Page 1

Service Manual

Fuller Medium Heavy Transmissions

TRSM0201

October 2007

Page 2

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 3

Page 4

Model Designations...........................................................................................................................2

Description........................................................................................................................................3

Specifications....................................................................................................................................4

Lubrication.........................................................................................................................................5

Conversion to Overdrive.....................................................................................................................6

Clutch Shaft Replacement..................................................................................................................6

General Precautions for Disassembly.................................................................................................6

Detailed Disassembly Instructions......................................................................................................7

Exploded Views

Drive Gear............................................................................................................................................8

Countershafts.....................................................................................................................................11

Reverse Idler Shaft............................................................................................................................11

Reverse Idler Gear and Shaft.............................................................................................................14

Mainshaft...........................................................................................................................................14

Tailshaft.............................................................................................................................................14

Tailshaft and Rear Bearing Cover.......................................................................................................17

Shifting Bar Housing.........................................................................................................................17

Inspection..........................................................................................................................................17

Torque Ratings...................................................................................................................................21

Gasket Location.................................................................................................................................21

Preventative Maintenance Check Chart..............................................................................................25

General Precautions for Reassembly.................................................................................................25

Detailed Reassembly Instructions......................................................................................................25

Tool Reference...................................................................................................................................25

Gear Chart for Part Numbers.............................................................................................................26

Page 5

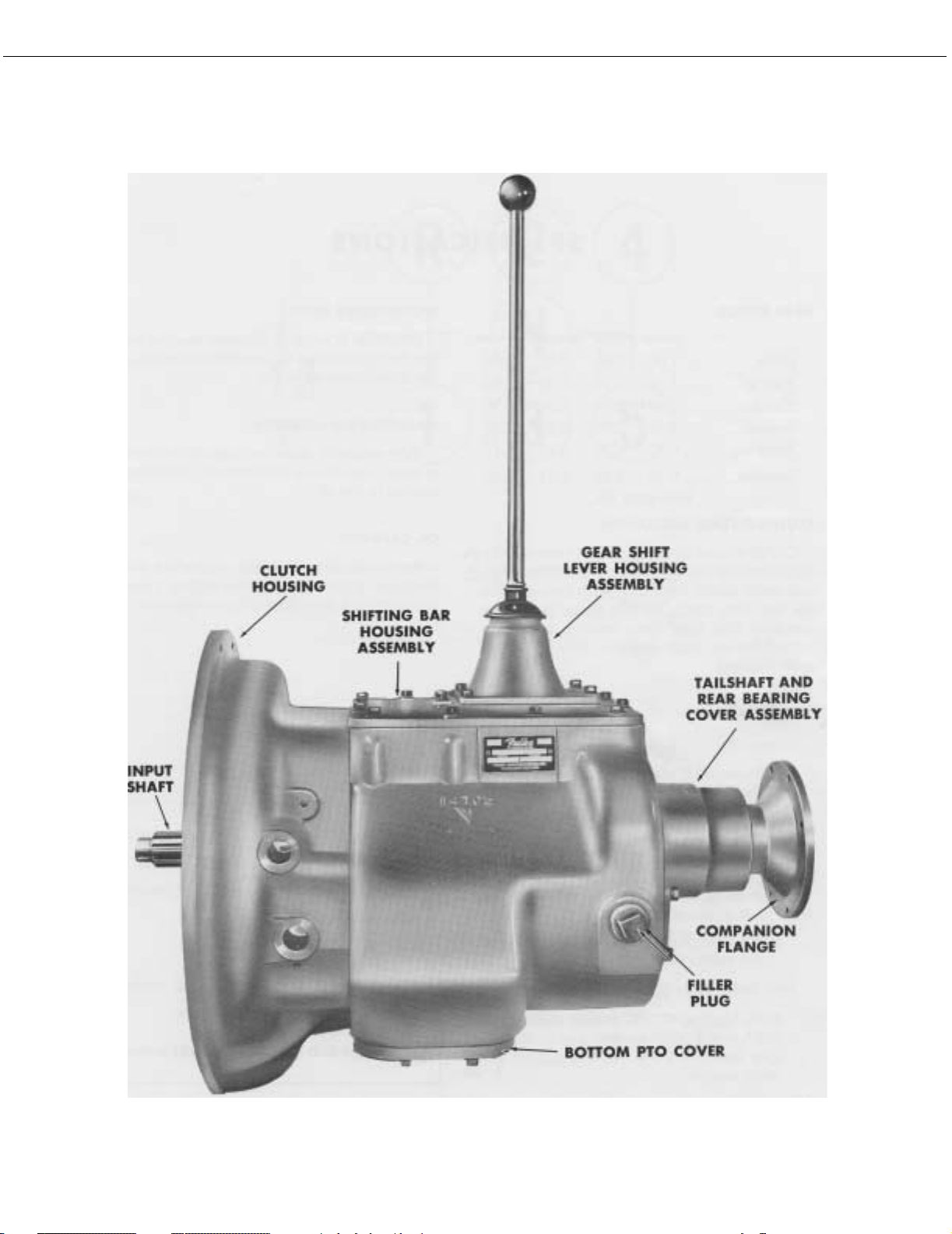

DESCRIPTION

CUTAWAY OF FIVE SPEED

TWIN-COUNTERSHAFT TRANSMISSION

2

Page 6

MODEL DESIGNATIONS

MODEL DESIGNATIONS

= Twin Countershaft Type

T

= Used as a letter, denotes overdrive model

O

= 900 lbs. ft. capacity rating

09

= Five speeds

05

“A”, “B”. etc.

= Following numbers indicates a specific set of ratios

Since the models in the T-905 series are identical in construction, references in this manual apply to all models unless

stated otherwise. This includes models not listed above which may have other ration combinations, designated by letters following the numerals.

PART NUMBERS SHOWN IN THIS MANUAL ARE SUBJECT TO CHANGE AND APPLY ONLY AT TIME OF PRINTING.

3

Page 7

DESCRIPTION

The T-905 model transmissions have five forward speeds and one reverse speed, and

are designed for heavy duty vehicles. These models are of twin countershaft design

which divides the torque equally between shafts and gears, providing a high capacity to

weight ratio.

The countershafts, identical except for the PTO gears, are short and bearings are of a

relative low capacity due to the split torque principle. All gears have spur type teeth.

The mainshaft floats free, receiving only minor radial loads. Mainshaft vertical displacement to conform to clutched gear position is allowed by rod-like springs which resist

float to right or left.

The mainshaft gears are not jounalled to the mainshaft, but are

located axially by washers and held in position by rotation of the

countershaft gears; this eliminates the need for bushings and

sleeves. Because of equal tooth loading on each side of gear,

pressure is reduced and gear face width can be narrowed. Gears

are clutched by internal splines in hubs of gears. The sliding

clutch gears with short, conical clutching teeth provide shorter

and easier shifts.

The input shaft and drive gear are not integral, thus they can be

changed individually.

4

Page 8

DESCRIPTION

5

Page 9

SPECIFICATIONS

SPECIFICATIONS

SPEEDOMETER DRIVE

GEAR RATIOS

T-905A T-905B TO-905A TO-905B

Fifth

Fourth

Third

Second

First

Reverse

1.00 1.00 0.65 0.86

1.54 1.16 1.00 1.00

2.38 2.04 1.54 1.76

3.75 3.75 2.44 3.23

6.35 6.35 4.12 5.47

6.48 6.48 4.21 5.58

SEE PAGE 68

Clutch Release Mechanism

Clutch release bearing carrier, release bearing, extended

front bearing cover, release yoke and pedal shafts furnished with transmission for use with single or two plate,

push type clutches. Flat type front bearing cover furnished for use with single or two plate, pull type clutches.

Power Take-Off

Openings

Bottom: SAE standard heavy-duty type, short length.

Right Side: SAE standard regular-duty type, short

length.

Provision is made in the rear bearing cover for the installation of speedometer gears and the attachment of cable.

MAGNETIC OIL CLEANERS

Two magnetic discs are installed in bottom of case to

catch and hold metallic particles deposited in the oil.

OIL CAPACITY

Approximately 22 pints, depending on inclination of

transmission and engine. Twenty-two pints is a zero

degree measurement.

Nominal torque rating

Clutch housing size

Weight, with grey iron case

Length

From face of clutch housing to rear shoulder

of mainshaft 27-19/32 inches

From face of clutch housing to front of

companion flange hub

900 foot-pounds

SAE No. 1 or 2

478 pounds

24-23/32 inches

PTO Drive Gear

Bottom: A 47-Tooth, 6/8 pitch gear on the left counterhshaft.

Right Side: A 45-Tooth, 6/8 pitch gear on the right

countershaft.

PTO Drive Gear Speeds

Both turning at .533 engine speed on T-905A and T905B models; and at .820 engine speed on TO-905A,

and .619 on TO-905B models.

6

Page 10

SPECIFICATIONS (SHIFTING DIAGRAMS)

Shifting Diagram for T-905 Model Transmissions

Shifting Diagram for TO-905 Model Transmissions

7

Page 11

LUBRICATION

Proper lubrication procedures are the key to a good allround maintenance program. If the oil is not doing its

job, or if the oil level is ignored, all the maintenance procedures in the world are not going to keep the transmission running or assure long transmission life.

Oil is important, because here are some of the things it

must do:

• Provide a protective film - to protect surface of

heavily loaded parts such as gear teeth and bearings,

thus preventing metal to metal contact which causes

scoring, scuffing and seizure.

• Act as a coolant - to dissipate heat.

LUBRICATION CHANGE AND INSPECTION

HIGHWAY USE

First 3,000-5,000 miles

(4827 - 8045 Km)

Every 5,000 miles

(8045 Km)

Every 50,000 miles

(80,450 Km)

First 30 hours Change transmission oil on new units.

First 40 hours Inspect oil level. Check for leaks.

Change transmission oil on new units.

Inspect oil level. Check for leaks.

Change transmission oil.

OFF-HIGHWAY

• Have sufficient fluidity - to follow, coat and cushion

all loaded surfaces.

• Be chemically stable - to withstand heat and agitation without separation, gumming-up, oxidizing or

corroding.

• Be non-foaming - to prevent excessive foam and

increased volume under severe conditions.

• Be free of sediment and water - to prevent sludge

and rust.

Fuller Transmissions are designed so that the internal

parts operate in a bath of oil circulated by the motion of

gears and shafts. Grey iron parts have built-in channels

where needed, to help lubricate bearings and shafts.

Thus, all parts will be amply lubricated if these procedures are closely followed:

1. Maintain oil level. Inspect regularly.

2. Change oil regularly.

3. Use the correct grade and type of oil.

Every 500 hours Change transmission oil where severe

Every 1,000 hours Change transmission oil (Normal off-

Change Oil Filter Element, If So Equipped, At Each Oil Change.

RECOMMENDED LUBRICANTS

TYPE GRADE TEMPERATURE

Heavy Duty Engine Oil MIL-L2104C, or MIL-L-46152, or

API-SE, or API-CC

Mineral Gear Oil SAE 90

Heavy Duty Engine Oil MIL-L2104C, or MIL-L-46152, or

API-SE, or API-CC

Special Recommendation - For extreme cold weather where

temperature is consistently below 0°F.

Heavy Duty Engine Oil MIL-L2104C, or MIL-L-46152, or

API-SE, or API-CC

dirt conditions exist.

highway use).

ON-HIGHWAY VEHICLES

SAE 50 or

SAE 40

SAE 30

SAE 80W

OFF-HIGHWAY

SAE 50 or

SAE 40

SAE 30

SAE 20W Below 0°F.

Above + 10°F.

(-12.5°C.)

Below + 10°F.

Above + 10°F.

Below + 10°F.

Above + 10°F.

Below + 10°F.

(-18°C.)

4. Buy from a reputable dealer.

Miscellaneous Lubricants

O-Rings and Surfaces - Dowing Corning #200 Silicone,

30,000 Centistokes. Union Carbide L-45 Silicone, 30,000

Centistokes.

8

Page 12

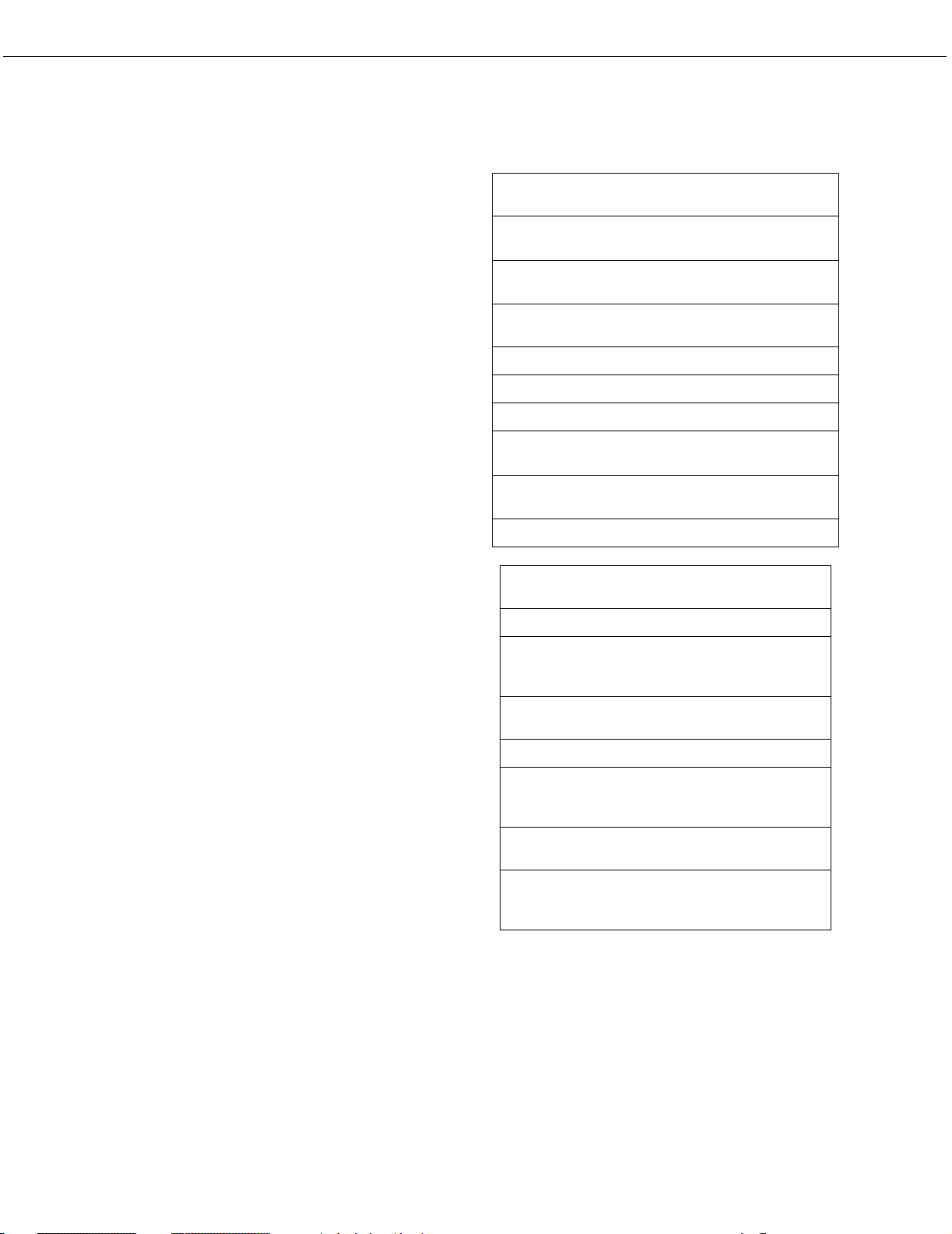

Lubrication

Proper Oil Level

Make sure oil is level with filler opening. Because you can

reach oil with your finger does not mean oil is at proper

level.

Draining Oil

Drain transmission while oil is warm. To drain oil, remove

the drain plug at bottom of case. Clean the drain plug

before re-installing.

Refilling

Clean area around filler plug and remove plug from side

of case. Fill transmission to the level of the filler opening.

If transmission has two filler openings, fill to level of rear

opening on single countershaft models; fell to level of

both openings on twin countershaft models.

The exact amount of oil will depend on the transmission

inclination and model. In every instance, fill to the level of

the filler opening.

Do not over fill. This will cause oil to be forced out of the

case through mainshaft openings.

External cooler kits are available to keep the transmission

operating temperature under 250°F. when the conditions

described above are encountered.

If the transmission operating angle is more than 12

degrees, improper lubrication can occur. The operating

angle is the transmission mounting angle in the chassis

plus the percent of upgrade (expressed in degrees).

Adding Oil

It is recommended that types and brands of oil should

not be intermixed because of possible incompatibility.

Operating Temperature

It is important that the transmission operating temperature does not exceed 250°F. (120°C.) for an extended

period of time. Operating temperatures above 250°F. will

cause breakdown of the oil and shorten transmission life.

The following conditions in any combination can cause

operating temperatures of over 250°F: (1) Operating consistently at roadspeeds under 20 MPH, (2) High engine

RPM, (3) High ambient temperature, (4) Restricted air

flow around transmission, (5) Exhaust system too close

to transmission, (6) high horsepower, over-drive operation. High operating temperatures may require more frequent oil changes.

The above chart illustrates the safe percent of upgrade on

which the transmission can be used with various chassis

mounting angles. For example: If you have a 4 degree

transmission mounting angel, then 8 degrees (or 14 percent of grade) is equal to the limit of 12 degrees. If you

have a 0 degree mounting angle, the transmission can be

operated on a 12 degree (21 percent) grade.

Anytime the transmission operating angle of 12 degrees

is exceeded for an extended period of time the transmission should be equipped with an oil pump or cooler kit to

insure proper lubrication.

Note on the chart the effect low oil levels can have on

safe operating angles. Allowing the oil level to fall ½”

below the filler plug hole reduces the degree of grade by

approximately 3 degrees (5.5)

PROPER LUBRICATION LEVELS ARE IMPORTANT!

9

Page 13

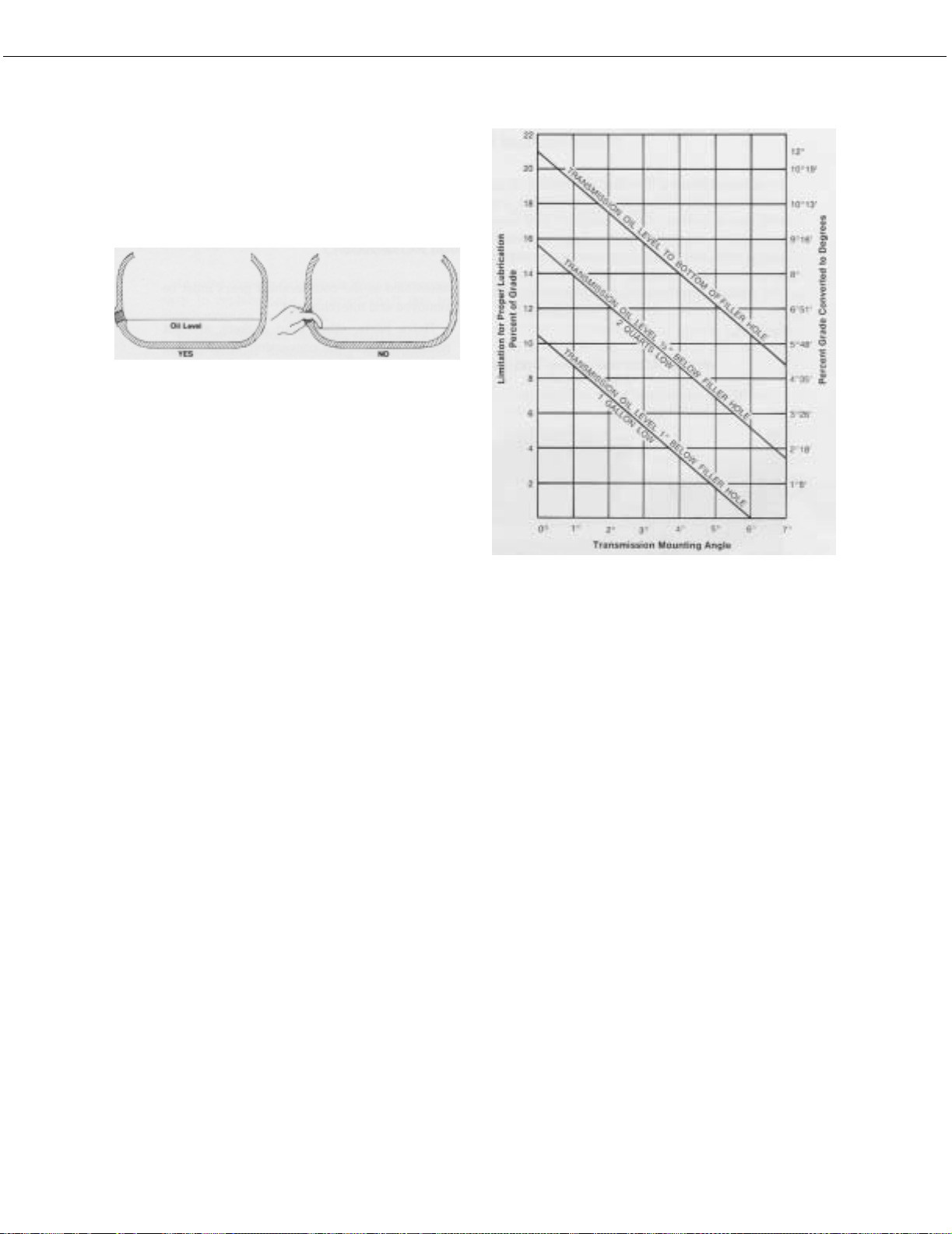

CONVERSION TO OVERDRIVE

TO CONVERT FROM T-905A To

TO-905A, or T-905B to TO-905B

To convert from a T-905A or T-905B to an overdrive

model TO-905A or TO-905B the 4th speed gear on the

mainshaft and mating gears, one on each countershaft,

are interchanged with the main drive gear and mating

countershaft drive gears.

The transmission must be completely disassembled as

the countershaft gears must be removed and interchanged.

Extra parts, other than gaskets are not needed to make

the conversion. A new drive gear bearing nut may be

needed as this part may be damaged during removal.

10

Page 14

SPECIAL PROCEDURE FOR CHANGING THE CLUTCH (INPUT) SHAFT

In some case it may be necessary to remove only the

input shaft due to clutch wear on the splines. In these

cases, the input shaft can be removed without disassembling the transmission other than removing the shift bar

housing. Removal of the clutch housing is optional. The

following is the detailed procedure:

Disassembly

1. Remove the gear shift lever housing and shift bar

housing from transmission.

2. Remove the front bearing cover.

3. Remove the drive gear bearing nut.

4. Move the drive gear assembly as far forward as possible and remove the drive gear bearing.

5. Remove the spacer from input shaft.

6. From the front, remove the snap ring from ID of

drive gear.

7. Peen nut into milled slot in shaft.

8. Re-install front bearing cover, shifting bar housing

and gear shift lever housing.

NOTE: The above instructions are for changing the

input shaft only. To change the drive gear,

removal of the mainshaft and countershaft

bearings is necessary.

7. Pull the input shaft forward and from splines of drive

gear.

Reassembly

1. Install new input shaft into splines of drive gear just

far enough to expose snap ring groove in ID of drive

gear.

2. Install snap ring in ID of drive gear.

3. Install spacer on shaft.

4. IMPORTANT - To prevent damaging the front quill

when installing bearing, move the 4th & 5th speed

sliding clutch gear forward to contact end of input

shaft in hub of drive gear. Block between rear of sliding clutch and front of the 4th speed gear. When

installing bearing this will hold input shaft away from

quill.

5. Install drive gear bearing on shaft and into case bore,

making sure blocking remains in place.

6. Remove blocking from mainshaft and install the

drive gear bearing nut, left-hand thread. Use Loctite

sealant on threads of nut and shaft.

11

Page 15

DISASSEMBLY PRECAUTIONS

GENERAL PRECAUTIONS FOR DISASSEMBLY

Important: Read this section before starting the detailed disassembly procedures.

It is assumed in the detailed disassembly instructions

that the transmission lubricant has been drained and the

transmission has been removed from the chassis.

Removal of the gear shift lever housing assembly is

included in the detailed instructions; however, this

assembly must also be removed from transmission

before removing unit from vehicle.

Follow each procedure closely in each section, making

use of both the text and pictures.

1. BEARINGS - Carefully wash and relubricate all bearings as removed and protectively wrap until ready

for use. Remove bearings with pullers designed for

this purpose.

2. SNAP RINGS - Remove snap rings with pliers

designed for this purpose. Rings removed in this

manner can be reused.

3. INPUT SHAFT - The clutch or input shaft can be

removed without removing the countershafts or

mainshaft (Refer to Page 11).

4. CLEANLINESS - Provide a clean place to work. It is

important that no dirt or foreign material enters the

unit during repairs. The outside of the unit should be

carefully cleaned before starting the disassembly.

Dirt is abrasive and can damage bearings.

5. WHEN DRIVING - Apply force to shafts, housings,

etc., with restraint. Movement of some parts is

restricted. Do not apply force after the part being

driven stops solidly. Use soft hammers and bars for

all disassembly work.

12

Page 16

DETAILED DISASSEMBLY INSTRUCTIONS

DETAILED DISASSEMBLY INSTRUCTIONS

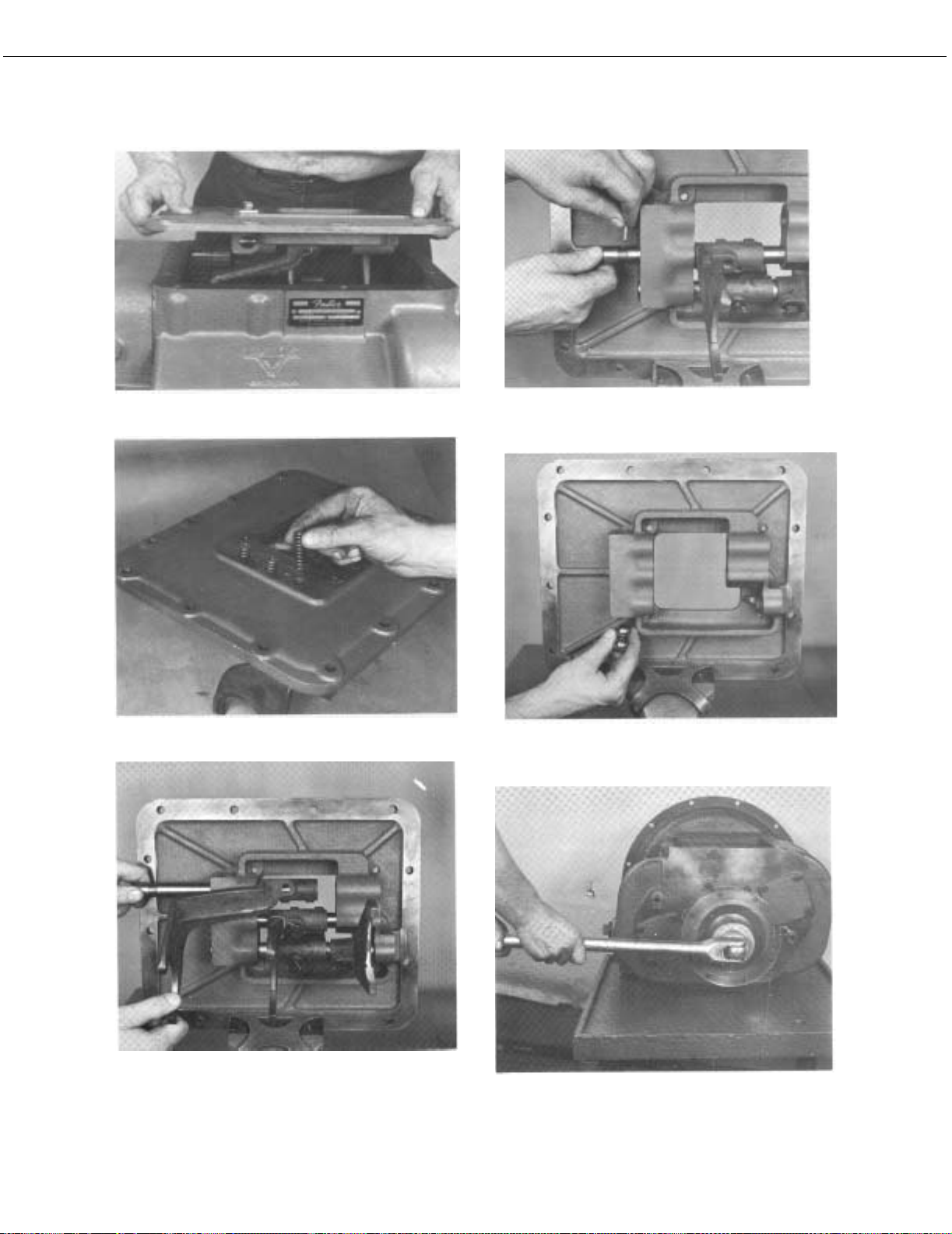

A. To Remove and Disassemble the Gear Shift Lever

Housing Assembly

1. Turn out the four capscrews and lift the gear

shift lever housing, or remote control housing,

from the shifting bar housing (See Illustration

1).

2. Remove the ball grip and rubber dust cover

from the gear shift lever.’

3. Mount the assembly in a vise with the large bottom opening upwards.

4. Free the tension spring by twisting a heavy

screwdriver between spring and housing, forcing spring from its seat in housing (See Illustration 2).

#1 - Lifting gear shift lever housing from shifting bar

housing.

5. Remove the tension spring from housing.

6. Withdraw the tension spring washer and gear

shift lever out through bottom housing (See

Illustration 3).

7. Remove nut and lockwasher from pivot pin.

8. Remove pivot pin by forcing it inward and

through wall of housing.

#2 - Removing the gear shift lever tension spring from

under lugs cast in housing.

#3 - Removing washer and gear shift lever from housing.

13

Page 17

DISASSEMBLY

#4 - Lifting the shifting bar housing from transmission.

#5 - Removing shifting bar tension springs.

#7 - Removing interlock pin from neutral notch in the 2nd

& 3rd speed shifting bar.

#8 - Two interlock balls are located in front boss, one

between each bar.

I#6 - Pulling the 4th-5th speed shifting bar from housing.

#9 - Turning companion flange nut from output shaft.

14

Page 18

DISASSEMBLY

B. To Remove the Shifting Bar Housing Assembly

1. Turn out the attaching capscrews.

2. Jar to break the gasket seal and lift the shifting

bar housing from transmission (See Illustration

#4).

C. To Disassemble the Shifting Bar Housing Assembly

NOTE: Lay all parts on a clean bench in the order in

which they are removed to facilitate reassembly. Keep bars not being removed in the neutral position or interlock parts will lock bars.

1. Turn out the two capscrews and remove the tension spring cover from top of housing.

2. Remove the three tension springs from bores in

housing (See Illustration #5).

3. Tilt housing and remove the tension balls

installed under the springs.

4. Place the housing in a vise with the left side up;

the long bar will be at the bottom.

D. To Remove the Companion Flange or Yoke

1. Lock the mainshaft by engaging two speeds

with the mainshaft sliding clutch gears.

2. Turn the elastic stop nut from the output shaft

(See Illustration #9).

3. Pull the flange or yoke from splines of the

tailshaft.

E. To Remove and Disassemble the Rear Bearing

Cover Assembly

1. Turn out the attaching capscrews from the rear

bearing cover.

2. Pry the bearing cover evenly to the rear to

unseat from tailshaft bearing (See Illustration

#10).

5. Cut lockwire and remove lockscrews from each

bar just prior to its removal.

6. Move the top, 4th-5th speed shifting bar to the

front and out of housing, removing shifting yoke

from bar (See Illustration #6).

7. Move the center, 2nd-3rd speed shifting bar to

the front and out of housing, removing the shifting yoke from bar. As the neutral notch in bar

clears housing boss, remove the small interlock

pin from bore in neutral notch (See Illustration

#7).

8. Move the bottom, 1st-Reverse speed shifting

bar to the front and out of housing, removing

the shifting yoke and block from bar.

9. Two interlock balls will fall from interlock ball

opening in front boss as the last bar is removed

(See Illustration #8).

#10 - Prying rear bearing cover evenly to rear.

3. Remove the bearing cover from tailshaft (See

Illustration #11).

4. Remove the speedometer gear, or replacement

spacer, and the bearing washer from tailshaft or

from cover.

5. Pull the outer bearing from tailshaft. (This bearing may remain in cover; in this case, move the

bearing evenly forward and from cover) See

Illustration #12.

6. Remove the oil seal from cover if necessary.

15

Page 19

DISASSEMBLY

#11 - Removing rear bearing cover from tailshaft.

#12 - Pulling the tailshaft outer bearing.

#15 - Removing tailshaft from case bore. Start assembly

to the rear by prying evenly against bearing snap ring.

#13 - Removing capscrews from flat keys.

#14 - Removing flat keys from tailshaft. These keys maintain relative position of mainshaft to tailshaft.

#16 - Removing key spacer ring from tailshaft.

#17 - Turning bearing nut from tailshaft, left-hand thread.

16

Page 20

DISASSEMBLY

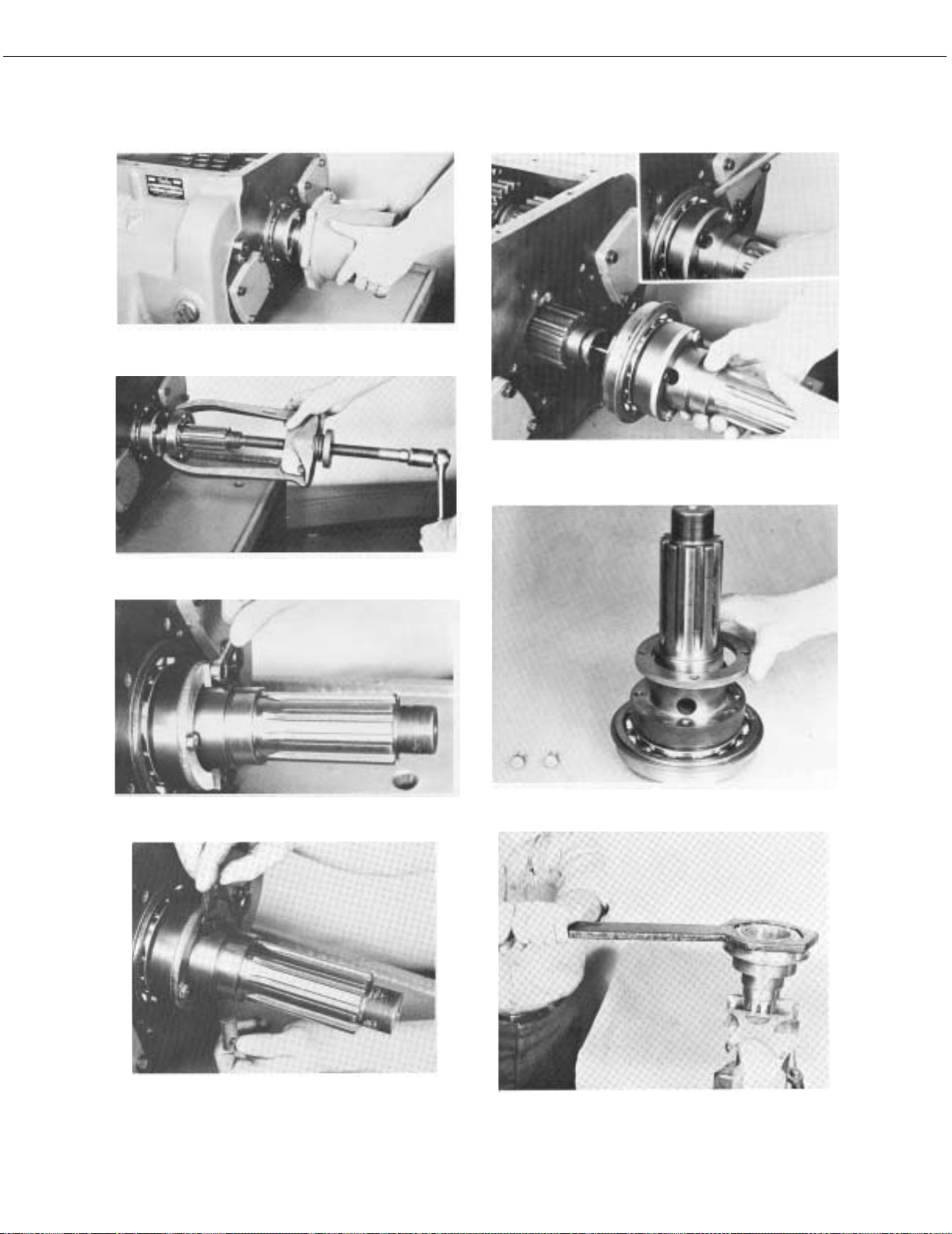

F. To Remove and Disassemble the Tailshaft Assem-

bly

1. Cut lockwire and turn out the two 5/16” capscrews from the two flat keys (See Illustration

#13).

2. Remove the two flat keys from bores in tailshaft.

These keys maintain the position of the mainshaft in relation to tailshaft (See Illustration

#14).

3. Move the tailshaft evenly to the rear and from

case bore. Moving the mainshaft assembly to

the rear will start moving tailshaft from bore

(See Illustration #15).

4. Remove the splined coupling gear from mainshaft, or from pocket in tailshaft.

5. Turn out the 5/16” capscrews and remove the

key spacer ring from tailshaft (See Illustration

#16).

6. Remove the bearing nut from tailshaft, left-hand

thread (Illustration #17).

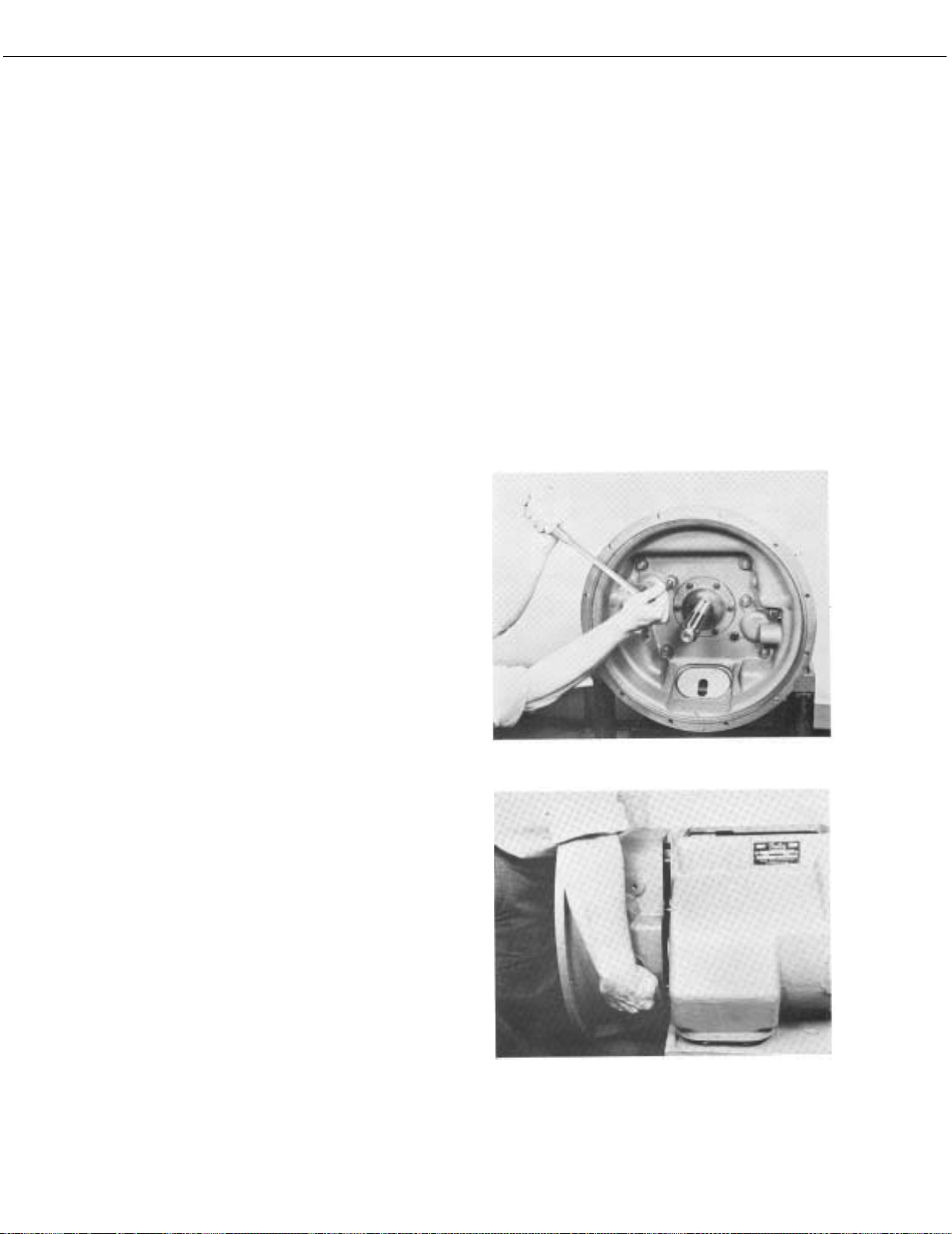

G. To Remove the Clutch Housing

NOTE: The clutch housing can be removed at any

time during transmission disassembly. However, it must be removed BEFORE the two

countershafts can be removed.

1. Remove the clutch release mechanism if the

transmission is so equipped.

2. Turn out the four bolts and remove the six nuts

and lockwashers from studs at front of case

(See Illustration #18).

3. Break gasket seal and pull clutch housing from

case (See Illustration #19).

7. Press the front bearing from tailshaft.

#18 - Turning attaching bolts from clutch housing.

#19 - Removing clutch housing from case.

17

Page 21

DISASSEMBLY

#20 - Removing snap ring from ID of the mainshaft

reverse gear.

#21 - Removing lockplate from left reverse idler shaft.

#23 - Removing left reverse idler gear and the two thrust

washers from case.

#24 - Removing rear bearing cover from right countershaft.

#22 - Removing left reverse idler shaft with impact puller.

#25 - Removing bearing retainer plat from front of right

countershaft.

18

Page 22

DISASSEMBLY

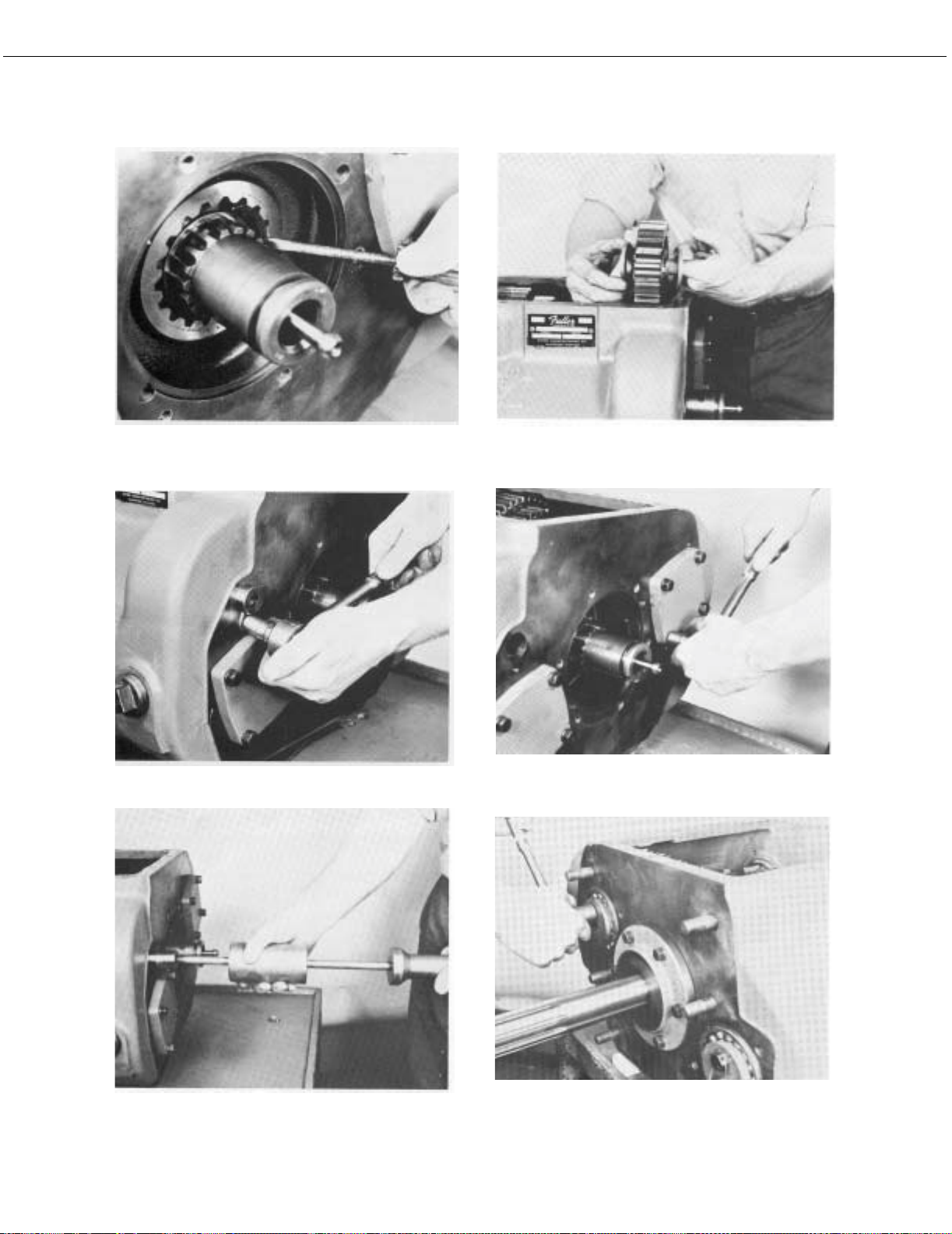

H. To Remove the Left Reverse Idler Gear

NOTE: The left reverse idler gear must be removed in

order to remove the mainshaft assembly.

1. Move the mainshaft assembly forward as far as

possible and the mainshaft reverse gear to the

rear against case.

2. Remove the snap ring from ID of the mainshaft

reverse gear (See Illustration #20).

3. Move the 1st-Reverse sliding clutch gear and

the reverse gear as far forward as possible on

the mainshaft.

4. Turn out capscrew at rear of transmission and

remove the lock plate from slot in the idler shaft

(See Illustration #21).

5. Use impact puller to withdraw the idler shaft

from case (See Illustration #22).

6. Remove the reverse idler gear and the two

thrust washers from case (See Illustration #23).

7. Remove inner race of bearing from gear bore.

8. Press needle bearing from gear bore.

4. Use puller to remove rear bearing from shaft. A

snap ring can be installed in rear bearing groove

to facilitate pulling if groove type puller is not

available (See Illustration #27).

5. Use soft bar and mall to move right countershaft

forward to partially unseat front bearing (See

Illustration #28).

6. Remove front bearing from countershaft (See

Illustration #29).

9. Remove plug from idler shaft if necessary.

I. To Remove Bearings from Right Countershaft

NOTE: In order to remove the mainshaft assembly it

will be necessary to move the right countershaft by removing bearings.

1. Turn out capscrews and remove rear bearing

cover from right countershaft (See Illustration

#24).

2. Cut lockwire, turn out the two capscrews and

remove bearing retainer plate from front of right

countershaft (See Illustration #25).

3. Use soft bar and mall to move the right countershaft to the rear until snap ring groove in rear

bearing is exposed. Do not unseat shaft from

front bearing (See Illustration #26).

#26 - Moving right countershaft to the rear to expose rear

bearing. DO NOT UNSEAT FRONT BEARING FROM

SHAFT.

#27 - Pulling rear bearing from right countershaft.

19

Page 23

DISASSEMBLY

#28 - Moving right countershaft forward to expose front

bearing.

#31 - Removing short key from keyway in mainshaft.

#29 - Pulling from bearing from right countershaft.

#30 - Removing mainshaft assembly from case.

#32 - Turning the 4th-speed gear washer to align with

mainshaft splines.

#33 - Removing 4th-speed gear, spacer and washer from

shaft.

20

Page 24

DISASSEMBLY

J. To Remove the Mainshaft Assembly

11. Remove the 1st and 2nd speed gears wi

w

ashers and spacers from mainshaft (See Illus-

tration #37).

th

1. With right countershaft moved toward wall of

case, pull the mainshaft to the rear, life fron

sh

aft and remove assembly from

llustration #30).

I

K. To Disassemble the Mainshaft Assembly

NOTE: When removing washers, spacers and gears,

note their location to facilitate reassembly.

Keep washers and spacers with the gear from

which they were removed; there is one spacer

and one washer for each gear. The spacers

have external splines to engage gear splines;

the washers have internal splines to engage

mainshaft splines.

1. Remove the Reverse gear from mainshaft.

2. Remove the 4th-5th speed sliding clutch from

front of shaft.

3. Remove the short key from keyway near front

sh

aft. This key locks the 4th speed gear w

n position (See Illustration #31).

i

case (See

t of

asher

12. Remove the quill bearing snap ring.

13. Pull the quill bearing from quill. Do not move

quill as relative position of quill and mainshaft

must be retained (See Illustration #38).

#34 - Removing key-retaining snap ring from mainshaft.

of

4. Turn the 4th speed gear washer, located in hub

of 4th speed gear, to align with splines in mainshaft (See Illustration #32).

5. Pull gear forward to remove the washer, spacer

and gear from shaft (See Illustration #33).

6. Remove the 3rd speed gear, washer and spacer

from shaft.

7. Remove the 2nd-3rd speed sliding clutch gear

from shaft.

8. Remove the key retaining snap ring from sl

n

ear rear of mainshaft (See Illustration #34).

9. Pull the long key from mainshaft (See Illustration #35).

10. Remove the Reverse gear spacer, washer an

the 1st-Rever

(See Il

se sliding clutch gear from sh

lustration #36).

ot

d

aft

#35 - Pulling the long key from mainshaft.

21

Page 25

DISASSEMBLY

#36 - Removing spacer, washer and sliding clutch from

mainshaft.

#39 - Lifting the right countershaft from case.

#37 - Removing remaining gears, spacers, and washers

from mainshaft.

#38 - Pulling the quill bearing.

#40 - Removing the right reverse idler shaft with impact

puller.

#41 - Removing the right reverse idler gear and two

thrust washers from case.

22

Page 26

DISASSEMBLY

L. To Remove the Right Countershaft Assembly

1. Move the countershaft to the rear, move front

sh

aft toward center of case and lift the assembl

fro

m case (See Illustration #39)

M. To Remove the Right Reverse Idler Gear

1. Turn out capscrews at rear of transmission

ove the lock plate from slot in the idler shaft.

rem

2. Use impact puller to withdraw the idler

fro

m case (See Illustration #40).

3. Remove the reverse idler gear and the tw

ust washers from case (See Illustration #41).

thr

4. Remove inner race of bearing from gear bore.

5. Press the needle bearing from gear bore.

N. To Remove the Left Countershaft Assembly

1. Turn out capscrews and remove the rear bearing

cover from left countershaft (See Illustration

#42).

of

y

and

shaft

o

#42 - Removing rear bearing cover from left countershaft.

2. Cut lockwire, turn out the two capscrews and

remove the bearing retaining plate from fron

countershaft (See Illustration #43).

left

3. Use soft bar and mall to move the counters

far

enough to the rear to expose the snap ring

groove in rear bearing.

4. Use puller to remove rear bearing from

ap ring can be installed in rear bearing groo

sn

facilitate pulling if groove type puller is no

to

lable (See Illustration #44).

avai

5. Use soft bar and mall to move countershaft forward to partially unseat front bearing. Keep r

o

f shaft centered in bore with block (See Illus-

tration #45).

6. Remove front bearing from countershaft and

case bore.

7. Move the countershaft to the rear, lift front of

shaft to the center and up to remove from

lustration #46).

(See Il

t of

haft

shaft. A

ve

t

ear

case

#43 - Removing bearing retainer plate from front of left

countershaft.

23

Page 27

DISASSEMBLY

#44 - Pulling rear bearing from left countershaft.

#45 - Moving left countershaft forward to unseat from

bearing.

#47 - Pressing drive gear, PTO gear, 4th speed gear and

3rd speed gear from countershaft.

#48 - Pressing 2nd speed gear from countershaft.

#46 - Removing left countershaft from case.

#49 - Turning capscrews from front bearing cover.

24

Page 28

DISASSEMBLY

O. To Disassemble the Countershaft Assemblies

NOTE: Both countershafts are disassembled in the

same manner.

1. Press the drive gear, PTO gear, 4th speed gear

and 3rd speed gear from countershaft. Use caution when pressing gears as it is necessary to

press these gears off in a cluster of four (See

Illustration #47).

2. Press the 2nd speed gear from countershaft

(See Illustration #48).

3. Remove the two keys from countershaft if necessary.

4. Remove the roll pin from countershaft if necessary.

P. To Remove the Drive Gear Assembly

#50 - Removing snap ring from drive gear bearing.

1. Turn out capscrews from the front bearing cover

(See Illustration #49).

2. Use soft bar and mall from inside case to move

the drive gear assembly forward as far as possible and remove the bearing cover.

3. Remove the snap ring from bearing (See Illustration #50).

4. Move the assembly to the inside of case and lift

through top of case (See Illustration #51).

#51 - Lifting gear assembly out through top of case.

25

Page 29

DISASSEMBLY

Q. To Disassemble the Drive Gear Assembly

1. Place the assembly in a vise, pilot end up.

#52 - Relieving bearing nut where peened into shaft.

2. Relieve the bearing nut where peened in

(See Il

lustration #52).

3. Turn the bearing nut from shaft, left-hand thr

(See Il

lustration #53).

4. Using the rear face of the drive gear as a b

unt the assembly in a press, and pr

mo

aft through the gear to unseat bearing from

sh

shaft. This will free the bearing, spacer and g

rm shaft (See Illustration #54).

fo

5. Remove snap ring from ID of drive gear if necessary.

to shaft

ead

ase,

ess the

ear

#53 - Turning drive gear bearing nut from shaft, left-hand

thread.

#54 - Pressing shaft through drive gear and bearing.

26

Page 30

DRIVE GEAR ASSEMBLY

27

Page 31

COUNTERSHAFT ASSEMBLY

28

Page 32

REVERSE IDLER SHAFT AND GEAR ASSEMBLY GRAPH-

ICS

29

Page 33

REVERSE IDLER GEAR AS ASSEMBLED IN CASE

30

Page 34

MAINSHAFT ASSEMBLY

31

Page 35

TAILSHAFT ASSEMBLY

32

Page 36

TAILSHAFT AND REAR BEARING COVER ASSEMBLY

33

Page 37

SHIFTING BAR HOUSING ASSEMBLY 35Inspection

34

Page 38

Before reassembling the transmission, the individual

parts should be carefully checked to eliminate those

damaged from previous service. This inspection procedure should be carefully followed to insure the maximum

of wear life from the rebuilt unit.

The cost of a new part is generally a small fraction of the

total cost of downtime and labor, should the use of a

questionable part make additional repairs necessary

before the next regularly scheduled overhaul.

Recommended inspection procedures are set forth in the

following checklist:

A. Bearings

1. Wash all bearings in clean solvent. Check balls,

rollers and races for pits and spalled areas.

Replace bearings which are pitted or spalled.

2. Lubricate bearings

which are not spalled

or pitted and check

for axial and radial

clearances. Replace

bearings with excessive clearances.

3. Check fits of bear-

ings in case bores. If

outer races turn

freely in the bores,

the case should be

replaced.

B. Gears

1. Check operating gear teeth for pitting on the

tooth faces. Gears with pitted teeth should be

replaced.

2. Check all engaging gear teeth. Gears with teeth

worn, tapered or reduced in length from clashing in shifting should be replaced.

3. Check axial clearances of gears. Where excessive clearance is found, check gear snap ring,

washer, spacer and gear hub for excessive wear.

Maintain .005 - .012 axial clearance of mainshaft forward speed gears, .005 minimum on

reverse gear.

C. Splines

1. Check splines on all shafts for wear. If sliding

clutch gears, companion flange or clutch hubs

have worn into the sides of the splines, the

shafts in this condition should be replaced.

D. Thrust Washers

1. Check surfaces of all

thrust washers. Washers

scored or reduced in

thickness should be

replaced.

E. Reverse Gear and Shaft

1. Check bearing sleeve for wear from action of

roller bearings.

F. G ray I ron P a rt s

1. Check all gray iron parts for cracks and breaks.

Replace or repair

parts found to be

damaged. Heavy

casting may be

welded or brazed

providing the cracks

do not extend into

bearing bores or

bolting surfaces.

G. Clutch Release Parts

1. Check clutch release parts. Replace yokes worn

at cam surfaces

and bearing carrier worn at contact pads.

2. Check pedal

shafts. Replace

those worn at

bearing surfaces.

H. Shifting Bar Housing Assembly

1. Check yokes and blocks for wear at pads and

lever slot. Replace worn parts.

2. Check yokes for alignment.

3. Check yokes for

excessive wear;

replace worn

yokes.

4. Check lockscrews in yokes

and blocks.

Tighten and

rewire those

found loose

Page 39

TORQUE RATINGS

Recommended torque ratings, location and thread sizes

of capscrews and nuts are listed below. Capscrew length

are given for reference purposes as a guide to installation

at proper locations.

CAPSCREWS

Correct torque application is extremely important to

assure long transmission life and dependable performance. Over-tightening or under-tightening can result in

a loose installation and, in many instances, eventually

causing damage to transmission gear, shafts or bearings.

Do not torque capscrews dry.

Location

P.T.O. Cover, Small

Tailshaft Key Spacer Ring

Tailshaft Key

Reverse Idler Shaft Lock

Poppet Spring Cover

Front Bearing Cover

Shifting Bar Housing

Gear Shift Lever Housing

Mainshaft Rear Bearing Cover

Countershaft Rear Bearing Cover

P.T.O. Cover, Large

Clutch Housing to Case

Countershaft Front Bearing Retainer

Clutch Housing to Case

Drive Gear

Tailshaft Front Bearing

Companion Flange or Yoke

NUTS

Thread Size

and Length

3/8-16 x ¾

5/16-24 x 5/8

5/16-24 x 1

3/8 -16 x 1

3/8-16 x1-¼

3/8-16 x1-¼

3/8-16 x1-¼

3/8-16 x1-¼

3/8-16 x1-¼

½-13 x 1-¼

½-13 x 3-¼

5/8-18

2-1/8-16

3-17/32-16

1-½-18

Qty.

6

2

2

2 5/16-18 x ¾ 25-35

2

6

13

4

6

8

8 7/16-14 x 1-¼ 50-65

2

2

4 ½-20 x1 100-115

6

1

1

1

Torque Rating

Foot-Pound

20-25

35-45

90-100

(70-75)*

180-190 (170-175)*

250-300

250-300

400-450

LOCATION OF GASKETS

Seat gaskets with shellac on part to be installed. Use new

gaskets throughout when reassembling transmission.

Gaskets are located on the following parts:

• P.T.O. Cover, Small

• P.T.O. Cover, Large

• Gear Shift Lever Housing

•Clutch Housing

• Front Bearing Cover

• Countershaft Rear Bearing Covers

• Shifting Bar Housing

• Mainshaft Rear Bearing Cover

37

Page 40

PREVENTATIVE MAINTENANCE CHECK CHART

38

Page 41

PREVENTATIVE MAINTENANCE CHECK CHART

CHECKS WITHOUT PARTIAL

DISASSEMBLY OF CHASSIS OR CAB

1. Clutch Housing Mounting

a. Check all capscrews in bolt circle of clutch hous-

ing for looseness.

2. Clutch Pedal Shaft and Bores

a. Pry upward on shaft to check wear.

b. If excessive movement is found, remove clutch

release mechanism and check bushings in bores

and wear on shafts.

3. Clutch Release Bearing

a. Remove hand hole cover and check radial and

axial clearance in release bearing.

b. Check relative position of thrust surface of

release bearing with thrust sleeve on push type

clutches.

4. Capscrews and Gaskets

a. Check all capscrews, especially those on PTO

covers and rear bearing covers for looseness

which would cause oil leakage.

b. Check PTO opening and rear bearing covers for

oil leakage due to faulty gasket.

5. Gear Lubricant

a. Change at specified service intervals.

b. Use only gear oils as recommended (See Lubrica-

tion Section).

6. Filler and Drain Plugs

8. Gear Shift Lever Housing Assembly

a. Remove the gear shift lever housing assembly

from transmission.

b. Check tension spring and washer for set and

wear.

c. Check the gear shift lever pivot pin and pivot pin

slot for wear.

d. Check bottom end of gear shift lever for wear and

check slot of yokes and blocks in shift bar housing for wear at contact points with shift lever.

CHECKS WITH DRIVE LINE DROPPED

9. Universal Joint Companion Flange Nut

a. Check for tightness. Tighten to recommended

torque.

CHECKS WITH UNIVERSAL JOINT COMPANION FLANGE

REMOVED

10. Splines on Output Shaft

a. Check for wear from movement and chucking

action of the universal join companion flange.

11. Mainshaft Rear Bearing Cover

a. Check oil seal for wear.

12. Output Shaft

a. Pry upward against output shaft to check radial

clearance in mainshaft rear bearing.

a. Remove filler plug and check level of lubricant at

specified intervals. Tighten filler and drain plugs

securely.

7. Gear Shift Lever

a. Check for looseness and free play in housing. If

lever is loose in housing, proceed with Check #8.

39

Page 42

GENERAL PRECAUTIONS FOR REASSEMBLY

IMPORTANT: Read this section before starting the

detailed reassembly procedures.

Make sure that interiors of case and housings are clean.

It is important that dirt be kept out of transmission during

reassembly. Dirt is abrasive and can damage polished

surfaces of bearings and washers. Use certain precautions, as listed below, during reassembly.

1.GASKETS - Use new gaskets

throughout the transmission as it

is being rebuilt. Make sure all gaskets are installed, as omission of

gasket can result in oil leakage or

misalignment of bearing covers

(See “Location of Gaskets” heading).

2. CAPSCREWS - To prevent oil leakage, use shellac on

all capscrews. See torque rating chart for recommended torque.

3. ASSEMBLY - Refer to the assembly illustration,

pages 27-34, as a guide to reassembly.

4. INITIAL LUBRICATION - Coat all thrust washers and

splines of shafts with Lubriplate during installation

to provide initial lubrication, preventing scoring and

galling.

5. AXIAL CLEARANCES - Maintain the following axial

clearances:

6.BEARINGS - Use of flangedend bearing drivers is recommended for the installation of

bearings. These drivers apply

equal force to both races of

bearing, preventing damage to

balls and races and maintaining

correct bearing alignment with shaft and bore. If

tubular or sleeve type driver is used, apply force only

to inner race.

7. UNIVERSAL JOINT COMPANION FLANGE - Pull the

companion flange tightly into place with the mainshaft nut, using 450-500 ft. lbs. of torque. Make sure

the speedometer gear is not used, a replacement

spacer of the same width must be used. Failure to

pull the yoke or flange tightly into place will permit

the shaft to move axially with resultant damage to

rear bearing.

Mainshaft Forward Speed Gears ...............................005”-.011

Mainshaft Reverse Speed Gear ..................................005-.023

Reverse Idler Gear ..................................................... .011-.032

Mainshaft................................................................... .002-.008

40

Page 43

DETAILED REASSEMBLY INSTRUCTIONS

A. To Reassemble the Drive Gear Assembly

1. Install snap ring in ID of drive gear (See Illustration #55).

2. Install the drive gear on shaft, engaging internal

splines of gear with teeth on shaft, snap ring of

gear towards the front (See Illustration #56).

3. Install drive gear spacer on shaft and against

gear (See Illustration #57).

4. Press the drive gear bearing on shaft, shield to

the front (See Illustration #58).

5. Clean threads of drive gear and nut and apply grade

AVV Loctite (See Illustration #59).

6. Install the bearing nut on shaft, left-hand thread,

with 250-300 ft. lbs of torque (See Illustration #60).

NOTE: If torque wrench is not available, torque can

be approximated by multiplying the pounds of

pull time the length of wrench handle. For

example: If there are 150 pounds of pull on a

wrench with a two-foot handle, multiply 150 x

2, which equals 300 ft. lbs. of torque. Ordinary pull scales can be used to measure

pounds of pull.

#55 - Installing snap ring in ID of drive gear.

#56 - Installing drive gear on input shaft, engaging gear

splines with shaft splines.

#57 - Installing spacer on shaft.

#58 - Drive gear bearing installed on shaft.

41

Page 44

REASSEMBLY

#59 - Applying Loctite sealant to threads of drive gear

nut.

#60 - Installing drive gear bearing nut, left-hand thread.

#62 - Drive gear teeth marked for timing, two adjacent

teeth plus two adjacent teeth directly opposite.

#63 - Installing the drive gear assembly through top of

case.

#61 - Peening nut into the two milled slots of shaft.

#64 - Installing snap ring on drive gear bearing.

42

Page 45

1. Clean threads of drive gear and nut and apply grade

A

VV Loctite (See Illustration #59).

2. Install the bearing nut on shaft, left-hand thread

w

ith 250-300 ft. lbs of torque (See Illustration #60).

NOTE: If torque wrench is not available, torque can

be approximated by multiplying the pounds of

pull time the length of wrench handle. For

example: If there are 150 pounds of pull on a

wrench with a two-foot handle, multiply 150 x

2, which equals 300 ft. lbs. of torque. Ordinary pull scales can be used to measure

pounds of pull.

,

B. To Reassemble the Countershaft Assemblies

NOTE: Except for the power take-off gears, the coun-

tershafts are identical.

1. Install roll pin in bore located in keyway of countershaft (See Illustration #66).

3. Peen the nut into the two milled slots of

llustration #61).

I

4. IMPORTANT: Mark the drive gear for timing. Ma

y two adjacent teeth on the drive gear, then

an

tw

o adjacent teeth which are directly opposite

fi

rst set marked (See Illustration #62).

A. To Install the Drive Gear Assembly

1. Remove the snap ring from drive gear bearing.

2. Insert the drive shaft from inside case through

front bore. Seat the drive gear bearing in

ore and move assembly forward until sn

b

ng groove in bearing is exposed (See Illustra-

ri

tion #63).

3. Install snap ring in bearing groove (See Illustration #64).

4. Seat bearing in case bore.

5. Install the drive gear bearing cover, aligning oil

return slot in cover with oil return bore in

ighten capscrews securely (See Illustration

T

#65).

shaft (See

mark

case

rk

the

#65 - Installing the drive gear bearing cover.

ap

case.

#66 - Installing roll pin in countershaft.

43

Page 46

REASSEMBLY

#67 - Installing keys in countershaft.

#70 - Pressing the power take-off gear on countershaft.

#68 - Pressing the 2nd speed gear on countershaft.

#69 - Pressing the 3rd speed gear on countershaft

#71 - Pressing the drive gear on countershaft.

#72 - Marking timing tooth on countershaft drive gear.

Tooth is aligned with keyway and is stamped with an “O”.

44

Page 47

REASSEMBLY

2. Install the short key in countershaft, tapered end

against roll pin.

3. Install the long key in keyway in countershaft

(See Illustration #67).

4. Align keyway in gear with keys in shaft and

press the 2nd speed gear on shaft, long hub

towards front of shaft (See Illustration #68).

5. Press the 3rd speed gear on countershaft, long

hub towards 2nd speed gear (See Illustration

#69).

6. Press the 4th speed gear on countershaft.

7. Press the power take-off gear on countershaft,

bullet nose teeth towards rear of shaft (See

Illustration #70).

NOTE: The left countershaft assembly has a 47-tooth

PTO gear; the right assembly has a 45-tooth

gear. Mark each assembly as “right” and

“left”.

8. Press the drive gear on countershaft (See Illustration #71).

9. IMPORTANT: Mark countershaft drive gears for

timing. On the drive gear of each countershaft,

mark tooth that is aligned with keyway in gear;

this tooth will be stamped with an “O” (See

Illustration #72).

C. To Time and Install the Left Countershaft Assembly

1. Place the left countershaft assembly with the

47-foot PTO gear into position in case (See

Illustration #73).

2. Center front of left countershaft in bore (See

Illustration #74).

Illustration #73 - Placing left countershaft into position in

case.

Illustration #74 - Centering left countershaft in front bore

with wood block.

45

Page 48

REASSEMBLY

#75 - Timing tooth on countershaft meshed with timing

teeth on drive gear.

#78 - Installing bearing retainer plate on front of left

countershaft.

#76 - Installing rear bearing on left countershaft.

#77 - Installing front bearing on left countershaft.

#79 - Installing rear bearing cover.

#80 - Installing plug in reverse idler shaft.

46

Page 49

REASSEMBLY

3. Mesh the marked tooth on countershaft drive

g

ear with two teeth marked on the main dri

g

ear (See Illustration #75).

4. Center countershaft in rear bore and install

r bearing on shaft and into case bore. Bear-

rea

ing can be started by installing partially on shaft

before seating in bore (See Illustration #76).

5. Install front bearing on countershaft and into

case bore (See Illustration #77).

6. Install the bearing retainer plate on fron

co

untershaft, tighten and wire capscrew

secu

rely (See Illustration #78).

7. Install the rear bearing cover, tighten capscrew

rely (Illustration #79).

secu

D. To Install the Right Reverse Idler Gear

1. Install plug in oil channel in idler

I

llustration #80).

2. Press needle bearing into bore of reverse g

ler gear.

id

shaft (See

t of

s

ve

the

ear

E. To Place Right Countershaft in Position

1. Lower the countershaft assembly through top

case,

small end through the rear countershaft

bore in case (See Illustration #82).

2. Move countershaft forward and into corr

osition, aligning timing tooth on countersha

p

ith those on main drive gear. Do not install

w

bearings.

s

of

ect

ft

3. Place inner race of bearing in gear.

4. Place a thrust washer on each side of gear, oil

slots to gear.

5. Place the reverse gear and the two thrust washers into position in case.

6. Thread the idler shaft through bore in rear of

case, washers and gear. Make sure slot in idle

aft is aligned with lockplate capscrew bore in

sh

case (See Illustration #81).

7. Install the lockplate in slot in idler shaft. Tigh

cap

screw securely.

ten

#81 - Threading the right reverse idler shaft through

reverse idler gear and the two thrust washers.

r

#82 - Placing the right countershaft into position in case.

Do not install bearings.

47

Page 50

REASSEMBLY

#83 - Drawing showing correct dimensions for mainshaft

quills.

#84 - Installing quill bearing snap ring.

#86 - Installing reverse gear washer on shaft and inserting key through keyway and washer.

#85 - Installing snap ring in ID of mainshaft gear.

#87 - Installing the 1st-Reverse sliding clutch gear on

shaft.

48

Page 51

REASSEMBLE

F. To Reassemble the Mainshaft Assembly

NOTE: Mainshaft should have quills assembled, one

in each end. In case it is necessary to install

quills, exact dimensions must be held

between end of shaft and end of quill (See

Illustration #83)

1. Place the mainshaft in a vise, pilot end up, so

that keyway in shaft is exposed for insertion of

key.

2. Install quill bearing on front quill. Do not move

quill.

3. Install bearing snap ring on quill (See Illustration #84).

4. Install snap rings in ID of all mainshaft gears

except the reverse gear (See Illustration #85).

5. Install the reverse gear washer in the lowest

radial groove in mainshaft, aligning keyway in

washer with keyway in shaft. Flat side of washer

is down.

NOTE: Gear WASHERS are internally splined and

contain a square keyway which locks washers

to mainshaft. Gear SPACERS are externally

splined to engage splines in gear hubs. There

is one washer and one spacer for each gear.

6. Install the long key from the bottom in mainshaft keyway and through keyway in washer,

snap ring groove in key to the rear and outside

(See Illustration #86).

NOTE: The long key is moved upward to engage each

washer as it is placed on mainshaft.

7. Install the 1st-Reverse sliding clutching gear on

mainshaft, aligning large keyway in gear with

key in shaft (See Illustration #87).

8. Install the 1st speed gear washer, flat side up, in

the third radial groove from top of shaft, aligning keyway in washer with keyway in shaft (See

Illustration #88).

9. Move the long key up to engage the 1st speed

gear washer.

#88 - Installing the 1st speed gear washer, flat side up,

engaging keyway with key.

49

Page 52

REASSEMBLY

#89 - Installing the 1st speed gear spacer, flat side to

washer.

#91 - Installing the 2nd speed gear.

#90 - Installing the 1st speed gear on shaft and splines of

spacer.

#92 - Installing the 2nd speed gear spacer into hub of

gear, flat side up.

50

Page 53

REASSEMBLY

10. Install the 1st speed gear spacer on shaft, flat

side to washer (See Illustration #89).

11. Install the 1st speed gear, snap ring up, on

shaft, engaging splines of gear with splines

acer (See Illustration #90)

sp

of

12. Install the 2nd speed gear, snap ring down,

aft and against the 1st speed gear (See Illus-

sh

tration #91).

13. Install the 2nd speed gear spacer on shaft and

into hub of gear, flat side up, engaging spli

o

f gear with splines of spacer (See Illustration

#92).

14. Install the 2nd speed gear washer, flat side

against spacer, aligning keyway in washer wi

ay in shaft (See Illustration #93).

keyw

15. Move key upward to engage the 2nd sp

w

asher.

16. Install the 2nd-3rd speed sliding clutch gear on

mainshaft, aligning large keyway in gear wi

n shaft (See Illustration #94).

key i

on

nes

th

eed gear

th

#93 - Installing the 2nd speed gear washer, engaging

keyway with key.

#94 - Installing the 2nd-3rd speed sliding clutch on shaft.

51

Page 54

REASSEMBLY

#95 - Installing the 3rd speed gear washer, flat side up,

engaging keyway with key.

#97 - Installing the 3rd speed gear on shaft and splines of

spacer.

#96 - Installing the 3rd speed gear spacer, flat side next

to washer.

Illustration #98 - Installing the 4th speed gear on shaft.

52

Page 55

REASSEMBLY

17. Install the 3rd speed gear washer, flat side up,

on mainshaft, aligning keyway in washer in

shaft (See Illustration #95).

18. Move the key upwards to engage the 3rd speed

gear washer. Align snap ring slot at rear of key

with snap ring groove in mainshaft.

19. Install the 3rd speed gear spacer, flat side

against washer (See Illustration #96).

20. Install the 3rd speed gear on shaft, snap ring up,

engaging gear splines with splines of spacer

(See Illustration #97).

21. Install the 4th speed gear on shaft, snap ring

down (See Illustration #98).

22. Install the 4th speed gear spacer, flat side up

(See Illustration #99).

23. Install the 4th speed gear washer on shaft, flat

side against spacer, aligning keyway in washer

with keyway in shaft (See Illustration #100).

24. Make sure pin is installed in the short 4th speed

gear mainshaft key.

#99 - Installing the 4th speed gear spacer, flat side up.

#100 - Installing the 4th speed gear washer on shaft and

aligning keyway in washer with keyway in shaft.

53

Page 56

REASSEMBLY

#103 - Installing the reverse gear on mainshaft.

#101 - Installing the short key in keyway in mainshaft to

lock the 4th speed gear washer.

#104 - Installing the reverse gear spacer on shaft.

#105 - Installing key retaining snap ring on mainshaft.

#102 - Installing the 4th-5th speed sliding clutch gear.

#106 - The right countershaft moved towards case wall.

54

Page 57

REASSEMBLY

25. Install the short key in keyway in mainshaft to

lock the 4th speed gear washer in position (See

Illustration #101).

26. Install the 4th-5th speed sliding clutch gear on

shaft, aligning large keyway in gear with key in

shaft (See Illustration #102).

27. Remove the assembly from vise and install the

reverse gear on rear of shaft, snap ring groove

in ID to the rear (See Illustration #103).

28. Move the reverse gear as far forward on shaft as

possible, against the first speed gear.

29. Install the reverse gear spacer on shaft, flat side

against washer (See Illustration #104).

30. Lock the long key in position by installing snap

ring in mainshaft groove and key slot (See Illustration #105).

G. To Install the Mainshaft Assembly

#107 - Lowering mainshaft in position in case; mesh corresponding gears on left countershaft with those on

mainshaft.

1. Move the right countershaft assembly as far as

possible towards case wall (See Illustration

#106).

2. With the reverse gear as far forward as possible,

install the mainshaft into position in case,

meshing corresponding gears on left countershaft with those on mainshaft (See Illustration

#107).

3. Block under rear of mainshaft to exactly center

shaft in rear bore. Front quill bearing should be

seated in pocket of drive gear (See Illustration

#108).

#108 - Mainshaft assembly in correct position in case.

55

Page 58

REASSEMBLY

#109 right countershaft moved into position to mesh

with gears of mainshaft. Timing tooth on drive gear must

mesh with tining teeth on main drive gear.

#110 Installing rear bearing on right countershaft.

#113 Installing rear bearing cover on right countershaft.

#114 Installing plug in left rererse idler gear shaft.

#111 Installing front bearing on right countershaft.

#112 Installing bearing retainer plate on front of right

countershaft.

#115 Place the two thust washers and reverse idler gear

into position in case.

56

Page 59

REASSEMBLY

H. To Time Right Countershaft and Complete Installa-

tion

1. Center front of right countershaft in front bore

with wood block and move the right countershaft into mesh with the mainshaft gears. At the

same time engage timing tooth on countershaft

drive gear with timing teeth on main drive gear.

2. Center countershaft in rear bore and install the

rear bearing on shaft and in case bore. Bearing

can be started by installing partially on shaft

before seating in bore (See Illustration #110).

3. Install front bearing on countershaft and into

case bore (See Illustration #111).

4. Install the bearing retainer plate on front of

countershaft. Tighten and wire capscrews

securely (See Illustration #112).

5. Install rear bearing cover on countershaft (See

Illustration #113).

#116 - Threading reverse idler shaft through reverse idler

gear and the two thrust washers.

I. To Install the Left Reverse Idler Gear

1. Install plug in oil channel in idler shaft (See

Illustration #114).

2. Press needle bearing into bore of reverse idler

gear.

3. Place inner race of bearing in gear.

4. Place a thrust washer on each side of gear, oil

slots to gear (See Illustration #115).

5. Place the reverse gear and the two thrust washers into position in case.

6. Thread the idler shaft through bore in rear of

case, washers and gear. Make sure slot in idler

shaft is aligned with lockplate capscrew bore in

case (See Illustration #116).

7. Install the lockplate in slot in idler shaft. Tighten

capscrew securely (See Illustration #117).

#117 - Installing lockplate in reverse idler shaft.

57

Page 60

REASSEMBLY

#118 - The mainshaft reverse gear moved to the rear to

mesh with the two reverse idler gears.

#121 - Installing nuts on case studs with 180-190 ft.lbs

of torque.

#119 - Installing snap ring in ID of mainshaft reverse

gear.

#120 - Installing clutch housing on front of transmission.

#122 - Installing bolts in clutch housing with 90-100

ft.lbs. of torque

Illustration #123 - Pressing bearing on tailshaft.

58

Page 61

REASSEMBLY

J. To Complete Installation of Mainshaft Assembly

1. Move the reverse gear to the rear on mainshaft

as far as possible, meshing teeth of gear with

teeth of the two reverse idler gears (See Illustration #118).

2. With mainshaft forward and reverse gear to the

rear, seat the reverse gear spacer previously

installed on shaft in hub of gear, and install the

snap ring in ID of reverse gear (See Illustration

#119).

K. To Install Clutch Housing

1. Place clutch housing in position on the six studs

in front case, piloting on drive gear cover (See

Illustration #120).

2. Install the six nuts with 180-190 ft.lbs. of torque

(See Illustration #121).

3. Install the four bolts in clutch housing with 90100 ft. lbs. of torque (See Illustration #122).

4. Install the clutch release mechanism if transmission is so equipped.

L. To Reassemble the Tailshaft Assembly

1. Press the front bearing on tailshaft, snap ring to

the rear (See Illustration #123).

2. Clean threads of tailshaft and bearing nut and

apply grade AVV Loctite (See Illustration #124).

3. Install the bearing nut on tailshaft with 250-300

ft.lbs. of torque (See Illustration #125).

#124 - Applying Loctite to threads of bearing nut.

#125 - Installing bearing nut, left hand thread, with 250300 ft.lbs. of torque.

#126 - Installing key-spacer ring on tailshaft.

59

Page 62

REASSEMBLY

#127 - Installing coupling gear on mainshaft, counterbore towards the front.

#128 - Installing tailshaft assembly over mainshaft and in

case bore.

#130 - Flat keys secured to spacer ring and properly

wired.

#131 - Installing outer bearing on tailshaft.

#129 - Installing flat keys in tailshaft to engage slot in

mainshaft.

#132 - Installing bearing washer on tailshaft.

60

Page 63

REASSEMBLY

M. To Install the Tailshaft Assembly

1. Install the coupling gear on splines of mainshaft

with the counterbore towards the front and keyway aligned with key in shaft (See Illustration

#127).

2. Install the tailshaft assembly over mainshaft,

seating bearing in case bore. MAKE SURE

SPLINES IN TAILSHAFT ENGAGE SPLINES OF

COUPLING GEAR (See Illustration #128).

3. Install the flat keys in bores in tailshaft to

engage slot in mainshaft (See Illustration #129)

4. Secure flat keys with 5/16” x 1” capscrews and

tighten all capscrews in spacer ring evenly and

securely. Install safety wire (See Illustration

#130).

5. Install outer bearing on tailshaft, seating against

shaft shoulder (See Illustration #131).

N. To Reassemble and Install the Rear Bearing Cover

Assembly

1. Install the tailshaft bearing washer on shaft and

against bearing, chamfered ID to bearing (See

Illustration #132).

2. Install the speedometer drive gear or replacement spacer on shaft and against washer (See

Illustration #133).

3. Install speedometer bushing in rear bearing

cover if required.

4. Install oil seal in rear bearing cover (See Illustration #134).

#133 - Installing speedometer drive gear on tailshaft.

#134 - Installing oil seal in rear bearing cover.

5. Install rear bearing cover evenly on tailshaft to

seat tailshaft bearing in cover, aligning oil slot in

cover with slot in case (See Illustration #135).

#135 - Installing rear bearing cover on tailshaft. Install

evenly to properly seat outer bearing.

61

Page 64

REASSEMBLY

#136 - Securing rear bearing cover to transmission case.

#137 - Installing companion flange nut with 400-500

ft.lbs. of torque.

#139 - Installing interlock ball in front boss.

#140 - Installing interlock pin in bore in neutral notch of

2nd-3rd speed shifting bar

#138 - Installing the 1st-Reverse speed shift bar and

shifting yoke and block.

#141 - Installing interlock ball in front boss.

62

Page 65

REASSEMBLY

6. Install attaching capscrews, tighten evenly and

securely (See Illustration #136).

O. To Install the Companion Flange or Yoke

1. Lock the mainshaft by engaging two speed

ith the sliding clutch gears.

w

2. Install Flange or yoke on tailshaft splines an

secu

re with tailshaft nut, using 400-450 ft. lb

o

f torque (See Illustration #137).

P. To Reassemble the Shifting Bar Housing

1. Install the housing in a vise with the left side up.

NOTE: Shift bars should be installed from the front

with neutral and shift notches to the front.

Keep bars in the neutral position when

installed.

2. Install the long 1st-Reverse shift bar in low

b

ore in housing, installing the shifting yoke and

block on bar, long hub of each to the front (See

Illustration #139).

3. Install lockscrew in yoke and block, tighten and

wire securely.

4. Install ¾” interlock ball in bore in front

(See Il

lustration #139).

s

d

est

boss

s.

#142 - Installing the 4th-5th speed shifting bar and shifting yoke.

5. Install the 2nd-3rd speed shifting bar in center

bore in housing and install shift yoke, long hu

to

the rear. At the same time install interlock pin

bore in neutral notch of bar as notch enters

front boss (See Illustration #140).

6. Install yoke lockscrew, tighten and wi

rely.

secu

7. Install ¾” interlock ball in bore in front

(See Il

lustration #141).

8. Install the 4th-5th speed shifting bar in upper

bore in housing installing shift yoke on bar, fo

the front (See Illustration #142).

to

9. Install yoke lockscrew, tighten and wire securely

(See Illustration #143).

10. Remove housing from vise.

re

boss

b

#143 - Shifting bar housing with yokes, blocks and bars

correctly installed.

rk

63

Page 66

REASSEMBLY

#144 - Installing tension balls in bores on top of housing.

#145 - Installing the three tension springs in bores.

#147 - Installing the shifting bar housing on transmission, fitting yokes in yoke slots of sliding gears.

#148 - Installing nut on gear shift lever pivot pin.

#146 - Shifting bars in the neutral position.

#149 - Installing the gear shift lever in housing.

64

Page 67

REASSEMBLY

11. Install the three shift bar tension balls in bores

in top of housing (See Illustration #144).

12. Install three tension springs in bores (See Illus-

tration #145).

13. Install tension spring cover, tighten capscrews

securely.

Q. To Install the Shifting Bar Housing Assembly

1. Place the sliding clutch gears in transmission in

the neutral position.

2. Make sure shifting bars in housing are in the

neutral position (See Illustration #146).

3. Install the shifting bar housing on transmission,

fitting yokes into corresponding yoke slots of

sliding gears, tighten capscrews securely (See

Illustration #147).

R. To Reassemble and Install the Gear Shift Lever

Housing Assembly

#150 - Installing the tension spring washer in housing.

1. Install the pivot pin in bore in housing, thread

end outward.

2. Install lockwasher and nut on pivot pin (See

Illustration #148).

3. Mount the housing in a vise with the large bot-

tom opening upwards.

4. Insert the gear shifts lever in housing, fitting

slot in pivot ball of shift lever on pivot pin (See

Illustration #149).

5. Install the tension spring washer in housing

(See Illustration #150).

65

Page 68

REASSEMBLY

6. Install the tension spring in housing, seating

spring under lugs cast inside the housing (See

Illustration #151).

7. Remove assembly from vise and install the rub-

ber protector over the gear shift lever and

against neck of housing.

8. Install ball grip on shift lever

9. Make sure the shifting notches in the shifting

bar housing are aligned in the neutral position.

10. Install the gear shift lever housing, fitting lever

into notches in block and yokes; tighten capscrews securely (See Illustration #152).

#151 - Installing tension spring in housing, fitting spring

under lugs cast inside the housing.

#152 - Installing the gear shift lever housing on shifting

bar housing.

66

Page 69

TOOL REFERENCE

Some illustrations in this manual show the use of specialized tools. These tools are recommended for transmission repair as they make repair easier, faster and

prevent costly damage to critical parts.

Prints are available for tools which have a Fuller tool

number; send request to:

Service Department, Fuller Transmission Division,

EATON YALE & TOWNE, Inc., Kalamazoo, Michigan.

Some of these tools can be obtained from a regular tool

supplier, while others can be made either from prints or

from dimensions as required by the individual user.

Listed below are illustrations which show these specialized tools, the tool name and how it can be obtained.

Illustration

12

17-125

22-40

27-44

29

34-84-105

38

53-60

76-110

77-11-131-

134-135

Jaw pullers, large Tool Supplier

Hexagonal wrench Make from 3/8” steel stock for 4 ½” hex. nut

Impact puller Make from 18” steel rod, threaded ½”-13 one end, attach end block and

Bearing puller, ring type Make from Fuller tool print T-22552

Jaw pullers, medium Tool Supplier

Snap ring pliers, medium Tool Supplier

Jaw puller, small Tool Supplier

Special slotted plate and tool Make from Fuller tool print T-15765, weld used sliding clutch to 3/8”

Flanged-end bearing driver Make from Fuller tool print T-18042-50

Flanged-end bearing driver Make from Fuller tool print T-10324

Tool How Obtained

Also available upon request is a tool booklet which gives

in detail the use and description of suggested specialized

tools for rebuilding Fuller Transmissions.

sliding block

steel lever

121-137

122

151

Torque wrench, 1,000 ft. lb. cap. Tool Supplier

Torque wrench, 150 ft. lb. cap. Tool Supplier

Tension spring driver Make from Fuller tool print T-11938

67

Page 70

GEAR CHART FOR T-905 SERIES TRANSMISSIONS

MODEL

T-905A

T-905B

T-905C

T905F

TO-905A

TO-905B

TO-905C

TO-905F

T-905H

T-905J

T-905M

Drive

Gear

24-T

14745

24-T

14745

24-T

15473

24-T

15473

32-T

14725

26-T

14892

26-T

15474

26-T

15585

24-T

14745

24-T

15473

26-T

14892

C.S.

Drive

Gear

45-T

14747

45-T

14747

47-T

15478

47-T

15478

39-T

14746

42-T

14891

43-T

15479

35-T

15584

45-T

14747

47-T

15478

42-T

14891

M.S.

4th

32-T

14725

26-T

14892

26-T

15474

26-T

15585

24-T

14745

24-T

14745

24-T

15473

24-T

15473

32-T

14725

32-T

14725

32-T

14725

C.S.

4th

39-T

14746

42-T

14891

43-T

15479

35-T

15584

45-T

14747

45-T

14747

47-T

15478

47-T

15478

39-T

14746

39-T

14746

39-T

14746

M.S.

3rd

38-T

14737

36-T

14890

32-T

15472

32-T

15472

38-T

14737

36-T

14890

32-T

15472

32-T

15472

38-T

14737

34-T

15464

36-T

14890

C.S.

3rd

30-T

14741

33-T

14889

29-T

15477

29-T

15477

30-T

14741

33-T

14889

29-T

15477

29-T

15477

30-T

14741

26-T

15465

33-T

14889

M.S.

2nd

40-T

14835

40-T

14835

38-T

15471

38-T

15471

40-T

14835

40-T

14835

38-T

15471

38-T

15471

40-T

14835

46-T

15466

38-

16373

M.S.

2nd

20-T

14836

20-T

14836

19-T

15476

19-T

15476

20-T

14836

20-T

14836

19-T

15476

19-T

15476

20-T

14836

22-T

15467

23-T

16372

M.S.

44-T

14734 14720

44-T

14734

48-T

15470

48-T

15470

44-T

14734

44-T

14734

48-T

15470

48-T

15470

48-T