Page 1

For U.S.A., Canada, Europe,

Korea & Japan model

SERVICE MANUAL

3

Ver. 3

Please refer to the

MODIFICATION NOTICE.

MODEL

STEREO CD/MP3 PLAYER

DN-C635

注 意

サービスをおこなう前に、このサービスマニュアルを

必ずお読みください。本機は、火災、感電、けがなど

に対する安全性を確保するために、さまざまな配慮を

おこなっており、また法的には「電気用品安全法」に

もとづき、所定の許可を得て製造されております。

従ってサービスをおこなう際は、これらの安全性が維

持されるよう、このサービスマニュアルに記載されて

いる注意事項を必ずお守りください。

●

For purposes of improvement, specifications and

design are subject to change without notice.

●

Please use this service manual with referring to the

operating instructions without fail.

●

Some illustrations using in this service manual are

slightly different from the actual set.

●

●

●

●

TOKYO, JAPAN

本機の仕様は性能改良のため、予告なく変更すること

があります。

補修用性能部品の保有期間は、製造打切後8年です。

修理の際は、必ず取扱説明書を参照の上、作業を行っ

てください。

本文中に使用しているイラストは、説明の都合上現物

と多少異なる場合があります。

X0169V.03 DE/CDM 0603

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power

cord is less than 460 kohms, the unit is defective.

LASER RADIATION

Do not stare into beam or view directly with optical instruments, class 3A laser product.

DN-C635

2

CAUTION

Please heed the points listed below during servicing and inspection.

◎ Heed the cautions!

Spots requiring particular attention when servicing, such as

the cabinet, parts, chassis, etc., have cautions indicated on

labels or seals. Be sure to heed these cautions and the cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching inter-

nal metal parts when the set is energized could cause

electric shock. Take care to avoid electric shock, by for example using an isolating transformer and gloves when

servicing while the set is energized, unplugging the power

cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra care

when the set is energized.

◎

Caution concerning disassembly and assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are moved

across them. Use gloves to protect your hands.

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked ! on wiring

diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange the

wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from the

surface of printed circuit boards. Care is also taken with the

positions of the wires inside and clamps are used to keep

wires away from heating and high voltage parts, so be sure to

set everything back as it was originally.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation

check on the external metal connectors and between the

blades of the power plug, and otherwise check that safety is

ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect the

antenna, plugs, etc., and turn the power switch on. Using a

500V insulation resistance tester, check that the insulation resistance between the terminals of the power plug and the externally exposed metal parts (antenna terminal, headphones

terminal, microphone terminal, input terminal, etc.) is 1MΩ or

greater. If it is less, the set must be inspected and repaired.

CAUTION

Many of the electric and structural parts used in the set have

special safety properties. In most cases these properties are

difficult to distinguish by sight, and using replacement parts

with higher ratings (rated power and withstand voltage) does

not necessarily guarantee that safety performance will be preserved. Parts with safety properties are indicated as shown

below on the wiring diagrams and parts lists is this service

manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the ! mark.

(2) Parts lists ... Indicated by the ! mark.

Concerning important safety parts

Using parts other than the designated parts

could result in electric shock, fires or other

dangerous situations.

注 意

サービス、点検時にはつぎのことにご注意願います。

◎注意事項をお守りください!

サービスのとき特に注意を必要とする個所についてはキャ

ビネット、部品、シャーシなどにラベルや捺印で注意事項を

表示しています。これらの注意書きおよび取扱説明書などの

注意事項を必ずお守りください。

◎感電に注意!

(1) このセットは、交流電圧が印加されていますので通電時

に内部金属部に触れると感電することがあります。従っ

て通電サービス時には、絶縁トランスの使用や手袋の着

用、部品交換には、電源プラグを抜くなどして感電にご

注意ください。

(2) 内部には高電圧の部分がありますので、通電時の取扱に

は十分ご注意ください。

◎分解、組み立て作業時のご注意!

板金部品の端面の『バリ』は、部品製造時に充分管理をして

おりますが、板金端面は鋭利となっている箇所が有りますの

で、部品端面に触れたまま指を動かすとまれに怪我をする場

合がありますので十分注意して作業して下さい。手の保護の

ために手袋を着用してください。

◎指定部品の使用!

セットの部品は難燃性や耐電圧など安全上の特性を持った

ものとなっています。従って交換部品は、使用されていたも

のと同じ特性の部品を使用してください。特に配線図、部品

!印で指定されている安全上重要な部品は必ず指定の

表に

ものをご使用ください。

◎部品の取付けや配線の引きまわしは、

元どおりに!

安全上、テープやチューブなどの絶縁材料を使用したり、プ

リント基板から浮かして取付けた部品があります。また内部

配線は引きまわしやクランパーによって発熱部品や高圧部

品に接近しないように配慮されていますので、これらは必ず

元どおりにしてください。

◎サービス後は安全点検を!

サービスのために取り外したねじ、部品、配線などが元どお

りになっているか、またサービスした個所の周辺を劣化させ

てしまったところがないかなどを点検し、外部金属端子部

と、電源プラグの刃の間の絶縁チェックをおこなうなど、安

全性が確保されていることを確認してください。

(絶縁チェックの方法)

電源コンセントから電源プラグを抜き、アンテナやプラグな

どを外し、電源スイッチを入れます。500V 絶縁抵抗計を用

いて、電源プラグのそれぞれの端子と外部露出金属部[アン

テナ端子、ヘッドホン端子マイク端子、入力端子など]との

間で、絶縁抵抗値が1 MΩ 以上であること、この値以下の

ときはセットの点検修理が必要です。

注 意

本機に使用している多くの電気部品、および機構部品は安全

上、特別な特性を持っています。この特性はほとんどの場合、

外観では判別つきにくく、またもとの部品より高い定格(定

格電力、耐圧)を持ったものを使用しても安全性が維持され

るとは、限りません。安全上の特性を持った部品は、この

サービスマニュアルの配線図、部品表につぎのように表示し

ていますので必ず指定されている部品番号のものを使用願

います。

(1) 配線図…!マークで表示しています。

(2) 部品表…!マークで表示しています。

安全上重要な部品について

指定された部品と異なるものを使用した場合に

は、感電、火災などの危険を生じる恐れがあり

ます。

2

Page 3

DN-C635

Top cover

3

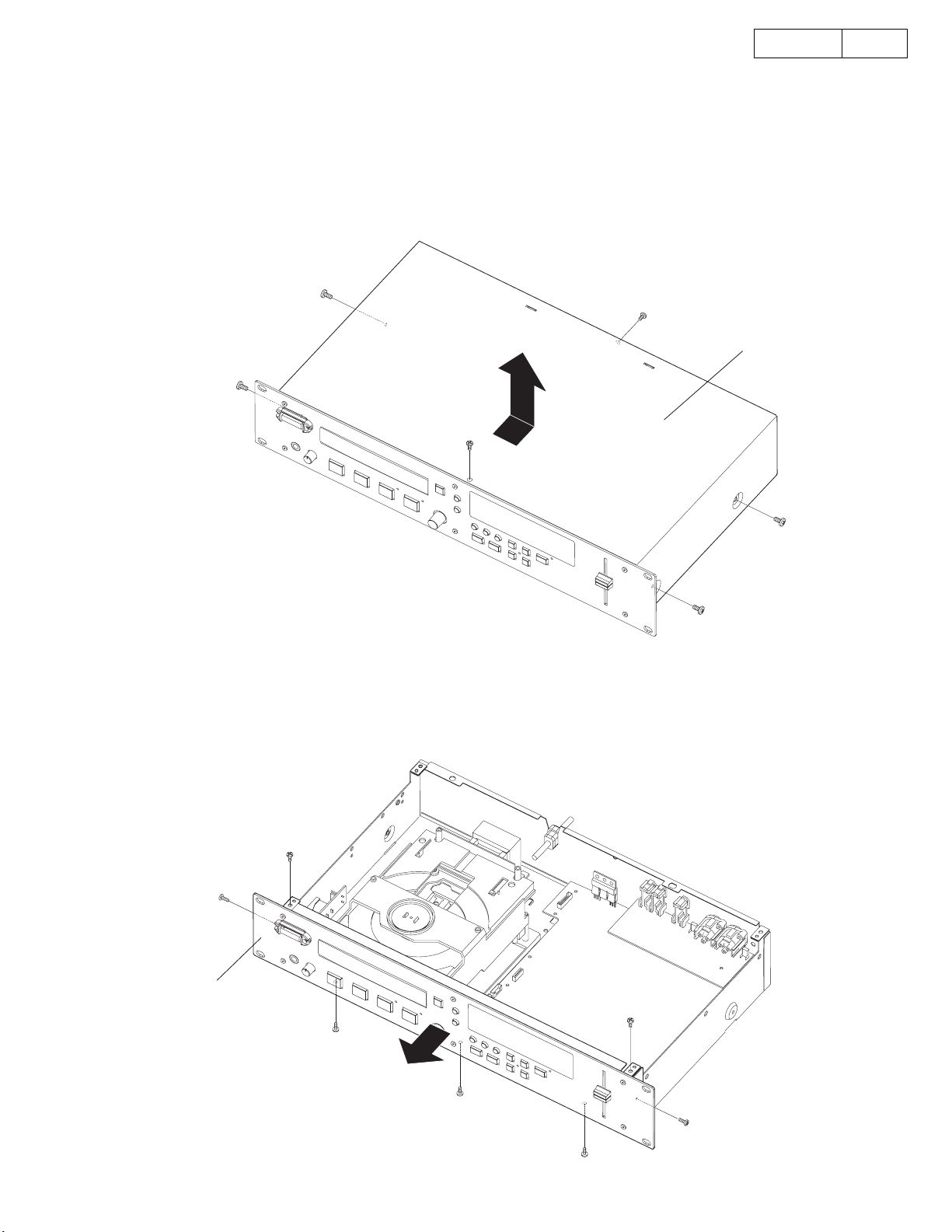

DISASSEMBLY

(To reassemble, reverse disassembly)

1. TOP COVER

(1) Remove 4 screws on both sides, 1 screw on the rear side,

and 1 screw on the top side.

(2) Detach the Top Cover as shown in the arrow direction.

各部のはずしかた

(組み立てるときは、逆の順序で行ってください。)

1. TOPCOVER

(1) 両側面のねじ 4 本、後部のねじ 1 本と上面のねじ 1 本を

はずします。

(2) 上カバーを矢印の方向に取りはずします。

2. FRONT PANEL

(1) Remove 2 upper screws, 3 lower screws and 2 screws on

the both side.

(2) Detach the Front Panel in the arrow direction.

Front Panel

2. FRONTPANEL

(1) 上部のねじ 2 本、下部のねじ 3 本と両側面のねじ 2 本を

はずします。

(2) フロントパネルを矢印の方向に取りはずします。

3

Page 4

DN-C635

Loader Panel

Mechanism Unit

4

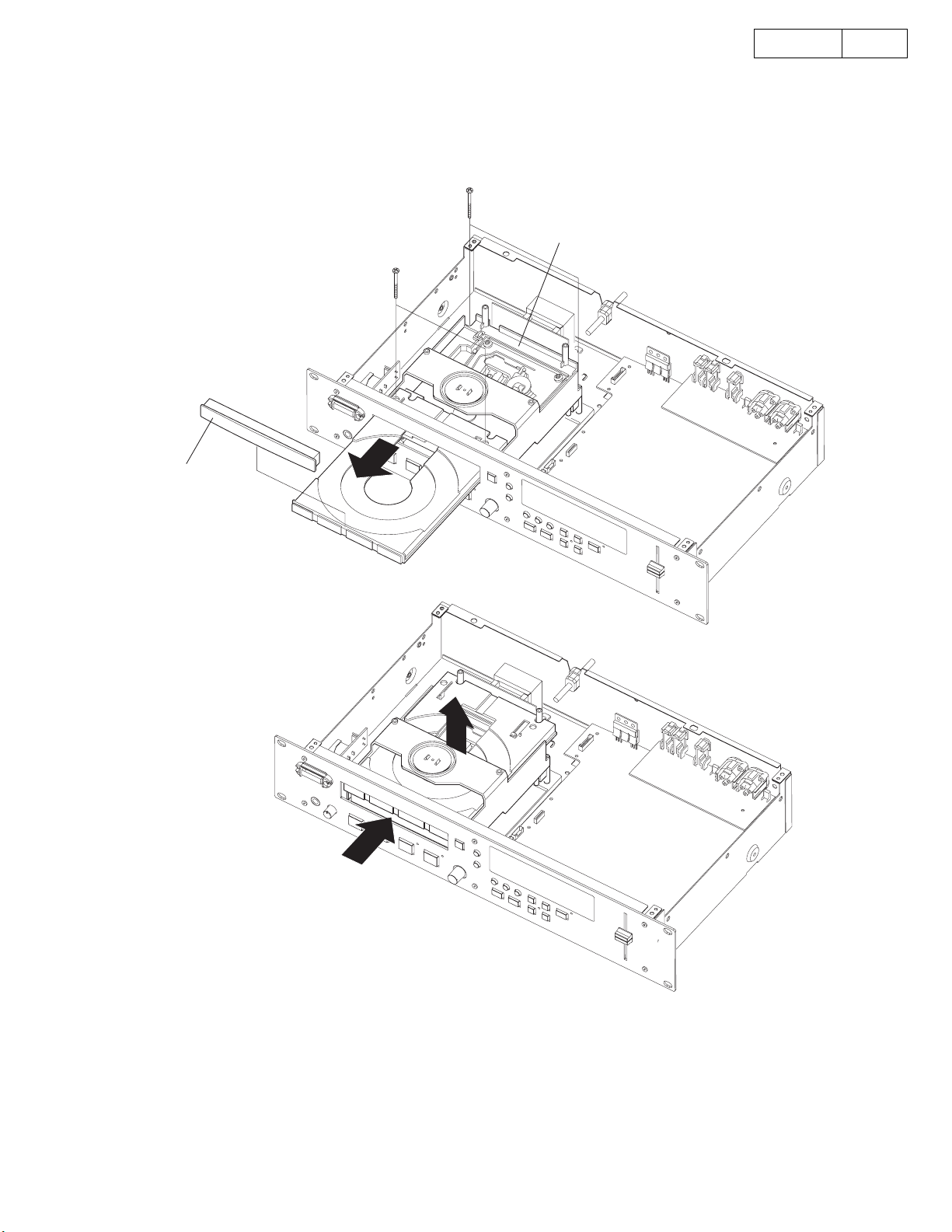

3. MECHANISM UNIT

(1) Remove the Loder Panel.

(2) Remove 4 screws fixing the Mechanism Unit and detach

the Mechanism Unit.

3. MECHANISMUNIT

(1) ローダーパネルをはずします。

(2) メカ取付けねじ 4 本をはずし、メカユニットを矢印の方

向に取りはずします。

4

Page 5

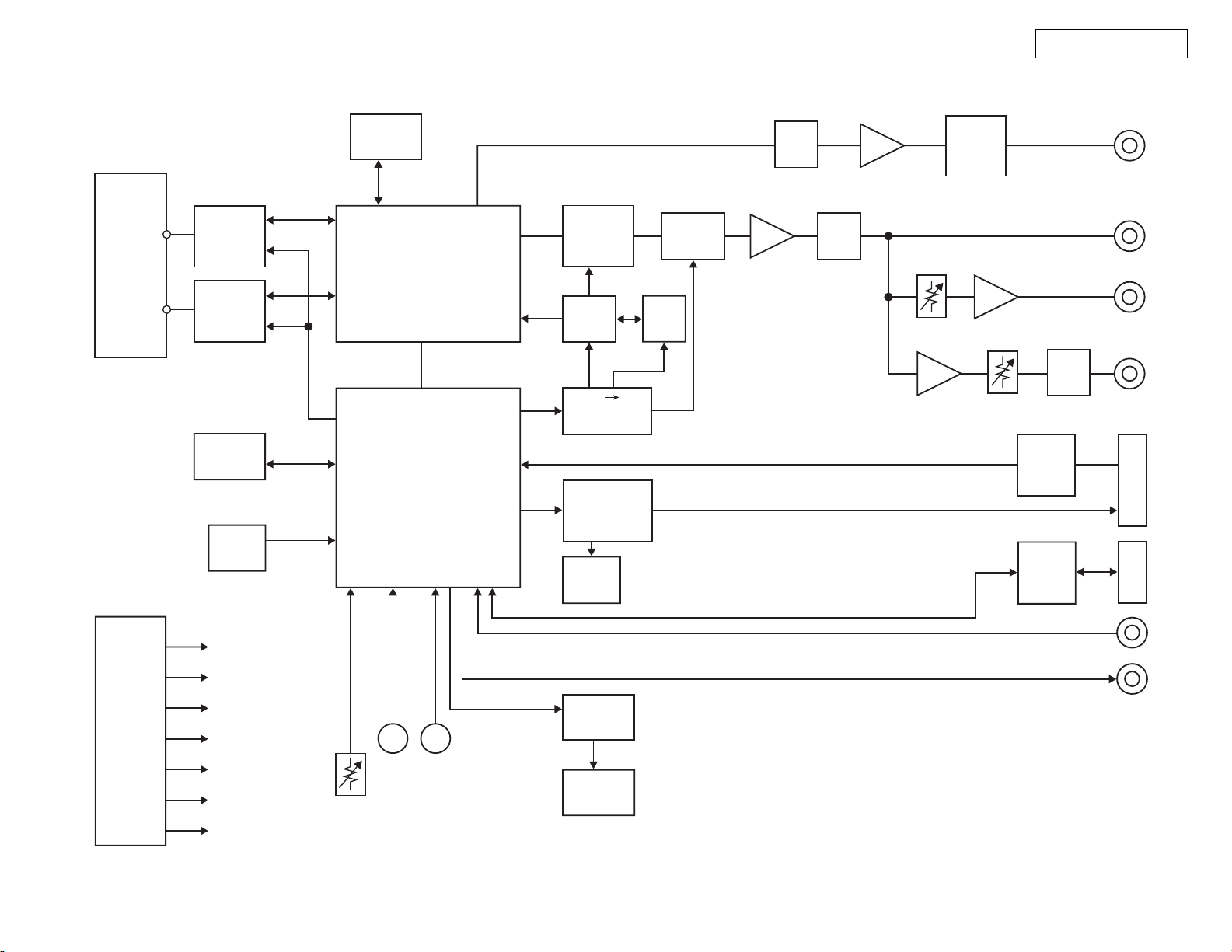

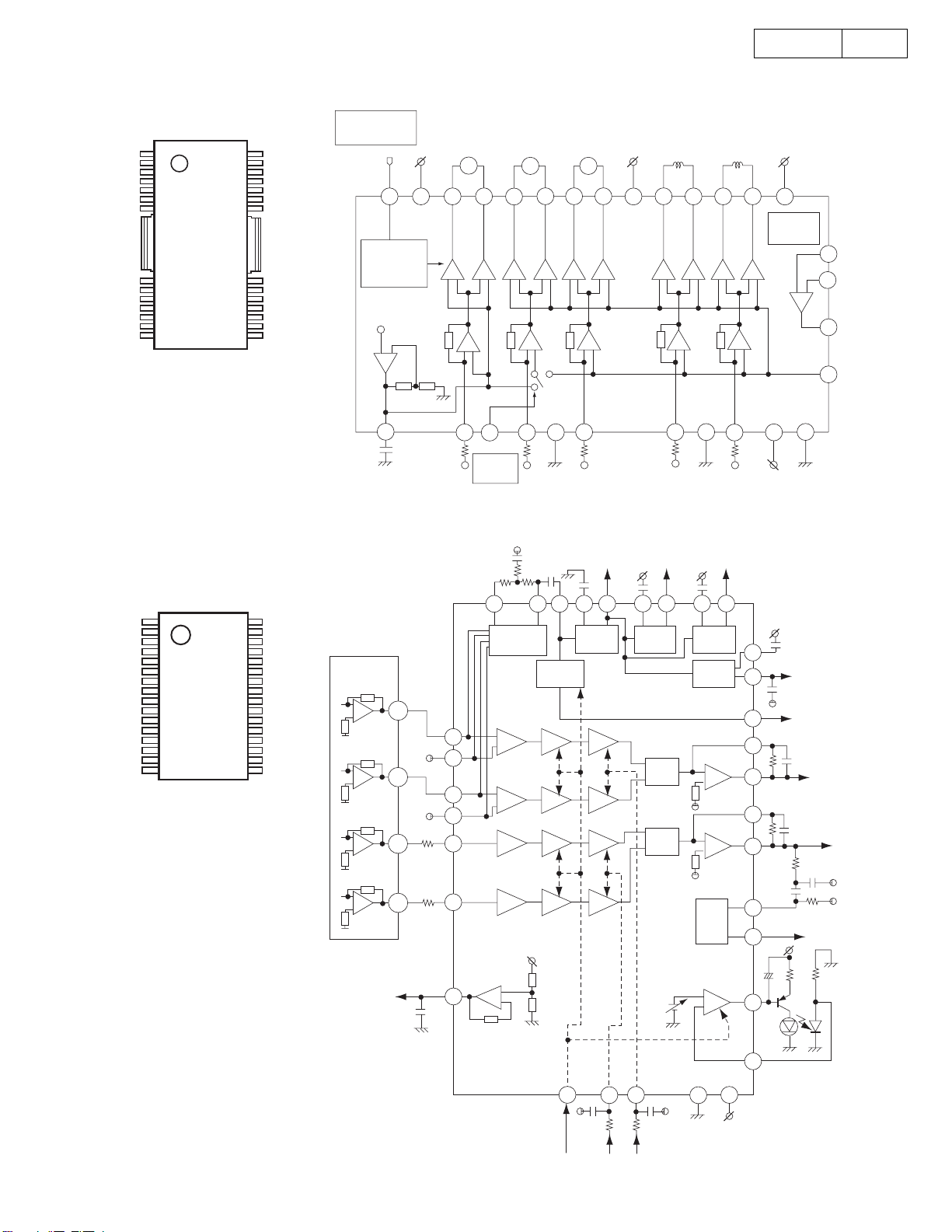

BLOCK DIAGRAM

5DN-C635

CD MECH.

MOTOR

ACTUATOR

P. U

DRIVER

AN8785SB

HEAD AMP

AN22002A

4M FLASH

ROM

KEY

16M DRAM

MN662791

SYSTEM µCOM

MN102H60KDA

DSP

DAC

PCM1716E

CLOCK

FIX/VARI

SELECT

3.3V 5V

I/F

TC74HCT7007

SERIAL/

PARALLEL

CONVERSION

LED

ST/MONO

SELECT

CLOCK

GEN.

±5V

MUTE

P. TRANS

DIGITAL

OUT

MUTE

CD OUT

±12V

XLR OUT

±5V

MUTE

H/P OUT

BUFFER

TALLY OUT

PARALLEL

RS232C

/422

POWER

SUPLY

±12V

±5V

+9V

+5V

+3.3V

-

HB

F1,F2

PITCH

ROTALY

ENCORDER

REMOTE

FLT

DRIVER

M66005FP

FLT

SERIAL

EXT IN

EXT OUT

5

Page 6

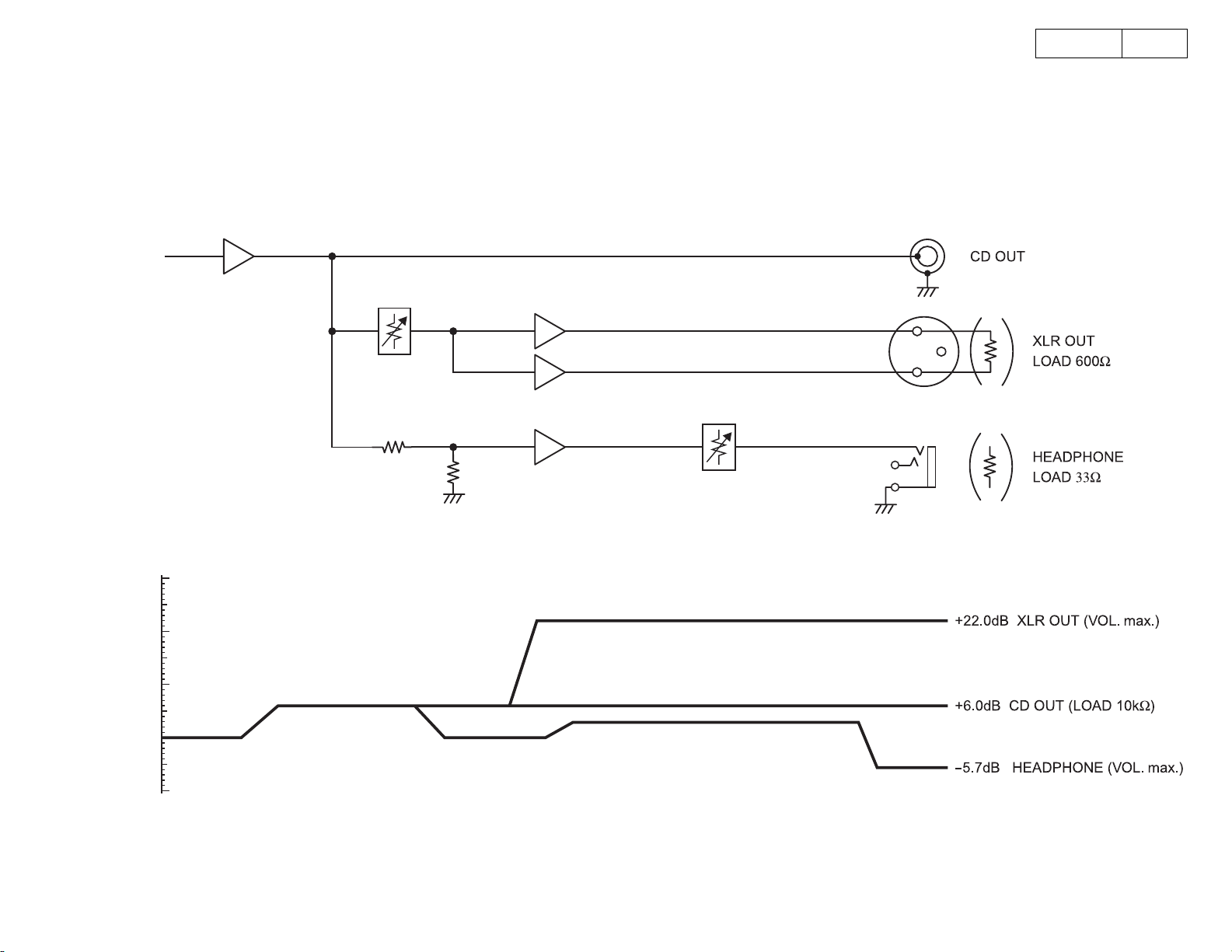

LEVEL DIAGRAM

6DN-C635

+30dB

+20dB

IC215

RCA

1 (7)

IC601 (602)

7

1

IC106

1 (7)

+10dB

0dB

-

10dB

0dB=1Vrms

0dB

+2.9dB

6

Page 7

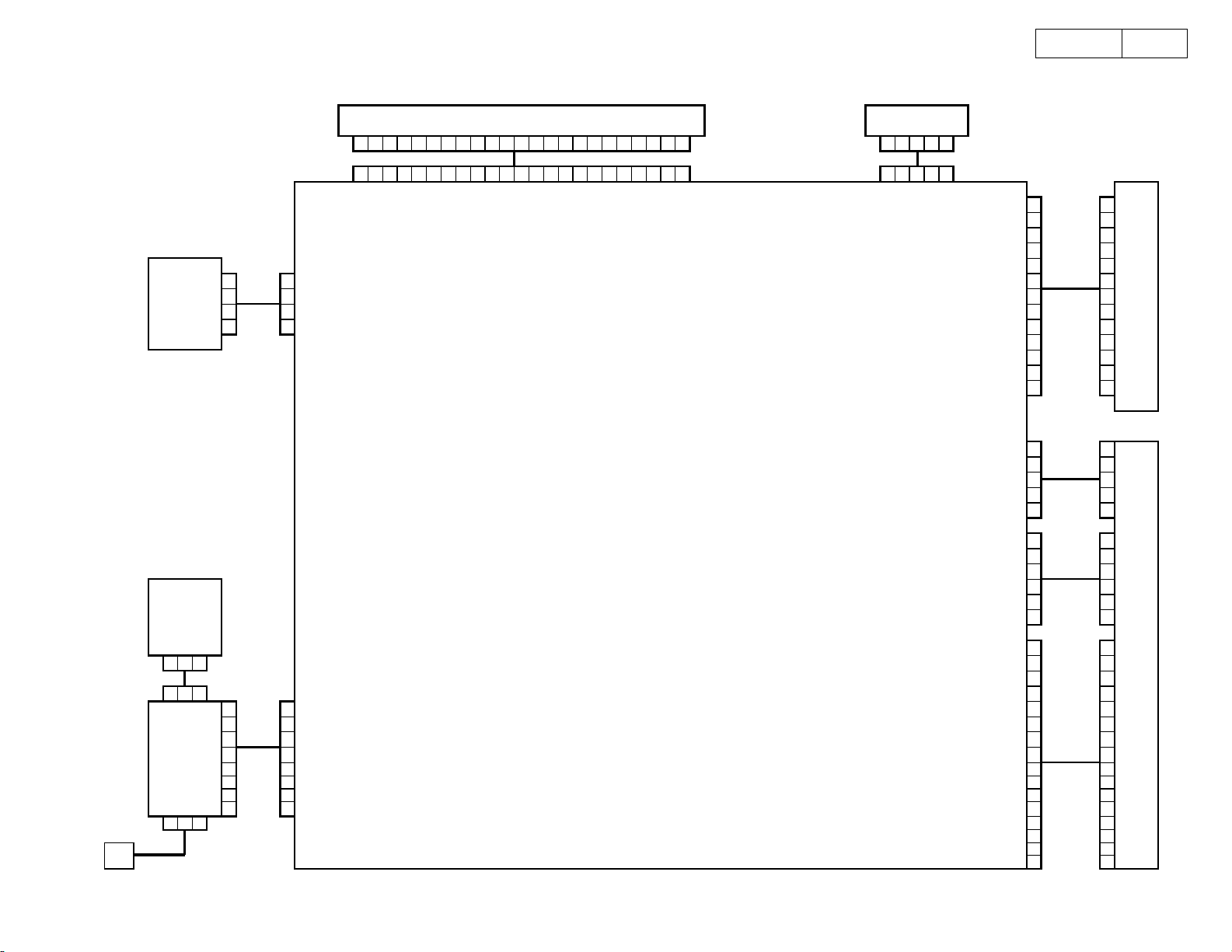

WIRING DIAGRAM

T

7DN-C635

AC

GU-3511-2

SLIDE VR.

UNIT

CW041

GU-3511-4

POWER SW

UNIT

CY022

12

12

CX022

GU-3511-6

TRANS UNI

CX021

12

GU-3511-1

PTHL

PRGL

CX231

CY231

KEYIN1

KEYIN2

KEYIN0

CY052

CX052

(RD) 1 1

23 22 21 20 19 18 17 16 15 14 13 12 11 10

123456789

F2

F1

-HB

GND

FLCK

FLRST-

11 66

22 77

33 88

44 99

PITCH

PITCHC

GND

+3.3V

10 11 12 13 14 15 16 17 18 19 20 21 22 23

FLDA

+3.3V

FLCS-

+3.3V

REMOTE

CX041

987654321 123

GND

GND

TRSLA-

PUSH-

TRSLB-

CUEL

PLYL

DISPLAY UNIT

GU-3511-3

H/P UNIT

45

45

123

GND

GND

H/P L

H/P R

MUTE

-12V

+12V

CDOUT R

GND

CDOUT L

MUTE

H/P R

GND

H/P L

GND

CAS IN

CAS OUT

EXT I/O

22

33

44

55

10 10

11 11

12 12

13 13

GU-3511-5 XLR UNIT

CX131

CW131

LOAD-

11

LOAD+

22

GU-3510

MAIN UNIT

(BK)

(BK)

11 55

22 66

33 77

44 88

55 99

66

77

88

CW081

CX081

CX051

CX062

CX161

OPEN

GND

CLOSE

LIMITSW-

LIMITSW+

SLED-

SLED+

SP-

SP+

VREF1

VCC

GND

NC

LPD

33

44

55

11

22

33

44

55

66

11

22

E

33

D

44

A

B

C

F

LD

10 10

11 11

12 12

F+

13 13

T-

14 14

T+

15 15

F-

16 16

CD MECH

7

Page 8

DN-C635

8

SERVICE PROGRAM

Required Measuring Implement

z Reference disc (TCD784 or CO-74176)

1. What is Service Program

Service program is a special program intended for confirming servo functions etc.

2. µcom Version Check

z Refer to "Preset Functions and Operations" of the instruction manual.

z You can check the µcom version.

3. Error Data Check

z Switch on the power while pushing the button and REPEAT button at the same time.

z After actuating the error data check program, press the CD's or button to display the logging error codes

in the occurred order.

XX Err** XX: occurred order

Err**: error code (Refer to the "Error Code Table" Page 9.)

z 10 error logs are memorized at maximum. Item 1 is newest data. Item 10 is oldest data. Item 2 is the 9th old data.

z Pressing the PAUSE button enters to data erase mode. ("Err Clear?" is displayed.)

If the PAUSE button is pressed again, the memorized error data are cleared.

To cancel the data erase mode, press the STOP button.

z To stop the Error Data check mode, please turn off the POWER switch.

NOTE: When the service is finished, delete the error logs.

4. Total Running Time

z Switch on the power while pushing the PROG. PLAY ON/OFF button and A-B button at the same time.

Total time span of CD that counted by the hour is displayed.

CD XXXXh

NOTE: Time is counted if the disc tray is opened first 30 minutes.

z Pressing the PAUSE button enters to data erase mode. ("Time Clear?" is displayed.)

If the PAUSE button is pressed again, the memorized time data are cleared.

To cancel the data erase mode, press the STOP button.

z To stop the Total Running Time check mode, please turn off the POWER switch.

NOTE: When the replacing the associated parts, delete the ranning time.

5. B.E.R. Checks and Automatic Servo Adjustment Call

z Switch on the power while pushing the button and END MON button at the same time.

And Loading a disc by OPEN/CLOSE button.

(1)Block Error Rate

Press the PLAY button. B.E.R. is displayed.

01Tr **m XXXX XXXX: Block Error Rate

You can select the track by the select knob.

(2)Tracking balance and Focus balance data

Press the TIME button. Tracking balance and Focus balance data is displayed.

2 ±XXX±@@@ XXX: Tracking balance

@@@: Focus balance

(3)Focus gain data

Press the END MON button. Focus gain data is displayed.

3 XXXX XXXX: Focus gain

(4)Tracking gain data

Press the REPEAT button. Tracking gain data is displayed.

4 XXXX XXXX: Tracking gain

(5)Tracking offset and Focus offset data

Press the A-B button. Tracking offset and Focus offset data is displayed.

5 ±XXX±@@@ XXX: Tracking offset

@@@: Focus offset

(6)Press the PLAY MODE button to select the Block Error Rate data.

(7)To stop the B.E.R. Check and Automatic Servo Adjustment Call mode,

please turn off the POWER switch.

No. botton Adjustment Item Adjustment Value indicator

-

2

3 Focus Gain 0576 ~ 2304

4 Tracking Gain 0392 ~ 1569

5

Tracking Balance

Focus Balance

Tracking Offset

Focus Offset

025 ~ +025

-

050 ~ +050

-

005 ~ +005

-

005 ~ +005

サービスプログラム

確認に必要な測定器具

●調整用ディスク:TCD784 又は CO-74176

1. サービスプログラムについて

サービスプログラムとは、サーボ機能等を確認するための特別なプログラムです。

2. マイコンバージョン確認

●取扱説明書の「プリセット機能と操作」を参照してください。

●マイコンバージョン確認ができます。

3. エラーデータ確認

● とREPEATボタンを同時に押しながら、電源スイッチを「ON」にします。

●エラーデータ確認プログラムが動作してから CD の または ボタンを押すと、エラーの発生した順にロギングされたエ

ラーコードが表示されます。

XXErr** XX:エラー発生順番(ログ番号)

Err**:エラーコード(9 ページの " エラーコード表 "を参照)

●最大10個のエラーが記録されます。(ログ番号1 が最も新しいデータで、ログ番号 10 が最も古いデータです。)

●PAUSE ボタンを押し続けると、エラーデータ消去モードになり、"ErrClear?" が表示されます。

この状態で再度 PAUSE ボタンを押すと、記録されたエラーデータが消去されます。

エラーデータ消去モードをキャンセルするには STOP ボタンを押します。

●エラーデータ確認モードを終わるには、電源スイッチを OFF にします。

注意:サービスプログラムを終了するときは、このエラーデータを消去して下さい。

4. トータルランニングタイム

●PROG.PLAYON/OFFと A-Bボタンを同時に押しながら、電源スイッチを「ON」にします。

CD のトータル再生時間が1時間単位で表示されます。

CDXXXXh

注意:ディスクトレイが最初の30分間でオープンになると(トータル再生)時間がカウントされます。

●PAUSE ボタンを押し続けると、トータルランニングタイム消去モードになり、"TimeClear?" が表示されます。

この状態で再度 PAUSE ボタンを押すと、記録されたトータルランニングタイムデータが消去されます。

トータルランニングタイム消去モードをキャンセルするには STOP ボタンを押します。

●トータルランニングタイム確認モードを終わるには、電源イッチを OFF にします。

注意:関連部品を交換したときは、このランニングタイムデータを消去して下さい。

5. B.E.R.確認と自動サーボ調整コール

● と ENDMONボタンを同時に押しながら、電源スイッチを「ON」にします。

OPEN/CLOSEボタンでディスクをローディングします。

(1) ブロックエラーレート

PLAYボタンを押すと、B.E.R. が表示されます。

01Tr**mXXXX XXXX:BlockErrorRate

SELECT ノブで測定するトラックを選択します。

(2) トラッキングバランスとフォーカスバランスデータ

TIMEボタンを押すと、トラッキングバランスとフォーカスバランスデータが表示されます。

2± XXX ± @@@ XXX:Trackingbalance

@@@:Focusbalance

(3) フォーカスゲインデータ

ENDMONボタンを押すと、フォーカスゲインデータが表示されます。

3XXXX XXXX:Focusgain

(4) トラッキングゲインデータ

REPEATボタンを押すと、トラッキングゲインデータが表示されます。

4XXXX XXXX:Trackinggain

(5) トラッキングオフセットとフォーカスオフセットデータ

A-Bボタンを押すと、トラッキンオフセットとフォーカスオフセットデータが表示されます。

5± XXX ± @@@ XXX:Trackingoffset

@@@:Focusoffset

(6)PLAYMODEボタンを押し、B.E.R.を表示させます。

(7) 電源スイッチを「OFF」にして、B.E.R.調整モードと自動サーボ調整コールモードを終了させます。

No.ボタン 調整項目 調整値

-

2

3 FocusGain 0576 〜 2304

4 TrackingGain 0392 〜 1569

5

TrackingBalance

FocusBalance

TrackingOffset

FocusOffset

025 〜 +025

-

050 〜 +050

-

005 〜 +005

-

005 〜 +005

8

Page 9

DN-C635

9

6. Test Mode (Heat Run mode)

z Switch on the power while pushing the FOLDER button and TIME button at the same time.

"000TroHR0000" is displayed. And the tray is opened.

(1)Hold the disc by the edges and place it on the disc tray.

(2)Starting with the OPEN/CLOSE button, it repeats open/close of the tray and playback.

***TrxHRXXXX ***: Track No.

x : o, c, s, t, r, and p

XXXX: Cycle quantity

All tracks are played back if the track count is less than 20.

Only the first and last tracks are played back if the tracks are more than 21.

When any errors, it stops and indicates error code (Refer to the Error Code Table).

(3)To stop the Test mode, please turn off the POWER switch.

7. Error Code Table

Error Code CONTENTS

Error 01 Unable to close the loader tray in the regulation time.

Error 02 Unable to open the loader tray in the regulation time.

Error 03 Inner circle switch ON error even if the time is over.

Error 04 Inner circle switch OFF error even if the time is over.

Error 05 The focus offset adjustment result is outside the regulation range.

Error 06 Unable to adjust the focus offset in the regulation time.

Error 07 The tracking offset adjustment result is outside the regulation range.

Error 08 Unable to adjust the tracking offset in the regulation time.

Error 09 The FE peak is outside the regulation range.

Error 0A The FE peak is outside the regulation range.

Error 0B Unable to adjust the focus rough gain in the regulation time.

Error 0C The focus rough gain is outside the regulation range.

Error 0D Unable to actuate focus in the regulation time.

Error 0E Unable to actuate tracking in the regulation time.

Error 0F Unable to adjust the tracking rough gain in the regulation time.

Error 10 The tracking rough gain is outside the regulation range.

Error 11 Unable to adjust the tracking balance in the regulation time.

Error 12 The tracking balance adjustment result is outside the regulation range.

Error 13 Focus servo down during automatic adjustment.

Error 14 Focus servo down during automatic adjustment.

Error 15 Unable to adjust the focus balance in the regulation time.

Error 16 The focus balance adjustment result is outside the regulation range.

Error 17 Track servo down during automatic adjustment.

Error 18 Unable to adjust the focus fine gain in the regulation time.

Error 19 The focus fine gain is outside the regulation range.

Error 1A Unable to adjust the tracking fine gain in the regulation time.

Error 1B The tracking fine gain is outside the regulation range.

Error 1C Unable to adjust automatically in the regulation time.

Error 1D Unable to read the subcode Q in the regulation time.

Error 1E Unable to read the TOC in the regulation time.

Error 1F Focus servo down during search (over the regulation time).

Error 20 Track servo down during search (over the regulation time).

Error 2116 Servo error during search.

Error 2103 Search error (over the regulation time).

Error 22 Discontinuity occurred, during write to the DRAM.

Error 23 The MP3 data could be read but not decoded.

Error 24 Unable to do the level detect.

6. テストモード(ヒートランモード)

●FOLDER と TIME ボタンを同時に押しながら、電源スイッチを「ON」にします。

"000TroHR0000"が表示され、トレイが開きます。

(1)ディスクをトレイに載せます。

(2)OPEN/CLOSE ボタンで(ヒートラン)を開始します。トレイの開閉と再生を繰り返します。

***TrxHRXXXX ***:TrackNo.

x:o,c,s,t,r,p

XXXX:ヒートランサイクル回数

20 トラック以下のディスクの場合、全トラックを再生します。

21 トラック以上のディスクの場合、最初のトラックと最終トラックのみを再生します。

(ヒートラン中に)エラーが発生すると、エラーコードを表示して停止します。(エラーコード表参照)

(3)テストモードを終了するには、電源スイッチを「OFF」にします。

7. エラーコード表

ErrorCode 内容

Error01 規定時間内にローダートレイがクローズできない

Error02 規定時間内にローダートレイがオープンできない

Error03 規定時間内に内周スイッチが ON されない

Error04 規定時間内に内周スイッチが OFF されない

Error05 フォーカスオフセット調整値が規定範囲外

Error06 規定時間内にフォーカスオフセット調整できない

Error07 トラッキングオフセット調整値が規定範囲外

Error08 規定時間内にトラッキングオフセット調整できない

Error09 FE ピークが規定の範囲外

Error0A FE ピークが規定の範囲外

Error0B 規定時間内にフォーカスラフゲインが調整できない

Error0C フォーカスラフゲインが規定範囲外

Error0D 規定時間内にフォーカスを駆動できない

Error0E 規定時間内にトラッキングを駆動できない

Error0F 規定時間内にトラッキングラフゲインを調整できない

Error10 トラッキングラフゲインが規定範囲外

Error11 規定時間内にトラッキングバランスが調整できない

Error12 トラッキングバランス調整値が規定範囲外

Error13 自動調整中にフォーカスサーボが落ちた

Error14 自動調整中にフォーカスサーボが落ちた

Error15 規定時間内にフォーカスバランスが調整できない

Error16 フォーカスバランス調整値が規定範囲外

Error17 自動調整中にトラックサーボが落ちた

Error18 規定時間内にフォーカスファインゲインが調整できない

Error19 フォーカスファインゲインが規定範囲外

Error1A 規定時間内にトラッキングファインゲインが調整できない

Error1B トラッキングファインゲインが規定範囲外

Error1C 規定時間内に自動調整ができない

Error1D 規定時間内にサブコード Q が読めない

Error1E 規定時間内に TOC が読めない

Error1F サーチ中にフォーカスサーボが規定時間以上落ちた

Error20 サーチ中にトラックサーボが規定時間以上落ちた

Error2116 サーチ中のサーボエラー

Error2103 (規定時間外での)サーチエラー

Error22 DRAM に書き込み中、不連続が発生

Error23 MP3 データはリードできたが、デコードすることができない

Error24 レベル検出できない

9

Page 10

DN-C635

10

Error Code CONTENTS

Error 25

Error 26 The error rate when recording on the memory is over the regulation value.

Error 27 The subcode jump more than regulation.

Error 28

Error 29 There was a subcode Q interruption, but the content of the subcode Q is abnormal.

Retried searching repeatedly, but the sound could not be connected, resulting in an

interruption of the sound.

The servo was turned on when the power was turned on, but did not start up in the regulation time.

µCOM VERSION UPGRADE

System µcom can be upgraded in the following manner.

Version Upgrade Method

1.Record the version upgrade software on a CD-R or CD-RW disc,

only as one file with the format ISO9660 Mode-1.

The file name of the supplied version upgrade software should be used as is and this disc needs

to finalize.

2.Hold the disc by the edges and place it on the disc tray.

3.Press the OPEN/CLOSE button to start the version upgrade.

"Versi on Up"→"Push Play!" "xxxx->XXXX" are displayed.

xxxx : current version

XXXX : upgrade version

4.Press the PLAY button.

"Now Writing" → "Writing-XXX" are displayed.

XXX : count up from 000 to129

5.When the version upgrade is finished, "Complete!" is indicated.

6.Turn off the power once and turn on again.

Press the OPEN/CLOSE button and remove the disc.

NOTE: When the power is turned off before "Complete!" is displayed,

µcom version is not written correctly.

ErrorCode 内容

Error25 サーチのリトライを繰り返したが、音をつなぐことができず音切れ発生

Error26 メモリに書き込み中にエラーレートが規定値を超えた

Error27 サブコードが規定以上飛んだ

Error28 電源投入時にサーボを起動したが、規定時間内にサーボがかからない

Error29 SUBQ の割り込みは入るが、Q データの内容が NG

マイコンアップグレード

本機は、次の方法でシステムマイコンのアップグレードを行うことができます。

アップグレードの方法

1.アップグレード用のソフトを、CD-R 又は CD-RW ディスクに ISO9660MODE1 のフォーマットでこのファイルだけを書き込みして

ください。

ファイル名は、配布された時のファイル名をそのまま使用し、ファイナライズしてください。

2.1 で作成したディスクをトレイに載せます。

3.OPEN/CLOSE ボタンを押すと、ディスクに書かれているアップグレードの情報を読み出します。

"VersionUp" → "PushPlay!""xxxx->XXXX"と表示されます。

xxxx:現在のバージョン

XXXX:新バージョン

4.PLAY ボタンを押すとアップグレードを開始します。

"NowWriting" → "Writing-XXX"と表示されます。

XXX:000から 129 までカウント Up します

5.アップグレードが終了すると"Complete!"が表示されます。

6.電源スイッチを切り、再び「ON」にします。

OPEN/CLOSE ボタンを押して、ディスクを取り出してください。

注意:"Complete!" が表示される前に電源スイッチを切ると、システムマイコンの新バージョンは正確に書き込みできません。

10

Page 11

DN-C635

DN-C635

BALANCED

OUT

Audio Transformer

1:1

600ohm

測定用LPF

(20kHz)

ひずみ率計/AFオシレータ

出力レベル調整用接続図

11

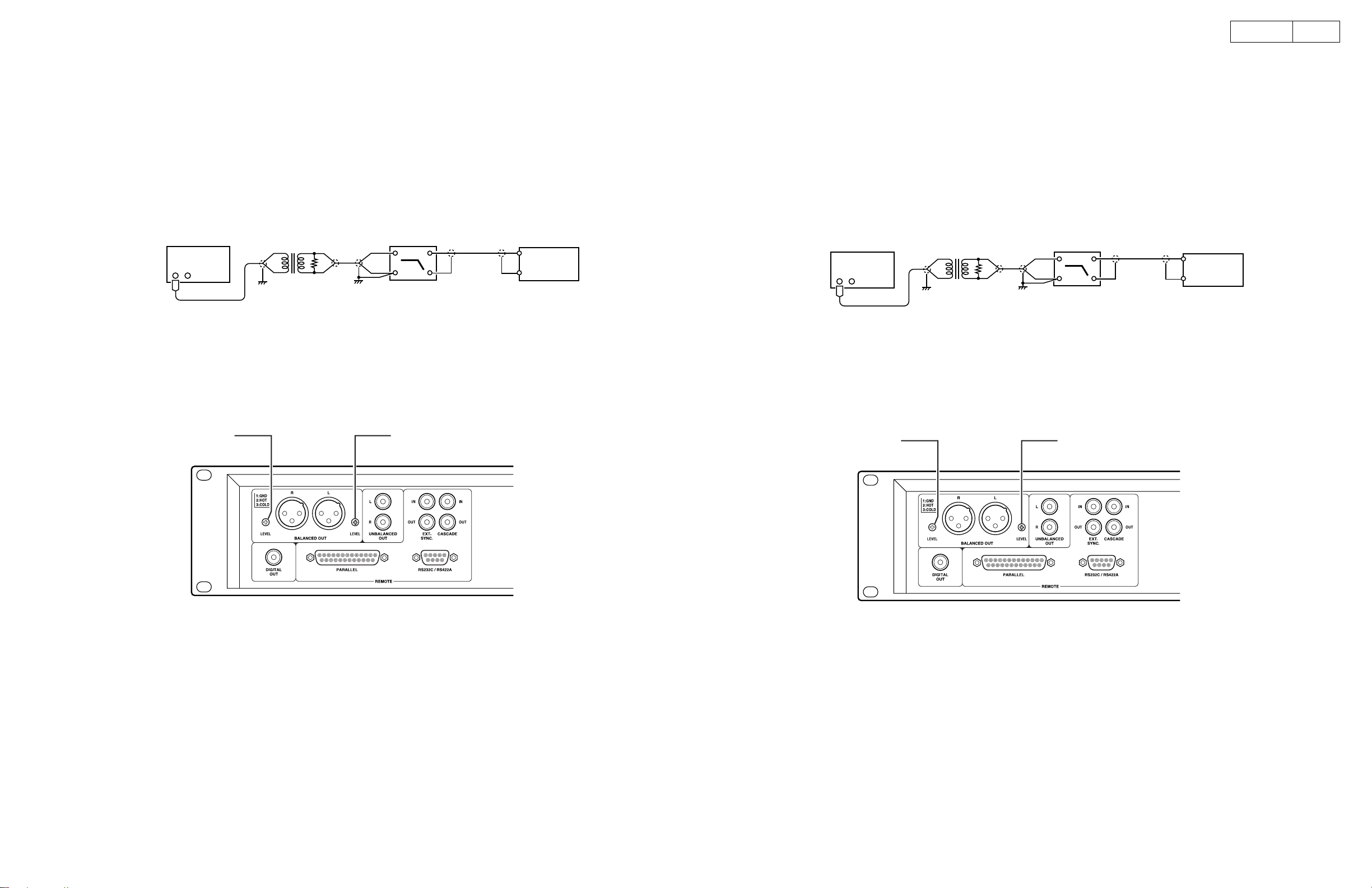

CONFIRMING THE AUDIO

1. Necessary Equipment for Adjustment

Distortion--Factor Meter

VTVM

Low-Pass Filter (20kHz)

AF Oscillator (20Hz ~ 20kHz, +18dBu)

Reference Disc; DENON Audio Technical CD (38C39-7174)

2. Output Level Adjustment

(1) Connect VTVM to the output connector of DN-C635.

Use 1:1 600 ohm Audio Transformer between the unit and VTVMs in order for matching the unbalanced input of

VTVM and the active balanced output of DN-C635 as shown in figure.

DN-C635

BALANCED

OUT

(2) Play track number "49".

(3) While reading VTVM indication, adjust VR602 (L-ch) and VR601 (R-ch) so that the output level attains +18dBu

(or desired level).

Audio Transformer

1:1

600ohm

LPF

(20kHz)

Connection for Output Level Adjustment

Distortion Meter

オーディオの確認方法

1. 必要な測定器具

ひずみ率計

VTVM

測定用フィルタ(20kHz)

AF オシレータ(20Hz 〜 20kHz,+18dBu)

調整用ディスク;DENONAudioTechnicalCD(38C39-7174)

2. 出力レベル調整

(1) VTVM を DN-C635 の BALANCEDOUT に接続します。

下図のとおり、DN-C635 のバランス出力と VTVM のバランス入力の間に入力インピーダンス 600Ω で 1:1 のレベル変換を行な

うオーディオトランスを接続して整合をとります。

(2) DN-C635 で調整用ディスクの 49 トラックを再生します。

(3) VTVM 表示は、出力レベルが +18dBu( 又は要求レベル ) になるように、レベル調整ボリューム VR602(L-ch)とVR601(R-ch)を

調整します。

R

VR601

Location of Level Adjustment VRs

L

VR602

R

VR601

L

VR602

レベル調整VRの位置

11

Page 12

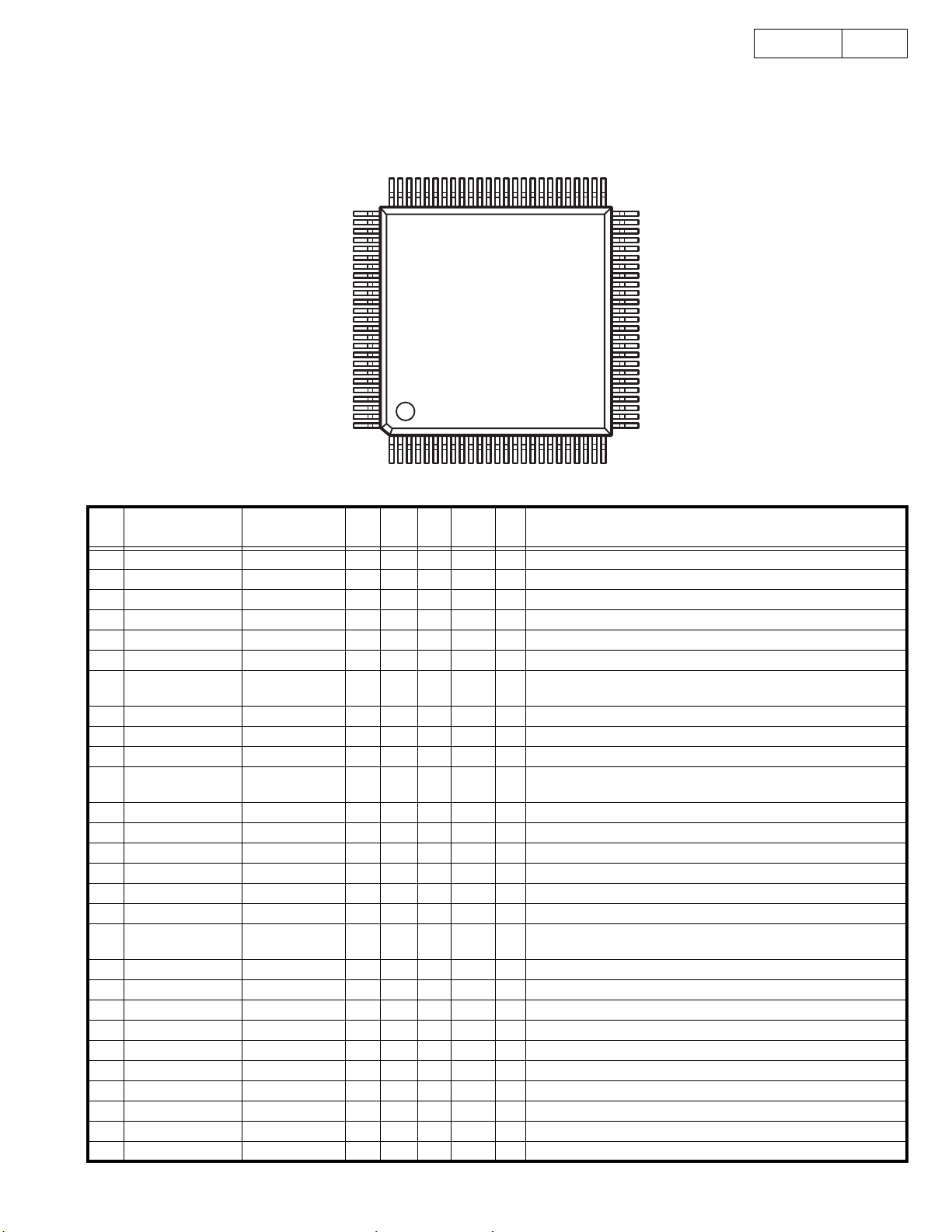

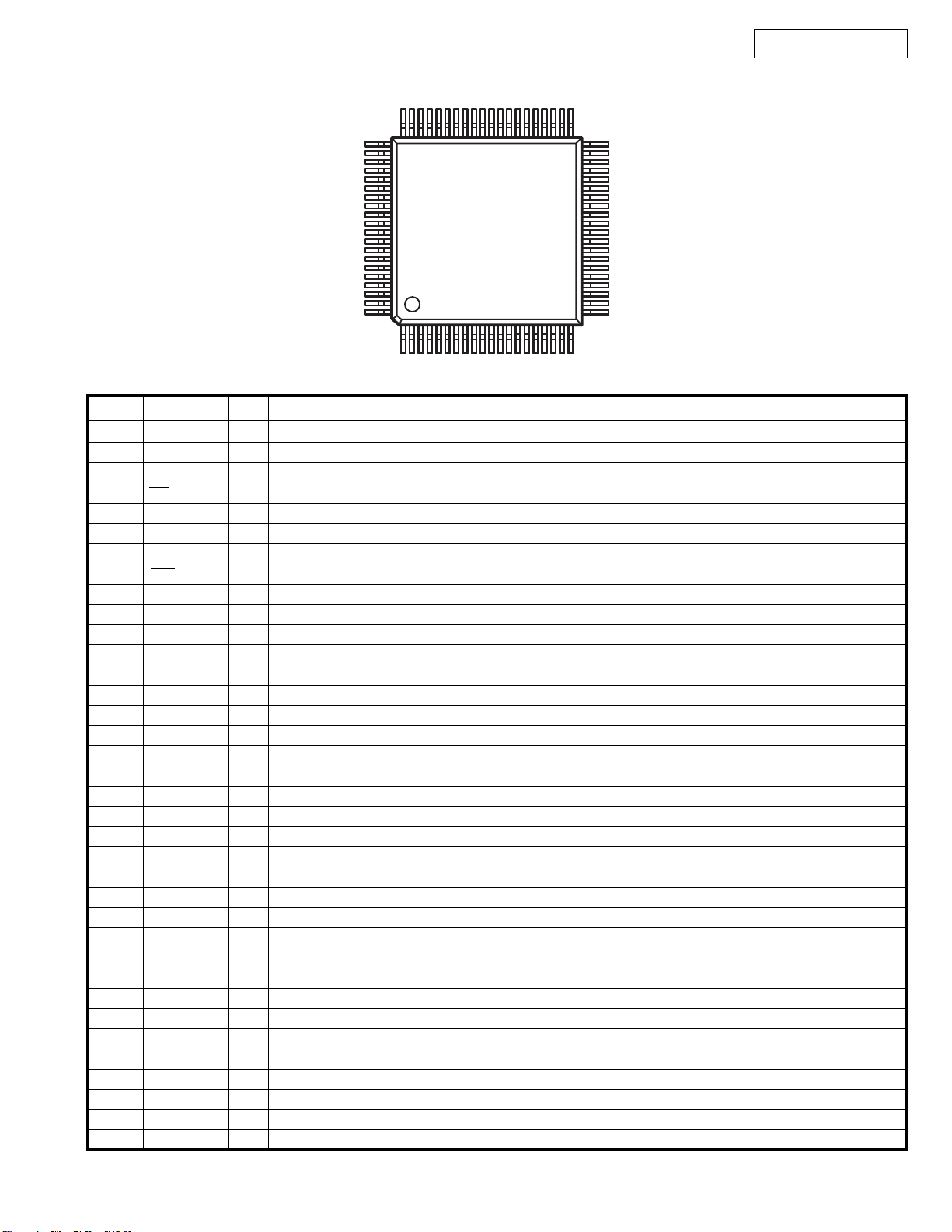

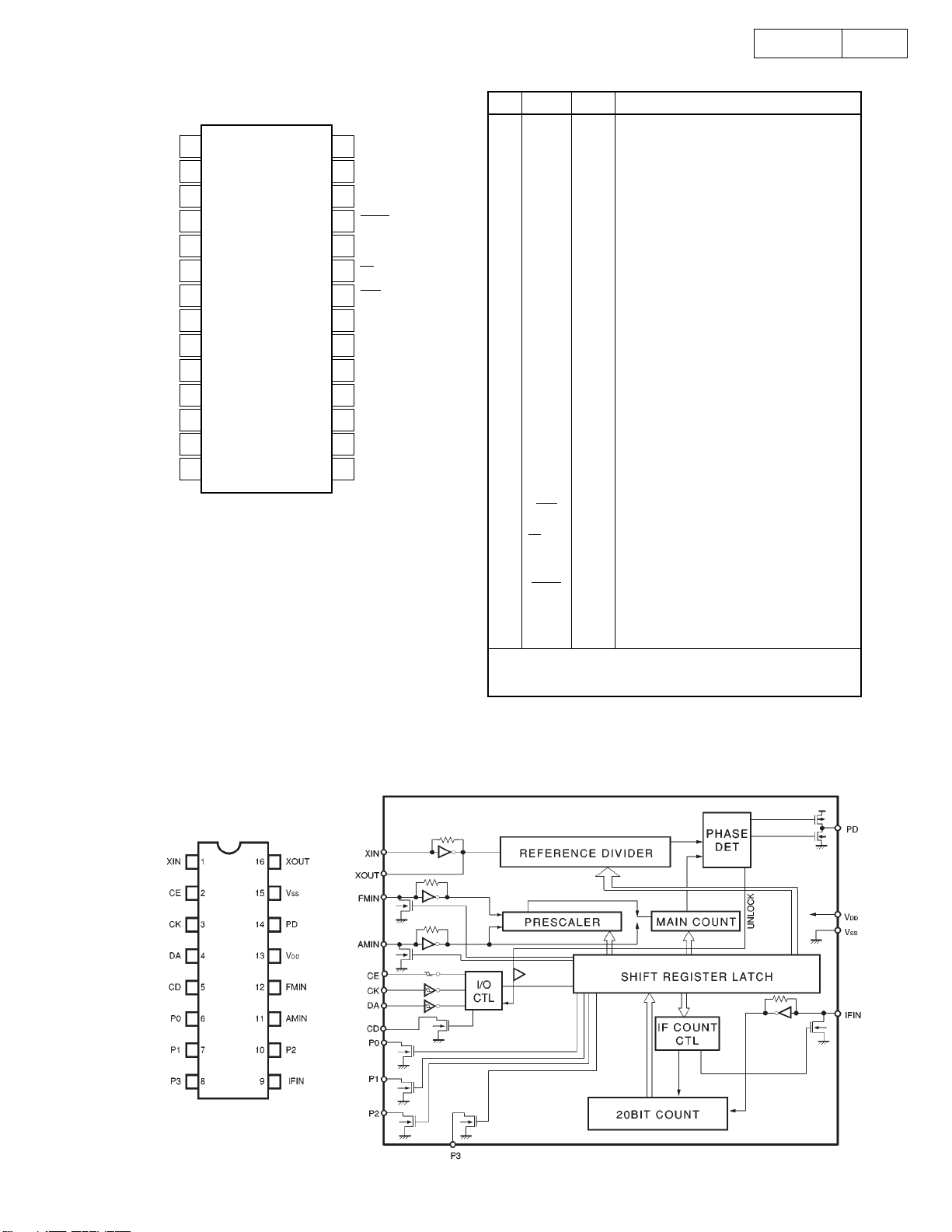

SEMICONDUCTORS

IC’s

MN102H60KDA

(IC103)

DN-C635

12

75

76

100

1

51

50

26

25

MN102H60KDA Terminal Function

Pin

No.

1 P60, WAIT, SBT2 PCDMUTE O - Pd L L Mute for CD

2 P61, _RE RD- O - Pu Hi-Z - Read signal

3 P62, _WEL WR- O - Pu Hi-Z - Write signal

4 P63, _WE, _WEH EXTIN- I - - Hi-Z - EXT.IN signal

5 _CS0,TM13OA FLASHROMCS- O - - Hi-Z - Chip select signal (MASK ROM operation : Input port)

6 _CS1, TM13OB PARALLELIN- O - - Hi-Z - Chip select signal (IN/OUT)

7 _CS2, TM14OA FLASHROMCS- I - - Hi-Z - Chip select signal (Normal operation : Input port, MASK ROM

8 _CS3, TM14OB -- O - - Hi-Z - Not used.

9 P54, _BREQ EXTOUT- O - - Hi-Z H EXT.OUT signal

10 P55, _BRACK RMTOUT- O - - Hi-Z H Remote output signal

11 P56, ALE, _ALE,

12 P57,_WORD WORD- I - H H H Data bit bus width select 'H': 8bit

13 P20,A00,SBT2 A00 A/O - - Unfix - Address bus

14 P21,A01,SBI2 A01 A/O - - Unfix - Address bus

15 P22,A02,SBO2 A02 A/O - - Unfix - Address bus

16 P23,A03 A03 A/O - - Unfix - Address bus

17 Vdd Vdd - - - - - Power supply (+3.3V)

18 BOSC,BIBT1,

19 Vss Vss - - - - - GND(0V)

20 XI,PB1 MCE O - Pd Hi-Z L Chip select 'L': MN662791 / 'H': BU2618

21 XO -- - - - - - Not used. OPEN

22 Vdd Vdd - - - - - Power supply (+3.3V)

23 OSCI OSCI I - - - -

24 OSCO OSCO O - - - - OSCI output

25 MODE MODE I - L L L Mode select 'L': Processor mode

26 P24,A04,TM15IA A04 A/O - - Unfix - Address bus

27 P25,A05 A05 A/O - - Unfix - Address bus

28 P26,A06 A06 A/O - - Unfix - Address bus

Pin Name Symbol I/O Det Ext Res Ini Function

operation : F. ROM Chip select)

MON2 I - - Hi-Z - Monitor signal 2

_BSTRE, TM15IA

IRINH O - - Hi-Z L Infrared remote 'L': Enable / 'H': Inhibit

BIBT2,PB0

12

Page 13

DN-C635

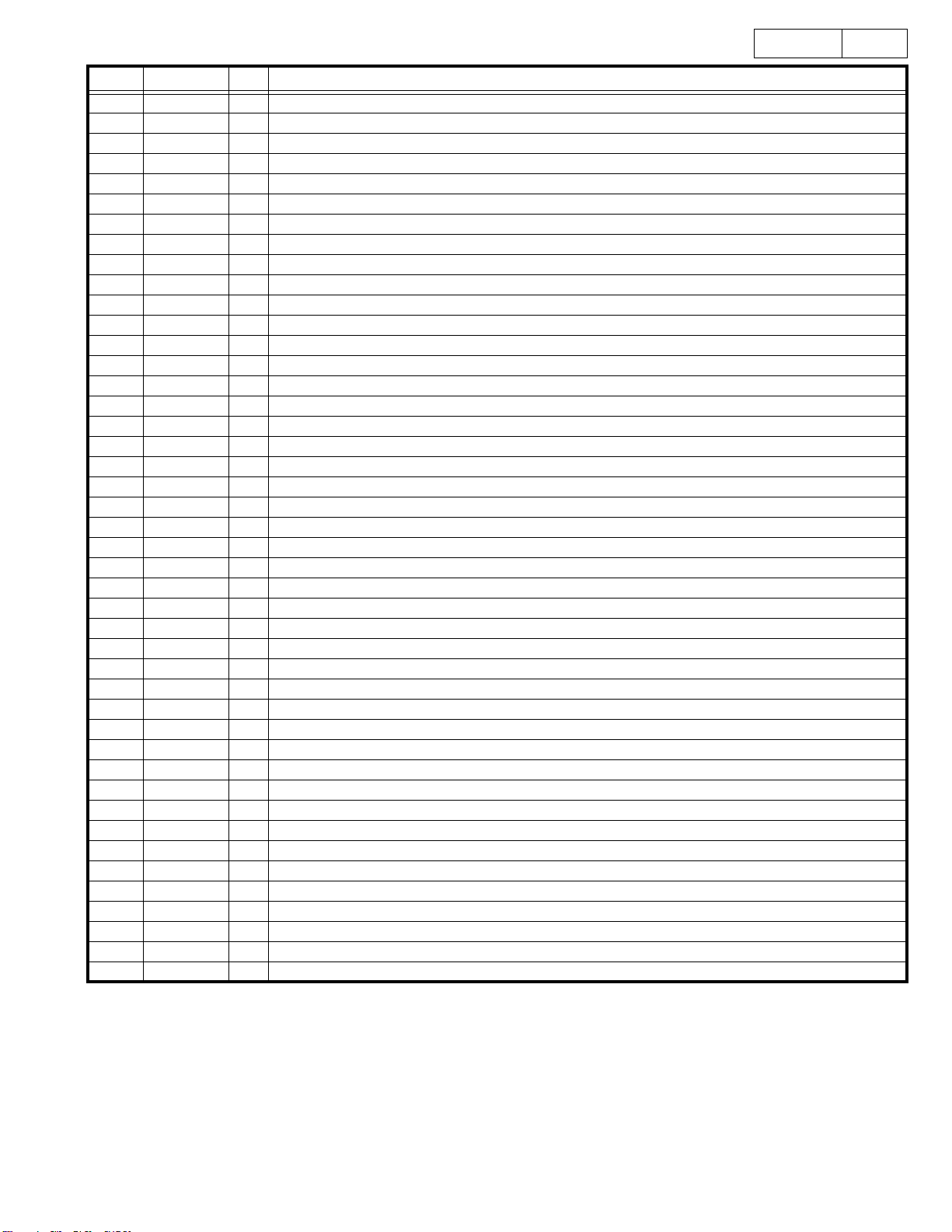

13

Pin

No.

29 P27,A07 A07 A/O - - Unfix - Address bus

30 P30,A08,_KI0 A08 A/O - - Unfix - Address bus

31 P31,A09,_KI1 A09 A/O - - Unfix - Address bus

32 P32,A10,_KI2 A10 A/O - - Unfix - Address bus

33 P33,A11,_KI3 A11 A/O - - Unfix - Address bus

34 AVDD AVDD - - - - - Analog power supply terminal

35 P34,A12,_KI4 A12 A/O - - Unfix - Address bus

36 P35,A13,_KI5 A13 A/O - - Unfix - Address bus

37 P36,A14,_KI6 A14 A/O - - Unfix - Address bus

38 P37,A15,_KI7 A15 A/O - - Unfix - Address bus

39 P40,A16 A16 A/O - - Unfix - Address bus

40 P41,A17 A17 A/O - - Unfix - Address bus

41 P42,A18 A18 A/O - - Unfix - Address bus

42 P43,A19 -- A/O - - Unfix - Address bus

43 Vref- Vref- - - - - - Standard analog power supply

44 P44,AN4,A20 KEYIN1 I Lv Pu Unfix - Panel key 1 (Use A/D converter)

45 P45,AN5,A21 KEYIN2 I Lv Pu Unfix - Panel key 2 (Use A/D converter)

46 P46,AN6,STOP,

47 P47,AN7,WDOUT,

48 P80,TM14OA TRSLA- I - Pu Hi-Z - Rotary switch A signal

49 P81,TM14OB TRSLB- I - Pu Hi-Z - Rotary switch B signal

50 P82,TM0IO,SBI2,

51 P83,TM4IO,SBI3 RxD I - - Hi-Z - Serial port (9600bps)

52 P84,TM7IO,SBO3,

53 P85,TM9IOA,

54 Vref+ Vref+ - - - - - Standard analog power supply

55 P86,TM9IOB,SBI4 FLCS- O - - Hi-Z H To FL driver CS

56 P87,TM9IC,SBO4,

57 P90,TM8IOA,

58 P91,TM10IOA,

59 P92,TM10IOB,

60 P93,TM10IC,

61 Vss Vss - - - - - GND (0V)

62 P94,AN0 -- I Lv Pd L - Not used.

63 P95,AN1 -- I Lv Pd L - Not used.

64 P96,AN2 PITCHC I Lv - Hi-Z - Use A/D converter

65 P97,AN3 PITCH I Lv - Hi-Z - Use A/D converter

66 Vdd Vdd - - - - - Power supply(+3.3V)

67 P70,SBT0,_RAS MCLK O - - Hi-Z H DSP interface Clock (clock synchronous formula)

68 P71,SBI0,_CAS,

69 P72,SBO0,_UCAS MDAT O - - Hi-Z H DSP interface Transmission (clock synchronous formula)

70 P73,SBT1,DUMX TXTCLK O - - Hi-Z H Use during CD-TEXT data read (clock synchronous formula)

71 P74,SBI1 PTXTD I - - Hi-Z - Use during CD-TEXT data read (clock synchronous formula)

Pin Name Symbol I/O Det Ext Res Ini Function

KEYIN3 I Lv Pu Unfix - Panel key 3 (Use A/D converter)

A22

SDA O - - Hi-Z L Serial data for BU2090

A23

MON1 I - - Hi-Z - Monitor signal 1

SBT3,SCL3

TxD O - - Hi-Z H Serial port (9600bps)

SDA3

FLCLK O - - Hi-Z H To FL driver SCK

SBO2,SBT4,SCL4

FLSD O - - Hi-Z H To FL driver SDATA

SDA4

LEDCK O - - Hi-Z L Clock for BU2090

BIBT1,_DMAREQ1

PUSH- I - Pu H - Not used.

BIBT2,_DMAACK1

LRCK I Ed - Hi-Z - LRCK : Use for time code creation during MP3 playback.

_DMAREQ0

NRST O - Pd L L Round IC reset signal

_DMAACK0

STAT I - - Hi-Z - DSP interface Reception (clock synchronous formula)

_LCAS

13

Page 14

DN-C635

14

Pin

No.

72 P75,SBO1 MLD O - - Hi-Z H DSP interface latch

73 TEST1 TEST1 I - Pu - - Pull up 33 - 50K

74 TEST2 TEST2 I - Pu - - Pull up 33 - 50K

75 _NMI -- I Lv Pu Hi-Z - Not used.

76 PA0,_IRQ0 BLKCK I Ed - Hi-Z - Sub code clock interruption

77 PA1,_IRQ1 DQSY I Ed - Hi-Z - CD-TEXT DQSY Interruption

78 PA2,_IRQ2 FADER ST I Ed - Hi-Z - Fader signal

79 PA3,_IRQ3 REMOTE- I Ed - Hi-Z - RC-5/Infrared remote signal input

80 PA4,_IRQ4,TM15IB CHGOFT O - Pu H L Off track signal

81 PA5,ADSEP ADSEP I - H H H H': Address data separation mode / 'L': Address data common mode

82 _RST RST- I Lv Pu L - Reset signal 'L': RESET

83 Vdd Vdd - - - - - Power supply (+3.3V)

84 P00,D00,AD00 D00 D/O - - Hi-Z - Data bus

85 P01,D01,AD01 D01 D/O - - Hi-Z - Data bus

86 P02,D02,AD02 D02 D/O - - Hi-Z - Data bus

87 P03,D03,AD03 D03 D/O - - Hi-Z - Data bus

88 P04,D04,AD04 D04 D/O - - Hi-Z - Data bus

89 P05,D05,AD05 D05 D/O - - Hi-Z - Data bus

90 P06,D06,AD06 D06 D/O - - Hi-Z - Data bus

91 P07,D07,AD07 D07 D/O - - Hi-Z - Data bus

92 Vss Vss - - - - - GND (0V)

93 P010,D08,AD08,

94 P011,D09,AD09,

95 P012,D10,AD10,

96 P013,D11,AD11,

97 P014,D12,AD12,

98 P015,D13,AD13,

99 P016,D14,AD14,

100 P017,D15,AD15,

Pin Name Symbol I/O Det Ext Res Ini Function

ST_MONO O - Pu H H Output mode STEREO/MONO=1/0

TM8IOB

FIX_VAR1 O - Pu H H VCO MORMAL/PITCH=0/1

TM8IC

TM11IOA

TM11IOB

TM11IC

TM12IOA

TM12IOB

TM12IC

DEBAG1 O - - - - Terminal 1 for debag

OPEN I - - Hi-Z - OPEN switch

CLOSE I - - Hi-Z - CLOSE switch

LOAD O - - Hi-Z H OPEN/CLOSE signal (PWM out put) (During Pnrst='L', out put

PWM(50%))

DEBAG1 O - - - H Terminal 2 for debag

LIMITSW- I O - Hi-Z - Inner circle SW

14

Page 15

MN6627911AC

(IC210)

61

60

41

40

DN-C635

15

80

1

20

MN6627911AC Terminal Function

Pin No. Pin Name I/O Function

1 DRVDD I Power supply for DRAM interface (Pin No.2 - 18, 80)

2 D0 I/O Data I/O signal 0 for DRAM

3 D1 I/O Data I/O signal 1 for DRAM

4 WE O Write enable signal for DRAM

5 RAS O RAS control signal for DRAM

6 D2 I/O Data I/O signal 2 for DRAM

7 D3 I/O Data I/O signal 3 for DRAM

8 CAS O CAS control signal 0 for DRAM

9 A10 O Address signal 10 for DRAM

10 A8 O Address signal 8 for DRAM

11 A7 O Address signal 7 for DRAM

12 A6 O Address signal 6 for DRAM

13 A5 O Address signal 5 for DRAM

14 A4 O Address signal 4 for DRAM

15 A9 O Address signal 9 for DRAM

16 A0 O Address signal 0 for DRAM

17 A1 O Address signal 1 for DRAM

18 A2 O Address signal 2 for DRAM

19 A3 O Address signal 3 for DRAM

20 DVSS2 I GND for digital

21 DVDD2 I Power supply for digital

22 SPOUT O Spindle motor drive signal

23 TRVP O Traverse drive signal

24 TRVM O Not used

25 TRP O Tracking drive

26 GCNTL O Gain control signal for CD-RW

27 FOP O Focus drive

28 CHGICO O EQ select signal

29 IOVDD1 I Power supply for IO

30 TBAL O Tracking balance adjust

31 FBAL O Focus balance adjust

32 FE I Focus error signal (Analog input)

33 TE I Tracking error signal (Analog input)

34 RFENV I RF envelope signal (Analog input)

35 OFT I Off track signal H : OFF TRACK

36 NRFDET I RF detect signal H : DETECT

21

15

Page 16

Pin No. Pin Name I/O Function

37 BDO I Drop out signal H : DROP OUT

38 LDON O Laser ON signal H : ON

39 ARF I RF signal

40 IREF I Standard current input terminal

41 ADPVCC I Voltage for power supply monitor

42 DSLF O Loop filter for DSL

43 RFSW I Loop filter for DSL

44 PLLF O Loop filter for PLL

45 PLLFO O Loop filter for PLL

46 AVDD2 I Power supply for analog (DSL, PLL, AD)

47 AVSS2 I GND for analog (DSL, PLL, AD)

48 OUTL O Not used

49 AVSS1 I GND for analog (Audio output)

50 OUTR O Not used

51 AVDD1 I Power supply for analog (Audio output)

52 DVSS3 I GND for digital

53 DVDD3 I Power supply for digital

54 TMOD2 I Test terminal L : Normal

55 MON2 O Serial monitor signal 2

56 BCLK O Bit clock for serial data

57 SRDATA O Serial data signal

58 LRCK O L, R discernment signal

59 IOVDD2 I Power supply for IO

60 TX O Digital audio interface signal

61 MCLK I ucon command clock signal

62 MDATA I ucon command data signal

63 MLD I ucon command load signal L : LOAD

64 BLKCK O Sub code block clock signal (f=75Hz : Normal speed playback)

65 PWMSEL I PWM output mode select L : Direct H : 3 values

66 SMCK O Not used

67 SBCK I Not used

68 STAT O Status signal

69 NRST I Reset L : RESET

70 SPPOL O Not used

71 PMCK O Not used

72 DQSY O Pack signal for CD TEXT data

73 TXTD O CD TEXT data signal

74 TXTCK O Ext. clock signal input for CD TEXT resister

75 NTEST I Test terminal H : Normal

76 X2 O Not used

77 X1 I 16.9344MHz input terminal

78 DVSS1 I GND for digital

79 DVDD1 I Power supply for digital

80 MON1 O Serial monitor signal

DN-C635

16

16

Page 17

AN8785SB

(IC202)

DN-C635

17

1

7

8

14 15

AN22002A

(IC201)

L: All mute

Hiz: ch2,4 ON

H: Active

28

22

21

Standby

16

Standby

Band-gap

Vcc/Vref

Reser Circuit

1.25V

+

-

7

IN2+

0.1µ

(2.5V)

PVcc2

10

[ Loading ]

D2+

D2-

M

12 11

-

-

+

-

+

9

ch.4 SW

H:2.5V

L or

IN2-

HIZ

+

8

:Vref

[ Traverse ]

D4-

18

-+-

21

IN4

-

D4+

+

17

+

switch

15

PGnd2

[ Others ]

[ Spindle ]

D3-

MM

14

-+-

-

20

IN3

CAGC

-

D1+

28

+

PGnd1

C0FTR

[ Tracking ]

D5-

D5+

26

+

-

+

2

IN5

0FTR

25

-

+

PVcc1

24

Protection

Circuit

22

SVcc

+

-

SGnd-Fin

4

IN-

5

IN+

3

OUT

6

Vref

[ Focus ]

D3+

PVcc3

D1-

13

+

19

1

-+-+-

+

23 27

IN1

CBD0

ARF

BD0

RFN

1

16

32

A

+

C

-

+

A

B

+

17

D

-

+

F

-

+

E

-

+

32

C

31

B

30

D

29

27

E

F

28

VREF

17

5

4

RFOUT

RF_EQ

AMP GCA BCA

AMP GCA BCA

AMP

AMP

+

-

6

NRFDET

GCA

GCA

8

7

RFIN

AGC BD0 0FTR

BCA

BCA

12

SUB

SUB

13

3TENV

-

+

-

+

14

9

CEA

10

3TOUT

15

NRFDET

FEN

22

23

FEOUT

TEN

21

20

TEOUT

TEBPF

11

19

VDET

-

+

LD

VDET

18

2

17

PD

1

TBAL

GCTL

24

26

FBAL

25

3

16

VCCGND

Page 18

PCM 1716E (IC211)

1

LRCIN

2

DIN

3

BCKIN

4

CLKO

5

XTI

6

XTO

7

DGND

8

V

DD

9

VCC2R

EXTR

NC

V

OUT

AGND1

10

11

12

13

R

14

AGND2R

28

27

26

25

24

23

22

21

20

19

18

17

16

15

ML/IIS

MC/DM1

MD/DM0

MUTE

MODE

CS/IWO

RST

ZERO

V

2L

CC

AGND2L

EXTL

NC

V

L

OUT

V

1

CC

DN-C635

PIN NAME I/O DESCRIPTION

1 LRCIN IN Left and Right Clock Input. This clock is equal to

the sampling rate - f

2 DIN IN Serial Audio Data Input

3 BCKIN IN Bit Clock Input for Serial Audio Data.

4 CLKO OUT Buffered Output of Oscillator. Equivalent to

System Clock.

5 XTI IN Oscillator Input (External Clock Input)

6 XTO OUT Oscillator Output

7 DGND

8V

9V

CC

10 AGND2R

-

Digital Ground

-

DD

2R

Digital Power +5V

-

Analog Power +5V

-

Analog Ground

11 EXTR OUT Rch, Common Pin of Analog Output Amp

-

12 NC

13 V

OUT

14 AGND1

15 V

CC

16 V

OUT

17 NC

R OUT Rch, Analog Voltage Output of Audio Signal

1

L OUT Lch, Analog Voltage Output of Audio Signal

No Connection

-

Analog Ground

-

Analog Power +5V

-

No Connection

18 EXTL OUT Lch, Common Pin of Analog Output Amp

-

19 AGND2L

20 V

2L

CC

Analog Ground

-

Analog Power +5V

21 ZERO OUT Zero Data Flag

22 RST IN Reset. When this pin is low, the DF and

modulators are held in reset.

23 CS/IWO IN Chip Select/Input Format Selection. When this

pin is low, the Mode Control is effective.

24 MODE IN

Mode Control Select. (H: Software, L: Hardware)

25 MUTE IN Mute Control

26 MD/DM0 IN Mode Control, DATA/De-emphasis Selection 1

27 MC/DM1 IN Mode Control, BCK/De-emphasis Selection 2

28 ML/I2S IN Mode Control, WDCK/Input Format Selection

NOTES: (1) Pins 1, 2, 3; Schmitt Trigger input. (2) Pins 22, 24, 25, 26, 27,

28; Schmitt Trigger input with pull-up resister. (3) Pin 23; Schmitt Trigger

input with pull-down resister.

(1)

.

S

(1)

(1)

(2)

(3)

18

(2)

(2)

(2)

(2)

BU2618FV (IC214)

18

Page 19

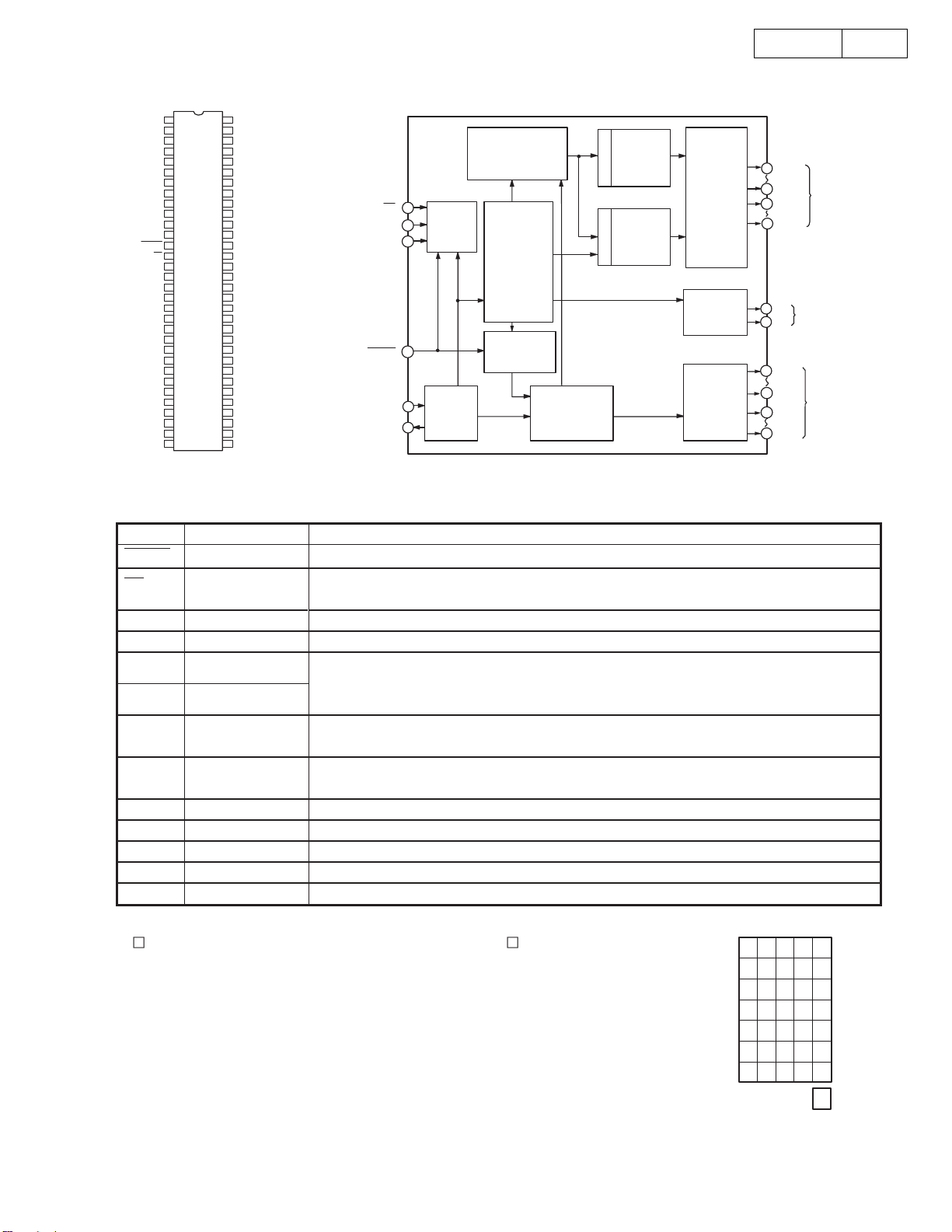

M66005FP (IC504)

D I G

1 1

1

2

D I G

1 0

3

D I G

0 9

D I G

0 8

4

D I G

0 7

5

D I G

0 6

6

D I G

0 5

7

D I G

0 4

8

9

D I G

0 3

D I G

0 2

1 0

D I G

0 1

1 1

D I G

0 0

1 2

1 3

R E S E T

C S

1 4

1 5

S C K

S D A T A

1 6

P I

1 7

P O

1 8

1 9

V c c 1

X

2 0

o u t

2 1

X

i n

2 2

V s s

S E G

2 3

3 5

2 4

S E G

3 4

S E G

3 3

2 5

S E G

3 2

2 6

S E G

3 1

2 7

2 8

S E G

3 0

S E G

2 9

2 9

S E G

2 8

3 0

S E G

2 7

3 1

V p S E G

3 2

D I G

6 4

6 3

D I G

6 2

D I G

D I G

6 1

6 0

V c c 2

5 9

S E G

S E G

5 8

S E G

5 7

5 6

S E G

5 5

S E G

5 4

S E G

5 3

S E G

5 2

S E G

5 1

S E G

5 0

S E G

4 9

S E G

4 8

S E G

4 7

S E G

4 6

S E G

S E G

4 5

S E G

4 4

4 3

S E G

4 2

S E G

4 1

S E G

S E G

4 0

3 9

S E G

3 8

S E G

S E G

3 7

S E G

3 6

3 5

S E G

3 4

S E G

3 3

1 2

1 3

1 4

1 5

0 0

0 1

0 2

0 3

0 4

0 5

0 6

0 7

0 8

0 9

1 0

1 1

1 2

1 3

1 4

1 5

1 6

1 7

1 8

1 9

2 0

2 1

2 2

2 3

2 4

2 5

2 6

C h i p S e l e c t I n p u t

S h i f t C l o c k I n p u t

S e r i a l D a t a I n p u t

R e s e t I n p u t

C l o c k I n p u t

C l o c k O u t p u t

S C K

S D A T A

R E S E T

X O U T

DN-C635

D i s p l a y C o d e R e g i s t e r

( 8 - b i t x 1 6 )

c o d e

1 4

C S

S e r i a l

1 5

R e c e p t i o n

C i r c u i t

1 6

1 3

C l o c k

2 1

X I N

2 0

G e n e r a t i o n

C i r c u i t

w r i t e

C o d e /

C o m m a n d

C o n t r o l C i r c u i t

D i s p l a y C o n t r o l

R e g i s t e r

R A M

w r i t e

c o d e s e l e c t

D i s p l a y C o n t r o l l e r

C G R O M

( 3 5 - b i t x 1 6 0 )

D e c o d e rD e c o d e r

C G R O M

( 3 5 - b i t x 1 6 )

S e g m e n t

O u t p u t

C i r c u i t

O u t p u t P o r t

( 2 - b i t )

D i g i t O u t p u t

C i r c u i t

S E G

0 0

5 9

2 6

S E G

3 3

3 1

2 3

1 8

1 7

1 2

1

6 4

6 1

S E G

S E G

P 0

P 1

D I G

D I G

D I G

D I G

2 7

3 5

O u t p u t P o r t

0 0

1 1

D i g i t O u t p u t

1 2

1 5

S e g m e n t

O u t p u t

19

M66005FP Terminal Function

Symbol Name Function

RESET Reset Input

CS Chip Select Input

SCK Shift Clock Input

SDATA Serial Data Input

X

IN

OUT

X

DIG 00~

DIG 15

SEG 00~

SEG 35

Clock Input

Clock Output

Digit Output

Segment Output

P0, P1

V

CC1

V

CC2

Vss

Vp

(Forwarding connection of segment output terminal.)

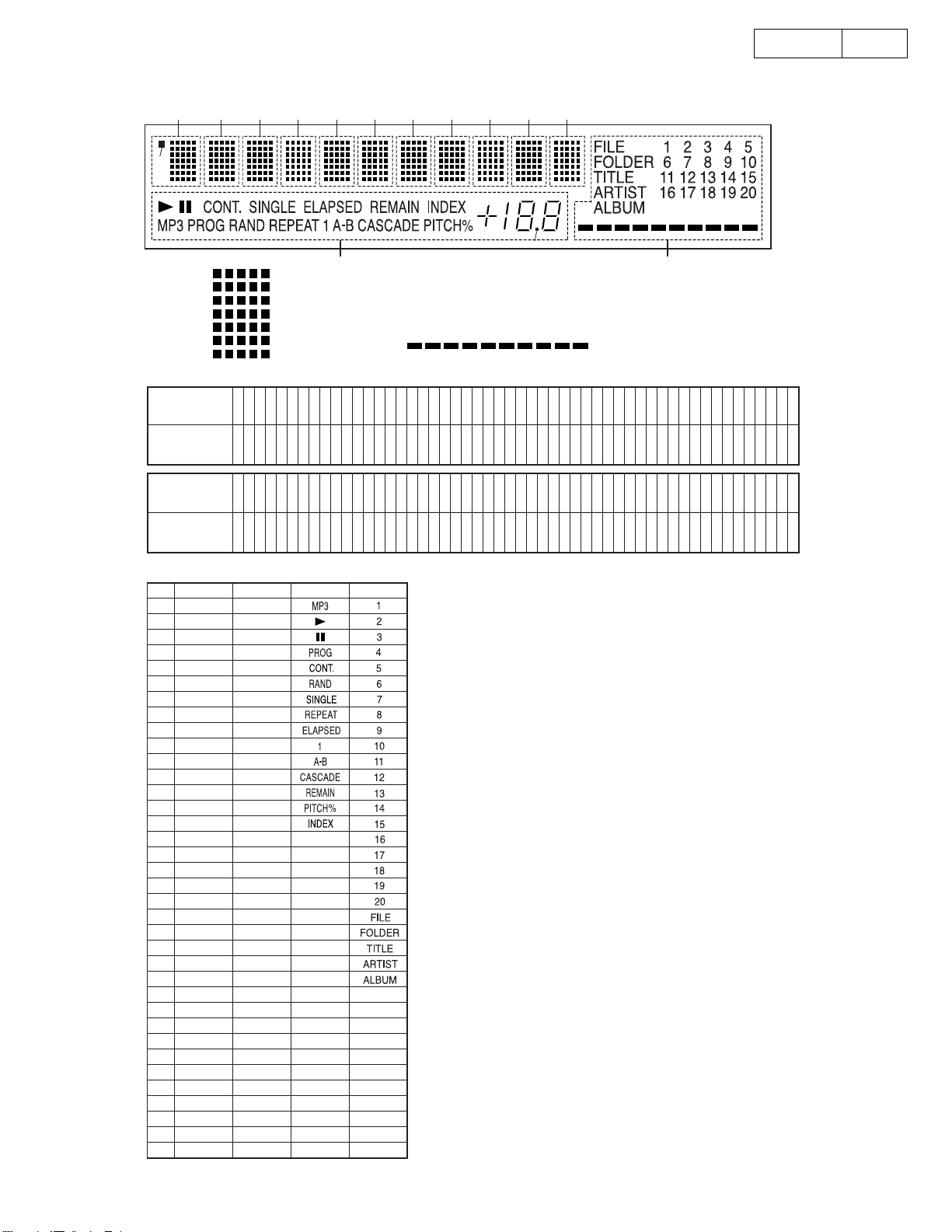

in the right figure indicates 1 dot of segment, the figure in shows the segment output

terminal number (00~35) to be connected.

(セグメント出力端子接続先)

右図における□はセグメントの 1 ドットを示し、□内の数字が接続すべきセグメント出力

端子番号(00 〜 35)を表します。

Initialzes internal state of M66005.

Able to communicate with MCU in "L" mode.

Command from MCU will be disregareded in "H" mode.

Shifts input data at rise from "L" to "H".

Inputs character code or command data needed to display from MSB.

Sets oscillation frquency by connecting external resistor and capacitor (maximum

oscillation frequency fosc (max)=1MHz). Also feasible to apply external clock. In this case,

inject external clock to Xin terminal and open Xout terminal.

Connect to digit terminal of VFD. DIG00~DIG15 correspond to the 1st figure to 16th figure

respectively.

Connect to segment terminal of VFD. For corresponding SEG00~SEG35 to segment

terminal of VFD, refer to the figure right.

Output port (static operation).

Positive power supply terminal for internal logic.

Positive power supply terminal for high tension output port.

GND terminal.

Negative power supply terminal for VFD drive.

00 01 02 03 04

05 06 07 08 09

10 11 12 13 14

15 16 17 18 19

20 21 22 23 24

25 26 27 28 29

30 31 32 33 34

19

35

Page 20

DN-C635

20

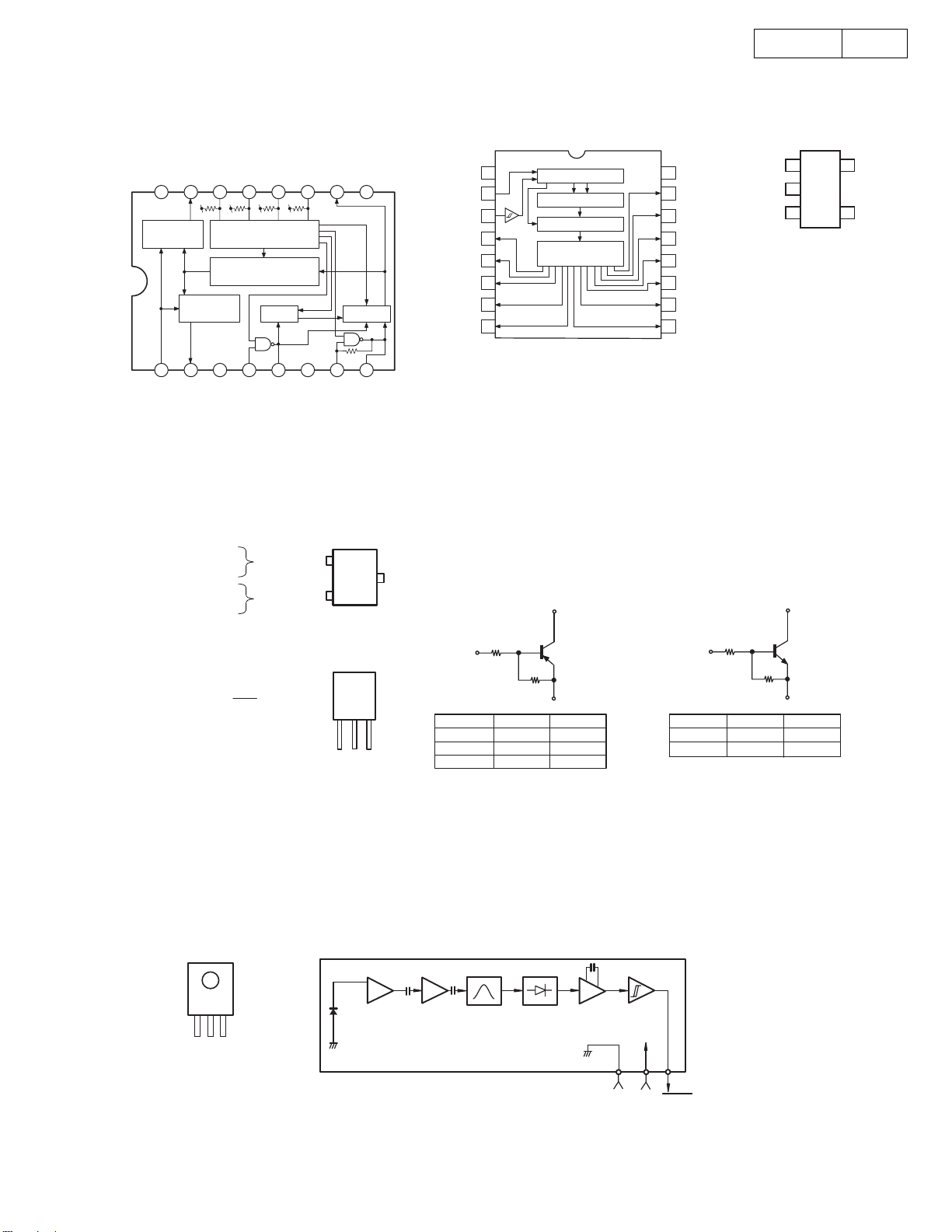

TC9246F (IC217)

VDD

LOCKS2S1

1611521431341251161079

Lock Ditection

Circuit

REF

REF

Microcomputer Interface

Programmable Counter

VAR

Phase

Comparator

PD

DDA

V

AMPI

M2

VCO

AMPO

1 TRANSISTORS

DTA114EK

DTA144EK

DTC114EK

DTC114YK

PNP

NPN

M1

VSSA

BU2090F (IC104)

CKO

Vss

Selector

8

XI

XO

B

TOP

C

VIEW

E

7Q3

8Q4

DTA Series

Control Circuit

12-Bit Shift Register

Latch

Output Buffer

(Open Drain)

C

16 VDD1Vss

15 Q112DATA

14 Q103CLOCK

13 Q94Q0

12 Q85Q1

11 Q76Q2

10 Q6

Q5

9

DTC Series

AN80L18RMS (IC208)

SW

GND

NC

5

4

3

C

1

IN

2

OUT

DTA144ES

PNP

FRONT

VIEW

C

E

B

1 OTHERS

GP1UE261XK (Remote Control Sensor)

(IC501)

TOP VIEW

Head

Amp

Vcc

VOUT

GND

Limiter

Amp

R1

B

R2

R1

DTA114EK

DTA144EK

DTA144ES

10kohm

47kohm

47kohm 47kohm

Detector &

BPF Integrator

Comparator

E

R2

10kohm

47kohm

Hysteresis

Comparator

B

DTC114EK

DTC114YK

R1

R2

R1

10kohm

10kohm 47kohm

E

R2

10kohm

20

GND Vcc

VOUT

Page 21

FL DISPLAY

BJ899GN (FL501)

S1

DN-C635

21

2G 1G3G4G5G6G7G8G9G10G11G

1-1

2-1 3-1 4-1 5-1

1-2

1-3

1-4

1-5

1-6

1-7

Pin connection

Pin No.

Connection

Pin No.

Connection

1

2

3

4

F

F

N

N

1

1

P

P

5

5

5

5

3

5

6

4

N

N

N

N

P

P

P

P

Anode connection

P1

P2

P3

P4

P5

P6

P7

P8

P9

P10

P11

P12

P13

P14

P15

P16

P17

P18

P19

P20

P21

P22

P23

P24

P25

P26

P27

P28

P29

P30

P31

P32

P33

P34

P35

P36

1G~10G

1-1

2-1

3-1

4-1

5-1

1-2

2-2

3-2

4-2

5-2

1-3

2-3

3-3

4-3

5-3

1-4

2-4

3-4

4-4

5-4

1-5

2-5

3-5

4-5

5-5

1-6

2-6

3-6

4-6

5-6

1-7

2-7

3-7

4-7

5-7

-

11G

1-1

2-1

3-1

4-1

5-1

1-2

2-2

3-2

4-2

5-2

1-3

2-3

3-3

4-3

5-3

1-4

2-4

3-4

4-4

5-4

1-5

2-5

3-5

4-5

5-5

1-6

2-6

3-6

4-6

5-6

1-7

2-7

3-7

4-7

5-7

S1

S3

S2

S2

S3

1a2a

1

3

b

3

c

1

1g

f

b

1

1

e

c

1d

Dp

12G

[1G~11G] [13G]

1

1

1

1

1

1

5

6

7

8

9

0

1

I

N

C

C

5

5

7

8

P

P

2

2

8

9

N

N

N

N

N

C

C

C

C

C

5

6

6

6

6

9

0

1

2

3

P

P

P

P

P

3

3

3

3

3

0

1

2

3

4

1

2

3

4

5

6

N

N

N

N

N

C

C

C

C

C

6

6

6

6

6

6

7

8

4

5

P

P

N

N

N

3

3

C

C

C

5

6

B8

B10

B9

B7

1

1

1

2

2

2

7

8

9

2

0

1

1

N

C

N

C

N

N

P

P

3

N

G

C

C

1

C

6

7

7

7

7

7

3

9

4

0

1

2

1

2

N

N

N

G

G

C

G

C

C

B4B6

B5

2

2

2

2

3

4

5

6

P

P

P

2

3

4

5

7

7

7

7

5

6

7

8

3

4

5

6

G

G

G

B2

B1

B3

2

2

2

3

3

3

3

7

8

9

P

P

P

6

7

8

7

8

8

9

0

1

7

8

9

G

G

G

3

0

1

2

3

4

P

P

P

P

P

1

1

1

1

9

0

1

2

3

8

8

8

8

8

3

4

5

6

2

1

1

1

1

2

N

N

0

G

G

G

C

C

NOTE 1) F1,F2 : Filament

12G

13G

2) NP : No pin

3) NC : No connection

4) DL : Datum Line

5) 1G~13G : Grid

6) IC : Internal connection

S2

S3

3b,3c

2d

2e

2c

2g

2f

2b

2a

Dp

1d

1e

1c

1g

1f

1b

1a

-

-

-

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

-

13G

4

5

5

3

3

3

3

3

4

4

4

4

4

4

4

5

6

7

8

9

0

1

2

P

P

P

P

P

P

P

1

1

1

4

5

6

8

8

8

7

8

9

N

N

N

C

C

C

P

1

1

1

2

2

7

8

9

0

1

9

9

9

9

9

0

1

2

3

4

N

N

N

N

N

C

C

C

C

C

4

3

4

5

6

7

P

P

P

P

P

2

2

2

2

2

2

3

4

5

6

9

9

9

9

9

5

6

7

8

9

N

N

N

N

N

C

C

C

C

C

5

4

9

0

1

2

8

P

N

N

F

F

2

P

P

2

2

7

1

1

1

1

1

0

0

0

0

0

0

1

2

3

4

I

N

N

N

N

C

P

P

P

P

21

Page 22

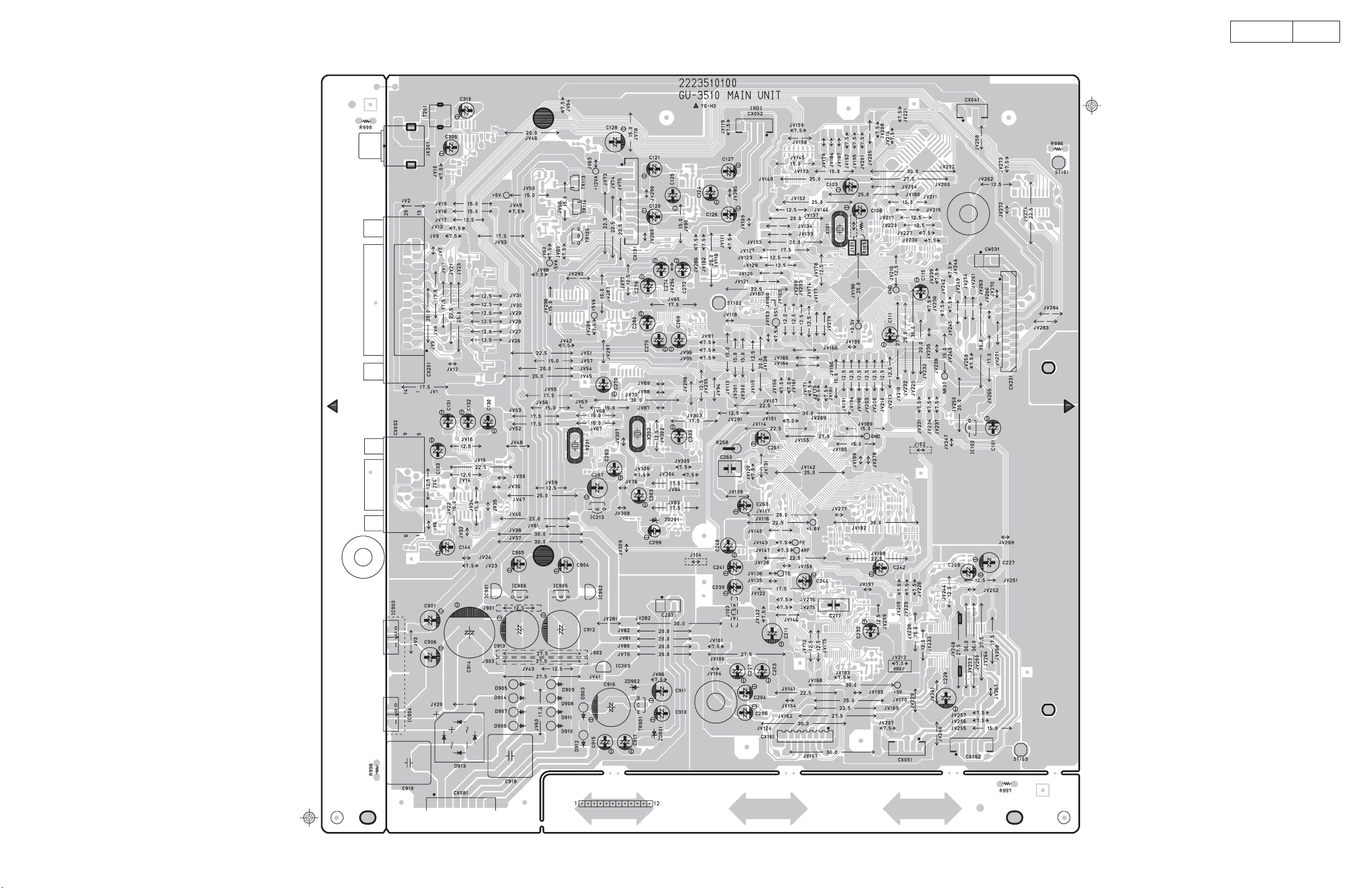

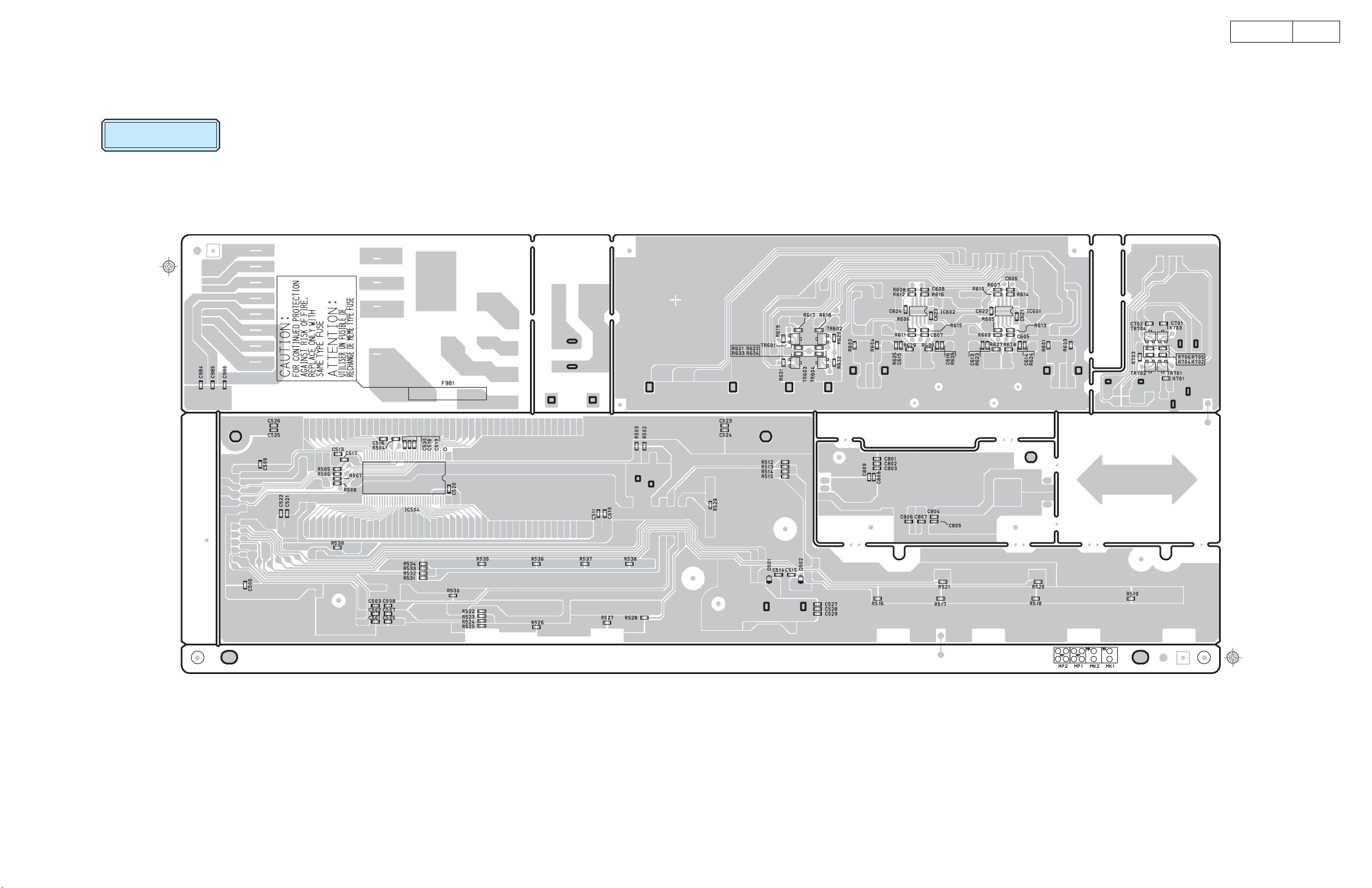

PRINTED WIRING BOARD

GU-3510 MAIN P.W.B. UNIT

DN-C635

22

22

COMPONENT SIDE

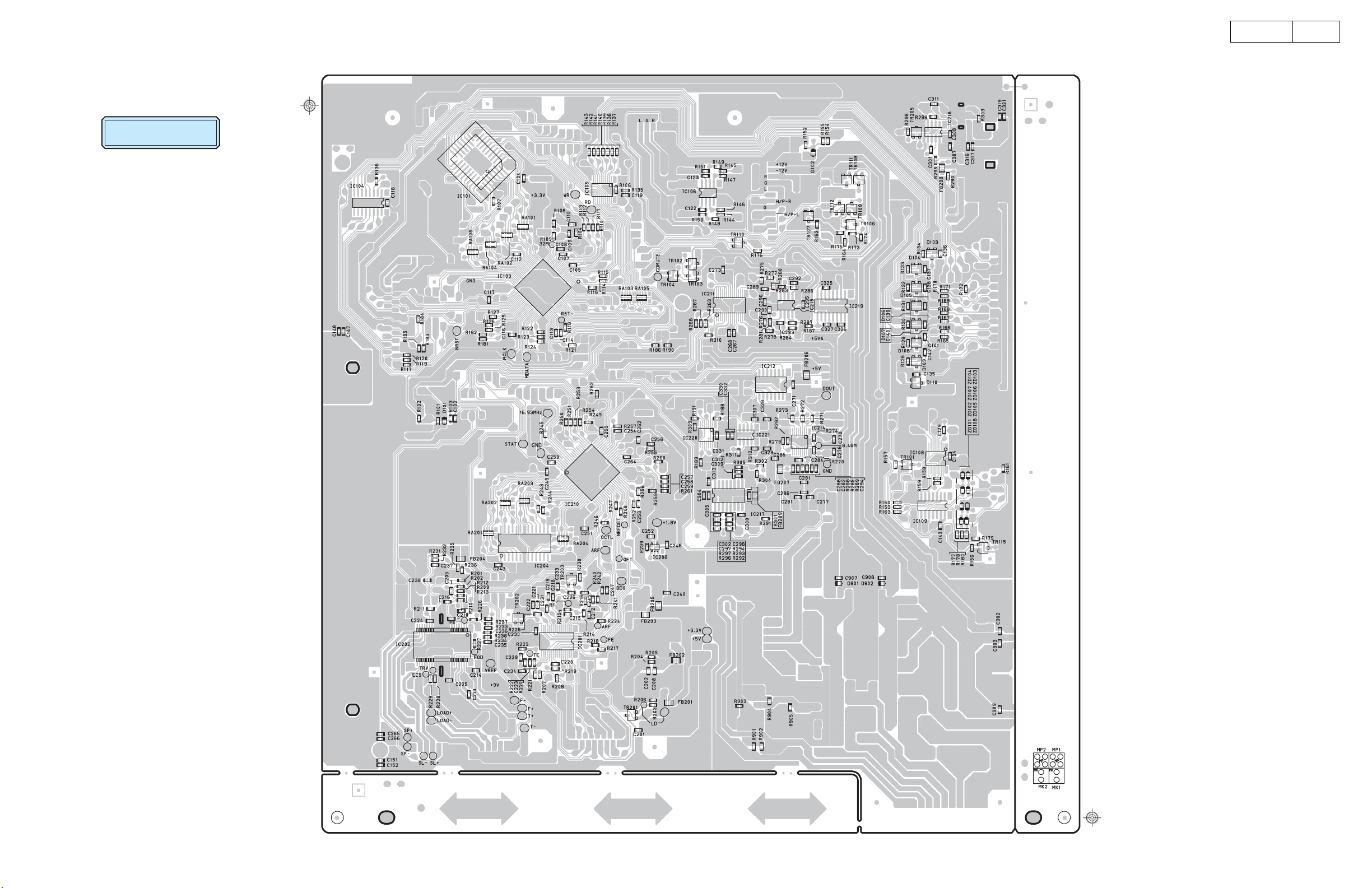

Page 23

Parts List

DN-C635

23

23

FOIL SIDE

Page 24

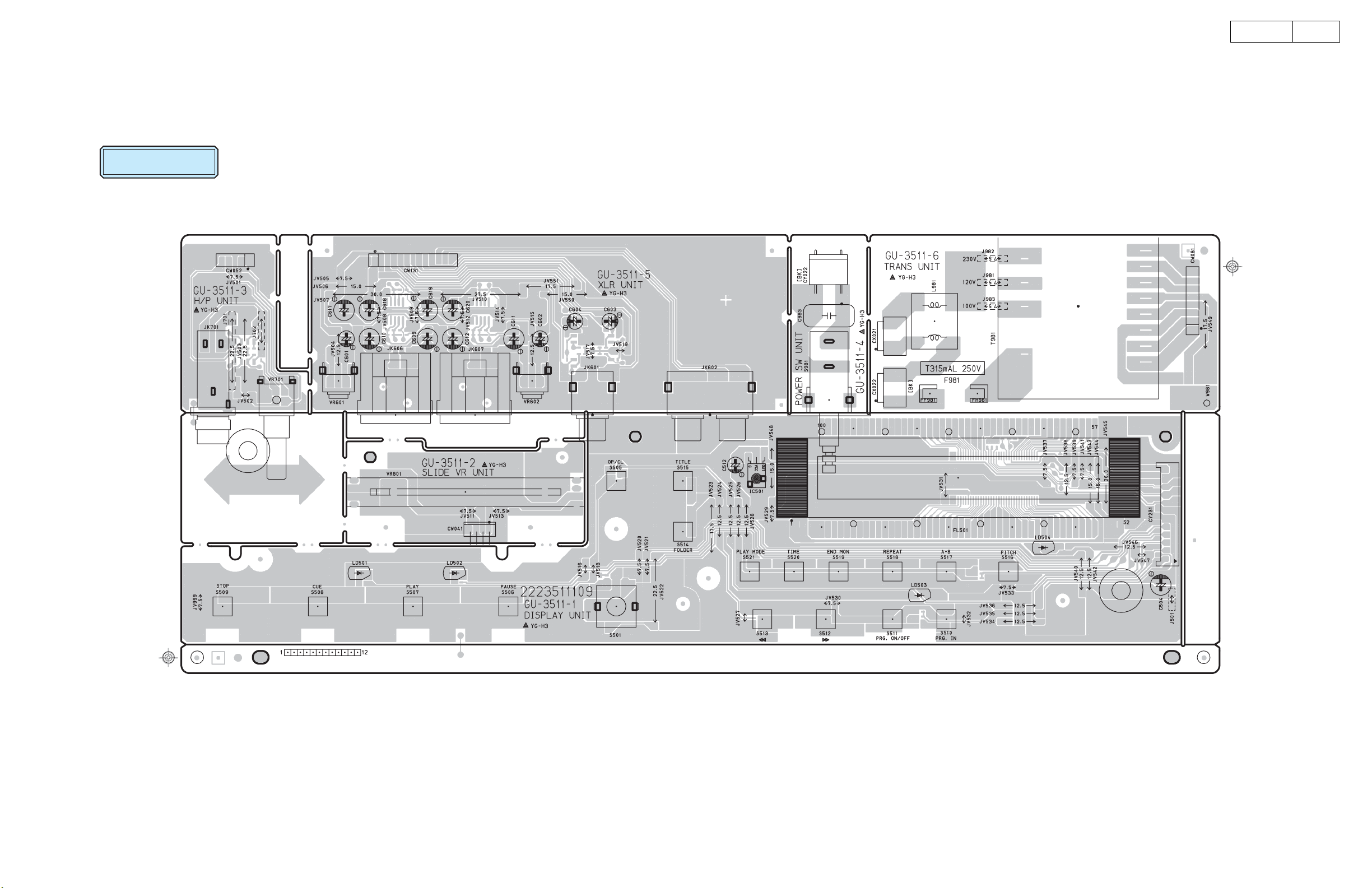

GU-3511 DISPLAY P.W.B. UNIT

Parts List

DN-C635

24

24

COMPONENT SIDE

Page 25

Parts List

DN-C635

25

25

FOIL SIDE

Page 26

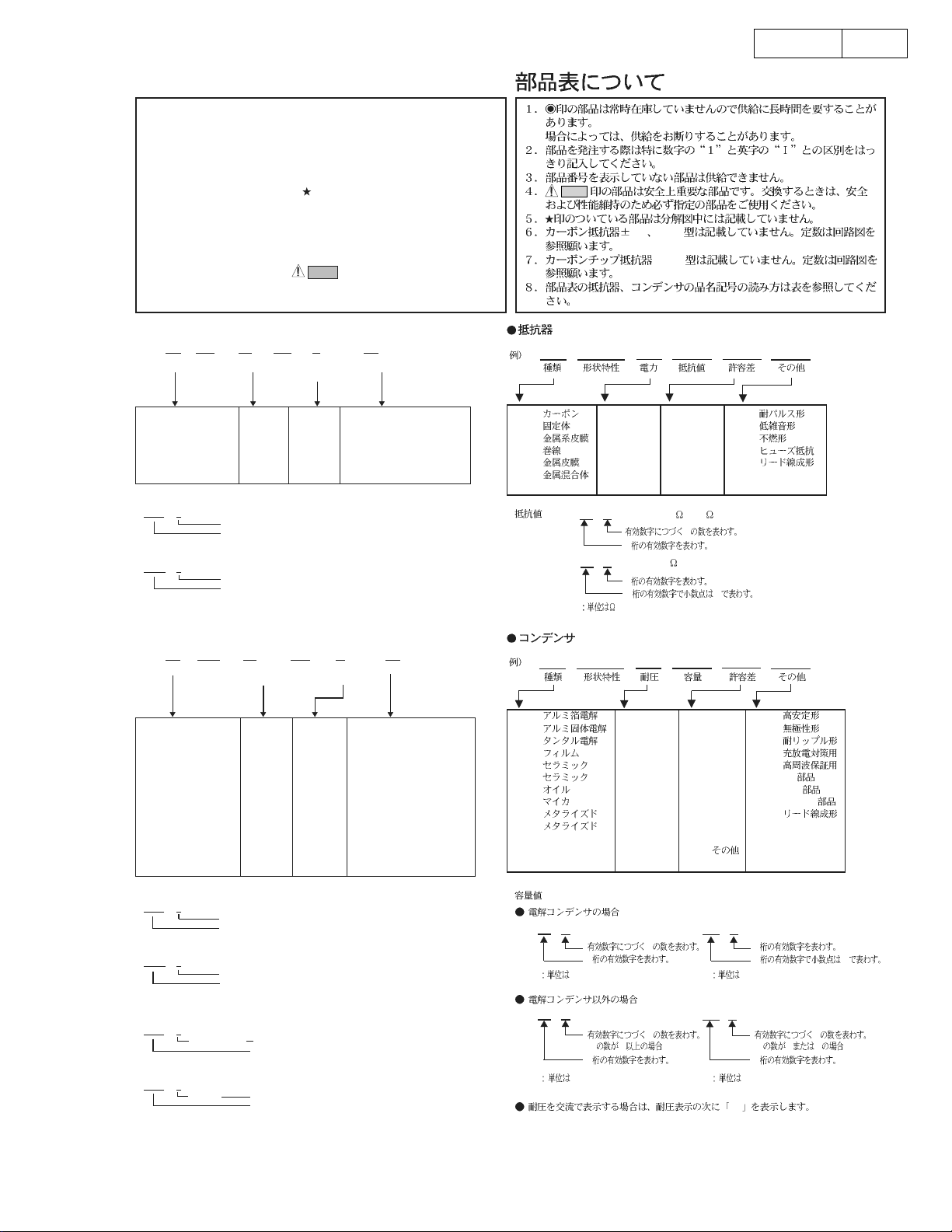

NOTE FOR PARTS LIST

l Part indicated with the mark "" are not always in stock and possibly to

take a long period of time for supplying, or in some case supplying of

part may be refused.

l When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-

supplying.

l Ordering part without stating its part number can not be supplied.

l Part indicated with the mark "

l Not including Carbon Film Resister ±5%, 1/4W Type in the P.W.Board

parts list. (Refer to the Schematic Diagram for those parts.)

l Not including Carbon Chip Resister 1/16W Type in the P.W.Board parts

list. (Refer to the Schematic Diagram for those parts.)

WARNING:

Parts marked with this symbol

Use ONLY replacement parts recommended by the manufacturer.

ll

Resistors

l

ll

Ex.: RN 14K 2E 182 G FR

Type Shape Power Resist- Allowable Others

and per- ance error

formance

" is not illustrated in the exploded view.

have critical characteristics.

DN-C635

5% 1/4W

1/16W

RN 14K 2E 182 G FR

26

RD : Carbon 2B : 1/8W F : ±1% P : Pulse-resistant type

RC : Composition 2E : 1/4W G : ±2% NL : Low noise type

RS : Metal oxide film 2H : 1/2W J : ±5% NB : Non-burning type

RW : Winding 3A : 1W K : ±10% FR : Fuse-resistor

RN : Metal film 3D : 2W M : ±20% F : Lead wire forming

RK : Metal mixture 3F : 3W

] Resistance

1 8 2 ⇒ 1800 ohm = 1.8 kohm

s

s

• Units: ohm

1 R 2 ⇒ 1.2 ohm

s

s

• Units: ohm

ll

l

Capacitors

ll

Ex.: CE 04W 1H 2R2 M BP

Type Shape Dielectric Capacity Allowable Others

CE : Aluminum foil 0J : 6.3V F : ±1% HS : High stability type

electrolytic

CA : Aluminum solid 1A : 10V G : ±2% BP : Non-polar type

electrolytic

CS : Tantalum electrolytic 1C : 16V J : ±5% HR : Ripple-resistant type

CQ : Film 1E : 25V K : ±10% DL : For change and discharge

CK : Ceramic 1V : 35V M : ±20% HF : For assuring high

CC : Ceramic 1H : 50V Z : +80% U : UL part

CP : Oil 2A : 100V –20% C : CSA part

CM : Mica 2B : 125V P : +100% W : UL-CSA type

CF : Metallized 2C : 160V –0% F : Lead wire forming

CH : Metallized 2D : 200V C : ±0.25pF

3H : 5W

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

and per- strength error

formance

requency

2E : 250V D : ±0.5pF

2H : 500V = : Others

2J : 630V

RD : 2B : 1/8 W F : ±1% P :

RC : 2E : 1/4 W G : ±2% NL :

RS : 2H : 1/2 W J : ±5% NB :

RW : 3A : 1 W K : ±10% FR :

RN : 3D : 2 W M : ±20% F :

RK : 3F : 3 W

∗

CE 04W 1H 2R2 M BP

CE : 0J : 6.3 V F : ±1% HS :

CA : 1A : 10 V G : ±2% BP :

CS : 1C : 16 V J : ±5% HR :

CQ : 1E : 25 V K : ±10% DL :

CK : 1V : 35 V M : ±20% HF :

CC : 1H : 50 V Z : +80% U : UL

CP : 2A : 100 V −20% C : CSA

CM : 2B : 125 V P : +100% W : UL-CSA

CF : 2C : 160 V − 0% F :

CH : 2D : 200 V C : ±0.25pF

3H : 5 W

18 2

1R 2

Ö

2

Ö

1

2 R

2E : 250 V D : ±0.5pF

2H : 500 V = :

2J : 630 V

1800

1.2

=1.8k

0

] Capacity (electrolyte only)

2 2 2 ⇒ 2200µF

s

s

• Units: µF.

2 R 2 ⇒ 2.2µF

s

s

• Units: µF.

] Capacity (except electrolyte)

2 2 2 ⇒ 2200pF=0.0022µF

s

s

• Units: pF.

2 2 1 ⇒ 220pF

s

s

• Units: pF.

• When the dielectric strength is indicated in AC, "AC" is included after the dieelectric

strength value.

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

(More than 2) Indicates number of zeros after effective number.

(0 or 1) Indicates number of zeros after effective number.

2-digit effective number.

2-digit effective number.

26

∗

22 2

µ

22 2

p

2200µF

Ö

2

F

2200pF=0.0022µF

Ö

(0 2 )

2

F

0

0

2R 2

µ

22 1

p

Ö

1

2 R

F

Ö

(0 0 1 )

2

F

AC

2.2µF

220pF

0

Page 27

PARTS LIST OF P.W.B. UNIT

Note: The symbols in the column "Remarks" indicate the following destinations.

E3: U.S.A./Canada model E2K: Korea model

E2: Europe model JP: Japan model

00DGU-3510 MAIN P.W.B. UNIT ASS'Y

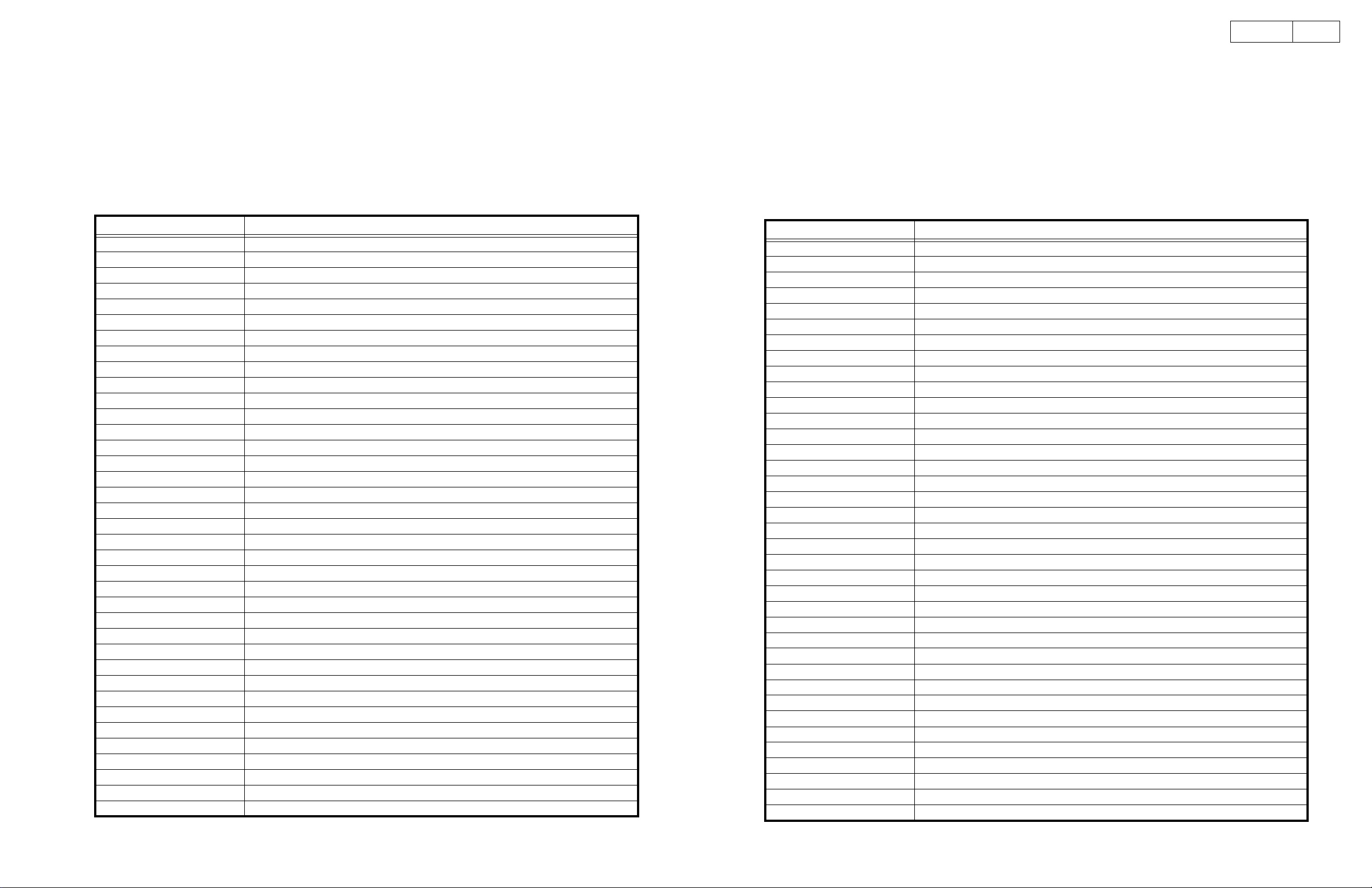

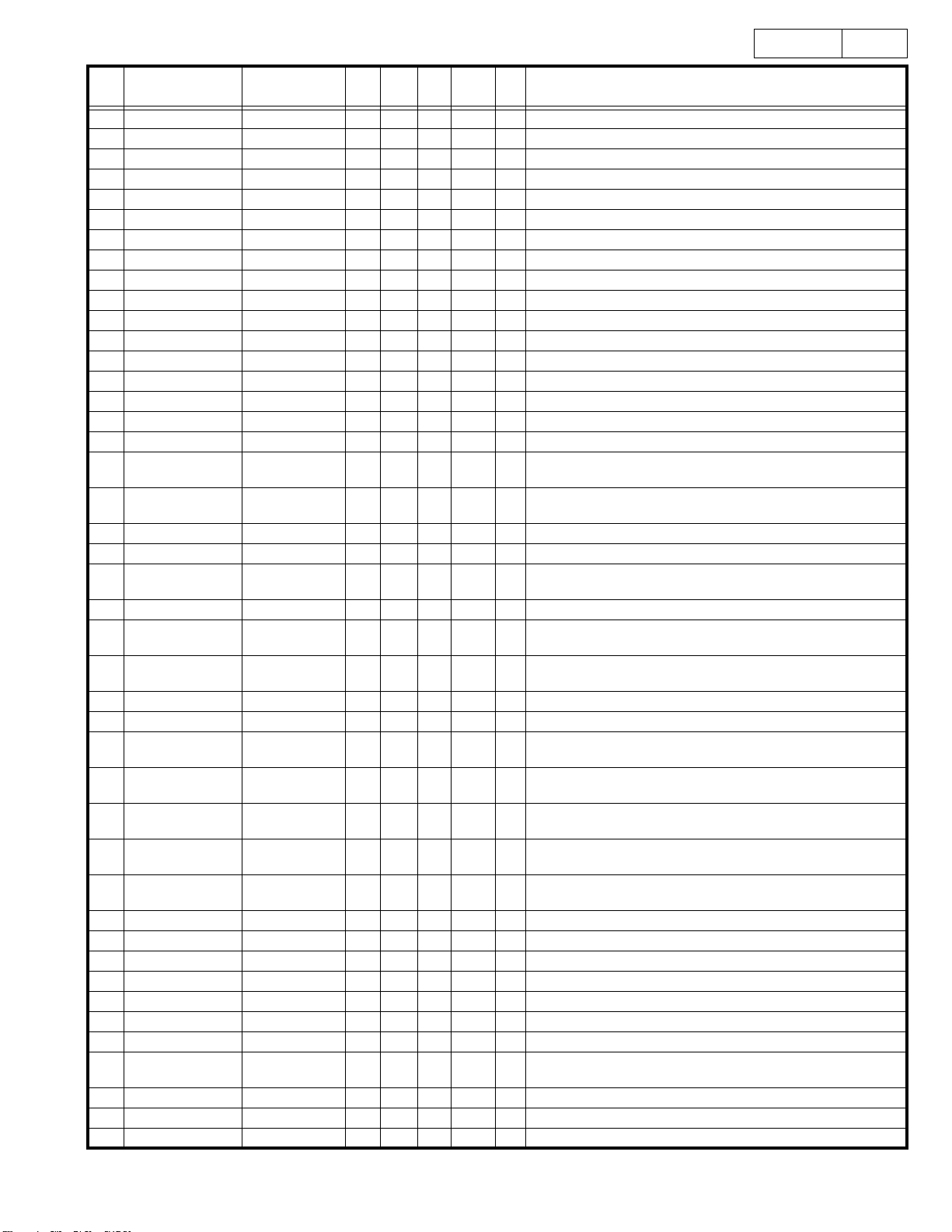

Ref. No. Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

IC101 00D GEN 6322 DNC635 SYSTEM ROM 4M FLASH MEM.(PLCC)

IC102 00D 263 0913 905 PST600C TP

IC103 00D 262 3171 000 MN102H60KDA +C

IC104 00D 262 2745 903 BU2090F(E2) +C

IC105 00D 262 2641 900 SN74LV541APW-EL2 +C

IC106 00D 263 0615 902 BA15218F-DXE2 +C

IC108 00D 262 3172 902 MAX3221CAE-T +C

IC109 00D 262 3173 901 SN75LBC180DR +C

IC201 00D 262 3160 901 AN22002A

IC202 00D 262 3159 909 AN8785SB

IC204 00D 262 2881 003 16M DRAM(3.3V)

IC208 00D 263 1178 901 AN80L20RMSTX

IC210 00D 262 3158 007 MN6627911AC

IC211 00D 262 2490 902 PCM1716E(TAPE) +C

IC212 00D 262 2376 903 TC74HCT7007AF(TP1) +C

IC213 00D 263 0432 907 NJM78L05AT

IC214 00D 262 2651 903 BU2618FV(E2) +C

IC215 00D 263 0615 902 BA15218F-DXE2 +C

IC217 00D 262 1883 905 TC9246F-TP1 +C

IC218 00D 262 1953 903 TC7WU04F +C

IC219 00D 262 0707 901 TC4053BF (TAPE) +C

IC220 00D 262 2519 906 SN74LV00APW-EL2 +C

IC221 00D 262 1953 903 TC7WU04F +C

IC903 00D 263 1048 002 BA033T

IC904 00D 263 0800 005 NJM78M05FA(S)

IC905 00D 263 0432 907 NJM78L05AT

IC906 00D 263 0722 905 NJM79L05AT

27DN-C635

TR101,102 00D 269 0082 902 DTC114EKT96 +C

TR103 00D 269 0083 901 DTA114EKT96 +C

TR104 00D 269 0082 902 DTC114EKT96 +C

TR105 00D 275 0042 905 2SK373(Y)TPE2

TR106 00D 269 0055 900 DTA144EKT96 +C

TR107 00D 269 0082 902 DTC114EKT96 +C

TR108,109 00D 269 0083 901 DTA114EKT96 +C

TR110-112 00D 269 0082 902 DTC114EKT96 +C

TR113,114 00D 269 0093 904 DTA144ES (47K-47K) T

TR115 00D 269 0055 900 DTA144EKT96 +C

TR201 00D 272 0125 904 2SB709A +C

TR202,203 00D 269 0144 905 DTC114YK-T146 +C

TR205 00D 273 0460 905 KTC2875B-RTK +C

TR901 00D 272 0025 907 2SB562(C)TF

D101,102 00D 276 0717 903 1SS355 TE-17 +C

D103-110 00D 276 0529 900 MA157A-TX +C

27

Page 28

Ref. No. Part No. Part Name Remarks Q'ty New

D901,902 00D 276 0717 903 1SS355 TE-17 +C

D903,904 00D 276 0550 908 1SR139-200T-62

D906 00D 276 0550 908 1SR139-200T-62

D908 00D 276 0550 908 1SR139-200T-62

D910 00D 276 0550 908 1SR139-200T-62

D912 00D 276 0550 908 1SR139-200T-62

D913 00D 276 0338 007 S4VB20F

ZD101-108 00D 276 0692 905 RD24SB-T1 +C

ZD201 00D 276 0450 901 HZS2B-1TD

ZD901 00D 276 0643 983 MTZJ5.1A T77

ZD902 00D 276 0762 929 MTZJ30B T77

RESISTORS GROUP

R101,102 00D 247 2007 943 RM73B--102JT +1608

R103 00D 247 2018 903 RM73B--0R0KT +1608

R104 00D 247 2011 942 RM73B--473JT +1608

R106,107 00D 247 2011 942 RM73B--473JT +1608

R108 00D 247 2018 903 RM73B--0R0KT +1608

R110-115 00D 247 2003 989 RM73B--330JT +1608

R116,117 00D 247 2011 942 RM73B--473JT +1608

R118 00D 247 2009 983 RM73B--103JT +1608

R119,120 00D 247 2011 942 RM73B--473JT +1608

R121 00D 247 2003 989 RM73B--330JT +1608

R122-126 00D 247 2011 942 RM73B--473JT +1608

R127 00D 247 2009 983 RM73B--103JT +1608

R128-135 00D 247 2011 942 RM73B--473JT +1608

R136-143 00D 247 2003 989 RM73B--330JT +1608

R144-147 00D 247 2011 942 RM73B--473JT +1608

R148,149 00D 247 2009 967 RM73B--822JT +1608

R150,151 00D 247 2008 968 RM73B--332JT +1608

R152 00D 247 2005 903 RM73B--101JT +1608

R153 00D 247 2009 983 RM73B--103JT +1608

R154,155 00D 247 2009 912 RM73B--512JT +1608

R156,157 00D 247 2009 983 RM73B--103JT +1608

R158 00D 247 2018 903 RM73B--0R0KT +1608

R160 00D 247 2008 955 RM73B--302JT +1608

R161 00D 247 2007 927 RM73B--821JT +1608

R163 00D 247 2007 998 RM73B--162JT +1608

R164 00D 247 2017 904 RM73B--106KT +1608

R165-172 00D 247 2009 909 RM73B--472JT (1608) +1608

R173,174 00D 247 2015 948 RM73B--225KT +1608

R175 00D 247 2012 925 RM73B--104JT +1608

R176 00D 247 2011 942 RM73B--473JT +1608

R179 00D 247 2007 927 RM73B--821JT +1608

R180 00D 247 2005 903 RM73B--101JT +1608

R181,182 00D 247 2018 903 RM73B--0R0KT +1608

R183-186 00D 247 2009 983 RM73B--103JT +1608

R187 00D 247 2007 943 RM73B--102JT +1608

28DN-C635

28

Page 29

Ref. No. Part No. Part Name Remarks Q'ty New

R188,189 00D 247 2003 989 RM73B--330JT +1608

R190 00D 247 2009 983 RM73B--103JT +1608

R191 00D 247 2005 961 RM73B--181JT +1608

R201 00D 247 2009 925 RM73B--562JT +1608

R202 00D 247 2009 983 RM73B--103JT +1608

R203 00D 247 2001 981 RM73B--4R7KT +1608

R204,205 00D 247 2004 991 RM73B--910JT +1608

R206 00D 247 2011 926 RM73B--393JT +1608

R207,208 00D 247 2009 967 RM73B--822JT +1608

R209,210 00D 247 2012 925 RM73B--104JT +1608

R211 00D 247 2009 983 RM73B--103JT +1608

R212,213 00D 247 2012 925 RM73B--104JT +1608

R214 00D 247 2008 955 RM73B--302JT +1608

R215 00D 247 2007 969 RM73B--122JT +1608

R216 00D 247 2006 986 RM73B--561JT +1608

R217 00D 247 2018 903 RM73B--0R0KT +1608

R218 00D 247 2009 941 RM73B--682JT +1608

R219 00D 247 2010 956 RM73B--203JT +1608

R220 00D 247 2011 997 RM73B--753JT +1608

R221 00D 247 2018 903 RM73B--0R0KT +1608

R223,224 00D 247 2018 903 RM73B--0R0KT +1608

R225 00D 247 2014 949 RM73B--824JT +1608

R226,227 00D 247 2008 984 RM73B--392JT +1608

R228,229 00D 247 2009 983 RM73B--103JT +1608

R230 00D 247 2013 940 RM73B--334JT +1608

R231 00D 247 2010 927 RM73B--153JT +1608

R232 00D 247 2010 969 RM73B--223JT +1608

R233 00D 247 2011 926 RM73B--393JT +1608

R234 00D 247 2010 927 RM73B--153JT +1608

R235,236 00D 247 2009 925 RM73B--562JT +1608

R237 00D 247 2007 943 RM73B--102JT +1608

R238 00D 247 2009 925 RM73B--562JT +1608

R239 00D 247 2010 985 RM73B--273JT +1608

R240 00D 247 2018 903 RM73B--0R0KT +1608

R241,242 00D 247 2012 925 RM73B--104JT +1608

R243,244 00D 247 2003 989 RM73B--330JT +1608

R245 00D 247 2010 985 RM73B--273JT +1608

R246 00D 247 2010 901 RM73B--123JT +1608

R247,248 00D 247 2008 968 RM73B--332JT +1608

R249 00D 247 2011 900 RM73B--333JT +1608

R250,251 00D 247 2005 903 RM73B--101JT +1608

R252 00D 247 2009 925 RM73B--562JT +1608

R253,254 00D 247 2005 903 RM73B--101JT +1608

R255,256 00D 247 2010 972 RM73B--243JT +1608

R257 00D 247 2010 985 RM73B--273JT +1608

R258 00D 244 2043 937 RS14B3A100JNBST(S)

R259 00D 247 2010 927 RM73B--153JT +1608

R260 00D 247 2006 986 RM73B--561JT +1608

R261 00D 247 2010 927 RM73B--153JT +1608

R262 00D 247 2005 903 RM73B--101JT +1608

R263 00D 247 2003 989 RM73B--330JT +1608

R267,268 00D 247 2003 989 RM73B--330JT +1608

29DN-C635

29

Page 30

Ref. No. Part No. Part Name Remarks Q'ty New

R270 00D 247 2018 903 RM73B--0R0KT +1608

R271-273 00D 247 2005 903 RM73B--101JT +1608

R274 00D 247 2014 965 RM73B--105JT +1608

R275,276 00D 247 2011 942 RM73B--473JT +1608

R277-281 00D 247 2009 983 RM73B--103JT +1608

R283,284 00D 247 2009 983 RM73B--103JT +1608

R285 00D 247 2009 925 RM73B--562JT +1608

R286,287 00D 247 2009 983 RM73B--103JT +1608

R288,289 00D 247 2012 925 RM73B--104JT +1608

R290 00D 247 2005 987 RM73B--221JT +1608

R291 00D 247 2012 912 RM73B--913JT +1608

R292 00D 247 2012 983 RM73B--184JT +1608

R293 00D 247 2005 903 RM73B--101JT +1608

R294 00D 247 2013 937 RM73B--304JT +1608

R295 00D 247 2006 960 RM73B--471JT +1608

R296 00D 247 2008 939 RM73B--242JT +1608

R297 00D 247 2009 912 RM73B--512JT +1608

R298 00D 247 2010 956 RM73B--203JT +1608

R299 00D 247 2014 965 RM73B--105JT +1608

R302 00D 247 2004 920 RM73B--470JT +1608

R303 00D 247 2004 975 RM73B--750JT +1608

R304 00D 247 2007 943 RM73B--102JT +1608

R307 00D 247 2014 965 RM73B--105JT +1608

R309 00D 247 2006 944 RM73B--391JT +1608

R310 00D 247 2004 920 RM73B--470JT +1608

R311 00D 247 2018 903 RM73B--0R0KT +1608

R312 00D 247 2007 901 RM73B--681JT +1608

R901,902 00D 247 2005 903 RM73B--101JT +1608

R903 00D 247 2011 942 RM73B--473JT +1608

R904 00D 247 2008 968 RM73B--332JT +1608

R905 00D 247 2012 925 RM73B--104JT +1608

30DN-C635

RA101-106 00D 247 9002 909 MNR14=330JE0AB +C

RA201-204 00D 247 9002 909 MNR14=330JE0AB +C

CAPACITORS GROUP

C101 00D 254 4538 900 CE04W1C100MT SMG/RE3

C102 00D 257 0509 929 CK73B1H102KT +1608

C103 00D 254 4536 915 CE04W1A470MT SMG/RE3

C104,105 00D 257 0512 903 CK73F1E104ZT +1608

C106 00D 254 4533 921 CE04W0J101MT SMG/RE3

C107 00D 257 0511 904 CK73F1H103ZT +1608

C108 00D 257 0512 903 CK73F1E104ZT +1608

C109 00D 257 0503 912 CC73CH1H9R0DT +1608

C110 00D 257 0503 925 CC73CH1H100DT +1608

C111 00D 254 4533 921 CE04W0J101MT SMG/RE3

C112 00D 257 0512 903 CK73F1E104ZT +1608

C113 00D 257 0511 904 CK73F1H103ZT +1608

C114 00D 257 0512 903 CK73F1E104ZT +1608

30

Page 31

Ref. No. Part No. Part Name Remarks Q'ty New

C115 00D 254 4533 921 CE04W0J101MT SMG/RE3

C116-119 00D 257 0512 903 CK73F1E104ZT +1608

C120,121 00D 254 4536 915 CE04W1A470MT SMG/RE3

C122,123 00D 257 0506 951 CC73CH1H101JT +1608

C124,125 00D 254 4533 921 CE04W0J101MT SMG/RE3

C126,127 00D 254 4538 900 CE04W1C100MT SMG/RE3

C128 00D 254 4538 955 CE04W1C221MT SMG/RE3

C129 00D 257 0517 908 CK73B1C473KT +1608

C130 00D 254 4524 930 CE04W1HR47MT SMG/RE3

C131,132 00D 254 4524 927 CE04W1HR33MT SMG/RE3

C133 00D 254 4538 900 CE04W1C100MT SMG/RE3

C134 00D 257 0512 903 CK73F1E104ZT +1608

C135-142 00D 257 0511 904 CK73F1H103ZT +1608

C143 00D 257 0512 903 CK73F1E104ZT +1608

C144 00D 254 4538 900 CE04W1C100MT SMG/RE3

C147 00D 257 0512 903 CK73F1E104ZT +1608

C148 00D 257 0511 904 CK73F1H103ZT +1608

C202 00D 257 0512 903 CK73F1E104ZT +1608

C203 00D 254 4524 969 CE04W1H3R3MT SMG/RE3

C204 00D 254 4536 915 CE04W1A470MT SMG/RE3

C205 00D 257 0512 903 CK73F1E104ZT +1608

C206 00D 254 4536 915 CE04W1A470MT SMG/RE3

C207 00D 254 4533 921 CE04W0J101MT SMG/RE3

C208 00D 257 0512 903 CK73F1E104ZT +1608

C209 00D 254 4538 939 CE04W1C470MT SMG/RE3

C210 00D 257 0512 903 CK73F1E104ZT +1608

C211 00D 254 4536 957 CE04W1A471MT SMG/RE3

C212 00D 257 0512 903 CK73F1E104ZT +1608

C216 00D 257 0512 903 CK73F1E104ZT +1608

C217 00D 256 1059 912 CF93A1H224JT (JL)

C218 00D 257 0512 903 CK73F1E104ZT +1608

C219 00D 257 0501 914 CK73B1H123KT +1608

C220 00D 257 0507 950 CC73CH1H271JT +1608

C221 00D 257 0510 947 CK73B1H562KT +1608

C222 00D 257 0516 909 CK73B1E223KT +1608

C223 00D 257 0506 993 CC73CH1H151JT +1608

C224,225 00D 257 0512 903 CK73F1E104ZT +1608

C226 00D 257 0506 935 CC73CH1H820JT +1608

C227,228 00D 254 4538 955 CE04W1C221MT SMG/RE3

C230 00D 257 0512 903 CK73F1E104ZT +1608

C231 00D 257 0501 927 CK73B1H153KT +1608

C232 00D 254 4533 921 CE04W0J101MT SMG/RE3

C233 00D 257 0506 948 CC73CH1H910JT +1608

C235-238 00D 257 0509 990 CK73B1H222KT +1608

C239 00D 254 4533 921 CE04W0J101MT SMG/RE3

C240 00D 257 0512 903 CK73F1E104ZT +1608

C241 00D 254 4538 900 CE04W1C100MT SMG/RE3

C242 00D 254 4533 921 CE04W0J101MT SMG/RE3

C243 00D 257 0513 902 CK73F1A105ZT +1608

C244 00D 254 4538 900 CE04W1C100MT SMG/RE3

C245 00D 257 0516 909 CK73B1E223KT +1608

C246 00D 257 0512 903 CK73F1E104ZT +1608

31DN-C635

31

Page 32

Ref. No. Part No. Part Name Remarks Q'ty New

C247 00D 257 0516 909 CK73B1E223KT +1608

C248 00D 254 4538 900 CE04W1C100MT SMG/RE3

C249-252 00D 257 0512 903 CK73F1E104ZT +1608

C253 00D 257 0509 929 CK73B1H102KT +1608

C254-256 00D 257 0512 903 CK73F1E104ZT +1608

C257 00D 257 0509 929 CK73B1H102KT +1608

C258 00D 257 0516 909 CK73B1E223KT +1608

C259 00D 257 0512 903 CK73F1E104ZT +1608

C260 00D 256 1058 984 CF93A1H124JT (JL)

C261 00D 254 4536 915 CE04W1A470MT SMG/RE3

C262 00D 257 0512 903 CK73F1E104ZT +1608

C263 00D 254 4533 934 CE04W0J221MT SMG/RE3

C264 00D 257 0512 903 CK73F1E104ZT +1608

C267 00D 257 0511 904 CK73F1H103ZT +1608

C268 00D 257 0512 903 CK73F1E104ZT +1608

C269 00D 254 4538 900 CE04W1C100MT SMG/RE3

C270 00D 254 4536 915 CE04W1A470MT SMG/RE3

C271 00D 257 0512 903 CK73F1E104ZT +1608

C272 00D 254 4538 900 CE04W1C100MT SMG/RE3

C273 00D 257 0512 903 CK73F1E104ZT +1608

C274,275 00D 254 4538 900 CE04W1C100MT SMG/RE3

C276 00D 257 0503 967 CC73CH1H150JT +1608

C277 00D 257 0512 903 CK73F1E104ZT +1608

C278 00D 257 0503 967 CC73CH1H150JT +1608

C279,280 00D 254 4538 900 CE04W1C100MT SMG/RE3

C281 00D 257 0512 903 CK73F1E104ZT +1608

C282 00D 257 0511 904 CK73F1H103ZT +1608

C283 00D 254 4533 921 CE04W0J101MT SMG/RE3

C284 00D 257 0511 904 CK73F1H103ZT +1608

C285,286 00D 257 0512 903 CK73F1E104ZT +1608

C287 00D 254 4536 944 CE04W1A331MT SMG/RE3

C288 00D 257 0512 903 CK73F1E104ZT +1608

C289,290 00D 257 0507 976 CC73CH1H331JT +1608

C291 00D 257 0511 904 CK73F1H103ZT +1608

C292,293 00D 257 0507 976 CC73CH1H331JT +1608

C294 00D 257 0507 992 CC73CH1H391JT +1608

C295,296 00D 257 0512 903 CK73F1E104ZT +1608

C297 00D 257 0506 951 CC73CH1H101JT +1608

C299 00D 254 4305 955 CE04W1HR68MT(SRE)

C301 00D 257 0509 929 CK73B1H102KT +1608

C302 00D 257 0512 903 CK73F1E104ZT +1608

C303 00D 254 4533 934 CE04W0J221MT SMG/RE3

C304 00D 257 0512 903 CK73F1E104ZT +1608

C305 00D 257 0511 904 CK73F1H103ZT +1608

C306 00D 254 4533 921 CE04W0J101MT SMG/RE3

C307 00D 257 0501 901 CK73B1H103KT (1608) +1608

C308,309 00D 257 0512 903 CK73F1E104ZT +1608

C310 00D 254 4538 926 CE04W1C330MT SMG/RE3

C311 00D 257 0501 901 CK73B1H103KT (1608) +1608

C313 00D 257 0512 903 CK73F1E104ZT +1608

C316 00D 257 0501 901 CK73B1H103KT (1608) +1608

C317 00D 257 0512 903 CK73F1E104ZT +1608

32DN-C635

32

Page 33

Ref. No. Part No. Part Name Remarks Q'ty New

C321 00D 257 0512 903 CK73F1E104ZT +1608

C325-327 00D 257 0512 903 CK73F1E104ZT +1608

C328,329 00D 257 0503 983 CC73CH1H180JT +1608

C330 00D 257 0509 929 CK73B1H102KT +1608

C331,332 00D 257 0512 903 CK73F1E104ZT +1608

C333 00D 254 4533 921 CE04W0J101MT SMG/RE3

C901 00D 254 4536 957 CE04W1A471MT SMG/RE3

C902,903 00D 257 0512 903 CK73F1E104ZT +1608

C904,905 00D 254 4536 928 CE04W1A101MT SMG/RE3

C906 00D 254 4536 957 CE04W1A471MT SMG/RE3

C907-909 00D 257 0512 903 CK73F1E104ZT +1608

C910 00D 254 4524 985 CE04W1H100MT SMG/RE3

C911 00D 254 4525 913 CE04W1H470MT SMG/RE3

C912,913 00D 254 4569 717 CE04W1E222MC (RA3)

C914 00D 254 4472 707 CE04W1C472MC (SMG)

C916 00D 254 4525 751 CE04W1H471MC SMG/RE3

OTHERS PARTS GROUP

33DN-C635

CW031 00D 203 5308 018 3P DA-DA CON CORD *

CX041 00D 205 0343 045 4P CONN.BASE(KR-PH)

CX051 00D 205 0343 058 5P CONN.BASE(KR-PH)

CX052 00D 205 0321 054 5P CONNE.BASE (RED)

CX062 00D 205 0343 061 6P CONN.BASE(KR-PH)

CX081 00D 205 0233 087 8P EH CON BASE

CX092 00D 205 1243 005 9P DSUB KIT

CX131 00D 205 0375 039 13P CONN.BASE(KR-PH)

CX161 00D 205 0892 033 16P FFC BASE (P=1)

CX231 00D 205 0880 003 23P FFC CON.BASE

CX251 00D 205 1244 004 25P DSUB KIT

FB201-203 00D 235 0106 908 CHIP EMIFIL (21A05) +C

FB205-209 00D 235 0106 908 CHIP EMIFIL (21A05) +C

JK201 00D 204 8593 001 1P PIN JACK(OR,NI)

ST101-103 00D 205 0452 017 STYLE PIN

T201 00D 231 8063 009 PULSE TRANS

X101 00D 399 0794 009 X'TAL (32.00M)

X201 00D 399 0595 004 XTAL(8.4672MHZ)

X202 00D 399 0165 007 XTAL (16.9344)

00D 417 0401 001 RADIATOR

0RD 477 0153 018 3X16 CPTS(B) SW W

33

Page 34

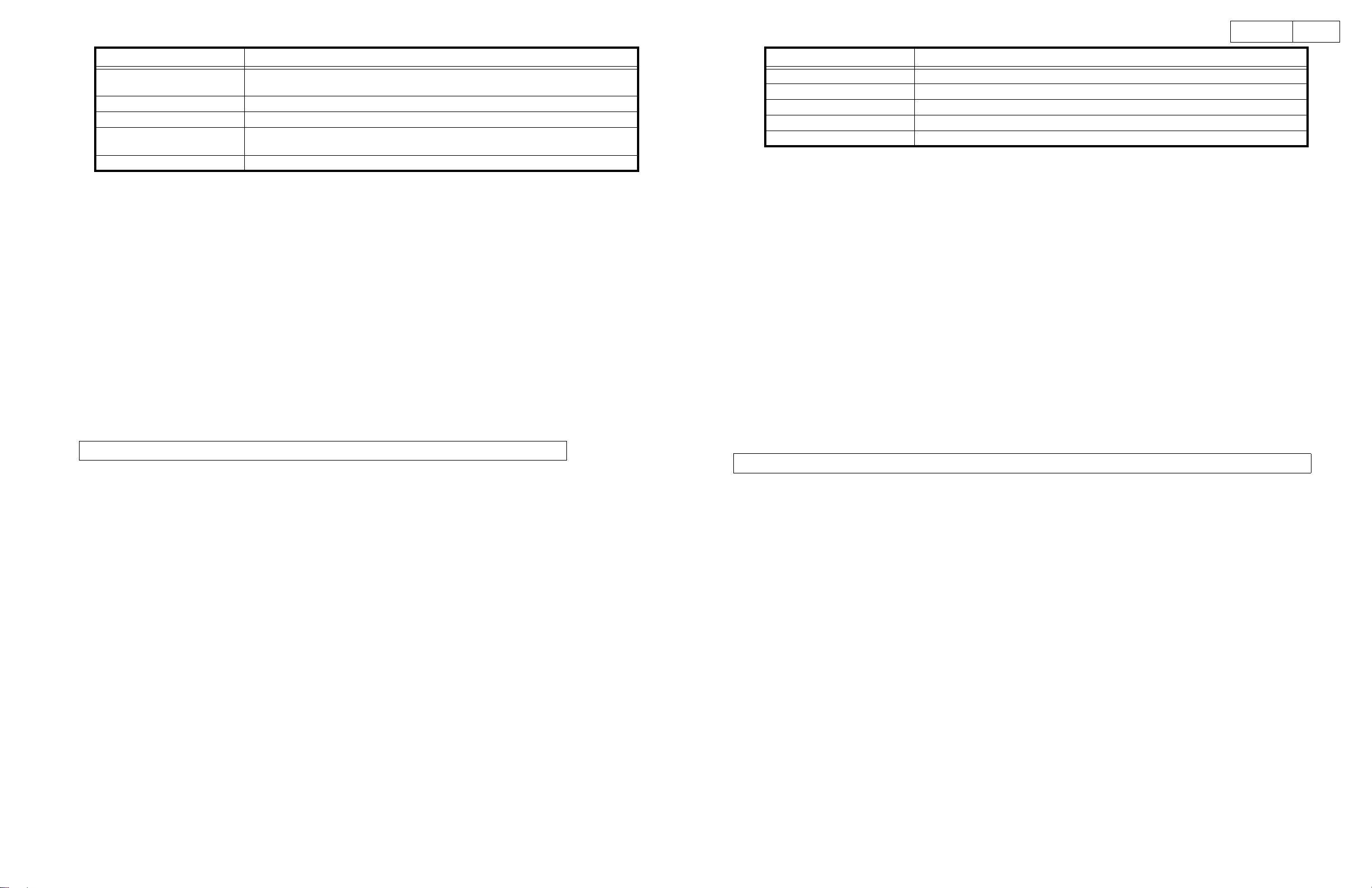

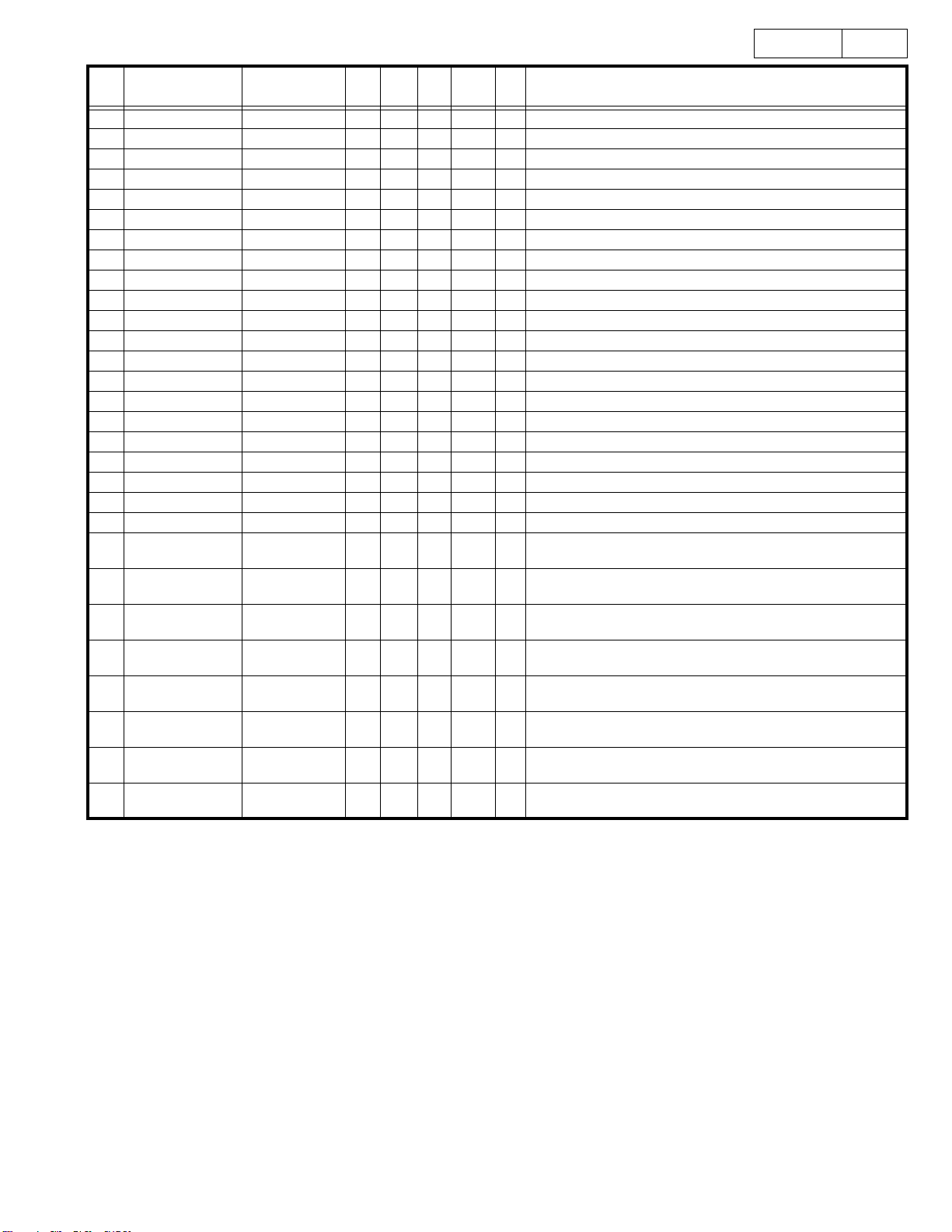

00DGU-3511/3511A/3511B DISPLAY P.W.B. UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

IC501 00D 499 0305 002 GP1UE261XK *

IC504 00D 262 3228 908 M66005AFP +C

IC601,602 00D 263 0615 902 BA15218F-DXE2 +C

TR601-604 00D 273 0460 905 KTC2875B-RTK +C

TR701,702 00D 273 0460 905 KTC2875B-RTK +C

D501,502 00D 276 0717 903 1SS355 TE-17 +C

LD501 00D 393 9543 923 SLR-325DC (ORG) TAPE

LD502-504 00D 393 9543 910 SLR-325MC (GRN) TAPE

RESISTORS GROUP

34DN-C635

R502 00D 247 2004 920 RM73B--470JT +1608

R503 00D 247 2009 983 RM73B--103JT +1608

R504 00D 247 2010 985 RM73B--273JT +1608

R505 00D 247 2009 983 RM73B--103JT +1608

R506,507 00D 247 2006 902 RM73B--331JT (1608) +1608

R508 00D 247 2009 983 RM73B--103JT +1608

R512 00D 247 2007 943 RM73B--102JT +1608

R513 00D 247 2005 945 RM73B--151JT +1608

R514 00D 247 2005 961 RM73B--181JT +1608

R515 00D 247 2006 915 RM73B--271JT +1608

R516 00D 247 2006 944 RM73B--391JT +1608

R517 00D 247 2007 901 RM73B--681JT +1608

R518 00D 247 2007 972 RM73B--132JT +1608

R519 00D 247 2008 984 RM73B--392JT +1608

R520 00D 247 2006 915 RM73B--271JT +1608

R521 00D 247 2005 932 RM73B--131JT +1608

R522 00D 247 2007 943 RM73B--102JT +1608

R523 00D 247 2005 945 RM73B--151JT +1608

R524 00D 247 2005 961 RM73B--181JT +1608

R525 00D 247 2006 915 RM73B--271JT +1608

R526 00D 247 2006 944 RM73B--391JT +1608