Page 1

S/5

Datex-Ohmeda Pressure Modules

TM

Pressure Temp Module, M-PT (Rev. 02)

S/5

TM

Pressure Module, M-P (Rev. 04)

Technical Reference Manual Slot

Datex-Ohmeda Inc.

3030 Ohmeda Drive

53707–7550 MADISON, WIS

USA

Tel. +1-608-221 1551, Fax +1-608-222 9147

www.us.datex-ohmeda.com

All specifications are subject to change without notice.

Document No. 800 1013-1

June 2001

Datex-Ohmeda Division,

Instrumentarium Corp.

P.O. Box 900, FIN-00031

DATEX-OHMEDA, FINLAND

Tel. +358 10 394 11 Fax +358 9 146 3310

www.datex-ohmeda.com

Instrumentarium Corp. All rights reserved.

Page 2

Page 3

Table of contents

TABLE OF CONTENTS

Pressure Module, M-P, Pressure Temp Module, M-PT

TABLE OF CONTENTS i

TABLE OF FIGURES ii

Introduction 1

1 Specifications 2

1.1 General specifications ..............................................................................................................................2

1.2 Typical performance .................................................................................................................................2

1.2.1 InvBP...............................................................................................................................................2

1.2.2 Temperature.....................................................................................................................................2

1.2.3 Signal output ...................................................................................................................................2

1.3 Technical specifications............................................................................................................................3

1.3.1 InvBP...............................................................................................................................................3

1.3.2 Temperature.....................................................................................................................................3

1.3.3 Signal output ...................................................................................................................................3

2 Functional Description 4

2.1 Measurement principle .............................................................................................................................4

2.1.1 Invasive blood pressure ....................................................................................................................4

2.1.2 Temperature.....................................................................................................................................4

2.2 Main components.....................................................................................................................................4

2.2.1 PT board ..........................................................................................................................................6

2.3 Connectors and signals...........................................................................................................................10

2.3.1 Module bus connector....................................................................................................................10

2.3.2 Front panel connectors...................................................................................................................11

2.3.3 Other connectors............................................................................................................................11

3 Service Procedures 13

3.1 General service information.....................................................................................................................13

3.2 Service check .........................................................................................................................................13

3.2.1 Recommended tools ......................................................................................................................13

3.3 Disassembly and reassembly..................................................................................................................18

3.4 Adjustments and calibrations..................................................................................................................19

3.4.1 Invasive pressure calibration...........................................................................................................19

3.4.2 Temperature calibration..................................................................................................................19

4 Troubleshooting 21

4.1 Troubleshooting chart .............................................................................................................................21

4.1.1 Invasive blood pressure ..................................................................................................................21

4.1.2 Temperature...................................................................................................................................22

Troubleshooting flowchart ..............................................................................................................................23

5Service Menu 24

5.1 P/PT menu .............................................................................................................................................25

5.2 P/PT calibration menu ............................................................................................................................26

6 Spare Parts 28

i

Document No. 800 1013-1

Page 4

Datex-Ohmeda S/5 monitors

6.1 Spare parts list.......................................................................................................................................28

6.1.1 Pressure Module, M-P, Rev. 00.......................................................................................................28

6.1.2 Pressure Module, M-P, Rev. 01.......................................................................................................29

6.1.3 Pressure Module, M-P, Rev. 02.......................................................................................................29

6.1.4 Pressure Module, M-P, Rev. 03.......................................................................................................29

6.1.5 Pressure Module, M-P, Rev. 04.......................................................................................................29

6.1.6 Pressure Temp Module, M-PT, Rev. 00 ............................................................................................30

6.1.7 Pressure Temp Module, M-PT, Rev. 01 ............................................................................................31

6.1.8 Pressure Temp Module, M-PT, Rev. 02 ............................................................................................31

6.1.9 Front panel stickers for AS/3 modules (square buttons)...................................................................31

6.1.10 Front panel stickers for S/5 modules (round buttons) .................................................................. 31

7 Earlier Revisions 33

APPENDIX A 35

Service check form A-1

TABLE OF FIGURES

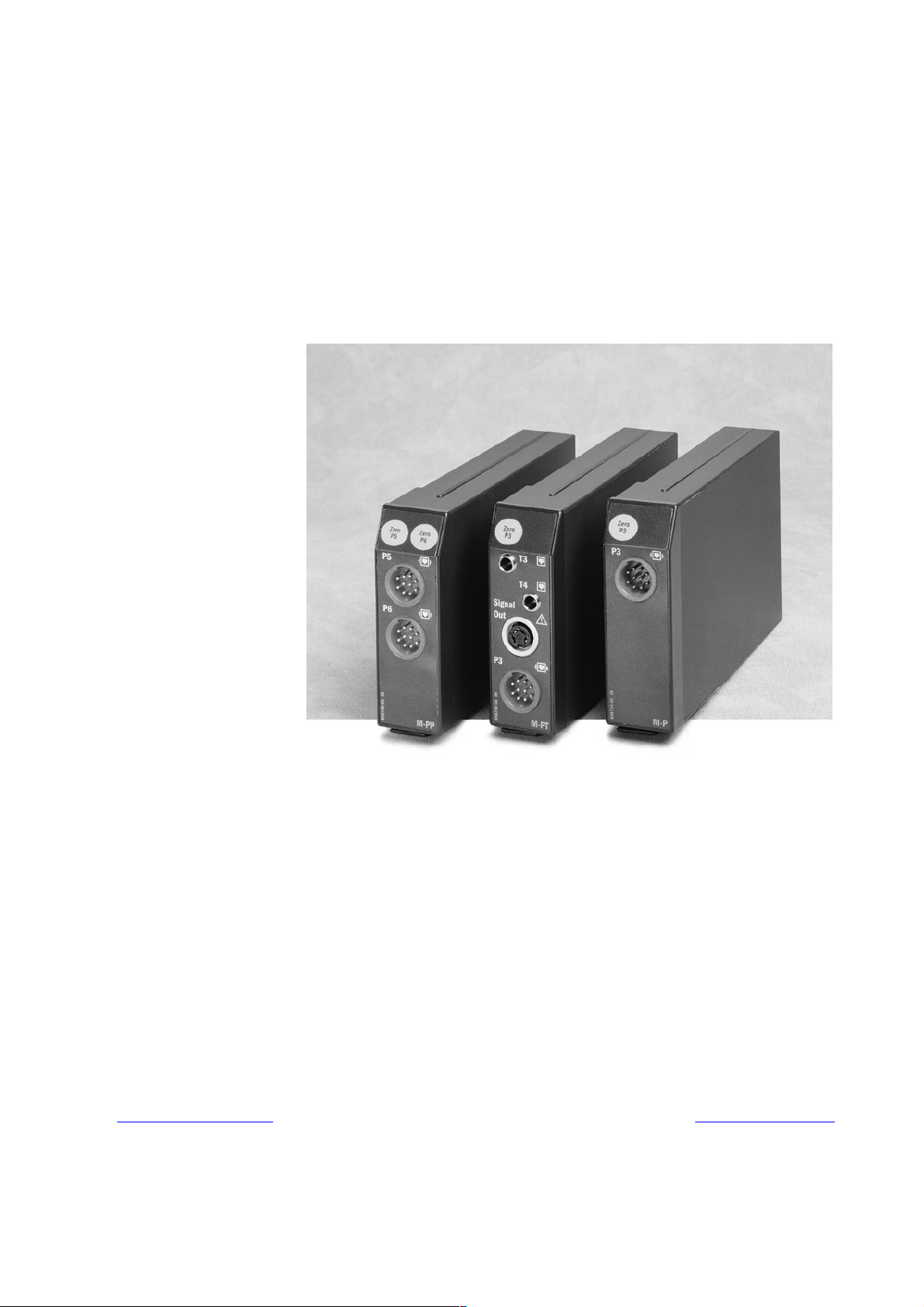

Figure 1 Datex-Ohmeda M-PT and M-P Module...................................................................................................1

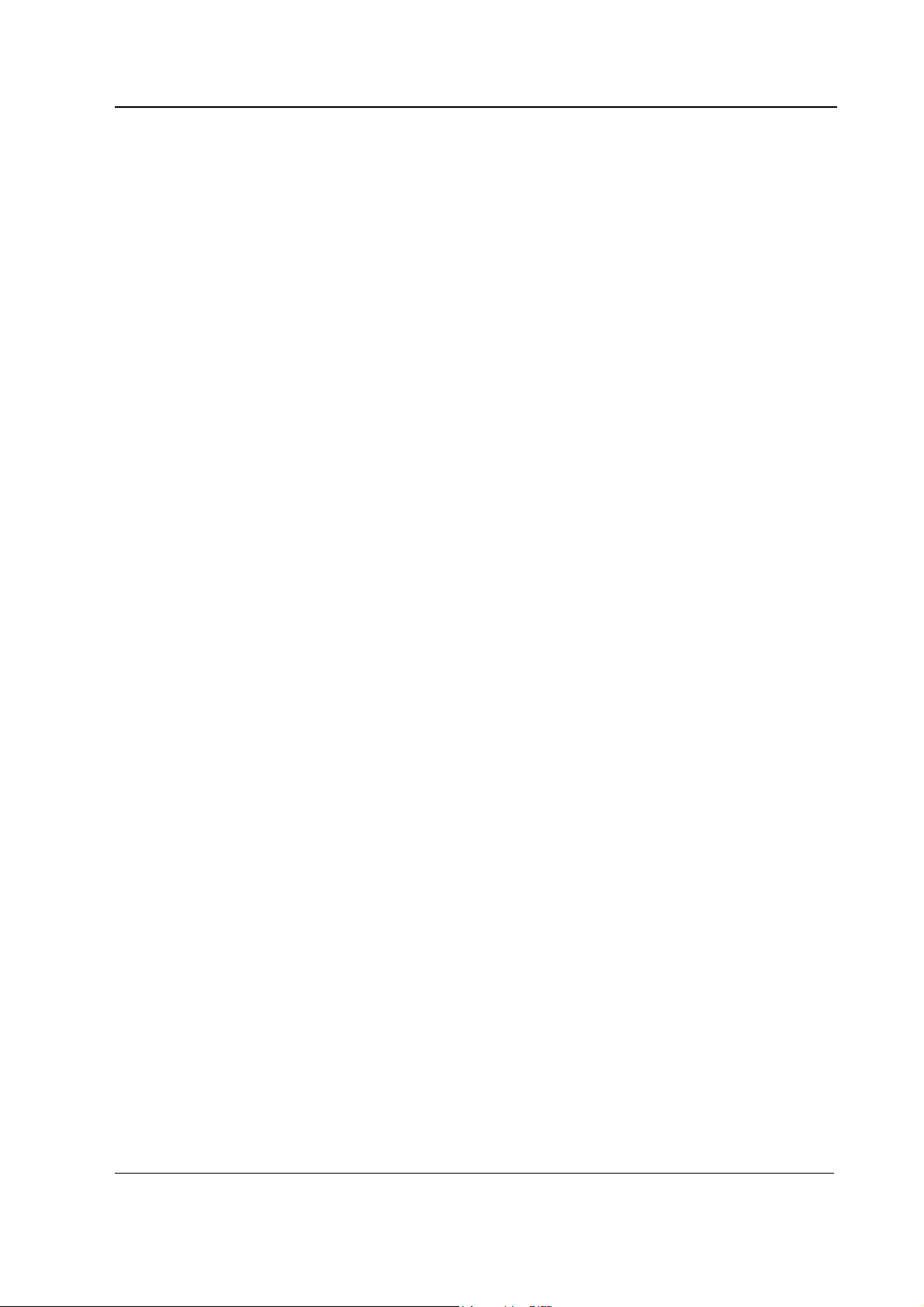

Figure 2 Front panel of M-P and M-PT Module..................................................................................................... 5

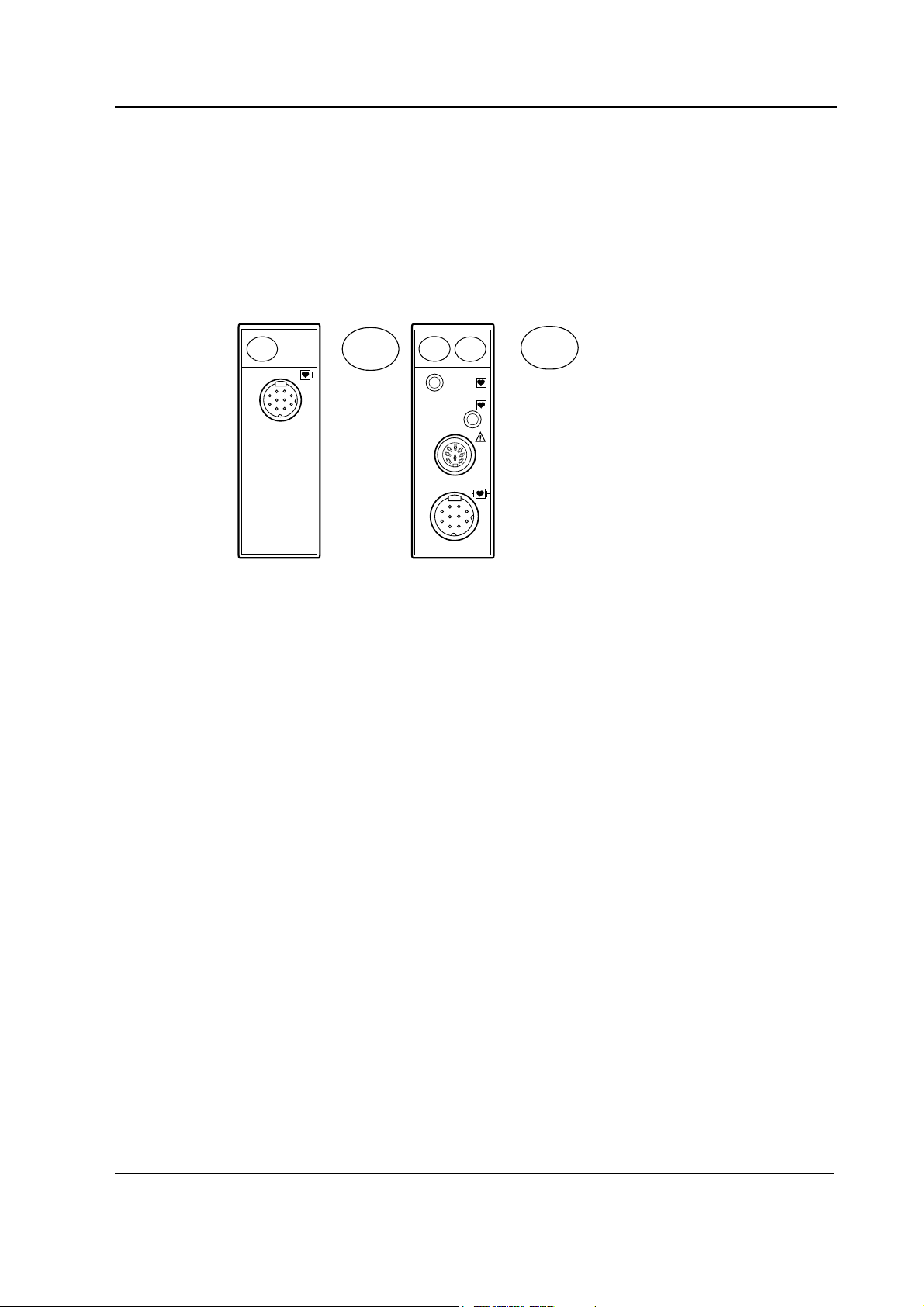

Figure 3 PT board block diagram ........................................................................................................................ 6

Figure 4 Pressure transducer principle of operation.............................................................................................7

Figure 5 Temperature measurement principle..................................................................................................... 8

Figure 6 Serial communication and opto isolation section................................................................................... 8

Figure 7 Module bus connector (X1) .................................................................................................................10

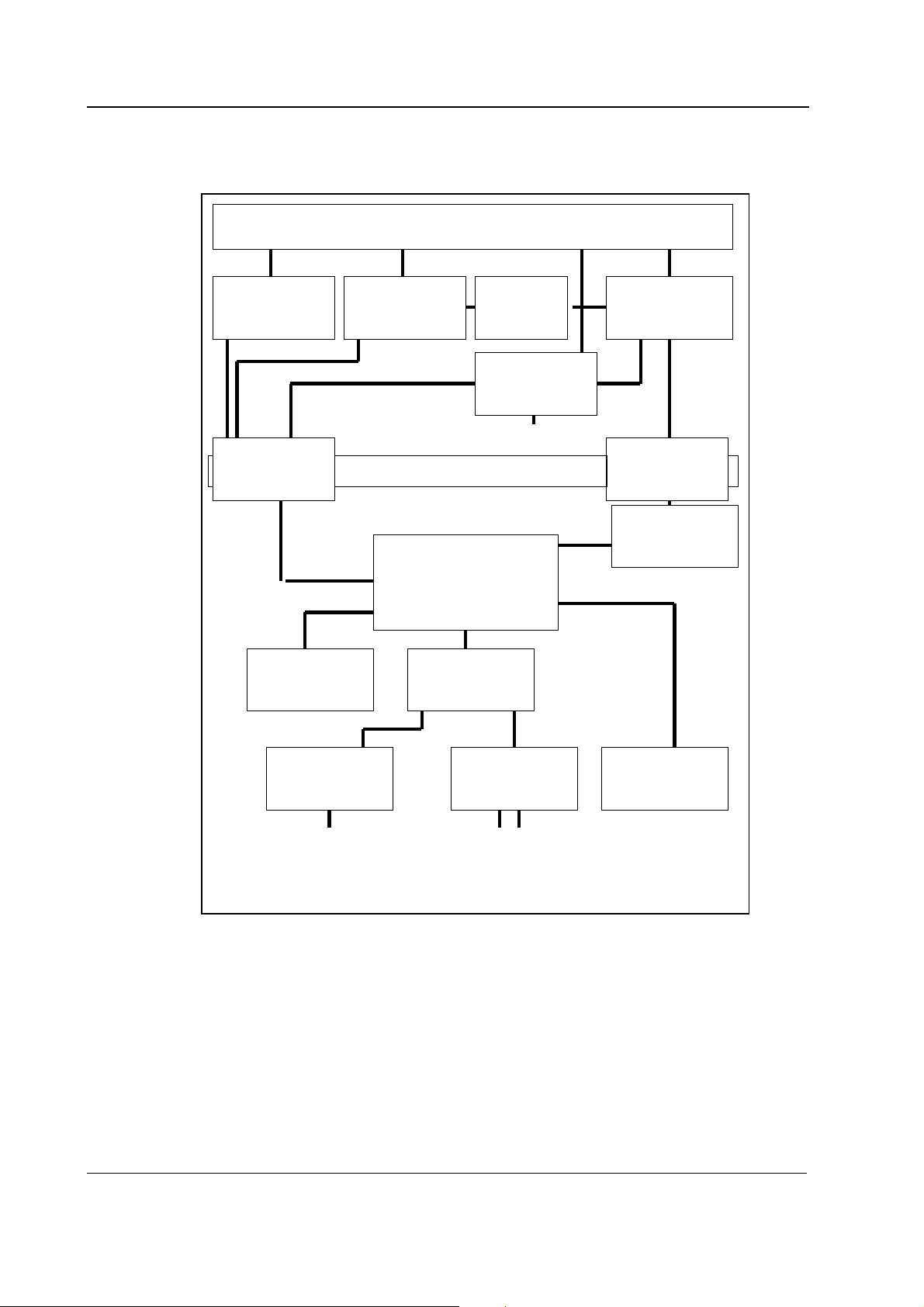

Figure 8 Troubleshooting flowchart...................................................................................................................23

ii

Document No. 8001013-1

Page 5

INTRODUCTION

This section provides information for the maintenance and service of the Pressure Module, M-P,

and Pressure Temp Module, M-PT. The M-P and M-PT modules are single width plug-in modules

designed for use with the S/5 monitors. Both modules provide invasive pressure measurement.

Additionally, the M-PT-module provides temperature measurement. The M-PT module also has a

connector for direct ECG and pressure signal output.

NOTE: Do not use identical modules in the same monitoring system. The modules M-P and M-PT

are considered as identical modules.

Pressure Module, M-P and Pressure Temp Module, M-PT

Figure 1 Datex-Ohmeda M-PT and M-P Module

1

Document No. 800 1013-1

Page 6

Datex-Ohmeda S/5 monitors

1 SPECIFICATIONS

1.1 General specifications

Module size, W × D × H 37 × 180 × 112 mm / 1.5 × 7.1 × 4.4 in

Module weight 0.35 kg / 0.8 lbs

Power consumption Approximately 3.5 W

1.2 Typical performance

1.2.1 InvBP

Measurement range -40...+320 mmHg

Accuracy ±5 % or ±2 mmHg, whichever is greater

Zero adjustment range ±150 mmHg

Calibration range ±20 %

Scales Upper limit is adjustable between 10 and 300 mmHg in steps of

Sweep speed 12.5, 25, 50 mm/s

10. Lower limit is 10 % of selected upper limit below zero.

DIGITAL DISPLAY

Range -40...+320 mmHg

Resolution ±1 mmHg

WAVEFORM DISPLAY

Range -30...+300 mmHg

HEART RATE FROM ARTERIAL PRESSURE

Measurement range 30...250 bpm

Resolution 1 bpm

Accuracy ±5 bpm or ±5 %, whichever is greater

1.2.2 Temperature

Measurement range 10...45 °C (50...113 °F)

Display resolution 0.1 °C (0.1 °F)

Temperature test Automatic (every 10 min.)

YSI 400 probe compatible

1.2.3 Signal output

ECG out 1 V/mV

Pressure P3 out 1 V/100 mmHg, (0...300 mmHg)

2

Document No. 8001013-1

Page 7

1.3 Technical specifications

1.3.1 InvBP

Accuracy ±5 % or ±2 mmHg, whichever is greater

Transducer and input sensitivity 5 µV/V/mmHg, 5 VDC, 20 mA max current

Nonlinearity <1 %, 0 to 200 mmHg

Filter 0...4 - 22 Hz adjustable

Zero set accuracy ±1 mmHg

Calibration resolution ±1 mmHg

Zero time less than 15 sec

Protection against electrical shock Type CF defibrillation proof

DIGITAL DISPLAY AVERAGING

Art and P1 digital displays are averaged over 5 seconds and updated at 5 seconds intervals. All

other pressures have respiration artifact rejection.

NOTE: The accuracy of the measurement may be different from that specified, depending on the

transducer/probe being used. Please check the transducer/probe specification.

Pressure Module, M-P and Pressure Temp Module, M-PT

<2 %, -40 to 0 and 200 to 320 mmHg

1.3.2 Temperature

Measurement accuracy ±0.1 °C (25.0...45.0 °C)

Protection against electrical shock Type CF

NOTE: The accuracy of the measurement may be different from the specified, depending on

transducer/probe used. Please check the transducer/probe specification.

1.3.3 Signal output

Max. delay: ECG1 15 ms

Pressure offset error max. 10 mmHg

±0.2 °C (10.0...24.9 °C)

Pressure P3 25 ms (0...300 mmHg)

Document No. 800 1013-1

3

Page 8

Datex-Ohmeda S/5 monitors

2 FUNCTIONAL DESCRIPTION

2.1 Measurement principle

2.1.1 Invasive blood pressure

To measure invasive blood pressure, a catheter is inserted into an artery or vein. The invasive

pressure setup, consisting of connecting tubing, pressure transducer, an intravenous bag of normal

saline all connected together by stopcocks, is attached to the catheter. The transducer is placed at

the same level with the heart, and is electrically zeroed.

The transducer is a piezo-resistive device that converts the pressure signal to a voltage. The monitor

interprets the voltage signal so that pressure data and pressure waveforms can be displayed.

2.1.2 Temperature

The temperature is measured by a probe whose resistance varies when the temperature changes,

called Negative Temperature Coefficient (NTC) resistor.

The resistance can be measured by two complementary methods:

• Applying a constant voltage across the resistor and measuring the current that flows through

it.

• Applying a constant current to flow through the resistor and measuring the voltage that is

generated across it.

In S/5 module the two methods are combined in a form of a voltage divider. The NTC-resistor is

connected in series with a normal resistor and a constant voltage is applied across them. The

temperature dependent voltage can be detected at the junction of the resistors, thus producing the

temperature signal from the patient. The signal is amplified by analog amplifiers and further

processed by digital electronics.

2.2 Main components

The M-PT module consists of the following main parts:

• PT board

• Two connectors for YSI 400 series temperature probes; temperature channels T3 and T4.

• Nicolay-type connector for an invasive blood pressure sensor; invasive blood pressure

channel P3.

• Key for pressure zeroing.

4

Document No. 8001013-1

• DIN-type connector for two direct ECG output signals and pressure 3.

NOTE: These output-signals are non-floating

The M-P module consists of the following main parts:

• PT board

• Nicolay-type connector for an invasive blood pressure sensor; invasive blood pressure

channel P3.

Page 9

Pressure Module, M-P and Pressure Temp Module, M-PT

• Key for pressure zeroing.

Communication between the module and the central unit is established through RS485 serial

interface.

The power supply voltages to the module are generated in the power supply section of the

monitor’s Central Unit. All electrical connections between the module and the Central Unit are

established via 25-pin D-type connector on the backside of the module.

Zero

P3

Signal

Out

P3

T3

T4

P3

Zero

P3

Figure 2 Front panel of M-P and M-PT Module

Document No. 800 1013-1

5

Page 10

Datex-Ohmeda S/5 monitors

A

2.2.1 PT board

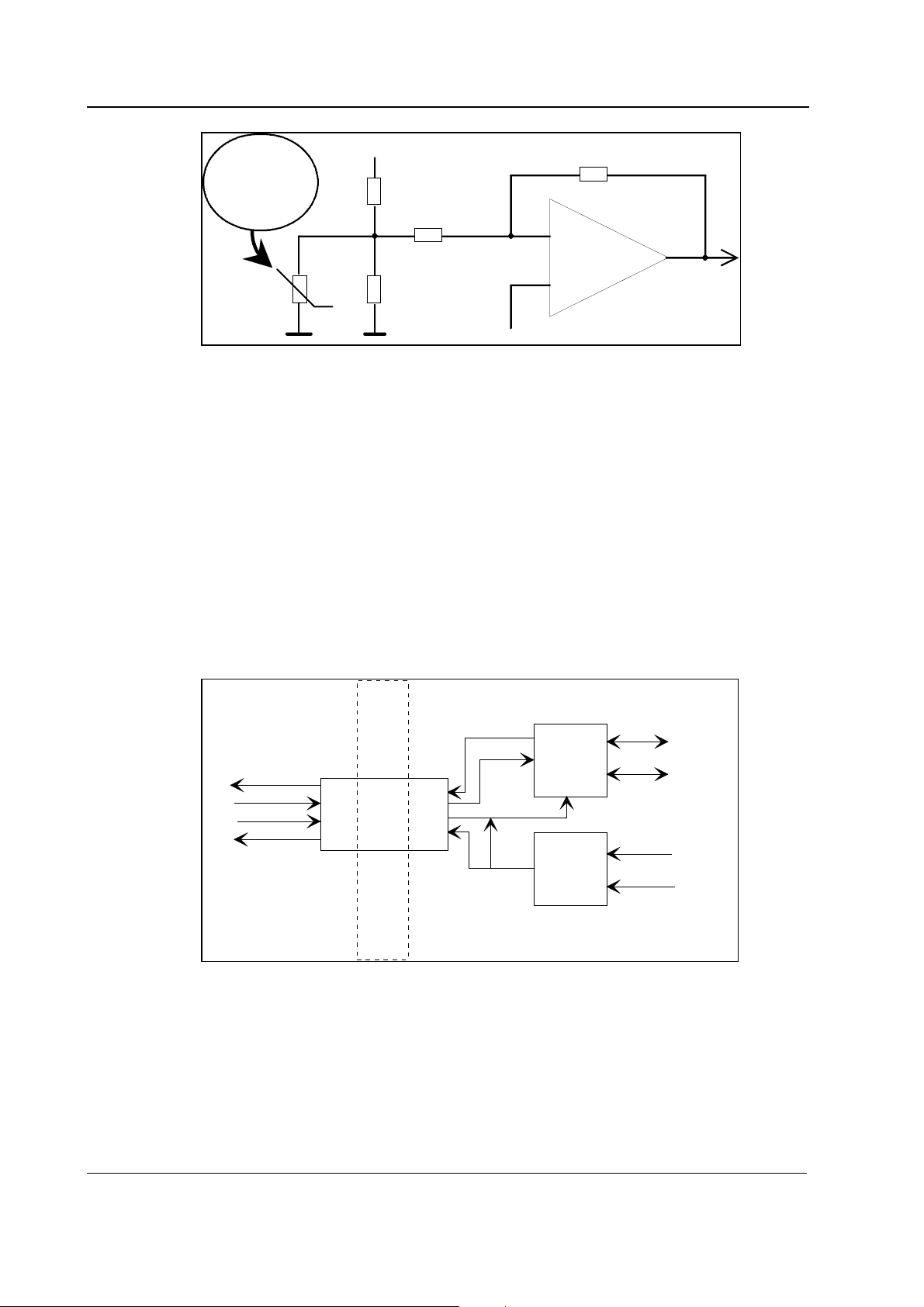

Module bus connector, D25

RS485 driver

for data

Opto

Isolation

non-volatile

memory

RS485 driver

for module

reset

Patient Isolation

Microprocessor

section

Power-up

reset

ECG OUT

PRESSURE OUT

to output connector

/D converter

Power

,

non-isolated

section

Isolation

transformer

Power,

isolated

section

INV.pressure

measuring

unit

to pressure

sensor

Figure 3 PT board block diagram

ECG and pressure signal prosessing

The PT-module has the Signal Out connector, for output of analog ECG and pressure signals.

The analog ECG-output signals are made by detecting the pulse-width modulated (PWM) ECG

signal of the module bus. The module detects the presence of the pacemaker pulses by following

the ECG module. Every time the pacer pulse has been detected, the microprocessor of the M-PT

module generates a 2.5 ms pacer pulse which is added to the analog ECG signal.

The PRESSURE OUT signal is generated from the P3 invasive pressure signal of the M-PT module.

6

Document No. 8001013-1

Temperature

measuring

unit

to temperature

sensors

Keyboard

Page 11

The P3 signal is transmitted as a pulse width modulated (PWM) signal over the patient isolation.

The analog signal is generated by low-pass filtering the PWM signal.

Microprocessor unit

The microprocessor uses the Intel 80C196KC-16 which includes three A/D converters and a UART.

There are external memories, an 8-bit data bus, a 16 MHz oscillator, an open collector reset, and a

watchdog timer. The internal UART communicates and transfers data between the module and the

CPU board in the monitor.

High speed I/O is used to obtain pulse control sequence necessary for pulse oximetry

measurement. It receives its timing clock from the oscillator.

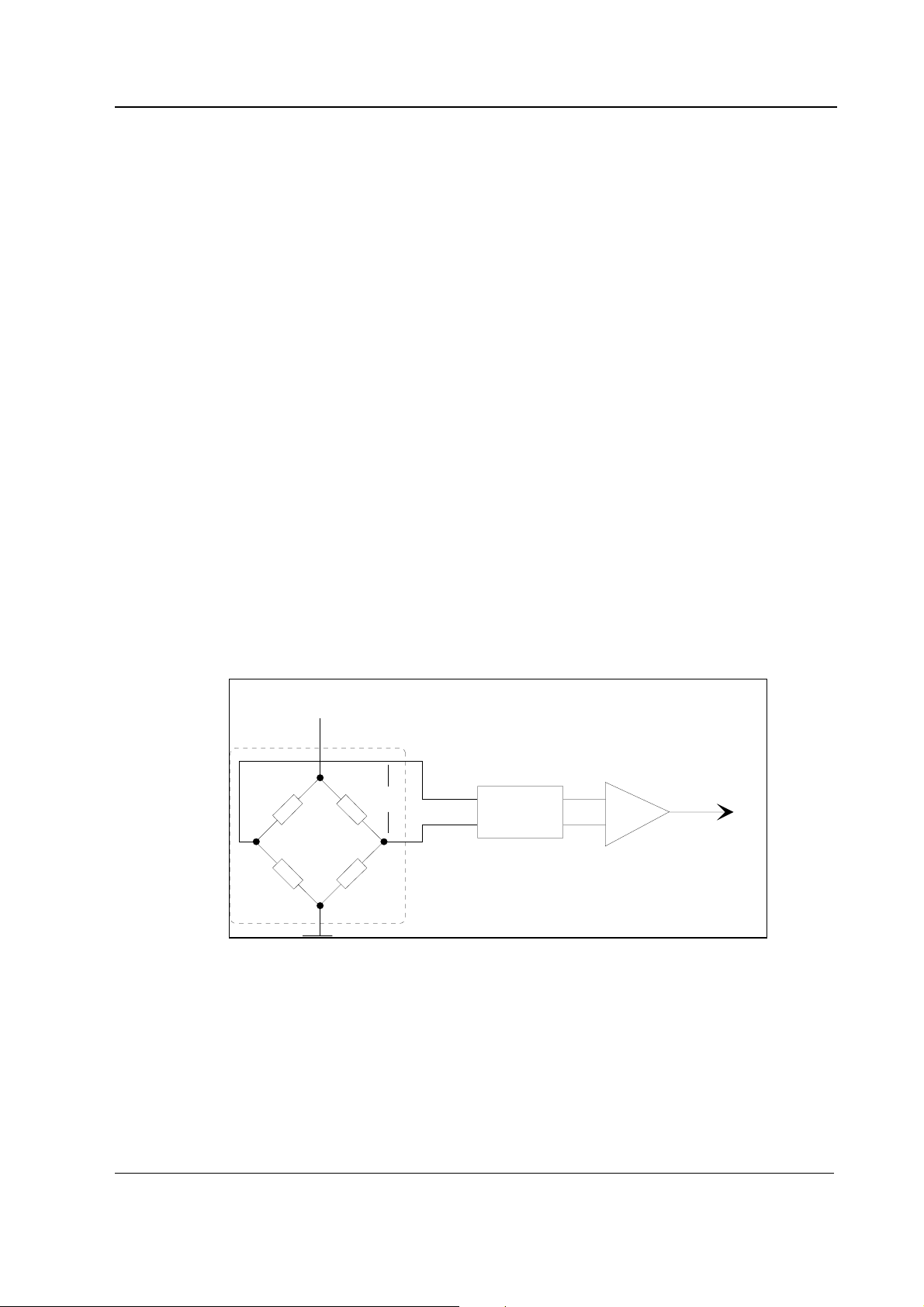

Invasive blood pressure measurement unit

An isolated +5 V supply is connected to the input of the pressure transducer bridge circuit. From

the bridge circuit output a differential voltage, which depends on blood pressure and input supply

voltage, is calculated using the following formula:

Uout = Uin × Pressure × 5 V

Pressure Module, M-P and Pressure Temp Module, M-PT

where Uin = 5 V

Uout = 25 V × Pressure [mmHg]

Pressure amplification is performed by the instrumentation amplifier. The gain of the amplifier is

set so that the level of the signal transferred to the A/D converter stays within the measurement

range even when there are circumstantial offsets or offsets caused by the pressure transducer. The

input filter before the amplifier attenuates high frequency disturbances.

Vin

Pressure

transducer

Vout

Input

Filter

Instrumentation

amplifier

G

to AD converter

Figure 4 Pressure transducer principle of operation

Temperature measurement unit

Value of NTC-resistor in the probe depends on patient’s temperature. It is measured with the

following principle.

The temperature signal(s) is produced by voltage dividers, part of which is the patient probe (YSI

400-series thermistor). The output is amplified by the calibrated amplifier(s) whose offset voltage

makes its output spread on both sides of zero. Wider output range (measurement range) means

better resolution.

7

Document No. 800 1013-1

Page 12

Datex-Ohmeda S/5 monitors

0 °C => 7K357

15 °C => 3K541

25 °C => 2K253

38 °C => 1K301

45 °C => 984R1

NTC

Figure 5 Temperature measurement principle

Serial communication

Serial communication between the module and the Central Unit is done by RS485 type bus whose

buffers get their supply voltage (+5 VDC) from the Central Unit and in the isolation section get the

supply voltage (+5 V) from the isolated power supply.

The communication drivers are controlled by a reset signal such that when the reset is active the

drivers do not transfer data.

Reset is also RS485 type and additionally, there is an auxiliary logic power reset, which keeps the

reset active for about 500 ms despite the state of reset in the module bus. A time constant

determines the power-up reset time. There are components to prevent the module from sending

data during reset. The data transmission rate is 500 kbps.

+5Vreference

A1

to AD

converter

offset

Isolated section

r

o

Receive data

sess

o

r

send

p

e

Send

/receive

dat

Reset

a

Opto isolation

Receive data

Send data

Reset

RS485

Driver

send/r

RS485

Driver

Data

NDa

eceive

Reset in

NReset in

)

nit

s

t

a

u

l

ra

bu

e

nt

ce

to

(modul

to modul

Patient

Isolation

Figure 6 Serial communication and opto isolation section

There are two opto isolators, one for data and one for the reset signal. Signals are processed on

logical high-low levels even though the output of the opto isolators in the isolation section are

analog signals.

8

Document No. 8001013-1

Page 13

The reset line is an open collector type with a pull-up resistor so that the microprocessor is able to

use its internal watchdog function.

Power supply section

Isolated supply voltage of the module is developed from +15 Vdirty voltage from the Central Unit.

Power supply is a switched-mode circuit, where FET transistor switch is controlled by an oscillator

using bipolar timer. The frequency of the oscillator is about 30 kHz and pulse ratio 50 %.

Controlling of the FET switch is slowed to suppress spurious interference.

A special pulse transformer is used in the circuit. The transformer secondary circuit uses normal

linear regulators except for +5 V which uses a low drop type linear regulator.

Pressure Module, M-P and Pressure Temp Module, M-PT

Document No. 800 1013-1

9

Page 14

Datex-Ohmeda S/5 monitors

2.3 Connectors and signals

2.3.1 Module bus connector

13

25

1

14

Figure 7 Module bus connector (X1)

Pin No I/O Signal

1 I RESET_RS485*

2 I -15 VDC*

3 I +15 VDIRTY*

4 I +15 Vin*

5 I/O NDATA_RS485*

6 I/O DATA_RS485*

7 Ground*

8 I NRESET_RS485*

9 I CTSB

10 O RTSB

11 I RXDB

12 O TXDB

13 Ground*

14 I +32 VDIRTY

15 I GroundDIRTY*

16 I CTSC

17 O RTSC

18 I RXDC

19 O TXDC

20 ON/STANDBY

21 O PWM_ECG*

22 RXDD_RS232

23 TXDD_RS232

24 I +5 VDCin*

25 I +5 VDC*

10

Document No. 8001013-1

* Used in the M-PT module

Page 15

2.3.2 Front panel connectors

Pressure connector (P3)

Pin No Signal

6

3

9

1

4

7

0

2

5

8

1 Pressure 3 +

2 Pressure 3 -

3 Polarization - (ground)

4 Polarization +

5 Not connected

6 Not connected

7 Not connected

8 Not connected

9 Ground

10 Cable detection

Signal out connector (Sync. out)

Pin No Signal

3

2

4

1

1 ECG out, 1 V/ 1 mV

2 Pressure out, 1 V/ 100 mmHg

3 ECG out, 1 V/ 1 mV

4 Ground

Pressure Module, M-P and Pressure Temp Module, M-PT

NOTE: The ECG out signal is not available with modules M-ESTP rev. 01, M-EST rev. 00 and M-ETP

rev. 00.

2.3.3 Other connectors

Keyboard connector (X3)

Pin No Signal Notes

1 N/C Not connected

2 COSWITCH Not used

3 PSWITCH for zeroing of P3

4 fGND Floating GND

5 fGND Floating GND

X3

1

5

11

Document No. 800 1013-1

Page 16

Datex-Ohmeda S/5 monitors

Pressure sensor connector (X4)

Pin No

board

1 0 PCABEL 5V if cable not connected

2 4 PCURRENT Pulsed supply to sensor

3 3,9 P3- Signal from the sensor

4 1 P3+ Signal from the sensor

5 2 fGND Floating GND

When the board is used in the M-PT module, there are the following connectors connected on the

board in addition to X1 and X4.

Signal out connector (X5)

Pin No

board

1 - ECG OUT ECG to (e.g.) IABP

2 - N/C Not connected

3 4 GND +5VDCin GND

4 1 ECG OUT ECG to (e.g.) defib.

5 - N/C Not connected

6 3 ECG OUT ECG to (e.g.) IABP

7 2 P OUT P3 to (e.g.) IABP

8 GND GND +5VDCin GND

Pin No

fr.panel

Pin No

fr.panel

Signal Notes

X4

1 5

Signal Notes

X5

1 8

Connector for temperature probes (X8)

Pin No Signal Notes

1T3-

2T4-

3 fGND Floating GND

4 CON Low if PT

5 fGND Floating GND

6 GND Floating GND

X8

1 6

12

Document No. 8001013-1

Page 17

Pressure Module, M-P and Pressure Temp Module, M-PT

3 SERVICE PROCEDURES

3.1 General service information

Field service of the M-P and M-PT modules is limited to replacing faulty circuit boards or

mechanical parts. The circuit boards should be returned to Datex-Ohmeda for repair.

Datex-Ohmeda is always available for service advice. Please provide the unit serial number, full

type designation, and a detailed description of the fault.

CAUTION Only trained personnel with appropriate equipment should perform the tests and

repairs outlined in this section. Unauthorized service may void warranty of the unit.

3.2 Service check

These instructions include complete procedures for a service check. The service check is

recommended to be performed after any service repair. However, the service check procedures can

also be used for determining possible failures.

The procedures should be performed in ascending order.

The instructions include a check form (Appendix A) which should be filled in when performing the

procedures.

The mark

procedure.

The procedures are designed for monitors with S/5 monitor software of revision 01. However, most

of the procedures also apply to monitors, which contain some other monitor software

type/revision.

? in the instructions means that the check list should be signed after performing the

3.2.1 Recommended tools

Tool Order No. Notes

M-NE(12)STPR/M-ESTPR/M-ESTP Not M-ESTP Rev. 01, M-EST Rev. 00 or M-ETP

Rev. 00

Patient simulator

Pressure manometer

Temperature test set 884515

InvBP transducer

Oscilloscope

Screwdriver

13

Document No. 800 1013-1

Page 18

Datex-Ohmeda S/5 monitors

All modules

• Detach the module box by removing the two screws from the back of the module. Be careful

with the loose latch and spring locking pin.

1. Check internal parts:

• screws are tightened properly

• cables are connected properly

• all socket mounted IC’s are inserted properly

• EMC covers are attached properly

• there are no loose objects inside the module

?

2. Check external parts:

• the front cover and the front panel sticker are intact

• all connectors are intact and are attached properly

• the module box, latch and spring locking pin are intact

?

• Reattach the module box and check that the latch is moving properly.

• Switch the monitor on and wait until the monitoring screen appears.

Configure the monitor screen so that all the needed parameters are shown, for example as

follows:

Monitor Setup - Screen 1 Setup - Waveform Fields - Field 1 - ECG1

Field 2 - P1

Field 3 - P3

Field 4 - P5

Digit Fields

Field 4 - T3+T4

3. Plug in the module. Check that it goes in smoothly and locks up properly.

?

• Preset InvBP measurement settings:

Invasive Pressures - P1 ‘Art’ Setup - Label - Art

P3 Setup - Label – PA

14

Document No. 8001013-1

Page 19

Pressure Module, M-P and Pressure Temp Module, M-PT

4. Enter the service menu:

Monitor Setup - Install/Service (password 16-4-34) - Service - (password 26-23-8)

Take down the information regarding module software by selecting SCROLL VERS and turning

the ComWheel.

?

5. Enter the P/PT service menu (according to the tested module):

Parameters - P/PT

Check that the “Timeouts”, “Bad checksums” and “Bad c-s by mod” values are not increasing

faster than by 50 per second. Check also that the module memories have passed the internal

memory test, i.e. the “RAM”, “ROM” and “EEPROM” show all OK.

?

Invasive blood pressure measurement

6. Check the front panel membrane key.

Press the key at least for one second. Check that the pressed key is identified, i.e. the text for

“Button” changes from OFF to ON in the service menu.

?

7. Check that the “Cable” and “Probe” show OFF.

Plug a cable with an invasive blood pressure transducer into the front panel connector P3.

Check that the “Cable” and “Probe” show ON and the pressure

8. waveform field appears onto the monitor screen..

NOTE: Test both invasive blood pressure channels with M-PP.

?

9. Calibrate the InvBP channel according to the instructions in the Technical Reference

Manual.

?

10. Check that the module configuration is correct with P and PT modules.

The configuration in use is shown beside the text “Configuration” in the service menu and it

can be either BP or PT.

Change the configuration in the CALIBRATIONS -menu, if necessary.

?

11. Check the InvBP channels with a patient simulator

Document No. 800 1013-1

15

Page 20

Datex-Ohmeda S/5 monitors

The settings and checks with a Dynatech Nevada medSim 300 Patient Simulator are:

SENSITIVITY switch position: 5 µV/V/mmHg

ECG - BASE - BPM - 60

ATM

connect a cable from the channel BP3 to the connector P3.

Ccheck that appropriate InvBP waveform is shown and the InvBP value is approximately

25/10 (±2 mmHg).

?

Modules with temperature measurement

BP - 2 - WAVE -

11. Check that the “Cable” and “Probe” show OFF for the channels T3 and T4 when no probes are

connected.

Connect a temperature test plug into the connector T3. Check that the “Cable” and “Probe”

for T3 show ON and the corresponding temperature value appears onto the screen.

Perform the same check also for the channel T4.

?

12. Check the temperature calibrations using temperature test plugs.

If the deviation on a temperature reading on the screen is more then 0.1 °C, calibrate the

temperature channels according to the instructions in the Technical Reference Manual.

?

13. Activate the temperature test by selecting TEMP TEST from the menu and pressing the

ComWheel twice. When the message “Performing temp test” disappears from the digit field

for T3+T4, check that no error messages appear and “Temp error” shows OFF for both

channels in the menu.

?

16

Document No. 8001013-1

Page 21

Modules with signal output connector

• Preset InvBP and ECG measurement settings:

Invasive Pressures - P3 Setup - Label - Art

ECG - ECG1 LEAD -I

Connect a patient simulator to the connector P3 and to the connector ECG on the used

M-NE(12)STPR/M-ESTPR/M-ESTP.

The settings and checks with a Dynatech Nevada medSim 300 Patient Simulator are:

SENSITIVITY switch position: 5 µV/V/mmHg

BP - 1 - WAVE - ART

ECG - BASE - BPM - 160

PACE - WAVE - NSR

Pressure Module, M-P and Pressure Temp Module, M-PT

Use the channel BP1 for the connector P3.

14. Connect an oscilloscope between the signal out connector pins 1 (ECG out) and 4 (Ground).

3

2

4

1

Check that an analog signal which corresponds with the ECG waveform on the screen comes

out. The output signal’s ratio to the actual ECG signal should be around 1V/1mV.

Check that a similar output signal is coming out also from the pin 3 (ECG out).

?

15. Connect the oscilloscope between the signal out connector pins 2 (Pressure out) and 4

(Ground).

Check that an analog signal which corresponds with the InvBP waveform on the screen

comes out. The output signal’s ratio to the actual InvBP signal should be around

1V/100mmHg.

?

17

Document No. 800 1013-1

Page 22

Datex-Ohmeda S/5 monitors

All modules

16. Perform electrical safety check and leakage current test.

?

17. Check that the module functions normally after the performed electrical safety check.

?

18. Clean the module with suitable detergent.

?

• Fill in all necessary documents.

3.3 Disassembly and reassembly

Disassemble the M-P and M-PT modules in the following way. See the exploded view of the

module.

1. Remove the two screws from the back of the module.

2. Pull the module box slowly backwards and detach it from main body. Be careful with loose

latch and spring pin for locking.

3. To detach the PT board. The board can be removed by detaching two screws on the folio

side of the board near the front panel and disconnecting the two ribbon cables coming from

the front panel.

To reassemble the module, reverse the order of the disassembly steps.

CAUTION When reassembling the module, make sure that all cables are connected properly.

18

Document No. 8001013-1

Page 23

3.4 Adjustments and calibrations

3.4.1 Invasive pressure calibration

Perform pressure calibration whenever the pressure transducer (probe) is replaced with different

type of transducer.

1. Enter P/PT service menu: Monitor Setup - Install/Service - Service - Parameters

2. Enter Calibrations menu.

Pressure Module, M-P and Pressure Temp Module, M-PT

3. Connect a pressure transducer with a pressure manometer to the P3 connector. Select

Calibrate P3. Leave the transducer to room air pressure.

4. Press the ComWheel to start zeroing.

5. Supply a pressure of 100 mmHg...300 mmHg to the transducer. The recommended pressure

is 200 mmHg.

6. Set the pressure on the display to match the pressure reading on manometer and press the

ComWheel. A tolerance of ±1 mmHg is allowed.

7. The text 'calibrated' will appear on the display.

3.4.2 Temperature calibration

NOTE: For the temperature calibration, separate test plugs (25 °C and 45 °C) are necessary. A test

set of two plugs is available from Datex-Ohmeda, order code 884515.

Performe temperature calibration whenever the measured values deviate more than ±0.1.

1. Enter P/PT service menu (Monitor Setup, Install/Service, Service, Parameters).

2. Enter Calibrations menu.

3. Press the protect button at the bottom of the module and select OFF protect mode. Release

the button.

4. Select Calibrate T3/Calibrate T4.

19

Document No. 800 1013-1

Page 24

Datex-Ohmeda S/5 monitors

5. Insert calibration plug (25 °C) into T3/T4 connector.

6. Press the ComWheel.

7. Insert calibration plug (45 °C) into T3/T4 connector.

8. Press the ComWheel.

9. Press in the protect button at the bottom of the module and select ON protect mode.

Release the button.

20

Document No. 8001013-1

Page 25

Pressure Module, M-P and Pressure Temp Module, M-PT

4 TROUBLESHOOTING

4.1 Troubleshooting chart

See also the User's Reference Manual for more troubleshooting procedures.

4.1.1 Invasive blood pressure

Trouble Cause Treatment

Abnormally low

pressure

No pressure Defective transducer. Check transducer.

Not zeroedmessage

Zeroing failedmessage

Calibration failedmessage

Transducer wrongly positioned. Check mid-heart level and reposition transducer.

No pressure module plugged in. Check the module.

No waveform selected on screen. Check selected pressure waveforms by pressing

Monitor Setup key and selecting modify

waveforms.

Check that pressure transducer open to patient.

Measurement on, channel not zeroed. Zero the channel.

Unsuccessful zeroing of P3 (number field). Possibly due to pulsating pressure waveform.

Open the transducer to air and zero the channel.

Offset is > 150 mmHg. Open the transducer to air

and zero the channel.

Defective transducer. Replace it and zero the

channel.

Unsuccessful calibrating of P3 (number

field), possibly due to pulsating waveform.

Turn the transducer to sphygmomanometer and

try again (zeroing takes place first).

Out of range ≤40

mmHg

Out of range >320

mmHg

Zero adj. >100

mmHg

Out of range Measured pressure is beyond the internal

Measurement pressure is beyond

measurement range.

Measurement pressure is beyond

measurement range.

Offset when zeroing is >100 mmHg (but

<150 mmHg) from the absolute zero of the

module (with default gain).

measurement range of the module.

Gain is beyond the limits (±20 % of the default

gain). Replace the transducer.

Check transducer level. Zero the channel.

Check transducer level. Zero the channel. The

patient may also have high pressure.

Check transducer. The waveform may hit the top

and the numeric display not shown.

The waveform hits the top and the numeric

display not shown. Check transducer and its

level. Zero the channel.

21

Document No. 800 1013-1

Page 26

Datex-Ohmeda S/5 monitors

4.1.2 Temperature

Trouble Cause Treatment

Message

'TEMPERATURE ERROR'

No temperature displayed Wrong type of probe.

Faulty calibration. Perform calibration. If it does not

Temperature out of measurable range.

Temperature calibration not protected.

help, check that front panel

connectors are properly connected to

STP board.

Use correct probe.

The range is between 10 and 45 °C.

Set the Protection ON in the Service

Menu.

22

Document No. 8001013-1

Page 27

4.2 Troubleshooting flowchart

Po ss ibl y fau lty

M-P/PT module

Take all modules out

of the Frame

Inse rt M-P /PT and turn

the power on

Pressure Module, M-P and Pressure Temp Module, M-PT

Does fault

still appear?

Yes

Enter the Service menu

Module-ID

on screen?

Yes

Check front panel key

functions in Service

menu

Do they work?

No

Check front panel unit

and PT board to

find culprit. Replace if

necessary

Yes

No

No

Has EEPROM

failed

No

Has Temp

measurement

failed?

No

Fault not in M-P/PT

module

No

Does another

module work

in the same slot?

Yes

Replace the PT board

Yes

Replace the PT board

Yes

Recalibrate the temp

channels

OK ?

No

Replace the PT board

No

Has InvBP

measurement

failed

Yes

Recalibrate the

InvBP channel

Figure 8 Troubleshooting flowchart

OK ?

23

Document No. 800 1013-1

Page 28

Datex-Ohmeda S/5 monitors

5 SERVICE MENU

1. Press the Monitor Setup key.

2. Select Install/Service (password 16-4-34).

3. Select Service (password 26-23-8).

4. Select Parameters.

5. Select P/PT module.

24

Document No. 8001013-1

Page 29

5.1 P/PT menu

Pressure Module, M-P and Pressure Temp Module, M-PT

Calibrations See section 5.2 “Calibrations menu.”

Record Data Record Data prints out the shown service data and board information (id., serial number, and

software id.) onto the recorder module, M-REC.

Service Data Gain is a coefficient to compensate gain error. Usually the value for P3 is between 17000 and

25000 and for T3 and T4 between 13000 and 14300. Zero indicates offset compensation value

of each parameter in A/D converter. Typically the values for P3 is within ±1000 and for T3 and T4

between -150 and +300. Calibrate if zero and/or gain value is outside the ranges.

Cable shows ON when the corresponding cable is connected to the front panel and Probe shows

ON when the corresponding probe is connected to the cable.

Under Value the measured numeric values are displayed simultaneously. Pressure value is a real

time value and shown in mmHg.

Button; the front panel key function can be confirmed by pressing the key and checking that OFF

turns to ON.

Temp error shows whether the calibration of the temperature was successful or not.

Protect key shows normally OFF but turns to ON when the button at the bottom of the module is

pressed.

Protect mode is normally ON. It turns to OFF when Protect is switched to OFF for the temperature

calibration in Calibration Menu.

Configuration shows the chosen module configuration: BP or PT.

Timeouts is a cumulative number that indicates how many times the module has not responded to

the monitor's inquiry.

Bad checksums is also a cumulative number that indicates how many times communication from

the module to monitor broke down.

Bad c-s by mod is a cumulative number that indicates how many communication errors the

module has detected.

The monitor starts counting these items at power up and resets to zero at power off. The nonzero

25

Document No. 800 1013-1

Page 30

Datex-Ohmeda S/5 monitors

values do not indicate a failure, but the continuous counting (more than 50 per second) during the

normal operation indicates either serial communication failure or module not in place.

RAM indicates the state of the RAM memory. ROM indicates whether the checksum in the EPROM

is in accordance with the one the software has calculated. EEPROM indicates if the values stored

in the permanent memory are valid. The state is either OK, Fail or ? (module not in place or a

communication error).

5.2 P/PT calibration menu

Protection Protection for the configuration and temperature calibrations can be set ON and OFF only when

protect button at the bottom of the module is pressed.

Set Config The module configuration should be set according to the module type. The setting is possible only

when the protection is set OFF. The available selections are BP or PT.

The configuration setting should be checked if the PT board is replaced.

Calibrate T3 and Calibrate T4

The functions are for calibrating the temperature channels T3 and T4. The calibrations are possible

only when the protection is set OFF. The temperature calibration requires accurate test plugs of

value 25 °C and 45 °C.

Calibration:

1. Select Calibrate T3 / Calibrate T4

2. Insert the test plug 25 °C into the T3 / T4 connector

3. Press the ComWheel

4. Insert the test plug 45 °C into the T3 / T4 connector

5. Press the ComWheel

Calibrate P3 The function is for calibrating the invasive blood pressure channel P3.

The calibration requires a pressure transducer (with an appropriate cable) and a pressure

manometer.

26

Document No. 8001013-1

Page 31

Pressure Module, M-P and Pressure Temp Module, M-PT

Calibration:

1. Connect the pressure transducer with the pressure manometer to the P3 connector. Select

Calibrate P3. Leave the transducer to room air pressure.

2. Press the ComWheel to start zeroing.

3. Supply a pressure of 100 mmHg to 300 mmHg to the transducer. The recommended

pressure is 200 mmHg.

4. Set the pressure on the display to match the pressure reading on the manometer and press

the ComWheel.

27

Document No. 800 1013-1

Page 32

Datex-Ohmeda S/5 monitors

6 SPARE PARTS

6.1 Spare parts list

NOTE: Only changed part numbers are listed under later revisions. To find the desired part: check

first the list of the revision that corresponds your device. If the part is not listed there, check the

previous revision, etc. until you find the right number.

NOTE: Accessories are listed in the Patient Monitor Supplies and Accessories.

6.1.1 Pressure Module, M-P, Rev. 00

4

1

3

2

5

Item Description Order No.

- Membrane keypad 880101

1 Module box (single width) 886167

2 Spring pin for module box 879182

3 Latch for module box 879181

4 Cross recess screw M3x8 black 616215

5 Front panel unit, M-P 880044

6 STP board, M-ESTP (Rev. 01), M-P (Rev. 00-01) *(880339) Use 885697

11 Metal frame 879184

13 Cross cylinder head screw M3x6 61721

14 Cross cylinder head screw M3x12 628700

15 Cross cylinder head screw M3x6 628710

16 Shakeproof washer 63611

28

Document No. 8001013-1

Page 33

6.1.2 Pressure Module, M-P, Rev. 01

No new spare parts.

6.1.3 Pressure Module, M-P, Rev. 02

Item Description Order No.

6 STP board, M-ESTP (Rev. 03-04), M-P (Rev. 02) *(882627) Use 885697

6.1.4 Pressure Module, M-P, Rev. 03

Item Description Order No.

6 PT board, M-PT (Rev. 01), M-P (Rev. 03) *895047

19 EMC cover 884099

20 Protection plate 883946

21 Insulation plate for 883946 884121

The front panel unit includes all the connectors and input boards.

* the part is recommended for stock

Pressure Module, M-P and Pressure Temp Module, M-PT

6.1.5 Pressure Module, M-P, Rev. 04

No new spare parts.

29

Document No. 800 1013-1

Page 34

Datex-Ohmeda S/5 monitors

6.1.6 Pressure Temp Module, M-PT, Rev. 00

Item Description Order No.

1 Module box (single width) 886167

2 Spring pin for module box 879182

3 Latch for module box 879181

5 Cross recess screw M3x8 black 616215

6 PT board, M-PT (Rev. 00) *885697

7 Signal out connector, M-PT 884316

8 T-Input connectors *884315

9 P-Input connector 884314

11 Metal frame 879184

13 Cross cylinder head screw M3x6 61721

14 Cross cylinder head screw M3x12 628700

15 Cross cylinder head screw M3x6 628710

16 Shakebroof washer 63611

17 Membrane keypad 880101

18 Front panel frame, M-PT 883801

19 EMC cover 884099

20 Protection plate 883946

21 Insulation plate for 883946 884121

30

Document No. 8001013-1

Page 35

Pressure Module, M-P and Pressure Temp Module, M-PT

6.1.7 Pressure Temp Module, M-PT, Rev. 01

Item Description Order no.

6 PT board, M-PT (Rev. 01), M-P (Rev.03) *895047

* the part is recommended for stock

6.1.8 Pressure Temp Module, M-PT, Rev. 02

No new spare parts.

6.1.9 Front panel stickers for AS/3 modules (square buttons)

Item No. 10

Front panel stickers that are related to the Compact Module type and adaptation:

Adaptation codes: DA=Danish, DE=German, EN=English, ES=Spanish, FI=Finnish,

FR=French, IT=Italian, JA=Japanese, NL=Dutch, NO=Norwegian, PT=Portuguese,

SV=Swedish

M-P

Adaptation

(Rev. 00-03)

Order No.

DA 892211 892210

DE 880488 885035

EN 880139 884004

ES 884201 886193

FI 888863 888864

FR 880130 885033

IT 886756 886758

JA 888308 888307

NL 886063 886330

NO 893569 893571

PT -- 895237

SV 885847 885845

M-PT

(Rev. 01)

Order No.

6.1.10 Front panel stickers for S/5 modules (round buttons)

Front panel stickers that are related to the Compact Module type and adaptation:

Adaptation codes: DA=Danish, DE=German, EN=English, ES=Spanish, FI=Finnish,

FR=French, IT=Italian, JA=Japanese, NL=Dutch, NO=Norwegian, PT=Portuguese,

SV=Swedish

31

Document No. 800 1013-1

Page 36

Datex-Ohmeda S/5 monitors

M-P

Adaptation

(Rev. 04)

Order No.

DA 898768 898768

DE 898735 898759

EN 898734 898758

ES 898738 898762

FI 898741 898765

FR 898736 898760

IT 898739 898763

JA 898745 898769

NL 898737 898761

NO 898743 898767

PT 898734 898764

SV 898742 898766

M-PT

(Rev. 02)

Order No.

32

Document No. 8001013-1

Page 37

7 EARLIER REVISIONS

This manual also supports M-P revisions 02 and 03.

For service information on the earlier revisions, please refer to:

P Module revision 00 Service Manual p/n 880850

P Module revision 01 Service Manual p/n 882580

Pressure Module, M-P and Pressure Temp Module, M-PT

33

Document No. 800 1013-1

Page 38

Datex-Ohmeda S/5 monitors

34

Document No. 8001013-1

Page 39

APPENDIX A, Service Check Form, M-P and M-PT

APPENDIX A

35

Document No. 800 1013-1

Page 40

Datex-Ohmeda S/5 monitors

36

Document No. 800 1013-1

Page 41

SERVICE CHECK FORM

Pressure Modules, M-P, M-PT

Customer

APPENDIX A, Service Check Form, M-P and M-PT

Service

Service engineer Date

OK = Test OK N.A. = Test not applicable Fail = Test Failed

All modules

OK N.A. Fail OK N.A. Fail

1. Internal parts 2. External parts

3. Installation

Notes

4. Module software

P

PT

Module type S/N

5. Communication and

memories

Notes

InvBP measurement

6. Membrane keys 7. Cable and transducer

detection

8. Calibration 9. Configuration BP/PT

10. Test with patient

simulator

Notes

A-1(2)

Document No. 8001013-1

Page 42

Datex-Ohmeda S/5 monitors

OK = Test OK N.A. = Test not applicable Fail = Test Failed

TEMP measurement

11. Temperature probe detection 12. Calibration check

13. Temp test -function

Notes

Signal output

14. ECG output 15. InvBP output

Notes

All modules

16. Electrical safety check 17. Functioning after

electrical safety

check

18. Final cleaning

Notes

Notes

Used Spare Parts

Signature

A-2(2)

Document No. 800 1013-1

Loading...

Loading...