DYMO 18058, 18057, 18056, 18055, 18054 Specsheet

...

Technical Data Sheet

DYMO Indust ial Heat Shrinka ble Tubing

Descripti on

Flame reta rdant (3:1 shrink ratio) poly olefin sleeves used for wire identification. The identification marks are permanent immediately after printing and remain le gible even wh en exposed to solvents, fuels and oils. The sleeves ar e low profile a nd lightweight. They may be used to provid e strain relief and insulation in addition to identificat on.

DYMO Part Numbers

18051 |

180 53 |

18055 |

18057 |

18052 |

180 54 |

18056 |

18058 |

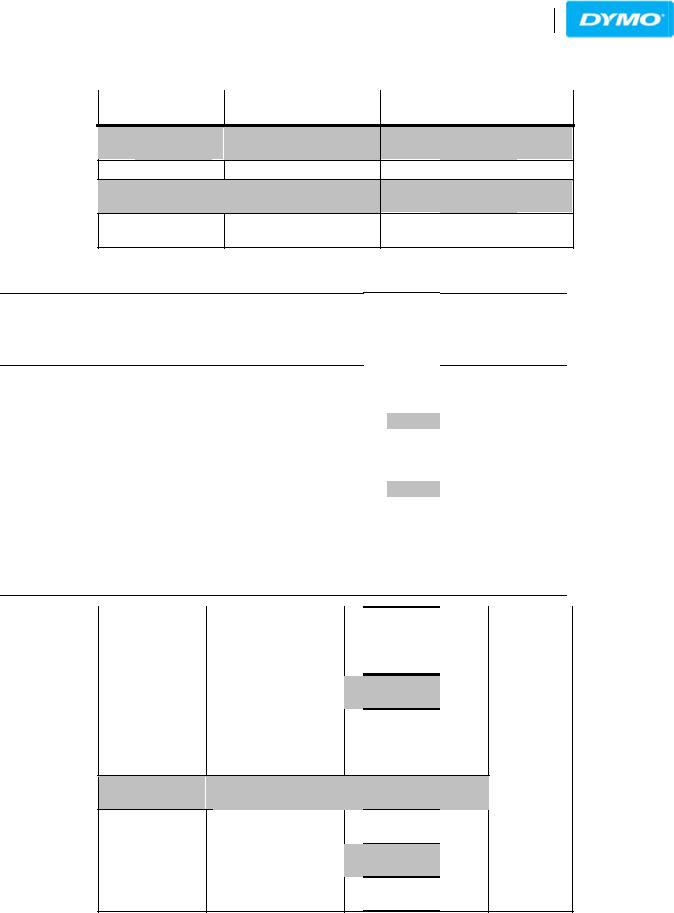

Available Colors & Sizes

|

Print Color |

|

Tape Color |

|

|

Available Widths (in, mm) |

||

|

|

|

|

|

|

|

|

|

|

Black |

|

White |

|

|

¼, 6 mm; |

⅜, 9mm; ½ , 12mm; |

|

|

|

|

|

|

|

¾, 1 9mm |

|

|

|

Black |

|

Yellow |

|

|

¼, 6 mm; |

⅜, 9mm; ½ , 12mm; |

|

|

|

|

|

|

|

¾, 1 9mm |

|

|

Certifications and & Standards Ad |

erence |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

-UL R ecognized as a component to UL224 (UL File Number E348356) All U L information can be found at UL.com und er certifications

-Mee ts the perform ance require ments of SAE DTL 23053/5 classes 1 & 3

-Printed tubing meets mark perm anence requirements of MI L M 81531 an d MIL STD 202G befo re and after s hrinking

-To the best of our company’s knowledge we d eclare that ou r products me et the most recent standards of the European Directives considering REACH and ROHS. None of the substances identified as “substance of conc ern“ has been and will be co ntained in the product(s), listed on this Technical Dat a Sheet, to a higher level than mentioned in the European Directives

con idering REACH and ROHS.

Tempera ture and Volt age Ratings (tested per UL224)

-Max Voltage (V): 6 00

-Max Operating te mperature: 12 5°C (257°F)

Physical roperties

- Tota l Thickness: 0.5mm (maximum)

Last Up dated 11/29/2011

Technical Data Sheet

- Shri nk Ratio: 3:1

Prop rty |

Result/Value |

Test Met hod |

Tensile strength |

10.3 MPa 1500 psi) |

SAE DTL 23053, section 4.6.13 |

|

minimum |

|

Ultimate elongation |

200% minimum |

SAE DTL 23053, section 4.6.13 |

Heat aging |

minimum 100% ultimate |

SAE DTL 23053, section 4.6.9 |

168 hours at 75°C |

elongation |

|

Heat shock |

no cracking, dripping or |

SAE DTL 23053, section 4.6.8 |

4 hours at 250°C |

flowing |

|

Electrical Properties

D ielectric stren gth: 19.7 kV/mm (500V/mil) minimum tested per ASTM D 2671

Chemical Properties

Prop rty |

Result/Value |

Test Met hod |

||||

|

|

|

|

|

|

|

Flam mability |

No flaming |

or glowing |

ASTM D |

2671, procedur |

e B |

|

|

after 1 mi |

ute |

|

|

|

|

|

No burnin g of cotton; no |

ASTM D 2671, procedure C |

||||

|

dripping |

|

|

|

|

|

Corrosive effect |

Non corro |

sive |

SAE DTL |

23053, section |

4.6.10.1 |

|

16 hours at 175°C |

(copper co |

ntact) |

|

|

|

|

|

No pitting or blackening |

SAE DTL 23053, section 4.6.10.2 |

||||

|

(copper mirror) |

|

|

|

|

|

Chemical Resistance ( rinted with the Rhino 6000)

|

|

|

|

|

|

|

|

|

Chem ical |

10 mins imm ersion, |

30 |

mins immersion, 30 |

Tes t |

||

|

|

|

30 mins recov ery, 5 |

m ins recovery, 5 cycles |

Me thod |

||

|

|

|

cycles without swab |

with swab rub |

|

||

|

|

|

rub |

|

|

|

|

|

IPA |

|

No visible defects on |

No |

visible defect |

s on |

Mil STD 202, |

|

|

|

the printing |

the printing |

|

met hod 215 |

|

|

|

|

|

|

|

|

|

|

MIL 5606 oil |

No visible defects on |

Slight Fading; |

|

|||

|

|

|

the printing; |

Discoloration on the |

|

||

|

|

|

Discoloration on the |

background |

|

||

|

|

|

background |

|

|

|

|

MIL 7808 oil |

No visible defects on |

No visible defect s on |

|

the printing |

the printing |

|

Skydrol* oil |

|

No visible defects on |

|

Slight smudging |

|

|||

|

|

|

|

the printing. |

|

|

|

|

|

|

Demi |

water |

|

No visible def |

ects on |

|

No |

visible defect |

s on |

|

|

|

|

the printing |

|

|

the printing |

|

|

|

Kerosene |

|

No visible defects on |

|

M |

oderate smud |

ging |

||

|

|

|

|

the printing. |

|

|

|

|

|

Last Up dated 11/29/2011

Loading...

Loading...