Page 1

S/5

Datex-Ohmeda

S/5TM Airway Module, G-AO (rev. 06)

TM

S/5

S/5

S/5

TM

Airway Module, G-AiO (rev. 05)

TM

Airway Module, G-AiOV (rev. 04)

TM

Airway Module, G-AOV (rev. 04)

Gas Interface Board, B-GAS (rev. 01)

Technical Reference Manual Slot

Datex-Ohmeda Inc.

3030 Ohmeda Drive

53707-7550 MADISON, WIS

USA

Tel. +1-608-221 1551, Fax +1-608-222 9147

www.us.datex-ohmeda.com

All specifications are subject to change without notice.

Document No. 800 1005-1

June 2001

Datex-Ohmeda Division,

Instrumentarium Corp.

P.O. Box 900, FIN-00031

DATEX-OHMEDA, FINLAND

Tel. +358 10 394 11 Fax +358 9 146 3310

www.datex-ohmeda.com

Instrumentarium Corp. All rights reserved.

Page 2

Page 3

Table of contents

TABLE OF CONTENTS

S/5 Airway modules and S/5 Gas Interface Board, B-GAS

TABLE OF CONTENTS i

TABLE OF FIGURES iii

INTRODUCTION 1

1 Specifications 2

1.1 General specifications..............................................................................................................................2

1.2 Typical performance.................................................................................................................................2

1.2.1 CO

1.2.2 Respiration rate................................................................................................................................2

1.2.3 O

1.2.4 N

1.2.5 Hal, Iso, Enf......................................................................................................................................2

1.2.6 Sev..................................................................................................................................................2

1.2.7 Des..................................................................................................................................................3

1.2.8 Agent identification..........................................................................................................................3

1.2.9 Patient Spirometry............................................................................................................................3

1.2.10 Airway Pressure (Paw)...................................................................................................................3

1.2.11 Tidal Volume (TV)..........................................................................................................................3

1.2.12 Minute Volume (MV).....................................................................................................................3

1.2.13 Airway flow...................................................................................................................................3

1.3 Technical specification .............................................................................................................................4

1.3.1 CO

1.3.2 O

1.3.3 N

1.3.4 AA...................................................................................................................................................4

..................................................................................................................................................2

2

....................................................................................................................................................2

2

O .................................................................................................................................................2

2

..................................................................................................................................................4

2

....................................................................................................................................................4

2

O .................................................................................................................................................4

2

2 Functional Description 5

2.1 Measurement principle.............................................................................................................................5

2.1.1 CO

2.1.2 O

2.1.3 Agent identification..........................................................................................................................7

2.1.4 Patient Spirometry............................................................................................................................ 8

2.2 Main components.....................................................................................................................................9

2.2.1 Gas sampling system......................................................................................................................10

2.2.2 ACX-200 measuring unit.................................................................................................................16

2.2.3 OM measuring unit.........................................................................................................................17

2.2.4 ACX measuring board.....................................................................................................................18

2.2.5 ASX agent identification bench........................................................................................................20

2.2.6 ASX measuring board.....................................................................................................................20

2.2.7 PVX board......................................................................................................................................22

2.2.8 Gas mother boar d...........................................................................................................................24

2.2.9 Gas interface board........................................................................................................................26

2.3 Connectors and signals...........................................................................................................................26

2.3.1 Module bus connector....................................................................................................................26

, N2O and Agent measurement....................................................................................................5

2

measurement..............................................................................................................................6

2

Document No. 800 1005-1

i

Page 4

Datex-Ohmeda S/5 Anesthesia Monitor

2.3.2 Gas mother board connectors.........................................................................................................27

3 Service Procedures 31

3.1 General service information....................................................................................................................31

3.2 Service check.........................................................................................................................................32

3.2.1 Recommended tools......................................................................................................................32

3.2.2 Recommended parts......................................................................................................................32

3.3 Disassembly and reassembly..................................................................................................................41

3.4 Adjustments and calibrations..................................................................................................................42

3.4.1 Gas sampling system adjustment...................................................................................................42

3.4.2 Flow rate measurement..................................................................................................................42

3.4.3 Oxygen measurement unit adjust ments...........................................................................................44

3.4.4 Flow calibration..............................................................................................................................46

4 Troubleshooting 47

4.1 Troubleshooting chart.............................................................................................................................47

4.1.1 Supply voltage troubleshooting.......................................................................................................48

4.2 Gas sampling system troubleshooting.....................................................................................................49

4.2.1 Sampling system leak test..............................................................................................................49

4.2.2 Water separation............................................................................................................................49

4.2.3 Steam test for the special tubes......................................................................................................49

4.3 OM measuring unit troubleshooting.........................................................................................................50

4.4 ACX troubleshooting...............................................................................................................................50

4.4.1 Cleaning the measuring chamber of ACX measuring unit..................................................................50

4.5 ASX agent identification unit troubleshooting...........................................................................................52

4.6 PVX board troubleshooting......................................................................................................................53

4.7 Gas mother board troubleshooting..........................................................................................................53

4.7.1 Instru ctions after replacing the software or Gas mother board...........................................................53

4.8 Error messages.......................................................................................................................................54

5Service menu 55

5.1 Gas mother board...................................................................................................................................56

5.2 ACX service menu...................................................................................................................................59

5.3 PVX service menu...................................................................................................................................61

5.3.1 Flow calibration..............................................................................................................................62

5.3.2 Temp & Hum service menu.............................................................................................................63

5.4 ASX service menu...................................................................................................................................64

6 Spare parts 65

6.1 Spare parts list.......................................................................................................................................65

6.1.1 G-AO rev. 01, G-A iO rev. 00............................................................................................................65

6.1.2 G-AO rev. 02, G-A iO rev. 01, G-AOV rev. 00, G-AiOV rev. 00.............................................................66

6.1.3 G-AO rev. 03, G-A iO rev. 02, G-AOV rev. 01, G-AiOV rev. 01.............................................................66

6.1.4 G-AO rev. 04, G-A iO rev. 03, G-AOV rev. 02, G-AiOV rev. 02, G-O rev. 00, G-OV rev. 00.....................67

6.1.5 G-AO rev. 05, G-A iO rev. 04, G-AOV rev. 03, G-AiOV rev. 03, G-O rev. 01, G-OV rev. 01.....................67

6.1.6 S/5 G-AO rev. 06, G-A iO rev. 05, G-AOV rev. 04, G-AiOV rev. 04......................................................67

6.1.7 Panel stickers................................................................................................................................67

6.1.8 S/5 panel stickers.........................................................................................................................68

6.1.9 Planned Maintenance (PM) Kits:.....................................................................................................69

6.1.10 Gas Interface Board, B-GAS.......................................................................................................69

7 Earlier Revisions 70

ii

Document No. 800 1005-1

Page 5

Table of contents

APPENDIX A

71

Service check FORM A-1

TABLE OF FIGURES

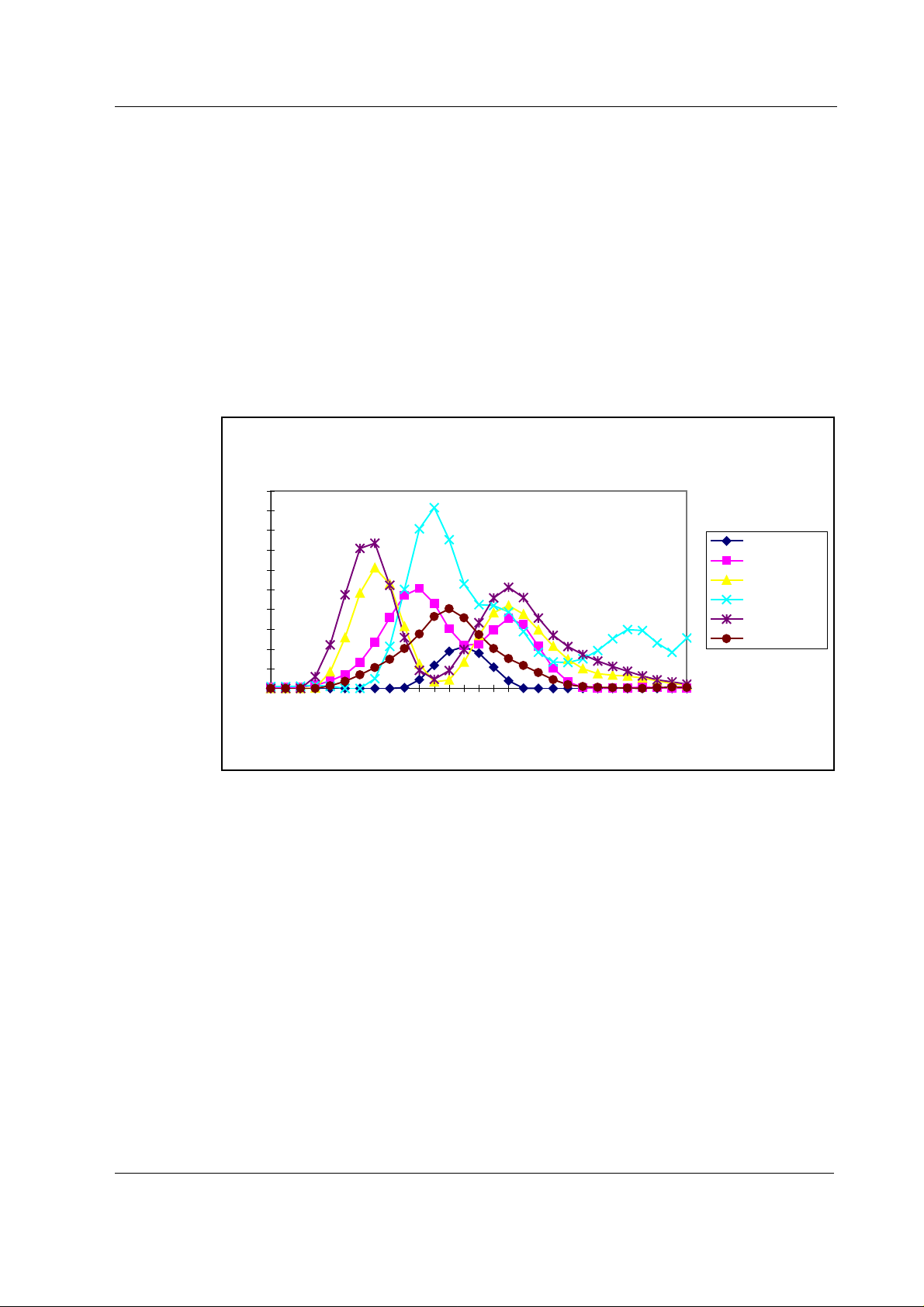

Figure 1 CO2/N2O/AA gas absorption spectra.....................................................................................................5

Figure 2 O

Figure 3 Anaesthetic Agents gas absorption spectra............................................................................................7

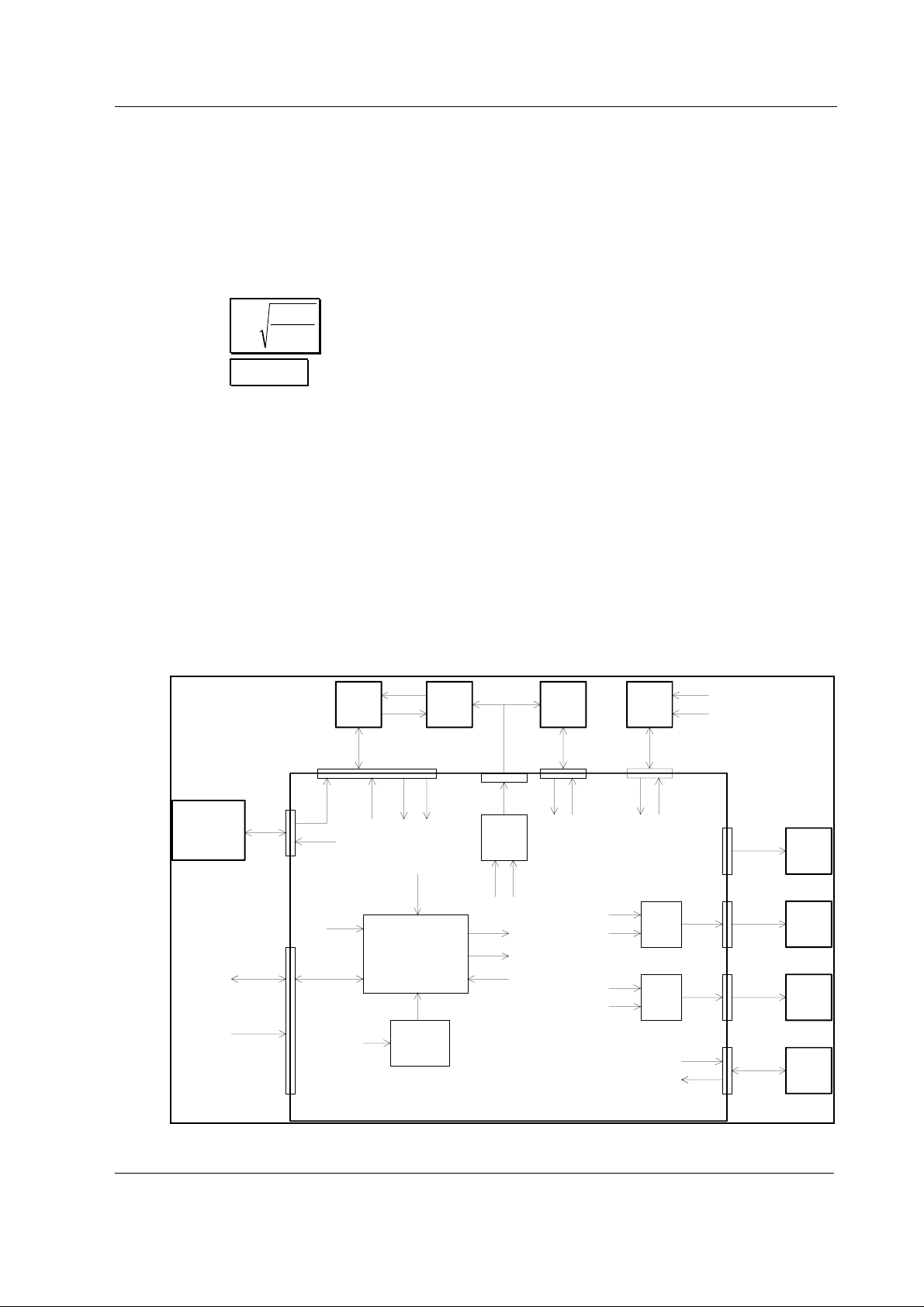

Figure 4 Airway module block diagram...............................................................................................................9

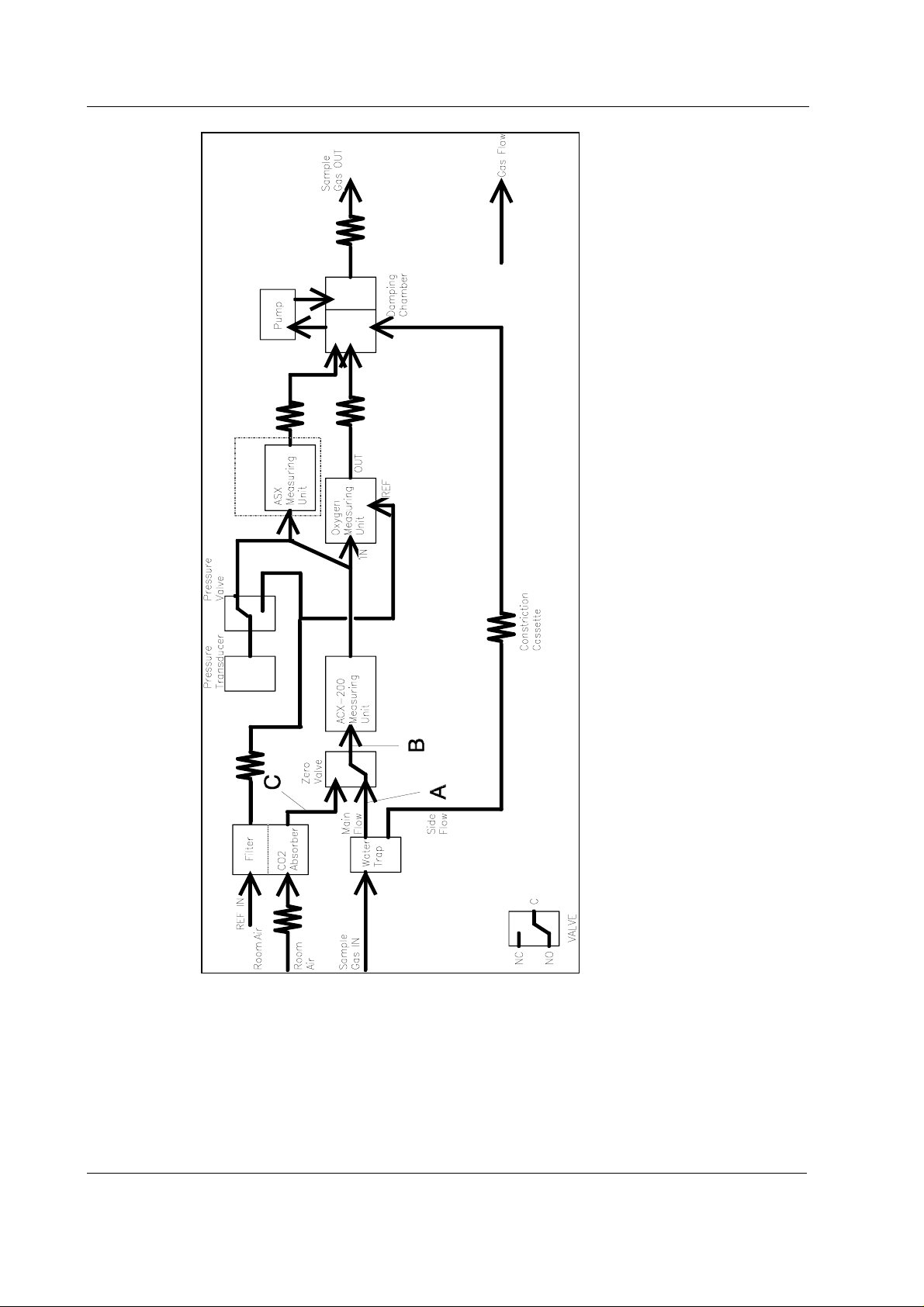

Figure 5 Gas sampling system block diagram ...................................................................................................12

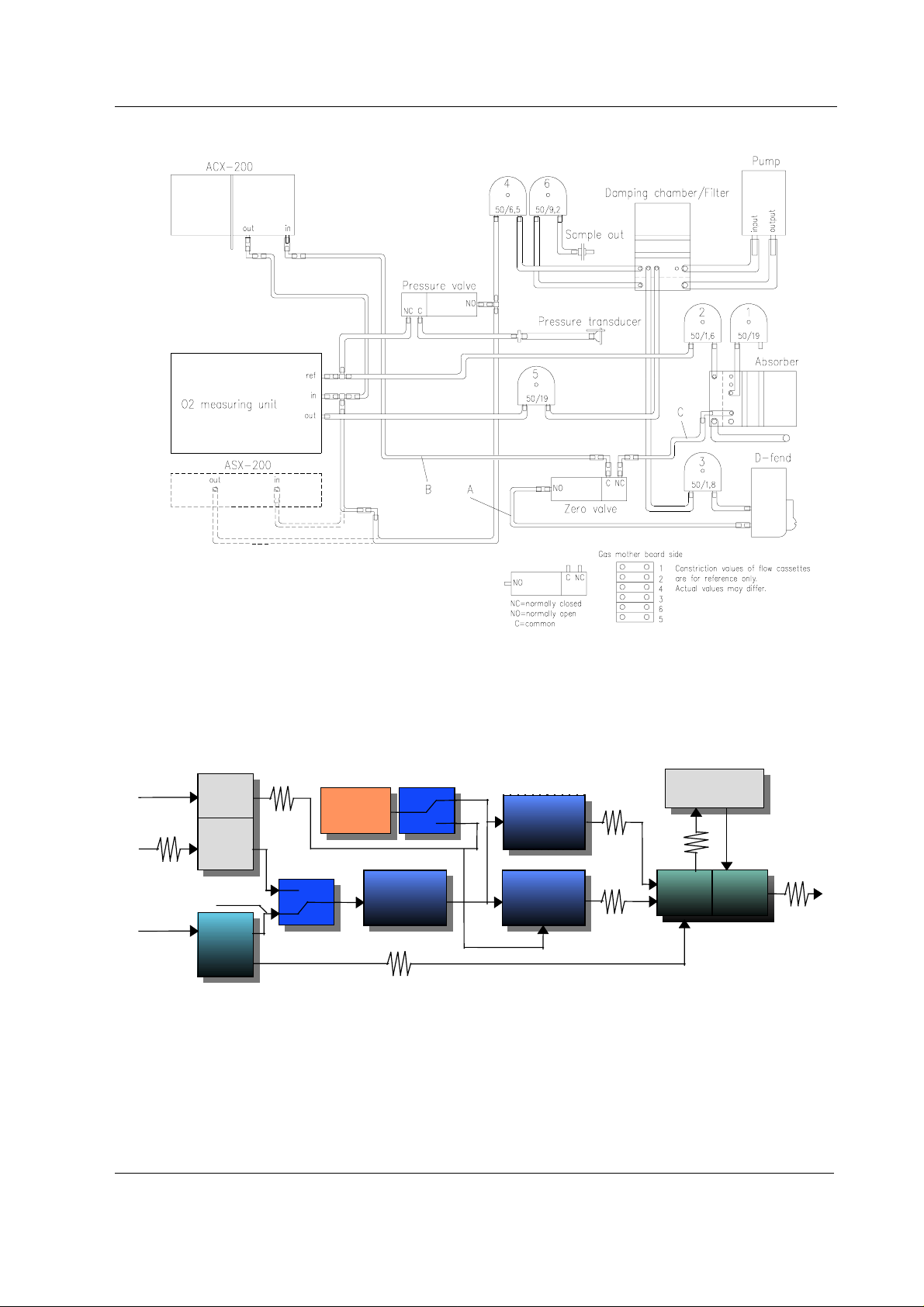

Figure 6 Gas sampling system layout................................................................................................................13

Figure 7 Gas sampling system block diagram ...................................................................................................13

Figure 8 Gas sampling system layout................................................................................................................14

Figure 9 ACX photometer (ACX-200 measuring unit)..........................................................................................16

Figure 10 CO

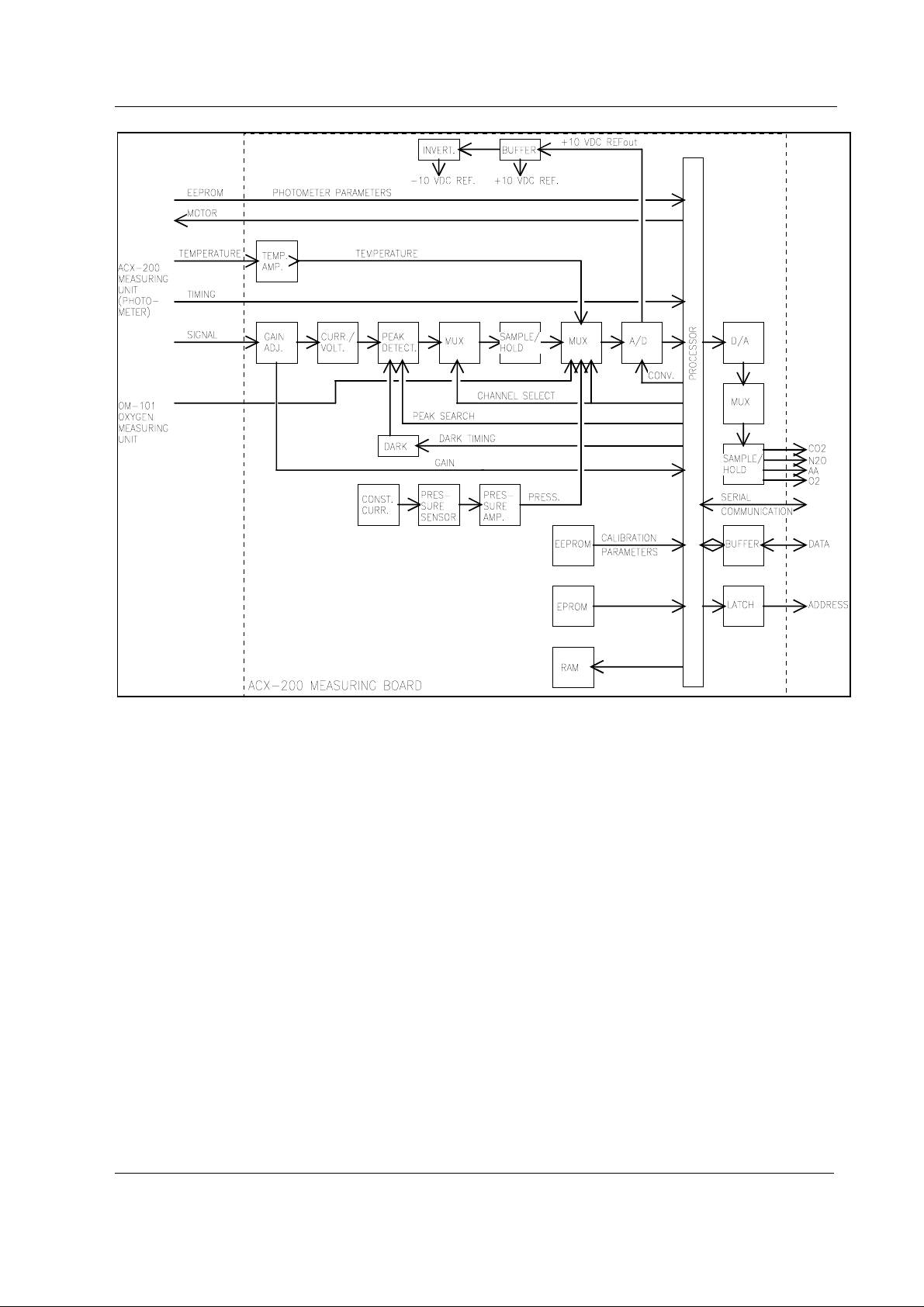

Figure 11 ACX measuring board block diagram...............................................................................................19

measurement principle....................................................................................................................6

2

O/AA measurement block diagram......................................................................................17

2/N2

Figure 12 ASX measuring unit ........................................................................................................................20

Figure 13 ASX measuring board block diagram...............................................................................................21

Figure 14 PVX board block diagram................................................................................................................23

Figure 15 Gas mother board block diagram....................................................................................................25

Figure 16 Gas sampling system adjustment chart...........................................................................................43

Figure 17 O

measuring unit adjustments.......................................................................................................46

2

Figure 18 ASX troubleshooting flowchart.........................................................................................................52

Figure 19 PVX board troubleshooting flowchart...............................................................................................53

Document No. 800 1005-1

iii

Page 6

Datex-Ohmeda S/5 Anesthesia Monitor

iv

Document No. 800 1005-1

Page 7

INTRODUCTION

The S/5 Airway Modules, G-AO, G-AiO, G-AOV and G-AiOV are designed for use with the S/5

Anesthesia Monitor and provide airway and respiratory parameters. Later in this manual modules

can be called w/o system name S/5.

This Technical Reference Manual Slot provides information for the maintenance and service of the

airway modules. Please see also related

system e.g. related documentation, conventions used, symbols on equipment, safety precautions,

system description, system installation, interfacing, functional check and planned maintenance.

Letters in the name stand for:

G = Side mountable gas module

O = CO

V = Patient Spirometry

A = Anesthetic agents

i = Agent identification

, Patient O2, and N2O

2

Technical Reference Manual

S/5 Airway modules

for information related to

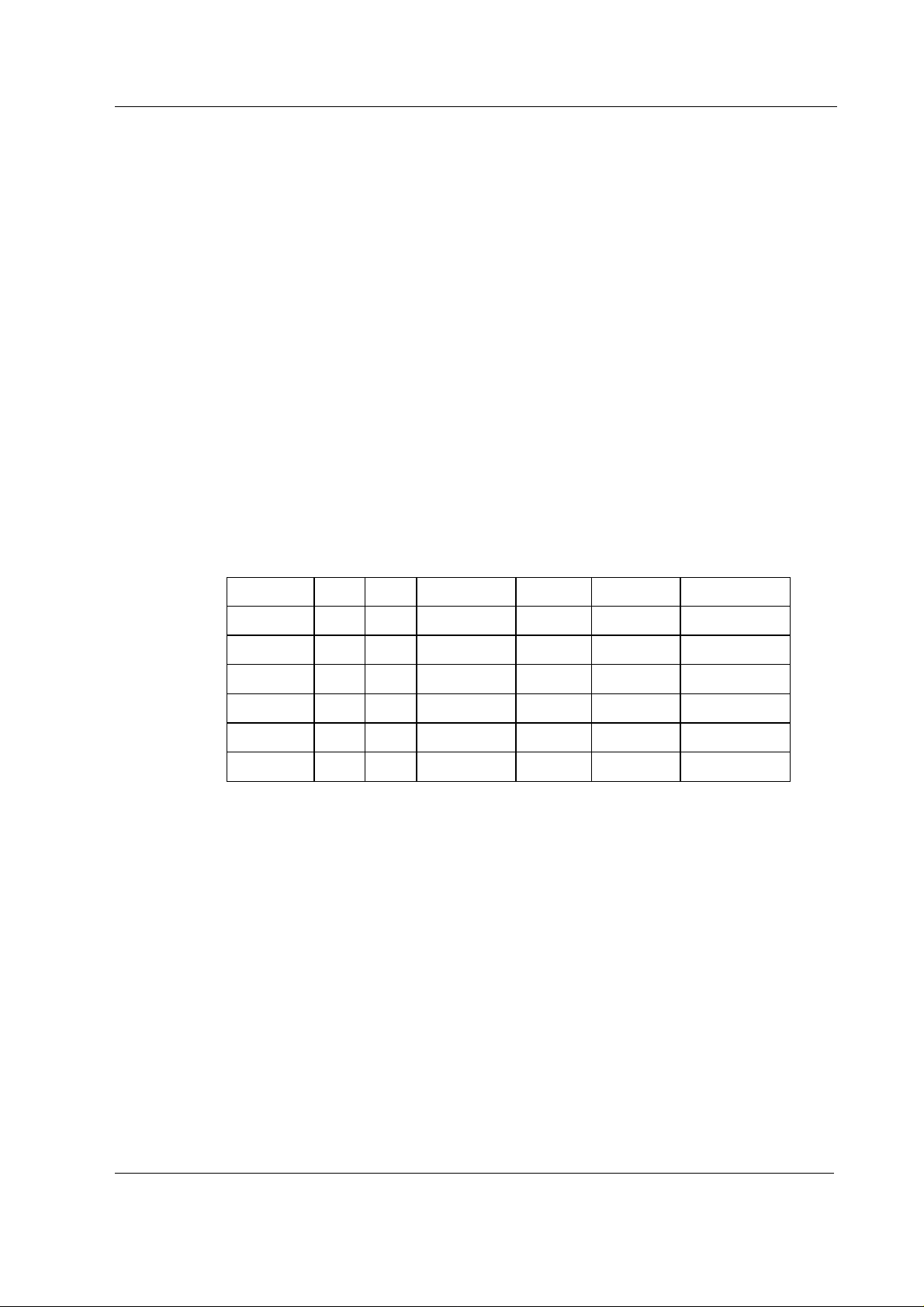

Table 1 Options of Parameter Modules

G-AO

G-AiO

G-AOV

G-AiOV

NOTE: The Airway Modules and Compact Airway Modules cannot be used simultaneously in the

same monitor.

Gas Interface Board

Gas Interface Board, B-GAS is used for connecting the airway module to the central unit. The

connection can also be made through the Interface Board, B-INT.

CO

N2O Patient O

2

•• • •

•• • • •

•• • • •

•• • • • •

Agents Agent id Spirometry

2

Document No. 800 1005-1

1

Page 8

Datex-Ohmeda S/5 Anesthesia Monitor

1 SPECIFICATIONS

1.1 General specifications

Module size, W × D × H 135 × 410 × 135 mm/5.3 × 15.0 × 5.3 in

Module weight 6 kg/13 lbs.

1.2 Typical performance

Sampling rate 200 ml/min nominal (180...220 ml/min)

Display update rate breath-by-breath

Automatic compensation for pressure, CO

Warm-up time 3 min for operation, 30 min for full specifications.

Auto-zeroing is performed at start-up, after 5 min + 5 min + 5 min + 15 min + 15 min + 15 min,

and after that every 60 min at regular intervals.

1.2.1 CO

2

Measurement range 0 to 10 %, (0 to 10 kPa), (0 to 76 mmHg)

Extended range 10 to 15 %, (10 to 15 kPa), (76 to 114 mmHg) (unspecified)

concentration is below 0.1 %, 0.0 % is displayed.

If CO

2

1.2.2 Respiration rate

Breath detection 1 % change in CO2 level

Measurement range 4 to 60 breaths/min

1.2.3 O

2

Measurement range 0 to 100 % O

1.2.4 N2O

O, and CO2-O2 collision broadening effect.

2-N2

2

Measurement range 0 to 100 % N2O

1.2.5 Hal, Iso, Enf

Measurement range 0 to 5 %

Extended range 5 to 15 % (unspecified)

1.2.6 Sev

Measurement range 0 to 8 %

Extended range 8 to 15 % (unspecified)

2

Document No. 800 1005-1

Page 9

1.2.7 Des

Measurement range 0 to 18 %

Extended range 18 to 30 % (unspecified)

Resolution two decimals when the AA concentration below 1.0 %

If AA concentration is below 0.10 %, 0.00 % is displayed.

1.2.8 Agent identification

Identified agents HAL, ENF, ISO, SEV, DES

Identification time 30 seconds (typical value with pure agents)

Identification threshold 0.15 vol% (typical)

Mixture warning when minor component concentration > 0.3 vol% and > 15 %of total agent

concentration

1.2.9 Patient Spirometry

Values are valid when:

Respiratory rate adult 4...30 pedi 4...50 breaths/min

I:E ratio 1:3 - 1:0.5

Inner diameter of ET tube is ≥ 5.5 mm (adult) or 3 to 6 mm (pediatric).

S/5 Airway modules

1.2.10 Airway Pressure (Paw)

Accuracy ±1.5 cmH2O

Resolution 1 cmH

Measuring range -20 to +80 cmH

1.2.11 Tidal Volume (TV)

Accuracy ±6 % or 30 ml (adult); ±6 % or 4 ml (ped)

Resolution 1 ml

Measurement range 150 to 2000 ml (adult)

1.2.12 Minute Volume (MV)

Resolution 0.1 l/min

Measurement range 2 to 15 l/min (adult)

1.2.13 Airway flow

Measurement range 1.5 to 100 l/min for both directions (adult)

O

2

O

2

15 to 300 ml (ped)

0.5 to 5 l/min (ped)

0.25 to 25 l/min for both directions (ped)

Document No. 800 1005-1

3

Page 10

Datex-Ohmeda S/5 Anesthesia Monitor

1.3 Technical specification

1.3.1 CO

1.3.2 O

2

1.3.3 N2O

2

Measurement rise time <360 ms (from 10 to 90 %)

Gain stability ≤0.2 %CO

≤0.4 %CO

Gain temperature drift ≤0.2 %CO

≤0.4 %CO

Nonlinearity error ≤0.2 %CO

≤0.4 %CO

/24 h (0 to 8 %)

2

/24 h (8 to 10 %)

2

/10 °C (0 to 8 %)

2

/10 °C (8 to 10 %)

2

(0 to 8 %)

2

(8 to 10 %)

2

Measurement rise time <480 ms (from 10 to 90 %)

Gain drift ≤2 % O

Gain temperature drift ≤3 % O

Nonlinearity error ≤2 % O

/24 h

2

/10 °C

2

2

Measurement rise time <360 ms (from 10 to 90 %)

Gain drift ≤2 % N

Gain temperature drift ≤3 % N

Nonlinearity error ≤2 % N

O/24 h

2

O/10 °C

2

O

2

1.3.4 AA

Measurement rise time <520 ms (from 10 to 90 %)

Gain drift ≤0.4 % AA/24 h

Gain temperature drift ≤0.4 % AA/10 °C

Nonlinearity error ≤0.2 % AA

Protection against electrical shock

Type BF

4

Document No. 800 1005-1

Page 11

2 FUNCTIONAL DESCRIPTION

2.1 Measurement principle

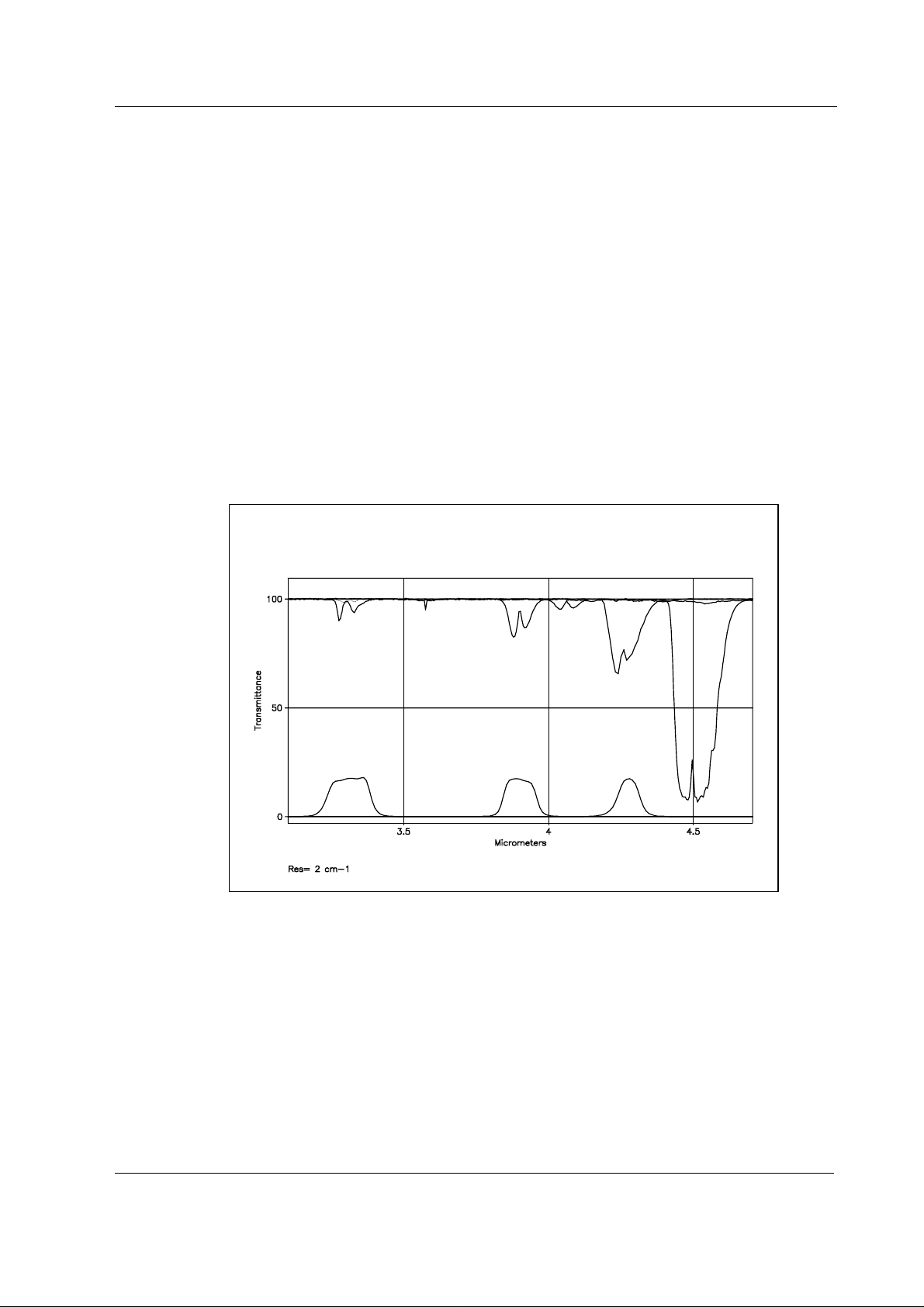

2.1.1 CO2, N2O and Agent measurement

The CO2, N2O, and anesthetic agent gas measurements are based on absorption of infrared light as

it passes through the gas sample in measuring chamber in the photometer. The light absorption is

measured at three wavelengths using an infrared detector. One of the wavelengths is that of the

absorption peak at 4.3 micrometers, the second is that of the N2O absorption peak at 3.9

CO

2

micrometers, and the third is that of the anesthetic agent absorption peak at 3.3 micrometers. The

signal processing electronics receive the signals from the IR detector and demodulate it to get DC

components out of these signals which correspond to the content of each gas in the sample.

S/5 Airway modules

Figure 1 CO2/N2O/AA gas absorption spectra

5

Document No. 800 1005-1

Page 12

Datex-Ohmeda S/5 Anesthesia Monitor

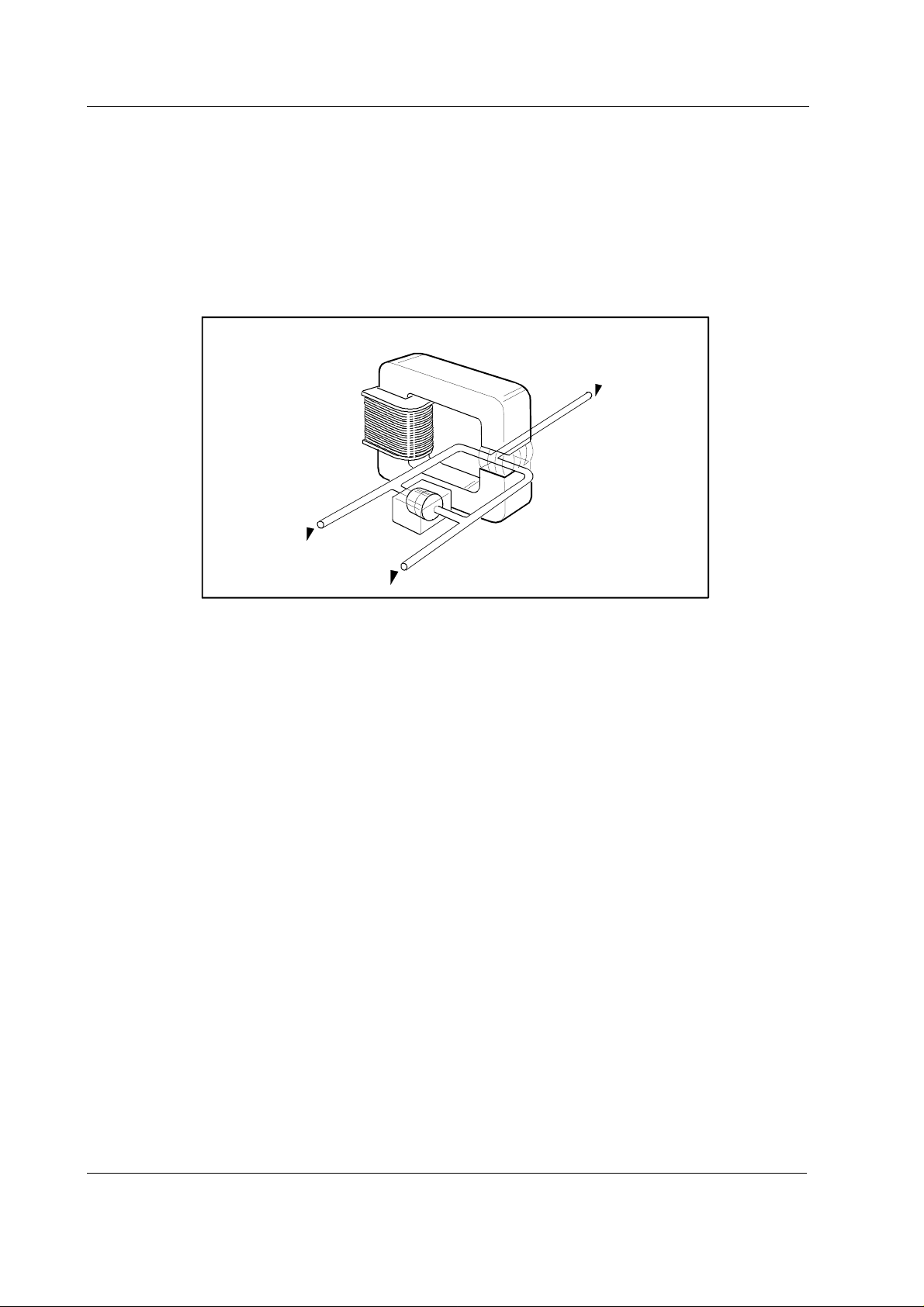

2.1.2 O2 measurement

The differential oxygen measuring unit uses the paramagnetic principle in a pneumatic bridge

configuration. The signal picked up with a differential pressure transducer is generated in a

measuring cell with a strong magnetic field that is switched on and off at a frequency of 110 Hz.

The output signal is a DC voltage proportional to the O

gases to be measured.

Microphone

2

Electromagnet

concentration difference between the two

Mixture

out

Switched

magnetic

field

Sample in

Reference in

Figure 2 O2 measurement principle

6

Document No. 800 1005-1

Page 13

2.1.3 Agent identification

The anesthetic agent identification bench identifies Halothane, Enflurane, Isoflurane, Desflurane

and Sevoflurane.

The bench measures the spectrum of the gas between 3.24 µm and 3.39 µm. Because the

spectrum of each of the anaesthetic agents is different it is possible to identify them.

The bench consists of an infrared source, a measuring chamber, a rotating filter and a detector. The

peak wavelength of the narrow bandpass filter changes when the angle between the light path and

the filter is changed. When the filter rotates the required spectrum is scanned through. The agent or

a mixture of agents is identified by comparing the measured spectrum with stored reference

spectra.

500

450

400

350

300

250

200

150

100

50

0

S/5 Airway modules

Anesthetic Agent Gas Absorption Spectra

Halothane 0

Enflurane 0

Isoflurane 0

Sevoflurane 0

Desflurane 0

Freon 0

3246

3306

Wavelength [nm]

Figure 3 Anaesthetic Agents gas absorption spectra

3386

Document No. 800 1005-1

7

Page 14

Datex-Ohmeda S/5 Anesthesia Monitor

2.1.4 Patient Spirometry

In anesthesia, CMV (Controlled Mechanical Ventilation) is the mostly used ventilation mode. In this

mode, mechanical breaths are delivered to the patient by a ventilator with a proper tidal volume

(TV), respiration rate (RR), and inspiration/expiration ratio in time (I:E) determined by the settings of

the ventilator.

Delivery of life support gases is based on pressure. However, without knowing volume measured of

exhalation, one cannot be sure that a breath occurred. The ultimate goal of ventilation is to use the

least amount of pressure to generate the most appropriate volume for each breath.

The Patient Spirometry monitors ventilation in anesthesia. Both patient breathing circuit and the

function of the ventilator are monitored. The following parameters are displayed:

Expiratory and inspiratory tidal volume (TV) in ml.

Expiratory and inspiratory minute volume (MV) in l/min.

Expiratory volume in first second (V1.0) in per cent for adults and in 0.5 seconds for children.

Inspiration/expiration ratio in time (I:E)

Airway pressures: Peak pressure (P

pressure (PEEP), Real time airway pressure waveform (P

Flow: Real time flow waveform (V')

Compliance (C)

Pressure volume loop

Flow volume loop

), End inspiratory pressure (P

peak

)

aw

), Positive end expiratory

plat

Airway pressure

Airway flow

PEEP, P

peak

, and P

are measured by pressure transducer on the PVX board. Atmospheric pressure

plat

is used as a reference in measurement. The pressure measurement is made from the airway part

that is closest to the patient between patient circuit and intubation tube.

The measurement is based on measuring the kinetic gas pressure and is performed using Pitot

effect. Pressure transducer is used to measure the Pitot pressure. The obtained pressure signal is

linearized and corrected according to the density of the gas. Speed of the flow is calculated from

these pressure values and TV value is then integrated. MV value is further calculated a nd averaged

using TV and RR (respiratory rate) values.

8

Document No. 800 1005-1

Page 15

Patient Spirometry sensor, D-lite

Patient Spirometry is measured with a specific sensor, D-lite or Pedi-lite.

D-lite and Pedi-lite sensors are designed to measure kinetic pressure by t wo-sided Pitot tube. The

pressure reduction caused by measuring cross is taken into account, too, especially in small flows.

Velocity is calculated from pressure difference according to Bernoulli's equation. Flow is then

determined using the calcula ted velocity.

2dP×

v=

ρ

S/5 Airway modules

(from Bernoulli's equation)

F=v A×

,

where,

F=flow (l/min)

v=velocity (m/s)

A=cross area (m

dP=pressure difference (cmH

ρ=density (kg/m

Finally the volume information is obtained by integrating the flow signal.

2.2 Main components

The airway modules consist of ACX-200 and OM-101 gas measuring units, ASX-200 agent

identification unit (G-AiO/AiOV), PVX board (G-OV/AiOV/AOV), gas sampling system, ACX

measuring board and gas mother board.

Oxygen

Measuing

Unit

Serial I/O

X4

Supply

voltages

+5 V, GND

X1

Serial I/O

2

)

3

)

O2

signal

ACX

Board

2

Signal out

Supply

voltages,

Control

ACX

Supply

serial

voltages

I/O

Gas Module CPU

O)

ACX

Bench

X1

X2

Valve

controls

ACX, ASX,

PVX serial

I/O

+5 Vref

X8

+5 VL

GND

GNDD

Lamp

Supply

Voltage

Lamp

Driver

Lamp

control

Pump control

Mod key in

X9

Lamp

control

ASX

Unit

Supply

voltages

ASX

serial

i/O

Valve controls

+15 VD, GNDD

Pump control

+15 VD, GNDD

PVX

Board

X5

Supply

voltages

PVX

serial

i/O

Valve

Driver

Pump

Driver

X1

X3

Gas pressure

and flow in

X10

+24/+32 VD

X12

+15 VD

X7

+15 VD

Fan

Valves

Pump

+5 V

+5 VL

+15 VD

+/-15 V

+24 /+32 VD

GND

GNDD

+15 V

Regulator

Figure 4 Airway module block diagram

Gas Mother Board

GND

Mod key in

X11

Module

Key

Document No. 800 1005-1

9

Page 16

Datex-Ohmeda S/5 Anesthesia Monitor

2.2.1 Gas sampling system

The gas sampling system samples the measured air to the module, and removes water and

impurities from it. A sampling line is connected to the water trap on the front panel. The pump

draws gas through the sampling line to gas measuring units. After the measurements, the gas is

exhausted from sample gas out connector on the rear panel of the module.

Water trap, D-fend

The gas sample enters the monitor through the water trap, where it is divided into two flows, main

flow and side flow (see Gas sampling system block diagram). The main flow goes into the

measuring system through a hydrophobic filter.

The side flow creates a slight sub-atmospheric pressure within the water trap container. This

facilitates gathering th e fluid removed by the hydrophobic filter.

Sampling line

The sampling line is an integral part of the total sampling system. The resistance established by the

sampling line is significant when the software determines the occlusion a nd air-leak alarm limits

during the turn-on sequence.

The Nafion

Zero valve

The small inner diameter causes fluids such as blood or mucus not to propagate within the tube, so

that when the line is clogged, it is replaced.

TM

tube

1)

A nafion tube (tubes A or B, and C: see figure 5) is used to balance the sample gas humidity with

that of ambient air. The tube will prevent errors caused by the effect of water vapor on gas partial

pressure when humid gases are measured after calibration with dry gases. It is inserted between

the water trap and the zero valve (G-AiO/A iOV) or between the zero valve and ACX-200 measuring

unit (G-O/OV/AO/AOV). The tube is also inserted between the CO

absorber and the zero valve.

2

The main flow passes through a solenoid valve before proceeding to the ACX-200 measuring unit.

This valve is activated to establish the zero points for the A CX-200 and O

measuring units at start-

2

up, at 5 minutes, and after that at regular intervals. After 1-hour monitoring, the auto-zeroing is

performed once an hour. When the valve is activated, room air is drawn through the CO

into the internal system and the gas sensors.

absorber

2

1)

10

Document No. 800 1005-1

Nafion is a trademark of Du Pont

Page 17

Gas measuring units, ACX-200 and O2 unit

After the zero valve, the gas passes through the ACX-200 and O2 measuring units. In the ACX-200

measuring unit, infrared light is passed through chambers containing the main flow gas

(measurement) and a chamber containing reference gas. The measurement is made by

determining the ratio between the two light intensities.

The oxygen sensor has two inputs. One input accepts the main flow and the other draws in room air

for reference. The sensor uses a differential pressure transducer to compare the pressure gradient

produced when both gases are exposed to an oscillating magnetic field. Both gas flows exit from a

single port.

In i model, the ASX agent identification unit is installed in parallel with the oxygen sensor . The task

of the ASX unit is to identify anesthesia agents by infrared light method used also in the ACX-200

unit.

Pressure valve

The pressure valve is used to meas ure the pressure gradient between the O2 measurement flow

and the O

filter.

reference flow. This pressure gradient reflects the condition of the D-fend water trap

2

S/5 Airway modules

Normally the pressure gradient between the O

approximately +8 mmHg. If the software detects the gradient to be between 0 and -5 mmHg, the

pressure valve will initiate pressure measurement of the reference flo w. If the gradient is greater

than -5 mmHg, the software triggers the message ’Replace Trap’.

Flow cassettes

The internal flow rates are set using flow cassettes. These cassettes are used to set the side flow

rate and the O

reference flow rate, the flow rates through the measuring units and the total flow

2

rate of the sampling system.

Sampling pump and damping chamber

The sampling pump is a vibrating membrane pump driven by a 50 Hz/12 V/0.4 A square wave

current.

The damping chamber is used to even out the pulsating flow and silence the exhaust flow.

measurement flow and the reference flow is

2

11

Document No. 800 1005-1

Page 18

Datex-Ohmeda S/5 Anesthesia Monitor

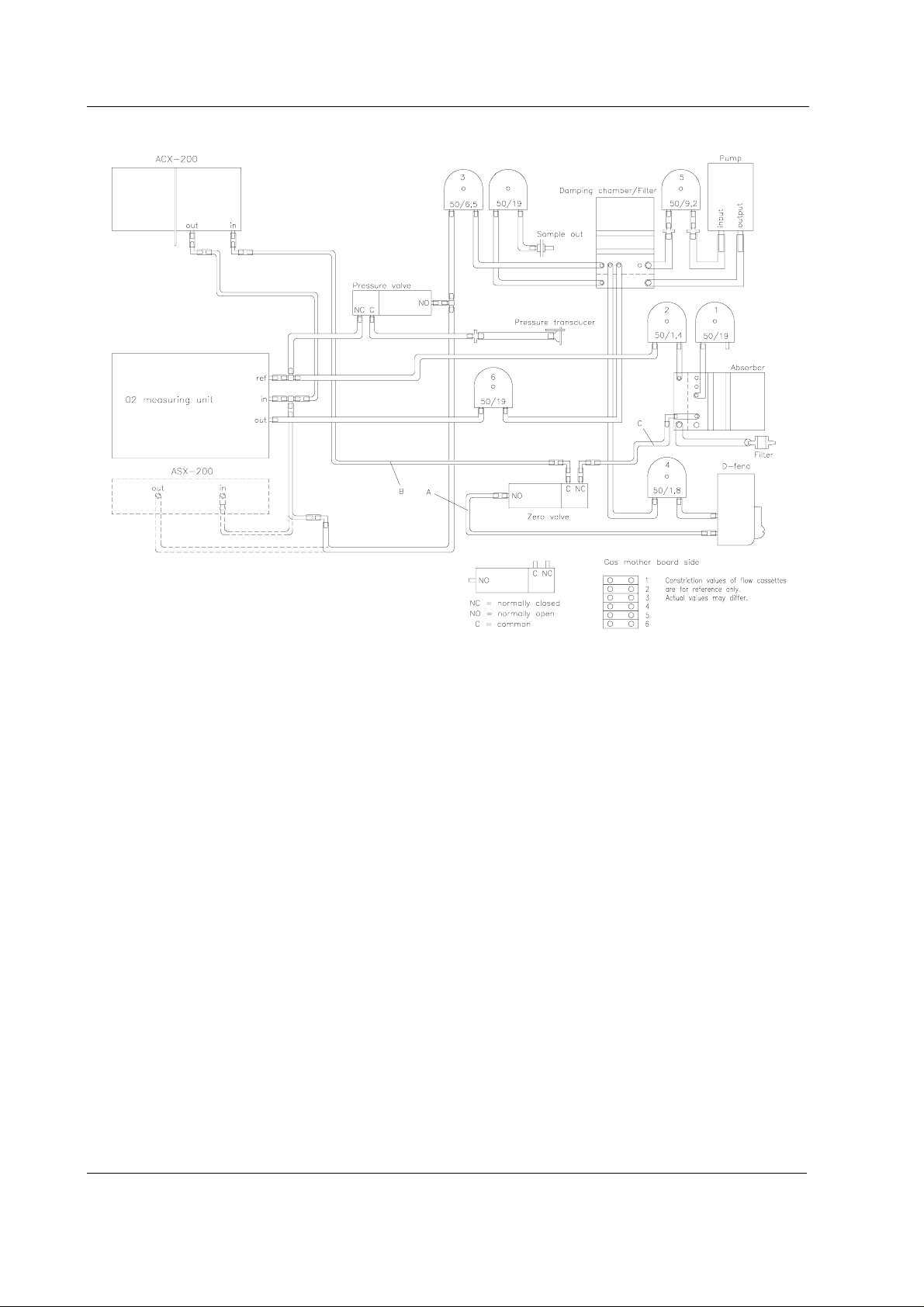

Figure 5 Gas sampling system block diagram

In G-AO, -AOV models, tube A is Teflon, B and C Nafion. In G-AiO, -AiOV models, tubes A and C are

Nafion, B is Teflon.

See new tubing since autumn 1998 in figure 7.

12

Document No. 800 1005-1

Page 19

S/5 Airway modules

A

Ref IN

Room AIR

Sample

Gas IN

Figure 6 Gas sampling system layout

See new sampling system layout since autumn 1998 in figure 8.

Filter

CO

2

absorber

Pressure valve

Pressure

transducer

C

ASX-200

in G-AiO/AiOV

Sample pump

Zero valve

main flow

D-fend

B

ACX-200

O2 sensor

Damping

chamber

side flow

Constriction casse tte

Figure 7 Gas sampling system block diagram

In G-AO, -AOV models, tube A is Teflon, B and C Nafion. In G-AiO, -AiOV models, tubes A and C are

Nafion, B is Teflon. Figure 7 is valid for modules manufactured since autumn 1998.

Sample

Gas OUT

13

Document No. 800 1005-1

Page 20

Datex-Ohmeda S/5 Anesthesia Monitor

Figure 8 Gas sampling system layout

Figure 8 is valid for modules manufactured since autumn 1998.

14

Document No. 800 1005-1

Page 21

Table 2 Flow cassettes

S/5 Airway modules

Flow

Code

cassette

50/26.0 878048

50/19.0 873800

50/16.3 878047

50/15.3 873801

50/14.1 878046

50/13.1 873802

50/12.4 878045

50/11.2 874770

50/10.4 873803

50/9.2 874509

50/8.7 873804

50/7.4 873805

50/6.5 878044

50/5.8 873806

50/5.1 878043

50/4.4 873807

50/3.8 878042

50/3.2 873808

50/3.0 878040

50/2.8 878039

50/2.5 878038

50/2.3 873809

50/2.0 878037

50/1.8 873810

50/1.6 878036

50/1.4 873811

50/1.1 873812

NOTE: The number on the cassette represents relative flow when a specific pressure is applied.

Therefore 50/26.0 presents the least resistance and 50/1.1 the most.

Document No. 800 1005-1

15

Page 22

Datex-Ohmeda S/5 Anesthesia Monitor

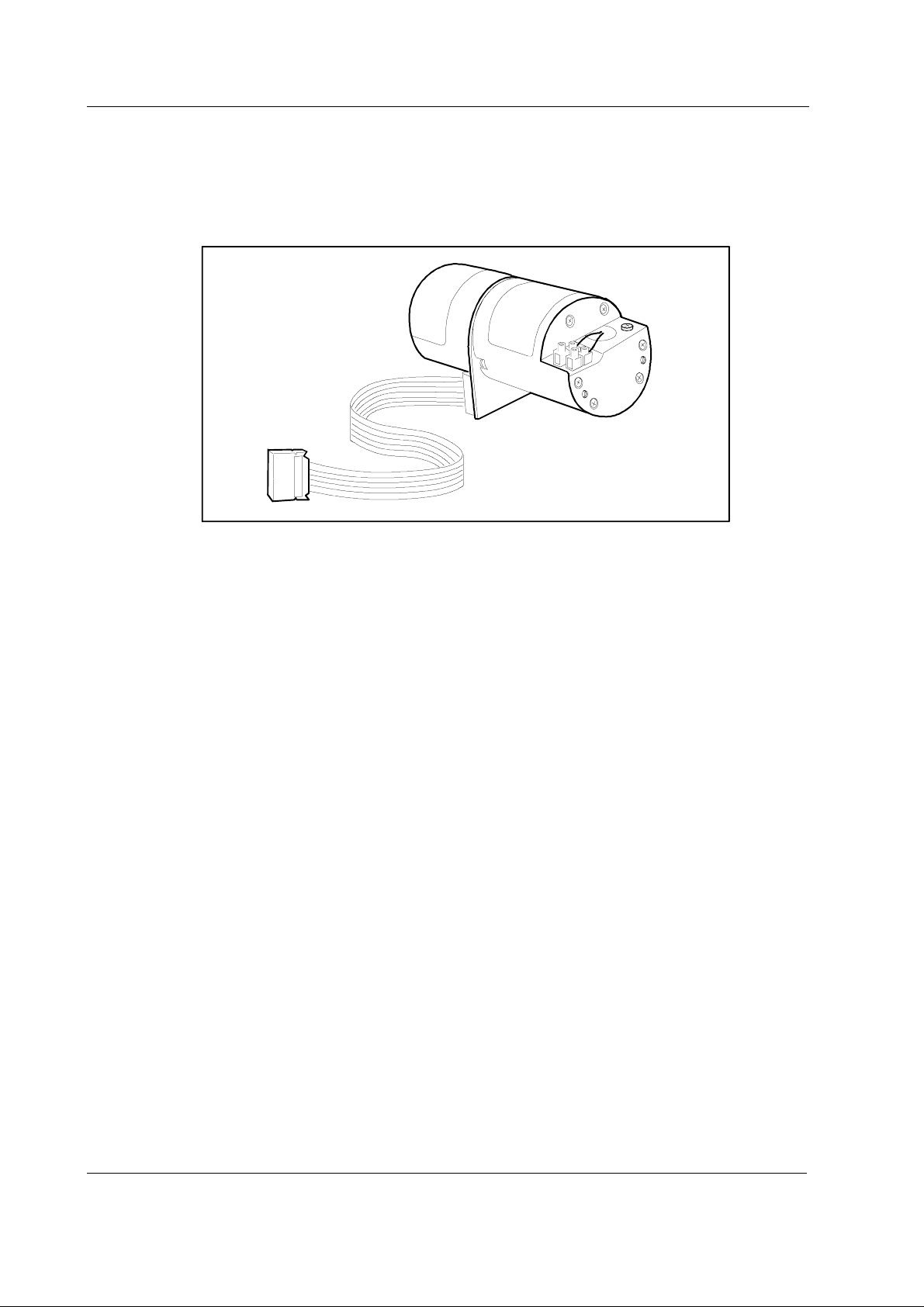

2.2.2 ACX-200 measuring unit

The ACX photometer is of dual path type. The infrared light beam passes through a measuring

chamber containing the gas to be analyzed, and a reference chamber, which is free of CO

and AA. The measurement is made by determining the ratio between the two light intensities.

, N2O,

2

Figure 9 ACX photometer (ACX-200 measuring unit)

A filter wheel is used to control the light from an incandescent lamp that passes through the

photometer. The filters are arranged so that the light is passed sequentially:

• first at the CO

• then through the measuring chamber

• finally it is blocked completely

The same sequence is repeated at the N

absorption wavelength through the reference chamber

2

O and anaesthetic agent gas absorption wavelengths.

2

After passing through the filters the light is reflected and focused by a mirror onto the infrared

detector. This detector measures the three light levels for each gas described above.

There is an optical sensor incorporated in the photometer which detects light from a reflective

surface on the filter wheel once every revolution. The pu lses from this sensor are us ed to

synchronize the electronics to the signal from the infrared detector. A stabilizing diode measures

the temperature, which is needed to compensate for thermal drifts. The infrar ed detector, the

optical sensor and the stabilizing diode are mounted on the preamplifier board.

16

Document No. 800 1005-1

Page 23

S/5 Airway modules

Figure 10 CO2/N2O/AA measurement block diagram

2.2.3 OM measuring unit

The oxygen measurement is based on the paramagnetic susceptibility, which is a unique property

of oxygen among all gases generally present in a breathing gas mixture. The gas to be measured

and the reference gas, which usually is room air, are conducted into a gap in an electromagnet with

a strong magnetic field switched on and off at a frequency of approximately 110 Hz.

An alternating differential pressure is generated between the sample and reference inputs due to

forces acting to the oxygen molecules in a magnetic field gradient.

The pressure is measured with a sensitive differential transducer, rectified with a synchronous

detector and amplified to produce a DC voltage proportional to the oxygen partial pressure

difference of the two gases.

17

Document No. 800 1005-1

Page 24

Datex-Ohmeda S/5 Anesthesia Monitor

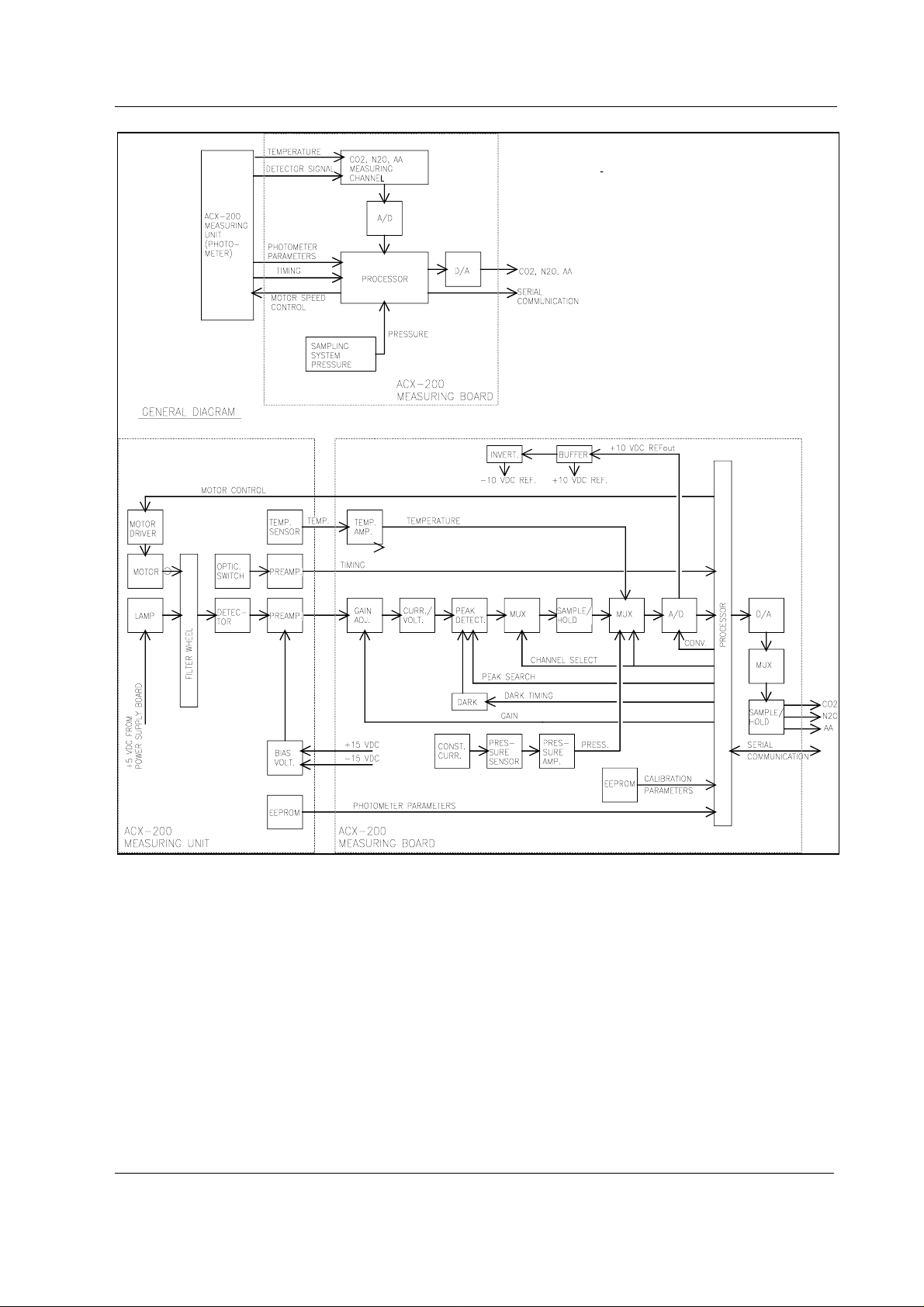

2.2.4 ACX measuring board

The measuring electronics can be divided into a few functional blocks, which are described below

(see the block diagram in figure 11).

The ACX Measuring board controls gas measurements. It converts the photometer signal into digital

data, calculates results and transmits it to Gas mother board. The board contains, in addition to

the 80C51FA processor, EPROM, RAM, and EEPROM, several analog and digital I/O functions.

Internal and external bus

The processor has access to the Measuring board peripherals (memory, A/D converter, D/A

converters, etc) via an internal bus. For communication between the Gas mother board and the

Measuring board, there is an external bus in connector X1.

Memory

Memory components include 64k × 8 bit EPROM program memory, 32k × 8 bit low current CMOS

RAM, and EEPROM for permanent calibration values and setup memory.

18

Document No. 800 1005-1

Page 25

S/5 Airway modules

Figure 11 ACX measuring board block diagram

19

Document No. 800 1005-1

Page 26

Datex-Ohmeda S/5 Anesthesia Monitor

2.2.5 ASX agent identification bench

The ASX-200 agent identification bench has one measuring chamber. Background compensation

is done by subtracting the background spectrum from the measured signal. Background spectrum

is measured simultaneously with the zeroing of the ACX-200 unit. The resulting spectrum is

analyzed to identify the agent.

The ASX unit requires two calibrations. One is the time between synchronization pulse and

measured spectrum (time offset) of the ASX-200 and the other is the peak wavelength of the

narrow bandpass filter. The former is calibrated automatically together with the gas calibration of

the ACX and the latter is calibrated at the factory.

Preamplifier

ASX Bord

Figure 12 ASX measuring unit

ASX preamplifier board

The absorption of infrared light is measured with a lead selenide detector. The signal is amplified

and then led to the measuring board.

2.2.6 ASX measuring board

The measuring electronics can be divided into a few functional blocks, which are described below

(See the block diagram in figure 13).

The ASX measuring board controls the measurement. It converts the ASX photometer signal to

digital data, calculates results and communicates with the main CPU through a serial channel. The

board contains, in addition to the 80C196 processor, EPROM, RAM, and EEPROM, several analog

and digital I/O functions.

Processor section

ASX Unit

Processor is a 80C196 and works at 12 MHz. It has an internal A/D-converter with a multiplexer.

One channel is used for converting temperature signal. Two others are for the measurement signal

from preamplifier board.

The processor uses an internal bus to access EPROM (64k x 8 bit), SRAM (8k x 8 bit) and two D/Aconverters. It communicates with the Gas mother board through a serial channel (RXD, TXDB).

20

Document No. 800 1005-1

Page 27

S/5 Airway modules

EEPROM is a 64 x 16 bit serial chip. It is partly protected so that if jumper X1 is installed the

processor can erase or write the protected registers by serial communication commands. The

protected section contains permanent factory calibrations.

Figure 13 ASX measuring board block diagram

21

Document No. 800 1005-1

Page 28

Datex-Ohmeda S/5 Anesthesia Monitor

2.2.7 PVX board

When Patient Spirometry is used, special sensors, D-lite or Pedi-lite, replaces the normal airway

adapter in the patient circuit. The spirometry tubing is attached to the two connectors on the sensor

and on the module front panel.

NOTE: Overpressure or negative pressure of more than 300 cmH

should never be applied.

The board is intended to perform the following tasks

• Measure the pressures in airways and the speed of breathing flow.

• Calculate tidal volume, minute volume, compliance and other useful information on patient

lungs.

Pressure transducers

There are two pressure transducers on the PVX board for airway pressure measuring purposes.

The breathing flow of a patient passing through D-lite adapter creates pressure difference. This

pressure difference is measured by pressure transducer, B1. Overpressure and negative pressure

in airways are measured by another pressure transducer B2.

NOTE: Never apply DIFFERENTIAL pressure higher than 25 cmH

sure that both spirometry tubes are always connected.

Temperature compensation

Temperature is measured by B1. This signal is used only for temperature compensation of the

pressure transducer B1 on the PVX board.

O to the flow and volume tubing

2

O to the spirometry tubing. Make

2

Data processing

After the multiplexer, the signals, PRESS, FLOW0, FLOW1, and TEMP are A/D converted for data

processing.

External communication

Communication between the PVX board and the Gas mother board is established in serial form,

using the serial channel (pins 10 and 11) of CPU on the PVX board.

22

Document No. 800 1005-1

Page 29

Figure 14 PVX board block diagram

Gas Pressure

and Flow

IN (from Front Panel)

Room Pressure

IN

Room Pressure

IN

Gas Pressure

and Flow

IN (from Front Panel)

Zero

Valve

Zero

Valve

to Gas mother bo ard

Vol

Flow

Pressure

OUT

OUT

+

-

Press

Sense

Temp sense

Press

Diff.

Sense

+

-

PRESS

MUX

TEMP

A/D

Converter

D12

Reset

from/to Gas mother board

FLOW1

+

-

A8

OFFSET

FLOW0

BUS

CPU

8051FA

D4

EPROM

MUX

D/A

Converter

EEPROM

D12

D12

D6

SRAM

Serial In

Serial Out

Document No. 800 1005-1

23

S/5 Airway modules

Page 30

Datex-Ohmeda S/5 Anesthesia Monitor

2.2.8 Gas mother board

The Gas mother board controls power supply to each measuring unit, as well as the serial

communication between the units and the module processor. There are connectors for the pump,

valves and gas measuring units on the board. The board contains a processor which controls the

functions within the module.

The tasks of the module processor are:

• to receive commands from the main CPU board and pass them on to Measuring boards.

• to gather measurement results from the Measuring boards, analyze them, and transmits

data to the main CPU board.

• to control the valves and pump based on the data which ACX Measuring board transmits.

Main parts

• Module processor 80C196KC/16 MHz

• 16 MHz oscillator

• EPROM program memory

• External RAM memory

• EEPROM

• Address and data bus latch

• Address decoding GAL-circuit

• 4-channel serial communication IC (QUART, D4)

External communication

Serial communication bus inside the module processor is used. The bus is connected to module

bus via RS-485 buffer. Transmit and reception controls of buffer are contro lled by the processor.

Connections to measuring boards

Data collection from the measuring units takes place in serial communication bus. Serial

communication lines of the measuring units are connected to QUART IC on the Gas mother board;

Channel 1 - ACX, channel 2 - ASX, channels 3 - PVX, channel 4 - not in use). The transmit side of

QUART has a buffer IC and the receipt side has a pull-up resistor.

24

Document No. 800 1005-1

Page 31

Valves, pump and infrared lamps control

Valves are controlled by ACX Measuring board from which the control signals are ran through buffer

IC to the valve connector. OCCLUS signal controls the pressure (occlusion) valve and ZERO signal

controls the zero valve.

Control signal for the pump comes from the module processor. The signal is 50 Hz pulse-width

modulated square wave. Control command is received from ACX Measuring board in serial

communication.

Control command (LAMP) of the infrared lamps of the chambers comes from the module

processor.

Key push reading

CPU reads the front panel key pushes.

Reset

Voltage supervising circuit performs power-on reset. Reset from the module bus is connected via

RS-485 buffer.

S/5 Airway modules

X4: OM

SENSOR

X2: ACX

UNIT

ZERO OCCLUS

MODULE BUS

RESET

RS-485 buffer

POWER RESET

buffer

EPROM

RAM

X5: ASX

SENSOR

SERIAL COMM. CHIP

CPURESN

Voltage

supervisor

NRESET

NRESET

X1:

AUX I/O

CPU

PUMPDRV

LAMPDRV

X3: PVX

SENSOR

buffer

LAMP DRIVER

VALVE DRIVERS

RS-485 buffer

PUMP DRIVER

ANALOG: VOL.

AWFLOW, AWPRE

MODULE BUS

SERIAL COMM.

X11: MODULE

KEYBOARD

X7: PUMP

X9: ACX. X8: ASX

LAMPS

X12: VALVES

Figure 15 Gas mother board block diagram

25

Document No. 800 1005-1

Page 32

Datex-Ohmeda S/5 Anesthesia Monitor

2.2.9 Gas interface board

The Gas interface board, B-GAS is used for connecting an Airway Module to the Central Unit.

The board connects Airway Module signals to the module bus and supplies voltages from the

module bus to the Airway Module.

On the board there is a fuse (T4A) and some capacitors to regulate the power supply.

2.3 Connectors and signals

2.3.1 Module bus connector

13

25

1

14

Pin No I/O Signal

1 I RESET RS485

2 I -15 VDC

3 I +15 VDIRTY

4 I +15VDC

5 I/O -DATA RS485

6 I/O DATA RS485

7 Ground and Shield

8 I -RESET RS485

9n/c

10 n/c

11 n/c

12 n/c

13 Ground and Shield

14 I +24/+32 VDIRTY Depends on power supply

15 I Ground DIRTY

16 n/c

17 n/c

18 n/c

19 n/c

20 I GASFR (not used)

21 I CTSD (not used)

22 I TXDD (not used)

23 O RXDD (not used)

24 I +5 VDC

25 I +5 VDC DIRTY, for infrared lamps

For B-GAS CPU Mother Board connector, see CPU Bus Connector in the Central Unit Section.

26

Document No. 800 1005-1

Page 33

2.3.2 Gas mother board connectors

X1 Module connector. Serial communication bus to the main CPU

board. Supply voltages.

X2 ACX Measuring board

X3 PVX board

X4 Oxygen measuring unit

X5 ASX Measuring board

X7 Sampling pump

X8, X9 Power supply for infrared lamps (ACX, ASX)

X10 Fan

X11 Module front panel keys

X12 Valves

S/5 Airway modules

27

Document No. 800 1005-1

Page 34

Datex-Ohmeda S/5 Anesthesia Monitor

ACX measuring board (X1) - Gas mother board (X2)

Pin No. a b c

1 +15 V NC AGND

2 -15 V NC +10 VREF

3 AOUT6 NC AOUT5 AA

4 AOUT4 VL NC AOUT3 CO

5AOUT2 O2NC AOUT1 N2O

6 DAC1 FLOW NC DAC0 PRES

7 AIN7 SAL NC ADC6 VOUT R

8 ADC5 AWL NC ADC4 VOUT IR

9ADC3 O2NC ADC2

10 ADC1 AWP NC AIN4 SSIGN

11 NC AGND NC

12 NC AGND NC

13 NC LAMP NC

14 NC PB5 NC

15 NC SSYNC NC

16 RBD2 SMOTOR NC

17 -RESET -PC0 TO RTSO

18 SEROUT 0 NC SERIN 0

19 P1.1 PC2 FGAIN 1 P1.0

20 OP0 RTSA PC3 FGAIN 2 INT0

21 SEROUT 1 PC4 OCCLUS SERIN 1

22 OP1 RTSB PC5 PUMPON IP2 TIMERIN 0

23 SEROUT 2 PC6 ZERO SERIN 2

24 NC PC7 RTS0 NC

25 NC PA0 NC

26 NC PA1 NC

27 NC PA2 NC

28 INT1 PA3 INT3

29 +5 V DRV PA4 +5 V

30 +15 VDIRTY PA5 +5 V

31 +12 V PA6 21 VAC

32 GND DIRTY PA7 ALR CALL DGND

2

NC = not connected

AIN is an AD-converter and AOUT is a DA-converter in ACX board.

ADC is an AD-converter and DAC is a DA-converter in the Gas mother board.

28

Document No. 800 1005-1

Page 35

ASX board (X5) - Gas mother board (X5)

Pin No. Signal

1 Analog ground

2N/C

3N/C

4N/C

5 +15 V

6 -15 V

7 DIRB (not used)

8RXD

9TXDB

10 N/C

11 -RESET

12 +5 V

13 +15 VDIRTY

14 Digital ground

S/5 Airway modules

29

Document No. 800 1005-1

Page 36

Datex-Ohmeda S/5 Anesthesia Monitor

PVX board (X1) - Gas mother board (X3)

Pin No. a b c

1 +15 V NC AGND

2 -15 V NC +10 VREF

3NC NCNC

4NC NCNC

5NC NCNC

6 DAC1 FLOWY NC DAC0 PRES

7 VOL NC NC

8FLOW NCNC

9NC NCNC

10 PRESS NC NC

11 NC NC NC

12 NC NC NC

13 NC NC NC

14 NC NC NC

15 NC NC NC

16 NC NC NC

17 -RESET NC NC

18 NC DIR NC

19 NC NC NC

20 NC NC NC

21 RxD NC TxDP

22 NC NC NC

23 NC NC NC

24 NC NC NC

25 NC NC NC

26 NC NC NC

27 NC NC NC

28 NC NC NC

29 NC NC +5 V

30 +15 VDIRTY NC +5 V

31 NC NC NC

32 GND DIRTY NC DGND

30

Document No. 800 1005-1

Page 37

S/5 Airway modules

3 SERVICE PROCEDURES

3.1 General service information

Field service of the airway modules is limited to replacing faulty circuit boards or mechanical parts.

The circuit boards should be returned to Datex-Ohmeda for repair.

Datex-Ohmeda is always available for service advice. Please provide the unit serial number, full

type designation, and a detailed fault description.

CAUTION Only trained personnel with appropriate equipment should perform the tests and

repairs outlined in this section. Unauthorized service may void warranty of the unit.

NOTE: After any component replacement see chapter

Adjustments and calibrations

CAUTION The ACX-200 photometer and its components are repaired/calibrated at the

factory. Attempts to repair/calibrate the unit elsewhere will adversely affect

operation of the unit. Datex-Ohmeda supplies spare ACX-200 photometers. The

information provided for the ACX-200 is for reference only.

CAUTION Due to the complicated and sensitive mechanical construction any service inside

the O

measuring unit should not be attempted.

2

CAUTION The ACX-200 Measuring board can be repaired and calibrated only at the factory.

CAUTION The PVX-100 measuring unit can be repaired only at the factory.

31

Document No. 800 1005-1

Page 38

Datex-Ohmeda S/5 Anesthesia Monitor

3.2 Service check

These instructions include complete procedures for a service check. The service check is

recommended to be performed after any service repair. However, the service check procedures can

also be used for determining possible failures.

The procedures should be performed in ascending order.

The instructions in clude a check form (

Appendix A

) which should be filled in when performing the

procedures.

The mark

? in the instructions means that the check form should be signed after performing

the procedure.

The procedures are designed for monitors with S/5 monitor software of revision 01. However, most

of the procedures also apply to monitors, which contain some other monitor software

type/revision.

3.2.1 Recommended tools

Tool Order No. Notes

Screwdrivers

Tools for blocking internal tubes

A glass of water

Flowmeter

Multimeter

Gas Interface Cable 2.5 m 884299

Sampling line 3.0 m 73319

Spirometry tube 884101

D-lite 733950

Calibration gas 755582

3.2.2 Recommended parts

Part Order No. Notes

Special tube 733383

Special tube 733382

OM ref. filter 86901

Fan filter 871558

Cable tie 64001

D-fend O-ring (2 pcs) 65312

D-fend (black) 876446

Sampling line 3.0 m 73319

Extra silicon tubing

Spare constriction cassettes

32

Document No. 800 1005-1

Page 39

All modules

S/5 Airway modules

• Remove the airway module case, the top protection cover and the bronze plate from the

side of the O

• Detach the ACX measuring board and the PVX board with the support plate, if installed.

NOTE: Wear a static control wrist strap when handling PC boards. Electrostatic discharge may

damage components on the board.

1. Check internal parts:

- screws are tightened properly

- cables are connected properly

- all IC’s that are on sockets are attached properly

- tubes are not pinched and there are no sharp bends on them

- tubes are connected properly

- there are no loose objects inside the module

sensor, if installed.

2

NOTE: Make sure that none of the tubes is in contact with the sampling pump or the O

sensor.

2

?

2. Check external parts:

- the module case is intact

- the four rubber pads under the frame are all in place

- the metal rear panel is intact

- the equipotential tap and the sample gas out connector are tightened properly

- the block screws for the gas interface cable are in place and are tightened properly

- the D-fend latch is functioning properly

?

• Install the ACX measuring board.

• Detach the D-fend.

3. Check the condition of the rubber O-rings on the metal D-fend connectors, located inside

the module front cover.

If necessary, detach the connectors by first disconnecting the tubes, then removing the

locking rings from the back of the front cover.

NOTE: The O-rings are recommended to be replaced annually.

?

4. Check the OM ref. filter (order code 86901) visually, if installed.

NOTE: The OM ref. filter is recommended to be replaced annually.

If the module does not contain the OM ref. filter, install it to prevent dirt entering the O

sensor reference channel:

2

33

Document No. 800 1005-1

Page 40

Datex-Ohmeda S/5 Anesthesia Monitor

a) shorten the thick O

to the upper part of the CO

b) connect the OM ref. filter to the loose end of the tube

c) fasten the filter to the outermost hole in the tubing plate (at the PVX board side) with a

cable tie (order code 64001)

reference channel tube by 4 centimeters (the tube that is connected

2

absorber)

2

?

• Replace the D-fend and the sampling line.

NOTE: Use only Datex-Ohmeda sampling lines in order to ensure proper functioning.

• Connect the module to the Central Unit with a long gas interface cable and switch the

monitor on.

• Configure the monitor screen so that all the needed parameters are shown, for example as

follows:

Monitor Setup

- Screen 1 Setup - Waveform Fields - Field 1 - Paw

Field 2 - Flow

Field 3 - Off

Field 4 - O2

Field 5 - AA

Field 6 - CO2

Digit Fields - Field 1 - Gases

5. Check that the module fan is running.

?

6. Wait until the message ‘Calibrating gas sensor’ disappears from the screen, then enter the

Service menu:

Monitor Setup

Take down the information regarding Airway module software.

NOTE: The PVX software string does n ot appear into the ‘Sw version/Unit id’ -list. Check PVX

software from the sticker that is located on the PVX software EPROM (if the PVX board was

installed originally).

- Install/Service

(password 16-4-34)

- Service

(password 26-23-8)

?

7. Enter the ACX service menu:

Parameters - Gas Unit - ACX

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ -values are not increasing

faster than by 50 per second. If one of the values is increasing faster, it indicates a failure in

module bus communication.

34

Document No. 800 1005-1

?

Page 41

S/5 Airway modules

8. If the module contains a membrane key on the front panel, press the key at least for one

second and check that it is identified, i.e. the text for Button changes from OFF to ON in the

menu.

?

• Select Halothane as anesthetic agent by first selecting AGENTS from the ACX service menu:

Agents - Select Agent - Hal - Previous Menu

9. Check that the Calib zero -value for N2O is less than 61000.

If the value exceeds the limit, it indicates bad contamination in the ACX measuring

chamber. The measuring chamber can be cleaned according to the special cleaning

instructions found in the chapter Cleaning the measuring chamber of ACX measuring unit.

However, if cleaning does not help, the whole ACX measuring unit should be exchanged.

NOTE: If the ACX measuring chamber was cleaned or the unit was replaced, then also the

tubing between the D-fend and the ACX measuring unit, including the zero valve, should be

replaced. The mentioned parts should not be cleaned.

NOTE: With monitor software S-___95 and S-___96 the Calib zero -value for N

shown as a negative value. The correct value can be calculated by adding the shown value

to the value 65536.

O is always

2

?

10. Check that the Ambient -value corresponds with the current ambient pressure (±20 mmHg).

?

11. Perform the steam test for the special tubes (Nafion), or replace the tubes.

NOTE: The special tubes are recommended to be replaced annually.

?

12. Check the CO2 absorber.

Keep the tip of the sampling line away from you and let the monitor draw in room air. Check

the “Insp CO

absorber.

” -value from the ACX service menu. If the value is less than 4, replace the CO

2

?

2

13. Check the zero valve.

Feed calibration gas into the sampling line and check that the gas readings in the service

menu correspond with the gas values on the calibration gas bottle. Keep feeding gas and

activate the zero valve from the menu. The O

other gas readings near 0 %. If the readings did not drop, replace the zero valve.

reading should drop back near 21 %, the

2

Document No. 800 1005-1

35

Page 42

Datex-Ohmeda S/5 Anesthesia Monitor

?

14. Perform the sampling system leak test.

?

15. Block the tip of the sampling line with your finger until the ‘Amb-Work’ -value becomes

stable. If the value does not reach 110, replace the sampling pump and repeat the leak

test.

?

16. Check the flow rates, adjust if necessary.

NOTE: If any of the constriction cassettes is replaced, the leak test should be repeated.

?

17. Check that the ‘Amb-Work’ -value is within 50... 75 and the OM (in-ref) -value is equal or

higher than 0. If the values differ, readjust the flows.

?

18. Check the O2 sensor output voltage.

Feed calibration gas and check that the value OM volt: mV in the menu rises at least to

2800 (3500 nominal). Adjust the O

NOTE: The voltage measurement requires module software 884295 or 885388.

If the value is not updated, measure the O

board connector X1, pin A9.

PVX boar d ACX meas. boar d

Gas mo t her boar d

ASX Me a suring un it

sensor output, if necessary.

2

sensor output voltage from the ACX measuring

2

C

B

A

19

36

Document No. 800 1005-1

The output voltage should rise at least to 2.8 V (3.5 V nominal).

?

Page 43

S/5 Airway modules

19. Perform gas calibration:

AIRWAY GAS - GAS CALIBRATION

NOTE: For maximum accuracy, a warm-up time of 30 minutes is recommended.

NOTE: If the module contains the agent identification unit, the ASX-100 or A SX-200, keep

feeding gas at least 15 seconds after the message ‘Adjust’ appears in the menu. This way

the agent identification unit has enough time for calibration.

?

• Enter the ACX service menu:

Monitor Setup

Parameters - Gas Unit - ACX

• Select Halothane as anesthetic agent:

Agents - Select Agent - Hal - Previous Menu

20. Perform the fall time measurement in the ACX service menu.

Check that the measured fall times are within the ranges that are given in the Technical

Reference Manual.

NOTE: The fall time measurement can be performed only with module software 884295 or

885388.

- Install/Service

(password 16-4-34)

- Service

(password 26-23-8) -

?

21. Perform the noise measurement.

Check that the measured noise values are within the ranges that are given in the Technical

Reference Manual.

NOTE: The noise measurement can be performed only with module software 884295 or

885388.

?

Document No. 800 1005-1

37

Page 44

Datex-Ohmeda S/5 Anesthesia Monitor

Agent identification option

22. Check that the ‘ACX_ASX Delay’ -value in the ACX service menu is within 400-800.

If the value is not within the range, readjust the flows and repeat the fall time measurement.

?

• Enter the ASX service menu:

Gas Unit - ASX

NOTE: The ASX service menu values are not updated with the anesthetic identification unit

ASX-100.

23. Feed calibration gas. When proper absorption spectrum is shown in the menu check that

the Peak normal value is close to 10.50 (±0.20). Check also that the difference between

the “Peak normal” and “Peak mirror” values is not higher than 0.30.

If the values do not meet the range, repeat the gas calibration.

?

• Set the AA identification to the automatic mode:

Agents - Select Agent - Auto - Previous Menu

24. Feed calibration gas (order code 755583) and check that the message 'Desflurane'

appears into the digit field for gases.

NOTE: The ASX-100 is not capable of identifying Desflurane.

NOTE: The ASX-100 with software 878364-1.1, or lower, is not capable of identifying

calibration gas R23 (order code 755582). Therefore, the message ‘Agent mixture’ should

appear instead.

?

38

Document No. 800 1005-1

Page 45

Patient spirometry option

• Switch the monitor off and install the PVX board, then switch the monitor back on.

• Preset gas measurement settings:

Airway Gas - Spirometry Setup - Paw Scale - 20

1. Check that the patient spirometry connectors on the front panel are clean and intact.

?

2. Connect a clean spirometry tube to the module and a clean D-lite to the other end of the

tube. Block the D-lite’s sampling line port, for example with a luer stopper.

Take the D-lite into your hand and occlude both ends tightly with your fingers (or with both

hands). Pressing firmly with the fingers creates a pressure inside the D-lite. Check that a

pressure of at least 5 cmH

NOTE: If the module has the male & female patient spirometry connectors (pediatric

option), make sure that the date marking on the D-lite is 10/94 or newer.

Flow Scale - 15

O is generated.

2

S/5 Airway modules

If the system leaks heavily, no pressure will be generated.

If there is a small leak in the connections, the monitor will measure a pressure difference

which is then interpreted as flow and seen on the monitor screen. The pressure waveform

decreases slowly and the flow waveform either goes above, or below the zero line,

depending on which of the connectors leaks.

In case of leakage, check all connections and try again.

?

3. Remove the blockage from the sampling line port and connect the sampling line. Breath

through the wider side of the D-lite. Check that the flow waveform moves downwards when

you breath in, and upwards when you breath out.

If the flow waveform moves in opposite manner, check the order of the PVX tubes inside the

module.

?

4. If possible, check the patient spirometry measurement also with the spirometry tester (order

code 884202). Follow the instructions that are supplied with the tester.

?

39

Document No. 800 1005-1

Page 46

Datex-Ohmeda S/5 Anesthesia Monitor

All Airway modules

• Switch the monitor off, disconnect the gas interface cable and reassemble the module.

NOTE: When reassembling the module, make sure that the tubes and cables are not

pinched between the PC boards and covers.

29. Clean, or replace the airway module fan filter.

?

30. Perform electrical safety check and leakage current test.

?

• Reconnect the gas interface cable and sampling line, switch the monitor on and wait until

the message ‘Calibrating gas sensor’ disappears from the screen.

31. Block the tip of the sampling line with your finger and check that the message ‘Sample line

blocked’ appears onto the monitor screen within 30 seconds.

?

32. Detach the D-fend and check that the message ‘Check D-fend’ appears onto the screen

within 30 seconds.

Reattach the D-fend.

?

• Simulate at least 5 breaths by feeding calibration gas into the sampling line.

Check that the shown gas information is correct.

33. Check that the monitor activates the APNEA -alarm within 30 seconds after you have

stopped feeding gas.

?

34. Switch the monitor off, disconnect the gas interface cable and clean the module.

?

• Fill in all necessary documents.

40

Document No. 800 1005-1

Page 47

3.3 Disassembly and reassembly

The airway module (G-AiOV) is disassem b led in the following way. See the exploded view.

1. Remove three screws from the rear panel.

2. Remove one thumb screw and one 5 mm cross recess screw from the bottom of the airway

module case.

3. Slide the case rearward and detach it from the module.

4. Lift off the top protection cover.

The PVX board can be detached by pulling sideways after two tubes are disconnected from two

valves.

The ACX measuring board can be detached by pulling sideways after a ribbon cable connector is

disconnected and a tube is pulled off from pressure transducer.

5. Remove the bronze plate from the right side of the module by pulling it up.

6. To remove the gas mother board cover, remove two front panel screws from the side of the

module, and the D-connector screws.

S/5 Airway modules

7. The front panel can be detached by removing three screws.

8. Tubing system plate with tubes and flow cassettes can be lifted off.

9. Fan can be lifted off after plastic pc board rail is detached.

Gas mother board is attached to the side of the module with screws.

The ASX unit, the ACX measuring unit, and the O

two screws each.

The pump and its magnetic shield can be removed from the chassis by unscrewing the two screws

beneath two springs at the port side of the pump.

Damping chamber/filter case can be slid out of hooks.

Reassembling is essentially reversing what was described above.

measuring unit are attached to the chassis with

2

CAUTION When reassembling the module, make sure that the tubes and cables are not

pinched between the boards and the cover.

41

Document No. 800 1005-1

Page 48

Datex-Ohmeda S/5 Anesthesia Monitor

3.4 Adjustments and calibrations

See

User’s Reference Manual

3.4.1 Gas sampling system adjustment

Flow rates should be measured and possibly adjusted under the following conditions:

• After any part within the sampling system has been replaced

• Gas response is slow

NOTE: Adjust the flows with a new, clean D-fend water trap and original Datex-Ohmeda sampling

line.

NOTE: Before adjusting the flows, make sure that there is no leakage in the sampling system.

NOTE: Let the monitor warm up for 30 minutes before measuring flow rates.

For the flow rate measur ements a flowmeter with a low flow r esistance and capability to measure

low flow rates is required. A normal length of sampling line has to be connected to the monitor as it

has a considerable effect on the flow.

for normal gas calibration instructions.

The flow rates are adjusted by changing the flow resistance cassettes (constriction cassettes) in the

sampling system. See Table 2 in chapter “

The adjustments and the respective constrictions to be adjusted are shown in the next figure, see

also chapter

manufactured since autumn 1998.

“Gas sampling system”

3.4.2 Flow rate measurement

If any flow rates are not correct, first replace the D-fend water trap. Then recheck the

incorrect flows before adjusting the flow rates.

The sampling flow rate is measured by a flowmeter at the sampling line. The rate should be

between 180 and 220 ml/min.

The sampling flow rate is adjusted by changing the flow cassette which is located between the

pump and the damping chamber.

Due to two different tubing layouts, if the described location does not contain a flow cassette, the

sampling flow rate is adjusted by changing the flow cassette that is located between the pump and

the sample gas out connector.

Gas sampling system”

to see gas sampling system block diagrams for modules

for the alternative cassettes.

42

Document No. 800 1005-1

Page 49

S/5 Airway modules

Figure 16 Gas sampling system adjustment chart

See also chapter

“Gas sampling system”

to see gas sampling system block diagrams for modules

manufactured since autumn 1998.

43

Document No. 800 1005-1

Page 50

Datex-Ohmeda S/5 Anesthesia Monitor

Rate of the side flow is checked by blocking the side flow after the water trap and measuring the

flow rate as above. The rate should decrease by 10 to 27 ml/min.

Measurement flow and reference flow of the oxygen measuring unit are checked as follows:

1. Connect the flowmeter behind the flow cassette (no. 2) ahead of the oxygen measuring unit

REF inlet. The flowmeter should show between 25 and 42 ml/min. The flow rate is adjusted

by changing the cassette.

2. Connect the flowmeter between the oxygen measuring unit IN inlet and the tube which is

connected to it. The flow rate should be between 18 and 25 ml/min larger than the REF

flow. This is adjusted by changing the flow cassettes (no. 4 and 5) which are located

between the IN and OUT inlets.

3. Flow rate of CO

absorber is measured by connecting the flowmeter to the unoccupied

2

connector of the flow cassette (no. 1). Make sure that the monitor is in normal situation

(APNEA text on the screen). The flow rate should be zero. When the gas zeroing takes place,

the rate should be between 180 and 220 ml/min. The gas zeroing can be simulated in the

ACX Service Menu manually (pump start, zero valve on). The flow rate is adjusted by

changing the cassette (no. 1).

CAUTION When changing cassettes make sure that the tubes are reconnected properly.

Flow to be adjusted Constr. No. (see figure 16) Nominal value (tolerance)

ml/min

sampling flow 6 200 (180 to 220)

side flow 3 10 to 27

O2 measurement in 4 and 5 45 to 60

O2 reference in 2 25 to 42

CO2 absorber flow 1 180 to 220 when zeroing

NOTE: Changing any of the cassettes will have some effect on the other flow rates. After any

adjustments check the other flow rates as well.

O2 measurement flow pressure

Gradual decrease of main flow rate due to the water trap filter clogging can be checked by

measuring pressure difference between the O

Remember that the sampling line should be attached to the water trap before starting the test.

The pressure difference is automatically checked after every gas zeroing.

See ACX Service menu chapter later in this manual for further information.

3.4.3 Oxygen measurement unit adjustments

The only field service procedures for the O2 measuring unit are the offset (zero), gain, and frequency

adjustments. In case of any other trouble, the measuring unit should be replaced and the faulty

one sent to Datex-Ohmeda for repair.

44

Document No. 800 1005-1

measurement flow and the O2 reference flow.

2

Page 51

Offset (zero) adjustment

Because the oxygen measuring unit is a differential sensor, which actually measures the difference

between the O

equal zero when atmospheric air is present at both inputs.

S/5 Airway modules

concentrations in the sample and reference gases, its output must be adjusted to

2

1. Connect a digital voltmeter to the output of the O

on the Gas mother board.

2. Let the monitor draw in room air and adjust the voltage to zero with the O

trim resistor designated 'ZERO' (see figure 17) in the O

potentiometers are located at the same side of the measuring unit as the tubing connectors.

3. Perform gas calibration (see

Gain adjustment

1. Adjust the O2 measuring unit offset as described in the previous section.

2. Sample 100 % oxygen and adjust the measuring unit output to between 7.7 V and 8.3 V

with the trim resistor designated 'GAIN' (see figure 17). If the output will not exceed 7.7 V, it

is acceptable that the output exceeds at least 5 V. At that level software is still able to

compensate the output.

3. Check and if necessary readjust the offset and gain until the readings remain stable.

4. Perform gas calibration (see

Temperature compensation adjustment

Factory calibrat ed.

measuring unit at pin 7 of connector X4

2

User’s Reference Manual

User’s Reference Manual

2

module PC board. The

2

).

).

measuring unit

Frequency adjustment

The switching frequency of the electromagnet of the O2 measuring unit has been selected to be

110 Hz to avoid interference from harmonics of both 50 Hz and 60 Hz mains frequency.

Fine adjustment is seldom necessary. However, if you wish to reduce the effects of mechanical

resonance peaks of the cabinet which appears as high noise level of the O

output (above 20 mV peak to peak) it is worth of trying the fine frequency adjustment. One turn of