Page 1

Datex-Ohmeda

S/5™ Anesthesia Monitor, S/5™ Critical Care Monitor

Planned Maintenance Instructions

Datex-Ohmeda Inc.

3030 Ohmeda Drive

53707-7550 MADISON, WIS

USA

Tel. +1-608-221 1551 Fax +1-608-2229147

www.us.datex-ohmeda.com

All specifications are subject to change without notice.

Document No. 8002949 - 0

June 2001

Datex-Ohmeda Division,

Instrumentarium Corp.

P.O. Box 900, FIN-00031

DATEX-OHMEDA, FINLAND

Tel. +358 10 394 11 Fax +358 9 146 3310

www.datex-ohmeda.com

Instrumentarium Corp. All rights reserved.

Page 2

Page 3

Table of contents

TABLE OF CONTENTS

PLANNED MAINTENANCE for S/5 AM and S/5 CCM

TABLE OF CONTENTS i

1 Introduction 1

1.1 About planned maintenance.....................................................................................................................1

1.2 Recommended tools.................................................................................................................................2

1.3 Recommended parts................................................................................................................................3

1.4 Planned maintenance parts......................................................................................................................3

1.4.1 PM parts for Airway Modules, G-XXXXX...............................................................................................3

1.4.2 PM parts for Compact Airway Modules, M-XXXXXX without CO2 absorber - Anesthesia.........................3

1.4.3 PM parts for Compact Airway Modules, M-XXXXXX without CO2 absorber - Critical Care.......................4

1.4.4 PM parts for Compact Airway Modules, M-XXXXXX with CO2 absorber - Anesthesia.............................4

1.4.5 PM parts for Compact Airway Modules, M-XXXXXX with CO2 absorber - Critical Care............................4

2 Planned maintenance checklist 6

2.1 Visual inspection/preparation...................................................................................................................6

2.1.1 General............................................................................................................................................6

2.1.2 Extension Frame, F-EXT4...................................................................................................................7

2.1.3 Airway Module, G-XXXXX...................................................................................................................7

2.1.4 Compact Airway Module, M-CXXXXX..................................................................................................8

2.1.5 Tonometry Module............................................................................................................................9

2.1.6 Recorder module..............................................................................................................................9

2.1.7 Modules with NIBP measurement......................................................................................................9

2.2 Functional Inspection..............................................................................................................................10

2.2.1 General..........................................................................................................................................10

2.2.2 Display(s).......................................................................................................................................12

2.2.3 Keyboard(s) ...................................................................................................................................12

2.2.4 8-Module Frame, F-CU8.................................................................................................................12

2.2.5 Extension Frame, F-EXT4.................................................................................................................13

2.2.6 Airway Module, G-XXXX...................................................................................................................13

For Airway Modules containing the Agent identification option..................................................................14

For Airway Modules containing the Patient Spirometry option....................................................................14

For all Airway Modules, G-XXXX................................................................................................................15

2.2.7 Compact Airway Module.................................................................................................................15

Compact Airway Modules w/ the Anesthesia Agent option........................................................................16

Compact Airway Modules w/ the Patient Spirometry option......................................................................16

For all Compact Airway Modules..............................................................................................................16

2.2.8 Tonometry Module, M-TONO...........................................................................................................17

2.2.9 Hemodynamic Modules..................................................................................................................17

ECG and RESP measurements.................................................................................................................17

Modules w/ temperature measurement...................................................................................................18

Modules w/ invasive blood pressure measurement..................................................................................19

i

Document No. 8002949

Page 4

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

Modules w/ SpO

measurement.............................................................................................................19

2

Modules w/ non invasive blood pressure measurement...........................................................................19

2.2.10 EEG Module, M-EEG and EEG Headbox, N-EEG ...........................................................................20

2.2.11 Pressure/Pressure Temp Modules, M-P/-PT................................................................................21

Invasive blood pressure measurement.....................................................................................................21

Modules w/ temperature measurement...................................................................................................21

2.2.12 Dual pressure Module, M-PP......................................................................................................21

2.2.13 Cardiac Output Modules, M-COP/-COPSv...................................................................................22

Invasive blood pressure measurement.....................................................................................................22

SvO

measurement.................................................................................................................................22

2

Cardiac Output measurement.................................................................................................................23

2.2.14 NIBP module, M-NIBP................................................................................................................23

2.2.15 NeuroMuscular Module, M-NMT.................................................................................................24

2.2.16 Nellcor Compatible Saturation module, M-NSAT..........................................................................24

2.2.17 Datex-Ohmeda Oxygen Saturation module, M-OSAT....................................................................25

2.2.18 Memory Module, M-MEM...........................................................................................................25

2.2.19 Recorder Module, M-REC...........................................................................................................26

2.2.20 Network Board, B-NET and UPINET board, B-UPI4NET..................................................................26

2.2.21 Interface Board/Module, B-INT/M-INT........................................................................................26

2.2.22 Device Interfacing Solution, N-DISxxx..........................................................................................27

2.2.23 General.....................................................................................................................................27

APPENDIX A

29

Planned Maintenance Check Form A-1

ii

Document No. 8002949

Page 5

1 INTRODUCTION

1.1 About planned maintenance

These instructions include procedures for a planned maintenance (PM) for Datex-Ohmeda S/5

Anesthesia Monitor and S/5 Critical Care Monitor. The Planned maintenance should be performed

once a year.

Planned maintenance instructions

These instructions include a Check Form

corresponding procedures.

The symbol

check form.

The procedures should be performed in ascending order, bypassing those that are not applicable

for a particular monitor.

If you need further information how to perform a certain PM procedure, please refer to the

corresponding slot in the Product Service Guide in the Technical Reference Manual.

All menu selections related to

e.g.

As you enter the service menus, you need following passwords:

Monitor Setup

In case you evaluate the measurement accuracy with a patient simulator, add simulator’s accuracy

specification to the one of the monitor.

The procedures are designed for monitors with S/5 monitor software L-ANE01(A) or L-ICU01(A).

However, most of the procedures also apply to monitors with older monitor software.

? in the instructions means that the performed procedure should be signed in the

Parameters - More... - TONO

- Install/Service

(APPENDIX A)

Datex-Ohmeda products are written in following typeface:

(password 16-4-34) -

to be filled in when performing th e

Service

(password 26-23-8)

Document No. 8002949

1

Page 6

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

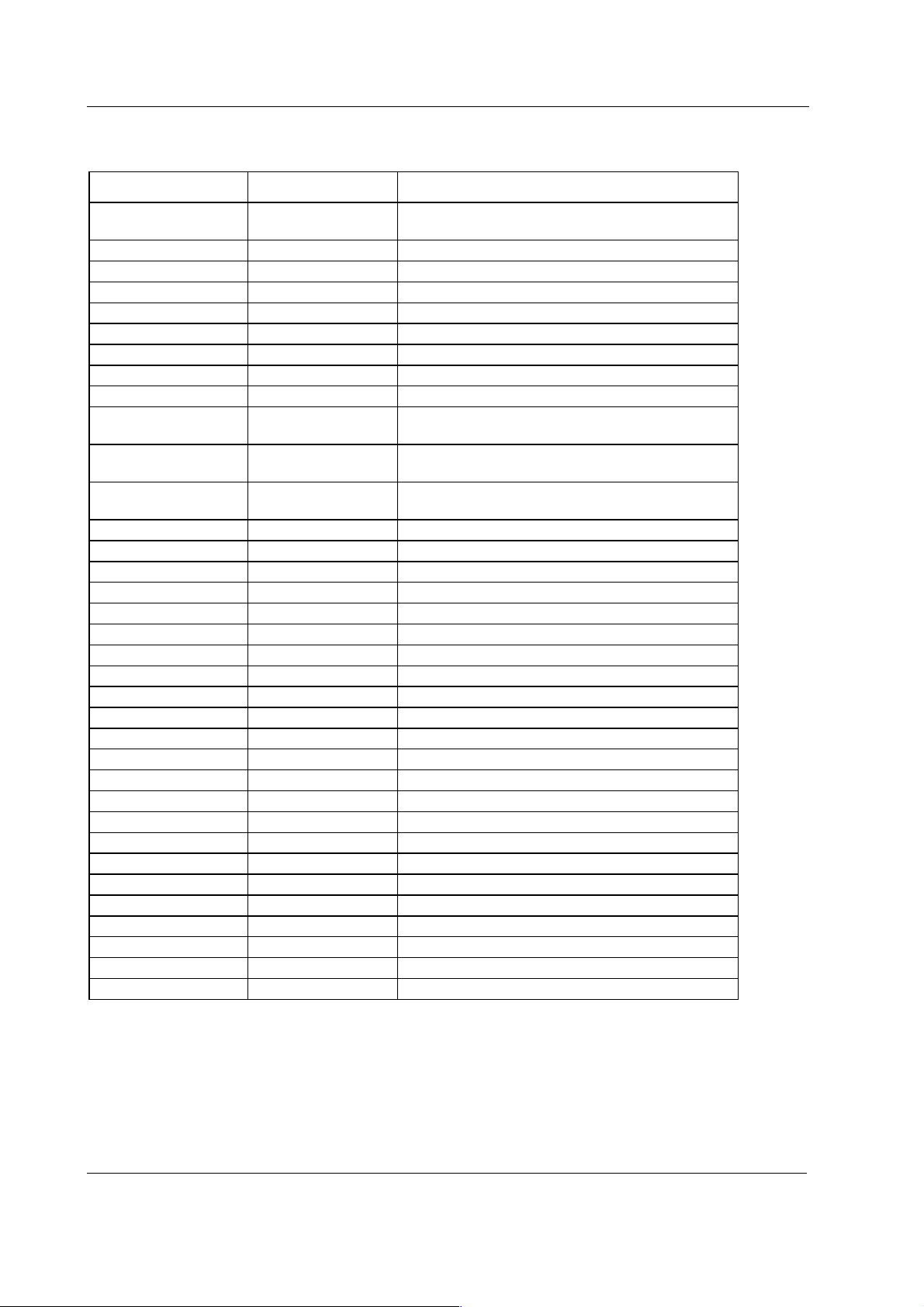

1.2 Recommended tools

Tool Order No. For product(s)

Calibration gas and

regulator

Sampling line 733251 Tonometry Module, M-TONO

TonometricsTM catheter Tonometry Module, M-TONO

Luer plug - Tonometry Module, M-TONO

Pressure manometer - Tonometry Module, M-TONO

Earphones - EEG Module, M-EEG

EEG simulator 90502 EEG Module, M-EEG

Flowmeter - All Airway modules

Calibration gas 755582 Airway Module, G-XXXXX

Calibration gas and

regulator

Calibration gas and

regulator

Calibration gas and

regulator

Sampling line 3.0 m 73319 All Airway modules

Sampling line 2.0 m 73318 Compact Airway Module, M-COVX/M-CAiOVX

Spirometry tube 884101 All Airway modules w/ (V)

D-lite 733950 All Airway modules w/ (V)

Patient simulator - Hemodynamic modules

Pressure manometer - Hemodynamic modules w/ (P), M-NIBP, M-TONO

Temperature test set 884515 Hemodynamic modules w/ (T)

3-lead ECG trunk cable - Hemodynamic modules w/ (E)

5-lead ECG cable - Hemodynamic modules w/ (E)

10-leadwire ECG cable Hemodynamic modules w/ (E12)

SpO2 finger probe SAS-F4 Hemodynamic modules w/ (S)

InvBP transducer - Hemodynamic modules w/ (P)

Adult NIBP cuff 572435 Hemodynamic modules w/ (NIBP)

Adult NIBP hose 877235 Hemodynamic modules w/ (NIBP)

SvO2 simulator 890121 M-COPSv

C.O. Catheter cable 16590 M-COP/COPSv

NMT simulator 871251 M-NMT

M-NMT ElectroSensor 888416 M-NMT

M-NMT sensor cable 888415 M-NMT

Nellcor SpO2 probe - M-NSAT

MemCard – Menu - M-MEM

MemCard – Data - M-MEM

Screwdriver - All

755580/755534 Tonometry Module, M-TONO

755583/755533 Compact Airway Module, M-CAiO(VX)

755587/755530 Compact Airway Module, M-COVX

755581/755533 Compact Airway Module, M-C, M-CO(V)

2

Document No. 8002949

Page 7

1.3 Recommended parts

Part Order No. For product(s)

Nafion tube 733382 Tonometry Module, M-TONO

Fan filter 871558 Central Unit, F-CU8

Fan filter 874594 Extension Frame, F-EXT4

Recorder paper 74205 M-REC

1.4 Planned maintenance parts

1.4.1 PM parts for Airway Modules, G-XXXXX

Part Order No. For product(s)

Special tube 733383 Airway Modules, G-XXXXX

Special tube 733382 All Airway modules

OM ref. Filter 86901 Airway Modules, G-XXXXX

Fan filter 871558 Airway Modules, G-XXXXX

Cable tie 64001 Airway Modules, G-XXXXX

D-fend O-ring (2 pcs) 65312 All Airway modules

D-fend (black) 876445 All Airway modules

Sampling line 3.0 m 73319 All Airway modules

PM sticker 893108 All Airway modules

Planned maintenance instructions

NOTE: Corresponding PM kit is available with Order No. 8001762.

1.4.2 PM parts for Compact Airway Modules, M-XXXXXX without CO2 absorber

- Anesthesia

Part Order No. For product(s)

Special tube 733382 All Airway modules

Ref. gas sticker 893110 Compact Airway Modules

Filter (2 pcs) 886136 Compact Airway Modules

Filter assembly 896025 Compact Airway Modules

Fan filter 886236 Compact Airway Modules

D-fend O-ring (2 pcs) 65312 All Airway modules

D-fend (black) 876445 All Airway modules

Sampling line 2.0 m 73318 Compact Airway Modules

PM sticker 893108 All Airway modules

NOTE: Corresponding PM kit is available with Order No. 8001758.

3

Document No. 8002949

Page 8

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

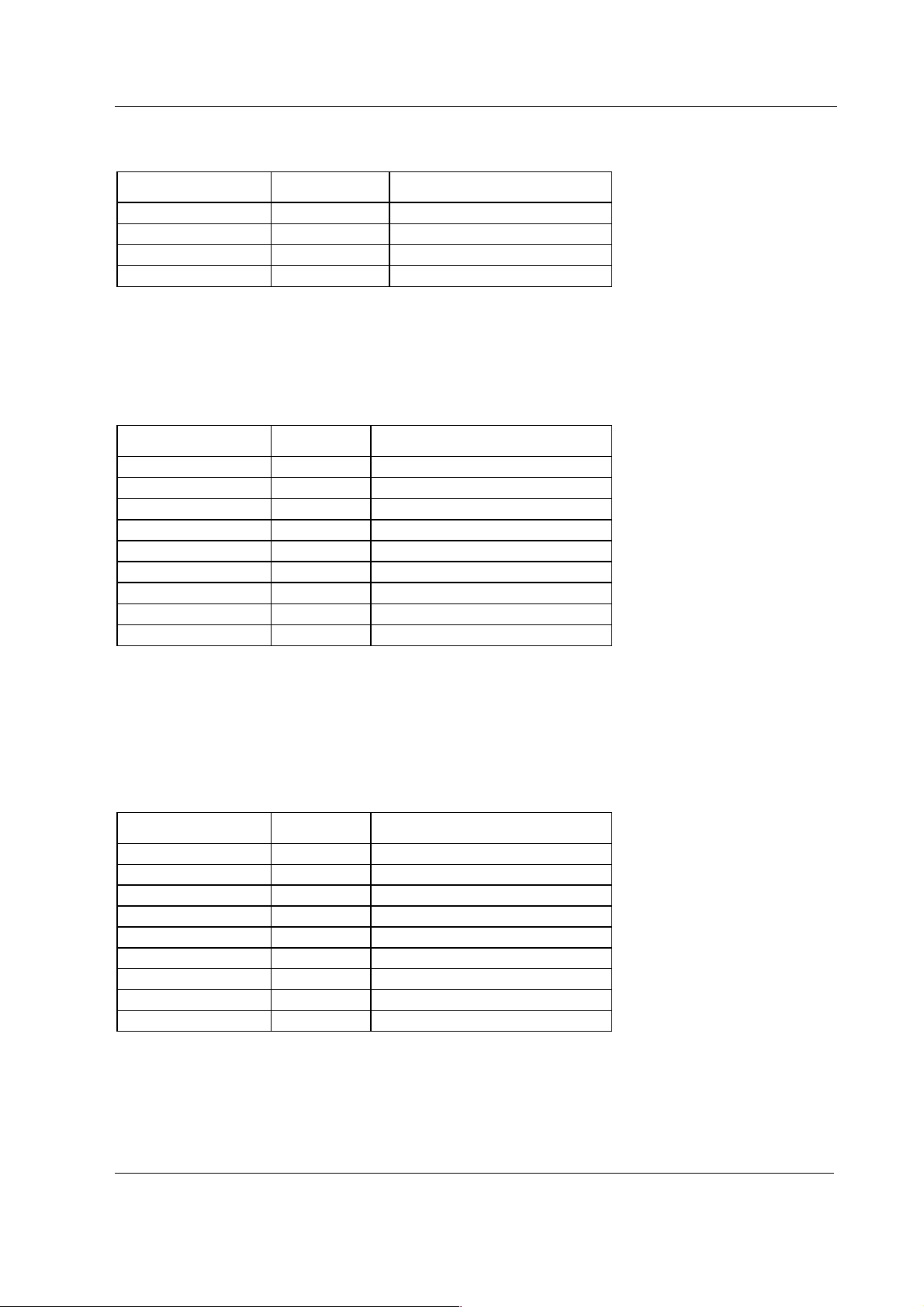

1.4.3 PM parts for Compact Airway Modules, M-XXXXXX without CO2 absorber

- Critical Care

Part Order No. For product(s)

Special tube 733382 All Airway modules

Ref. gas sticker 893110 Compact Airway Modules

Filter (2 pcs) 886136 Compact Airway Modules

Filter assembly 896025 Compact Airway Modules

Fan filter 886236 Compact Airway Modules

D-fend O-ring (2 pcs) 65312 All Airway modules

D-fend+ (green) 893200 All Airway modules

Sampling line 2.0 m 733162 Compact Airway Module, M-COVX

PM sticker 893108 All Airway modules

NOTE: Corresponding PM kit is available with Order No. 8001759.

1.4.4 PM parts for Compact Airway Modules, M-XXXXXX with CO2 absorber

- Anesthesia

Part Order No. For product(s)

Special tube (2 pcs) 733382 All Airway modules

Ref. gas sticker 893110 Compact Airway Modules

Filter (2 pcs) 886136 Compact Airway Modules

Filter assembly 896025 Compact Airway Modules

Fan filter 886236 Compact Airway Modules

D-fend O-ring (2 pcs) 65312 All Airway modules

D-fend (black) 876445 All Airway modules

Sampling line 2.0 m 73318 Compact Airway Modules

PM sticker 893108 All Airway modules

NOTE: Corresponding PM kit is available with Order No. 8001760.

1.4.5 PM parts for Compact Airway Modules, M-XXXXXX with CO2 absorber

- Critical Care

Part Order No. For product(s)

Special tube (2 pcs) 733382 All Airway modules

Ref. gas sticker 893110 Compact Airway Modules

Filter (2 pcs) 886136 Compact Airway Modules

Filter assembly 896025 Compact Airway Modules

Fan filter 886236 Compact Airway Modules

D-fend O-ring (2 pcs) 65312 All Airway modules

4

Document No. 8002949

Page 9

D-fend+ (green) 893200 All Airway modules

Sampling line 2.0 m 733162 Compact Airway Module, M-COVX

PM sticker 893108 All Airway modules

NOTE: Corresponding PM kit is available with Order No. 8001761.

Planned maintenance instructions

5

Document No. 8002949

Page 10

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

2 PLANNED MAINTENANCE CHECKLIST

2.1 Visual inspection/preparation

2.1.1 General

NOTE: Wear a static control wrist strap when handling PC boards. Electrostatic discharge may

damage components on the board.

• Make sure that the monitor is switched to standby.

Disconnect the mains power cord from the 8-Module Frame, F-CU8. If the monitor is

connected to the Datex-Ohmeda network, disconnect the Mon-Net cable from the Network

Board, B-NET or UPI4NET board, B-UPI4NET. If the Memory Module, M-MEM is connected,

remove any memory cards.

1. Check all units visually. Check e.g. that all parts are intact, the cables and screws are

connected and tightened properly.

Especially check the following parts:

Video displays : the display power cord is locked to the display.

F-CU8: the equipotential tap and all the screws are tightened properly.

Airway Module, G-XXXXX: the equipotential tap is tightened properly.

Check that modules go in smoothly and lock up properly in all module slots.

2. The lead-acid battery in the power supply unit is recommend to be replaced after every 4

years. Replace the battery, if necessary.

The SRAM/Timekeeper battery on the CPU board is recommend to be replaced after every 8

years. Replace the battery, if necessary.

NOTE: The Factory Reset should be performed if the SRAM/Timekeeper battery, or the

SRAM/Timekeeper chip is replaced.

3. Clean or replace the F-CU8 fan filter.

6

Document No. 8002949

4. Check that the fuses are of the correct rating.

?

Page 11

2.1.2 Extension Frame, F-EXT4

1. If the F-EXT4 contains a fan, clean or replace the fan filter.

?

2.1.3 Airway Module, G-XXXXX

1. Remove the Airway Module case, the top protection cover and the bronze plate from the

side of the O2 sensor, if installed.

Detach the PVX board with the support plate, if installed, and leave the board detached

until further notice.

Check that all cables and tubes are connected properly and there are no loose objects

inside the module.

NOTE: Make sure that none of the tubes are in contact with the sampling pump or with the

O2 sensor.

Planned maintenance instructions

2. Install the PM Kit

Replace the special tubes (Nafion™).

Replace or install the OM ref. filter, order code 86901.

Check the D-fend O-rings and replace them, if necessary

Replace the D-fend and the sampling lin e.

Clean or replace the fan filter.

NOTE: Use only Datex-Ohmeda sampling lines to ensure proper functioning.

3. The CO

necessary.

absorber is recommend to be replaced after every 4 years. Replace the absorber, if

2

?

Connect the Airway Module to the F-CU8 with a long gas interface cable.

7

Document No. 8002949

Page 12

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

2.1.4 Compact Airway Module, M-CXXXXX

1. Detach the module box.

Check that all cables and tubes are connected properly and there are no loose objects

inside the module.

NOTE: The tubes connected to the Oxygen board pressure transducers should not be

pressed too deep.

NOTE: Make sure that tubes are not in contact with the sampling pump or the O

its springs.

2. Install the PM Kit:

Replace the special tubes (Nafion™).

Replace the Ref. filter assembly.

Replace the filters in the pneum atic unit (2 pcs).

Check the D-fend O-rings and replace them, if necessary.

Replace the D-fend and sampling line.

Clean or replace the fan filter.

NOTE: Use only Datex-Ohmeda sampling lines to ensure proper functioning.

Use a 2 m/7 ft sampling line with Compact Airway Modules M-COVX and M-CAiOVX.

3. The CO

necessary.

Note: All Compact Airway Modules do not contain a CO

absorber is recommend to be replaced after every 4 years. Replace the absorber if

2

absorber.

2

?

sensor, or

2

8

Document No. 8002949

Connect the Compact Airway Module to one of the F-CU8 module slots with a long gas

interface cable (the grounding plates of the cable should be removed).

Page 13

2.1.5 Tonometry Module

1. Detach the module box.

Check that all cables and tubes are connected properly and there are no loose objects

inside the module.

2. Replace the special tube (Nafion™)

Reattach the module box and check that the latch moves properly. Plug the module back

into the F-CU8.

?

2.1.6 Recorder module

1. Clean the Recorder Module, M-REC.

Open the paper compartment hatch and remove the paper roll, if installed.

Remove any paper chaff from the paper compartment.

Planned maintenance instructions

Clean the thermal printhead and the small glass window in front of the static brush with a

cotton swab dipped in isopropyl alcohol, if necessary.

NOTE: Avoid contact with the rubber paper roller. Be careful to limit the application of

alcohol to the thermal printhead and the window.

Reinstall the paper roll.

?

2.1.7 Modules with NIBP measurement

1. Check the NIBP pump filter. Replace the filter, if necessary.

Note: M-NIBP Rev. 00-03 do not contain a NIBP pump filter.

Plug the module back into the frame.

?

9

Document No. 8002949

Page 14

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

2.2 Functional Inspection

2.2.1 General

1. Connect the mains power cord to the F-CU8.

Check that the stand-by LED is lit.

2. Switch the monitor on.

Check that the monitor starts up properly, i.e. the alarm LEDs turn on and off, normal start-

up sound is heard from the loudspeaker and monitoring screen appears.

No error messages should appear onto the screen.

3. Check that all of the connected modules are recognized, i.e. the required parameter

information is shown on the screen.

If the Recorder Module, M-REC, is connected, the module should record two lines of startup information.

Preset measurement settings for those parameters that are connected are, for example:

Others

Others

Others

Others

Others -

- EEG - Montage - EEG Channels - 4

- EEG - Montage - Montage type - Bip

- EEG - EEG Setup - Numeric 1 - MF

- EEG - EEG Setup - Numeric 2 - Ampl.

EP - Cycle - Cont.

- EP - AEP Setup - AEP Channels - 2

- EP - AEP Setup - Responses -100

- EP - AEP Setup - Stim. Frequency - 1.1Hz

- EP - AEP Setup - Stim. Intensity - 90 dB

- EP - AEP Setup - Sweep length - 100 ms

- EP - EP size - 1

Recorder

- Record Waveforms - Waveform 1 - ECG1

- Waveform 2 - P1

- Waveform 3 - P2

Invasive Pressures

- P1 ‘ART’ Setup - Label - ART

P2 ‘CVP’ Setup - Label - CVP

-

- P3 Setup - Label - PA

- P4 Setup - Label - P4

- P5 Setup - Label - P5

- P6 Setup - Label - P6

10

Document No. 8002949

Page 15

Planned maintenance instructions

Pulse Oximetry

or

Others

Airway Gas

or

Ventil.

Others

Others

or

- SPO2 Setup - Pleth Scale - AUTO

- Spirometry View - Scaling - Indep

- Spirometry Setup - Scaling - Indep

- C.O. View - C.O. Setup - Scale - 1.0 °C

- SvO2 - Update HGB - 115 g/l

- Pleth Scale - AUTO

- Paw Scale - 20

- Flow Scale - 15

- Paw Scale - 20

- Flow Scale - 15

- Injectate Volume - 10 ml

- Measurement Mode - SET

.

.

Wedge C.O: SVO2 -

Wedge C.O: SVO2

Others -

NMT - Stimulus Mode - TOF

- Set Cycle Time - 10 sec

Others

Others

- NMT -NMT Setup - Current - s(70mA)

-

Resp Setup - Size - 1.0

C.O. View - C.O. Setup - Scale - 1.0 °C

- Injectate Volume - 10 ml

- Measurement Mode - SET

- SvO2 - Update HGB - 115 g/l

- Pulse Width - 200 µµµµs

- Stim. Beep Volume - 2

- Resp Rate Source - AUTO

- Measurement - ON

- Detection Limit - AUTO

11

Document No. 8002949

Page 16

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

2.2.2 Disp lay(s)

1. Check that the pictur e on the screen is adjusted correct ly. Readjust the picture with the

adjustment knobs or with the display menu keys, if necessary.

?

2.2.3 Keyboard(s)

1. Tests with the Command Bar / Command Board:

Press the

menu moves correspondingly. Highlight

that the menu disappears from the screen.

Check the rest of the menu keys by pressing them one by one.

Tests with the ARK Keyboard:

Enter the

Check functioning of the ComWheel.

Press all keys, except

loudspeaker, or the ‘Message count’ value in the service menu increases.

Press the Modify and Print keys and check that the corresponding menus appear on the

monitor screen.

Tests with the Remote Controller:

Enter the

Check functioning of the ComWheel.

Press all keys. Check that each key produces a sound from the loudspeaker, or the

‘Message count’ value in the service menu increases.

Help key. Turn the ComWheel in both directions and check that the cursor in the

Keyboard

Keyboard

Normal Screen

service menu

Modify and Print. Check that each key produces a sound from the

service menu

, press the ComWheel and check

?

2.2.4 8-Module Frame, F-CU8

1. Check that the fan is running.

2. Check that the clock on the screen shows correct time.

Readjust the time and date, if necessary.

3. Enter the

Check the content of the Service Log for possible problems.

Service Log

?

12

Document No. 8002949

service menu.

Page 17

2.2.5 Extension Frame, F-EXT4

1. If the F-EXT4 contains a fan, check that the fan is running.

2. Check that the modules in the F-EXT4 are recogn ized, i.e. the required parameter

information is shown on the monitor screen.

Disconnect the Extension Module, M-EXT shortly, then reconnect the module back into the

F-CU8.

Check that the modules in t he F-EXT4 are still recognized.

?

2.2.6 Airway Module, G-XXXX

1. Check that the Airway Module fan is running.

2. Wait until the message ‘Calibrating gas sensor’ disappears from the screen, then enter the

ACX

service menu.

Planned maintenance instructions

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ -values are not increasing

faster than by 50 per second.

3. If the module contains a membrane key on the front panel, press the key for at least one

second and check that it is identified.

4. Check that the ‘Calib zero’ value for N2O is less than 61000.

5. Check that the ‘Ambient’ value corresponds with the current ambient pressure

(±20 mmHg).

6. Check the CO

Keep the tip of the sampling line away from you and let the monitor draw in room air. Check

that the ‘Insp CO

7. Perform a sampling system leak test.

8. Block the tip of the sampling line with your finger until the ‘Amb-Work’ value becomes

stable. Check that the value reaches 110.

absorber.

2

’ value on the

2

ACX

service menu is higher than 3.

9. Check the flow rates and adjust them, if necessary.

NOTE: If any of the constriction cassettes is replaced, the leak test should be repeated.

13

Document No. 8002949

Page 18

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

10. Perform a gas calibration:

NOTE: For maximum accuracy, a warm-up time of 30 minutes is recommended.

NOTE: If the module contains the agent identification unit, ASX-100 or ASX-200, keep

feeding gas at least 15 seconds after the message ‘Adjust’ appears on the menu. This gives

the agent identification unit enough time for calibration.

11. Switch the monitor to standby.

Install the PVX board, if inst alled originally, and reassemble the module.

Connect the Airway Module to the F-CU8 with the original gas interface cable.

Switch the monitor back on and wait until the message ‘Calibrating gas sensor’ disappears

from the screen.

?

For Airway Modules containing the Agent identification option

12. Enter the

Feed calibration gas. When a proper absorption spectrum is shown in the menu check that

the module identifies the gas and the ‘Peak normal’ value is close to 10.50 ( ±0.20). Check

also that the difference between the displayed ‘Peak normal’ and ‘Peak mirror’ values is not

greater than 0.30.

NOTE: The ASX-100 is not capable of identifying all calibration gases. The

menu values are not updated with the ASX-100.

ASX

service menu:

?

For Airway Modules containing the Patient Spirometry option

13. Connect a clean spirometry tube and D-lite to the module.

Perform the spirometry tubing leak test.

14. Connect the sampling line to the D-lite. Breathe through the wider side of the D-lite. Check

that the flow waveform moves downwards when you breathe in, and upwards when you

breathe out.

ASX

service

14

Document No. 8002949

?

Page 19

For all Airway Modules, G-XXXX

15. Block the tip of the sampling line with your finger and check that the message ‘Sample line

blocked’ appears onto the monitor screen within 30 seconds.

16. Remove the D-fend and check that the message ‘Check D-fend’ appears on the screen

within 30 seconds.

?

2.2.7 Compact Airway Module

1. Check that the fan is running.

2. If the module contains membrane keys on the front panel, press each of the keys for at least

one second and check that their are identified.

NOTE: The Compact Airway Module membrane keys require S/5 main software.

Planned maintenance instructions

3. Wait until the message ‘Calibrating gas sensor’ disappears from the screen, then enter the

Compact Airway Module

Check that the module configuration displayed corresponds with the Compact Airway

Module type being used.

4. Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ values are not increasing

faster than by 50 per second.

5. Enter the

the current ambient pressure (±20 mmHg).

6. Check that the flow measurement offset, i.e. the sample ‘Zero’ value displayed is within ±10

ml/min.

7. Perform a sampling system leak test.

8. Check the flow rates. Adjust the sampling flow, if necessary.

9. Perform a gas calibration:

Gases

General

service menu: Check that t he ‘Ambient’ value displayed corresponds with

service menu.

NOTE: For maximum accuracy, a warm-up time of 30 minutes is recommended.

NOTE: For correct measurement values, modules need different amounts of oxygen in the

calibration. If you do not use the recommended calibration gases, the calibration does not

succeed.

?

15

Document No. 8002949

Page 20

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

Compact Airway Modules w/ the Anesthesia Agent option

10. Enter the

Feed calibration gas (order code 755583) continuously for at least for 30 seconds and

check that the ‘ID’ in the service menu shows ‘DES’ and that the value for ‘ID unrel.’ is lower

than 50.

Gases

service menu.

?

Compact Airway Modules w/ the Patient Spirometry option

11. Enter the

Connect a clean spirometry tube and D-lite to the module.

Perform spirometry leak test.

12. Connect the sampling line. Breath through the wider side of the D-lite. Check that the flow

waveform moves downwards when you breathe in, and upwards when you breathe out.

Spirometry

service menu.

?

For all Compact Airway Modules

• Switch the monitor to standby and reassemble the module.

NOTE: Attach the plastic cover to the CPU Board before fitting the module box. Make sure

that the grounding claws in the front panel frame make good contact with the module box.

NOTE: When reassembling the module make sure that the tubes are not pinched between

the module box and internal parts.

Install the Compact Airway Module into the F-CU8. Switch the monitor back on and wait

until the message ‘Calibrating gas sensor’ disappears from the screen.

13. Block the tip of the sampling line with your finger and check that the message ‘Sample line

blocked’ appears on the monitor screen within 30 seconds.

14. Detach the D-fend and check that the messages ‘Check D-fend’ appears on the monitor

screen within 30 seconds.

?

16

Document No. 8002949

Page 21

2.2.8 Tonometry Module, M-TONO

Planned maintenance instructions

1. Enter the

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ values are not increasing

faster than by 50 per second.

Check that the memories of the module have passed the internal memory test, i.e. ‘RAM’,

‘ROM’ and ‘EEPROM’ all state OK.

Check that the ‘general error status’, ‘module pneumatics error status’, ‘module hardware

error status’ and ‘testbit status’ are all zero.

2. Check functioning of the front panel

3. Perform the pressure sensor calibration.

4. Perform the system test.

5. Perform the gas calibration.

6. Connect the catheter to the module. Start measurement by pressing the

the module. Check that th e catheter fills up.

TONO

service menu:

Start-Stop and Lab Data membrane keys.

Start-Stop key on

Stop the measurement by pressing the

on the digit field.

?

2.2.9 Hemodynamic Modules

ECG and RESP measurements

1. Enter the

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ values are not increasing

faster than by 50 per second. Check that the ECG/RESP board memories have passed the

internal memory test, i.e. ‘RAM’, ‘ROM’ and ‘EEPROM’ a ll state OK.

2. Check the front panel membrane key ECG LEAD, if available.

3. Check that the ‘Power Freq’ value is set according to the mains power frequency. Correct the

setting, if necessary.

ESTP : ECG

Start-Stop key. Check that Meas. Off text appears

service menu.

4. Connect a 3-lead ECG trunk cable without a lead set to the module. Check that the

message "Leads off" is displayed on the screen.

Document No. 8002949

17

Page 22

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

5. @ M-ESTPR, M-ETPR , M-ESTR, M-NESTPR, M-NETPR and M-NESTR modules: connect a 5lead ECG cable to the module. Connect the cable leads to a patient simulator.

Check that the ‘Cable type’ shows 5 lead.

@ M-NE12STPR, M-NE12TPR and M-NE12STR modules: connect a 10-leadwire ECG cable

to the module. Connect the cable leads to a patient simulator . Check that the ‘Cable type’

shows 10 lead.

6. Disconnect one of the leads and check that the corresponding electrode in the service

menu shows OFF within 10 seconds from the disconnection, then reconnect the lead.

Check the rest of the leads using the same method.

NOTE: When the ground lead (black) is disconnected all the electrodes should show OFF.

NOTE: The asystole and different leads off -messages are shown using certain priority, Even

though one of the leads is disconnected, the related leads off -message may not appear

onto the screen.

NOTE: When RA, LA or LL electrode is disconnected, all V electrodes show OFF.

NOTE: With NESTPR/ESTPR type modules and 5 lead cable the state of V2, V3, V4, V5 and

V6 electrodes follow the sta te of the V electrode.

7. Check that all ECG and impedance respiration information is shown on the monitor screen

as configured on the simulator.

Check that the pacer count value in the service menu is shown according the simulator

configuration.

Change baseline impedance on the simulator and check that appropriate RESP waveform

and RR -value are shown again within 30 seconds.

Turn the simulator off. Check that the ‘Asystole’ and ‘Apnea” messages are displayed.

?

Modules w/ temperature measurement

8. Enter the

ESTP : STP

service menu.

18

Document No. 8002949

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ values are not increasing

faster than by 50 per second. Check that the STP board memories have passed the internal

memory test, i.e. ‘RAM’, ‘ROM’ and ‘EEPROM’ all show OK.

9. Check the temperature measurement calibration using temperature test plugs.

Page 23

NOTE: Make sure that the protection for temperature calibration is set on.

?

Modules w/ invasive blood pressure measurem ent

10. Check functioning of the front panel membrane keys.

11. Check the InvBP channels with a patient simulator.

Zero the InvBP channels, then check that the values and waveforms correspond to the

simulator settings.

?

Planned maintenance instructions

Modules w/ SpO2 measurement Check that the message ‘No probe’ is shown when no SpO

connected.

Connect SpO

when the probe is not connected to a finger.

13. Attach the SpO

appear onto the screen.

finger probe to the module. Check that the message ‘Probe off’ is shown

2

probe to your finger. Check that a reading of 95-99 and a pleth waveform

2

?

Modules w/ non invasive blood pressure measurem ent

14. Enter the

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ values are not increasing

faster than by 50 per second. Check that the NIBP board memories have passed the

internal memory test, i.e. ‘RAM’, ‘ROM’ and ‘EEPROM’ all sh ow

15. Check functioning the front panel membrane keys.

16. Check the NIBP tubing system for leakages by performing

NIBP

module service menu.

OK

.

Active leak test.

sensor is

2

17. Check NIBP calibration by performing

18. Enter the

Check the NIBP watchdog timer activation pressure with a pressure manometer.

19. Check the NIBP watchdog timer by performing

20. Check the safety valve by performing

21. Attach an adult NIBP cuff onto your arm and perform one NIBP measurement. Check the

module identifies the cuff, i.e. the text ‘Adult’ appears in the NIBP digit field for a short time.

Pneumatics

service menu.

Calibration Check.

Watchdog –Test Adult

Safety Valve – Adult

and

Infant.

and

Test Infant

Document No. 8002949

.

19

Page 24

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

Check that the module gives a reasonable measurement result.

?

2.2.10 EEG Module, M-EEG and EEG Headbox, N-EEG

1. Enter the

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ values in the module view

are not increasing faster than by 50 per second. Check that the memories of the module

have passed the internal memory test, i.e. ‘RAM’, ‘ROM’ and ‘EEPROM’ all state OK.

Check that the ‘HB Mod Timeouts’, ‘HB Mod Bad Checksum’ and ‘Mod HB Bad Checksum’

values are not increasing faster than by 50 per second. Check that the memory of the

headbox has passed the internal memory test, i.e. ‘HB Rom Error’ in the headbox view

states 0.

2. Check the

headbox.

3. Connect the EEG simulator to the headbox . Select 10 kΩ as imped. pos. and imped. neg.

value on the simulator. Go to

headbox view check that the impedances in all four channels are 10 kΩ ±1 kΩ.

4. Select 2 kΩ as imped. pos. and imped. neg. value on the simulator. Select 10 Hz 200 µV

sinewave on the simulator and check that all the four waveforms have same form. Check

that the size of the waveforms is 200 µV

Check that the amp value is 71 µV ±3 µV.

EEG & EP

service menu:

EP Start/Stop and Imp. Check membrane keys both in the module and the

EEG & EP

service menu and select

±5 µV. Check that the MF value is 10 ±0.5 Hz.

pp

Check Electr

. From the

20

Document No. 8002949

5. Plug in the earphones to the headbox.

NOTE: Be careful with loud stimulation from the earphones when starting AEP stimulation.

Start AEP stimulation by pressing the EP Start/Stop button on the module. Check that the

clicking sound comes from the earphones in 1.1 Hz frequency. Stop the stimulation by

pressing again the

EP Start/Stop button on the module. Check that the clicking stopped.

?

Page 25

2.2.11 Pressure/Pressure Temp Modules, M-P/-PT

Planned maintenance instructions

1. Enter the

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ values are not increasing

faster than by 50 per second. Check that the PT board memories have passed the internal

memory test, i.e. ‘RAM’, ‘ROM’ and ‘EEPROM’ all show

P/P

module service menu:

?

Invasive blood pressure measurement

2. Check the functioning of the front panel Zero P3 membrane key.

3. Check the InvBP channel with a patient simulator.

Zero the InvBP channel. Then check that the values and waveforms correspond to the

simulator settings.

?

Modules w/ temperature measurement

OK

.

4. Check the temperature measurement calibration using temperature test plugs.

NOTE: Make sure that the protection for temperature calibration is set on

?

2.2.12 Dual pressure Module, M-PP

1. Enter the PP module service menu:

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ values are not increasing

faster than by 50 per second. Check that the Dual Pressure module, M-PP, memories have

passed the internal memory test, i.e. ‘RAM’, ‘ROM’ a nd ‘EEPROM’ all show

2. Check the functioning of the front panel Zero P5 and Zero P6 membrane keys.

3. Check the InvBP channels with a patient simulator.

Zero the InvBP channels. Then check that the values and waveforms correspond to the

simulator settings.

OK

.

?

21

Document No. 8002949

Page 26

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

2.2.13 Cardiac Output Modules, M-COP/-COPSv

1. Enter the

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ values are not increasing

faster than by 50 per second. Check that the module’s memories have passed the internal

memory test, i.e. ‘RAM’, ‘ROM’ and ‘EEPROM’ all show

COP

module service menu:

?

Invasive blood pressure measurement

2. Check the functioning of the front panel membrane Zero P4 key.

3. Check the InvBP channel with a patient simulator.

Zero the InvBP channel. Then check that the values and waveforms correspond to the

simulator settings.

?

SvO2 measurement

4. Check that the SvO2 values ‘Meas. state’, ‘OM fail’ and ‘OM temp.’ in the

service menu all show

NO OM

OK

.

COP

module

.

5. Checks with the SvO

Turn the SvO

pulse’. Connect the simulator to the module and check that the following messages appear

in the digit field for SvO

Initializing, please wait > Warming up > Not calibrated

Check that ‘Meas. state’ has changed to

NOTE: The ‘OM temp.’ may show

within a half a minute.

6. Perform an In Vitro calibration with the SvO

Check that the calibration date for In Vitro calibration was updated correctly and the SvO

reading on the screen is 81% (±2%).

simulator pulsation switch to ‘Medium’ and the range switch to ‘Normal

2

simulator:

2

:

2

NORMAL

UNSTABLE

2

and ‘OM fail’ and ‘OM temp.’ show OK.

at first, but the message should change to

simulator.

?

OK

2

22

Document No. 8002949

Page 27

Cardiac Output measurement

Planned maintenance instructions

7. Enter the

Check the front panel

8. Enter the

Others

Connect a catheter connecting cable to module connector C.O.

If the module contains a C.O. Test connector (M-COP), attach the catheter connector of the

connecting cable to the C.O. Test connector. Check that the message ‘Cable OK’ appears in

the menu after the self-test.

No Catheter > Self Test in Progress > Cable OK

9. Check the C.O. measurement with a patient simulator.

?

COP

C.O. View

- C.O. View

2.2.14 NIBP module, M-NIBP

1. Enter the

NIBP

module service menu.

Start C.O. membrane key.

menu:

service menu:

Check that the Timeouts, Bad checksums and Bad c-s by mod values are not increasing

faster than by 50 per second. Check that the NIBP board memories have passed the

OK

internal memory test, i.e. ‘RAM’, ‘ROM’ and ‘EEPROM’ all sh ow

2. Check the front panel LEDs and membrane keys using the

3. Check the NIBP tubing system for leakages by performing

4. Check NIBP calibration by performing

5. Enter the

Check the NIBP watchdog timer activation pressure with a pressure manometer.

6. Check the NIBP watchdog timer by performing

7. Check the safety valve by performing

8. Attach an adult NIBP cuff onto your arm and perform one NIBP measurement. Check the

module identifies the cuff, i.e. the text ‘Adult’ appears on the NIBP digit field for a short time.

Check that the module gives a reasonable measurement result.

Pneumatics

service menu.

Calibration Check

Watchdog –Test Adult

Safety Valve – Adult

Buttons/Leds

Active leak test.

.

and

.

Infant

service menu.

and

Test Infant

.

.

?

23

Document No. 8002949

Page 28

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

2.2.15 NeuroMuscular Module, M-NMT

1. Enter the

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ values are not increasing

faster than by 50 per second. Check that the module’s memories have passed the internal

memory test, i.e. ‘RAM’, ‘ROM’ and ‘EEPROM’ all state

2. Check the functioning of the front panel membrane keys Start-Up and Stop/Continue.

3. Check that the message ‘Cable off’ is shown in the digit field and that ‘Cable’ on the service

menu states

Plug the M-NMT Sensor Cable with the M-NMT ElectroSensor into the front panel connector

NMT. Check that the message in the digit field changes to ‘Measurement OFF’ and ‘Cable’ in

the service menu states

4. Place a 3 kΩ resistor between the ElectroSensor’s stimulus electrode leads (brown and

white). Perform

Check that the test was successful, i.e. the ‘Current test (mA):’ in the menu states

OK

and

NMT

module service menu:

OFF

.

Start Curr. Test.

70 OK

.

EMG

and

ELECTR. OFF

OK

.

.

30 OK, 50

5. Connect the M-NMT ElectroSensor leads to the NMT simulator. Set the switch on the

simulator to FADE OFF and turn the knob to MAX. Check ‘Cable’ in the service menu states

EMG

now only

Start the NMT measurement (TOF) by pressing the START-UP key on the module.

Check that the found supramaximal current is less than 70 mA, i.e. the ‘Current set’ value in

the service menu is less than 700.

6. Check that the digit field ‘TOF%’ value is within 95-105, ‘Count’ is 4 and ‘T1%’ is within 95-

105.

7. Check that the ‘Noise’ value in the service menu remains under 50.

.

?

2.2.16 Nellcor Compatible Saturation module, M-NSAT

1. Enter the

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ values are not increasing

faster than by 50 per second. Check that the NSAT module’s ROM memory has passed the

internal memory test, i.e. ‘ROM’ shows

M-SAT

service menu:

OK

.

24

Document No. 8002949

Check that all three error indicators, ‘Preamp Error’, ‘QUART Error’ and ‘I/O Error’ state

NO

.

Page 29

Planned maintenance instructions

2. Check that the SpO

‘NoProbe’ should be active (1) when no probe is connected.

3. Connect a Nellcor SpO

is shown and the corresponding status information in the menu is active. Check that the

shown message changes to ‘Check probe’ within 30 seconds.

4. Attach the SpO

waveform appear.

probe related status information in the menu is correct. Only the

2

finger probe to the module. Check that the message ‘Pulse search’

2

probe on your finger. Check that a reading of 95-100 and a proper SpO

2

?

2.2.17 Datex-Ohmeda Oxygen Saturation module, M-OSAT

1. Enter the

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ values are not increasing

faster than by 50 per second. Check also that the module’s ROM memory has passed the

internal memory test, i.e. the ‘ROM’ shows

2. Check that the message ‘No probe’ is displayed on the screen when no probe is connected.

M-SAT

service menu:

OK

2

.

3. Connect a suitable SpO2 finger probe to the module. Check that the message ‘Check probe’

is displayed on the screen within 30 seconds

4. Attach the SpO

waveform appear.

?

2.2.18 Memory Module, M-MEM

1. Enter the

Check that the module is recognized properly, i.e. ‘Present’ and ‘Active’ state

2. Check that the Memory board memories and the PCMCIA controller have passed the tests.

The status for each should be

3. Select

Check that ‘Interface status’ states

bottom part of the menu are stable.

MemCards

Communication

probe on your finger. Check that a reading of 95-100 and a proper SpO

2

service menu:

YES

.

OK

.

Active

continuously and the error counter values on the

2

Status

4. Select

Insert Menu card and Data card into their slots.

.

25

Document No. 8002949

Page 30

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

Wait until the information is fully updated in the service menu then check that the Card

types are correct and the ‘File system ’ states ATA

Check that the rest of the information is reliable and no errors have bee detected.

?

2.2.19 Recorder Module, M-REC

1. Open the paper compartment cover. Check that the message ‘Recorder: Cover open’

appears on the screen, then close the cover.

2. Press the Record Wave key and check that the module starts recording the selected

waveforms. Press the

Press the Print Trends key and check that the module starts recording trends. Press the

Stop key on the module to stop recording.

Stop key on the module to stop recording.

3. Check that the quality of the recordings is acceptable.

?

2.2.20 Network Board, B-NET and UPINET board, B-UPI4NET

1. Check that the Mon-Net cable connector and the Identification plug are clean and intact,

then connect them to the Network/UPI4NET Board.

2. Check that the monitor connects to the S/5 Network, i.e. the network symbol appears under

the clock on the upper right-hand corner of the screen. Also a message regarding the

connected Central should appear in the message field on the screen.

NOTE: If necessary, the monitor's network communication should be reselected according

to the used network software in the

3. Enter the

Check that the counters for data errors (‘CRC’, ‘Frame’, ‘Transm.’) are stable.

Check that the counters for hardware errors (‘Intern.’, ‘Missed’, ‘FIFO’, ‘Overrun’) all show 0.

Network

service menu:

Network

service menu..

?

2.2.21 Interface Board/Module, B-INT/M-INT

1. Enter the

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ values are not increasing

faster than by 50 per second. Check that the memories have passed the internal memory

26

Document No. 8002949

Interface

service menu:

Page 31

test, i.e. ‘RAM’ and ‘ROM’ state

?

2.2.22 Device Interfacing Solution, N-DISxxx

OK

Planned maintenance instructions

.

2.2.23 General

1. Enter t he

Check that the DIS module ‘tout' and ‘cse’ values do not increase faster than by 50 per

second. Check also that the DIS module memories have passed the internal memory test, i.e.

‘Ram’, ‘Rom’ and 'EEPROM' state all OK.

Perform the same check for all connected DIS modules.

DIS Interfacing

service menu:

?

1. Check that the monitor is capable of storing the trend information and temporary settings in

a short (max. 15 minutes) standby situation with no power cord.

2. Check the Service Reset switch. Switch the monitor to standby and press the Service Reset

switch for at least five seconds. Switch the monitor back on and check that the monitor

performs a ‘Cold Start.’, i.e. all trend information is cleared.

3. Enter the

Check that the monitor restarts.

Set/Test

service menu and perform

WD by GSP

4. Enter the

Clear the content of the Service Log by selecting

Service Log

service menu:

Reset Log

from the menu.

?

5. Perform an Electrical safety check and a leakage current test.

Check that the monitor and all connected units function normally after the performed test

6. Save information about the performed planned maintenance into the

menu by performing

Plan. Maint - 1 year PM - Save

Maintenance

?

7. Switch the monitor to standby and perform final cleaning.

Fill in all necessary documents.

?

service

27

Document No. 8002949

Page 32

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

28

Document No. 8002949

Page 33

APPENDIX A, Planned maintenance check form, S/5 AM, S/5 CCM

APPENDIX A

29

Document No. 8002949

Page 34

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

30

Document No. 8002949

Page 35

APPENDIX A, Planned maintenance check form, S/5 AM, S/5 CCM

)

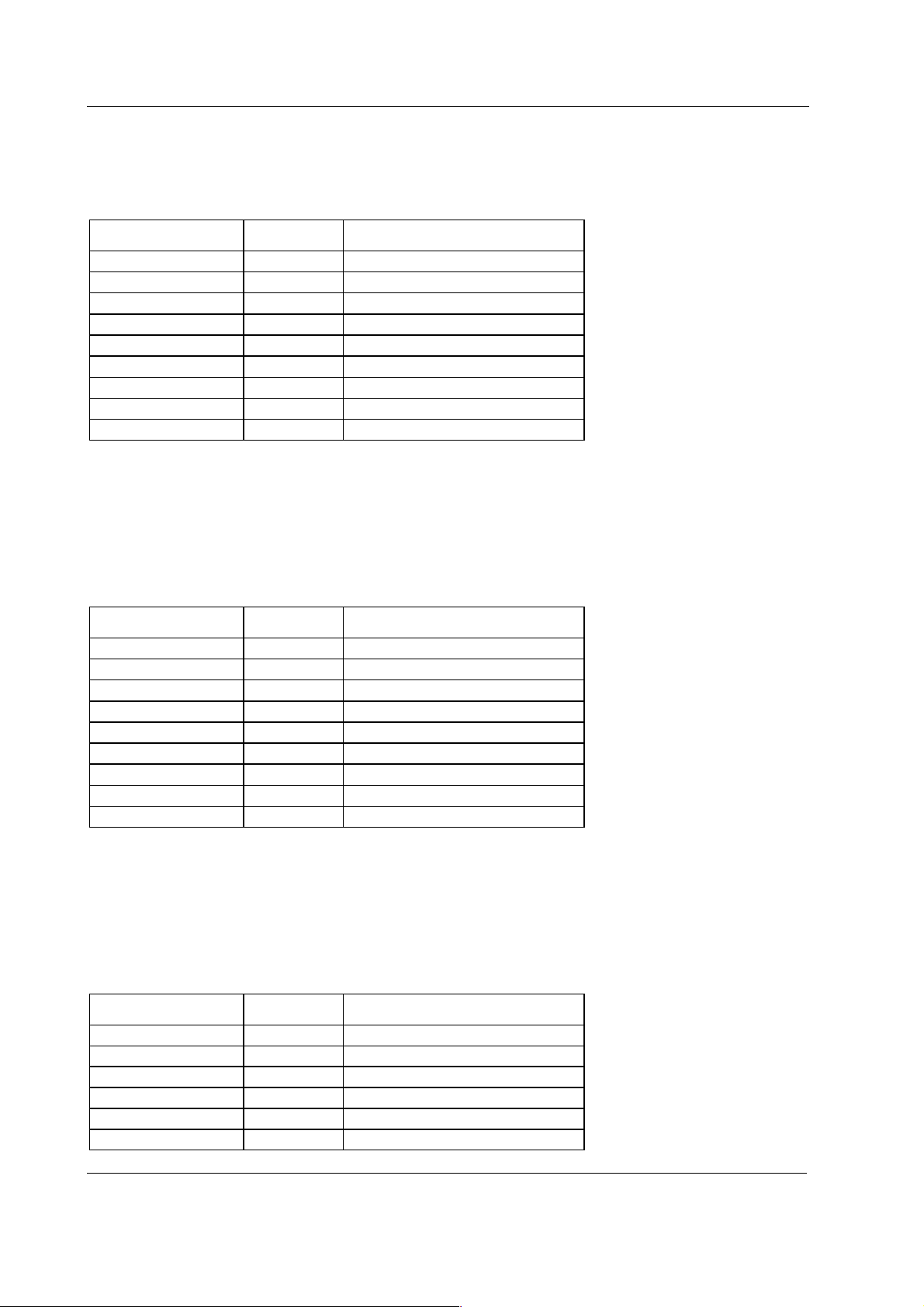

PLANNED MAINTENANCE CHECK FORM

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

Customer

Service

Service engineer Date

Monitor installation

F-CU8

S- L- M- MB- M- M- FB- M- M- NB- B- M-

OK = Test OK N.A. = Test not applicable Fail = Test Failed

Visual inspection/preparation

2.1.1. General

2.1.2. Extension Frame, F-EXT4

2.1.3. Airway Module, G-XXXXX

2.1.4. Compact Airway Module, M-CXXXXX

D- K- G-

S/N

S/N

S/N

OK N.A. Fail

2.1.5. Tonometry Module

2.1.6. Recorder module

2.1.7. Modules with NIBP measurement

Notes

S/N

S/N

A-1(4

Document No. 8002949

Page 36

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

A

Functional Inspection

2.2.1. General

2.2.2. Display(s)

2.2.3. Keyboard(s)

OK N.A. Fail

2.2.4. 8-Module Frame, F-CU8

2.2.5. Extension Frame, F-EXT4

Notes

2.2.6. Airway Module, G-XXXX

Agent identification

Patient Spirometry

General

Notes

2.2.7. Compact Airway Module

Agent identification

S/N

Patient Spirometry

General

Notes

2.2.8. Tonometry Module, M-TONO

Notes

2.2.9. Hemodynamic Modules

ECG and RESP measurements

Temperature measurement

-2(4)

Document No. 8002949

S/N

Page 37

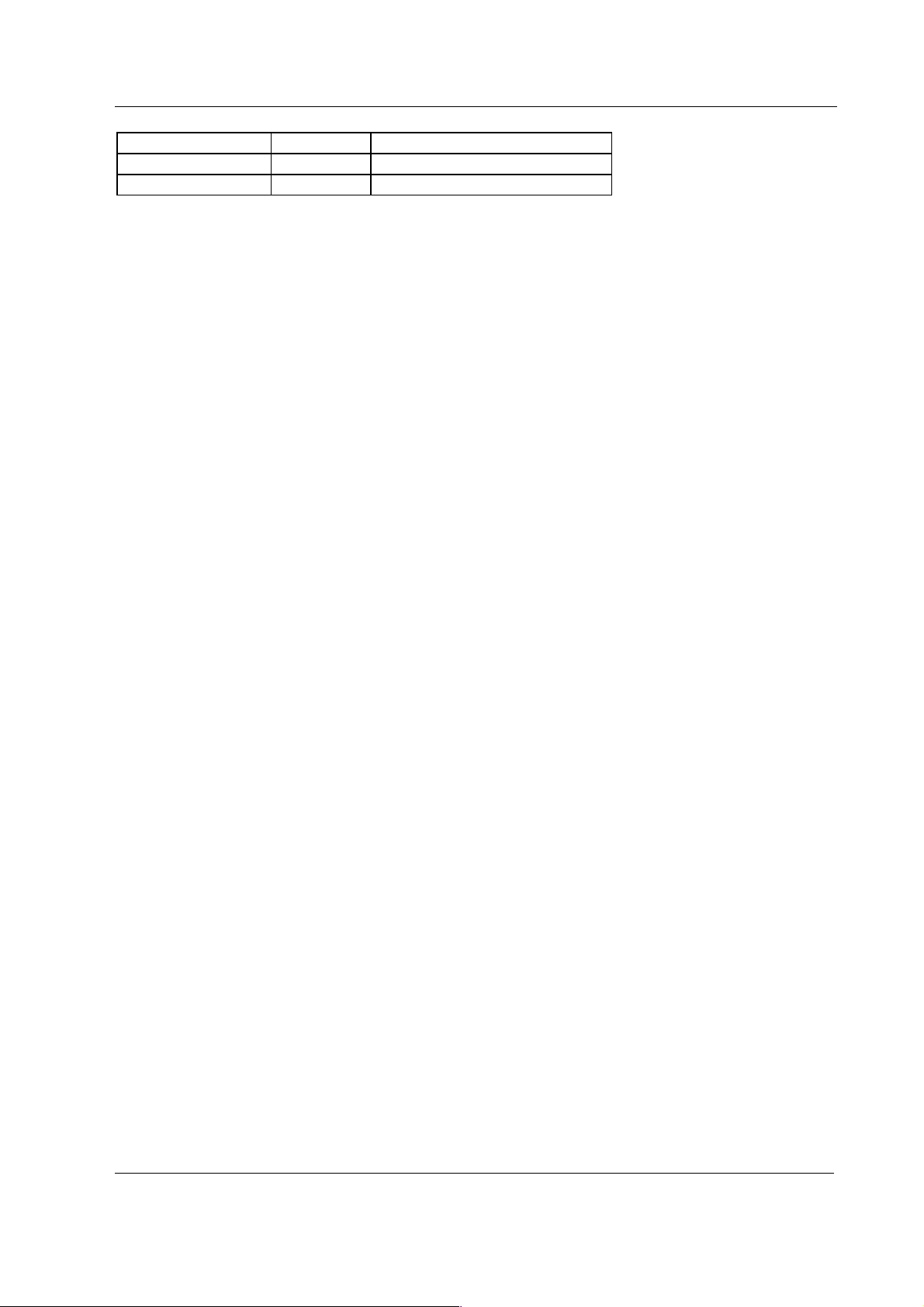

APPENDIX A, Planned maintenance check form, S/5 AM, S/5 CCM

)

InvBP measurement

SpO2—measurement

NIBP measurement

Notes

2.2.10. EEG Module, M-EEG and EEG Headbox, N-EEG

Notes

2.2.11. Pressure/Pressure Temp Modules, M-P/-PT

InvBP measurement

Modules w/ temperature measurement

Notes

OK N.A. Fail

S/N

S/N

2.2.12. Dual pressure Module, M-PP

Notes

2.2.13. Cardiac Output Modules, M-COP/-COPSv

Invasive blood pressure measurement

SvO2 measurement

Cardiac Output measurement

Notes

2.2.14. NIBP module, M-NIBP

2.2.15. NeuroMuscular Module, M-NMT

2.2.16. Nellcor Compatible Saturation module, M-NSAT

2.2.17. Datex-Ohmeda Oxygen Saturation module, MOSAT

2.2.18. Memory Module, M-MEM

S/N

S/N

S/N

S/N

S/N

S/N

S/N

2.2.19. Recorder Module, M-REC

S/N

A-3(4

Document No. 8002949

Page 38

Datex-Ohmeda S/5 Anesthesia Monitor, S/5 Critical Care Monitor

A

2.2.20. Network Board, B-NET and UPINET board, BUPI4NET

2.2.21. Interface Board/Module, B-INT/M-INT

2.2.22. Device Interfacing Solution, N-DISxxx

Notes

2.2.23. General

Service Log reset

S/N

S/N

S/N

S/N

S/N

S/N

S/N

Electrical safety check

Final cleaning

Notes

Used Spare Parts

Signature

-4(4)

Document No. 8002949

Loading...

Loading...