#0 MIR For each axis, specifies whether to use its mirror image.

0: Do not use mirror image (normal).

1: Use mirror image (mirror).

#1 SCL For this axis, specifies whether scaling is used.

0: Do not use scaling.

1: Use scaling.

#7 RMV For each axis, specifies whether to detach the shaft corresponding to

the control axis.

0: Do not detach.

1: Detach.

(Equivalent to the control axis detach signals DTCH1, DTCH2, and

so on.)

Effective when RMB (bit 7 of parameter No. 1005) is set to 1.

- 34 -

Page 45

B-63790EN/01 4.DESCRIPTION OF PARAMETERS

A

#7 #6 #5 #4 #3 #2 #1 #0

0013 DSL HDE HKE

[Input type] Setting input

[Data type] Bit

#4 HKE Specifies whether to store the history of key operations.

0: Do not store the history.

1: Store the history.

#5 HDE Specifies whether to store the history of DI/DO.

0: Do not store the history.

1: Store the history.

#6 DSL Specifies whether to display the system log screen.

0: Do not display the screen.

1: Display the screen.

#7 #6 #5 #4 #3 #2 #1 #0

0014 HD2 NIC

SG FAN

[Input type] Setting input

[Data type] Bit

#1 FAN Specifies whether to ignore alarm FAN MOTOR STOP (OH002).

0: Do not ignore the alarm.

1: Ignore the alarm.

#4 ASG Specifies what compensation is to be changed in the Changing Active

Offset Value with Manual Move mode for offset memory B/C, as

follows:

0: Wear compensation

1: Geometry compensation

This parameter is valid for offset memory B/C.

#5 NIC Specifies whether to perform an interference check when

compensation plane switching occurs during three-dimensional cutter

compensation.

0: Perform.

1: Do not perform.

#7 HD2 Specifies whether the size of one file can exceed 2000 m when using

a floppy cassette, the PROGRAM FILE Mate, HANDY FILE, or FA

card.

0: Within 2000 m

1: Can exceed 2000 m

- 35 -

Page 46

4.DESCRIPTION OF PARAMETERS B-63790EN/01

#7 #6 #5 #4 #3 #2 #1 #0

0015 NDM EKE OHS HPC SPS SVS

[Input type] Setting input

[Data type] Bit

#0 SVS Specifies whether to display the servo screen.

0: Display the servo screen.

1: Do not display the servo screen.

Specifies whether to display or hide the servo setting screen, servo

adjustment/monitor screen, servo function setting screen, servo alarm

screen, and backlash screen.

#1 SPS Specifies whether to display the spindle screen.

0: Display the spindle screen.

1: Do not display the spindle screen.

#2 HPC Specifies whether to enable the high-speed and high-precision

machining setting screen.

0: Enable the screen.

1: Disable the screen.

#3 OHS Specifies whether to display the operation history screen and the

signal selection screen.

0: Do not display the screens. (The alarm history screen can be

displayed.)

1: Display the screens.

#4 EKE Specifies whether to enable the [ALL CLEAR] soft key that erases

history data.

0: Disable the soft key.

1: Enable the soft key.

#7 NDM

The PROFIBUS-DP screen is

0: Displayed.

1: Not displayed.

The change of this bit takes effect at the next startup.

0016 Screen saver start time

[Input type] Setting input

[Data type] Integer

[Unit of data] min

[Valid data range] 0 - 127

When the operator does not operate the keyboard for the period

specified in this parameter, the saver screen is displayed. When 0 is

specified, the screen save function is disabled.

0020 Interface No. of input device for foreground

[Input type] Setting input

[Data type] Integer

[Valid data range] 0 - 21

This parameter specifies an interface number for a foreground input

device.

- 36 -

Page 47

B-63790EN/01 4.DESCRIPTION OF PARAMETERS

The device numbers for each device are listed below:

Device

number

1 RS-232-C channel 1 (JD5A on the main CPU board)

2 RS-232-C channel 2 (JD5B on the main CPU board)

3 RS-232-C channel 3 (JD36A on the display unit)

8 Memory card

9 PMC C board

10 Remote buffer

12 Remote Diagnose

13 RS-422 channel 1 (JD6A on the display unit)

14 Data server

15 Open CNC DNC operation interface

16 Open CNC Upload/Download interface

18 C language executor DNC operation interface

19 C language executor Upload/Download interface

20 RS-232-C channel 4 (JD5C on the additional-axis board)

21 RS-422 channel 2 (JD6B on the additional-axis board)

0021 Interface No. of output device for foreground

Device name

[Input type] Setting input

[Data type] Integer

[Valid data range] 0 - 21

This parameter specifies an interface number for a foreground output

device.

See the descriptions about parameter No. 0020 for the device

numbers.

If the screen hard copy function is enabled (parameter HDC (bit 7 of

parameter No. 2240) = 1), set this parameter to 8 (memory card).

0022 Interface No. of input device for background

[Input type] Setting input

[Data type] Integer

[Valid data range] 0 - 21

This parameter specifies an interface number for a background input

device.

See the descriptions about parameter No. 0020 for the device

numbers.

0023 Interface No. of output device for background

[Input type] Setting input

[Data type] Integer

[Valid data range] 0 - 21

This parameter specifies an interface number for a background output

device.

See the descriptions about parameter No. 0020 for the device

numbers.

- 37 -

Page 48

4.DESCRIPTION OF PARAMETERS B-63790EN/01

0024 Assignment of the communication with the PMC Ladder development tool

(FAPT LADDER-II, Ladder editing package)

[Input type] Setting input

[Data type] Integer

[Valid data range] 0 - 255

Assigns the communication with the PMC Ladder development tool

(FAPT LADDER-II, Ladder editing package).

The value of this parameter determines the communication to be

started, as follows:

0: At power-on, communication conforms to the settings on the

PMC setting screen (displayed by selecting [PMC], [SETING],

and the [ONLINE] screen in this order).*1

Communication stops if this parameter is changed from another

value to 0.

1: RS-232-C serial port 1 (JD5A)

2: RS-232-C serial port 2 (JD5B)

3: RS-232-C serial port 3 (JD36A)

4: RS-422 serial port (JD6A)

255: Do not allow communication with the PMC Ladder development

tool.

*1 When using HSSB, set the parameter to 0.

After system startup, communication settings can be changed with

this parameter or on the PMC setting screen.

Refer to the PMC Ladder Language Programming Manual (B61863E).

To use the online monitor function of the PMC Ladder development

tool, set the desired communication port number in this parameter.

To transfer sequence programs in offline mode, set this parameter to

"0." In addition, on the PMC [ONLINE] screen, select "NOT USE" in

the "RS-232C" field.

To forcibly stop the communication with the PMC Ladder

development tool, set this parameter to "255."

0031 Initial value used for automatic setting of sequence Nos.

[Input type] Setting input

[Data type] Integer

[Valid data range] 0 - 99999999

0032 Increment used for automatic setting of sequence No.

[Input type] Setting input

[Data type] Integer

[Valid data range] 0 - 99999999

If the increment is set to 0, no sequence Nos. are inserted.

- 38 -

Page 49

B-63790EN/01 4.DESCRIPTION OF PARAMETERS

0040 Serial port channel for Remote Diagnostic Function

[Input type] Setting input

[Data type] Integer

[Valid data range] 1 - 3

Selection of serial port channel for Remote Diagnostic Function.

1: RS-232-C Serial port1 (JD5A)

2: RS-232-C Serial port2 (JD5B)

3: RS-232-C Serial port3 (JD36A)

17: Modem card (PCMCIA card slot on the LCD unit)

0042 Password 1 for Remote Diagnostic Function

[Input type] Locked parameter

[Data type] Integer

[Valid data range] 0 - 99999999

0043 Keyword 1 for Remote Diagnostic Function

[Input type] Locked parameter

[Data type] Integer

[Valid data range] 0 - 99999999

0044 Password 2 for Remote Diagnostic Function

[Input type] Locked parameter

[Data type] Integer

[Valid data range] 0 - 99999999

0045 Keyword 2 for Remote Diagnostic Function

[Input type] Locked parameter

[Data type] Integer

[Valid data range] 0 - 99999999

0046 Password 3 for Remote Diagnostic Function

[Input type] Locked parameter

[Data type] Integer

[Valid data range] 0 - 99999999

0047 Keyword 3 for Remote Diagnostic Function

[Input type] Locked parameter

[Data type] Integer

[Valid data range] 0 - 99999999

Parameters (No.0042, 0044, 0046) set passwords for using the remote

diagnosis function.

With the remote diagnostic function, three types of passwords are

available for protecting data. These passwords help to prevent

- 39 -

Page 50

4.DESCRIPTION OF PARAMETERS B-63790EN/01

unauthorized persons from accessing system parameters and

machining programs.

Password 1:

Sets a password for all services of the remote diagnosis function.

(No remote diagnosis function services are available until this

password is entered on the host computer (personal or other)).

Password 2:

Sets a password for part programs. (Program-related operations

such as program data input/output and check cannot be

performed until this password is entered on the host computer

(personal or other)).

Password 3:

Sets a password for parameters. (Parameter-related operations

such as parameter data input/output and cannot be performed

until this password is entered on the host computer (personal or

other)).

Parameters (No.0043, 0045, 0047) set the keywords for passwords

used with the remote diagnostic function.

Keyword 1:

Keyword for password 1(parameter No.0042)

Keyword 2:

Keyword for password 2(parameter No.0044)

Keyword 3:

Keyword for password 3(parameter No.0046)

When a value other than 0 is specified as a password (parameter

No.0042, 0044, 0046), the password cannot be modified until the

same value is set in the corresponding keyword parameter.

NOTE

Once a value other than 0 is set as a password, the

password cannot be modified until the same value is

set in the corresponding keyword parameter

(parameters No.0043, No.0045, and No.0047). When

a value other than 0 is set as a password, only blanks

are displayed. Care must be taken in setting a

password.

Upon power-up, the keyword parameters are set to 0.

The parameter screen does not display any set

keyword value, only blanks are displayed.

- 40 -

Page 51

B-63790EN/01 4.DESCRIPTION OF PARAMETERS

4.5 Timer Parameters (Data No. 0100 and later)

0100 Time accumulated since power-on

[Input type] Parameter input

[Data type] Integer

[Unit of data] min

[Valid data range] 0 - 999999999

Stores the time accumulated since power-on.

0101 Time 1 accumulated during automatic operation

[Input type] Setting input

[Data type] Integer

[Unit of data] msec

[Valid data range] 0 - 59999

Stores the time accumulated during automatic operation that is less

than one minute. The actual time accumulated during automatic

operation is the sum of this parameter and parameter No. 102.

0102 Time 2 accumulated during automatic operation

[Input type] Setting input

[Data type] Integer

[Unit of data] min

[Valid data range] 0 - 999999999

Stores the time accumulated during automatic operation that is equal

to or greater than one minute. The actual time accumulated during

automatic operation is the sum of this parameter and parameter No.

101.

0103 Time 1 accumulated during cutting

[Input type] Setting input

[Data type] Integer

[Unit of data] msec

[Valid data range] 0 - 59999

Stores the time accumulated during cutting that is less than one

minute. The actual time accumulated during cutting is the sum of this

parameter and parameter No. 104.

- 41 -

Page 52

4.DESCRIPTION OF PARAMETERS B-63790EN/01

0104 Time 2 accumulated during cutting

[Input type] Setting input

[Data type] Integer

[Unit of data] min

[Valid data range] 0 - 999999999

Stores the time accumulated during cutting that is equal to or greater

than one minute. The actual time accumulated during cutting is the

sum of this parameter and parameter No. 103.

0105 Time 1 accumulated by the general-purpose timer

[Input type] Setting input

[Data type] Integer

[Unit of data] msec

[Valid data range] 0 - 59999

Stores the time accumulated by the general-purpose timer that is less

than one minute. The actual time accumulated by the general-purpose

time is the sum of this parameter and parameter No. 106.

0106 Time 2 accumulated by the general-purpose timer

[Input type] Setting input

[Data type] Integer

[Unit of data] min

[Valid data range] 0 - 999999999

Stores the time accumulated by the general-purpose time that is equal

to or greater than one minute. The actual time accumulated by the

general-purpose time is the sum of this parameter and parameter No.

105.

0107 Total number of parts machined

[Input type] Setting input

[Data type] Integer

[Valid data range] 0 - 999999999

Stores the total number of parts machined.

0108 Total number of parts

[Input type] Setting input

[Data type] Integer

[Valid data range] 0 - 999999999

Stores the total number of parts.

- 42 -

Page 53

B-63790EN/01 4.DESCRIPTION OF PARAMETERS

0109 Number of parts required

[Input type] Setting input

[Data type] Integer

[Valid data range] 0 - 999999999

Sets the number of parts required. When the total number of

machined parts exceeds the value of this parameter, a signal

indicating that the number of parts required is exceeded is output.

0130 Time by which to go back to delete alarms from the history

[Input type] Parameter input

[Data type] Integer

[Unit of data] sec

[Valid data range] 0 - 255

When the power to the NC is turned ON, the NC goes back from the

time the NC was turned OFF by the specified time and deletes from

the history any alarms that occurred during this period.

If this parameter is set to 0, one second is assumed.

- 43 -

Page 54

4.DESCRIPTION OF PARAMETERS B-63790EN/01

XIK

4.6 AXIS CONTROL PARAMETERS (DATA NO. 1000 AND

LATER)

#7 #6 #5 #4 #3 #2 #1 #0

1000 EMI EHM FPI

[Input type] Parameter input

[Data type] Bit

#0 CIP Specifies what to confirm with an in-position check.

0: Merely confirm that the specified feedrate reaches zero during

deceleration (the acceleration/deceleration delay becomes zero).

1: Confirm that the specified feedrate reaches zero during

deceleration (the acceleration/deceleration delay becomes zero)

and that the machine reaches the specified position (the servo

position deviation falls within the valid area set for parameter No.

1827).

#1 CSZ Specifies whether to enable the in-position check signal (*CSMZ).

0: Disable

1: Enable

#2 XIK When axis interlock is applied during non-linear interpolation

positioning (when LRP, a bit of parameter No. 1400 is set to 0),

specifies whether to stop only the axis to which interlock was applied

or all axes.

0: Stop axis to which interlock was applied. Other axes continue

operation.

1: Stop all axes.

#3 FPI Specifies whether to perform an in-position check at the temporary

stop-point in G60 mode.

0: Do not perform in-position check.

1: Perform in-position check.

#5 EHM Specifies conditions when handle interruption is valid.

0: When in G01, G02, or G03 mode, handle interruption is valid

during automatic operation startup, stopping, and resting.

1: Handle interruption is only valid for G01, G02, and G03 blocks

during automatic operation startup.

#6 EMI Specifies validity of manual interrupts and manual setup operations

during simultaneous manual-automatic operation.

0: Manual interrupts are invalid and manual setup operations are

valid.

1: Manual interrupts and manual setup operations are valid.

CSZ CIP

- 44 -

Page 55

B-63790EN/01 4.DESCRIPTION OF PARAMETERS

#7 #6 #5 #4 #3 #2 #1 #0

1001 CAF PED PDC RPC

[Input type] Setting input

[Data type] Bit

#0 RPC Specifies whether axes are switched when a reference position return

(G29) is performed.

0: Axes are not switched.

1: Axes are switched.

#5 PDC Specifies whether the G10.9 code (for selecting diameter or radius

programming) and PDA (bit 3 of parameter No. 1009) are valid.

0: Invalid.

1: Valid.

This parameter is related to DIA (bit 3 of parameter No. 1006). Also

see the item on that parameter.

#6 PED Specifies whether to enable the external deceleration function in PMC

axis control.

0: Disables the external deceleration function.

1: Enables the external deceleration function.

#7 CAF Specifies whether to enable chopping axis and rate data to be set on

the setting screen, as follows:

0: Enables.

1: Disables.

#7 #6 #5 #4 #3 #2 #1 #0

1002 DC4 INM

[Input type] Parameter input

[Data type] Bit

NOTE

After this parameter has been set, the power must be

off turned off then back on for the setting to become

effective.

#1 INM Specifies whether the least command increment for the linear axis is

metric or in inches.

0: Metric. (The machine is a millimeter machine.)

1: Inches. (The machine is an inch machine.)

#3 DC4 Specifies how to establish a reference position for a linear scale

having reference marks.

0: An absolute position is established by detecting three reference

marks.

1: An absolute position is established by detecting four reference

marks.

- 45 -

Page 56

4.DESCRIPTION OF PARAMETERS B-63790EN/01

A

#7 #6 #5 #4 #3 #2 #1 #0

1004 DSP

[Input type] Parameter input

[Data type] Bit axis

#6 DSP Specifies whether to display axis positions in the position screen and

the program check screen.

0: Display axis positions.

1: Do not display axis positions.

NOTE

When using the electronic gear box function (EGB),

specify 1 for the dummy axis of the EGB to disable

position display.

#7 #6 #5 #4 #3 #2 #1 #0

1005 RMB MLE EDM EDP PLZ

[Input type] Parameter input

[Data type] Bit axis

LZ ZRN

#0 ZRN Specifies whether to issue an alarm if reference position return has

not been performed since power-on and an attempt is made to execute

a command involving movement other than that with G28 during

automatic operation.

0: Issue an alarm ("PS181 ZERO RETURN NOT FINISHED").

1: Do not issue an alarm but execute operation.

#2 ALZ Specifies the method to use for automatic reference position return

(G28).

0: Return to reference position using positioning (rapid traverse).

If reference position return has not been performed since power-on, it

is performed using the same operation sequence for manual

reference position return.

1: Use the same operation sequence as for manual reference

position return.

Usually, set this bit to 0.

#3 PLZ Specifies the condition for presetting the work coordinate system

when manual reference position return is performed.

0: Preset only when in reset state (e.g. OP signal is off).

1: Always preset.

See ZNP, bit 2 of parameter No. 2402, which is common to all axes.

#4 EDP For each axis, specifies whether the external deceleration signal for

the positive direction is valid during cutting feed.

0: Invalid.

1: Valid.

#5 EDM For each axis, specifies whether the external deceleration signal for

the negative direction is valid during cutting feed.

0: Invalid.

1: Valid.

- 46 -

Page 57

B-63790EN/01 4.DESCRIPTION OF PARAMETERS

A

#6 MLE Specifies whether machine lock is valid for each axis.

0: Invalid.

1: Valid.

#7 RMB For each axis, specifies whether the control axis detach signal and

setting input RMV (bit 7 of parameter No. 0012) is valid.

0: Invalid.

1: Valid.

#7 #6 #5 #4 #3 #2 #1 #0

1006 NDC ZMI DI

ROP ROS ROT

[Input type] Parameter input

[Data type] Bit axis

NOTE

After this parameter has been set, the power must be off

turned off then back on for the setting to become effective.

#0 ROT Specifies whether the axis requires inch/metric conversion.

0: Axis requires inch/metric conversion (linear axis).

1: Axis does not require inch/metric conversion (rotation axis).

#1 ROS Specifies whether the machine coordinate system used for stroke

check and automatic reference position return is linear or rotational.

0: Linear (linear axis)

1: Rotation (rotation axis)

For a rotation axis, the machine coordinate system is normalized

within the angular displacement per rotation specified for parameter

No. 1260. In this case, automatic reference position return (G28, G30)

is performed in the same direction as manual reference position return

and the angular displacement does not exceed 360 degrees. Also see

the item on parameter No. 1260.

#2 ROP Specifies whether the machine coordinate system used to perform the

retained pitch error compensation is linear or rotational.

0: Linear (linear axis)

1: Rotation (rotation axis)

When the coordinate system used is rotational, up to the angle which

corresponds to one cycle of retained pitch error compensation data

can be specified. This allows pitch compensation to be performed for

pitch compensation cycles of other than 360 degrees. Also see the

item on parameter No. 5425.

#3 DIA Move commands for each axis are specified using:

0: Radius specification

1: Diameter specification

If bit 5 (PDC) of parameter No. 1001 is 1, DIA has the following

meaning:

The scale of the parameter, offset, and graphic screens is indicated

using:

0: Radius specification

1: Diameter specification

- 47 -

Page 58

4.DESCRIPTION OF PARAMETERS B-63790EN/01

R

#5 ZMI Specifies the direction of manual reference position return.

0: Positive direction

1: Negative direction

#6 NDC Specifies the normal direction control function.

0: Not normal direction control axis

1: Normal direction control axis

Only one axis can be specified as the normal direction control axis.

#7 #6 #5 #4 #3 #2 #1 #0

1007 DOG GRD INC REL G90 RS

[Input type] Parameter input

[Data type] Bit axis

#0 FAX Specifies whether the fixture offset is valid for each axis.

0: Invalid.

1: Valid.

#2 RSR When an absolute command is executed (when INC, bit 5 of

parameter No. 1007, is set to 0), specifies whether the direction of

rotation is determined by the sign of the value specified by the

command.

0: Not determined.

1: Determined by command value (counterclockwise when value is

positive and clockwise when value is negative)

#3 G90 Specifies the type of commands used for the rotary control axes.

0: Either absolute or incremental commands determined by G90 or

G91 mode

1: Absolute commands

#4 REL Specifies whether the current position of rotary control axes in the

relative coordinate system is displayed with the value rounded off

within one rotation.

0: Not performed.

1: Performed.

#5 INC In rotary axis control, when the NC converts the command value to

the corresponding value within one rotation and the current position

being regarded as the angular displacement through which the axis is

to be rotated, this bit specifies whether to turn in whichever direction

minimizes the displacement in G90 mode.

0: Do not turn to closest direction.

1: Turn to closest direction.

#6 GRD Dog-less reference position setting is

0: Performed more than once.

1: Not performed more than once.

#7 DOG In the manual reference position return mode

0: Dog-less reference position setting is disabled.

1: Dog-less reference position setting is enabled.

FAX

- 48 -

Page 59

B-63790EN/01 4.DESCRIPTION OF PARAMETERS

A

#7 #6 #5 #4 #3 #2 #1 #0

1008 DCL SFD ROT

[Input type] Parameter input

[Data type] Bit axis

NOTE

After this parameter has been set, the power must be

off turned off then back on for the setting to become

effective.

#1 ROT

0: Not multiple rotary control axes.

1: Multiple rotary control axes.

#4 SFD Specifies whether to enable the reference position shift function in

reference position return with the grid method.

0: Disable the function.

1: Enable the function.