Page 1

FANUC Series 0

+

PARAMETER MANUAL

-PD

B-64560EN/01

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan may be subject to an export license by the

government of Japan. Further, re-export to another country may be subject to the license

of the government of the country from where the product is re-exported. Furthermore, the

product may also be controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

The products in this manual are manufactured under strict quality control. However, when

using any of the products in a facility in which a serious accident or loss is predicted due to

a failure of the product, install a safety device.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by ® or ™ in the main body.

Page 3

B-64560EN/01 DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine.

Precautions are classified into Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly

before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a

danger of both the user being injured and the equipment being damaged if the

approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the

approved procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and

Caution.

• Read this manual carefully, and store it in a safe place.

s-1

Page 4

Page 5

B-64560EN/01 PREFACE

PREFACE

Applicable models

The models covered by this manual, and their abbreviations are :

Model name Abbreviation

FANUC Series 0i -PD 0i -PD Series 0i -PD

NOTE

1 For details of parameters that are not described in this manual, please refer to

FANUC Series 0i-D / 0i Mate-D PARAMETER MANUAL (B-64310EN).

2 Some functions described in this manual may not be applied to some products.

For details, refer to the DESCRIPTIONS (B-64302EN).

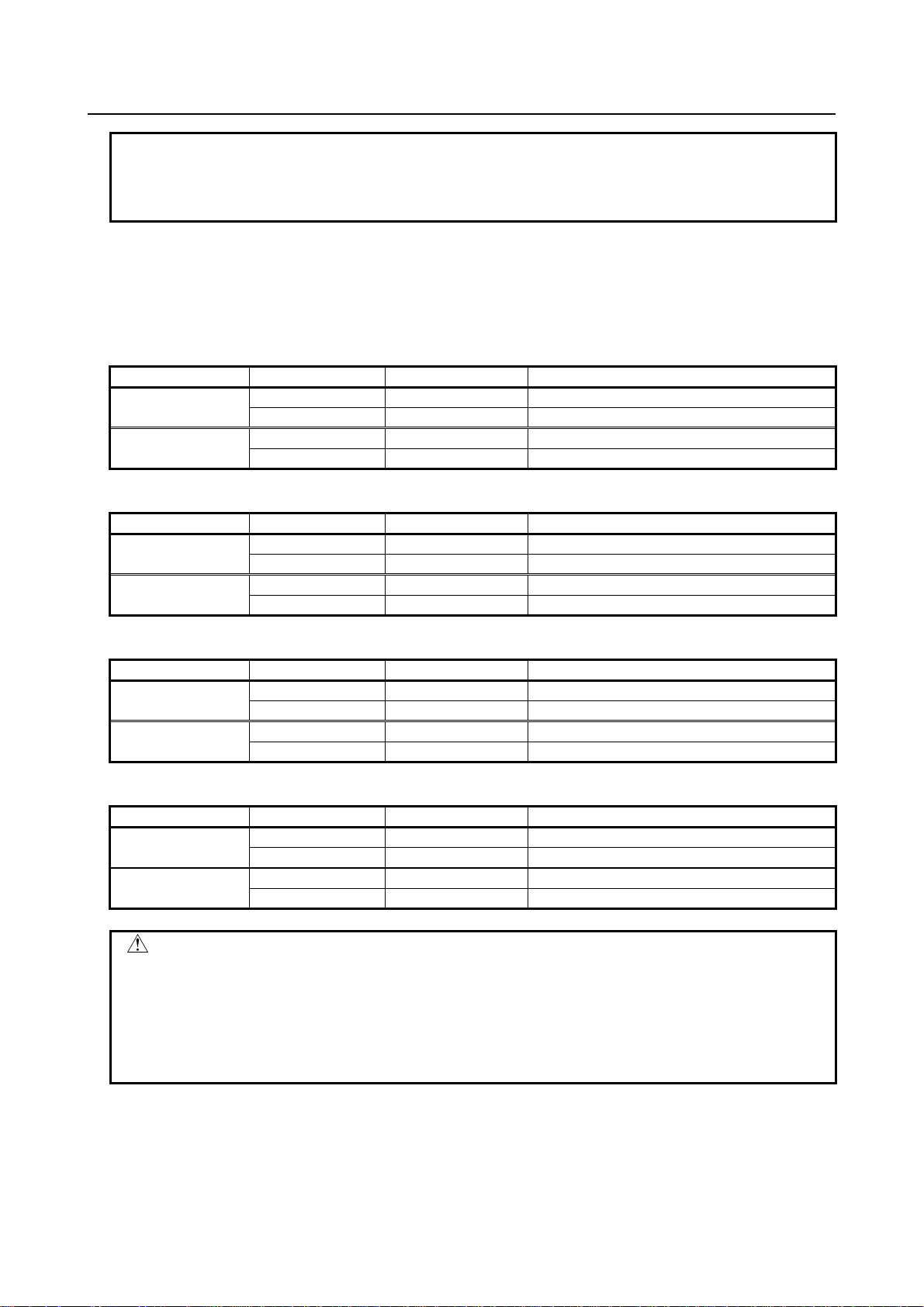

Description of parameters

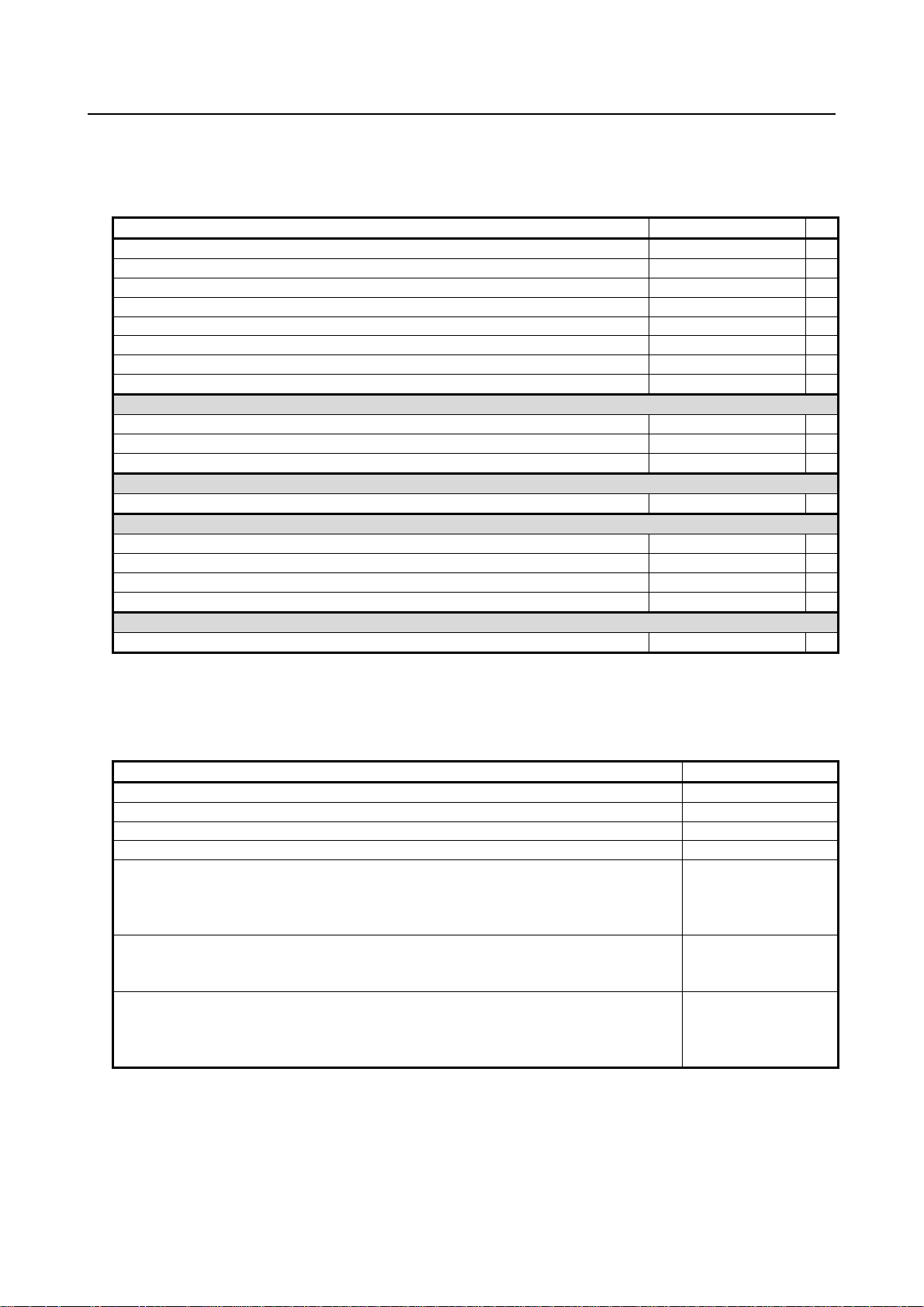

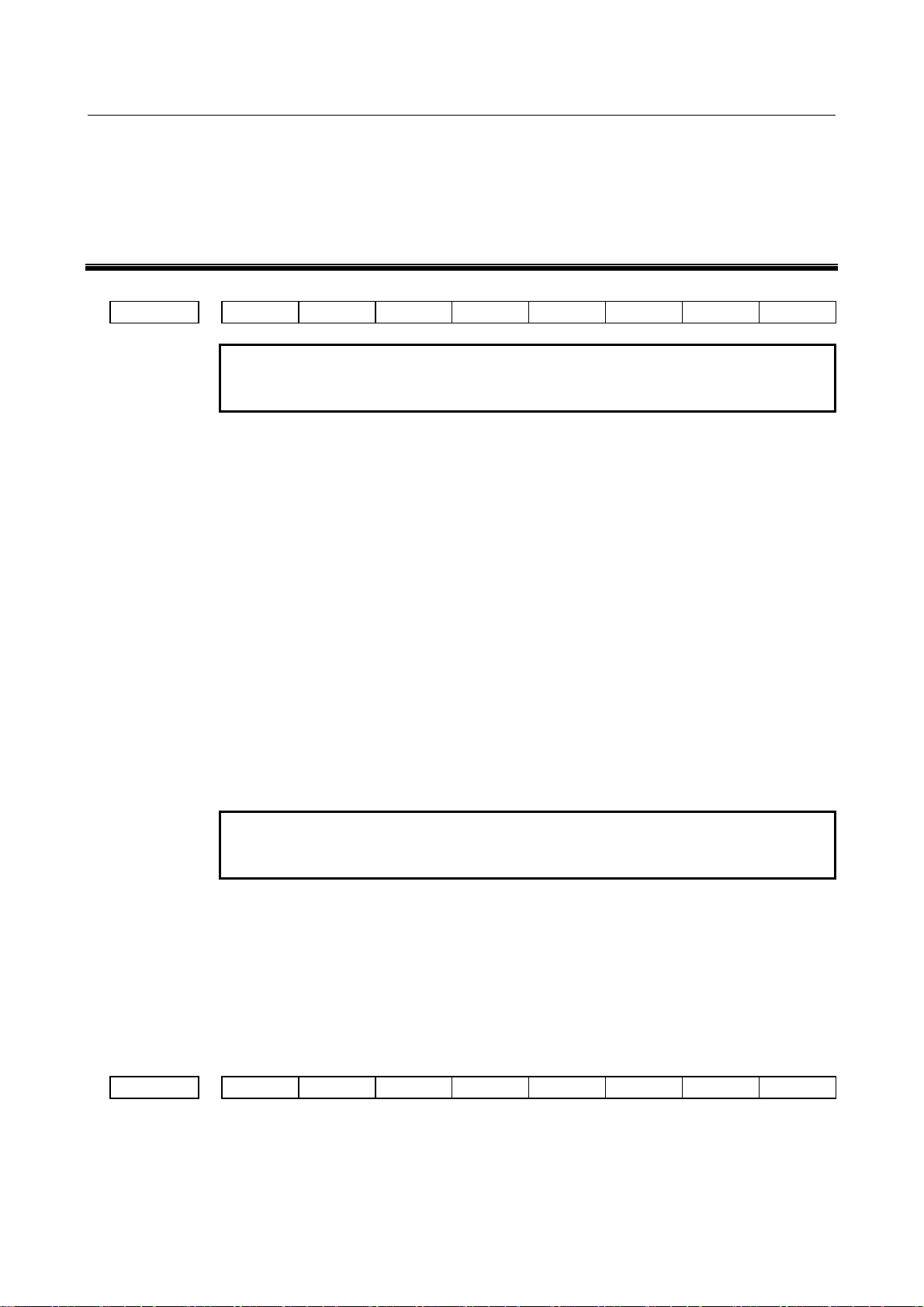

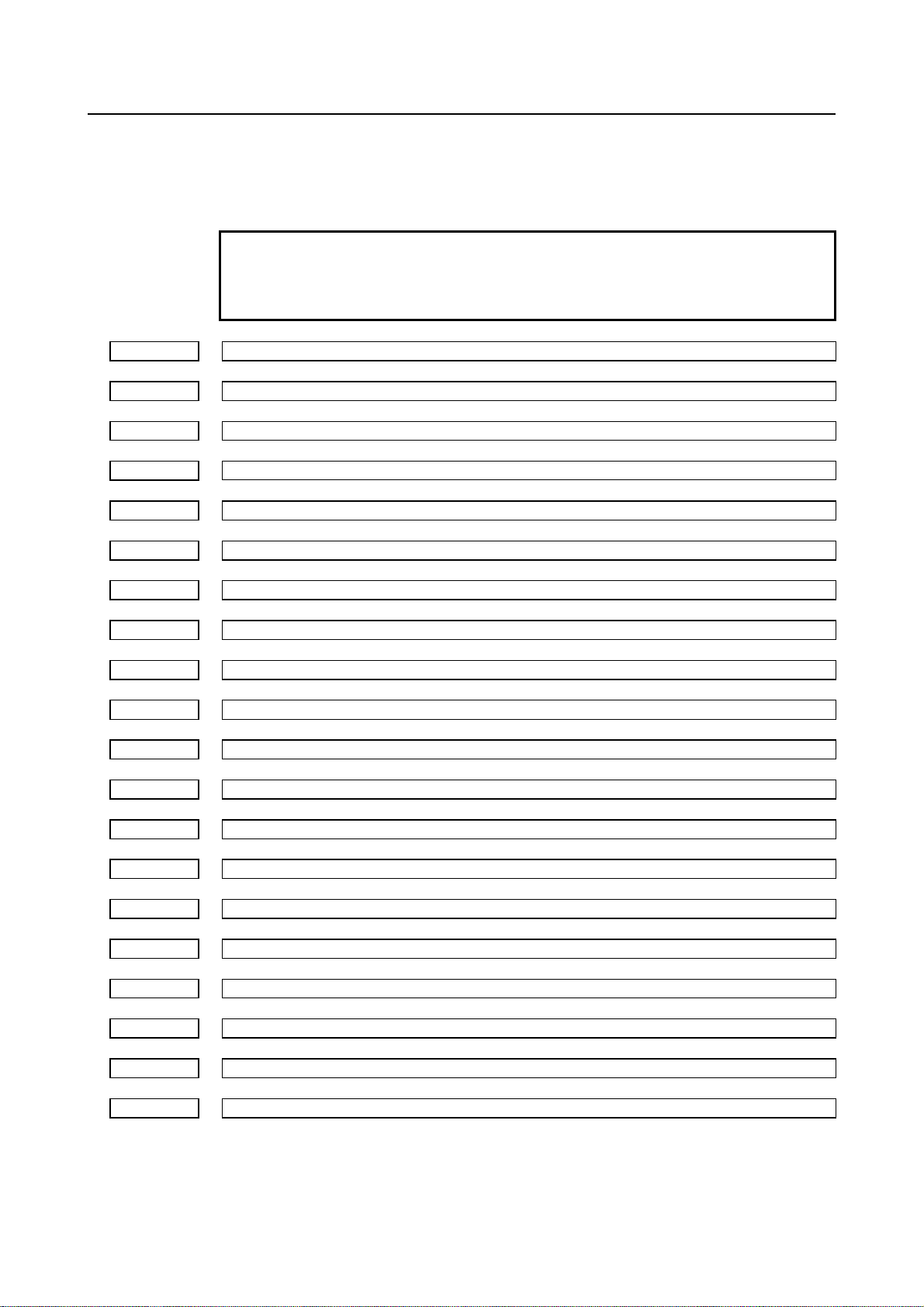

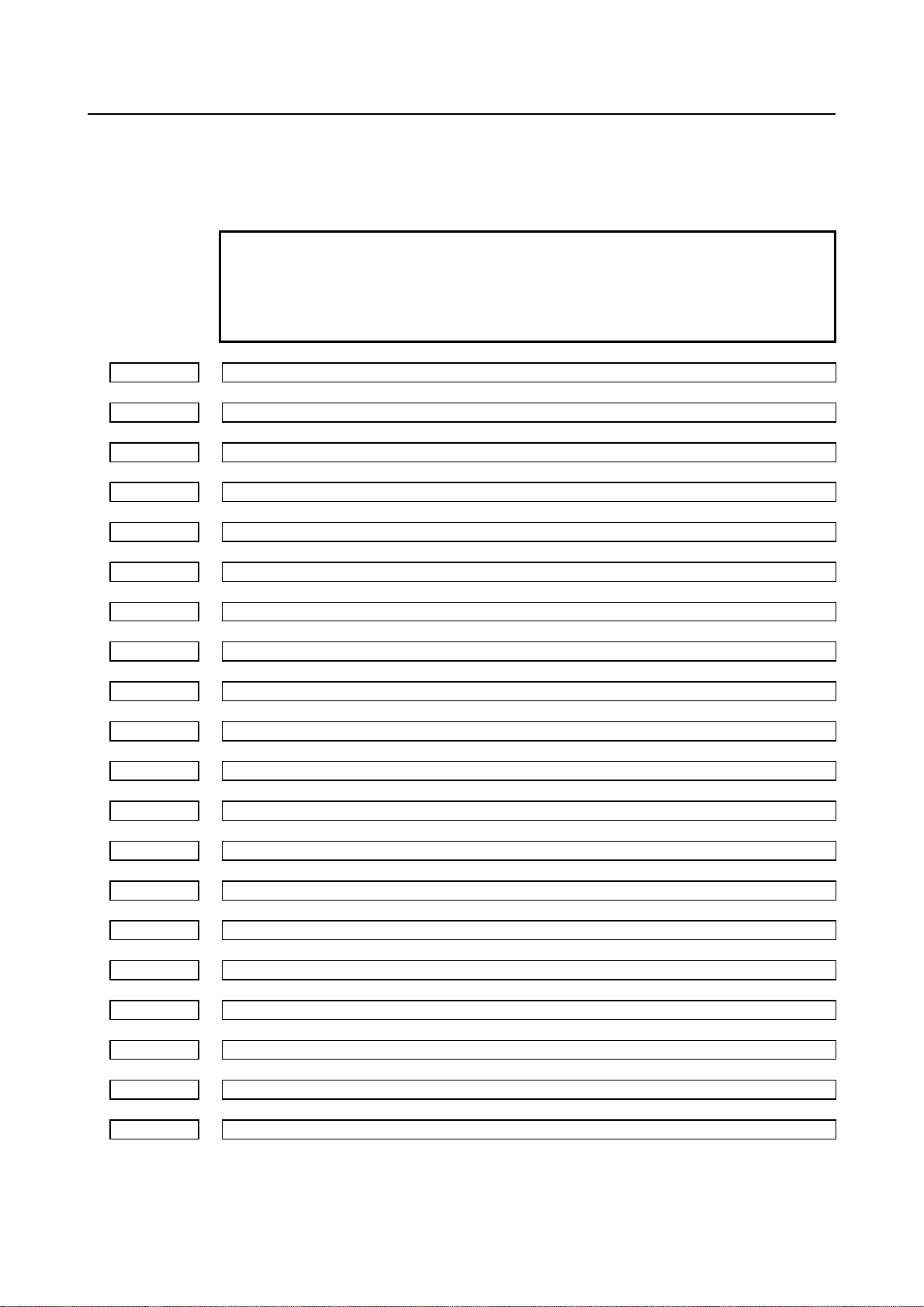

Parameters are classified by data type as follows:

Data type Valid data range Remarks

Bit

Bit machine group

Bit path

Bit axis

Byte

Byte machine group

Byte path

Byte axis

Word

Word machine group

Word path

Word axis

2-word

2-word machine group

2-word path

2-word axis

Real

Real machine group

Real path

Real axis

See the Standard Parameter

0 or 1

-128 to 127

0 to 255

-32768 to 32767

0 to 65535

0 to ±999999999

Setting Tables.

NOTE

1 Each of the parameters of the bit, bit machine group, bit path, and bit axis types

consists of 8 bits for one data number (parameters with eight different

meanings).

2 For machine group types, parameters corresponding to the maximum number of

machine groups are present, so that independent data can be set for each

machine group.

In the FANUC Series 0i-PD, the maximum number of machine group is 1.

3 For path types, parameters corresponding to the maximum number of paths are

present, so that independent data can be set for each path.

In the FANUC Series 0i-PD, the maximum number of controlled path is 1.

4 For axis types, parameters corresponding to the maximum number of control

axes are present, so that independent data can be set for each control axis.

p-1

Some parameters handle these types of

data as unsigned data.

Some parameters handle these types of

data as unsigned data.

Some parameters handle these types of

data as unsigned data.

Page 6

PREFACE B-64560EN/01

NOTE

5 The valid data range for each data type indicates a general range. The range

varies according to the parameters. For the valid data range of a specific

parameter, see the explanation of the parameter.

- Standard parameter setting tables

This section defines the standard minimum data units and valid data ranges of the CNC parameters of the

real type, real machine group type, real path type, and real axis type. The data type and unit of data of

each parameter conform to the specifications of each function.

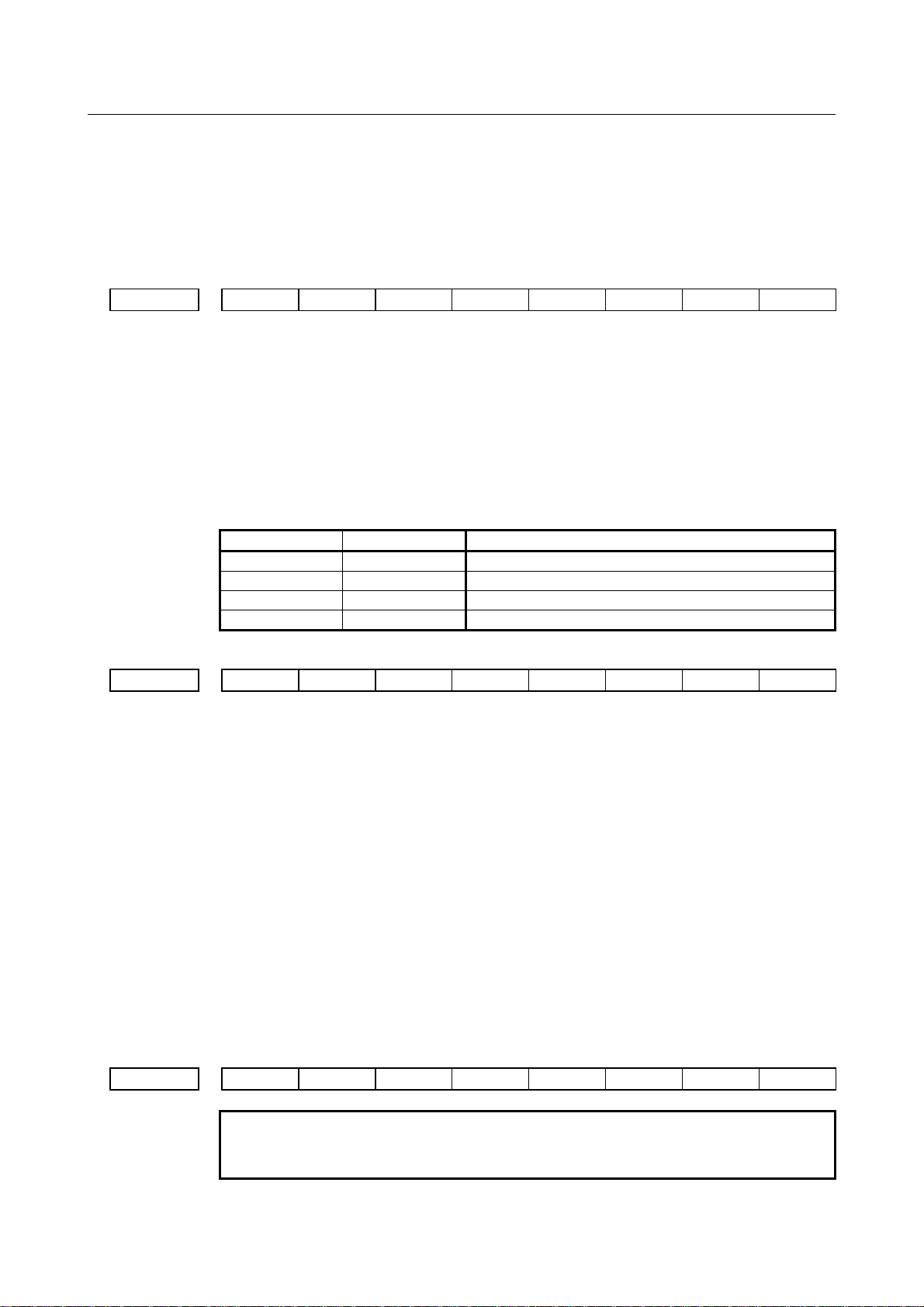

(A) Length and angle parameters (type 1)

Unit of data Increment system Minimum data unit Valid data range

IS-A 0.01 -999999.99 to +999999.99 mm

deg.

inch

IS-B 0.001 -999999.999 to +999999.999

IS-A 0.001 -99999.999 to +99999.999

IS-B 0.0001 -99999.9999 to +99999.9999

(B) Length and angle parameters (type 2)

Unit of data Increment system Minimum data unit Valid data range

IS-A 0.01 0.00 to +999999.99 mm

deg.

inch

IS-B 0.001 0.000 to +999999.999

IS-A 0.001 0.000 to +99999.999

IS-B 0.0001 0.0000 to +99999.9999

(C) Velocity and angular velocity parameters

Unit of data Increment system Minimum data unit Valid data range

IS-A 0.01 0.0 to +999000.00 mm/min

degree/min

inch/min

IS-B 0.001 0.0 to +999000.000

IS-A 0.001 0.0 to +96000.000

IS-B 0.0001 0.0 to +9600.0000

(D) Acceleration and angular acceleration parameters

Unit of data Increment system Minimum data unit Valid data range

IS-A 0.01 0.00 to +999999.99 mm/sec2

IS-B 0.001 0.000 to +999999.999

IS-A 0.001 0.000 to +99999.999

IS-B 0.0001 0.0000 to +99999.9999

deg./sec

inch/sec2

2

CAUTION

1 Values are rounded up or down to the nearest multiples of the minimum data

unit.

2 A valid data range means data input limits, and may differ from values

representing actual performance.

3 For information on the ranges of commands to the CNC, refer to Appendix D,

"Range of Command Value" of the Operator’s Manual (B-64554EN).

p-2

Page 7

B-64560EN/01 PREFACE

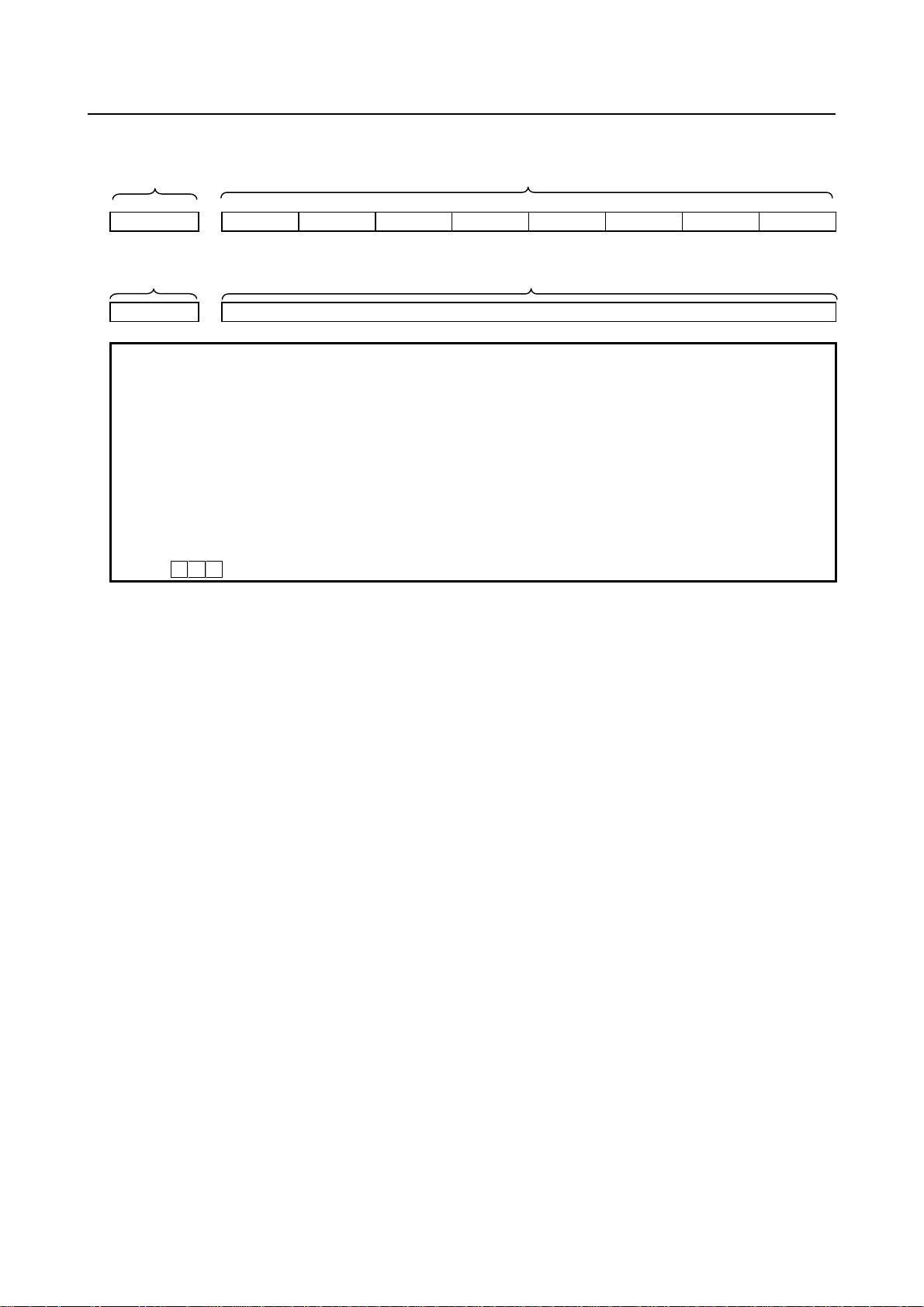

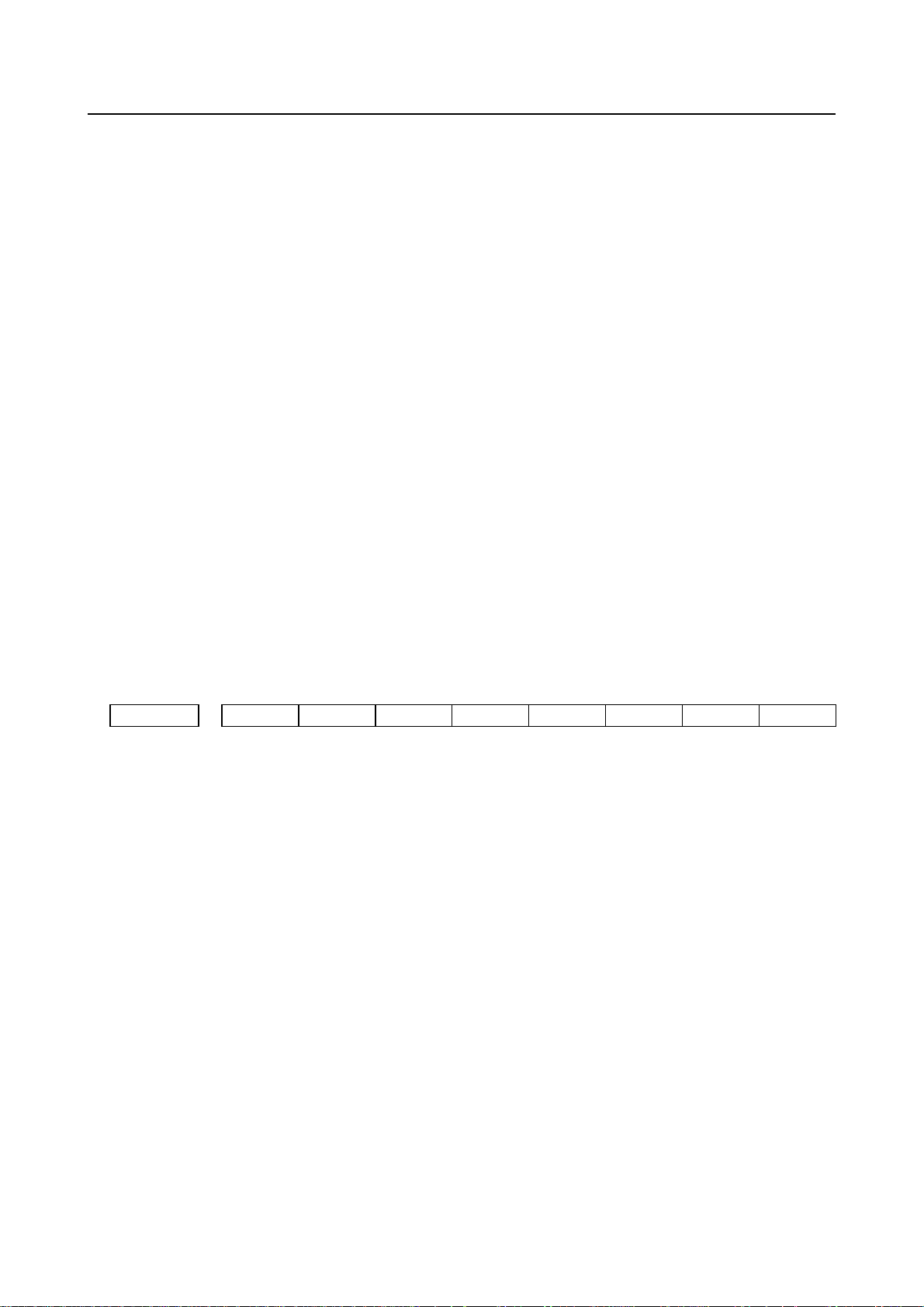

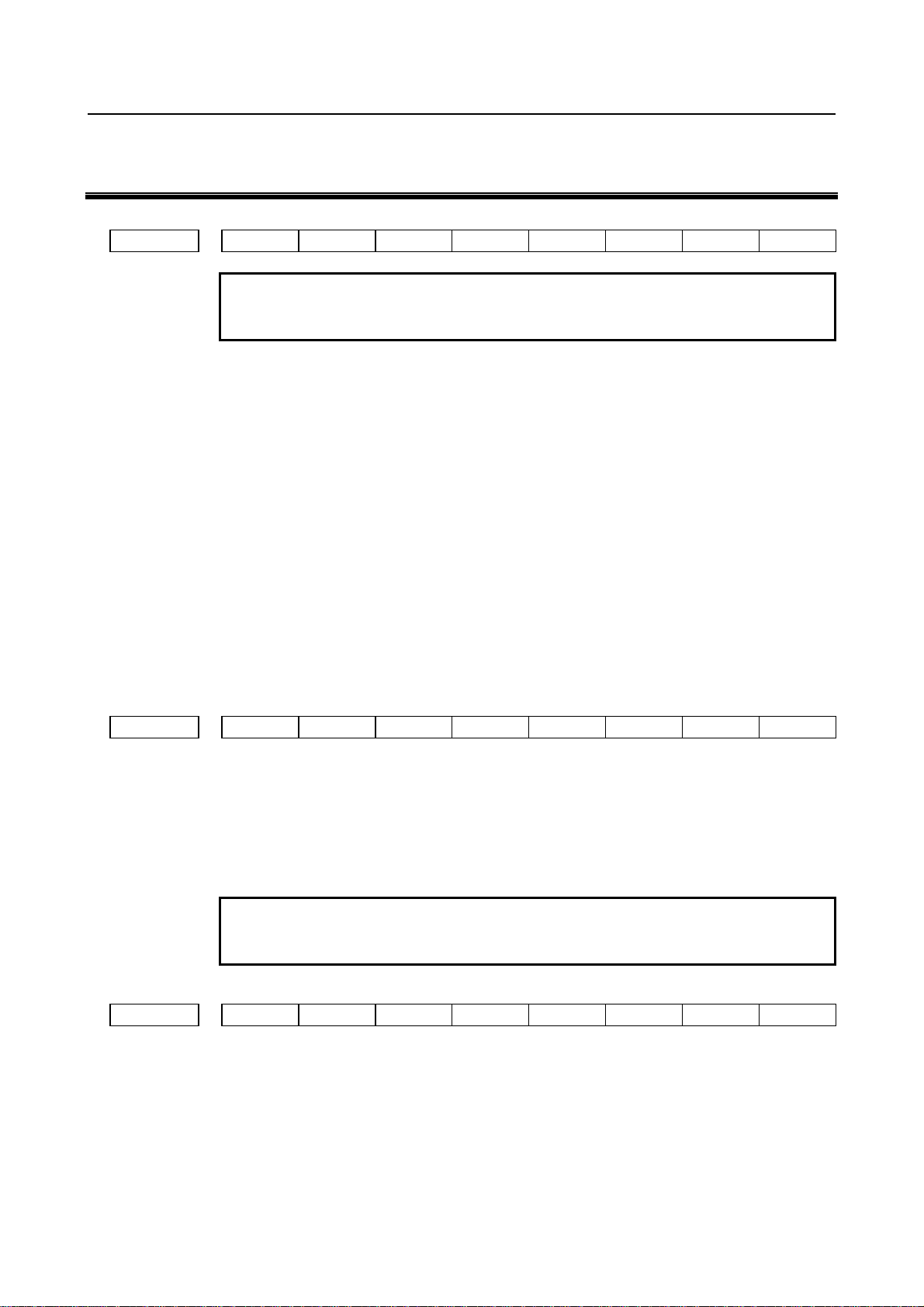

- Parameters of the bit type, bit machine group type, bit path type, and bit axis

type

Data No. Data (Data #0 to #7 are bit positions.)

#7 #6 #5 #4 #3 #2 #1 #0

0000 SEQ INI ISO TVC

- Parameters other than the bit-type parameters above

Data No. Data

1023 Number of the servo axis for each axis

NOTE

1 The bits left blank in “description of parameters” and parameter numbers that

appear on the display but are not found in the parameter list are reserved for

future expansion. They must always be 0.

2 When "to" is inserted between two parameter numbers, there are parameters

with successive numbers between the two starting and ending parameter

numbers, but those intermediate parameter numbers are omitted for

convenience.

3 The lower-case letter "x" following the name of a bit-type parameter indicates the

following:

- ” x” : Bit axis type parameters

p-3

Page 8

PREFACE B-64560EN/01

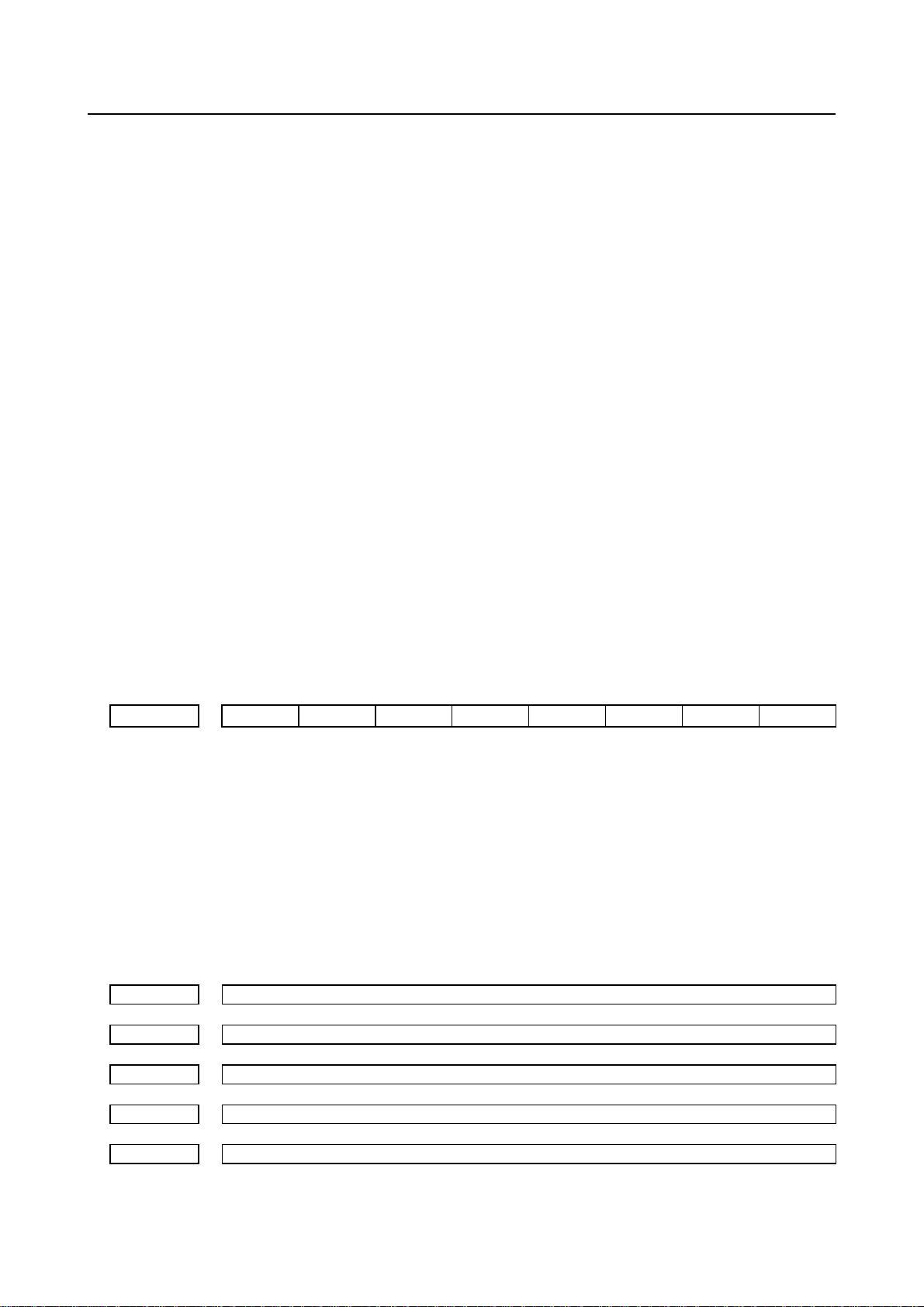

Related manuals of Series 0i-PD

The following table lists the manuals related to Series 0i-PD. This manual is indicated by an asterisk(*).

Table 1 Related manuals

Manual name Specification number

FANUC Series 0i-D / 0i Mate-D DESCRIPTIONS

FANUC Series 0i-D / 0i Mate-D CONNECTION MANUAL (HARDWARE)

FANUC Series 0i-D / 0i Mate-D CONNECTION MANUAL (FUNCTION)

FANUC Series 0i-PD CONNECTION MANUAL (FUNCTION)

FANUC Series 0i-PD OPERATOR’S MANUAL

FANUC Series 0i-D / 0i Mate-D MAINTENANCE MANUAL

FANUC Series 0i-D / 0i Mate-D PARAMETER MANUAL

FANUC Series 0i-PD PARAMETER MANUAL

Programming

Macro Executor PROGRAMMING MANUAL B-64303EN-2

Macro Compiler PROGRAMMING MANUAL B-64303EN-5

C Language Executor PROGRAMMING MANUAL B-64303EN-3

PMC

PMC PROGRAMMING MANUAL B-64393EN

Network

PROFIBUS-DP Board CONNECTION MANUAL B-64403EN

Fast Ethernet / Fast Data Server OPERATOR’S MANUAL B-64414EN

DeviceNet Board CONNECTION MANUAL B-64443EN

FL-net Board CONNECTION MANUAL B-64453EN

Dual Check Safety

Dual Check Safety CONNECTION MANUAL B-64303EN-4

B-64302EN

B-64303EN

B-64303EN-1

B-64553EN

B-64554EN

B-64305EN

B-64310EN

B-64560EN *

Related manuals of SERVO MOTOR αi/βi series

The following table lists the manuals related to SERVO MOTOR αi/βi series

Table 2 Related manuals

Manual name Specification number

FANUC AC SERVO MOTOR αi series DESCRIPTIONS

FANUC AC SERVO MOTOR βi series DESCRIPTIONS

FANUC SERVO AMPLIFIER αi series DESCRIPTIONS

FANUC SERVO AMPLIFIER βi series DESCRIPTIONS

FANUC AC SERVO MOTOR αis series

FANUC AC SERVO MOTOR αi series

FANUC AC SPINDLE MOTOR αi series

FANUC SERVO AMPLIFIER αi series MAINTENANCE MANUAL

FANUC AC SERVO MOTOR βis series

FANUC AC SPINDLE MOTOR βi series

FANUC SERVO AMPLIFIER βi series MAINTENANCE MANUAL

FANUC AC SERVO MOTOR αi series

FANUC AC SERVO MOTOR βi series

FANUC LINEAR MOTOR LiS series

FANUC SYNCHRONOUS BUILT-IN SERVO MOTOR DiS series PARAMETER MANUAL

CNCs that are described in this manual can be connected to above servo motors.

This manual mainly assumes that the FANUC SERVO MOTOR αi series of servo motor is used. For

servo motor information, refer to the manuals for the servo motor that are actually connected.

B-65262EN

B-65302EN

B-65282EN

B-65322EN

B-65285EN

B-65325EN

B-65270EN

p-4

Page 9

B-64560EN/01 TABLE OF CONTENTS

TABLE OF CONTENTS

DEFINITION OF WARNING, CAUTION, AND NOTE .................................s-1

PREFACE....................................................................................................p-1

TABLE OF CONTENTS .................................................................................1

1 PARAMETERS FOR THE PRESS FUNCTION ...................................... 1

2 PARAMETERS FOR THE SPEED AND LOOP GAIN SWITCH........... 10

3 PARAMETERS FOR THE NIBBLING FUNCTION ...............................13

4 PARAMETERS FOR THE PATTERN FUNCTION AND THE U/V/W

MACRO FUNCTION (1 OF 2) ............................................................... 16

5 PARAMETERS FOR THE PUNCH AND LASER SWITCH .................. 21

6 PARAMETERS FOR THE TOOL FUNCTION (T FUNCTION) (1 OF 2)23

7 PARAMETERS FOR C–AXIS CONTROL ............................................27

8 PARAMETERS FOR THE SAFETY ZONE........................................... 36

9 PARAMETERS FOR THE DI/DO SIGNALS ......................................... 43

10 PARAMETERS FOR THE Y–AXIS CRACK CANCEL .........................44

11 PARAMETERS FOR THE TOOL FUNCTION (T FUNCTION) (2 OF 2)45

12 PARAMETERS FOR THE PATTERN FUNCTION AND THE U/V/W

MACRO FUNCTION (2 OF 2) ............................................................... 46

13 PARAMETERS FOR THE RAM-AXIS CONTROL................................ 47

14 SPEED AND SERVO PARAMETER SWITCHING PARAMETERS ..... 49

15 PARAMETERS OF POSITIONING BY OPTIMUM ACCELERATION..51

APPENDIX

A CHARACTER CODE LIST .................................................................... 57

c-1

Page 10

Page 11

B-64560EN/01 1.PARAMETERS FOR THE PRESS FUNCTION

1 PARAMETERS FOR THE PRESS

FUNCTION

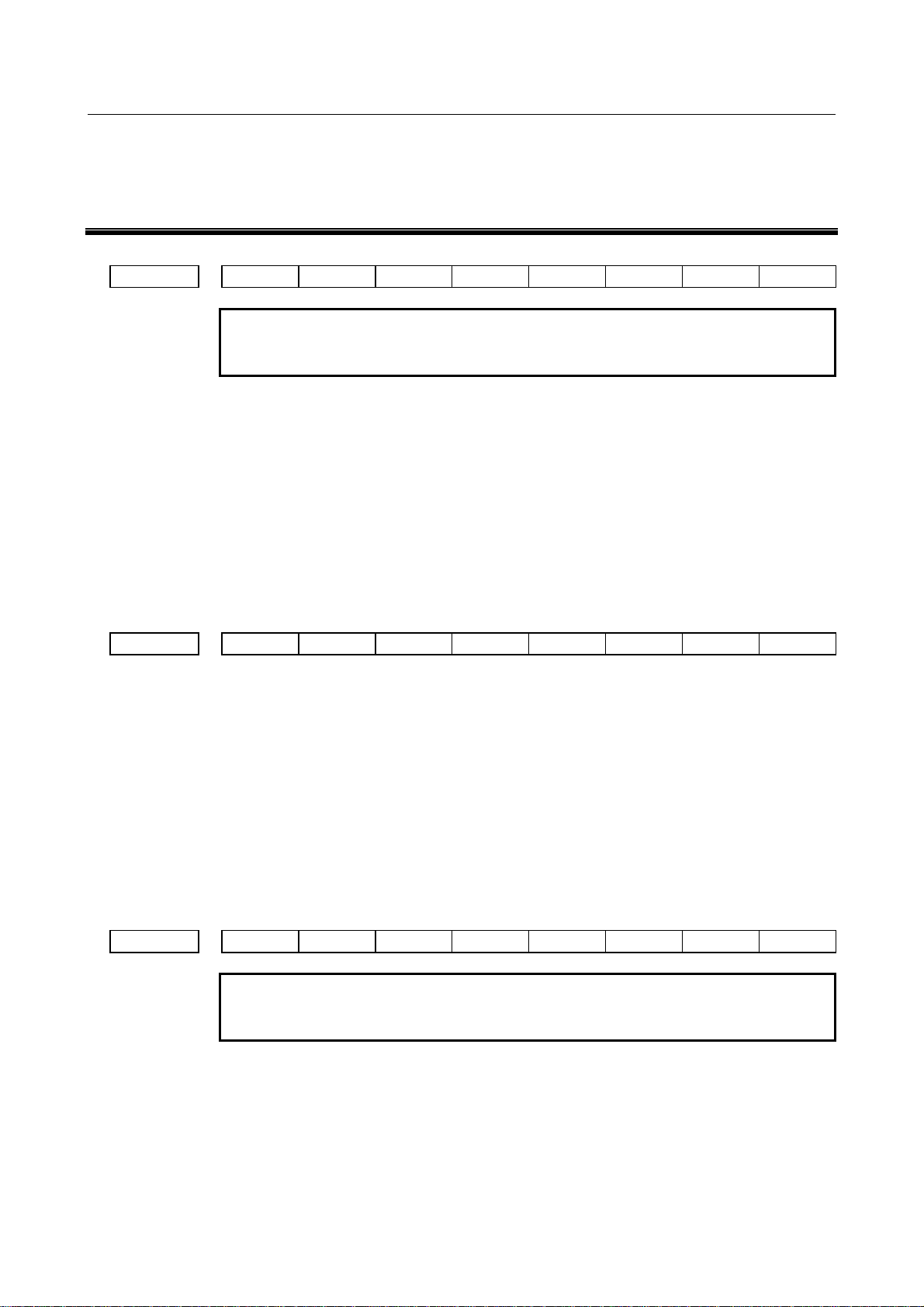

#7 #6 #5 #4 #3 #2 #1 #0

16000 PEI NFI PFI YSG RPF

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

[Input type] Parameter input

[Data type] Bit path

#2 RPF When the RESET key is pressed or when external reset, reset and rewind, or emergency

stop is activated, the PF signal to start pressing is:

0: Set to “0”.

1: Not set to “0”.

#3 YSG A signal for the press function assigned to an Y address is:

0: Fixed at the address <Y004>.

1: Able to be reassigned to an arbitrary Y address.

NOTE

If bit 3 (YSG) of parameter No.16000 is set to 1, parameter No.

16046 shall be set.

#5 PFI The logic of the *PFIN signal to complete punching for single–cycle pressing is:

0: The same as the logic described in the ”Connection Manual.”

1: The reverse of the logic described in the ”Connection Manual.”

#6 NFI The logic of the *NFIN signal to complete punching for continuous pressing is:

0: The same as the logic described in the “Connection Manual.”

1: The reverse of the logic described in the “Connection Manual.”

#7 PEI The logic of the *PE signal to stop pressing is:

0: The same as the logic described in the “Connection Manual.”

1: The reverse of the logic described in the “Connection Manual.”

#7 #6 #5 #4 #3 #2 #1 #0

16001 CPF MPF PMA PSY PFE MNP

[Input type] Parameter input

[Data type] Bit path

#0 MNP If there remains a distance to be traveled when automatic operation is halted, manual

pressing or continuous manual pressing is:

0: Valid.

1: Invalid.

- 1 -

Page 12

1.PARAMETERS FOR THE PRESS FUNCTION B-64560EN/01

#1 PFE When the PF signal to start pressing is set to “1”, the absolute value of positional

deviation for the X– and Y– axes:

0: Must be less than or equal to the value set in parameter No. 16010.

1: Need not be less than or equal to the value set in parameter No. 16010.

#4 PSY Under axis synchronous control, the PF signal to start pressing is output:

0: Irrespective of the machine coordinates of the synchronous axes.

1: After it has been confirmed that the machine coordinates of the synchronous axes

agree with each other.

If the machine coordinates differ, alarm (PS0213) will be issued and the PF signal

will not be output.

#5 PMA When the AFL signal to lock auxiliary functions is set to “1”, M code signals for forming,

repositioning, and nibbling are:

0: Not output to the machine.

1: Output to the machine.

#6 MPF In a block containing an M code, the PF signal to start pressing is:

0: Not set to “1”.

1: Set to “1”.

PF is set to 1 when movement along an axis terminates or when completion of the

miscellaneous function is returned.

#7 CPF At the end of the 01 group containing the G01, G02, or G03 code, the PF signal to start

pressing is:

0: Not set to “1”.

1: Set to “1”.

#7 #6 #5 #4 #3 #2 #1 #0

16002 EUP PF9 PWB SPR PFB PEM AET

[Input type] Parameter input

[Data type] Bit path

#0 AET The timer for issuing the EF signal to start external operation in advance (parameter No.

16041) is:

0: Disabled.

1: Enabled.

#2 PEM MDI operation:

0: Does not start pressing.

1: Starts pressing.

#3 PFB The PFB signal to start pressing is:

0: Enabled.

1: Disabled.

#4 SPR The *SPR signal to halt automatic operation B is:

0: Invalid.

1: Valid.

#5 PWB The PFWB signal to wait for the start of pressing B is:

0: Invalid.

1: Valid.

- 2 -

Page 13

B-64560EN/01 1.PARAMETERS FOR THE PRESS FUNCTION

#6 PF9 The time interval between setting of the PFB signal to start pressing B to “0” and setting

of the PF signal to start pressing to “0” is set to the value in:

0: Parameter No. 16037.

1: Parameter No. 16038.

#7 EUP By executing the external operation function, the number of punching cycles is:

0: Not aggregated.

1: Aggregated.

One is added when the PF signal to start pressing and the EF signal to external

operation are set to “1”.

#7 #6 #5 #4 #3 #2 #1 #0

16003 NED DPE TCF NPF

[Input type] Parameter input

[Data type] Bit path

#2 NPF The G01, G02, or G03 code specified in normal direction control:

0: Sets PF to “1”.

1: Does not set PF to “1”.

Bit 2 (NPF) of parameter No. 16003 is validated when bit 7 (CPF) of parameter No.

16001 is set to 1.

#5 TCF After the OP signal indicating that automatic operation is in progress is set from “0” to

“1”, the PF signal to start pressing is set to “1”:

0: Only when a T command is found.

This status is the same as the status in which the PFW signal to wait for the start of

pressing is set to “1”.

1: Even if no T commands are found.

#6 DPE The relationship between the *PE signal to stop pressing and the EPE signal for ignoring

the signal to stop pressing is as follows:

0: *PE is always validated irrespective of the status of EPE.

1: *PE is validated when EPE is set to “1”, and invalidated when EPE is set to “0”.

#7 NED After the last positioning ends in a nibbling block, the PF signal to start pressing is set to

“0”:

0: When the contact of the *PE signal to stop pressing is set to “0”.

1: When the two contacts of the *NFIN signal to complete punching for continuous

pressing and the *PE signal stop pressing are set to “0”.

16008 M code for setting the forming mode

16009 M code for canceling the forming mode

[Input type] Parameter input

[Data type] 2-word path

[Valid data range] 1 to 97

Parameter No. 16008 sets the M code for setting the forming mode.

Parameter No. 16009 sets the M code for canceling the forming mode.

- 3 -

Page 14

1.PARAMETERS FOR THE PRESS FUNCTION B-64560EN/01

16010 Upper limit of the position deviation at which PF is set to “1”

[Input type] Parameter input

[Data type] Word axis

[Unit of data] Detection unit

[Valid data range] 0 to 32767

For each axis, parameter No. 16010 sets the upper limit of the positional deviation at

which the PF signal to start pressing is set to “1”. When the absolute value of the

positional deviation does not exceed this highest limit, PF is set to “1”.

Parameter No.16010 is validated when parameter bit 1 (PFE) of parameter No. 16001 is

set to 1.

NOTE

The parameter can only be set for the X, Y, and C axes.

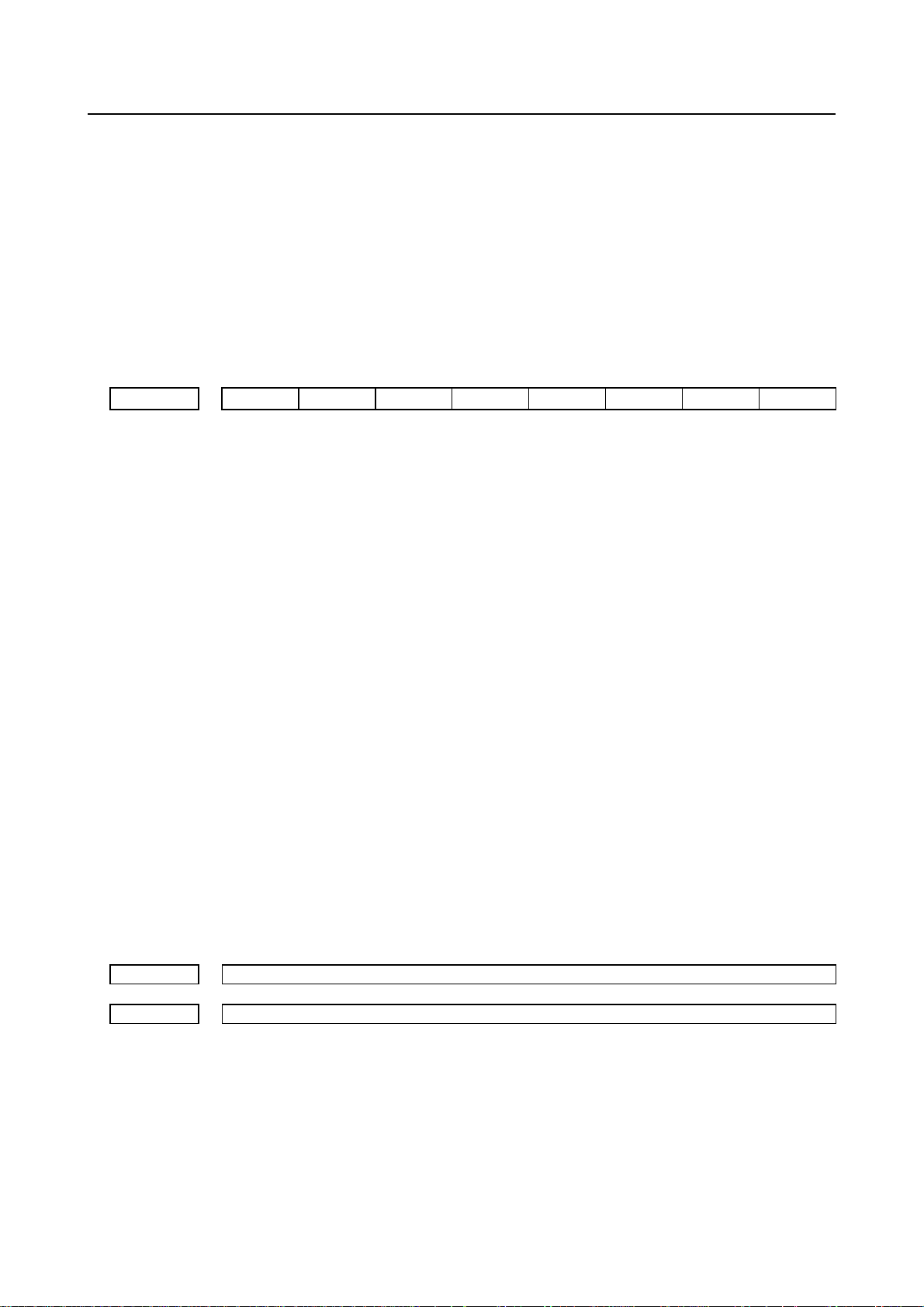

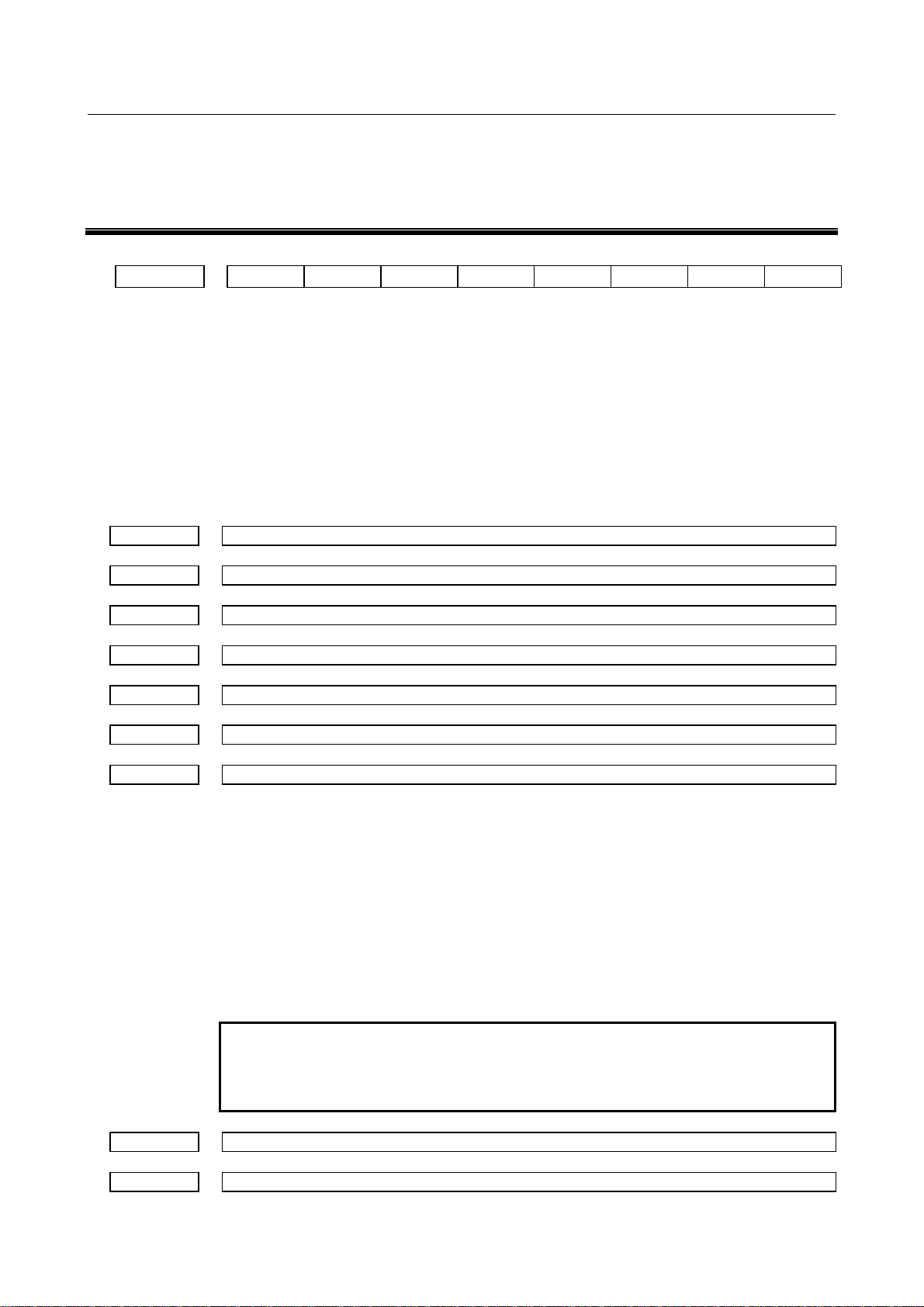

16011 Duration for which the start of positioning is delayed

[Input type] Parameter input

[Data type] Word axis

[Unit of data] msec

[Valid data range] 0 to 248

For each axis, parameter No. 16011 sets the duration for which the start of positioning is

delayed.

NOTE

Only a multiple of 8 can be set for parameter

1

The parameter can only be set for the X, Y, and C axes.

2

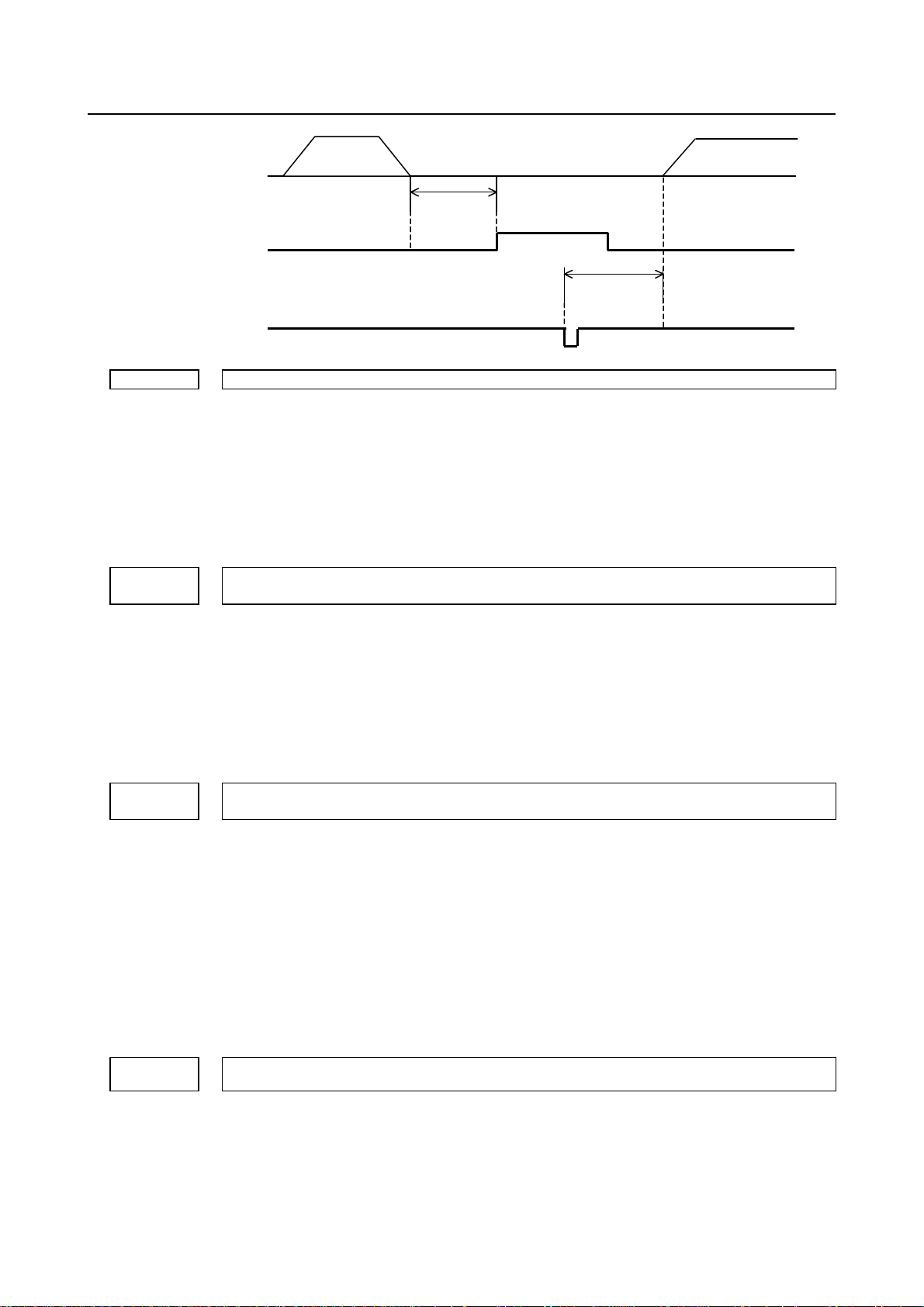

Positioning

Positioning in

the next block

No.

16011.

16012 Time interval by which setting of PF to “1” precedes completion of positioning

[Input type] Parameter input

[Data type:] Byte axis

[Unit of data] msec

[Valid data range] -120 to 120

For each axis, parameter No. 16012 sets the time interval by which setting of the PF

signal to start pressing to “1” precedes completion of positioning.(Function to advance

setting of the PF signal)

Time set in parameter No. 16011

- 4 -

Page 15

B-64560EN/01 1.PARAMETERS FOR THE PRESS FUNCTION

NOTE

1 If a negative value is specified, the PF signal is set to “1” when the

corresponding time period elapses after the completion of the

positioning.

2 When bit 0 (OAD) of parameter No. 6131 is set to 1, the data is

invalidated. If it is invalidated, see the descriptions of parameters

Nos. 16857 to 16863.

3 The parameter can only be set for the X, Y, and C axes.

16030

[Input type] Parameter input

[Data type] Word path

[Unit of data] msec

[Valid data range] 0 to 248

16031

[Input type] Parameter input

[Data type] Word path

[Unit of data] msec

[Valid data range] 0 to 248

16032 Time interval by which setting of PF to “1” follows positioning in the forming mode

[Input type] Parameter input

[Data type] Word path

[Unit of data] msec

[Valid data range] 0 to 248

16033

[Input type] Parameter input

[Data type] Word path

[Unit of data] msec

[Valid data range] 0 to 248

Time interval by which setting PF to “0” follows setting *PE to “0” in

single–cycle pressing

Parameter No. 16030 sets the time interval by which setting the PF signal to start pressing

to “0” follows setting the contact of the *PE signal to stop pressing to “0” in single–cycle

pressing.

Time interval between completion of positioning and the start of the next

block when PFL is set to “1”

Parameter No. 16031 sets the time interval between completion of positioning and the

start of the next block when are PFL signal to lock the start of pressing is set to “1”.

Parameter No. 16032 sets the time interval by which setting the PF signal to start pressing

to “1” follows positioning in the forming mode (except for nibbling).

Time interval by which the start of the next block follows setting of *PFIN to

“0” in the forming mode

Parameter No. 16033 sets the time interval by which the start of the next block follows

setting the contact of the *PFIN signal to complete punching for single–cycle pressing to

“0” in the forming mode.

- 5 -

Page 16

1.PARAMETERS FOR THE PRESS FUNCTION B-64560EN/01

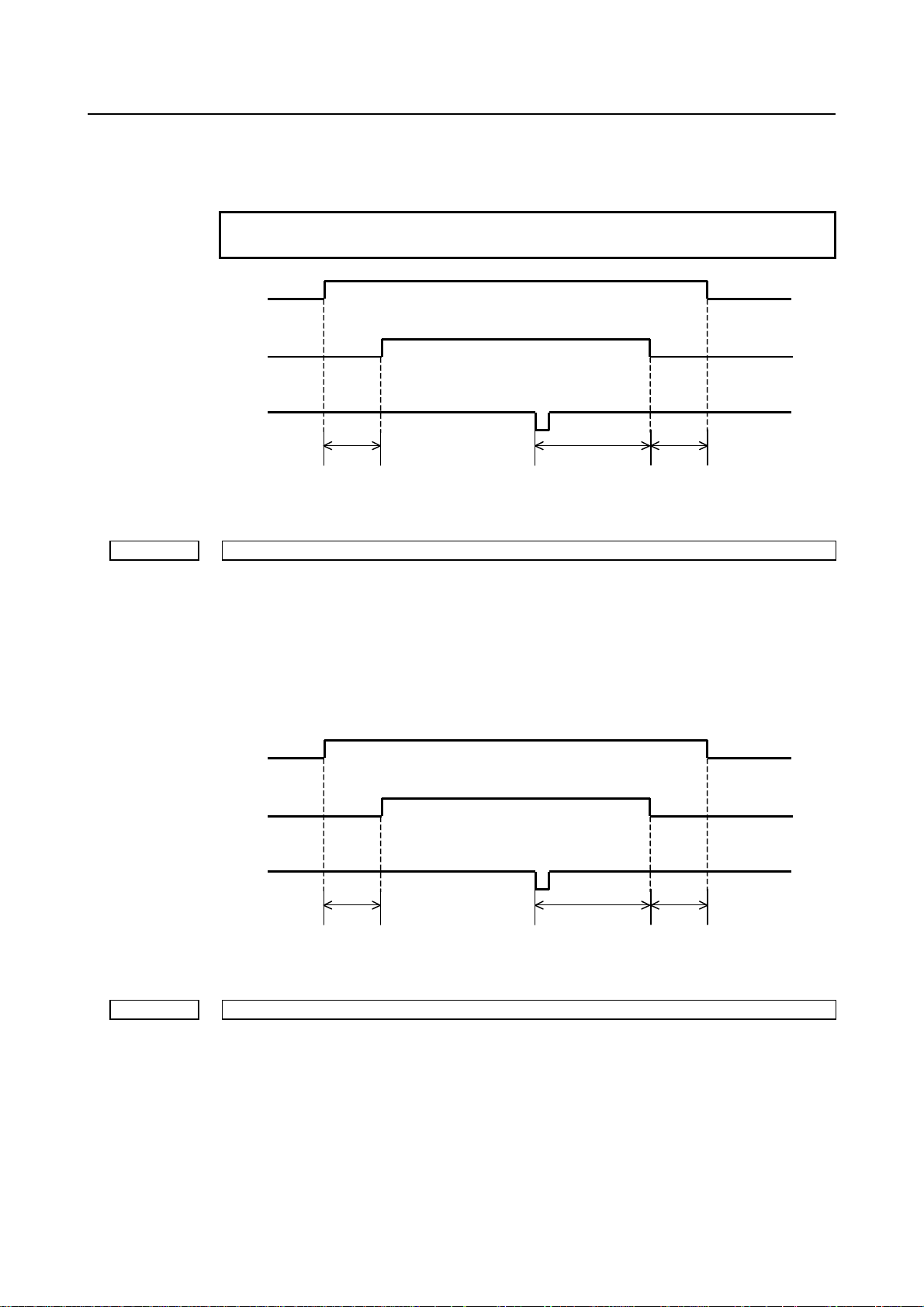

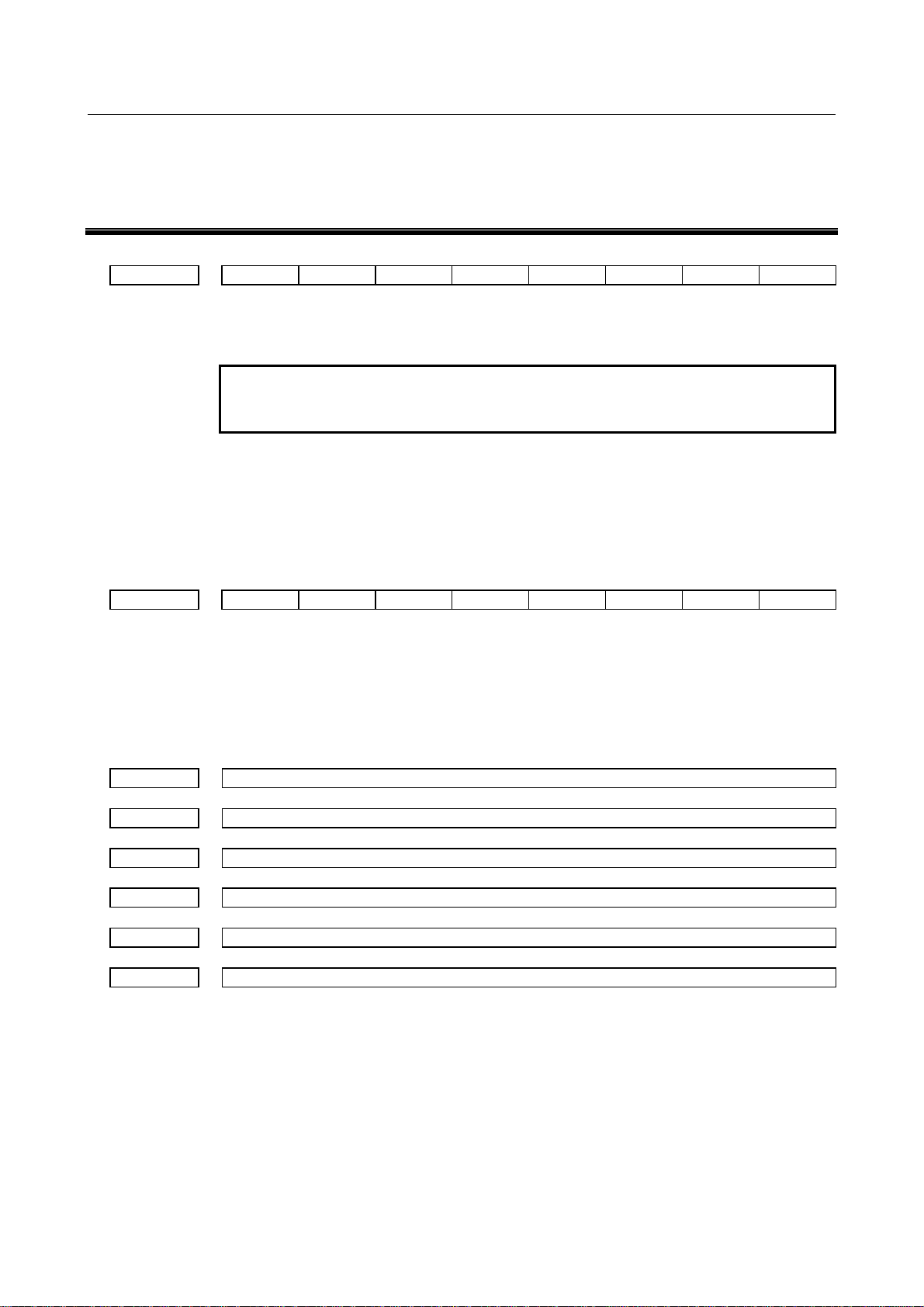

Positionin

PF

*PFIN

16034 Time interval by which setting PF to “1” follows first positioning in nibbling

[Input type] Parameter input

[Data type] Word path

[Unit of data] msec

[Valid data range] 0 to 248

Parameter No. 16034 sets the time interval by which setting the PF signal to start pressing

to “1” follows positioning at the first punch point in nibbling (nibbling by G68, G69, and

M code).

16035

Time interval by which the start of the next block follows setting *NFIN to “0”

[Input type] Parameter input

[Data type] Word path

[Unit of data] msec

[Valid data range] 0 to 248

Parameter No. 16035 sets the time interval by which the start of the next block follows

setting the contact of the *NFIN signal to complete punching for continuous pressing to

“0” at positioning at the last punch point in nibbling (nibbling by G68, G69, and M code).

16036

Minimum time interval by which setting of PF to “1” follows setting of *PFIN

[Input type] Parameter input

[Data type] Word path

[Unit of data] msec

[Valid data range] 0 to 248

Parameter No. 16036 sets the minimum time interval by which setting the PF signal to

start pressing to “1” follows setting the contact of the *PFIN signal to complete punching

for single–cycle pressing to “0” in single–cycle pressing. After the contact of *PFIN is set

to “0”, PF is set to “1” when the time set here elapses. PF is not set to “1” even if

positioning for the next block completes and other conditions are satisfied before the time

elapses.

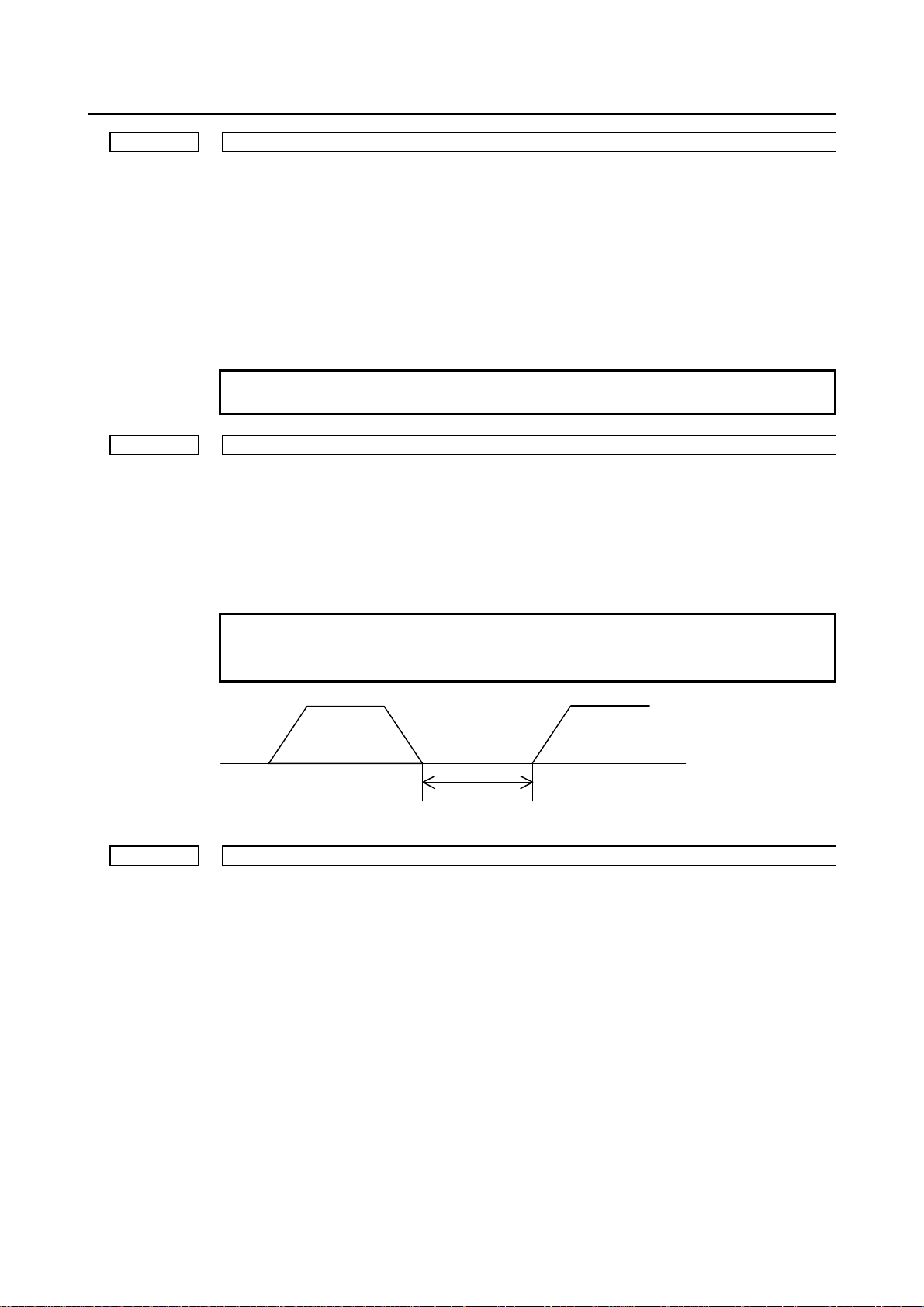

16037

Time interval by which setting PFB to “1” follows setting PF to “1”

[Input type] Parameter input

[Data type] Byte path

[Unit of data] msec

[Valid data range] 0 to 20

Time set in

parameter

No. 16032

at the last positioning in nibbling

and setting PF to “0” follows setting PFB to “0”

Time set in

parameter

No. 16033

to “0” in single–cycle pressing

Next block

- 6 -

Page 17

B-64560EN/01 1.PARAMETERS FOR THE PRESS FUNCTION

Parameter No. 16037 sets the time interval by which setting the PFB signal to start

pressing B to 1follows setting the PF signal to start pressing to “1” and setting PF to “0”

follows setting PFB to “0”.

NOTE

The parameter must be set to 0 when the PFB signal is not used.

PF

PFB

*PE

16038 Time interval by which setting PF to “0” follows setting PFB to “0”

[Input type] Parameter input

[Data type] Byte path

[Unit of data] msec

[Valid data range] 0 to 20

Parameter No. 16038 sets the time interval by which setting the PF signal to start pressing

to “0” follows setting the PFB signal to start pressing B to “0”.

The data is validated when bit 6 (PF9) of parameter No. 16002 is set to 1.

PF

PFB

*PE

Time set in

parameter

No. 16037

Time set in

parameter

No. 16030

Time set in

parameter

No. 16037

16039 Time interval by which setting PF to 0 follows setting *PE to “0” in nibbling

[Input type] Parameter input

[Data type] Word path

[Unit of data] msec

[Valid data range] 0 to 248

Parameter No. 16039 sets the time interval by which setting the PF signal to start pressing

to “0” follows setting the contact of the *PE signal to stop pressing to “0” in nibbling.

Time set in

parameter

No. 16037

Time set in

parameter

No. 16030

Time set in

parameter

No. 16038

- 7 -

Page 18

1.PARAMETERS FOR THE PRESS FUNCTION B-64560EN/01

16040 Time interval by which the start of the next block follows setting *PFIN to “0”

[Input type] Parameter input

[Data type] Word path

[Unit of data] msec

[Valid data range] 0 to 248

Parameter No. 16040 sets the time interval by which the start of the next block follows

setting the contact of the *PFIN signal to complete single–cycle pressing to “0” in a block

where the PF signal to start pressing is set to “1” (except for the nibbling or forming

mode).

16041 Time interval by which setting of EF to “1” precedes the completion of positioning

[Input type] Parameter input

[Data type] Byte axis

[Unit of data] msec

[Valid data range] -120 to 120s

This parameter sets the time interval by which setting of the EF signal to “1” by the

external operation function precedes the completion of positioning. If a negative value is

specified, the EF signal is set to “1” when the corresponding time period elapses after the

completion of positioning.

16044 Punching count of every one program execution

[Input type] Setting input

[Data type] 2-word path

[Unit of data] count

[Valid data range] 0 to 99999999

This parameter sets the amount of punching count of every program execution

In other words, this parameter sets the amount of punching count between cycle start

performed and cycle start performed again

When the CNC power-on and cycle start performed, this parameter sets 0

This parameter counts up to 99999999, and counts from 0 again afterwards.

16045

X address to which press stop signal *PE, punch finish signal for 1-cycle press *PFIN, and the press

start waiting signal B PFWB is assigned

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

[Input type] Parameter input

[Data type] word path

[Valid data range] 0 to 327

Set an X address to which press stop signal *PE<X004.7>, punch finish signal for 1-cycle

press *PFIN<X004.5>, and the press start waiting signal B PFWB<X004.4> is to be

assigned.

- 8 -

Page 19

B-64560EN/01 1.PARAMETERS FOR THE PRESS FUNCTION

NOTE

When bit 2 (XSG) of parameter No.3008 is set to 1, the data is

validated.

Depending on the option configuration of the I/O Link expansion,

the actually usable X addresses are:

<X0000 to X0127>, <X0200 to X0327>

16046 Address to which press start signal B PFB and press start signal PF is assigned

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

[Input type] Parameter input

[Data type] word path

[Valid data range] 0 to 327

Set a Y address to which press start signal B PFB<Y004.3> and press start signal

PF<Y004.2> is to be assigned.

NOTE

When bit 3 (YSG) of parameter No. 16000 is set to 1, the data is

validated.

Depending on the option configuration of the I/O Link expansion,

the actually usable Y addresses are:

<Y0 to Y127>, <Y200 to Y327>

16047 Delay time from the punch finish to the table axes movement start

[Input type] Parameter input

[Data type] word path

[Unit of data] msec

[Valid data range] 0 to 248

Set the delay time from setting the punch finish signal for 1-cycle press *PFIN<X004.5>

to “0” to the next block on account of compatible with FANUC Series 0i-PC

- 9 -

Page 20

2.PARAMETERS FOR THE SPEED AND LOOP GAIN SWITCH B-64560EN/01

2 PARAMETERS FOR THE SPEED AND

LOOP GAIN SWITCH

#7 #6 #5 #4 #3 #2 #1 #0

16050 NCT PCF G0F

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

[Input type] Parameter input

[Data type] Bit path

#0 G0F For a rapid traverse command (G00), the X–axis or Y–axis rapid traverse feedrate is set to

the value:

0: Specified in the parameter.

1: Specified by the F code.

The maximum feedrate of the F command is limited to the rapid traverse feedrate in the

parameter. Bit 0 (OADx) of parameter No.6131 and bit 0 (ILG) of parameter No.6132 are

valid.

#1 PCF The X–axis or Y–axis movement mode is selected for the following blocks:

(1) Movement to each punch point with the pattern function (G26, G76, G77, G78, etc.)

(2) Operation in automatic repositioning (G75)

(3) Movement to the first punch point with the nibbling function (G68, G69, and M

code)

0: Rapid traverse is executed.

1: For G00, rapid traverse is executed. For G01, G02, or G03, linear interpolation

cutting feed is executed.

#3 NCT Constant control of positioning time is:

0: Always enabled.

1: Enabled only when the nibbling command is executed.

This parameter is valid when the bit 6 (PT2x) of parameter No.16844 is set to 1.

#7 #6 #5 #4 #3 #2 #1 #0

16051 PGC PLG

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

[Input type] Parameter input

[Data type] Bit path

#6 PLG When the punching and laser modes are used, the servo loop gains of X–axis and Y–axis

position control in cutting feed:

0: Cannot be switched.

1: Can be switched.

- 10 -

Page 21

B-64560EN/01 2.PARAMETERS FOR THE SPEED AND LOOP GAIN SWITCH

#7 PGC Servo loop gains of X–axis and Y–axis position control to be used in rapid traverse and

cutting feed:

0: Are the same.

1: Can be set separately.

See the description of parameter No. 16160.

Servo loop gains to be used in cutting feed are set in parameter No. 16160.

#7 #6 #5 #4 #3 #2 #1 #0

16052 TJG NJC

[Input type] Parameter input

[Data type] Bit path

#0 NJC The jog feedrate is:

0: Limited to the manual rapid traverse rate.

1: Not limited to the manual rapid traverse rate.

#5 TJG The jog override signals for the T–axis and C–axis *JVT1,*JVT2<Gn233.0,.1> are:

0: Not used.

1: Used.

*JVT2 *JVT1 T–axis or C–axis override

0 0 100%

0 1 75%

1 0 50%

1 1 25%

#7 #6 #5 #4 #3 #2 #1 #0

16053 BLN ROM TMO

[Input type] Parameter input

[Data type] Bit path

#0 TMO Override for a linear acceleration/deceleration time constant for rapid traverse is:

0: Disabled

1: Enabled

#2 ROM Rapid traverse override is carried out:

0: According to the specification for the 0i -PD.

1: According to the specification for the 0i -MD.

The PF signal is issued in advance only when the override is100%.

The constant positioning–time control function cannot be used.

#3 BLN For the nibbling command, rapid traverse bell-shaped acceleration/deceleration is:

0: Enabled.

1: Disabled.

#7 #6 #5 #4 #3 #2 #1 #0

16054 NAZ

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

[Input type] Parameter input

- 11 -

Page 22

2.PARAMETERS FOR THE SPEED AND LOOP GAIN SWITCH B-64560EN/01

[Data type] Bit axis

#6 NAZ Specifies whether to make a return to the reference position of the CNC controlled axis

using G28 as follows:

0: Make a return.

1: Do not make a return.

16160 Servo loop gain in cutting feed

[Input type] Parameter input

[Data type] Word axis

[Unit of data] 0.01/sec

[Valid data range] 1 to 9999

For each axis, the parameter sets the servo loop gain of position control in cutting feed.

NOTE

1 The parameter is validated when bit 7 (PGC) of parameter No.

16051 is set to 1.

The parameter can only be set for the X and Y axes.

2

16161 Servo loop gain in cutting feed When the punching modes is used

[Input type] Parameter input

[Data type] Word axis

[Unit of data] 0.01/sec

[Valid data range] 1 to 9999

Sets the loop gain of each axis position control in cutting feed when the punching mode is

used.

When the laser mode is used, the value set in parameter No.16160 is valid.

NOTE

1 The parameter is validated when bit 7 (PGC) of parameter No.

16051 and bit 6 (PLG) of parameter No. 16051 are set to 1.

The parameter can only be set for the X and Y axes.

2

- 12 -

Page 23

B-64560EN/01 3.PARAMETERS FOR THE NIBBLING FUNCTION

3 PARAMETERS FOR THE NIBBLING

FUNCTION

#7 #6 #5 #4 #3 #2 #1 #0

16181 NEF NPF NSP NPC NMG

[Input type] Parameter input

[Data type] Bit path

#0 NMG When the M code for canceling the nibbling mode (No. 16184) is specified, the G code in

the 01 group is:

0: Not changed.

1: Changed to G00 (rapid traverse).

#1 NPC The function to change maximum pitch in the nibbling mode between two levels is:

0: Not used.

1: Used.

The function can be executed by the SNP signal for changing nibbling between two levels

or by the M code (No. 16185).

#2 NSP When the *SP signal to halt automatic operation is set to “0” in nibbling, automatic

operation is:

0: Decelerated and halted immediately.

1: Halted after positioning for a nibbling pitch completes.

#3 NPF In nibbling mode, a press sequence is:

0: Executed according to signals, NBL and *NFIN.

1: Executed according to signals PF, *PFIN, and *PE.

When this parameter is set to 1, a press sequence is executed in the same way as a

sequence for single–cycle press.

#6 NEF In nibbling mode, the

0: Disabled.

1: Enabled.

16183 M code for setting the nibbling mode

[Input type] Parameter input

[Data type] Word path

[Valid data range] 1 to 255

Parameter No.16183 sets the M code for setting the nibbling mode.

16184 M code for canceling the nibbling mode

[Input type] Parameter input

[Data type] Word path

[Valid data range] 1 to 255

Parameter No. 16184 sets the M code for canceling the nibbling mode.

external operation function is:

- 13 -

Page 24

3.PARAMETERS FOR THE NIBBLING FUNCTION B-64560EN/01

16185

M code for setting the nibbling mode in which nibbling is changed between

two levels

[Input type] Parameter input

[Data type] Word path

[Valid data range] 1 to 255

Parameter No. 16185 sets the M code for setting the nibbling mode in which nibbling is

changed between two levels.

NOTE

1 The data is validated when bit 1 (NPC) of parameter No. 16181 is

set to 1.

The M code in parameter

2

if set.

16186

Maximum pitch that can be specified with G01, G02, or G03 for nibbling

by G68 or G69 or by an M code

[Input type] Parameter input

[Data type] Real path

[Unit of data] mm, inch (input unit)

[Min. unit of data] Depend on the increment system of the reference axis

[Valid data range] Positive 9 digit of minimum unit of data

(When the increment system is IS-B, 0.001 to +999999.999)

Parameter No. 16186 specifies the maximum pitch that can be specified with G01, G02,

or G03 for nibbling by G68 or G69 or by an M code.

16188 Maximum pitch of the G00 command for nibbling by the M code

[Input type] Parameter input

[Data type] Real path

[Unit of data] mm, inch (input unit)

[Min. unit of data] Depend on the increment system of the reference axis

[Valid data range] Positive 9 digit of minimum unit of data

(When the increment system is IS-B, 0.001 to +999999.999)

Parameter No. 16188 specifies the maximum pitch of the G00 command for nibbling by

the M code.

Maximum pitch that can be specified with G01, G02, or G03 for nibbling

16190

Maximum pitch of 3rd level for the nibbling parameter switching control using an external signal

by G68 or G69 or by an M code (for changing nibbling between two levels)

[Input type] Parameter input

[Data type] Real path

[Unit of data] mm, inch (input unit)

[Min. unit of data] Depend on the increment system of the reference axis

[Valid data range] Positive 9 digit of minimum unit of data

(When the increment system is IS-B, 0.001 to +999999.999)

When the 2nd level is executed while the function for changing nibbling maximum pitch

between two levels is used, this parameter sets the maximum pitch that can be specified

with G01, G02, or G03 for nibbling by G68 or G69 or by an M code.

When the nibbling parameter switching control using an external signal is used, this

parameter sets the maximum pitch of 3rd level.

- 14 -

16184 is used to cancel the nibbling mode

No.

or

Page 25

B-64560EN/01 3.PARAMETERS FOR THE NIBBLING FUNCTION

16192 Maximum pitch of G00 command by an M code (for changing nibbling between two levels

[Input type] Parameter input

[Data type] Real path

[Unit of data] mm, inch (input unit)

[Min. unit of data] Depend on the increment system of the reference axis

[Valid data range] Positive 9 digit of minimum unit of data

(When the increment system is IS-B, 0.001 to +999999.999)

When the 2nd level is executed while the function for changing nibbling maximum pitch

between two levels is used, this parameter sets the maximum pitch of the G00 command

by an M code.

16194 Maximum distance traveled along C–axis in nibbling

[Input type] Parameter input

[Data type] Real path

[Unit of data] degree (input unit)

[Min. unit of data] Depend on the increment system of the applied axis

[Valid data range] Positive 9 digit of minimum unit of data

(When the increment system is IS-B, 0.001 to +999999.999)

The parameter sets the maximum distance traveled along the C–axis for the nibbling

mode.

- 15 -

Page 26

4. PARAMETERS FOR THE PATTERN FUNCTION AND THE U/V/W MACRO

FUNCTION (1 OF 2)

B-64560EN/01

4 PARAMETERS FOR THE PATTERN

FUNCTION AND THE U/V/W MACRO

FUNCTION (1 OF 2)

#7 #6 #5 #4 #3 #2 #1 #0

16200 UVW ABM MUR UVC

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

[Input type] Parameter input

[Data type] Bit path

#0 UVC In the reset status, the macro stored under a U or V macro number is:

0: Deleted.

1: Not deleted.

#5 MUR U or V macro numbers are handled:

0: According to the standard specifications.

Storage and execution: U1 to 59

Storage: U60 to 89

Representation of several macros: U90 to 99

1: According to the following specifications.

Storage and execution: U1 to 69、90 to 99

Storage: U70 to 79

Representation of several macros: U80 to 89

Macro numbers are handled in the same way as when parameter No. 16206 of the

G73 or G74 command for taking multiple workpieces is set to 2.

NOTE

When bit 5 (MUR) of parameter No.16200 is set to 1, parameter

No. 16206 is invalidated.

#6 ABM To execute a macro function, addresses A, and B:

0: Are used.

1: Are not used. (The A and B axes can be used.)

#7 UVW To execute a macro function, addresses U, V, and W:

0: Are used.

1: Are not used. (The U, V, and W axes can be used.)

#7 #6 #5 #4 #3 #2 #1 #0

16201 MSA AWP IPA APR MLP MPC LIP

[Input type] Parameter input

[Data type] Bit path

- 16 -

Page 27

4.PARAMETERS FOR THE PATTERN FUNCTION AND THE U/V/W MACRO

B-64560EN/01

#0 LIP In the block immediately following setting a local coordinate system (G52), an

incremental command specifies an incremental value from:

0: The origin of the local coordinate system.

1: The current tool position.

#2 MPC When the number of machined workpieces is counted in multiple–workpiece machining:

0: The number of actually machined workpieces is counted.

1: The number is incremented by one when complete machining or remainder

machining is executed (but not when trial machining is executed).

#3 MLP Setting for taking multiple workpieces depends on:

0: The set parameter (No.16206).

1: A signal (MLP1 or MLP2) input from the PMC machine.

#4 APR Upon reset, the compensation value of the reference point in the workpiece coordinate

system in the cause of repositioning

0: Not cleared.

1: Added to the workpiece coordinate system and cleared.

#5 IPA Although positioning is to be executed in the block immediately following execution of

the pattern function (including G68 orG69), only a command for either the X– or Y–axis

is specified. Movement to the pattern reference point:

0: Is not executed for the axis which is not specified.

1: Is executed for the axis which is not specified.

#6 AWP When a workpiece coordinate system is specified, automatic coordinate system setting is

executed as designed for:

0: The FANUC Series 0i-MD.

When manual return to the reference position is completed, the origin of the

coordinate system is shifted by the amount set for the selected workpiece coordinate

system (G54 to G59).

1: The FANUC Series 0i-PD.

When manual return to the reference position is completed, the coordinates of the

automatic coordinate system setting are shifted by the amount set for the selected

workpiece coordinate system (G54 to G59).

#7 MSA When the MUR bit (bit 5 of parameter No. 16200) is set to 1, the machining pattern set

for multiple–workpiece machining is:

0: Disabled.

When this is selected, the value of parameter No. 16206 is always assumed to be 2.

1: Enabled.

#7 #6 #5 #4 #3 #2 #1 #0

16202 AIP

[Input type] Parameter input

[Data type] Bit path

#0 AIP Specifies the condition for the share–proof command (G86).

0: Alarm (PS4506) is issued when I < 1.5P.

1: Alarm (PS4506) is issued when I < P.

FUNCTION (1 OF 2)

- 17 -

Page 28

4. PARAMETERS FOR THE PATTERN FUNCTION AND THE U/V/W MACRO

FUNCTION (1 OF 2)

B-64560EN/01

#7 #6 #5 #4 #3 #2 #1 #0

16203 PCU

[Input type] Parameter input

[Data type] Bit path

#0 PCU The number of machined workpieces is:

0: Counted by an MDI command.

1: Not counted by an MDI command.

#7 #6 #5 #4 #3 #2 #1 #0

16204 PDG BKR

[Input type] Parameter input

[Data type] Bit path

#2 BKR The first automatic repositioning command (G75) that sets automatic operation signal OP

from 0 to 1 uses:

0: The values set in parameter No. 16209 as the clearance and amount of return for the

Y–axis.

(The clearance and amount of return are identical values.)

1: The values set in parameter No. 16209 as the clearance for the Y–axis, and the

values set in parameter No. 16211 as the amount of return.

(The clearance and amount of return are different values.)

#4 PDG On the graphic screen, a program being drawn is:

0: Not displayed.

1: Displayed.

#7 #6 #5 #4 #3 #2 #1 #0

16205 SZR

[Input type] Parameter input

[Data type] Bit path

#0 SZR Automatic reference position return (G28) commands:

0: The axis returns directly to the reference position without passing through any

intermediate points.

1: The axis returns to the reference position via the specified intermediate point.

16206 Machining pattern when multiple workpieces are taken

[Input type] Setting input

[Data type] Byte path

[Valid data range] 0 to 3

Parameter No. 16206 sets a machining pattern when multiple workpieces are taken

- 18 -

Page 29

4.PARAMETERS FOR THE PATTERN FUNCTION AND THE U/V/W MACRO

B-64560EN/01

FUNCTION (1 OF 2)

Settable value

0 A program without the G73 or G74 command for machining when multiple

workpieces are taken is used.

1 A program containing the G73 or G74 command is used and test machining

is executed.

2 A program containing the G73 or G74 command is used and the remaining

processing is executed after test machining.

3 A program containing the G73 or G74 command is used and the entire

machining is executed.

Machining process when multiple workpieces are taken

NOTE

1 When bit 3 (MLP) of parameter No.16201 is set to 0, parameter No.

16206 is validated.

hen

2 W

parameter No. 16206 is set to 0, a

G73 or G74 command is found.

16207 M code for clamping a workpiece

16208 M code for releasing the workpiece

[Input type] Parameter input

[Data type] 2-word path

[Valid data range] 1 to 255

Parameter No. 16207 sets the M code for clamping a workpiece. Parameter No. 16208

sets the M code for releasing the workpiece.

In blocks between the M code for clamping a workpiece and the M code for releasing the

workpiece, the distances traveled along the X–axis and Y–axis are not take into account

in the workpiece coordinate system. The PF signal to start pressing is not set to “1”.

16209 Clearance and amount of return for the Y axis in automatic repositioning

[Input type] Parameter input

[Data type] Real path

[Unit of data] mm, inch (input unit)

[Min. unit of data] Depend on the increment system of the reference axis

[Valid data range] 0 or positive 9 digit of minimum unit of data (refer to standard parameter setting table

(B))

(When the increment system is IS-B, 0.001 to +999999.999)

The parameter sets the clearance and amount of return for the Y–axis in automatic

repositioning (G75).

16211 Amount of return for the Y axis in automatic repositioning

[Input type] Parameter input

[Data type] Real path

[Unit of data] mm, inch (input unit)

[Min. unit of data] Depend on the increment system of the reference axis

[Valid data range] 0 or positive 9 digit of minimum unit of data (refer to standard parameter setting table

(B))

(When the increment system is IS-B, 0.0 to +999999.999)

The parameter sets the amount of return for the Y–axis in automatic repositioning (G75).

The clearance is set in the parameter No. 16209.

larm (PS4539) is issued if the

- 19 -

Page 30

4. PARAMETERS FOR THE PATTERN FUNCTION AND THE U/V/W MACRO

FUNCTION (1 OF 2)

B-64560EN/01

NOTE

This parameter is valid when the BKR bit (bit 2 of parameter No.

16204) is set to 1.

16230 number of machined workpieces in multiple–workpiece machining

[Input type] Setting input

[Data type] 2-word path

[Unit of data] sheet

[Valid data range] 0 to 999999999

When U or V macro or subprogram called using a W code ends while multiple–

workpiece machining is executed by G73 or G74, this parameter increases by 1.

When the CNC is reset or multiple–workpiece machining is not executed, this parameter

sets 0.

- 20 -

Page 31

B-64560EN/01 5.PARAMETERS FOR THE PUNCH AND LASER SWITCH

5 PARAMETERS FOR THE PUNCH AND

LASER SWITCH

#7 #6 #5 #4 #3 #2 #1 #0

16240 RLM RPL

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

[Input type] Parameter input

[Data type] Bit path

#4 RPL When the system is reset, the punch mode and laser mode:

0: Can be switched by bit 5 (RLM) of parameter No.16240.

1: Can not be switched.

#5 RLM When the power is turned on or in the clear status, the machine is set in the:

0: Punch mode.

1: Laser mode.

#7 #6 #5 #4 #3 #2 #1 #0

16241 ILM

[Input type] Parameter input

[Data type] Bit path

#3 ILM In a block other than cutting feed blocks or blocks between the two cutting feed blocks

when the laser mode is selected, the next block is started:

0: After the following is checked: The specified speed is reduced to zero and the

machine reaches the specified position. (A position check is carried out.)

1: After checking that the specified speed is reduced to zero.(No position check is

carried out.)

The parameter is validated when bit 0 (ALA) of parameter No. 16242 is set to 1.

In punching mode, bit 5 (NCI) of parameter No. 1601 is valid.

#7 #6 #5 #4 #3 #2 #1 #0

16242

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

[Input type] Parameter input

[Data type] Bit

#0 ALA Switching between the punch mode and laser mode is:

0: Invalidated.

1: Validated.

ALA

- 21 -

Page 32

5.PARAMETERS FOR THE PUNCH AND LASER SWITCH B-64560EN/01

16244 M code for setting the punch mode

16245 M code for setting the laser mode

[Input type] Parameter input

[Data type] 2-word path

[Valid data range] 0 to 255

Each of the parameters set the M code for setting the punch mode or laser mode.

The parameters are validated when bit 0 (ALA) of parameter No. 16242 is set to 1.

- 22 -

Page 33

B-64560EN/01 6.PARAMETERS FOR THE TOOL FUNCTION (T FUNCTION) (1 OF 2)

6 PARAMETERS FOR THE TOOL FUNCTION

(T FUNCTION) (1 OF 2)

#7 #6 #5 #4 #3 #2 #1 #0

16260 TNM TCL

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

[Input type] Parameter input

[Data type] Bit path

#4 TCL The T axis is:

0: Not controlled by the CNC machine.

1: Controlled the CNC machine.

NOTE

1 When this parameter is set to 1, the T axis should be set as a

rotation axis. (bit 0 (ROTx) of parameter No. 1006 is set to 1)

2 When this parameter is set to 1, setting the following parameters

allows the CNC to be compatible with FANUC Series 0i-PC, as

follows:

Setting Meaning

Bit 0 (ROTx) of parameter No.1006=1

Bit 1 (ROSx) of parameter No.1006=0

Bit 0 (ROAx) of parameter No.1008=1 The rotary axis roll-over is valid.

Bit 1 (RABx) of parameter No.1008=0 The axis rotates in the direction in which

Bit 2 (RRLx) of parameter No.1008=1 Relative coordinates are rounded by the

Rotary axis (A type)

the distance to the target is shorter.

amount of the shift per one rotation

#5 TNM When machine lock signal MLK and the TNG signal for ignoring a T command are on,

whether the number following address T is cataloged as a tool number is:

0: Not checked.

1: Checked.

NOTE

Generally, the tool number is not checked when the TNG

set to “1”.

#7 #6 #5 #4 #3 #2 #1 #0

16262 MBT DTF TNA TND TDP PWT JGT NTD

[Input type] Parameter input

[Data type] Bit path

- 23 -

signal is

Page 34

6.PARAMETERS FOR THE TOOL FUNCTION (T FUNCTION) (1 OF 2) B-64560EN/01

#0 NTD The tool data input screen and the tool number registration screen for multiple tools are:

0: Displayed.

1: Not displayed.

#1 JGT On the position display screen in jog mode and incremental (INC) mode,, a T code (tool

number) is:

0: Not displayed by a signal input from the PMC.

1: Displayed by a signal (addresses G234 to G237) input from the PMC.

#2 PWT When the power is turned on, the T code (tool number) on the position display screen is:

0: Not represented by signal input from the PMC machine.

1: Represented by signal input from the PMC machine (addresses G234 to G237).

#3 TDP On the position screen, a T code is:

0: Not displayed.

1: Displayed.

NOTE

This parameter is invalid when the TCL bit (bit 4 of parameter No.

16260) is set to 1 and when the NDPx bit (bit 0 of parameter No.

3115) is set to 0.

#4 TND When the T–axis position is displayed,

0: The current position is indicated in units of minimum travel increments.

1: The number of the tool at the current position is indicated.

NOTE

This is validated when bit 3 (TDP) of parameter No. 16262 is set to

1.

#5 TNA When a tool number which is not cataloged is specified,

0: Alarm (PS4692) is issued.

1: No alarm are issued but a T code is output.

#6 DTF When T codes are specified in automatic operation, a TF signal for reading the code of

the tool function and the tool function code signal are output:

0: For each T code.

1: For the first T code command when the machine enters the status in which automatic

operation is started from the status in which automatic operation is halted or stopped.

For the second and subsequent T code commands specified until the machine returns

to the status in which automatic operation is halted or stopped, the TF signal and tool

function code signal are output only when the T code signal is different from the

previous one.

#7 MBT In a block in which a T code is specified, buffering is:

0: Executed.

1: Not executed.

#7 #6 #5 #4 #3 #2 #1 #0

16263 NDA IDX ROF TOF ATO OFM

[Input type] Parameter input

[Data type] Bit path

- 24 -

Page 35

B-64560EN/01 6.PARAMETERS FOR THE TOOL FUNCTION (T FUNCTION) (1 OF 2)

#0 OFM In a block containing a T command, the tool position is compensated:

0: Even if there is no movement along an axis.

1: Only when there is movement along an axis. If a block does not contain any

movements along an axis, the compensation is executed in the next block containing

movement along an axis.

#1 ATO The tool position is compensated:

0: Only when a tool command is specified.

1: According to the T code currently specified, even if no tool commands are specified.

#2 TOF The function for compensating the tool position is:

0: Invalidated.

1: Validated.

Specify a tool position compensation value on the tool input screen.

#3 ROF At reset, compensation of tool position is:

0: Not canceled.

1: Canceled.

#6 IDX The tool position is not compensated in a block in which no movement along an axis

occurs. In the next block containing movement along an axis the tool position is

compensated:

0: For each T code.

1: Only for T codes with which turret indexing is not executed.

NOTE

This is validated when bit 0 (OFM) of parameter No. 16263 is set to

1.

#7 NDA If a T command is specified in normal direction mode:

0: An alarm is issued (alarm PS 4606).

1: An alarm is not issued.

If a multi–tool command is specified, however, an alarm is issued.

16265 Total number of tools to be used

[Input type] Parameter input

[Data type] Word path

[Valid data range] 0 to 136

This parameter specifies the total number of tools to be used by the tool function. If

T–axis control is selected (TCL bit (bit 4 of parameter No. 16260) is set to 1), the total

number should include the number of tools for which T–axis control (turret index) is not

executed. This parameter can be specified on the tool input screen. The tool numbers to

be used should be specified on the tool input screen.

16266 Number of tools for which T–axis control is executed

[Input type] Parameter input

[Data type] Word path

[Valid data range] 0 to 136

This parameter specifies the number of tools for which T–axis control (turret index) is

executed. The parameter can be specified on the tool input screen.

- 25 -

Page 36

6.PARAMETERS FOR THE TOOL FUNCTION (T FUNCTION) (1 OF 2) B-64560EN/01

NOTE

This parameter is valid when the TCL bit (bit 4 of parameter No.

16260) is set to 1.

16267 Reference–position tool number under T–axis control

[Input type] Parameter input

[Data type] 2-word path

[Valid data range] 0 to 99999999

This parameter specifies the tool number to be selected upon reference position return for

the T–axis. The parameter can be specified on the tool input screen.

NOTE

This parameter is valid when the TCL bit (bit 4 of parameter No.

16260) is set to 1.

16269 Punching count for all tools (low–order)

16270 Punching count for all tools (high–order)

[Input type] Parameter input

[Data type] 2-word path

[Valid data range] 0 to 99999999

These parameters preset the punching count for all tools to be used.

Parameter No. 16269 and No. 16270 can be preset on the tool input screen.

- 26 -

Page 37

B-64560EN/01 7.PARAMETERS FOR C–AXIS CONTROL

7 PARAMETERS FOR C–AXIS CONTROL

#7 #6 #5 #4 #3 #2 #1 #0

16360 CBR CIP ACS MAB MAI SYN

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

[Input type] Parameter input

[Data type] Bit path

#0 SYN C-axis synchronous control is:

0: Disabled.

1: Enabled.

#2 MAI The function for compensating the C–axis position is:

0: Invalidated.

1: Validated.

#3 MAB The function B for compensating the C-axis position is:

0: Invalidated.

1: Validated.

#4 ACS Under C–axis synchronous control, synchronization is:

0: Invalidated.

1: Validated.

#5 CIP In G01, G02, and G03 modes, a C–axis command is:

0: Invalidated.

1: Validated.

#7 CBR For a tool for which C–axis control can be executed, a C–axis backlash compensation

value is:

0: Not separately specified.

The compensation value set in parameter No.1852 is validated.

1: Separately specified.

The compensation value set in parameter No.1852 is invalidated.

The compensation value for each tool is set in the corresponding parameter among

parameter No.16390 to No.16429.

#7 #6 #5 #4 #3 #2 #1 #0

16362 NRC CRM G92 CNT CR0 RCO

[Input type] Parameter input

[Data type] Bit path

#0 RCO At reset, compensation of C–axis position is:

0: Not canceled.

1: Canceled.

- 27 -

Page 38

7.PARAMETERS FOR C–AXIS CONTROL B-64560EN/01

#1 CR0 When reference position return is performed for the C–axis,:

0: C-axis is positioned to the absolute position set in parameter No.1250.

1: C-axis is positioned to the 1st reference position.

NOTE

This parameter is effective to automatic reference position return

(G28) and reference position return of C-axis under C-axis control.

#2 CNT If a T code with which turret indexing is not executed is specified when the C axis is not

at the reference point, the machine is:

0: Moved along the C–axis to the reference point.

1: Not moved along the C–axis to the reference point.

NOTE

This is validated when bit 5 (CRM) of parameter No. 16362 is set to

0.

#3 G92 Under C–axis control, G92 command for C–axis control is:

0: Invalidated.

1: Validated.

#5 CRM According to a T command, the machine is:

0: Moved along the C–axis to the reference point.

1: Not moved along the C–axis to the reference point.

#7 NRC According to the command of automatic return to the reference point (G28), the machine

is:

0: Moved along the C–axis to the reference point.

1: Not moved along the C–axis to the reference point.

NOTE

This is validated when bit 5 (CRM) of parameter No. 16362 is set to

0.

#7 #6 #5 #4 #3 #2 #1 #0

16363 NDD C2D NDC NDB G91

[Input type] Parameter input

[Data type] Bit path

#0 G91 For C-axis control, a G91 command is:

0: Disabled

1: Enabled

#1 NDB Positioning under normal direction control is carried out:

0: According to the specification for the 0i-MD.

1: By handling the C-axis angle immediately before the beginning of the normal

direction control mode, as an offset value.

#3 NDC Positioning under normal direction control is carried out:

0: According to the specification for the 0i-MD.

1: By handling the C–axis angle immediately before the beginning of the normal

direction control mode, as the direction normal to the next traveling direction.

- 28 -

Page 39

B-64560EN/01 7.PARAMETERS FOR C–AXIS CONTROL

NOTE

When bit 1 (NDB) and bit 3 (NDC) of parameter No. 16363 are set

to 1, the movement specified by bit 1 (NDB) of parameter No.

16363 has priority over the movement by bit 3 (NDC) of parameter

No. 16363.

#6 C2D C–axis non-synchronization control signal C2DABL<Gn231.7> is:

0: Disabled.

1: Enabled.

NOTE

When C–axis synchronization control is used, this parameter is

enabled.

#7 NDD When circular interpolation (G02, G03) is specified under normal direction control and

the rotation insertion angle calculated during normal direction control does not exceed the

value is set in the parameter No.5482,:

0: The CNC gentles normal direction control axis simultaneously with the X/Y-axis

motion.(FANUC Series 0i-PC system compatible specification)

1: The CNC moves normal direction control axis to the end of the block. (FANUC

Series 0i-PD system specification)

16364 Upper limit of error under C–axis synchronous control

[Input type] Parameter input

[Data type] 2-word path

[Unit of data] Detection unit

[Valid data range] 0 to 999999999

When the absolute value of the position error between the C

1–axis and C2–axis exceeds

the value set in this parameter under C–axis synchronous control, alarm (DS4603) occurs.

NOTE

This parameter is valid when the SYN bit (bit 0 of parameter No.

16360) is set to 1.

16365 Upper limit of error under C–axis synchronous control (during continuous pressing)

[Input type] Parameter input

[Data type] 2-word path

[Unit of data] Detection unit

[Valid data range] 0 to 999999999

When the absolute value of the position error between the C

1–axis and C2–axis exceeds

the value set in this parameter while continuous pressing signal NBL is set to “1”, alarm

(DS4603) occurs.

NOTE

This parameter is valid when the SYN bit (bit 0 of parameter No.

16360) is set to 1.

- 29 -

Page 40

7.PARAMETERS FOR C–AXIS CONTROL B-64560EN/01

16368 Maximum compensation in C–axis synchronization

[Input type] Parameter input

[Data type] Real path

[Unit of data] degree (machine unit)

[Min. unit of data] Depend on the increment system of the reference axis

[Valid data range] 0 or positive 9 digit of minimum unit of data (refer to the standard parameter setting

table(B))

(When the increment system is IS-B, 0.0 to +999999.999)

This parameter specifies the maximum compensation in C–axis synchronization under

C–axis synchronous control. If an actual compensation value exceeds this value, alarm

(SV0410) occurs in the stop state or during travel.

NOTE

This parameter is valid when the ACS bit (bit 4 of parameter No.

16360) is set to 1.

16370 Number of tool 1 for which C–axis control can be executed

16371 Number of tool 2 for which C–axis control can be executed

16372 Number of tool 3 for which C–axis control can be executed

16373 Number of tool 4 for which C–axis control can be executed

16374 Number of tool 5 for which C–axis control can be executed

16375 Number of tool 6 for which C–axis control can be executed

16376 Number of tool 7 for which C–axis control can be executed

16377 Number of tool 8 for which C–axis control can be executed

16378 Number of tool 9 for which C–axis control can be executed

16379 Number of tool 10 for which C–axis control can be executed

16380 Number of tool 11 for which C–axis control can be executed

16381 Number of tool 12 for which C–axis control can be executed

16382 Number of tool 13 for which C–axis control can be executed

16383 Number of tool 14 for which C–axis control can be executed

16384 Number of tool 15 for which C–axis control can be executed

16385 Number of tool 16 for which C–axis control can be executed

16386 Number of tool 17 for which C–axis control can be executed

16387 Number of tool 18 for which C–axis control can be executed

- 30 -

Page 41

B-64560EN/01 7.PARAMETERS FOR C–AXIS CONTROL

16388 Number of tool 19 for which C–axis control can be executed

16389 Number of tool 20 for which C–axis control can be executed

[Input type] Parameter input

[Data type] 2-word path

[Valid data range] 0 to 99999999

Each of the parameters set the number of a tool for which C–axis control can be executed.

C–axis control can be effective for the tool set to this parameter.

16390 C-axis backlash 1

16391 C-axis backlash 2

16392 C-axis backlash 3

16393 C-axis backlash 4

16394 C-axis backlash 5

16395 C-axis backlash 6

16396 C-axis backlash 7

16397 C-axis backlash 8

16398 C-axis backlash 9

16399 C-axis backlash 10

16400 C-axis backlash 11

16401 C-axis backlash 12

16402 C-axis backlash 13

16403 C-axis backlash 14

16404 C-axis backlash 15

16405 C-axis backlash 16

16406 C-axis backlash 17

16407 C-axis backlash 18

16408 C-axis backlash 19

16409 C-axis backlash 20

[Input type] Parameter input

[Data type] Word path

[Unit of data] Detection unit

[Valid data range] -9999 to 9999

- 31 -

Page 42

7.PARAMETERS FOR C–AXIS CONTROL B-64560EN/01

Each of these parameters specifies a C–axis backlash for each tool for which C–axis

control can be executed (C

1–axis backlash under C–axis synchronous control).

The parameter values correspond to the tool numbers specified in parameter Nos. 16370

to 16389, respectively.

NOTE

These parameters are valid when the CBR bit (bit 7 of parameter

16360) is set to 1. When these parameters are valid, the C–axis

backlash specified in parameter No. 1852 is invalid.

16410 C2 axis backlash 1

16411 C2 axis backlash 2

16412 C2 axis backlash 3

16413 C2 axis backlash 4

16414 C2 axis backlash 5

16415 C2 axis backlash 6

16416 C2 axis backlash7

16417 C2 axis backlash8

16418 C2 axis backlash 9

16419 C2 axis backlash 10

16420 C2 axis backlash 11

16421 C2 axis backlash 12

16422 C2 axis backlash 13

16423 C2 axis backlash 14

16424 C2 axis backlash 15

16425 C2 axis backlash 16

16426 C2 axis backlash 17

16427 C2 axis backlash 18

16428 C2 axis backlash 19

16429 C2 axis backlash 20

[Input type] Parameter input

[Data type] Word path

[Unit of data] Detection unit

[Valid data range] -9999 to 9999

- 32 -

Page 43

B-64560EN/01 7.PARAMETERS FOR C–AXIS CONTROL

Each of these parameters specifies a C2–axis backlash for each tool for which C–axis

control can be executed.

The parameter values correspond to the tool numbers specified in parameter Nos. 16370

to 16389, respectively.

NOTE

These parameters are valid when both the SYN and CBR bits (bits

0 and 7 of parameter 16360) are set to 1. When these parameters

are valid, the C–axis backlash specified in parameter No. 1852 is

invalid.

16430 C–axis position compensation 1

16431 C–axis position compensation 2

16432 C–axis position compensation 3

16433 C–axis position compensation 4

16434 C–axis position compensation 5

16435 C–axis position compensation 6

16436 C–axis position compensation 7

16437 C–axis position compensation 8

16438 C–axis position compensation 9

16439 C–axis position compensation 10

16440 C–axis position compensation 11

16441 C–axis position compensation 12

16442 C–axis position compensation 13

16443 C–axis position compensation 14

16444 C–axis position compensation 15

16445 C–axis position compensation 16

16446 C–axis position compensation 17

16447 C–axis position compensation 18

16448 C–axis position compensation 19

16449 C–axis position compensation 20

[Input type] Parameter input

[Data type] Real path

[Unit of data] degree (machine unit)

- 33 -

Page 44

7.PARAMETERS FOR C–AXIS CONTROL B-64560EN/01

[Min. unit of data] Depend on the increment system of the reference axis

[Valid data range] 9 digit of minimum unit of data (refer to standard parameter setting table (A))

(When the increment system is IS-B, -999999.999 to +999999.999)

Each of these parameters specifies a C–axis position compensation value (C

1–axis

backlash under C–axis synchronous control).

These compensated values correspond to the tool numbers set in parameter Nos. 16370 to

16389.

NOTE

The values validated when bit 2 (MAI) of parameter MAI is set to 1.

16450 C2–axis position compensation 1

16451 C2–axis position compensation 2

16452 C2–axis position compensation 3

16453 C2–axis position compensation 4

16454 C2–axis position compensation 5

16455 C2–axis position compensation 6

16456 C2–axis position compensation 7

16457 C2–axis position compensation 8

16458 C2–axis position compensation 9

16459 C2–axis position compensation 10

16460 C2–axis position compensation 11

16461 C2–axis position compensation 12

16462 C2–axis position compensation 13

16463 C2–axis position compensation 14

16464 C2–axis position compensation 15

16465 C2–axis position compensation 16

16466 C2–axis position compensation 17

16467 C2–axis position compensation 18

16468 C2–axis position compensation 19

16469 C2–axis position compensation 20

[Input type] Parameter input

[Data type] Real path

- 34 -

Page 45

B-64560EN/01 7.PARAMETERS FOR C–AXIS CONTROL

[Unit of data] degree (machine unit)

[Min. unit of data] Depend on the increment system of the reference axis

[Valid data range] 9 digit of minimum unit of data (refer to standard parameter setting table (A))

(When the increment system is IS-B, -999999.999 to +999999.999)

Each of these parameters specifies a C

–axis position compensation value.

2

These compensated values correspond to the tool numbers set in parameter Nos. 16370 to

16389.

NOTE

These parameters are valid when both the SYN and MAI bits (bits

0 and 2 of parameter No. 16360) are set to 1.

16480 Axis number of C2–axis under C–axis synchronization control

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

[Input type] Parameter input

[Data type] Word path

[Valid data range] 0 to Number of controlled axes

This parameter sets the axis number of the C

-axis under C–axis synchronization control.

2

NOTE

These parameters are valid when both the SYN bit (bits 0 of

parameter No. 16360) are set to 1.

- 35 -

Page 46

8.PARAMETERS FOR THE SAFETY ZONE B-64560EN/01

8 PARAMETERS FOR THE SAFETY ZONE

#7 #6 #5 #4 #3 #2 #1 #0

16500 YSF SAT SF0

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

[Input type] Parameter input

[Data type] Bit path

#0 SF0 The safety zone of type:

0: A is used.

1: B is used.

#5 SAT When punching is inhibited in the safety zone, the block in which a T command is

specified is checked:

0: In advance.

1: After the FIN signal to complete the T command has been received.

#7 YSF When a safety zone check is executed, the inhibited area along the Y axis extends from

the values:

0: In the negative direction.

1: In the positive direction.

#7 #6 #5 #4 #3 #2 #1 #0

16501 SZ4 SZ3 SZ2 SZ1

[Input type] Parameter input

[Data type] Bit path

#0 to 3 SFj When a safety zone check is executed, in the #j (j=1 to 4) area,

0: An entry is inhibited.

1: Punching is inhibited.

NOTE

When type B of safety zone check is used, this parameter is

disabled.

#7 #6 #5 #4 #3 #2 #1 #0

16502 SOF ZNO SZI GSZ ZIO SZC MDP

[Input type] Parameter input

[Data type] Bit path

#0 MDP On the safety zone setting display,

0: The workpiece coordinate system is indicated.

1: The machine coordinate system is indicated.

- 36 -

Page 47

B-64560EN/01 8.PARAMETERS FOR THE SAFETY ZONE

#1 SZC On the safety zone setting display, the data for:

0: Any zone can be changed.

1: Those zones to be set automatically (parameter No. 16534) can be changed.

#2 ZIO When the safety zone is automatically set by an external signal, the position of a

workpiece holder is detected according to:

0: The on and off states of the SAFZ signal used to detect the position of a workpiece

holder.

1: The on state of the SAFZ signal used to detect the position of a workpiece holder.

#3 GSZ On the graphic screen, the safety zone is checked according to the position of a workpiece

holder:

0: Specified on the safety zone screen.

1: Specified by graphic parameters.

(On the graphic screen, this check is executed in an area that is not related to the

actual machining check.)

#4 SZI Data set on the safety zone setting display is:

0: Invalidated.

1: Validated.

#5 ZNO In the safety zone area setting screen of the safety zone B specification, :

0: Number of zone and other number than number of zone can be inputted.

1: Number of zone can be inputted.

#7 SOF In the safety zone check, tool position compensation is:

0: Not considered.

1: Considered.

#7 #6 #5 #4 #3 #2 #1 #0

16504 RTZ SPA

[Input type] Parameter input

[Data type] Bit path

#0 SPA In the case of type A of the safety zone check, when the end point of positioning is in the

safety zone or the tool path is interfered with the safety zone, :

0: An alarm is not given.

1: An alarm is given without moving the axis. (Previous check)

#1 RTZ In the safety zone check, setting area of the circle tool figure is:

0: Disabled.

1: Enabled.

16505 Positive X coordinate for safety zone 1

16506 Negative X coordinate for safety zone 1

16507 Y coordinate for safety zone 1

16508 Positive X coordinate for safety zone 2

16509 Negative X coordinate for safety zone 2

- 37 -

Page 48

8.PARAMETERS FOR THE SAFETY ZONE B-64560EN/01

16510 Y coordinate for safety zone 2

16511 Positive X coordinate for safety zone 3

16512 Negative X coordinate for safety zone 3

16513 Y coordinate for safety zone 3

16514 Positive X coordinate for safety zone 4

16515 Negative X coordinate for safety zone 4

16516 Y coordinate for safety zone 4

[Input type] Parameter input

[Data type] Real path

[Unit of data] mm, inch (machine unit)

[Min. unit of data] Depend on the increment system of the reference axis

[Valid data range] 9 digit of minimum unit of data (refer to standard parameter setting table (A))