Emerson Fisher 657, Fisher 667 Installation Instructions

Instruction Manual |

667 Size 30-76 and 87 Actuators |

D100310X012 |

November 2013 |

|

|

Fisherr 667 Diaphragm Actuator

Sizes 30-76 and 87

Contents |

|

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

Scope of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

Educational Services . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

Maximum Pressure Limitations . . . . . . . . . . . . . . . . |

3 |

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

Mounting the Actuator on the Valve . . . . . . . . . . . . |

5 |

Discussion of Bench Set . . . . . . . . . . . . . . . . . . . . . . . |

6 |

Spring Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

Installing the Stem Connector Assembly . . . . . . . . . |

9 |

Friction Discussion . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

Deadband Measurement . . . . . . . . . . . . . . . . . . . . . |

11 |

Loading Connection . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

Top-Mounted Handwheel Assembly |

|

(Adjustable Down Travel Stop) . . . . . . . . . . . . . |

15 |

Side-Mounted Handwheel Assembly for |

|

Size 34 through 60 Actuators . . . . . . . . . . . . . . . |

19 |

Side-Mounted Handwheel Assembly for |

|

Size 70, 76, and 87 Actuators . . . . . . . . . . . . . . . |

20 |

Casing-Mounted Travel Stops . . . . . . . . . . . . . . . . . |

22 |

Parts Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

Side-Mounted Handwheels Retrofit Kits . . . . . . . . |

24 |

Top-Mounted Handwheel Retrofit Kits . . . . . . . . . |

24 |

Actuator Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

Figure 1. Fisher 667 or 667-4 Actuator Mounted on easy-e™ Valve

W1916-1*

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Actuator Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Top-Mounted Handwheel . . . . . . . . . . . . . . . . . . . 25

Side-Mounted Handwheel (34-60) . . . . . . . . . . . 33

Side-Mounted Handwheel (70, 76, and 87) . . . . 33

Casing Mounted Travel Stops . . . . . . . . . . . . . . . . . 35

Introduction

Scope of Manual

This instruction manual provides information on installation, adjustment, maintenance, and parts ordering for the Fisher 667 actuator in sizes 30 through 76 and size 87. The 667-4 actuator in sizes 70 and 87 is also covered. Refer to separate instruction manuals for information about the valve positioner and other accessories used with these actuators.

Do not install, operate, or maintain a 667 actuator (see figure 1) without being fully trained and qualified in valve, actuator, and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you have any questions about these instructions, contact your Emerson Process Management sales office before proceeding.

www.Fisher.com

667 Size 30-76 and 87 Actuators |

|

|

|

|

|

|

|

|

Instruction Manual |

|

|||||||

November 2013 |

|

|

|

|

|

|

|

|

|

|

|

D100310X012 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 1. Specifications |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

ACTUATOR SIZE |

|

|

|

|

|

|

||

|

|

SPECIFICATION(1) |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

30 |

34 |

40 |

45 |

46 |

50 |

|

60 |

|

70(1) |

76 |

87(1) |

|

|||

|

|

|

|

|

|

|

|

||||||||||

Nominal Effective Area |

|

Sq cm |

297 |

445 |

445 |

667 |

1006 |

677 |

|

1006 |

|

1419 |

1006 |

1419 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Sq Inch |

46 |

69 |

69 |

105 |

156 |

105 |

|

156 |

|

220 |

156 |

220 |

|

|||

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Yoke Boss Diameter |

|

mm |

54 |

54 |

71 |

71 |

71 |

90 |

|

90 |

|

90 |

90 |

125 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Inch |

2-1/8 |

2-1/8 |

2-13/16 |

2-13/16 |

2-13/16 |

3-9/16 |

|

3-9/16 |

|

3-9/16 |

3-9/16 |

5 |

|

|||

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Acceptable Valve Stem Diameter |

|

mm |

9.5 |

9.5 |

12.7 |

12.7 |

12.7 |

19.1 |

|

19.1 |

|

19.1 |

19.1 |

25.4 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Inch |

3/8 |

3/8 |

1/2 |

1/2 |

1/2 |

3/4 |

|

3/4 |

|

3/4 |

3/4 |

1 |

|

|||

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Maximum Allowable Output Thrust(4) |

|

N |

10230 |

10230 |

12010 |

25131 |

33582 |

25131 |

|

30246 |

|

39142 |

30246 |

39142 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

LB |

2300 |

2300 |

2700 |

5650 |

7550 |

5650 |

|

6800 |

|

8800 |

6800 |

8800 |

|

|||

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Maximum Travel(2) |

|

mm |

19 |

29 |

38 |

51 |

51 |

51 |

|

51 |

|

76(3) |

51 |

76(3) |

|

||

|

Inch |

0.75 |

1.125 |

1.5 |

2 |

2 |

2 |

|

2 |

|

3(3) |

2 |

3(3) |

|

|||

|

|

|

|

|

|

|

|||||||||||

Maximum Casing Pressure for Actuator |

|

Bar |

3.8 |

4.8 |

4.8 |

4.5 |

3.8 |

4.5 |

|

3.8 |

|

3.4 |

3.4 |

3.4 |

|

||

|

|

Sizing(4,6) |

|

Psig |

55 |

70 |

70 |

65 |

55 |

65 |

|

55 |

|

50 |

50 |

50 |

|

Maximum Excess Diaphragm |

|

Bar |

3.8 |

1.4 |

1.4 |

0.7 |

0.7 |

0.7 |

|

0.7 |

|

0.7 |

0.7 |

0.7 |

|

||

|

Pressure(4,5) |

|

Psig |

55 |

20 |

20 |

10 |

10 |

10 |

|

10 |

|

10 |

10 |

10 |

|

|

Maximum Diaphragm Casing |

|

Bar |

7.6 |

6.2 |

6.2 |

5.2 |

4.5 |

5.2 |

|

4.5 |

|

4.1 |

4.1 |

4.1 |

|

||

|

Pressure(4,6,7) |

|

Psig |

110 |

90 |

90 |

75 |

65 |

75 |

|

65 |

|

60 |

60 |

60 |

|

|

Approximate Weight |

|

Kg |

15 |

22 |

23 |

41 |

55 |

43 |

|

55 |

|

115 |

86 |

118 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Pounds |

34 |

48 |

50 |

90 |

121 |

94 |

|

122 |

|

254 |

190 |

260 |

|

|||

|

|

|

|

|

|

|

|||||||||||

Material |

|

Nitrile Elastomers |

|

|

|

|

-40 to 82_C (-40 to 180_F) |

|

|

|

|

|

|

||||

Temperature |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Silicone Elastomers |

|

|

|

|

-54 to 149_C (-65 to 300_F) |

|

|

|

|

|

||||||

Capabilities |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.These values also apply to the 667-4 actuator construction.

2.Actuator travel may be less than the value listed after connected to the valve.

3.Maximum actuator travel for 667-4 is 102 mm (4 inches).

4.See also the Specifications portion of the introduction section.

5.Additional pressure may be added when the actuator is at full travel. If the Maximum Excess Diaphragm Pressure is exceeded, damage to the diaphragm or diaphragm casing might result. See the Maximum Pressure Limitation section.

6.Maximum diaphragm casing pressure must not be exceeded and must not produce a force on the actuator stem greater than the maximum allowable actuator output thrust or the maxi mum allowable stem load. See the Maximum Pressure Limitation section.

7.This maximum casing pressure is not to be used for normal operating pressure. Its purpose is to allow for typical regulator supply settings and/or relief valve tolerances.

Description

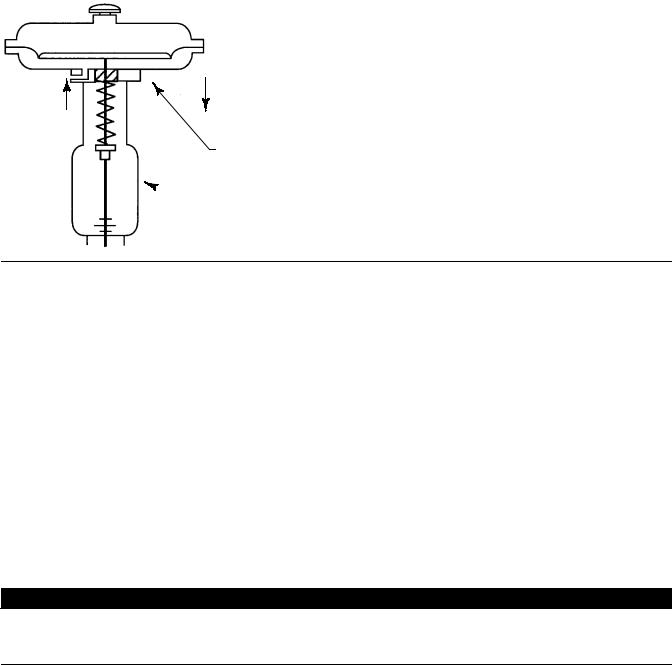

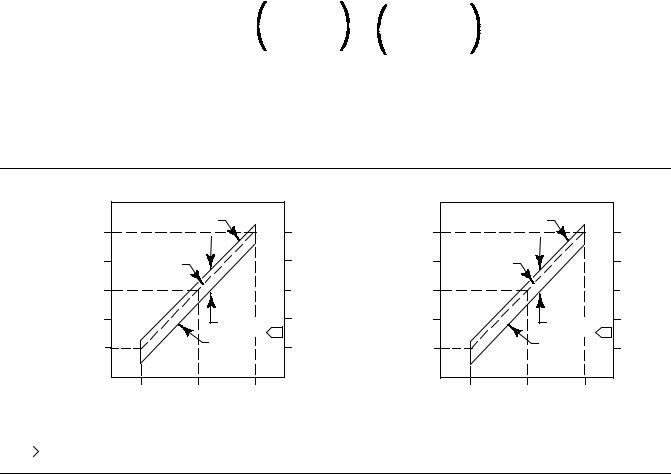

The 667 actuator (figure 1) and the 667-4 actuator are reverse-acting, spring-opposed diaphragm actuators. They provide automatic operation of control valves. The 667 actuator provides 76 mm (3 inches) maximum actuator travel. The 667-4 actuator provides 102 mm (4 inches) maximum actuator travel. Both actuators position the valve plug in response to varying pneumatic loading pressure on the diaphragm. Figure 2 shows the operation of these actuators.

A 667 or 667-4 actuator can be furnished with either a top-mounted or a side-mounted handwheel assembly. A top-mounted handwheel assembly is normally used as an adjustable down travel stop. (A down travel stop limits actuator travel in the down direction [when the stem is traveling out of the actuator]. Travel in the up direction is when the stem is traveling into the actuator.) A side-mounted handwheel assembly is normally used as an auxiliary manual actuator. The side-mounted handwheel can also be used as an adjustable up or down travel stop. Casing-Mounted adjustable up or down travel stops are also available on this actuator.

Note

If repeated or daily manual operation is expected, the actuator should be equipped with a side-mounted handwheel rather than a casing-mounted travel stop or top-mounted handwheel. The side-mounted handwheel is designed for more frequent use as a manual operator.

2

Instruction Manual |

667 Size 30-76 and 87 Actuators |

D100310X012 |

November 2013 |

|

|

|

|

Figure 2. Schematic of Fisher 667 and 667-4 Actuators |

|

AIR LIFTS |

SPRING PUSHES |

|

STEM DOWN |

||

STEM UP |

||

|

STEM

SEAL

STEM

STEM

A6759

Specifications

Refer to table 1 for Specifications of the 667 and 667-4 actuators. See the actuator nameplate for specific information for your actuator.

Educational Services

For information on available courses for Fisher 667 diaphragm actuators, as well as a variety of other products, contact:

Emerson Process Management Educational Services, Registration P.O. Box 190; 301 S. 1st Ave. Marshalltown, IA 50158-2823 Phone: 800-338-8158 or

Phone: 641-754-3771

FAX: 641-754-3431

e-mail: education@emerson.com

WARNING

WARNING

To avoid personal injury or damage to equipment that may result in the malfunction of the control valve or loss of control of the process caused by excessive pressure, do not exceed the Maximum Pressures listed in table 1. Refer to the Maximum Pressure Limitations section.

Maximum Pressure Limitations

The casing and diaphragm of 667 actuators are pressure operated. This air pressure provides energy to compress the spring, to stroke the actuator, and to seat the valve. The following explanations describe the maximum pressure limits for an actuator. Refer to the nameplate or table 1 for maximum values for your actuator.

3

667 Size 30-76 and 87 Actuators |

Instruction Manual |

November 2013 |

D100310X012 |

|

|

DMaximum Casing Pressure for Actuator Sizing: This is the maximum pressure that can be applied at less than full travel of the actuator. If this stroking pressure is exceeded before the upper diaphragm plate contacts the travel stop, damage to the stem or other parts might result.

DMaximum Excess Diaphragm Pressure: Additional pressure may be added when the actuator is at full travel. If the Maximum Excess Diaphragm Pressure is exceeded, damage to the diaphragm or diaphragm casing might result.

Because the actuator has traveled its specified travel, and the diaphragm head is physically stopped from movement, the energy from any additional air pressure is transmitted to the diaphragm and diaphragm casings. The amount of air pressure that can be added once the actuator has traveled to the stops is limited by the resultant adverse effects that may occur. Exceeding this limiting factor could result in leakage or casing fatigue due to the deformation of the upper diaphragm casing.

DMaximum Diaphragm Casing Pressure: If the Maximum Diaphragm Casing Pressure is exceeded, damage to the diaphragm, diaphragm casing, or actuator might result.

Installation

WARNING

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations.

Check with your process or safety engineer for any other hazards that may be present from exposure to process media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this instruction manual.

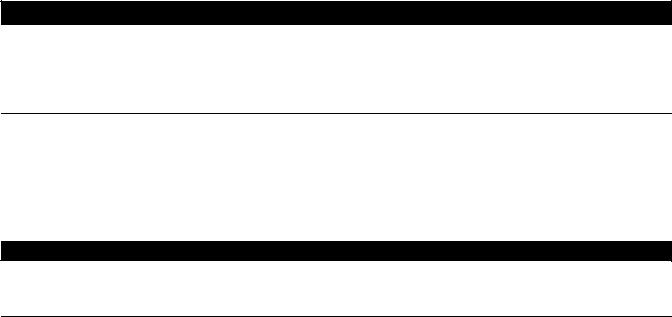

Key number locations are shown in figures 6, 7, and 8, unless otherwise noted. Also, refer to figure 3 for location of parts.

CAUTION

To avoid parts damage, do not use an operating pressure that exceeds the Maximum Diaphragm Casing Pressure (table 1) or produces a force on the actuator stem greater than the Maximum Allowable Output Thrust (table 1) or the Maximum Allowable Valve Stem Load.

DValve/Actuator Assembly: If the actuator and valve are shipped together as a control valve assembly, it has been adjusted at the factory, and may be installed in the pipeline. After installing the valve in the pipeline, refer to the Loading Connection procedures.

DActuator Mounting: If the actuator is shipped separately or the actuator has been removed from the valve, it is necessary to mount the actuator on the valve before placing the valve in the pipeline. Refer to the following actuator mounting procedures before placing the valve in service. It is recommended that you perform the Bench Set Spring Adjustment procedures in this section to confirm that the actuator is adjusted correctly for the valve travel.

DPositioner: If a positioner is installed, or is to be installed on the actuator, refer to the positioner instruction manual for installation. During the adjustment procedures, it will be necessary to provide a temporary loading pressure to the actuator diaphragm.

4

Instruction Manual |

667 Size 30-76 and 87 Actuators |

D100310X012 |

November 2013 |

|

|

DHandwheel Cap: If the handwheel cap (key 247, figures 9, 11, or 17) is not in place, install the cap by pushing it on by hand until it snaps into place.

Mounting the Actuator on the Valve

CAUTION

The 667 actuator spring load pushes the stem down out of the actuator yoke (see figure 2), and it can come in contact with the valve stem during actuator mounting.

If the valve stem is allowed to remain in the up position (towards the actuator) during actuator mounting, it can interfere with the actuator stem during mounting. It is possible to damage valve stem threads or bend the valve stem. Be sure the valve stem is pushed down (into the valve body), away from the actuator while mounting.

It may be necessary to apply a temporary loading pressure to the actuator to move the actuator stem away from the valve during installation.

If it is not possible to provide a temporary loading pressure, be very careful when lowering the actuator over the valve stem to prevent damage to valve stem and threads.

WARNING

WARNING

When moving the actuator stem with loading pressure applied, exercise caution to keep hands and tools out of the actuator stem travel path. If the loading pressure is accidently disconnected, personal injury and property damage may result if something is caught between the actuator stem and other control valve parts.

1.Provide a vise or some other method of supporting the valve and the weight of the actuator during assembly. For direct or reverse acting valves, push the valve stem down away from the actuator while mounting the actuator.

2.Screw the stem locknuts all the way onto the valve stem. With the concave side of the travel indicator disk (key 34) facing the valve, install the travel indicator disk on the valve stem. (Note: The travel indicator disk is not used with size 87 actuators.)

3.Lift or hoist the actuator onto the valve bonnet:

a. For size 87 actuators: Slowly lower the actuator down onto the valve while guiding the valve stem into the opening in the end of the actuator stem (see figure 4). Once the actuator is in place, insert the cap screws and tighten the hex nuts, securing the actuator to the bonnet.

b. For all other size actuators:

DSlowly lower the actuator down onto the valve. As the yoke passes over the end of the valve stem, place the yoke locknut over the valve stem. (Note: On small size actuators, it may be necessary to remove the indicator disk and re-install it while lowering the actuator onto the valve because the disk will not go through the actuator yoke opening).

DContinue to lower the actuator while guiding the valve stem into the opening in the end of the actuator stem until the actuator is in place (see figure 4).

D Screw the yoke locknut onto the valve bonnet and tighten the locknut.

4.Do not connect the actuator stem to the valve stem at this time. Whenever the actuator is installed on the valve, it is recommended that you perform the Bench Set Spring Adjustment procedures below, to verify that the actuator is still adjusted correctly.

5

667 Size 30-76 and 87 Actuators |

Instruction Manual |

November 2013 |

D100310X012 |

|

|

|

|

Figure 3. Actuator-Mounting Components for Size 30 through 70 Actuators |

|

VENT ASSEMBLY DIAPHRAGM CASINGS

DIAPHRAGM CASINGS

DIAPHRAGM AND STEM SHOWN IN DOWN POSITION

DIAPHRAGM PLATE

LOADING AIR PRESSURE CONNECTION

ACTUATOR SPRING

ACTUATOR STEM

SPRING SEAT  SPRING ADJUSTOR

SPRING ADJUSTOR  STEM CONNECTOR

STEM CONNECTOR

YOKE TRAVEL INDICATOR DISK

TRAVEL INDICATOR DISK

INDICATOR SCALE

W0364-1

VALVE STEM  YOKE LOCK NUT

YOKE LOCK NUT

YOKE BOSS DIAMETER BONNET

BONNET

TYPICAL VALVE (REFER TO VALVE MANUAL)

MATCH LINE FOR ACTUATOR

W6199-1

Discussion of Bench Set

The bench set pressure values are used to adjust the initial compression of the actuator spring with the valve-actuator assembly “on the bench.” The correct initial compression ensures that the valve-actuator assembly will function properly when it is put into service and the proper actuator diaphragm operating pressure is applied.

The bench set values are established with the assumption that there is no packing friction. When attempting to adjust the spring in the field, it is very difficult to ensure that there is no friction being applied by “loose” packing.

Accurate adjustment to the bench set range can be made during the actuator mounting process by making the adjustment before the actuator is connected to the valve (see the Spring Verification Procedure).

6

Instruction Manual |

667 Size 30-76 and 87 Actuators |

D100310X012 |

November 2013 |

|

|

|

|

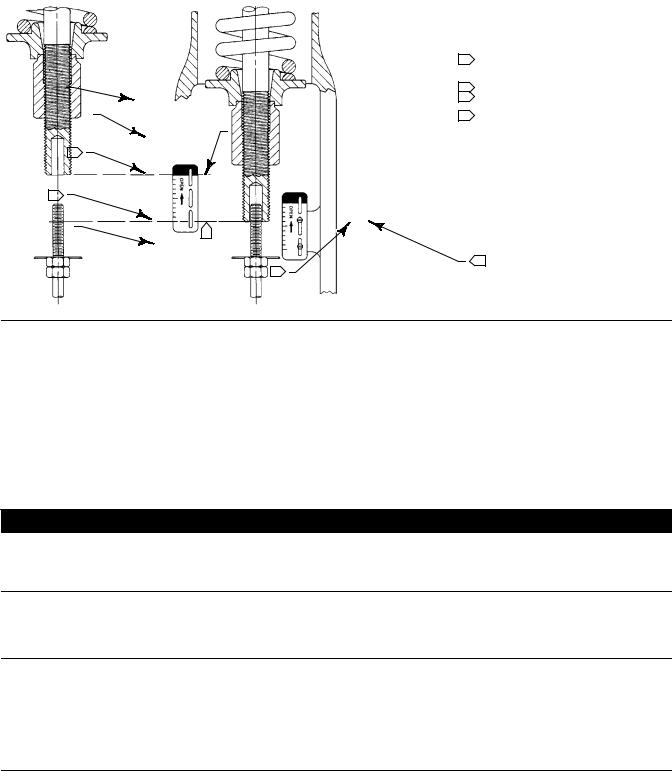

Figure 4. Bench Set Adjustment |

|

SPRING

ADJUSTER

ACTUATOR STEM |

|

||

UPPER BENCH |

RATED VALVE |

||

SET LOADING |

|||

TRAVEL MEASURE |

|||

PRESSURE |

3 |

||

|

|||

LOWER BENCH |

|

||

SET PRESSURE |

|

||

MARK 4 |

|

|

|

VALVE STEM |

|

4 |

|

|

|

||

|

|

MARK VALVE |

|

|

|

STEM HERE 2 |

|

NOTES:

1THE LOWER PSIG LOADING PRESSURE (MARKED ON NAMEPLATE) WHERE THE FIRST MOVEMENT OF ACTUATOR STEM IS DETECTED.

2MARK THIS POINT WITH TAPE OR A MARKER.

3THE UPPER PSIG LOADING PRESSURE RETRACTS ACTUATOR STEM.

4MEASURE DISTANCE OF TRAVEL. IT SHOULDEQUAL THE TRAVEL SHOWN ON THE NAMEPLATE.

1LOWER BENCH SET LOADING PRESSURE

50A8379-C

B2429-1

Spring Verification

Ensure that the actuator diaphragm is at the bottom of its travel as shown in figure 4 and not connected to the valve. (Note: Some spring compression is required to move the diaphragm to the bottom of its travel.)

Also, provide a certified pressure gauge that will accurately read the diaphragm pressure from 0 through 0.3 bar (5 psig) above the upper operating range pressure marked on the nameplate. Apply loading pressure to the diaphragm.

Stroke the actuator a few times to ensure that the pressure gauge is working correctly, and that the actuator is functioning properly.

CAUTION

To prevent actuator damage, it is important to ensure that the actuator stem is stroking smoothly and not exhibiting binding or excessive friction between the actuator stem and the bushing (key 7). Binding or excessive friction could be an indicator of incorrect assembly or damaged parts.

Key numbers are shown in figures 6, 7, and 8.

Note

For 667 actuators installed on push-down-to-close (direct acting) valves with fail-close action, the valve plug seat is the limit for downward travel and the actuator is the limit for upward (away from the valve) movement.

For 667 actuators installed on push-down-to-open (reverse acting) valves with fail-open action, the actuator down stop is the limit for downward movement, and the valve seat is the limit for upward (away from the valve) movement.

Ensure the correct Spring Verification procedure is followed for the type of valve on which the 667 actuator is installed.

7

667 Size 30-76 and 87 Actuators |

Instruction Manual |

November 2013 |

D100310X012 |

|

|

For Push Down to Close (Direct Acting) Valves

1.If not already accomplished, push the valve stem down away from the actuator to the closed position.

2.Set the diaphragm loading pressure to 0.3 bar (5 psig) over the upper operating range pressure. The travel stop cap screw (key 12) should be contacting the upper diaphragm casing.

3.Slowly decrease the pressure towards the upper bench set pressure, as indicated on the nameplate, while checking for the first linear movement of the actuator stem.

Note

Before turning the spring adjuster on size 70, 76, or 87 actuators, assemble the stem connector around the actuator stem and the anti-rotating lug on the yoke. Mark the actuator stem as a visual reference to verify that stem rotation does not occur. Remove the stem connector before rechecking the bench set.

4.If movement occurs before or after the upper bench set pressure is reached, adjust the spring adjuster (see figure 4). Thread the adjuster up or down on the actuator stem until the actuator stem movement is first detected at the upper bench set pressure. (Note: You may need to lower the loading pressure to reduce spring compression, allowing the spring adjuster to turn.)

5.Be sure the spring adjuster is adjusted to meet the requirements of step 4 above.

6.Slowly decrease diaphragm loading pressure to the lower bench set pressure, as indicated on the nameplate. This will extend the actuator stem toward the valve. Mark the end of the actuator stem on a nearby surface using tape or some other method.

7.Slowly increase the diaphragm loading pressure until the upper bench set pressure is reached. Again, the travel stop cap screw (key 12) should be against the upper diaphragm casing.

8.Measure the distance between the mark or tape to the end of the actuator stem. This distance should match the rated travel indicated on the nameplate.

9.If the measured travel matches the nameplate travel, bench set is complete. Proceed to the Installing the Stem Connector Assembly subsection.

10.If the measured travel is not exact, consider the spring free-length and spring rate tolerances may produce a slightly different bench set than specified. Contact your Emerson Process Management sales office for assistance.

For Push Down to Open (Reverse Acting) Valves

1.If not already accomplished, push the valve stem down away from the actuator to the open position. Later, when installing the connector, pull up the valve stem to the closed position.

2.Set the diaphragm loading pressure to a value less than the lower bench set pressure, as indicated on the nameplate, or near zero. The down travel stops (key 77) should be contacting the yoke.

3.Slowly increase the pressure towards the lower bench set pressure while checking for the first linear movement of the actuator stem.

Note

Before turning the spring adjuster on size 70, 76, or 87 actuators, assemble the stem connector around the actuator stem and the anti-rotating lug on the yoke. Mark the actuator stem as a visual reference to verify that stem rotation does not occur. Remove the stem connector before rechecking the bench set.

8

Instruction Manual |

667 Size 30-76 and 87 Actuators |

D100310X012 |

November 2013 |

|

|

4.If movement occurs before or after the lower pressure is reached, adjust the spring adjuster (see figure 4). Thread the adjuster up or down on the actuator stem until the actuator stem movement is first detected at the lower bench set pressure.

5.Apply the upper bench set pressure indicated on the nameplate to the diaphragm. This will retract the actuator stem away from the valve. Mark the end of the actuator stem on a nearby surface using tape or some other method.

6.Slowly decrease the diaphragm pressure until the lower bench set pressure is applied. Again, the down travel stops (key 77) should be against the yoke.

7.Measure the distance between the mark or tape to the end of the actuator stem. This distance should match the rated travel indicated on the nameplate.

8.If the measured travel matches the nameplate travel, bench set is complete. Proceed to the Installing the Stem Connector Assembly subsection.

9.If the measured travel is not exact, consider the spring free-length and spring rate tolerances may produce a slightly different bench set than specified. Contact your Emerson Process Management sales office for assistance.

Installing the Stem Connector Assembly

When installing the stem connector assembly (key 31), the actuator and valve stem threads should engage the threads of the stem connector by a distance equal to the diameter of the stem.

WARNING

WARNING

Install the stem connector securely before a positioner is mounted to the actuator and pressurized, using only a regulator-controlled air supply, not the positioner, to move the actuator stem.

To avoid personal injury or property damage, keep hands and tools out of the actuator stem travel path while applying loading pressure to move the actuator stem in the following steps.

CAUTION

To avoid damaging the seating surfaces, do not rotate the valve plug while it is seated. Exercise care while installing the stem connector assembly to avoid damage to the valve plug stem and valve stem threads.

Note

Replacement stem connectors are an assembly of two stem connector halves, cap screws, and a spacer between the connector halves. Remove the spacer and discard it, if present, before clamping the actuator and valve stems together. Use only a mated pair of stem connectors.

1.If necessary, push the valve stem down so that the valve plug is touching the seat ring on direct-acting valves. For reverse-acting valves, pull the stem up to the closed position. Always start with the valve plug on the seat.

2.If necessary, screw the valve stem locknuts down, away from the connector location. For all actuators except size 87, ensure that the travel indicator disk (key 34) is on top of the locknuts.

3.Adjust the diaphragm pressure to the lower bench set pressure (or, the upper bench set pressure for reverse-acting valves.) This should be the same pressure used in the Spring Verification steps, and it is marked on the nameplate.

4.Place the stem connector half with the threaded holes approximately half way between the actuator and valve stems, and align the actuator stem and valve stem with threads from both stems mated root-to-crest with the stem connector. If the threads from one of the stems do not fully align with the stem connector, a slight change to

9

667 Size 30-76 and 87 Actuators |

Instruction Manual |

November 2013 |

D100310X012 |

|

|

loading pressure may be necessary to align the threads. Refer to figures 6, 7, and 8 to help locate the connector position.

CAUTION

Incomplete engagement of either the valve stem or actuator stem in the stem connector can result in stripped threads or improper operation. Be sure that the length of each stem clamped in the stem connector is equal to or greater than one diameter of that stem. Damage to threads on either stem or in the stem connector can cause the parts to be replaced prematurely. Do not loosen the cap screws when the stem connector has spring or loading pressure force applied.

5.Install the other half of the stem connector and insert the cap screws and tighten them while ensuring even spacing between the stem connector halves on all sides. If installing a positioner, also attach the feedback bracket at the same time.

CAUTION

Over-tightening the valve stem locknuts can make disassembly difficult.

6.Screw the valve stem locknuts up against the stem connector for the size 87 actuator. For all other actuator sizes, screw the valve stem locknuts up until the indicator disk contacts the bottom of the stem connector. Do not overtighten the locknuts.

7.Slowly stroke the valve from fully open to fully closed and verify full rated travel is achieved.

Be sure that the valve is in the closed position. Loosen the screws on the travel indicator scale (key 32), and align it with the travel indicator disk (key 34). Stroke the valve full travel to ensure that the travel matches the rated valve travel on the nameplate. If valve travel is not correct, repeat the stem connector procedure.

Friction Discussion

If you are attempting to adjust the bench set after the actuator is connected to the valve and the packing tightened, you must take friction into account. Make the spring adjustment so full actuator travel occurs at the bench set values

(a) plus the friction force divided by the effective diaphragm area with increasing diaphragm pressure or (b) minus the friction force divided by the effective diaphragm area with decreasing diaphragm pressure.

If the stem connector assembly has been installed, the valve friction may be determined by the following procedure: 1. Install a pressure gauge in the actuator loading pressure line that connects to the actuator diaphragm casing.

Note

Steps 2 and 4 require that you read and record the pressure shown on the pressure gauge.

2.Increase the actuator diaphragm pressure and read the diaphragm pressure as the actuator reaches a travel position in the rated travel of the valve that does not contact a travel stop. Make a reference mark on the travel indicator scale using tape or some other method at this point.

3.Increase the actuator diaphragm pressure until the actuator is at a travel position greater than the position referenced in step 2 using the reference point to identify first movement.

10

Instruction Manual |

667 Size 30-76 and 87 Actuators |

D100310X012 |

November 2013 |

|

|

4.Decrease the actuator diaphragm pressure and read the diaphragm pressure as the actuator returns to the position referenced in step 2.

The difference between the two diaphragm pressure readings is the change in the diaphragm pressure required to overcome the friction forces in the two directions of travel.

5. Calculate the actual friction force:

Friction |

Difference |

|

Effective |

Force, = 0.5 |

in pressure |

¢ |

diaphragm area, |

pounds |

readings, psig |

|

inches2 |

Refer to table 1 for the effective diaphragm area.

It is difficult to rotate the spring adjustor (key 74, figures 6, 7, and 8) when the full actuator loading pressure is applied to the actuator. Release the actuator loading pressure before adjusting. Then re-apply loading pressure to check the adjustment.

Figure 5. Typical Valve Response to Deadband

|

|

|

CLOSING |

|

|

||

PSIG |

UPPER |

|

VALVE |

|

1.0 |

BAR |

|

BENCH SET 15 |

|

|

|||||

PRESSURE |

|

|

|

|

|||

PRESSURE, |

|

|

|

|

PRESSURE, |

||

|

BENCH SET |

|

|

||||

|

9 |

|

|

0.6 |

|||

DIAPHRAGM |

|

|

|

RANGE OF |

|

DIAPHRAGM |

|

LOWER |

|

|

DEADBAND |

1 |

|||

3 |

OPENING |

0.2 |

|||||

|

BENCH SET |

|

|||||

|

VALVE |

|

|||||

|

PRESSURE |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

OPEN |

MID RANGE |

CLOSED |

|

||

VALVE TRAVEL

|

|

DIRECT ACTING VALVE |

NOTE: |

DEADBAND IS CAUSED BY FRICTION. |

|

1 |

|

|

A6763-2 |

|

|

|

|

|

OPENING |

|

|

||

PSIG |

UPPER |

|

VALVE |

|

1.0 |

BAR |

|

BENCH SET 15 |

|

|

|||||

PRESSURE |

|

|

|

|

|||

PRESSURE, |

|

|

|

|

PRESSURE, |

||

|

BENCH SET |

|

|

||||

|

9 |

|

|

0.6 |

|||

DIAPHRAGM |

|

|

|

RANGE OF |

|

DIAPHRAGM |

|

LOWER |

|

|

DEADBAND |

1 |

|||

3 |

CLOSING |

0.2 |

|||||

|

BENCH SET |

|

|||||

|

VALVE |

|

|||||

|

|

|

|||||

|

PRESSURE |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

CLOSED |

MID RANGE |

OPEN |

|

|

|

VALVE TRAVEL

REVERSE ACTING VALVE

Deadband Measurement

Deadband is caused by packing friction, unbalanced forces, and other factors in the control valve assembly. Deadband is the range a measured signal can vary without initiating a response from the actuator (see figure 5). Each actuator spring has a fixed spring rate (force divided by compression). You have verified that the right spring was installed in the actuator by completing the Spring Verification steps.

Deadband is one factor that affects the control valve assembly operation during automatic loop control. The control loop tolerance for deadband varies widely depending on the loop response. Some common symptoms of the deadband being too wide are no movement, a “jump” movement, or oscillating movements of the actuator during automatic loop control. The following steps are provided to determine the span of deadband. The percent of deadband is helpful in troubleshooting problems with the process control loop.

1.Start at a pressure near the lower bench set pressure, slowly increase pressure until the valve is approximately at mid-travel. Note this pressure reading.

11

Loading...

Loading...