Page 1

FANUC Series 15/150-Model B

for Machining Center

DESCRIPTIONS

B-62082E/04

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The export of this product is subject to the authorization of the government of the country

from where the product is exported.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by or in the main body.

Page 3

B–62082E/04

DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the

machine. Precautions are classified into W arning and Caution according to their bearing on safety.

Also, supplementary information is described as a Note. Read the Warning, Caution, and Note

thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

Read this manual carefully, and store it in a safe place.

s–1

Page 4

B–62082E/04

Series 15

PREFACE

PREFACE

The models covered by this manual, and their abbreviations are :

Product Name Abbreviations

FANUC Series 15–MB 15–MB

FANUC Series 15–MFB 15–MFB

FANUC Series 15MEK–MODEL B–4 (*) 15MEK

FANUC Series 15MEL–MODEL B–4 (*) 15MEL

FANUC Series 150–MB 150–MB Series 150

(*)The FANUC Series 15MEK/MEL–MODEL B–4 is a software–fixed

CNC capable of 4 contouring axes switchable out of 8 axes for milling

machines and machining centers.

Further the following functions can not be used in the 15MEK or

15MEL.

D Increment system D/E (Increment system C is an option function)

D Helical interpolation B

D Plane switching

D Designation direction tool length compensation

D 2 axes electric gear box

D Manual interruption of 3–dimensional coordinate system

conversion

D 3–dimensional cutter compensation

D Trouble diagnosis guidance

D OSI/ETHERNET function

D High–precision contour control using RISC

D Macro compiler (self compile function)

D MMC–III, MMC–IV

D Smooth interpolation

D Connecting for personal computer by high–speed serial–bus

p–1

Page 5

PREFACE

B–62082E/04

Manuals related to

Series 15/150–MODEL B

Manuals related to FANUC Series 15/150–MODEL B are as follows.

This manual is marked with an asterisk (*).

List of Manuals Related to Series 15/150–MODEL B

Manual Name

FANUC Series 15–TB/TFB/TTB/TTFB DESCRIPTIONS B–62072E

FANUC Series 15/150–MODEL B For Machining Center DESCRIPTIONS B–62082E *

FANUC Series 15/150–MODEL B CONNECTION MANUAL B–62073E

FANUC Series 15/150–MODEL B CONNECTION MANUAL (BMI Interface) B–62073E–1

FANUC Series 15–MODEL B For Lathe OPERATOR’S MANUAL (Programming) B–62554E

FANUC Series 15–MODEL B For Lathe OPERATOR’S MANUAL (Operation) B–62554E–1

FANUC Series 15/150–MODEL B For Machining Center OPERATOR’S MANUAL (Programming) B–62564E

FANUC Series 15/150–MODEL B For Machining Center OPERATOR’S MANUAL (Operation) B–62564E–1

FANUC Series 15/150–MODEL B PARAMETER MANUAL B–62560E

FANUC Series 15/150–MODEL B MAINTENANCE MANUAL B–62075E

FANUC Series 15–MODEL B DESCRIPTIONS (Supplement for Remote Buffer) B–62072E–1

FANUC Series 15–MODEL B PROGRAMMING MANUAL (Macro Compiler / Macro Executer) B–62073E–2

PMC

FANUC PMC–MODEL N/NA PROGRAMMING MANUAL (Ladder Language) B–61013E

FANUC PMC–MODEL NB/NB2 PROGRAMMING MANUAL (Ladder Language) B–61863E

FANUC PMC–MODEL N/NA PROGRAMMING MANUAL (C Language) B–61013E–2

FANUC PMC–MODEL NB PROGRAMMING MANUAL (C Language) B–61863E–1

FANUC PMC–MODEL N/NA

PROGRAMMING MANUAL (C Language – Tool Management Library)

Conversational Automatic Programming Function

CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION FOR MACHINING CENTER

(Series 15–MF/MFB) PROGRAMMING MANUAL

CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION FOR MACHINING CENTER

(Series 15–MF/MFB) OPERATOR’S MANUAL

CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION FOR LATHE

(Series 15–TF/TTF/TFB/TTFB) OPERATOR’S MANUAL

CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION II FOR LATHE

(Series 15–TFB/TTFB) OPERATOR’S MANUAL

Tracing / Digitizing

FANUC Series 15–MB DESCRIPTIONS (Supplement for Tracing / Digitizing) B–62472E

FANUC Series 15–MB CONNECTION MANUAL (Supplement for Tracing / Digitizing) B–62473E

FANUC Series 15–MB OPERATOR’S MANUAL (Supplement for Tracing / Digitizing) B–62474E

Gas, Laser Plasma Cutting Machine

FANUC Series 15–MB DESCRIPTIONS (FOR GAS, LASER, PLASMA CUTTING MACHINE) B–62082EN–1

Multi–T eaching Function

FANUC Series 15–MB CONNECTION MANUAL (Multi–Teaching Function) B–62083E–1

Multiple–axis and Multiple–path Control Function

FANUC Series 15–TTB OPERATOR’S MANUAL

(Supplement Explanations for Multiple–axis and Multiple–path Control Function)

Specification

Number

B–61013E–4

B–61263E

B–61264E

B–61234E

B–61804E–2

B–62074E–1

p–2

Page 6

B–62082E/04

Table of Contents

DEFINITION OF WARNING, CAUTION, AND NOTE s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I. GENERAL

1. GENERAL 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. LIST OF SPECIFICATIONS 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II. NC FUNCTIONS

1. CONTROLLED AXES 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 BASIC CONTROLLED AXES 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 CONTROLLABLE AXES EXPANSION 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 BASIC SIMULTANEOUSLY CONTROLLABLE AXES 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 SIMULTANEOUSLY CONTROLLABLE AXES EXP ANSION 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 NAME OF AXES 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 PROGRAMMING AXIS NAME ADDITION 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 INCREMENT SYSTEM 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 MAXIMUM STROKE 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. PREPARATORY FUNCTIONS 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INTERPOLATION FUNCTIONS 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 POSITIONING (G00) 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 SINGLE DIRECTION POSITIONING (G60) 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 LINEAR INTERPOLATION 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 CIRCULAR INTERPOLATION (G02, G03) 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 3–DIMENSIONAL CIRCULAR INTERPOLATION FUNCTION 36. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 HELICAL INTERPOLATION (G02, G03) 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 HELICAL INTERPOLATION B (G02, G03) 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 HYPOTHETICAL AXIS INTERPOLATION (G07) 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 POLAR COORDINATE INTERPOLA TION (G12.1, G13.1) 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.10 CYLINDRICAL INTERPOLATION (G07.1) 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.11 EXPONENTIAL FUNCTION INTERPOLATION (G02.3, G03.3) 45. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12 CIRCULAR THREADING B (G02.1, G03.1) 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.13 INVOLUTE INTERPOLATION 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.14 HELICAL INVOLUTE INTERPOLATION 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.15 SPLINE INTERPOLATION 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.16 SPIRAL INTERPOLATION AND CONICAL INTERPOLATION 51. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.17 SMOOTH INTERPOLATION FUNCTION 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Page 7

T ABLE OF CONTENTS

B–62082E/04

4. THREAD CUTTING 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 EQUAL LEAD THREAD CUTTING (G33) 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 INCH THREAD CUTTING (G33) 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 CONTINUOUS THREAD CUTTING 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. FEED FUNCTIONS 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 RAPID TRAVERSE 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 CUTTING FEEDRATE 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Tangential Speed Constant Control 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Cutting Feedrate Clamp 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Per Minute Feed (G94) 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Per Revolution Feed (G95) 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.5 Inverse Time Feed (G93) 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.6 F1–digit Feed 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 OVERRIDE 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Feedrate Override 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Second Feedrate Override 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Second Feedrate Override B 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.4 Rapid Traverse Override 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.5 Function for Overriding the Rapid Traverse Feedrate in 1% Unit 62. . . . . . . . . . . . . . . . . . . . . . . .

5.3.6 Override Cancel 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 AUTOMATIC ACCELERATION/DECELERA TION 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 LINEAR ACCELERATION/DECELERA TION AFTER CUTTING FEED INTERPOLATION 64. . . .

5.6 BELL–SHAPED ACCELERATION/DECELERATION

AFTER CUTTING FEED INTERPOLATION 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 ACCELERATION/DECELERA TION BEFORE CUTTING FEED 66. . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 ACCELERA TION/DECELERATION BEFORE PRE–READ INTERPOLATION 67. . . . . . . . . . . . . .

5.9 BELL–SHAPED ACCELERATION/DECELERATION

AFTER RAPID TRAVERSE INTERPOLATION 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 CUTTING POINT SPEED CONTROL FUNCTION 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11 ACCELERATION/DECELERATION FUNCTION FOR THE CONSTANT SPEED

SPECIFIED BY THE PMC AXIS CONTROL FUNCTION 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.12 EXACT STOP (G09) 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.13 CUTTING/RAPID TRAVERSE POSITION CHECK FUNCTION 68. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.14 EXACT STOP MODE (G61) 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.15 CUTTING MODE (G64) 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.16 TAPPING MODE (G63) 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.17 AUTOMATIC CORNER OVERRIDE (G62) 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.18 DWELL (G04) 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.19 FEED PER ROTA TION WITHOUT A POSITION CODER 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. REFERENCE POSITION 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 MANUAL REFERENCE POSITION RETURN 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 AUTOMATIC REFERENCE POSITION RETURN (G28, G29) 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 REFERENCE POSITION RETURN CHECK (G27) 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 2ND, 3RD AND 4TH REFERENCE POINT RETURN (G30) 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 FLOATING REFERENCE POSITION RETURN (G30.1) 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 REFERENCE POSITION AUTOMATIC SETTING FUNCTION 75. . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 DOG–LESS REFERENCE POSITION SETTING FUNCTION 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

Page 8

B–62082E/04

T ABLE OF CONTENTS

7. COORDINATE SYSTEMS 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 MACHINE COORDINATE SYSTEM (G53) 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 WORKPIECE COORDINATE SYSTEM (G54 TO G59) 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 LOCAL COORDINATE SYSTEM (G52) 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 WORKPIECE COORDINATES SYSTEM CHANGE (G92) 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 WORKPIECE ORIGIN OFFSET VALUE CHANGE

(PROGRAMMABLE DATA INPUT) (G10) 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 ADDITIONAL WORKPIECE COORDINATE SYSTEMS (G54.1) 81. . . . . . . . . . . . . . . . . . . . . . . . . .

7.7 WORKPIECE COORDINATE SYSTEM PRESET (G92.1) 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8 PLANE SWITCHING FUNCTION 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. COORDINATE VALUE AND DIMENSION 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 ABSOLUTE AND INCREMENTAL PROGRAMMING (G90, G91) 85. . . . . . . . . . . . . . . . . . . . . . . . .

8.2 POLAR COORDINATE COMMAND (G15, G16) 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 INCH/METRIC CONVERSION (G20, G21) 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 DECIMAL POINT INPUT/POCKET CALCULATOR TYPE DECIMAL POINT INPUT 87. . . . . . . .

8.5 DIAMETER AND RADIUS PROGRAMMING 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 FUNCTION FOR SWITCHING BETWEEN DIAMETER AND RADIUS PROGRAMMING 87. . . .

9. SPINDLE FUNCTIONS 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 S CODE OUTPUT 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 SPINDLE SPEED BINARY CODE OUTPUT 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 SPINDLE SPEED ANALOG OUTPUT 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 CONSTANT SURFACE SPEED CONTROL (G96, G97) 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 SPINDLE SPEED CLAMP (G92) 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6 ACTUAL SPINDLE SPEED OUTPUT 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7 SPINDLE POSITIONING 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8 SPINDLE SPEED FLUCTUATION DETECTION (G25, G26) 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. TOOL FUNCTIONS 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 T CODE OUTPUT 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 TOOL LIFE MANAGEMENT 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. MISCELLANEOUS FUNCTIONS 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 MISCELLANEOUS FUNCTIONS 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 SECOND MISCELLANEOUS FUNCTIONS 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 HIGH–SPEED M/S/T/B INTERFACE 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 1–BLOCK PLURAL M COMMAND 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12. PROGRAM CONFIGURATION 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 PROGRAM NUMBER 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 PROGRAM NAME 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3 PROGRAM NAME (48 CHARACTERS) 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4 MAIN PROGRAM 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.5 SUB PROGRAM 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

Page 9

T ABLE OF CONTENTS

12.6 SEQUENCE NUMBER 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.7 TAPE CODES 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.8 BASIC ADDRESSES AND COMMAND VALUE RANGE 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.9 COMMAND FORMAT 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.10 LABEL SKIP 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.11 CONTROL–IN/CONTROL–OUT 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.12 OPTIONAL BLOCK SKIP 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.13 ADDITIONAL OPTIONAL BLOCK SKIP 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–62082E/04

13. FUNCTIONS TO SIMPLIFY PROGRAMMING 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 CANNED CYCLES(G73, G74, G76, G80–G89, G98, G99) 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2 RIGID TAPPING (G84.2, G84.3) 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.3 EXTERNAL OPERATION FUNCTION (G80, G81) 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4 OPTIONAL ANGLE CORNER ROUNDING 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5 OPTIONAL ANGLE CHAMFERING 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.6 CIRCULAR INTERPOLATION BY RADIUS PROGRAMMING 112. . . . . . . . . . . . . . . . . . . . . . . . . .

13.7 PROGRAMMABLE MIRROR IMAGE (G50.1, G51.1) 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.8 INDEX TABLE INDEXING 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.9 FIGURE COPYING (G72.1, G72.2) 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.10 CIRCLE CUTTING FUNCTION 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14. COMPENSATION FUNCTIONS 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 TOOL LENGTH COMPENSATION (G43, G44, G49) 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2 TOOL OFFSET (G45, G46, G47, G48) 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3 CUTTER COMPENSATION 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.1 Cutter Compensation B (G40 – 42) 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.2 Cutter Compensation C (G40 – G42) 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4 3–DIMENSIONAL TOOL COMPENSATION (G40, G41) 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.5 TOOL OFFSET BY TOOL NUMBER 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.6 TOOL COMPENSATION MEMORY 126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.6.1 Tool Compensation Memory A 126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.6.2 Tool Compensation Memory B 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.6.3 Tool Compensation Memory C 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.7 NUMBER OF TOOL OFFSETS 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.8 CHANGING OF TOOL OFFSET AMOUNT (PROGRAMMABLE DATA INPUT) (G10) 128. . . . . .

14.9 ROTARY TABLE DYNAMIC FIXTURE OFFSET 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.10 THREE–DIMENSIONAL CUTTER COMPENSATION 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.11 DESIGNATION DIRECTION TOOL LENGTH COMPENSATION 131. . . . . . . . . . . . . . . . . . . . . . . .

15. ACCURACY COMPENSATION FUNCTION 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1 STORED PITCH ERROR COMPENSATION 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.2 INTERPOLATION TYPE PITCH ERROR COMPENSATION 133. . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3 THE SECOND CYLINDRICAL PITCH ERROR COMPENSATION METHOD 134. . . . . . . . . . . . . .

15.4 INCLINATION COMPENSATION 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.5 STRAIGHTNESS COMPENSATION 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.6 BACKLASH COMPENSATION 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–4

Page 10

B–62082E/04

15.7 PROGRAMMABLE PARAMETER ENTRY (G10, G11) 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.8 INTERPOLATION–TYPE STRAIGHTNESS COMPENSATION 137. . . . . . . . . . . . . . . . . . . . . . . . . .

15.9 STRAIGHTNESS COMPENSATION A T 128–POINT 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.10 BI–DIRECTIONAL PITCH ERROR COMPENSATION FUNCTION 137. . . . . . . . . . . . . . . . . . . . . . .

T ABLE OF CONTENTS

16. COORDINATE SYSTEM CONVERSION 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.1 AXIS SWITCHING 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2 SCALING (G50, G51) 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3 COORDINATE SYSTEM ROTATION (G68, G69) 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.4 THREE–DIMENSIONAL COORDINATE CONVERSION 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17. MEASUREMENT FUNCTIONS 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.1 SKIP FUNCTION (G31) 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.2 MULTI–STEP SKIP FUNCTION (G31.1 – G31.3) 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.3 HIGH–SPEED SKIP SIGNAL INPUT 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.4 SKIPPING THE COMMANDS FOR SEVERAL AXES 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.5 AUTOMATIC TOOL LENGTH MEASUREMENT (G37) 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.6 HIGH–SPEED MEASURING POSITION REACH SIGNAL INPUT 149. . . . . . . . . . . . . . . . . . . . . . .

17.7 TOOL LENGTH MEASUREMENT 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.8 TOOL LENGTH/WORKPIECE ZERO POINT MEASUREMENT B 150. . . . . . . . . . . . . . . . . . . . . . .

17.9 TORQUE LIMIT SKIP 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18. CUSTOM MACRO 152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.1 CUSTOM MACRO 153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.2 NUMBER OF COMMON VARIABLES 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.3 READ/PUNCH FUNCTION FOR CUSTOM MACRO COMMON VARIABLES 162. . . . . . . . . . . . .

18.4 INTERRUPTION TYPE CUSTOM MACRO 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.5 KEY AND PROGRAM ENCRYPTION 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19. FUNCTIONS FOR HIGH SPEED CUTTING 164. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.1 HIGH SPEED MACHINING (G10.3, G11.3, G65.3) 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.2 MULTI–BUFFER (G05.1) 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.3 AUTOMATIC CORNER DECELERATION 166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.4 FEEDRATE CLAMP BY CIRCULAR RADIUS 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.5 ADVANCED PREVIEW CONTROL FUNCTION 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.6 HIGH–PRECISION CONTOUR CONTROL 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.7 FEED FORWARD CONTROL 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.8 HIGH–SPEED DISTRIBUTION BY DNC OPERATION USING REMOTE BUFFER 170. . . . . . . . .

19.9 BINARY DATA INPUT OPERATION BY REMOTE BUFFER 171. . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.10 DISTRIBUTION PROCESS BY REMOTE BUFFER 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.11 HIGH–PRECISION CONTOUR CONTROL USING 64–BIT RISC PROCESSOR 174. . . . . . . . . . . .

20. AXES CONTROL 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.1 FOLLOW UP FUNCTION 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.2 FOLLOW–UP FOR EACH AXIS 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.3 MECHANICAL HANDLE FEED 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–5

Page 11

T ABLE OF CONTENTS

20.4 SERVO OFF 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.5 MIRROR IMAGE 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.6 CONTROL AXIS DETACH 177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.7 SIMPLE SYNCHRONOUS CONTROL 177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.8 FEED STOP 178. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.9 ARBITRAR Y COMMAND MULTIPLY (CMR) 178. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.10 TWIN TABLE CONTROL 179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.11 SIMPLE SYNCHRONIZATION CONTROL POSITIONAL DEVIATION

CHECK FUNCTION 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.12 NORMAL DIRECTION CONTROL (G41.1, G42.1) 181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.13 CHOPPING FUNCTION (G81.1) 182. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.14 AXIS CONTROL WITH PMC 183. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.15 UPGRADED 5–AXIS CONTROL COMPENSATION PARAMETER 184. . . . . . . . . . . . . . . . . . . . . . .

20.16 ROLL–OVER FUNCTION FOR A ROTA TION AXIS 184. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.17 TWO AXES ELECTRONIC GEAR BOX 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.18 SKIP FUNCTION FOR EGB AXIS 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.19 ELECTRONIC GEARBOX AUTOMATIC PHASE SYNCHRONIZATION 187. . . . . . . . . . . . . . . . . .

B–62082E/04

21. AUTOMATIC OPERATION 188. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.1 OPERATION MODE 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.1.1 Tape Operation 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.1.2 Memory Operation 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.1.3 MDI Operation 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.2 SELECTION OF EXECUTION PROGRAMS 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.2.1 Program Number Search 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.2.2 Program Search with Program Names 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.2.3 Sequence Number Search 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.2.4 Rewind 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.3 ACTIVATION OF AUTOMATIC OPERATION 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.3.1 Cycle Start 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.4 EXECUTION OF AUTOMATIC OPERATION 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.4.1 Buf fer Register 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.5 AUTOMATIC OPERATION STOP 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.5.1 Program Stop (M00, M01) 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.5.2 Program End (M02, M30) 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.5.3 Sequence Number Comparison and Stop 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.5.4 Feed Hold 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.5.5 Reset 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.6 RESTART OF AUTOMATIC OPERATION 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.6.1 Program Restart 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.6.2 Program Reset Function and Output of M, S, T, and B, Codes 192. . . . . . . . . . . . . . . . . . . . . . . . .

21.6.3 Restart of Block 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.6.4 Tool Retract & Recover 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.7 MANUAL INTERRUPTION DURING AUTOMATIC OPERATION 196. . . . . . . . . . . . . . . . . . . . . . .

21.7.1 Handle Interruption 196. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.7.2 Automatic/Manual Simultaneous Operation 196. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.8 RETRACE 197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.9 ACTIVE BLOCK CANCEL 198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.10 TRANSVERSE INHIBIT LIMIT FUNCTION 198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–6

Page 12

B–62082E/04

T ABLE OF CONTENTS

22. MANUAL OPERATION 199. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.1 MANUAL FEED 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.2 INCREMENTAL FEED 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.3 MANUAL HANDLE FEED (1ST) 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.4 MANUAL HANDLE FEED (2ND, 3RD) 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.5 MANUAL ARBITRARY ANGLE FEED 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.6 MANUAL NUMERIC COMMAND 202. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.7 MANUAL ABSOLUTE ON/OFF 202. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.8 MANUAL INTERRUPTION FUNCTION FOR THREE–DIMENSIONAL

COORDINATE SYSTEM CONVERSION 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.9 STORED STROKE LIMIT CHECK IN MANUAL OPERATION 203. . . . . . . . . . . . . . . . . . . . . . . . . .

23. PROGRAM TEST FUNCTIONS 204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.1 ALL AXES MACHINE LOCK 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.2 MACHINE LOCK ON EACH AXIS (Z AXIS COMMAND CANCEL) 205. . . . . . . . . . . . . . . . . . . . .

23.3 AUXILIARY FUNCTION LOCK 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.4 DRY RUN 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.5 SINGLE BLOCK 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.6 RETRACE PROGRAM EDITING FUNCTION 206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24. SETTING AND DISPLAY UNIT 208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.1 SETTING AND DISPLAY UNIT 209. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.2 EXPLANATION OF THE KEYBOARD 210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.3 SOFT KEYS AND CALCULATION KEYS 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.4 MANUAL DATA INPUT (MDI) 215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.5 DISPLAY 216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.6 LANGUAGE SELECTION 219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.7 CLOCK FUNCTION 220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.8 RUN HOUR & PARTS NUMBER DISPLAY 220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.9 LOAD METER DISPLAY 221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.10 MENU SWITCH 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.11 SOFTWARE OPERATOR’S PANEL 223. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.12 GRAPHIC DISPLAY FUNCTION 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.13 NC FORMAT GUIDANCE 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.14 NC FORMAT GUIDANCE WITH PICTURE 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.15 SIMPLE CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION 226. . . . . . . . . . . . . . .

24.16 DAT A PROTECTION KEY 227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.17 DIRECTORY DISPLAY OF FLOPPY CASSETTE/PROGRAM FILE 227. . . . . . . . . . . . . . . . . . . . . . .

24.18 MACHINING TIME STAMP FUNCTION 228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.19 DIRECTORY DISPLAY AND PUNCHING ON EACH GROUP 229. . . . . . . . . . . . . . . . . . . . . . . . . . .

24.20 FUNCTION FOR DISPLAYING MULTIPLE SUBSCREENS 230. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.21 HELP FUNCTION 231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.22 PARAMETER SETTING (RS–232–C) SCREEN 231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.23 SCREEN FOR SPECIFYING HIGH–SPEED AND HIGH–PRECISION MACHINING 231. . . . . . . .

24.24 OPERATION HISTORY 232. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.25 WAVEFORM DIAGNOSIS FUNCTION 233. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–7

Page 13

T ABLE OF CONTENTS

24.26 CR T SCREEN SAVING FUNCTION 234. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.27 M–CODE GROUP FUNCTION 234. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.28 WORKPIECE ZERO POINT MANUAL SETTING FUNCTION 234. . . . . . . . . . . . . . . . . . . . . . . . . . .

24.29 SCREEN SAVER FUNCTION 235. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–62082E/04

25. PART PROGRAM STORAGE AND EDITING 236. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.1 FOREGROUND EDITING 237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.2 BACKGROUND EDITING 237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.3 EXPANDED PART PROGRAM EDITING 238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.4 NUMBER OF REGISTERED PROGRAMS 238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.5 PART PROGRAM STORAGE LENGTH 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.6 PLAY BACK 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.7 OVERRIDE PLAY BACK 241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.8 EXTERNAL I/O DEVICE CONTROL 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.9 HIGH–SPEED PART PROGRAM REGISTRATION FUNCTION 242. . . . . . . . . . . . . . . . . . . . . . . . . .

25.10 FUNCTION SELECTION WITH HARD KEYS 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.11 MULTI–EDIT FUNCTION 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26. DIAGNOSIS FUNCTIONS 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.1 SELF DIAGNOSIS FUNCTIONS 244. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.2 TROUBLE DIAGNOSIS GUIDANCE 244. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27. DATA INPUT/OUTPUT 246. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.1 TAPE READER 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.1.1 Tape Reader without Reels 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.1.2 Tape Reader with Reels 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.2 READER/PUNCHER INTERF ACES 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.3 INPUT/OUTPUT DEVICES 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.3.1 FANUC FLOPPY CASSETTE 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.3.2 Portable Tape Reader 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.3.3 FANUC PROGRAM FILE Mate 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.3.4 FANUC Handy File 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28. SAFETY FUNCTIONS 249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.1 EMERGENCY STOP 250. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.2 OVER TRAVEL FUNCTIONS 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.2.1 Overtravel 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.2.2 Stored Stroke Check 1 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.2.3 Stored Stroke Check 2 (G22, G23) (M Series) 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.2.4 Stroke Check before Move 252. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.3 INTERLOCK 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.3.1 Interlock per Axis 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.3.2 All Axes Interlock 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.3.3 Automatic Operation All Axes Interlock 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.3.4 Block Start Interlock 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.3.5 Cutting Block Start Interlock 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.4 EXTERNAL DECELERATION 254. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.5 UNEXPECTED DISTURBANCE TORQUE DETECTION FUNCTION 255. . . . . . . . . . . . . . . . . . . .

c–8

Page 14

B–62082E/04

T ABLE OF CONTENTS

29. STATUS OUTPUT 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.1 NC READY SIGNAL 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.2 SERVO READY SIGNAL 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.3 REWINDING SIGNAL 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.4 ALARM SIGNAL 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.5 DISTRIBUTION END SIGNAL 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.6 AUTOMATIC OPERATION SIGNAL 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.7 AUTOMATIC OPERATION START LAMP SIGNAL 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.8 FEED HOLD SIGNAL 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.9 RESET SIGNAL 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.10 INPOSITION SIGNAL 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.11 MOVE SIGNAL 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.12 AXIS MOVE DIRECTION SIGNAL 259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.13 RAPID TRAVERSING SIGNAL 259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.14 TAPPING SIGNAL 259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.15 THREAD CUTTING SIGNAL 259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.16 CONSTANT SURFACE SPEED CONTROL SIGNAL 259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.17 INCH INPUT SIGNAL 259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.18 DI STA TUS OUTPUT SIGNAL 259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30. EXTERNAL DATA INPUT/OUTPUT 260. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.1 EXTERNAL TOOL COMPENSATION 261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.2 EXTERNAL PROGRAM NUMBER SEARCH 261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.3 EXTERNAL SEQUENCE NUMBER SEARCH 261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.4 EXTERNAL WORKPIECE COORDINATE SYSTEM SHIFT 261. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.5 EXTERNAL MACHINE COORDINATE SYSTEM COMPENSATION 262. . . . . . . . . . . . . . . . . . . . .

30.6 EXTERNAL ALARM MESSAGE 262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.7 EXTERNAL OPERATORS MESSAGE 262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.8 EXTERNAL CUSTOM MACRO VARIABLE VALUE INPUT 262. . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.9 EXTERNAL TOOL OFFSET AMOUNT OUTPUT 262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.10 EXTERNAL PROGRAM NUMBER OUTPUT 262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.11 EXTERNAL SEQUENCE NUMBER OUTPUT 263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.12 EXTERNAL WORKPIECE COORDINATE SYSTEM SHIFT AMOUNT OUTPUT 263. . . . . . . . . . .

30.13 EXTERNAL MACHINE COORDINATE SYSTEM COMPENSATION AMOUNT OUTPUT 263. . .

30.14 EXTERNAL CUSTOM MACRO VARIABLE VALUE OUTPUT 263. . . . . . . . . . . . . . . . . . . . . . . . . .

31. EXTERNAL WORKPIECE NUMBER SEARCH 264. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32. MACHINE INTERFACE 265. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32.1 BASIC MACHINE INTERFACE (BMI) 266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32.2 3M INTERF ACE 266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32.3 6M INTERF ACE 266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–9

Page 15

T ABLE OF CONTENTS

B–62082E/04

33. PROGRAMMABLE MACHINE CONTROLLER (PMC–NA/NB) 267. . . . . . . . . . . . . . . . .

33.1 PMC INSTRUCTION 268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33.2 NC WINDOW 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33.3 NC WINDOW B 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33.4 KEY INPUT FROM PMC 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33.5 OUTPUT AND SETTING OF PMC PARAMETERS 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34. MAN MACHINE CONTROL (MMC) (ONLY 150–MB) 272. . . . . . . . . . . . . . . . . . . . . . . . . .

34.1 HARDWARE SPECIFICATIONS 273. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34.2 SOFTWARE SPECIFICATIONS 274. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34.3 MMC/CNC WINDOW 275. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34.4 MMC/PMC WINDOW 276. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35. CONTROL UNIT 277. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35.1 CONTROL UNIT 278. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35.2 POWER SUPPLY 278. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35.3 ENVIRONMENTAL CONDITIONS 278. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

36. SERVO 279. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37. POSITION DETECTOR 280. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38. SPINDLE 281. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

39. MACHINE INTERFACE 282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40. POSITION SWITCHING FUNCTION 283. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX

A. RANGE OF COMMAND VALUE 287. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. FUNCTIONS AND COMMAND FORMAT LIST 292. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. LIST OF TAPE CODE 297. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. EXTERNAL DIMENSIONS BASIC UNIT 299. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. EXTERNAL DIMENSIONS CRT/MDI UNIT 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F. EXTERNAL DIMENSIONS OF EACH UNIT 322. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G. POWER SUPPLY AND HEAT LOSS 334. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–10

Page 16

I. GENERAL

Page 17

B–62082E/04

1

GENERAL

GENERAL

To achieve high–speed, highly accurate, and highly efficient processes

required for future machining needs, the Series 15, an advanced industrial

computer, was developed as the high–grade AI–CNC.

It uses surface–mounted electronic parts to enable the control unit to be

made compact and the high–speed multi–master bus (FANUC BUS) to

standardize all the printed– circuit boards for providing a series of systems

in different sizes from small to large.

The sophisticated functions such as the world’s fastest CNC function

using a 32–bit microprocessor, high–speed and highly accurate digital

servo system, and high–speed PMC function provided with the newly

developed processor dedicated to PMC allow great enhancement of

machining throughput. The high–grade AI–CNC has AI functions such

as intelligent failure diagnosis guidance which allow full use of the user’s

know–how.

The 15–MB with the addition of a man–machine control (MMC) function

which enables the incorporation of a high level man–machine interface.

1. GENERAL

3

Page 18

2. LIST OF SPECIFICATIONS

LIST OF SPECIFICATIONS

2

GENERAL

Series 15 has the basic machine interface (BMI), FS3 interface and the

FS6 interface and there are some limitations on functions depending on

the machine interfaces.

The specification list also informs which functions are effective for each

machine interface.

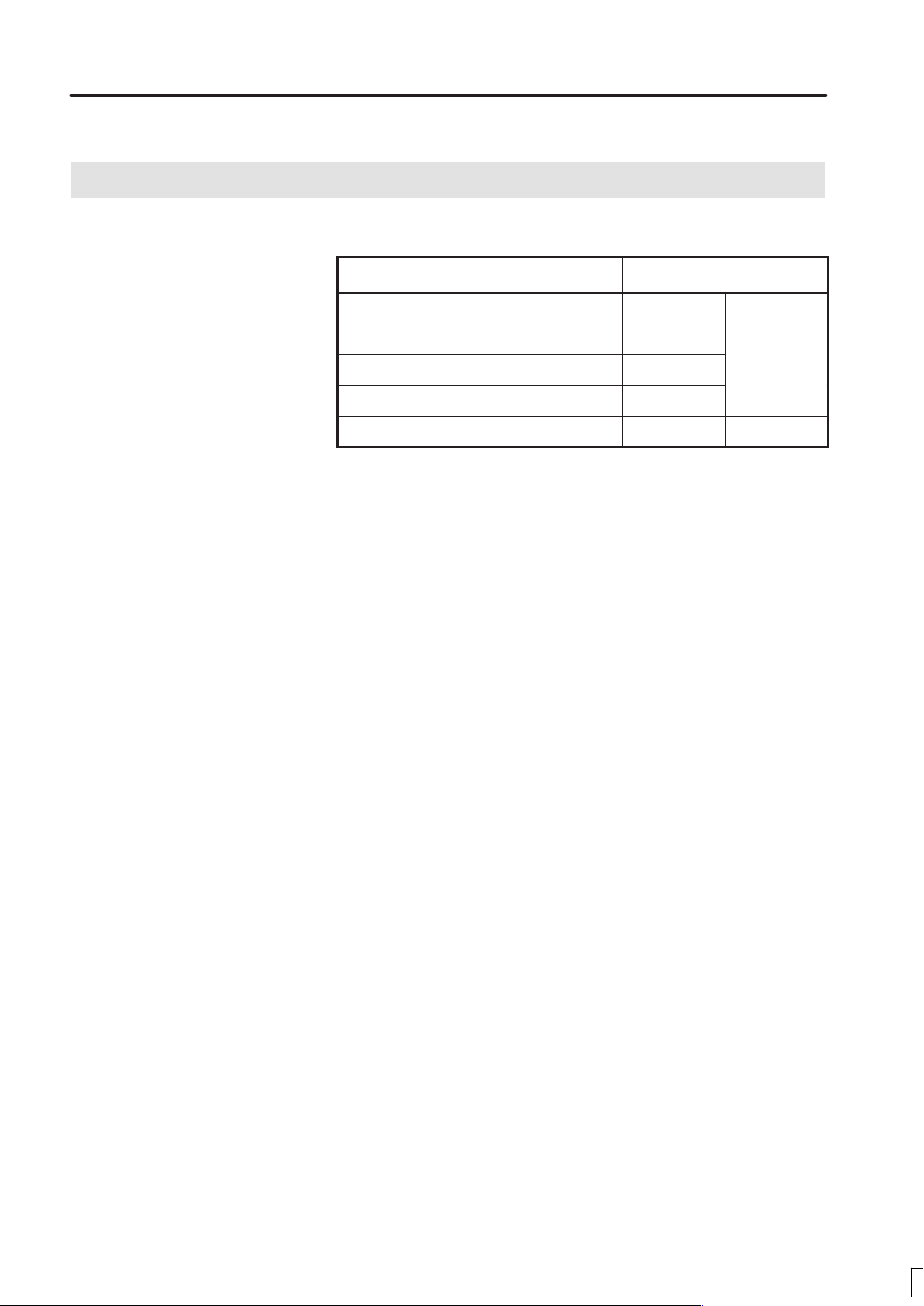

The features of CNCs mentioned here are classified as in the following

table and the lists of specifications are written according to this

classification.

Classification of specification T able No. of specification list

Standard specification Table 2 (a)

B–62082E/04

Optional specification Table 2 (b)

Detailed explanations of each function is mentioned in an item of the text

indicated in the specification list.

1) List of standard specification

The list indicates the standard features.

2) List of optional specification

The list indicated features which can be added to the standard features.

See DESCRIPTIONS (Supplement for Tracong/Digitizing) (B–62472E)

of FANUC Series 15–MB for the following functions.

D Tracing functions

D Digitizing functions

See DESCRIPTIONS (B–62082EN–1) (For Gas, Laser, Plasma Cutting

Machine) of FANUC Series 15–MB for the following functions.

D Automatic exact stop check

D Gradual curve cutting

D Torch swivel control function

D Error detect function

D Prallel axis control function

D Accelerating/decelerating signal

D Background graphic display

4

Page 19

B–62082E/04

item

GENERAL

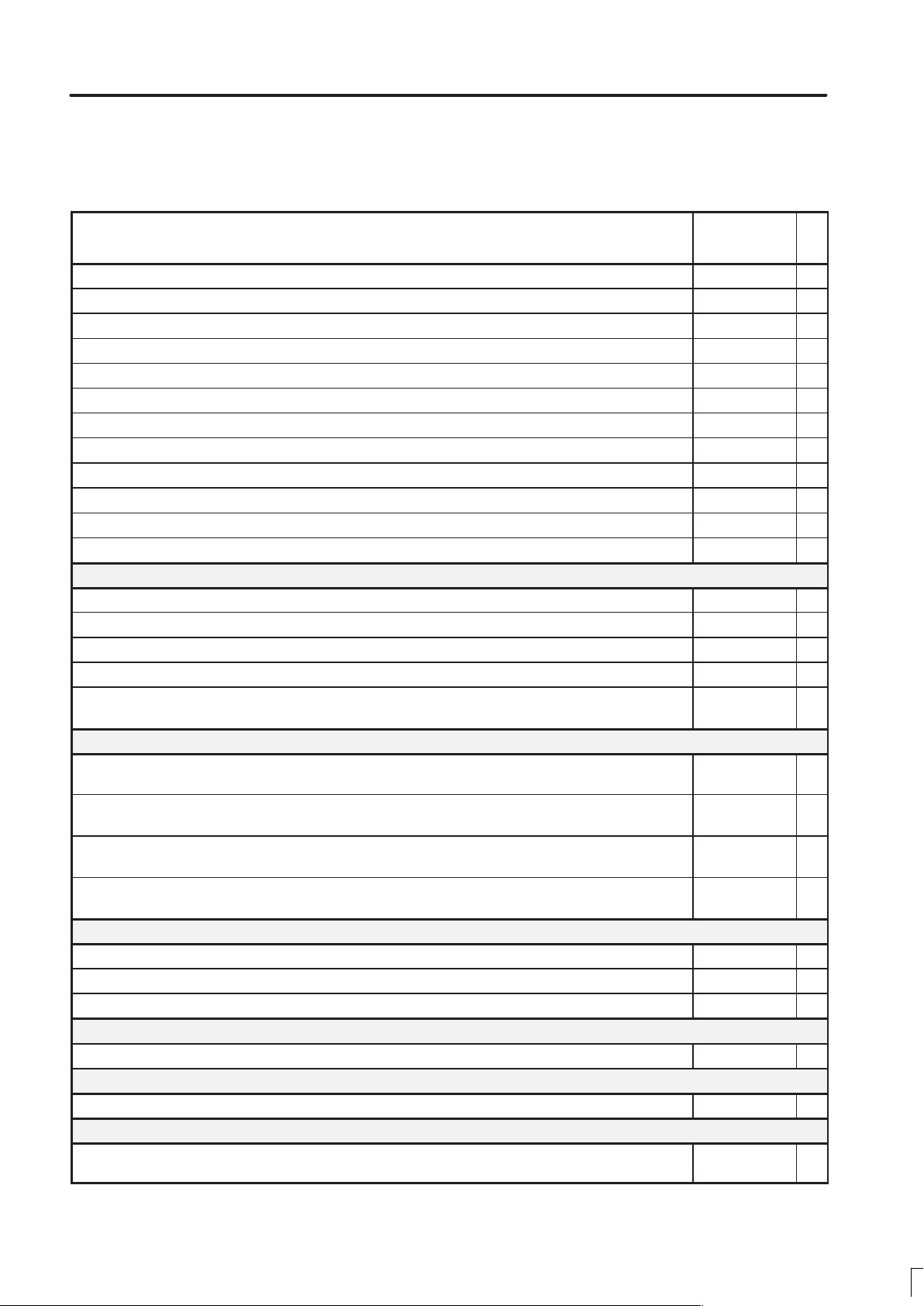

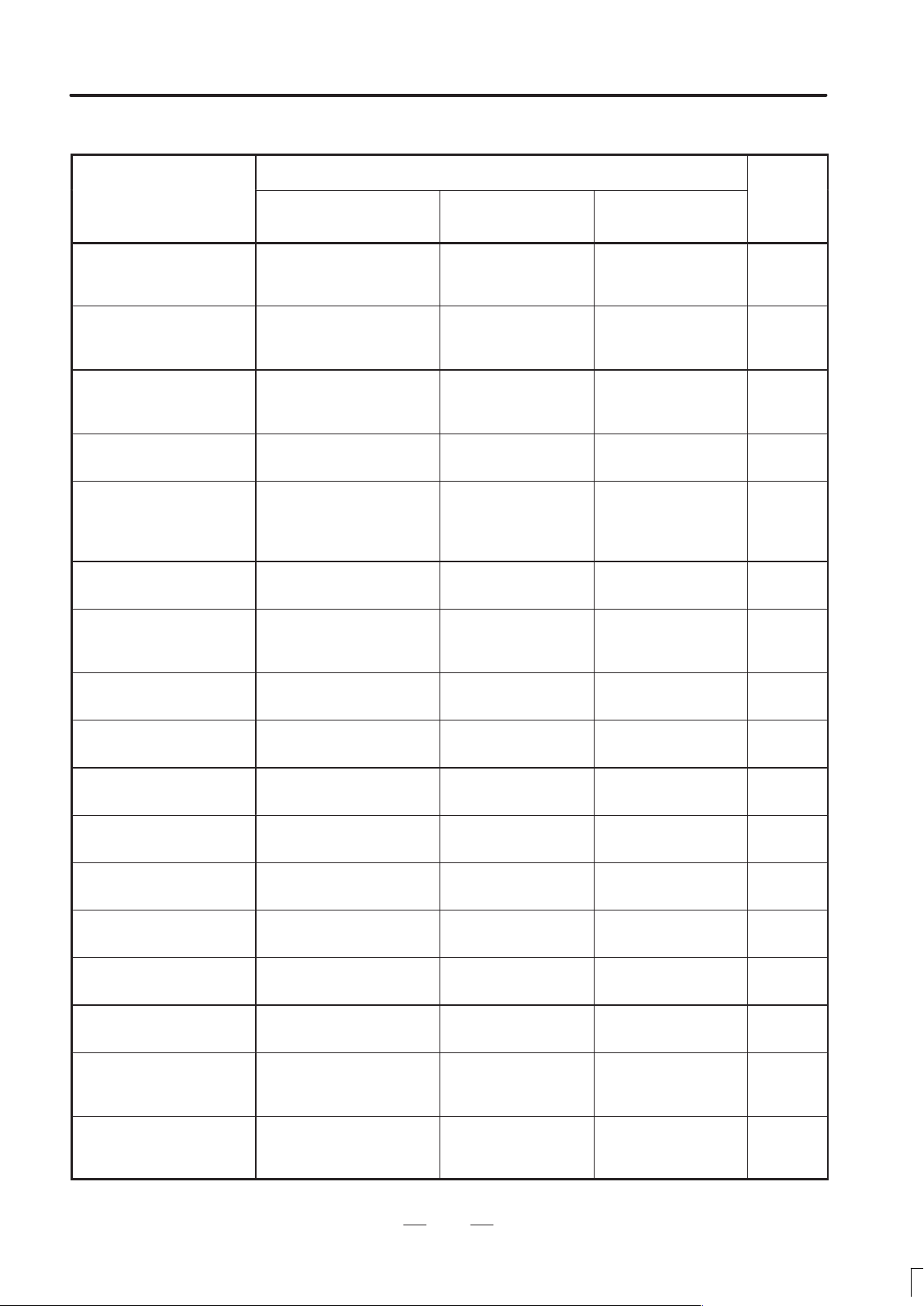

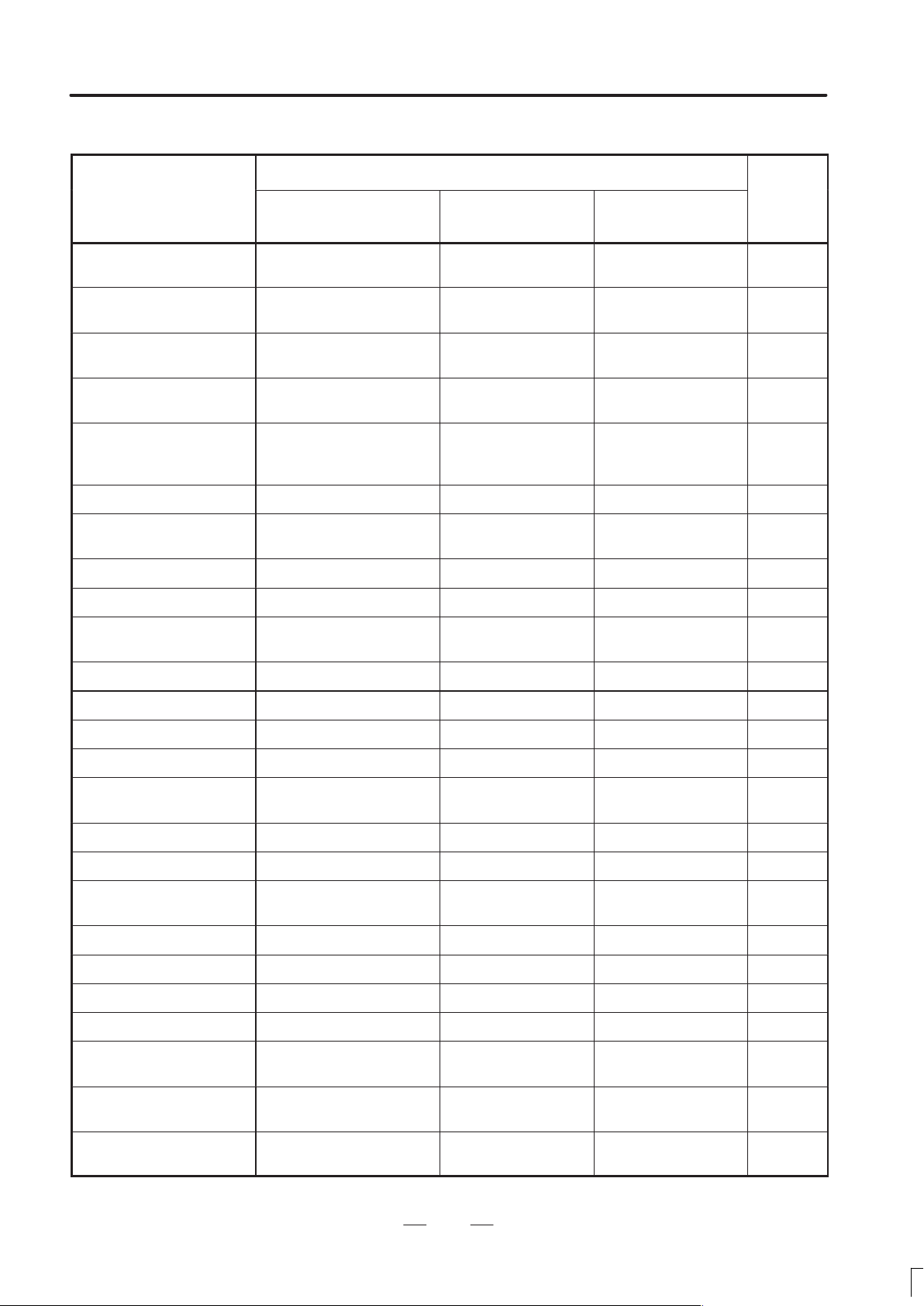

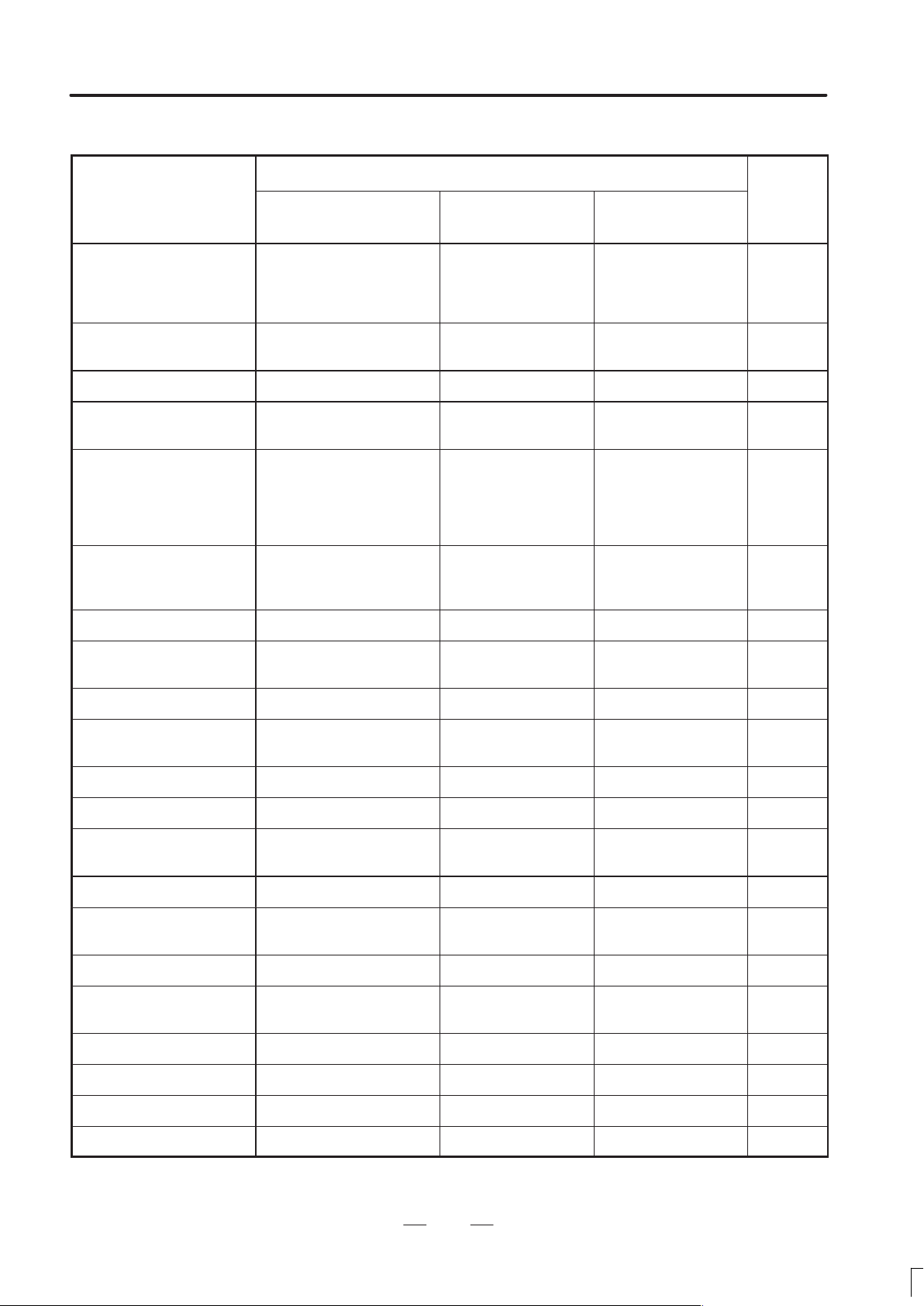

Table 2 (a) Standard specification (1/6)

2. LIST OF SPECIFICATIONS

Items

Basic machine

interface (BMI)

Controlled axis 3 axes

(2 axes also possible)

Simultaneous controllable

axes

Axis name Optional from

X, Y, Z, U, V, W, A, B, C

Increment system 0.01, 0.001, 0.0001 mm

0.001, 0.0001, 0.00001 inch

Interpolation unit 0.005, 0.0005,

0.00005 mm, 0.0005,

0.00005, 0.000005 inch

Maximum commandable

value

High resolution detection

interface

Positioning Linear interpolation type

positioning is also available

2 axes Same as left Same as left II 1.3

8 digits Same as left Same as left Appendix

YES YES YES

Functions

3M interface 6M interface

Same as left Same as left II 1.1

Same as left Same as left II 1.5

Same as left Same as left II 1.7

Same as left Same as left Appendix

Same as left Same as left II 3.1

Reference

A

A

Linear interpolation YES YES YES II 3.3

Multi–quadrant circuit

interpolation

Rapid traverse rate YES YES YES II 5.1

Tangential speed constant

control

Cutting feedrate clamp For each axis Same as left Same as left II 5.2.2

Feed per minute YES YES YES II 5.2.3

Feedrate override 0–254%

Rapid traverse override F0, F1, 50%, 100% Same as left Same as left II 5.3.4

Function for overriding the

rapid traverse feedrate in

1% units

Automatic acceleration/

deceleration

Rapid traverse:

Linear acceleration/deceleration

Cutting feed:

Exponential acceleration/

deceleration

YES YES YES II 3.4

YES YES YES II 5.2.1

0–150%

1% step

YES YES YES II 5.3.5

10% step

Same as left Same as left II 5.4

0–200%

10% step

II 5.3.1

Linear acceleration/

deceleration after cutting

feed interpolation

YES YES YES II 5.5

5

Page 20

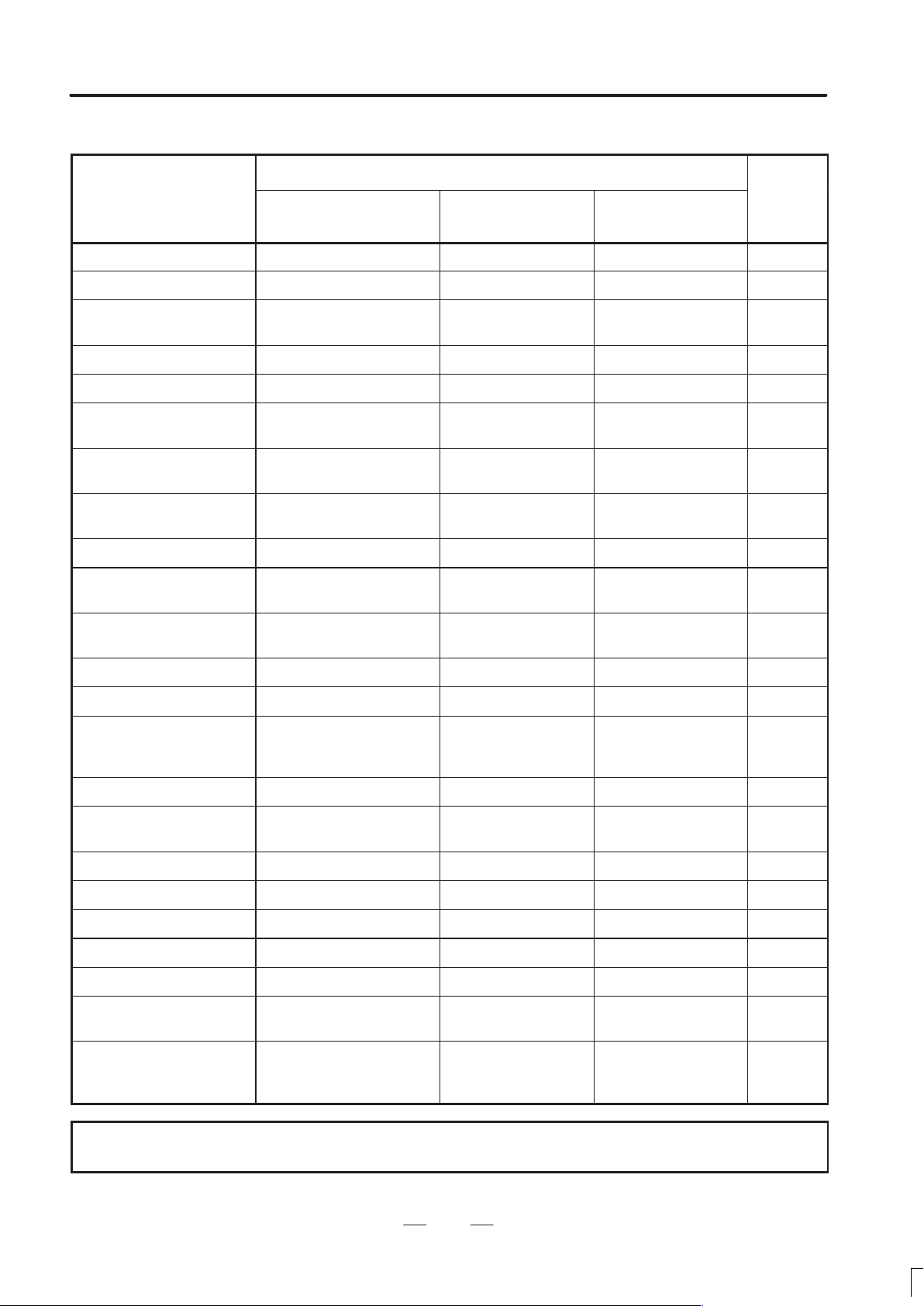

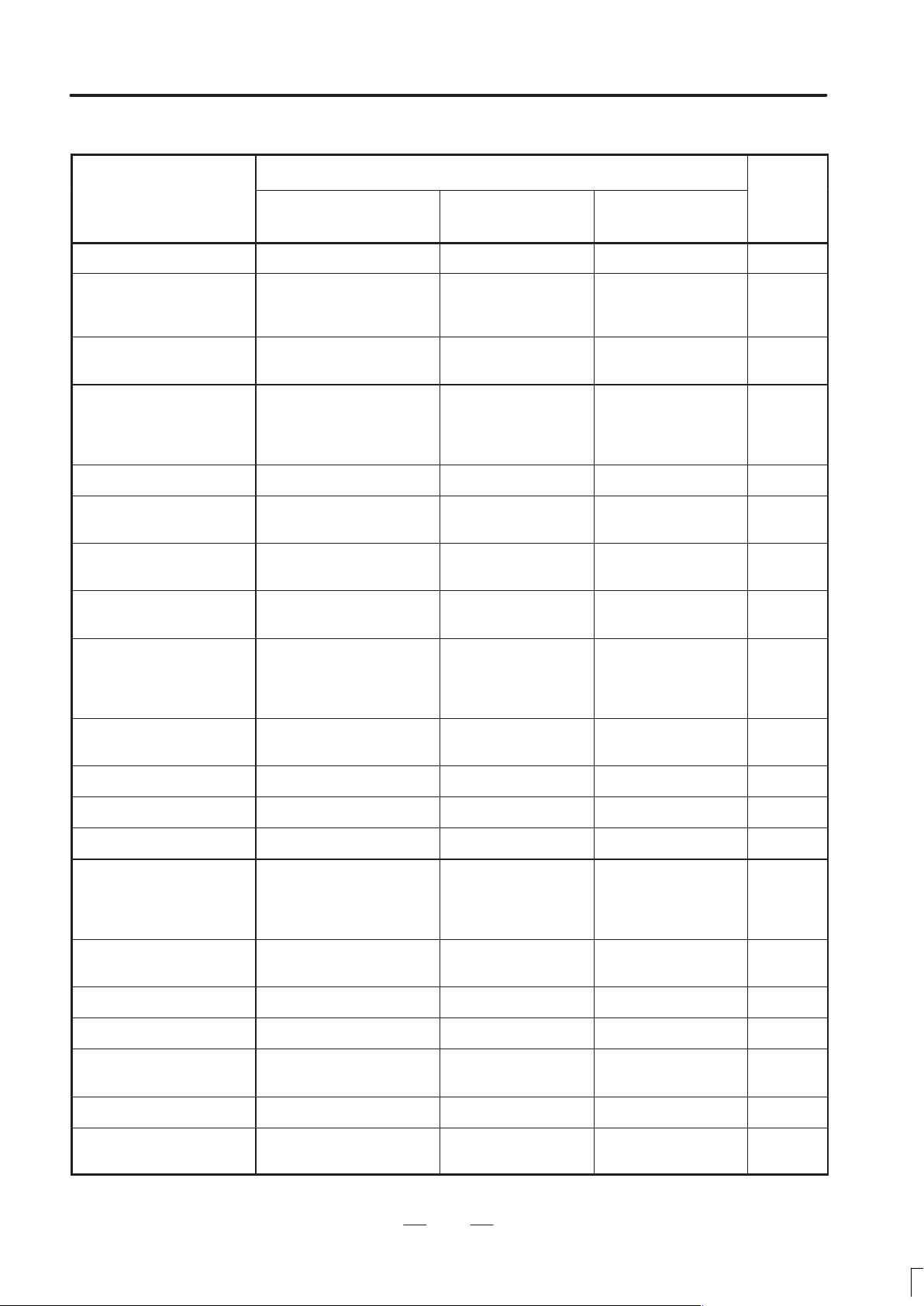

2. LIST OF SPECIFICATIONS

GENERAL

Table 2 (a) Standard specification (2/6)

B–62082E/04

Items Reference

interface (BMI)

Acceleration/deceleration

before cutting feed

interpolation

Acceleration/deceleration

prior to pre–read

interpolation

Bell–shaped acceleration/

deceleration after rapid

traverse interpolation

Cutting/rapid traverse

position check function

Exact stop,

Exact stop mode

Cutting mode

Tapping mode

Dwell Per second dwell and per

YES YES YES II 5.7

YES YES YES II 5.8

YES YES YES II 5.9

YES YES YES II 5.13

YES YES

revolution dwell

FunctionsItems Reference

item

item

6M interface3M interfaceBasic machine

YES II 5.14–

(Tapping mode signal

is not available)

Same as left Same as left II 5.18

5.16

Reference position return Manual, automatic

(G27, G28, G29)

Reference position

automatic setting function

Dog–less reference

position setting function

Machine coordinate system

selection (G53)

Workpiece coordinate

system selection (G54–G59)

Local coordinate system

setting (G52)

Workpiece coordinate

system change (G92)

Workpiece coordinate

system presetting

Absolute/incremental

programming

Decimal point input/pocket

calculator type decimal

point input

Can be combined in the

YES NO NO II 6.6

YES YES YES II 6.7

YES YES YES II 7.1

YES YES YES II 7.2

YES YES YES II 7.3

YES YES YES II 7.4

YES YES YES II 7.7

same block

YES YES YES II 8.4

Same as left Same as left II 6.1

II 6.2

II 6.3

Same as left Same as left II 8.1

Function for switching

between diameter and

radius programming

YES YES YES II 8.6

6

Page 21

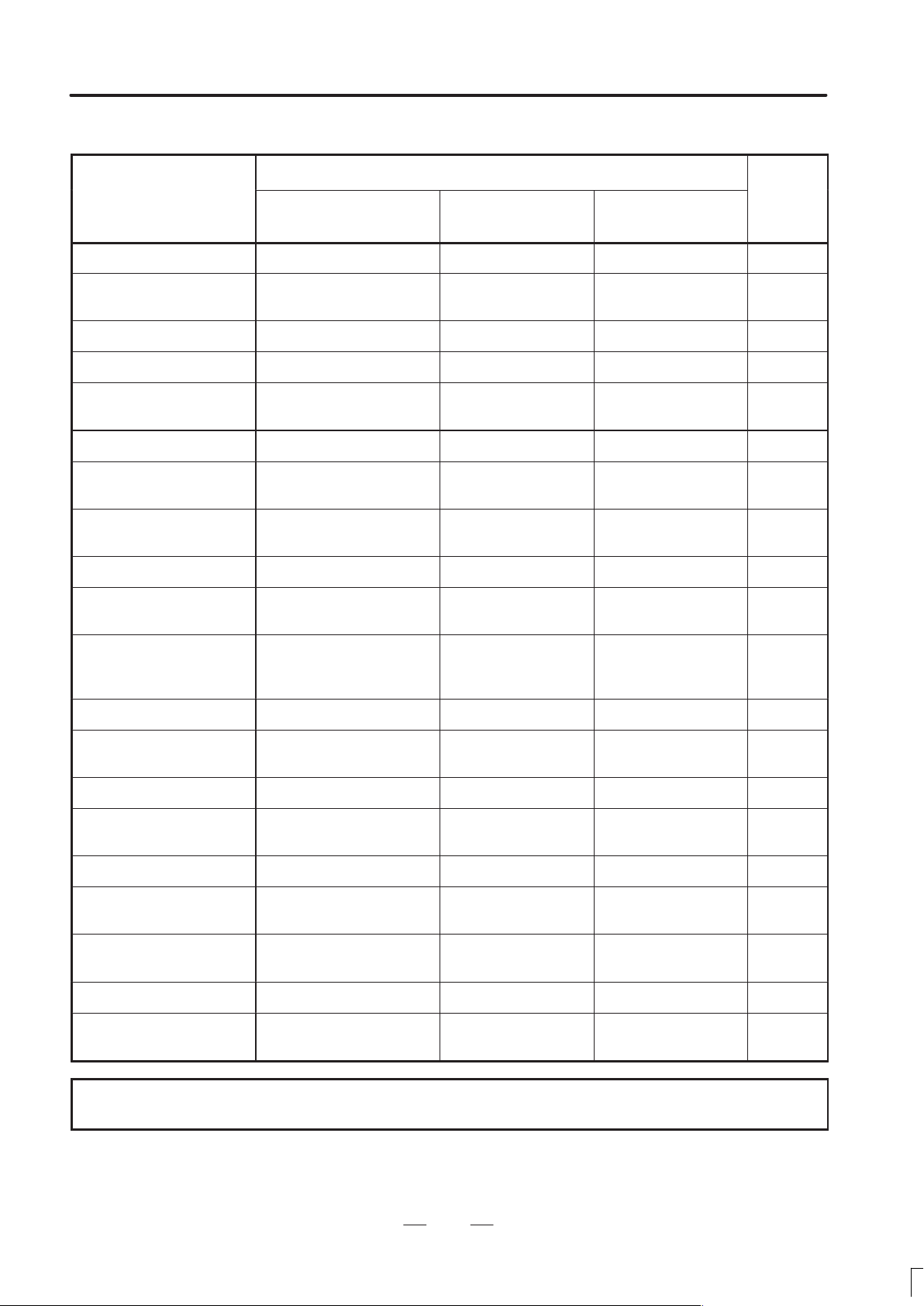

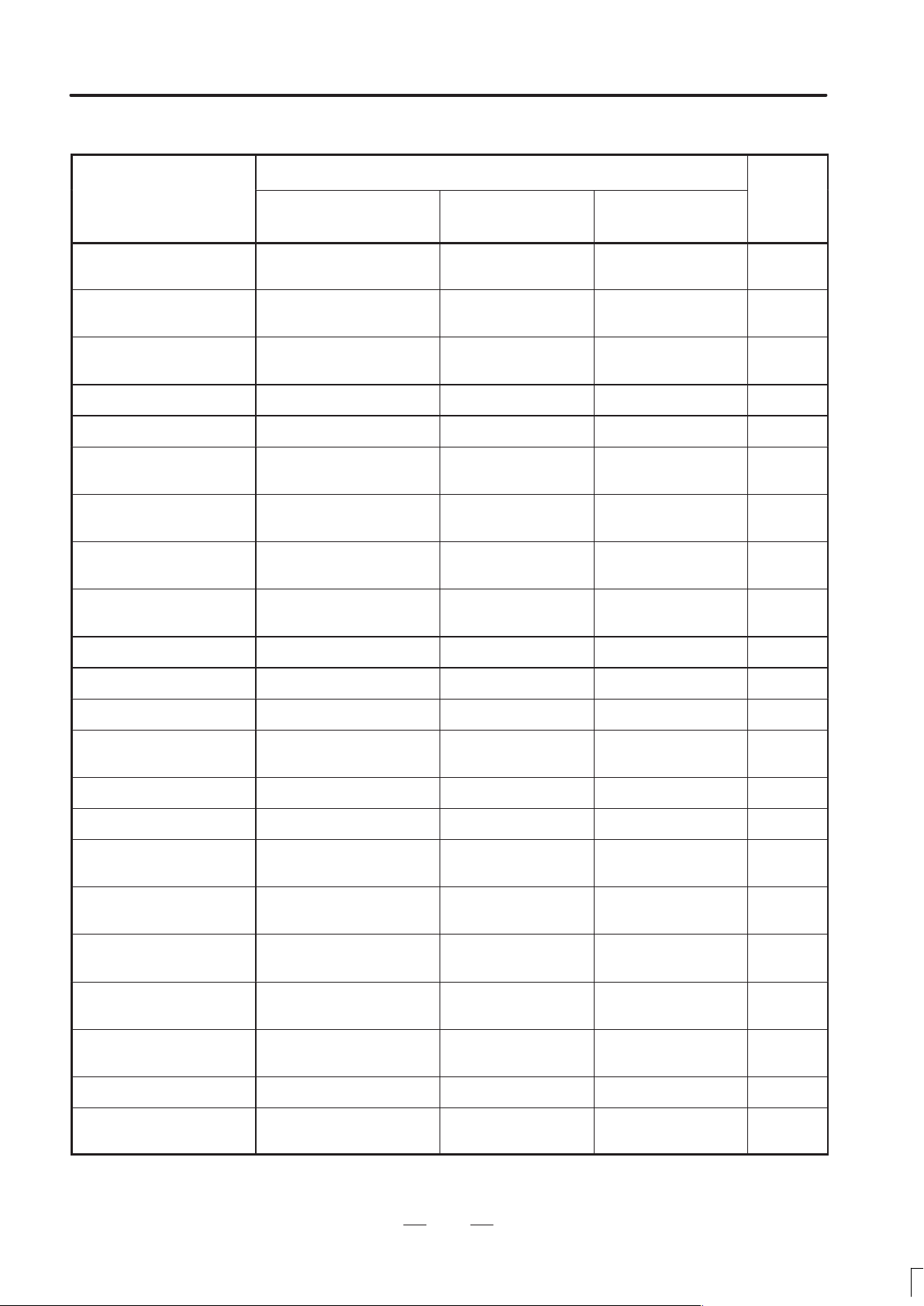

B–62082E/04

GENERAL

Table 2 (a) Standard specification (3/6)

2. LIST OF SPECIFICATIONS

Items Reference

interface (BMI)

S code output S8–digit command

(Binary output)

T code output T8–digit command

(Binary output)

Miscellaneous function M8–digit command

(Binary output)

High speed M/S/T/B

interface

Program number/program

name

Program number search YES YES YES II 12.1

Main program/subprogram Subprogram:

Sequence number 5–digit Same as left Same as left II 12.6

Sequence number search YES YES YES II 12.6

Program number: 4 digits

Program name:

YES NO NO II 1 1.3

16 characters

Fourfold nesting

FunctionsItems Reference

item

item

6M interface3M interfaceBasic machine

S2–digit command

(BCD output)

T2–digit command

(BCD output)

M2–digit

(BCD output)

Same as left Same as left II 12.1

Same as left Same as left II 12.4

Same as left II 9.1

Same as left II 10.1

M3–digit

(BCD output)

II 1 1.1

II 12.2

II 12.5

Tape code EIA RS244, ISO840

automatic recognition

Command format Word–address format Same as left Same as left II 12.9

Label skip YES YES YES II 12.10

Control in/out YES YES YES II 12.11

Optional block skip YES YES YES II 12.12

Circular interpolation radius

programming

Circle cutting function YES YES YES II 13.10

Tool length compensation YES YES YES II 14.1

Tool offset amount memory

A

32 tool offsets YES YES YES II 14.7

Incremental offset input YES YES YES

Backlash compensation Max. 9999 pulses Same as left Same as left II 15.6

Tool length measurement YES YES YES III 17.7

Automatic corner

deceleration

Common to all tools Same as left Same as left II 14.6.1

YES YES YES II 13.6

YES YES YES II 19.3

Same as left Same as left II 12.7

Feedrate clamp by circular

radius

Advanced preview control

function

YES YES YES II 19.4

YES YES YES II 19.5

7

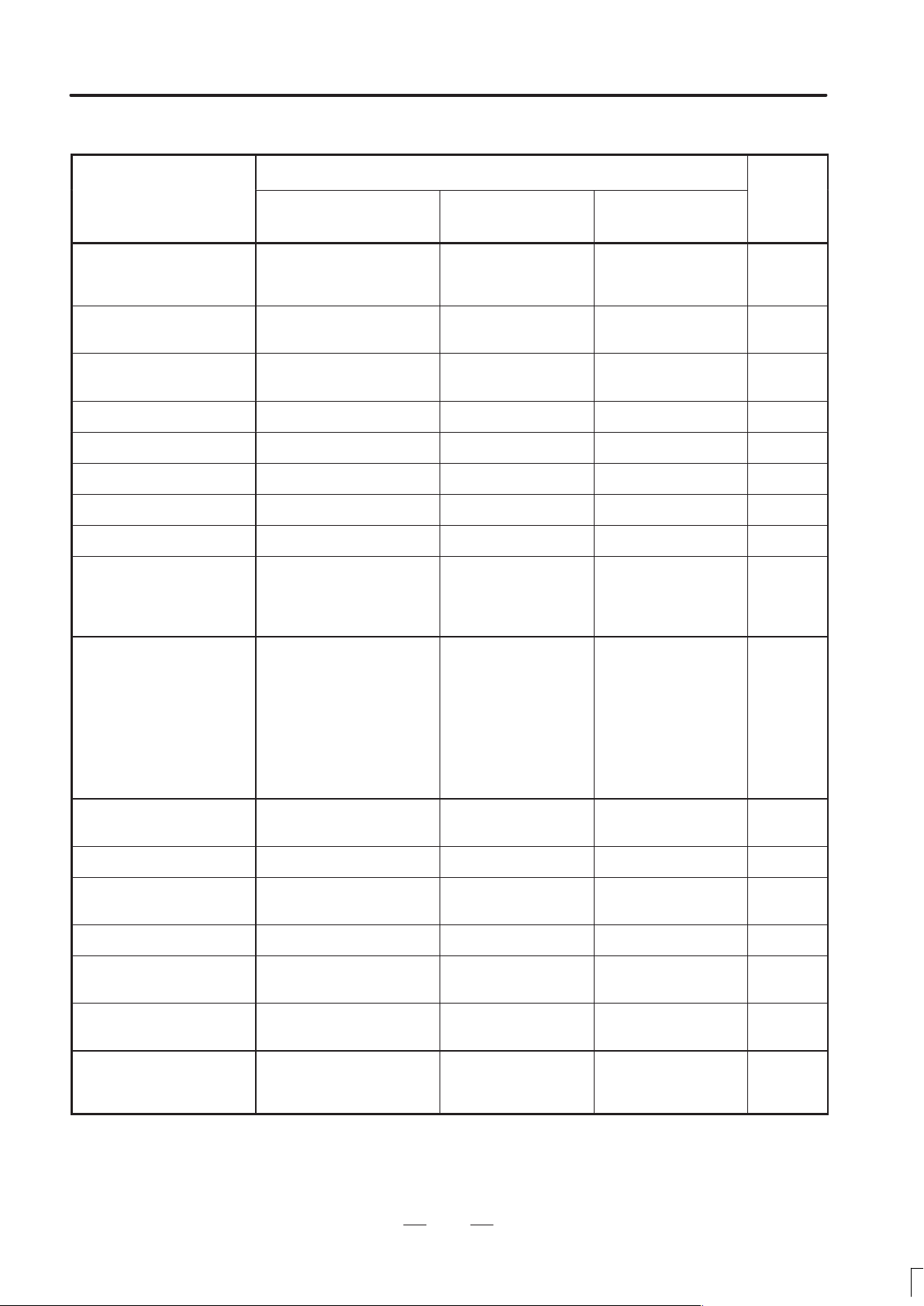

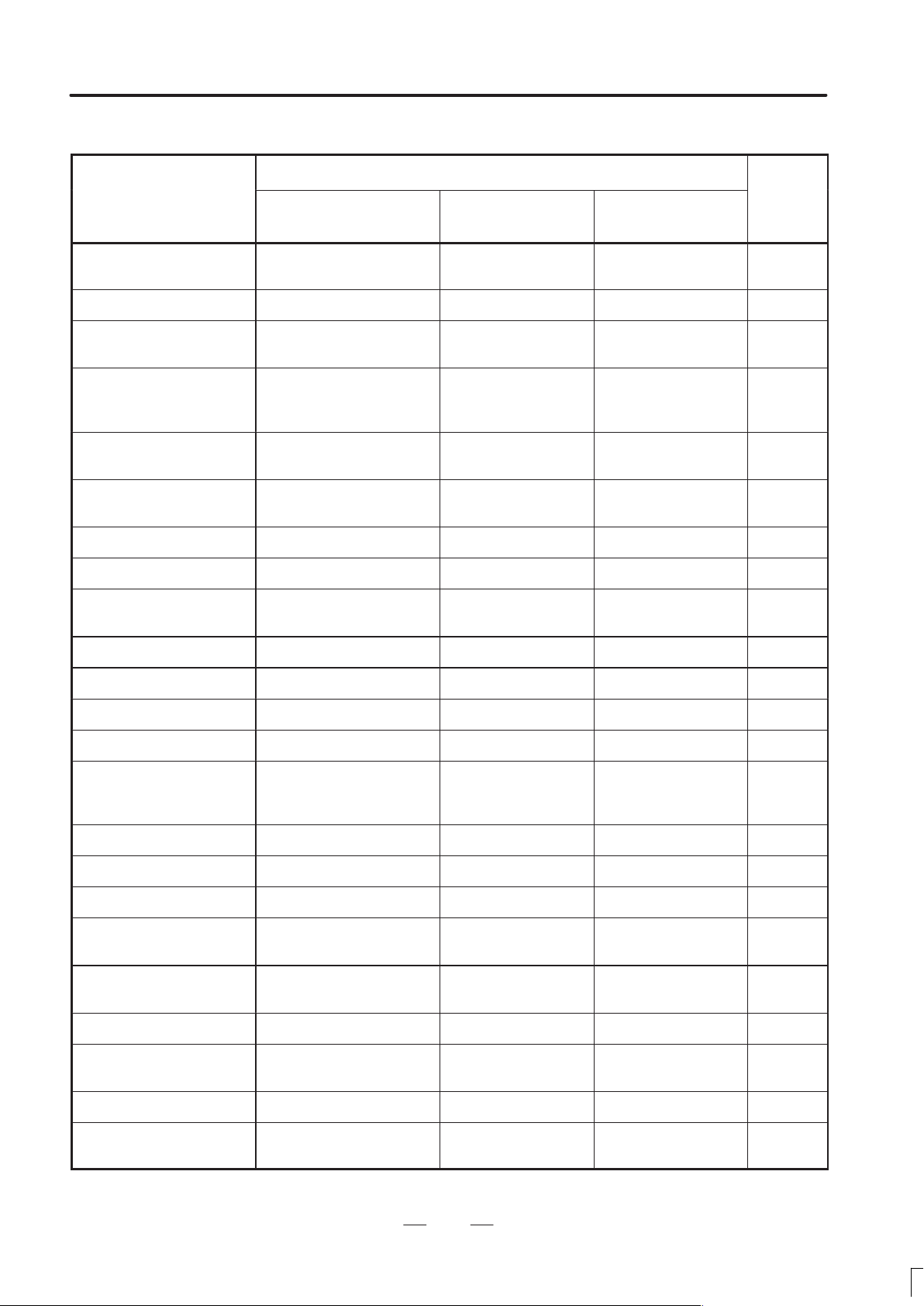

Page 22

2. LIST OF SPECIFICATIONS

GENERAL

Table 2 (a) Standard specification (4/6)

B–62082E/04

Items Reference

interface (BMI)

Follow–up YES YES YES II 20.1

Follow–up for each axis YES YES YES II 20.2

Servo off and mechanical

handle feed

External mirror image Possible on all axes Possible on all axes Possible on all axes II 20.5

Controlled axis detach YES YES YES II 20.6

Roll–over function for a

rotation axis

Automatic operation Tape operation/Memory

operation/MDI operation

Cycle start/feed hold YES YES YES II 21.3.1

Buffer register YES YES YES II 21.4.1

Program stop/program end YES YES YES II 21.5.1

YES YES YES II 20.3

YES YES YES II 20.16

FunctionsItems Reference

item

item

6M interface3M interfaceBasic machine

II 20.4

Same as left Same as left II 21

II 21.5.4

II 21.5.2

Reset and rewind YES YES YES II 21.2.4

II 21.5.5

Transverse inhibit limit YES NO NO II 21.10

Jog feed YES YES YES II 22.1

Incremental feed 1, 10, 100, 1000,

10000, 100000

Manual absolute on/off YES YES YES II 22.7

Manual operation stored

stroke check

Machine lock on all axes YES YES YES II 23.1

Machine lock on each axis YES YES YES II 23.2

Auxiliary function lock YES YES YES II 23.3

Dry run YES YES YES II 23.4

Single block YES YES YES II 23.5

Retrace program editing

function

Keyboards type manual

data input (MDI),

CRT character display

YES NO NO II 22.9

YES NO NO II 23.6

9″ monochrome

(Note)

1, 10, 100,

1000

Same as left Same as left II 24.1

1, 10, 100,

1000, 10000,

100000

II 22.2

NOTE

The applicable display unit is limited.

8

Page 23

B–62082E/04

GENERAL

Table 2 (a) Standard specification (5/6)

2. LIST OF SPECIFICATIONS

Items Reference

interface (BMI)

Clock function YES YES YES II 24.7

Run hour and parts number

display

Load meter display YES YES YES II 24.9

NC format guidance YES YES YES II 24.13

NC format guidance with

figure

Data protection key 3 types 1 type 1 type II 24.16

Directory display and

punching on each group

Function for displaying

multiple subscreens

Help function YES YES YES II 24.21

Parameter setting

(RS–232–C) screen

YES YES YES II 24.8

YES

(Note)

YES YES YES II 24.19

YES YES YES II 24.20

YES YES YES II 24. 22

FunctionsItems Reference

item

item

6M interface3M interfaceBasic machine

YES

(Note)

YES

(Note)

II 24.14

Screen for specifying high–

speed and high–precision

machining

Operation history YES YES YES II 24.24

Waveform diagnosis

function

CRT screen saving function YES YES YES II 24.26

Workpiece origin manual

setting

Screen saver YES NO NO II 24.29

Part program storage &

editing

Expanded part program

editing

Background editing YES YES YES II 25.2

Part program storage

length

YES YES YES II 24.23

YES YES YES II 24.25

YES NO NO II 24.28

YES YES YES II 25

YES YES YES II 25.3

80 m Same as left Same as left II 25.5

NOTE

The applicable display unit is limited.

9

Page 24

2. LIST OF SPECIFICATIONS

GENERAL

Table 2 (a) Standard specification (6/6)

B–62082E/04

Items Reference

interface (BMI)

Resisterable programs

(Program name display is

also possible)

High–speed part program

registeration function

Function selection with

hard keys

Multi–edit function YES YES YES II 25.11

Self–diagnosis functions YES YES YES II 26.1

Emergency stop YES YES YES II 28.1

Overtravel YES YES YES II 28.2.1

Stored stroke check 1 YES YES YES II 28.2.2

Interlock Each axis/all axes/all axes

in automatic operation/

block start/cutting block

100 100 100 II 25.4

YES YES YES II 25.9

YES YES YES II 25.10

start interlock

FunctionsItems Reference

6M interface3M interfaceBasic machine

All axes or Z–axis only Each axis, cutting

block start

item

item

II 28.3

Status output NC ready, servo ready, re-

winding, alarm, distribution

end, automatic operation,

automatic operation start

lamp, feed hold reset, imposition, rapid traversing,

tapping, constant surface

speed control, inch input

and DI status

Connectable servo motor FANUC AC SERVO

MOTOR series

Connectable servo unit PWM transistor drive Same as left Same as left II 36

Connectable position

detector

Absolute position detector YES YES YES II 37

Connectable spindle motor FANUC AC SPINDLE

Connectable spindle servo

unit

Power

(About the CNC unit)

Pulse coder/optical scale Same as left Same as left II 37

MOTOR series

PWM transistor drive Same as left Same as left II 38

200 to 240 V AC

+10%, –15%

50 to 60 Hz 3 Hz

NC ready, servo ready,

rewinding, alarm, dis-

tribution end, automat-

ic operation start lamp,

feed hold, reset

Same as left Same as left II 36

Same as left Same as left II 38

Same as left Same as left II 35.2

Same as left II 29

10

Page 25

B–62082E/04

item

GENERAL

Table 2 (b) Optional specification (1/8)

2. LIST OF SPECIFICATIONS

Items

Basic machine

interface (BMI)

Controlled axes expansion

Name of axes:

Select from X, Y, Z, A, B, C,

U, V, W axis optionally

Simultaneous controllable

axes expansion

Single direction positioning YES YES YES II 3.2

3–dimensional circular

interpolation function

Helical interpolation Also applied to

Helical interpolation B (*) Circular interpolation plus

Max. 8 axes plus spindle

control 2 axes

Max. simultaneous

controlled axes

Basic 3 axes puls

rotation 2 axes

additional axes,

Circular interpolation plus

max. 2 axes linear

interpolation

max. 4 axes linear

interpolation

Functions

3M interface 6M interface

NO Max. 5 axes plus

spindle control

Same as left Same as left II 1.4

Basic 3 axes plus

rotation 1 axis

Also applied to

additional axes

NO Circular interpolation

Basic 3 axes plus

rotation 2 axes

Also applied to

additional axes

plus max. 3 axes linear

interpolation

Reference

II 1.2

II 3.5

II 3.6

II 3.7

Hypothetical axis YES YES YES II 3.8

Polar coordinate

interpolation

Cylindrical interpolation YES YES YES II 3.10

Exponential function inter-

polation

Circular threading B YES YES YES II 3.12

Involute interpolation YES YES YES II 3.13

Helical involute interruption Involute interpolation

Spline interpolation YES YES YES II 3.15

Spiral interpolation and

conical interpolation

Smooth interpolation (*) YES NO NO II 3.17

Thread cutting, inch thread-

ing, continuous threading

Per revolution feed YES YES YES II 5.2.4

YES YES YES II 3.9

YES YES YES II 3.11

Involute interpolation

plus linear 4 axes

YES YES YES II 3.16

YES YES YES II 4

plus linear 4 axes

Involute interpolation

plus linear 4 axes

II 3.14

Inverse time feed YES YES YES II 5.2.5

F–1 digit feed YES NO YES II 5.2.6

Second feedrate override YES NO NO II 5.3.2

11

Page 26

2. LIST OF SPECIFICATIONS

GENERAL

Table 2 (b) Optional specification (2/8)

B–62082E/04

Items Reference

interface (BMI)

Second feedrate override B YES NO NO II 5.3.3

Bell–shaped acceleration/

deceleration after cutting

feed interpolation

Cutting point speed control

function

Acceleration/deceleration

function for the constant

speed specified by the

PMC axis control function

Automatic corner override YES YES YES II 5.17

Feed per rotation without a

position coder

2nd to 4th reference

position return

Floating reference point

return

YES YES YES II 5.6

YES YES YES II 5.10

YES YES YES II 5.11

YES YES YES II 5.19

YES 2nd reference

YES YES

FunctionsItems Reference

item

item

6M interface3M interfaceBasic machine

YES II 6.4

position return

(Note 3)

YES

(Note 3)

II 6.5

Programmable data input G10, tool offset amount,

Work zero pint offset

amount can be changed by

programming

Additional workpiece

coordinate systems

Plane switching (*) YES YES YES II 7.8

Polar coordinate command YES YES YES II 8.2

Inch/metric conversion YES YES YES II 8.3

Spindle speed binary/

analog output/spindle

speed clamp (G92)

Constant surface speed

control