Page 1

DESCRIPTIONS

B-63782EN/01

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The export of this product is subject to the authorization of the government of the country

from where the product is exported.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by or in the main body.

Page 3

B-63782EN/01 DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine.

Precautions are classified into Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly

before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved

procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and

Caution.

- Read this manual carefully, and store it in a safe place.

s-1

Page 4

Page 5

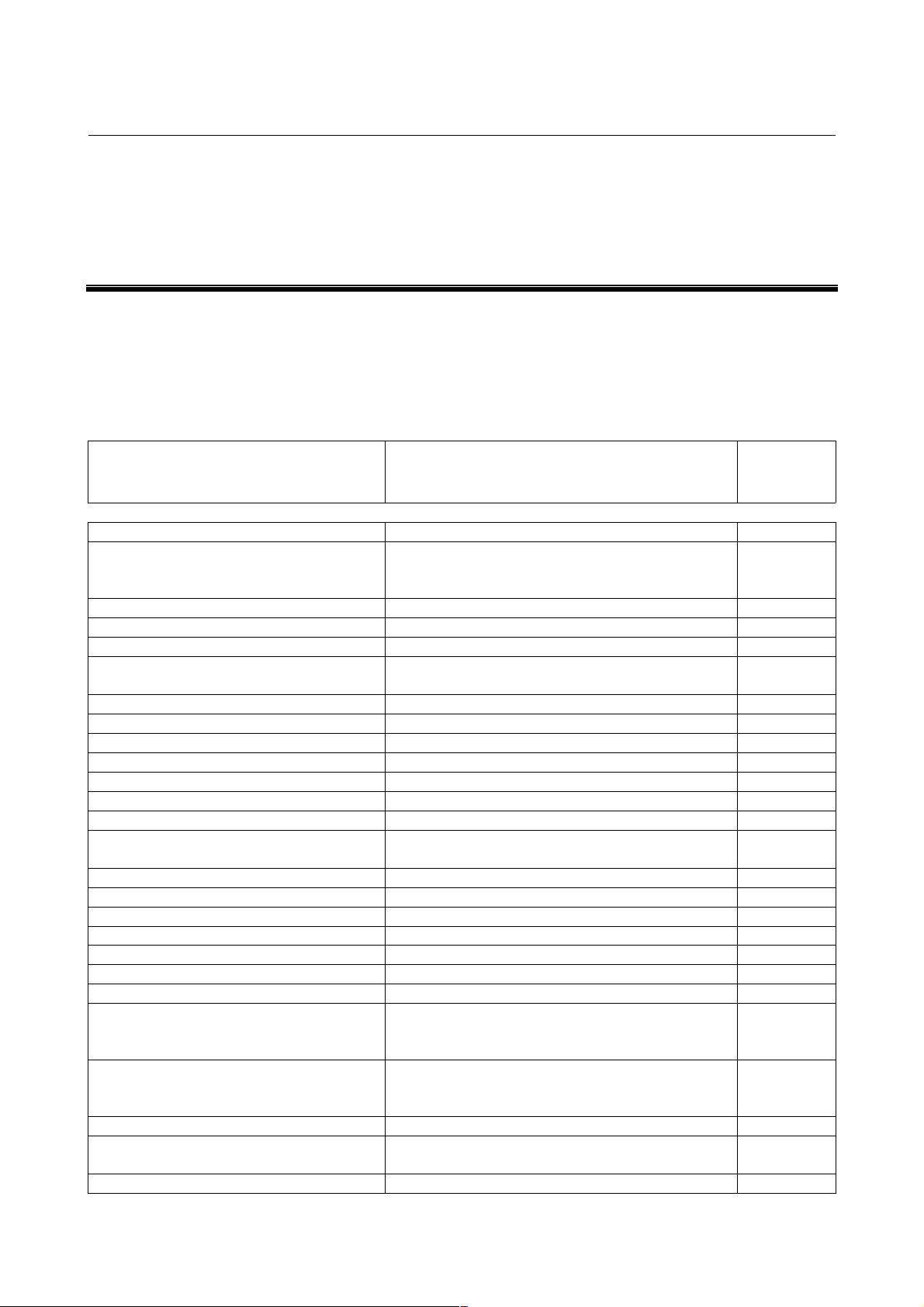

B-63782EN/01 TABLE OF CONTENTS

TABLE OF CONTENTS

DEFINITION OF WARNING, CAUTION, AND NOTE................................ s-1

I. GENERAL

1 GENERAL ..............................................................................................3

2 LIST OF SPECIFICATIONS...................................................................5

II NC FUNCTIONS

PREFACE....................................................................................................19

1 CONROLLED AXES ............................................................................20

1.1 CONTROLLED AXES..................................................................................21

1.2 AXIS NAME .................................................................................................22

1.3 INCREMENT SYSTEM................................................................................23

1.4 MAXIMUM STROKE....................................................................................25

2 PREPARATORY FUNCTION (G FUNCTION)......................................26

3 INTERPOLATION FUNCTION .............................................................30

3.1 POSITIONING (G00) ...................................................................................31

3.2 SINGLE DIRECTION POSITIONING (G60) ................................................32

3.3 LINEAR INTERPOLATION (G01)................................................................33

3.4 CIRCULAR INTERPOLATION (G02,G03)...................................................34

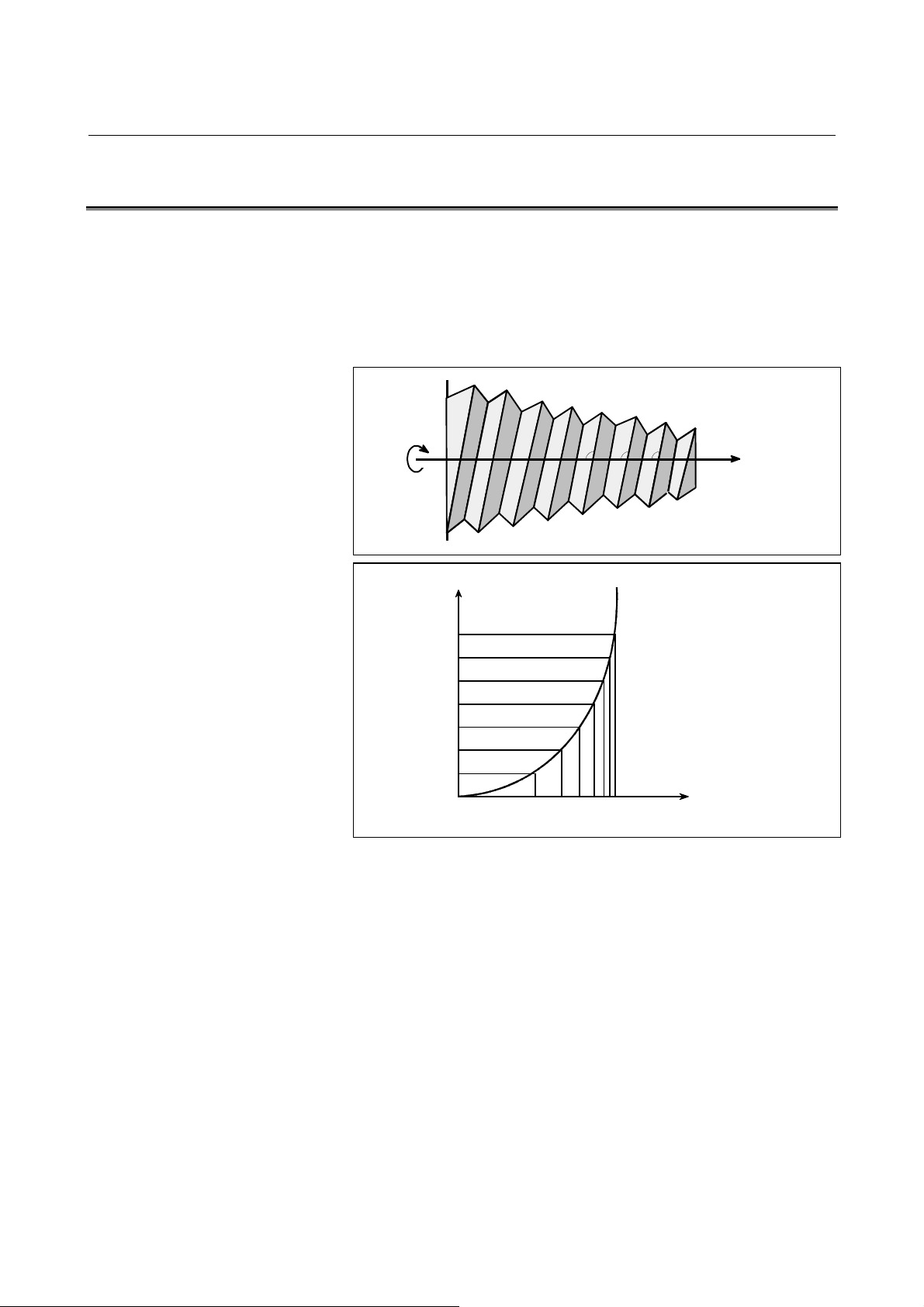

3.5 HELICAL INTERPOLATION (G02,G03) ......................................................36

3.6 HELICAL INTERPOLATION B (G02,G03)...................................................38

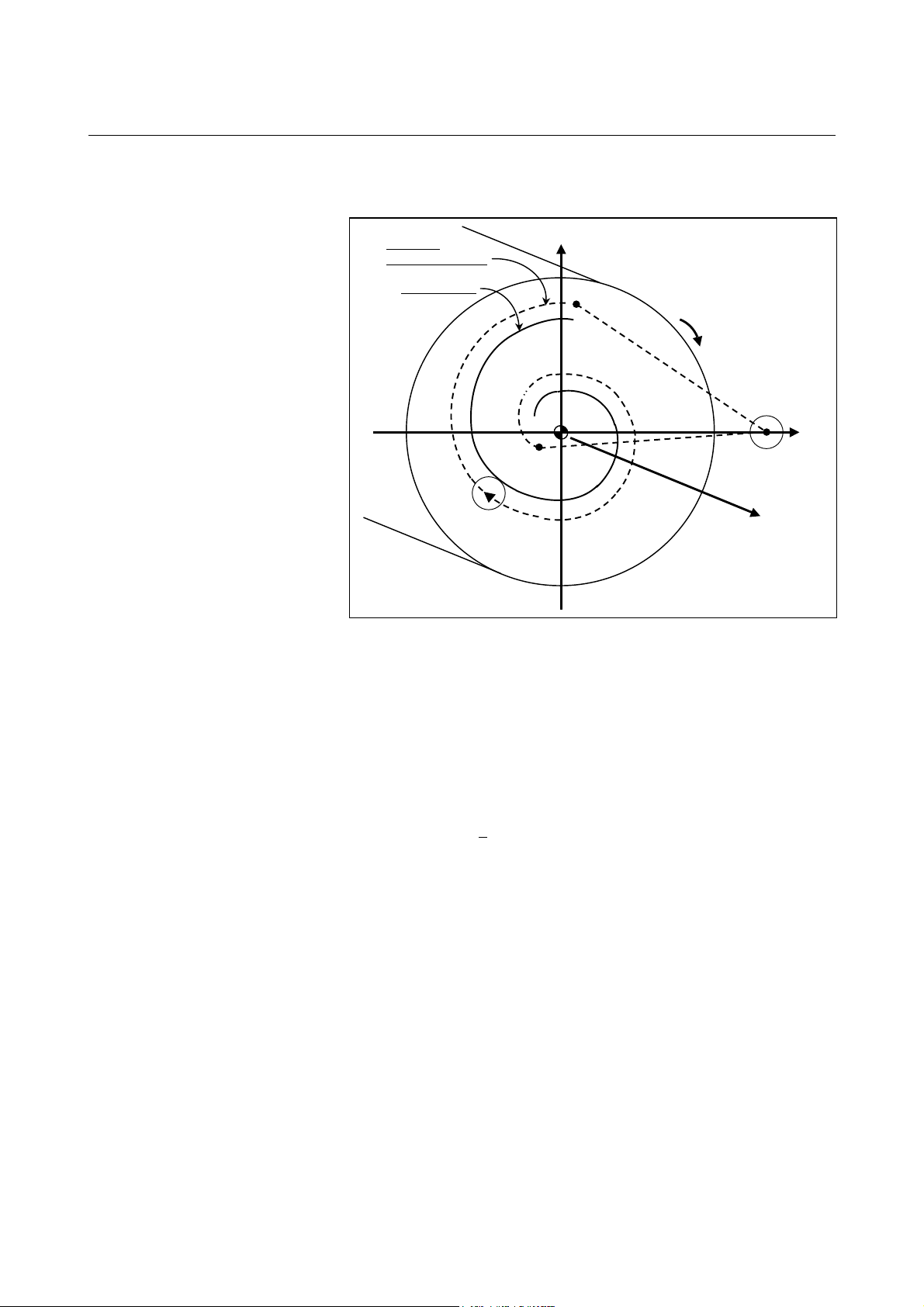

3.7 POLAR COORDINATE INTERPOLATION (G12.1,G13.1) ..........................39

3.7.1 Virtual Axis Direction Compensation for Polar Coordinate Interpolation ........... 41

3.8 CYLINDRICAL INTERPOLATION (G07.1) ..................................................42

3.9 CYLINDRICAL INTERPOLATION CUTTING POINT CONTROL (G07.1)...44

3.10 INVOLUTE INTERPOLATION (G02.2,G03.2) .............................................48

3.11 HELICAL INVOLUTE INTERPOLATION (G02.2,G03.3) .............................50

3.11.1 Involute Interpolation with a Linear Axis and Rotation Axis (G02.2,G03.3)....... 51

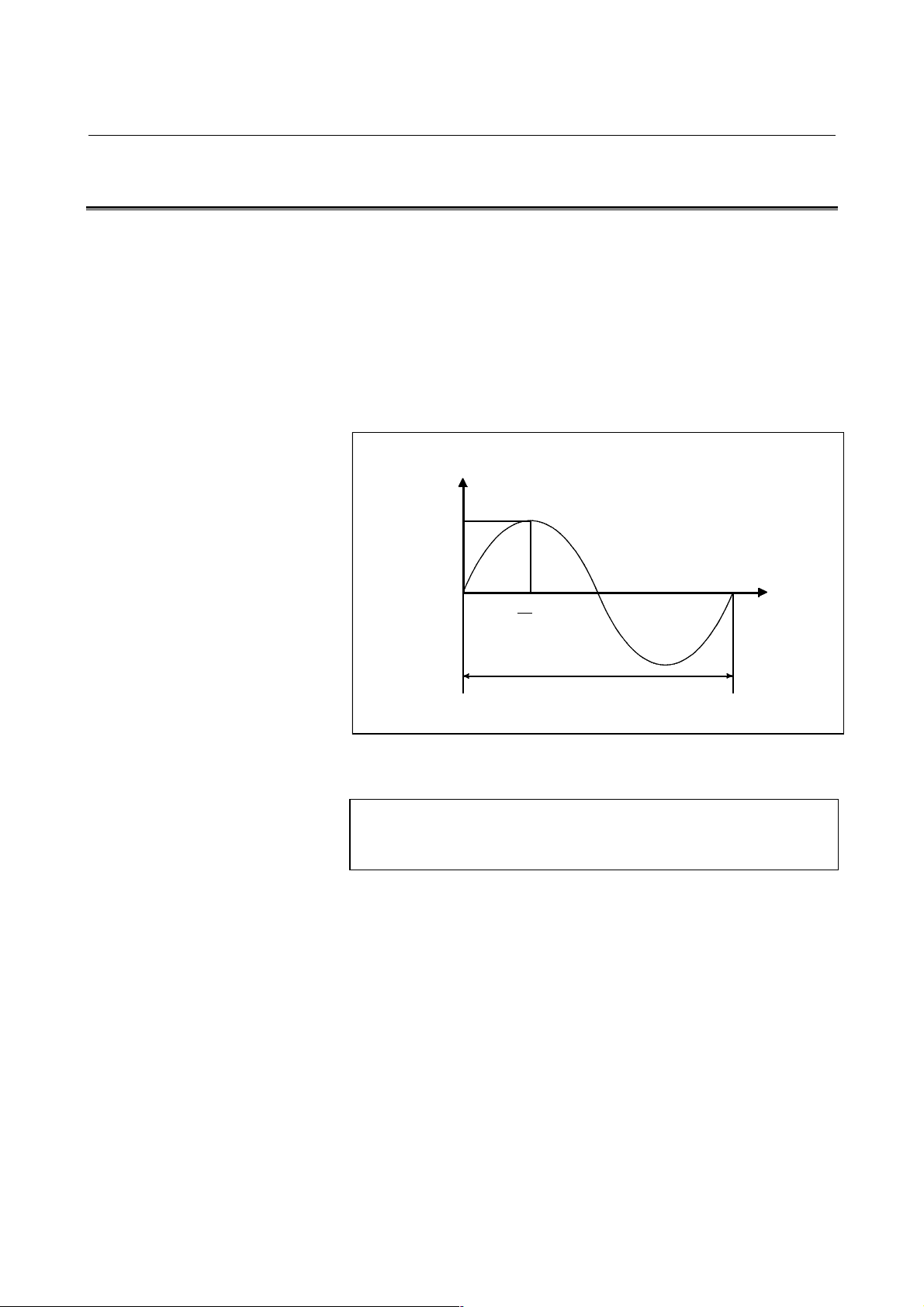

3.12 EXPONENTIAL INTERPOLATION (G02.3,G03.3)......................................53

3.13 SPLINE INTERPOLATION (G06.1) .............................................................55

3.14 SMOOTH INTERPOLATION .......................................................................56

3.15 HYPOTHETICAL AXIS INTERPOLATION (G07) ........................................57

3.16 SPIRAL INTERPOLATION, CONICAL INTERPOLATION (G02,G03) ........58

c-1

Page 6

TABLE OF CONTENTS B-63782EN/01

3.17 NURBS INTERPOLATION(G06.2) ..............................................................61

3.17.1 NURBS Interpolation Additional Functions ......................................................... 63

3.18 3-DIMENSIONAL CIRCULAR INTERPOLATION (G02.4 AND G03.4) .......65

4 THREAD CUTTING ..............................................................................66

4.1 THREAD CUTTING (G33) ...........................................................................67

4.2 INCH THREADING (G33)............................................................................69

4.3 CONTINUOUS THREADING (G33).............................................................70

5 FEED FUNCTION.................................................................................71

5.1 RAPID TRAVERSE......................................................................................72

5.2 CUTTING FEED ..........................................................................................73

5.2.1 Tangential Speed Constant Control....................................................................... 73

5.2.2 Cutting Feedrate Clamp......................................................................................... 73

5.2.3 Feed Per Minute (G94).......................................................................................... 73

5.2.4 Feed Per Revolution (G95).................................................................................... 74

5.2.5 Inverse Time Feed (G93)....................................................................................... 74

5.2.6 One-digit F Code Feed........................................................................................... 74

5.2.7 Setting Input of Cutting Feedrate .......................................................................... 75

5.2.8 Feedrate Specification on a Virtual Circle for a Rotary Axis ............................... 75

5.3 OVERRIDE ..................................................................................................76

5.3.1 Feedrate Override .................................................................................................. 76

5.3.2 Second Feed Rate Override ................................................................................... 76

5.3.3 Rapid Traverse Override ....................................................................................... 76

5.3.4 Override Cancel..................................................................................................... 76

5.3.5 Jog Override .......................................................................................................... 76

5.4 ACCELERATION/DECELERATION CONTROL..........................................77

5.4.1 Automatic Acceleration/Deceleration Control After Interpolation....................... 77

5.4.2 Acceleration/Deceleration before Interpolation of Linear-Type Rapid Traverse . 79

5.4.3 Optimum Torque Acceleration/Deceleration ........................................................ 80

5.5 PMC AXIS CONTROL CONSTANT FEEDRATE COMMAND

ACCELERATION/DECELERATION FUNCTION.........................................81

5.6 SPEED CNTROL COMMAND AT THE CORNER OF BLOCK....................82

5.6.1 Exact Stop (G09) ................................................................................................... 82

5.6.2 Exact Stop Mode (G61)......................................................................................... 82

5.6.3 Cutting Mode (G64) .............................................................................................. 82

5.6.4 Tapping Mode (G63)............................................................................................. 82

5.6.5 Automatic Corner Override (G62) ........................................................................ 83

c-2

Page 7

B-63782EN/01 TABLE OF CONTENTS

5.7 DWELL MODE (G04) ..................................................................................84

5.8 AUTOMATIC FEEDRATE CONTROL BY AREA.........................................85

6 REFERENCE POSITION......................................................................86

6.1 MANUAL REFERENCE POSITION RETURN.............................................87

6.2 SETTING THE REFERENCE POSITION WITHOUT DOGS ......................88

6.3 AUTOMATIC REFERENCE POSITION RETURN (G28, G29)....................89

6.4 REFERENCE POSITION RETURN CHECK (G27) .....................................90

6.5 2ND, 3RD AND 4TH REFERENCE POSITION RETURN (G30) .................90

6.6 FLOATING REFERENCE POSITION RETURN (G30.1).............................91

6.7 REFERENCE POSITION SHIFT .................................................................93

7 COORDINATE SYSTEM ......................................................................94

7.1 MACHINE COORDINATE SYSTEM (G53)..................................................95

7.2 WORKPIECE COORDINATE SYSTEM ......................................................96

7.2.1 Setting a Workpiece Coordinate System (G92) .................................................... 96

7.2.2 Setting Workpiece Coordinate System (G54 to G59) ........................................... 98

7.3 LOCAL COORDINATE SYSTEM ................................................................99

7.3.1 Workpiece Origin Offset Value Change ............................................................. 100

7.3.2 Adding Workpiece Coordinate Systems (G54.1) ................................................ 100

7.3.3 Workpiece Coordinate System Preset (G92.1).................................................... 101

7.3.4 Automatically Presetting the Workpiece Coordinate System ............................. 102

7.4 PLANE SELECTION..................................................................................103

7.5 PLANE CONVERSION FUNCTION...........................................................104

7.6 ROTARY TABLE DYNAMIC FIXTURE OFFSET.......................................107

8 COORDINATE VALUE AND DIMENSION .........................................108

8.1 ABSOLUTE AND INCREMENTAL PROGRAMMING................................109

8.2 POLAR COORDINATE COMMAND (G15, G16) .......................................110

8.3 INCH/METRIC CONVERSION (G20,G21) ................................................112

8.4 DECIMAL POINT INPUT/POCKET CALCULATOR TYPE DECIMAL

POINT INPUT ............................................................................................113

8.5 DIAMETER AND RADIUS PROGRAMMING ............................................114

8.6 PROGRAMMABLE SWITCHING OF DIAMETER/RADIUS

SPECIFICATION .......................................................................................115

8.7 LINEAR AXIS AND ROTATION AXIS........................................................116

9 SPINDLE SPEED FUNCTION............................................................117

9.1 S CODE OUTPUT .....................................................................................118

9.2 SPINDLE SPEED BYNARY OUTPUT .......................................................118

c-3

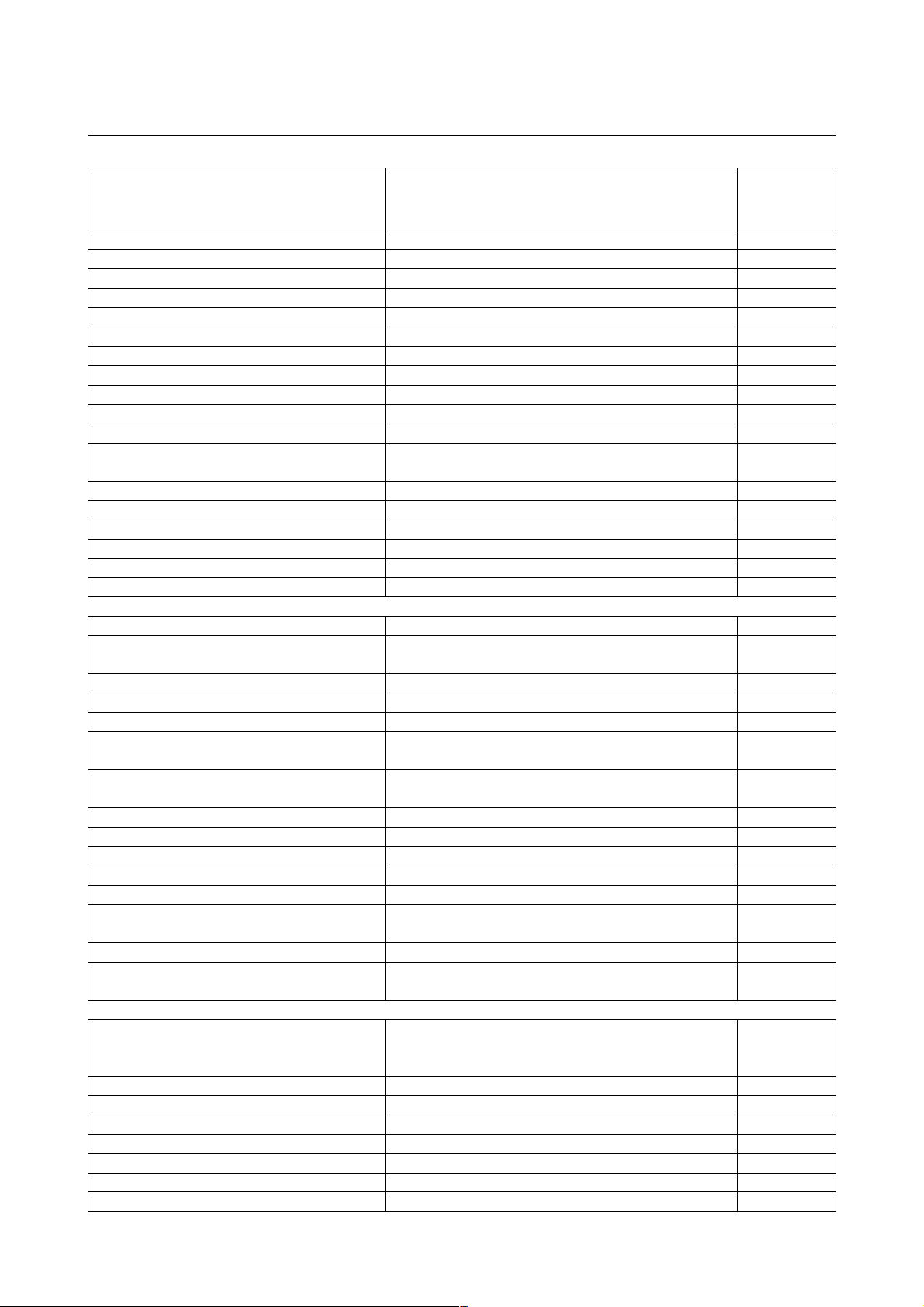

Page 8

TABLE OF CONTENTS B-63782EN/01

9.3 SPINDLE SPEED ANALOG OUTPUT.......................................................118

9.4 SPINDLE SPEED SERIAL OUTPUT.........................................................118

9.5 CONSTANT SURFACE SPEED CONTROL (G96, G97) ..........................119

9.6 SPINDLE SPEED CLAMP (G92)...............................................................120

9.7 ACTUAL SPINDLE SPEED OUTPUT .......................................................120

9.8 SPINDLE POSITIONING ...........................................................................121

9.9 SPINDLE ORIENTATION ..........................................................................122

9.10 SPINDLE OUTPUT SWITCHING ..............................................................122

9.11 SPINDLE SPEED FLUCTUATION DETECTION.......................................123

10 TOOL FUNCTION ..............................................................................125

10.1 TOOL SELECTION FUNCTION ................................................................126

10.2 TOOL LIFE MANAGEMENT FUNCTION ..................................................127

10.2.1 Tool Life Management Function......................................................................... 127

10.2.2 Addition of Tool Pairs for Tool Life Management 512 Pairs ............................. 129

10.2.3 Addition of Tool Pairs for Tool Life Management 1024 Pairs ........................... 129

11 MISCELLANEOUS FUNCTIONS .......................................................130

11.1 AUXILIARY FUNCTION.............................................................................131

11.2 MULTIPLE M COMMANDS IN A SINGLE BLOCK....................................132

11.3 THE SECOND AUXILIARY FUNCTIONS..................................................133

11.4 HIGH-SPEED M/S/T/B INTERFACE .........................................................134

12 PROGRAM CONFIGURATION ..........................................................136

12.1 PROGRAM NUMBER................................................................................137

12.2 PROGRAM NAME .....................................................................................137

12.3 MAIN PROGRAM ......................................................................................137

12.4 SUB PROGRAM ........................................................................................138

12.5 EXTERNAL DEVICE SUBPROGRAM CALL (M198) ................................140

12.6 SEQUENCE NUMBER ..............................................................................141

12.7 PROGRAM CODES...................................................................................141

12.8 BASIC ADDRESSES AND COMMAND VALUE RANGE ..........................142

12.9 PROGRAM FORMAT ................................................................................144

12.10 LABEL SKIP ..............................................................................................144

12.11 CONTROL-IN/CONTROL-OUT .................................................................144

12.12 OPTIONAL BLOCK SKIP ..........................................................................145

12.13 ADDITIONAL OPTIONAL BLOCK SKIP....................................................145

12.14 TAPE HORIZONTAL (TH) PARITY CHECK AND

TAPE VERTICAL(TV) PARITY CHECK ....................................................145

c-4

Page 9

B-63782EN/01 TABLE OF CONTENTS

13 FUNCTIONS TO SIMPLIFY PROGRAMMING...................................146

13.1 CANNED CYCLE.......................................................................................147

13.2 RIGID TAPPING ........................................................................................155

13.2.1 Rigid Tapping Additional Function..................................................................... 157

13.3 EXTERNAL MOTION FUNCTION (G81) ...................................................158

13.4 OPTIONAL ANGLE CHAMFERING AND CORNER ROUNDING .............159

13.5 PROGRAMMABLE MIRROR IMAGE (G50.1, G51.1) ...............................160

13.6 INDEX TABLE INDEXING FUNCTION......................................................162

13.7 FIGURE COPY (G72.1,G72.2) ..................................................................163

13.7.1 Rotation Copy...................................................................................................... 164

13.7.2 Linear Copy ......................................................................................................... 166

13.8 NORMAL DIRECTION CONTROL (G40.1, G41.1, G42.1)........................168

14 TOOL COMPENSATION FUNCTION ................................................170

14.1 TOOL LENGTH OFFSET ..........................................................................171

14.2 TOOL OFFSET(G45-G48).........................................................................173

14.3 CUTTER COMPENSATION ......................................................................175

14.4 TOOL COMPENSATION VALUES............................................................178

14.5 NUMBER OF TOOL COMPENSATION SETTINGS..................................180

14.6 CHANGING THE TOOL COMPENSATION AMOUNT ..............................181

14.7 THREE-DIMENSIONAL TOOL COMPENSATION (G40, G41) .................182

14.8 TOOL OFFSETS BASED ON TOOL NUMBERS ......................................184

14.9 TOOL AXIS DIRECTION TOOL LENGTH COMPENSATION...................186

14.10 DESIGNATION DIRECTION TOOL LENGTH COMPENSATION .............190

14.11 THREE-DIMENSIONAL CUTTER COMPENSATION ...............................194

14.11.1 Three-dimensional Cutter Compensation At Tool Center Point......................... 195

14.12 TOOL CENTER POINT CONTROL...........................................................196

14.12.1 Tool Center Point Control For 5-Axis Machining .............................................. 197

14.13 GRINDING WHEEL WEAR COMPENSATION .........................................200

14.14 DIAMETER ENTRY FOR TOOL COMPENSATION VALUE .....................201

14.15 CUTTER COMPENSATION FOR ROTARY TABLE .................................202

14.16 THREE-DIMENSIONAL CUTTER COMPENSATION FOR ROTARY TABLE

...................................................................................................................203

15 ACCURACY COMPENSATION FUNCTION ......................................204

15.1 STORED PITCH ERROR COMPENSATION ............................................205

15.2 STRAIGHTNESS COMPENSATION.........................................................206

15.3 INTERPOLATED STRAIGHTNESS COMPENSATION ............................207

c-5

Page 10

TABLE OF CONTENTS B-63782EN/01

15.4 128 STRAIGHTNESS COMPENSATION POINTS....................................208

15.5 BACKLASH COMPENSATION..................................................................209

15.6 INTERPOLATED PITCH ERROR COMPENSATION................................210

15.7 CYCLIC SECOND PITCH ERROR COMPENSATION..............................211

15.8 GRADIENT COMPENSATION ..................................................................212

15.9 BI-DIRECTIONAL PITCH ERROR COMPENSATION ..............................213

15.10 THREE-DIMENSIONAL ERROR COMPENSATION.................................214

15.11 PROGRAMMABLE PARAMETER ENTRY (G10)......................................216

15.12 NANO INTERPOLATION TYPE ERROR COMPENSATION ....................218

15.13 SMOOTH BACKLASH COMPENSATION.................................................219

15.14 ADDITION OF 5000 PITCH ERROR COMPENSATION POINTS.............220

15.15 THERMAL GROWTH COMPENSATION ALONG TOOL VECTOR ..........221

16 COORDINATE SYSTEM CONVERSION FUNCTION........................222

16.1 AXIS INTERCHANGE................................................................................223

16.2 COORDINATE SYSTEM ROTATION........................................................224

16.3 SCALING ...................................................................................................226

16.4 THREE-DIMENSIONAL COORDINATE CONVERSION ...........................229

16.4.1 Three-Dimensional Coordinate Conversion and Parallel Axis Control.............. 231

16.5 TILTED WORKING PLANE COMMAND ...................................................232

17 MEASUREMENT FUNCTIOM............................................................235

17.1 SKIP FUNCTION (G31) .............................................................................236

17.2 SKIPPING THE COMMANDS FOR SEVERAL AXES...............................237

17.3 MULTISTAGE SKIP (G31.1 to G31.4).......................................................237

17.4 HIGH SPEED SKIP SIGNAL (G31) ...........................................................237

17.5 TORQUE LIMIT SKIP ................................................................................238

17.6 TOOL LENGTH MANUAL MEASUREMENT.............................................239

17.7 WORKPIECE ORIGIN MANUAL SETTING...............................................240

17.8 TOOL LENGTH/WORKPIECE ORIGIN MEASUREMENT ........................240

17.9 AUTOMATIC TOOL LENGTH MEASUREMENT (G37) ............................241

17.10 CHANGING ACTIVE OFFSET VALUE WITH MANUAL MOVE ................242

18 CUSTOM MACRO..............................................................................243

18.1 CUSTOM MACRO .....................................................................................244

18.1.1 Custom Macro ..................................................................................................... 244

18.1.2 Increased 900 Custom Macro Common Variables.............................................. 250

18.2 INTERRUPTION TYPE CUSTOM MACRO...............................................251

18.3 MACRO EXECUTOR.................................................................................252

c-6

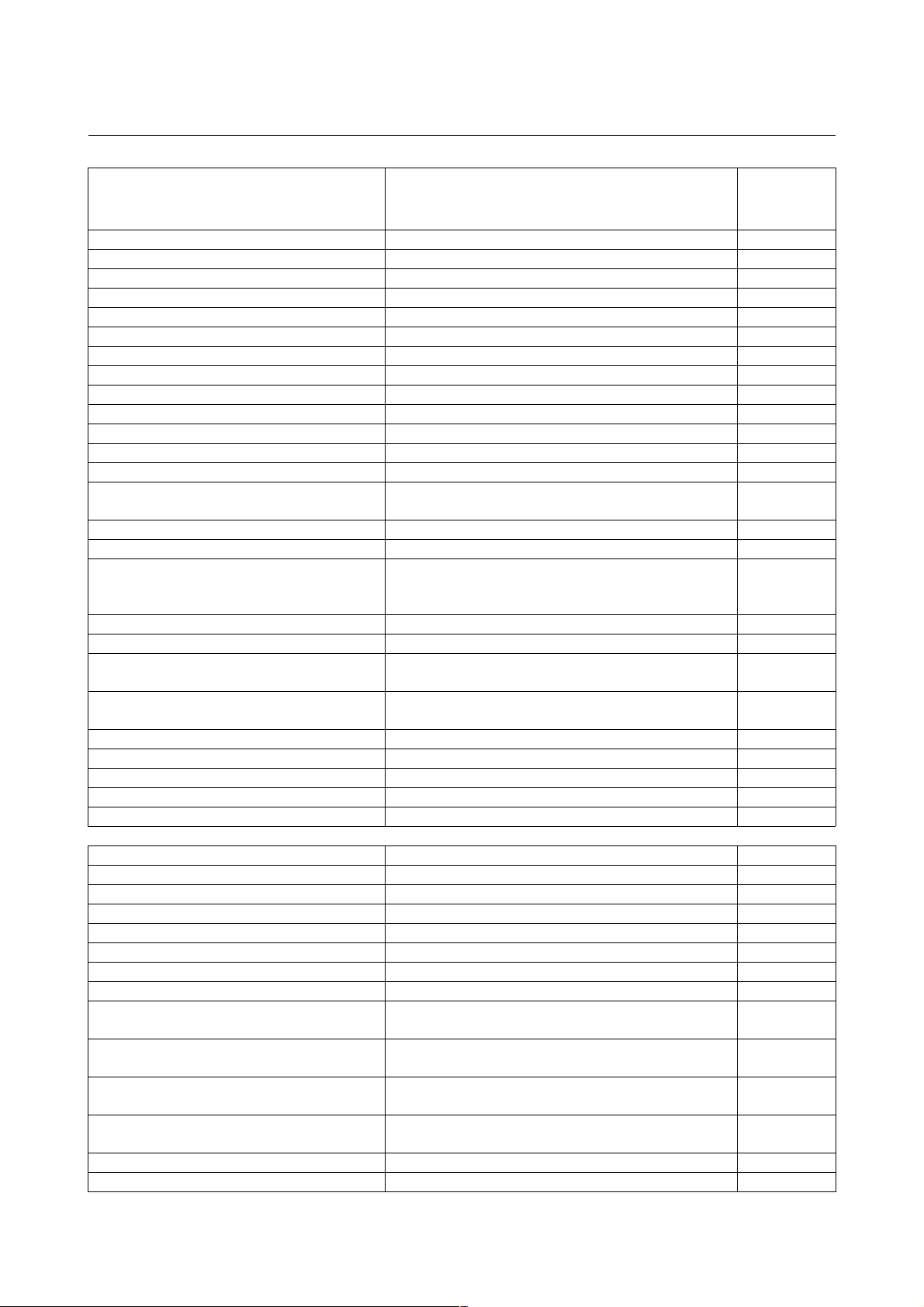

Page 11

B-63782EN/01 TABLE OF CONTENTS

18.4 C Executor .................................................................................................253

19 FUNCTIONS FOR HIGH-SPEED CUTTING ......................................255

19.1 DECELERATION BASED ON ACCELERATION DURING CIRCULAR

INTERPOLATION ......................................................................................256

19.2 ADVANCED PREVIEW CONTROL ...........................................................257

19.3 NANO INTERPOLATION...........................................................................257

19.4 LOOK-AHEAD ACCELERATION/DECELERATION BEFORE

INTERPOLATION ......................................................................................258

19.4.1 Bell-Shaped Acceleration/Deceleration Time Constant Change ........................ 259

19.5 FINE HPCC................................................................................................261

19.6 MACHINING TYPE IN HPCC SCREEN PROGRAMMING

(G05.1 OR G10).........................................................................................263

19.7 REMOTE BUFFER ....................................................................................264

19.7.1 Remote Buffer ..................................................................................................... 264

19.7.2 Binary Input Operation Function......................................................................... 266

19.8 JERK CONTROL .......................................................................................267

20 AXIS CONTROL FUNCTIONS...........................................................268

20.1 FOLLOW-UP .............................................................................................269

20.2 MECHANICAL HANDLE FEED .................................................................269

20.3 SERVO OFF ..............................................................................................269

20.4 MIRROR IMAGE........................................................................................269

20.5 CONTROLLED AXES DETACH ................................................................270

20.6 TWIN TABLE CONTROL...........................................................................271

20.6.1 Tool Length Compensation in tool axis direction with Twin Table Control...... 272

20.7 SYNCHRONOUS CONTROL ....................................................................273

20.8 TANDEM CONTROL .................................................................................273

20.9 PARALLEL AXIS CONTROL .....................................................................274

20.10 PMC AXIS CONTROL ...............................................................................275

20.11 CHOPPING FUNCTION (G81.1) ...............................................................276

20.12 ELECTRONIC GEAR BOX (G80, G81, G80.5, G81.5)..............................278

20.13 AUTOMATIC PHASE MATCHING FUNCTION WITH ELECTRONIC

GEAR BOX ................................................................................................279

20.14 SKIP FUNCTION FOR EGB AXIS(G31.8).................................................280

20.15 ROTARY AXIS ROLL-OVER.....................................................................280

20.16 MULTIPLE ROTARY CONTROL AXIS FUNCTION ..................................281

20.17 ABSOLUTE POSITION DETECTION........................................................281

c-7

Page 12

TABLE OF CONTENTS B-63782EN/01

20.18 VERTICAL AXIS DROP PREVENTION FUNCTION .................................282

20.19 CUTTING/RAPID TRAVERSE IN-POSITION CHECK ..............................282

20.20 DECELERATION STOP UPON A POWER FAILURE...............................282

20.21 HIGH SPEED HRV MODE ........................................................................282

20.22 GENERAL PURPOSE RETRACT .............................................................283

21 MANUAL OPERATION ......................................................................284

21.1 JOG FEED.................................................................................................285

21.2 INCREMENTAL FEED...............................................................................285

21.3 MANUAL HANDLE FEED (1ST)................................................................285

21.4 MANUAL HANDLE FEED (2ND, 3RD) ......................................................285

21.5 MANUAL FEED IN A SPECIFIED DIRECTION.........................................286

21.6 MANUAL ABSOLUTE ON AND OFF.........................................................287

21.7 THREE-DIMENSIONAL HANDLE FEED...................................................288

21.7.1 Handle Feed/Interruption in the Longitudinal Direction of the Tool.................. 289

21.7.2 Handle Feed/Interruption in the Transverse Direction of the Tool..................... 290

21.7.3 Rotational Handle/Interruption Feed Around the Center of the Tool Tip........... 291

21.7.4 Control Point Compensation in Three-Dimensional Handle Feed...................... 292

21.8 CHANGING TOOL LENGTH COMPENSATION IN

THE LONGITUDINAL DIRECTION OF THE TOOL...................................293

21.9 TOOL HOLDER OFFSET ..........................................................................293

21.10 DISPLAYING THE COORDINATES OF THE TOOL TIP ..........................294

21.11 DISPLAYING PULSE VALUES AND AMOUNT OF MOVEMENT

BY MANUAL INTERRUPT.........................................................................295

21.12 MANUAL NUMERIC COMMAND ..............................................................295

21.13 MANUAL INTERRUPTION FUNCTION FOR THREE-DIMENSIONAL

COORDINATE CONVERSION..................................................................296

22 AUTOMATIC OPERATION ................................................................297

22.1 OPERATION MODE ..................................................................................298

22.1.1 DNC Operation.................................................................................................... 298

22.1.2 Memory Operation .............................................................................................. 298

22.1.3 MDI Operation .................................................................................................... 298

22.2 SELECTION OF EXECUTION PROGRAMS.............................................298

22.2.1 Program Number Search...................................................................................... 298

22.2.2 Sequence Number Search.................................................................................... 298

22.2.3 Rewind................................................................................................................. 298

22.3 ACTIVATION OF AUTOMATIC OPERATION ...........................................298

c-8

Page 13

B-63782EN/01 TABLE OF CONTENTS

22.3.1 Cycle Start ........................................................................................................... 298

22.4 EXECUTION OF AUTOMATIC OPERATION............................................299

22.4.1 Buffering.............................................................................................................. 299

22.5 STOP/TERMINATION OF AUTOMATIC OPERATION .............................299

22.5.1 Program Stop (M00)............................................................................................ 299

22.5.2 Program End (M02, M30) ................................................................................... 299

22.5.3 Sequence Number Comparison and Stop ............................................................ 299

22.5.4 Feed Hold ............................................................................................................ 299

22.5.5 Reset 299

22.6 AUTOMATIC OPERATION RESART ........................................................300

22.6.1 Program Restart ................................................................................................... 300

22.6.2 Output of Program Restart M, S, T and B (2nd Auxiliary Function) Codes....... 301

22.6.3 Block Restart ....................................................................................................... 302

22.6.4 Retrace................................................................................................................. 304

22.6.5 Active Block Cancel............................................................................................ 305

22.6.6 Tool Withdrawal and Return ............................................................................... 306

22.7 MANUAL INTERRUPTION ........................................................................307

22.7.1 Manual Handle Interrupt ..................................................................................... 307

22.7.2 Simultaneous Automatic and Manual Operation ................................................ 307

22.8 MANUAL INTERVENTION AMOUNT RETURN DURING

AUTOMATIC OPERATION........................................................................308

23 TEST FUNCTIONS FOR PROGRAM.................................................309

23.1 ALL-AXES MACHINE LOCK .....................................................................310

23.2 MACHINE LOCK ON EACH AXIS .............................................................310

23.3 AUXILIARY FUNCTION LOCK..................................................................310

23.4 DRY RUN...................................................................................................310

23.5 SINGLE BLOCK.........................................................................................310

24 SETTING AND DISPLAY UNIT..........................................................311

24.1 SETTING AND DISPLAY UNITS...............................................................312

24.1.1 9.5"/10.5" LCD Unit............................................................................................ 313

24.1.2 MDI Unit ............................................................................................................. 314

24.1.3 MDI Unit (Full-keyboard)................................................................................... 315

24.1.4 MDI Unit (Main Panel A/B) for Machine Operator's Panel................................ 316

24.2 EXPLANATION OF THE KEYBOARD.......................................................317

24.2.1 Function Keys...................................................................................................... 319

24.2.2 Soft Keys ............................................................................................................. 320

c-9

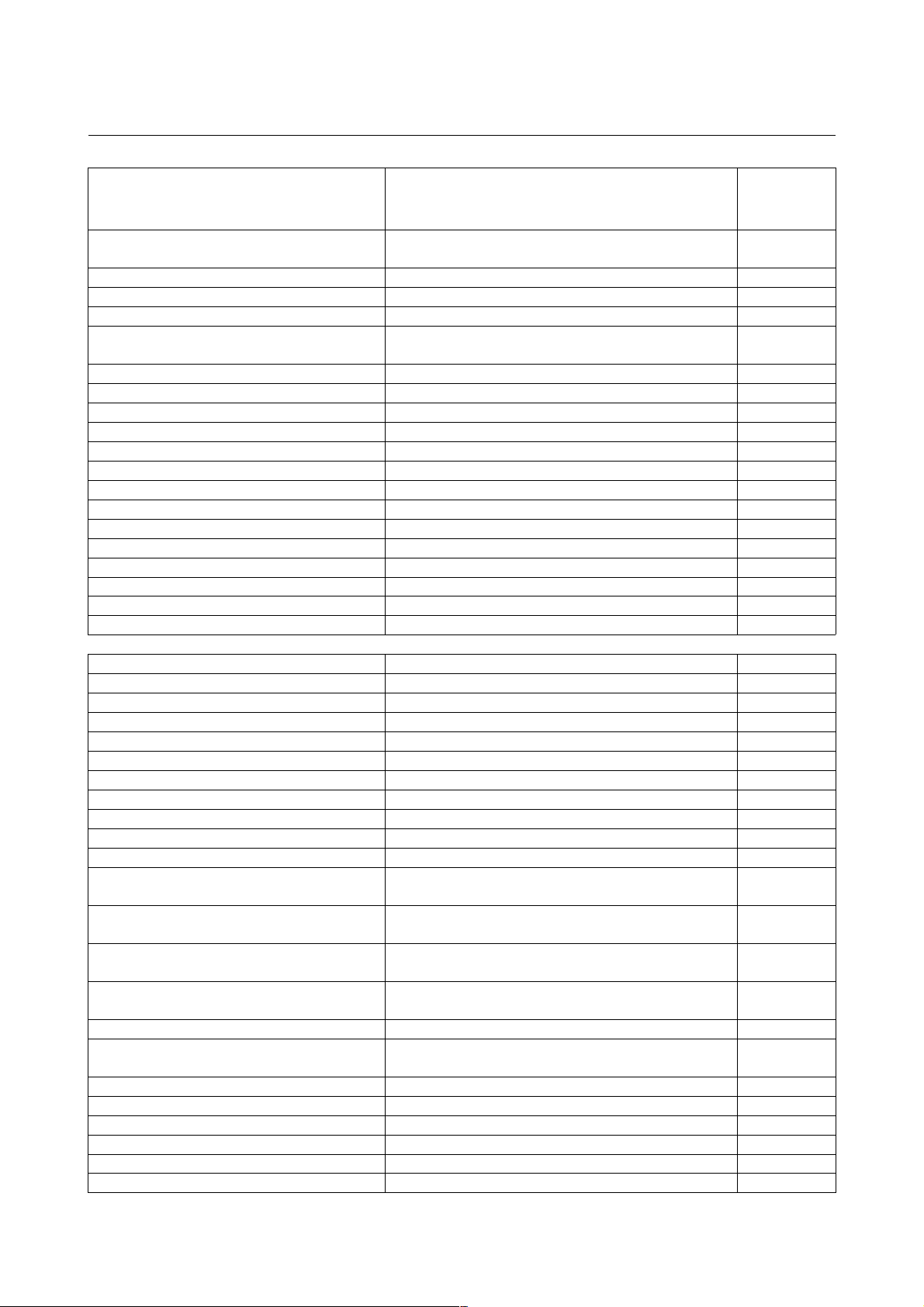

Page 14

TABLE OF CONTENTS B-63782EN/01

25 DISPLAY AND SETTING ...................................................................321

25.1 DISPLAY....................................................................................................322

25.2 LANGUAGE SELECTION..........................................................................325

25.3 CLOCK FUNCTION ...................................................................................325

25.4 COMMUNICATION SETTING SCREEN ...................................................325

25.5 RUN TIME & PARTS NUMBER DISPLAY.................................................326

25.6 MENU SWITCHES ....................................................................................327

25.7 DISPLAYING AND SETTING THE SOFTWARE OPERATOR'S PANEL..328

25.8 FLOPPY CASSETTE DIRECTRY DISPLAY .............................................330

25.9 GRAPHIC FUNCTION ...............................................................................331

25.9.1 Tool Path Drawing............................................................................................... 331

25.9.2 Background Drawing........................................................................................... 332

25.10 WAVEFORM DIAGNOSIS FUNCTION .....................................................333

25.11 SERVO SPINDLE SCREEN ......................................................................335

25.11.1 Servo Setting Screen............................................................................................ 335

25.11.2 Servo Adjustment/Monitor Screen...................................................................... 336

25.11.3 Servo Function Setting Screen ............................................................................ 336

25.11.4 Servo Alarm Screen............................................................................................. 337

25.11.5 Backlash Adjustment Screen............................................................................... 338

25.11.6 Spindle Screen ..................................................................................................... 339

25.12 OPERATING MONITOR SCREEN............................................................340

25.13 DISPLAY OF HARDWARE/SOFTWARE SYSTEM CONFIGURATION

SCREEN....................................................................................................341

25.14 OPERATIONS AND ALARM HISTORY SCREENS ..................................344

25.14.1 Alarm History Screen .......................................................................................... 344

25.14.2 Operation History Screen .................................................................................... 345

25.14.3 DI/DO Selection Screen ...................................................................................... 346

25.15 STAMPING THE MACHINING TIME.........................................................347

25.15.1 Machining Time Display Screen ......................................................................... 347

25.15.2 Program Directory Screen ................................................................................... 348

25.15.3 Tool Path Drawing Screen................................................................................... 348

25.16 CLEARING THE SCREEN ........................................................................349

25.17 PERIODIC MAINTENANCE SCREEN.......................................................349

25.18 MAINTENANCE INFORMATION SCREEN...............................................350

25.19 HIGH-SPEED HIGH-PRECISION MACHINING SETTING SCREEN........351

25.19.1 Adjustment Screen............................................................................................... 351

25.19.2 Setting Screen...................................................................................................... 353

c-10

Page 15

B-63782EN/01 TABLE OF CONTENTS

25.20 SUBSCREENS ..........................................................................................354

25.21 DIRECTORY DISPLAY / PUNCH FOR EACH GROUP ............................356

25.22 PROGRAM NAME 48 CHARACTERS ......................................................357

25.23 CALCULATION KEY..................................................................................358

25.24 POWER MATE CNC MANAGER FUNCTION ...........................................359

25.25 HELP FUNCTION......................................................................................360

25.26 MEMORY CARD SCREEN........................................................................361

25.27 MODEM CARD SETTING SCREEN..........................................................362

25.28 BRIGHTNESS ADJUSTMENT SCREEN FOR

MONOCHROME DISPLAY UNIT WITH GRAPHIC FUNCTION ...............363

25.29 REMOTE DIAGNOSTIC FUNCTION.........................................................364

25.30 FINE TORQUE SENSING .........................................................................366

25.31 DO SIGNAL OUTPUT BY SOFT KEY .......................................................367

25.32 2-LCD-UNIT CONNECTION FUNCTION ..................................................368

25.33 αi SERVO INFORMATION SCREEN ........................................................369

25.34 αi SPINDLE INFORMATION SCREEN .....................................................370

26 PROGRAM EDITING .........................................................................371

26.1 PROGRAM EDITING.................................................................................372

26.1.1 Program Editing................................................................................................... 372

26.1.2 Background Editing............................................................................................. 372

26.2 PROGRAM INPUT/OUTPUT AND COLLATION .......................................373

26.2.1 Program Input/Output.......................................................................................... 373

26.2.2 Part program Collation ........................................................................................ 373

26.2.3 Keys and Program Encryption............................................................................. 373

26.2.4 External I/O Device Control................................................................................ 373

26.3 ADVANCED PROGRAM EDITING/OPERATION......................................374

26.3.1 Automatically Inserting Sequence Numbers ....................................................... 374

26.3.2 Editing Two Programs Simultaneously............................................................... 374

26.3.3 Editing Programs in Operation............................................................................ 374

26.3.4 Playback............................................................................................................... 375

26.4 STORED PROGRAM LENGTHS AND NUMBER OF

REGISTERABLE PROGRAMS .................................................................376

27 DIAGNOSIS FUNCTIONS..................................................................377

27.1 SELF-DIAGNOSIS FUNCTION .................................................................378

27.1.1 Self-diagnosis Screen .......................................................................................... 378

27.1.2 Group Selection Screen ....................................................................................... 379

c-11

Page 16

TABLE OF CONTENTS B-63782EN/01

28 DATA INPUT/OUTPUT.......................................................................380

28.1 READER/PUNCHER INTERFACES..........................................................381

28.1.1 Connection Port ................................................................................................... 381

28.2 INPUT/OUTPUT DEVICES........................................................................382

28.2.1 FANUC FLOPPY CASSETTE ........................................................................... 382

28.2.2 FANUC PROGRAM FILE Mate ........................................................................ 382

28.2.3 FANUC Handy File............................................................................................. 382

28.3 DATA SERVER..........................................................................................383

28.4 SCREEN HARD COPY FUNCTION ..........................................................384

29 SAFETY FUNCTIONS........................................................................385

29.1 EMERGENCY STOP .................................................................................386

29.2 OVERTRAVEL FUNCTIONS.....................................................................387

29.2.1 Overtravel ............................................................................................................ 387

29.2.2 Stored Stroke Check 1 ......................................................................................... 387

29.2.3 Stored Stroke Check 2 (G22, G23)...................................................................... 388

29.2.4 Stroke Limit Check Before Movement................................................................ 388

29.3 INTERLOCK ..............................................................................................389

29.3.1 Interlock per Axis ................................................................................................ 389

29.3.2 All Axes Interlock ............................................................................................... 389

29.3.3 Automatic-Operation All-Axis Interlock............................................................. 389

29.3.4 Block Start Interlock............................................................................................ 389

29.3.5 Cutting Block Start Interlock............................................................................... 389

29.4 EXTERNAL DECELERATION ...................................................................390

29.5 ABNORMAL LOAD DETECTION ..............................................................391

30 STATUS OUTPUT..............................................................................392

30.1 NC READY SIGNAL ..................................................................................393

30.2 SERVO READY SIGNAL...........................................................................393

30.3 REWINDING SIGNAL................................................................................393

30.4 ALARM SIGNAL ........................................................................................393

30.5 DISTRIBUTION END SIGNAL...................................................................393

30.6 AUTOMATIC OPERATION SIGNAL .........................................................393

30.7 AUTOMATIC OPERATION START SIGNAL.............................................393

30.8 FEED HOLD SIGNAL ................................................................................394

30.9 RESET SIGNAL.........................................................................................394

30.10 IN-POSITION SIGNAL...............................................................................394

30.11 MOVE SIGNAL ..........................................................................................394

c-12

Page 17

B-63782EN/01 TABLE OF CONTENTS

30.12 AXIS MOVE DIRECTION SIGNAL ............................................................394

30.13 RAPID TRAVERSING SIGNAL .................................................................394

30.14 TAPPING SIGNAL.....................................................................................394

30.15 THREAD CUTTING SIGNAL .....................................................................395

30.16 CONSTANT SURFACE SPEED CONTROL SIGNAL ...............................395

30.17 INCH INPUT SIGNAL ................................................................................395

30.18 DI STATUS OUTPUT SIGNAL ..................................................................395

30.19 POSITION SWITCH FUNCTION ...............................................................395

30.20 OILING SIGNAL (CANNED CYCLE) .........................................................396

31 EXTERNAL DATA INPUT ..................................................................397

32 KEY INPUT FORM PMC ....................................................................401

APPENDIX

A RANGE OF COMMAND VALUE........................................................405

B LIST OF FUNCTION AND TAPE FORMAT........................................409

C TAPE CODE LIST ..............................................................................414

c-13

Page 18

Page 19

I. GENERAL

Page 20

Page 21

B-63782EN/01 GENERAL 1.GENERAL

1 GENERAL

The FANUC Series 15i CNC provides the highest level of performance

for very-high-speed and very-high-precision machining. It can control

24 axes simultaneously.

With functions such as precise trace control, called nano-interpolation,

and fine HPCC for applying optimum acceleration/deceleration control,

the CNC maximizes the performance of machine tools, allowing

complicated free surface figures such as aircraft parts and metal molds

to be machined with very high precision and at very high speed.

The FANUC Series 15i CNC uses the CNC technology and expertise

that FANUC has accumulated over many years. At the same time, it

has been made extremely compact by incorporating the latest

semiconductor and electronics technology. Moreover, it features

improvements such as reduced amounts of wiring in the electrical

section to facilitate the engineering design of machine tools, a

significantly reduced parts count, and the incorporation of many

environmental considerations.

The FANUC Series 150i open CNC is a FANUC Series 15i that has a

Windows-capable personal computer function built in, such that

Windows-compatible software and development environments to be

used.

This manual describes the following models and may use the following

abbreviations.

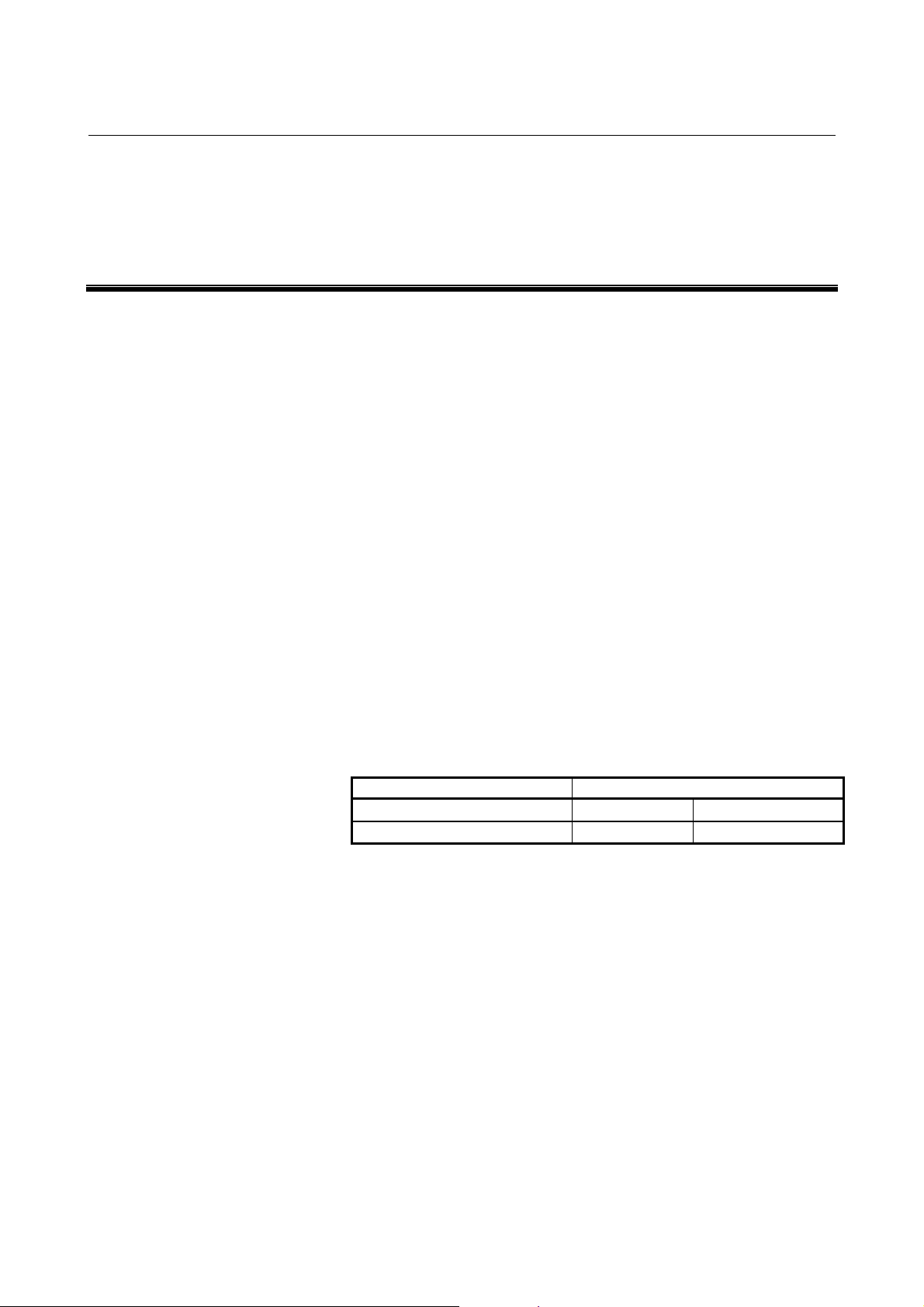

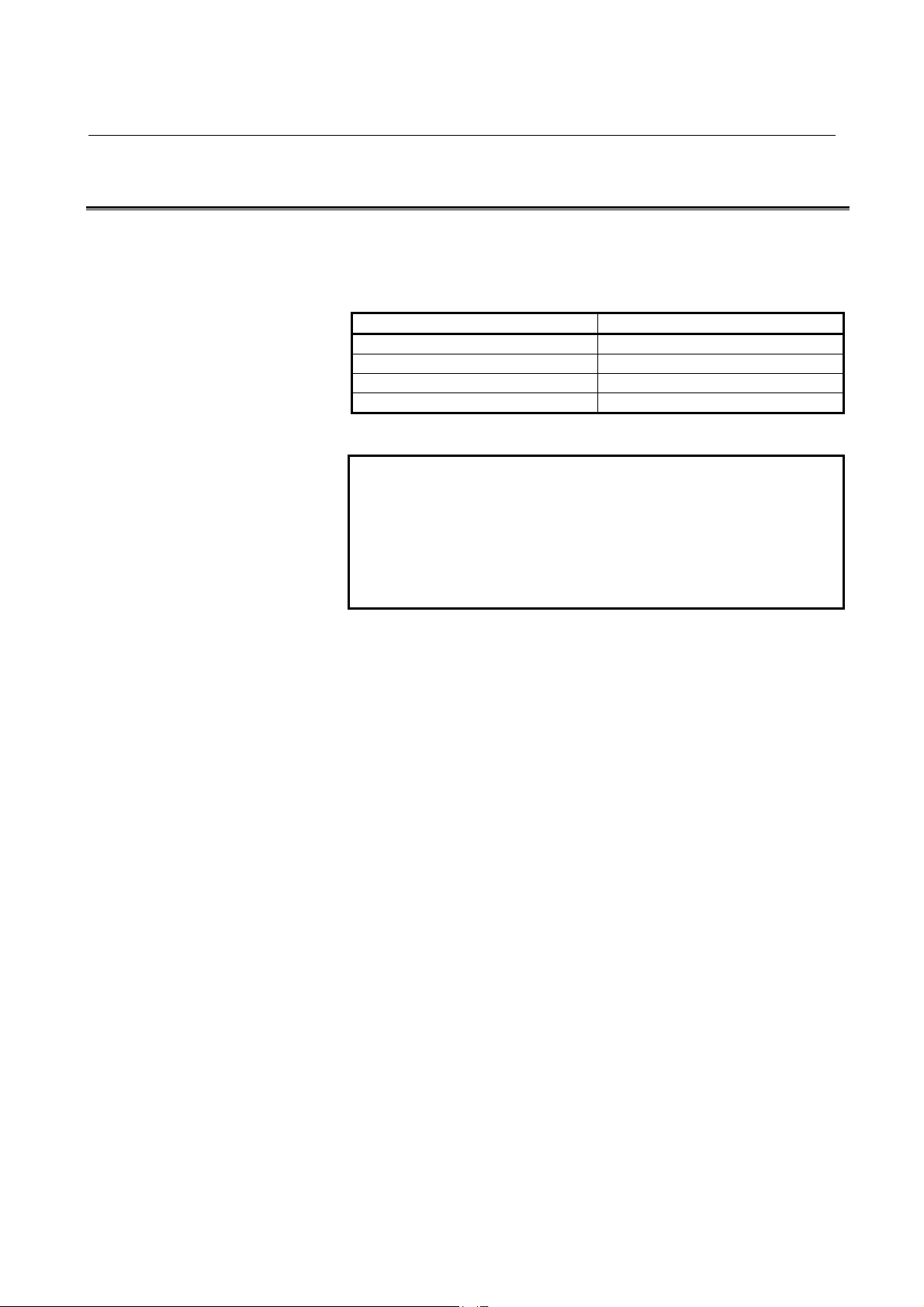

Model name Abbreviation

FANUC Series 15i-MB 15i-MB Series15i

FANUC Series 150i-MB 150i-MB Series150i

- 3 -

Page 22

1.GENERAL GENERAL B-63782EN/01

Related manuals

The following table lists the manuals related to the FANUC Series 15i,

150i. This manual is indicated by an asterisk(*).

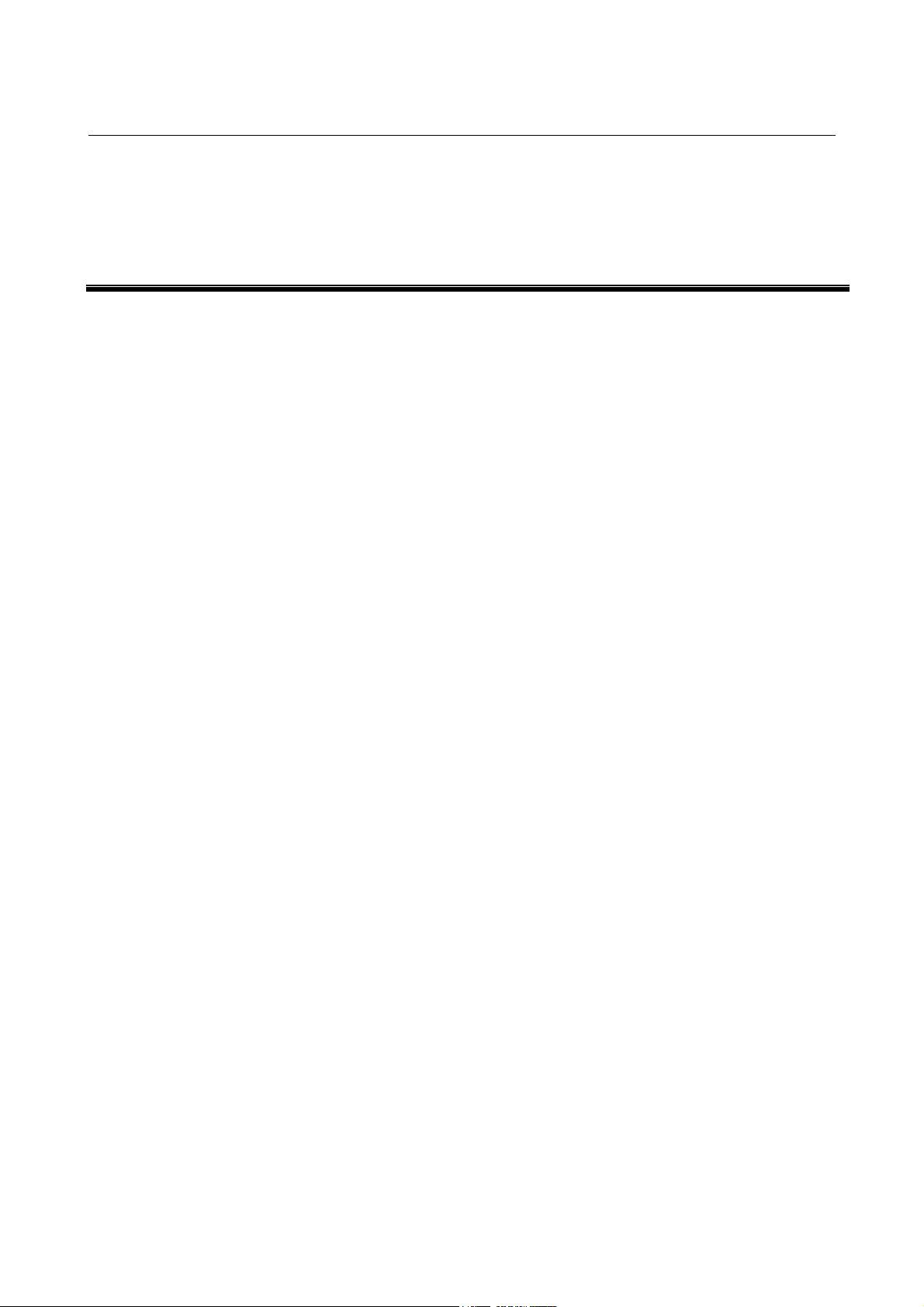

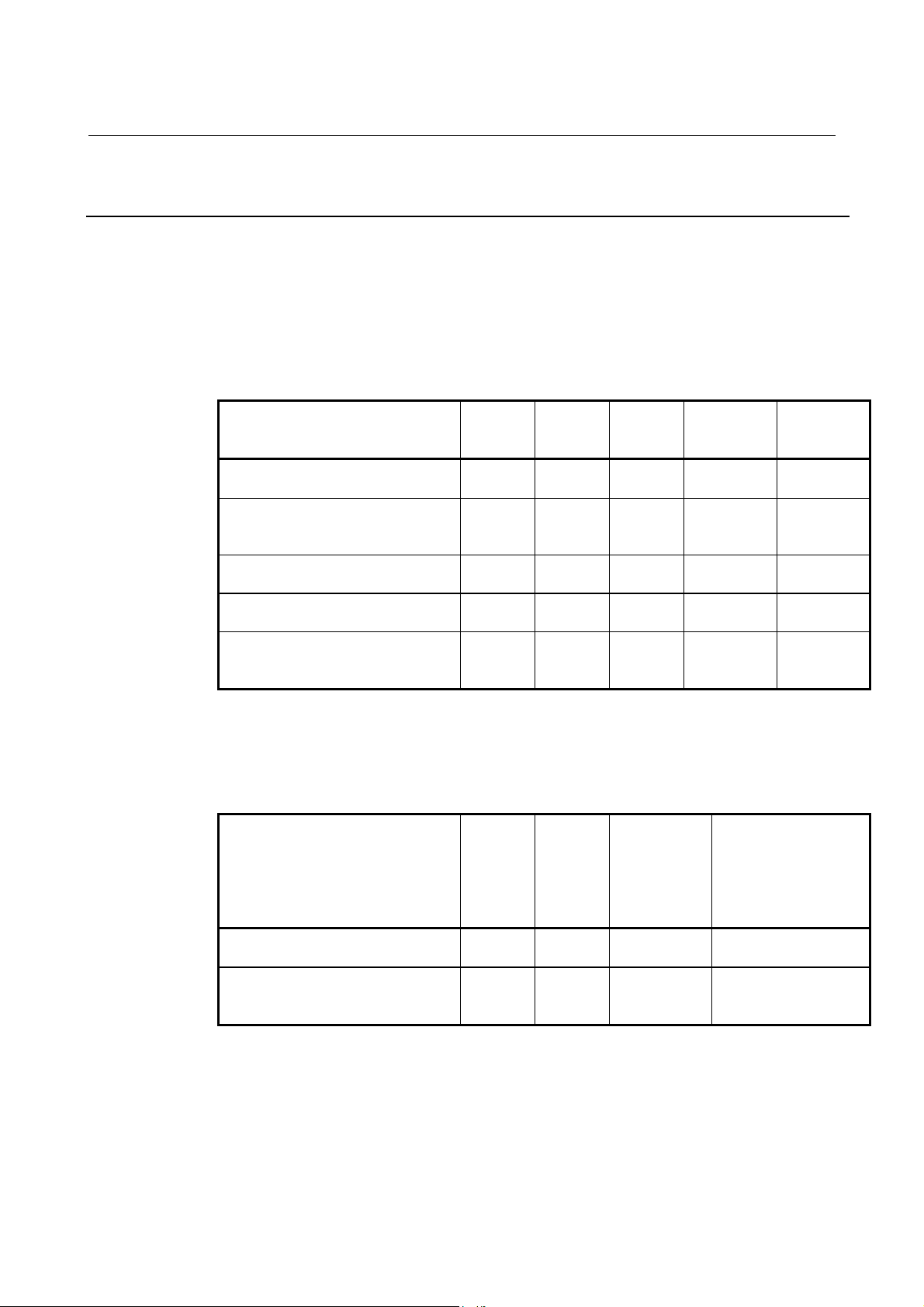

Table 1 (a) Manuals Related to the Series 15i, 150i

Manual name Specification

number

DESCRIPTIONS B-63782EN *

CONNECTION-MBNUAL (Hardware) B-63783EN

CONNECTION-MBNUAL (Function) B-63783EN-1

OPERATOR'S-MBNUAL (PROGRAMMING)

for Machining Center

OPERATOR'S-MBNUAL (OPERATION)

for Machining Center

MAINTENANCE-MBNUAL B-63785EN

PARAMETER-MBNUAL B-63790EN

B-63784EN

B-63784EN-1

Related manuals for Servo Motor ααααi/ββββ series

The following table lists the manuals related to the FANUC Servo

Motor αi/β series.

Table 1 (b) Manuals Related to the Servo Motor ααααi/ββββ series.

Manual name Specification

FANUC AC SERVO MOTOR αi series

DESCRIPTIONS

FANUC AC SPINDLE MOTOR αi series

DESCRIPTIONS

FANUC SERVO AMPLIFIER αi series

DESCRIPTIONS

FANUC SERVO MOTOR αi series

MAINTENANCE-MBNUAL

FANUC AC SERVO MOTOR αi series

PARAMETER-MBNUAL

FANUC AC SPINDLE MOTOR αi series

PARAMETER-MBNUAL

FANUC SERVO MOTOR β series

DESCRIPTIONS

FANUC SERVO MOTOR β series

MAINTENANCE-MBNUAL

FANUC SERVO MOTOR β series

MAINTENANCE-MBNUAL

(I/O Link Option)

number

B-65262EN

B-65272EN

B-65282EN

B-65265EN

B-65270EN

B-65280EN

B-65232EN

B-65235EN

B-65245EN

- 4 -

Page 23

B-63782EN/01 GENERAL 2.LIST OF SPECIFICATIONS

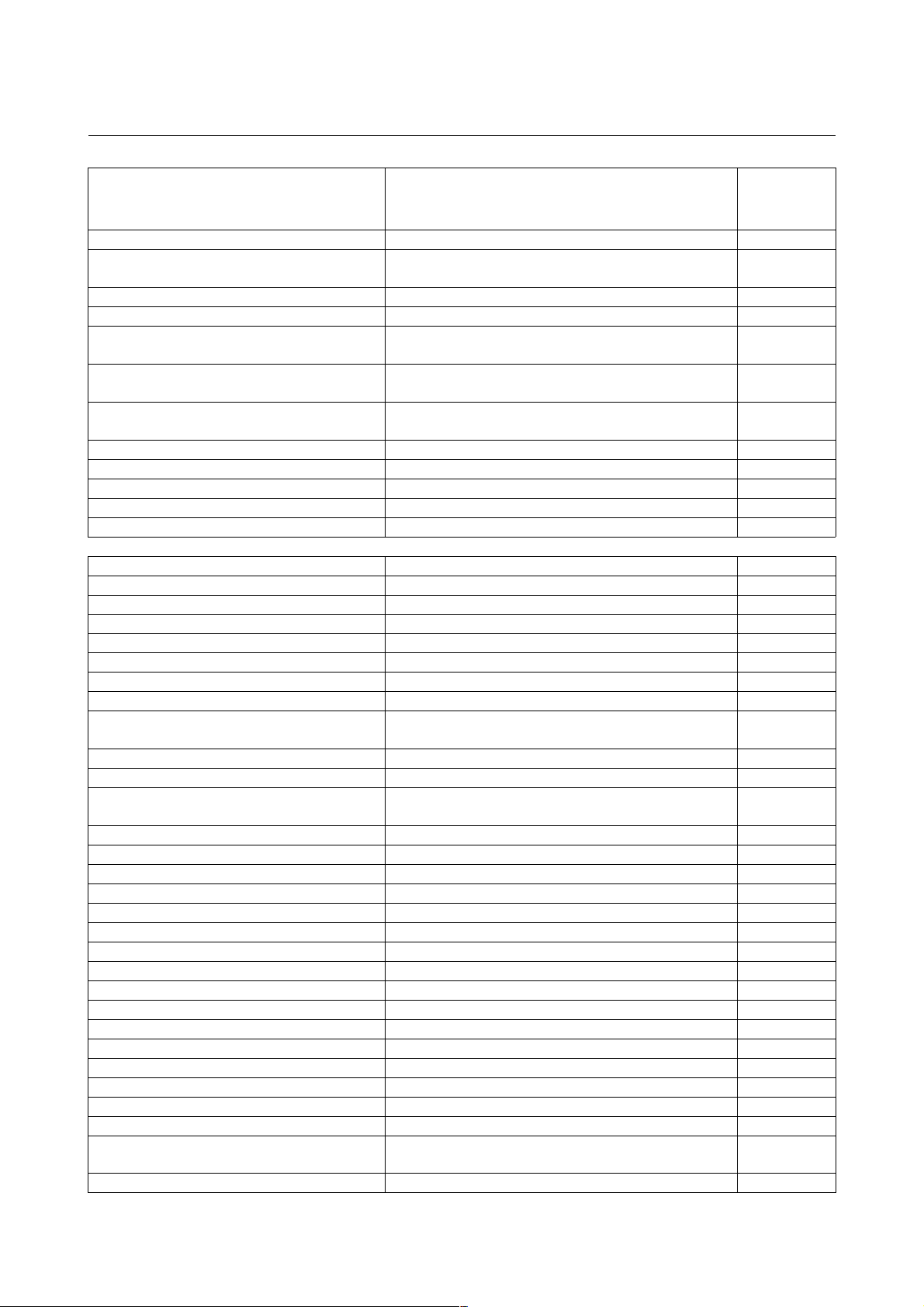

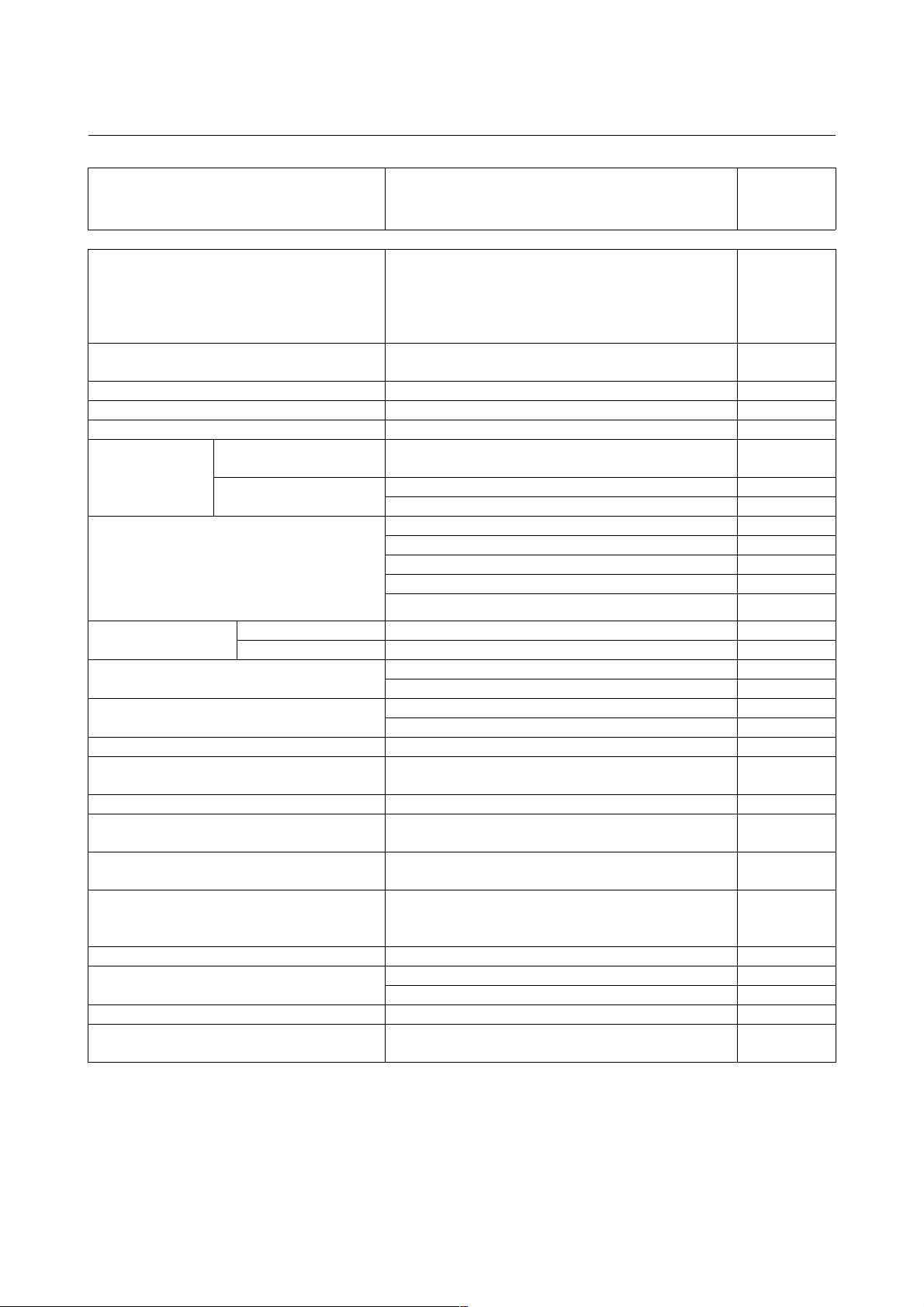

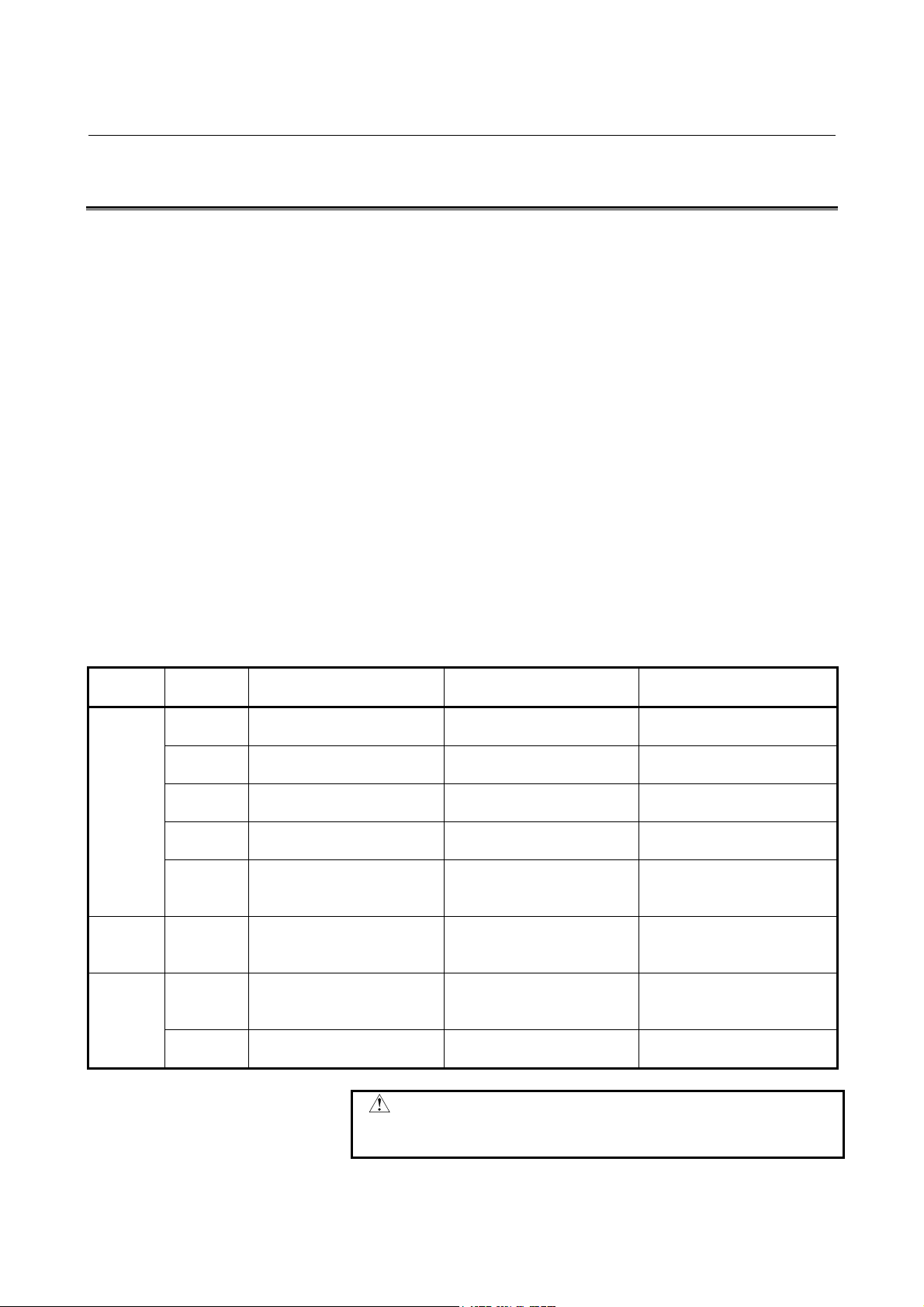

2 LIST OF SPECIFICATIONS

AA: Standard

BB : Standard option

CC : Option

DD : Function included in another option

NOTE) The use of some combinations of options is restricted.

Series 15i

Item Specifications

Axis control

Controlled axes 3 axes (including axis control by PMC) AA

Maximum total controlled axes Up to 24 axes (multi-axes specification)

Up to 10 axes (standard specification)

(including two Cs axes)

Simultaneously controlled axes 2 axes AA

Simultaneously controlled axis expansion Up to maximum total controlled axes CC

Axis control by PMC Up to 8 axes CC

Cs contour control Up to 4 axes

Speed control is possible.

Axis name Optional form X, Y, Z, U, V, W, A , B, C AA

Axis name expansion Addition of I, J, K, and E CC

Controlled axis detach AA

Flexible feed gear Optional DMR AA

Optional command multiplier Use this function when flexible feed gear is not applied. CC

Parallel axes control Available on both standard type and Multi-axes type CC

Twin table function CC

Synchronous control Synchronous error compensation is possible.

Available on both standard type and Multi-axes type

Tandem control CC

Tandem disturbance elimination control Synchronous control is needed. CC

Simple synchronous control Synchronous error compensation is possible. DD

Synchronous tandem control Possible by synchronous control and tandem control DD

Dual position feedback CC

Chopping CC

Increment system IS-A,IS-B,IS-C AA

Increment system D 0.00001mm

0.00001deg

0.000001inck

Increment system E 0.000001mm

0.000001deg

0.0000001inch

Inch/metric switching CC

Interlock All axes/Each axes/Automatic operation axis/Block

start/Cutting block start

Machine lock All axes/each axes AA

Series 150i

MB

CC

CC

CC

CC

CC

AA

- 5 -

Page 24

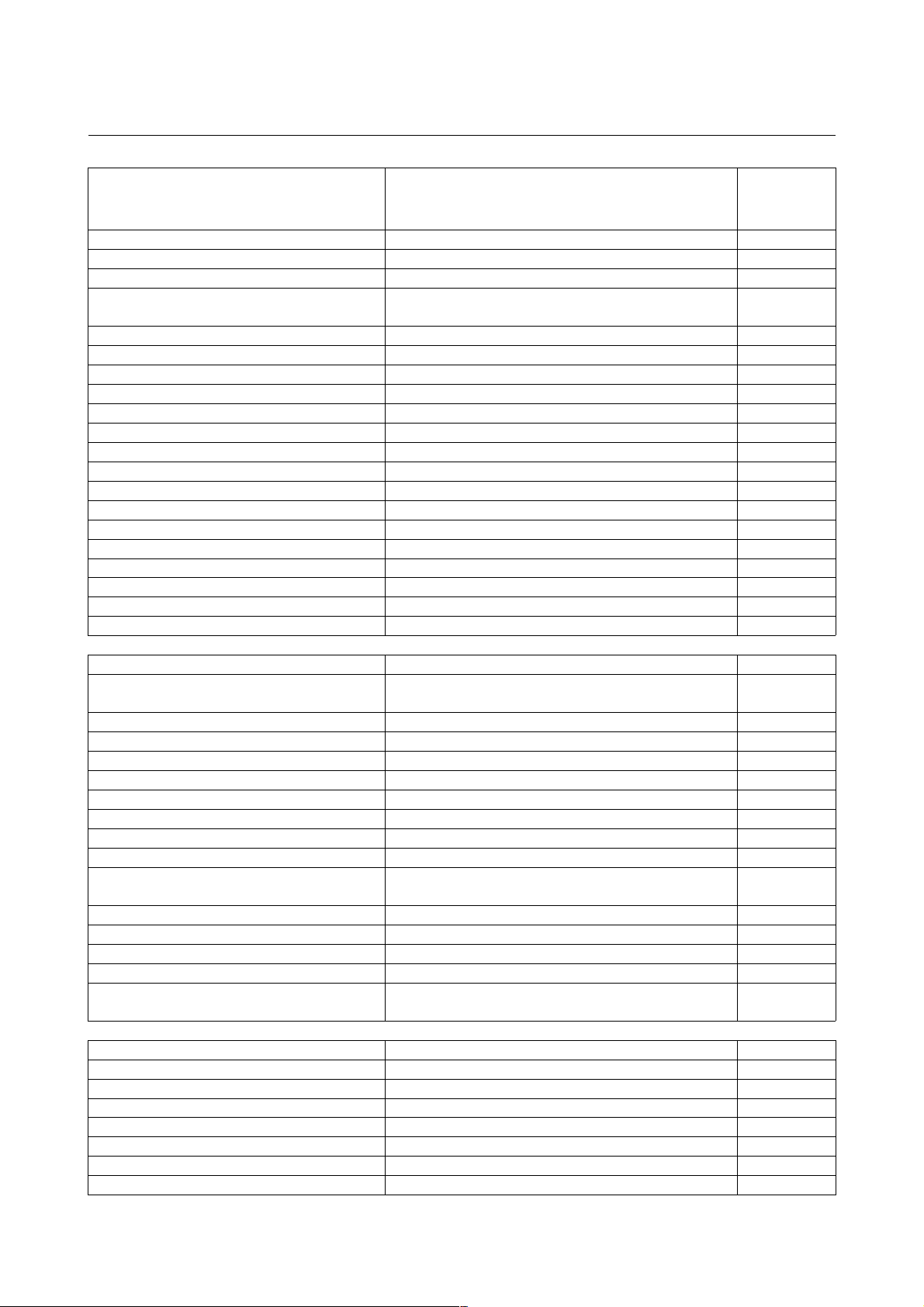

2.LIST OF SPECIFICATIONS GENERAL B-63782EN/01

Series 15i

Item Specifications

Emergency stop AA

Overtravel AA

Stored stroke check 1 AA

Stored stroke check 2 CC

External stroke limit setting CC

Stroke limit check before travel CC

Mirror image Each axis AA

Follow-up At emergency stop and at Servo alarm and so on AA

Servo-off/mechanical handle feed AA

Position switch CC

Absolute position detection AA

Linear scale I/F with absolute address

reference mark

Feed forward for rapid traverse AA

Abnormal load detection CC

Linear motor AA

HRV control AA

Level-up HRV control AA

Fine acceleration/deceleration AA

Accuracy compensation functions

Backlash compensation AA

Separate backlash compensation for rapid

traverse and cutting feed

Smooth backlash compensation AA

Stored pitch error compensation CC

Interpolated pitch error compensation CC

Periodical secondary pitch error

compensation

Nano based error compensation Included in Interpolated pitch error compensation and

Interpolation type straightness compensation

Gradient compensation CC

Straightness deviation compensation CC

Straightness compensation at 128 points CC

Interpolation type straightness compensation CC

Bi-directional pitch error compensation CC

Pitch error compensation additional 5000

points

Three-dimensional error compensation CC

Thermal growth compensation along tool

vector

Operation

Automatic operation DNC operation (Reader/puncher interface is required)

Memory operation

MDI operation

DNC operation with memory card AA

Cycle start/Feed hold AA

Program stop/Program end AA

Reset/Rewind AA

Program number search AA

Sequence number search AA

Sequence number collation stop AA

Series 150i

MB

CC

AA

CC

DD

CC

CC

AA

- 6 -

Page 25

B-63782EN/01 GENERAL 2.LIST OF SPECIFICATIONS

Series 15i

Item Specifications

Program restart CC

Block restart CC

Tool retract & recover CC

Active block cancel CC

Buffer register AA

Multi buffer (5 blocks) AA

Multi buffer (15 blocks) CC

Multi buffer (100 blocks) CC

Dry run AA

Single block AA

Jog feed AA

Manual reference position return AA

Reference position return setting without dog AA

Reference position shift Same as “Adjustment for reference return deceleration

limit” in 15B

Manual handle feed (1 unit) CC

Manual handle feed (2 or 3 units) CC

Manual handle feed magnification Including manual handle

×1, ×10, ×M, ×N

M, N : Up to 2000

Manual handle interrupt CC

Three-dimensional handle feed CC

Control point compensation of tool length

compensation along tool axis

Manual interruption of three-dimensional

coordinate system conversion

Incremental feed ×1, ×10, ×100, ×1000, ×10000, ×100000 AA

Automatic/manual simultaneous operation CC

Manual arbitrary angle feed Unit of angle : 1/16 deg. CC

Manual numeric command CC

Recovery of manual intervention amount AA

Interpolation functions

Positioning G00 (Linear interpolation type positioning enabled) AA

Single direction positioning G60 CC

Exact stop mode G61 AA

Tapping mode G63 AA

Cutting mode G64 AA

Exact stop G09 AA

Linear interpolation AA

Circular interpolation AA

Dwell Dwell in seconds and dwell in revolution (It is possible

Helical interpolation (Circular interpolation) +

Helical interpolation B (Circular interpolation) +

Involute interpolation Involute interpolation by linear and rotary axis is

Helical involute interpolation CC

Spline interpolation Same as “Spline interpolation B” in 15-B CC

Included in Three-dimensional handle feed DD

with thread cutting option)

(Linear interpolation for up to 2 axes)

(Linear interpolation for up to 4 axes)

possible

Series 150i

MB

AA

DD

CC

AA

CC

CC

CC

- 7 -

Page 26

2.LIST OF SPECIFICATIONS GENERAL B-63782EN/01

Series 15i

Item Specifications

Threading/Feed per revolution Equal lead thread cutting, inch thread cutting,

continuous thread cutting

Arbitrary spindle gear ratio thread cutting Included in “Thread cutting, per revolution feed”. DD

Polar coordinate interpolation CC

Cylindrical interpolation CC

Cutting point interpolation for cylindrical

interpolation

Exponential interpolation CC

Hypothetical axis interpolation CC

Spiral/conical interpolation CC

Three-dimensional circular interpolation CC

Reference position return G27, G28, G29 AA

2nd reference position return CC

3rd/4th reference position return CC

Floating reference position return CC

Normal-direction control CC

Index table indexing CC

Multiple rotary axis control CC

Smooth interpolation CC

NURBS interpolation CC

General purpose retract CC

Feed functions

Rapid traverse 240m/min(1 µm) AA

Rapid traverse 99m/min(0.1 µm) AA

Rapid traverse 9.9m/min(0.01 µm) Included in “Least input increment D” DD

Rapid traverse 0.99m/min(0.001 µm) Included in “Least input increment E” DD

Rapid traverse override F0, Fm, 50%, 100% AA

Rapid traverse override 1% 0 to 100% (1%step) AA

Feed per minute mm/min AA

Feed per rotation Included in “Thread cutting, per revolution feed”. DD

Feed per rotation without position coder Included in “Thread cutting, per revolution feed”. DD

Constant tangential speed control AA

Cutting feedrate clamp AA

Automatic acceleration/deceleration Rapid traverse : Linear or exponential

Linear acceleration/deceleration after cutting

feed interpolation

Bell-shaped acceleration/deceleration after

cutting feed interpolation

Bell-shaped acceleration/deceleration after

rapid traverse interpolation

Feedrate override 0 to 254% (1%step) AA

2nd feedrate override 0 to 254% (1%step)

Feed by F with one digit CC

Inverse time feed CC

Jog override 0 to 655.34% (0.01%step) AA

Override cancel AA

External deceleration CC

Feed stop CC

Included in “Cylindrical interpolation”. DD

Cutting feed : Linear or exponential

0 to 655.34% (0.01%step)

Series 150i

MB

CC

AA

AA

CC

AA

CC

- 8 -

Page 27

B-63782EN/01 GENERAL 2.LIST OF SPECIFICATIONS

Series 15i

Item Specifications

Automatic feedrate control by area CC

Look-ahead acceleration/deceleration before

interpolation

Cutting point feedrate control Included in “Automatic corner override”. DD

Advanced preview control AA

Look-ahead bell-shaped

acceleration/deceleration before interpolation

Acc/dec before interpolation of linear type

rapid

Time constant change of bell-shaped

acceleration/ deceleration

Optimum torque acceleration/deceleration CC

Nano interpolation AA

Fine HPCC CC

Fine HPCC smooth velocity control Included in “Fine HPCC”. DD

Jerk control CC

Program input

Program code Automatic recognition of EIA and ISO AA

Program format Word address format AA

Label skip AA

Parity check Horizontal parity, vertical parity AA

Control in/out AA

Optional block skip 1 block AA

Additional optional block skip 9 blocks CC

Maximum value ±9 digit (±12 digit for R, I, J, K) AA

Program number/Program name Program number : O with 8 digits

Program name : 16 characters

Sequence number N with 8 digits AA

Absolute/incremental programming AA

Decimal point input, pocket calculator type

decimal point input

Input unit (10 times) AA

Diameter/radius programming AA

Programmable diameter/radius switching AA

Plane selection G17, G18, G19 AA

Plane switching CC

Rotary axis designation AA

Rotary axis roll-over AA

Polar coordinate command CC

Workpiece coordinate system setting G92 AA

Workpiece coordinate system preset G92.1 AA

Local coordinate system setting G52 AA

Machine coordinate system G53 AA

Workpiece coordinate system G54 to G59 AA

Addition of workpiece coordinate systems 48 sets CC

Manual absolute on/off AA

Optional-angle chamfering/corner rounding CC

Programmable data input G10, tool offset amount , workpiece zero point offset

amount can be changed by programming

Programmable parameter input CC

Series 150i

MB

AA

AA

AA

AA

AA

AA

CC

- 9 -

Page 28

2.LIST OF SPECIFICATIONS GENERAL B-63782EN/01

Series 15i

Item Specifications

Main program/sub program Sub program : 10 folds nested AA

External device subprogram call function AA

Custom macro Common variable : 600 CC

Addition to custom macro common variables :

total 900

Interrupt-type custom macro CC

Canned cycle CC

Arc radius R programming AA

Automatic corner override CC

Feedrate clamp by arc radius AA

Scaling CC

Coordinate system rotation CC

Three-dimensional coordinate conversion CC

Axis switching CC

Programmable mirror image CC

Figure copy CC

Retrace CC

Macro Executor Capacity of user program : 256KB CC

Macro executor +C language executor CC

Custom software size for Main-CPU 6MB CC

Machining type in HPCC screen programming AA

Miscellaneous/spindle functions

Miscellaneous function M with 8 digits, binary output AA

Second auxiliary function M with 8 digits Select address from A, B, C, U, V, W so

that it does not duplicate with control axis address)

Second auxiliary function with a decimal point Included in “Second auxiliary function” DD

Miscellaneous function lock AA

High-speed M/S/T/B interface AA

Multiple miscellaneous-function commands CC

Spindle function S with 8 digits, binary output AA

Spindle serial output Four spindle output is available CC

Spindle analog output Available to use with Spindle serial output CC

Constant surface speed control CC

Actual spindle speed output Included in “Spindle serial output” and “Spindle analog

output”

Spindle speed fluctuation detection CC

Spindle orientation CC

Spindle output switching CC

Spindle positioning CC

Rigid tapping Orientation, pecking cycle and return speed override

function is also possible

Tool functions, tool compensation functions

Tool function T with 8 digits, binary output AA

Tool compensation data, 32 items AA

Tool compensation data, 99 items CC

Tool compensation data, 200 items CC

Tool compensation data, 499 items CC

Tool compensation data, 999 items CC

Tool offset memory A Common with all tool offset AA

Tool offset memory B Separate memory for geometry and wear CC

Series 150i

MB

CC

CC

DD

CC

- 10 -

Page 29

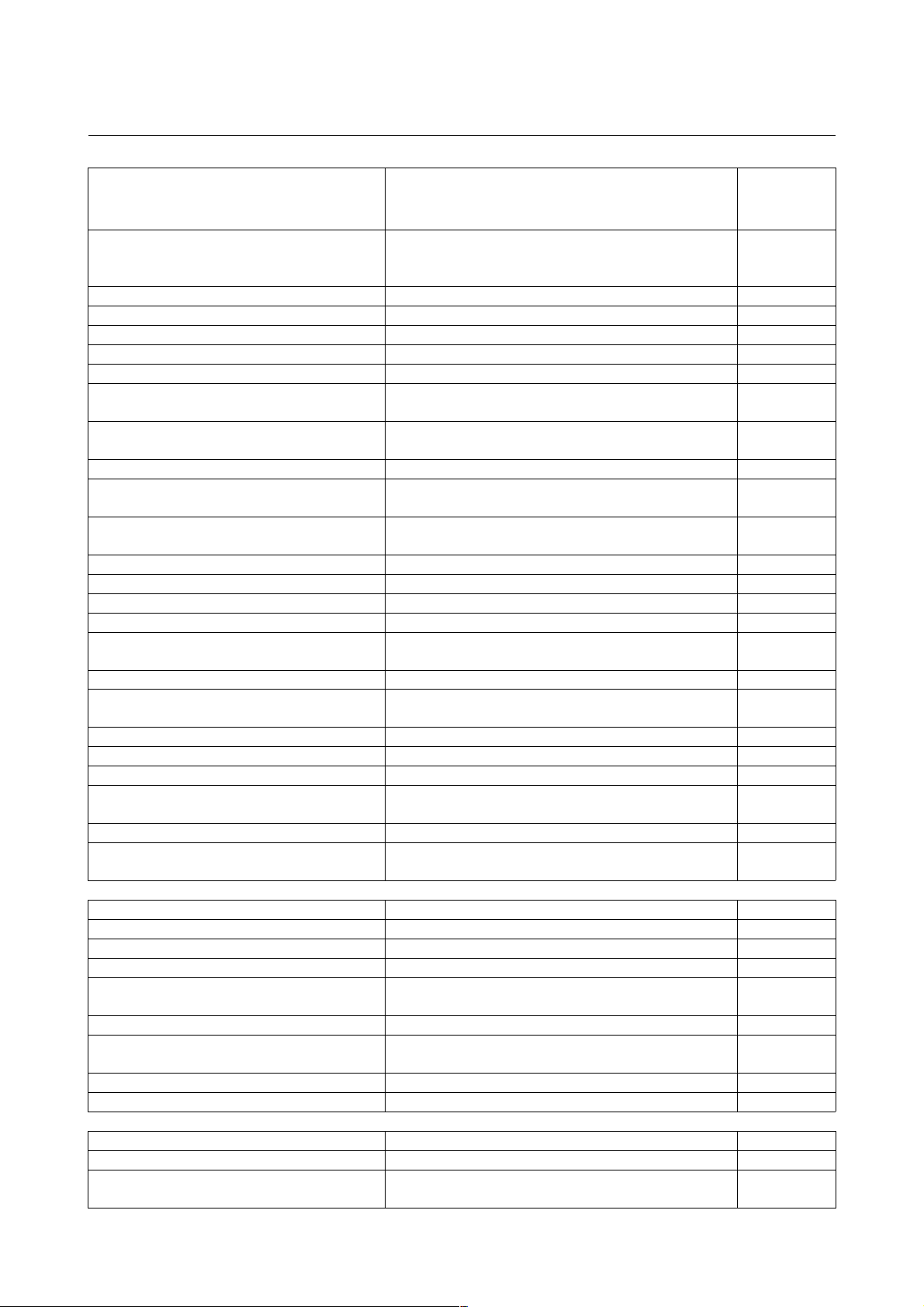

B-63782EN/01 GENERAL 2.LIST OF SPECIFICATIONS

Series 15i

Item Specifications

Tool offset memory C Separate memory for geometry and wear

Separate memory for length compensation and cutter

compensation

Tool length compensation AA

Tool offset CC

Cutter compensation Same as “Cutter compensation C” in 15B CC

Three-dimensional cutter compensation CC

Cutter compensation for rotary table CC

Three-dimensional cutter compensation for

rotary table

Three-dimensional cutter compensation at

tool center point

Tool life management Time/number of cycle CC

Addition to tool life management sets (512

sets)

Addition to tool life management sets (1024

sets)

Incremental offset AA

Three-dimensional tool offset CC

Tool offset selection by T code CC

Tool offset value digit expansion AA

Tool length compensation in tool axis

direction

Tool center point control CC

Control point compensation of tool length

compensation along tool axis

Tool center point control for 5-axis machining CC

Tilted working plane command CC

Rotary table dynamic fixture offset CC

Designation direction tool length

compensation

Grinding wheel wear compensation CC

Tool length compensation in tool axis

direction with twin table control

Measurement function

Manual tool length measurement Same as “Tool length measurement” in 15B AA

Automatic tool length measurement CC

Skip function G31, Plural axes can be commanded CC

High-speed skip signal input 8 points CC

High-speed measuring position reach signal

input

Multi-step skip function CC

Tool length workpiece zero point

measurement

Workpiece zero point manual setting AA

Torque-limit skip Included in “Skip function” DD

Function for hobbing machine

Electronic gear box CC

2-axes electronic gear box Included in “Electronic gear box” DD

Electronic gear box automatic phase

synchronization

Included in tool length compensation in tool axis

direction or tool center point control

Tool length compensation in tool axis direction and

twin table function are needed.

Signal an be output to PMC CC

Included in “Electronic gear box” DD

Series 150i

MB

CC

CC

CC

CC

CC

CC

DD

CC

DD

CC

- 11 -

Page 30

2.LIST OF SPECIFICATIONS GENERAL B-63782EN/01

Series 15i

Item Specifications

Automatic exact stop check CC

Skip for EGB axis CC

Editing

Part program storage length 80m (32Kbytes) AA

Part program storage length 160m (64Kbytes) CC

Part program storage length 320m

(128Kbytes)

Part program storage length 640m

(256Kbytes)

Part program storage length 1280m

(512Kbytes)

Part program storage length 2560m

(1024Kbytes)

Part program storage length 5120m

(2048Kbytes)

Registered 100 programs AA

Expanded Registered programs CC

Part program storage editing AA

Key and program encryption CC

Back ground editing AA

Expanded part program editing AA

Play back CC

Machining time stamp CC

2 programs displaying and editing

synchronously

Setting, display

Status display AA

Clock function AA

Current position display AA

Program display 16-character program name AA

Program name 48 characters CC

Parameter setting display AA

Input/output device setting screen Included in “Reader/puncher interface” DD

Self-diagnosis function AA

Alarm display AA

Alarm history display AA

Operation history display AA

Help function Display unit with graphic display function is required. AA

Remote diagnosis function AA

Run time and parts number display AA

Actual machining speed display AA

Floppy Cassette directory display Included in “Reader/puncher interface” DD

Directory display / punch for each group AA

Tool path drawing Same as “Graphic display” in 15B CC

Background drawing CC

Servo adjustment screen AA

Spindle adjustment screen Included in “Spindle serial output” and “Spindle analog

output”

Waveform diagnosis screen Display unit with Graphic display function is needed. AA

Load meter display AA

Series 150i

MB

CC

CC

CC

CC

CC

AA

DD

- 12 -

Page 31

B-63782EN/01 GENERAL 2.LIST OF SPECIFICATIONS

Series 15i

Item Specifications

Fine torque sensing Display unit with Graphic display function is needed. CC

Hardware/software system configuration

display

NC format guidance Included in “Help function” AA

Sub screen Display unit with Graphic display function is needed. AA

Menu switch CC

Software operator's panel CC

Display language switching (English) AA

Display language switching (Japanese) AA

Display language switching (German) Included in “Display language switching A” CC

Display language switching (French) Included in “Display language switching A” CC

Display language switching (Italian) Included in “Display language switching A” CC

Display language switching (Spanish) Included in “Display language switching B” CC

Display language switching (Swedish) Included in “Display language switching B” CC

Display language switching (Chinese) Included in “Display language switching B” CC

Data protection key 3 types AA

Calculation key AA

Erase screen display/screen saver AA

Internal position compensation data display AA

Maintenance information display AA

Touch panel CC

Periodic maintenance screen AA

High-speed and high precision setting screen AA

DO signal output by softkey CC

Data input/output

Reader/punch interface A CC

Reader/punch interface B CC

Reader/punch interface C CC

Remote buffer CC

External I/O device control CC

Modem card control AA

Analog input Included in “NC window” DD

External data input/output Input/output of tool offset amount, workpiece zero

offset amount, machine zero offset amount, alarm

message, operator message, program number search,

sequence number search are available

External workpiece number search 31 points CC

FANUC Handy File CC

Memory card interface AA

Data server CC

Data server buffer mode CC

Fast data server CC

Screen hard copy function Display unit with graphic display function is required. AA

Power mate CNC manager CC

Network

Ethernet Ethernet board is needed. CC

Fast Ethernet Fast Ethernet board is needed. CC

PROFIBUS-DP Master/Slave CC

DeviceNet Master/Slave CC

Series 150i

MB

AA

CC

- 13 -

Page 32

2.LIST OF SPECIFICATIONS GENERAL B-63782EN/01

Series 15i

Item Specifications

Others

Status output signal NC ready, servo ready, rewinding, NC alarm,

distribution completion, automatic operation,

automatic operation start, automatic operation halt,

reset, in-position, rapid traverse, tapping, threading,

etc.

Axis moving signal Axis moving signal output, Axis moving direction signal

output

Key input form PMC CC

NC window CC

NC window B Included in “NC window” DD

PMC system

Machine interface (I/O Link)

Maximum DI/DO points: 1024/1024

PMC-NB6 Basic instruction: 0.085 µs/step

Program memory : Max. 32,000 step

C language

Up to 2MB (PMC-NB6 required) CC

Expanded non-volatile memory 64KB CC

Operator's panel I/O module BB

Connector panel I/O module BB

Power magnetics cabinet I/O module BB

I/O Unit-MODEL A BB

I/O Unit-MODEL B BB

Series 150i

MB

AA

CC

AA

2-slot W : 112 mm / H : 380mm / D : 172mm BBControl unit

dimensions

Manual pulse generator CC

Pendant-type manual pulse generator With axis selection switch and magnification selection

Handy machine operator’s panel CC

Applicable servo motor

Applicable servo amplifier

Separate position detector interface unit (for

closed control)

Applicable spindle motor

Applicable spindle amplifier

Multi-tap transformer 200/220/230/240/380/415/440/460/480/550VAC CC

Power supply 200 to 240VAC +10%-15%

4-slot W : 224 mm / H : 380mm / D : 172mm BB

9.5” monochrome LCD (stand-alone type) BBDisplay unit

10.4” color LCD (stand-alone type) BB

Stand-alone type MDI (vertical) BBMDI unit

Stand-alone type MDI (horizontal) BB

CC

switch

FANUC servo motor αi series and α series (with serial

interface pulse coder)

FANUC servo amplifier αi series and α series

(FSSB interface)

For separate pulse coder /Linear optical scale

2-phase pulse interface for separate pulse coder/linear

optical scale

FANUC spindle motor αi series and α series, etc.

FANUC servo amplifier αi series and α series

Analog interface AA

50 to 60HZ ±3HZ

AA

AA

CC

AA

AA

AA

- 14 -

Page 33

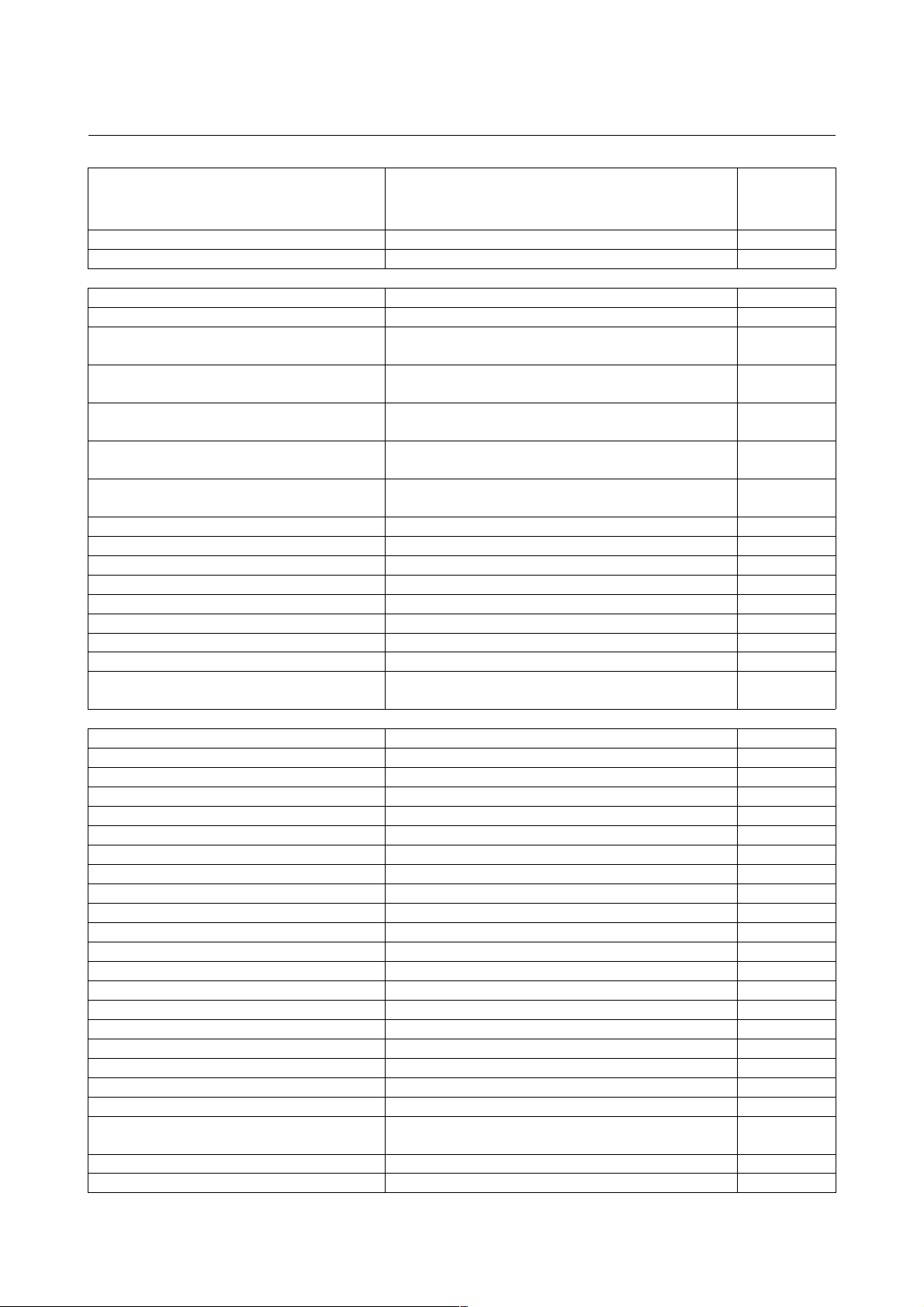

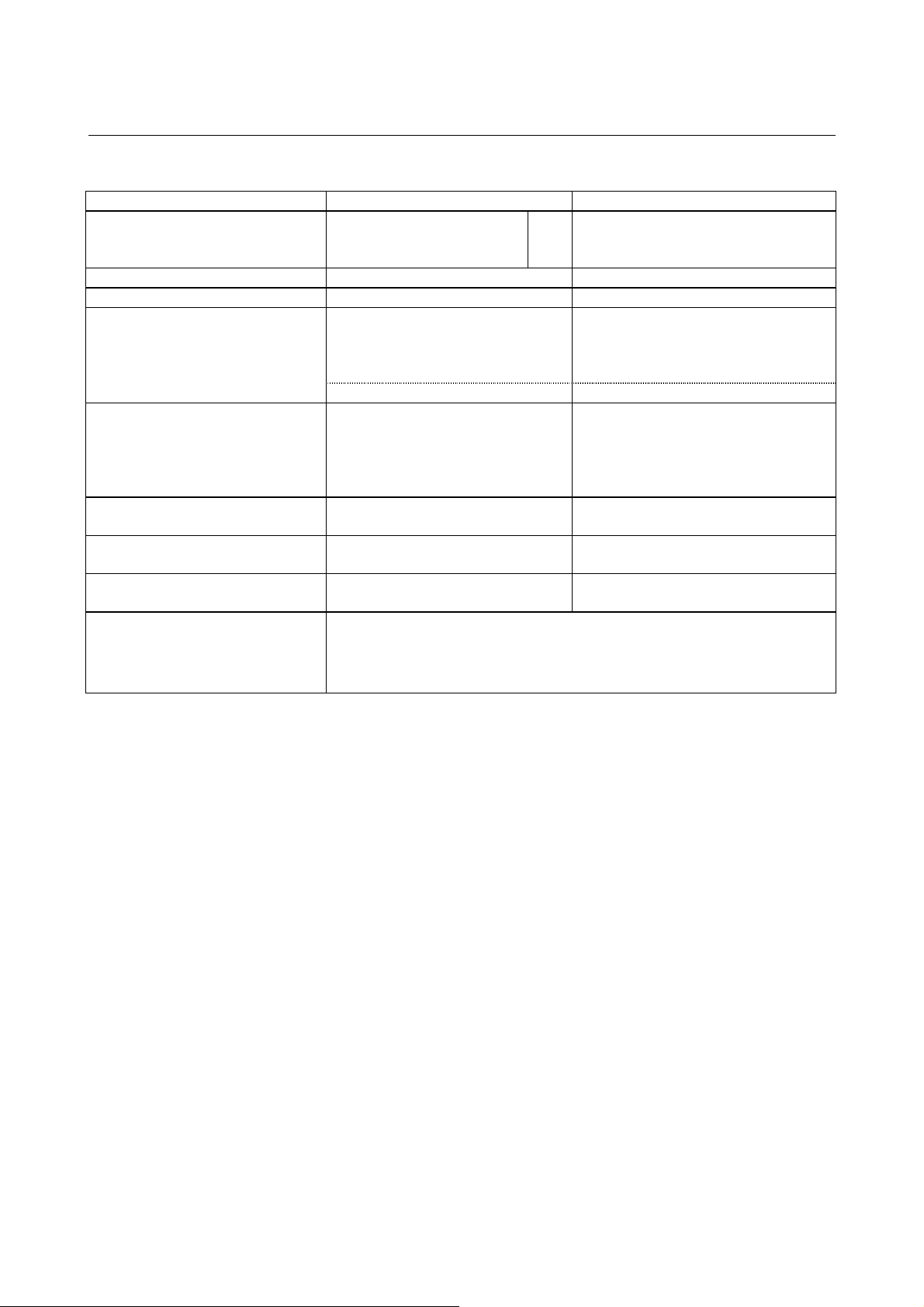

B-63782EN/01 GENERAL 2.LIST OF SPECIFICATIONS

Software of personal computer part in case of the CNC system which is 150i or

connected with personal computer via HSSB(High Speed Serial Bus)

Items Specifications Remarks

Operating system Windows® 2000 *1

Extended library FOCAS1 *4

Software packages

Development tools Visual C++

CNC basic operation package Option

Milling animation function Option

CNC screen display function Option

Ladder editing package Option

DNC operation management

package

Machining status monitor package Option

Visual Basic

®

®

Option

*1*1Microsoft Corp.

Microsoft Corp.

Hardware of HSSB(High Speed Serial Bus) and Required hardware of

commercially available personal computer in case of the CNC system which is

connected with the personal computer via HSSB(High Speed Serial Bus).

Items Specifications Remarks

CNC side interface board

Personal computer side interface

board

Connecting cable Optical fiber cable Max. length: 100m

Personal computer requirements CPU: Pentium® or more

ISA Bus and HSSB for 1 channel For ISA slot in the personal

computer

Using voltage: +5V only

ISA Bus and HSSB for 2 channel

PCI Bus and HSSB for 1 channel For PCI slot in the personal

computer

Using voltage: +5V only

PCI Bus and HSSB for 2 channel

For environmental

ISA slot or PCI slot 1 or more

(By selectable personal computer side interface

board)

requirements of the personal

computer, refer to the manual

supplied with the machine.

- 15 -

Page 34

2.LIST OF SPECIFICATIONS GENERAL B-63782EN/01

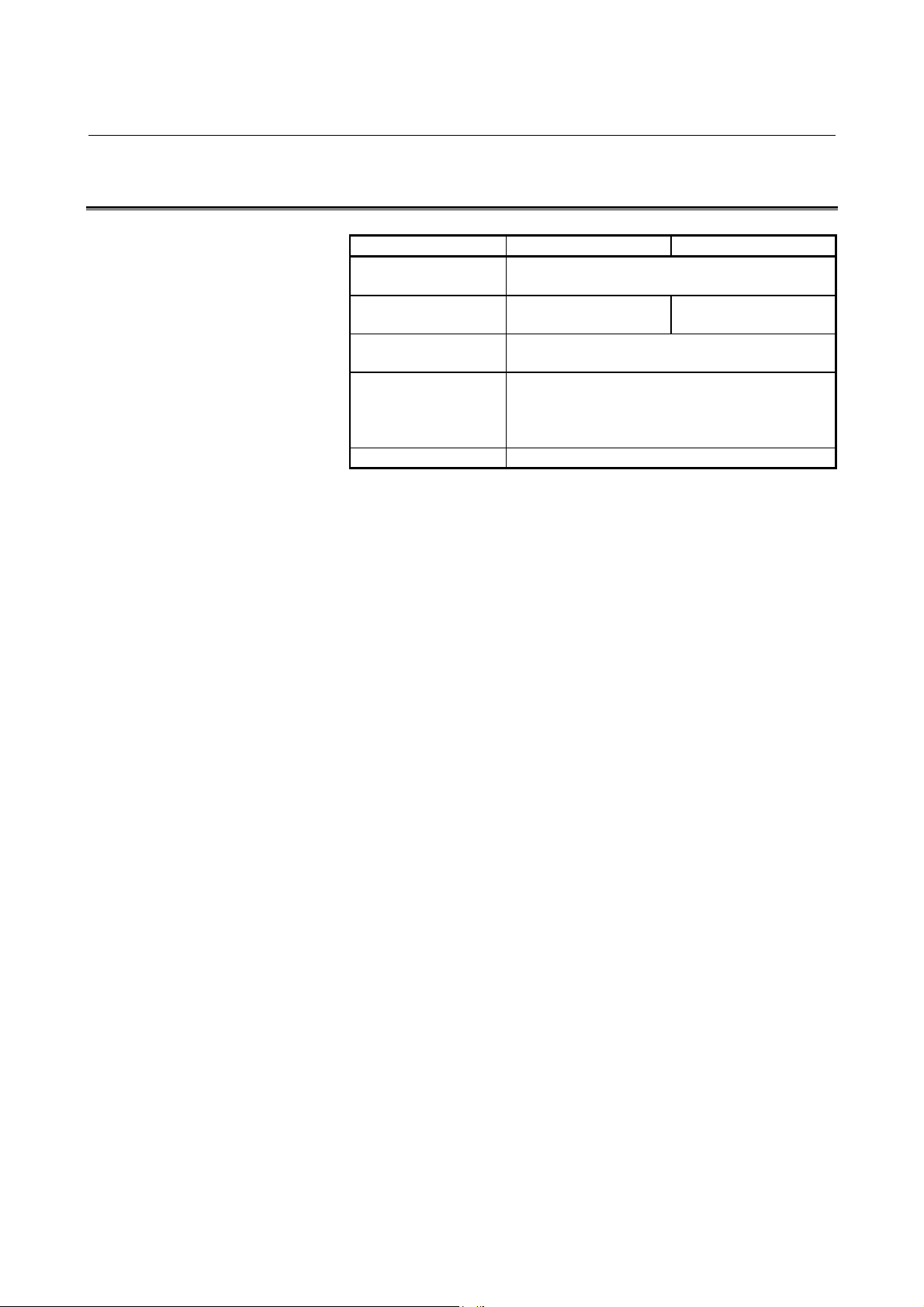

Hardware of CNC Display Unit with Personal Computer Function used in 150i

Items Specifications Remarks

CPU Pentium® III,

Celeron

MMX Pentium

Main memory Max. 128MBytes

Hard disk 10GBytes

Monitor

Ports PCMCIA x1 slot

CNC interface High-Speed Serial Bus

Extension slot PCI spec. extension slot

Ambient temperature of unit

Ambient relative humidity Normally: 10% to 75%RH or less (No dew, nor frost allowed)

10.4" color TFT LCD (640×480 dots),

12.1" color TFT LCD (800×600 dots),

or 15.0" color TFT LCD (1024×768

dots)

Touch panel Option

Full keyboard x1/Mouse x1

Serial (RS-232C) x2/Parallel x1

Floppy disk x1

USB×2

(Optical fiber cable)

(Short card size) x2

At operating: 5°C to 45°C

At nonoperating: -20°C to 60°C

Short term (within one month): 10% to 90%RH or less

(No dew, nor frost allowed)

Wet humidity: 29°C or less

TM

,

®

*1

Display Max. 65536 colors

Several models limited to Max. 4096

colors *2 *5

Touch panel is connected to serial port 1.

Max. length: 100m

*3

(Note)

*1: Intel, Pentium are registered trademarks of Intel Corporation.

Celeron is the trademark of Intel Corporation.

Microsoft, Windows, Visual C++, Visual Basic are registered

trademarks of Microsoft Corporation.

Each companie's name and product's name is the trademark or

registered trademark.

*2 : A special driver is necessary to display 16 or more colors.

*3 : Extension Board for IBM PC should be prepared by MTB.

*4 : FOCAS1 = FANUC Open Cnc API Specifications version 1

*5 : LCD is manufactured by using high precision technology,

however it has points which are always bright or dark.

This phenomenon is caused by LCD's structure, and not defects.

- 16 -

Page 35

II NC FUNCTIONS

Page 36

Page 37

B-63782EN/01 NC FUNCTIONS PREFACE

PREFACE

This part describes the functions that can be performed on all models.

For the functions available with each model, see the list of

specifications in Part I.

- 19 -

Page 38

1.CONROLLED AXES NC FUNCTIONS B-63782EN/01

1 CONROLLED AXES

- 20 -

Page 39

B-63782EN/01 NC FUNCTIONS 1.CONROLLED AXES

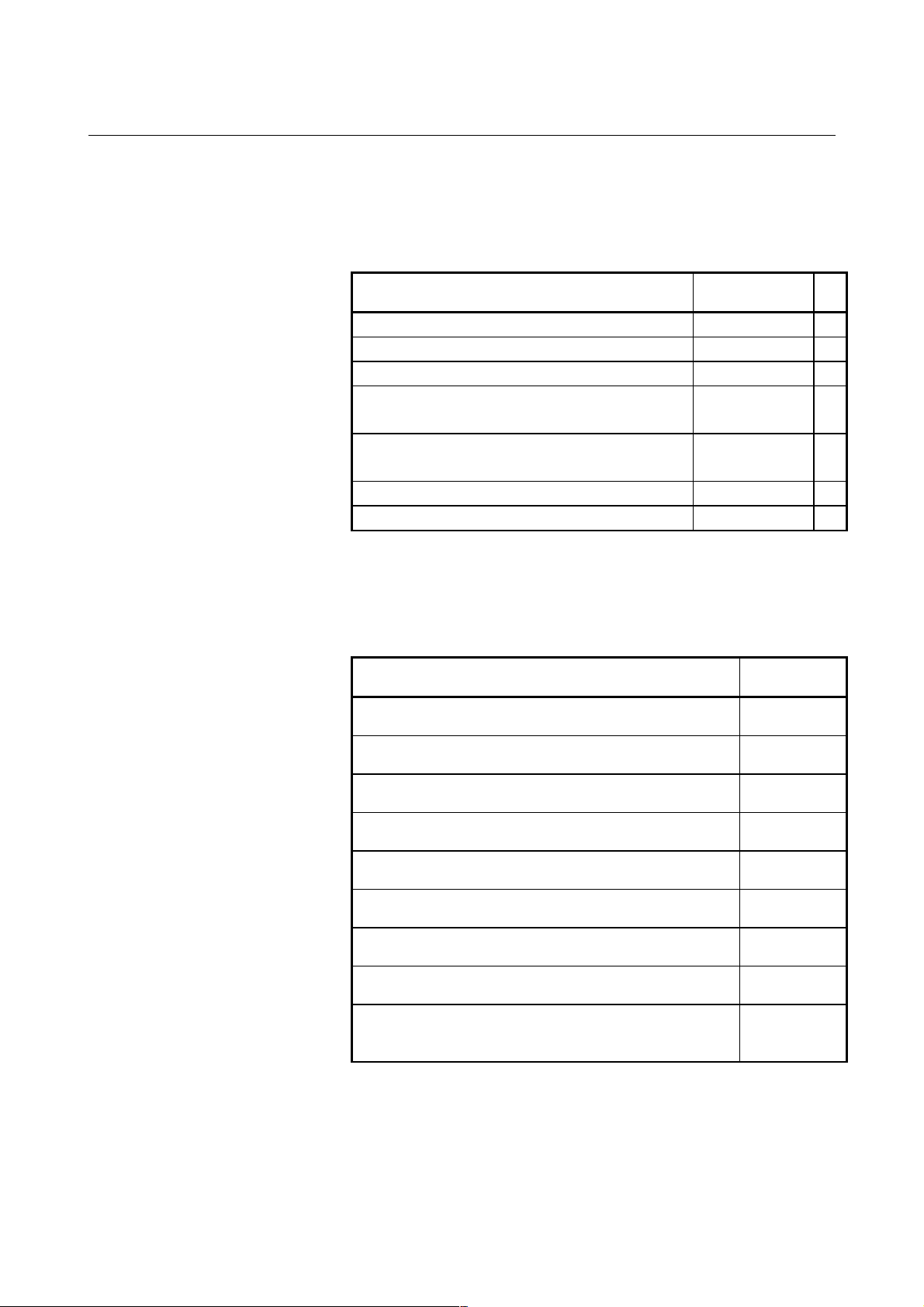

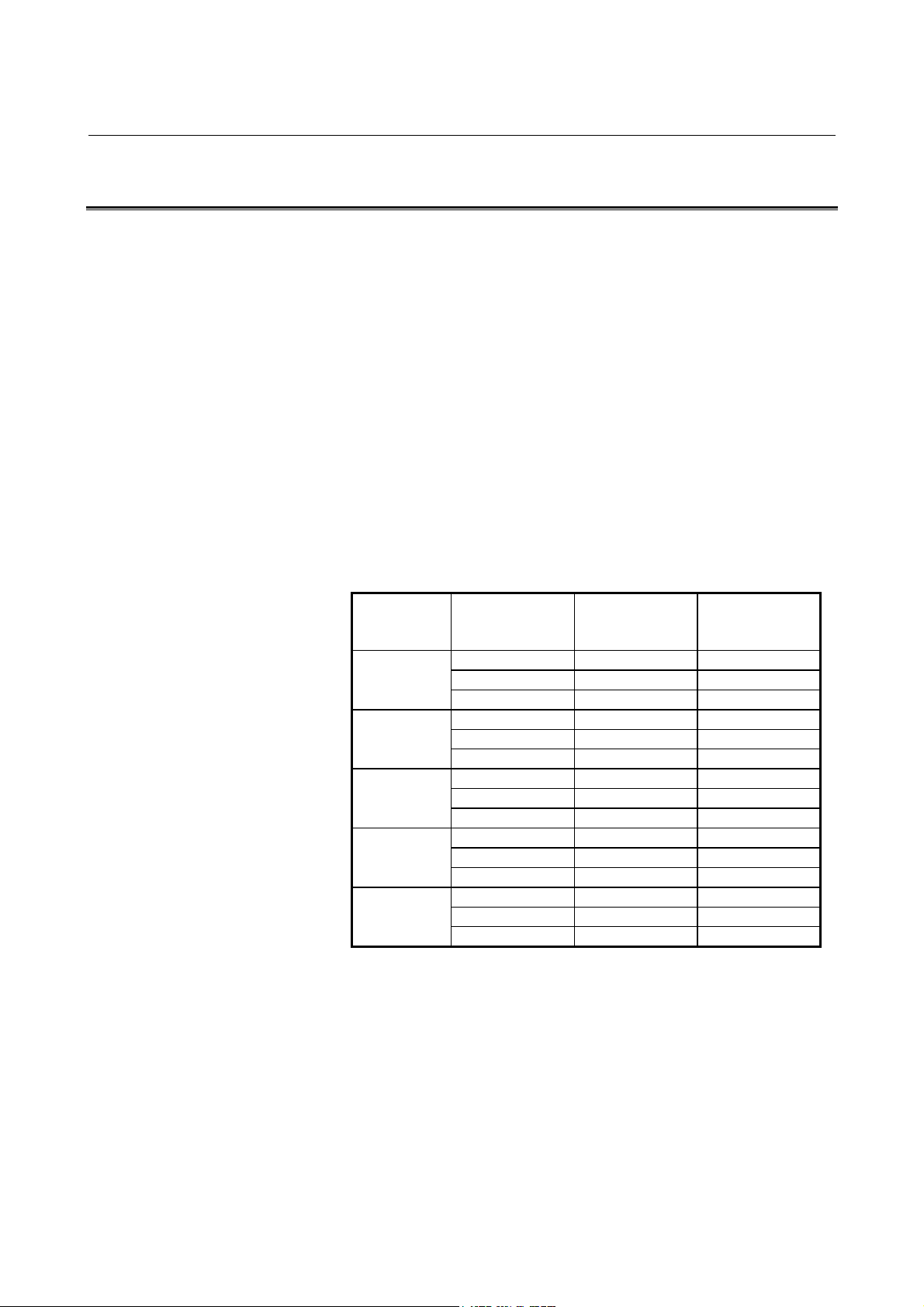

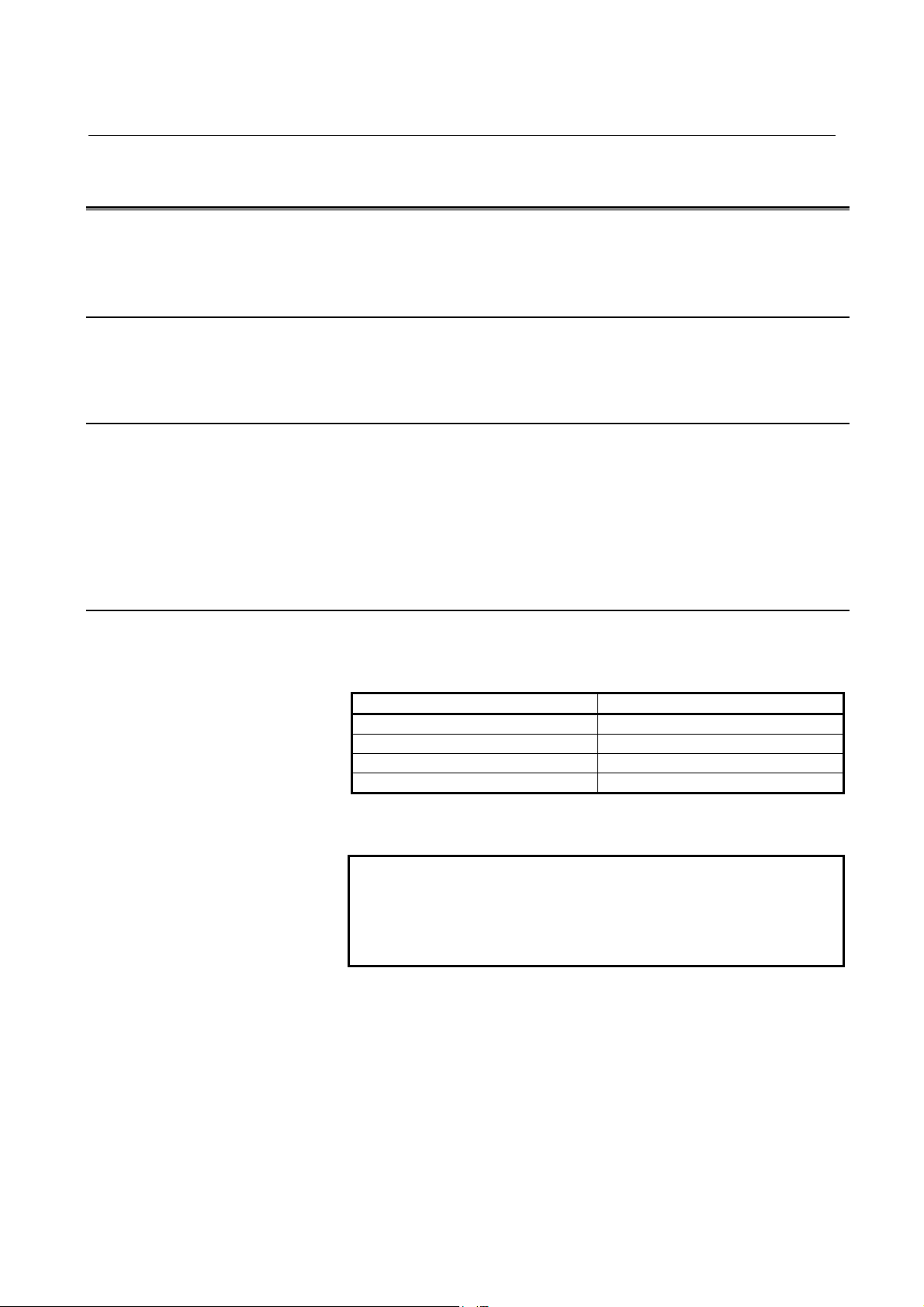

1.1 CONTROLLED AXES

Item Standard type Multiple axes type

No. of basic controlled

axes

Controlled axes

expansion (total)

Basic simultaneously

controlled axes

Simultaneously

controlled

axes expansion (total)

PMC axis control Up to Max. control axes (Cs axis is disabled.)

Max. 10 axes (Cs axis is 2

axes)

Up to Max. controlled axes

Simultaneously all axes :

Positioning, linear interpolation, jog feed (specified

axes only), and incremental feed

3 axes (2 axes)

Max. 24 axes

2 axes

- 21 -

Page 40

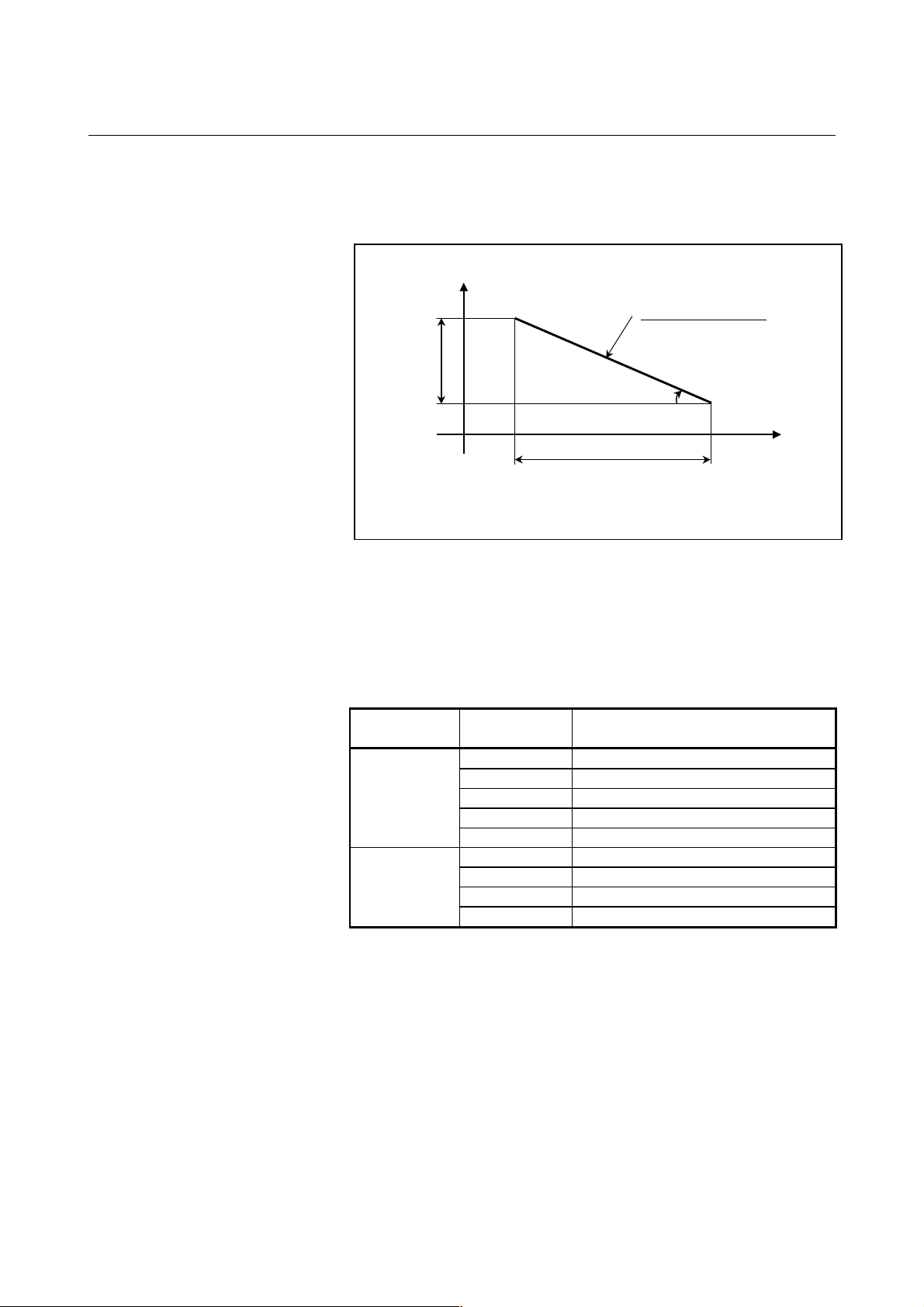

1.CONROLLED AXES NC FUNCTIONS B-63782EN/01