Page 1

Instruction Manual

D251400X012

8510B Valve (EMA)

Fisherr 8510B Eccentric Disc Control Valve

November 2011

(EMA

(1)

)

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 3.................................

Specifications 3...............................

Installation 3..................................

Maintenance 6.................................

Packing Maintenance 7.........................

Stopping Leakage 7........................

Replacing the Packing 8.....................

Replacing the Seal Ring 11......................

Replacing the Disc and Shaft Assembly

or the Bearings 12...........................

Actuator Mounting 17.........................

Parts Ordering 19...............................

Parts Kits 20...................................

ENVIRO-SEAL™ Packing System Retrofit Kits 20.....

ENVIRO-SEAL Packing System Repair Kits 20.......

Parts List 21...................................

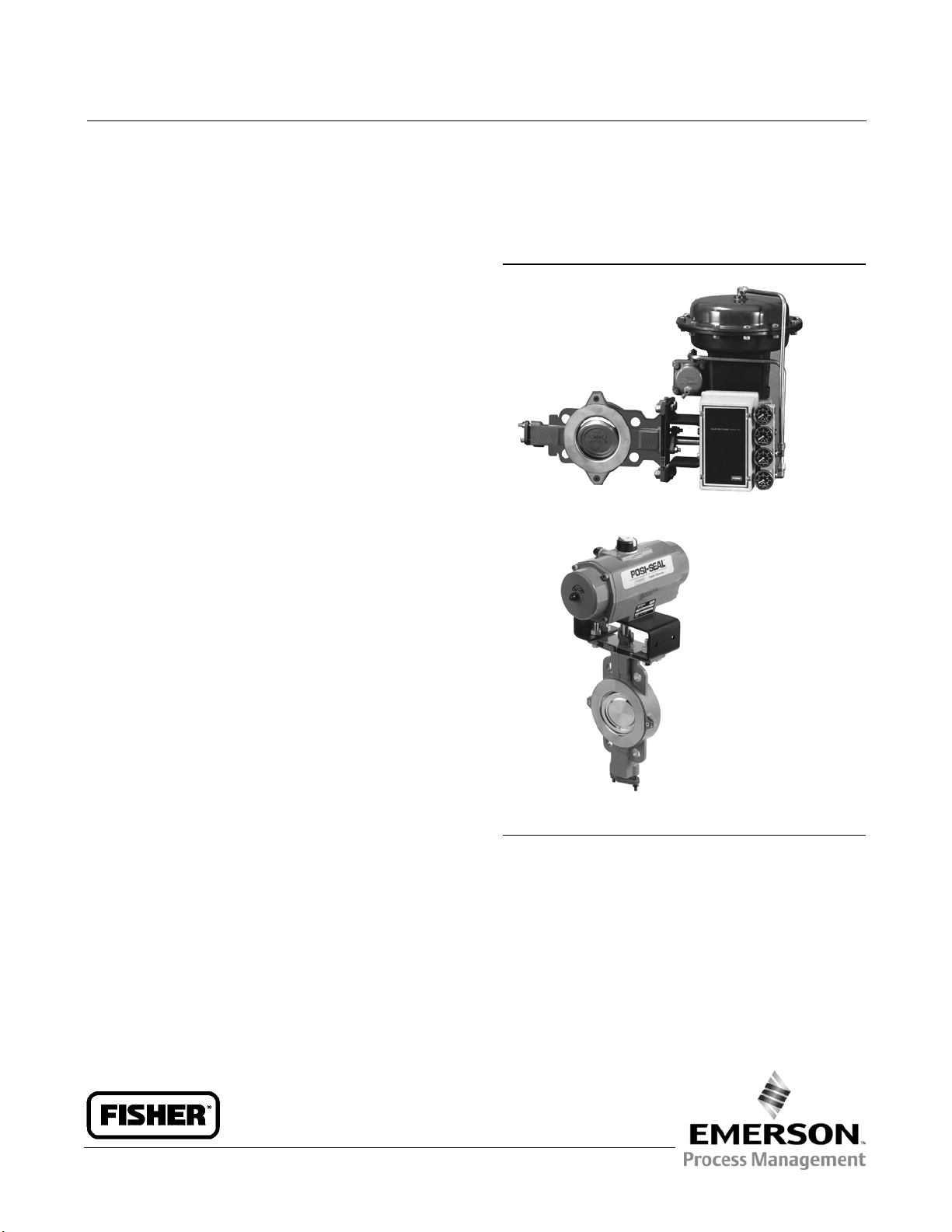

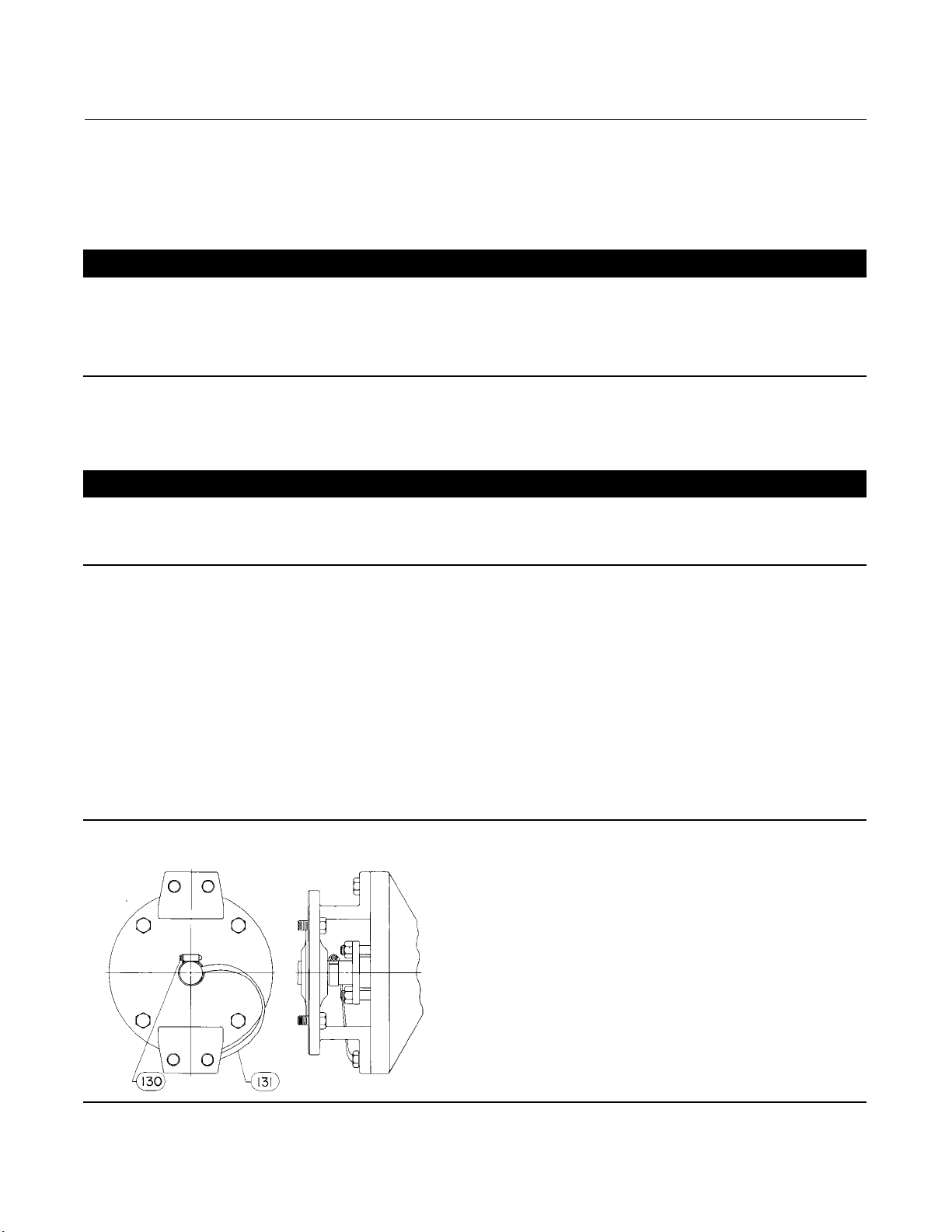

Figure 1. Fisher 8510B Eccentric Disc Control Valve

W4739-2

8510B CONTROL VALVE WITH FISHER 1052 ACTUATOR

AND 3610J POSTIONER

W8326

8510B VALVE WITH ALTERNATE DOUBLE D SHAFT WITH

ANTI-BLOWOUT AND FISHER 1035 ACTUATOR

Introduction

Scope of Manual

This instruction manual includes installation, maintenance, and parts information for NPS 2 through 12 Fisher 8510B

eccentric disc control valves that mate with ASME, EN, or JIS flanges (see figure 1). Refer to separate instruction

manuals for information covering the actuator and accessories.

www.Fisher.com

Page 2

8510B Valve (EMA)

November 2011

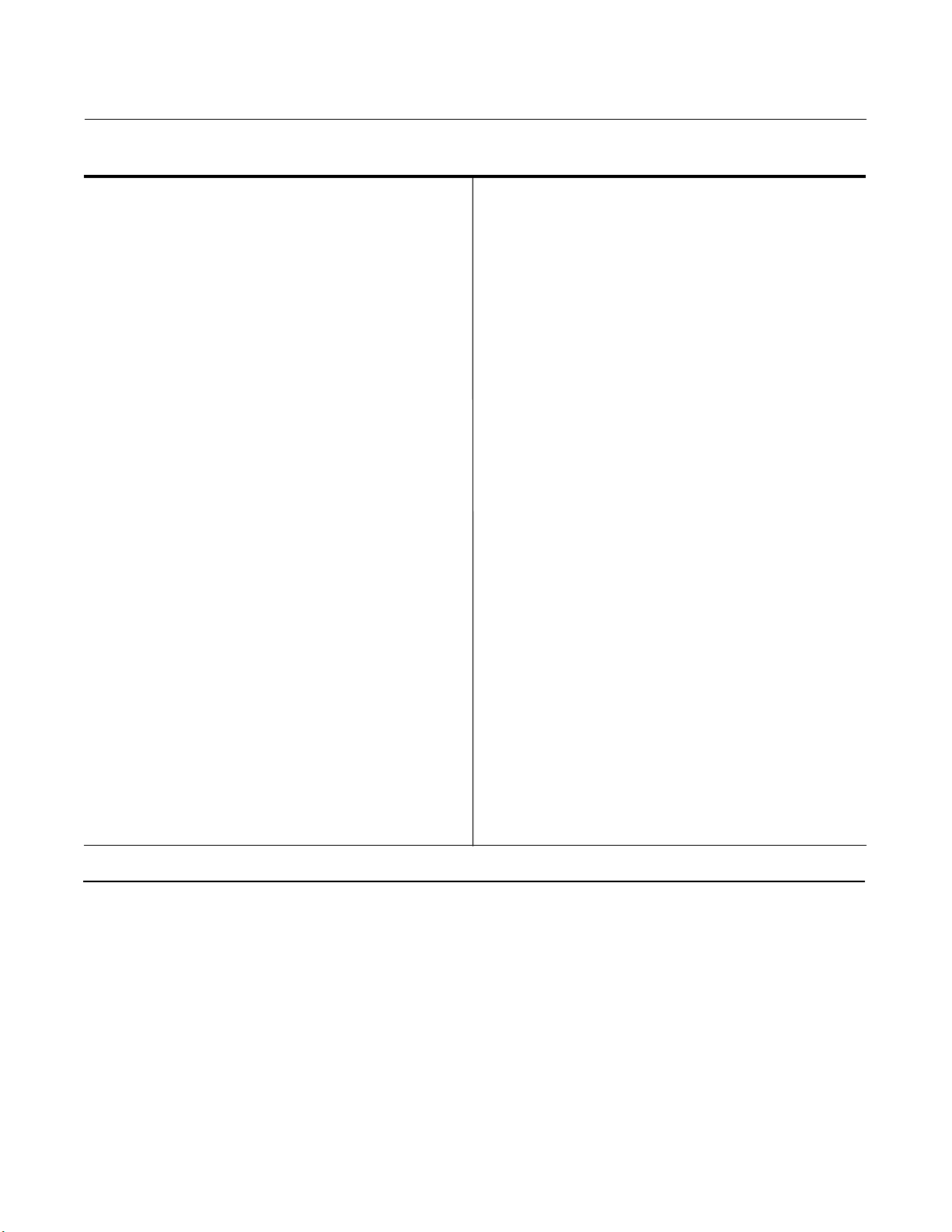

Table 1. Specifications

Instruction Manual

D251400X012

Valve Body Sizes and End Connection Style

For flangeless valves that install between ASME and

EN flanges, see table 2

Maximum Inlet Pressure

(2)

contact your Emerson Process Management sales

office with application limits

Disc Rotation

Clockwise to close (when viewed from actuator end

of valve body) through 90 degrees of disc rotation

Consistent with applicable ASME B16.34 or

EN 12516-1 ratings

Maximum Inlet Pressures, Temperatures, and

Pressure Drops

(1,2)

WCC Steel, CF3M Stainless Steel (316L SST), CN7M

(Alloy 20), and M35-1 Valve Bodies: Consistent with

applicable pressure-temperature ratings per table 2

up to the maximum material temperature capabilities

listed in table 3, but do not exceed the pressure,

temperature, and pressure drop conditions of the

valve construction. Also see the Installation section.

Actuator/Valve Action

With diaphragm or piston rotary actuators, they are

field reversible between:

J Push-down-to-open (extending actuator rod

opens the valve) and

J Push-down-to-close (extending actuator rod

closes the valve)

With 1035 Rack and Pinion actuator with spring

return or double acting action, field-reversible

between

J fail-to-open and J fail-to-close

Valve Body Classification

Shutoff Classifications

PTFE Seal Ring: Bidirectional shutoff to Class VI is

standard

All-Metal Seal Ring: 0.001% of maximum valve

capacity (one tenth of Class IV per ANSI/FCI 70-2 and

IEC 60534-4)

J ASME face-to-face dimensions for NPS 3 through 6

CL150 and 300, and face-to-face dimensions for NPS

8 through 12 CL150 meet API 609 standard

J Face-to-face dimensions for all sizes meet

EN 558 Series 25, and

J JIS B2210 standard face-to-face dimensions are

available upon request

Material Temperature Capabilities

See table 3

Flow Characteristic

Approximately linear

(1)

Mating Flange Capabilities

All sizes compatible with welding-neck and slip-on

flanges (schedule 80 or lighter for NPS 2 through 12)

Shaft Diameters

See table 2

Flow Direction

Standard (forward flow) is with seal retainer (key 2,

figure 8) facing upstream; reverse flow is permissible,

1. The pressure/temperature limits in this manual and any applicable standard or code limitation should not be exceeded.

2. The maximum allowable body inlet pressure might exceed the flange joint pressure rating. If so, actual inlet pressure must not exceed the flange joint pressure rating.

Approximate Weights

See table 2

Do not install, operate, or maintain 8510B valves without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

2

Page 3

Instruction Manual

D251400X012

8510B Valve (EMA)

November 2011

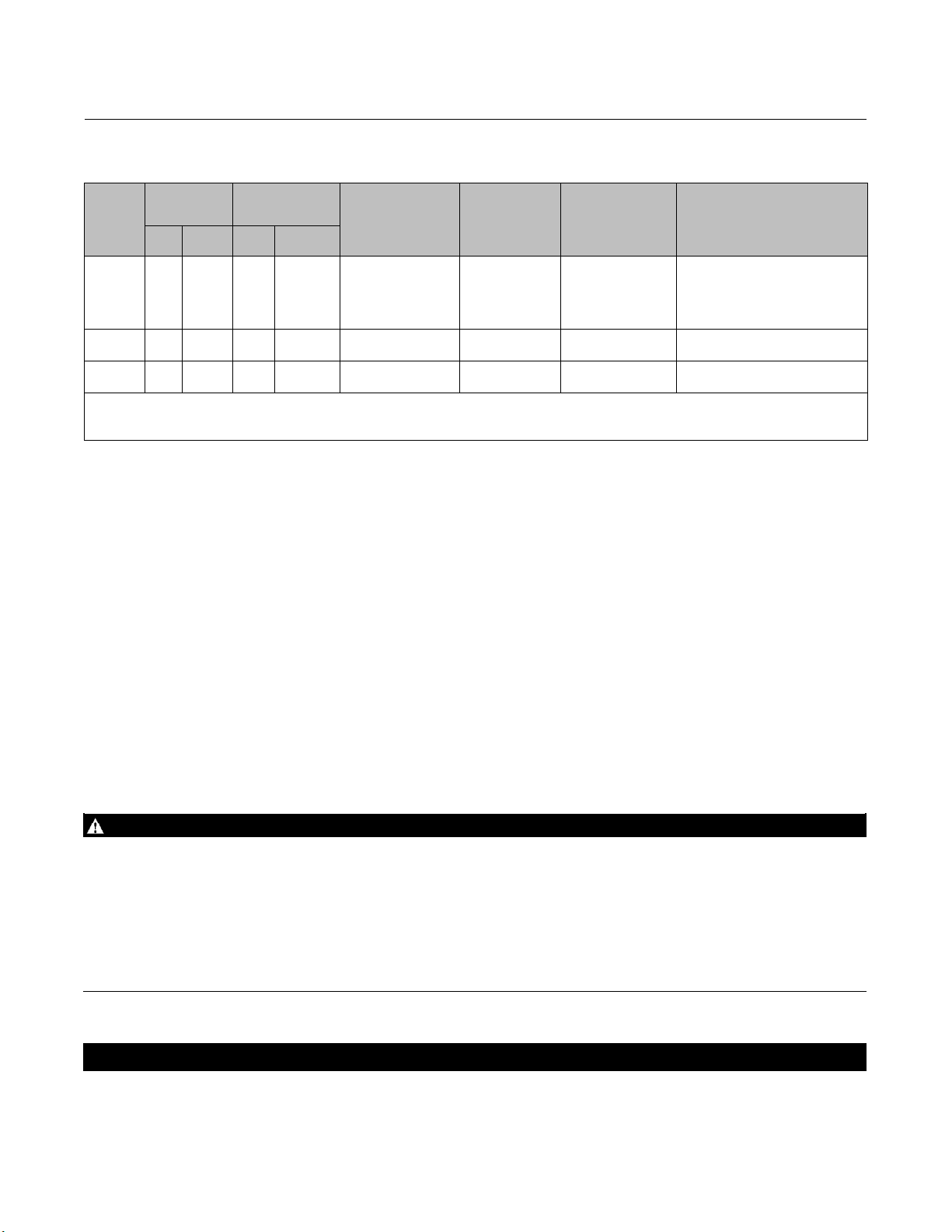

Table 2. Valve Body Size, Shaft Diameter, Approximate Weight, and ASME Rating and Flange Compatibility

VALVE

SIZE,

NPS

2

3

4

6

8

10 31.8 1-1/4 46 102

12 38.1 1-1/2 72 158

1. M35-1 valve materials are notincludedin ASME B16.34 pressure/temperature ratings. See table 3 for pressure/temperature information forM35-1valve bodies. The designations CL150,

CL300, and CL600 for thesevalve bodies are used only to indicate relativepressure-retaining capabilities and are not ASME pressure/temperature rating class designations.

2. The Double D end connection with anti-blowout s haft is only available in CL150.

3. The Double D end connection withanti-blowout shaft is available only in PN10 and PN16.

SHAFT

DIAMETER

mm Inches kg Pounds

12.7

1/2

15.9

5/8

19.1

3/4

25.4

31.8

1-1/4

1

APPROXIMATE

WEIGHT

4.3

5.9

9.1

19

31

9.5

13

20

41

69

ASME RATING

COMPATIBILITY–

STEEL, STAINLESS

STEEL, AND ALLOY 20

VALVE BODIES

CL150, 300, & 600

CL150

CL300

CL150

CL300

(2)

VALVE BODY

DESIGNATION–

(1)(2)

M35-1

CL150, 300, &

600

CL150

CL300

CL150

CL300

ASME FLANGE

COMPATIBILITY

CL150, 300, & 600

CL150

CL300

CL150

CL300

EN FLANGE COMPATIBILITY

(2)

PN10, PN16, & PN25

PN40, PN63, & PN100

PN10 & PN16

PN25 & PN40

PN10 & PN16

PN25 & PN40

(3)

Description

The 8510B flangeless control valve has an eccentrically mounted disc that self-centers in the line during installation.

The valve includes built-in electrical bonding of the shaft to the valve body. This valve has either a splined shaft for use

with power, handwheel, or handlever rotary actuators, or a double D end connection with anti-blowout shaft for use

with 1035 Rack and Pinion actuators and other quarter-turn actuators. It is used for throttling or on/off control of a

wide variety of liquids and gases. The 8510B is a balanced construction available in CL150 through 600. Figure 8

illustrates the various constructions.

Specifications

Specifications for the 8510B valve body are shown in table 1.

Installation

Key numbers in this procedure are shown in figure 8 unless otherwise indicated.

WARNING

Always wear protective gloves, clothing and eyewear when performing any installation operations to avoid personal

injury.

To avoid personal injury or property damage resulting from the bursting of pressure retaining parts, be c ertain the service

conditions do not exceed either the valve body rating or the flange joint rating, or other limits given in table 1 or on the

nameplate. Use pressure-relieving or pressure-limiting devices to prevent the service conditions from exceeding these

limits.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

CAUTION

The valve configuration and construction materials were selected to meet particular pressure, temperature, pressure drop,

and controlled fluid conditions specified in the customer's order. Because some valve body/trim material combinations are

3

Page 4

8510B Valve (EMA)

November 2011

Instruction Manual

D251400X012

limited in their pressure drop and temperature range capabilities (especially due to differences in thermal expansion rates),

do not apply any other conditions to the valve without first contacting your Emerson Process Management sales office.

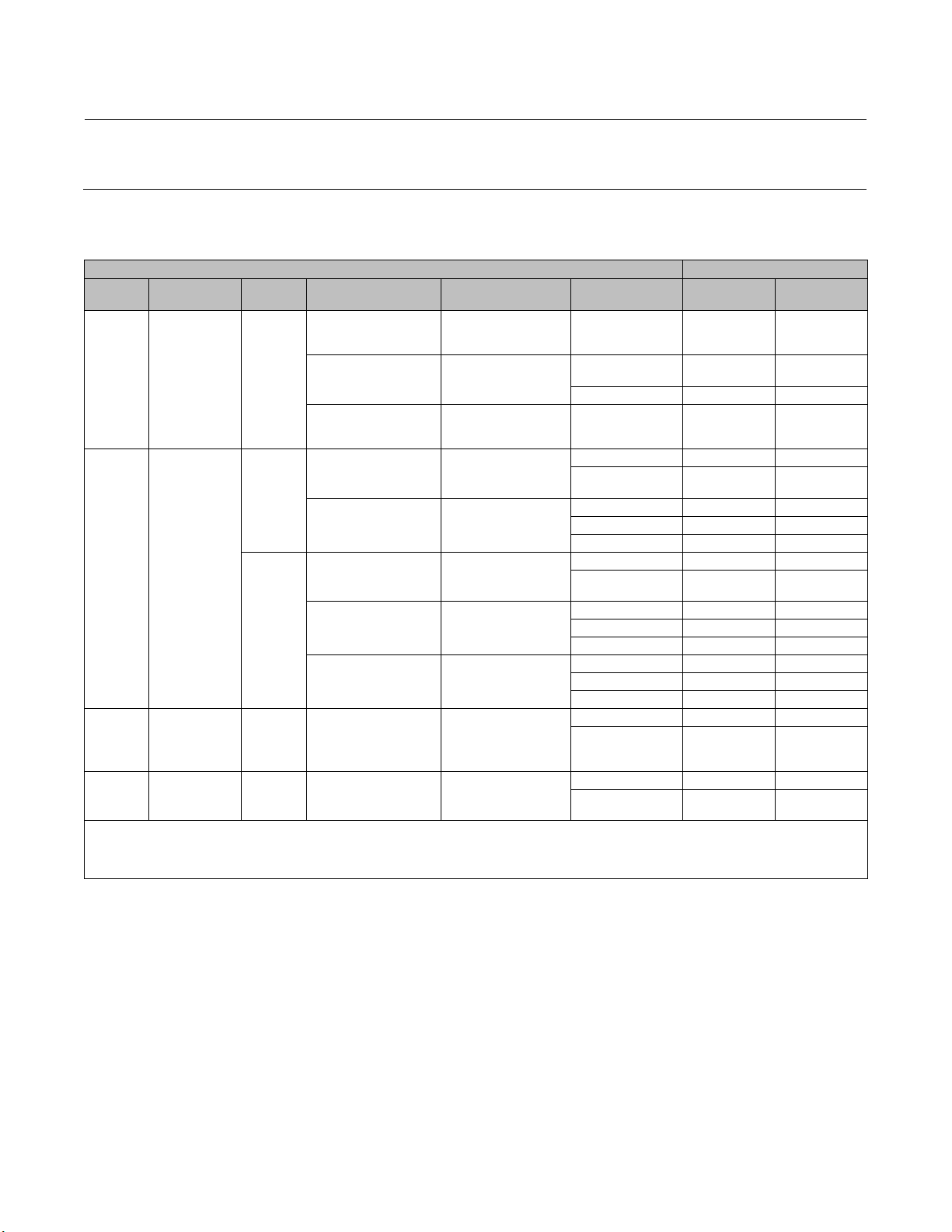

Table 3. Material Temperature Capabilities

MATERIAL TEMPERATURE CAPABILITY

Valve

Body

Disc Shaft

WCC steel with

WCC steel

chrome-plated

seating surface,

or S31603

S17400

(17-4PH)

(316L SST)

S17400

S31603 (316L

SST) with

CF3M

(316L

stainless

steel)

M35-1

CN7M

(alloy 20)

1. For hot water or steam service, limit maximum temperature to 207_C (405_F).

2. Reinforced PTFE in phenolic resin. Emerson Process Managementdesignation is FMS 30B4.

3. PTFE with selected fillers. EmersonProcess Management designation is FMS 30B5.

4. For temperature limits of ENVIRO-SEAL packing systems, see the instruction manual Fisher ENVIRO-SEAL Packing System for Rotary Valves (D101643X012).

5. These materials are only available inthesplined shaft version of 8510B, and not in the double D end connection with anti-blowoutshaft.

chrome-plated

S31603 (316L

SST) without

with PTFE seat

(5)

(5)

CN7M (alloy 20)

surface or

plating

only)

S20910

M35-1 N05500

N08020

(alloy 20)

Bearing Lining and

Jacket

(2)

PTFE

/Composition

lined with S31603 (316L

SST) jacket

S44004 (440-C SST) All

metal bearing

(2)

PTFE

/Composition lined

with S31603 (316L SST)

jacket

(2)

PTFE

/Composition lined

with S31603 (316L SST

Filled PTFE

jacket

(3)

(5)

S31603 (316L SST jacket

(2)

PTFE

/Composition

lined with S31603 (316L

SST jacket

Silver plated alloy 6B

(CoCr-A)

Alloy 6B S31600

Filled PTFE

(5)

(5)

N04400 jacket

Filled PTFE

N08020 jacket

lined with

(3)

with

(3)

with

Seal Packing

PTFE Composition or

S31600 (316 SST)

(4)

All —29 to 232

PTFE V-ring or

S31600

PTFE/Combustion

Graphite ribbon —29 to 427 —20 to 800

S31600 All —29 to 232

PTFE V-ring —40 to 232

PTFE Composition

PTFE/Composition

or graphite ribbon

PTFE V-ring —40 to 232 —40 to 450

S31600

PTFE/Composition —46 to 260 —50 to 500

Graphite ribbon —46 to 427 —50 to 800

PTFE V-ring —40 to 232

PTFE Composition

PTFE/Composition

or graphite ribbon

PTFE V-ring —40 to 232

S31600

PTFE/Composition —46 to 232

Graphite ribbon —46 to 232

PTFE V-ring —40 to 232 —40 to 450

PTFE/Composition —46 to 232 —50 to 450

Graphite ribbon —46 to 538 —50 to 1000

PTFE V-ring —40 to 232

PTFE Composition

PTFE/Composition

or

graphite ribbon

PTFE V-ring —40 to 149 —40 to 300

PTFE Composition

PTFE/Composition

or graphite ribbon

_C _F

(1)

—20 to 450

—29 to 232 —20 to 450

(1)

—20 to 450

(1)

—40 to 450

—46 to 232

—46 to 232

—46 to 232

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

—50 to 450

—40 to 450

—50 to 450

—40 to 450

—50 to 450

—50 to 450

—40 to 450

—50 to 450

—46 to 149 —50 to 300

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

The maximum allowable inlet pressures for steel, stainless steel, alloy 20, and M35-1 valve bodies are consistent with

the pressure-temperature ratings shown in table 2, except where further limited by the trim and packing material

temperature capabilities given in table 3.

1. Install a three-valve bypass around the control valve assembly if continuous operation is necessary during

inspection and maintenance of the valve body.

2. Inspect the valve body to be certain that it is free of foreign material.

3. The valve is normally shipped as part of a control valve assembly, with a power or manual actuator mounted on the

valve body.

If the valve body and actuator have been purchased separately or if the actuator has been removed for maintenance,

mount the actuator, and adjust actuator travel before inserting the valve body into the line. This is necessary due to

the measurements that must be made during the actuator adjustment process. Refer to the Actuator Mounting

4

Page 5

Instruction Manual

D251400X012

8510B Valve (EMA)

November 2011

section of this manual and to the separate actuator instruction manual for mounting and adjusting instructions before

proceeding.

4. Be certain that adjacent pipelines are free of any foreign material, such as pipe scale or welding slag, that could

damage the valve body seating surfaces.

CAUTION

Damage to the disc (key 3) will occur if any pipe flanges or piping connected to the valve body interfere with the disc

rotation path. However, the disc can be rotated without interference when the valve body is installed between adjacent

pipe flanges or piping that has an inside diameter equal to or greater than either schedule 80 pipe or compatible DIN or JIS

pipe sizes. If piping with a smaller inner diameter than specified above is connected to the valve, measure carefully to be

certain the disc rotates without interference before putting the valve into operation.

5. Flow is in the standard direction when the seal retainer (key 2) is facing upstream. Standard flow direction is also

indicated by the flow direction arrow cast into the valve body. Flow in the reverse direction is permissible.

CAUTION

Rotating the disc (key 3) past either t he open or closed position could damage the seal and disc sealing surfaces and could

cause the disc to jam in the valve body bore. The disc stop should be zeroed in its flat position as shown in figure 7. Do not

use the disc stop as a travel stop for the actuator. Use the actuator travel stop provisions.

6. With the disc in the closed position, install line flange gaskets, and insert the valve between the pipeline flanges.

Use either flat sheet gaskets or spiral-wound gaskets with compression-controlling centering rings. Spiral-wound

gaskets without compression-controlling centering rings are not recommended for this purpose. Composition

gaskets may be used to 343_C (650_F), and the optional FGM gaskets (key 29, not shown) may be used for —129 to

538_C (—200 to 1000_F) temperatures.

7. There are four flange bolt holes in the valve body (key 1), and each hole engages one corresponding line flange

stud. Insert the valve between the flanges and i nstall the four line flange studs to roughly center the valve body in

the pipeline.

8. After centering the valve body, first lubricate and then install the remaining line flange studs to secure the valve in

the pipeline. Tighten the nuts to the line flange studs in a crisscross sequence to ensure proper alignment of the

valve body with the flanges.

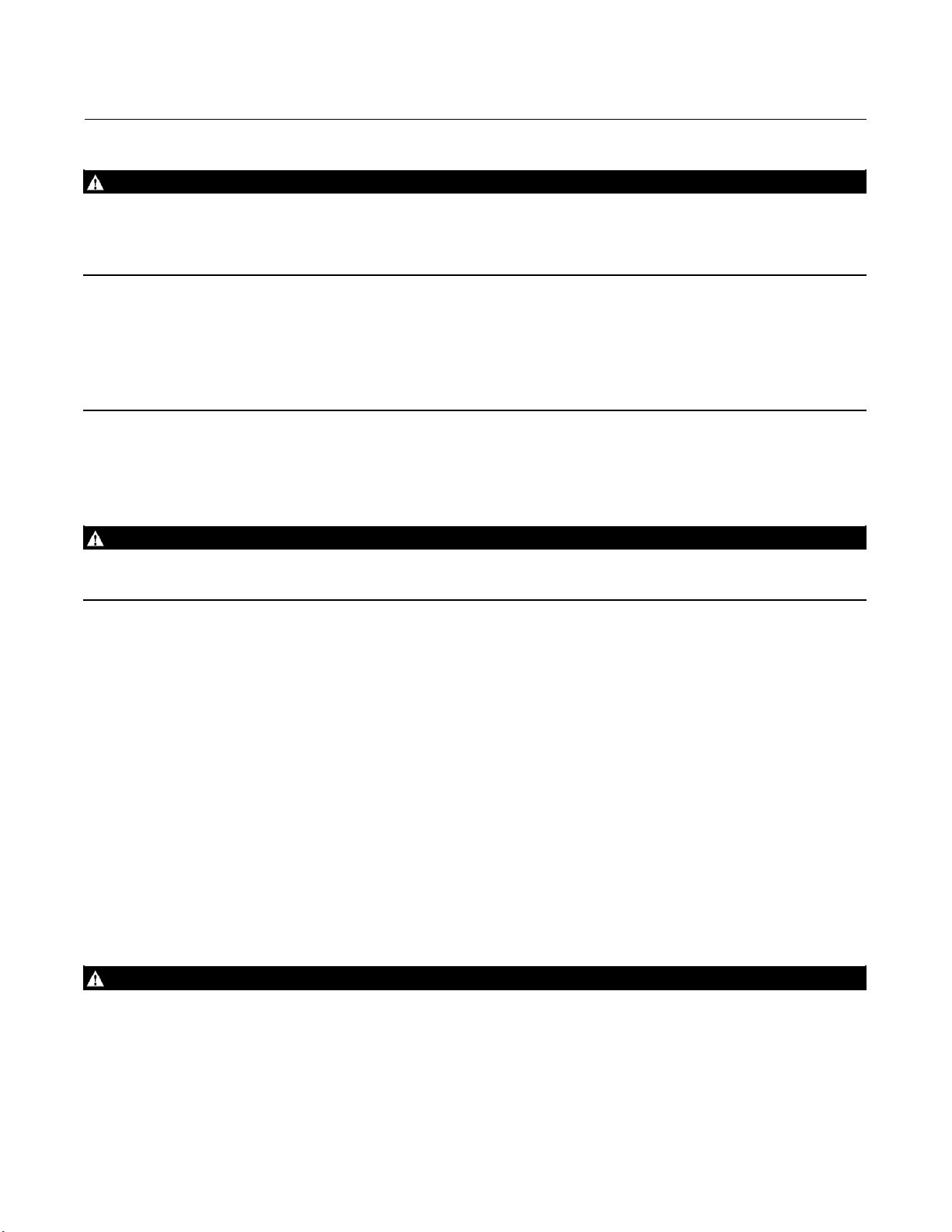

Figure 2. Optional Shaft-to-Valve Body Bonding Strap Assembly

5

Page 6

8510B Valve (EMA)

November 2011

Instruction Manual

D251400X012

WARNING

An 8510B valve body is not necessarily grounded when installed in a pipeline. If the valve is used in a flammable or

hazardous atmosphere or for oxygen service, an explosion could result due to a discharge of static electricity from the valve

components. To avoid personal injury or property damage, always make sure that the valve body is grounded to the

pipeline before putting the control valve assembly into operation in a flammable or hazardous atmosphere.

Note

Standard 8510B packings are composed of all conductive packing rings (graphite ribbon packing) or partially conductive packing

rings (such as a carbon-filled PTFE female adaptor with PTFE V-ring packing or a graphite composition packing ring with

PTFE/composition packing) to electrically bond the shaft to the valve body for hazardous area service. For oxygen service

applications, provide alternate shaft-to-valve body bonding according to the following step.

9. For oxygen service applications, attach the bonding strap assembly (key 131, figure 2) to the shaft with the clamp

(key 130, figure 2), and connect the other end of the bonding strap assembly to the valve body with the cap screw

(key 22). Secure each cap screw with a hex nut (key 30).

WARNING

Personal injury could result from packing leakage. Valve packing was tightened prior to shipment; however, the packing

might require some readjustment to meet specific service conditions.

Valves with ENVIRO-SEAL packing systems will not require this initial re-adjustment. See ENVIRO-SEAL Packing System

for Rotary Valves Instruction Manual (D101643X012) for packing instructions. If you wish to convert your present

packing arrangement to ENVIRO-SEAL packing, refer to the retrofit kits listed in the parts kit sub-section near the end

of this manual.

Maintenance

Valve body parts are subject to normal wear and must be inspected regularly and replaced as necessary. The frequency

of inspection and replacement depends upon the severity of service conditions. Instructions are given in this section

for: replacing packing; replacing disc, shaft, or bearing(s); changing disc rotation or valve action; and mounting and

adjusting the actuator.

As used in these instructions, actuator refers to power actuators (such as pneumatic diaphragm, piston actuators, and

rack and pinion actuators) or manual actuators (such as handwheel or handlever actuators).

WARNING

Avoid personal injury and property damage from sudden release of process pressure or bursting of parts. Before

performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

6

Page 7

Instruction Manual

D251400X012

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any spring precompression.

D Uselock-outprocedurestobesurethattheabovemeasures s tay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out from under pressure when removing the packing hardware or packing rings, or

when loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

8510B Valve (EMA)

November 2011

Packing Maintenance

Key numbers are referenced in figure 3 unless otherwise indicated. All maintenance operations in this section may be

performed with the valve in the line. Packing may be PTFE V-ring or graphite.

An ENVIRO-SEAL packing system is also available with the 8510B control valve. To install the ENVIRO-SEAL packing

system in an existing valve, follow the instructions in the instruction manual included with the packing system

(D101643X012). To remove packing parts in a valve with the ENVIRO-SEAL packing system, follow the procedures for

valves with the ENVIRO-SEAL packing system in this section. Install the replacement packing following the instructions

in the packing system instruction manual (D101643X012).

Stopping Leakage

For valves with PTFE or graphite packing:

CAUTION

Tighten the packing flange only enough to prevent shaft leakage. Excessive tightening will only accelerate wear of the

packing and could produce higher torques on the valve.

Leakage around the packing followers can be stopped by tightening the packing flange nuts (key 12, figure 8).

If the packing is relatively new and tight on the shaft, and if tightening the packing flange nuts does not stop leakage,

the shaft may be worn or nicked so that a seal cannot be made. If the leakage comes from the outside diameter of the

packing, the leakage may be caused by nicks or scratches around the packing box wall. Inspect the shaft and packing

box wall for nicks and scratches when performing the packing replacement procedures.

For valves with the ENVIRO-SEAL packing system:

Optimum performance of the ENVIRO-SEAL packing system is obtained when the Belleville springs are tightened to

their “target load.” The target load is the point where the springs are compressed to 85% of their maximum deflection,

or nearly flat. Maximum deflection is when the springs are 100% compressed, or completely flat.

Under normal conditions, the packing nuts should not require re-tightening. However, when servicing, if the springs

do not remain at the target load of 85% compression, retighten the packing box nuts according to the following

procedure:

1. Tighten the packing flange nuts alternately and evenly, keeping the packing flange parallel with the valve flange

(see figure 3), until the Belleville springs are compressed 100% (or completely flat).

7

Page 8

8510B Valve (EMA)

November 2011

Instruction Manual

D251400X012

D For PTFE packing, loosen each packing flange nut one half turn (180_ of rotation).

D For Graphite packing, loosen each packing flange nut one quarter turn (90_ of rotation).

The target load of 85% compression has now been reached. If leakage continues, replace the packing components as

described in the following procedures.

Replacing the Packing

For valves with PTFE or graphite packing:

This procedure may be performed without removing the actuator from the valve body if adding split

PTFE/composition packing rings as a temporary measure on the actuator side of the valve body. However, the actuator

must be removed from the valve body if replacing any other kind of packing on the actuator side of the valve body.

Key numbers in this procedure are shown in figure 8 unless otherwise indicated.

1. Isolate the control valve from the line pressure, release pressure from both sides of the valve body, and drain the

process media from both sides of the valve. If using a power actuator, also shutoff all pressure lines to the power

actuator, release all pressure from the actuator. Use lock-out procedures to be sure that the above measures stay in

effect while you work on the equipment.

2. Remove the packing flange nuts (key 12) and packing follower (key 15), plus the packing flange (key 9) if used, from

thesideofthevalvebodyoppositetheactuator.

CAUTION

If removing the actuator in the following step, use a wheel puller to separate the actuator parts from the valve shaft. Do not

drive the actuator parts off the valve shaft because this could move the valve bearings and disc away from the centered

position, thereby damaging the disc and the valve body.

3. If necessary to remove the actuator, remove the cap screws and nuts (keys 22 and 30). Remove the clamp (key 130,

figure 2) if the strap (key 131, figure 2) is used. If necessary, refer to separate actuator instruction manuals for

assistance in removing the actuator.

4. Remove the packing flange nuts and pull out the packing follower (key 16), plus the packing flange (key 10) if used,

fromtheactuatorsideofthevalvebody.

5. Remove the old packing rings (key 13) and, if used, the packing washers (key 27). Carefully avoid scratching the

shaft or packing box wall to avoid damage that could cause leakage around the shaft. Clean all accessible metal

parts and surfaces to remove particles that would prevent the packing from sealing.

8

Page 9

Instruction Manual

D251400X012

Figure 3. Packing Arrangement Details

8510B Valve (EMA)

November 2011

PTFE V-RING

SINGLE PTFE PACKING FOR

ACTUATOR END

PTFE COMPOSITION

STANDARD PACKING

GRAPHITE RIBBON

SINGLE PTFE PACKING FOR

OUTBOARD END

GRAPHITE PACKING FOR

ACTUATOR END

GRAPHITE PACKING FOR

OUTBOARD END

ENVIRO-SEAL PACKING

NOTES:

1

WITH CONDUCTIVE PACKING, THE FEMALE ADAPTORIN PTFE V-RING PACKING IS CARBON-FILLED PTFE AND THE TOP RING IN COMPOSITION PACKING IS GRAPHITE/N06600.

2

APPLY LUBRICANT.

THESE TWO SURFACES SHOULD REMAIN PARALLEL AS YOU ALTERNATELYAND EVENLY TIGHTEN THE PACKING NUTS (KEY 101).

3

9

Page 10

8510B Valve (EMA)

November 2011

Note

Except with oxygen service, lightly lubricate new PTFE V-rings with phenylmethyl silicone lubricant to aid in assembly.

Instruction Manual

D251400X012

WARNING

Do not lubricate parts when used in oxygen service, or where the lubrication is incompatible with the process media. Any

use of lubricant can lead to the sudden explosion of media due to the oil/oxygen mixture, causing personal injury or

property damage.

6. Use the appropriate procedures below for installing packing in either end of the valve.

D Install the packing washers (key 14), and packing rings (key 13). Make sure that PTFE/composition packing rings are

installed so that the ring splits do not line up to form a leak path.

D With graphite ribbon packing, stack the packing rings and packing washers together as shown in figure 3, and slide

the stack into the packing box as far as it will go while carefully avoiding trapping air among the rings.

D Install both packing followers and, if used, the packing flanges.

D Install the packing flange nuts, and tighten them only far enough to stop leakage under normal operating

conditions. For oxygen service applications, perform the next step.

D For oxygen service applications, attach the bonding strap assembly (key 131, figure 2) to the shaft with the clamp

(key 130, figure 2), and connect the other end of the bonding strap assembly to the valve body with a cap screw

(key 22). Secure each cap screw with a hex nut (key 30).

7. Mount the actuator, if it was removed from the valve body, and adjust the actuator travel before returning the valve

to service. This is necessary due to the measurements that must be made during the actuator adjustment process.

Refer to the Actuator Mounting section of this manual or to the separate actuator instruction manual for mounting

and adjusting instructions before proceeding.

8. When placing the control valve into operation, check around the packing follower or leakage; retighten the packing

flange nuts as required according to accepted bolting procedures.

For valves with ENVIRO-SEAL packing systems:

To replace the packing at the actuator side of the valve, the actuator must be removed. Also, the valve should be

removed from the pipeline to allow proper readjustment of the disc position.

CAUTION

If removing the actuator, use a wheel puller to separate the actuator parts from the valve shaft. Do not drive the actuator

parts off the valve shaft because this could move the valve bearings and disc away from the centered position, thereby

damaging the disc and the valve body.

1. Isolate the control valve, and shut off all pressure lines to the power actuator. Release pressure from the valve body

and actuator, and disconnect the pressure lines from the actuator if it will be removed from the valve body.

10

Page 11

Instruction Manual

D251400X012

2. Loosen the two packing hex nuts evenly to remove spring tension, then remove the nuts.

3. Remove the packing flange and spring pack assembly. The spring pack assembly consists of the spring stack and

packing follower. The spring stack is retained on the packing follower by an O-ring. Remove the anti-extrusion

washer, the packing set, and the packing ring.

8510B Valve (EMA)

November 2011

CAUTION

The valve shaft surface condition is critical in making and maintaining a good seal. If the valve shaft surface is scratched,

nicked, dented, or worn, replace the valve shaft before replacing the packing system.

4. Inspect the existing valve shaft. If necessary, replace the valve shaft as described in the procedures in this section.

5. Install the new packing system components as described in the ENVIRO-SEAL Packing System for Rotary Valves

Instruction Manual (D101643X012).

6. Mount the actuator, if it was removed from the valve body, and adjust the actuator travel before returning the valve

to service. This is necessary due to the measurements that must be made during the actuator adjustment process.

Refer to the Actuator Mounting section of this manual or to the separate actuator instruction manual for mounting

and adjusting instructions.

Replacing the Seal Ring

Perform this procedure only if the control valve is not shutting off properly (that is, leaking downstream). This

procedure does not require removing the actuator from the valve body.

Key numbers in this procedure are shown in figure 8 unless otherwise indicated.

1. Isolate the control valve from line pressure, and relieve pressure from the valve body. Shut off and disconnect all

lines from the power actuator.

WARNING

The edges of a rotating disc have a shearing effect that may result in personal injury. To help prevent such injury, stay clear

of the disc edges when rotating the disc (key 3).

CAUTION

Damage to the disc (key 3) may occur if the disc is not closed when the valve is being removed from the pipeline. If

necessary, apply operating pressure to the actuator temporarily to retain the disc in the closed position while removing the

valve from the pipeline.

2. Unscrew the flange bolts, and remove the valve from the pipeline.

3. Unscrew the machine screws (key 8), and remove the seal retainer (key 2) and the retainer clip (key 34).

4. Remove the seal ring or seal ring assembly (key 4). The spring (key 5) is removed with a PTFE seal ring.

5. For metal seal ring assemblies, replace the gaskets (key 4C) if the entire seal ring assembly is not replaced. Scrape

off the old gaskets from both sides of the seal ring and the seal ring sides of the valve body (key 1) and seal retainer.

Clean the gasket surfaces.

11

Page 12

8510B Valve (EMA)

November 2011

6. Reconnect or mount the actuator (if it was removed) before proceeding.

For an actuator with adjustable travel, also adjust the actuator before proceeding. This is necessary due to the

measurements that must be made during the actuator adjustment process.

Refer to the Actuator Mounting section of this manual and to the separate actuator instruction manual for mounting

and adjusting instructions.

7. The valve should be closed during seal ring installation to permit accurate centering of the seal. To install the new

seal ring:

D For a PTFE seal, if the spring (key 5) was disassembled, hook the spring ends together. Work the spring into the

recess in the seal ring (key 4). Install the seal ring and spring assembly into the recess in the valve body as shown in

figure 8.

D For the metal seal ring assembly, install the seal ring assembly (key 4) as shown in figure 8.

Instruction Manual

D251400X012

CAUTION

New seal ring gaskets (key 4C) are very fragile and must be handled very carefully to avoid gasket kinking, cracking, or

breakage that can cause leakage between the seal ring, seal retainer, and valve body. To avoid gasket damage, make sure

that the valve body is lying flat so that the gaskets do not shift before the following step and step 8 are completed.

D For a metal seal ring on which the gaskets will be replaced, lay the following parts down in order so that they are

accurately centered on the valve body: one new gasket; thesealringorientedasshowninfigure8,andthesecond

new gasket.

8. Attach the seal retainer (key 2) and the retainer clips (key 34) to the valve body and secure with the machine screws

(key 8). Tighten the machine screws evenly so as not to crack or break the metal seal gaskets.

9. Be certain the disc is closed before installing the valve according to the Installation section of this instruction

manual.

Replacing the Disc and Shaft Assembly or the Bearings

Perform this procedure to replace the valve disc, shaft, and taper key assembly if the disc does not rotate in response

to rotation of the actuator end of the valve shaft. Key numbers in this procedure are shown in figure 8 unless otherwise

indicated.

Disassembly

1. Remove the seal ring according to steps 1 through 5 of the Replacing Seal Ring section.

CAUTION

Use a wheel puller to separate actuator parts from the valve shaft. Driving the parts off the valve shaft could move the valve

bearings and disc away from the centered position, damaging the disc and valve body.

2. Remove the cap screws (key 22) and hex nuts (key 30). Remove the clamp (key 130, figure 2) if the strap (key 131,

figure 2) is used. Remove the actuator from the valve body (key 1) while referring to the separate actuator

instruction manual for assistance.

12

Page 13

Instruction Manual

D251400X012

8510B Valve (EMA)

November 2011

3. Rotate the disc (key 3) to the fully open position.

4. Refer to figure 8 and determine the location of the smaller end of the taper key (key 21). Drive out the taper key

towards the larger end.

5. Unscrew and remove the packing flange nuts (key 12), packing followers (keys 15 and 16), and packing flanges

(keys 9 and 10) if used, from both sides of the valve body.

WARNING

Once the shaft has been removed in the following step, the disc may fall from the valve body. To avoid personal injury and

disc damage, support the disc to prevent it from falling as the shaft is being removed.

6. Pulltheshaftoutthroughtheactuatorsideofthevalvebody.Iftheshaftcannotbepulledfree,carefullyuseapin

punch to drive the shaft out from the side opposite the actuator. Do not damage the end of the shaft with the

punch.

7. Remove the disc and spacers (key 7) from the valve body.

8. Remove the packing rings (key 13, figure 3), the packing washers (key 27, figure 3) if used, and the packing box

rings (key 14, figure 3) from both sides of the valve body.

9. If either of the bearings (key 6) require maintenance or replacement, press them out, or remove them using a

bearing puller. (See figure 4 for the puller dimensions.) For constructions with a metal bearing, also remove the

bearing stop (key 25) with the bearing.

10. Clean the packing boxes andmetalpackingboxparts.

Assembly

Note

Before performing the following step, lubricate the outer bearing surfaces--except on oxygen service--with dry-film lubricant to

facilitate future removal. Do not lubricate the insides of PTFE-lined bearings.

WARNING

Do not lubricate bearings that will be used for oxygen service, or where the lubrication is incompatible with the process

media. Any

injury or property damage.

1. If new bearings and, if used, bearing stops (key 25) are required, insert them through the packing boxes. Press the

bearings in until the bearing end is flush with the valve body bore at one point and the remainder of the bearing end

protrudes into the valve body bore. Or, use a bearing puller (see figure 4 for puller dimensions) to properly install

and locate the new bearings and the bearing stops.

2. Install spacers (key 7) into the disc (key 3). The spacers fit loosely in the disc.

Note

If contaminating the process fluid with grease is a concern, do not apply grease according to the following step; especially if the

thorough cleaning in step 7 cannot be performed.

use of lubricant can lead to the sudden explosion of media due to the oil/oxygen mixture, causing personal

13

Page 14

8510B Valve (EMA)

November 2011

Figure 4. Bearing Puller Dimensions

Instruction Manual

D251400X012

REFERTOTABLES4,5,AND6

mm

47A8111-C

A2882-3

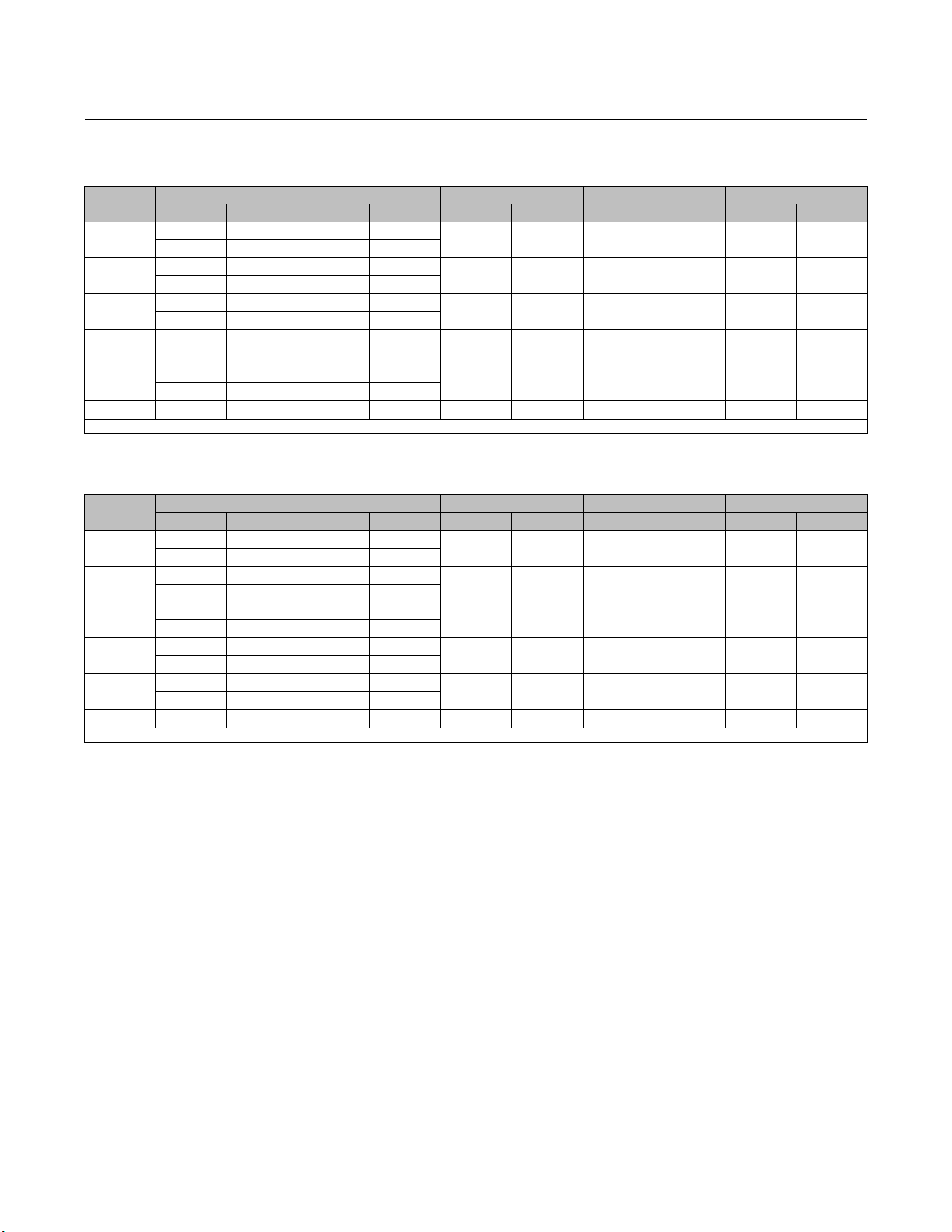

Table 4. Puller Dimensions for Bearing Stop

VALVE

SIZE, NPS

2

3

4

6

8&10

12 41.76 1.644 38.96 1.534 35.71 1.406 41.28 1.625 60.33 2.375

1. Tolerance for the A&B dimensions are indicated by showing maximum and minimum dimensions.

A B C D E

mm Inch mm Inch mm Inch mm Inch mm Inch

15.49 0.610 13.56 0.534

15.37 0.605 13.44 0.529

18.67 0.735 16.74 0.659

18.54 0.730 16.61 0.654

22.71 0.894 19.91 0.784

22.58 0.889 19.79 0.779

29.06 1.144 26.26 1.034

28.93 1.139 26.14 1.029

35.41 1.394 32.61 1.284

35.28 1.389 32.49 1.279

(INCH)

(1)

10.31 0.406 14.29 0.563 33.34 1.313

13.49 0.531 15.88 0.625 34.93 1.375

16.66 0.656 22.23 0.875 41.28 1.625

23.01 0.906 28.58 1.125 47.63 1.875

29.36 1.156 34.93 1.375 53.98 2.125

14

Page 15

Instruction Manual

D251400X012

8510B Valve (EMA)

November 2011

Table 5. Puller Dimensions for PTFE Bearings

VALVE

SIZE, NPS

2

3

4

6

8&10

12 41.76 1.644 38.05 1.498 34.93 1.375 85.73 3.375 104.8 4.125

1. Tolerance for the A&B dimensions are indicated by showing maximum and minimum dimensions.

A B C D E

mm Inch mm Inch mm Inch mm Inch mm Inch

15.49 0.610 12.65 0.498

15.37 0.605 12.52 0.493

18.67 0.735 15.82 0.623

18.54 0.730 15.70 0.618

22.71 0.894 19.00 0.748

22.58 0.889 18.87 0.743

29.06 1.144 25.35 0.998

28.93 1.139 25.22 0.993

35.41 1.394 31.70 1.248

35.28 1.389 31.57 1.243

Table 6. Puller Dimensions for Metal Bearings

VALVE

SIZE, NPS

2

3

4

6

8&10

12 41.76 1.644 38.10 1.500 34.93 1.375 41.28 1.625 60.33 2.375

1. Tolerance for the A&B dimensions are indicated by showing maximum and minimum dimensions.

A B C D E

mm Inch mm Inch mm Inch mm Inch mm Inch

15.49 0.610 12.70 0.500

15.37 0.605 12.57 0.495

18.67 0.735 15.88 0.625

18.54 0.730 15.72 0.619

22.71 0.894 19.05 0.750

22.58 0.889 18.92 0.745

29.06 1.144 25.40 1.000

28.93 1.139 25.27 .995

35.41 1.394 31.75 1.250

35.28 1.389 31.62 1.245

(1)

9.53 0.375 33.24 1.313 50.80 2.000

12.70 0.500 39.70 1.563 58.74 2.313

15.88 0.625 47.63 1.875 66.68 2.625

22.23 0.875 60.33 2.375 79.38 3.125

28.58 1.125 73.03 2.875 92.08 3.625

(1)

9.53 0.375 15.88 0.625 34.93 1.375

12.70 0.500 20.64 0.813 39.69 1.563

15.88 0.625 22.23 0.875 41.28 1.625

22.23 0.875 28.58 1.125 47.63 1.875

28.58 1.125 34.93 1.375 53.98 2.125

3. Apply a small amount of heavy grease to the spacers. The grease will help to hold the spacers in place during the

subsequent centering procedure.

D Valves with PTFE bearings use one PTFE coated spacer on each side of the disc. Install the spacer with the PTFE side

against the disc.

D Valves with metal bearings use two metal spacers on each side of the disc.

4. Insert the disc into the valve body. Be certain the taper key hole in the disc is on the actuator side of the valve body.

5. Slide the shaft through the valve body and disc.

6. Rotate the disc to the closed position. Measuring carefully, center the disc in the valve body bore. With the disc

centered, use a feeler gauge to measure the clearance between each spacer and bearing. The clearance between

each spacer and bearing should be equal and should be as close as possible to the value given in figure 5. If

necessary, remove the disc and shaft, and reposition the bearings. Reinstall the disc and shaft, and repeat the

centering and measuring process.

7. If the grease used to hold the spacers will contaminate the process fluid, disassemble the shaft and disc, remove the

spacers, and clean the shaft, disc, valve body bore, and spacers thoroughly. Reinstall the disc and spacers into the

valve body. Insert the shaft into the valve body and through the disc.

15

Page 16

8510B Valve (EMA)

November 2011

Figure 5. Spacer-Bearing Clearance (Metal Bearing Assembly Shown)

MEASURE

CLEARANCE

HERE

41B6065-A

SPACER TO BEARING CLEARANCE

VALVE BODY SIZE, NPS

2,3, & 4

6

8

10

12

mm Inches mm Inches

0.102

0.152

0.203

0.254

0.305

Minimum Maximum

0.004

0.006

0.008

0.010

0.012

0.229

0.279

0.330

0.381

0.432

Instruction Manual

D251400X012

0.009

0.011

0.013

0.015

0.017

Table 7. Recommended Bolt Torques for Actuator-Mounting Cap Screws

VALVE SIZE, NPS

2, 3, 4, and 6 87.7 60

8, 10, and 12 135 100

RECOMMENDED TORQUE RECOMMENDED TORQUE

NSm lbfSin.

8. Slide the shaft all the way into the valve body.

9. Temporarily install the packing follower (key 16) or, if used, the packing flange (key 9). With the disc fully open,

rotate the shaft until the hole in the disc (key 3) aligns with the slot in the shaft. Insert the taper key (key 21), small

end first, into the taper key hole. Do not drive in the taper key. Remove the packing follower or flange.

D Current standard construction materials require the taper key (key 21) to be tack welded in place after properly

seating.

Note

Make sure the drive shaft (key 20) is free of oil or grease, otherwise the taper key will not seat properly.

Failure to properly set the taper key could result in it coming loose while in service.

10. Insert a packing box ring (key 14) into each packing box.

11. Install the packing according to the appropriate instructions presented in steps 5 through 8 of the Replacing

Packing section.

16

Page 17

Instruction Manual

D251400X012

8510B Valve (EMA)

November 2011

12. Drive in the taper key until solid contact is felt, then:

a. Drive the taper key in farther as follows:

VALVE BODY SIZE, NPS MINIMUM ALLOWABLE DEPTH TO DRIVE TAPER KEY AFTER INITIAL SOLID CONTACT, mm (INCH)

2

3,4,6

8, 10, 12

3.2 (0.125)

4.8 (0.188)

5.7 (0.219)

b. The disc, shaft and taper key assembly must be inspected to verify that the taper key spans the entire shaft flat

width. If not, the taper key must be driven in farther until this condition i s satisfied. However, the following depth

limits must not be exceeded:

VALVE BODY SIZE, NPS MAXIMUM ALLOWABLE DEPTH TO DRIVE TAPER KEY AFTER INITIAL SOLID CONTACT, mm (INCH)

2

3&4

6

8&10

12

5.6 (0.219)

7.1 (0.281)

7.9 (0.312)

9.5 (0.375)

10.3 (0.406)

13. When the above conditions are met, tack weld the taper key (key 21) to the valve disc (key 3). Use a :

D 1/8inchdiameterweldonNPS2through6valves,

D 3/16 inch diameter weld on NPS 8 through 10 valves, and

D 1/4inchdiameterweldonNPS12valves.

14. Rotate the disc to the closed position.

15. Refer to the Replacing Seal Ring and Packing Maintenance procedures in this section.

Actuator Mounting

With the valve body out of the line, mount the actuator on the valve body in accordance with the instructions in the

actuator instruction manual. Mount the actuator yoke to the valve body, and tighten the actuator-mounting cap

screws and nuts (keys 22 and 30) to the appropriate torque from table 7. The valve body might have an optional disc

stop. Do not use the disc stop as a travel stop; use the actuator travel stop (if necessary, refer to the actuator

instruction manual).

Key numbers in this procedure are shown in figure 8 unless otherwise indicated.

1. If using a power actuator, determine the actuator mounting style and position from figure 6.

If using a manual handwheel or handlever actuator, refer to the appropriate actuator instruction manual for mounting

positions.

CAUTION

Rotating the disc (key 3) in the wrong direction will damage the seal ring (key 4). To avoid such damage, remove the seal

ring according to the following step before mounting the actuator.

2. Mark the orientation of the seal ring with respect to the valve body so that the seal can be reinstalled in its original

position. Remove the seal ring according to the procedure in the Replacing Seal Ring section of this instruction

manual.

17

Page 18

8510B Valve (EMA)

November 2011

Figure 6. Lever/Shaft/Disc Orientation with Valve Closed

TYPICAL ACTUATOR (1052) SECTIONAL THROUGH HOUSING

A3344

ACTUATOR

MOUNTING STYLE

VALVE CLOSED

4

MOUNTING

POSITION 1

5

ACTUATOR ROD

ACTUATOR ROD END BEARING

ACTUATOR LEVEL

LEVER INDEX MARKS (4)

VALVE SHAFT INDEX MARK

MOUNTING

POSITION 2

5

MOUNTING

POSITION 3

Instruction Manual

D251400X012

MOUNTING

5

POSITION 4

5

STYLE A

(PDTO)

RIGHTHAND

1

STYLE B

(PDTC)

3

STYLE C

(PDTC)

3

LEFTHAND

2

STYLE D

(PDTO)

NOTES:

1

WHENONEISFACINGTHEINLET,THEACTUATORISTOTHERIGHTOFTHEVALVEBODY.

2

WHEN ONE IS FACING THE INLET, THEACTUATOR IS TO THE LEFT OF THE VALVE BODY.

3

FOR 60-DEGREEOPERATION WITH PUSH-DOWN-TO-CLOSEACTION(EXTENDING ACTUATORRODCLOSES VALVE), ROTATEACTUATOR LEVER COUNTERCLOCKWISESO THAT

LEVER INDEX MARK IS OFFSET 1 SPLINETOOTHFROM VALVE SHAFT INDEX MARK FOR NPS 2 THROUGH 4 VALVES AND2 SPLINE TEETH FROM VALVE SHAFT INDEX MARK FOR

NPS 6 THROUGH 12 VALVES.

4

CURVED ARROWS IN ”VALVE CLOSED' COLUMN INDICATE ROTATION REQUIRED TO OPEN VALVE (COUNTERCLOCKWISE WHEN VIEWED FROMACTUATOR SIDE OF VALVE).

5

ARROWS IN ”MOUNTING POSITION'' COLUMNSINDICATE DIRECTION OF ACTUATOR ROD TRAVEL REQUIRED TO OPEN VALVE.

6. PDTC–PUSH DOWN TO CLOSE;PDTO–PUSHDOWN TO OPEN.

43A5323-B

B1125-1

FORWARD

FLOW

FORWARD

FLOW

FORWARD

FLOW

FORWARD

FLOW

18

Page 19

Instruction Manual

D251400X012

8510B Valve (EMA)

November 2011

CAUTION

To prevent damage to the valve seal, due to the disc rotating past the fully closed position, use the following procedures:

D For actuators with an adjustable turnbuckle, such as the Fisher 1051, 1052, or 1061 actuator, the turnbuc kle must be

adjusted so that the valve is closed (determined by measuring as shown in figure 7) when the diaphragm plate or piston

is against the actuator travel stop.

D For manually-operated actuators or actuators without adj ustable linkage, such as a Fisher 1066 or 1066SR actuator,

make certain the actuator travel stop prevents the disc from rotating past the fully closed position.

3. For actuators with an adjustable turnbuckle, adjust the turnbuckle to its minimum length to prevent damage. If

necessary, refer to the appropriate actuator instruction manual for assistance with adjustment.

4. For power actuators, refer to figure 6 to locate the view of the mounting style and position to be used. When

adjusting the actuator, be certain that the disc is rotated in the proper direction (clockwise to close when viewed

from the actuator side of the valve) and that the disc is not rotated beyond the limits defined in the Installation

section of this instruction manual.

5. For actuators with turnbuckles, adjust the turnbuckle to bring the disc to the fully closed position at the end of the

actuator stroke. Refer to the appropriate actuator instruction manual for assistance.

6. To determine the fully closed disc position (zero degrees of disc rotation), measure the distances between the disc

face and the retaining ring face (or from a line from the top to the bottom of the valve body) at the top and bottom

of the valve as shown in figure 7. When necessary, adjust the actuator to rotate the disc slightly until the two

measurements are equal.

7. Reinstall the seal ring according to the procedure in the Replacing Seal Ring section.

Figure 7. Sectional of Typical Valve Body

DISC STOP

STANDARD

FLOW

DIRECTION

NOTE:

1

THESE TWO MEASUREMENTS MUST BE EQUALTO ENSURE THAT THE DISC IS FULLY CLOSED

OPEN

Parts Ordering

When corresponding with your Emerson Process Management sales office about this equipment, always mention the

valve serial number. When ordering replacement parts, also specify the complete 11-character part number of each

part required from the following parts list.

19

Page 20

8510B Valve (EMA)

November 2011

Instruction Manual

D251400X012

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

Parts Kits

Retrofit Kits for ENVIRO-SEAL Packing

Retrofit kits are available for replacing the packing in an existing valve with an ENVIRO-SEAL packing system. These kits

are available for single PTFE or graphite packing. All parts required for installation of the ENVIRO-SEAL packing system

into an existing 8510B control valve are included in the kits. Select two kits, one for the actuator end of the valve and

one for the outboard end.

Worn shafts, packing box damage, or other components that do not meet Emerson Process Management finish

specifications, dimensional tolerances, and design specifications, may adversely alter the performance of the retrofit

kit.

ENVIRO-SEAL Packing System Retrofit Kits for Splined Shafts

SHAFT DIAMETER SINGLE PTFE PACKING GRAPHITE PACKING

mm Inches ForActuatorEndPackingBox For Outboard End Packing Box ForActuatorEndPackingBox For Outboard End Packing Box

12.7

15.9

19.1

25.4

31.8

38.1

1/2

5/8

3/4

1

1-1/4

1-1/2

RRTYXRT0012

RRTYXRT0022

RRTYXRT0032

RRTYXRT0052

RRTYXRT0062

RRTYXRT0072

RRTYXRT0082

RRTYXRT0092

RRTYXRT0102

RRTYXRT0112

RRTYXRT0122

RRTYXRT0132

RRTYXRT0312

RRTYXRT0322

RRTYXRT0332

RRTYXRT0352

RRTYXRT0362

RRTYXRT0372

RRTYXRT0382

RRTYXRT0392

RRTYXRT0402

RRTYXRT0412

RRTYXRT0422

RRTYXRT0432

ENVIRO-SEAL Packing System Retrofit Kits for Double D End Connection with Anti-Blowout Shaft

SHAFT DIAMETER SINGLE PTFE PACKING GRAPHITE PACKING

mm Inches ForActuatorEndPackingBox For Outboard End Packing Box ForActuatorEndPackingBox For Outboard End Packing Box

12.7

15.9

19.1

25.4

31.8

38.1

1/2

5/8

3/4

1

1-1/4

1-1/2

RRTYXRT0972

RRTYXRT0982

RRTYXRT0992

RRTYXRT1012

RRTYXRT1022

RRTYXRT1032

RRTYXRT0082

RRTYXRT0092

RRTYXRT0102

RRTYXRT0112

RRTYXRT0122

RRTYXRT0132

RRTYXRT1072

RRTYXRT1082

RRTYXRT1092

RRTYXRT1102

RRTYXRT1112

RRTYXRT1122

RRTYXRT0382

RRTYXRT0392

RRTYXRT0402

RRTYXRT0412

RRTYXRT0422

RRTYXRT0432

Repair Kits for ENVIRO-SEAL Packing

Repair kits for ENVIRO-SEAL PTFE packing include one packing set and two anti-extrusion washers. Repair kits for

ENVIRO-SEAL graphite packing include two packing rings and two anti-extrusion rings. A quantity of two of the

appropriate kit is required to repair both ends of the valve.

Worn shafts, packing box damage, or other components that do not meet Emerson Process Management finish

specifications, dimensional tolerances, and design specifications, may adversely alter the performance of the repair

kit.

20

Page 21

Instruction Manual

D251400X012

ENVIRO-SEAL Packing System Repair Kits

SHAFT DIAMETER

mm Inches

12.7

15.9

19.1

25.4

31.8

38.1

1/2

5/8

3/4

1

1-1/4

1-1/2

FOR PTFE PACKING FOR GRAPHITE PACKING

Parts List

Note

Part numbers are shown for recommended spares only. For part

numbers not shown, contact your Emerson Process Management sales

office.

Except where indicated, sizes shown are v alve body sizes.

Key Description Part Number

1 Valve Body ---

Note

The valve body is available as an assembly only. If valve body

replacement information is necessary, contact your Emerson Process

Management sales office.

2* Seal Retainer See following table

Part numbers are listed for steel and stainless steel only. For alloy

construction part numbers, contact your Emerson Process

Management sales office.

3ValveDisc

4* Seal Ring

4* Seal Ring Assembly, All-metal seal

4C* Gasket, graphite laminate (2 req'd)

5* Spring (PTFE seal ring only)

6* Bearing (2 req'd)

*Recommended spare parts

1. To make certain that a springisavailablewith each seal ring, a new spring (key 5) should

be ordered to be stocked with each ring ordered.

(1)

, PTFE See following table

S31600 (316 SST) & graphite laminate (Assembly

includes gaskets. For gasket only, see key 4C below)

NPS 2 17A7544X022

NPS 3 17A7550X022

NPS 4 17A7556X022

NPS 6 17A8171X022

NPS 8 17A8172X022

NPS 10 18A1129X022

NPS 12 18A1139X022

NPS 8 17A7567X012

NPS 10 18A1128X012

PTFE/composition lining with S31603 (316L SST) jacket

(Reinforced PTFE in phenolic resin. Emerson Process Management

designation is FMS 30B4.)

NPS 2 12A9015X272

NPS 3 12A8904X292

NPS 4 12A8985X332

NPS 6 12A8819X362

(1)

See following table

RRTYX000012

RRTYX000022

RRTYX000032

RRTYX000052

RRTYX000062

RRTYX000072

8510B Valve (EMA)

November 2011

13B8816X012

13B8816X032

13B8816X052

13B8816X092

13B8816X112

13B8816X142

Key Description Part Number

NPS 8 & 10 12A8965X262

NPS 12 12A8928X242

Filled PTFE with S31603 (316L SST) jacket (PTFE with selected

fillers. Emerson Process Management designation is FMS 30B5.)

NPS 2 12A9015X282

NPS 3 12A8904X302

NPS 4 12A8985X322

NPS 6 12A8819X372

NPS 8 & 10 12A8965X272

NPS 12 12A8928X272

S44004 (440C SST)

NPS 2 14A6543X012

NPS 3 12A9300X012

NPS 4 14A5698X012

NPS 6 14A4618X012

NPS 8 & 10 14A5699X012

NPS 12 14A6549X012

Alloy 6B

NPS 2 14A6544X012

NPS 3 14A6545X012

NPS 4 14A6546X012

NPS 6 14A6547X012

NPS 8 & 10 14A6548X012

NPS 12 14A6550X012

Silver-plated alloy 6B

NPS 2 14A6536X012

NPS 3 12A9161X012

NPS 4 14A6537X012

NPS 6 14A2498X012

NPS 8 & 10 14A6538X012

NPS 12 14A6539X012

7* Spacer

For PTFE lined or filled PTFE bearings

PTFE/S31603 (316LSST) (2 req'd)

NPS 2 16A6036X092

NPS 3 16A6045X162

NPS 4 16A6041X152

NPS 6 16A6033X102

NPS 8 & 10 16A6055X062

NPS 12 16A6061X152

For S44004 (440C SST) bearings

S17700 (17-7 PH SST) (4 req'd)

NPS 2 18B9857X022

NPS 3 11B9444X012

NPS 4 11B9608X012

NPS 6 12B1356X012

NPS 8 & 10 12B1997X012

NPS 12 12B3905X012

For alloy 6B or silver-plated alloy 6B bearings

Alloy6B(4req'd)

NPS 2 18B9857X022

NPS 3 11B9444X022

NPS 4 11B9608X022

21

Page 22

8510B Valve (EMA)

November 2011

Key Description Part Number

Instruction Manual

D251400X012

NPS 6 12A1356X022

NPS 8 & 10 12B1997X022

NPS 12 12B3905X022

8 Cap Screw (SST)

NPS2through8(2req'd) NPS10&12(4req'd)

9 Packing Flange

10 Packing Flange

11 Packing Flange Stud (4 req'd)

12 Packing Flange Nut (4 req'd)

13* PackingSet (2 req'd)

PTFE & carbon-filled PTFE V-ring

(standard)

NPS 2 12A9016X022

NPS 3 1R5795X0012

NPS 4 12A8995X022

NPS 6 12A8832X022

NPS 8 & 10 12A8951X022

NPS 12 12A8935X022

PTFE V-ring (nonconductive)

NPS 2 12A9016X012

NPS 3 1R579501012

NPS 4 12A8995X012

NPS 6 12A8832X012

NPS 8 & 10 12A8951X012

NPS 12 12A8935X012

Packing Parts (included in packing set)

Female Adaptor (2 req'd)

Carbon-filled PTFE (standard)

NPS 2 1H7844X0012

NPS 3 1R5794X0012

NPS 4 12A8992X022

NPS 6 12A8831X022

NPS 8 & 10 12A8953X022

NPS 12 12A8932X022

PTFE (nonconductive)

NPS 2 1H784401012

NPS 3 1R579401012

NPS 4 12A8992X012

NPS 6 12A8831X012

PTFE (nonconductive)

NPS 8 & 10 12A8953X012

NPS 12 12A8932X012

Packing Ring, PTFE (6 req'd)

NPS 2 1H784301012

NPS 3 1R579301012

NPS 4 12A8994X012

NPS 6 12A8830X012

NPS 8 & 10 12A8954X012

NPS 12 12A8933X012

Male Adaptor, PTFE (2 req'd)

NPS 2 1H784201012

NPS 3 1R579201012

NPS 4 12A8993X012

NPS 6 12A8829X012

NPS 8 & 10 12A8952X012

NPS 12 12A8934X012

13* Packing Ring (8 req'd) (not req'd for V-ring packing set)

Graphite ribbon

NPS 2 12A9134X012

NPS 3 12A9135X012

NPS 4 12A9136X012

NPS 6 12A9137X012

NPS 8 & 10 12A9138X012

NPS 12 12A9139X012

Note

When ordering a PTFE-composition & graphite composition/N06600

packing ring arrangement, order 6 PTFE-composition packing rings and

2 graphite composition/N06600 packing rings per valve.

Key Description Part Number

PTFE-composition (6 req'd)

NPS 2 1P390501042

NPS 3 1J822501042

NPS 4 14A1937X012

NPS 6 14A0915X012

NPS 8 & 10 14A0916X012

NPS 12 14A1933X012

Graphite composition/N06600 (2 req'd)

NPS 2 1P3905X0172

NPS 3 1J8225X0182

NPS 4 14A1937X042

6-inch 14A0915X042

NPS 8 & 10 14A0916X072

NPS 12 14A1933X022

14* PackingBox Ring

S31600 (316L SST) (2 req'd)

NPS 2 16A6082X052

NPS 3 16A6083X092

NPS 4 16A6084X062

NPS 6 16A6085X062

NPS 8 & 10 16A6086X082

NPS 12 16A6087X072

15 Packing follower, CF8M (316 SST)

16 Packing follower, SST

18 DriveScrew, SST (2 req'd)

20 Valve Shaft

Splined Shaft Connection

S17400 (17-4 PH SST)

NPS 2 31B2526X012

NPS 3 31B6892X012

NPS 4 31B9456X012

NPS 6 32B1347X012

NPS 8 32B1994X012

NPS 10 32B2824X012

NPS 12 32B3901X012

S20190

Do not use with S44004 (440C SST) bearings

NPS 2 31B2526X022

NPS 3 31B6892X022

NPS 4 31B9456X022

NPS 6 32B1347X022

NPS 8 32B1994X022

NPS 10 32B2824X022

NPS 12 32B3887X022

Double D End Connection and Anti-Blowout Shaft

S17400 (17-4 PH SST)

NPS 2 3Q57352F012

NPS 3 3Q57353F012

NPS 4 3Q57354F012

NPS 6 3Q57355F012

NPS 8 3Q57356F012

NPS 10 3Q57357F012

NPS 12 3Q57358F012

22

*Recommended spare parts

Page 23

Instruction Manual

D251400X012

Figure 8. Typical Fisher 8510B Valve Assemblies

INBOARD CONSTRUCTION DETAIL

CONSTRUCTION DETAIL

8510B Valve (EMA)

November 2011

FOR METAL BEARING ASSEMBLY

OUTBOARD ALLOY

41B6065-A

SEE VIEW A IN

FIGURE 9

WITH SPLINED SHAFT CONNECTION

INBOARD ALLOY

CONSTRUCTION DETAIL

41B6065

WITH DOUBLE D CONNECTION AND BLOWOUT SHAFT

23

Page 24

8510B Valve (EMA)

November 2011

Figure 9. Seal Details

METALSEALASSEMBLY

SEAL RETAINER

SCREW

RETAINER CLIP

SPRING

Instruction Manual

SEE VIEW B

NOTE:

KEY NUMBERS 4A AND 4B ARENOT SHOWN

SEAL RETAINER

D251400X012

PTFE SEAL RING

41b6065-A

A5540-1

VIEW A DETAIL OF PTFE SEAL

Key Description Part Number

20 Valve Shaft (continued)

Double D End Connection and Anti-Blowout Shaft

S20190

Do not use with S44004 (440C SST) bearings

NPS 2 3Q57352F022

NPS 3 3Q57353F022

NPS 4 3Q57354F022

NPS 6 3Q57355F022

NPS 8 3Q57356F022

NPS 10 3Q57357F022

21* Taper Key, S20910

22 Cap Screw (2 req'd for 2 & 3-inch;

23 Nameplate, stainless steel 11B9434X0A2

25* Bearing Stop (2 req'd) S31600 (316 SST)

NPS 12 3Q57358F022

NPS 2 11B0654X012

NPS 3 11B0674X012

NPS 4 11B0674X012

NPS 6 11B0695X012

NPS 8 & 10 11B0722X012

NPS 12 11B4684X012

4 req'd on all other sizes)

For use with metal bearings (not shown)

NPS 2 14A6531X022

NPS 3 12A9162X012

NPS 4 14A5697X022

NPS 6 14A2497X012

NPS 8 & 10 14A5700X022

NPS 12 14A6532X022

GASKET

BACKUP RING

METALSEALRING

VIEW B DETAIL OF METAL SEAL

Key Description Part Number

26 Line Flange Stud (not shown)

27 Packing Washer, zinc (6 req'd)

29* LineFlange Gasket, FGM (2 req'd)

(use only when specified) (not shown)

Recommended for temperatures

above 650_F (343_C)

CL150

NPS 2 16A6224X012

NPS 3 16A6226X012

NPS 4 16A6228X012

NPS 6 & 8 16A6231X012

NPS 10 16A6237X012

NPS 12 16A6239X012

CL300

NPS 2 16A6225X012

NPS 3 16A6227X012

NPS 4 16A6229X012

NPS 6 & 8 16A6232X012

NPS 10 16A6238X012

NPS 12 16A6240X012

CL600

NPS 2 16A6225X012

NPS 3 16A6227X012

NPS 4 16A6230X012

NPS 6 & 8 16A6233X012

30 Hex Nut

32 Nameplate, stainless steel

33 Nameplate Wire

34 Retainer Clip, S31600

130 Clamp, stainless steel (req'd w/nonconductive packing)

131 Bonding Strap Assembly (req'd w/nonconductive packing)

24

*Recommended spare parts

Page 25

Instruction Manual

D251400X012

8510B Valve (EMA)

November 2011

ENVIRO-SEAL PACKING

Key Description Part Number

100 Packing Stud (4 required)

101 Packing Nut (4 required)

102 Packing Flange (2 required)

103 Spring Pack Assembly

104 Spring Pack Outboard

105* Packing Set

Single PTFE Packing

NPS 2 12B7053X012

NPS 3 12B7402X012

NPS 4 12B7414X012

NPS 6 12B7438X012

NPS 8 12B7450X012

NPS 10 12B7450X012

NPS 12 12B7643X012

Graphite Packing

NPS 2 13B8816X012

NPS 3 13B8816X032

NPS 3 13B8816X052

Key 2*, Seal Retainer, ASME

VALVE SIZE, NPS

2

3

4

6

8

10

12

FOR COMPOSITION SEAL FOR ALL-METAL SEAL

SA-514-70

Steel

21B4666X012

21B6894X012

21B9458X012

22B1343X012

22B1988X012

28A1124X012

28A1134X012

S31603

(316L SST)

21B4666X062

21B6894X062

21B9458X062

22B1343X032

22B1988X032

28A1124X132

28A1134X172

Key Description Part Number

NPS 6 13B8816X092

NPS 8 13B8816X112

NPS 10 13B8816X112

106* Anti-extrusion Ring

107* Packing Box Ring

111 Tag

112 Cable Tie

NPS 12 13B8816X142

Single PTFE Packing

NPS 2 12B7054X012

NPS 3 12B7406X012

NPS 4 12B7418X012

NPS 6 12B7442X012

NPS 8 12B7454X012

NPS 10 12B7454X012

NPS 12 12B7646X012

NPS 2 16A6082X012

NPS 3 16A6083X012

NPS 4 16A6084X012

NPS 6 16A6085X012

NPS 8 16A6086X012

NPS 10 16A6086X012

NPS 12 16A6086X012

SA-515-70

Steel

21B4667X012

21B6895X012

21B9459X012

22B1344X012

22B1989X012

28A1125X012

28A1135X012

S31603

(316L SST)

21B4667X032

21B6895X032

21B9459X032

22B1344X032

22B1989X032

28A1125X132

28A1135X092

*Recommended spare parts

25

Page 26

8510B Valve (EMA)

November 2011

Key 2* Seal Retainer, DIN

VALVE

SIZE,

NPS

2

3

4

6

8

2

3

4

6

8

10

8

10

12

12

12

12

12

SEAL MATERIAL

PTFE Composition 21B4668X092 21B4668X152 21B4668X162 21B4668X142

All-Metal Seal 21B4669X062 21B4669X092 21B4669X102 21B4669X082

PTFE Composition 21B6896X092 21B6896X152 21B6896X162 21B6896X142

All-Metal Seal 21B6897X062 21B6897X092 21B6897X102 21B6897X082

PTFE Composition 21B9458X212 21B9458X272 21B9458X282 21B9458X262

All-Metal Seal 21B9459X112 21B9459X142 21B9459X152 21B9459X132

PTFE Composition 22B1345X092 22B1345X152 22B1345X162 22B1345X142

All-Metal Seal 22B1346X062 22B1346X092 22B1346X102 22B1346X082

PTFE Composition 22B1992X092 22B1992X152 22B1992X162 22B1992X142

All-Metal Seal 22B1993X062 22B1993X092 22B1993X102 22B1993X082

PTFE Composition 21B4668X012 21B4668X072 21B4668X082 21B4668X062

All-Metal Seal 21B4669X012 21B4669X042 21B4669X052 21B4669X032

PTFE Composition 21B6896X012 21B6896X072 21B6896X082 21B6896X062

All-Metal Seal 21B6897X012 21B6897X042 21B6897X052 21B6897X032

PTFE Composition 21B9458X012 21B9458X192 21B9458X202 21B9458X062

All-Metal Seal 21B9459X012 21B9459X092 21B9459X102 21B9459X032

PTFE Composition 22B1345X012 22B1345X072 22B1345X082 22B1345X062

All-Metal Seal 22B1346X012 22B1346X042 22B1346X052 22B1346X032

PTFE Composition 22B1990X012 22B1990X072 22B1990X082 22B1990X062

All-Metal Seal 22B1991X012 22B1991X042 22B1991X052 22B1991X032

PTFE Composition 22B2826X012 22B2826X072 22B2826X082 22B2826X062

All-Metal Seal 22B2827X012 22B2827X042 22B2827X052 22B2827X032

PTFE Composition 22B1992X012 22B1992X072 22B1992X082 22B1992X062

All-Metal Seal 22B1993X012 22B1993X042 22B1993X052 22B1993X032

PTFE Composition 22B2828X012 22B2828X072 22B2828X082 22B2828X062

All-Metal Seal 22B2829X012 22B2829X042 22B2829X052 22B2829X032

PTFE Composition 22B3889X012 22B3889X072 22B3889X082 22B3889X062

All-Metal Seal 22B3890X012 22B3890X042 22B3890X052 22B3890X032

PTFE Composition 22B3891X012 22B3891X072 22B3891X082 22B3891X062

All-Metal Seal 22B3892X012 22B3892X042 22B3892X052 22B3892X032

PTFE Composition 22B3893X012 22B3893X072 22B3893X082 22B3893X062

All-Metal Seal 22B3894X012 22B3894X042 22B3894X052 22B3894X032

PTFE Composition 22B3895X012 22B3895X072 22B3895X082 22B3895X062

All-Metal Seal 22B3896X012 22B3896X042 22B3896X052 22B3896X032

PTFE Composition 22B3895X092 22B3895X152 22B3895X162 22B3895X142

All-Metal Seal 22B3896X062 22B3896X092 22B3896X102 22B3896X082

SA-515-70

1.0481 Steel

DIN 17155

For PN 63-100

For PN 10-40

For PN 10-16

For PN 25-40

For PN 10

For PN 16

For PN 25

For PN 40

For PN 63

SEAL RETAINER MATERIAL

1.4571 Steel

DIN 17440

Instruction Manual

D251400X012

S31603

(316L SST)

26

*Recommended spare parts

Page 27

Instruction Manual

D251400X012

Key4*SealRingandKey5*SealSpringusedwithPTFECompositionSeals

VALVE

SIZE,

NPS

2

3

4

6

8

10

12

KEY

NUMBER

4

5

4

5

4

5

4

5

4

5

4

5

4

5

S31600

(316 SST)

22A9023X012

12A9022X012

22A8897X012

12A8902X012

22A8986X012

12A8991X012

22A8825X012

12A8818X012

22A8961X012

12A8974X012

22A8946X012

12A8948X012

22A8920X012

12A8922X012

SEAL RING MATERIAL IS PTFE (KEY 4)

Spring Material (Key 5)

N05500

22A9023X012

12A9022X022

22A8897X012

12A8902X022

22A8986X012

12A8991X022

22A8825X012

12A8818X022

22A8961X012

12A8974X022

22A8946X012

12A8948X022

22A8920X012

12A8922X022

N10276

(Alloy 276)

22A9023X012

12A9022X032

22A8897X012

12A8902X032

22A8986X012

12A8991X032

22A8825X012

12A8818X032

22A8961X012

12A8974X032

22A8946X012

12A8948X032

22A8920X012

12A8922X032

8510B Valve (EMA)

November 2011

N08020

(Alloy 20)

22A9023X012

12A9022X042

22A8897X012

12A8902X042

22A8986X012

12A8991X042

22A8825X012

12A8818X042

22A8961X012

12A8974X042

22A8946X012

12A8948X042

22A8920X012

12A8922X042

*Recommended spare parts

27

Page 28

8510B Valve (EMA)

November 2011

Instruction Manual

D251400X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and ENVIRO-SEAL are marks owned by one of the companies in the Emerson Process Management business division of Emerson Electric Co. Emerson

Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and whileevery effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

28

EFisher Controls International LLC 1990, 2011; All Rights Reserved

Loading...

Loading...