Page 1

Datex-Ohmeda Compact Airway modules

S/5TM Compact Airway Module, M-CAiOVX (rev. 01)

TM

S/5

S/5

S/5

Compact Airway Module, M-CAiOV (rev. 03)

TM

Compact Airway Module, M-CAiO (rev. 02)

TM

Compact Airway Module, M-COVX (rev. 02)

TM

S/5

S/5

Compact Airway Module, M-COV (rev. 03)

TM

Compact Airway Module, M-CO (rev. 02)

TM

S/5

Compact Airway Module, M-C (rev. 02)

Technical Reference Manual Slot

Datex-Ohmeda Inc.

3030 Ohmeda Drive

53707-7550 MADISON, WIS

USA

Tel. +1-608-221 1551, Fax +1-608-222 9147

www.us.datex-ohmeda.com

All specifications are subject to change without notice.

Document No. 800 1009-1

June 2001

Datex-Ohmeda Division,

Instrumentarium Corp.

P.O. Box 900, FIN-00031

DATEX-OHMEDA, FINLAND

Tel. +358 10 394 11 Fax +358 9 146 3310

www.datex-ohmeda.com

Instrumentarium Corp. All rights reserved.

Page 2

Page 3

Table of contents

TABLE OF CONTENTS

S/5 Compact Airway Modules

TABLE OF CONTENTS I

TABLE OF FIGURES III

INTRODUCTION 1

1 SPECIFICATIONS 2

1.1 General specifications ..............................................................................................................................2

1.2 Typical performance .................................................................................................................................2

1.2.1 CO

1.2.2 O

1.2.3 N

1.2.4 Respiration Rate (RR) .......................................................................................................................3

1.2.5 Anesthetic Agents (AA)......................................................................................................................3

1.2.6 MAC ................................................................................................................................................3

1.3 Gas specifications ....................................................................................................................................3

1.3.1 Normal conditions............................................................................................................................4

1.3.2 Conditions exceeding normal............................................................................................................4

1.4 Patient spirometry specifications...............................................................................................................5

1.4.1 Normal conditions............................................................................................................................5

1.4.2 Conditions exceeding normal............................................................................................................6

1.5 Gas exchange specifications .....................................................................................................................7

1.5.1 VO

1.5.2 RQ...................................................................................................................................................7

..................................................................................................................................................2

2

....................................................................................................................................................2

2

O .................................................................................................................................................2

2

and VCO2...................................................................................................................................7

2

2 FUNCTIONAL DESCRIPTION 8

2.1 Measurement principle .............................................................................................................................8

2.1.1 CO

2.1.2 O

, N2O, and agent measurement ...................................................................................................8

2

measurement ............................................................................................................................10

2

2.1.3 Patient spirometry ..........................................................................................................................10

2.1.4 Gas exchange measurement...........................................................................................................12

2.2 Main components...................................................................................................................................13

2.2.1 Gas sampling system......................................................................................................................13

2.2.2 TPX measuring unit.........................................................................................................................17

2.2.3 OM measuring unit .........................................................................................................................17

2.2.4 PVX measuring unit.........................................................................................................................18

2.2.5 Gas exchange ................................................................................................................................19

2.2.6 CPU board .....................................................................................................................................19

2.2.7 OM board.......................................................................................................................................20

2.2.8 PVX board ......................................................................................................................................20

2.3 Connectors and signals...........................................................................................................................21

3 SERVICE PROCEDURES 22

3.1 General service information.....................................................................................................................22

3.1.1 OM measuring unit .........................................................................................................................22

3.1.2 TPX measuring unit.........................................................................................................................22

3.1.3 OM, TPX, and PVX measuring unit....................................................................................................22

Document No. 800 1009-1

i

Page 4

Datex-Ohmeda S/5 monitors

3.1.4 Serviceable or exchangeable parts..................................................................................................22

3.2 Service check.........................................................................................................................................23

3.2.1 Recommended tools......................................................................................................................23

3.2.2 Recommended parts......................................................................................................................23

3.3 Disassembly and reassembly..................................................................................................................31

3.3.1 PVX unit.........................................................................................................................................31

3.3.2 Pump unit......................................................................................................................................31

3.3.3 CPU board .....................................................................................................................................31

3.3.4 Software of CPU board ...................................................................................................................32

3.3.5 Instructions after replacing software or CPU board ...........................................................................32

3.4 Adjustments and calibrations..................................................................................................................32

3.4.1 Gas sampling system adjustment ...................................................................................................32

3.4.2 Flow rate measurement..................................................................................................................32

3.4.3 Flow rate adjustment......................................................................................................................33

3.4.4 Gas calibration...............................................................................................................................33

3.4.5 Flow calibration..............................................................................................................................33

4 TROUBLESHOOTING 34

4.1 Troubleshooting charts ...........................................................................................................................34

4.1.1 CO

4.1.2 Patient spirometry..........................................................................................................................36

4.1.3 Gas exchange ................................................................................................................................38

4.2 Gas sampling system troubleshooting .....................................................................................................39

4.2.1 Sampling system leak test..............................................................................................................39

4.2.2 Steam test for the Nafion

4.3 OM measuring unit troubleshooting.........................................................................................................40

4.4 TPX measuring unit troubleshooting.........................................................................................................40

4.5 PVX measuring unit troubleshooting ........................................................................................................40

4.6 CPU board troubleshooting .....................................................................................................................40

4.7 Error messages.......................................................................................................................................41

measurement..........................................................................................................................35

2

TM

tubes....................................................................................................39

5SERVICE MENU 42

5.1 General menu ........................................................................................................................................43

5.2 Gases service menu ...............................................................................................................................44

5.3 Spirometry service menu ........................................................................................................................46

6 SPARE PARTS 48

6.1 Spare parts list.......................................................................................................................................48

6.1.1 M-C rev. 00, M-CO rev. 00, M-CAiO rev. 00, M-COV rev. 01, M-CAiOV rev. 01, M-COVX rev. 00 ..........48

6.1.2 M-CAiOVX rev. 00, M-CAiOV rev. 02, M-CAiO rev. 01, M-COVX rev. 01, M-COV rev. 02, M-CO rev. 01, M-

C rev. 01..................................................................................................................................................49

6.1.3 S/5 M-CAiOVX rev. 01, S/5 M-CAiOV rev. 03, S/5 M-CAiO rev. 02, S/5 M-COVX rev. 02, S/5 M-COV

rev. 03, S/5 M-CO rev. 02, S/5 M-C rev. 02 ..............................................................................................49

6.1.4 Front panel stickers........................................................................................................................49

6.1.5 S/5 stickers...................................................................................................................................50

6.1.6 Planned Maintenance (PM) Kits: .....................................................................................................51

7 EARLIER REVISIONS 52

APPENDIX A 53

SERVICE CHECK FORM A-1

ii

Document No. 800 1009-1

Page 5

Table of contents

TABLE OF FIGURES

Figure 1 TPX sensor principle..............................................................................................................................8

Figure 2 Absorbance of N

O and CO2..................................................................................................................9

2

Figure 3 Infrared absorbance of AAs ...................................................................................................................9

Figure 4 O

measurement principle ..................................................................................................................10

2

Figure 5 Absorber ............................................................................................................................................14

Figure 6 Gas sampling system layout, M-C........................................................................................................15

Figure 7 Gas sampling system layout, M-CAiOV, M-CAiOVX, M-CAiO, M-COVX, M-COV, M-CO..............................16

Figure 8 Gas tubing layout ...............................................................................................................................16

Figure 9 TPX measuring unit .............................................................................................................................17

Figure 10 OM measuring unit .........................................................................................................................18

Figure 11 PVX measuring unit.........................................................................................................................18

Figure 12 Signal processing...........................................................................................................................19

Figure 13 Control logic...................................................................................................................................20

Figure 14 Calibration data stored in EEPROM..................................................................................................20

Figure 15 Module bus connector pin layout ....................................................................................................21

Figure 16 Pneumatic unit and reference gas connection block.........................................................................25

Document No. 800 1009-1

iii

Page 6

Datex-Ohmeda S/5 monitors

iv

Document No. 800 1009-1

Page 7

INTRODUCTION

X

V

V

X

This section provides information for maintenance and service of the S/5 Compact Airway

modules. The Compact Airway modules are double width plug-in modules. M-C, M-CO, M-COV, MCOVX, M-CAiO, M-CAiOV, M-CAiOVX and M-CAiOVX/SERVICE are designed for use with the S/5

monitors. The modules provide airway and respiratory measurements.

Letters in the module name stand for:

M = plug-in module, C = CO

A = anesthetic agents, and i = agent identification

About M-CAiOVX/SERVICE module

The M-CAiOVX/SERVICE module is meant for service purposes only. It can be used as a loan

module if the module in the hospital should be sent to the factory for repair. The specifications that

apply to the M-CAiOVX apply also to the M-CAiOVX/SERVICE module. Module differences: the

colour of the front mask is green, the front panel has a “SERVICE” text and there are no front panel

keys equipped.

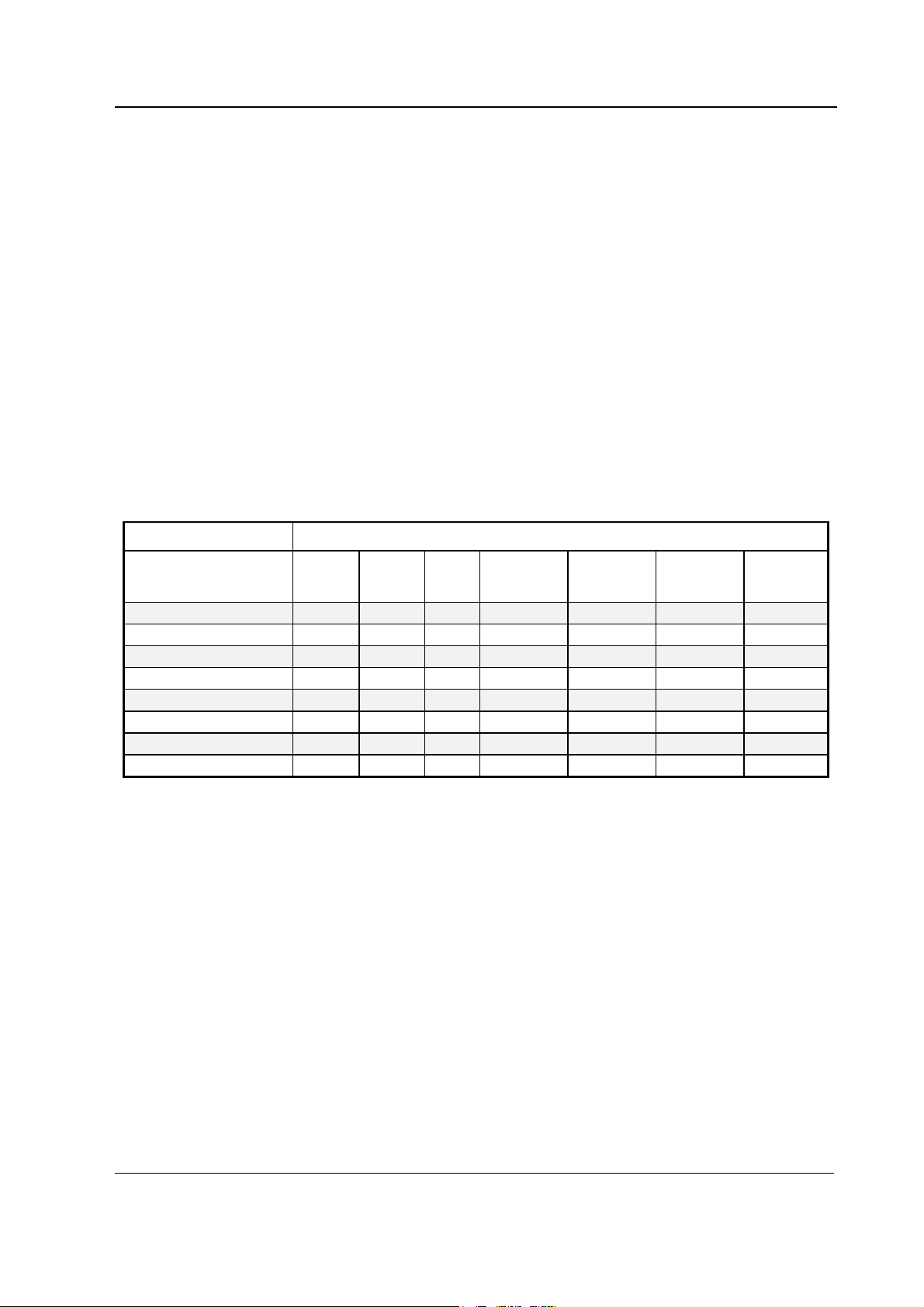

Table 1 Options for Compact Airway modules

Compact Airway modules

and N2O, O = patient O2, V = patient spirometry, X = gas exchange,

2

Modules Parameters/measurements

M-CAiOV

M-CAiO

M-CAiO

M-CO

M-COV

M-CO

M-C

M-CAiOVX/SERVICE

CO

2

• • • • • • •

••• • • •

• • • • •

••• •

• • • • •

•••

• •

••• • • • •

N2OO2Anesthetic

NOTE: Do not use identical modules in the same monitor simultaneously. The M-C, M-CO, M-COV,

M-COVX, M-CAiO, M-CAiOV, M-CAiOVX and M-CAiOVX/SERVICE are considered identical modules.

NOTE: The Compact Airway Module and Airway Module, G-XXXX, cannot be used simultaneously in

the same monitor.

NOTE: The Compact Airway modules cannot be used in the Extension Frame, F-EXT4.

NOTE: Anesthetic agents and N

O values are not displayed with Critical Care main software, but

2

when present in the module they are calculated for compensation of CO

agents

Agent ID Spirometry Gas

exchange

and O2.

2

1

Document No. 800 1009-1

Page 8

Datex-Ohmeda S/5 monitors

1 SPECIFICATIONS

1.1 General specifications

Module size, W × D × H 75 × 228 × 112 mm, 2.9 × 9.0 × 4.4 in

Module weight 1.6 kg/3.7 lbs

Operating temperature +10...+40 °C

Storage temperature -25...+70 °C

Atmospheric pressure 666...1060 hPa /

Humidity 10...95 % non-condensing (in airway 0...100 %, condensing)

Power consumption 12.6 W Prms, 14.6 W momentary

Protection against electrical shock

(67...106 kPa)

(500...800 mmHg)

(666...1060 mbar)

Type BF

1.2 Typical performance

1.2.1 CO

1.2.2 O

1.2.3 N2O

2

Measurement range 0...15 vol% (0...15 kPa, 0...113 mmHg)

Measurement rise time < 400 ms typical

Accuracy ±(0.2 vol% +2 % of reading)

Gas cross effects < 0.2 vol% (O

concentration is below 0.1%, 0.0% is displayed.

If CO

2

2

Measurement range 0 to 100 vol%

Measurement rise time < 400 ms typically

Accuracy ±(1 vol% +2% of reading)

Gas cross effects < 1 vol%; anesthetic agents

Fi-Et difference resolution 0.1 vol%

O

2

Measurement range 0 to 100 %; N2O

Measurement rise time < 450 ms typically

Accuracy ±(2 vol% +2% of reading)

Gas cross effects < 2 vol%; anesthetic agents

< 2 vol%; N

, N2O, anesthetic agents)

2

O

2

2

Document No. 800 1009-1

Page 9

1.2.4 Respiration Rate (RR)

Measurement range 4...60 breaths/min

Detection criteria 1 % variation in CO

1.2.5 Anesthetic Agents (AA)

Measuring range

Hal, Enf, Iso 0 to 6 vol%

Sev 0 to 8 vol%

Des 0 to 20 vol%

Measurement rise time < 400 ms typically

Accuracy ±(0.15 vol% +5% of reading)

Gas cross effects < 0.15 vol% N

Resolution is two digits when the AA concentration is below 1.0 vol%.

If AA concentration is below 0.1 vol%, 0.0% is displayed.

Identification threshold 0.15 vol% typically

Identification time < 20 s (for pure agents)

Compact Airway modules

2

O

2

Mixture identification threshold for 2. agent:

1.2.6 MAC

Range 0...9.9 MAC

Equation:

%(ETAA)

=MAC(AA)

x(AA)

where x(AA): Hal=0.75 %, Enf=1.7 %, Iso=1.15 %, Sev=2.05 %, Des=6.0 %.

1.3 Gas specifications

Airway humidity 0...100 %, condensing

Sampling rate 200 ±20 ml/min. (sampling line 2-3 m, normal conditions)

Sampling delay 2.5 seconds typical with a 3 m sampling line

Total system response time 2.9 seconds typical with a 3 m sampling line, including sampling

Display update rate breath-by-breath

Automatic compensation for pressure, CO

0.2 vol% +10% of total conc.

OETN

+

2%

Formula 1

100

delay and rise time

O and CO2-O2 collision broadening effect.

2-N2

Warm up time 2 min. for operation with CO

, O2, and N2O

2

5 min. for operation of anesthetic agents

30 min. for full specifications

Autozeroing interval Immediately after ‘calibrating gas sensor’ and 2, 5, 10, 15, 30, 45,

60 minutes after start-up, then every 60 minutes

Document No. 800 1009-1

3

Page 10

Datex-Ohmeda S/5 monitors

1.3.1 Normal conditions

Accuracy specifications apply in normal conditions (after 30 minutes warm-up period):

Ambient temperature 18...28 °C, within ±5 °C of calibration

Ambient pressure 500...800 mmHg, ±50 mmHg of cal.

Ambient humidity 20...80 % RH, ±20 % RH of cal.

Non-disturbing gases

− Ethanol C

− Acetone (< 0.1%)

− Methane CH

− Nitrogen N

− Carbon monoxide CO

− Nitric Oxide NO (< 200 ppm)

− water vapor

Maximum effect on readings

− CO

− O

− anesthetic agents < 0.15 vol%

Effect of Helium decreases CO

OH(< 0.3%)

2H5

(< 0.2%)

4

2

< 0.2 vol%

2

, N2O < 2 vol%

2

readings < 0.6 vol% typically

2

1.3.2 Conditions exceeding normal

Accuracy specifications under the following conditions; :

Ambient temperature 10...40 °C, within ±5 °C of calibration

Ambient pressure 500...800 mmHg, ±50 mmHg of calibration

Ambient humidity 10...98 % RH, ±20 % RH of calibration

During warm-up 2 to 10 minutes (anesthetic agents 5-10 minutes), under normal conditions

During warm-up 10 to 30 minutes, under normal conditions

CO

2

O

2

N2O

Agents: Hal, Enf, Iso,

Sev, Des

Accuracy under different conditions (see above)

Condition and Condition

±(0.3 vol% + 4 % of reading)

(at 5 vol% error ±0.5 vol%)

±(0.4 vol% + 7 % of reading)

(at 5 vol% error ±0.75 vol%)

±(2 vol% + 2% of reading) ±(3 vol% + 3% of reading)

±(3 vol% + 3% of reading) ±(3 vol% + 5% of reading)

±(0.2 vol% + 10% of reading) ±(0.3 vol% + 10% of reading)

4

Document No. 800 1009-1

Page 11

1.4 Patient spirometry specifications

1.4.1 Normal conditions

Accuracy specifications apply in normal conditions (after 10 minutes warm-up period):

Ambient temperature 10...40 °C

Ambient pressure 500...800 mmHg

Ambient humidity 10...98 %RH

Airway humidity 10...100 %RH

Respiration rate 4...35 breaths/min (adults)

4...50 breaths/min (pediatric)

I:E ratio 1:4.5...2:1

Intubation tube 5.5...10 mm (adults), 3...6 mm (pediatric)

Compact Airway modules

Airway pressures (Paw, P

Measurement range -20...+100 cmH2O

Resolution 0.5 cmH

Accuracy ±1 cmH

Airway flow

Measurement range 1.5...100 l/min (adults)

(for both directions) 0.25...25 l/min (pediatric)

Tidal volume

Measurement range 150...2000 ml (adults), 15...300 ml (pediatric)

Resolution 1 ml

Accuracy ±6 % or 30 ml (adult), ±6 % or 4 ml (pediatric)

Minute volume

Measurement range 2...20 l/min (adults), 0.5...5 l/min (pediatric)

Resolution 0.1 l/min

peak

, P

, PEEPe, PEEP

plat

iStat

O

2

O

2

, PEEP

iDyn

, P

mean

)

Compliance

Measurement range 4...100 ml/cmH2O (adult), 1...100 ml/cmH2O (pediatric)

Resolution 1 ml/cmH

Airway resistance

Measurement range 0...40 cmH2O/ l/s

Resolution 1 cmH

O (adult), 0.1 ml/cmH2O (pediatric)

2

O/ l/s

2

5

Document No. 800 1009-1

Page 12

Datex-Ohmeda S/5 monitors

Other parameters

Specifications apply in conditions listed in patient spirometry specifications.

Dead space of the sensor

9.5 ml (adult), 2.5 ml (pediatric)

Resistance of the sensor

0.5 cmH2O @ 30 l/min (adult), 1.0 cmH2O @ 10 l/min (pediatric)

1.4.2 Conditions exceeding normal

Accuracy specifications under the following condition (during warm-up 2 to 10 minutes):

Airway Pressure(Paw)

Accuracy ±2 cmH2O

Tidal volume

Accuracy ±10 % or 100 ml (adult), ±10 % or 10 ml (pediatric)

6

Document No. 800 1009-1

Page 13

1.5 Gas exchange specifications

Mathemathical integration of airway flow and gas concentration for intubated, mechanically

ventilated and/or partly spontaneously breathing patients.

NOTE: These specifications apply only when a 2 meter gas sampling line is used, and a Y-piece

with a physical dead space less than 8 ml.

Compact Airway modules

NOTE: These specifications only apply if the FiO

0.2 % during the inspiratory cycle at the measurement point.

1.5.1 VO2 and VCO

Measurement range 50...1000 ml/min

Resolution 10 ml/min

Accuracy ±10 % or 10 ml; when FiO

1.5.2 RQ

Measurement range 0.6...1.2

Resolution 0.05

level delivered to the patient is varing by less than

2

2

< 65 %

2

±15 % or 15 ml; when 65 % < FiO

< 85 %

2

Document No. 800 1009-1

7

Page 14

Datex-Ohmeda S/5 monitors

2 FUNCTIONAL DESCRIPTION

2.1 Measurement principle

2.1.1 CO2, N2O, and agent measurement

TPX is a side stream gas analyzer, measuring real time concentrations of CO2, N2O and anesthetic

agents (Halothane, Enflurane, Isoflurane, Desflurane, and Sevoflurane).

Sample

chamber

Temp sensor

Thermopile

detectors

Sample

gas out

Figure 1 TPX sensor principle

Anesthetic agents or mixtures of two anesthetic agents are automatically identified and

concentrations of the identified agents are measured. TPX also detects mixtures of more than two

agents and issues an alarm.

TPX is a nondispersive infrared analyzer, measuring absorption of the gas sample at seven infrared

wavelengths, which are selected using optical narrow band filters.

The infrared radiation detectors are thermopiles.

Concentrations of CO

Sample

gas in

and N2O are calculated from absorption measured at 3-5 µm.

2

8

Document No. 800 1009-1

Page 15

Compact Airway modules

Figure 2 Absorbance of N2O and CO

2

Identification of anesthetic agents and calculation of their concentrations is performed by

measuring absorptions at five wavelengths in the 8-9 µm band and solving the concentrations

from a set of five equations.

Figure 3 Infrared absorbance of AAs

The measuring accuracy is achieved utilizing numerous software compensations. The

compensation parameters are determined individually for each TPX during the factory calibration.

Document No. 800 1009-1

9

Page 16

Datex-Ohmeda S/5 monitors

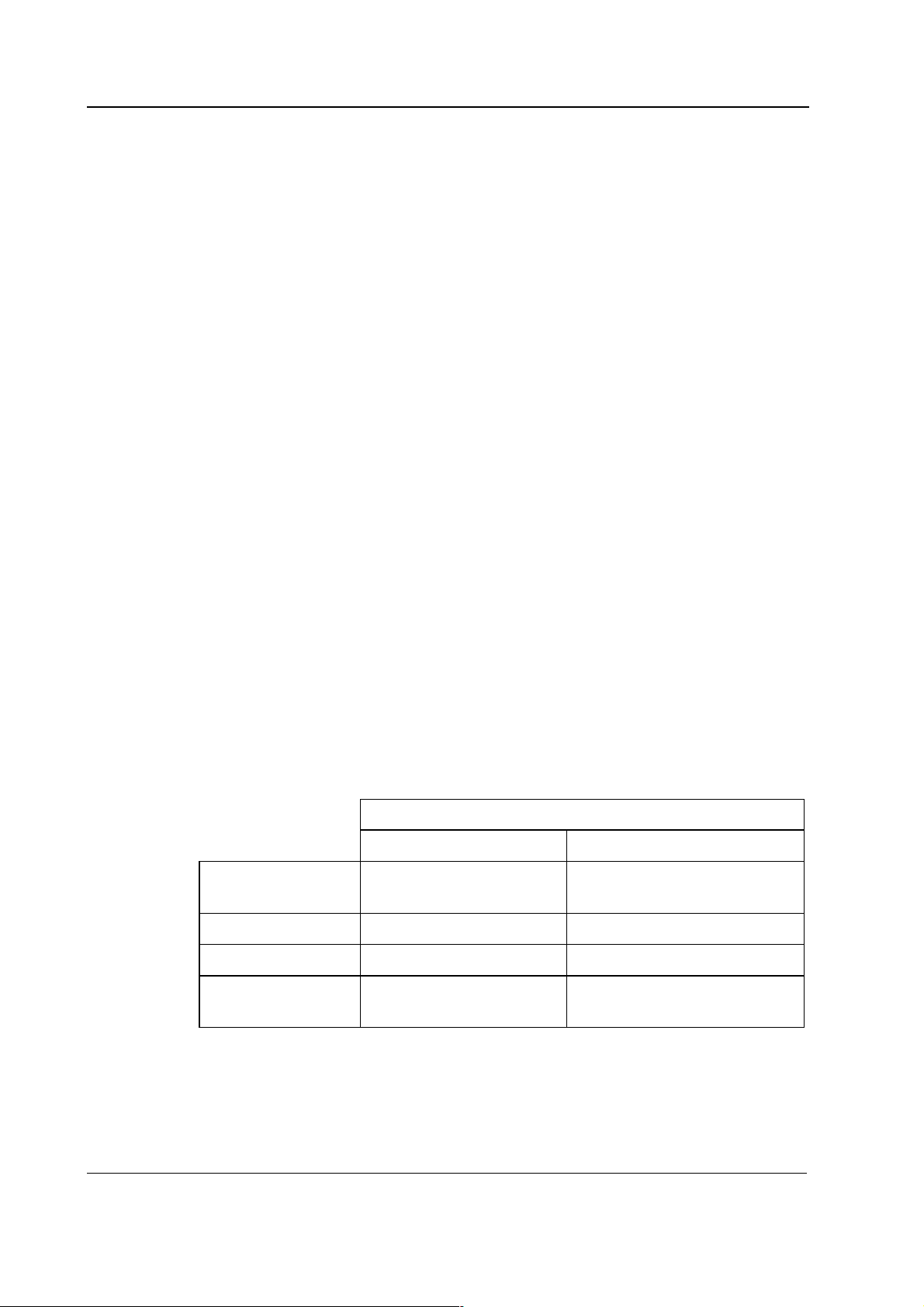

2.1.2 O2 measurement

The differential oxygen measuring unit uses the paramagnetic principle in a pneumatic bridge

configuration. The signal picked up with a differential pressure transducer is generated in a

measuring cell with a strong magnetic field that is switched on and off at a frequency of 165 Hz.

The output signal is a DC voltage proportional to the O

gases to be measured.

Sample in

Microphone

Electromagnet

concentration difference between the two

2

Mixture

out

Switched

magnetic

field

Figure 4 O2 measurement principle

2.1.3 Patient spirometry

In mechanical ventilation breaths are delivered to the patient by a ventilator with a proper tidal

volume (TV), respiration rate (RR), and inspiration / expiration ratio in time (I:E) determined by the

settings of the ventilator.

The Patient Spirometry monitors patient ventilation. The following parameters are displayed:

− Expiratory and inspiratory tidal volume (TV) in ml

− Expiratory and inspiratory minute volume (MV) in l/min

− Expiratory spontaneous minute volume in l/min

− Inspiration/expiration ratio (I:E)

Airway pressure

− Peak pressure (P

− Mean airway pressure (P

monitors

− End inspiratory pressure (P

− PEEPi, PEEPe; available only in S/5 Critical Care and Compact Critical Care monitors

− Total positive end expiratory pressure (PEEP

Compact Anesthesia monitors

− Real time airway pressure waveform (P

− Static Positive end expiratory pressures (Static PEEP

S/5 Critical Care and Compact Critical Care monitors

Reference in

)

peak

); available only in S/5 Critical Care and Compact Critical Care

mean

)

plat

); available only in S/5 Anesthesia and

tot

)

aw

and Static PEEPe); available only in

i

10

Document No. 800 1009-1

Page 17

Compact Airway modules

− Static Plateau pressure (Static Pplat); available only in S/5 Critical Care and Compact

Critical Care monitors

− Static Compliance (Static Compl); available only in S/5 Critical Care and Compact Critical

Care monitors

Airway flow

PEEP, P

peak

, P

mean

, and P

are measured by pressure transducer on the PVX board. Atmospheric

plat

pressure is used as a reference in measurement. The pressure measurement is made from the

airway part that is closest to the patient between patient circuit and intubation tube.

=intrinsic PEEP, PEEP

PEEP

i

-PEEP

tot

e

Static pressure measurement maneuvres are automatically identified based on a increased zero

flow period at the end of the inspiration or expiration.

Static Compliance is calculated if Static PEEP and Static P

measurements were done within a 2

plat

minutes period.

− Real time flow waveform (V')

− Compliance (Compl)

− Airway resistance (Raw)

− Pressure volume loop

− Flow volume loop

The measurement is based on measuring the kinetic gas pressure and is performed using the Pitot

effect. A pressure transducer is used to measure the Pitot pressure. The obtained pressure signal is

linearized and corrected according to the density of the gas. Speed of the flow is calculated from

these pressure values and TV value is then integrated. MV value is further calculated and averaged

using TV and RR (respiratory rate) values.

Compliance and airway resistance

Compliance is calculated for each breath from the equation

TV

Compl−−=

plat

exp

ei

PEEPPEEPP

Formula 2

Compliance tells how big a pressure difference is needed to deliver a certain amount of gas into

the patient.

The airway resistance, Raw, is calculated using an equation, that describes the kinetics of the gas

flow between the lungs and the D-lite. The equation states that the pressure at the D-lite can at any

moment of the breath be approximated using the equation

tVtVRaw

)()('

tp

=

)(

+×

++

ie PEEPPEEPCompl

Formula 3

where p(t), V’(t) and V(t) are the pressure, flow and volume measured at the D-lite at a time t, Raw is

the airway resistance, Compl is the compliance and PEEP

expiratory pressure (PEEP

).

tot

+PEEPi is the total positive end

e

11

Document No. 800 1009-1

Page 18

Datex-Ohmeda S/5 monitors

TM

D-lite

Patient Spirometry uses a specific sensor called D-liteTM flow sensor. Different types of the D-lite

sensors are available: adult sensor for measuring adults and pediatric sensor for children. Both are

available as reusable versions and D-lite sensor also for single use.

D-lite adapter is designed to measure kinetic pressure by two-sided Pitot tube. Velocity is

calculated from pressure difference according to Bernoulli's equation. Flow is then determined

using the calculated velocity.

v=

2dP×

(from Bernoulli's equation) Formula 4

ρ

F=v A× ,

where:

F = flow (l/min), v = velocity (m/s), A = cross area (m

ρ

= density (kg/m3)

Finally the volume information is obtained by integrating the flow signal.

2.1.4 Gas exchange measurement

The gas exchange measurement uses the D-liteTM flow sensor and the gas sampler.

The basic data which is needed to obtain O

concentrations.

Concentrations have been corrected for delay and deformation during the transport of the gas

sample in a sidestream gas measurement sensor.

To obtain the amount of O

the amount that is inhaled.

2

), dP = pressure difference (cmH2O),

consumption and CO2 production are volumes and

2

consumed in ml/min, the amount which is exhaled is subtracted from

2

To obtain the amount of CO

the amount that is exhaled.

These amounts can be obtained by multiplying each measured volume piece (dv) by the

corresponding gas concentration:

and

Using inspiratory and expiratory minute volumes MV

concentrations fi and fe these equations can be rewritten as:

12

Document No. 800 1009-1

producted in ml/min, the amount which is inhaled is subtracted from

2

−

dvfdvf OO

VO

=2

ò

insp

VCO 22 Formula 6

=2

ò

exp

22

ò

dvfdvf COCOò−

inspexp

and MVe and volume-weighted inspiratory

i

eOiO=2 MVfe-MVfiVO 22 ×× [ml/min] Formula 7

Formula 5

Page 19

Compact Airway modules

iCOeCO=2 MVfi-MVfeVCO 22 ×× [ml/min] Formula 8

To obtain results which are less sensitive to errors in volume measurements, so-called Haldane

transformation is used. This means taking advantage of the fact that the patient is not consuming

nor producing nitrogen: the amount of nitrogen inhaled is equal to the amount

exhaled fi

and VCO2 can then be written as:

VO

2

× MVi=feN2×MVe.

N2

iOHaldO2 )MVfef-(fi=VO 22 × [ml/min] Formula 9

iCOCOHald2 )MVfi-fe(f=VCO 22× [ml/min] Formula 10

with

f

Hald

= (1-fi

– fiO2 – fi

CO2

N2O

- fi

Ane1

– fi

Ane2

) / (1-fe

– feO2 – fe

CO2

N2O

- fe

Ane1

– fe

Ane2

)

EE=(5.5 × VCO

2

with Un=Urea Nitrogen Excretion = 13 g/day (for adults only).

2.2 Main components

The compact airway modules consist of:

• Gas sampling system

• TPX measuring unit

• OM measuring unit

• PVX measuring unit

• CPU board

• OM board

• PVX board

2.2.1 Gas sampling system

The sampling system takes care of drawing a gas sample to the analyzers at a fixed rate.

The gas sampling system samples the measured air to the module, and removes water and

impurities from it. A sampling line is connected to the water trap. The pump draws gas through the

sampling line to gas measuring units. After the measurements, the gas is exhausted from sample

gas out connector.

) + (1.76 × VO2) + (1.99 × Un) [kcal/day] Formula 11

The M-COVX and M-CAiOVX modules have a different gas sampling system compared to the other

modules. A number of flow restrictors have been changed to create a bigger pressure difference

with ambient pressure in the gas sensors. The sample flow is however about the same (200

ml/min).

A bigger pressure difference makes the deformations of the gas concentration curves less sensitive

to high variations of the airway pressures thus meeting also the accuracy requirements of gas

exchange for these applications.

13

Document No. 800 1009-1

Page 20

Datex-Ohmeda S/5 monitors

D-fend

TM

The sample is drawn through a sampling line. Then gas enters the monitor through the water trap,

where it is divided into two flows, a main flow and a side flow. The main flow goes into the

analyzers. This flow is separated from the patient side by a hydrophobic filter. The side flow creates

a slight subatmospheric pressure within the D-fend water trap which causes fluid removed by the

hydrophobic filter to collect in the bottle.

Zero valve and absorber

Figure 5 Absorber

NafionTM tubes

1)

A nafion tube is used between the water trap and the zero valve to balance the sample gas

humidity with that of ambient air. The tube will prevent errors caused by the effect of water vapor on

gas partial pressure when humid gases are measured after calibration with dry gases. Another

nafion tube is used between the absorper and the pneumatic unit to prevent humidity caused by

absorb of CO

The main flow passes through a magnetic valve before

proceeding to the analyzers. This valve is activated to establish

the zero points for the TPX and OM units. When the valve is

activated, room air is drawn through the absorber into the internal

system and the gas sensors. Paralyme is used as an absorbent.

.

2

Gas analyzers

After the zero valve and nafion tube the gas passes through TPX and OM units. The oxygen sensor

has two inputs. One input accepts the main flow and the other draws in room air for reference. Both

gas flows exit from a single port.

Sample flow differential pressure transducer

The sample flow differential pressure transducer measures pressure drop across OM inlet restrictor

and calculates sample flow from the pressure difference.

Working pressure transducer

The working pressure transducer measures absolute working pressure between the TPX unit and

OM unit. It is used for messages: ‘sample line blocked’, ‘check D-fend’, ‘replace D-fend’ and

‘check sample gas outlet’.

1)

Nafion is a trademark of Perma Pure Inc.

14

Document No. 800 1009-1

Page 21

Pneumatic unit

The pneumatic unit contains zeroing valve, occlusion valve and tubing connections. There is a

series of restrictors and chambers forming a pneumatic filter to prevent pressure oscillations from

the pump to reach the measuring units. The occlusion valve connection to room air includes a dust

filter and the zero valve connection to room air includes an absorber.

Connection block

The connection block contains sample gas outlet connector and OM unit reference gas inlet. The

inlet is equipped with a dust filter.

Occlusion valve

The valve is activated when the sampling line gets occluded. The main flow is then diverted to the

side flow of the D-fend water trap to faster remove the occlusion.

Sampling pump and damping chamber

Compact Airway modules

The gas sampling pump is a membrane pump that is run by a brushless DC-motor. Sample flow is

measured with a differential pressure transducer across a known restriction. The motor is

automatically controlled to maintain a constant flow, even when the D-fend water trap ages and

starts to get occluded. It also enables use of sample tubes with varying lengths and diameters.

The damping chamber is used to even out the pulsating flow and silence the exhaust flow.

NOTE: In no occasion is the flow reversed towards patient.

CO2 absorber

Nafion tube

Pneumatic unit

G

F

E

D

C

B

A

Pressure transducers

B1

B2

D-fend

Water trap

Nafion tube

Connection block

OUT

IN

Damping champer

Sampling pump

OUT

Figure 6 Gas sampling system layout, M-C

TPX unit

IN

15

Document No. 800 1009-1

Page 22

Datex-Ohmeda S/5 monitors

Nafion tube

CO2 absorber

Pneumatic unit

G

F

E

D

C

B

A

Pressure transducers

P

OUT

OM unit

REF

IN

D-fend

Water trap

Nafion tube

B1

B2

OUT

IN

Damping champer

Sampling pump

TPX unit

IN

OUT

Connection block

Figure 7 Gas sampling system layout, M-CAiOV, M-CAiOVX, M-CAiO, M-COVX, M-COV,

M-CO

Front panel

Sample

line

Filter

Zero

valve

D-fend

D-fend

1)

Absorber

Reference gas

Room air

1)

TPX

Pressure

transducer

p

Pressure

transducer

p

dp

OM

1)

Tubing marked with 1) is thinner in M-CAiOVX and M-COVX module.

Figure 8 Gas tubing layout

Room air

Filter

Occlusion

valve

Pump

16

Document No. 800 1009-1

Page 23

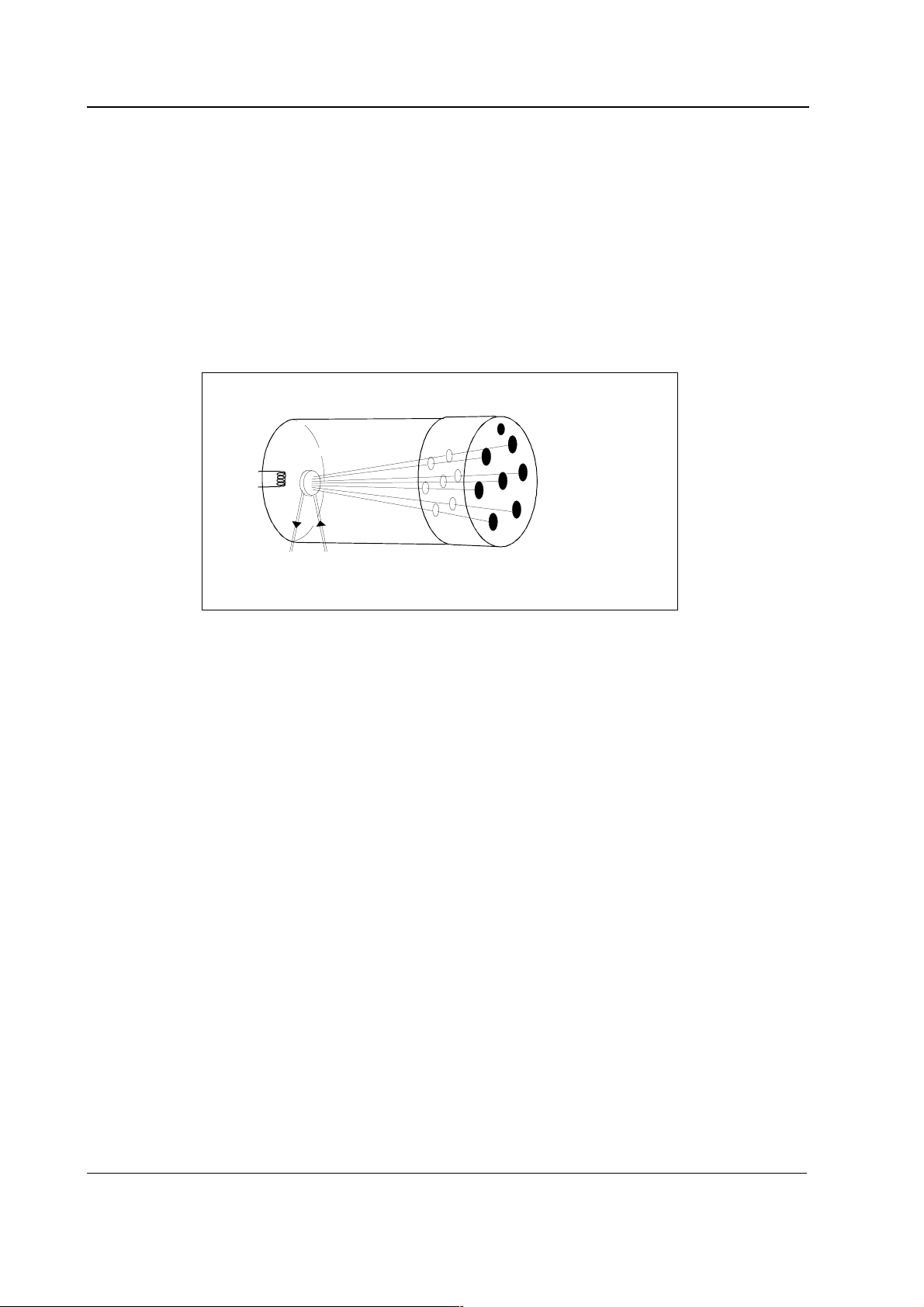

2.2.2 TPX measuring unit

The TPX unit is a non dispersive infrared analyzer, measuring absorption of the gas sample at seven

infrared wavelengths, which are selected using optical narrow band filters. The IR lamp is a 4 W

filament, surrounded by thermal isolation. There is a hole in the isolation, passing the radiation to a

conical measuring chamber with 4 mm length.

From the sample chamber, radiation goes into seven tubular light guides with reflective inner

surface. At the other end of each light guide, there is a thermopile detector with an optical filter in

front of it.

The Temp sensor measures TPX units’ temperature and it is used for temparature compensation.

The TPX unit includes TPX board located at the end of the unit. Its function is to connect the 7

thermopile signals and the temperature sensor signal to the CPU board.

Compact Airway modules

Figure 9 TPX measuring unit

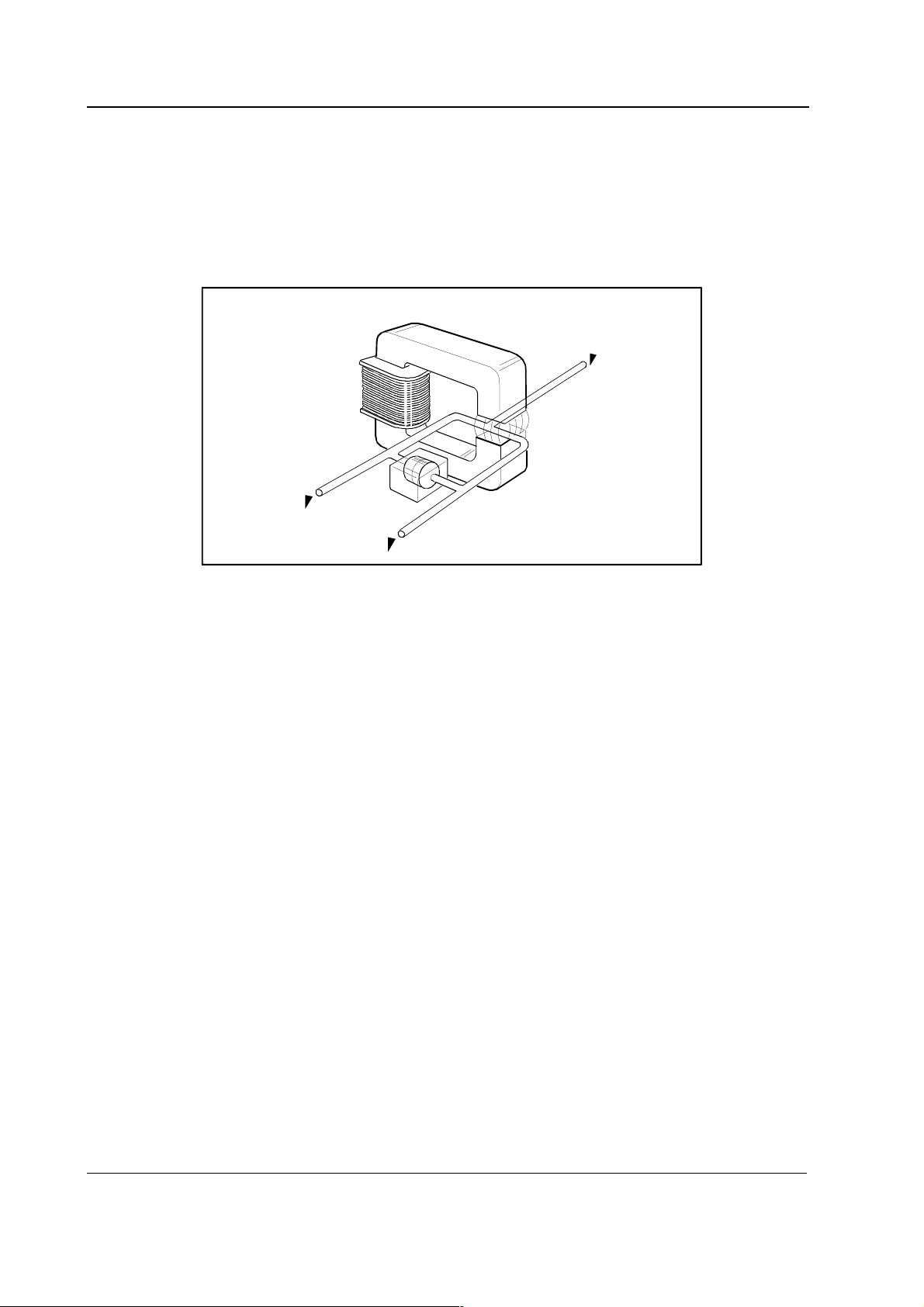

2.2.3 OM measuring unit

The oxygen measurement is based on paramagnetic susceptibility. The gas and the reference gas,

which usually is room air, are conducted into a gap in an electromagnet with a strong magnetic

field switched on and off at a frequency of approximately 165 Hz.

An alternating differential pressure is generated between the sample and reference inputs due to

forces acting to the oxygen molecules in a magnetic field gradient.

The pressure is measured with a sensitive differential transducer, rectified with a synchronous

detector and amplified to produce a DC voltage proportional to the oxygen partial pressure

difference of the two gases.

17

Document No. 800 1009-1

Page 24

Datex-Ohmeda S/5 monitors

Figure 10 OM measuring unit

2.2.4 PVX measuring unit

NOTE: Never apply overpressure or negative pressure of more than 300 cmH2O to the flow and

volume tubing. Differential pressure max 25 cmH2O on one port at a time e.g. when connecting

tubes.

When Patient Spirometry is used, a special sensor, D-lite, replaces the normal airway adapter in

the patient circuit. A double lumen tubing is attached to the two connectors on the adapter and on

the module front panel.

The Patient Spirometry provides patient respiration monitoring capabilities using the D-lite and

Pedi-lite flow sensors.

Figure 11 PVX measuring unit

The measurement is based on measuring the kinetic gas pressure and is performed using the Pitot

effect. A pressure transducer is used to measure the Pitot pressure. The signal is then linearized

and corrected according to the density of the gas. Speed of the flow is calculated from the pressure

and TV is integrated from it.

The Patient Spirometry consists of airway connections, two pressure transducers, valves and

preamplifiers. The preamplifiers are connected to the A/D-converter on module main CPU.

The breathing flow of a patient passing through the D-lite adapter creates a pressure difference.

This pressure difference is measured by pressure transducer, B1. Overpressure and negative

pressure in airways are measured by another pressure transducer B2.

18

Document No. 800 1009-1

Page 25

Compact Airway modules

2.2.5 Gas exchange

The gas exchange measurement uses the concentrations measured by the TPX measurement unit

and the O

measurement unit, in combination with the flow from the PVX measurement unit. The

2

gas exchange calculation is done by software.

CAUTION The gas exchange measurement in the M-CAiOVX and M-COVX modules works

accurately only with 2 meter gas sampling lines.

2.2.6 CPU board

The CPU board contains the processor and memories and A/D-converters that are common to the

whole module. The CPU board also contains preamplifiers of TPX-sensor and drivers for valves, fan,

pump and lamp. The module is connected to the module bus through a RS-485 serial channel.

CPU boardTPX board

IR Thermopile Sensors

preamps

x 5

Anes.

Agents

N2O

CO

2

T Sensor

OM Board

MUX

Spirometry keyboard

PVX Board

T Sensor

O

2

Flow Press

Figure 12 Signal processing

x 2

MUX

and

buffer

MUX

and

buffer

2 ch

A / D

16 bit

RS-485

driver

CPU

80C196NT

Module Bus

19

Document No. 800 1009-1

Page 26

Datex-Ohmeda S/5 monitors

Lamp Unit

TPX

Lamp

Gas press

Diff press

MUX

OM Board

PVX

valves

Figure 13 Control logic

TPX Board

CPU Board

Lamp

Current

Sensing

MUX &

buffer

Temp

sensor

A / D

A / D

CPU Board

Valves

Valves

CPU

80C196NT

pneumatics

unit

Fan

Module Bus

reset

data

Figure 14 Calibration data stored in EEPROM

2.2.7 OM board

The Oxygen board contains the specific electronics for the oxygen sensor. Sample flow

measurement and sampling system pressure sensors are on this board. It also contains EEPROM’s

that store calibration data of both TPX and OM-sensors. The spirometry keyboard connection is on

this board.

EEPROM

OM Board

EEPROM

EEPROM

PVX Board

Factory calibration

data for OM and TPX

Factory calibration

data for PVX

EEPROM

Correction data for

amplification and

offset of all amplification

channels

CPU

80C196NT

RS-485

driver

Module Bus

2.2.8 PVX board

The Spirometry board is connected to the oxygen board. It contains pressure sensors for airway

pressure and flow measurement differential pressure and preamplifiers for those. Calibration data

of spirometry is stored on it’s own EEPROM.

20

Document No. 800 1009-1

Page 27

2.3 Connectors and signals

Compact Airway modules

13

25

1

14

Figure 15 Module bus connector pin layout

Table 2 Module bus connector pin description

Pin No I/O Signal

1 I RESET RS485

2 I -15 VDC

3 I +15 VDIRTY

4 I +15VDC

5 I/O -DATA RS485

6 I/O DATA RS485

7 Ground and Shield

8 I -RESET RS485

9n/c

10 n/c

11 n/c

12 n/c

13 Ground and Shield

14 I +24/+32 VDIRTY depends on power supply (not used)

15 I Ground DIRTY

16 n/c

17 n/c

18 n/c

19 n/c

20 I GASFR (not used)

21 I CTSD (not used)

22 I TXDD (not used)

23 O RXDD (not used)

24 I +5 VDC

25 I +5 VDC DIRTY, for infrared lamps

21

Document No. 800 1009-1

Page 28

Datex-Ohmeda S/5 monitors

3 SERVICE PROCEDURES

3.1 General service information

Field service of the compact airway modules is limited to replacing faulty circuit boards or

mechanical parts. The circuit boards should be returned to Datex-Ohmeda for repair.

Datex-Ohmeda is always available for service advice. Please provide the unit serial number, full

type designation and a detailed fault description.

CAUTION Only trained personnel with appropriate equipment should perform the tests and

repairs outlined in this section. Unauthorized service may void warranty of the unit.

CAUTION The module electronics can only be repaired and calibrated at the factory.

3.1.1 OM measuring unit

CAUTION Due to the complicated and sensitive mechanical construction any service inside

the O

measuring unit should not be attempted.

2

3.1.2 TPX measuring unit

CAUTION The TPX photometer and its components are repaired/calibrated at the factory.

Attempts to repair/calibrate the unit elsewhere will adversely affect operation of the

unit. The information provided is for reference only.

3.1.3 OM, TPX, and PVX measuring unit

CAUTION The OM, TPX, and PVX measuring units can be repaired only at the factory.

3.1.4 Serviceable or exchangeable parts

• Absorber

• D-fend

• Nafion tubes

• Fan filter

• Fan

• CPU board

• CPU software

• PVX Unit including PVX board

• Pump

NOTE: After any component replacement see chapter Adjustments and calibrations.

22

Document No. 800 1009-1

Page 29

3.2 Service check

These instructions include complete procedures for a service check. The service check is

recommended to be performed after any service repair. However, the service check procedures can

also be used for determining possible failures.

The procedures should be performed in ascending order.

The instructions include a check form, Appendix A, which should be filled in when performing the

procedures.

Compact Airway modules

The mark

the procedure.

The procedures are designed for monitors with software of level 00.

? in the instructions means that the check form should be signed after performing

3.2.1 Recommended tools

Tool Order No. Notes

Screwdriver

Ambient pressure manometer

Flowmeter

Flow cassette 50/1.1 873812

Extra silicon tubing

Calibration gas and the regulator 755583 (gas)

755533

Calibration gas and the regulator 755587 (gas)

755530

Calibration gas and the regulator 755581 (gas)

755533

for M-CAiOVX/M-CAiOV/M-CAiO

for M-COVX

for M-COV/M-CO/M-C

Gas Interface Cable 2.5 m / 8 ft 884299

3.2.2 Recommended parts

Part Order No. Notes

Absorber 895933

D-fend 876446

D-fend+ 881319 for M-COVX

Sampling line 3 m/10 ft 73319 anesthesia gas sampling line

Sampling line 2 m/7 ft 73318 for M-CAiOVX/M-COVX

D-lite / Pedi-lite 733950/73393

D-lite+ for condensing active humidification circuits

Document No. 800 1009-1

23

Page 30

Datex-Ohmeda S/5 monitors

Part Order No. Notes

Spirometry tube 2 m 890031

Spirometry tube 3 m 884101

D-fend O-ring (2 pcs) 65312

Filter (3 pcs) 886136 1 pcs @ latest revisions

Filter assembly 896025 @ latest revisions

Nafion tubes (2 pcs) 733382

Fan filter 886236

All modules

Detach the module box by removing the two screws from the back of the module. Be careful with

loose latch and spring pin for locking.

1. Check internal parts:

− all screws are tightened properly

− all cables are connected properly

− tubes are not pinched and there are no sharp bends on them

− all tubes are connected properly

− the front cover grounding pins are not bent against the CPU board

− there are no loose objects inside the module

NOTE: The tubes that are connected to the Oxygen board pressure transducers should not

be pressed too deep.

NOTE: Make sure that tubes are not in contact with the sampling pump or the O

its springs.

sensor, or

2

2. Check external parts:

?

3. Clean or replace the fan filter.

?

4. Detach the D-fend. Check the condition of the rubber O-rings on the metal D-fend

24

Document No. 800 1009-1

?

− the front cover and the front panel stickers are intact

− all connectors are intact and are attached properly

− the D-fend latch is moving properly

− the module box, the latch and the spring pin are intact

connectors, located in the Compact Airway Module front cover.

If necessary, detach the connectors by first disconnecting the tubes, then removing the

locking rings from the back of the front cover.

NOTE: The O-rings are recommended to be replaced annually.

?

Page 31

Compact Airway modules

5. Check that flow of air through the filters in the reference gas connection block (1 pc) and in

the pneumatic unit (2 pcs) is not obstructed.

Z

e

r

o

f

i

l

t

e

r

F

E

D

O

c

c

l

u

s

i

o

n

f

i

l

t

e

C

r

B

A

Reference gas

connection block

Figure 16 Pneumatic unit and reference gas connection block

NOTE: The filters are recommended to be replaced annually.

?

• Replace the D-fend and sampling line by new.

NOTE: Use only Datex-Ohmeda sampling lines in order to ensure proper functioning. 2

m/7 ft sampling line should be used with M-COVX and M-CAiOVX.

• Connect the Compact Airway Module to the Central Unit’s Module motherboard

using the Gas interface cable (the grounding plates of the cable should be removed).

• Turn the monitor on.

• Configure the monitor screen so that all the needed parameters are shown, for

example as follows:

Monitor Setup - Screen 1 Setup - Waveform fields - Field 1 - Paw

Field 2 - Flow

Field 3 - Off

Field 4 - O2

Field 5 - AA

Field 6 - CO2

Digit Fields

Lower Field 1 - Gases

• Preset the following gas measurement settings (if available):

Airway Gas - Select Agent - Hal

Spirometry Setup - Scaling Vol

Paw Scale - 20

Flow Scale - 15

6. Check that the fan is running.

?

25

Document No. 800 1009-1

Page 32

Datex-Ohmeda S/5 monitors

7. Wait until the message ‘Calibrating gas sensor’ disappears from the screen, then enter the

Service menu.

Monitor Setup - Install/Service (password 16-4-34) - Service (password 26-23-8)

Take down the information regarding Compact Airway Module software.

?

8. Enter the Compact Airway Module service menu.

Parameters - Gas Unit - General

Check that the shown module configuration corresponds with the used Compact Airway

Module type.

?

9. Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ -values are not increasing

faster than by 50 per second.

If one of the values is increasing faster it indicates a failure in module bus communication.

?

10. Enter the service menu Gases:

Gas Unit - Gases

Check that the flow measurement offset, i.e. the shown sample ‘Zero’ -value is within ±10

ml/min.

?

11. Check that the shown ‘Ambient’ -value corresponds with the current ambient pressure (±20

mmHg).

?

12. Check the zero valve.

Feed calibration gas and check that the gas readings in the service menu correspond with

the values on the gas bottle sticker. Keep feeding gas, then activate the zero valve from the

menu. The CO

(N2O, AA) reading should drop back near 0 %, the O2 reading near 21 %.

2

?

13. Perform the steam test for the Nafion tubes, or replace those by new. Replace the

absorber, if necessary.

CO

2

26

Document No. 800 1009-1

NOTE: The Nafion tubes are recommended to be replaced annually. In case of exchanging

the absorber it is recommended to replaced also this nafion tube.

NOTE: The CO

absorber is recommended to be replaced once in four years.

2

?

Page 33

Compact Airway modules

14. Perform sampling system leak test.

Prevent the module from performing the normal occlusion functions, i.e. controlling the

valves, by turning the pump first off, then on again from the menu.

Block the reference gas connector at the front panel.

Connect a flow cassette with high flow resistance value (50/1.1) to the end of the sampling

line and start following the ‘Amb-Work’ -value in the service menu. When the value exceeds

170 mmHg connect the other port of the flow cassette to the sample gas out connector and

switch the pump off.

Wait until pressure inside the sampling system is stabilized then notice the shown ‘AmbWork’ -value. The value, i.e. the pressure inside the sampling system should not drop more

than 6 mmHg in one minute.

If the pressure drops more, first ensure the made connections and repeat the test.

?

15. Check the flow rates.

Wait until the ‘Sample Flow’ -value is back near 200 ml /min.

Connect a flowmeter to the 3 meter sampling line (use a 2 meter sampling line for MCAiOVX and M-COVX) and check that the flow (the flowmeter reading) is within the following

range:

Sampling flow (ml/min) 180...220

If necessary, readjust the sampling flow:

Select ‘Sample gain adj’ from the menu. To increase the sampling flow, turn the ComWheel

counterclockwise, to decrease the flow, turn the ComWheel clockwise.

A change of 0.050 in the ‘Gain’ -value changes the flow approximately 10 ml/min.

After you have changed the gain, wait until the ‘Sample Flow’ -value on the screen gets back

near the original then check the flowmeter reading again.

Connect the flowmeter to the reference gas connector, check that the flow is within the

following range:

Reference flow

(ml/min)

M-CAiOVX/

M-COVX

27...40 25...45 31...45

M-C Others

Activate the zero valve on from the service menu. The ‘Sample Flow’ -value should not

change more than 20 ml/min. If the absorber is connected the value is 30 ml/min.

?

Document No. 800 1009-1

27

Page 34

Datex-Ohmeda S/5 monitors

16. Check that the ‘Amb-Work’ -value in the service menu is within the following range:

Amb-Work (mmHg) M-CAiOVX/M-COVX Others

?

17. Perform the gas calibration.

Airway Gas - Gas Calibration

NOTE: The calibration is not recommended to be performed before 30 minutes warm-up time.

Use calibration gas 755587 (5 % CO

and calibration gas 755583 (2 % Desflurane, 5 % CO

M-CAiOVX/M-CAiOV/M-CAiO,

and calibration gas 755581 (5 % CO

M-COV/M-CO/M-C.

70...115 40...75

, 95 % O2) for calibrating Airway Module, M-COVX,

2

, 33 % N2O, 55 % O2, balance N2) for

2

, 40 % N2O, 55 % O2) for calibrating

2

NOTE: You can calibrate the modules M-CO and M-COV also with the same calibration gas as

the M-COVX module, but M-C must always be calibrated with the gas 755581.

NOTE: For correct measurement values, modules need different amounts of oxygen in the

calibration. If you do not use the recommended calibration gases, the calibration does not

succeed.

?

18. Perform the fall time measurement in the GASES service menu.

Monitor Setup - Install/Service (password 16-4-34) - Service (password 26-23-8) -

Parameters - Gas Unit - Gases

Activate the measurement by selecting Fall Time Meas from the service menu. Feed

calibration gas until the message ‘Feed’ near the fall time values changes to ‘READY’. If

necessary, repeat the same procedure to get all the values on the screen.

Check that the measured values are within the following ranges:

fall time < 400 ms

CO

2

fall time < 400 ms

O

2

delay < 800 ms

CO

2-O2

?

28

Document No. 800 1009-1

Page 35

Anesthesia Agent measurement

19. Agent ID reliability.

Feed calibration gas (order code 755583) continuously at least for 30 seconds and check

that the ‘ID’ in the service menu shows ‘DES’ and that the value for ‘ID unrel.’ is lower than 50.

If the value is higher, repeat the gas calibration and check the value again.

?

Patient Spirometry measurement

20. Enter the service menu Spirometry:

Gas Unit - Spirometry

Connect a clean Spirometry tube to the module and a clean D-lite to the other end of the

tube. Block the D-lite’s sampling line port, for example with a Luer stopper.

Compact Airway modules

NOTE: Make sure that the date marking on the D-lite is 10/94 or newer.

Take the D-lite into your hand and occlude both ends tightly with your fingers (or with both

hands). Pressing creates a pressure inside the D-lite. Check that pressure near 5 cmH

generated (the ‘Aw Pressure’ -value in the service menu).

If the system leaks heavily, no pressure will be generated.

If there is a small leak in the connections, the monitor will measure a pressure difference

which is then interpreted as flow and seen on the monitor screen. The pressure waveform

(and the ‘Aw Pressure’ -value) decreases slowly and the flow waveform (the ‘Flow’ -value)

either goes above, or below the zero line, depending on which of the connectors is leaking.

In case of leakage, first check all the connections and try again.

2

O is

?

21. Remove the blockage from the sampling line port and connect the sampling line. Breath

through the wider side of the D-lite. Check that the flow waveform moves downwards when

you breath in, and upwards when you breath out.

?

22. If possible, check the Side Stream Spirometry measurement also with the Spirometry Tester

(order code 884202). Follow the instructions that are supplied with the tester.

?

29

Document No. 800 1009-1

Page 36

Datex-Ohmeda S/5 monitors

All modules

Turn the monitor off, disconnect the Gas interface cable and reassemble the module. Remember to

attach the plastic cover against the CPU board before installing the module box.

NOTE: When reassembling the module make sure that the tubes are not pinched between the

module box and internal parts.

23. Perform electrical safety check and leakage current test.

?

Install the Compact Airway Module into the Central Unit, turn the monitor on and wait until the

message ‘Calibrating gas sensor’ disappears from the screen.

24. Block the tip of the sampling line by your finger and check that the message ‘Sample line

blocked’ appears onto the monitor screen within 60 seconds.

?

25. Detach the D-fend and check that the messages ‘Check D-fend’ appears onto the monitor

screen within 30 seconds.

?

Reattach the D-fend. Simulate at least 5 breaths by feeding calibration gas into the

sampling line. Check that the shown gas information is correct.

26. Check that the monitor shows the message ‘Apnea’ within 30 seconds after you have

stopped feeding the gas.

?

27. Turn the monitor off, disconnect and clean the module.

?

• Fill in all necessary documents.

• It is recommended to fill in the PM sticker, since the service check includes all the

Planned Maintenance actions. Attach it to a suitable place on the module box.

30

Document No. 800 1009-1

Page 37

Compact Airway modules

3.3 Disassembly and reassembly

Disassemble the compact airway module in the following way. See also the exploded view of the

module.

1. Remove two screws from the back of the module.

2. Pull the module box slowly backwards and detach it from the main body.

Reassembling is essentially reversing what was described above.

CAUTION When reassembling the module, make sure that the tubes and cables are not

pinched between the boards and the cover.

3.3.1 PVX unit

1. Remove the module box.

2. Detach the CPU board and OM board from the module chassis (4 screws).

3. Disconnect the pump cable, pneumatics unit cable, fan cable, and the other cable of the

TPX unit from CPU board.

4. Disconnect OM unit’s cables, spirometry keyboard cable and PVX unit’s cables from the OM

5. Detach the front panel from the module chassis (1 screw).

6. Detach the PVX unit from the front panel (1 screw).

7. Reassembling is essentially reversing what was described above.

3.3.2 Pump unit

1. Remove the module box.

2. Cut off the pump’s clamp (panduit).

3. Unplug the hoses of the pump.

4. Disconnect the pump’s cable from CPU board. Pass the cable under the pneumatic unit by

5. Reassembling is essentially reversing what was described above.

3.3.3 CPU board

1. Remove the module box.

2. Detach the CPU board and OM board from the module chassis (4 screws).

board.

lifting it.

3. Disconnect the pump cable, pneumatics unit cable, fan cable, and both cables of the TPX

unit from CPU board.

4. Detach the CPU board from the OM board.

5. Reassembling is essentially reversing what was described above.

Document No. 800 1009-1

31

Page 38

Datex-Ohmeda S/5 monitors

3.3.4 Software of CPU board

1. Remove the module box.

2. Detach the CPU board and OM board from the module chassis (4 screws).

3. Disconnect the pump cable, pneumatics unit cable, fan cable, and the other cable of the

TPX unit from CPU board.

4. Detach the CPU board from the OM board.

5. Detach the software from the CPU board.

6. Reassembling is essentially reversing what was described above.

3.3.5 Instructions after replacing software or CPU board

After replacing the software or CPU board:

• perform the sampling system leak test.

• perform the occlusion test

• perform the gas calibration.

• perform Fall time Measurement

3.4 Adjustments and calibrations

See User’s Reference Manual for normal gas calibration instructions.

3.4.1 Gas sampling system adjustment

NOTE: Let the monitor run for 15 minutes before measuring flow rates.

For the flow rate measurements a flowmeter with a low flow resistance and capability to measure

low flow rates is required. A normal length of sampling line has to be connected to the monitor as it

has a considerable effect on the flow.

3.4.2 Flow rate measurement

If any flow rates are not correct, first replace the D-fend water trap. Then recheck the

incorrect flows.

Sampling flow rate is measured by rotameter at the sampling line. The rate should be between 180

and 220 ml/min. The flow rate is adjusted in the Gas Service Menu with ‘Sample Gain Adj.’.

Reference flow of the oxygen measuring unit are checked as follows:

Connect rotameter to the Gas Ref. inlet on the front panel. The flow rate should be between 31 and

45 ml/min (M-CAiOVX/M-COVX: 27-40 ml/min, M-C: 24-45 ml/min). The flow rate is not

adjustable.

32

Document No. 800 1009-1

Page 39

3.4.3 Flow rate adjustment

NOTE: Before adjusting the sampling flow make sure there is no leakage in the sampling system.

Refer to chapter 3.2 Service check, step 15; Check the flow rates.

Wait until the ‘Sample Flow’ -value is back near 200 ml /min.

Connect a flowmeter to the 3 meter sampling line (use a 2 meter sampling line for M-CAiOVX and

M-COVX) and check that the flow (the flowmeter reading) is within the following range:

3.4.4 Gas calibration

The gas calibration is performed in the Airway Gas menu. Please refer User’s Reference Manual.

3.4.5 Flow calibration

PVX measuring unit is calibrated at the factory and due to the unit’s design calibration is not

regularly needed. The calibration data is saved into the board’s EEPROM. In case calibration is

needed, it is recommended to perform the calibration both with adult values using the D-lite, and

with pediatric values using Pedi-lite.

Compact Airway modules

1. Connect a spirometry tube with a D-lite sensor to the compact airway module. To improve

the accuracy, the endotracheal tube and all accessories which normally are in use should

be attached also during the calibration.

2. Enter the Gas Unit service menu:

Enter the Spirometry menu.

3. After the flow is zeroed ('Zero OK' message displayed ) attach a preferably spirometry tester

to the flow sensor (D-lite or Pedi-lite). Select the sensor type.

4. Perform the calibration according to the tester instructions. Observe the values of inspired

and expired tidal volumes.

5. Adjust the reading to match the calibration volume (about 1000 ml for the D-lite and 300

ml for the Pedi-lite). Adjust Exp Flow Gain and Insp Flow Gain values in proportion to the

difference between measured values and the spirometry tester reading.

Monitor Setup - Install Service - Service - Parameters.

33

Document No. 800 1009-1

Page 40

Datex-Ohmeda S/5 monitors

4 TROUBLESHOOTING

4.1 Troubleshooting charts

Trouble Possible cause/treatment

No response to breathing Sampling line or water trap blocked or loose, or improperly attached.

Water trap container full.

See the gas sampling system troubleshooting.

SENSOR INOP. -message The temperature is too high, check fan and filter at the front panel

Communication error, check timeout and bad checksum values at the

service menu

xx ZEROING ERROR -message Gas zeroing failed. Condensation or residual gases are affecting zero

measurement. Allow module to run drawing room air for half an hour and

calibrate again.

CHECK D-FEND -message

(Air leak-message)

1)

REPLACE D-FEND -message

(Replace water trap -message)

REBREATHING-message

high -message)

(FiCO

2

SAMPLE LINE BLOCKED-message

(Air leak -message)

(SELECT AGENT -message)

1)

1)

1)

Probably water trap or the sampling line is not attached properly. Gas zero

valve failure. Pump failure or gas outlet blockage.

Indicates residue build-up on the water trap membrane. This decreases air

1)

flow. Replace the D-fend.

CO2 concentration in inspiratory air is too high. Possibly CO2 absorber in

ventilation is saturated. Change the ventilation absorber.

Sampling line or water trap is occluded. Water trap container is full. If

occlusion persists check internal tubing for blockages.

No anesthetic agent is selected though delivery is started. Vaporizer valve is

broken, or traces of cleaning or disinfecting agent in the water trap container

affecting the readouts. Let the container dry properly after disinfection

before use.

No response to any gas Sampling line, water trap, or internal tubing blocked or loose, or improperly

attached.

Occlusion or zero valve malfunction. Pump failure. Supply voltage missing.

Serial communication error.

Trouble Possible cause/treatment

Sudden increase in gas display Water trap malfunction. Check all internal tubing and the interior of the water

trap for occlusions or leaks. Replace water trap. Check flow rates.

Abnormally high

Pressure transducer failure.

response to all gases

(or abnormally low) or sudden

occlusion warning

1)

@ earlier revisions

34

Document No. 800 1009-1

Page 41

Compact Airway modules

Trouble Possible cause/treatment

Strong drift in all gases Leak in sampling line or internal tubing (especially in conjunction with too

low readings).

MVexp << MVinsp message Leak in patient circuit between patient and D-lite, or in the patient lungs, or

leak in tubes from D-lite to module. Check D-lite connection and D-lite

tubing.

(Disconnection)

(MVexp < 0.5 l/min message)

Low volumes

1)

1)

Too small tidal volumes for accurate measurement (not shown during

Apnea). Gas sampling is working correctly. Check D-lite connections and Dlite tubing.

4.1.1 CO2 measurement

Problem Possible clinical cause Possible technical cause Action

too low ETCO2 value • sudden decrease in

circulation

• pulmonary embolism

• hyperventilation

• leak in sampling system

• calibration error

• high by-pass flow from

ventilator

• check all connections

• check calibration

• very large dead-space

• large shunting

too high ETCO

2

• hypoventilation

• increased metabolism

• D-fend contaminated

• calibration error

• change D-fend

• check calibration

waveform clipped • • incorrect scaling • change scale

no response to

breathing

• apnea

• (disconnection)

• sampling line or water

1)

trap loose or blocked (air

1)

leak)

• check all connections

• sample gas outlet blocked • check that outlet is

open

ETCO2 overscale >15

% (>20 %)

1)

• abnormally high ETCO

(permissive hypercapnia)

• CO2 sensor contaminated

2

• D-fend malfunction

• call service technician

• change D-fend

Shown untill 32 %,

specified range

0...15 %

ETCO2>PaCO

2

• unit is mmHg or kPa and

ETCO

2

PCO

2

1)

@ earlier revisions

is close to arterial

• “dry gas” as default • change to “wet gas”

by using

install/service menu

35

Document No. 800 1009-1

Page 42

Datex-Ohmeda S/5 monitors

4.1.2 Patient spirometry

Problem Possible clinical cause Possible technical cause Action

insp TV>exp TV • leak in lungs • spirometry tube leak • check leakages --

perform leak test

• ET tube cuff leak • water inside D-lite or tubings • change tubings

and D-lite

• don’t use active

humidification

• another side stream gas

sampling between D-lite and

patient

• D-fend leaks

• connect gas

sampling only and

always to D-lite

• check D-fend

exp TV> insp TV • spirometry tube leak • check leakages --

perform leak test

• water inside D-lite or tubings • change tubings

and D-lite

• don’t use active

humidification

loop overscale • wrong scale selected • change scaling

monitored volumes < set

volumes

• leak between ventilator and

D-lite

• check ventilator

connections

strongly vibrating loop • mucus in ET tube - • suction the patient

• water or secretions in hoses

or D-lite

• change dry D-lite

and/or empty the

water from hoses

too large or too small

volumes

• wrong mode vs sensor

selection

• check mode and

sensor

36

Document No. 800 1009-1

• incompatible between

selected sensor and sensor

used

− D-lite for adult

− Pedi-lite for

pediatric

Page 43

Compact Airway modules

Problem Possible clinical cause Possible technical cause Action

fluctuating Raw • mucus in airways or tubings

• breathing effort against the

ventilator

• patient triggered breaths

too high Raw • kink in tubing

• mucus

• asthmatic patient

• bronchospasm

Raw value invalid • spontaneous breaths

• breathing efforts against the

ventilator

• patient triggered breaths

too high Ppeak • bronchospasm

• patient is coughing

• patient breaths against the

ventilator

• ventilator exp. valve causes

fluctuations during exp.

flow

• obstruction in airways

• HME obstructed

static PEEPi not

measured

Compl value invalid • spontaneous breaths

• CO2 measurement is not

connected

• stat PEEPi measurement

not selected

1)

• exp. pause did not last at

least 4 sec.

• connect CO

meas. to D-lite

• go to

spirometry

1)

setup

2

1)

only @ earlier revisions

37

Document No. 800 1009-1

Page 44

Datex-Ohmeda S/5 monitors

4.1.3 Gas exchange

Problem Possible clinical cause Possible technical cause Action

“Strange” values • ventilation mode:

BiPaP, CPAP with high

continuous by-pass

flow

• presence of N2O or

anesthetic agents in

ICU applications

Unphysiological VO

readings

2

• unstable O

− gas mixer

delivery

2