Datex-Ohmeda Engstrom Service manual

Engström Ventilator

Technical Reference Manual

Engström Ventilator

10/04 1505-1018-000

Datex-Ohmeda products have unit serial numbers with coded logic which indicates a product

group code, the year of manufacture, and a sequential unit number for identification. The serial

number can be in one of two formats.

Engström Ventilator, ComWheel, D-fend

and

EVair 03

are registered trademarks of

Datex-Ohmeda Inc.

Other brand names or product names used in this manual are trademarks or registered

trademarks of their respective holders.

AAA

X

11111 AA A

XX

111111A A

The

X

represents an alpha character

indicating the year the product was

manufactured;

J

= 2004,

K

= 2005, etc.

II

II

and

O

are not used.

The

XX

represents a number indicating

the year the product was manufactured;

04

= 2004,

05

= 2005, etc.

Technical Reference Manual

1505-1018-000 10/04

i

This document is not to be reproduced in any manner, nor are the contents to be disclosed to

anyone, without the express authorization of the product service department, Datex-Ohmeda,

Ohmeda Drive, PO Box 7550, Madison, Wisconsin, 53707.

©

2004 Datex-Ohmeda Inc.

Engström Ventilator

Engström Ventilator

ii

10/04 1505-1018-000

Important

The information contained in this Technical Reference manual pertains only to those models of

products which are marketed by Datex-Ohmeda as of the effective date of this manual or the

latest revision thereof. This Technical Reference manual was prepared for exclusive use by

Datex-Ohmeda service personnel in light of their training and experience as well as the

availability to them of parts, proper tools and test equipment. Consequently, Datex-Ohmeda

provides this Technical Reference manual to its customers purely as a business convenience

and for the customer's general information only without warranty of the results with respect to

any application of such information. Furthermore, because of the wide variety of circumstances

under which maintenance and repair activities may be performed and the unique nature of each

individual's own experience, capacity, and qualifications, the fact that customer has received

such information from Datex-Ohmeda does not imply in anyway that Datex-Ohmeda deems said

individual to be qualified to perform any such maintenance or repair service. Moreover, it should

not be assumed that every acceptable test and safety procedure or method, precaution, tool,

equipment or device is referred to within, or that abnormal or unusual circumstances, may not

warrant or suggest different or additional procedures or requirements.

This manual is subject to periodic review, update and revision. Customers are cautioned to

obtain and consult the latest revision before undertaking any service of the equipment.

Comments and suggestions on this manual are invited from our customers. Send your

comments and suggestions to the Manager of Technical Communications, Datex-Ohmeda,

Ohmeda Drive, PO Box 7550, Madison, Wisconsin 53707.

ww

ww

CAUTION

Servicing of this product in accordance with this

Technical Reference

manual should never

be undertaken in the absence of proper tools, test equipment and the most recent

revision to this service manual which is clearly and thoroughly understood.

Technical Competence

The procedures described in this Technical Reference manual should be performed by trained

and authorized personnel only. Maintenance should only be undertaken by competent

individuals who have a general knowledge of and experience with devices of this nature. No

repairs should ever be undertaken or attempted by anyone not having such qualifications.

Datex-Ohmeda strongly recommends using only genuine replacement parts, manufactured or

sold by Datex-Ohmeda for all repair parts replacements.

Read completely through each step in every procedure before starting the procedure; any

exceptions may result in a failure to properly and safely complete the attempted procedure.

1505-1018-000 10/04 1

Table of Contents

Important . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Technical Competence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

1 Introduction

1.1 What this manual includes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 User’s Reference manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 Conventions used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.3 What is an Engström Ventilator? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.4 Ventilator overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.5 Display controls and indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.6 Ventilator display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.6.1 Using menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.7 Symbols used in the manual or on the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Engström Ventilator

2 10/04 1505-1018-000

2 Theory of Operation

2.1 Pneumatic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.1 Inspiratory circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.2 Expiratory circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.1.3 Associated circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.1.4 Electronic micropump nebulizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.2 Electrical Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.2.1 Display Unit (DU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.2.2 Communication channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.2.3 Ventilator Control Board - VCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.2.4 Ventilator Monitoring Board - VMB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.2.5 Power Management Board – PMB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.2.6 Other Electronic Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.2.7 Motherboard (backplane) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.2.8 Monitoring Interface Board – Monitoring Module Bays . . . . . . . . . . . . . . . . . . . . 2-17

3 Checkout Procedure

3.1 Inspect the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.2 Automated Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.3 Backlight test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.4 Power failure test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.5 Electrical safety tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

4 Installation and Service Menus

4.1 Service and Installation menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.2 Install/Service Menu (Super User) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.2.1 Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.2.2 Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.3 Calibration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.4 Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.4.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4.4.2 Copy Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4.4.3 Service Log menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.4.4 Software/Hardware version menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Table of Contents

1505-1018-000 10/04 3

5 Service Tests and Calibration

5.1 Calibration (super-user) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.1.1 Calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.2 Service level tests and calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.2.1 Service application setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.2.2 Test setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.2.3 Vent engine debris clean-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5.2.4 Vent engine leak test (low pressure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.2.5 Vent engine leak test (high O

2

pressure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

5.2.6 Vent engine leak test (high Air pressure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.2.7 Calibrate airway pressure transducer Zero and Span . . . . . . . . . . . . . . . . . . . . . 5-12

5.2.8 Verify operation of free- breathing valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.2.9 Verify operation of inspiratory effort valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.2.10 Verify operation of auxiliary pressure relief valve . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.2.11 Mechanical over-pressure valve test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.2.12 Verify regulator output pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

6 Maintenance

6.1 Engström Ventilator planned maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.1.1 Every twelve (12) months . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.1.2 Every forty-eight (48) months . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.2 Battery capacity test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

7 Troubleshooting

7.1 Troubleshooting Checkout Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.1.1 Paw Transducer Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.1.2 Barometric pressure test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.1.3 Low Pressure Leak and Compliance Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.1.4 Safety Valve Relief and Back Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.1.5 Exhalation Valve Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

7.1.6 Exhalation Flow Sensor Calibration Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

7.1.7 Measure Breathing Circuit Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

7.1.8 Air Inspiratory Flow Sensor Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.1.9 O

2

Inspiratory Flow Sensor Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.1.10 O

2

Sensor Test and Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.2 Troubleshooting Vent Engine Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

7.3 Alarm message troubleshooting chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

7.4 Troubleshooting Service App messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Engström Ventilator

4 10/04 1505-1018-000

8 Service Diagnostics and Software Download

8.1 EV Service Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

8.1.1 Main Menu and System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

8.1.2 Power Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

8.1.3 Power Controller Power Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

8.1.4 Display Unit Power Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

8.2 Display Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

8.3 Special Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

8.3.1 View Revision Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

8.3.2 View PC Card Install Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

8.4 Software Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8.5 EV Service Application (PC based) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8.5.1 Port Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8.5.2 Main Menu and System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8.6 VCB Diagnostics and Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.6.1 Sensirion Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.6.2 VCB Input Signal Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

8.6.3 VCB Channel Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8.6.4 VCB Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8.6.5 Calibrations and Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8.7 VMB Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

8.7.1 VMB Channel Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

8.7.2 VMB Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

8.7.3 VMB Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

8.7.4 Baro P Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

9 Repair Procedures

9.1 Circuit Board Replacement precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

9.1.1 Software download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

9.1.2 Required calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

9.2 How to bleed gas pressure from the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

9.3 Accessing chassis components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

9.3.1 To remove the chassis from the housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

9.3.2 To remove the Vent Engine from the chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

9.3.3 To replace chassis mounted components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-6

9.3.4 To replace Vent Engine components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-6

Engström Ventilator

1505-1018-000 10/04 5

9.4 Servicing the Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-7

9.4.1 Remove the Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-7

9.4.2 Disassemble the Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-8

9.4.3 To replace the CPU board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-9

9.4.4 To replace the LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

9.4.5 To replace the backlights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.4.6 To replace the Inverters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

9.4.7 To replace the front enclosure or components . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

9.5 Adjusting the display arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

9.5.1 Adjust upper pivot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

9.5.2 Adjust lower pivot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

9.5.3 Adjust arm bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

9.6 Removing a compressor from the cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

10 Illustrated Parts

10.1 Service tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.1.1 Software tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.1.2 Manual shut-off valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.1.3 Special tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.1.4 Leak test devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

10.1.5 Lubricants and Adhesives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.2 External components - front view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10.3 External components - rear view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

10.4 Display arm mounting hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10.5 Display arm assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10.6 Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10.7 Main enclosure (external) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

10.8 Main enclosure (internal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-16

10.9 Vent Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-18

10.10 Outlet manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-20

10.11 Inlet manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

10.12 AC power cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-23

10.13 AC Inlet/Outlet Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-24

10.14 Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-26

10.15 Module rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-28

10.16 Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-29

10.16 Exhalation valve assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-30

Schematics and Diagrams

Notes

6 10/04 1505-1018-000

1505-1018-000 10/04 1-1

1 Introduction

In this section

This section provides a general overview of the Engström Ventilator.

1.1 What this manual includes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 User’s Reference manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 Conventions used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.3 What is an Engström Ventilator? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.4 Ventilator overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.5 Display controls and indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.6 Ventilator display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.6.1 Using menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.7 Symbols used in the manual or on the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Engström Ventilator

1-2 10/04 1505-1018-000

1.1 What this manual includes

This manual covers the service information for the Engström Ventilator.

It covers the following components:

• Display Unit

• Integral electronics

• Gas delivery components

• Frame component

Other equipment

Other equipment may be attached to the system. Consult separate

documentation relative to these items for details.

1.2 User’s Reference manuals

Some sections of this manual refer you to the User’s Reference manual for the

Engström Ventilator. To expedite repairs, you must have, and be familiar with,

the User’s Reference manual for this product.

Refer to the Engström Ventilator User’s Reference manual if you need further

information about the operation of the system.

Conventions used

Hard keys

Names of the hard keys on the display and modules are written in bold

typeface, for example,

Normal Screen

.

Menu selections

Menu selections are written in bold italic typeface, for example,

Patient

Setup

.

Messages

Messages that are displayed on the screen are enclosed in single quotes, for

example, ‘Check sample gas out.’

Sections and headings

When referring to different sections or headings in the User’s Reference

manual, the name is written in italic typeface and is enclosed in double

quotes, for example,

“System Controls and Menus.”

1 Introduction

1505-1018-000 10/04 1-3

1.3 What is an Engström Ventilator?

The Engström Ventilator (EV) is a flexible, adaptable, and intuitive critical care

ventilator. A wide selection of performance options gives the user full control

of the system configuration.

The EV must only be operated by authorized medical personnel well trained in

the use of this product, for patient ventilation in the intensive care

environment. It must be operated according to the instructions in this User’s

Reference manual.

The ventilator is designed to be used with infant through adult patients with a

body weight of 5 kg or greater. The EV is designed to maintain lung ventilation

in the absence of spontaneous breathing effort as well as in support of the

patient’s existing spontaneous breathing effort.

The system is designed for facility use, including within-facility transport.

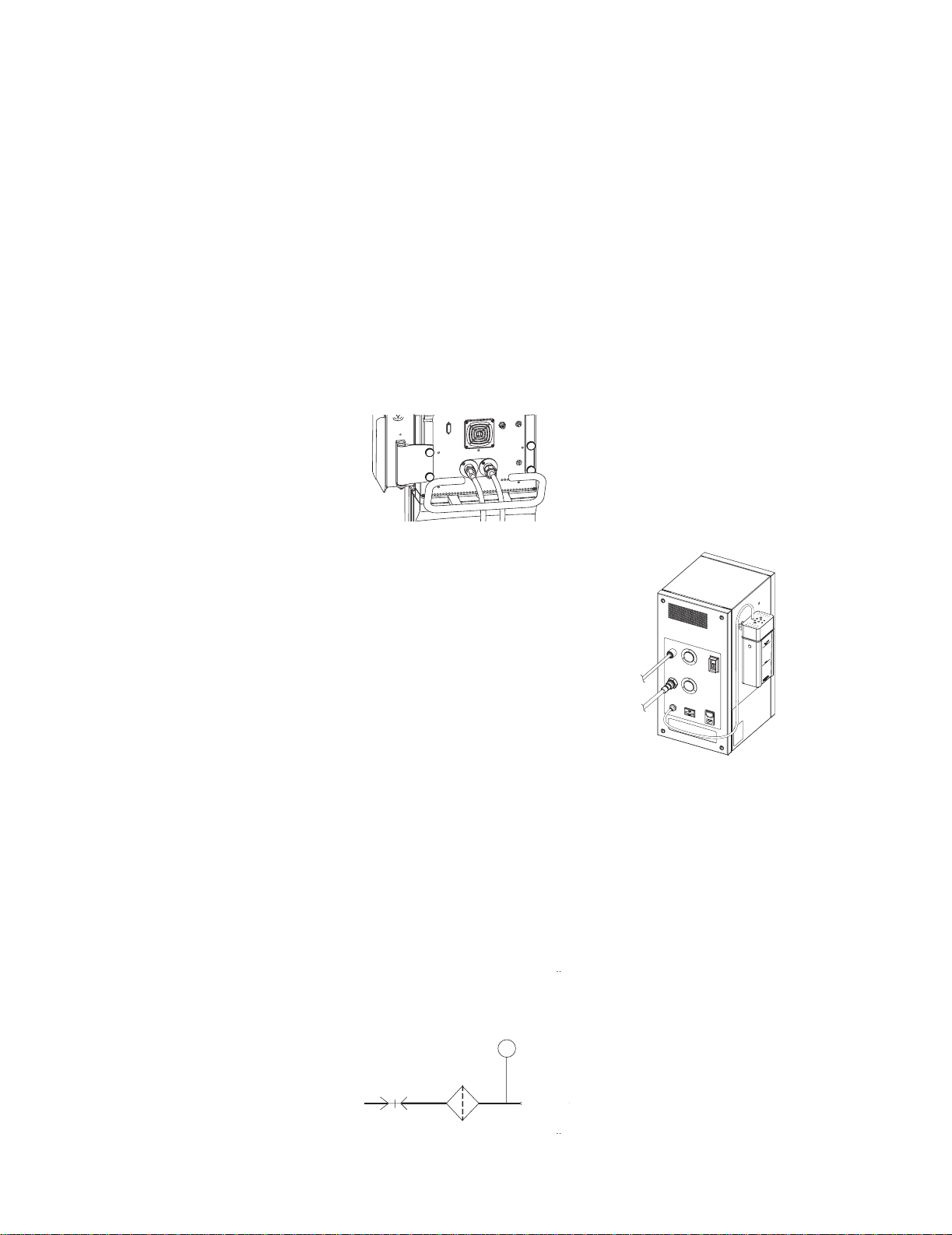

The ventilator consists of three main components: a display, a ventilator unit,

and an optional module bay. The display allows the user to interface with the

system and control settings. The ventilator unit controls electrical power,

nebulization, and pneumatic gas flow to and from the patient. The module bay

allows the integration of various patient monitoring modules with the

ventilator.

Optional accessories include an air compressor, airway modules, module

bay, humidifier and water trap mounting brackets, and auxiliary electrical

outlets.

Figure 1-1 • Engström Ventilator (EV)

Engström Ventilator

1-4 10/04 1505-1018-000

1.4 Ventilator overview

1. Module bay (optional)

2. Ventilator lock [locks Ventilator unit (item 6) to Cart (item 3)]

3. Cart

4. Caster

5. Dovetail rails

6. Ventilator unit

7. Display

8. Nebulizer connection

9. Exhalation valve housing

10. Expiratory inlet

11. Expiratory flow sensor

12. Gas exhaust port

13. Leak test plug

14. Exhalation valve housing latch

15. Water trap

16. Auxiliary pressure port

17. Inspiratory outlet

Figure 1-2 • Front view of the EV

1

2

3

4

5

6

AB.98.007

AB.98.011

891011

13

1415

12

1617

7

1 Introduction

1505-1018-000 10/04 1-5

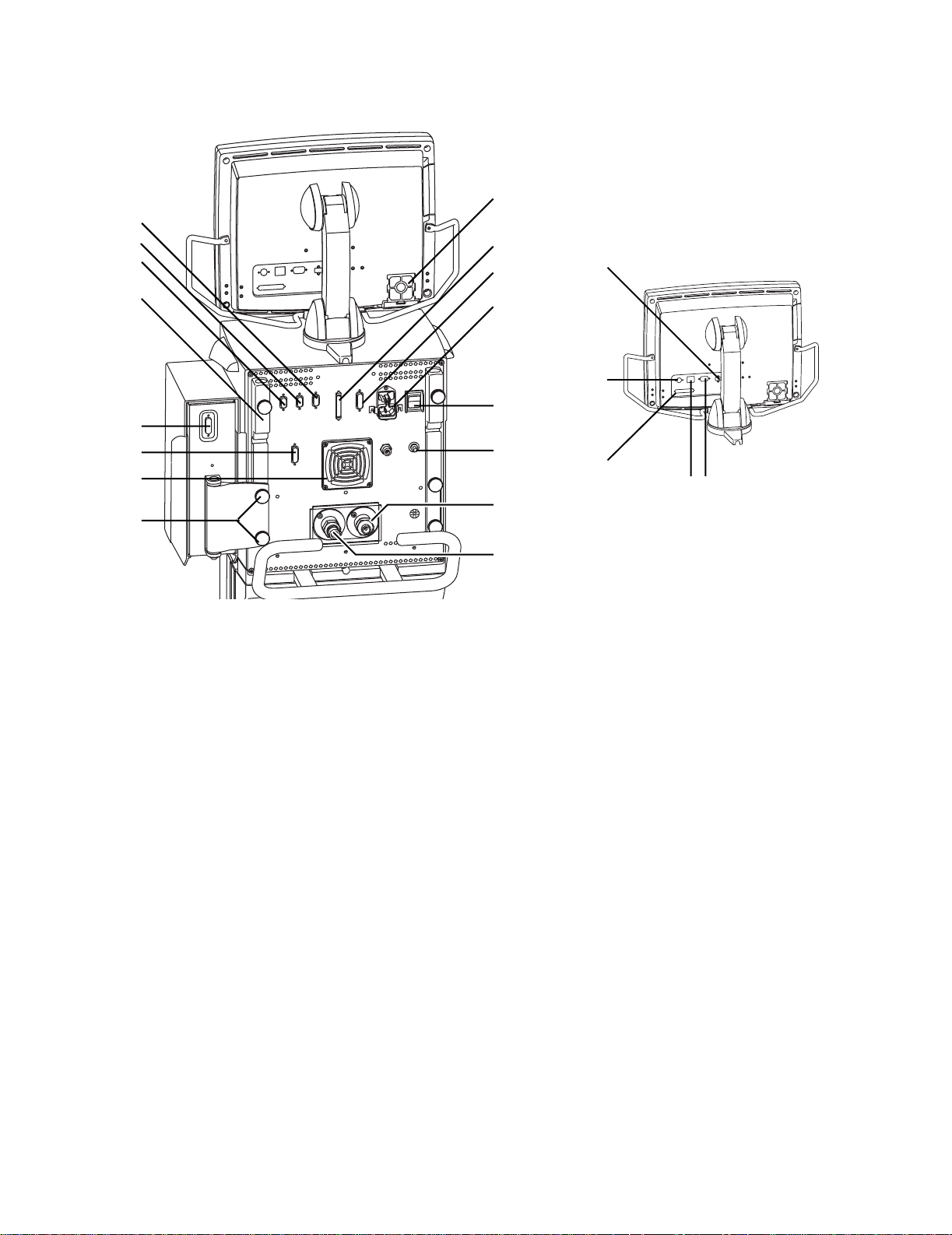

1. Display fan filter

2. Display connection

3. Module bay connection

4. AC mains inlet

5. System switch

6. Equipotential connector

7. Oxygen supply connection (pipeline)

8. Air supply connection (pipeline or compressor)

9. Module bay mounting thumbscrews

10. Ventilator unit fan filter

11. Serial communication port (RS 232 port)

12. Arm holder

13. RS 485 port (not currently supported)

14. RS 485 port (not currently supported)

15. RS 422 port (used to communicate with PC based Service Application — Refer to Section 8.5)

16. Network ID connection

17. Ethernet connection

18. DIS port (not currently supported)

19. USB port

Figure 1-3 • Back view of the E V

2

3

4

5

6

8

10

11

3

AB.98.009

9

7

1

12

13

14

15

18

1617

2

AB.98.045

19

Engström Ventilator

1-6 10/04 1505-1018-000

1.5 Display controls and indicators

Figure 1-4 • Controls and indicators

2

4

3

5

3

AB.98.012

3

7

8

1

6

1 Alarm LEDs The red and yellow LEDs indicate the priority of active alarms.

2 Alarm Silence key Push to silence any active, silenceable high and medium priority alarms or

to suspend any non-active medium priority alarms. Alarm audio is silenced

or suspended for 120 seconds. Push to clear resolved alarms.

3 Menu keys Push to show corresponding menu.

4 ComWheel Push to select a menu item or confirm a setting. Turn clockwise or

counterclockwise to scroll menu items or change settings.

5 Normal Screen key Push to remove all menus from the screen.

6AC mains indicator The green LED lights continuously when the EV is connected to an AC mains

source. The internal batteries are charging when the LED is lit.

7 Quick keys Push to change corresponding ventilator setting. Turn the ComWheel to

make a change. Push the Quick key or ComWheel to activate the change.

8100% O2 key Push to deliver 100% O

2

for 2 minutes.

1 Introduction

1505-1018-000 10/04 1-7

1.6 Ventilator display

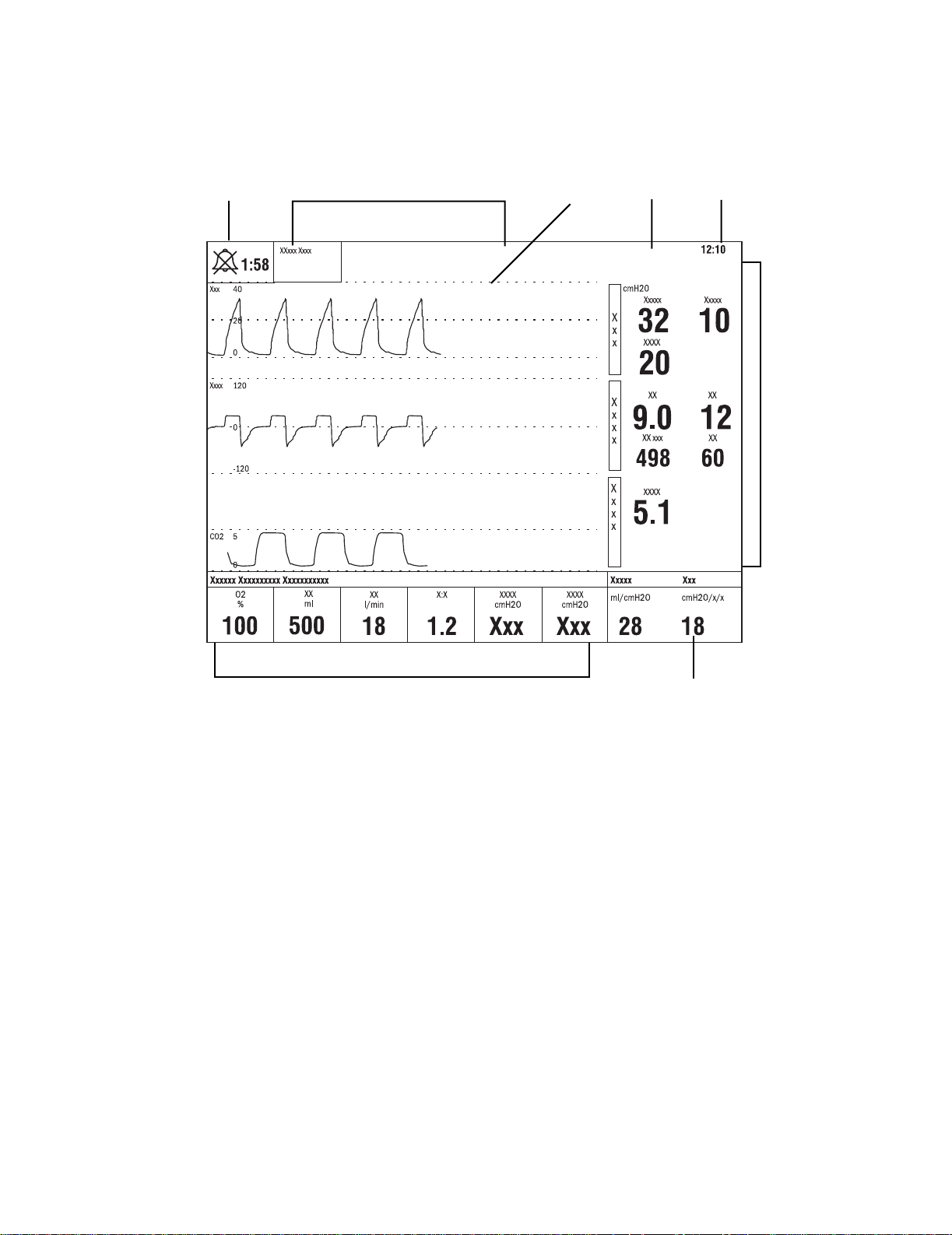

Figure 1-5 • Normal Screen view

12 34

6

7

8

AB.98.013

5

•

1 Alarm silence symbol

and countdown

Displays the time remaining during an alarm silence or alarm suspend period.

2 Alarm message fields Alarms will appear in order of priority. Refer to

“Alarms and Troubleshooting”

for more information

on alarm behavior.

3Waveform fields The top two waveforms are permanently set to Paw and Flow. The third waveform may be selected

as CO

2

, O

2

, Vol, Paux, or Off.

4 General message field Displays informational messages.

5 Clock The time may be set in 12 or 24 hour format in the Time and Date menu.

6 Measured value fields Displays current measured values corresponding to the waveforms.

7 Digit field Displays information related to Volume, CO

2

, O

2

, Compliance or Spirometry.

8Ventilator settings Displays several of the settings for the current mode of ventilation.

Engström Ventilator

1-8 10/04 1505-1018-000

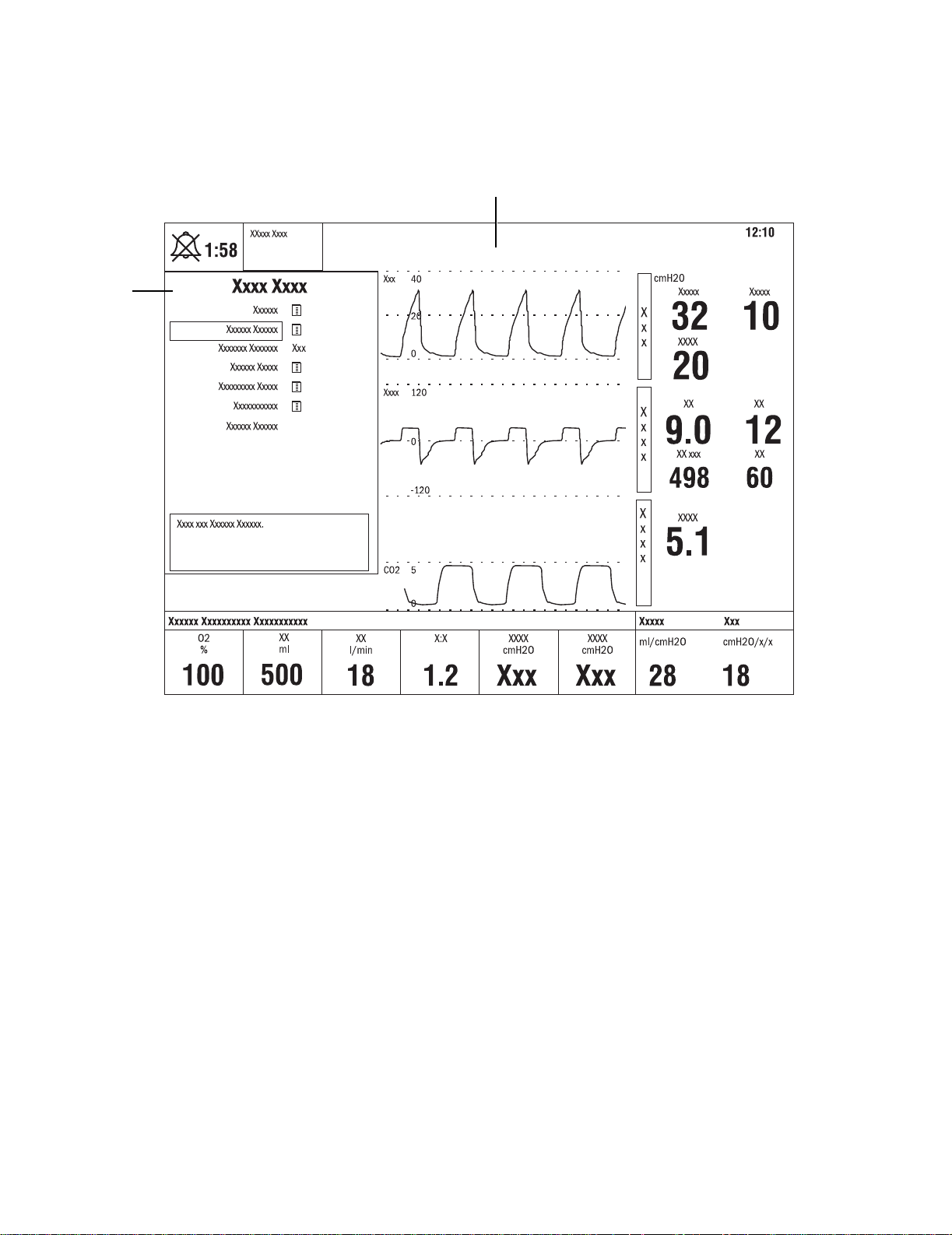

When a menu key is selected the waveform fields start at the right edge of the

menu. The entire waveform is always displayed.

1. Menu

2. Waveform fields

Figure 1-6 • Menu view

1

2

AB.98.014

1 Introduction

1505-1018-000 10/04 1-9

1.6.1 Using menus

Push a menu key to display the corresponding menu. Use the ComWheel to

navigate through the menu.

1. Menu title

2. Present selection

3. Adjustment window

4. Indicates submenu

5. Short instructions

6. Menu selections

Figure 1-7 • Example menu

1. Push the menu key to display the corresponding menu.

2. Turn the ComWheel counterclockwise to highlight the next menu item.

(Turn the ComWheel clockwise to highlight the previous menu item.)

3. Push the ComWheel to enter the adjustment window or a submenu.

4. Turn the ComWheel clockwise or counterclockwise to highlight the

desired selection.

5. Push the ComWheel to confirm the selection.

6. Select

Normal Screen

or push the

Normal Screen

key to exit the menu

and return to the normal monitoring display. (Select

Previous Menu

to

return to the last displayed menu, if available.)

Xxxxxx Xxxxxx

1

2

3

4

6

5

AB.91.007

Engström Ventilator

1-10 10/04 1505-1018-000

1.7 Symbols used in the manual or on the equipment

Symbols replace words on the equipment, on the display, or in

Datex-Ohmeda manuals.

Warnings and Cautions tell about the dangerous conditions that can occur if

the instructions in the manual are not followed.

Warnings tell about a condition that can cause injury to the operator or the

patient.

Cautions tell about a condition that can cause damage to the equipment.

Read and follow all warnings and cautions.

l

On (power)

O

Off (power)

p

On for part of the equipment

œ

Off for part of the equipment

o

Standby

m

Type B protection against

electrical shock

wW

Attention, refer to product instructions

IEC 60601-1

w

Caution, ISO 7000-0434

REF

Stock number

SN

Serial number

†

Direct current

∏

Alternating current

y

Earth ground

x

Protective earth ground

Y

Equipotential connector Fuse

z

Lock

Z

Unlock

t

Variability

T

Variability in steps

+

Plus, positive polarity

-

Minus, negative polarity

N

Movement in one direction

ˆ

Movement in both directions

This way up Warning, dangerous voltage

N

N

1 Introduction

1505-1018-000 10/04 1-11

Pneumatic inlet Pneumatic outlet

Electrical input Electrical output

Inspiratory port Expiratory port

Electrical testing certification Inspiratory breath identifier

Serial port Module data indicator

Module bay port Electronic micropump nebulizer

Auxiliary pressure port Display signal input/output

No battery/battery failure Battery in use. Bar indicates

amount of battery power

remaining.

Silence alarms Submenu

Hourmeter Drain outlet

Engström Ventilator

1-12 10/04 1505-1018-000

Air Pump

Heavy object USB port

Ethernet connection Network ID connection

(Datex-Ohmeda proprietary port)

134°C

Autoclavable

Í

Not autoclavable

Authorized representative in the

European Community

Systems with this mark agree with

the European Council Directive

(93/42/EEC) for Medical Devices

when they are used as specified in

their User’s Reference Manuals.

The xxxx is the certification number

of the Notified Body used by

Datex-Ohmeda’s Quality Systems.

ID

X1

XXXX

1505-1018-000 10/04 2-1

2 Theory of Operation

In this section

2.1 Pneumatic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.1 Inspiratory circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.2 Expiratory circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.1.3 Associated circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.1.4 Electronic micropump nebulizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.2 Electrical Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.2.1 Display Unit (DU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.2.2 Communication channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.2.3 Ventilator Control Board - VCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.2.4 Ventilator Monitoring Board - VMB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.2.5 Power Management Board – PMB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.2.6 Other Electronic Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.2.7 Motherboard (backplane) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.2.8 Monitoring Interface Board – Monitoring Module Bays . . . . . . . . . . . . . . . . . . . . 2-17

Engström Ventilator

2-2 10/04 1505-1018-000

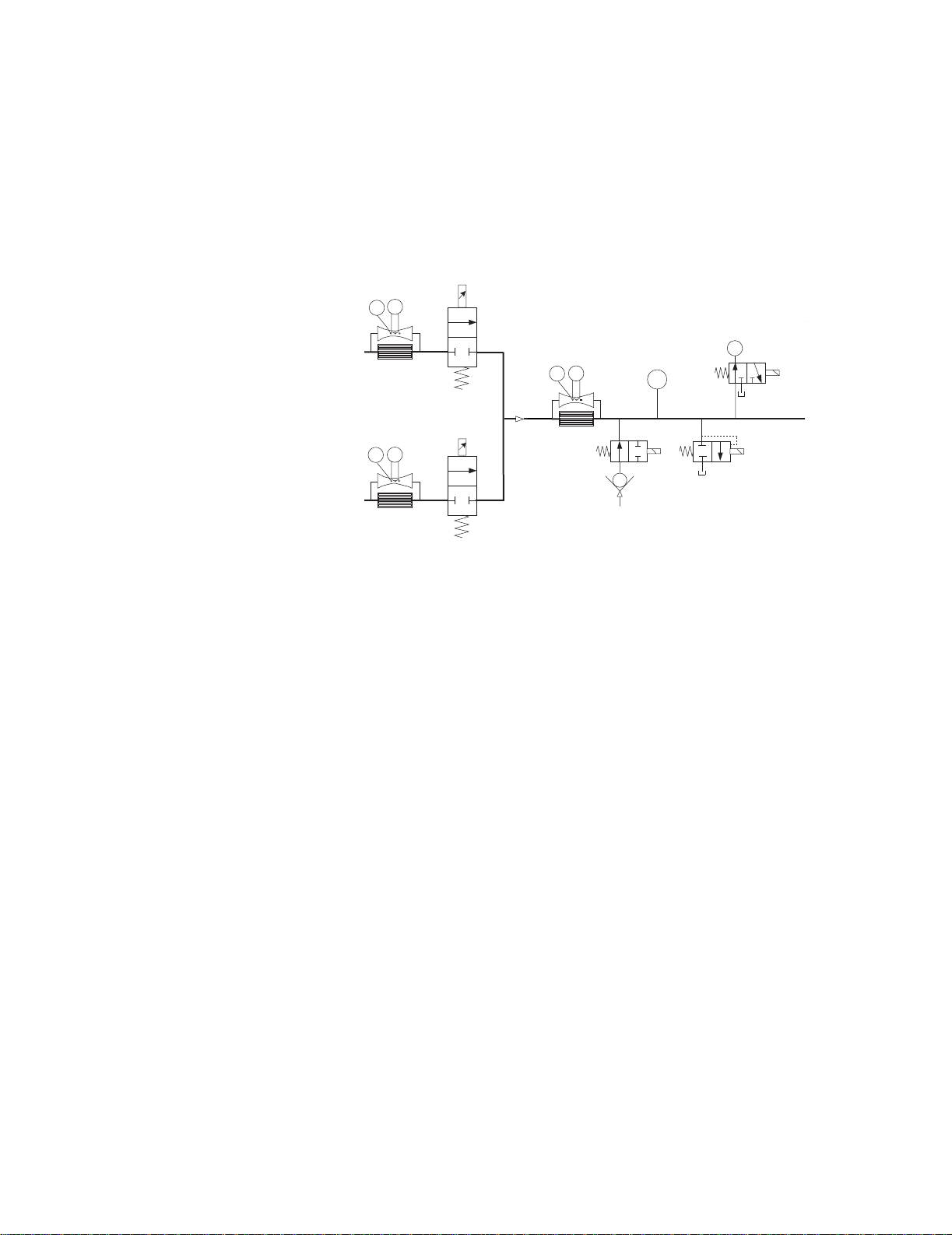

2.1 Pneumatic Operation

For a complete diagram of the pneumatic system, refer to Figure 11-2, "

Vent

Engine manifold flow diagram

" in Section11.

The EV requires a medical-grade oxygen (O

2

) and Air source ranging from 2.4

to 6.5 bar (35 to 94 psi).

The system includes two separate channels (O

2

and Air) to provide dynamic

mixture control of the delivered O

2

percentage.

The Air supply may include an optional compressor unit {1} for applications

where pipeline Air is not available or to provide a continued Air supply if the

pipeline supply goes down.

2.1.1 Inspiratory circuit

Compressed gas enters the EV through an inlet fitting {2} that is particular to

the institution’s supply system. The gas is filtered through a 2-micron

particulate filter {3} as it enters the ventilator’s “pneumatic engine” manifold.

A high-pressure transducer {4} having a dynamic range of 0 to 8.3 bar

(0 to 120 psi) is tapped at the outlet of the filter. This transducer monitors the

adequacy of the supply pressure. Failures of supply gas, coupling hoses or an

occluded filter are identified by the supply pressure transducer.

O2

Air

Air

{1}

Check

Valve

High Pressure

Transducer

Inlet

Filter

Primary

Inlet

P

{2}

{3}

{4}

2 Theory of Operation

1505-1018-000 10/04 2-3

Next in the downstream path of flow is a check valve {5}. The check valve

prevents backflow from the EV that would possibly contaminate the supply

pressure lines. For example; if the O

2

supply were to be lost, the check valve in

the O

2

channel will prevent Air from moving back into the O

2

supply lines.

Downstream from the check valve is a 172 kPa (25 psi) pressure regulator {6}.

(The regulator is a non-relieving type that does not bleed gas into the

ventilator’s enclosure.) The regulator ensures a constant pressure supply to

the flow valve {8}. The regulated supply is flow rate dependant, which is

compensated for in the flow valve’s on-site calibration.

Between the regulator and the flow valves is the inspiratory flow sensor {7}.

The sensor is a thermal mass-flow type that injects heat into the flow stream

and monitors the associated temperature rise at a downstream location. The

temperature change is dependent on the mass flow of the flow stream and

the specific heat of the gas moving through the sensor. Since the composition

of gas in the sensor is known, a conversion of mass-flow rate to volumetric

flow at ambient conditions can be made using the ambient density of the gas.

The sensor uses a laminar (two channel) flow element to split a portion of the

flow through the sensor past the heat injection and temperature sensing

elements. The sensor is pre-calibrated and includes an electronic PCB that

produces direct digital output of mass flow through an RS-232 interface.

Individual flow sensors measure the volume of gas dispensed from the O

2

and

Air channels during inspiration and expiration. The relative proportion of gas

dispensed from each channel is continuously adjusted to precisely control the

percentage of O

2

delivered to the patient.

Check

Valv e

High Pressure

Transducer

Inlet

Filter

Primary

Inlet

P

{5}

25 psi

172 kPa

Flow

Sensor

H

T

Regulator

Flow

Valv e

Check

Valv e

High Pressure

Transducer

Inlet

Filter

Primary

Inlet

Test

Port

P

{6}

{8}

{7}

Engström Ventilator

2-4 10/04 1505-1018-000

Downstream of the flow sensor is a flow valve {8} that meters flows from

approximately 0.05 l/min (leakage level) to a full flow value of 160 l/min. The

valve is a normally- closed proportional solenoid that is powered by a current

feedback loop. When calibrated on-site, using data from the inspiratory flow

sensor, a precise volumetric flow versus input current profile is developed that

includes both the valve and regulator characteristics.

Following the two individual flow valves is the total flow sensor {10}. This

sensor is the same type as the individual flow sensors and is used to measure

the combined inspiratory flow being dispensed from the system. Using the

known mixture composition along with atmospheric pressure and gas

temperature information, mass-flow data from the sensor is converted to

delivered volumetric flow towards the patient. During calibration, the sensor is

checked against the output of the O

2

and Air flow sensors to ensure proper

operation.

25 psi

172 kPa

Flow

Sensor

H

T

Regulator

Flow

Valv e

Check

Valv e

High Pressure

Transducer

Inlet

Filter

Primary

Inlet

Test

Port

P

{8}

Flow

Sensor

Flow

Sensor

Tot al Flow

Inspiratory

Effort

Valv e

Free Breathing

Check Valve

H

T

H

T

Pneumatic

Resistor

Flow

Valv e

Flow

Valv e

H

T

{10}

O

2

Air

2 Theory of Operation

1505-1018-000 10/04 2-5

Following the total flow sensor are the free-breathing check valve {11} and the

inspiratory effort valve {12}.

During normal operation, the inspiratory effort valve is open, allowing the

free-breathing check valve to admit flow if the patient draws a significant

amount of inspiratory pressure, causing the airway pressure to become more

negative than -0.5 cm H

2

O. The free-breathing check valve allows the patient

to spontaneously breathe in case of a ventilation delivery failure.

On occasion, to assess the patient’s tolerance to be weaned from the

ventilator, clinicians can determine the amplitude of inspiratory effort that the

patient can create. During this “procedure”, the inspiratory effort valve is

closed, effectively locking out the free breathing valve from the patient circuit.

Next in the flow path is the O

2

sensor {13}. The sensor is used to monitor the

O

2

concentration produced by the combined O

2

and Air flows.

The O

2

sensor uses the paramagnetic principle (oxygen molecules are

attracted in magnetic fields) to measure the oxygen concentration. The sensor

includes two nitrogen-filled glass spheres mounted on a suspension

containing a conductive coil that is located in a non-uniform magnetic field.

When the system is disturbed by an impulse of current, the suspension begins

to oscillate, inducing an EMF into the coil. The oscillation period of the

induced EMF is dependent on the partial pressure of oxygen surrounding the

suspension.

As sample gas fills the sensor, oxygen that is present in the sample is

attracted into the strongest part of the magnetic field. This congregation of O

2

molecules alters the natural oscillation frequency of the suspension.

Calculations based on the difference between the oscillation period for an

oxygen sample and that for nitrogen, and readings from the absolute pressure

transducer, determine the measured O

2

percentage.

O

2

Flow

Sensor

Flow

Sensor

Tot al Flow

Inspiratory

Effort

Valv e

Free Breathing

Check Valve

H

T

H

T

Pneumatic

Resistor

O2 Sensor

Auxil

Flow

Valv e

Flow

Valv e

Expiratory Press

P

H

T

{13}

O

2

Air

{11}

{12}

Engström Ventilator

2-6 10/04 1505-1018-000

As a safety measure, a relief valve {14}, located downstream from the O

2

sensor, can be energized to vent the full flow rate of the inspiratory delivery

side of the system. If an overpressure condition is detected, the valve can be

opened by either of the EV’s two control processors. To provide redundant

safety (independent of the electronic circuits), the valve begins to

mechanically relieve pressure at a nominal 115 cm H

2

O.

The inspiratory airway pressure transducer {15}, along with its associated

zeroing valve, is located just prior to the inspiratory outlet port. This

transducer has a range of –20 to 120 cm H

2

O and serves as one of three

airway pressure measuring devices in the EV.

O

2

Safety

Relief Valve

Flow

Sensor

Flow

Sensor

Tot al Flow

Inspiratory

Effort

Valv e

Free Breathing

Check Valve

H

T

H

T

P

Pneumatic

Resistor

O2 Sensor

Inspiratory Zero

Valv e

Auxiliary Pressure

Inspiratory Pressure

Flow

Valv e

Flow

Valv e

R

e

li

e

f

Exhalatio

n

Valv e

E

xp

i

ra

t

ory

Z

ero

Valv e

Expiratory Pressure

P

H

T

O

2

Air

{14}

{15}

2 Theory of Operation

1505-1018-000 10/04 2-7

2.1.2 Expiratory circuit At the expiratory side of the ventilator, a solenoid powered exhalation valve

{16} controls exhaust from the breathing circuit. The valve contains an

elastomer diaphragm that is held against a rigid seat by a solenoid (voice coil)

driven piston. The valve achieves a balance between the pressure generated

within its 21-mm diameter seat area and the force applied by the piston,

releasing exhalation flow as necessary to maintain balance. The proportional

solenoid controls the exhalation sealing pressure within a range of 0 to 100

cm H

2

O. Software control provides continuous oscillatory movement

(dithering) of the exhalation valve to minimize static friction effects.

Immediately upstream of the exhalation valve is a tap for the expiratory

pressure transducer {17} and its associated zeroing valve. The expiratory

pressure tap is continuously purged with 35 ml/min of air to ensure that

exhaled condensate does not occlude the tap. The air flow is established from

the regulated Air supply using a fixed orifice (pneumatic resistor) {18}.

Downstream of the exhalation valve is the expiratory flow transducer {19}. In

principle, the transducer is similar to a hot-wire anemometer. A wire having a

large “temperature to electrical resistance” relationship is placed in the

flowstream. The wire is kept at a constant temperature using a Wheatstone

bridge circuit. The current necessary to maintain the resistance of the sensor

portion of the bridge is a function of the flow through the sensor.

At the output of the flow sensor is a flapper type check valve {20} that

prevents gas from being drawn in through the expiratory valve and minimizes

patient rebreathing in the event of a ventilator failure.

O

2

Safety

Tot al Flow

Inspiratory

Effort

Valv e

P

22 / 15 mm

Male / Female

Pneumatic

Resistor

O2 Sensor

Inspiratory Zero

Valv e

Inspiratory Pressure

Micropump

Nebulizer

Patient

H

30 mm Male Cone

22 / 15 mm

Male / Female

Exhalation

Valv e

Exhalation

Flow Sensor

Pneumatic

Resistor

Expiratory Zero

Valv e

Expiratory Pressure

EXP

INSP

P

H

T

{16}

Air

{17}

{18}

{19}

{20}

Patient

From

To

Engström Ventilator

2-8 10/04 1505-1018-000

2.1.3 Associated circuits Associated with the inspiratory and expiratory pressure transducers are two

“zeroing” solenoid valves {21} and {22}. These valves are used to disconnect

the pressure transducers from circuit pressure and vent them to atmosphere

during zero bias calibration. This zeroing procedure is conducted routinely

(every 12 hours) under the control of the Vent Engine software.

A third (auxiliary) pressure channel {23} is used to measure additional patient

“airway” pressures at the discretion of the clinician. This port could be used to

measure circuit pressure directly at the airway, laryngeal cuff pressures or

pressures lower in the airway tract. The transducer circuit includes a valve {24}

to provide a 35 ml/min purge flow as required by the particular clinical

application. For example, in measuring airway pressure at the endotracheal

tube the purge would most likely be turned on, but for measuring laryngeal

cuff pressures (closed system) the purge would be turned off. The purge flow

is established from the regulated Air supply using a fixed orifice (pneumatic

resistor) {25}. The relief valve {26} limits pressure in the auxiliary channel to

less than 230 cm H

2

O.

2.1.4 Electronic

micropump nebulizer

The Aeroneb Professional Nebulizer System (Aeroneb Pro) by Aerogen, Inc.

{27} is integrated into the EV. This nebulizer is electrically connected to the EV

and uses proprietary technology to produce a fine-droplet, low-velocity

aerosolized drug delivered into the breathing circuit.

The Aeroneb Pro is designed to operate in-line with standard ventilator

circuits and mechanical ventilators. It operates without changing the patient

ventilator parameters.

Air

O

2

25 psi

172 kPa

25 psi

172 kPa

Safety

Relief Valve

Flow

Sensor

Flow

Sensor

O

2

Tota l Flow

Inspiratory

Effort

Valve

Free Breathing

Check Valve

H

T

H

T

P

22 / 15 mm

Male / Female

Auxiliary Pressure

Purge Valve

Pneumatic

Resistor

O2 Sensor

Inspiratory Zero

Valve

Auxiliary Pressure

Transducer

Inlet

Filter

High Pressure

Transducer

Primary

Inlet

Check

Valve

Regulator

Inspiratory Pressure

Flow

Valve

Regulator

Flow

Valve

Check

Valve

High Pressure

Transducer

Inlet

Filter

Primary

Inlet

Relief

Valve

Test

Port

Test

Port

Micropump

Nebulizer

P

a

tie

n

t

H

30 mm Male Cone

22 / 15 mm

Male / Female

Exhalation

Valve

Exhalation

Flow Sensor

Pneumatic

Resistor

Expiratory Zero

Valve

Expiratory Pressure

EXP

INSP

1/8,3/16, 1/4 inch Stepped Hose Barb

P

P

P

P

H

T

Paux

{21}

{22}

{23}

{24}

{26}

{25}

{27}

Loading...

Loading...