Desa DNV25NB, DNV40NB User Manual

DYNAVENT

WINDOW WALL FURNACE

DIRECT-VENT NATURAL GAS HEATER

OWNER’S OPERATION AND INSTALLATION MANUAL

DNV25NB

DNV40NB

50 60 70 80 90

SOLID STATE IGNITION

50 60 70 80 90

25,000 and 40,000 BTU/Hr “B” Model Furnaces

WARNING: If the information in these instructions is not

followed exactly, a fire or explosion may result causing

property damage, personal injury, or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

WARNING: Improper installation, adjustment,

alteration, service, or

maintenance can cause

injury or property damage. Refer to this manual

for correct installation

and operational procedures. For assistance or

additional information

consult a qualified installer, service agency,

or the gas supplier.

— Installation and service must be performed

by a qualified installer,

service agency, or the

gas supplier.

This appliance may be installed in an aftermarket*, permanently located, manufactured (mobile) home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This

appliance is not convertible for use with other gases.

* Aftermarket: Completion of sale, not for purpose of resale, from the manufacturer

Save this manual for future reference.

®

DYNAVENT

DIRECT-VENT NATURAL GAS HEATER

SAFETY

INFORMATION

WARNINGS

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble, operate,

or service this furnace. Improper

use of this furnace can cause serious injury or death from burns, fire,

explosion, electrical shock, and

carbon monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

Carbon Monoxide Poisoning: Early signs of

carbon monoxide poisoning resemble the flu,

with headaches, dizziness, and/or nausea. If

you have these signs, the furnace may not be

working properly. Get fresh air at once! Have

furnace serviced. Some people are more affected by carbon monoxide than others. These

include pregnant women, people with heart or

lung disease or anemia, those under the influence of alcohol, and those at high altitudes.

Natural Gas: Natural gas is odorless. An odor-

making agent is added to natural gas. The odor

helps you detect a natural gas leak. However,

the odor added to natural gas can fade. Natural

gas may be present even though no odor exists.

Make certain you read and understand all warnings. Keep this manual for reference. It is your

guide to safe and proper operation of this furnace.

WARNING: Any change to

this heater or its controls can

be dangerous.

Due to high temperatures, the

appliance should be located out

of traffic and away from furniture

and draperies.

Carefully supervise young children when they are in the same

room with furnace.

Do not place clothing or other

flammable material on or near

the appliance. Never place any

objects on the furnace.

Surface of furnace becomes very

hot when running furnace. Keep

children and adults away from

hot surface to avoid burns or

clothing ignition. Furnace will remain hot for a time after shutdown. Allow surface to cool before touching.

Turn off furnace and unplug and let

cool before servicing. Unless you

need gas supply for testing, shut

off equipment shutoff valve before

servicing. Only a qualified service

person should service and repair

furnace and venting system.

Replace any safety screen or

guard removed for servicing before operating furnace.

You must keep control compartments, burners, and circulating

air passages clean. More frequent

cleaning may be needed due to

excessive lint and dust from carpeting, bedding material, etc.

Turn off the gas valve and unplug

before cleaning furnace.

1. A qualified service person must install

furnace.

2. This appliance is only for use with the

type of gas indicated on the rating plate.

This appliance is not convertible for use

with other gases.

3. Use only natural gas. Do not convert

furnace to use different fuel type.

4. If you smell gas

• Shut off gas supply.

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

5. Do not block the flow of combustion

air (outside air) or heated air (room air)

to the furnace.

6. This furnace must have fresh air for

proper operation. If not, poor fuel combustion and improper venting of flue

gases will result. Carbon monoxide

poisoning from backed-up flue gases

could occur. The State of California

lists carbon monoxide as a reproductive toxin under Proposition 65.

7. Never install the furnace

• in a recreational vehicle

• in an alcove

• on an inside wall

• as a fireplace insert

• in high traffic areas

• in windy or drafty areas

• behind a door or where an open door

would block normal air flow

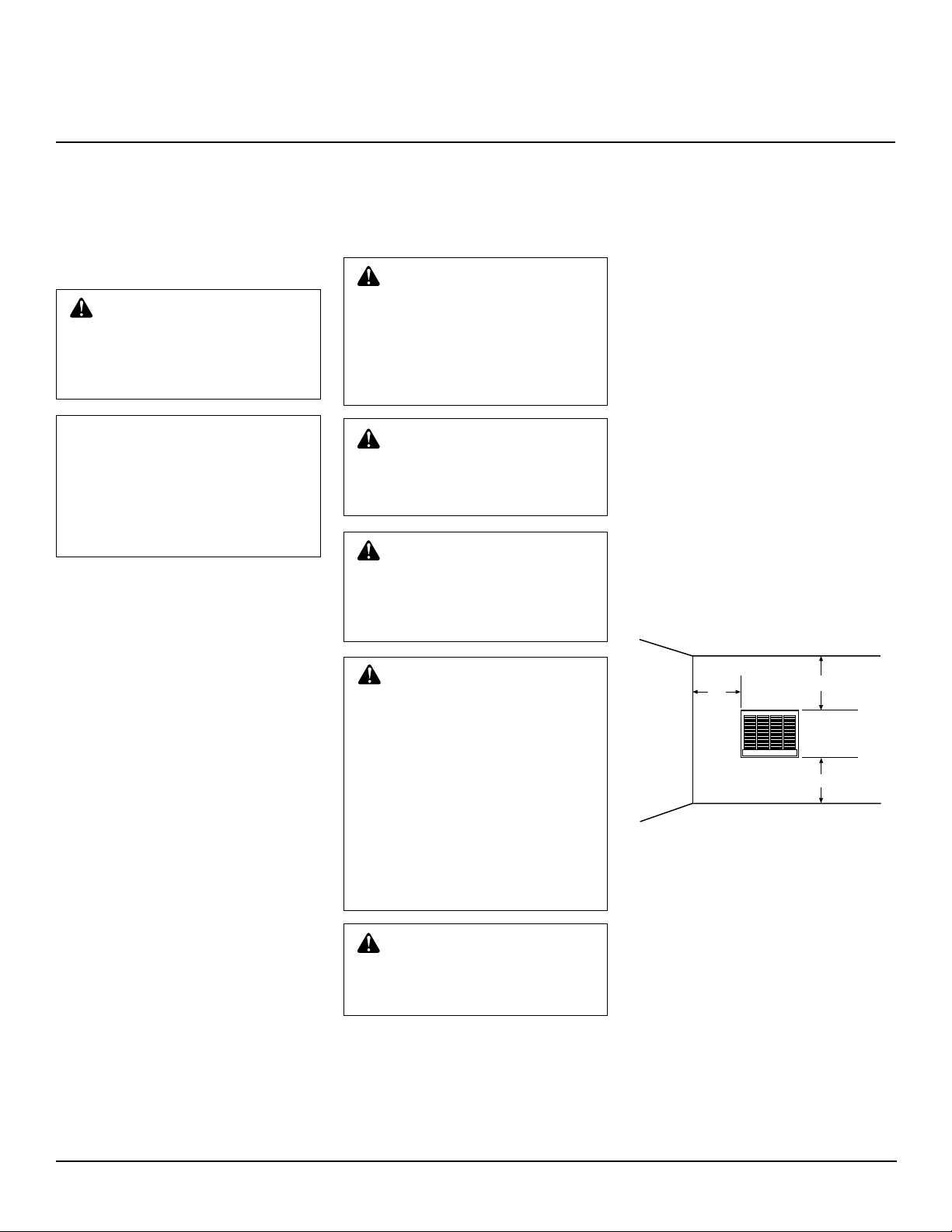

8. Provide the following minimum furnace clearances from furnace front

cover to combustibles (as viewed from

the front of furnace):

Below Front Cover: 6 inches

Adjoining Wall: 12 inches

Above Front Cover: 12 inches

Front: 8 feet

9. Do not obstruct the flow of combustion and ventilation air in any way . Provide adequate clearances around air

openings into the combustion chamber

along with adequate accessibility clearance for servicing and proper operation.

10. Provide the following minimum furnace

clearances from furnace cabinet (portion

of cabinet extending into outside air, as

viewed from the rear of furnace):

Cabinet Back: 36 inches

Cabinet Sides: 6 inches

Cabinet Bottom: Must be high enough

off the ground to prevent snow, water,

leaves, or any other objects from blocking cabinet vents.

11. Always follow lighting instructions.

Never attempt to light burner with a

match or butane torch.

12. Do not run furnace

• where flammable liquids or vapors

are used or stored

• under dusty conditions

13. Do not use furnace as a cooking device.

14. Do not alter furnace or its controls. Any

change may create a safety hazard.

15. Do not use furnace if any part has been

under water. Immediately call a qualified service person to inspect the furnace and to replace any part of the control system and any gas control which

has been under water.

2

201835

OWNER’S MANUAL

LOCAL CODES

Install and use furnace with care. Follow all

local codes. In the absence of local codes, use

the latest edition of the following:

• National Fuel Gas Code ANS Z223.1,

also known as NFPA 54 * (USA)

• National Electric Code ANS/NFPA 70*

• CAN/CGA-B149[.1 or .2] Installation

Codes** (Canada).

*Available from:

American National Standards Institute, Inc.

1430 Broadway

New York, NY 10018

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

**Available from:

Standards Council of Canada

350 Sparks Street

Ottawa, Ontario K1R 7S8

This furnace must be grounded when installed. Follow all local codes. In the absence of local codes, refer to the National

Electrical Code ANS/NFPA No. 70 (U.S.A.)

or CSA C22.1 Canadian Electrical Code,

Part I (Canada).

The installation must conform with local

codes, in the absence of local codes, with the

National Fuel Gas Code, ANS Z223.1/Canadian Installation Code, CAN/CGA B149.

When installing furnace in a manufactured

(mobile) home, follow the Manufactured

Home Construction and Safety Standard,

Title 24CFR, Part 3280 (formerly the Federal Standard for Mobile Home Construction and Safety, Title 24, part 280; 1975).

When such a standard is not applicable,

follow the Standard for Manufactured Home

Installations, 1982 (Manufactured Home

Sites, Communities, and Set-Ups), ANS

A225.1/NFPA 501A.

In Canada, install furnace in accordance with

Standard CSA Z240.4 - Gas Equipped Recreational Vehicles and Mobile Housing and

any applicable local codes and regulations.

Appliance input ratings are based on sea

level operation and need not be changed for

operation up to 2,000 feet elevation. For

operation at elevations above 2,000 feet,

manufactured to specified deration conditions for Canada and the United States.

UNPACKING

1. Remove furnace from carton.

2. Remove all protective packaging applied to furnace for shipment.

3. Remove the following items from carton:

• Hardware package containing four

large screws, two small screws, and

thermostat mounting plate

• Hardware package (thermostat and

two screws)

• Equipment shutoff valve

If any of these items are missing,

promptly inform dealer where you

bought furnace.

4. Check furnace for any shipping damage.

If furnace is damaged, promptly inform

dealer where you bought furnace.

PRODUCT

FEATURES

HOT SURFACE IGNITOR

This furnace has an electronic ignitor. There

is no standing pilot. No matches or batteries

are required.

THERMOSTATIC HEAT

CONTROL

The thermostat is temperature sensitive. It

automatically turns the furnace on and off.

This results in the greatest heating comfort.

This can also result in lower gas bills.

LIMIT SWITCH

The limit switch shuts off the gas to the main

burner if the furnace becomes too hot to

operate safely.

SPECIFICATIONS

DNV25NB DNV40NB

*Rated Heating Input (BTU/Hr) 25,000 40,000

Thermal Output Capacity

(average loss calculation) 18,750 Btu/Hr 30,000 Btu/Hr

Type Gas Natural Only Natural Only

Ignition Hot Surface Ignitor Hot Surface Ignitor

Operating Amps 1.5 2

Volts/Cycles 120/60 120/60

Main Burner 1 2

Pressure Regulator Setting 3.5" W.C. 3.5" W.C.

Inlet Connection 3/8 NPT 3/8 NPT

Inlet Gas Pressure (in. of water)*

Maximum 7" 7"

Minimum 5" 5"

Dimensions, Inches (H x W x D)

Furnace 15 3/32 x 16 1/8 x 23 5/8 15 3/32 x 21 3/4 x 23 5/8

Weight (pounds)

Furnace 53 71

Shipping 65 98

* For purposes of input adjustment.

201835

3

®

6" Minimum

Adjacent

Side

Wall

Ceiling

Finished Floor, Carpet, Tile, etc.

12"

Minimum

12" Minimum

DYNAVENT

DIRECT-VENT NATURAL GAS HEATER

INSTALLATION

Mounting hardware needed to mount furnace into wall is included with the furnace.

No venting material is needed. You must

furnish tools and all gas piping from the gas

source to the furnace inlet.

WARNING: A qualified service person must install furnace.

Have service person inspect furnace before use and at least annually. Follow all local codes.

NOTICE: This furnace must be

electrically grounded. Follow all

local codes. In the absence of

local codes, follow the

Electric Code, ANS/NFPA 70

(U.S.) or Canadian Electrical Code

Part I-CSA C22.1 (Canada).

CHECK GAS TYPE

Use only natural gas. If your gas supply is

not natural gas, do not install furnace. Call

dealer where you bought furnace for proper

type furnace.

INSTALLATION ITEMS

Before installing furnace, make sure you

have all items below:

• electric drill

• drill bits

• Phillips screwdriver

• hammer

• pipe wrench

• stud locator or small finishing nails

• equipment shutoff valve (supplied)

• test gauge connection (see Figure 15,

page 10)

• piping (check local codes)

• sealant (resistant to propane/LP gas)

• ground joint union

• sediment trap

• tee joint

National

LOCATING FURNACE

This furnace is designed to be mounted in a

wall that is 4 to 18 inches thick. You can also

mount furnace in a window.

WARNING: Do not install furnace in interior wall of building. You

must install furnace in exterior wall

of building. Rear of furnace must

extend into open, outside air. This

lets poisonous exhaust gases ventilate to the outdoors.

WARNING: Turn off electrical

circuits that pass through the wall

where you are going to install the

furnace.

WARNING: Maintain the minimum clearances shown in Figure

1. If you can, provide greater clearances from floor, ceiling, and

joining wall.

WARNING: Due to high temperatures, never install the furnace:

• in an inside wall

• in a recreation vehicle

• in a window recessed in a thick

wall (creating an alcove)

• in an alcove

• behind a door or where an open

door would block normal air flow

• as a fireplace insert

• in high traffic areas

• near furniture or draperies

• in windy or drafty areas

CAUTION: If you install the

furnace in a home garage, locate

furnace where moving vehicle will

not hit it.

For convenience and efficiency, install furnace:

• where there is easy access for operation,

inspection, and service

• in a central location, near an electrical

outlet

• where there is adequate clearance around

vents outside

Before installing furnace, inspect the wall,

floor, and outside areas. Make sure there are

no pipes, wiring, or anything else that would

interfere with furnace installation. If you are

installing thermostat in a wall, make sure

there are no pipes or wiring in the hollow

wall above the furnace. The thermostat wires

will pass through this wall from the attic.

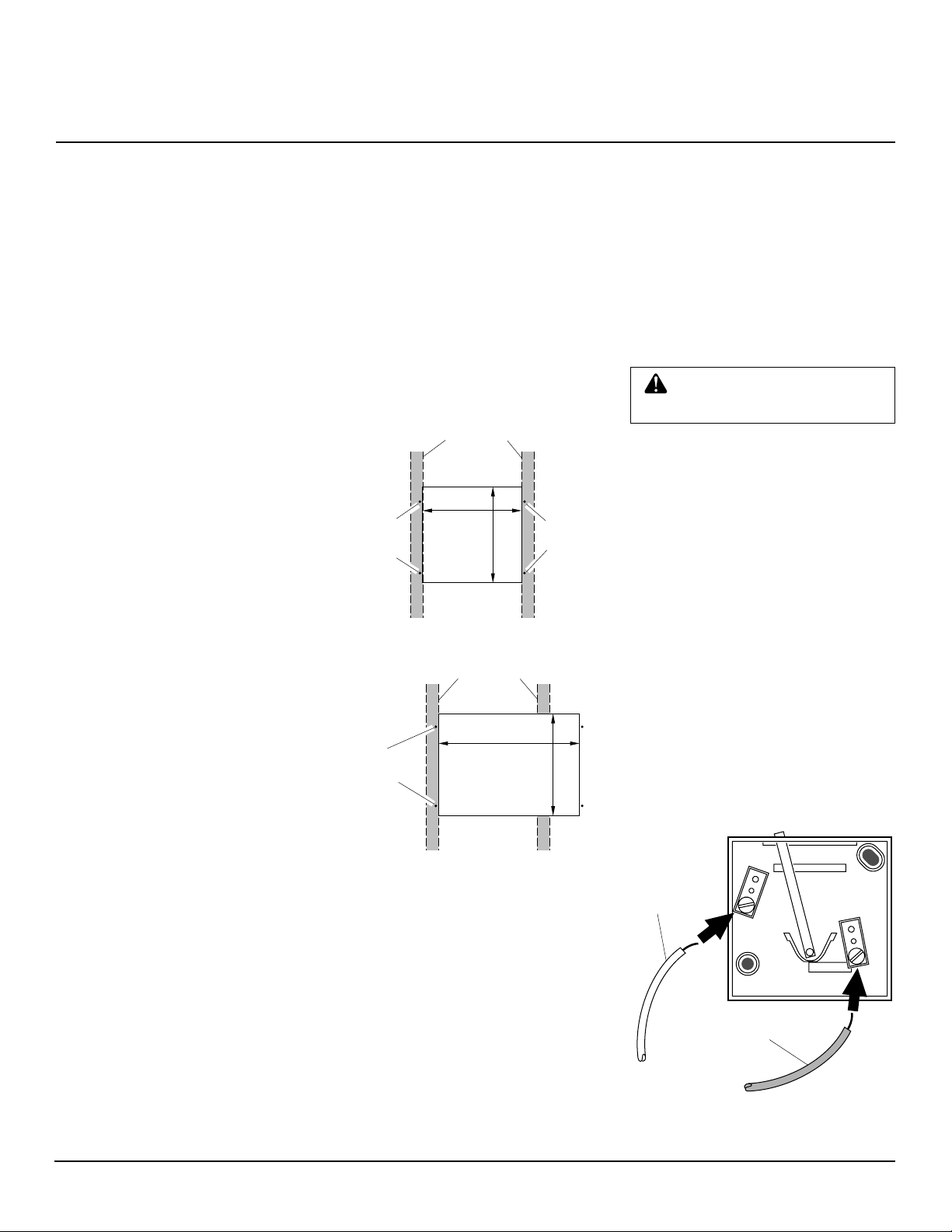

Minimum Clearances

Provide the following minimum clearances

from furnace front cover to combustibles

(as viewed from the front of furnace, see

Figure 1):

Below Front Cover: 6 inches

Above Front Cover: 12 inches

Adjoining Wall: 12 inches

Front: 8 feet

Figure 1 - Mounting Clearances as Viewed

from Front of Furnace

The clearance between the cabinet and the

wall it passes through is 0 inches.

Provide the following minimum clearances

from furnace cabinet (portion of cabinet

extending into outside air, as viewed from

the rear of furnace) to obstructions:

Cabinet Back: 36 inches

Cabinet Sides: 6 inches

Cabinet Bottom: Must be high enough

off the ground to prevent snow, water,

leaves, or any other objects from blocking vents.

4

201835

OWNER’S MANUAL

INSTALLATION

(Continued)

CREATING WALL OPENING

AND MOUNTING FURNACE

Remove furnace front cover. Remove the

two screws at the lower edges of front cover.

Lift front cover away.

Installing in Normal Frame Wall

The 25,000 BTU/Hr model is designed to fit

between two wall studs set at 16 inch on

center. The 40,000 BTU/Hr model will not

fit between wall studs. Follow the steps

below to install.

1. Turn off electrical circuits that pass

through mounting wall. Make sure

there are no pipes or electrical wires in

area you intend to cut.

2. Use stud locator or small finishing nail

to find wall studs. When you locate

studs, drive a small finishing nail into

each stud. This provides a visual reference for stud locations.

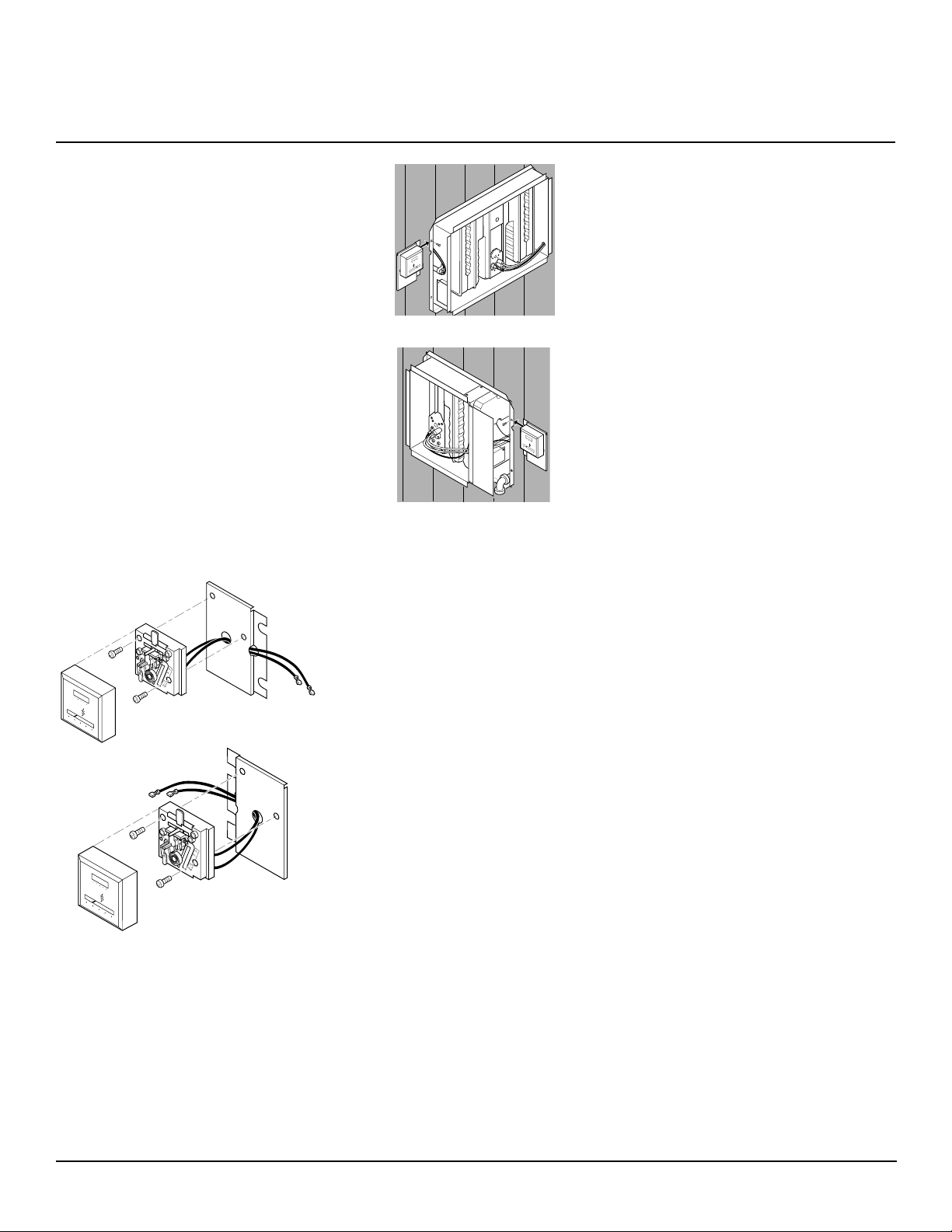

3. 25,000 BTU/Hr Model: Cut an opening in wall between the two studs. Make

opening 141/4" wide by 135/8" high

(see Figure 2).

must install furnace horizontally. Do

not install furnace vertically.

40,000 BTU/Hr Model: Cut a 20

wide by 14 3/8" high opening in wall (see

Figure 2). Start your cut right next to

stud you are going to anchor cabinet to.

Cut across wall and through the next

stud. Stop cut at proper width.

IMPORTANT:

horizontally . Do not install furnace vertically .

4. 25,000 BTU/Hr Model: Mark screw

locations on wall (see Figure 2). Make

sure screws will anchor into studs.

Make sure screw locations match screw

holes on cabinet flange.

40,000 BTU/Hr Model: Mark screw

locations on wall (see Figure 2). Make

sure screws on one side will anchor into

studs. Screws on other side will only

anchor in wall material. Make sure

screw locations match screw holes on

IMPORTANT:

Yo u

5

/16"

Y ou must install furnace

cabinet flange.

5. 25,000 BTU/Hr Model: Use a propersized drill bit. Drill holes through wall

and into studs at marked locations.

40,000 BTU/Hr Model: Use a proper-

sized drill bit. On wall stud side of

opening, drill holes through wall and

into studs at marked locations. On other

side, drill holes through wall material.

6. Insert furnace into opening. Do this

from inside the room. Secure furnace

to wall with four large screws provided.

7. On outside of wall, caulk opening between the cabinet and the rough edges

of opening.

Approx.

Screw

Locations

Wall Studs

1

/4"

14

Wall

Opening

13

5

/8"

Approx.

Screw

Locations

25,000 BTU/Hr Model

Wall Studs

Approx.

Screw

Locations

20 5/16"

Wall Opening

14

3

/8"

40,000 BTU/Hr Model

Figure 2 - Wall Openings and Screw

Locations

Installing in Masonry Wall

You can mount both models in a masonry

wall. Follow the steps below to install.

1. Cut opening in wall. Make opening 14 1/4"

wide by 13 5/8" high for 25,000 BTU/Hr

models. Make opening 20 5/16" wide by

14 3/8" high for 40,000 BTU/Hr models.

IMPORTANT:

furnace horizontally . Do not install furnace vertically.

You must install

2. Secure furnace to wall with toggle bolts

or hook bolts set in mortar.

3. Insert furnace into opening. Do this

from inside the room. Secure furnace

to wall with toggle bolts or hook bolts.

4. On outside of wall, caulk opening between the cabinet and the rough edges

of opening. You can also use mortar to

seal opening.

INSTALLING THERMOSTAT

WARNING: Unplug furnace

before installing thermostat.

Mount the thermostat directly on the furnace or on a wall in another part of the room.

If you have solid or masonry walls, mount

the thermostat on the furnace.

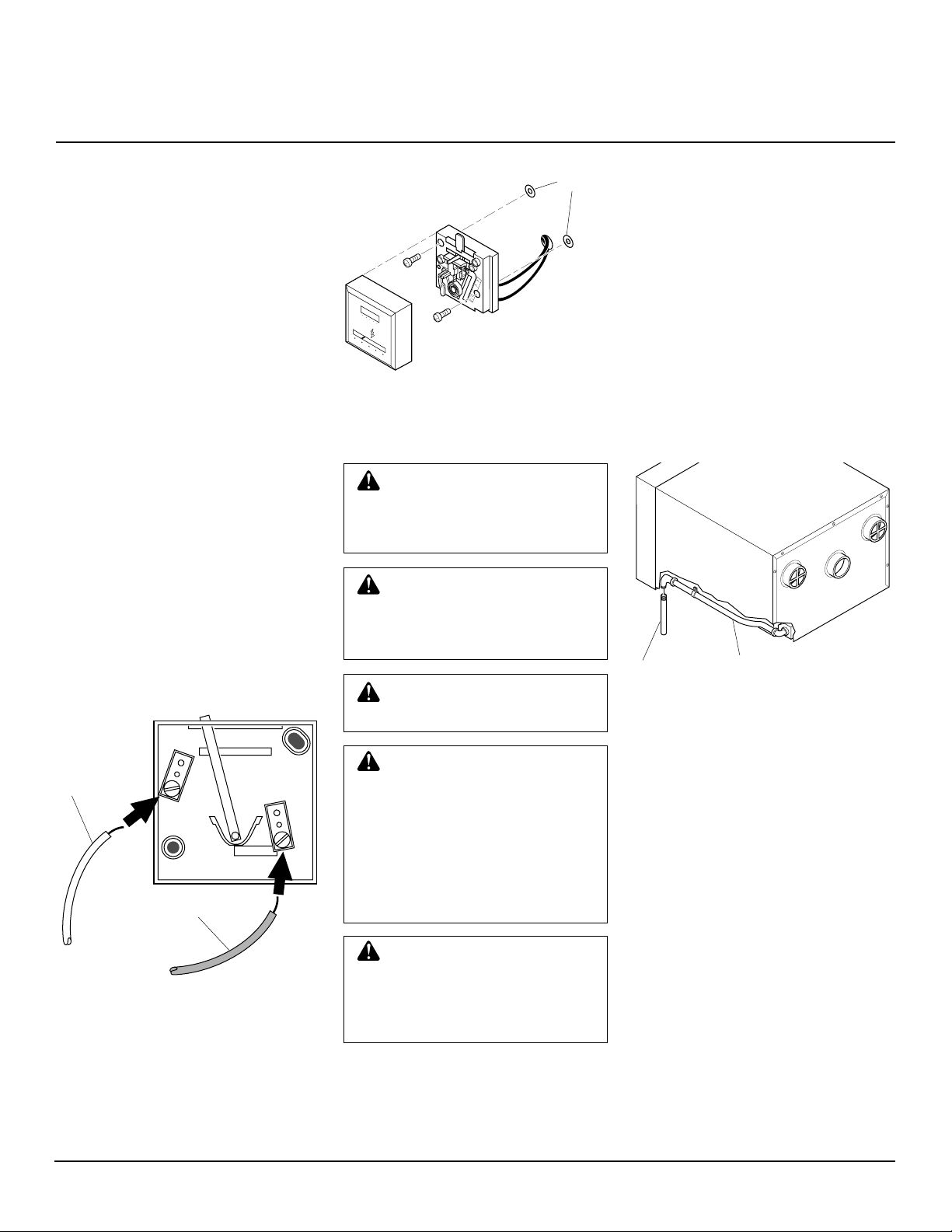

Mounting Thermostat to Furnace

1. Unplug furnace.

2. Locate red and white thermostat wires

coming out of side of furnace. These

wires are labeled “Thermostat.”

3. Cut thermostat wires to desired length.

4. Route thermostat wires through slot/

hole in side of thermostat mounting

plate. Then route wires through 5/8"

diameter hole in center of plate (see

Figure 4, page 6).

5. Connect thermostat wires to the two

terminal screws on back of thermostat

(see Figure 3). Connect red wire to “R”

terminal. Connect white wire to “W”

terminal.

White Wire

W

R

Red Wire

Figure 3 - Connecting Thermostat Wires

to Thermostat

Continued

201835

5

®

DYNAVENT

DIRECT-VENT NATURAL GAS HEATER

INSTALLATION

(Continued)

6. Attach thermostat to thermostat mounting plate with screws provided (see Figure 4).

IMPORTANT:

plate position in Figure 4. Correctly

position mounting plate for your model

furnace.

7. Insert thermostat mounting plate between wall and cabinet flange. Line up

top notch on mounting plate with top

screw on flange (see Figure 5).

IMPORTANT:

BTU/Hr model mounts on right side of

furnace (see Figure 5). Thermostat for

40,000 BTU/Hr model mounts on left

side of furnace (see Figure 5).

8. Insert screw in cabinet flange and thermostat mounting plate and tighten firmly .

IMPORT ANT :

wires do not touch combustion chamber.

.2

.3

.4

OFF

.5

.7

50 60 70 80 90

SOLID STATE IGNITION

50 60 70 80 90

50 60 70 80 90

SOLID STATE IGNITION

50 60 70 80 90

Figure 4 - Attaching Thermostat to

Thermostat Mounting Plate

1.0

40,000 BTU/Hr Models

OFF

25,000 BTU/Hr Models

Note mounting

Thermostat for 25,000

Make sure thermostat

.2

.3

.4

.5

.7

1.0

00

0

0 00

00

00

00000000000 00000000

00 00 00 00 00

40,000 BTU/Hr Models

50 60 70 80 90

S

O

L

ID

S

T

A

T

E

IG

N

IT

IO

50 60 70 80 90

N

25,000 BTU/Hr Models

Figure 5 - Inserting Thermostat Mounting

Plate Between Wall and Cabinet Flange

Locating Thermostat on Wall

1. Locate thermostat 4 1/2 to 5 feet above

the floor on an inside wall away from

any heat sources. The thermostat needs

to sense average room temperature.

Avoid the following:

HOT SPOTS

Concealed pipes or ducts

Fireplaces

Registers

TV sets and radios

Lamps or direct sunlight

Kitchen

COLD SPOTS

Concealed pipes or ducts

Stairwells (drafts) or doors (drafts)

Unheated rooms on other side of wall

DEAD SPOTS

Behind doors

Corners and alcoves

2. Before installing thermostat, inspect the

wall, floor, and attic areas. Make sure

there are no pipes, wiring, or anything

else that would interfere with installing thermostat. Do not mount thermostat to stud. If there are any obstructions, choose a new location.

3. Provide two 18-gauge insulated stranded

wires for the thermostat wire. Also provide two wire nuts, and two wall anchors.

There is a red and a white thermostat wire

coming from the furnace. The extra thermostat wires you furnish attach to these

wires. Make sure you furnish a red and a

white wire. This will insure correct

hookup. Purchase enough thermostat wire

to go from the furnace to the thermostat

location. Do not cut and splice this wire.

The thermostat wire must be unbroken.

Routing Thermostat Cable

All wiring must meet local codes. The following instructions cover routing the wire

through the attic. You can run wiring from

a basement or crawl space.

1. Unplug furnace.

2. Before drilling hole in wall, drive a small

finishing nail through ceiling directly

above thermostat location. Pull nail out

and push a small stiff wire through hole.

This helps you locate thermostat mounting location when in attic.

3. In attic, locate stiff wire. Drill 1/2" hole

in center of ceiling wall plate next to

stiff wire. Remove wire.

4. Probe through drilled hole in wall plate

with a stiff wire to make sure there are

no pipes, wiring, or anything else

blocking the way for thermostat wires.

If you find blockage, choose new location for thermostat.

5. Drill a 1/2" hole through the wall at

thermostat mounting location.

6. From attic, feed thermostat wires

through hole in ceiling plate until wires

reach thermostat location.

7. Make a small hook with a piece of stiff

wire. Run wire hook through 1/2" hole

in wall. Hook thermostat wires. Pull

wires through hole in wall. Make sure

6" of wires stick out.

8. Drive a small finishing nail in ceiling

above furnace.

25,000 BTU/Hr Model - Drive nail

above right side of furnace.

40,000 BTU/Hr Model - Drive nail

above left side of furnace.

Pull nail out and push a small stiff wire

through hole. This helps you locate wire

routing location when in attic.

9. Repeat steps 3 and 4 above.

6

201835

OWNER’S MANUAL

INSTALLATION

(Continued)

10. Feed thermostat wires from attic to

furnace through 1/2" hole in ceiling

wall plate.

11. Connect thermostat wires from attic to

thermostat wires on furnace. Connect

red wires together, then connect white

wires together. Use wire nuts to make

connections.

thermostat wires do not touch combustion chamber.

Mounting the Thermostat to Wall

1. Connect thermostat wires to the two

terminal screws on back of thermostat

(see Figure 6). Connect red wire to “R”

terminal. Connect white wire to “W”

terminal.

2. Push any excess wire back through hole

in wall and plug hole with insulation

to prevent drafts. Drafts affect the thermostat operation.

3. Use thermostat base to mark mounting

screw locations.

4. Drill proper-sized holes for wall anchors.

5. Attach thermostat to wall using screws

provided (see Figure 7).

IMPORTANT:

Make sure

Wall

Anchors

.2

.3

.4

OFF

.5

.7

1.0

50 60 70 80 90

SOLID STATE IGNITION

50 60 70 80 90

Figure 7 - Mounting Thermostat to Wall

CONNECTING TO GAS

SUPPLY

WARNING: A qualified service person must connect furnace to gas supply. Follow all

local codes.

WARNING: Never connect

furnace to private (non-utility) gas

wells. This gas is commonly

known as wellhead gas.

WARNING: Unplug furnace

before connecting to gas supply.

All piping must comply with local codes

and ordinances or with the National Fuel

Gas Code (ANS Z223.1 NFPA No. 54),

whichever applies.

You can connect furnace to gas supply at

front of furnace (inside) or at rear of furnace

(outside).

Connecting Furnace to Gas

Supply at Front of Furnace

1. Locate gas inlet pipe on lower, right

front of furnace (see Figure 8).

2. Connect 3/8" NPT pipe or nipple to gas

inlet pipe (see Figure 8). See Provid-

ing Gas Piping to Furnace, pages 9 and

10, for correct gas pipe installation.

3/8" NPT

Pipe or

Nipple

Figure 8 - Connecting Gas from Inside of

Room

Gas Inlet Pipe

White Wire

W

R

Red Wire

Figure 6 - Connecting Thermostat Wires

to Thermostat

201835

CAUTION: Use only new,

black iron or steel pipe. Copper

tubing may be acceptable in certain areas. Check local codes.

Use pipe large enough in diameter to allow proper gas volume

to furnace. If pipe is too small,

undue loss of pressure will occur. Refer to chart on page 9.

CAUTION: Lightly apply pipe

joint sealant to male threads before connecting. Use pipe joint

sealant that is resistant to liquid

petroleum (LP) gas.

Continued

7

®

DYNAVENT

DIRECT-VENT NATURAL GAS HEATER

INSTALLATION

(Continued)

Connecting Furnace to Gas

Supply at Rear of Furnace

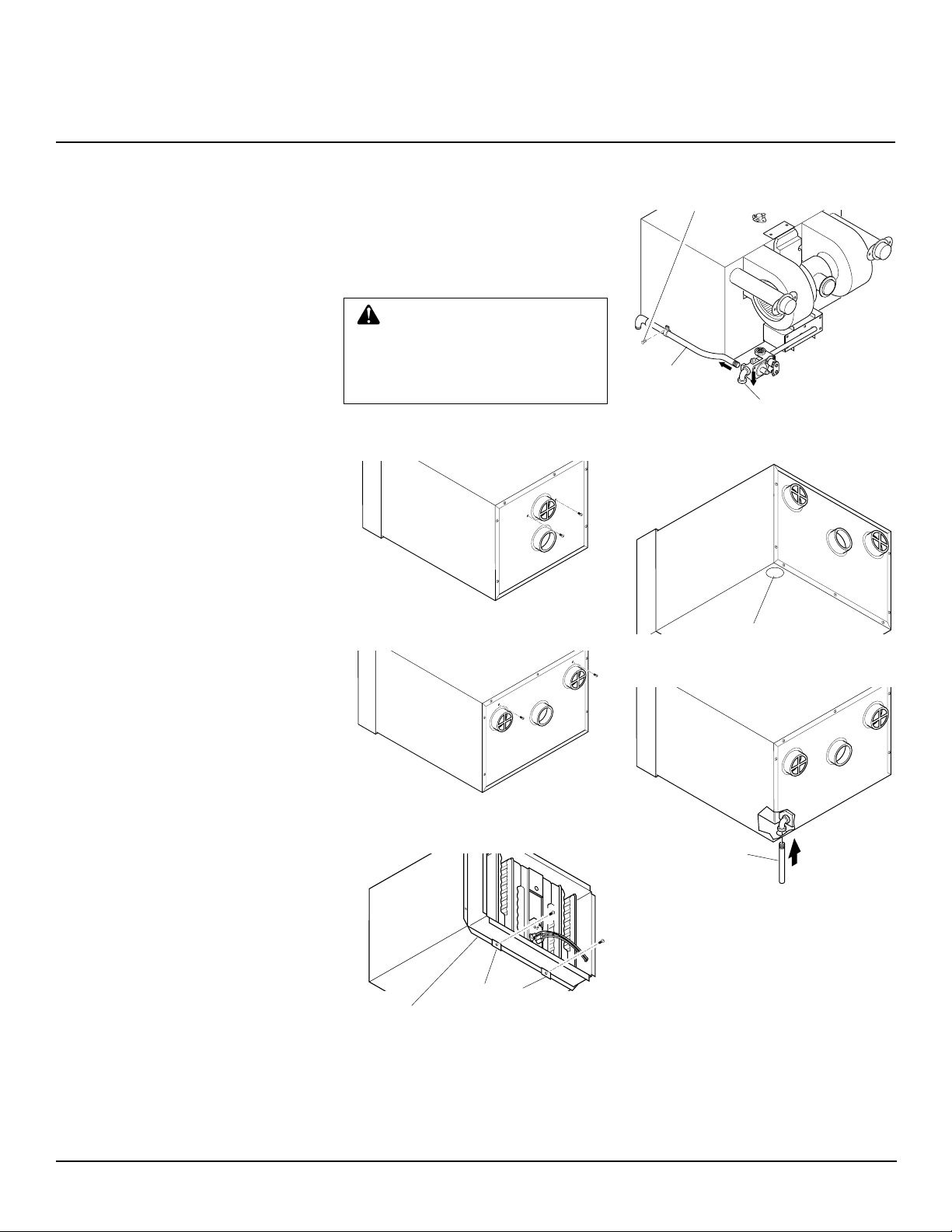

1. Remove the two screws in back of furnace cabinet located by the exhaust

vent(s) (see Figures 9 and 10).

2. Remove two screws on front lower

flange that attach furnace flange to furnace cabinet flange (see Figure 11).

Note:

40,000 BTU/Hr model has a bottom shield (see parts list, page 22, for

location). Removing two screws will

detach bottom shield.

3. Slide furnace out of furnace cabinet.

4. Locate gas inlet pipe on lower, right

front of furnace.

5. 40,000 BTU/Hr Model Only: Remove

screw holding gas inlet pipe clamp to

furnace.

6. Disconnect gas inlet pipe from 3/8"

manifold elbow. Turn gas inlet pipe

counterclockwise to disconnect (see

Figure 12).

7. Rotate the 3/8" manifold elbow 90° so

the opening is pointing downward (see

Figure 12).

8. Locate knockout plug in furnace cabinet. Knockout plug is in lower left rear

of furnace cabinet (as viewed from rear,

see Figure 13). Remove knockout plug.

9. Slide furnace back into furnace cabinet. Make sure exhaust tube gaskets are

in place. Make sure exhaust and intake

vent tubes extend into vent caps on

back of cabinet. Replace two screws by

exhaust vent(s) removed in step 1.

10. 25,000 BTU/Hr Model: Replace two

screws removed in step 2. Attach furnace flange and furnace cabinet lower

flange together.

40,000 BTU/Hr Model: Place bottom

shield back in place. Replace two

screws removed in step 2. Attach bottom shield, furnace flange, and furnace

cabinet lower flange together.

11. Run 3/8" pipe or nipple through knockout hole. Connect 3/8" pipe or nipple

to manifold elbow (see Figure 14). See

Providing Gas Piping to Furnace,

pages 9 and 10 for correct gas pipe installation.

12. Check connections for gas leak.

WARNING: Never use an open

flame to check for a leak. Apply a

mixture of liquid soap and water

to all joints. Bubbles forming show

a leak. Correct all leaks at once.

13. Caulk around pipe or nipple. This prevents cold air entering knockout hole.

Figure 9 - Locations of Screws in Back of

Furnace Cabinet (25,000 BTU/Hr Model)

Figure 10 - Locations of Screws in Back

of Furnace Cabinet (40,000 BTU/Hr Model)

Furnace

Furnace

Cabinet

Flange

Figure 11 - Removing Screws on Lower

Flange (40,000 BTU/Hr Model Shown)

Flange

Remove Screw,

40,000 BTU/Hr

Model Only

Gas Inlet

Pipe

Manifold Elbow

Figure 12 - Disconnecting Gas Inlet Pipe

(40,000 BTU/Hr Model Shown)

Knockout Plug

Figure 13 - Location of Knockout Plug

3/8" NPT

Figure 14 - Inserting Pipe through

Knockout Hole

8

201835

OWNER’S MANUAL

INSTALLATION

(Continued)

Providing Gas Piping to Furnace

You must provide gas piping from gas source to furnace. The gas piping must be in a vertical

position where it connects to the furnace. This prevents interference with front cover

installation.

Consult your local gas company for proper routing of the gas lines.

Pipe size is determined by the length of pipe from the gas source to the furnace and the total

BTU load on the gas source.

Add the total BTUs required for all appliances connected to the gas source including this furnace.

Divide this number by 1030. This will give you the approximate cubic feet per hour needed.

Example:

40,000 BTU/Hr

+ 15,000 BTU/Hr for other gas appliances

55,000 BTU/Hr total

55,000 ÷ 1030 = 53.4

Locate 53.4 or higher on chart below.

According to the chart below, you should use 50 feet or less of 1/2" pipe, 200 feet

or less of 3/4" pipe, etc...

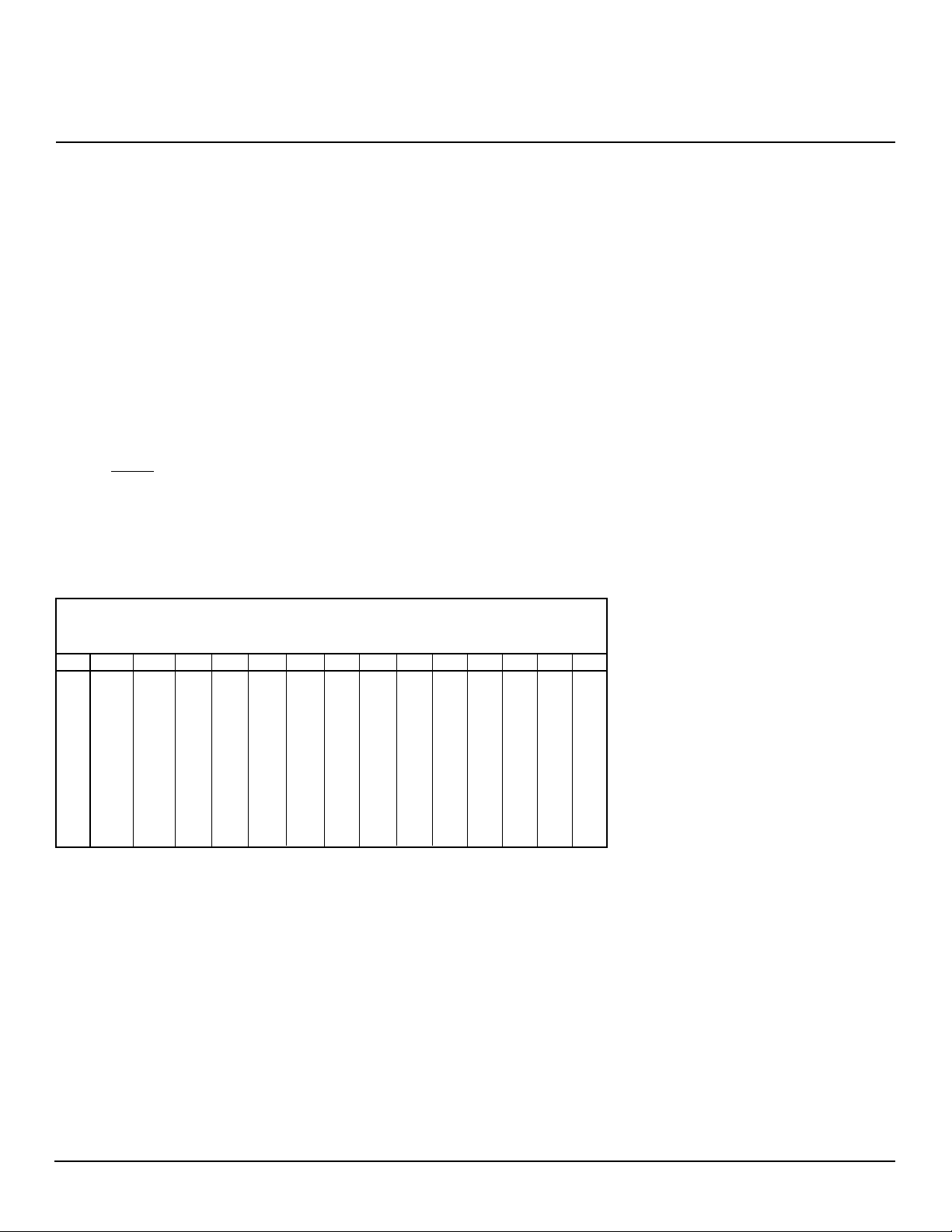

MINIMUM

IRON PIPE

SIZE LENGTH OF PIPE (FEET)

10 20 30 40 50 60 70 80 90 100 125 150 175 200

3/8" 72 49 40 34 30 27 25 23 22 21 18 17 15 14

1/2" 132 92 73 63 56 50 46 43 40 38 34 31 28 26

3/4" 278 190 152 130 115 105 96 90 84 79 72 64 59 55

1" 520 350 285 245 215 195 180 170 160 150 130 120 110 100

1

/4" 1050 730 590 500 440 400 370 350 320 305 275 250 225 210

1

11/2" 1600 1100 890 760 670 610 560 530 490 460 410 380 350 320

2" 3050 2100 1650 1450 1270 1150 1050 990 930 870 780 710 650 610

21/2" 4800 3300 2700 2300 2000 1850 1700 1600 1500 1400 1250 1130 1050 980

3" 8500 5900 4700 4100 3600 3250 3000 2800 2600 2500 2200 2000 1850 1700

4" 17500 12000 9700 8300 7400 6800 6200 5800 5400 5100 4500 4100 3800 3500

IMPORTANT:

Check gas line pressure at gas meter before connecting furnace to gas line. Gas

line pressure must be no less than 5 inches of water and no greater than 7 inches of water. Gas

pressures and input to the burners must not exceed the rated input and pressure shown on the

rating plate. For natural gas, manifold pressure should be 3.5 inches of water. For elevations

above 2000 feet, reduce rating 4% for each 1000 feet above sea level (U.S.A. only).

201835

Continued

9

Loading...

Loading...