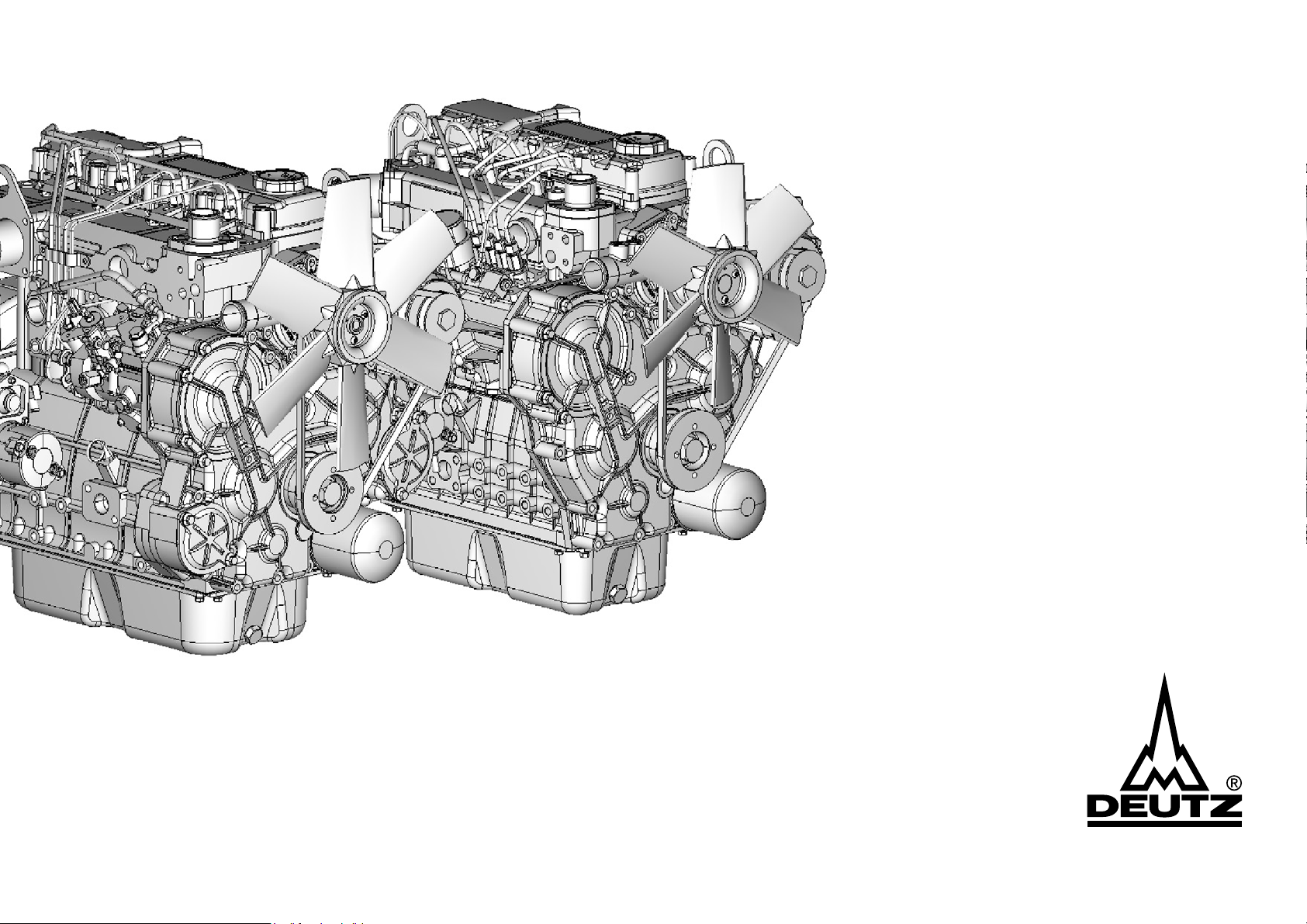

Page 1

Operation Manual

2008

2009

Page 2

zRead and observe the information in this

instruction manual. You will avoid accidents,

retain the manufacturer’s warranty and have

a fully functional, ready to use engine at your

disposal.

z This engine is exclusively for the purpose

according to the scope of delivery - defined

and built by the equipment manufacturer

(use for the intended purpose). Any use

above and beyond this is considered

improper use. The manufacturer will not be

liable for damages resulting from this. The

user will bear the sole risk in this case.

z The manufacturer will not be liable for

damages resulting from unauthorised

modification of the engine.

Equally, manipulations to the injection

and control system can affect the engine’s

performance and the exhaust

characteristics. Compliance with environmental regulations will no longer be

guaranteed in this case.

z Do not alter, obstruct or block the area of

the cool air supply to the fan.

The manufacturer will accept no liability for

damages resulting from this.

z Use for the intended purpose also includes

observance of the operating, maintenance

and repair instructions specified by the

manufacturer. The engine may only be used,

maintained and repaired by persons who

are familiar with it and instructed in the

dangers.

z The pertinent rules for the prevention of

accidents and other generally recognised

safety and industrial medicine rules must be

observed.

z When the engine is running there is a danger

of injury caused by:

- rotating / hot components

- engines with extraneous ignition

- ignition systems (high electrical voltage)

Contact must be avoided!

z Only DEUTZ original parts may be used

when carrying out maintenance/repair

work on the engine. These have been

designed especially for your engine and

ensure a trouble-free operation.

Failure to observe this will lead to voiding

of the warranty!

z Maintenance/cleaning work on the engine

may only be carried out when the engine

is not running and has cooled down.

When doing this, make sure that the electrical

system is switched off. Remove ignition

key.

The specifications for accident prevention

with electrical systems (e.g. VDE-0100/0101/-0104/-0105 Electrical protective

measures against dangerous touch

voltages) must be observed.

Cover all electrical components tightly when

cleaning with liquids.

Page 3

Engine number

Operation Manual

2008

2009

0312 1419 en

Please enter the engine number here. This will

simplify the handling of customer service,

repair and spare parts queries (see Section

2.1).

Illustrations and data in this instruction manual

are subject to technical changes in the course

of improvements to the engines. Reprinting and

reproductions of any kind, even in part, require

our written permission.

Page 4

1

Foreword

Dear customer,

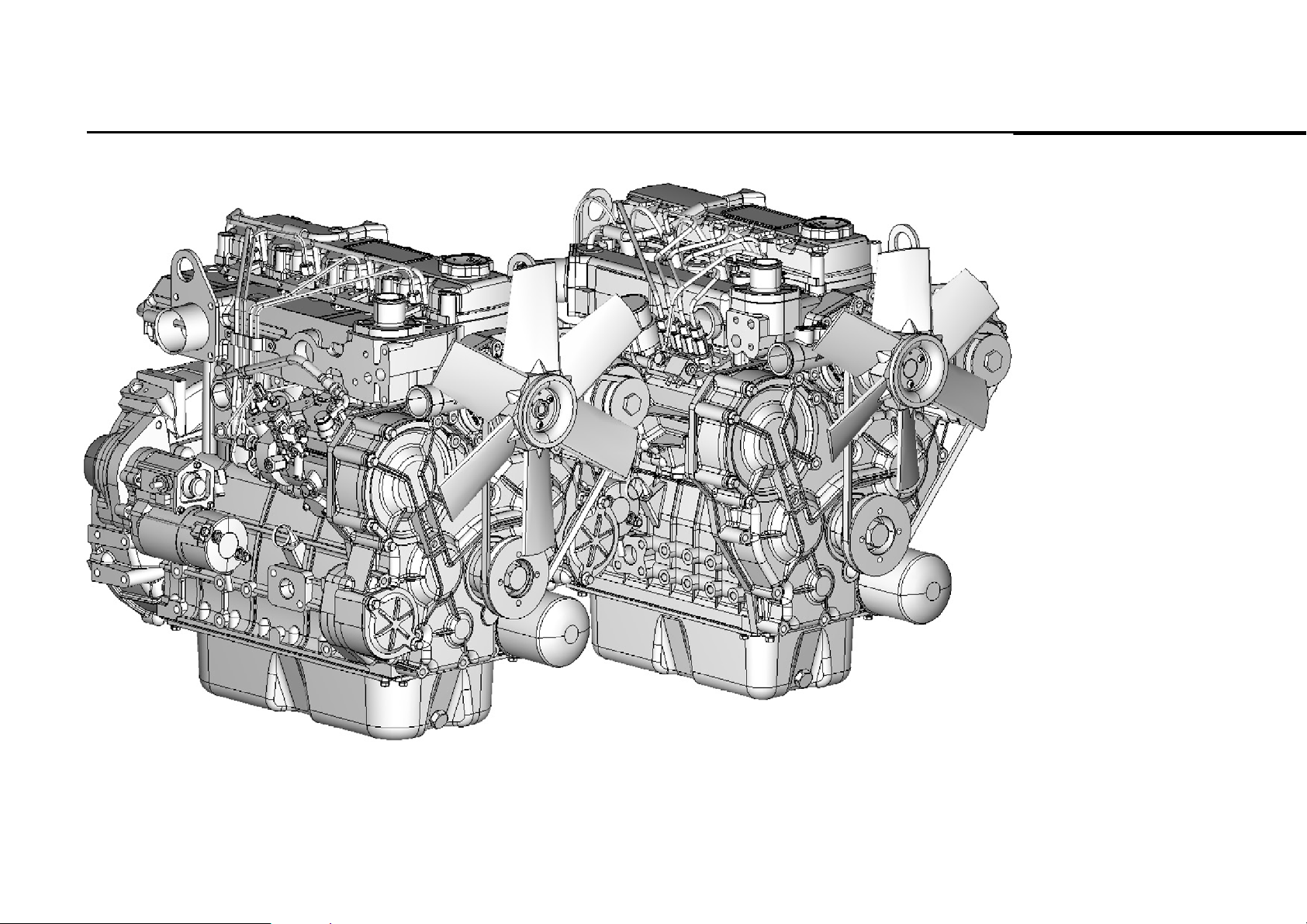

DEUTZ air/liquid-cooled engines are developed

for a broad spectrum of applications. A

comprehensive range of variants on offer

ensures that the respective special

requirements are met.

The engine is equipped according to the

installation case, i.e. not all the parts and

components described in this instruction manual

are installed in your engine.

We have done our best to clearly identify the

differences, so that you can easily find the

operating, maintenance and repair instructions

appropriate to your engine.

Please read these instructions before you

start your engine and observe the operating

and maintenance instructions.

We are at your service for any questions you

may have in this matter.

Your

DEUTZ AG

Page 5

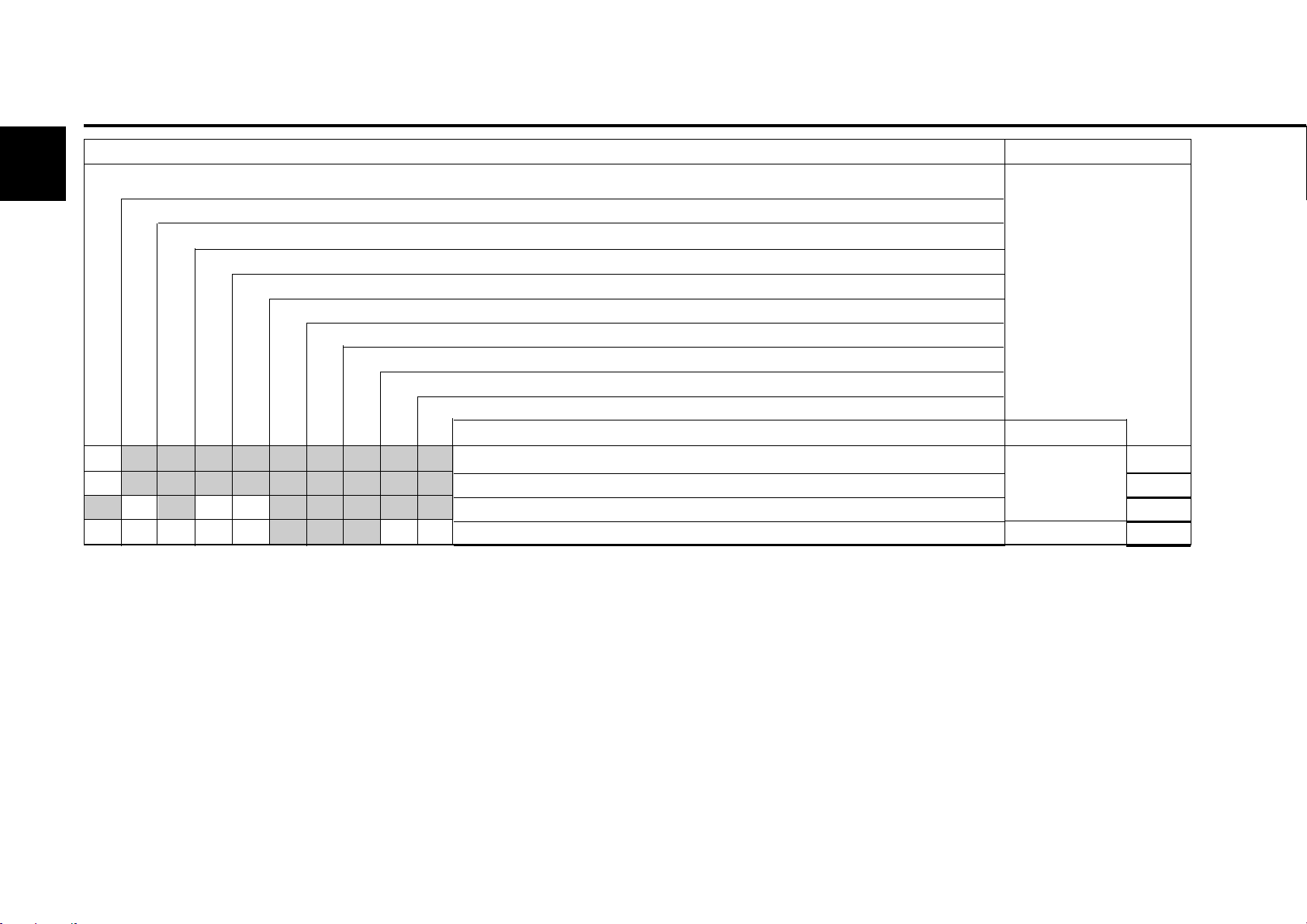

Contents

1 General

2 Engine description

2.1 Engine type

2.1.1. Company plate

2.1.2 Location of company plate

2.1.3 Cylinder numbering

2.2 Engine illustrations

2.2.1 Operation side D 2008 L04

2.2.2 Exhaust side D 2008 L04

2.2.3 Operation side D 2009 L04

2.2.4 Exhaust side D 2009 L04

2.2.5 Operation side TD 2009 L04

2.2.6 Exhaust side TD 2009 L04

2.3 Fuel diagram

2.3.1 Fuel circuit

3 Operating

3.1 Initial commisioning

3.1.1 Engine oil filling

3.1.2 Filling oil bath air filter with engine oil

3.1.3 Coolant initial filling with cooler

3.1.4 Other preparations

3.1.5 Additional maintenance work

3.2 Starting

3.2.1 Starting

3.3 Operation monitoring

3.3.1 Engine oil pressure

3.3.2 Engine temperature

3.4 Switching off

3.4.1 Mechanical switching off

3.4.2 Electrical switching off

3.5 Operating conditions

3.5.1 Winter operation

3.5.2 High ambient temperature,

high altitude

4 Operating substances

4.1 Lube oil

4.1.1 Quality

4.1.2 Viscosity

4.2 Fuel

4.2.1 Quality

4.2.2 Winter fuel

4.3 Coolant

4.3.1 Water quality for coolant

4.3.2 Coolant preparation

4.3.3 Cooling system preservative

5 Maintenance

5.1 Maintenance schedule

5.2 Standard maintenance schedule

5.3 Maintenance diagram

5.4 Maintenance work carried out

6 Care and maintenance work

6.1 Lubrication system

6.1.1 Oil change intervals

6.1.2 Checking oil level, changing engine oil

6.1.3 Changing oil filter

6.2 Fuel system

6.2.1 Changing fuel filter

6.2.2 Bleeding fuel system

6.2.3 Draining water from fuel system

6.2.4 Changing diaphragm pump

6.3 Cooling system

6.3.1 Cleaning intervals

6.4 Combustion air filter

6.4.1 Cleaning intervals

6.4.2 Emptying cyclone pre-separator

6.4.3. Dry air filter

6.5 Belt drive

6.5.1 Test V-belt

6.5.2 Tightening/changing V-belt

6.5.3 Changing generator V-belt

6.6 Add-on components

6.6.1 Battery

6.6.2 Three-phase current generator

6.6.3 Transportation suspension

6.7 Engine cleaning

6.7.1 Engine cleaning

7 Faults, causes and remedies

7.1 Fault table

8 Engine corrosion protection

8.1 Corrosion protection

8.1.1 Protecting engine from corrosion

8.1.2 Removing engine corrosion

protection

9 Technical data

9.1 Engine and setting data

9.2 Screw tightening torques

10 Service

1

Page 6

1

Page 7

General

DEUTZ Diesel Engines

are the product of many years of research and

development. The resulting know-how, coupled

with stringent quality standards, guarantee their

long service life, high reliability and low fuel

consumption.

It goes without saying that DEUTZ Diesel Engines

meet the highest standards for environmental

protection.

Beware of Running Engine

Shut the engine down before carrying out maintenance or repair work. Ensure that the engine cannot

be accidentally started. Risk of accidents.

When the work is complete, be sure to refit any

panels and guards that may have been removed.

Never fill the fuel tank while the engine is running.

Observe industrial safety regulations when running

the engine in an enclosed space or underground.

Care and Maintenance

Sound care and maintenance practices will ensure

that the engine continues to meet the requirements

placed on it. Recommended service intervals must

be observed and service and maintenance work

carried out conscientiously.

Special care should be taken under abnormally

demanding operating conditions.

Safety

This symbol is used for all safety

warnings. Please follow them

!

and accident prevention regulations laid down by

law must also be observed.

carefully. The attention of operating

personnel should be drawn to these

safety instructions. General safety

Service

1

Please contact one of our authorized service

representatives in the event of breakdowns or for

spare parts inquiries. Our trained specialists will

carry out repairs quickly and professionally, using

only genuine spare parts.

Original parts from DEUTZ AG are always produced

in accordance with state-of-the-art technology.

Please turn to the end of this manual for further

service information.

California

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known to the State of California to

cause cancer, birth defects, and other reproductive harm.

Asbestos

DEUTZ original parts are asbestosfree.

Page 8

1

Page 9

2.1 Engine type

2.2 Engine illustrations

2.3 Fuel diagram

Engine description

2

© 2005

Page 10

Engine description

2.1 Engine type

2

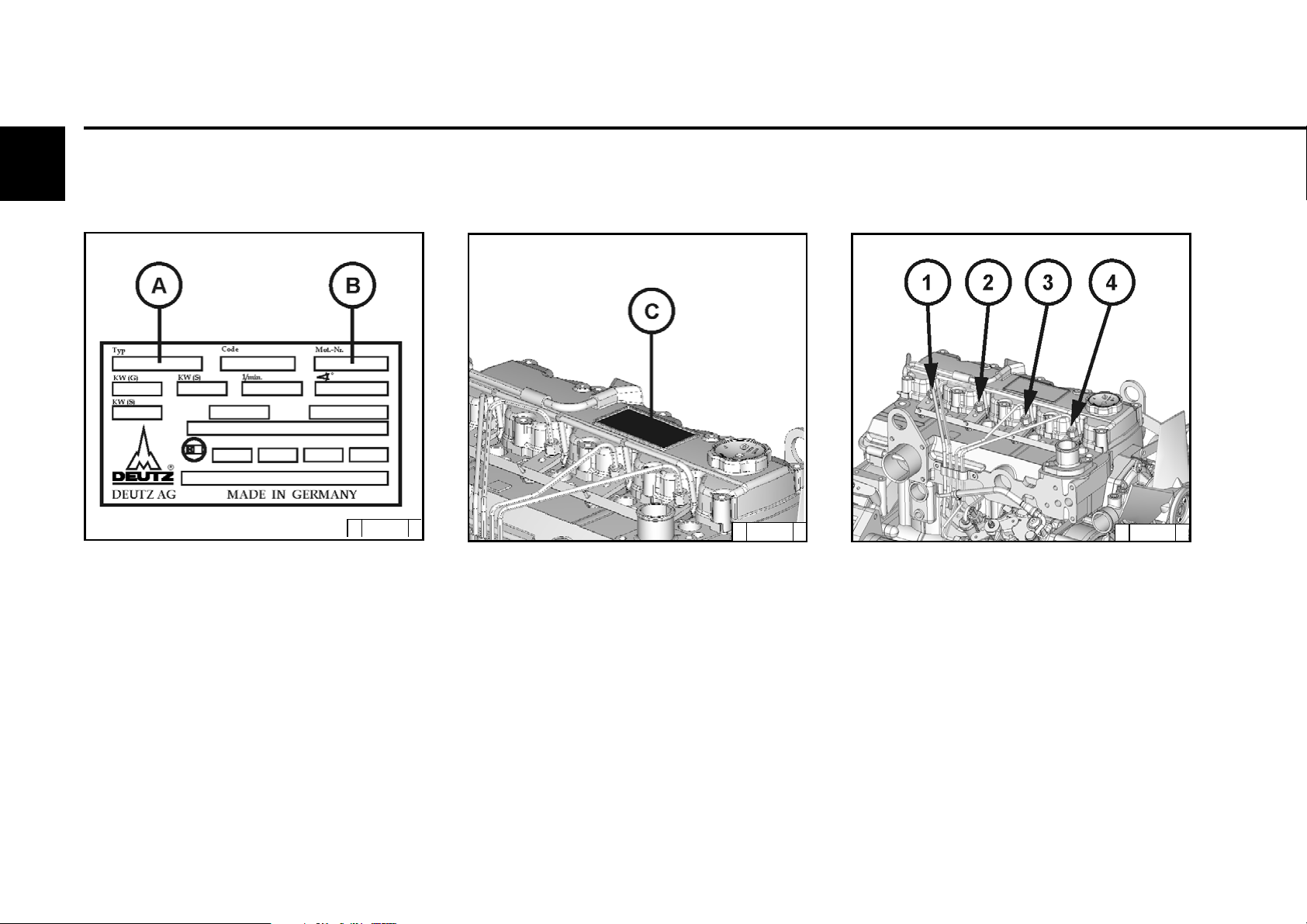

2.1.1 Company plate

© 43 870 0

The engine type A, engine number B and the

power data are stamped on the company plate.

The engine type and number must be stated

when purchasing spare parts.

2.1.2 Location of company plate

© 43 868 0

The company plate C is fixed to the valve

covering hood.

2.1.3 Cylinder numbering

© 43 869 0

The cylinders are counted consecutively,

starting from the flywheel.

© 2005

Page 11

2.1 Engine type

Engine description

2

© 2005

Page 12

2

Engine description

2.2.1 Operation side

Example: D 2008 L04

2.2 Engine illustration

1 Oil filler neck (valve cover)

2 Valve cover

3 Exhaust manifold

4 Fuel supply pump

5 Exchangeable fuel filter

6 Generator

7 Oil tray

8 Crankcase

9 Auxiliary drive possibility e.g. hydr. pump

10 Narrow V-belt

11 Exchangeable lube oil filter

12 V-belt pulley on crankshaft

13 Fan

14 Coolant pump, coolant inlet from cooler

15 Coolant outlet from engine to cooler

© 2005

© 43 862 0

Page 13

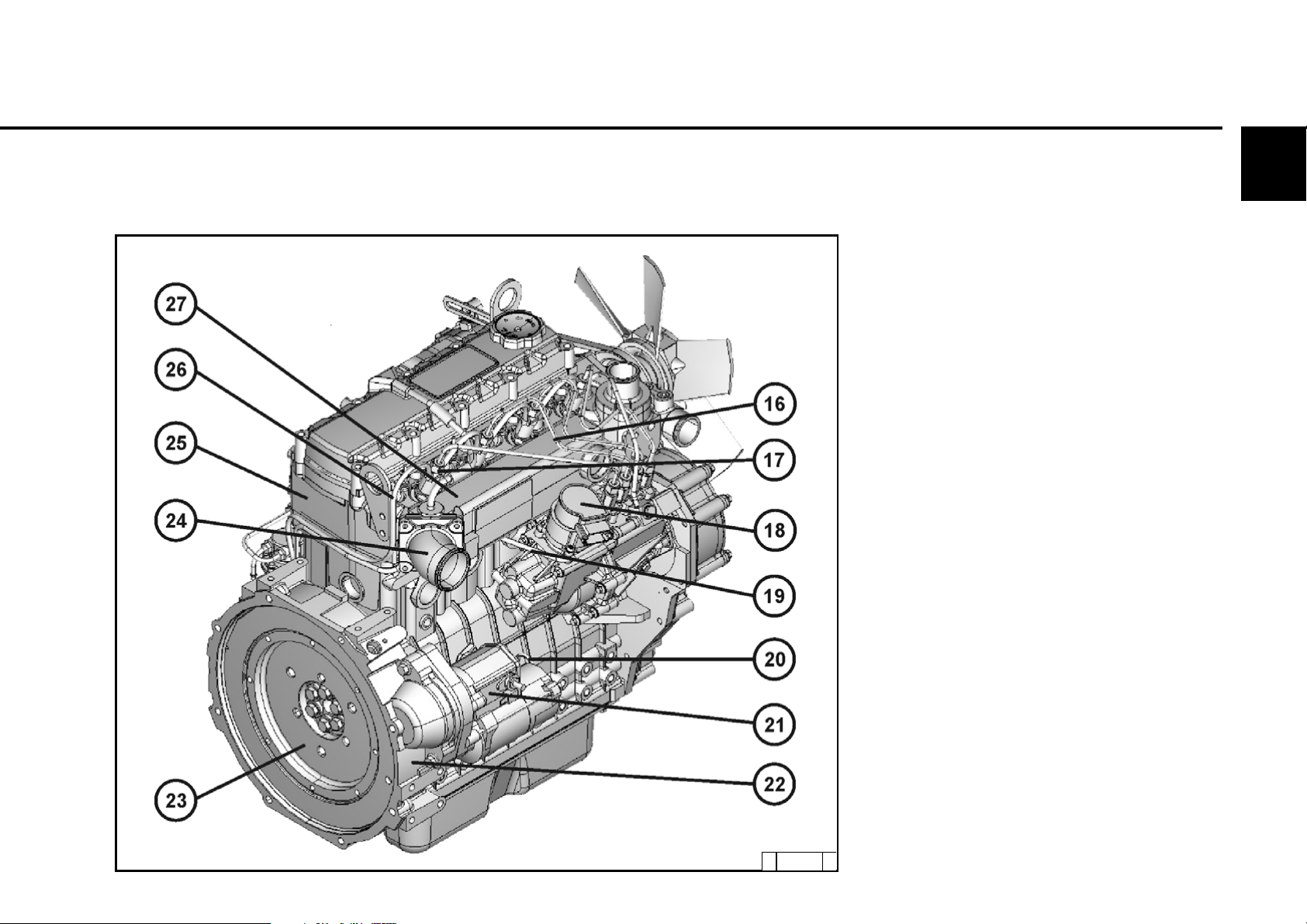

2.2 Engine illustration

2.2.2Exhaust side

Example: D 2008 L04

Engine description

2

16 Injection line

17 Injection valve

18 Speed governor

19 Injection pump

20 Oil dipstick

21 Starter

22 Connection housing (SAE)

23 Flywheel with gear rim

24 Air intake pipe

25 Crankcase

26 Fuel return line

27 Charge air manifold from air filter

© 43 863 0

© 2005

Page 14

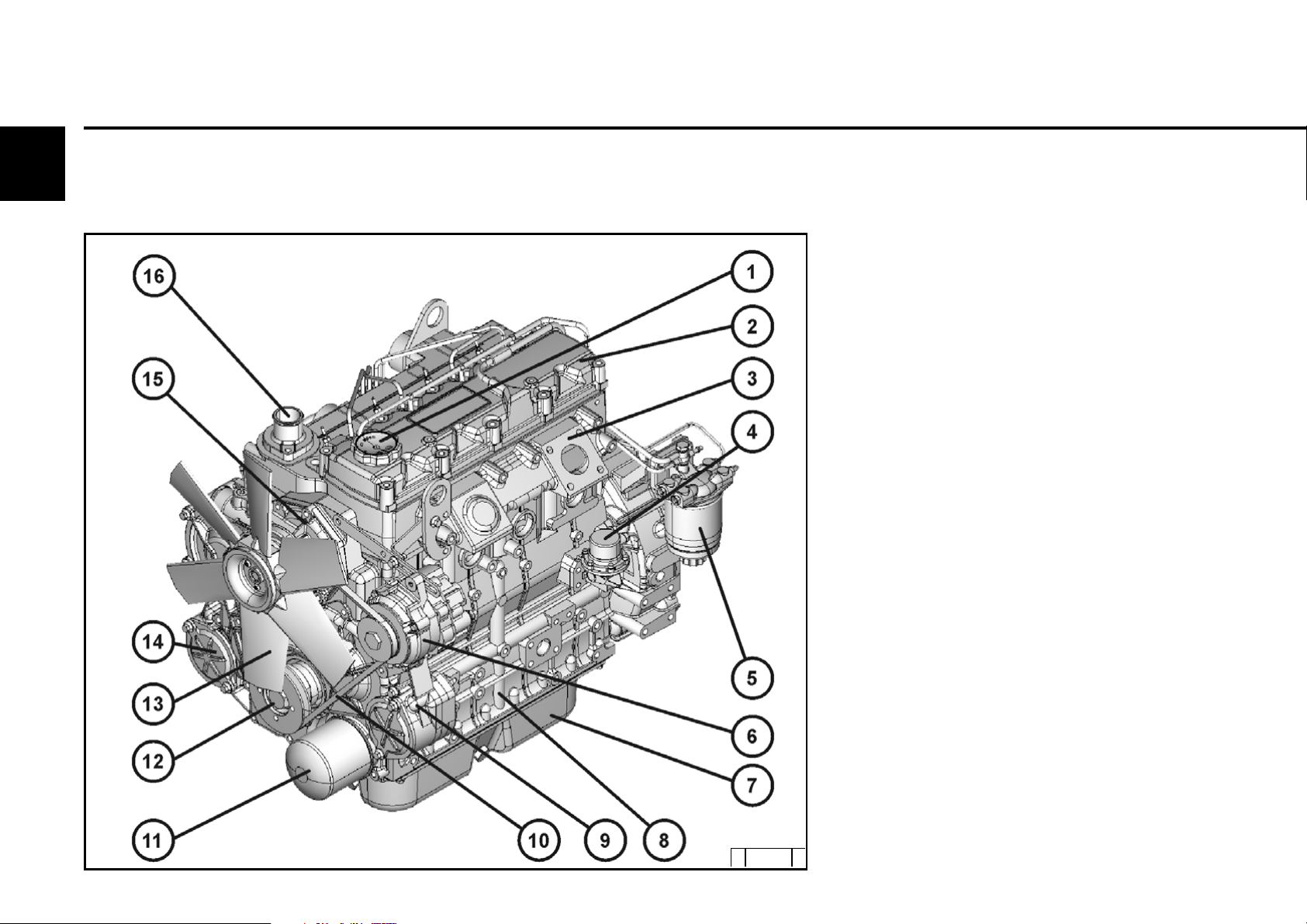

2

Engine description

2.2.3 Operation side

Example: D 2009 L04

2.2 Engine illustration

1 Oil filler neck (valve cover)

2 Valve cover

3 Exhaust manifold

4 Fuel supply pump

5 Exchangeable fuel filter with water

separator

6 Generator

7 Oil tray

8 Crankcase

9 Auxiliary drive possibility e.g. hydr. pump

10 Narrow V-belt

11 Exchangeable lube oil filter

12 Crankshaft drive flange

13 Fan

14 Auxiliary drive possibility e.g. hydr. pump

15 Coolant pump, coolant inlet from cooler

16 Coolant outlet from engine to cooler

© 2005

© 43 864 0

Page 15

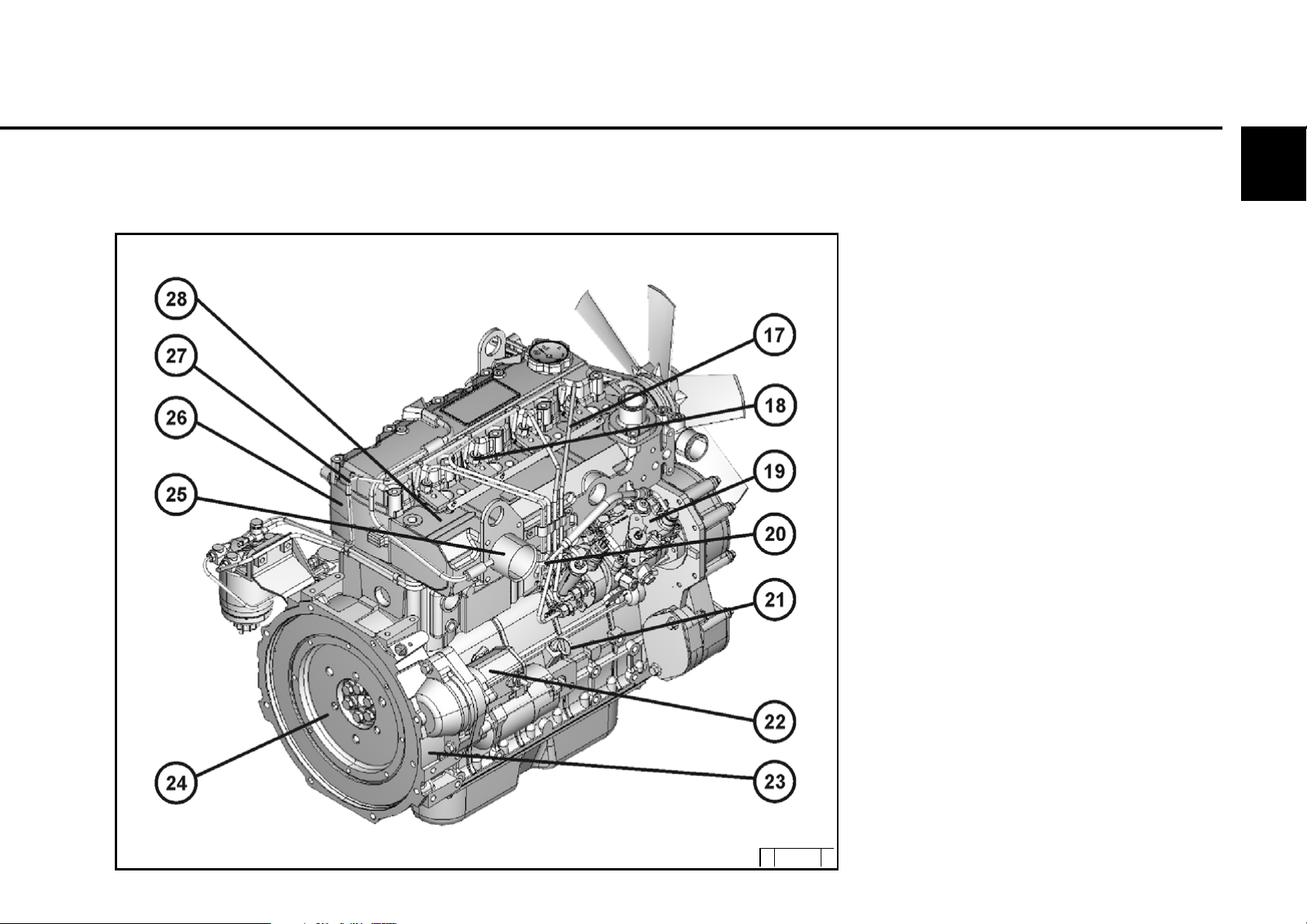

2.2 Engine illustration

2.2.4Exhaust side

Example: D 2009 L04

Engine description

2

17 Injection line

18 Injection valve

19 Speed governor/injection pump

20 Injection line

21 Oil dipstick

22 Starter

23 Connection housing (SAE)

24 Flywheel with gear rim

25 Air intake pipe

26 Crankcase

27 Fuel return line

28 Charge air manifold from air filter

© 43 865 0

© 2005

Page 16

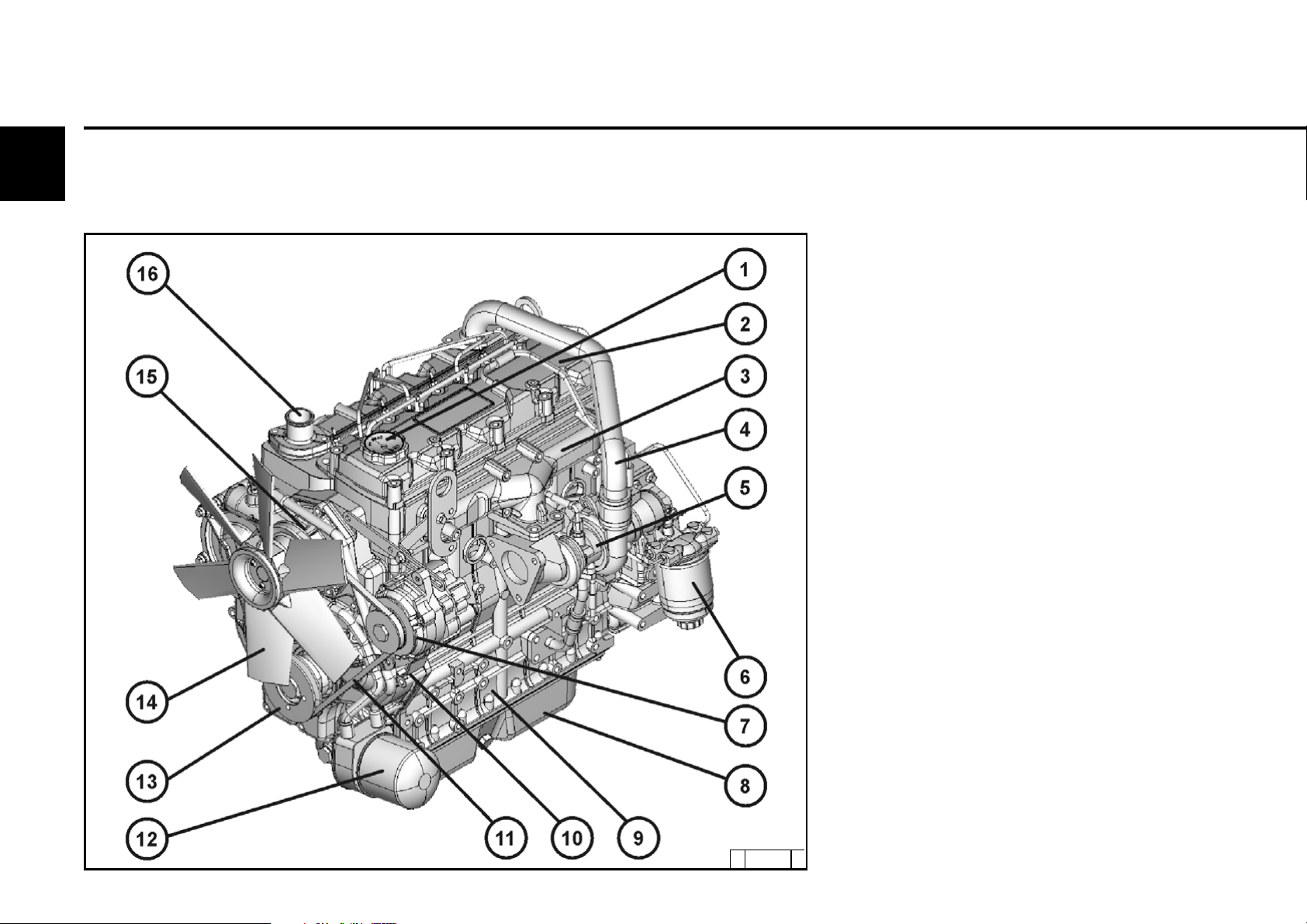

2

Engine description

2.2.5 Operation side

TD 2009 L04

2.2 Engine illustration

1 Oil filler neck

2 Valve cover

3 Exhaust manifold

4 Charge air line from turbocharger to

charge air manifold

5 Turbocharger

6 Exchangeable fuel filter with water

separator

7 Generator

8 Oil tray

9 Crankcase

10 Gearcase

11 Narrow V-belt

12 Exchangeable lube oil filter

13 V-belt pulley on crankshaft

14 Fan

15 Coolant pump, coolant inlet from cooler

16 Coolant outlet from engine to cooler

© 2005

© 43 866 0

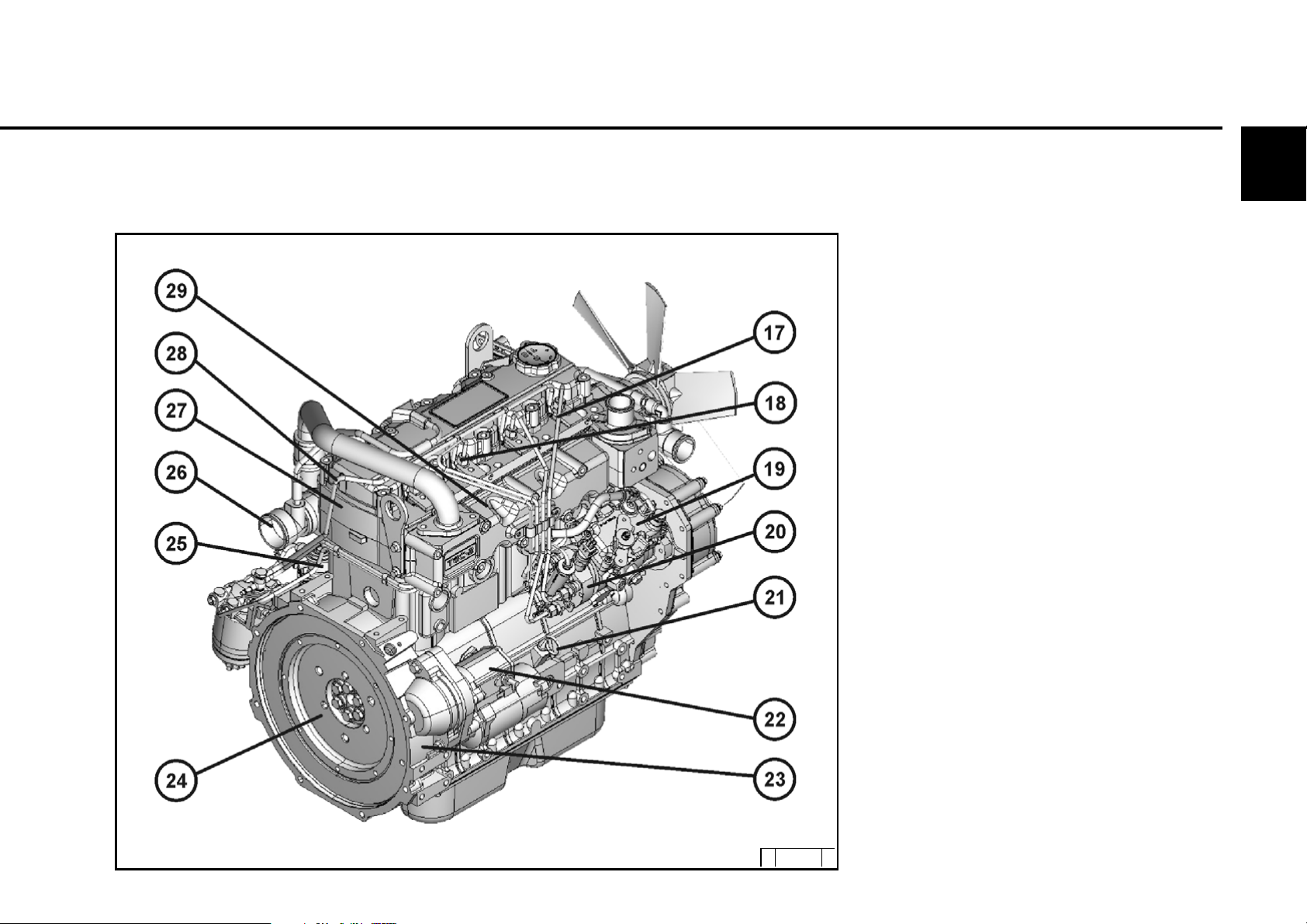

Page 17

2.2 Engine illustration

2.2.6Exhaust side

TD 2009 L04

Engine description

2

17 Injection line

18 Injection valve

19 Speed governor

20 Injection pump

21 Oil dipstick

22 Starter

23 Connection housing (SAE)

24 Flywheel with gear rim

25 Fuel supply pump

26 Air intake pipe from air filter

27 Crankcase

28 Fuel return line

29 Charge air manifold

©43 867 0

© 2005

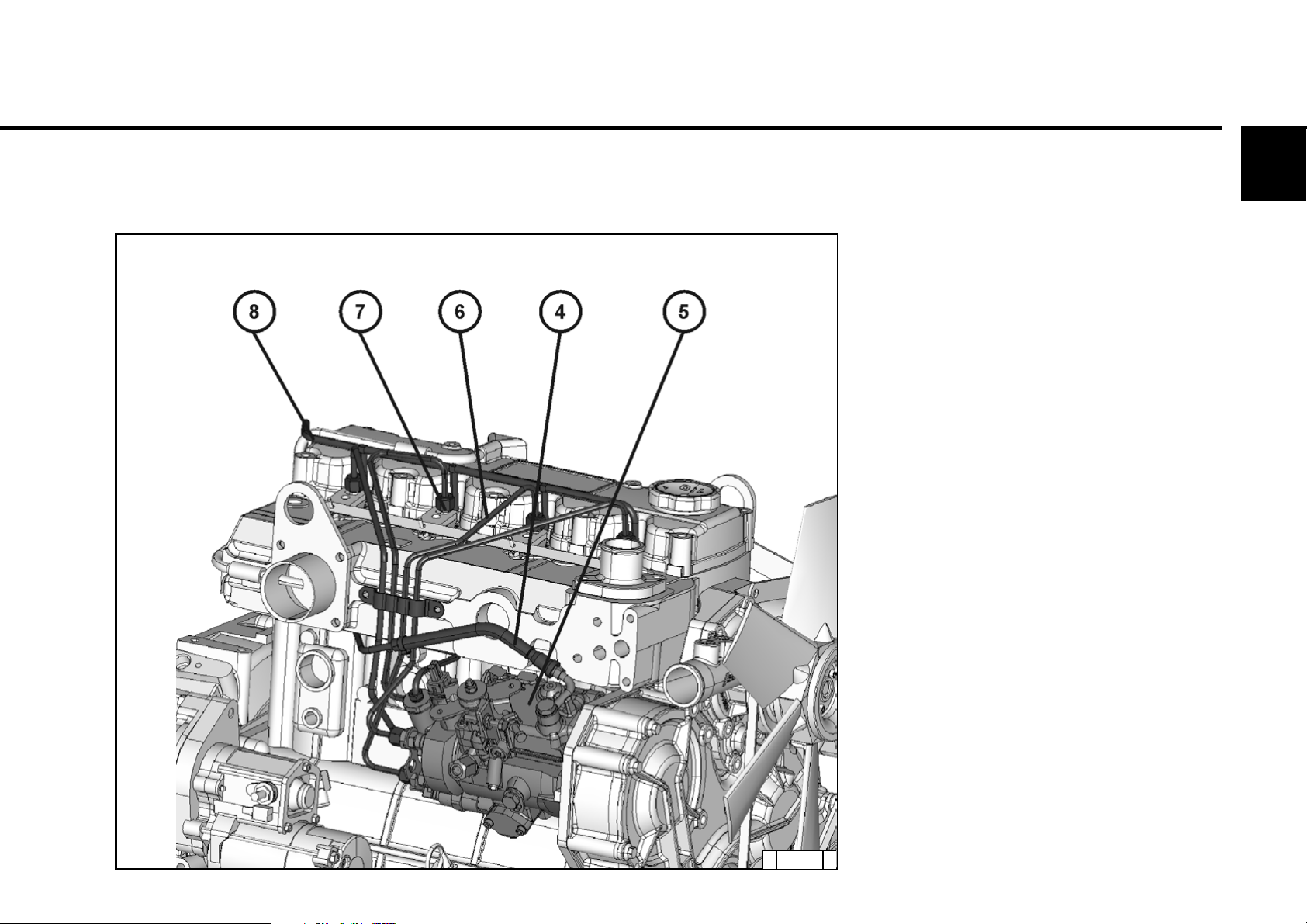

Page 18

2

Engine description

2.3.1 Fuel circuit

2.3 Fuel diagram

1 Fuel feed pump (connection line from

customer fuel container)

2 Fuel line from feed pump to fuel filter

3 Exchangeable fuel filter

© 2005

© 43 874 0

Page 19

2.3 Fuel diagram

Engine description

2

4 Fuel line from filter to injection pump

5 Injection pump

6 Injection line to injection valve

7 Injection valve

8 Fuel return line to customer fuel container

©43 873 0

© 2005

Page 20

3.1 Initial commissioning

3.2 Starting

3.3 Operation monitoring

3.4 Switching off

3.5 Operating conditions

Operation

3

© 2005

Page 21

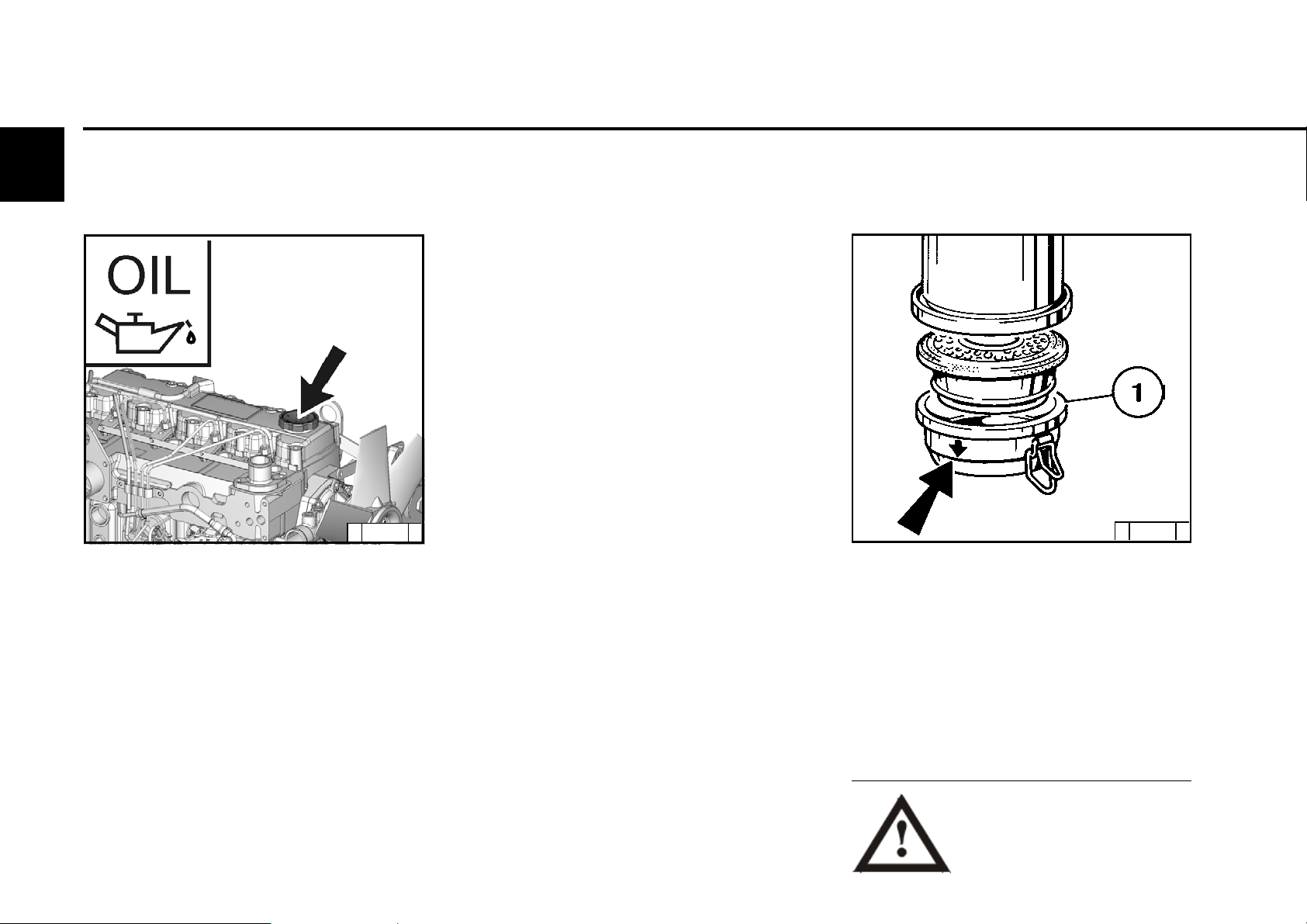

Operation 3.1 Initial commissioning

3

3.1.1 Engine oil filling

© 43 871 0

The engines are generally supplied without

oil filling.

Fill the engine with lube oil via the oil filler neck

(A).

For quality and viscosity of oil see 4.1.

3.1.1.1 Initial engine oil filling

z Fill the oil tray with oil up to the marking

"Max" on the oil dipstick (for oil filling

quantities see 9.1).

z Start the engine and run at a low idling

speed for approx. 2 minutes.

z Switch off the engine

z Check the oil level. If necessary, fill with oil

up to upper "Max" line marking.

3.1.2 Filling oil bath air filter with

engine oil

© 24 980 2

Fill the oil pan 1 of the oil bath air filter with

engine oil up to the arrow marking.

For quality and viscosity of oil see 4.1.

© 2005

Do not pour oil into the dust

collecting tank of the preseparator, if there is one

present.

Page 22

L

3.1 Initial commissioning Operation

3.1.3 Initial coolant filling

with cooler

z Fill honeycomb cooler with coolant up to

the marking " Max ".

z Also fill the supply hoses and the external

honeycomb cooler to coolant capacity (per

manufacturer specifications).

z Allow the engine to warm up until the

thermostat has opened (at approx. 86-90

°C ).

z Leave the engine running for approx. 2

minutes.

z Switch off the engine

z Check the oil level. If necessary, fill with

coolant up to upper " Max " line marking.

3.1.4 Fuel filling

3

FUE

© 26 398 0

Only use standard branded diesel fuel. For fuel

quality see 4.2. Depending on the outside

temperature, use either summer or winter diesel

fuel.

If the engine is not warmed up following

the initial filling, the oil level will be above

the "Max" marking on the oil dipstick.

Therefore, it is only possible to assess the

oil level after the warm up.

Only re-fuel when the engine is

not running!

Pay attention to cleanliness!

Do not spill any fuel!

© 2005

Page 23

Operation 3.1 Initial commissioning

3

3.1.5 Other preparations

z Check battery and cable connections,

see 6.6.1.

z Transportation eyelets

If installed, remove, see 6.6.3

z Trial run

After preparations carry out a short

trial run of approx. 10 min. Do not apply

load to the engine in doing this.

Work during and after the trial run

- Check engine for tightness.

z With engine not running

- Check oil level, see 6.1.2, if necessary

re-fill oil, see 3.1.1

- Check coolant level, see 3.1.3

- Re-tighten V-belts, see 6.5

z Running-in

It is recommended to check the oil level twice

a day during the running-in phase

(approx. 200 oh). After the running-in phase

checking once a day is sufficient.

3.1.6 Additional maintenance work

The following additional maintenance work is

to be carried out for the commissioning of

new and overhauled engines:

After 50-150 oh

z Change lube oil,

see 6.1.2

z Change oil filter cartridge,

see 6.1.3

z Change fuel filter cartridge,

see 6.2.1

z Check V-belt tension, if necessary

re-tighten, see 6.5.

z Check engine for tightness (leakages).

z Check engine bearing, re-tighten if

necessary.

© 2005

Page 24

3

© 2005

Page 25

Operation 3.2 Starting

3

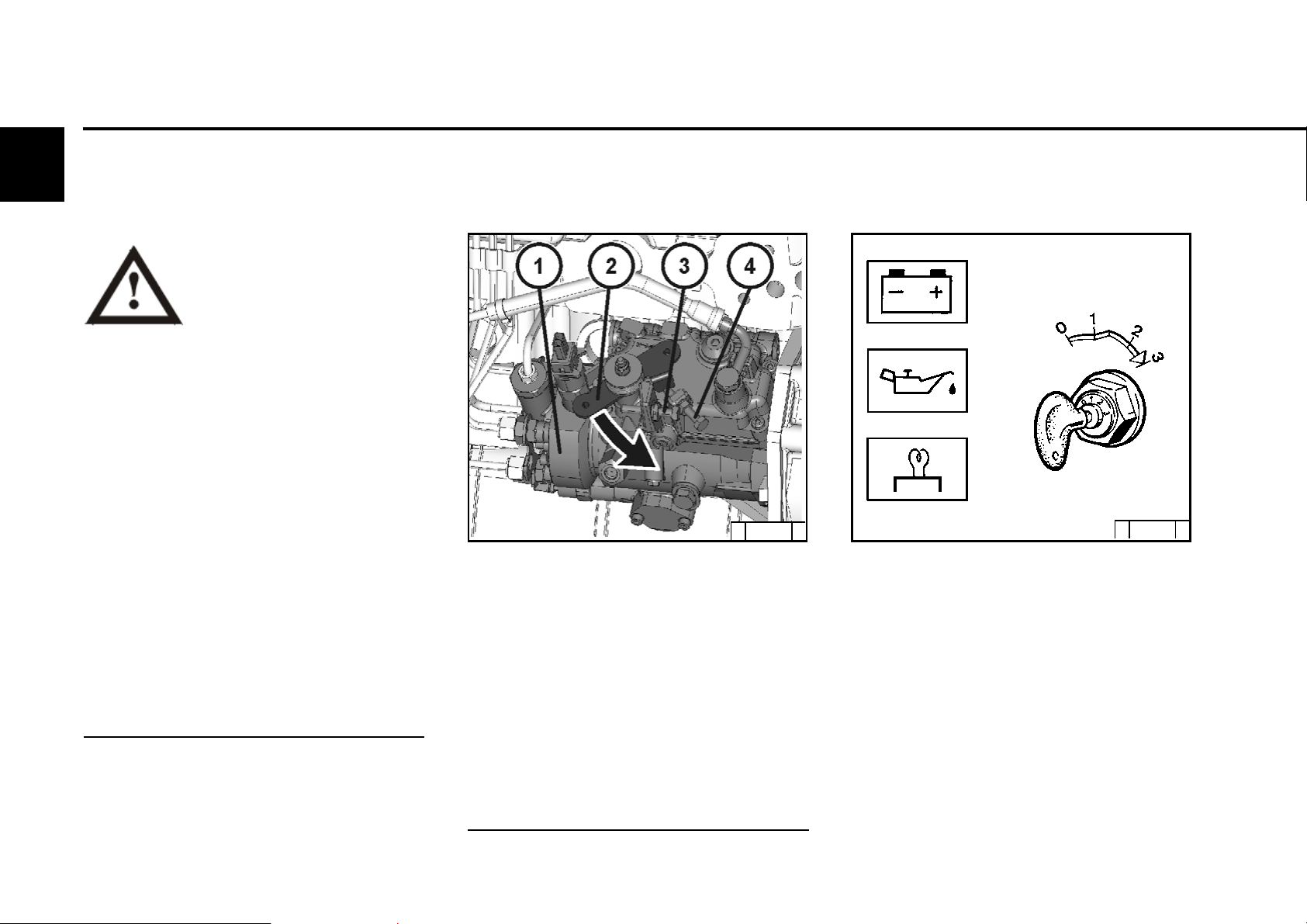

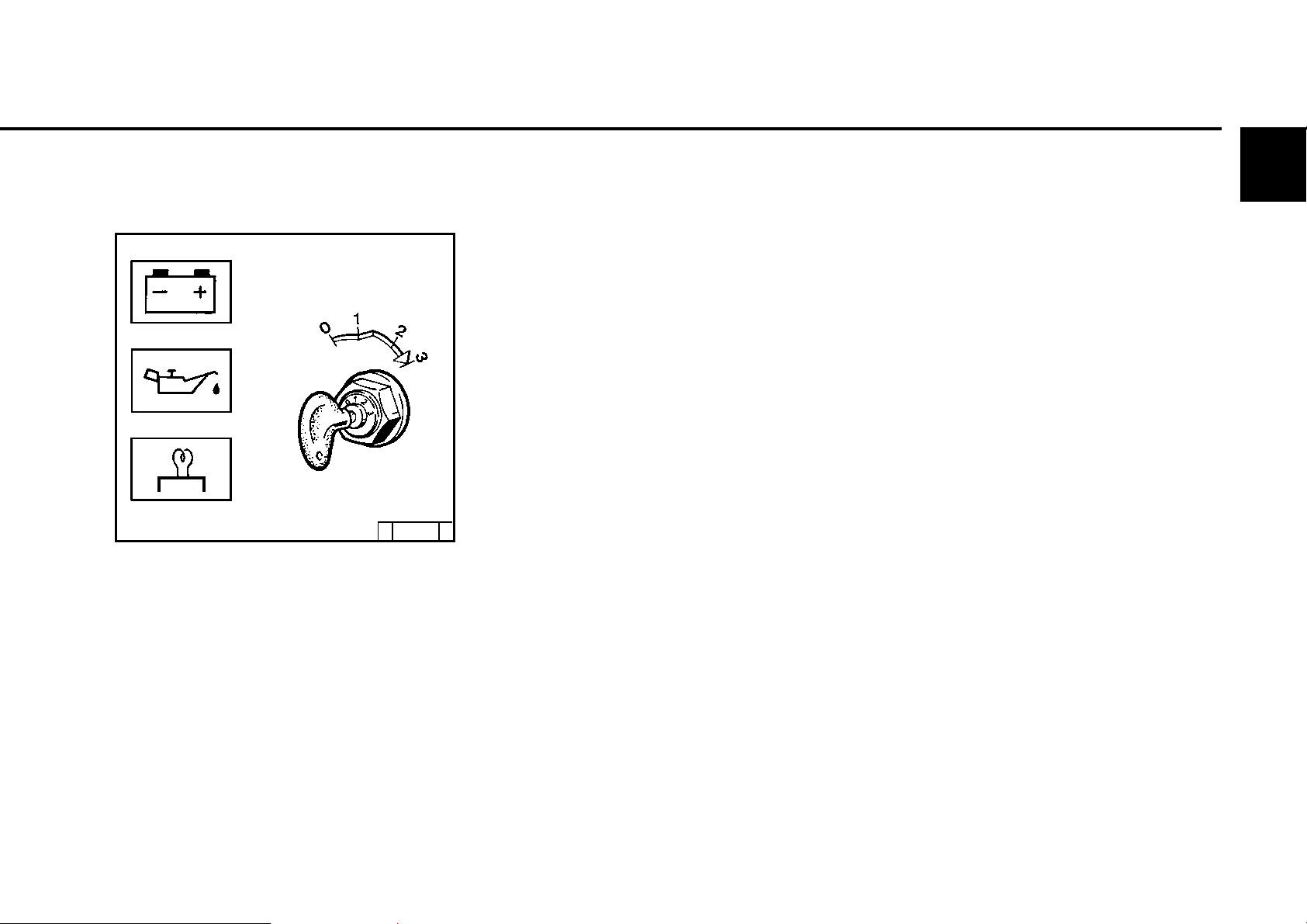

3.2.1 Electrical starting

Before starting make sure that

there is nobody in the engine /

work machine danger area.

After repairs:

Check that all protective

equipment has been mounted

and all tools have been removed from the

vehicle.

When starting with heating flange do not use

any additional starting devices (e.g. injection

with start pilot). Danger of accidents!

Caution: Under no circumstances may the

engine be tested with a dismantled speed

governor:

Separate battery connections!

In cold ambient temperatures warm-up the

engine first - do not operate it straight away at

full load!

Start the engine for a maximum of 20 seconds

uninterrupted. If the engine does not start up, wait

for one minute and then repeat the starting

process.

If the engine does not start up after two starting

processes determine the cause as per fault table

(see 7.1).

© 2005

© 43 882 0

z Separate engine from devices which it powers,

by decoupling, as far as possible.

z Bring the speed adjustment lever 1 to the idling

position (idling setting screw 4).

z Bring the shutdown lever 2 to operating position

(direction of arrow, 3 max. speed stop).

Note: Setting screws 3+4 are factory set and

may not be changed

without cold start aid

© 25 746 2

z Insert key.

- Step 0 - no operating voltage

z Turn key to the right.

- Step 1 = operating voltage

- Warning lights light up

z Push in the key and turn further to the

right against the spring load

- Step 2 = without function

- Step 3 = start

z Release key as soon as the engine

starts up

- Warning lights go out

Page 26

3.2 Starting Operation

with cold start aid

- heating flange

©25 746 2

z Insert key.

- Step 0 = no operating voltage

z Turn key to the right.

- Step 1 = operating voltage

- Warning lights light up

z Push in the key and turn further to the right

against the spring load

- Step 2 = pre-heating, hold for approx. one

minute

- Pre-heating light lights up

- Step 3 = start

z Release key as soon as the engine starts up.

- Warning lights go out

3

© 2005

Page 27

Operation 3.3 Operation monitoring

3

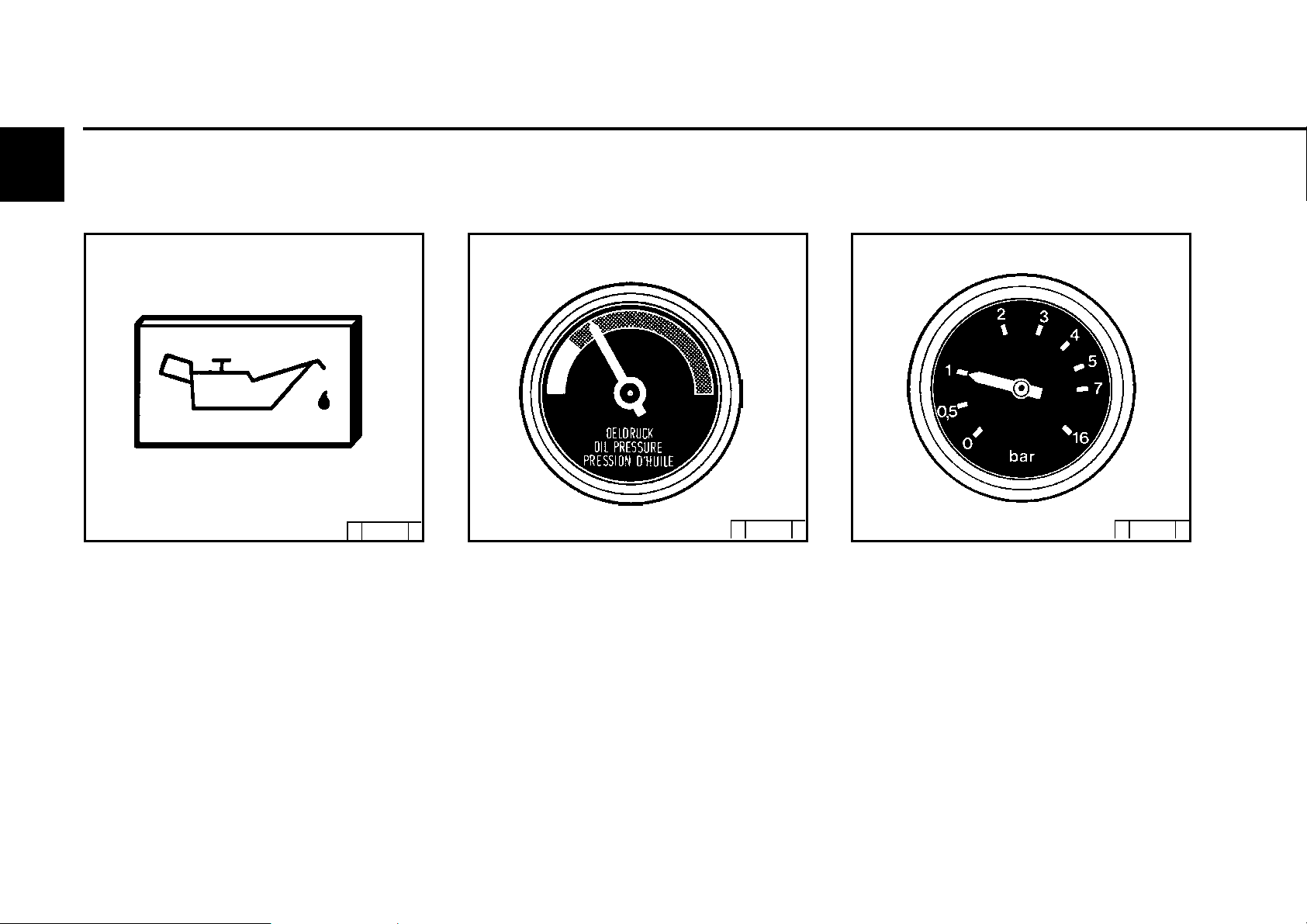

3.3.1 Engine oil pressure

Oil pressure warning light

© 25 752 1

z Oil pressure warning light lights up when

operating voltage is switched on, and when

the engine is not running.

z Oil pressure control light must be extinguished

during engine operation.

Oil pressure display

© 25 753 0 © 25 754 0

z Needle must be in the green field in the total

operating range.

Oil pressure gauge

z Needle of oil pressure measuring instrument

must indicate the minimum oil pressure (see

9.1).

© 2005

Page 28

3.3 Operation monitoring Operation

3.3.2 Engine temperature

Temperature display

©24 985 0

z The needle of the temperature display should

always be in the green area, and only as an

exception in the yellow/green area. If the

needle rises into the orange area the engine is

getting too hot. Switch off the engine and

determine the cause as per fault table (see

7.1).

3

© 2005

Page 29

Operation 3.4 Switching off

3

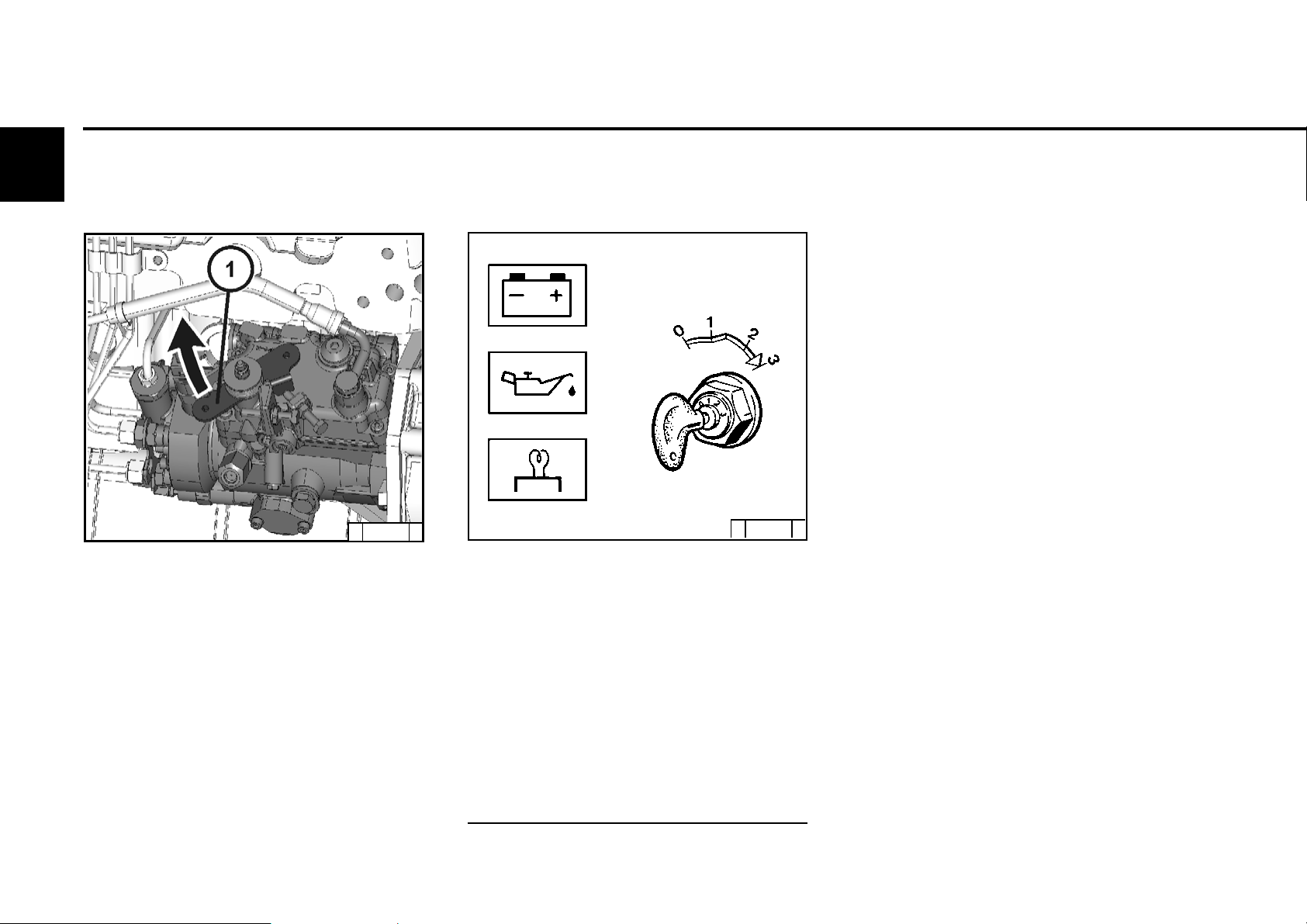

3.4.1 Mechanical switching-off

© 43 872 2

z Position the speed adjustment lever 1 to low

speed.

z Turn the speed adjustment lever 1 in the

direction of the arrow until it reaches idle stop.

Charge warning light and oil pressure warning

light light up after the engine has not been

running.

z Turn the key to the left (to step 0) and remove.

Warning lights go out

3.4.2 Electrical switching off

(ignition key)

© 25 746 0

z Turn the key to the left (to step 0) shutdown

magnet switches the engine off and remove.

Warning lights go out

© 2005

If possible, do not suddenly switch-off engine

from full-load operation.

Page 30

3.5 Operating conditions Operation

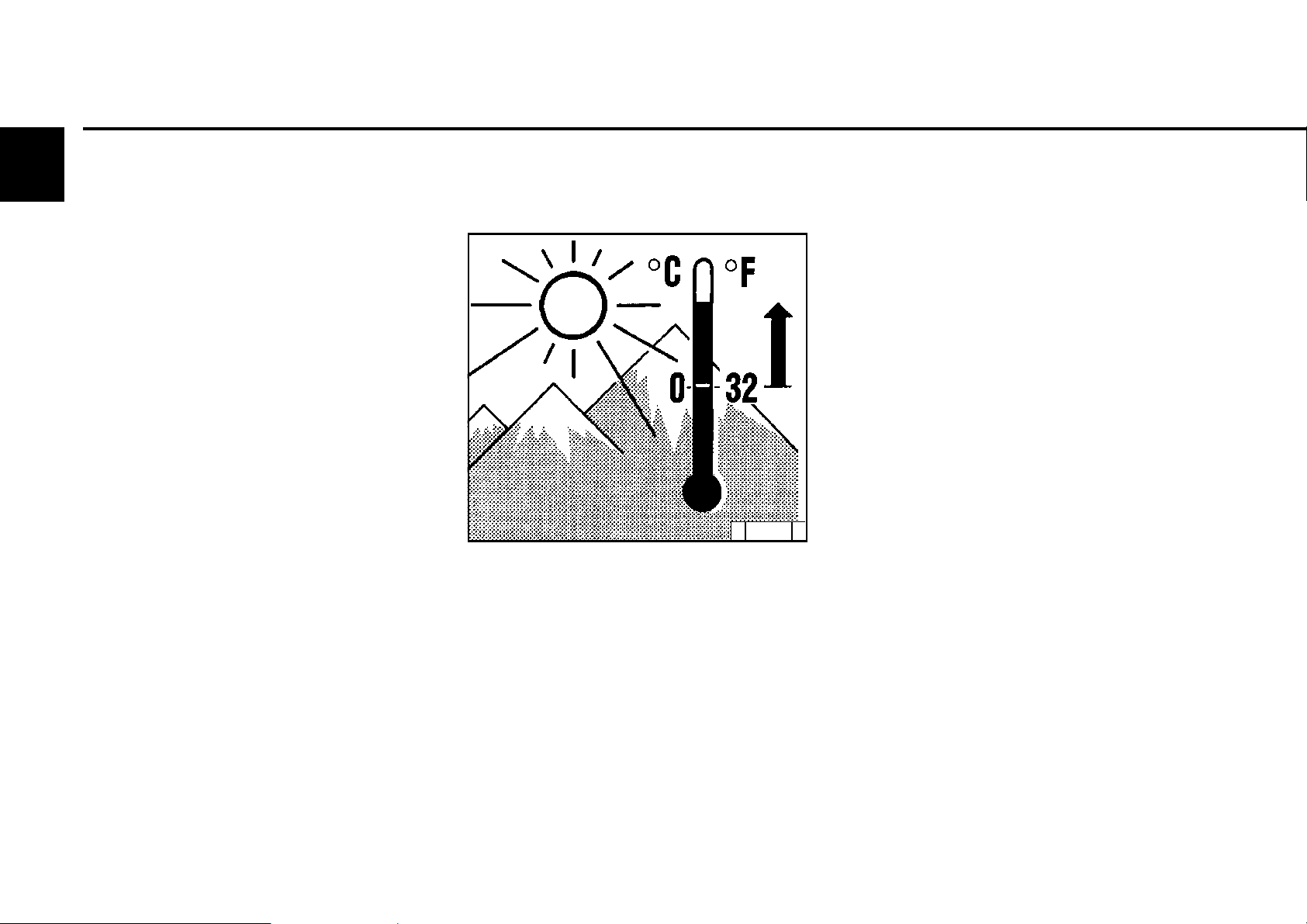

3.5.1 Winter operation

z Lube oil viscosity

- Select the viscosity (SAE class) according

to ambient temperature when starting the

engine, see 4.1.2.

- Observe shorter oil change times when

operating under -10 °C, see 6.1.1.

z Diesel fuel

- Under 0 °C use winter fuel, see 4.2.2.

z Additional maintenance work

- Drain the liquid sludge from the fuel container

weekly. (Loosen the sludge bleed screw)

- If necessary, adjust the oil filling of the oil bath

air filter and engine oil to the outside

temperature.

- At temperatures under -20 °C, possibly after

the starter has slowed-down, occasionally

lubricate the gear rim on the flywheel with

cold resistant grease through the pinion hole.

(e.g. Bosch grease FT 1 V 31).

3

z Battery

- A well charged battery is a prerequisite

for a good cold start, see 6.7.1.

- Heating the battery to approx. +20 °C

(dismantle and store in a warm room) lowers

the starting limit temperature by 4-5 °C.

© 26 248 0

z Cold start aids

- When there is a frost, start the engine with

heating flange if necessary, see 3.2.1.

This does not only lower the starting limit

temperature, but also eases starting at

temperatures which do not actually require

a starting aid.

© 2005

Page 31

3

Operation 3.5 Operating conditions

3.5.2 High ambient temperature

high altitude

z When the altitude or ambient temperature

increases, the air density decreases. This

impairs the maximum engine performance,

exhaust quality, temperature level and, in extreme cases, the starting performance. For

transient operation, usage up to 300 m and

25 °C is permissible. When using the engine

under adverse conditions (high altitude or high

temperatures) it is necessary to reduce the

amount of fuel injected and with it the engine

power.

z In case of doubt regarding engine usage, ask

your engine or equipment supplier whether

necessary fuel stop reduction has been carried

out in the interest of operational safety, service

life and exhaust quality (smoke), or contact

your DEUTZ SERVICE.

© 25 901 1

© 2005

Page 32

4.1 Lube oil

4.2 Fuel

4.3 Coolant

Operating substances

4

© 2005

Page 33

Operating substances 4.1 Lube oil

4

4.1.1 Quality

Lube oils are classified by Deutz according

to their performance capability into quality

classes. Oils according to other comparable

specifications can be used.

Recommended oils:

Deutz DQC II DQC I II *+DQC IV

ACEA E3-96/E5-02/ E4-99/

E7-04 E6-04

API CH-4/CG-4 -

CI -4

DHD DHD-1

DQC III * see chap. 6.1.1.2

DQC IV

The exact assignment of permissible oil quality

and oil change intervals is listed in chapter

6.1.1.

#

only fully synthetic oils

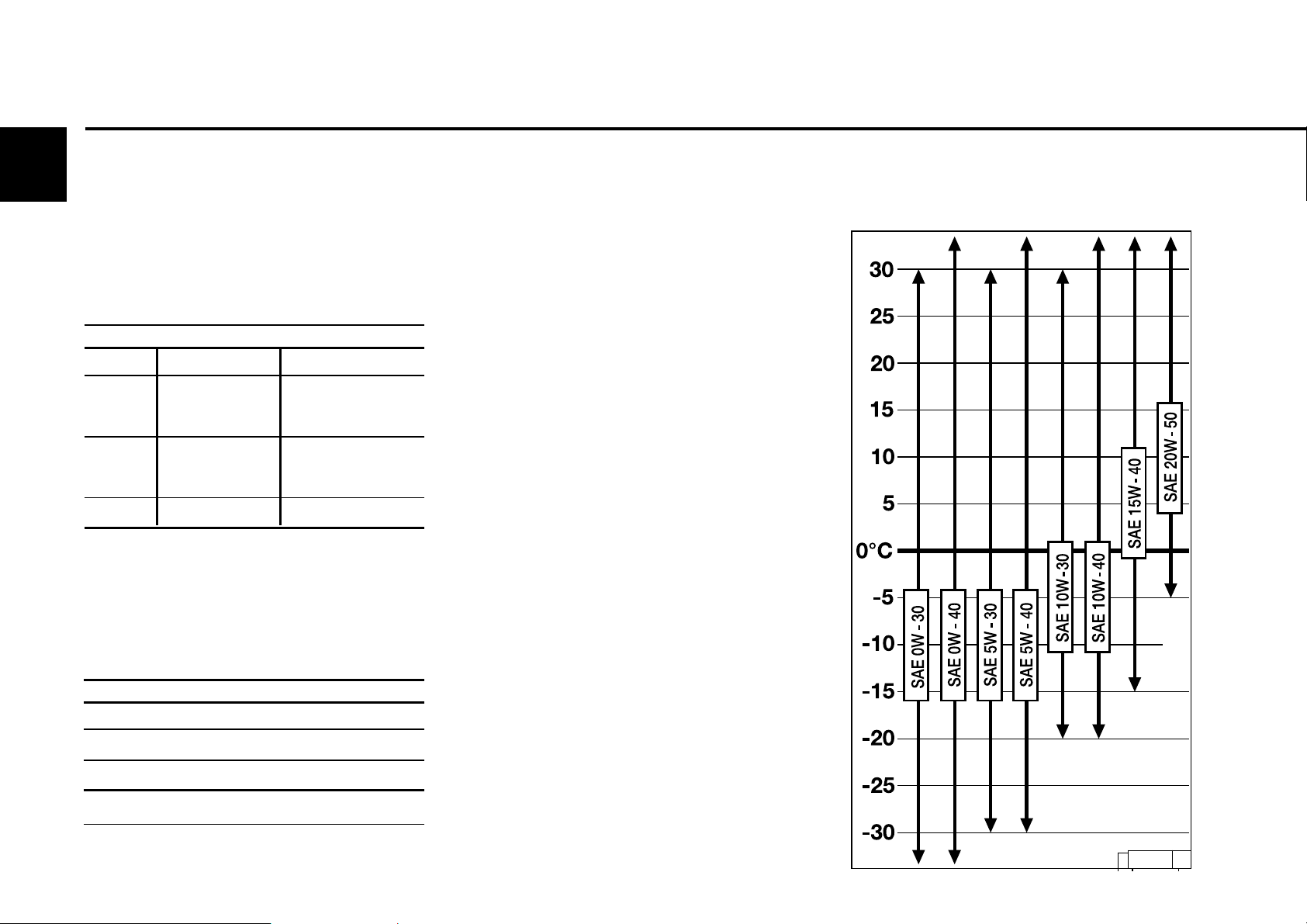

4.1.2 Viscosity

Generally, multi-viscosity oils are should be

used. Single-viscosity oils can also be used

in enclosed, heated spaces at temperatures

>5° C.

Since lube oil changes its viscosity (viscidity)

#

depending on temperature, the ambient

temperature of the location of engine operation

is decisive for the selection of viscosity class

(SAE class).

Refer to the oil viscosity diagram on the right

to achieve optimal operating proportions.

Falling below the temperature limits

occasionally can impair the cold starting ability,

but will not lead to engine damages.

In order to minimise wear, the operating limits

should not be exceeded over a long period of

time.

Synthetic lube oils are advantageous due to

their greater temperature and oxidisation

stability.

Minimum requirement:

Deutz DQC I

ACEA E2-96

API CF/CF-4

*For oil change intervals see 6.1.1

For oil filling amounts see 9.1

© 2005

only with pre-heating

30 298 1

© 30 298 1

Page 34

4.2 Fuel Operating substances

4.2.1 Quality

Use standard diesel fuels with a sulphur content

of less than 0.5 %. If the sulphur content is higher,

the oil change intervals must be reduced (see

6.1.1).

The following fuel specifications are

permitted: (see TR 0199-99-3005)

The Technical Circular provides details on

fuel specifications and can be obtained from

the DEUTZ Service Organisation.

● Diesel fuel

- EN 590

- ASTM D 975-88 grade no. 1-D and 2-D

- NATO code F-54

- JIS K2204 grade 1 and 2

●●

● Light fuel oils

●●

- DIN 51603

- ASTM D 396 grade no. 1 and 2

- BS 2869 class A 2

The certification measurements for the

observance of legal emission limits are carried

out with the test fuels defined by legislation.

These correspond with the diesel fuels

described in section 1 in accordance with D

EN 590 and ASTM D 975. Emission values

cannot be guaranteed with the other fuels

described in this circular

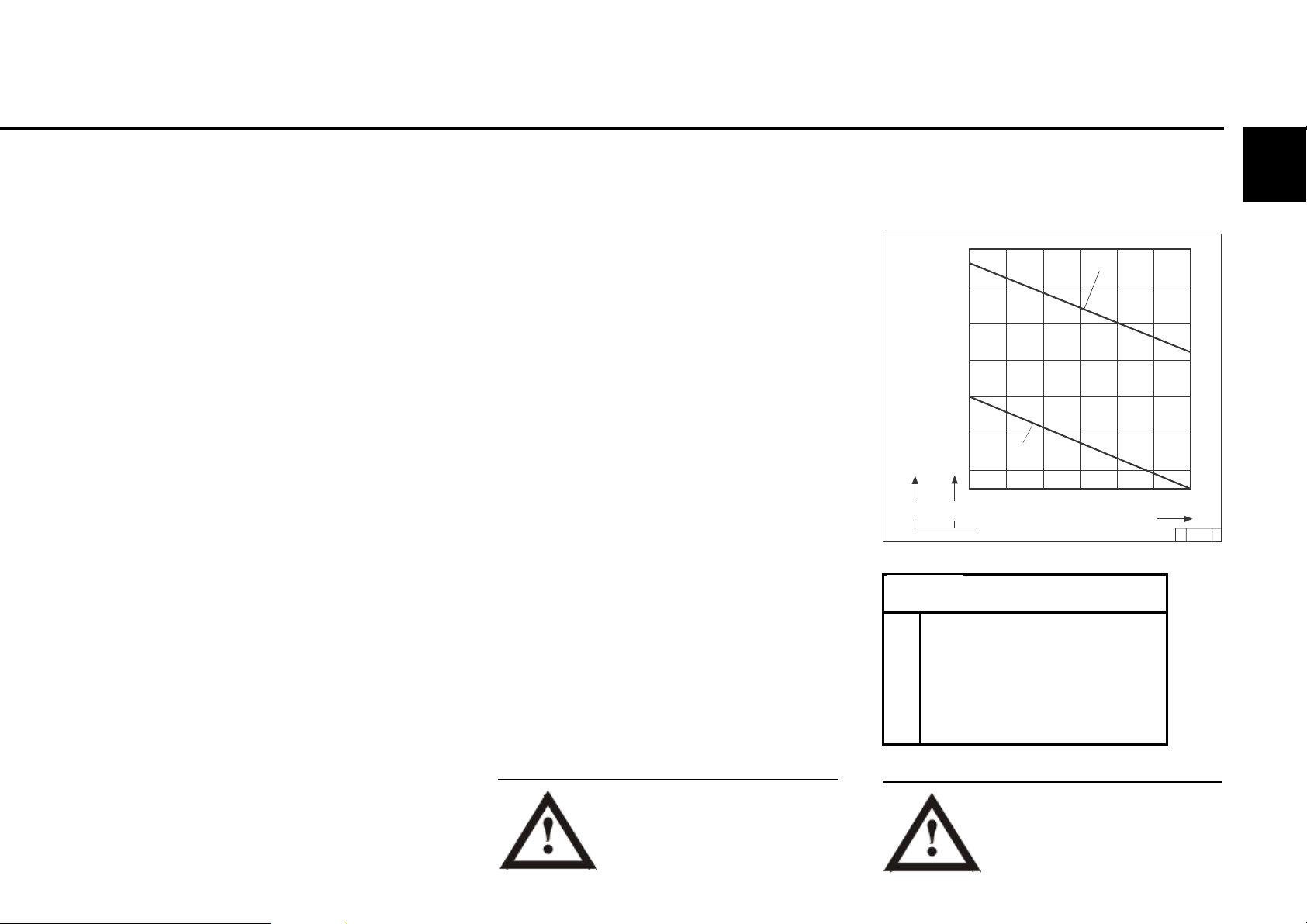

4.2.2 Winter fuel

At low temperatures paraffin discharges

can lead to blockages in the fuel system and

cause operating faults. Use winter fuel at

outside temperatures under 0 °C (to -15 °C)

(generally offered by petrol stations in good

time before the cold season begins).

Frequently it is possible to buy diesel fuel with

additives, which has an operational

temperature of up to approx. -20 °C ("Super

diesel“).

● Paraffin should be added at temperatures

below -15 °C or -20 °C. The mixing ratios

required are as per the diagram on the right.

Íf it is necessary to use summer diesel fuel

under 0 °C, paraffin can also be added by up

to 60% as per the diagram on the right.

Generally, sufficient resistance to cold can

also be achieved by adding a flow ameliorant

(fuel additive). For questions regarding this

please contact your DEUTZ Service

Diesel fuels must never be

mixed with petrol (normal and

super)!

+32

+23

+14

+ 5

- 4

- 13

- 22

°F

0

I

- 5

- 10

- 15

- 20

- 25

II

- 30

0 10 20 30 40 50 60 %

°C

A

Diagram key:

I Summer diesel fuel

I I Winter diesel fuel

A Outside temperature

B Paraffin mixing proportion

Only carry out mixing in the

tank! First pour in the necessary

amount of paraffin, then the

diesel fuel.

4

B

' 26441 1

© 2005

Page 35

Operating substances 4.3 Coolant

4

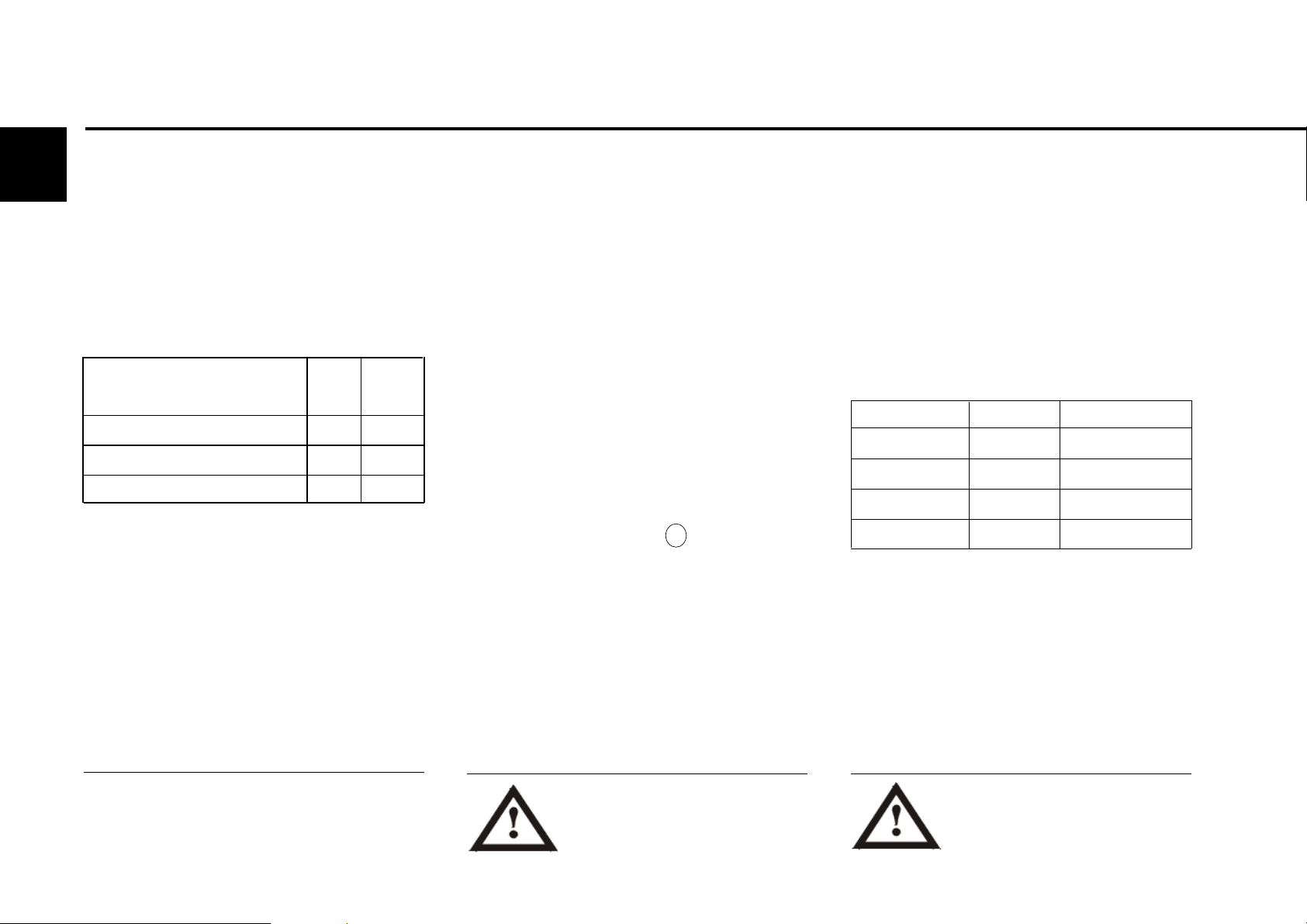

4.3.1 Water quality for coolant

The water may not fall short of or exceed the

following values.

A test case can be requested from DEUTZ

Service under the order no. 1213 0382 for

checking your water quality.

Analysis values min. max.

ph value at 20 °C 6.5 8.5

Chloride ion content[mg/dm3] - 100

Sulphate ion content[mg/dm3] - 100

Total hardness [°dGH] 3 20

* Carbonate hardness proportion of total

hardness min 3 dGH

4.3.2 Coolant preparation

Particular attention should be paid to preparing

and inspecting the coolant in liquid-cooled

engines, as otherwise corrosion, cavitation

and freezing damages can occur on the

engine.

Preparation of the coolant involves mixing a

cooling system preservative to the cooling

water.

The cooling system must be monitored

regularly, see 5.1. This includes checking the

concentration of the cooling system

preservative, as well as inspecting the coolant

level.

The inspection of the concentration of cooling

system preservative can be carried out with

standard testing devices.

(Example: gefo glycomat R ).

4.3.3 Cooling system preservative

Using the cooling system preservative, order

no. 01011490/ 01016416/12211500 (nitrite,

amine and phosphate free, available in 5/ 20/

210 litre containers), provides effective

protection against corrosion, cavitation and

freezing.

The cooling system preservative in the coolant

must not fall below or exceed the following

concentrations:

Cooling system Water Cold protection

prot.proportion proportion to

min. 35 % 65% -22 °C

40 % 60% -28 °C

max. 45 % 55% -35 °C

For filling amounts see the table overleaf in

combination with the information in chapter

9.1.

The use of other cooling system preservatives, e.g. chemical corrosion preservatives,

is possible in exceptional cases, consult

DEUTZ Service.

Contact your local waterworks for information

regarding the water quality.

© 2005

Mixing cooling system

preservatives of a nitrite

basis with substances of an

amine basis forms harmful

nitrosamines.

Order the cooling system preservative from:

DEUTZ AG

Cooling system preservatives

must be disposed of in an

environmentally friendly manner.

Page 36

Maintenance

5.1 Maintenance schedule

5.2 Standard maintenance schedule

5.3 Maintenance diagram

5.4 Maintenance work carried out

5

© 2005

Page 37

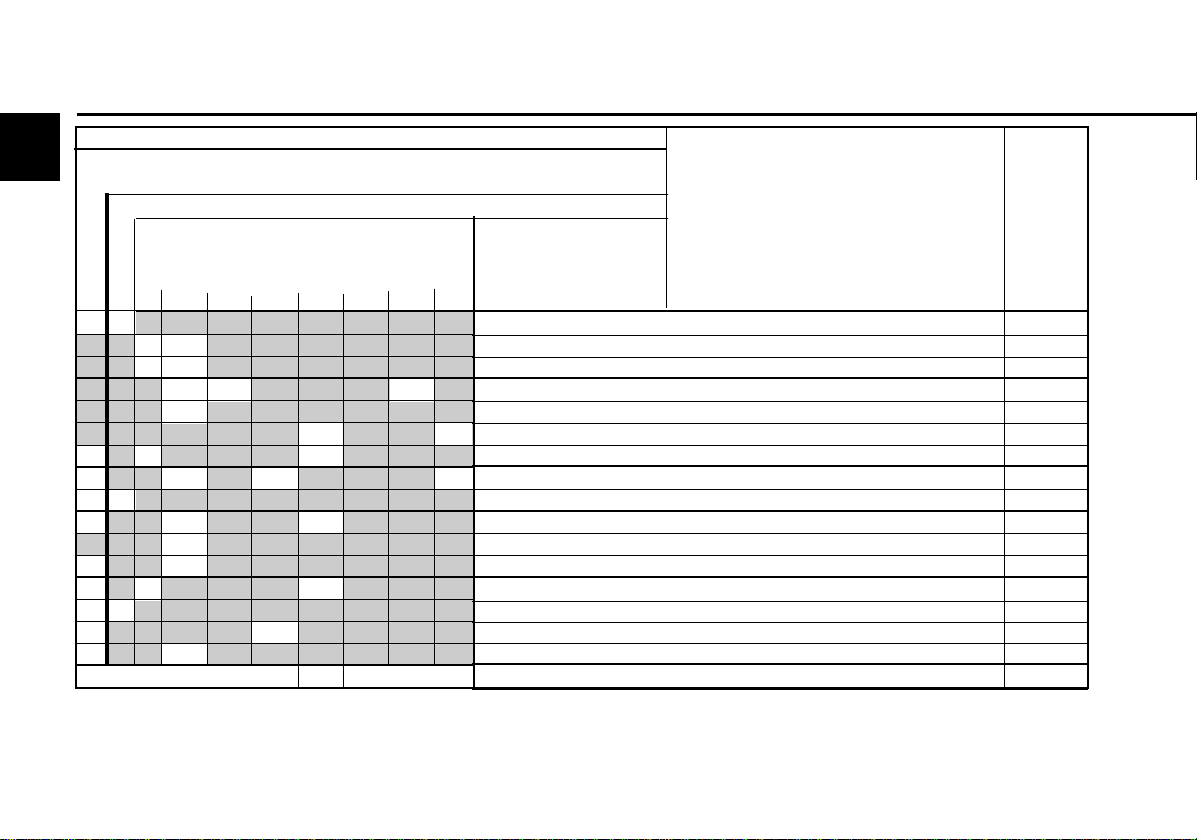

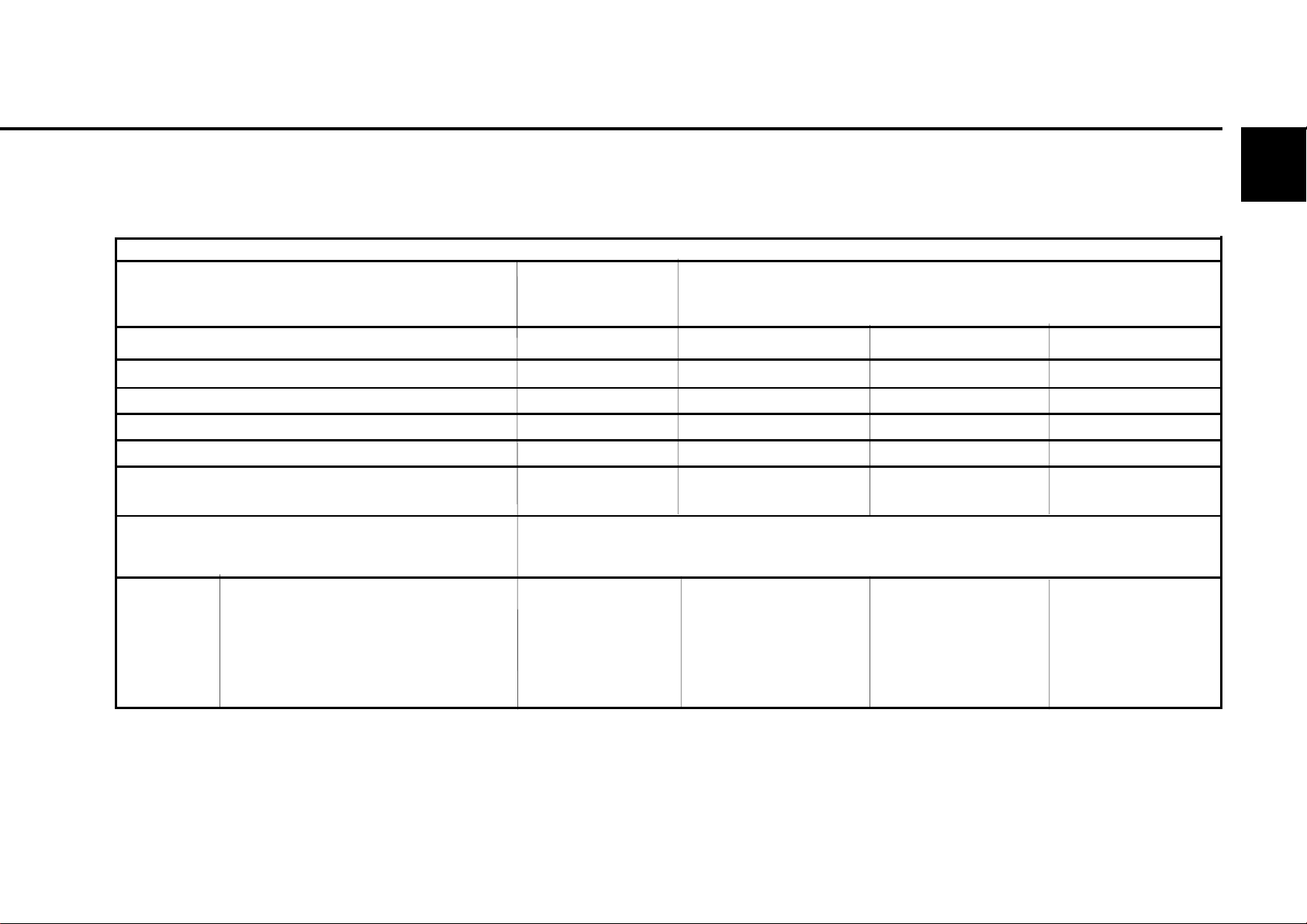

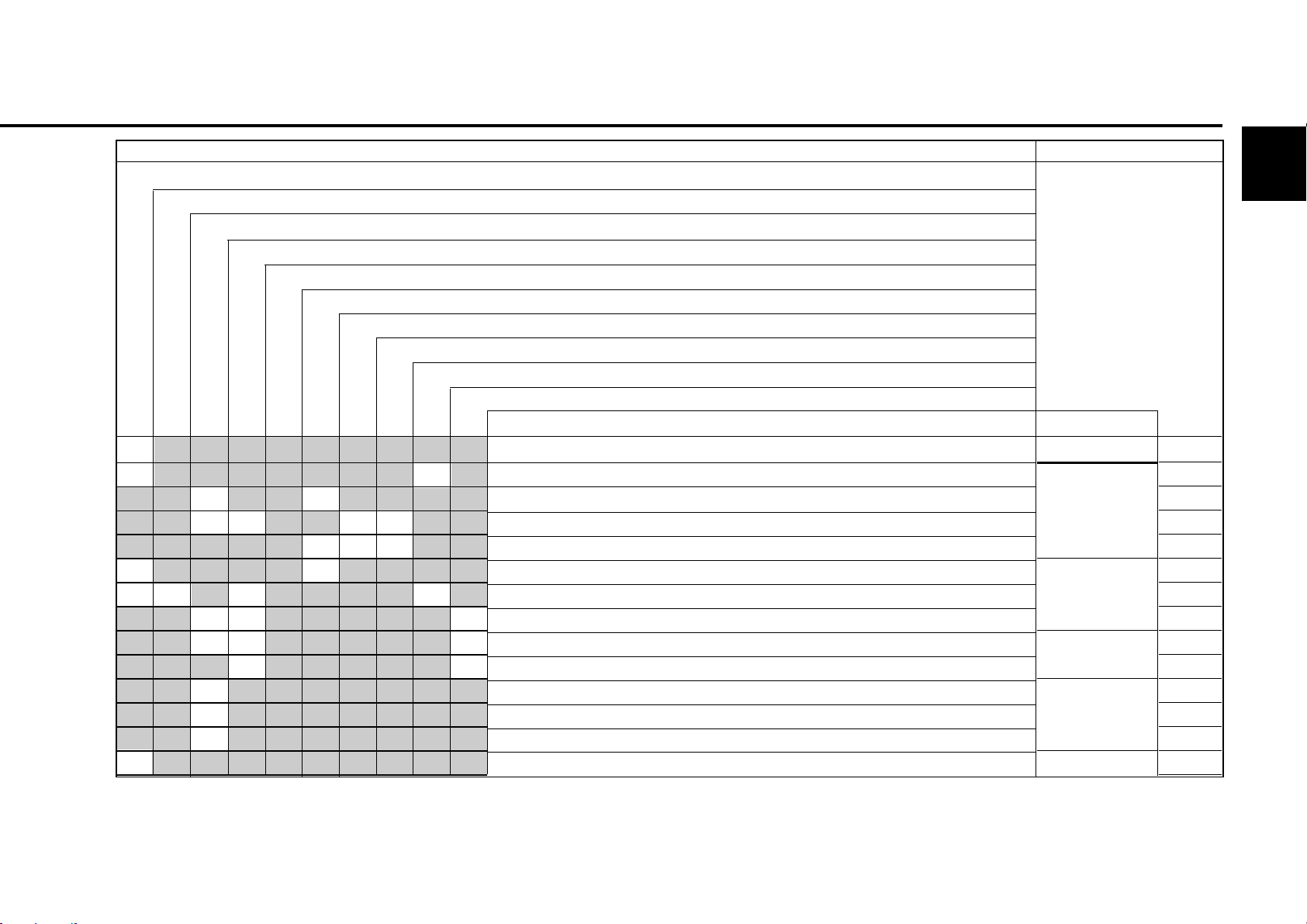

Maintenance 5.1 Maintenance schedule

5

check= l set= m clean= s renew= n

check 2x daily before or during the 1st trial run during the running-in phase or

when commissioning new and overhauled engines.

every 10 oh or daily

in operating hours (oh) every

E 10 E20 E25 E30 E40 E45 E60

250 500 1000

ll

°n°

n

°n°

n

ln n

n

l s n

lln n

ll

ll n

l

ll

ll n

ll

ll

ll

2000 3000 6000

nn

n

Years

12

Industrial engines

The engine maintenance times given are

maximum permissible job times. Depending on

the usage circumstances, shorter maintenance

times may be necessary. Observe the instruction

manual of the equipment manufacturer.

# Maintenance only to be carried out by authorised

Activity

Lube oil level, if necessary re-fill 6.1.2/3.3.4

Lube oil

( ° oil change intervals depending on type of engine use)

Oil filter cartridge (at each lube oil change) 6.1.3

Fuel diaphragm pump 6.2.4

Fuel filter cartridge 6.2.1

Injection valve

Fuel pre-cleaner / Fuel pre-filter* (change filter insert if necessary) 4.2

Coolant (additive concentration) 4.3.1/ 2/

Coolant level –

Intake air filter

Battery and cable connections 6.7.1

Engine monitoring, warning system 3.3

V-belts (if necessary, re-tighten or renew ) 6.5.1

Engine for tightness (visual inspection for leaks). –

Engine bearing (renew in case of damage) 9.2

Fixings, hose connections / clamps (renew in case of damage) –

Part overhauling #

(if available, as per maintenance display)

service personnel

, see TR 0199-99-3002 6.1.1/ 6.1.2

Section

6.4.3 /6.4.4

#

* If the warning system (light/siren) is activated, the fuel pre-filter must be emptied immediately.

© 2005

Page 38

5.1 Maintenance schedule Maintenance

check= l set= m clean= s renew= n

max. permissible job times in operating hours (oh) every

check 2x daily before or during the 1st trial run during the running-in phase or

when commissioning new and overhauled engines.

every 10 oh or daily

in operating hours (oh) every

250 500 1000

3000 6000

n

Years

12

Activity

Injection valve

Enhancements or modifications

for engines with EPA acceptance

The engine maintenance times given are maximum

permissible job times. Depending on the usage

circumstances, shorter maintenance times may

be necessary. Observe the instruction manual of

the equipment manufacturer.

# Maintenance only to be carried out by authorised

service personnel

5

Section

#

© 2005

Page 39

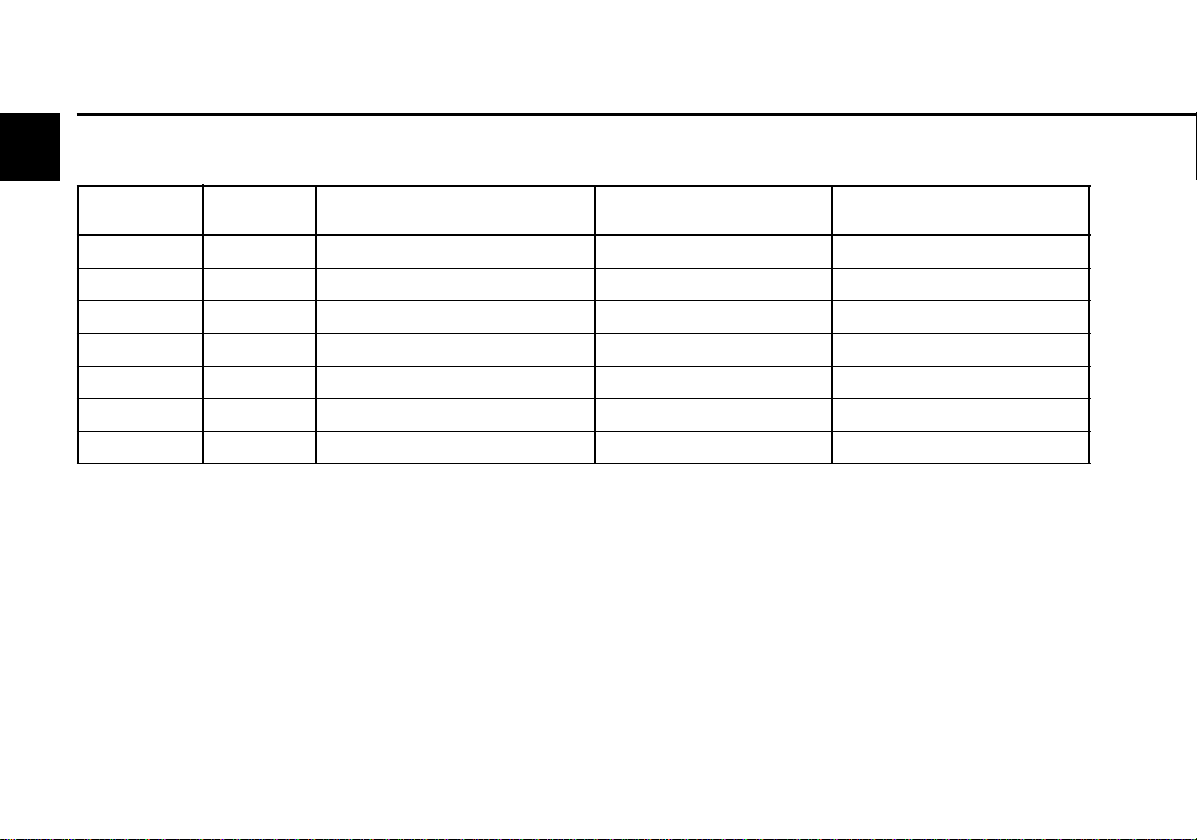

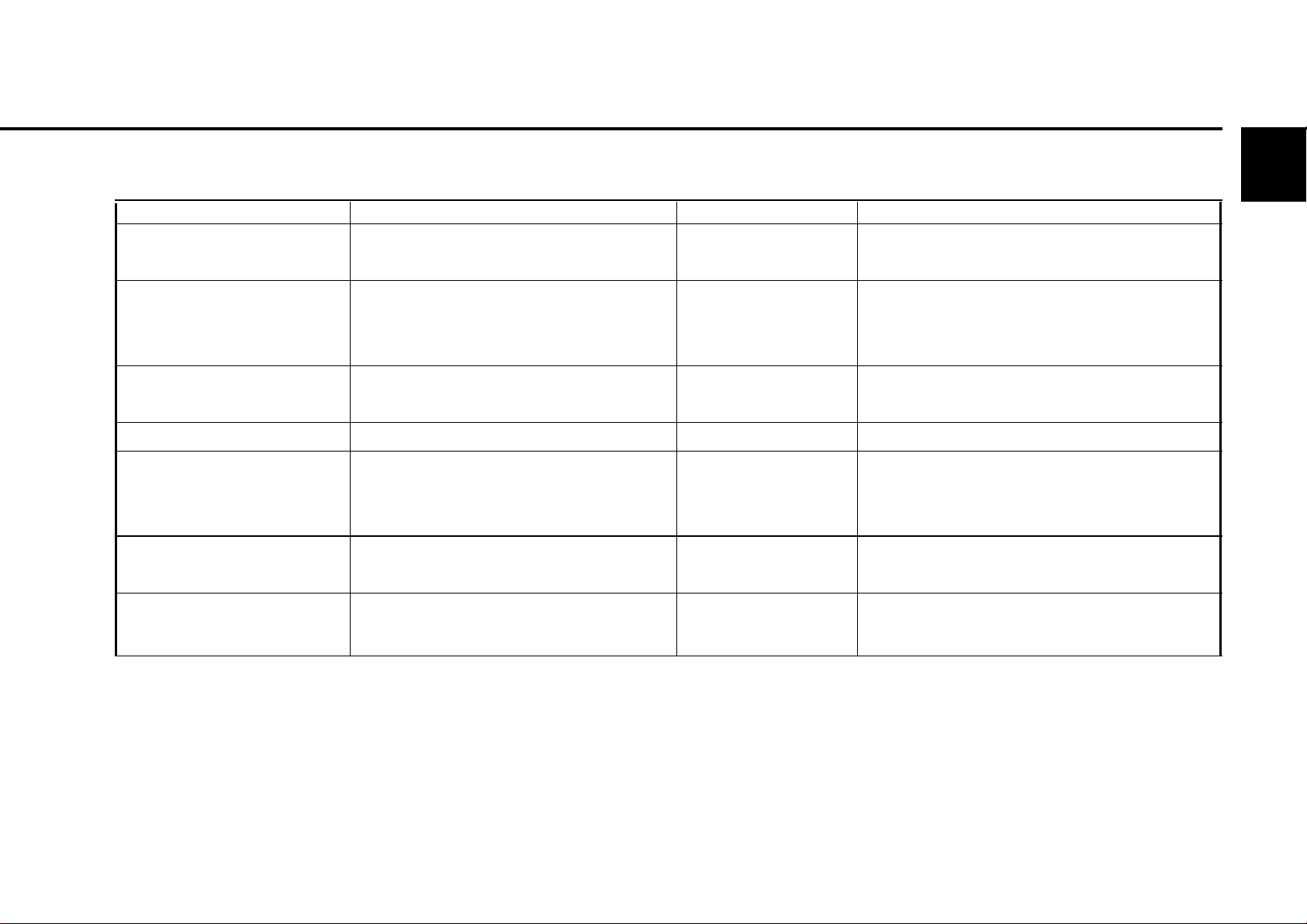

Repairs 5.2 Standard maintenance schedule

5.2.1 Standard maintenance schedule

5

Intervals Service Activity Execution by: Comments

at/after schedule

50 oh E 10 after commissioning and E 45-E60 authorised specialists

daily E 20 daily inspection round operator

250 oh E 25 inspection authorised specialists

500 oh E 30 extended inspection authorised specialists

1000 oh E 40 intermediate overhaul authorised specialists

2000 oh E 45 intermediate overhaul authorised specialists

3 000 oh E60 part overhaul authorised specialists

© 2005

Page 40

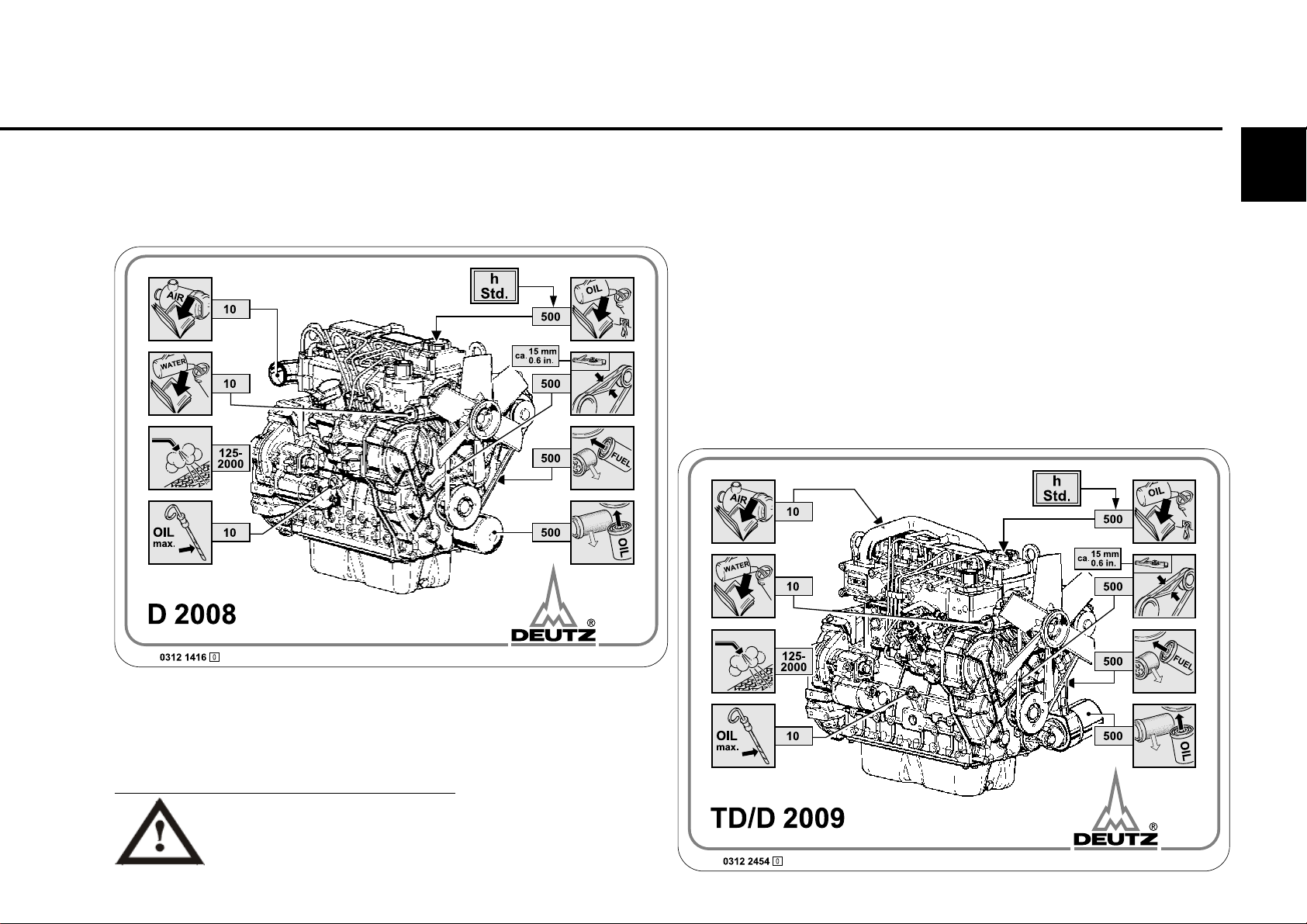

5.3 Maintenance diagram Maintenance

The maintenance diagram shown on this page is supplied with every engine in self-adhesive form. It should be stuck onto a well visible location

on the engine or equipment.

Check that this is the case!

If not, request a replacement from your engine or equipment supplier!

The maintenance schedule is decisive for standard maintenance, see 5.1.

5

All maintenance work should

only be carried out when the

engine is not running.

© 2005

Page 41

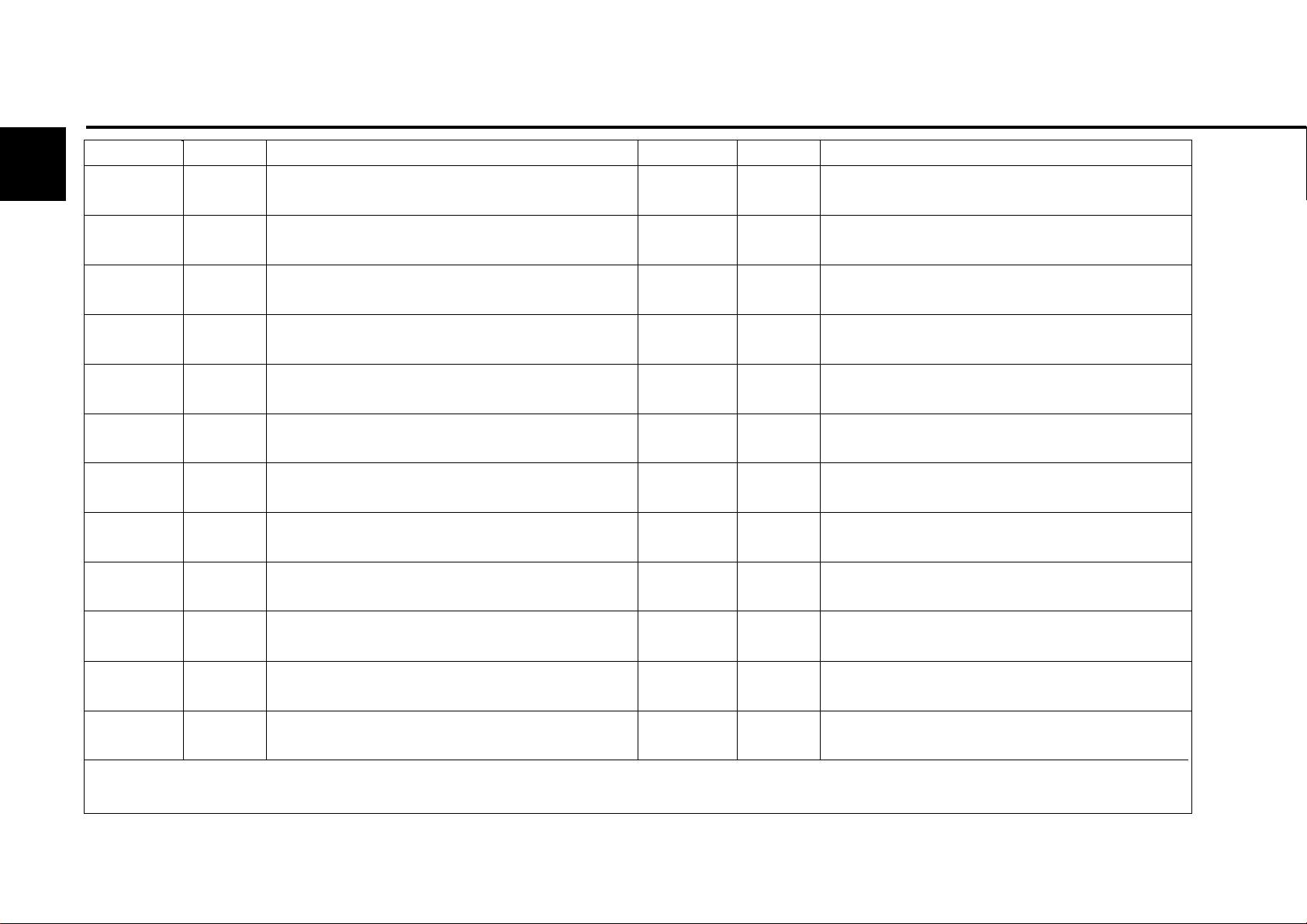

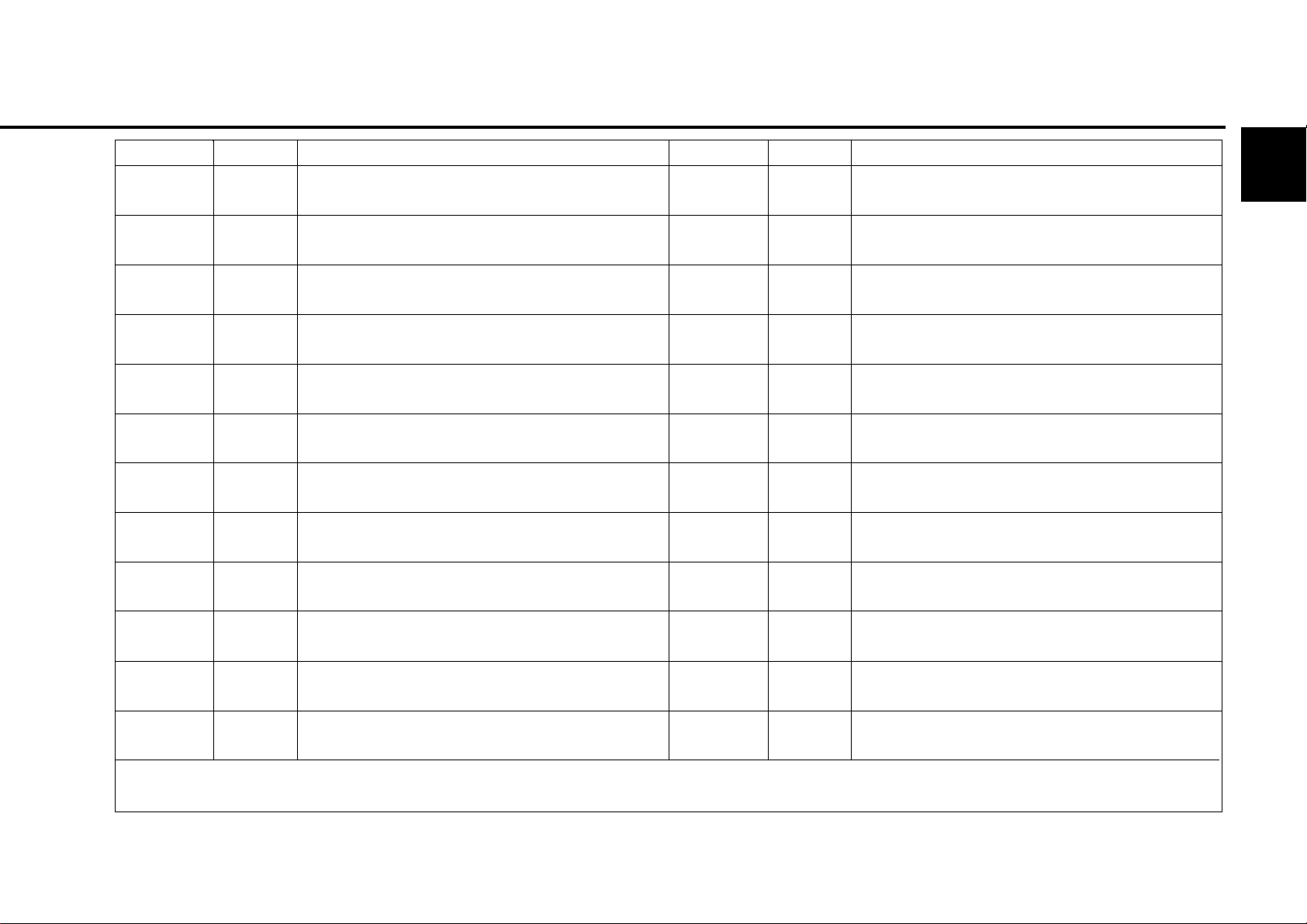

Maintenance

5.4 Maintenance work carried out

5

Op. hrs.

50-150

125

375

625

875

1125

1375

1625

1875

Date Signature / stamp

*

Op. hrs. Signature / stamp

Date

-

250

500

750

1000

1250

1500

1750

2000

© 2005

2115

2375

2625

2250

2500

2750

* after commissioning new and overhauled engines

The maintenance work carried out methodically can be recorded in the table and confirmed.

Page 42

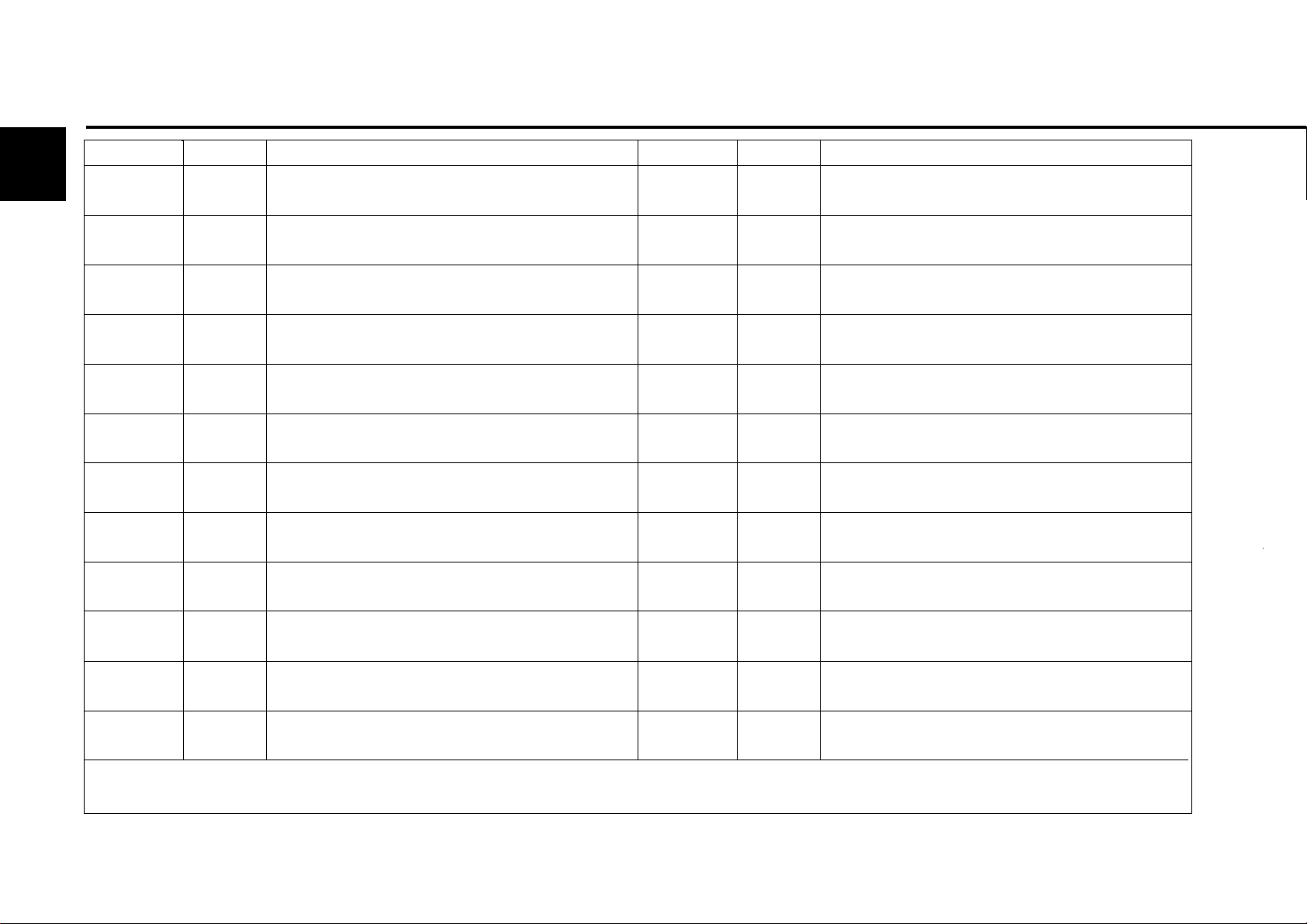

5.4 Maintenance work carried out Maintenance

Op. hrs.

2875

3125

3375

3625

3875

4125

4375

4625

4875

Date

Signature / stamp Op. hrs. Date

3000

3250

3500

3750

4000

4250

4500

4750

5000

Signature / stamp

5

5125

5375

5625

5250

5500

5750

The maintenance work carried out methodically can be recorded in the table and confirmed.

© 2005

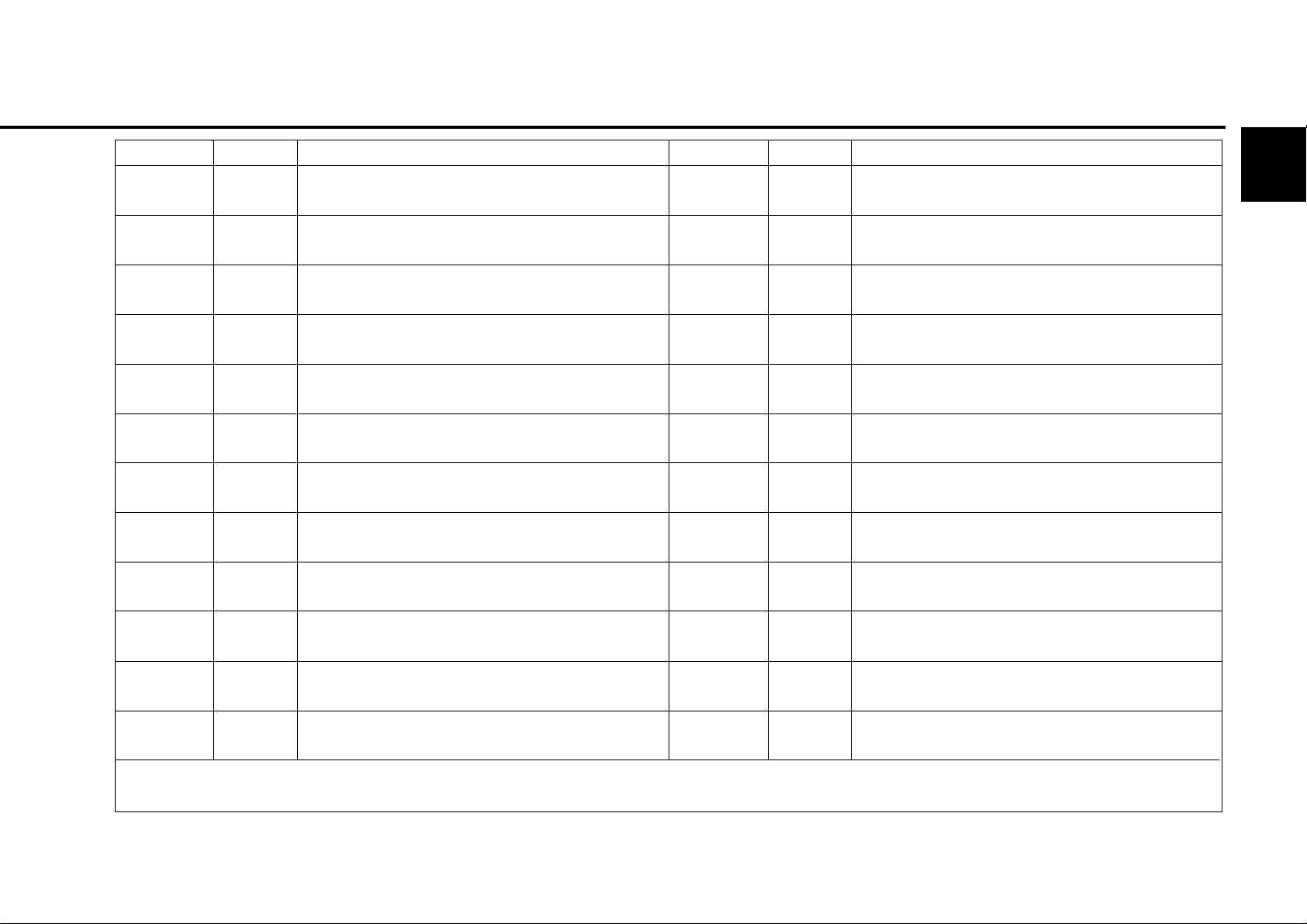

Page 43

Maintenance

5.4 Maintenance work carried out

5

Op. hrs.

5875

6125

6375

6625

6875

7125

7375

7625

7825

Date Signature / stamp

Op. hrs. Signature / stamp

6000

6250

6500

6750

7000

7250

7500

7750

8000

Date

© 2005

8125

8375

8625

8250

8500

8750

The maintenance work carried out methodically can be recorded in the table and confirmed.

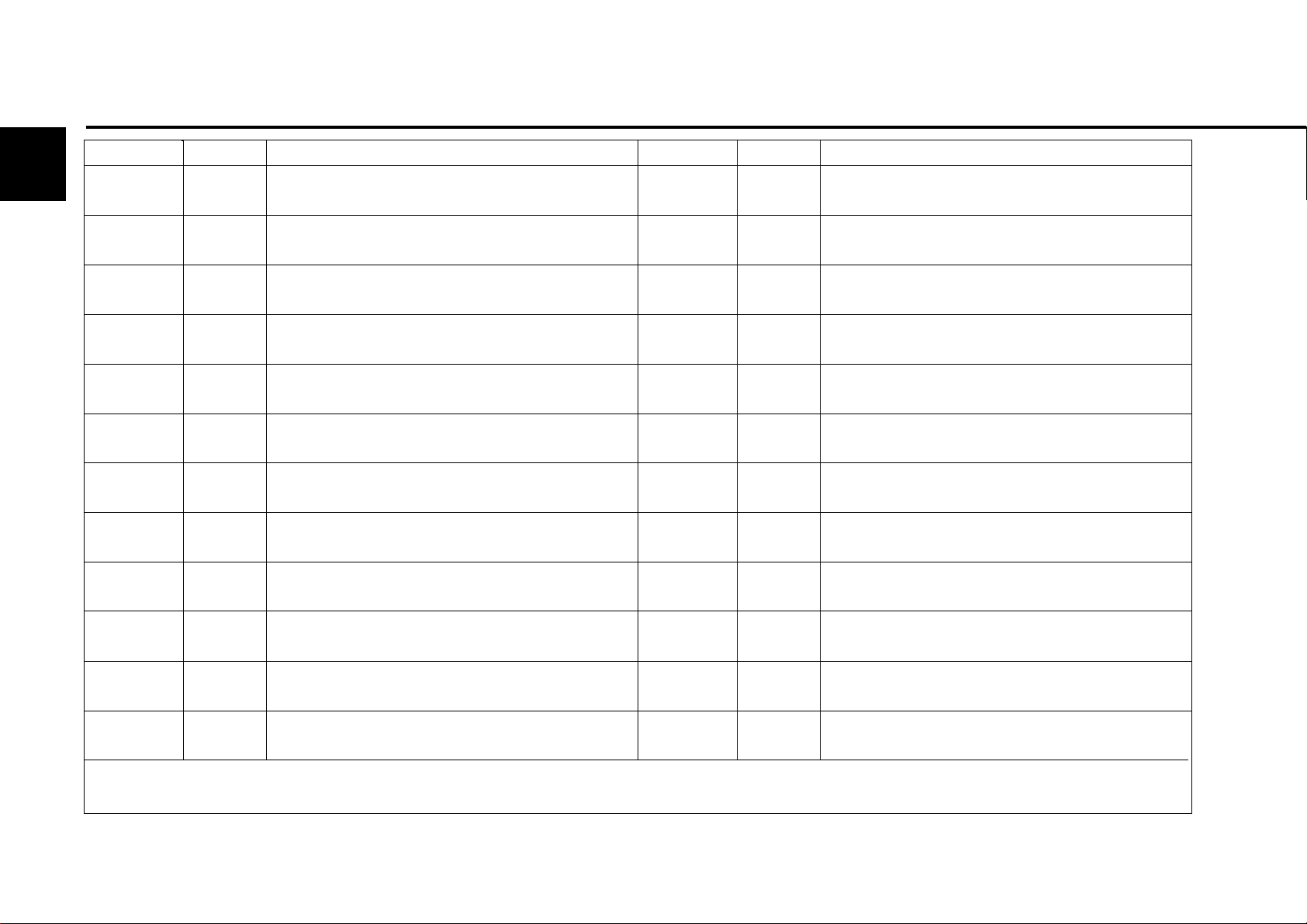

Page 44

5.4 Maintenance work carried out Maintenance

Op. hrs.

8875

9125

9375

9625

9875

10125

10375

10625

10875

Date

Signature / stamp Op. hrs. Date

9000

9250

9500

9750

10000

10250

10500

10750

11000

Signature / stamp

5

10125

10375

10625

11250

11500

11750

The maintenance work carried out methodically can be recorded in the table and confirmed.

© 2005

Page 45

Maintenance

5.4 Maintenance work carried out

5

Op. hrs.

Date Signature / stamp

Op. hrs. Signature / stamp

Date

© 2005

Page 46

Care and maintenance work

6.1 Lubrication system

6.2 Fuel system

6.3 Cooling system

6.4 Combustion air filter

6.5 Belt drive

6.6 Setting work

6.7 Add-on components

6.8 Engine cleaning

6

© 2005

Page 47

6

Care and maintenance work 6.1 Lubrication system

6.1.1 Oil change intervals

z The oil change times depend on the engine

application and the quality of the lube oil.

z If the oil change times are not reached within a

year, the oil change should be carried out at least

1x yearly.

z The following conditions apply for the table

- Sulphur content max. 0.5% of weight of diesel

fuel.

- Constant ambient temperature to

- 10 °C (+14 °F).

z The oil change times should be halved for fuels

with a sulphur content of > 0.5 to 1% or a

constant ambient temperature below -10 °C

(+14 °F).

z For fuels with a sulphur content higher than 1%

ask your responsible

service representative.

Carry out oil changes on warm engine when the

engine is not running (lube oil temperature approx.

© 2005

80 °C).

Page 48

6.1 Lubrication system Care and maintenance work

6.1.1.1 Lube oil change intervals

Lube oil quality

Minimum Recommended oils:

requirement

Deutz lube oil quality class DQC I DQC II DQC II DQC IV

AC EA sp ecif icat ion E2-96 E3-96/E5-02/E7-04 E4-99/E6-04 E4-99/E6-04

API specification CF/CF-4 CH-4/CG-4 - w or l d wi d e s p ec if ic a t io n - DHD-1 - special DEUTZ release list - - see 6.1.1.2 only fully synthetic

Standard lubricant code designation EO... EO...C - -

for building machines and building vehicles EO...A, EO...B

Engine Lube oil change intervals in oh

Series Engine version

normal normal normal normal

oil demands

6

D 2008

TD / D 2009 Charged and

* Under particularly severe ambient conditions the oil change intervals should be halved.

This includes ambient temperatures greater than 35° C (95° F), high dust exposure, power factor over 70% or high dynamic stress. In case

of doubt, please ask your service representative.

Naturally aspirated engines

naturally aspirated engines

250* 500* 500* 500*

500 500 500 500

© 2005

Page 49

6

Care and maintenance work 6.1 Lubrication system

6.1.1.2 Release list DEUTZ lube oil quality level

DQC II

Manufacturer Lube oil type SAE class Availability

DEUTZ DEUTZ oil TLX-10W40FE 10W-40 Europe

ADDINOL ADDINOL Super Truck MD 1048 10W-40 Europe, Asia

ADDINOL Ultra Truck MD 0538 5W-30 Europe, Asia

AGIP Agip Sigma Ultra TFE 10W-40 worldwide

Autol Valve Ultra FE 10W-40 Germany

ARAL Aral MegaTurboral 10W-40 worldwide

Aral SuperTurboral 5W-30 worldwide

AVIA TURBOSYNTH HT-E 10W-40 Germany

BAYWA BayWa Super Truck 1040 MC 10W-40 South Germany

BayWa Turbo 4000 10W-40 South Germany

BP OIL International BP Vanellus E7 Plus 10W-40 Europe

BP Vanellus E7 Supreme 5W-40 Europe

Castrol Castrol SYNTRUCK 5W-40 Europe, North America, Brazil

Argentina, Australia, South Africa

Castrol DYNAMAX 7.5W-40 Europe, North America, Brazil

Argentina, Australia, South Africa

CEPSA EUROTRANS SHPD 10W-40 Spain, Portugal

CHEVRON Chevron Delo 400 Synthtic 5W-40 North America

DEA DEA Cronos Synth 5W-30 Germany, Europe

DEA Cronos Premium LD 10W-40 Germany, Europe

DEA Cronos Premium FX 10W-40 Europe

© 2005

Page 50

6.1 Lubrication system Care and maintenance work

ESSO Essolube XTS 501 10W-40 Europe

FUCHS EUROPE Fuchs Titan Cargo MC 10W-40 worldwide

Fuchs Titan Unic Plus MC 10W-40 worldwide

MOBIL OIL Mobil Delvac 1 SHC 5W-40 Europe, SE Asia, Africa

Mobil Delvac 1 5W-40 worldwide

Mobil Delvac XHP Extra 10W-40 Europe, SE Asia

Lube oil refinery Wintershall TFG 10W-40 Europe

Salzbergen

Shell International Shell Myrina TX / 5W-30 Europe, code

Shell Rimula Ultra country specific, varies

Shell Myrina TX / 10W-40 Europe, code

6

Shell Rimula Ultra country specific, varies

Texaco Ursa Super TDX 10W-40 10W-40 Europe

Ursa Premium FE 5W-30 5W-30 Europe

TOTAL TOTAL RUBIA TIR 8600 10W-40 worldwide

EXPERTY

10W-40 worldwide

This table will be extended if necessary.

© 2005

Page 51

6

Care and maintenance work 6.1 Lubrication system

6.1.2 Checking oil level /

changing engine oil

6.1.2.1Checking oil level 6.1.2.2Changing engine oil

z Oil level on switched off engine, check

z Position the engine or vehicle so as to be level.

z Extract oil dipstick.

z Wipe with a fibre-free, clean cloth.

z Insert until it stops and extract again.

"MAX"

z Check oil level and re-fill to

- If the oil level lies just above the "MIN"

line marking, re-filling is necessary.

The oil level may not fall short of the "MIN" line

marking.

© 2005

if necessary.

© 26 022 0© 25 729 0

z Warm up the engine

z Position the engine or vehicle so as to be level.

- lube oil temperature approx. 80 °C.

z Switch off the engine.

Caution when draining

hot oil: danger of scalding !

Collect the used oil, do not

allow to seep into floor!

Dispose of according to

instructions!

© 26 023 0

z Position oil drip cup under the engine.

z Unscrew oil drain screw.

z Drain off oil.

z Screw in oil drain screw with new sealing ring

and tighten. (For tightening torque see 9.2).

z Pour in lube oil

- For quality / viscosity data see 4.1.

- For filling amounts see 9.1.

z Check oil level, see 6.1.2.1

Page 52

6.1 Lubrication system Care and maintenance work

6.1.3 Changing oil filter

B

6

G

C

© 43 917 0 © 43 918 0

z Loosen the lube oil filter cartridge A in the

direction of the arrow with a standard tool and

unscrew.

z Collect any oil which may run out.

Careful with hot oil: Danger of

scalding!

C

z Clean the sealing surface B of the filter support

for any possible dirt.

z Lightly oil the rubber seal of the new lube oil

cartridge A.

F

© 43 919 0

z Screw on the cartridge in the direction of the

arrow by hand until the seal makes contact.

z Tighten the lube oil filter cartridge A with one

more half turn.

z Check oil level, see 6.1.2.

z Check oil pressure, see 3.3.1.

z Check the seal of the lube oil cartridge for

tightness.

© 2005

Page 53

6

Care and maintenance work 6.2 Fuel system

6.2.1 Changing fuel filter

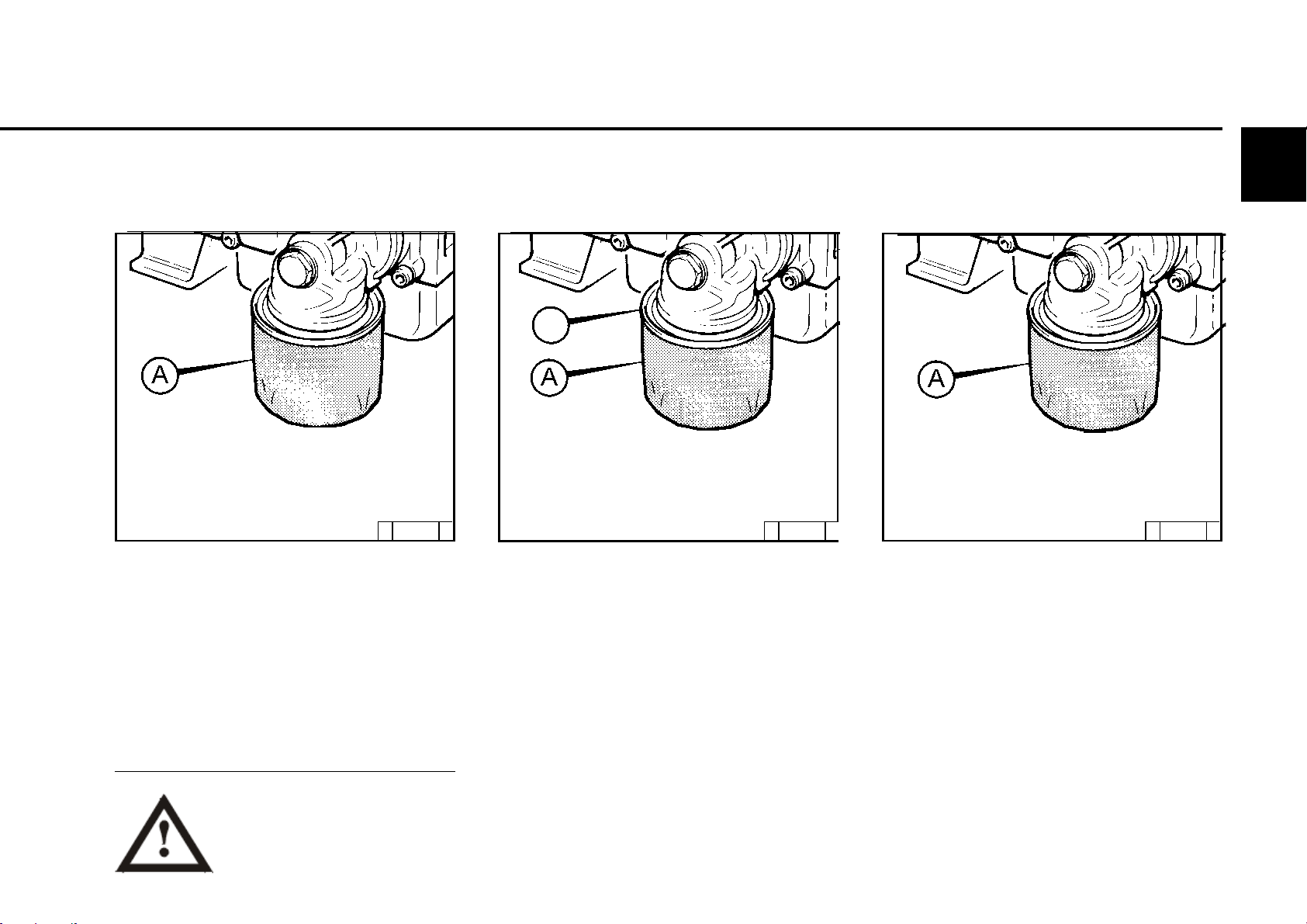

© 25 880 0 © 25 882 0© 25 881 0

z Close fuel stopcock.

z Loosen fuel filter cartridge with standard tool

and unscrew.

z Collect fuel which runs out.

No open fire when working on

the fuel system!

Do not smoke!

© 2005

z Clean the sealing surface of the filter support

for any possible dirt.

z Lightly oil the rubber surface of the new fuel

filter cartridge or wet with diesel fuel.

z Screw on the cartridge by hand until the seal

makes contact.

z Tighten the fuel filter cartridge with one more

half turn.

z Open fuel stopcock.

z Check for tightness.

It is not necessary to bleed the fuel system.

Page 54

6.2 Fuel system Care and maintenance work

6.2.2 Bleeding fuel system

© 43 879 0

z Position collecting vessel underneath filter.

z Open fuel stopcock.

z Loosen bleed screw 1

z Turn the lever on the fuel pump 2 until the fuel

escapes from the bleed screw 1 without

bubbles.

z Tighten bleed screw 1

zDispose of the fuel from the collecting vessel

in an environmentally sound manner.

z Check tightness after commissioning.

6.2.3 Draining water from fuel

system

© 43 880 0

z Position collecting vessel underneath filter.

z Loosen drainage screw 1

z Drain water from the drainage screw 1.

z Tighten drainage screw 1.

zDispose of the water from the collecting vessel

in an environmentally sound manner.

z Check tightness after commissioning.

6.2.4 Changing fuel diaphragm

pump

© 43 878 0

z Position collecting vessel underneath fuel

diaphragm pump 3.

z Loosen screw on fuel line 1 to filter support and

separate from fuel diaphragm pump 3.

z Loosen screw 2.

z Remove fuel diaphragm pump 3.

z Install fuel diaphragm pump 3 with new sealing

ring 4.

z Tighten fuel line 1 to filter support.

z Bleed fuel system, see 6.2.2

z Check tightness after commissioning.

If possible, do not let the tank run

empty! No open fire when working

on the fuel system!

Do not smoke!

If possible, do not let the tank run

empty! No open fire when working

on the fuel system!

Do not smoke!

No open fire when working on the

fuel system!

Do not smoke!

Dispose of used fuel in an

environmentally sound manner

Page 55

6.3 Cooling system Care and maintenance work

6.3.1 Cleaning intervals

6©

z The soiling of the cooling system depends on

the type of engine application.

z The risk of soiling is increased by oil and fuel

residues on the engine. Therefore pay particular

attention to tightness when operating under

high dust exposure.

z Increased soiling occurs, for example, during:

- building site application from high dust content

of air.

- harvesting application from high proportion

of chaff and chopped straw, for example, in

the area of the work machine.

z Due to the various application conditions, the

cleaning intervals must be defined according

to each case. Therefore, the cleaning intervals

given in the table on the right can be used as

guidelines.

Checking or cleaning intervals

Guideline oh Type of engine application

2000 Ships, electronic units in enclosed spaces.

pumps

1000 Vehicles on paved roads

500 Tractors, fork lift trucks, drivable electronic units

250 Vehicles on building sites and unpaved roads

Building machines, compressors, mining equipment

125 Agricultural machinery, tractors with harvesting application

© 2004

Page 56

Care and maintenance work 6.4 Combustion air filter

6

6.4.1 Cleaning intervals

● The soiling of the combustion air filter depends

on the dust content of the air and the selected

filter size. If a high dust exposure is to be

expected, a cyclone pre-separator can be

connected to the combustion air filter.

● The cleaning intervals cannot be generally

defined. They must be defined depending on

each case.

● If dry air filters are used, cleaning should only

be carried out according to the maintenance

display or maintenance switch.

● Filter maintenance is required when on the

- maintenance display

the red service field 1 is fully visible when the

engine is not running.

- maintenance switch

the yellow warning light lights up when the

engine is running.

● After completion of the maintenance work

push the reset button on the maintenance

display. The maintenance display is ready for

operation again.

© 25 885 1

6.4.2 Emptying cyclone

pre-separator

© 25 886 0

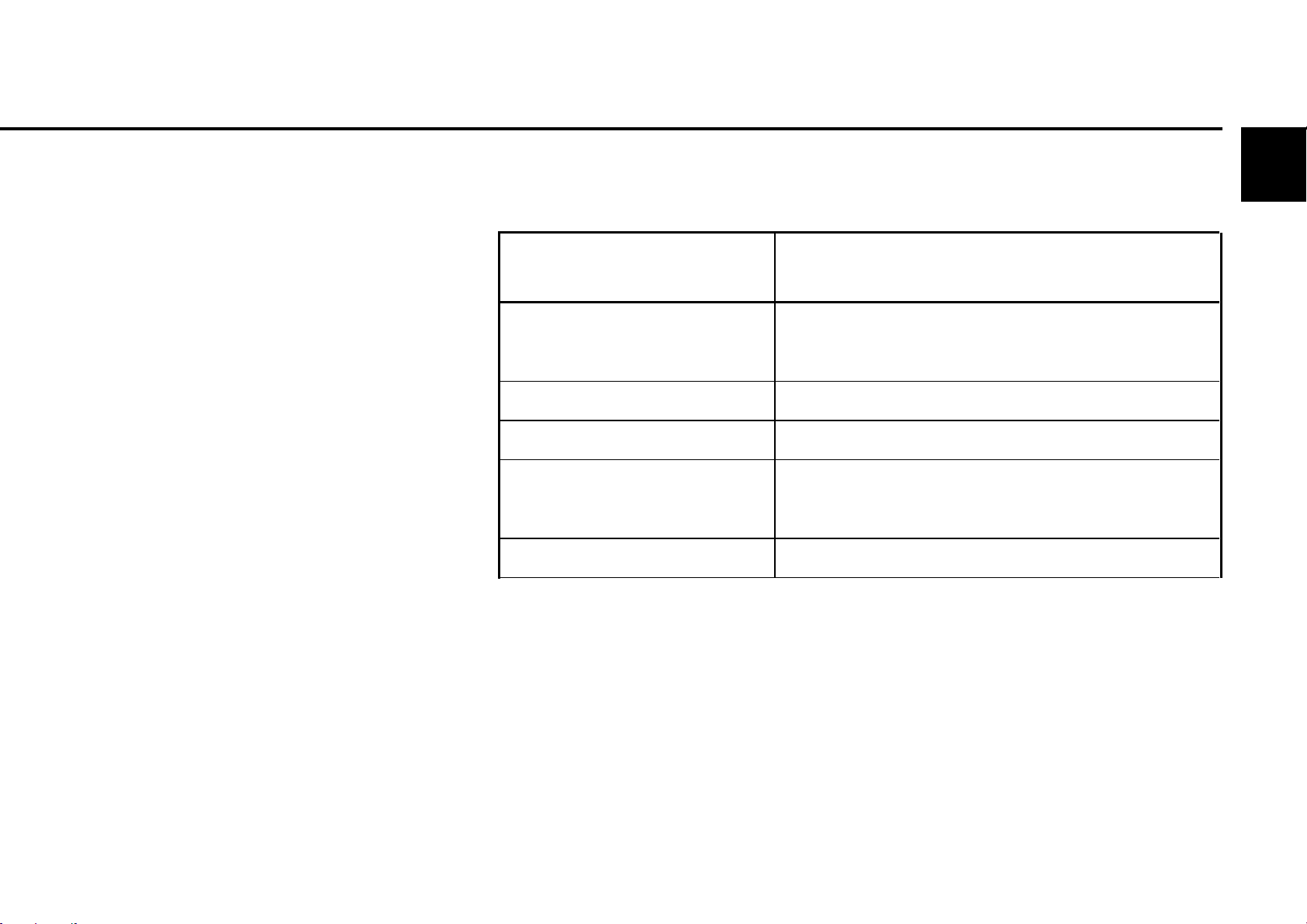

● Loosen wing nut 1 and lift housing cover 2.

● Remove the dust container 3 from the base of

the cyclone 4 and empty. Clean foliage, straw

and the like from the cylone base.

● Place the dust container 3 on the base 4 and

tighten the housing cover 2 with wing nut 1.

© 2004

Never fill the dust container with oil, replace

damaged containers.

Page 57

6.4 Combustion air filter Care and maintenance work

6.4.3 Dry air filter

dust discharge valve

Filter cartridges

6©

© 25 888 1

● Empty the dust discharge valve 1 by squeezing

the discharge slot in the direction of the arrow.

● Clean the discharge slot occasionally.

● Remove any stuck on dust residues by

squeezing the upper area of the valve.

© 43 920 0

● Open clamping bracket A.

● Remove filter hood B and pull out filter cartridge

C.

● Clean filter cartridge, renew after a year at the

latest.

● Clean filter cartridge C.

Blast out from the inside out with dry

compressed air (max. 5 bar) (only beat out in

extreme cases or only wash according to

manufacturer’s specifications, not damaging

the cartridge).

● The seal of the filter cartridge C can be

damaged by frequent removal and installation.

Check filter cartridge C for damage to the filter

paper (shine light through) and check the seal.

Exchange if necessary.

● Renew the safety cartridge after five filter

maintenances, after two years at the latest

(never clean).

To do this:

- Loosen the hexagonal nut and pull out the

cartridge.

- Insert new cartridge and re-tighten with

hexagonal nut.

● Insert filter cartridge C, put on hood B and

fasten clamping bracket A.

Never clean filter cartridge C with

petrol or hot liquids!

© 2004

Page 58

6

Care and maintenance work 6.5 Belt drive

6.5.1 Checking V-belt6.5.1 Checking V-belt

© 43 875 0

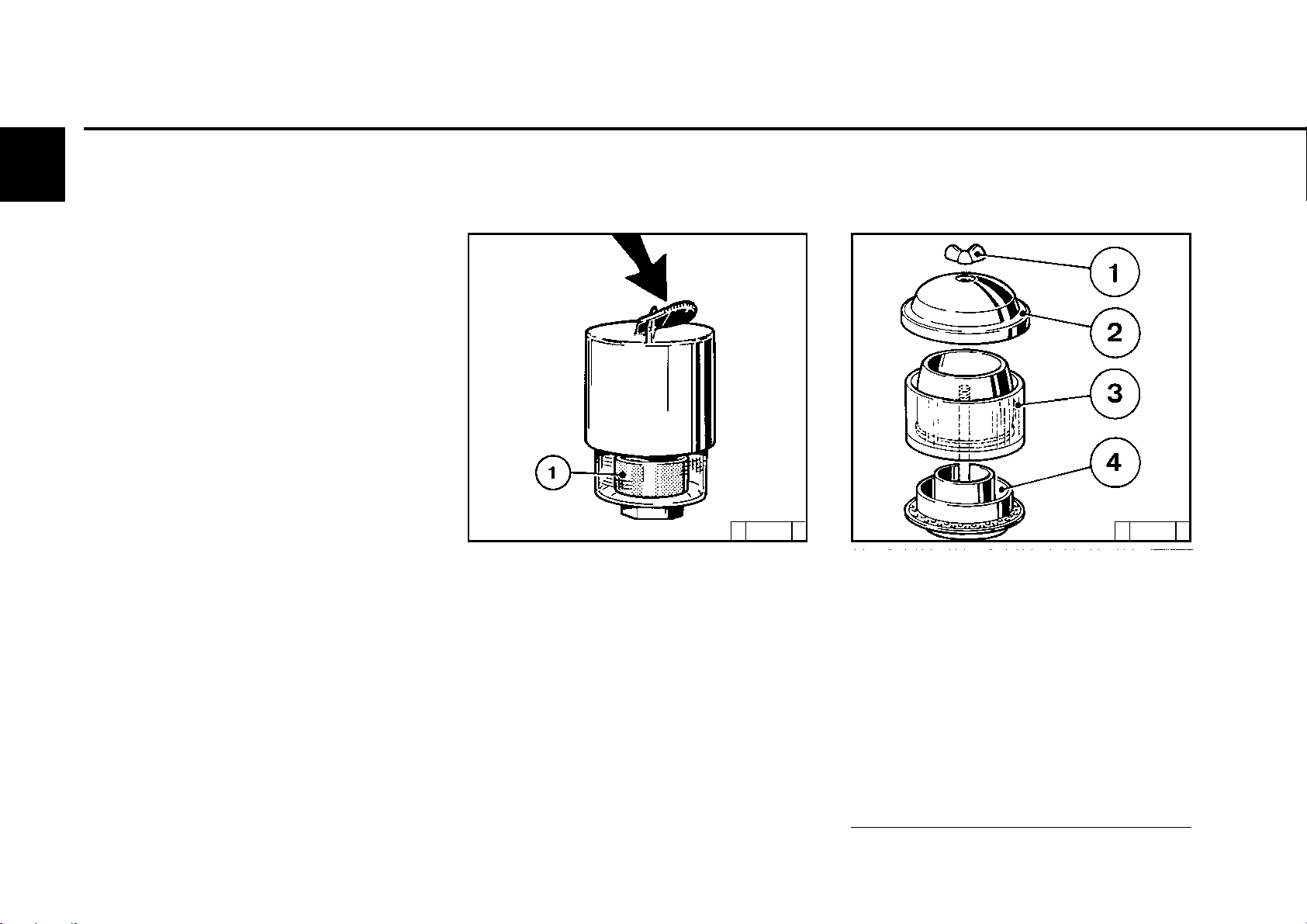

● Visual inspection of entire length of V-belt

for damages.

● Renew damaged V-belts.

● Check the belt tension of new V-belts

after 15 minutes running time.

● Use a V-belt tension measuring device

(see chap. 9.3) to check the V-belt tension.

- Lower indicator arm 1 into the measuring

device.

- Lay the guide 3 between two belt pulleys

on the V-belt 2. The stop should lie sideways.

- Press the button 4 at right angles to the

V-belt 2 steadily, until the spring is heard or

felt to unlock.

© 2004

© 26 261 0

- Carefully lift the measuring device, without

altering the position of the indicator arm 1.

- Read off the measured value on the

intersection (arrow), scale 5 and indicator 1.

For setting values see 9.1.

- If necessary, re-tighten and repeat measurement.

Only test / tighten / change

V-belts when the engine is not

running. If necessary, re-mount

V-belt guard.

Check the belt tension of new V-belts after 15

minutes running time.

Page 59

6.5 Belt drive Care and maintenance work

6.5.2 Tightening/changing

V-belts

1

2

6©

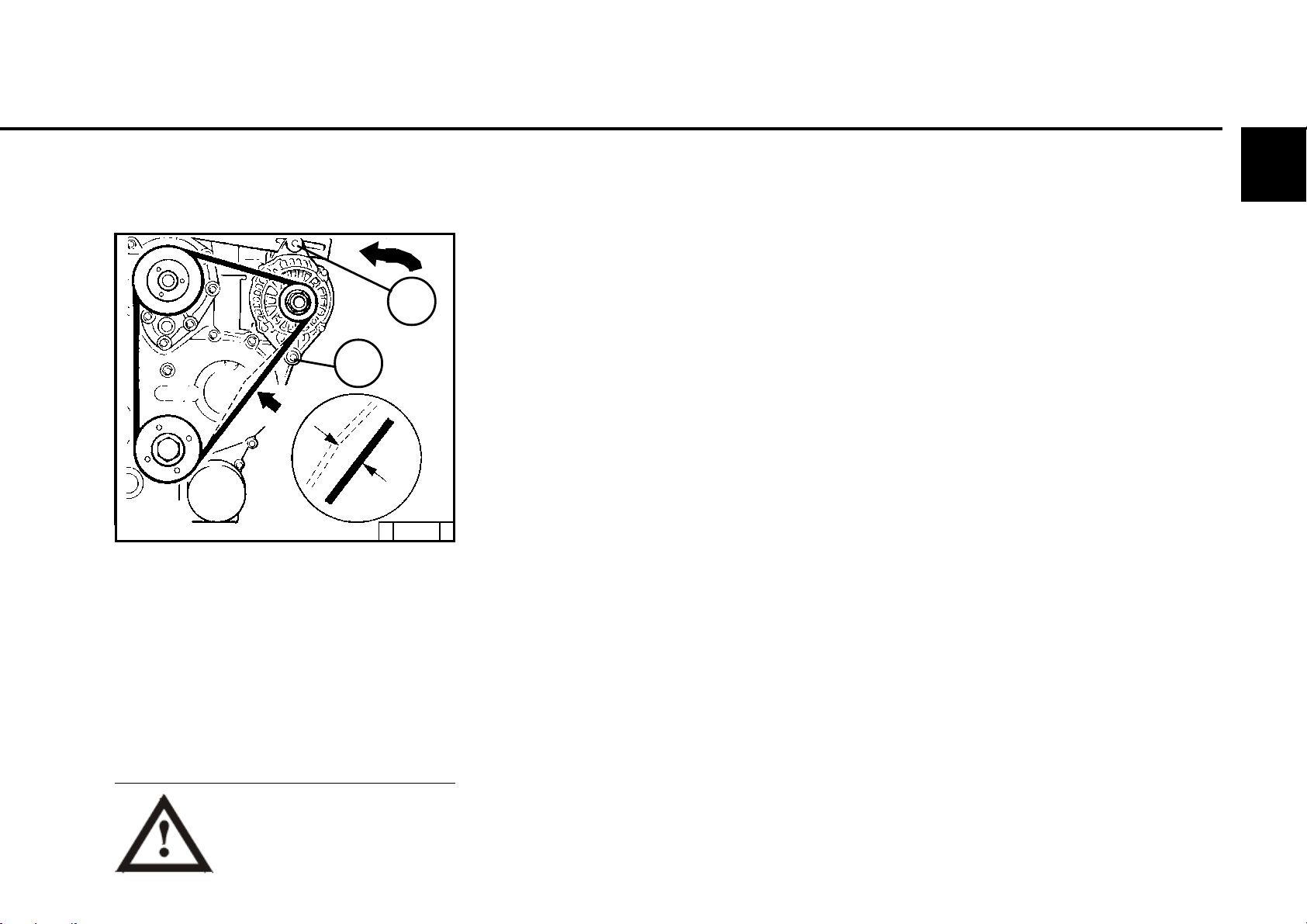

© 31 859 0

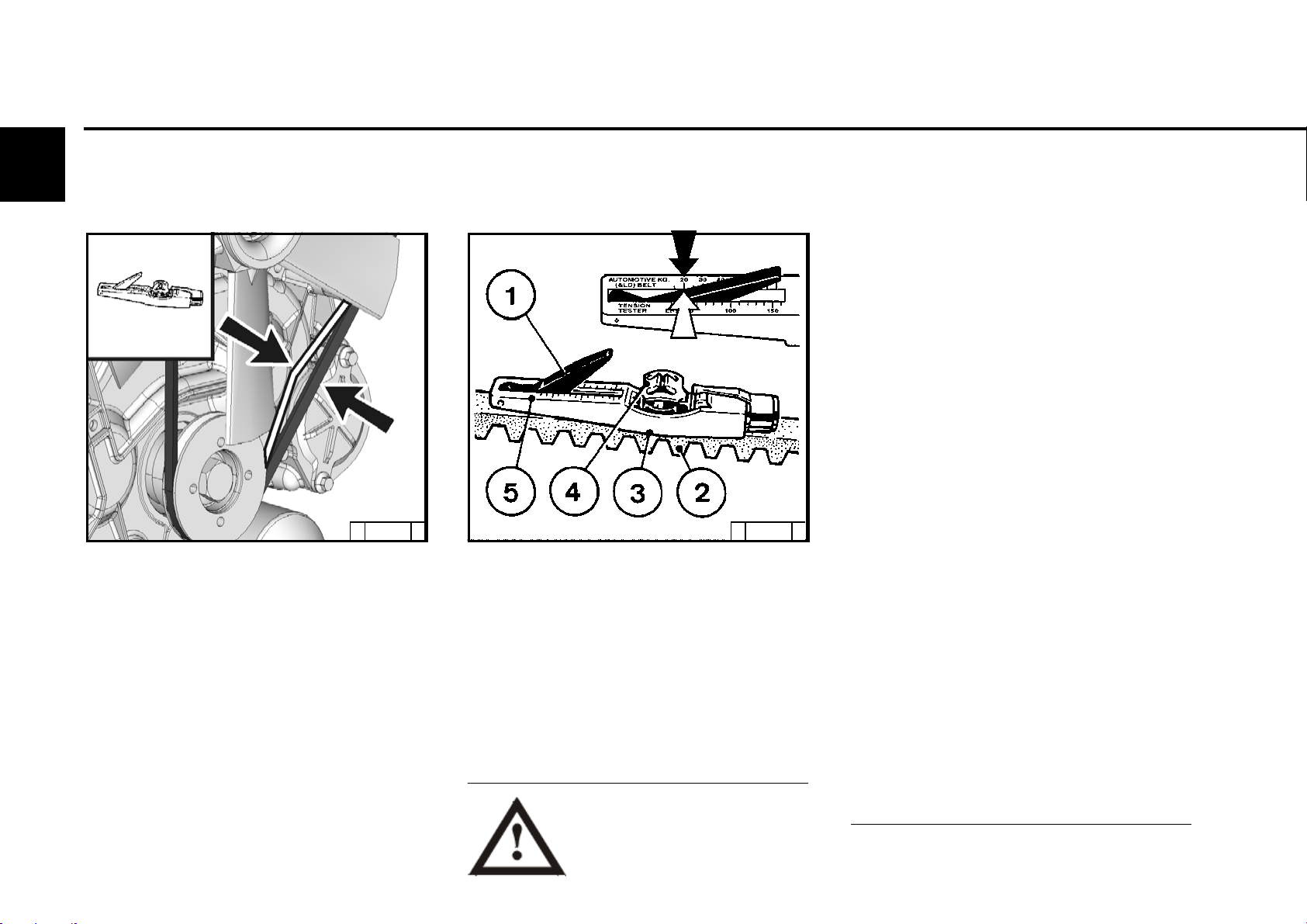

Tightening

● Loosen screw 1.

● Actuate the generator against the direction of

the arrow.

● Re-tighten screw 1.

● Check V-belt tension.

Only test / tighten / change

V-belts when the engine is not

running. If necessary, re-mount

V-belt guard.

Changing

● Loosen screws 1 and 2.

● Adjust the generator in the direction of the

arrow.

● Remove V-belt and put new belt on.

● Actuate the generator against the direction of

the arrow.

● Re-tighten screws 2 and 1.

● Check V-belt tension (see 6.5.1).

© 2004

Page 60

6

Care and maintenance work 6.6 Add-on components

6.6.1 Battery

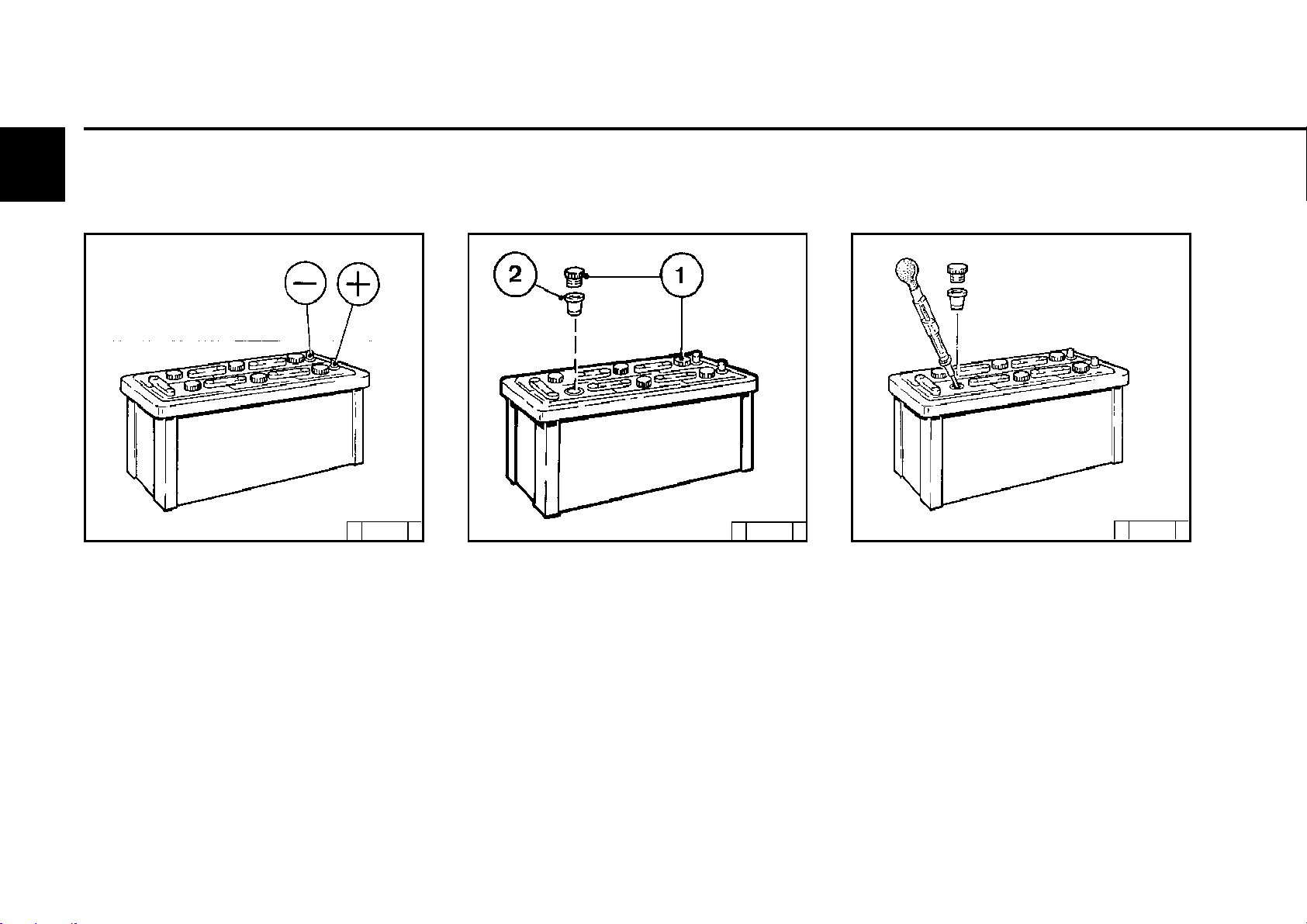

6.6.1.1Checking battery and cable

connections

6.6.1.2Checking the acid level 6.6.1.3 Checking acid density

© 25 895 0

● Keep the battery clean and dry.

● Loosen soiled connection terminals.

● Clean the battery poles (+ and -) and terminals,

and grease with an acid-free and acid-resistant

grease.

● Ensure that the terminal connections contact

well when assembling. Tighten the clamping

screws by hand.

© 2004

© 24 232 3

● Remove sealing cap 1.

● If a checking insert 2 is available:

the liquid level should reach to the bottom.

● Without checking insert:

the liquid level should reach 10-15 mm above

the upper edge of the plate.

● If necessary, re-fill with distilled water.

● Screw sealing cap back on.

© 25 896 0

● Measure the acid density of individual cells

with a standard acid testing device.

The measured values (see following table)

provide information on the charged level of the

battery.

The acid temperature when measuring should

be +20 °C if possible.

Page 61

6.6 Add-on components Care and maintenance work

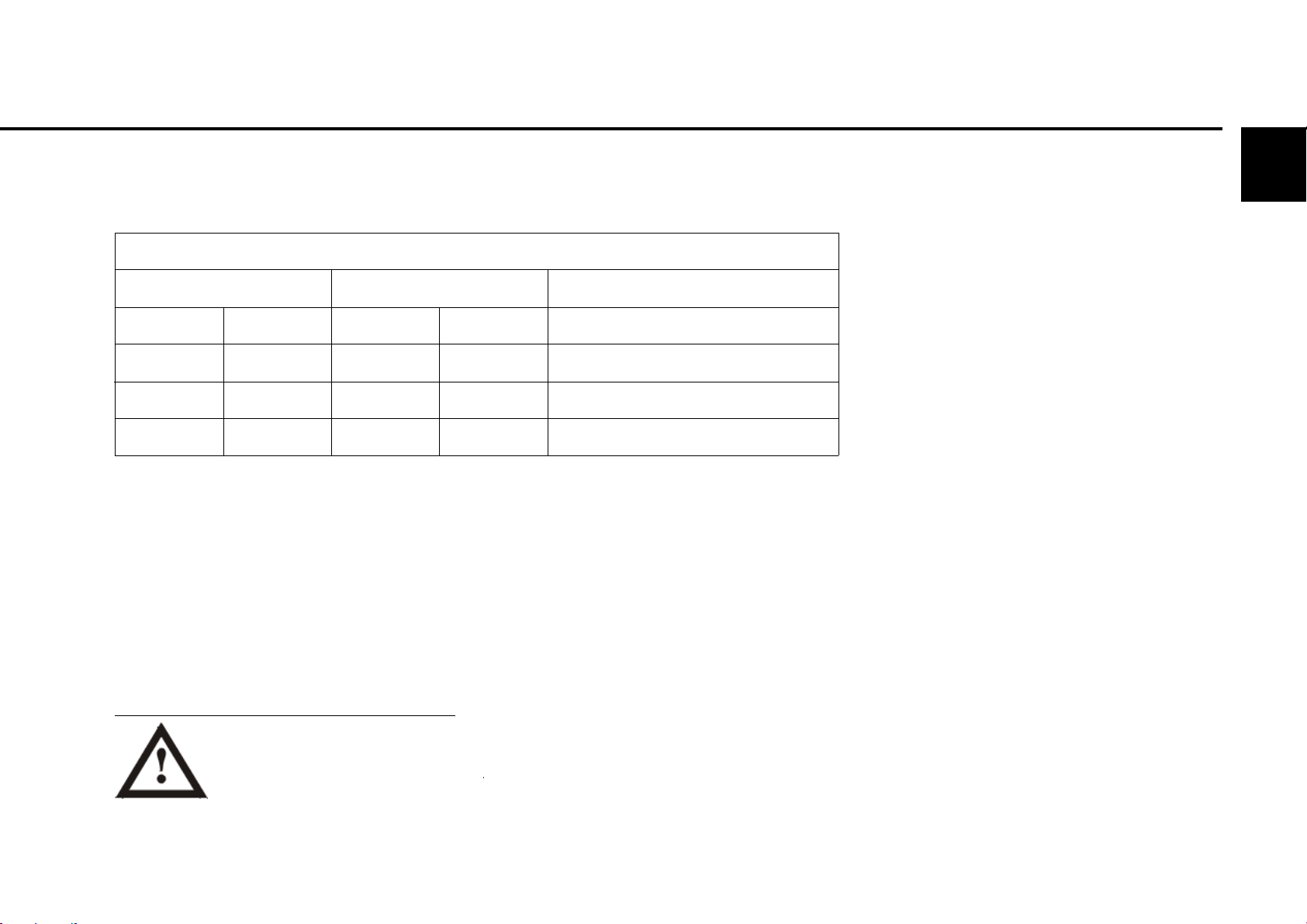

Acid density

6©

in [kg/ l]

Normal

1.28

1.20

1.12

* The data for acid density in °Bé (Baumé

degree) is out of date and rarely still in use.

Wear protective glasses!

Do not place any tools on the battery!

Tropics

1.23

1.12

1.08

The gases released by the battery

are explosive! Avoid sparks and

open fire in the vicinity of the

battery!

Do not allow acid to get on skin or

clothes!

in [°Bé (Baumé degree)*]

Normal

32

24

16

Tropics

27

16

11

Charge level

well charged

half charged, re-charge

discharged, charge immediately

© 2004

Page 62

Care and maintenance work 6.6 Add-on components

6

6.6.2 Three-phase current

generator

Notes on three-phase current system:

● Do not interrupt the connections between the

battery, generator and governor when the

engine is running.

● If, however, an engine must be started and

operated without battery, the connection

governor / generator is to be separated before

starting.

● Do not exchange battery connections.

● Replace defective charge warning light

immediately.

● Cover generator and governor when washing the engine.

● Under no circumstances may the voltage of a

three-phase current system be tested by

tapping against the earth cable.

● When carrying out electrical welding work,

clamp the earth terminal of the welding device

directly to the part to be clamped.

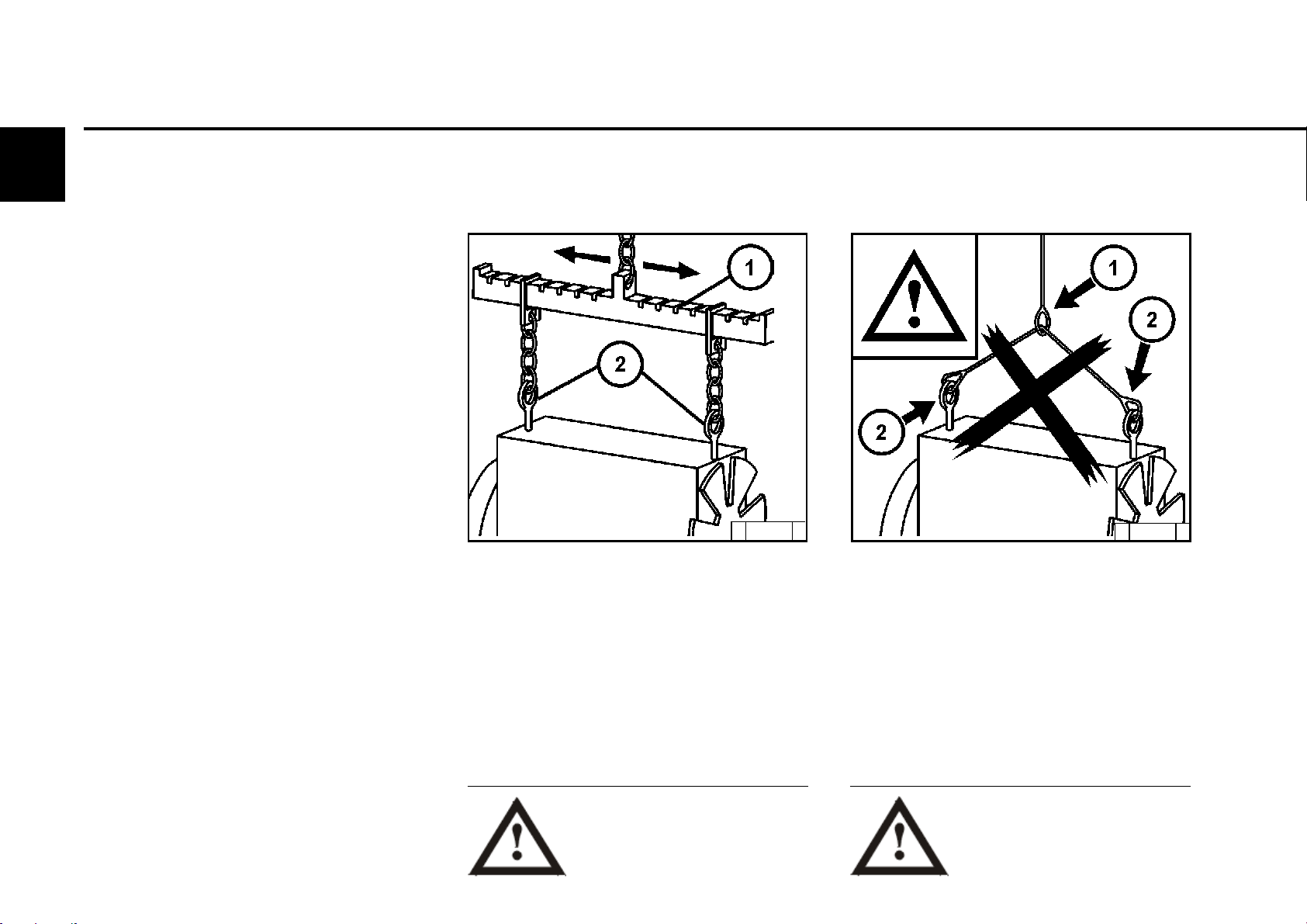

6.6.3 Transportation suspension

© 31 871 0

● Only use the correct suspension equipment 1

for engine transportation. Suspension

equipment must be adjustable for the engine

centre of gravity.

© 31 870 0

● Fastening devices cannot be fixed safely over

the centre of gravity (1).

● Fastening devices can slip, engine capsizes

(1).

● Short fastening device causes bending

moments in the suspension. This can damage

the suspension. (2)

© 2004

Only use correct suspension

equipment!

Engine can fall.

Danger to life!

Page 63

6.7 ENGINE CLEANING Care and maintenance work

6.7.1 Engine cleaning

Preparation

● Switch off engine

● Remove engine cover, cool air hood. Re-

assemble after cleaning and before trial run.

● Cover electrical / electronic components and

connections (e.g. generator, starter, governor,

lifting magnet).

With compressed air

● Blast out engine paying particular attention to

cooler and cooling fins (blast out beginning

from the exhaust side).

Remove any dirt blown inside.

With cold cleaner

● Spray the engine with standard cold cleaner

and leave to work for approx. 10 minutes.

● Spray the engine clean with an acute water jet,

repeat process if necessary.

● Warm up the engine so that the water residues

evaporate.

With a high pressure device

● Clean engine with steam jet (max. spray

pressure 60 bar, max. steam temperature

90 °C).

● Warm up the engine so that the water residues

evaporate.

6©

Only carry out cleaning work on

the engine when it is not running!

© 2004

Page 64

6

Care and maintenance work 6.7 Engine cleaning

© 2004

Page 65

7.1 Fault table

Faults, causes and remedies

7

© 2004

Page 66

7

Faults, causes and remedies 7.1 Fault table

z Faults can often be put down to the engine

not being operated correctly or not being

maintained.

z For every fault, check whether all operating

and maintenance instructions were

observed.

z A corresponding fault table can be found

overleaf.

z If you cannot recognise the cause of a fault

or cannot remedy a fault yourself please

contact your DEUTZ AG

© 2004

Page 67

7.1 Fault table Faults, causes and remedies

Faults Measures

Engine doesn’t start up, or starts up with difficulty Check P

Engines starts up, but runs irregularly or misfires Set E

Engine gets too hot. Temperature warning system is activated Change W

Engine lacks power Clean R

Engine doesn’t work on all cylinders Fill up A

Engine has no, or too little, oil pressure Lower S

Engine oil consumption is too high

Engine smoulders - blue

- white

- black

Causes

z

zz

zz

zz zz

zzz

zz

zz z z

zz z

zz z

zz

z

z

z

z

Not declutched (if possible)

Starting limit temperature not reached

Oil level too low

Oil level too high

Engine is tilted too far

Incorrect SAE class of engine lube oil and oil quality

Fuel quality does not comply with instruction manual

Air filter soiled / turbocharger defective

Air filter maintenance switch / display defective

Charge air line leaking

Fan defective / V-belt torn or loose

Cool air heating / heat short circuit

Resistance in cooling system is too high / flow volume too low

Battery defective or not charged

Section

Operation

Operating

substance

Combustion air

Cooling system

Electrics

P

P

A

P

S

W

W

P / W

P / W

P

P / W

P

P

P / A

7

© 2004

Page 68

7

Faults, causes and remedies 7.1 Fault table

Faults Measures

Engine doesn’t start up, or starts up with difficulty Check P

Engines starts up, but runs irregularly or misfires Set E

Engine gets too hot. Temperature warning system is activated Change W

Engine lacks power Clean R

Engine doesn’t work on all cylinders Fill up A

Engine has no, or too little, oil pressure Lower S

Engine oil consumption is too high

Engine smoulders - blue

- white

- black

z

z

zzz

zzzzz zz

Causes

Cable connections in starter circuit are loose or oxidised

Starter defective or pinion doesn’t mesh

Injection line leaking

Injection valve defective

Section

Electrics

Engine

P

P

P

P / W

© 2004

Page 69

Engine corrosion protection

8.1 Corrosion protection

8

Page 70

Engine corrosion protection

8.1 Corrosion protection

8

If the engine should be shut down for a long

period of time, corrosion protection will be

necessary in order to prevent rust formation.

The measures described here apply for a

shutdown period of up to 6 months.

Before the engine is commissioned again the

corrosion protection should be removed.

z Corrosion protection oils according to

specification:

MIL-L-21260B

TL 9150-037/2

Nato Code C 640 / 642

z Corrosion protection agent only for

exterior corrosion protection according

to specification:

Nato Code C 632

z Recommended cleaning agent for

removal of corrosion protection:

Petroleum benzine

(hazard class A3)

8.1.1 Protecting engine from

corrosion

z Clean engine with high-pressure

appliance (with cold cleaner if

absolutely necessary).

z Warm up the engine and switch off.

z Drain off engine oil, see chapter 6.1.2

and pour in corrosion protection oil.

z Clean oil discharge filter if necessary,

see chapter 6.4.3, and pour in corrosion

protection oil.

z Drain fuel from tank.

z Make fuel mixture from 90 % diesel fuel

and 10 % corrosion protection oil and fill

up tank.

z Leave the engine running for approx. 10

minutes.

z Switch off engine.

z Turn the engine several times by hand to

apply corrosion protection to the

cylinders and combustion chamber.

z Remove V-belt, pack up and store.

z Spray the grooves of the V-belt pulley

with corrosion protection agent.

z Seal intake and exhaust openings.

8.1.2 Removing engine corrosion

protection

z Remove corrosion protection agent from

grooves of V-belt pulley.

z Assemble V-belt. If necessary, re-

tighten after a short operating time, see

6.5.

z Remove seals from intake and exhaust

openings.

z Start up the engine.

Page 71

9.1 Engine and setting data

9.2 Screw tightening torques

Technical data

9

Page 72

Technical data 9.1 Engine and setting data

9

Engine type

Number of cylinders ----------------------------------------------------------------Cylinder arrangement ---------------------------------------------------------------Bore ------------------------------------------------------------------------------------ [mm]

Stroke ---------------------------------------------------------------------------------- [mm]

Total displacement -------------------------------------------------------------------- [cm

Compression ratio -------------------------------------------------------------------- [ε]

Working principle ---------------------------------------------------------------------

Combustion process----------------------------------------------------------------Direction of rotation ------------------------------------------------------------------Weight without cooling system (with starter, with generator) ----------------- ca [kg]

Engine power (at rpm) --------------------------------------------------------------- [kW]

Speed (example) --------------------------------------------------------------------- [rpm]

Lubrication / oil SAE -----------------------------------------------------------------Maximum oil temperature in oil tray ----------------------------------------------- [°C]

Minimum oil pressure in warm engine, oil temp. 110°C/ 230°F at:

max. 3000 rpm ------------------------------------------------------------------- [kPa/bar]

Engine with thermostat:

Oil change volume without external cooler / without filter approx. ------------ [ltr.]

Oil change volume without external cooler +

filter change (standard 0.5 ltr.) approx. ------------------------------------------- [ltr.]

Valve clearance:

Hydraulic tappet: Setting valve clearance is not necessary ---------

Start of pumping ----------------------------------------------------------- [°KW before TDC]

Engine ignition sequence ------------------------------------------------------------

V-belt tension: pre-tighten/re-tighten

(after the engine has been driven under load for 15 minutes): ---------------- [N]

3

]

------ D 2008 L03 -------------------------------- D 2008 L04 ------------

------------ 3 -------------------------------------------- 4 ------------------

------------------------------------ In-line -------------------------------------

-------------------------------------- 76 ---------------------------------------

-------------------------------------- 86 ---------------------------------------

---------- 1170 ---------------------------------------- 1560 ----------------

------------------------------------- 23.5 --------------------------------------

------------------------ Four-stroke diesel engine -------------------------

------------- Naturally aspirated engine with direct injection ------------

-------------------------- Left seen on fly wheel --------------------------

----------- 155 ------------------------------------------ 189 -----------------

------------------------------------- 3000 -------------------------------------

-------------------------- Forced feed lubrication / 20 W 20 -------------

--------------------------------------130 --------------------------------------

-------- 480 / 4.8 ------------------------------------- 400 / 4 ---------------

----------- 4.8 ------------------------------------------ 6.9 -----------------

----------- 5.3 ------------------------------------------ 7.4 -----------------

.1)

---------------------------------------

-------- 1 - 2 - 3 ----------------------------------- 1 - 3 - 4 - 2 ------------

------------------------------- 450 / 350 ±20 --------------------------------

. ---------------------------------------

1)

Engine power, speed and start of pumping, among other things, are stamped on the engine company plate, see also 2.1.

2)

Approx. value can vary depending on oil tray or cooler version (external cooling system). The upper oil dipstick marking is always decisive.

Page 73

Technical data 9.1 Engine and setting data

Engine type ---------------------------------------------------------------------------Number of cylinders ----------------------------------------------------------------Cylinder arrangement ---------------------------------------------------------------Bore ------------------------------------------------------------------------------------ [mm]

Stroke ---------------------------------------------------------------------------------- [mm]

Total displacement -------------------------------------------------------------------- [cm

3

]

Compression ratio -------------------------------------------------------------------- [ε]

Working principle ---------------------------------------------------------------------

Combustion process-----------------------------------------------------------------

------------------------------------------------------------------------------------------

Direction of rotation ------------------------------------------------------------------Weight without cooling system (with starter, with generator) ----------------- ca [kg]

Engine power (at rpm) --------------------------------------------------------------- [kW]

Speed (example) --------------------------------------------------------------------- [rpm]

Lubrication / oil SAE -----------------------------------------------------------------Maximum oil temperature in oil tray ----------------------------------------------- [°C]

Minimum oil pressure in warm engine, oil temp. 110°C/ 230°F at:

max. 3000 rpm ------------------------------------------------------------------- [kPa/bar]

Oil change volume without filter approx. ------------------------------------------ [ltr.]

Oil change volume with filter change (standard 0.5 ltr.) approx. -------------- [ltr.]

Valve clearance:

Hydraulic tappet: Setting valve clearance is not necessary ---------

-------- Start of pumping ------------------------------------------------- [°KW before TDC]

Engine ignition sequence ----------------------------------------------------------V-belt tension: pre-tighten/re-tighten

(after the engine has been driven under load for 15 minutes): ---------------- [N]

- D 2009 L03 ---------------- D 2009 L04 --------------- TD 2009 L04 ----

------- 3 ----------------------------- 4 ---------------------------- 4 -----------

------------------------------------ In-line -----------------------------------------

-------------------------------------- 90 -------------------------------------------

-------------------------------------- 90 -------------------------------------------

----- 1718 ------------------------ 2289 ------------------------ 2289 ---------

----- 19.6 -------------------------- 18 --------------------------- 18 -----------

------------------------ Four-stroke diesel engine -----------------------------

--Naturally aspirated ---- Naturally aspirated ----------- with charging ----

---- engine ---------------------- engine ----------------------------------------

----------------------------- and direct injection ---------------------------------

-------------------------- Left seen on fly wheel ------------------------------

----- 180 -------------------------- 205 -------------------------- 220 ----------

--------------------------------------- 1) -------------------------------------------

--------------------------------- max. 3000 --------------------------------------

-------------------- Forced feed lubrication/ 20 W 20 -------------------------

--------------------------------------130 ------------------------------------------

-- 200 / 2

---- 4.9

3)

. -------------------- 200 /2 3). ------------------- 220 /2,2 3). ------

2)

. ------------------------ 6.52). ------------------------ 6.52). ---------

------ 5.8--------------------------- 7.5 -------------------------- 7.5 ----------

------------------------------------------------------------------- 1) -------------------------------------------

---- 1-2-3 -------------------- 1 - 3 - 4 - 2 ------------------- 1-3-4-2--------

------------------------------- 450 / 350 ±20 ------------------------------------

9

1)

Engine power, speed and start of pumping, among other things, are stamped on the engine company plate, see also 2.1.

2)

Approx. value can vary depending on oil tray or cooler version (external cooling system). The upper oil dipstick marking is always decisive.

3)

Date for engines without engine oil heating.

Page 74

9

Technical data

Installation Pre-tightening Re-tightening Total Comments

[Nm] 1st step 2nd step 3rd step 4th step Nm

Cylinder head cover 27

Rocker arm setting screw – – – – – 27 ± 2

Intake elbow – – – – – 27 M8x125

Air intake pipe – – – – – 27

Exhaust manifold – – – – – 27

Oil drain screw sheet metal oil tray – – – – – 32 M14x1.50

Injection valve fastening – – – – – 28

Lube oil filter cartridge – – – – – 27

9.2 Screw tightening torques

Starter – ––––41

Page 75

Notes

en

Warnings to Place on Equipment

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its

constituents are known to the State of

California to cause cancer, birth

defects, and other reproductive harm.

Warning in the Manual

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its

constituents are known to the State of

California to cause cancer, birth

defects, and other reproductive harm.

or

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

Page 76

C

ALIFORNIA

P

ROPOSITION

65 I

NFORMATION

Notes

en

TOC

TO CUSTOMERS SELLING DIESEL ENGINE EQUIPMENT INTO OR

Proposition 65, a California law, requires warnings on products which expose individuals in California to chemicals listed under that law,

including certain chemicals in diesel engine exhaust.

Obligations of Manufactures of Diesel-Powered Off-Road Equipment. The California Superior Court has approved either of the following

two methods of compliance with Proposition 65 requirements by manufactures of off-road equipment containing diesel engines. (The court

order containing these provisions is attached.)

1.

On-Equipment Warning. Place the warning pictured in attachment 1 on all equipment shipped by you into or for sale in California after

January 1, 1996. The warning must be in a location where it is easily visible to the operator of the equipment when (s)he is operating the

equipment. The warning must be secured to the equipment. If warnings or operating instructions are provided through a digital display,

you may usee that method of providing warning.

Operator Manual Warning. When the operator manual is next revised or by December 31, 1995 whichever is earlier, place the warning

2.

in attachment 2 in the operator manual. The warning may be either printed in the manual or on a sticker.

The warning must appear in one of the following locations:

●

Inside The front cover

●

Inside the back cover

●

Outside the front cover

●

Outside the back cover

●

As the first page of text

ALIFORNIA CUSTOMERS AND

C

FOR USE IN

ALIFORNIA.

en

Under either alternative, the warning must appear in the same size, print and format as the attachment selected or be of an equally conspicuous

size and format. If the warning is provided in an on-screen display, the warning must contain the language in the attachment and must be

provided at the time of or in connection with ignition in the same manner as other safety warnings electronically communicated on screen.

Obligation of Resellers of Diesel Engines. This letter must accompany any loose diesel engine sold in California.

Should you have any questions, please call Deutz Corporation Product Support Department.

Page 77

Service

de

For many years DEUTZ has stood for pioneering

development in engine construction. As an independent engine manufacturer we offer a

complete palette of diesel and gas engines

worldwide. Our products are perfectly tailored

to meet the requirements of our customers.

More than 1.4 million DEUTZ engines reliably

perform their service all over the world. We want

to preserve the operational readiness of our

engines and with it the satisfaction of our

customers. Therefore we are represented

worldwide by a network of competent partners,

the concentration of whom corresponds to the

regional distribution of our engines.

Thus, DEUTZ is not just a name for innovative

engines. But also for a complete service package

for every aspect of engines, and a service that

you can rely on.

You can find a complete overview of DEUTZ

partners in your area, their product competencies and their services on the DEUTZ website

(see below).

Also if there is no direct product competency

specified, your DEUTZ partner will be able to help

you further with professional advice.

10

Your DEUTZ AG

Deutz-Mülheimer Str. 147-149

D-51063 Cologne

Telephone: 0049-221-822-0

Fax: 0049-221-822-3523

Telex: 8812-0 khd d

http://www.deutz.de

Page 78

Impressum:

DEUTZ AG

Service Informatin Systems