Page 1

Product Bulletin

8532 Valve

D101552X012

Fisherr 8532 High-Performance Butterfly

Valve

The Fisher 8532 high-performance butterfly valve

provides outstanding performance under extreme

pressure and temperature conditions. The 8532 valve

maintains tight shutoff, is available in a fire-tested

version, and can be specified for cryogenic

applications.

The 8532 valve is available as either a flangeless,

wafer-style design or as a single-flange (lugged)

design. A splined drive shaftcombineswithavarietyof

spring-and-diaphragm or pneumatic piston actuators

to make the 8532 a reliable, high-performance

butterfly valve for a variety of throttling and on-off

applications in the various process industries.

The8532valvecanbesuppliedwithoneofseveral

dynamic seals (figure 4) that can be used in a variety of

demanding applications. With the appropriate seal

selection and materials of construction, the

pressure-assisted seal provides excellent shutoff

against the full CL150 or CL300 pressure ratings.

Unless otherwise noted, all NACE references are to

NACE MR0175-2002.

W9138-2

Economically Designed for Minimal Deadband–A

splined end connection on the drive shaft allows

lever clamping by most Fisher rotary actuators.

Application Versatility–Standard construction

materials and seal assemblies provide long life and

outstanding performance in a broad range of liquid

and gas applications.

51.6:8532

April 2013

Features

Economical Tight Shutoff–The pressure-assisted

seal design provides tight shutoff against the full

pressure rating of the specified valve.

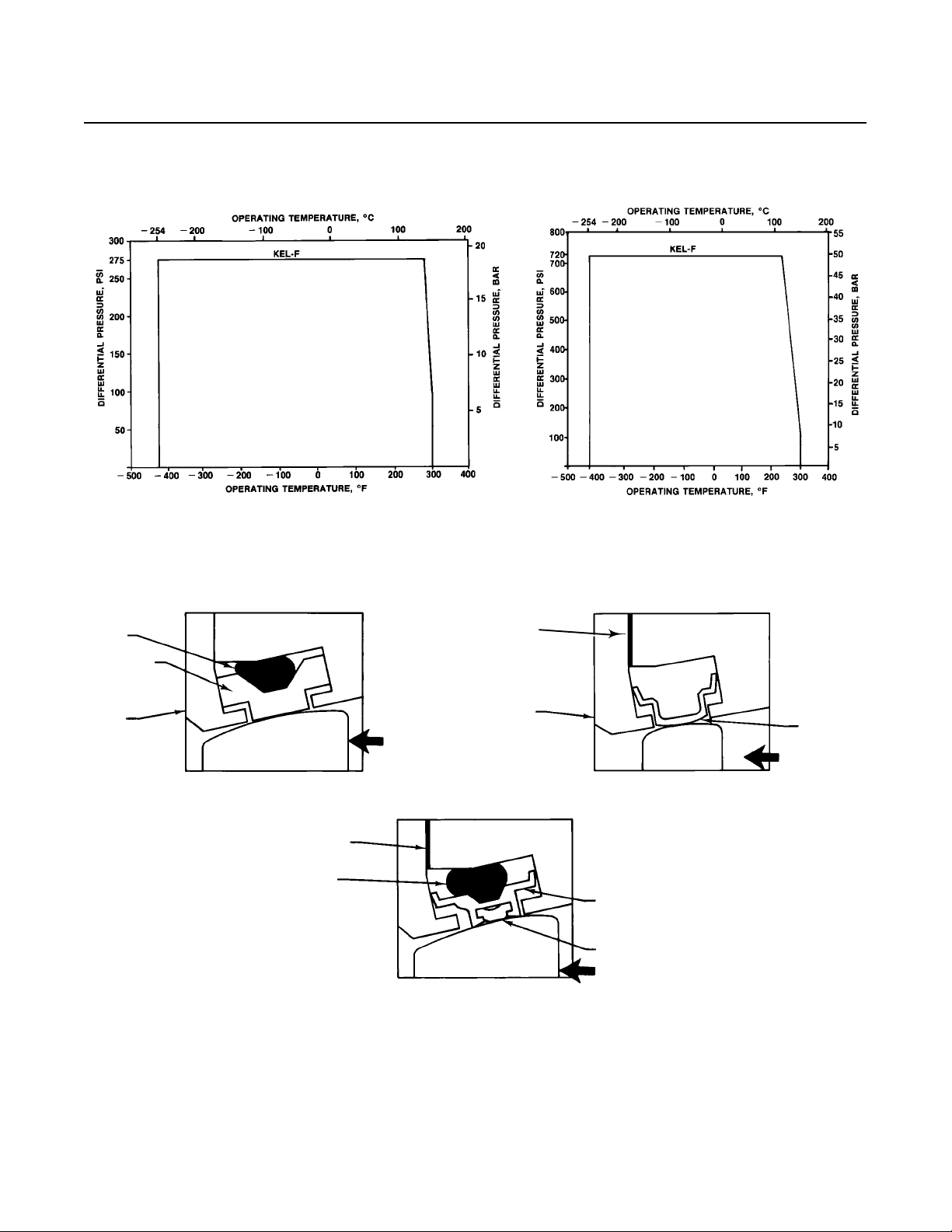

Safety–Shaft blowout protection is designed into

the8532valve(figure6).Theanti-blowout gland

fits securely over the valve shaft which has been

turned down to form a circumferential shoulder

that contacts the anti-blowout gland.

Excellent Flow Control–With a modified equal

percentage flow characteristic, the 8532 can be

used for throttling applications through 90 degrees

of disc rotation. Rangeability is 100 to 1.

Ease of Maintenance–Interchangeability of all parts

including shafts and discs simplifies service and

reduces maintenance costs.

Improved Environmental Capabilities– The optional

ENVIRO-SEALpackingsystemisdesignedwithvery

smooth stem surfaces and live-loading provides

improved sealing, guiding, and loading force

transmission. The ENVIRO-SEAL packing system can

control emissions below the EPA (Environmental

Protection Agency) limit of 100 ppm (parts per

million).

Easy Installation–The valve body self-centers on the

line flange bolts as a fast, accurate means of

centering the valve in the pipeline.

Reliable Flange Gasketing Surface–Seal retainer

screws are located so there is no interference with

the sealing function of either flat sheet or spiral

woundlineflangegaskets.

www.Fisher.com

Page 2

Product Bulletin

51.6:8532

April 2013

Specifications

8532 Valve

D101552X012

Available Valve Configurations

J Flangeless, wafer-style or J single-flange (lugged)

controlvalvewithaone-piece valve body, a

two-component seal/backup O-ring, and a splined

drive shaft

Valve Body Sizes

NPS J 14, J 16, J 18, J 20, and J 24

End Connection Style

J Flangeless, wafer-style or J single flange valve

body designed to fit between raised-face mating

flanges per ASME B16.5 CL150 or CL300

Maximum Inlet Pressure/Temperature

(1)

Consistent with J CL150 and J CL300

pressure/temperature ratings per ASME B16.34. Also,

see figures 2 and 3 for additional information

Available Seal Configurations

Standard Constructions

Seefigure4andtable2

Standard Construction Materials

Valve Body and Disc: ASTM grades of J carbon steel

or J stainless steel

Disc Coating:

Hardcoating (also see table 2): J Standard when used

with NOVEX seal, J Phoenix III seal, or J Cryogenic

seal

Chromium Carbide: Standard when service

temperature exceeds 538_C (1000_F)

Shaft: ASTM grade of J S17400 (17-4PH H1025 SST),

J S17400 (17-4PH H1150M SST), or J S20910

Shaft Extension Lengths:

High Temperature J None required for temperatures

less than 343_C(650_F),

J 6 inches for temperatures from 343 to 538_C(650

to 1000_F), or J 12 inches for temperatures above

538_C (1000_F)

Cryogenic J 914mm (36 inches)

Seal Ring: J PTFE, J S31600 (316 SST), J S21800,

J S31600/PTFE, J UHMWPE

(4)

,orJ CTFE

(5).

Backup ring: J Nitrile, J Chloroprene, J PTFE,

J Fluorocarbon--for a broad range of hydrocarbon

and chemical process applications

process applications including steam and water

(1)

or J EPR--for

(1)

backup ring is not used with the NOVEX seal

Packing: J PTFE V-ring (standard packing),

J Graphite (optional), or J ENVIRO-SEALt

packing (optional)

Bearings: J PEEK

.

(2)

(standard material), and

J S31600, J PTFE Composition, or J CoCr-A(Alloy

6) (optional)

Valve Body Classification

Face-to-face dimensions are in compliance with MSS

SP68 and API 609 standards; valve bodies are

designed for installation between ASME B16.5 CL150

or CL300 raised-face flanges

Shutoff Classification. Per ANSI/FCI 70-2and

IEC 60534-4

Standard Soft Seal: Bidirectional bubble-tight shutoff

NOVEX Seal: Unidirectional shutoff

1% of Class IV (preferred flow direction only

(3)

),

optional Class VI

Phoenix III Seal: Bidirectional bubble-tight

Phoenix III Seal for Fire Tested Applications: Class VI

shutoff. Contact your Emerson Process Management

sales office for more information.

Flow Characteristic

Modified equal percentage

Flow Coefficients

See table 1 and Fisher Catalog 12

Noise Levels

See Catalog 12 for sound pressure level prediction

Available Actuators

J Spring-and-diaphragm, or J pneumatic piston

.A

(continued)

2

Page 3

8532 Valve

D101552X012

Specifications (continued)

Product Bulletin

51.6:8532

April 2013

Disc Rotation

Clockwise to close

ENVIRO-SEAL Packing

This optional

J PTFE or J graphite packing system

provides improved sealing, guiding, and transmission

Valve Dimensions and Approximate Weights

See figures 7, 8, 9 and 10

1. The pressure/temperature limits in this bulletin (figures 2 and 3), and any application code or standardlimitation, should not be exceeded.

2. PEEK stands for poly-ether-ether-ketone.

3. For optimumseal performance, thepreferred valve orientationat shutoff is with the retaining ring downstream from the high pressure side of the valve.

4. UHMWPE standsfor ultra highmolecular weight polyethylene.

5. CTFE not recommended for fast cycling, less than 2 seconds.Contact your Emerson Process Management sales office for other seals available for fast cycling or tighter shutoff.

of loading force to control liquid and gas emissions.

See Bulletin 59.3:041 ENVIRO-SEAL Packing Systems

for Rotary Valves for more information.

Figure 1. Flow Direction

REVERSE

FLOW (NORMAL FLOW DIRECTION)

FORWARD

FLOW

A7092

Table 1. Flow Coefficients

VALVE SIZE,

NPS

14

16

18

20

24

1. To obtain the flow coefficient Kvin terms of cubic meters per hour at one kilogram

force per square centimeter differential pressure across the valve, usingthe following

multiplier: K

2. Measured in gallons per minutes at 1 psi differential pressure across the valve.

3. See the section titled Coefficients in this bulletin, and also Catalog 12 for a

complete listing of flow coefficients.

=0.856Cv.

v

FACE SIDE OF DISC

(1)(3)

(2)

MAX C

CL150 CL300

6320

8600

11,050

13,850

21,500

, VALVE 90_ OPEN

v

4550

5630

8230

9530

12,510

Installation

Recommended installation for the 8532 valve is with

the shaft horizontal in a normal-flow direction.

Horizontal installation will enhance valve performance

because process fluid flow will sweep entrained solids

from valve surfaces. This sweeping action prevents

particle buildup on seal surfaces. However, the valve

may be installed in either the forward or reverse flow

direction.

The standard soft seal offers bubble-tight, bidirectional

shutoff. To meet the performance requirements of

many of today's fire-tested requirements, a Phoenix III

valvemustbeinstalledinthepreferredvalve

orientation. Both the NOVEX and cryogenic seals are

uni-directional and should be installed with the shaft

upstream of the seal.

Unique operating conditions may require a specific

combination of actuator motion. To satisfy unique

operating requirements, the valve and actuator can be

assembled in eight ways, providing for actuator

motion and open disc position. For assistance in

selecting the appropriate combination of actuator

action and open valve position, consult your Emerson

Process Management sales office.

Dimensions and weights for wafer-style and

single-flange valves are shown in figures 7, 8, 9 and 10.

3

Page 4

Product Bulletin

51.6:8532

April 2013

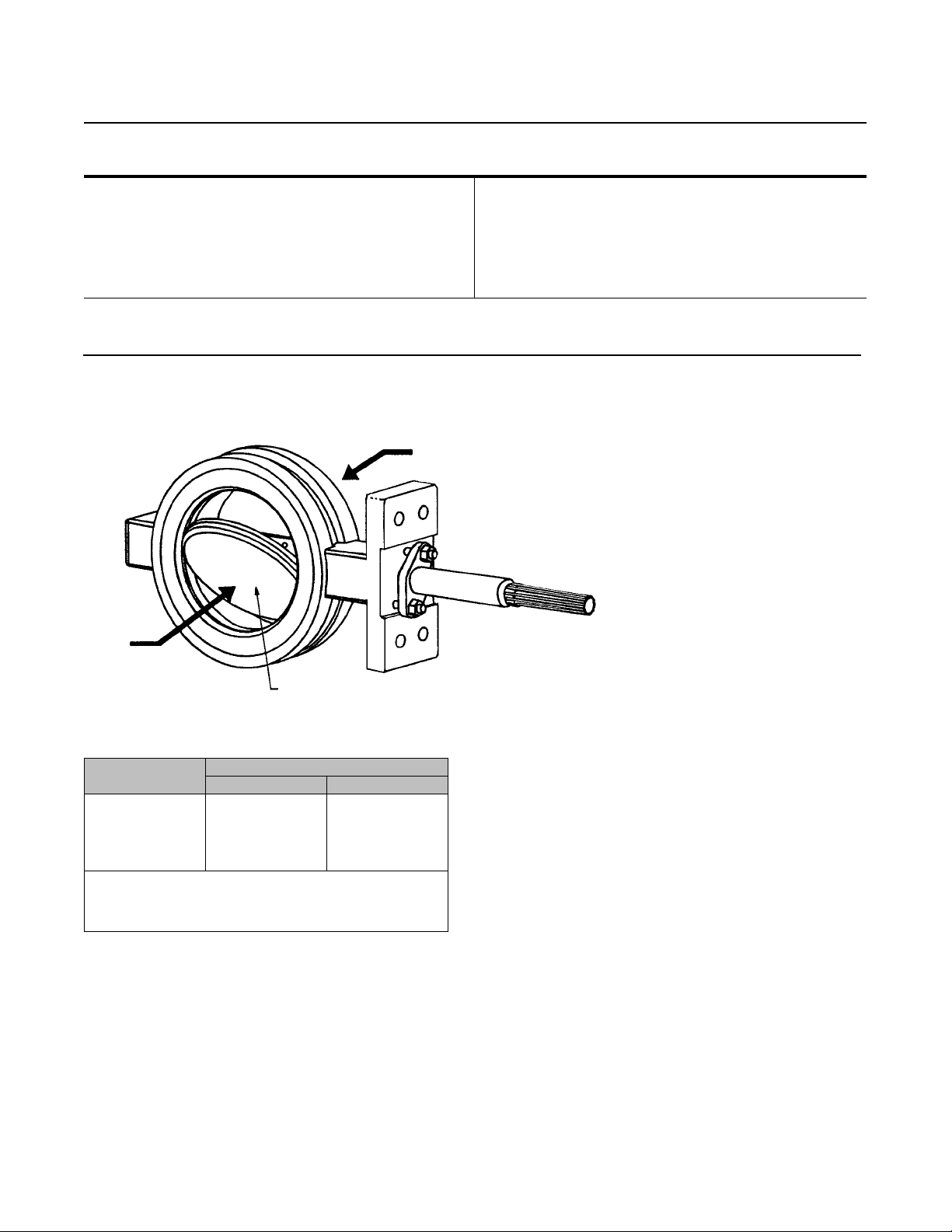

Figure 2. Maximum Pressure/Temperature Ratings for Soft Seal, NOVEX Seal and Phoenix III Seal, CL150 and CL300

8532 Valve

D101552X012

CL150 SOFT SEAL

CL150 NOVEX SEAL

CL300 SOFT SEAL

CL300 NOVEX SEAL

CL150 PHOENIX II SEAL

C0759-1

Note

1

Becauseof potential erosive effects andpremature seal failure thatcan occur, throttling PTFE seals at differential pressures greater than 300 psidat diskangleslessthan

20 degrees open is not recommended.

2

Temperature limitations do not account forthe additional limitations imposed by thebackup O-ring usedwith this seal. Todetermine theeffective temperature limita

tion of the appropriate seal backup O-ring combination, refer to table 1.

4

CL300 PHOENIX II SEAL

Page 5

8532 Valve

D101552X012

Figure 3. Maximum Pressure/Temperature Ratings for Cryogenic Seal, CL150 and CL300

Product Bulletin

51.6:8532

April 2013

B2336

CL150 CRYOGENIC SEAL

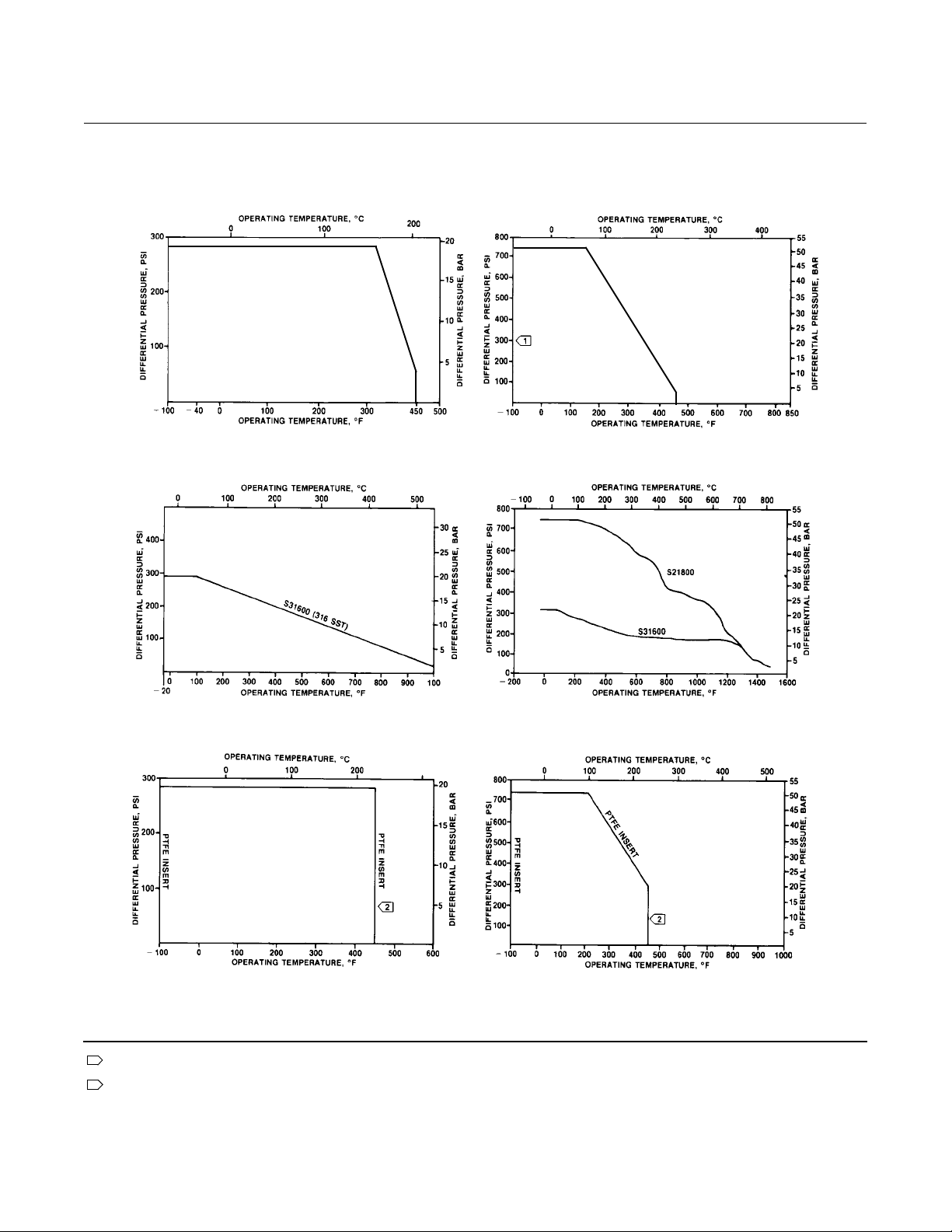

Figure 4. Available Seal Configurations

BACKUP

O-RING

SEAL RING

RETAINING

RING

PTFE OR UHMWPE SOFT

SEAL WITH BACKUP O-RING

B2313-2

BODY

VALVE DISK VALVE DISK

GRAPHITE

GASKET

BACKUP

O-RING

NORMAL

FLOW DIRECTION

(REVERSE FLOW)

VALVE DISK

PHOENIX III

FIRE SAFE SEAL

BODY

GRAPHITE

GASKET

RETAINING

RING

CL300 CRYOGENIC SEAL

BODY

NOVEX METAL SEAL

METAL

SEAL RING

RESILIENT

INSERT

NORMAL

FLOW DIRECTION

(REVERSE FLOW)

METAL

SEAL RING

NORMAL

FLOW

DIRECTION

(REVERSE

FLOW)

5

Page 6

Product Bulletin

51.6:8532

April 2013

8532 Valve

D101552X012

Figure 5. Typical Valve Assembly

SEEFIGURE3

THRUST BEARING

GASKET RETAINER

GASKET

DISC

DISC PINS

UPPER SHAFT

SEAT RETAINING RING

BEARINGS ANTI-BLOWOUT GLAND

THRUST

BEARING

ANTI-BLOWOUT FOLLOWER

PACKING FOLLOWER

A7093

Figure 6. Blowout Protection

PACKING

FLANGE

ANTIBLOWOUT

FLANGE

SHAFT SHOULDER

A7090

STANDARD PACKING ARRANGEMENT ENVIRO-SEAL ARRANGEMENT (PTFE SHOWN)

SHAFT

HEX NUT

STUD

HEX NUT

PACKING

FOLLOWER

TYPICAL PTFE V-RING

PACKING

VALVE BODY

HEX NUT

PACKING

FLANGE

SPRING PACK

ASSEMBLY

SHAFT

SHOULDER

ANTI-EXTRUSION

RING

STUD

LUBRICANT

HEX NUT

ANTIBLOWOUT

FLANGE

PACKING

SET

PACKING

BOX RING

6

Page 7

Product Bulletin

8532 Valve

D101552X012

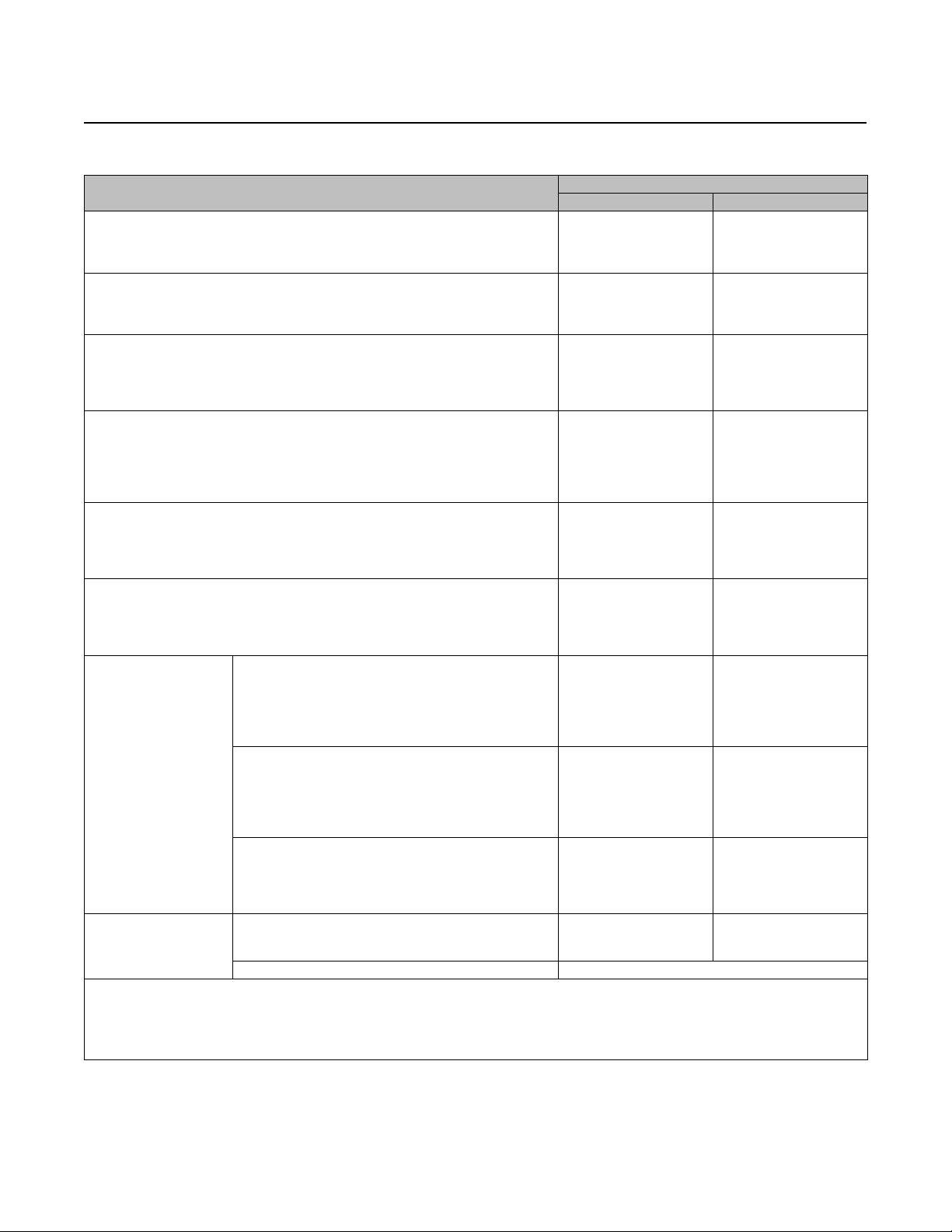

Table 2. Material Temperature Ratings

COMPONENT AND MATERIAL OF CONSTRUCTION

Valve Body

(2)

Carbon Steel (WCC or SA 516-70)

(3)

FMS 20B16a Fisher material standard (0.04% min carbon) CL300

CF8M

CF8M (316SST) CL150and CL300

(1)

(7)

-198 to538

over 538 to 816

Disc

WCC carbon steel

(3)

FMS 20B16a Fisher material standard (0.04% min carbon) CL300

CF8M

CF8M (316SST)

-198 to538

over 538 to 816

Disc Coating

Chromium Carbide

Chrome Plating

Chromium Coating

Electroless Nickel Coating (ENC)

-198 to916

-254 to316

-254 to593

-254 to343

Shaft

S20910

-198 to538

S17400 (17-4pH 1025)

S17400 (17-4pH H1150M)

N07718

N07750

(6)

Bearings

PEEK (standard)

S31600

(4)

R30006 (Alloy6)

Bronze

-196 to427

-254 to704

over 593 to 816

-198 to816

-198 to816

-254 to302

Packing

PTFE Packing and PTFE ENVIRO-SEAL Packing

Graphite packing

Graphite packing with oxidizing media

Graphite ENVIRO-SEAL Packing

-148 to232

-198 to916

-198 to538

-148 to315

PTFE Seal Ring

Nitrile Backup O-Ring

Chloroprene Backup O-Ring

EPR Backup O-Ring

Fluorocarbon Backup O-Ring

PTFE BackupO-Ring

UHMWPE

Seal Ring and

Backup Ring

(5)

Seal Ring (CL150 Only)

Nitrile Backup O-Ring

Chloroprene Backup O-Ring

EPR Backup O-Ring

Fluorocarbon Backup O-Ring

PTFE BackupO-Ring

Phoenix III and/or Fire Tested Construction

S31600 and PTFE Seal Ring with Nitrile Backup O-Ring

Chloroprene Backup O-Ring

EPR Backup O-Ring

Fluorocarbon Backup O-Ring

(4)

Ring (CL150)

(4)

Ring (CL300)

(4)

Ring (CL300)

Seal Ring

NOVEX S31600Seal

NOVEX S31600Seal

NOVEX S21800Seal

Cryogenic Seal Ring Contact your Emerson Process Management sales office

1. NACE trim constructions areavailable; consult your Emerson Process Management sales office.

2. Special gasket retainer bolts are required for over 482_C(900_F)

3. Special retainingring screws for single flange valves over 538_C (1000_F)

4. For a complete materialdes cription, contact your Emerson Process Management sales office.

5. UHMWPE standsfor ultra high molecular weight polyethylene.

6. Special thrust bearings are required for hightemp. applications over 343_C(650_F) (with 6- and12-inch shaft extensions). Constructions withcarbon steel valves and SST discs may require

special thrust bearings at temperatures less than 343_C (650_F).

7. Cast or wrought /plate grades used interchangeably,depending upon availability - unless requested bycustomer.

TEMPERATURE RANGE

_C _F

-29 to 427

over 1000 to 1500

-29 to 427

over 1000 to 1500

-73 to 427

over 1100 to 1500

-73 to 260

-29 to 93

-43 to 149

-54 to 182

-29 to 204

-73 to 204

-29 to 93

-43 to 93

-54 to 93

-29 to 93

-73 to 93

-40 to 149

-54 to 149

-62 to 204

-40 to 232

-29 to 538

-29 to 816

-29 to 816

51.6:8532

April 2013

-20 to 800

-325 to1000

-20 to 800

-325 to1000

-325 to1500

-425 to600

-425 to1100

-425 to650

-325 to1000

-100 to800

-320 to800

-425 to1300

-100 to500

-325 to1500

-325 to1500

-425 to575

-325 to450

-325 to1500

-325 to1000

-325 to600

-20 to 200

-45 to 300

-65 to 360

-20 to 400

-100 to400

-20 to 200

-45 to 200

-65 to 200

-20 to 200

-40 to 200

-40 to 300

-65 to 300

-80 to 400

-100 to200

-20 to 1000

-20 to 1500

-40 to 1500

7

Page 8

Product Bulletin

51.6:8532

April 2013

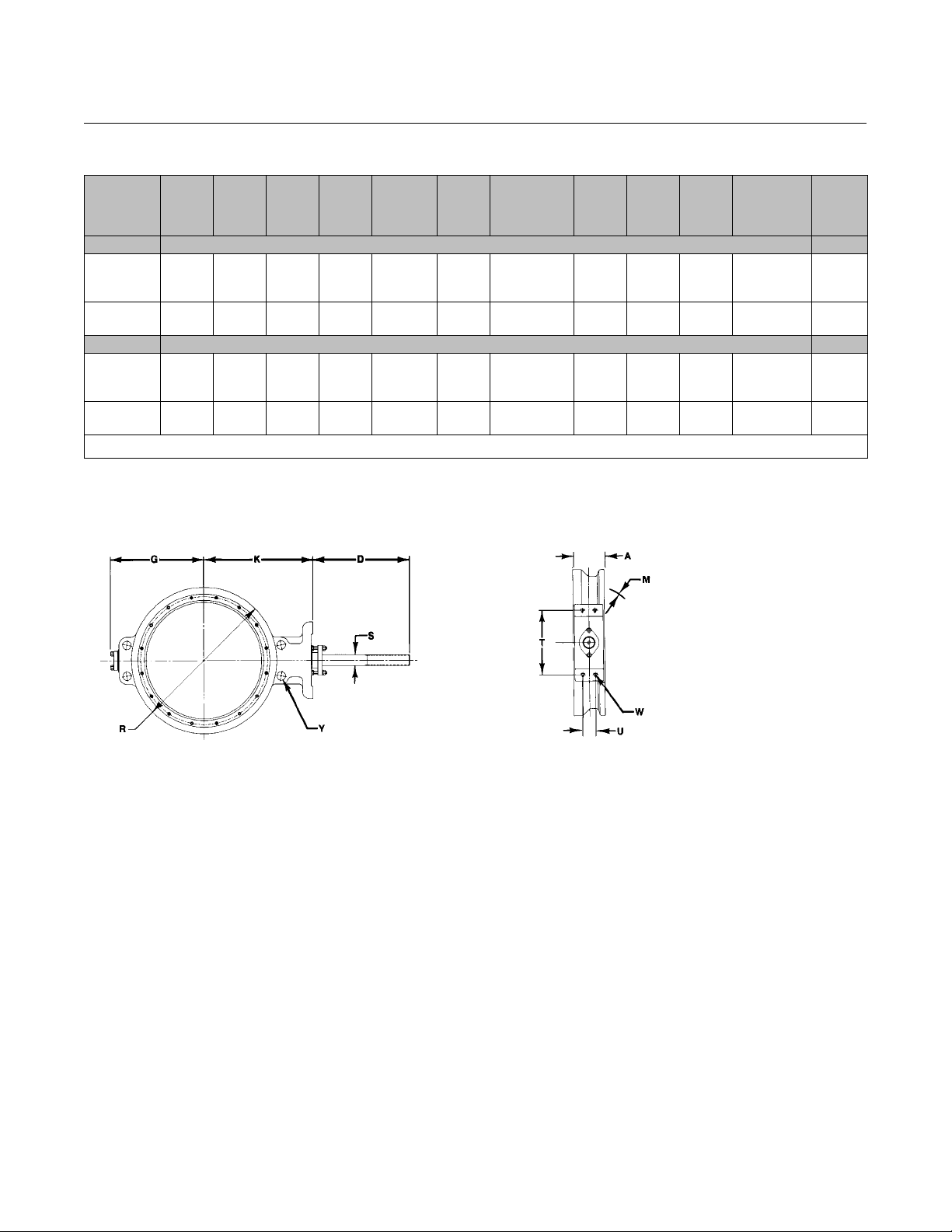

Table 3. Dimensions and Weights, Wafer Style Valves, CL150

S

Valve Size,

NPS

14

16

18

20

24

14

16

18

20

24

1. Face-to-face dimensions are in compliance with MSS SP68 and API 609 specifications.

2. M is the minimum pipe or flange I.D. required fordisc swing clearance.

(1)

A

91.9

102

114

127

154

3.62

4.00

4.50

5.00

6.06

D G K M

208

208

356

356

356

8.19

8.19

14

141415.00

295

318

349

381

438

11.62

12.50

13.75

17.25

327

371

400

432

492

12.88

14.62

15.75

17.00

19.38

(2)

331

375

419

464

581

13.04

14.77

16.49

18.27

22.87

422

465

529

584

692

16.62

18.31

20.81

23.00

27.25

Figure 7. Dimensions and Weights, Wafer Style Valves, CL150 (also see table 3)

(Shaft Dia

R

at Yoke

Bearings)

mm kg

31.8

31.8

39.6

44.5

57.2

Inches Pounds

1-1/4

1-1/4

1-9/16

1-3/4

2-1/4

T U W Y

235

235

273

273

337

9.25

9.25

10.75

10.75

13.25

46.0

46.0

50.8

50.8

76.2

1.81

1.81

2.00

2.00

3.00

17.5

17.5

20.1

20.1

23.9

0.69

0.69

0.81

0.81

0.94

8532 Valve

D101552X012

---

28.6 4 holes

31.8 4 holes

31.8 4 holes

34.9 4 holes

---

1-1/8 4 holes

1-1/4 4 holes

1-1/4 4 holes

1-3/8 4 holes

Approx

Weight

72

94

139

167

255

158

207

307

368

563

C0729-1

8

Page 9

8532 Valve

D101552X012

Table 4. Dimensions and Weights, Single Flange Valves, CL150

S

Valve Size,

NPS

14

16

18

20

24

14

16

18

20

24

1. Face-to-face dimensions are in compliance with MSS SP68 and API 609 specifications.

2. M is the minimum pipe or flange I.D. required fordisc swing clearance.

(1)

A

91.9

102

114

127

154

3.62

4.00

4.50

5.00

6.061414

208

208

356

356

356

8.19

8.19

14

D G K M

295

327

318

371

349

400

381

432

438

492

11.62

12.50

13.75

15.00

17.25

12.88

14.62

15.75

17.00

19.38

13.04

14.77

16.49

18.27

22.87

331

375

419

464

581

(2)

531

607

645

696

822

20.88

23.88

25.38

27.38

32.38

Figure 8. Dimensions and Weights, Single Flange Valves, CL150 (also see table 4)

(Shaft Dia

R

at Yoke

Bearings)

mm kg

31.8

31.8

39.7

44.5

57.2

Inches Pounds

1-1/4

1-1/4

1-9/16

1-3/4

2-1/4

T U W Y

235

235

273

273

337

9.25

9.25

10.75

10.75

13.25

46.0

46.0

50.8

50.8

76.2

1.81

1.81

2.00

2.00

3.00

14.2

14.2

20.1

20.1

23.9

0.56

0.56

0.81

0.81

0.94

Product Bulletin

51.6:8532

April 2013

Approx

Weight

---

---

---

---

---

1-812Holes

1-816Holes

1-1/8-816Holes

1-1/8-820Holes

1-1/4-820Holes

95

138

178

224

315

209

304

393

493

773

C0730-1

9

Page 10

Product Bulletin

51.6:8532

April 2013

Table 5. Dimensions and Weights, Wafer Style Valves, CL300

S

Valve Size,

NPS

14

16

18

20

24

14

16

18

20

24

1. Face-to-face dimensions are in compliance with MSS SP68 and API 609 specifications.

2. M is the minimum pipe or flange I.D. required fordisc swing clearance.

(1)

A

117

133

149

159

181

4.62

5.25

5.88

6.25

7.12

D G K M

356

356

356

265

546

14

14

14

10-7/16

21-1/2

319

353

384

416

483

12.56

13.88

15.12

16.38

19.00

364

397

419

483

546

14.31

15.62

16.50

19.00

21.50

304

346

389

442

523

12

13.6

15.3

17.4

20.6

(2)

437

498

556

605

716

17.19

19.62

21.88

23.81

28.19

Figure 9. Dimensions and Weights, Wafer Style Valves, CL300 (also see table 5)

(Shaft Dia

R

at Yoke

Bearings)

mm kg

44.5

44.5

57.2

76

76

Inches Pounds

1-3/4

1-3/4

2-1/4

3

3

T U W Y

273

273

337

337

337

10.75

10.75

13.25

13.25

13.2533

50.8

50.8

76.2

76.2

76.2

2

2

3

20.6

20.6

23.9

23.9

23.9

0.81

0.81

0.94

0.94

0.94

8532 Valve

D101552X012

---

---

---

---

---

1-1/8-84Holes

1-1/4-84Holes

1-1/4-84Holes

1-1/4-84Holes

1-1/2-84Holes

Approx

Weight

121

183

227

364

469

266

403

500

802

1035

10

B2352

Page 11

8532 Valve

D101552X012

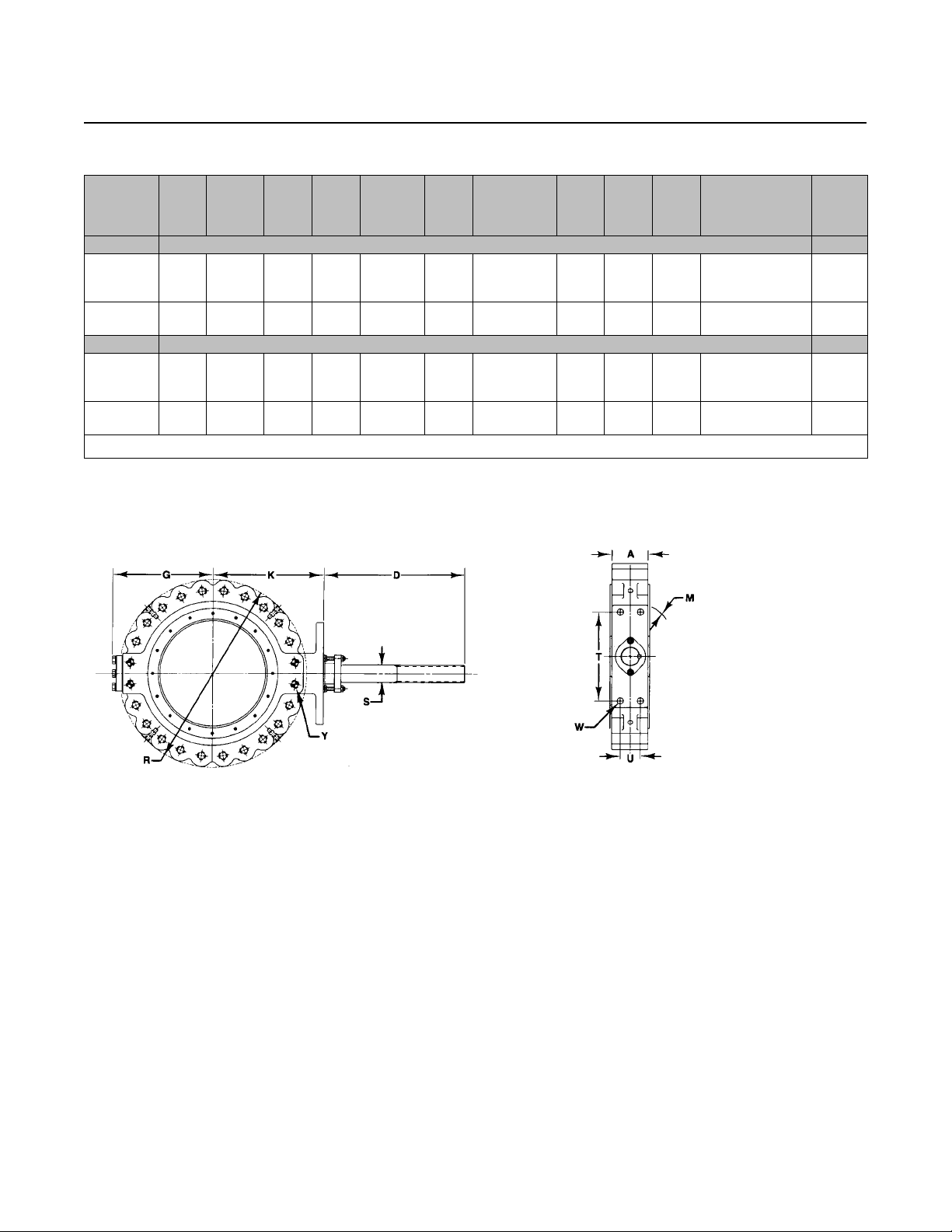

Table 6. Dimensions and Weights, Single Flange Valves, CL300

S

Valve Size,

NPS

14

16

18

20

24

14

16

18

20

24

1. Face-to-face dimensions are in compliance with MSS SP68 and API 609 specifications.

2. M is the minimum pipe or flange I.D. required fordisc swing clearance.

(1)

A

117

133

149

159

181

4.62

5.25

5.88

6.25

7.12

D G K M

356

356

356

265

546

14

14

14

10-7/16

21-1/2

319

353

384

416

483

12.56

13.88

15.12

16.38

19.00

364

397

419

483

546

14.31

15.62

16.50

19.00

21.50

304

346

389

442

523

12.0

13.6

15.3

17.4

20.

(2)

594

657

721

784

924

23.38

25.88

28.38

30.88

36.38

Figure 10. Dimensions and Weights, Single Flange Valves, CL300 (also see table 6)

(Shaft Dia

R

at Yoke

Bearings)

mm kg

44.5

44.5

57.2

76

76

Inches Pounds

1-3/4

1-3/4

2-1/4

3

3

T U W Y

273

50.8

273

50.8

337

76.2

337

76.2

337

76.2

10.75

10.75

13.25

13.25

13.2533

Product Bulletin

51.6:8532

April 2013

Approx

Weight

20.6

20.6

23.9

23.9

23.9

2

0.81

2

0.81

3

0.94

0.94

0.94

---

---

---

---

---

1-1/8-816Holes

1-1/4-820Holes

1-1/4-824Holes

1-1/4-824Holes

1-1/2-824Holes

227

294

402

544

821

500

649

886

1200

1810

B2353

11

Page 12

Product Bulletin

51.6:8532

April 2013

8532 Valve

D101552X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility forproper selection, use,and maintenanceof any product remains solely with thepurchaser and end user.

Fisher and ENVIRO-SEAL are marks owned by one of the companies in the Emerson Process Management business unitof Emerson Electric Co.Emerson

Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request.We reservethe right to modify or improve the designs or specifications ofsuch

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1991, 2013 Fisher ControlsInternational LLC. All rights reserved.

12

Loading...

Loading...