Page 1

S/5

Datex-Ohmeda

TM

NIBP Module, M-NIBP (Rev. 05)

Technical Reference Manual Slot

Datex-Ohmeda Inc.

3030 Ohmeda Drive

53707-7550 MADISON, WIS

USA

Tel. +1-608-221 1551, Fax. +1-608-222 9147

www.us.datex-ohmeda.com

All specifications are subject to change without notice.

Document No. 800 1015-1

June 2001

Datex-Ohmeda Division,

Instrumentarium Corp.

P.O. Box 900, FIN-00031

DATEX-OHMEDA, FINLAND

Tel. +358 10 394 11 Fax +358 9 146 3310

www.datex-ohmeda.com

Instrumentarium Corp. All rights reserved.

Page 2

Page 3

Table of contents

TABLE OF CONTENTS

NIBP Module, M-NIBP

TABLE OF CONTENTS i

TABLE OF FIGURES ii

Introduction 1

1 Specifications 2

1.1 General specifications ..............................................................................................................................2

1.2 Typical performance .................................................................................................................................2

1.3 Technical specifications............................................................................................................................2

2 Functional Description 4

2.1 Measurement principle .............................................................................................................................4

2.2 Main components.....................................................................................................................................4

2.2.1 NIBP board ......................................................................................................................................5

2.3 Connectors and signals.............................................................................................................................7

2.3.1 Module bus connector......................................................................................................................7

2.3.2 Test points .......................................................................................................................................8

3 Service Procedures 9

3.1 General service information.......................................................................................................................9

3.2 Service check .........................................................................................................................................10

3.2.1 Recommended tools ......................................................................................................................10

3.2.2 Recommended parts......................................................................................................................10

3.3 Disassembly and reassembly..................................................................................................................16

3.4 Adjustments and calibrations..................................................................................................................17

3.4.1 Pressure safety level detection “OFFSET” .........................................................................................17

3.4.2 NIBP calibrations............................................................................................................................17

4 Troubleshooting 19

4.1 Troubleshooting chart .............................................................................................................................19

4.2 NIBP error code explanation ....................................................................................................................21

4.3 Troubleshooting flowchart .......................................................................................................................22

5Service Menu 23

5.1 NIBP Service menu .................................................................................................................................24

5.1.1 NIBP Demo menu...........................................................................................................................25

5.1.2 NIBP Calibration menu ...................................................................................................................26

5.1.3 NIBP Safety Valve menu .................................................................................................................27

5.1.4 NIBP Pulse Valve menu...................................................................................................................28

5.1.5 NIBP Buttons/Leds menu...............................................................................................................29

5.1.6 NIBP Pneumatics menu..................................................................................................................30

5.1.7 NIBP Watchdog menu.....................................................................................................................31

6 Spare Parts 33

6.1 Spare parts list .......................................................................................................................................33

6.1.1 NIBP Module, M-NIBP Rev. 01........................................................................................................33

6.1.2 NIBP Module, M-NIBP Rev. 02........................................................................................................35

Document No. 8001015-1

i

Page 4

Datex-Ohmeda S/5 monitors

6.1.3 NIBP Module, M-NIBP Rev. 03........................................................................................................35

6.1.4 NIBP Module, M-NIBP Rev. 04........................................................................................................36

6.1.5 NIBP Module, M-NIBP Rev. 05........................................................................................................37

6.1.6 Front panel stickers for AS/3 modules (square buttons)...................................................................37

6.1.7 Front panel stickers for S/5 modules (round buttons).......................................................................38

7 Earlier Revisions 39

APPENDIX A 41

Service check form A-1

TABLE OF FIGURES

Figure 1 Non-invasive blood pressure Module, M-NIBP ....................................................................................... 1

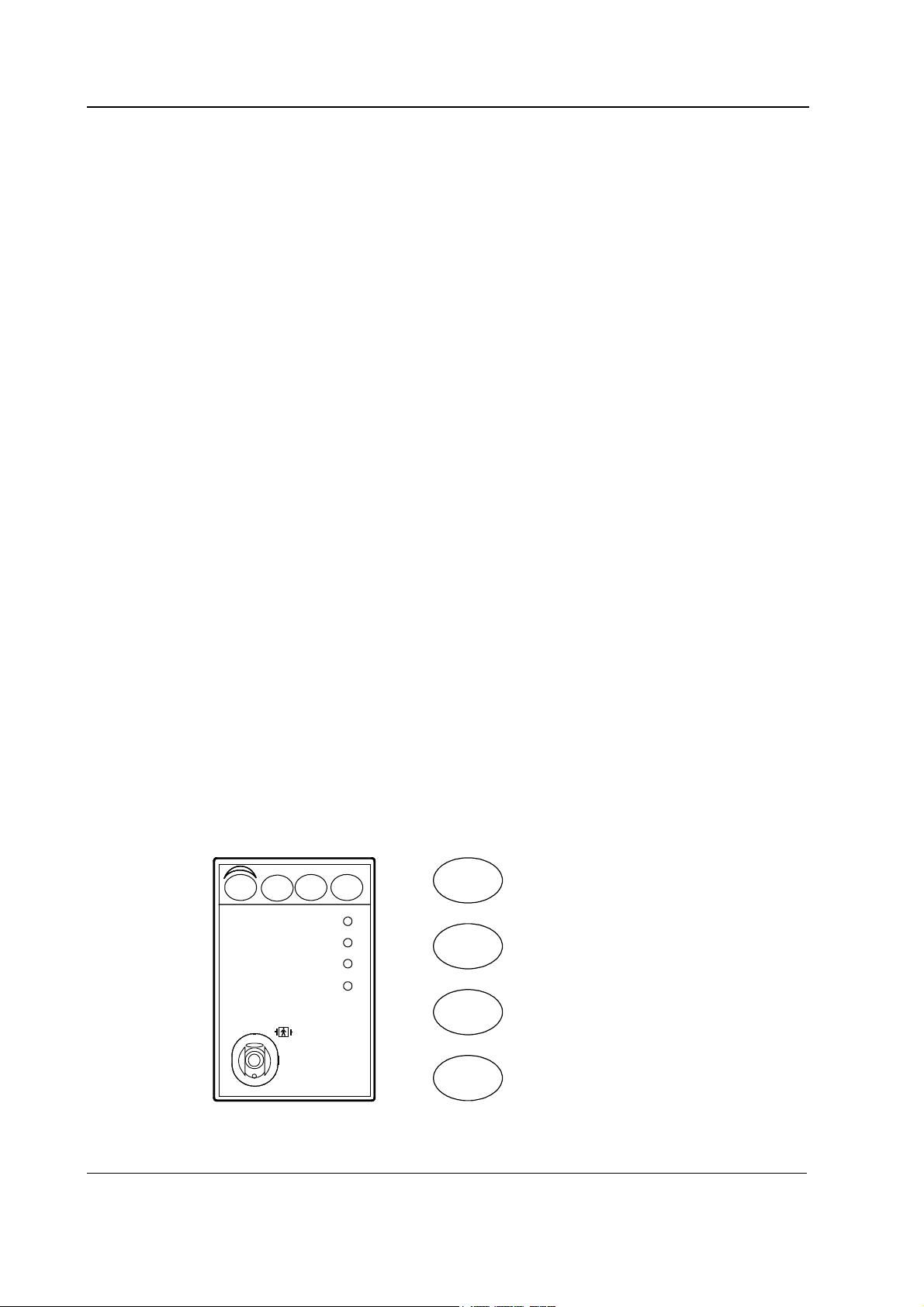

Figure 2 Front panel of NIBP Module ..................................................................................................................4

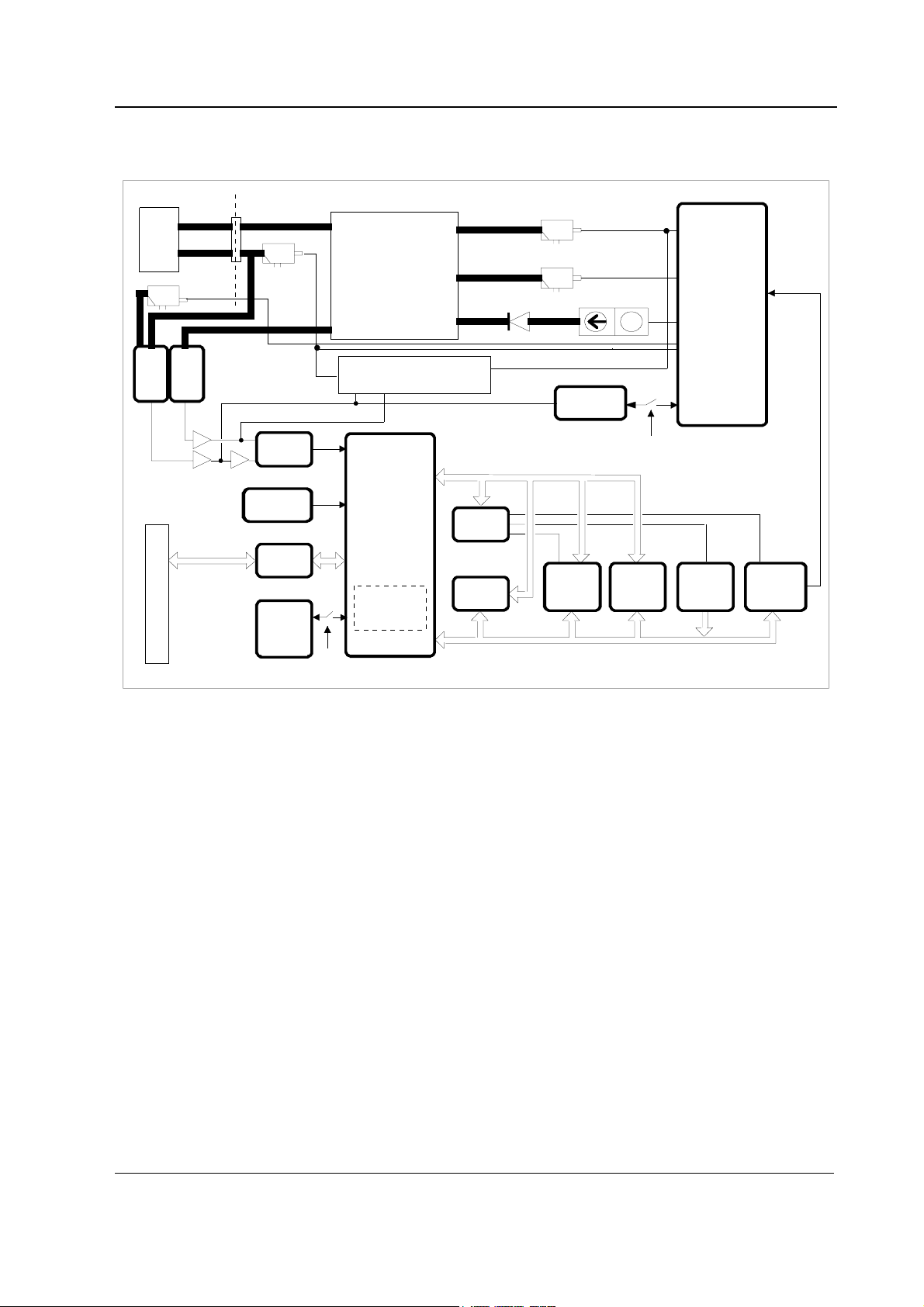

Figure 3 NIBP board functional block diagram ....................................................................................................5

Figure 4 NIBP Module troubleshooting flowchart...............................................................................................22

ii

Document No. 800 1015-1

Page 5

INTRODUCTION

This section provides information for the maintenance and service of the Non-Invasive Blood

Pressure parameter module, M-NIBP. The Non-Invasive Blood Pressure Module, M-NIBP, is a

double width plug-in module designed for use with the S/5 monitors.

NIBP Module, M-NIBP

Figure 1 Non-invasive blood pressure Module, M-NIBP

NOTE: Do not use identical modules in the same monitor simultaneously. The M-NIBP and MNE(12)STPR/-NESTR/-NETPR/M-MRI/M-MRIP are considered as identical modules.

Document No. 800 1015-1

1

Page 6

Datex-Ohmeda S/5 monitors

1 SPECIFICATIONS

1.1 General specifications

Module size, W × D × H 75 × 180 × 112 mm/3.0 × 7.1 × 4.4 in

Module weight 0.7 kg/1.5 lbs

Power consumption about 4 W

1.2 Typical performance

Oscillometric measurement principle.

Measurement range adult 25...260 mmHg

Accepted HR 30...250 bpm

Measurement interval from continuous to 1h, 2h, 4h

Measurement time, typical adult 23 s

child 25...195 mmHg

infant 15...145 mmHg

infant 20 s

Initial inflation pressure adult 185 ±10 mmHg

Venous stasis adult 80 ±10 mmHg / 2 min

Cuff widths Please see User’s Guide

1.3 Technical specifications

Deflation rate, HR dep. 5...13 mmHg/sec

Inflation rate, typical 20...185 mmHg, 1...5 s

Automatic software control, max. inflation pressure

Over pressure limit, stops measurement after 2 seconds

child 150 ±10 mmHg

infant 120 ±10 mmHg

child 60 ±10 mmHg / 2 min

infant 40 ±10 mmHg / 1 min

adult 280 ±10 mmHg

child 200 ±10 mmHg

infant 150 ±10 mmHg

adult 320 mmHg

child 220 mmHg

infant 165 mmHg

2

Document No. 800 1015-1

Safety valve limits the maximum cuff pressure to 320 mmHg in adult/child mode or 165 mmHg in

infant mode. Independent timing circuit limits pressurizing (>5 mmHg) time to 2 minutes 10

seconds maximum in adult/child mode, and 1 minute 5 seconds in infant mode.

Zeroing to ambient pressure is done automatically.

Page 7

NIBP Module, M-NIBP

Inflation pressure is adjusted according to the previous systolic pressure, typically 40 mmHg

above. If the systolic pressure is not found, inflation pressure is increased typically 50 mmHg.

Max. measurement time adult 2 min.

child 2 min.

infant 1 min.

Pressure transducer accuracy is better than ±3 mmHg or ±2 % (whichever is greater). Max. error ±4

mmHg.

Protection against electrical shock Type BF defibrillation proof

Document No. 800 1015-1

3

Page 8

Datex-Ohmeda S/5 monitors

2 FUNCTIONAL DESCRIPTION

2.1 Measurement principle

NIBP (Non-Invasive Blood Pressure) is an indirect method for measuring blood pressure.

The NIBP measurement is performed according to the oscillometric measuring principle. The cuff is

inflated with a pressure slightly higher than the presumed systolic pressure, and deflated at a

speed based on the patient’s pulse, collecting data from the oscillations caused by the pulsating

artery. Based on these oscillations, values for systolic, mean, and diastolic pressures are

calculated.

The following parts are necessary for NIBP measurement:

• NIBP module

• Twin hose (adult or infant model)

• Blood pressure cuffs (different sizes)

2.2 Main components

The NIBP module consists the following parts:

• NIBP board

• Pneumatics and hosing

• NIBP air pump

• Zero valve

• Check valve

• Bleed valve

• Exhaust valves (2)

• Pressure transducers (2)

• Module keyboard and status indicator LEDs

• Front panel keys: Auto On/Off, Set Cycle Time, Stat On/Off, Start/Cancel

Measuring

NIBP

Auto

Manual

STAT

Auto

On/Off

Set

Cycle

Time

STAT

On/Off

4

Document No. 800 1015-1

Start

Cancel

Figure 2 Front panel of NIBP Module

Page 9

2.2.1 NIBP board

CUFF

ZERO

VALVE

EXHAUST

VALVE 2

JOIN ING

CHAMBER

EXHAUST VALVE 1

BLEED VALVE

CHECK VALVE

PUMP

NIBP Module, M-NIBP

PUMP and

VALVE

M

DRIVER

B1 B2

t

o

/

f

r

o

m

m

o

d

u

l

e

b

u

s

X1

PRESSURE

S

TRAN

-

D

UCERS

AD-CONVERTER

POWER-UP

RESET

RS485

INTER F.

EEPRO

(C alibration

Data)

Figure 3 NIBP board functional block diagram

Pressure transducers

OVERPRESSURE CONTROL

M

Write protect switch

CPU

80C51FA

NTERNAL

I

WATCHDOG

ADDRESS

DECODER

ADDRESS

LATCH

ADDRESS BUS

WATCHDO G

TIMER

RAM

DATABUS

+

1

5

EPROM

D

V

FRONT

PANEL

KEYS

SOFT WAR E

CON TRO L

The NIBP board contains two pressure transducers. They are of piezoresistive type. One is used for

measuring the pressure of the blood pressure cuff and the pressure fluctuations caused by arterial

wall movement (B1). The other is used for detection of cuff hose type, cuff loose and cuff occlusion

situations etc. (B2). The transducers are internally temperature compensated. They are supplied by

a constant voltage and their output voltage changes up to 40 mV max. (50 kPa, 375 mmHg).

Signal processing

Two signals from the pressure transducers are amplified and sent to A/D converter. After the

converter, digitized signals are sent to microprocessor for data processing. Before the converter,

one of the signals is used to adjust the offset to the pressure safety level.

The NIBP board is controlled with 80C51FA microprocessor at 16 MHz oscillator frequency.

Communication between the module and the monitor CPU board is established through RS485

serial interface at 500 kbps data transfer rate.

5

Document No. 800 1015-1

Page 10

Datex-Ohmeda S/5 monitors

Memory

NIBP program memory (EPROM) size is 128k × 8. RAM size is 32k × 8 bit and it stores variable

values in NIBP measurement. EEPROM is size 64 × 16 bit and is used to store the calibration

values for the pressure transducers, the pulse valve constants gained during measurements, the

PC board identification, and module serial number.

Software control

Software controls valves and pump. In addition to the individual on/off signals for each component

there is a common power switch for the valves and the pump that can be used at pump/valve

failures.

In addition to external RS485 reset line the microprocessor system is equipped with its own powerup reset.

Watchdog timer

The NIBP board is equipped with software independent safety circuit to disconnect supply voltages

from the pump and the valves if the cuff has been pressurized longer than preset time. As soon as

the cuff pressure rises over a specified pressure limit, timer starts counting. The timer is adjusted to

stop the pump and open the valves in 2 minutes 10 seconds in adult/child mode and in 1 minute

5 seconds in infant mode.

Valves

Exhaust valves are used for emptying the cuff and the joining chamber after the measurement.

Exhaust valve 1 is also used as safety valve in infant mode. Valve opens at 165 mmHg. Exhaust

valve 2 is also used as safety valve in adult mode and opens at 320 mmHg.

Bleed valve is used for emptying the cuff during measurement. Zero valve is used for connecting

the pressure transducer B1 to open air.

Power supply section

All connections are established via 25-pin connector (D-type, female). The module needs +5 V,

±15 V, and +15 VD (dirty) power supply to operate. The pump and the valves use separate +15 VD

power line. The supply voltages are generated in the power supply section of the S/5 monitor. The

reference voltages ±5 V

ref and +10 Vref are generated on the NIBP board.

6

Document No. 800 1015-1

Page 11

2.3 Connectors and signals

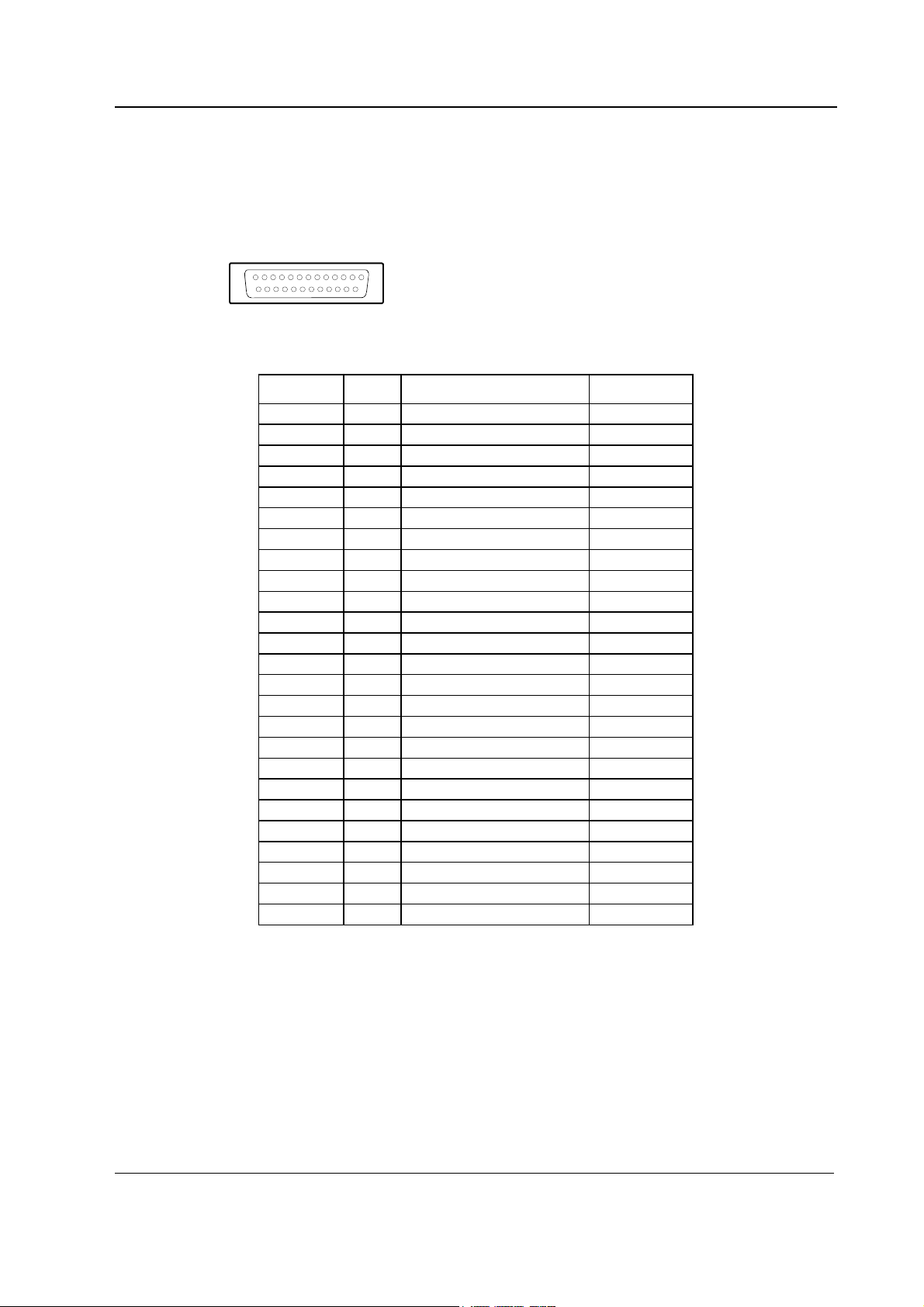

2.3.1 Module bus connector

NIBP Module, M-NIBP

13

25

1

14

Module Bus connector (X1)

Pin No I/O Signal Not used

1 I RESET_RS485

2 I -15 VDC

3 I +15 VDIRTY

4 I +15 VDC

5 I/O -DATA_RS485

6 I/O DATA_RS485

7 - Ground & Shield

8 I -RESET_RS485

9 I CTSB *

10 O RTSB *

11 I RXDB *

12 O TXDB *

13 - Ground & Shield

14 I +32 VDIRTY *

15 I GroundDIRTY

16 I CTSC *

17 O RTSC *

18 I RXDC *

19 O TXDC *

20 - ON/STANDBY *

21 - PWM_ECG *

22 - RXDD_RS232 *

23 - TXDD_RS232 *

24 I +5 VDC

25 I +5 VDC

*Not used in the M-NIBP module

7

Document No. 800 1015-1

Page 12

Datex-Ohmeda S/5 monitors

2

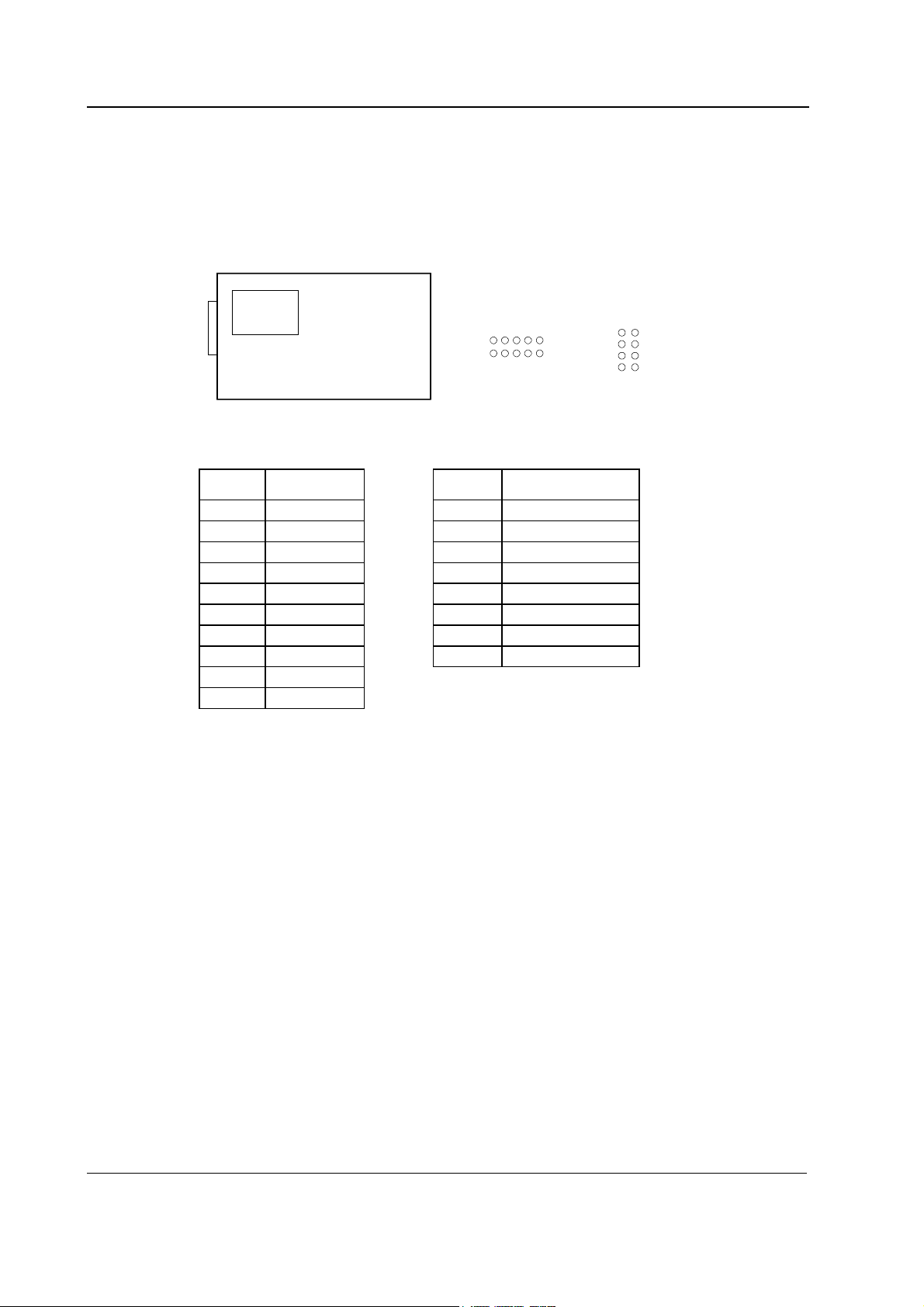

2.3.2 Test points

NIBP board

There are test pad blocks on solder side.

X8 and X6 pads and voltages are:

Pump

X6

X8

X3

X5

X7

10

9

1

X8

X8 X6

Pin No Signal Pin No Signal

1 GND 1 GND

2 WD out 2 A1 output

3 reset 3 - 5 V

4 +5 V 4 +5 V ref

5 +15 V dirty 5 B1 out - (A1 input)

6 +15 V 6 B1 out +

7 -15 V 7 B2 out +

8 - 8 B2 out -

9-

10 GND

X6

12

78

8

Document No. 800 1015-1

Page 13

NIBP Module, M-NIBP

3 SERVICE PROCEDURES

3.1 General service information

Field service of the M-NIBP module is limited to replacing faulty circuit boards or mechanical parts.

The circuit boards should be returned to Datex-Ohmeda for repair.

Datex-Ohmeda is always available for service advice. Please provide the unit serial number, full

type designation, and a detailed description of the fault.

CAUTION Only trained personnel with the appropriate tools and equipment should perform

the tests and repairs outlined in this section. Unauthorized service may void

warranty of the unit.

Document No. 800 1015-1

9

Page 14

Datex-Ohmeda S/5 monitors

3.2 Service check

These instructions include complete procedures for a service check. The service check is

recommended to be performed after any service repair. However, the service check procedures can

also be used for determining possible failures.

The procedures should be performed in ascending order.

The instructions include a check form (Appendix A) which should be filled in when performing the

procedures.

The mark

the procedure.

The procedures are designed for monitors with S/5 monitor software of revision 01. However, most

of the procedures also apply to monitors, which contain some other monitor software

type/revision.

? in the instructions means that the check form should be signed after performing

3.2.1 Recommended tools

Tool Order No. Notes

Pressure manometer

Adult cuff & hose

Infant cuff & hose

Screwdriver

3.2.2 Recommended parts

Part Order No. Notes

NIBP pump filter 57142

• Detach the module box by removing the two screws from the back of the module. Be careful

with loose latch and spring pin for locking.

10

Document No. 800 1015-1

1. Check internal parts:

− screws are tightened properly

− cables are connected properly

− all IC’s that are on sockets are attached properly

− EMC covers are attached properly

− the calibration protection switch on the NIBP board is intact

− tubes are not pinched and there are no sharp bends on them

Page 15

− tubes are connected properly

− the upper of the cuff connector tubes, as well as the related tube connector are

marked

− there are no loose objects inside the module

?

2. Check external parts:

− the front cover and the front panel sticker are intact

− the cuff connector is intact and is attached properly

− the module box, the latch and the spring pin are intact

?

3. Replace the NIBP pump filter, if necessary.

?

NIBP Module, M-NIBP

• Reattach the module box and check that the latch is moving properly.

• Switch the monitor on and wait until the monitoring screen appears.

• Make sure that NIBP information is selected to be shown on the screen:

Monitor Setup - Screen 1 Setup - Digit Fields - Field 2 - NIBP

4. Plug in the module. Check that it goes in smoothly and locks up properly

?

5. Check that the module is recognized, i.e. the NIBP headers appear on the selected digit

field.

?

6. Enter the service menu:

Monitor Setup - Install/Service (password 16-4-34) - Service (password 26-23-8)

Take down the information regarding NIBP module software by selecting Scroll Vers and

turning the ComWheel.

?

11

Document No. 800 1015-1

Page 16

Datex-Ohmeda S/5 monitors

7. Enter the NIBP module service menu:

Parameters - NIBP

Check that the ‘Timeouts’, ‘Bad checksums’ and ‘Bad c-s by mod’ values are not increasing

faster than by 50 per second. Check also that the NIBP board memories have passed the

internal memory test, i.e. the ‘RAM’, ‘ROM’ and ‘EEPROM’ show all OK.

?

8. Check the front panel LEDs and membrane keys.

Select Buttons/Leds

Highlight the text Auto ON. Check that the LED for the autocycle measurement is turning on

and off on the module front panel when pressing the ComWheel. Check also the other LEDs

by selecting Manual ON, STAT ON and Measur. ON.

Press each of the module’s membrane keys at least for one second. Check that the pressed

key is identified, i.e. the text OFF changes to ON for the key in the menu.

?

9. Check the pump and valves.

Select Pneumatics from the NIBP menu. Connect a pressure manometer to the NIBP

module cuff connector.

Highlight Start Pump and press the ComWheel. Check that the pump turns on and the

pressure inside the tubing system starts to increase. Stop the pump by pressing the

ComWheel again when the pressure reaches 280 mmHg.

Highlight Open Exh1. Press the ComWeel and check that the pressure inside the tubing

system starts to drop then press the ComWheel again. Check the other exhaust valve by the

same way by selecting Open Exh2 from the menu.

If necessary, turn the pump on again for a moment to increase the pressure inside the

tubing system.

Highlight Open Zerovalve. Press the ComWheel and check that the pressure B1 ≅ 0 mmHg.

Close the zero valve by pressing the ComWheel again and check that the pressure B1 is

equal with the pressure B2.

Highlight Set Valve. Press the ComWheel and set the value under the text ‘Pulse Valve’ to

number 150 by turning the ComWheel. Press the ComWheel again and check that the

pressure inside the tubing system starts to drop. Finish the test by selecting Previous Menu.

12

Document No. 800 1015-1

?

Page 17

NIBP Module, M-NIBP

10. Check the NIBP tubing system for leakages.

Select Calibrations from the NIBP service menu.

Keep the pressure manometer connected to the NIBP module cuff connector. Start the

active leak test from the menu by pressing the ComWheel. The module pumps a pressure of

about 265 mmHg and then the pump stops.

Wait for 15 seconds for the pressure to stabilize then check that the pressure does not drop

more than 5 mmHg per one minute. Release the pressure by pressing the ComWheel once

more.

?

11. Calibration check.

Disconnect the pressure manometer. Select Calibrations and then highlight Calibration

Check. Press the ComWheel and take down the zero offset values for both pressure

transducers, B1 and B2. The values should be within ±10 mmHg.

Connect the pressure manometer to the cuff connector and check the calibration with

pressures 100 mmHg, 200 mmHg and 260 mmHg. The zero offset value must be added to

the displayed pressure value in order to determine the real pressure.

Recalibrate the NIBP measurement according to the instructions in the Technical Reference

Manual, if necessary. Remember to set the calibration protection back on after the

calibration.

?

12. Check the watchdog timer activation pressure.

Select Pneumatics from the NIBP service menu.

Keep the pressure manometer connected to the cuff connector. Pump up the pressure very

slowly and note the value on the manometer when your hear a signal from the loudspeaker.

The pressure at where the watchdog timer should activate with an audible signal is

Rev. 00-03 = 14 mmHg (9...19 mmHg)

Rev. 04 -> = 7.5 mmHg (5...10 mmHg)

Adjust the limit with the trimmer on the NIBP board, if necessary.

?

13. Check the watchdog timer.

Select Watchdog from the NIBP service menu.

Check the watchdog timer in the adult mode. Activate the timer by highlighting Test ADULT

and then pressing the ComWheel. Check that the time beside the text ‘Watchdog Interval’

starts to run. Wait until you hear a signal from the loudspeaker and then check the time

again. The time from the adult test should fall within 120...140 seconds.

Document No. 800 1015-1

13

Page 18

Datex-Ohmeda S/5 monitors

Check the watchdog timer also in the infant mode by first selecting Test INFANT from the

menu. The time from the infant test should fall within 60...70 seconds.

?

14. Check the safety valve.

Select Safety Valve from the NIBP service menu.

Keep the pressure manometer connected to the cuff connector.

NOTE: Make sure your pressure manometer can be used to measure pressures over 300

mmHg. If such a pressure manometer is not available, perform the check with an adult cuff

that is connected around some round object, for example calibration gas bottle.

Highlight Start Test. Start the adult safety valve test by pressing the ComWheel. Wait until

the pump stops and the pressure is deflated. Check the pressure values ‘Max press’ and ‘2

s after stop’ for both transducers. All the values should be within 290...330 mmHg.

Highlight Adult. Press the ComWheel and check that the text changes now to Infant. Select

Start Test and wait until the pump stops and the pressure values on the screen have been

updated. Check that the values ‘Max press’ and ‘2 s after stop’ are all now within

154...165 mmHg.

Return to the normal monitoring mode by pressing

Normal Screen.

?

15. Connect an adult NIBP cuff to the cuff connector and disconnect one of its hoses.

Start NIBP measurement by pressing the key

the message ‘Cuff loose’ appears on the screen within 30 seconds.

Reconnect the hose and then bend it with your fingers. Restart the measurement and check

that the message ‘Cuff occlusion’ appears on the screen within 30 seconds.

Start/Cancel on the module and check that

?

16. Check that automatic inflation limits are in use:

NIBP - NIBP Setup - Inflation Limits - Auto - Previous Menu

Connect the cuff onto your arm, highlight Start Ven.Stasis in the NIBP menu and press the

ComWheel. Check the module identifies the cuff, i.e. the text ‘Adult’ appears into the NIBP

digit field for a short moment.

Keep the pressure inside the cuff for about half a minute in order to see that the cuff is not

leaking, then press the ComWheel again. Select

Normal Screen.

14

Document No. 800 1015-1

?

Page 19

NIBP Module, M-NIBP

17. Keep the cuff on your arm and perform one NIBP measurement. Check that the module

gives a reasonable measuring result.

?

18. Connect an infant cuff to cuff connector and wrap it around your fingers.

Start NIBP measurement and check that the module identifies the cuff, i.e. the text ‘Infant’

appears into the NIBP digit field. Cancel the measurement after the cuff identification.

?

19. Perform electrical safety check and leakage current test.

?

20. Check that the module functions normally after the performed electrical safety check.

?

21. Clean the module with suitable detergent.

?

• Fill in all necessary documents.

15

Document No. 800 1015-1

Page 20

Datex-Ohmeda S/5 monitors

3.3 Disassembly and reassembly

Rev. 01-03 Disassemble the M-NIBP module in the following way. See the exploded view of the module.

1. Remove the two screws from the back of the module.

2. Pull the module box slowly rearward and detach it from main body. Be careful with loose

latch and spring pin for locking.

3. To detach the NIBP board remove the four corner screws from the back of NIBP board. The

NIBP board and the front panel can be detached.

4. To free the front panel and the NIBP board, disconnect tubes and connectors.

5. Remove the five screws and lift off the plastic pump cover. NIBP pump, safety (over

pressure) valve, and valve unit which includes two valves, wires and a connector will be

exposed. Remove them.

6. Pull out pulse valve from the bottom of the NIBP frame.

Rev. 04 -> Disassemble the M-NIBP module in the following way. See the exploded view of the module.

1. Remove the two screws from the back of the module.

2. Pull the module box slowly rearward and detach it from main body. Be careful with loose

latch and spring pin for locking.

3. To detach the NIBP board remove the support plate by 2 screws (item 25).

4. Remove the metal frame (item 26).

5. Detach the damping chamber with 3 screws.

6. Detach 2 screws (item 9).

7. To free the front panel and the NIBP board, disconnect tubes and connectors.

8. Remove the two screws and lift off the pump. NIBP pump, and valve unit which includes four

valves, wires and a connector will be exposed. Remove them.

CAUTION Before reattaching the module box, make sure that the tubes are not pinched

between the NIBP frame and the PC board.

NOTE: Take care that the connectors and especially the tubes are reconnected properly and to the

right ports.

16

Document No. 800 1015-1

Page 21

3.4 Adjustments and calibrations

3.4.1 Pressure safety level detection “OFFSET”

Remove two screws at the rear of the module. Remove the module box. Connect first the service

cable (e.g. a long Gas interface cable) to the module connector inside the monitor frame and then

to the rear connector of the module. Switch the monitor on. Go to the NIBP service menu and select

Pneumatics. Pump reference pressure into the module:

Rev. 00-03 = 14 mmHg (9...19 mmHg)

Rev. 04 -> = 7.5 mmHg (5...10 mmHg)

Adjust the trimmer until AD5 signal sign changes from negative to positive. Re-check the

adjustement, then lock the trimmer with for example nail polish.

3.4.2 NIBP calibrations

The electronics of NIBP pressure measurement is calibrated at the factory. Zeroing pressure is

automatically maintained by the processor. If the zero point of the pressure transducer drifts more

than specified, an error message is given and the NIBP board should be recalibrated or replaced.

The calibration can be checked and recalibrated in the NIBP service menu.

The calibration of the primary pressure channel can also be checked from the NIBP setup menu

(NIBP, NIBP Setup, Calibration Check). In this case the auto zeroing is performed at start - remove

hose before entering to ensure atmospheric pressure to the pressure transducers - the primary

pressure is displayed. The zero-offset value should then be zero.

NIBP Module, M-NIBP

Calibration check

1. Enter Calibration menu.

2. Select ‘Calibration Check’ and press the ComWheel.

3. Connect an external precision manometer to the module.

4. Pump the following pressures to manometer and check the difference between the

manometer and monitor pressure display:

17

Document No. 800 1015-1

Page 22

Datex-Ohmeda S/5 monitors

Pressure Max. error Example

0 mmHg ±9 mmHg (=zero offset) -2

100 mmHg 100 + zero offset ±2 mmHg 98 ±2

200 mmHg 200 + zero offset ±3 mmHg 198 ±2

If the error of pressure channel B1 is larger than specified above, the module should be

recalibrated. The error of B2 is allowed to be even twice as large because it has no effect on blood

pressure measurement accuracy. However, it is recommended to recalibrate the module also when

the error of B2 is larger than specified above to ensure best possible operation.

Calibration

1. Enter Calibration menu.

2. Remove hoses from front panel connector to enable proper zeroing.

3. Select Calibration. If it is not available, perform the steps A, B and C.

NOTE: Do not pull out the NIBP module from the monitor frame. The module must be in the frame

during the whole procedure.

A) Turn the toggle switch at the bottom of the NIBP module to enable the calibration.

Turn the switch to the right by, for example, a sharp pencil. This enables menu

selection ‘Protection’. the message ‘Calibration switch ON!’ appears.

B) Select Protection OFF in the Calibration menu and press the ComWheel.

C) Return the toggle switch to the left. Menu selection Calibration is now enabled, and

Protection is disabled. When the calibration is enabled, a message ‘Calibration not

protected’ appears.

4. Start Calibration by pressing the ComWheel. Messages ‘ZEROING’ and ‘ZEROED’ will appear

in the NIBP message field. After this a pressure bar will appear.

5. Connect an external mercury manometer with pump to module through the both tubes of

the hose - both transducers B1 and B2 must be calibrated simultaneously. Pump up to a

pressure about 200 mmHg according to the manometer. Calibration is possible in the range

150 to 300 mmHg.

6. Verify that both pressure values in the prompt field match the manometer reading. If not,

adjust by turning the ComWheel. When the values of the pressure bar and the manometer

are equal, press the ComWheel to confirm the calibration. The message ‘Calibrating’ will

appear onto the NIBP digit field. After a few seconds it is followed by ‘Calibrated’, which

means that the calibration has succeeded, and the new calibration data has been saved

into EEPROM.

18

Document No. 800 1015-1

To set the protection on:

Turn the toggle switch to the right. Select Protection ON and press the ComWheel. Then turn

the toggle switch back to the left.

7. Remove the module from the frame and plug it back again. Then perform Calibration Check

(see the preceding page) to verify the new calibration.

Page 23

4 TROUBLESHOOTING

4.1 Troubleshooting chart

Trouble Cause Treatment

No NIBP value displayed NIBP not selected on screen. Check monitor setup.

NIBP menu fading No M-NIBP module, module not properly connected,

or NIBP and NE(12)STPR/MRI module connected at

the same time.

Artifacts-message Unsuccessful measurement due to patient

movements or shivering.

Weak pulsation-message Weak or unstable oscillation pulses due to:

− artifacts (accurate diastolic pressure difficult to

measure)

− marked arrhythmia

− marked drop in diastolic pressure

− diastolic pressure difficult to measure

− improper cuff position or attachment

− too few pulses detected

− weak or unusual blood circulation

− may give systolic value

Plug in the module.

Check patient condition and retry.

Check any leaks and retry.

Use proper size of cuff. Check attachment.

NIBP Module, M-NIBP

Call service

Error X-message

‘Cuff loose’ message

NIBP hardware error.

X = error number.

1. Hose and/or cuff not connected.

2. Hose and cuff connected.

Reason:

− cuff loosely wrapped

− leakage in cuff or hose

− leakage inside module

− pump does not work

− no pulses during the last three measurements

See the description of the error message code, the

causes and the solutions listed in the next chapter.

1. Connect the hose and the cuff.

2.

− tighten the cuff

− replace cuff/hose

− check internal tubing and air chamber, and fix if

necessary

− check pump connector; if OK, replace pump

− check cuff positioning

19

Document No. 800 1015-1

Page 24

Datex-Ohmeda S/5 monitors

Trouble Cause Treatment

‘Air leakage’ message

1. Hose or cuff leaking.

Reason:

− cuff damaged

− cuff connector damaged

− O-ring damaged or missing

− hose double connector damaged

2. Hose and cuff OK.

Reason:

− leakage inside the module

− tube disconnected or damaged

− air chamber leaking

− tubes or valve(s) damaged

1. Replace cuff

− replace cuff connector (if the fault is in hose

connector, replace hose)

− replace O-ring

2. Connect or replace tube

− replace the whole tubing

− fix connections

− replace valve(s)

‘Unable to measure Sys’

message

‘Cuff occlusion’ message

‘Calibration switch on’

message

‘Calibration not protected’

message.

Systolic blood pressure probably higher than the

Automatic retrial with increased pressure.

maximum inflation pressure.

1. Cuff and/or hose occluded.

Reason:

− cuff tube kinked

− tube inside module kinked

− occlusion inside/outside module

2. Cuff, hose, and tubes OK.

Reason:

− fault in pressure transducer

− fault in A/D converter

− faulty calibration

− missing voltages

EEPROM protection switch at the bottom of the module

is turned to right.

1.

− straighten tube

− remove occlusion

2.

− replace the NIBP board

− check calibration

− recalibrate

Enables setting the protection OFF in the Calibration

menu. Turn switch to left if you are not going to

calibrate.

Calibration protection is set to OFF. Set the protection ON in the NIBP Calibration menu.

20

Document No. 800 1015-1

Page 25

4.2 NIBP error code explanation

Code Explanation

0 RAM failure

Memory failure. Change NIBP board.

1 ROM checksum error

Memory failure. Change NIBP board.

2 +15V failure

Check short circuits. Change NIBP board.

3 -15V failure

Check short circuits. Change NIBP board.

4 EEPROM protection switch error. (only with S-STD93)

Turn the toggle switch to the left at the bottom of the module.

5 Calibration not protected. (only with S-STD93)

Protect calibration by selecting Protection ON in the NIBP calibration menu

6 ADC error

ADC circuit failure. Change NIBP board.

NIBP Module, M-NIBP

7 Watchdog time too short

Change NIBP board.

8 Watchdog time too long

Change NIBP board.

9 Watchdog activated

Change NIBP board.

10 EEPROM checksum error

Memory failure. Change NIBP board.

11 Auto zero range exceeded

Calibrate NIBP.

12 Communication break

Temporal break down of communication from monitor detected. Automatic

recovery.

14 Too early Auto Start (needs 25 seconds without pressure).

21

Document No. 800 1015-1

Page 26

Datex-Ohmeda S/5 monitors

4.3 Troubleshooting flowchart

START

Insert NIBP

module and turn

power on.

Does

the fault still

appear?

YES

Module ID on

screen?

YES

Error

message on

screen?

Possible fault in

NIBP module.

Remove all

modules from

C.Monitor Frame.

Fault not in NIBP

NO

NO YES

NO

module.

Does

another module

work in the

same slot?

LED

check in

Service Menu

OK?

NO

Check and replace

NIBP board.

Replace LED

board.

Replace NIBP

module.

NO

OK?

Check and replace

NIBP board.

NO

OK?

YES

See error code

explanation in

Service Manual

and fix it.

Do they work?

NO

Check tubes and

connectors. Find

leak and fix it.

NO

YES

Key

check in

Service Menu

OK?

YES

Pump

check in

Service Menu

OK?

YES

Leak test

in Service

Menu OK?

NO

NO

Check keyboard

connector. If OK,

change front panel.

Check pump

connector. If OK,

change pump.

Figure 4 NIBP Module troubleshooting flowchart

YES

22

Document No. 800 1015-1

Page 27

5 SERVICE MENU

NIBP Module, M-NIBP

1. Press the Monitor Setup key.

2. Select Install/Service (password 16-4-34).

3. Select Service (password 26-23-8).

4. Select Parameters - NIBP.

23

Document No. 800 1015-1

Page 28

Datex-Ohmeda S/5 monitors

5.1 NIBP Service menu

Service Data Pressure shows measured pressure multiplied by 10.

Zero shows pressure at auto zeroing multiplied by 10 and changes between +20 and -20 mmHg.

Absolute pressure is the sum of Pressure and Zero.

Protect handle indicates hardware protection for EEPROM memory. It should be ON all the time in

normal operation. If it is OFF data can not be read from or written to EEPROM, only the calibration

protection can be set or reset by software. It can be turned to OFF by turning the toggle switch to the

right at the bottom of the module, which also enables 'Protection ON/OFF' menu selection in the

calibration menu.

Calibr. prot. shows software calibration protection and should be OFF to enable calibration.

+15 V power indicates the condition of the supply voltage +15 Vdirty for the pump and valves. It

exists (ON) or not (OFF) depending on service menu function. The supply voltage can be turned on

by selecting the previous menu and then the desired menu again.

AD0 to AD7 show the values of each eight channels of A/D converter.

Timeouts is a cumulative number that indicates how many times the module has not responded to

the monitor's inquiry. Bad checksums is a cumulative number that indicates how many times

communication from the module to monitor broke down.

Bad c-s by mod is a cumulative number that indicates how many communication errors the

module has detected.

The monitor starts counting these items at power up and resets to zero at power off. The nonzero

values do not indicate a failure, but the continuous counting (more than 50 per second) indicates

either serial communication failure, or module not in place. Also other modules can cause

communication errors that cause these numbers rise.

RAM indicates the state of the RAM memory.

ROM indicates whether the checksum in the EPROM is in accordance with the one the software has

calculated.

EEPROM indicates if the values stored in the permanent memory are valid.

The state is either OK, Fail or ? (module not in place or a communication error).

24

Document No. 800 1015-1

Page 29

5.1.1 NIBP Demo menu

A service menu for demonstarting the oscillometric method of NIBP measurement. The menu

shows the realtime pressure signals that are measured from the NIBP cuff. The measurement result

is shown in the adjoining digit field.

NIBP Module, M-NIBP

Wave Recording Wave Recording is for selecting the recording option. If ON is selected, the pressure signals are

recorded in realtime onto the M-REC paper.

Remove menu Remove menu widens the displayed waveform area.

Previous Menu The menu can be closed by selecting the Previous Menu or just by pressing the ComWheel if the

Remove menu was selected.

25

Document No. 800 1015-1

Page 30

Datex-Ohmeda S/5 monitors

5.1.2 NIBP Calibration menu

Active Leak Test Wrap an adult cuff around a pipe and connect the cuff to the module. Select the active leak test

(ON). The module automatically pumps a pressure of 260 mmHg into the cuff. Wait for several

seconds until the pressure stabilizes. Then check that the pressure reading does not drop more

than 5 mmHg per minute. If it does, leaking point(s) should be detected and fixed. Cancel the test

by selecting Active leak test OFF.

Calibration Check

After the calibration check is selected (ON), manually pump pressure into the module and make

sure that the same pressure values are shown both on the display and on manometer. Pressure of

both pressure channels B1 and B2 are shown. Note that if the display shows +2 mmHg at zero

pressure and if you pumped +200 mmHg into the module, the display should show +202 mmHg.

Protection Software calibration protection (ON/OFF). Select OFF when calibrating. Protection can be set to ON

or OFF only when the toggle switch at the bottom of the module is set to the right.

Calibration Calibration selection is available only when protection is OFF.

NIBP calibration can be performed in the NIBP Service menu as follows:

NOTE: Both channels B1 and B2 must be calibrated simultaneously.

1. If Protection is ON change it to OFF by first turning the toggle switch to the right at the

bottom of the module, which enables the Protection selection. Then turn the toggle switch

to the left to enable Calibration.

NOTE : Do not disconnect the module from the frame when turning the switch. The module must be

in the frame during the whole procedure.

26

Document No. 800 1015-1

NOTE: When the switch is at the right, the NIBP field shows an error message ‘Calibration switch

on!’.

NOTE: When calibration is enabled, a message ‘Calibration not protected’ appears.

2. For proper zeroing to take place, remove the hose from the front panel connector. Select

Calibration and press the ComWheel. Messages ‘ZEROING’ and ‘ZEROED’ will appear in the

NIBP message field. After this a pressure bar will appear beside the menu.

Page 31

3. Connect an external mercury manometer with pump to module through the both tubes of

the hose. Pump up to about 200 mmHg pressure (range of 150 to 300 mmHg allowed)

according to the manometer. Verify that both pressure values in the prompt field match the

manometer reading. If not, adjust by turning the ComWheel.

4. When the values are equal, press the ComWheel to confirm the calibration. First the

message ‘Calibrating’ will appear in the digit field for NIBP followed after a few seconds

‘Calibrated’, which means that the calibration data has now been saved.

5. Use the bottom switch to enable Protection setting and set it ON, and finally disable

Protection setting.

5.1.3 NIBP Safety Valve menu

NIBP Module, M-NIBP

Start Test Start test is for starting and Stop test is for stopping the Safety Valve test.

NOTE: Parameter values in Service Data are for reference only.

Safety Valve Data

See NIBP Service menu in chapter 5.1 for information on general items Pressure, Zero, Protect

handle, Calibr. prot., +15 V power, AD0 to AD7 as well as Timeouts etc.

Max. press and 2 s after stop show the measured values at Safety Valve test.

Safety Valve Test Adult/Infant

Wrap an adult cuff around a pipe and connect the cuff to the module. Highlight Start test and give

the ComWheel a press. The test ends automatically or when Stop test (appears in place of Start

test) is pressed.

Max. press indicates the pressure at which the safety valve opens and is normally 310 ±15 mmHg

for adult and 150 mmHg ±15 mmHg for infant. 2 s after stop indicates the pressure at 2 seconds

after the pump has stopped and is normally > 280 mmHg for adult and > 120 mmHg for infant. If

the value is less, check leakage by the active leak test.

27

Document No. 800 1015-1

Page 32

Datex-Ohmeda S/5 monitors

5.1.4 NIBP Pulse Valve menu

NOTE: Parameter values in Service Data are for reference only.

Start Test Start test is for starting and Stop test is for stopping the test.

Set Valve Set Valve lets you adjust the opening of the pulse valve.

Pulse Valve Data

See NIBP Service menu in chapter 5.1 for information on general items Pressure, Zero, Protect

handle, Calibr. prot., +15 V power, AD0 to AD7 as well as Timeouts etc.

Pulse Valve Checking

Wrap an adult cuff around a pipe and connect the cuff to the module. Select the Start test and

press the ComWheel. The pressure rises beyond 240 mmHg and stops. The pulse valve opens. The

module counts the time it takes for the pressure to go down from 240 mmHg to 50 mmHg and

displays it on the screen. The test can be manually stopped by selecting Stop test.

The valve can be adjusted between 0 and 255 (0 for fully closed and 255 for fully open). First

select Set Valve and press the ComWheel. See the pulse valve value and adjust it by turning the

ComWheel. Then press the ComWheel to confirm the value.

The ‘Interval 240 mmHg -> 50 mmHg’ time should be less than 60 seconds when the valve is

'150' and less than 10 when fully opened (255). When fully closed (0), the system should be

airtight and the pressure does not drop. Depending on an individual, the pulse valve may remain

closed up to approx. value 45.

If the measured time deviates much from those above, then the pulse valve or its tubes are faulty.

28

Document No. 800 1015-1

Page 33

5.1.5 NIBP Buttons/Leds menu

NIBP Module, M-NIBP

NOTE: Parameter values in Service Data are for reference only.

The front panel LEDs can be turned manually ON and OFF by selecting Auto ON/OFF, Manual

ON/OFF, STAT ON/OFF, and Measur. ON/OFF from the menu.

Buttons/Leds Data

See NIBP Service menu in chapter 5.1 for information on general items Pressure, Zero, Protect

handle, Calibr. prot., +15 V power, AD0 to AD7 as well as Timeouts etc.

Buttons Checking

The front panel keys function is confirmed by pressing the key and observing OFF turns to ON at the

corresponding text in the menu.

29

Document No. 800 1015-1

Page 34

Datex-Ohmeda S/5 monitors

5.1.6 NIBP Pneumatics menu

NOTE: Parameter values in Service Data are for reference only.

Start Pump/Stop Pump

A manual control for the pump. The selection changes to Stop Pump when the pump turns on.

Open Exh1/Close Exh1

A manual control for the exhaust valve 1. The selection changes to Close Exh1 when the valve is

opened.

Open Exh2/Close Exh2

A manual control for the exhaust valve 2. The selection changes to Close Exh2 when the valve is

opened.

Open Zerovalve/Close Zerovalve

A manual control for the zero valve. The selection changes to Close Zerovalve when the valve is

opened.

Set Valve With Set Valve, the opening of the pulse valve is adjusted between 0 and 255 (0 for fully closed

and 255 for fully open). First press the ComWheel, then turn it to adjust the value on screen and

finally press to set the value.

Reset Clock Reset Clock will zero the time on the display.

Pneumatics Data

See NIBP service menu in chapter 5.1 for information on general items Pressure, Zero, Protect

handle, Calibr. prot., +15 V power, AD0 to AD7 as well as Timeouts etc.

30

Document No. 800 1015-1

Pump, Exh1 Valve, and Exh2 Valve show their states.

Pulse Valve shows how much the valve is opened (0 to 255) during Valve Setting.

Interval 20 mmHg -> 185 mmHg Checking

Select the Start pump at different combinations of the valves open/closed and press the

ComWheel. The module counts the time it takes for the pressure to go up from 20 mmHg to 185

mmHg and displays it. When all the valves are closed, the pump should be able to pump the

pressure in about 1 to 4 seconds into an adult cuff wrapped around a pipe. The pump does not

stop without selecting the Stop Pump by pressing the ComWheel.

Page 35

Watchdog BEEP

Connect manometer to the front panel and pump pressure into the module. When the AD5 value

changes from negative to positive value (at about 5 mmHg) a beep is heard. This is the watchdog

threshold pressure. Beyond this pressure the watchdog is active and cut pressures at about 2 min.

(adult).

5.1.7 NIBP Watchdog menu

NIBP Module, M-NIBP

NOTE: Parameter values in Service Data are for reference only.

Test ADULT Test ADULT is to test watchdog timer in adult mode (120 to 140 seconds).

Test INFANT Test INFANT is to test watchdog timer in infant mode (about 60 to 70 seconds).

Stop Test Stop Test is for stopping the test.

Watchdog Data

See NIBP Service menu in chapter 5.1 for information on general items Pressure, Zero, Protect

handle, Calibr. prot., +15 V power, AD0 to AD7 as well as Timeouts etc.

Watchdog Interval shows the time the +15 Vdirty stays on during the test.

Adult watchdog time testing

Select Test ADULT and press the ComWheel. Watchdog interval starts counting up seconds and

keeps on counting as long as the +15 Vdirty is on. The time should be 120 to 140 seconds.

Infant watchdog time testing

Select Test INFANT and press the ComWheel. Watchdog interval starts counting up seconds and

keeps on counting as long as the +15 Vdirty is on. The time should be 60 to 70 seconds.

31

Document No. 800 1015-1

Page 36

Datex-Ohmeda S/5 monitors

This page intentionally left blank.

32

Document No. 800 1015-1

Page 37

6 SPARE PARTS

6.1 Spare parts list

NOTE: Only changed part numbers are listed under later revisions. To find the desired part: check

first the list of the revision that corresponds your device. If the part is not listed there, check the

previous revision, etc. until you find the right number.

* this part is recommended for stock

6.1.1 NIBP Module, M-NIBP Rev. 01

NIBP Module, M-NIBP

4

1

3

2

5

Item Item description Order No.

- Membrane keypad 879374

1 Module box (wide) 886168

2 Spring pin 879182

3 Latch 879181

4 Cross recess PT screw 3x8 black 628706

5 Front panel unit, M-NIBP (includes all the connectors and input boards) 881335

33

Document No. 800 1015-1

Page 38

Datex-Ohmeda S/5 monitors

Item Item description Order No.

8 NIBP board, M-NIBP (Rev. 01) *(880359) Use 883011

9 Cross cylinder-head PT screw 3x20 628709

1)

883902

34

Document No. 800 1015-1

Page 39

NIBP Module, M-NIBP

Item Item description Order No.

10 Cross cylinder-head PT screw 3x10 628703

11 NIBP frame, M-NIBP 880427

13 Safety valve (overpressure valve) 877109

14 NIBP pump, M-NIBP (Rev. 01-02) *(880363) Use 883346

15 Plastic pump cover, M-NIBP 879176

16 Front panel sticker see 6.1.5

17 LED board, M-NIBP (Rev. 01-03) 880361

18 Hose connector 64654

19 Cross cylinder-head screw M2.5x6 628700

20 Port plug for magnetic valve 58535

21 Magnetic valve *58534

22 Pulse valve *880365

6.1.2 NIBP Module, M-NIBP Rev. 02

Item Item description Order No.

8 NIBP board, M-NIBP (Rev. 02) *(882418) Use 883011

23 Check valve 58542

1)

NOTE: The NIBP board 883011 can be used as a replacement only with NIBP software 883902.

1)

883902

6.1.3 NIBP Module, M-NIBP Rev. 03

Item Item description Order No.

- NIBP software *883902

8 NIBP board, M-NIBP (Rev. 03) *883011

14 NIBP pump, M-NIBP (Rev. 03) *883346

35

Document No. 800 1015-1

Page 40

Datex-Ohmeda S/5 monitors

6.1.4 NIBP Module, M-NIBP Rev. 04

Item Item description Order No.

4 Cross recess screw M3×8 black 616215

8 NIBP board, M-NIBP (Rev. 04) *894368

36

Document No. 800 1015-1

Page 41

Item Item description Order No.

9Screw STZN 3.5×9.5 DIN 7981 62539

10 Cross cylinder-head screw M3×6 61721

14 NIBP pump, M-NESTPR, M-NIBP (Rev. 04) *889993

17 LED board, M-NIBP (Rev. 04) 893882

21 Magnetic valve 58562

24 EMC cover 888236

25 Support plate 893881

26 Metal frame 888230

27 Flat cable; LED 894118

28 NIBP pump filter *57142

29 Damping chamber, M-NESTPR, M-NIBP (Rev. 04) 888240

30 Bleed valve, M-NESTPR, M-NIBP (Rev. 04) 58566

31 Spring 892676

- Check valve 58542

6.1.5 NIBP Module, M-NIBP Rev. 05

NIBP Module, M-NIBP

No new spare parts.

6.1.6 Front panel stickers for AS/3 modules (square buttons)

Front panel stickers that are related to the Compact Module type and adaptation:

Adaptation codes: DA=Danish, DE=German, EN=English, ES=Spanish, FI=Finnish,

FR=French, IT=Italian, JA=Japanese, NL=Dutch, NO=Norwegian, PT=Portuguese,

SV=Swedish

Item no. 16

Adaptation M-NIBP

(Rev. 00-04)

Order no.

DA 892215

DE 880476

EN 879482

ES 884386

FI 888872

FR 880159

IT 886752

JA 888316

NL 886124

NO 893559

PT 895254

SV 885870

37

Document No. 800 1015-1

Page 42

Datex-Ohmeda S/5 monitors

6.1.7 Front panel stickers for S/5 modules (round buttons)

Front panel stickers that are related to the Compact Module type and adaptation:

Adaptation codes: DA=Danish, DE=German, EN=English, ES=Spanish, FI=Finnish,

FR=French, IT=Italian, JA=Japanese, NL=Dutch, NO=Norwegian, PT=Portuguese,

SV=Swedish

Adaptation M-NIBP

(Rev.05)

Order no.

DA 898609

DE 898600

EN 898599

ES 898603

FI 898606

FR 898601

IT 898604

JA 898606

NL 898602

NO 898608

PT 898605

SV 898607

38

Document No. 800 1015-1

Page 43

7 EARLIER REVISIONS

For service information on the earlier revisions, please refer to:

NIBP Module revision 01 Service Manual p/n 880850

NIBP Module revision 02 Service Manual p/n 882580

NIBP Module revision 03 Technical Reference Manual p/n 892953

NIBP Module, M-NIBP

39

Document No. 800 1015-1

Page 44

Datex-Ohmeda S/5 monitors

40

Document No. 800 1015-1

Page 45

APPENDIX A, NIBP Module, M-NIBP

APPENDIX A

41

Document No. 8001015-1

Page 46

Datex-Ohmeda S/5 monitors

42

Document No. 800 1015-1

Page 47

APPENDIX A, Service check form, NIBP Module, M-NIBP

SERVICE CHECK FORM

Non-Invasive Blood Pressure Module, M-NIBP

Customer

Service

Service engineer Date

OK = Test OK N.A. = Test not applicable Fail = Test Failed

OK N.A. Fail OK N.A. Fail

1. Internal parts 2. External parts

3. Pump’s filter 4. Installation

Notes

5. Recognition

6. Module software

7. Communication and

memories

9. Pump and valves

NIBP

Module type S/N

8. LEDs and membrane

keys

10. Leak test ≤ 5 mmHg/min

11. Calibration check

Measured B1 Measured B2 Allowed range

0 mmHg ±10 mmHg

100 mmHg 100 + z.o. ±2 mmHg

200 mmHg 200 + z.o. ±3 mmHg

260 mmHg 260 + z.o. ±4 mmHg

z.o. = zero offset at 0 mmHg pressure

12. Watchdog timer activation pressure 9...19 / 5...10 mmHg

A-1(2)

Document No. 8001015-1

Page 48

Datex-Ohmeda S/5 monitors

13. Watchdog timer

Allowed range

Adult 120...140 s

Infant 60...70 s

14. Safety valve

B1 B2 Allowed range

‘Max press’ ADULT 290...330 mmHg

‘2 s after stop’ ADULT 290...330 mmHg

‘Max press’ INFANT 154...165 mmHg

‘2 s after stop’ INFANT 154...165 mmHg

OK N.A. Fail OK N.A. Fail

15. Cuff related messages 16. Adult cuff detection

17. Test measurement 18. Infant cuff detection

Notes

19. Electrical safety check 20. Functioning after

electrical safety

check

21. Final cleaning

Notes

Notes

Used Spare Parts

Signature

A-2(2)

Document No. 8001015-1

Loading...

Loading...