Page 1

Datex-Ohmeda

S/5™ CPU Board, B-CPU5 (Rev. 00)

S/5™ CPU Board, B-CPU4 (Rev. 01)

Software Cards

Technical Reference Manual

Datex-Ohmeda Inc.

3030 Ohmeda Drive

MADISON, WI 53718

U.S.A.

Tel. +1-608-221 1551 Fax +1-608-222 9147

www.us.datex-ohmeda.com

All specifications are subject to change without notice.

Document No.8002948-0

October 2001

Datex-Ohmeda Division,

Instrumentarium Corp.

P.O. Box 900, FIN-00031

DATEX-OHMEDA, FINLAND

Tel. +358 10 394 11 Fax +358 9 146 3310

www.datex-ohmeda.com

Instrumentarium Corp. All rights reserved.

Page 2

Page 3

Table of contents

TABLE OF CONTENTS

CPU Boards and Software Cards

TABLE OF CONTENTS i

Introduction 1

1 Specifications 2

1.1 Electrical requirements .............................................................................................................................2

1.2 Environmental requirements .....................................................................................................................2

2 Functional Description 3

2.1 CPU board, B-CPU5/B-CPU4 ....................................................................................................................3

2.2 Software Cards, U-xxxxxx/L-xxxxxxS/S-xxxxxS..............................................................................................5

2.3 Connectors and signals.............................................................................................................................6

2.3.1 Internal connectors...........................................................................................................................6

3 Service Procedures 7

3.1 General service information.......................................................................................................................7

3.2 Service check ...........................................................................................................................................7

3.2.1 Recommended tools ........................................................................................................................7

3.3 Disassembly and reassembly..................................................................................................................10

3.3.1 Downloading/replacing software on CPU Board, B-CPU5/B-CPU4 ...................................................10

3.3.2 Performing Factory Reset ................................................................................................................12

3.4 Adjustments and calibrations..................................................................................................................12

4 Troubleshooting 13

4.1 Troubleshooting flowcharts......................................................................................................................13

4.1.1 Monitor..........................................................................................................................................13

4.1.2 Digital section................................................................................................................................14

4.1.3 Software Card ................................................................................................................................15

4.2 Error messages.......................................................................................................................................16

5Service menu 17

5.1 Service menu structure ...........................................................................................................................17

5.2 Service...................................................................................................................................................18

5.3 Service menu .........................................................................................................................................19

5.4 Frame ....................................................................................................................................................19

5.4.1 Memory .........................................................................................................................................20

5.4.2 Communication..............................................................................................................................20

5.5 Parameters.............................................................................................................................................21

5.6 Set/Test.................................................................................................................................................22

5.6.1 Country Settings .............................................................................................................................23

5.7 Service Log.............................................................................................................................................24

5.7.1 Error History ...................................................................................................................................24

5.7.2 Event History ..................................................................................................................................25

5.7.3 Alarm History..................................................................................................................................25

5.7.4 Maintenance..................................................................................................................................26

5.8 Record Data ...........................................................................................................................................28

5.9 Remote Access.......................................................................................................................................28

Document No.8002948

i

Page 4

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

6 Spare Parts 29

6.1 Spare parts list.......................................................................................................................................29

6.2 Products ................................................................................................................................................29

6.2.1 CPU boards and software ...............................................................................................................29

6.2.2 CPU Board, B-CPU5/B-CPU4 .........................................................................................................29

7 Earlier Revisions 30

APPENDIX A 31

Service check form A-1

TABLE OF FIGURES

Figure 1 B-CPU5 / B-CPU4 ................................................................................................................................1

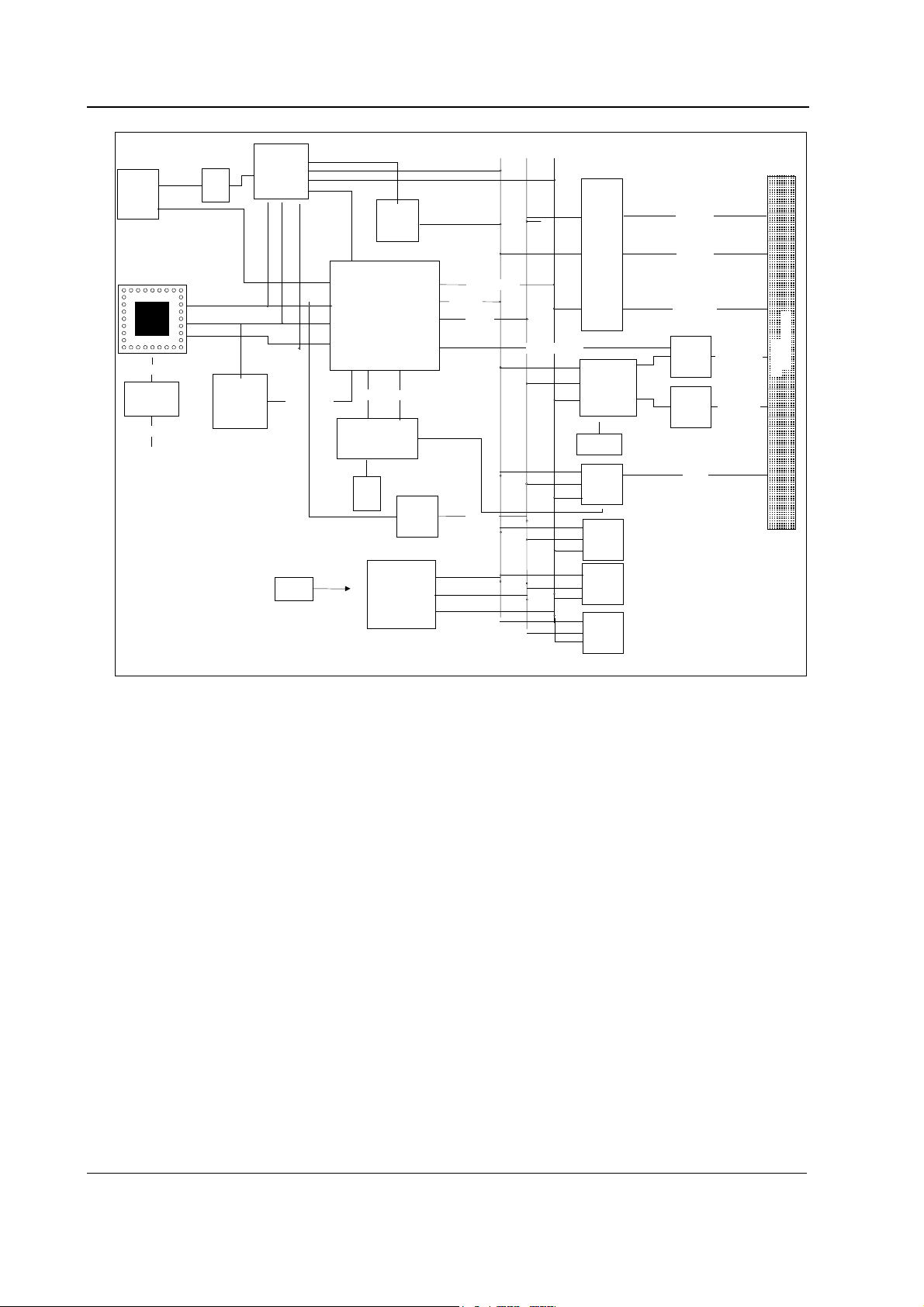

Figure 2 CPU board block diagram, B-CPU5/B-CPU4..........................................................................................4

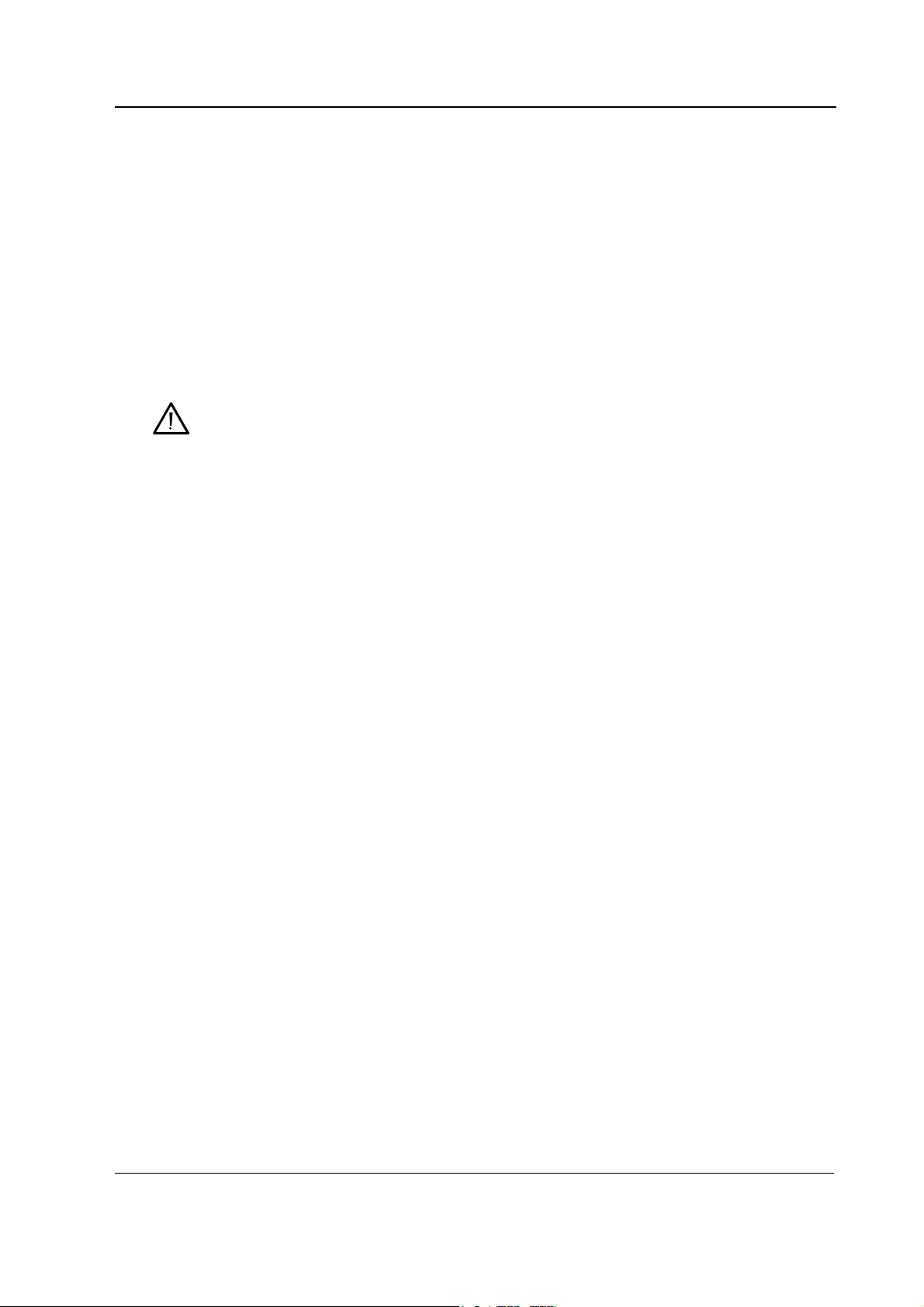

Figure 3 Monitor troubleshooting flowchart.......................................................................................................13

Figure 4 Digital section troubleshooting flowchart .............................................................................................14

Figure 5 Software Card troubleshooting flowchart .............................................................................................15

ii

Document No. 8002948

Page 5

INTRODUCTION

This section provides information for the maintenance and service of the following products:

• CPU board, B-CPU5

• CPU board, B-CPU4

• Software Cards, U-xxxxxx/L-xxxxxxS/S-xxxxxS

CPU boards and softwares

Figure 1 B-CPU5 / B-CPU4

Document No.8002948

1

Page 6

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

1 SPECIFICATIONS

1.1 Electrical requirements

Interruptibility Data memory and alarm settings are saved during power failures up

to 15 minutes

1.2 Environmental requirements

Operating temperature 10...35 °C / 50...95 °F

Storage temperature -10...+50 °C / 14...122 °F

Atmospheric pressure 660...1060 hPa (660...1060 mbar)

Humidity 10...90 % non-condensing

2

Document No. 8002948

Page 7

2 FUNCTIONAL DESCRIPTION

2.1 CPU board, B-CPU5/B-CPU4

The CPU board takes care of the central processing.

The main features of the CPU board are:

• AMD 486DX4 or 486DX5 processor

• Internal clock frequency 75 MHz

• 32 MB DRAM / 16MB DRAM (B-CPU4)

• 64 MB program flash memory / 32MB (B-CPU4)

• 8 kB static RAM with real time clock

• 32 kB EEPROM memory

• 2 + 2 channels UART:

• 3 serial channels with signals in AC-logic level

• 1 serial channel signals in RS232-level

• Programmable alarm sound generator

• PC-card slot for software updates

CPU boards and softwares

Document No.8002948

3

Page 8

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

A

X

CONTRO L

PS2

KEYB

CONN

DAC

2 CH.

PLD

NAND

FLASH

4Mx8

ISA BUS

Buffer

BSA[0..23]

BSD[0.15]

80486

DX4/DX5

3.3V

3.3V

5V->3.3V

REGULAT OR

5V

[2..31]

D[0..31]

CONTROL

72 pin SIMM

DRAM

MODULE

16..32MB

MA,RAS,CAS

FLASH

CARD

RADISYS

R400E

PC-ChipSet

50MHz

14.3MHz

FREQUENCY

GENERATOR

14.318

MHz

XTAL

PCMCIA

-controller

Buffer

ISA CON TROL

SD[0..15]

SA[0..1]

SA[2..23]

SD[0..15]

2 x serial cannel

ISA CO NTROL

SA[0..23]

Figure 2 CPU board block diagram, B-CPU5/B-CPU4

DUART

7.3728MHz

XTAL

Audio

Generator

EEPROM

64Kx8

BOOT

FLASH

2Mx16

SRAM

& RTC

8kx8

BCONTROL

Buffer

TXDA..CTSC

232-Buffer TXDD..RXD

AUDIO

D

96-pin connector

CPU BUS

The CPU board, B-CPU5/B-CPU4 is made with PC-technology components. Radisys chipset and

PLD handle all timings and signaling for ISA type CPU bus.

The B-CPU5/B-CPU4 contains an onboard flash memory where software is downloaded from a

software card.

Powerfail or standby

When the monitor is turned to standby or the mains voltage fails, NMI-interrupt is generated by the

power control logic. The interrupt signal in the CPU means that all supply voltages except +5V for

the CPU board will be switched off shortly. NMI interrupt service program then saves all necessary

parameters in the static RAM before supply voltages fail.

When hardware detects HALT command generated from power down; all the outputs to the CPU

motherboard are left floating in high impedance state. Only DRAM refreshing cycle continues to

occur. The halt state will continue until a RESET pulse from the power control logic circuit is

received.

4

Document No. 8002948

Page 9

Watchdog functions

There are certain watchdog functions to ensure the monitor’s performance. The UPI4(NET) board

and the primary display controller board interrupt the CPU board continuously in order to state that

they function properly. The CPU board refreshes the watchdog timer in the power supply unit in

order to prevent reset pulse. If the primary display controller board or the CPU board stops the

refreshment, the monitor will be reset in order to prevent false information to be displayed on the

screen. If the UPI4(NET) board stops the refreshment, the board will be reset internally.

SRAM M48T18

Lithium battery back-up 8 kB static RAM with a real-time clock.

CAUTION The IC contains a lithium battery. Discard the battery according

to local regulations

CPU boards and softwares

.

2.2 Software Cards, U-xxxxxx/L-xxxxxxS/S-xxxxxS

Upgrade software, U-xxxxxx and Service software, L-xxxxxxS/S-xxxxxS are delivered on an 8 MB/4

MB PCMCIA flash memory card.

The upgrade software has been developed for monitor software upgrades. The uprgade software

can be downloaded onto a monitor that is equipped with the B-CPU5/B-CPU4.

The service software has been developed to replace the original monitor software in case of a BCPU5/B-CPU4 failure. The service software is downloaded onto a replacement empty B-CPU5/BCPU4. See section 3.3.1 “Downloading/replacing software on CPU Board, B-CPU.””

There is service software available of each S/5 monitor software version. The functionality of the

service software is equal to the functionality of the corresponding original S/5 monitor software.

The Service software, L-xxxxxxS is license software. The license agreement that is delivered with the

software should be archived in a secure location. Relevant license number may have to be referred

when contacting Datex-Ohmeda for service/support. The licence number is needed also for

possible software upgrades.

CAUTION The software card is not write-protected. For safety reasons do not use software

cards in any other purposes, or on any other platforms than they are designed for.

Document No.8002948

5

Page 10

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

2.3 Connectors and signals

2.3.1 Internal connectors

CPU board - CPU mother board

AB C

1 +15 V AGND DGND

2 -15 V BALE DGND

3 SA0 SA1 DGND

4 SA2 SA3 RESET_RS485

5 SA4 SA5 -RESET_RS485

6 SA6 SA7 DATA_RS485

7 SA8 SA9 -DATA_RS485

8 SA10 SA11 TXDD_RS232

9 SA12 SA13 RXDD_RS232

10 SA14 SA15 PWM_ECG

11 SA16 SA17 BIT1IN

12 SA18 SA19 TXDC

13 SA20 SA21 RXDC

14 SA22 SA23 RTSC

15 -SMEMR -SMEMW CTSC

16 -SIOR -SIOW TXDB

17 CLK -RESET RXDB

18 -IOCHRDY IRQ10 RTSB

19 N/C_1 IRQ11 CTSB

20 N/C_2 IRQ12 TXDA

21 -SBHE IRQ15 RXDA

22 SD0 SD1 RTSA

23 SD2 SD3 CTSA

24 SD4 SD5 AUDIO_OUT

25 SD6 SD7 +5 V

26 SD8 SD9 +5 V

27 SD10 SD11 +5 V

28 SD12 SD13 +5 V

29 SD14 SD15 ON/STBY

30 +15 VD -RESET_CPU +5 V_CPU

31 +15 VD +32 VD REFRESH_WD

32 GNDD GNDD POWER_FAIL

6

Document No. 8002948

Page 11

CPU boards and softwares

3 SERVICE PROCEDURES

3.1 General service information

The field service of the B-CPU5/B-CPU4 is limited to replacing the actual CPU board, the

SRAM/Timekeeper battery, or mechanical parts. Faulty CPU boards and used service software

cards can be returned to Datex-Ohmeda for repair/exchange.

Datex-Ohmeda is always available for service advice. Please provide the unit serial number, full

type designation and a detailed description of the fault.

CAUTION Only trained personnel with appropriate equipment should perform the tests and

repair outlined in this section. Unauthorized service may void warranty of the unit.

3.2 Service check

These instructions include complete procedures for a service check. The service check is

recommended to be performed after any service repair. However, the service check procedures can

also be used for determining possible failures.

The procedures should be performed in ascending order.

The instructions include a check form (Appendix A) which should be filled in when performing the

procedures.

The mark

the procedure.

The procedures are designed for monitors that contain the S/5 monitor software, L-xxx01(A).

However, most of the procedures also apply to monitors that contain some other monitor software

revision / type.

? in the instructions means that the check form should be signed after performing

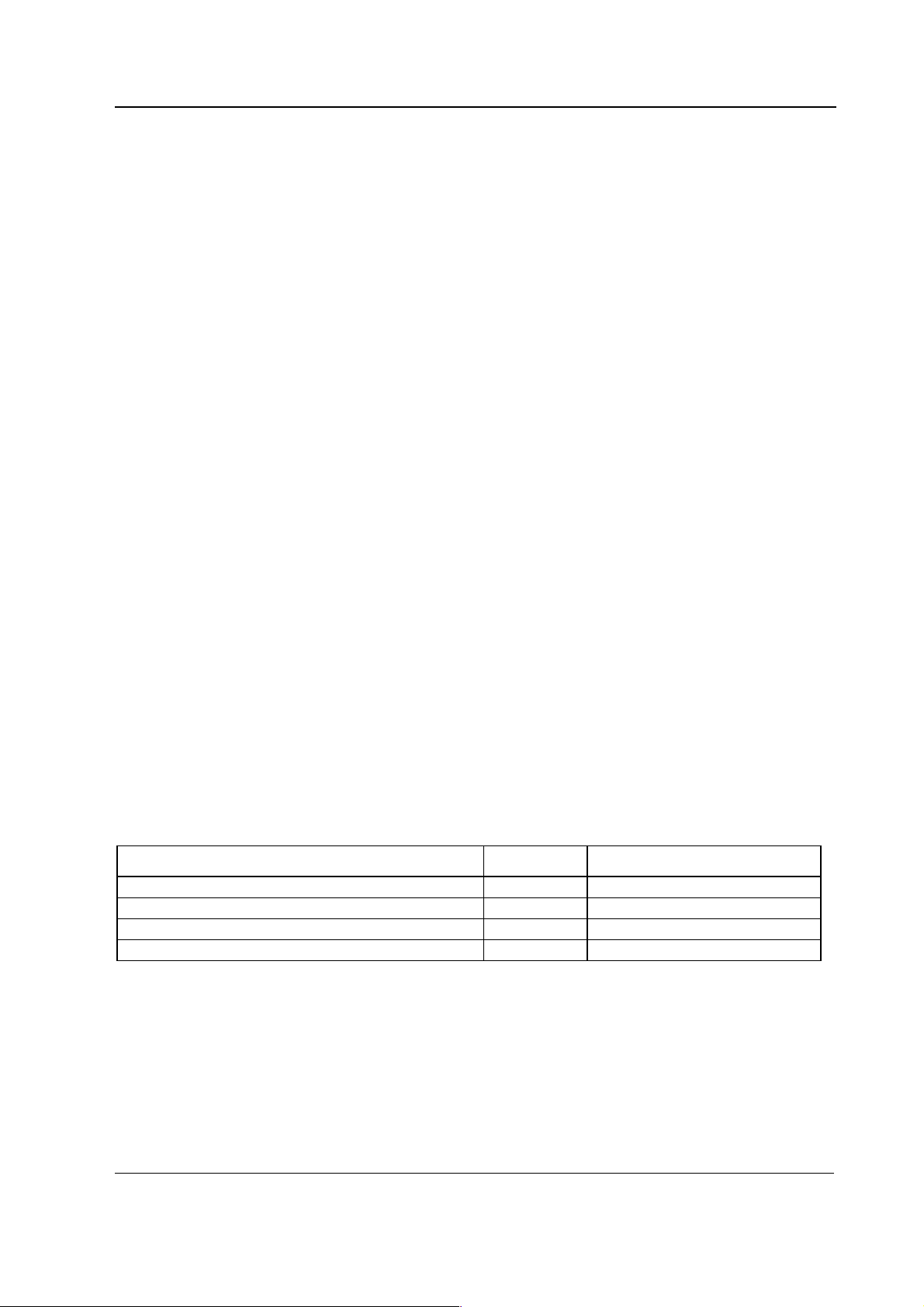

3.2.1 Recommended tools

Tool Order No. Notes

Command Bar / Command Board

M-REC

M-NE(12)STPR/M-ESTPR/M-ESTP

Screwdriver

General

Make sure that no cables or modules are connected to the Central Unit, F-CU8. Lift off the video

display with its stand, if placed on the Central Unit.

Document No.8002948

7

Page 12

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

CPU board

1. Check that the CPU board rear panel is clean and intact. Check that both CPU and software

device plates are intact.

?

2. Check that the grounding plate under the CPU board rear panel is attached properly and is

not bent.

?

3. The SRAM/Timekeeper battery on the CPU board is recommend to be replaced after every 8

years. Replace the battery, if necessary.

NOTE: The Factory Reset must be performed, if the SRAM/Timekeeper battery is replaced.

?

General

4. Check that all the rear side PC boards are secured to the Central Unit with two screws.

?

5. Install the video display together with the Command Bar/Ccommand Board, the M-

NE(12)STPR/M-ESTPR/M-ESTP and the M-REC. Connect the power cord and turn the

monitor on.

Check that the fan is running.

?

6. Check that the monitor starts up properly, i.e. the alarm LEDs on the Command

Bar/Command Board turn blank, the start-up sound is heard from the loudspeaker and the

normal monitoring screen appears. No error messages should appear onto the screen.

?

7. Check that the connected modules are recognized, i.e. the needed parameter information is

shown on the screen and the M-REC records two lines of start-up information.

If some parameter information is missing, check the screen configuration from the

MONITOR SETUP -menu.

?

8. Check that the clock on the screen shows correct time. Adjust the time, if necessary.

Monitor Setup - Time And Date

8

Document No. 8002948

NOTE: If the clock shows time 0:00 continuously (at successive start-ups), the

SRAM/TIMEKEEPER battery should be replaced. The FACTORY RESET must be performed

after the battery is replaced.

?

Page 13

CPU boards and softwares

9. Check the loudspeaker volume settings by setting the alarm sound:

Alarms Setup - Alarm Volume

Test the whole volume scale from 1 to 10 by turning the ComWheel and check that the

alarm volume changes correspondingly. The alarm sound should be clear and audible with

all the settings.

?

10. Enter the service menu.

Monitor Setup - Install/Service (password 16-4-34) - Service (password 26-23-8)

Take down the information regarding the monitor software.

?

11. Select SERVICE LOG from the menu. Record the Service Log onto the M-REC by selecting

RECORD LOG. Check the content of recording for possible problems, then empty the Service

Log by selecting RESET LOG from the menu.

?

12. Test the Central Unit watchdog circuitry:

Monitor Setup - Install/Service (password 16-4-34) - Service (password 26-23-8) Set/Test -

Select the watchdog tests one by one and check that the monitor performs a restart in all

other cases except when selecting the WD by UPI .

NOTE: When selecting WD BY OVERLOAD, restarting should take place approximately after

15 seconds. With the other tests restarting takes place within a couple of seconds.

If restarting did not take place, try to locate the fault:

Watchdog --> CPU board/Power supply unit

WD by Overload --> CPU board

WD by GSP --> Primary display controller board/CPU board

?

13. Check that the monitor is capable of storing the trend information and temporary settings in

a short (max. 15 minutes) standby.

Turn the monitor to standby and disconnect the power cord. Wait for two minutes, then

reconnect the power cord and turn the monitor back on. The monitor should perform a

“Warm start” which means the trend information and temporary settings should still be

available. If the monitor performed a “Cold start” instead, the battery fuse or the lead acid

battery of F-CU8 should be replaced.

NOTE: The B-CPU5/B-CPU4 requires 2 Amps battery fuse (P/N 51063).

The information regarding a start-up is also saved in the Service Log.

?

9

Document No.8002948

Page 14

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

14. Perform an electrical safety check and leakage current test.

?

15. Check that the Central Unit functions normally after the performed electrical safety check.

?

• Fill in all necessary documents.

3.3 Disassembly and reassembly

NOTE: Switch the monitor to standby and press the service reset -switch at least for five seconds

before detaching any PC boards.

1. Remove screws and detach all PC boards and cover plates from the right side of the CPU

board.

2. Remove the screws on the CPU board.

3. Detach the CPU board.

Reassembly should be made in reversed order.

NOTE: When reinstalling PC boards, push the boards carefully until they stop before fastening them

with screws.

3.3.1 Downloading/replacing software on CPU Board, B-CPU5/B-CPU4

See also “Replacing CPU Board, B-CPU5/B-CPU4” on Part I/System Installation.

NOTE: All user settings will be lost after downloading/replacing monitor software.

NOTE: During the downloading of monitor software the serial number of the CPU board is written

onto the software card and is matched with the downloaded monitor software serial number. If the

downloading of monitor software would fail, the same monitor software could be downloaded

again only onto the same CPU board, but not onto any other CPU board.

1. Make sure that the monitor is turned to standby. Press and hold the service reset switch on

the Central Unit rear panel for at least five seconds, or until an audible tone is generated.

2. Move off the lid for software card on the B-CPU5 / B-CPU4 rear panel.

10

Document No. 8002948

Page 15

CPU boards and softwares

!

3. Insert the software card into the card drive slot and firmly press the card in position.

4. Turn the power on.

5. Wait for approximately 80 seconds. After the start up screen appears enter the Service View

and make sure that the information regarding monitor software has been updated. Memorize

the serial number of new software.

6. Remove the software card and attach the lid.

7. Pick up the software device plate with the serial number of the new software and attach the

device plate on the B-CPU5/B-CPU4 rear panel.

NOTE: The license agreement, if delivered with the monitor software, needs to be in accordance

with the corresponding monitor software serial number. Make sure you archive the license

agreement in a secure location.

8. Perform Factory Reset.

9. Set the time and date.

10. Set the monitor’s network communication according to the used network software, if

necessary.

Network –service menu:

Network software S-CNET99 -> DRI Level = 1999

Network software S-CNET01 -> DRI Level = 2001

NOTE: If the DRI level is changed, the monitor will restart automatically.

11. Check that there are no error messages on the screen.

12. Restore the original user settings, if necessary.

See the troubleshooting flowchart for software card, if the downloading of new software failed.

NOTE: Right after the monitor software downloading the start-up time is considerably longer.

Document No.8002948

11

Page 16

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

3.3.2 Performing Factory Reset

NOTE: The Factory Reset is necessary after downloading of monitor software and after replacing the

CPU board or SRAM/Timekeeper battery.

NOTE: The Factory Reset will restore all your customized defaults, including language selection, to

factory defaults.

1. Press the

2. Select Install/Service and password (16-4-34).

3. Select Service and password (26-23-8).

4. Select Set/Test and perform Factory Reset.

5. The monitor will perform an automatic restart. After the restart is completed, restart the

monitor also manually by the On/Standby –switch.

Monitor Setup key.

3.4 Adjustments and calibrations

No calibrations or adjustments are needed on the CPU board, B-CPU5/B-CPU4.

12

Document No. 8002948

Page 17

4 TROUBLESHOOTING

4.1 Troubleshooting flowcharts

4.1.1 Monitor

M onitor not functioning

CPU boards and softwares

O n/S T B Y sw itch 'O N '

D isplay connected?

Keyboard connected?

Pow er cord

connected?

No

C onnect pow er cord

R em ove all m odules

a n d tu rn p o w e r o n

Is fan running?

Yes

Any LEDs lit

on keyboard?

Yes

Start-up texts

appear on

screen?

Yes

Yes

No

No

OK?

No

No

No

C onnect and check

No

OK?

D isconnect and reconnect the pow er cord

Yes

OK?

No

Turn pow er on by shorting

13 (GND) and 20 (ON/STBY)

at G as Interface board connector

Is fan running?

Yes

Keyboard trouble. S ee part II

for troubleshooting.

Yes

The pow er supply unit

w as shut dow n by instant over

voltage in the m ains.*)

*) N O T E ! In c a s e o f s h o rt p o w e r o ff

and autom atic start-up see section

"P ow er logic board/P rotections" to find

possible reason.

No

C lock etc

appears on

th e scre en ?

Yes

Plug in a m odule

M odule data

appear on

th e scre en ?

No

Yes

Pick up next

m odule

Faulty C entral U nit. G o to

No

next page.

A nother

m odule w orks

in sam e place?

No

C h e c k o th e r

positions w ith sam e

m o d u le , W o rk ?

Figure 3 Monitor troubleshooting flowchart

Yes

Faulty m odule. G o to M odule

troubleshooting.

Yes

Faulty m odule m other board

F a u lty C e n tra l U n it, g o to

No

next page.

13

Document No.8002948

Page 18

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

4.1.2 Digital section

Digital section faulty.

Remove all modules and boards

except CPU, UPI and display

controller board

A

Turn

the monitor on.

OK ?

Yes

No

beep is

heard when

monitor is

turned

on ?

Yes

No

Replace CPU board.

Insert one of the removed

boards.

Turn

the monitor on.

OK ?

No

Replace faulty board

Figure 4 Digital section troubleshooting flowchart

Yes

Is tone

same as at

OK start ?

No

Is tone

same as at

OK start but

longer ?

No

Is tone

lower and longer

than at OK

start ?

Yes

Try with another display

OK?

No

Yes

Replace Display controller.

Yes

Replace UPI-board

Yes

Replace display

14

Document No. 8002948

Page 19

4.1.3 Software Card

A

CPU boards and softwares

SERVICE PROCEDURE:

Downloading of Service software or

Upgrade software from a software

card onto the CPU board.

Insert the software card into

the card slot.

Turn the power ON.

Wait for 80

seconds.

Start-up display

appears?

Yes

Has the information

regarding monitor software

been updated on the

Service View?

Yes

Remove the

software card.

Perform Factory

Reset.

OK.

ttach the device plate with the serial

number of new software.

No

No

Check the software

card's connection

in the card slot

and try again.

OK ?

No

Try with another

software card.

Please read the

note below.

No

Replace the CPU

board and try again.

NOTE:

The software card may be

defective, or all available

software has already been

downloaded from the

software card.

Yes

OK

OK

Figure 5 Software Card troubleshooting flowchart

15

Document No.8002948

Page 20

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

4.2 Error messages

SRAM Error

The SRAM memory is located on the CPU board. The SRAM Error is due to memory malfunction.

Restart the monitor. If the problem persists, replace the SRAM/Timekeeper battery. Remember to

perform factory reset after the replacement.

EPROM Error

The EPROM Error message is displayed due to problems in the communication between the CPU

board and the software flash memory. Replace the CPU board. Remember to perform factory reset

after the replacement.

EEPROM Error

The EEPROM memory is located on the CPU board. The EEPROM Error message is displayed due to

memory malfunction. Perform factory reset. If the problem persists, replace the CPU board.

Remember to perform factory reset after the replacement.

RAM Error

The RAM memory is located on the CPU board. The RAM Error message is displayed due to memory

malfunction. Replace the CPU board. Remember to perform factory reset after the replacement.

16

Document No. 8002948

Page 21

5 SERVICE MENU

The monitor software contains service menus, which can be used in examining the monitor

functions and also in troubleshooting in case a fault occurs.

5.1 Service menu structure

Service M enu

Frame

CPU boards and softwares

Memory

Communication Analog Outputs

Network

MemCards

Display

Keyboard Keyboard Type

Parameters Gas Unit

Set/Test

Power Supply Battery

Keyboard Log

ECG

STP

P / PT

PP

COP

NIBP

NMT

M-SAT

More . . .

Country Settings

Network Comm

Network Status

MemCard Comm

MemCard Status

General

Gases

Spirometry

Interface

TONO

EEG

DIS Interfacing

Service Log

Record Data

Remote Access

Error History

Event History

Alarm History

Maintenance Planned Maint.

Repair

Upgrade

17

Document No.8002948

Page 22

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

5.2 Service

1. Press the Monitor Setup key.

2. Select Install/Service (password 16-4-34).

3. Select Service (password 26-23-8).

18

Document No. 8002948

Page 23

5.3 Service menu

The field on the right shows software versions and their release dates of different parts of the

monitor, control numbers of measuring boards and serial numbers of modules (if available).

See descriptions for Service Menu submenus from

sections:

5.4 Frame

5.5 Display

5.6 Keyboard

5.7 Parameters

5.8 Set/Test

5.9 Service Log

5.10 Record Data

5.11 Remote Access

Scroll Vers enables to scroll the field on the right side.

‘-More-’ indicates that there are more lines to be viewed.

Record Vers

By choosing this selection, the software versions and

other information are printed onto the device defined in

the Record Data menu.

CPU boards and softwares

5.4 Frame

The frame menu includes service menus common for the

frame.

19

Document No.8002948

Page 24

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

5.4.1 Memory

A service menu to check the status of the memory used in

CPU board of the monitor.

Test Memory tests the condition of the EEPROM/Flash

memory component of the CPU board. If the result of the

test is Fail, see section “Error messages.”

Test SRAM tests the Static RAM memory of the CPU

board in a similar way as the EEPROM/Flash memory. If

the result of the test is Fail, see section “Error

messages.”

Real time clock test is run at every start up and also

during the operation of the monitor. If the result of the

test is fail, the battery for SRAM timekeeper should be

replaced.

5.4.2 Communication

A service menu for showing information about internal

RS-485 and external RS-232 communication.

Module Bus (RS485) view shows information related to

the module bus.

UPI ints shows the number how many times the CPU

board has sent an interrupt to UPI board. The running

number should raise at a frequence of at least 100 Hz. If

the numbers don't raise there is trouble with the interrupt

line between CPU board and UPI board or with the boards

themselves.

The 10 ms tick shows how many 10 ms intervals the UPI

microprocessor has been on after last UPI reset. The UPI

microprocessor counts the 10 ms intervals. The number

must be running all the time at the frequency of 100 Hz. If

the number doesn't rise, the problem is in the UPI board.

Serial I/O (RS-232) view shows information about the

communication through the UPI board RS232 serial

connector X3.

Interface status shows whether the interface through the

connector is OPENED, ACTIVE or CLOSED. Opened

indicates that the hardware and software for the interface

is running but there is no connection or that there have

been errors in using the interface. Active indicates that

the interface is operating normally. Closed indicates that

the necessary hardware is not present.

Statistics In/Out show the numbers of received and

transmitted data packets and data bytes.

Rx errors show the number of received erroneous data

packets.

20

Document No. 8002948

Page 25

5.5 Parameters

The parameter menus are

explained in each parameter

chapter.

CPU boards and softwares

21

Document No.8002948

Page 26

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

5.6 Set/Test

The power supply unit contains a watchdog circuitry,

which needs refreshment at every 1.5 seconds. If the

refreshment did not occur, the watchdog circuitry will

reset the main CPU. In normal operation the main CPU

refreshes the watchdog circuitry at every 0.2 seconds.

The purpose of the watchdog circuitry is to restart the

monitor if there was a serious malfunction. This feature is

useful in two cases: when the main CPU is not able to

control the monitor, or when the CPU controls the monitor

but detects a serious malfunction. Watchdog tests check

proper functionality of the watchdog circuitry in various

conditions.

Watchdog test ensures directly that the watchdog of the

power unit functions properly. Choosing this test prevents

the watchdog circuitry from refreshing and shows running

seconds with an accuracy of 0.1 seconds.

The test should have the following result when the

watchdog circuitry is working properly: The monitor will

restart after 1.5 seconds from the start of the test. In

malfunction: ‘>20 s’ is displayed, and the test will

interrupt. In this case, the fault is in the watchdog circuitry

of the power unit.

WD by Overload test ensures the functionality of a

feature, where the software controls the monitor, but

detects an overload situation in the main CPU.

The test should have the following result when the feature

is working properly: The monitor will restart after 15

seconds from the start of the test.

WD by UPI test ensures the functionality of a feature,

where the software controls the monitor, but detects a

malfunction in the UPI processor and restarts the

UPI4(NET) board. The test will prevent the UPI processor

from functioning during the test.

The test should have the following result when the feature

is working properly: The monitor will restart the UPI4(NET)

board without any visual effects.

WD by GSP ensures the functionality of a feature, where

the software controls the monitor, but detects a

malfunction in GSP processor (located on the primary

display controller board) and performs a restart. The test

will prevent GSP processor from functioning during the

test.

Immediately after the test starts, the screen update

stops. The test should have the following result when the

feature is working properly: The monitor will restart after 5

seconds from the start of the test.

Factory Reset restore factory default settings and clear

data memories. Factory reset should be run if monitor

software is replaced or if the SRAM/Timekeeper battery is

replaced.

22

Document No. 8002948

Page 27

5.6.1 Country Settings

National Reqs

Select software features, which include national

requirements.

Power Frequency

Set power frequency (50 Hz/60 Hz). This setting is used

to filter out possible power frequency interference from

the parameter measurements.

Time format

Set time format of the real time clock (24 h/12 h).

CPU boards and softwares

23

Document No.8002948

Page 28

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

5.7 Service Log

Error, event, alarm and maintenance data is stored in

Service Log.

The service log contains information about the occurred

monitor errors, events and alarms since the last factory

reset or service log reset. The service log is saved in the

EEPROM memory of the main CPU board. The user can

also store different maintenance events to the

maintenance log.

Maintenance menu is for setting and viewing the

maintenance information of the monitor

Error History is for selecting the error history view onto the right side of the menu. Event History is for selecting the event history view onto the right side of the menu. Alarm History is for selecting the alarm history view onto the right side of the menu. Scroll Last Er (Ev) is for scrolling the error / event / alarm information on the right side of the menu. Scroll Counters is for scrolling the error / event / alarm counters on the right side of the menu. Record Data is for recording the service log information onto the M-REC paper, the laser printer or the memory module depending on the selection in the Record Data service menu. Reset Log is for clearing up the content of the service log. This function is recommended to be run after a performed maintenance. In Error/Event history view the Reset Log command clears up both error and event log. In Alarm History view the Reset Log command resets only the alarm history log.

5.7.1 Error History

Last errors: The section shows the last monitor errors

and the time of their occurrence.

Error counters: The section contains counters for each

different (detected) monitor errors. The time of

occurrence of the last error is shown beside each counter.

Last log reset: The date and the time of last Error/Event

log reset.

Possible errors:

Fast cold start indicates a number of erroneous cold

starts with power off time less than 20 seconds. The

reason can be either a failing lead acid battery or a

software problem that was solved by the hardware

watchdog circuitry located in the monitor’s power supply

unit.

GSP watch-dog time-out indicates an erroneous restart

controlled by the main CPU board and caused by the

display controller board. The restart is listed as a fast cold

start.

UPI watch-dog time-out indicates an erroneous restart

controlled by the main CPU board and caused by the UPI

or UPINET board. The restart is listed as a fast cold start.

24

Document No. 8002948

Page 29

5.7.2 Event History

Last events: The section shows the last events and the

time of their occurrence.

Event counters: The section contains counters for each

different (detected) events. The time of occurrence of the

last event is shown beside each counter.

Last log reset: The date and the time of last Error/Event

log reset.

Possible events:

Cold start is a start-up with power off time more than 15

minutes. The trend memory is cleared and monitoring

starts with the user default settings.

Warm start is a start-up with power off time less than 15

minutes. The trend information and possible temporary

settings are still available.

CPU boards and softwares

5.7.3 Alarm History

Last alarms: The section shows the last events and the

time of their occurrence.

Alarm counters: The section contains counters for each

different (detected) events. The time of occurrence of the

last event is shown beside each counter.

Last log reset: The date and the time of last alarm log

reset.

25

Document No.8002948

Page 30

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

5.7.4 Maintenance

The Maintenance History Log gives the user a possibility

to store the maintenance history of the monitor. The user

can store different planned maintenance (PM) events,

repairs and upgrades to the maintenance history log.

Running hours: shows how many hours the monitor has

been on. This value cannot be reset by user.

since This date and time is set at the factory and it shows

the manufacturing date and time. This date and time

cannot be reset by user.

since last 1 year PM: shows the running hours since the

last 1 year PM storing.

Last events: The section shows the last maintenance

events and the time of their occurrence.

Event counters: The section contains counters for each

different maintenance events. The time of occurrence of

the last event is shown beside each counter.

Planned Maintenance

1 Year PM gives you possibility to store a 1 year PM event

to the maintenance history log.

Other PM gives you possibility to store another PM event

to the maintenance history log.

Notify on PM if yes is selected, the “Planned

maintenance recommended” notification is shown on the

message field on the display at the startup of the monitor

after one year has passed since the last 1 year PM. To

remove this message you can store a new 1 year PM to

the maintenance history log. If no is selected, the monitor

won’t display the “Planned maintenance recommended”

notification. Configure this setting according the

agreement with the customer.

26

Document No. 8002948

Page 31

Repair

The repair menu gives the user a possibility to store repair

events to the maintenance history log. The different

repairs that can be saved are: Display, Power Supply,

Recorder, Frame (e.g. board in the frame), Parameters

(e.g. a board in the parameter module) or Other (a

miscellaneous repair not specified by previous options).

CPU boards and softwares

Upgrade

The upgrade menu gives the user a possibility to store the

upgrades to the maintenance history log.

27

Document No.8002948

Page 32

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

5.8 Record Data

In this menu the user can specify where to print from any

service menu. The setting goes into the permanent

memory of the monitor. Only one option can be chosen at

a time. The options where to print are: To Printer, To

Recorder and To Memory Card. Only the option To

Recorder can be selected currently. When any of the

front panel keys of the recorder module, M-REC is

pressed the output is the recorder module despite of the

setting of Record Data menu.

5.9 Remote Access

Remote Access menu is for setting the interface with an

external PC that runs the Virtual Support

which is a service diagnostic tool for remote diagnostics

purposes.

When the access mode is set to Normal (the default), the

PC can only read service menu data from the monitor.

With the access mode Extended the PC can also activate

the monitor’s service menu functions.

NOTE: Patient monitoring is not possible when

the access mode Extended is selected. The

access mode turns back Normal if the monitor

is restarted or if the service menu is closed.

TM

software,

28

Document No. 8002948

Page 33

6 SPARE PARTS

6.1 Spare parts list

NOTE: Only changed part numbers are listed under later revisions. To find the desired part: check

first the list of the revision that corresponds your device. If the part is not listed there, check the

previous revision, etc. until you find the right number.

6.2 Products

* this part is recommended for stock

6.2.1 CPU boards and software

Item Description Order no.

- CPU Board *B-CPU5

- CPU Board *B-CPU4

Service Software S-ANE98S

Service Software S-ICU98S

Service Software L-ANE01(A)S

- Service Software L-ICU01(A)S

CPU boards and softwares

6.2.2 CPU Board, B-CPU5/B-CPU4

Item Description Order no.

- Battery for SRAM/Timekeeper *197230

- Lid for back plate 894934

- Screw 617110

29

Document No.8002948

Page 34

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

7 EARLIER REVISIONS

This service manual fully supports earlier revisions except,

Item Manual and document number

Service Menu descriptions related to softwares of level 97/98

B-CPU2, B-CPU3

Technical Reference Manual 896624

slot 895 704

Technical Reference Manual 896624

manual slot 895704

30

Document No. 8002948

Page 35

Appendix A, CPU boards and softwares

APPENDIX A

31

Document No. 8002948

Page 36

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

32

Document No. 8002948

Page 37

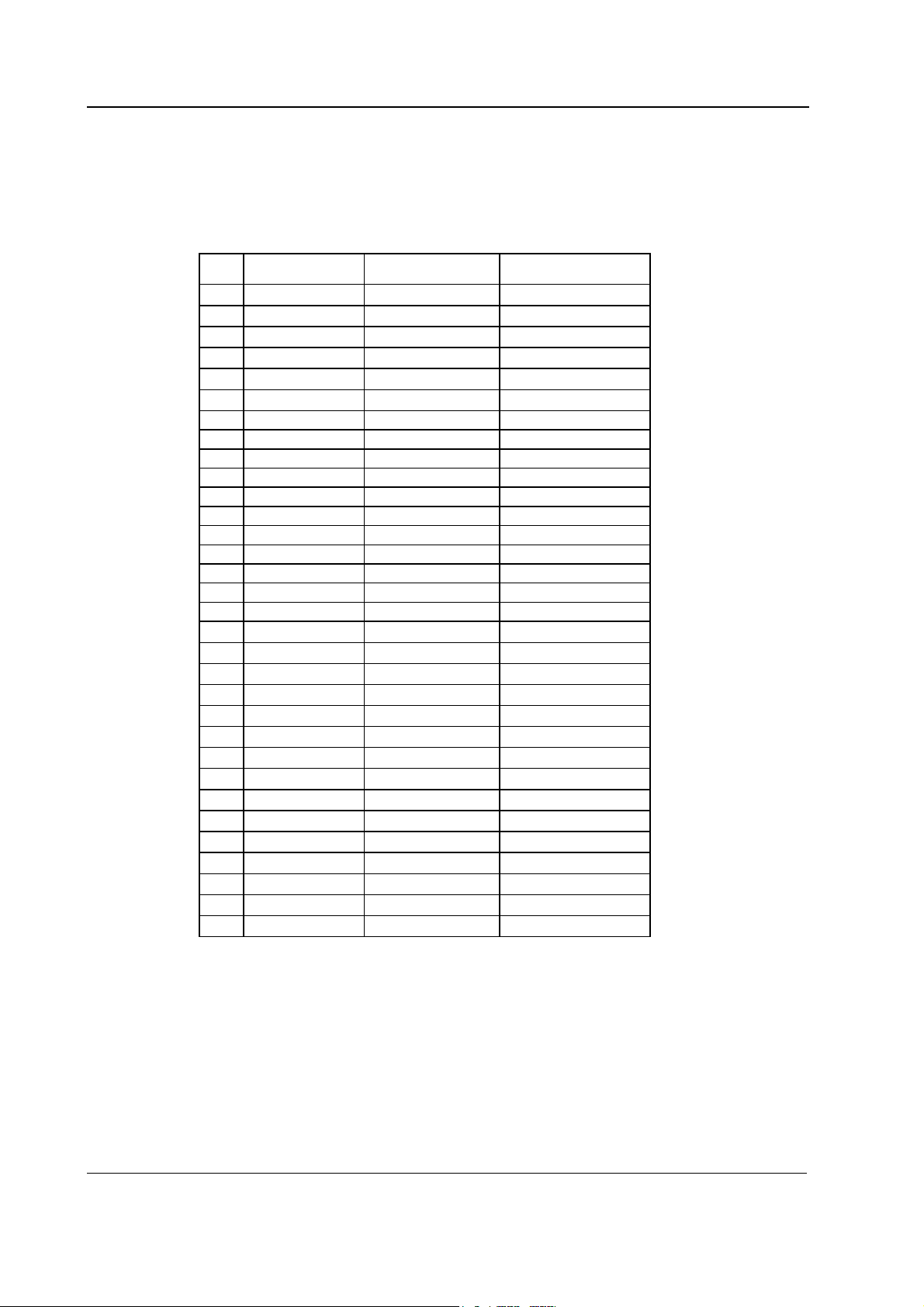

SERVICE CHECK FORM

CPU Boards

Customer

Appendix A,Service c heck form, CPU boards and softwares

Service

Service engineer Date

OK = Test OK N.A. = Test not applicable Fail = Test Failed

OK N.A. Fail OK N.A. Fail

1. Device plates 2. Grounding plate

3. SRAM/Timekeeper

battery

5. Fan 6. Starting

7. Module

communication

9. Loudspeaker sound 10. Service reset -switch

10. Monitor software

11. Content of service log

CPU board revision S/N

4. PC board screws

8. Real time clock

OK N.A. Fail OK N.A. Fail

12. Watchdog circuitry 13. Recovering from power

loss

14. Electrical safety check 15. Functioning after

electrical safety check

Notes

Used Spare Parts

Signature

A-1(1)

Document No. 8002948

Page 38

S/5 Anesthesia Monitor and S/5 Critical Care Monitor

A

-2

Document No. 8002948

Loading...

Loading...