Page 1

Datex-Ohmeda

S/5TM BIS Module

Technical Reference Manual Slot

Datex-Ohmeda, Inc.

P.O. Box 7550, Madison

WI 53707-7550, USA

Tel. 1-608-221-1551 Fax 1-608-222-9147

www.us.datex-ohmeda.com

mailto:product.support.ussub@us.datex-ohmeda.com

All specifications are subject to change without notice.

Document No. 800 3476

April 2002

Datex-Ohmeda Division, Instrumentarium Corp.

P.O. Box 900, FIN-00031

DATEX-OHMEDA, FINLAND

Tel. +358 10 394 11 Fax +358 9 146 3310

www.datex-ohmeda.com

Instrumentarium Corp. All rights reserved.

Page 2

Page 3

Table of contents

TABLE OF CONTENTS

BIS Module, M-BIS

TABLE OF CONTENTS I

TABLE OF FIGURES II

TABLE OF TABLES II

INTRODUCTION 1

1 SPECIFICATIONS 3

1.1 General specifications ..............................................................................................................................3

1.1.1 BIS Module......................................................................................................................................3

1.1.2 Digital Signal Converter, DSC ............................................................................................................3

1.1.3 Environmental specifications ............................................................................................................3

1.2 Technical specifications............................................................................................................................3

2 FUNCTIONAL DESCRIPTION 5

2.1 Measurements principle ...........................................................................................................................5

2.2 Sensor Check ...........................................................................................................................................5

2.3 Main components.....................................................................................................................................7

2.3.1 Digital Signal Converter, DSC ............................................................................................................7

2.3.2 BIS Module......................................................................................................................................8

2.4 Connectors and signals.............................................................................................................................9

2.4.1 Module bus connector......................................................................................................................9

2.4.2 H8 programming connectors pin order...............................................................................................9

2.4.3 BIS Engine connectors pin order......................................................................................................10

2.4.4 Keys ..............................................................................................................................................10

3 SERVICE PROCEDURES 11

3.1 General service information.....................................................................................................................11

3.2 Service check .........................................................................................................................................11

3.2.1 Recommended tools ......................................................................................................................11

3.3 Disassembly and reassembly..................................................................................................................15

4 TROUBLESHOOTING 16

4.1 Troubleshooting chart .............................................................................................................................16

4.2 Messages...............................................................................................................................................17

4.3 Troubleshooting flowchart .......................................................................................................................18

5 SERVICE MENU 19

5.1 BIS service menu....................................................................................................................................20

5.1.1 Module service page ......................................................................................................................20

5.1.2 Sensor...........................................................................................................................................24

5.1.3 Setup.............................................................................................................................................26

6 SPARE PARTS 27

6.1 Spare part list.........................................................................................................................................27

6.1.1 M-BIS ............................................................................................................................................27

7 EARLIER REVISIONS 29

Document No. 800 3476

i

Page 4

Datex-Ohmeda S/5 monitors

APPENDICES A, B 31

SERVICE CHECK FORM A-1

APPENDIX B, HOW TO READ HEX NUMBERS B-1

TABLE OF FIGURES

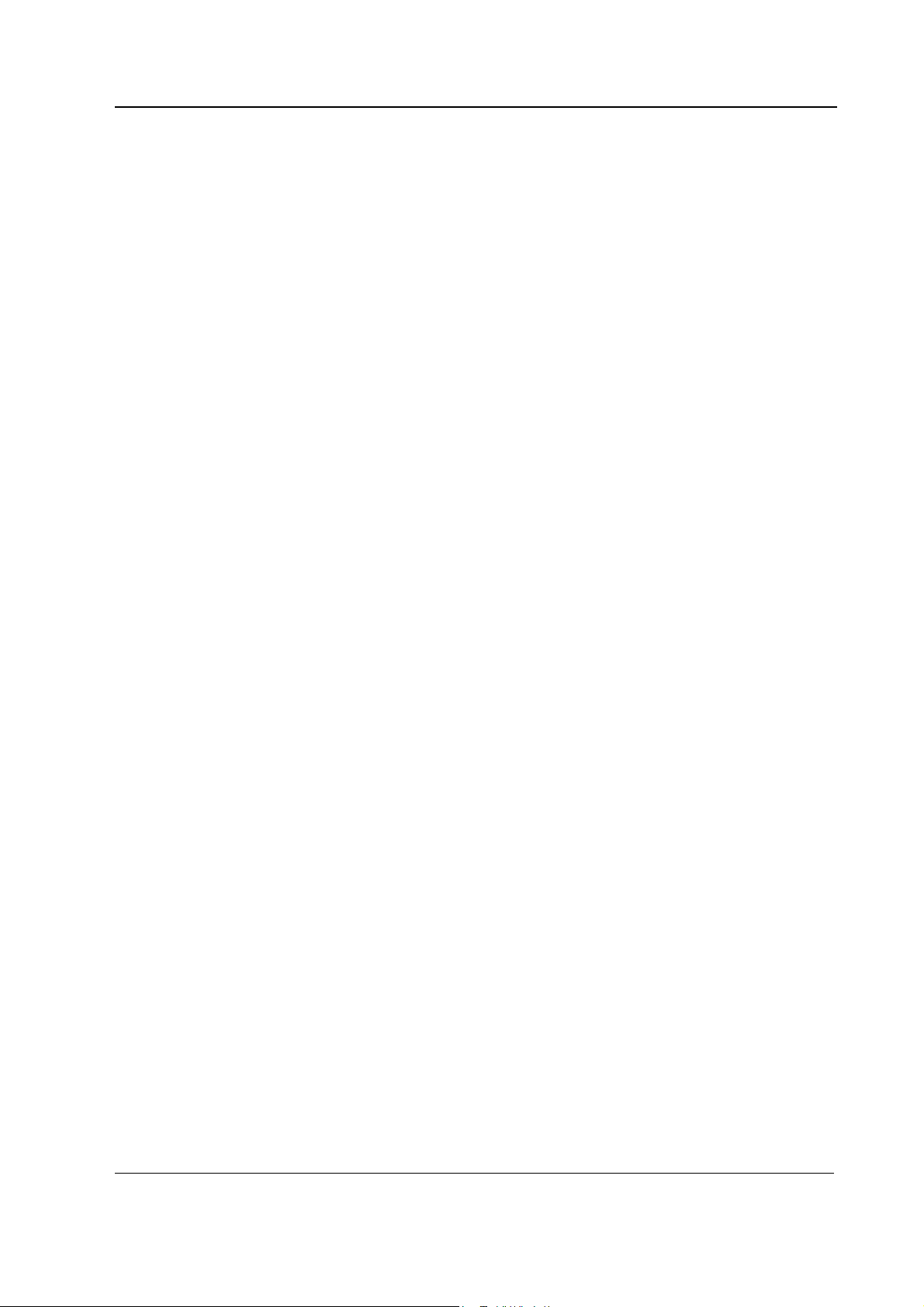

Figure 1 Measurement setup .............................................................................................................................1

Figure 2 BIS sensor check..................................................................................................................................5

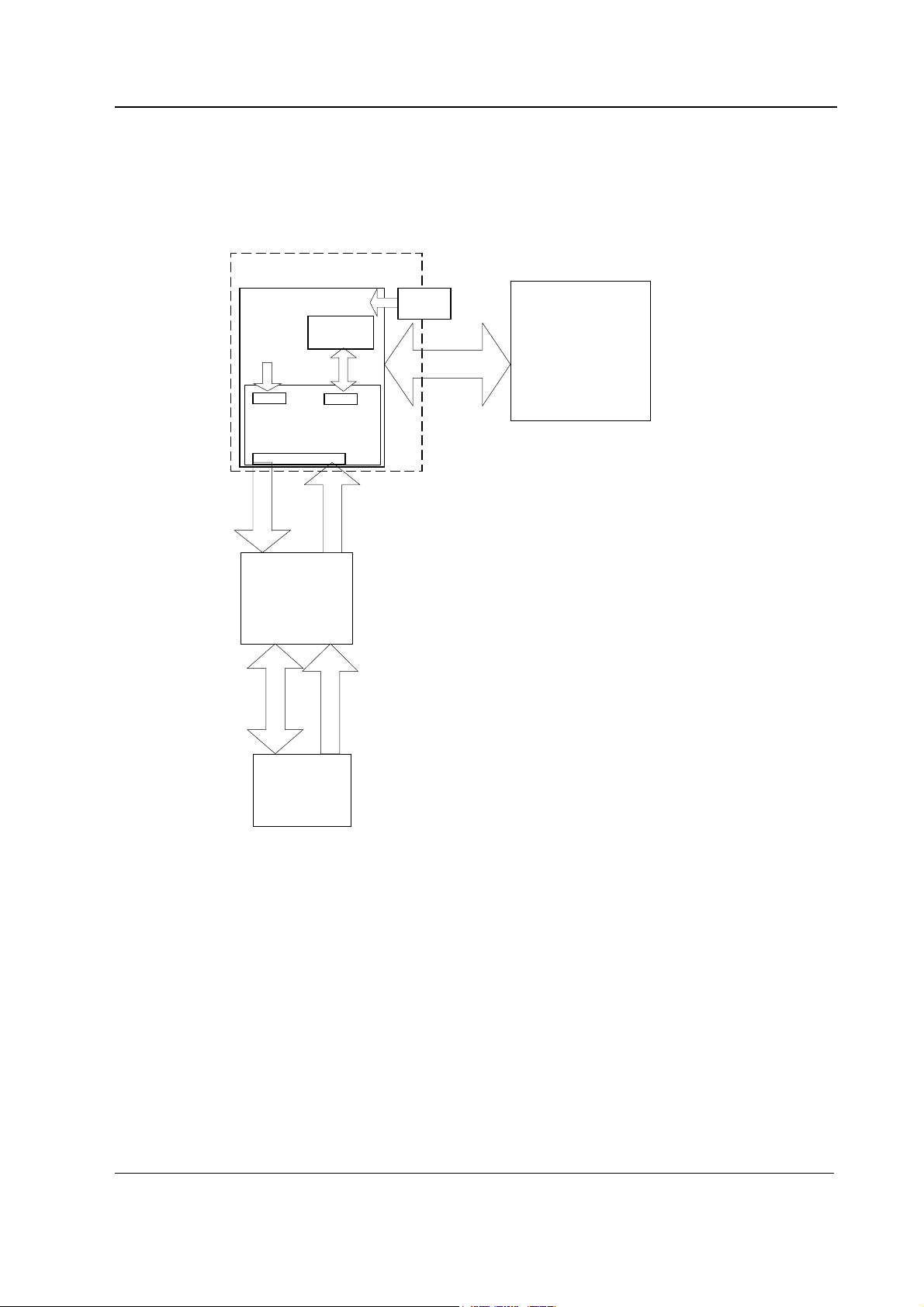

Figure 3 BIS measurement system block diagram............................................................................................... 7

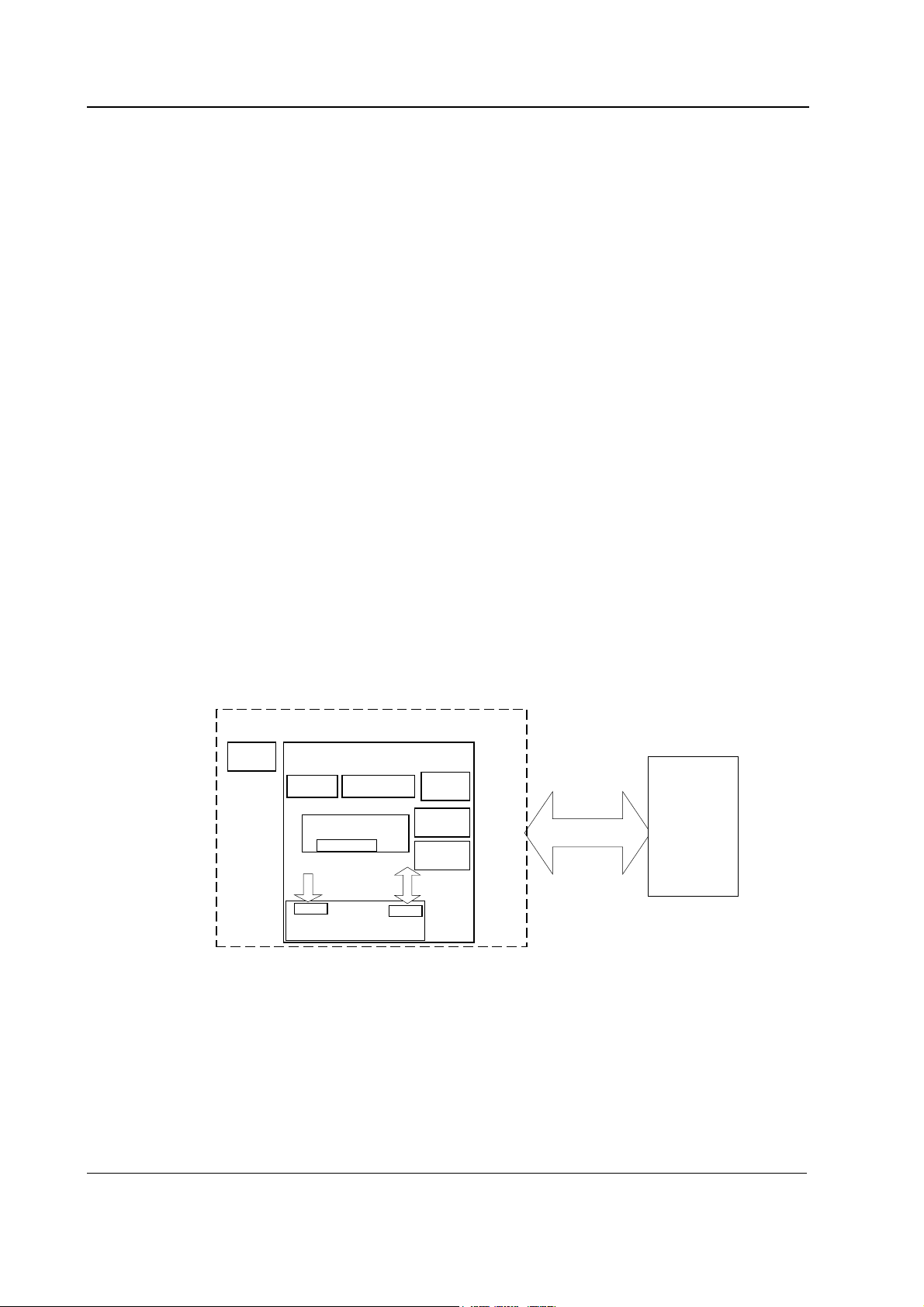

Figure 4 Block diagram of setup.........................................................................................................................8

Figure 5 BIS module disassembly and reassembly............................................................................................15

Figure 6 BIS module troubleshooting flowchart ................................................................................................. 18

Figure 7 Exploded view of module box and BIS module .....................................................................................27

TABLE OF TABLES

Table 1 Module bus connector (X1) pin description............................................................................................ 9

Table 2 Connector pinning for H8 programming connector................................................................................. 9

Table 3 Connector pinning for DSC and BIS Engine connectors........................................................................10

Table 4 Connector pinning BIS Engine power connector ..................................................................................10

Table 5 Connector pinning for BIS Engine serial data connector.......................................................................10

Table 6 Key connector pin assignments...........................................................................................................10

Table 7 Module general status........................................................................................................................21

Table 8 BIS Engine status ..............................................................................................................................21

Table 9 BIS Engine and DSC error messages ...................................................................................................22

Table 10 DSC status....................................................................................................................................25

Table 11 Sensor status................................................................................................................................25

Table 12 BE powup stat...............................................................................................................................25

Table 13 HEX to binary conversion ...............................................................................................................B-1

ii

Document No. 800 3476

Page 5

INTRODUCTION

This Technical Reference Manual Slot provides information for the maintenance and service of the

Datex-Ohmeda S/5 BIS Module, M-BIS. The BIS module is a single width plug-in module designed

for use with the S/5 monitors. Later in this manual modules can be called w/o system name

Datex-Ohmeda S/5.

BIS, and the BIS logo are trademarks of Aspect Medical Systems Inc., and are registered in the

USA, EU and other countries. Later in this manual Aspect Medical Systems Inc. will be called

Aspect.

Please see also the Technical Reference Manual of the S/5 monitor for system specific information

e.g. related documentation, conventions used, symbols on equipment, safety precautions, system

description, system installation, interfacing, functional check and planned maintenance.

The BIS module is indicated for monitoring the state of the brain by data acquisition of EEG signals.

BIS may be used as an aid in monitoring the effects of certain anesthetic agents. The raw EEG

signals are processed to produce a single number, ranging from 100 for a patient being wide

awake to 0 in the absence of brain activity.

Calculated parameters are:

S/5 BIS Module, M-BIS

• Bispectral Index, BIS

• Suppression Ratio, SR

• Electromyograph EMG

• Signal Quality Index, SQI

The calculated parameters can be selected on the display, and trended, (excluding SQI).

Module has two user keys, BIS for BIS menu and Check Sensor for impedance check.

3

1

2

1

4

2

4

3

Figure 1 Measurement setup

(1) Module with BIS measurement capability, M-BIS

(2) Digital Signal Converter

(3) Patient Interface Cable

(4) BIS Sensor

NOTE: M-BIS module functions only with monitor software versions 02 or later.

1

Document No. 800 3476

Page 6

Datex-Ohmeda S/5 monitors

Accessories

The BIS measurement is based on Aspect Medical Systems Inc. technology, and all accessories

are developed and manufactured by Aspect.

NOTE: Only Aspect accessories can be used with the M-BIS module.

2

Document No. 800 3476

Page 7

1 SPECIFICATIONS

1.1 General specifications

1.1.1 BIS Module

Module size, W × D × H 37 × 180 × 112 mm/1.5 × 7.1 × 4.4 in

Module weight 0.3 kg/0.7 lbs

Power consumption 2.2 W

1.1.2 Digital Signal Converter, DSC

DSC size, W × D × H 66 × 108 × 25 mm/2.6 × 4.3 × 1.0 in

DSC weight 0.134 kg/0.3 lbs

Integral DSC Cable length 3.6m / 12.5 ft

Patient Interface Cable (PIC Plus)

length 1.2m / 4 ft

S/5 BIS Module, M-BIS

1.1.3 Environmental specifications

Operating temperature +10 … +40°C

storage temperature -25 … +70°C

relative humidity 10 … 95%, non -condensing

atmospheric pressure 700 … 1060 mbar

Protection against electrical shock Type BF

1.2 Technical specifications

Parameter specifications

BIS EEG

Epoch duration 2 seconds

Artifact rejection automatic

EEG scales 25 to 400 µV

EEG sweep speeds 12.5 / 25 / 50 mm /sec

Bispectral index (BIS) 0 to 100

Signal quality index (SQI) 0 to 100

EMG 30 to 80 db (70 to 110 Hz)

Suppression ratio (SR) 0 to 100 %

Update rate 1 second for BIS index

Filters 2 - 70 Hz bandpass (default) / 0.25Hz highpass

Smoothing rate 15 seconds, default in S/5 AM and CAM

30 seconds, default in S/5 CCM and CCCM

3

Document No. 800 3476

Page 8

Datex-Ohmeda S/5 monitors

DSC

Analog to digital converter noise-shaped sigma-delta

Sampling rate 16384 samples/second

Resolution 16 bits at 256 samples/second

Input impedance >50 Mohms

Noise < 0,3µV RMS (2.0µV peak-to-peak) 0.25 to 50 Hz

Common mode rejection 110 dB at 50/60 Hz to earth ground (Isolation mode)

Bandwith 0.16 to 450 Hz

4

Document No. 800 3476

Page 9

2 FUNCTIONAL DESCRIPTION

2.1 Measurements principle

The BIS measurement is based on EEG signals, these are processed as BIS index. The BIS sensor is

placed on the patient’s forehead to acquire the high-resolution signals required. These EEG signals

are transferred to digital signal converter DSC that amplifies and digitizes the EEG signal and sends

it to the module. The module calculates BIS index and sends it to the monitor via MBUS.

BIS measurement on the monitor screen

The waveform field shows the BIS EEG waveform. The following BIS related data appears in digit

fields and graphical trends (except SQI):

BIS number indicates the patient’s level of hypnosis, ranging from 100 for wide awake to 0 in the

absence of brain activity.

Signal Quality Index (SQI ) bar graph indicates the quality of the EEG signal in the range of 0 to

100.

S/5 BIS Module, M-BIS

Electromyograph (EMG) bar graph represents the absolute power in the 70 to 110 Hz frequency

band and ranges from 30 to 55 dB. This frequency band contains power from muscle activity

(electromyograph) as well as power from high frequency artifacts.

Suppression ratio (SR) number indicates the percentage of suppressed (flatline) EEG detected

over the last 63 seconds. It ranges from 0 to 100%.

2.2 Sensor Check

Sensor check is performed automatically at the beginning of each case when the sensor is

attached to the patient interface cable (monitor). An initial check-up message is shown at digit

field together with an appropriate sensor picture. The information of the passed or failed sensor

check is printed to this picture at each electrode’s location. The BIS measurement can’t continue if

the first sensor check fails. In such case a message “Sensor check failed” is shown at the digit and

waveform field.

Figure 2 BIS sensor check

Continuous checking of the reference and signal electrodes and periodic checking of the ground

electrode is performed by default. It can be switched off by selecting appropriate comand from

menu – message “Automatic check off” will appear. Sensor check can be started manually by

pushing a module key or selecting appropriate command from menu. Manual sensor check can be

useful e.g. when AEP's are being monitored at the same time, as the continuous sensor check

Document No. 800 3476

5

Page 10

Datex-Ohmeda S/5 monitors

might disturb the AEP measurement.

During periodic ground checks, the signal disappears momentarily and the message “Checking

sensor” is printed in the digit and waveform fields. Also, all BIS calculation stops during this check,

and no measurement values are shown.

CAUTION Continuous impedance check may need to be disabled if the 1 nA 128 Hz

impedance check signal interferes with other equipment such as evoked potential.

WARNING Make sure that the electrodes, sensor and connectors do not touch any

electrically conductive material, including earth.

6

Document No. 800 3476

Page 11

2.3 Main components

BIS measurement chain is composed of Aspect BIS Sensor, Aspect digital signal converter, M-BIS

module containing Aspect BIS Engine board and Datex-Ohmeda’s interfacing board, and host

monitor. Block diagram of the system below.

M-BIS Module

S/5 BIS Module, M-BIS

BIS Interfac ing Boar d

Controller

DSC

data

Serial

Digital signal

Measurement

Power

BIS Engine

Power

Digital Signal

Converter

Patient Isolation

Control

PIC+

Keys

MBUS

Serial

data

Power

Host Monitor

BIS Sensor

Figure 3 BIS measurement system block diagram

2.3.1 Digital Signal Converter, DSC

The digital signal converter, DSC, receives, amplifies and digitizes patient EEG signals. It is placed

close to the patient's head where the EEG signal is less subject to interference from other medical

equipment. The digital signal converter is connected to the module with a 3.6m long shielded

cable and to the BIS sensor with 1.2m long patient interface cable, see Figure 1. For BIS Sensor

related documentation refer to BIS documentation by Aspect, Inc.

CAUTION Do not autoclave the DSC. Do not open it for any reason.

MBIS_meas_blockdiag.vs d

7

Document No. 800 3476

Page 12

Datex-Ohmeda S/5 monitors

WARNING When using the electrosurgery unit, ensure proper contact of the ESU return

electrode to the patient to avoid burns at monitor measurement sites. Also

ensure that the ESU return electrode is near the operating area.

WARNING Radiated field strengths above 1V/m may cause erroneous measurements at

various frequencies. Do not use electrical radiating equipment close to the

DSC.

2.3.2 BIS Module

Aspect BIS Engine

The BIS Module provides Bispectral index values to monitor. The BIS Engine processes the digital

signal from DSC and outputs the BIS index and other supporting parameters through the

asynchronous serial connection. The BIS Engine outputs the BIS Index, raw EEG, EMG, Signal

Quality Index (SQI), Suppression Ratio (SR) and electrode impedance’s. The BIS Engine software

includes Aspects' proprietary algorithm for BIS calculation.

BIS interfacing board

The BIS interfacing board supplies the data from BIS Engine to the monitor via module bus. As well

the module accepts commands from the monitor via module bus. In addition, the module provides

supply voltages and all the required control signals to the BIS Engine and DSC.

Controller H8 has on-chip RAM and FLASH ROM, external SRAM and EEPROM.

Figure 4 Block diagram of setup

Keys

M-BIS Module

BIS Interfacing Board

SRAM EEPROM

H8 Controller

FLASH

Power

Aspect BIS Engine

data

Serial

Prog

RS485

RESET

MBUS

Serial

data,

Power

Host Monitor

BIS Interface board Block.vsd

8

Document No. 800 3476

Page 13

2.4 Connectors and signals

2.4.1 Module bus connector

S/5 BIS Module, M-BIS

13

25

1

14

Table 1 Module bus connector (X1) pin description

PIN Name Description

1 Reset_ RS485 Module Bus Reset +

8 Nreset_ RS485 Module Bus Reset -

6 Data_ RS485 Module Bus Data +

5 Ndata_ RS485 Module Bus Data -

3 +15VD +15V Supply voltage

7 GND Ground

13 GND Ground

15 GND Ground

22 RS232_TXD BIS-Engine SW update, data out,

no monitor use

23 RS232_RXD BIS-Engine SW update, data in,

no monitor use

24 +5,1V +5V Supply voltage

25 +5,1V +5V Supply voltage

Other NC Not Connected

2.4.2 H8 programming connectors pin order

10

9

Table 2 Connector pinning for H8 programming connector

PIN Name Description

1 GND Ground

2 PRG_FB Program feedback

3 TxD Data output to programmer

4 RxD Data input from programmer

5 /RESET RESET input from programmer

6 VDD Power input from programmer

7 PRG_VCC Programming voltage from programmer

8 MODE.2/BOOT Control input from programmer

9 PCFB Programmer Connector feedback / GND

10 CODE_RES Coding resistor output to programmer

2

1

Document No. 800 3476

9

Page 14

Datex-Ohmeda S/5 monitors

2.4.3 BIS Engine connectors pin order

Table 3 Connector pinning for DSC and BIS Engine connectors

PIN

Redel

1 DSC_OUTA 2 Power out A

2 DSC_OUTB 4 Power out B

3 DSC_IN 6 Data input

4 DGND 7,8,9,10 Ground

5 Chassis Ground 1,3,5, Ground

Name PIN

Samtec

Description

Table 4 Connector pinning BIS Engine power connector

PIN Name Description

1, 2 +12V +12V Power output for BE

5,6,7,8 +5V +5V Power output for BE

3,4,9,10 GND Ground

Table 5 Connector pinning for BIS Engine serial data connector

PIN Name Description

1 RS232_RXD Data input to BE

2 TTL_RXD Data input to BE

3 RS232_TXD Data output from BE

4 TTL_TXD Data output from BE

5 NC Not Connected

6 NC Not Connected

7 RS232_RESET Reset input to BE

8 /TTL_RESET /RESET input to BE

9 GND Ground

10 /USE_TTL TTL/RS232 selection input to BE

2.4.4 Keys

10

Document No. 800 3476

Table 6 Key connector pin assignments

PIN Name Description

1 GND Ground /NC

2 Key 1 Key 1, right

3 Key 2 Key 2 left

4 GND Ground

5 GND Ground / Shield

5

1

Page 15

S/5 BIS Module, M-BIS

3 SERVICE PROCEDURES

3.1 General service information

Field service of the M-BIS is limited to replacing faulty circuit boards or mechanical parts. Faulty

circuit boards should be returned to Datex-Ohmeda for repair.

Datex-Ohmeda is always available for service advice. Please provide the unit serial number, full

type designation, and a detailed description of the fault.

The Datex-Ohmeda BIS Simulator (order No. 900509) is recommended for functional checks.

CAUTION Only trained personnel with appropriate equipment should perform the tests and

repairs outlined in this section. Unauthorized service may void warranty of the unit.

3.2 Service check

These instructions include complete procedures for a service check. The service check should be

performed after any service repair. However, the service check procedures can also be used for

determining possible failures.

The procedures should be performed in ascending order.

The instructions include a check form, Service check form, which should be filled in when

performing the procedures.

The mark

the procedure.

The procedures are designed for monitors with S/5 monitor software of revision 02.

? in the instructions means that the check form should be signed after performing

3.2.1 Recommended tools

Tool Order No. Notes

BIS Simulator or

BIS Sensor simulator

Screwdriver

900509

900508

11

Document No. 800 3476

Page 16

Datex-Ohmeda S/5 monitors

• Detach the module box by removing the two screws from the back of the module. Be careful

with the loose latch and spring pin for locking.

1. Check internal parts:

− screws are tightened properly

− cables are connected properly

− there are no loose objects inside the module

?

2. Check external parts of the module:

− the front cover and the front panel sticker are intact

− connectors are intact and are attached properly

− the module box, latch and spring pin for locking are intact

Reattach the module box

?

3. Check the external parts of the Digital Signal Converter

− - the cover and the panel stickers are intact

− - cables and their connections are intact

Do not connect DSC to the module yet

?

Turn the monitor on and wait until the normal monitoring screen appears.

• Configure the monitor screen so that information regarding the BIS measurement is shown:

Monitor Setup - Screen 1 Setup – Waveform Fields – Field1 – BIS EEG

Others – BIS – Scale - 100uV

Others – BIS – Smoothing Rate 15s

4. Installation

Plug in the module. Check that it goes in smoothly and engages properly

?

12

Document No. 800 3476

5. Recognition of module

Check that the module is recognized, i.e. the BIS header with related information appears in

the chosen waveform field and ‘Cable off’ message is shown on field.

?

Page 17

S/5 BIS Module, M-BIS

6. Enter the service menu:

Monitor Setup - Install/Service (password 16-4-34) - Service (password 26-23-8)

Record the information regarding the module software of M-BIS by selecting SCROLL VERS

and turning the ComWheel.

Note! DSC related data will appear only when the DSC is connected for the first time after

start-up.

?

7. Recognition of DSC

Connect the PIC+ cable to the DSC.

Connect the DSC to the module.

- Check that the DSC is recognized (DSC related data appears to the page)

- Check that ‘No sensor’ appears to the selected waveform field.

?

8. Enter the BIS module service menu:

Parameters - More… - BIS

Check that the ‘Mod Mon Timeouts’, ‘ Mon Mod Bad checksums’ , ‘ Mod Mon Bad

Checksums’, ‘ Bad Checksums from BIS’ values in the module view are not increasing faster

than by 5 per second. Check that the memories of the module have passed the internal

memory test, i.e. ‘RAM’, ‘ROM’ and ‘EEPROM’ all state OK.

?

9. Check the BIS and Sensor Check membrane keys of the module. Stay in the module view

and press each key for at least one second and check that the key being pressed is identified,

i.e. the corresponding PRESSED text appears in the service menu.

?

10. Check that ‘ Messages from BE ’ are increasing steadily.

?

13

Document No. 800 3476

Page 18

Datex-Ohmeda S/5 monitors

11. Go to the Sensor page.

Check that

- no sensor is identified

- mains frequency is set correctly

- check that ‘ BE powerup test’, ‘DSC selftest Ch1’ and ‘DSC selftest Ch2’ all show PASs

(if not, go to BIS Setup page, perform DSC Test and check the results again)

?

12. Sensor check

Connect the BIS simulator to the PIC+ cable. See that ‘Checking sensor’ text and image

appear. Wait for a while seconds and check that all sensors show PASS. Check that the

‘Sensor type’ shows Demo Sensor.

?

13. Check that the ‘BIS’, ‘SQI’ and ‘SR’ values are between 0..1000, and the ‘EMG’ value

between 0..10000. Note! If Sensor simulator 900508 is used, the values can be out of the

given range.

?

14. Go to the Module page

Check that no BIS Engine errors appear.

?

15. Perform sensor check by pressing ‘Check Sensor’ and verify sensor passes.

?

16. Perform an electrical safety check and a leakage current test.

?

17. Check that the module functions normally after performing the electrical safety check.

?

14

Document No. 800 3476

18. Clean the module with suitable detergent.

?

• Fill in all necessary documents.

Page 19

3.3 Disassembly and reassembly

S/5 BIS Module, M-BIS

Figure 5 BIS module disassembly and reassembly

Disassemble the M-BIS in the following way.

1. Remove the two screws from the back of the module.

2. Pull the module box slowly rearward and detach it from main body. Be careful with the loose

latch and spring locking pin.

3. Detach the BIS Engine board by removing the four screws located at the corners of the board

and disconnecting the front panel connector cable.

4. Detach the interface board by removing the two screws located near the front panel frame,

disconnect the cable and pull out the front panel frame.

To reassemble the module, reverse the order of the disassembly steps.

CAUTION When reassembling the module, make sure that the cables are reconnected

properly.

15

Document No. 800 3476

Page 20

Datex-Ohmeda S/5 monitors

4 TROUBLESHOOTING

4.1 Troubleshooting chart

Trouble Cause Treatment

No BIS waveforms on screen. BIS waveforms not selected on screen. Press Monitor Setup key and select BIS

waveforms on the screen.

Sensor impedance check is not available on

menus.

Sensor impedance check fails Sensor poorly attached Attach the sensor by following the sensor

Sensor is not connected to the DSC or DSC

is not connected to the module

Connect the sensor and the DSC

instructions

16

Document No. 800 3476

Page 21

S/5 BIS Module, M-BIS

4.2 Messages

The messages below will appear in the BIS digit field (DF), BIS waveform field (WF) or at the message field (MF) at

the upper section of the Datex-Ohmeda S/5 patient monitor display.

Message Location Cause Treatment

Cable off

BIS cable off

No Sensor

No BIS Sensor

Incompatible sensor DF Sensor is not recognized.

Incompatible DSC DF Current module hw/sw is incompatible

Sensor check failed

BIS sensor

check failed

Poor signal DF Artifacts, or the amount of EMG activity

Checking sensor DF Sensor check in progress. Can be either

Checking Sensor –

message stays more

than 2 min.

Automatic check off DF Continuous sensor checking has been

Replace Sensor DF The sensor has passed its use by date

High BIS impedance DF Sensor is not attached properly to the

Artifact DF Non-EEG data such as EMG, eyeblinks or

Module error DF BIS Engine failure

DSC Error DF

Demo data MF BIS simulator is connected Disconnect the BIS simulator

DF

MF

DF

MF

DF

MF

DF Sensor check fails, the sensor is not

MF

DSC cable is not connected to the module. Connect the DSC to the module

Sensor is not connected to PIC+ cable or

PIC+ cable is not connected to the DSC

Sensor is not a BIS sensor.

with this DSC

E.g. DSC-2

Sensor check failed, one or more of the

electrode impedances exceeds the

threshold.

prevents calculating BIS, data excluded.

SQI < 50

the initial sensor check, manual check or

the periodic check.

attached to the patient while connected to

the PIC+ cable

turned off

The sensor has been used for 24h

patient

shivering present.

for more information see service page

description

The DSC is not communicating or

operating properly. This may occur during

the use of electrocautery device.

For more information see service page

description

Connect the Sensor to the PIC+ cable

Connect the PIC+ cable to the DSC

Replace sensor and then PIC+ cable.

Connect correct type of sensor

Make sure PIC connector is clean and dry

Connect correct type of DSC

Reattach the sensor to the patient by

following the sensor instructions

Replace the sensor

Check PIC+ cable and then DSC

Check the sensor then the PIC cable.

Reattach the sensor to the patient by

following the sensor instructions

Wait until the check has been performed

Attach the sensor to the patient and press

the Check Sensor button on the module

front panel

Turn the check on from the BIS menu

Replace with a new sensor

Check the cable connections

Reattach the sensor to the patient by

following the sensor instructions

Wait for good data

Replace the BIS Engine

Replace the DSC

If the message persists, the BIS Engine

may require service.

17

Document No. 800 3476

Page 22

Datex-Ohmeda S/5 monitors

4.3 Troubleshooting flowchart

Probably faulty

BIS Module

Take all modules

out of the frame.

Enter the Service

menu ID page

Is the module

ID displayed?

K

?

O

Yes

Enter the BIS

Service menu

Check are the Mod Mon Timeouts,

Mod Mon Bad checksums,

Mon Mod Bad Checksums or

Bad checksums from BE running?

?

O

K

Yes

Check RAM, ROM

and EEPROM

Insert M-BIS and turn power on

(keep DSC disconnected)

Y

s

e

Fault not in BIS

No

Y

s

e

m

a

f

a

module

a

u

d

o

h

t

s

e

D

o

l

l

i

t

t

s

l

u

?

r

a

e

p

p

No

No

s

e

D

o

r

e

h

t

o

n

n

i

k

r

w

o

e

l

e

m

a

s

e

?

t

o

l

s

Yes

O

K

?

Yes

Connect DSC into

module connector

D

C

S

s

I

t

s

e

t

f

l

e

s

d

e

s

s

a

p

Check BIS Engine

errors

O

K

?

Check front panel

key functions

O

K

?

Yes

Fault not in BIS

module

Yes

Replace

interface board

N

o

N

o

Replace the DSC

Replace the BIS Engine or DSC

(depending on the error message)

s

e

D

e

h

t

s

o

N

I

y

a

e

p

k

c

e

n

n

o

c

No

Y

s

d

e

t

e

?

d

Connect the

keypad

o

s

a

p

t

s

e

t

e

h

t

e

h

t

o

n

a

h

t

i

w

?

d

a

p

k

y

e

No

Replace BIS

interface board

e

s

Y

s

r

Replace the

keypad

BIS_trbl.vsd

18

Document No. 800 3476

Figure 6 BIS module troubleshooting flowchart

Page 23

5 SERVICE MENU

S/5 BIS Module, M-BIS

Press the Monitor Setup key - select Install/Service (password: 16-4-34) - select Service

(password: 26-23-8) - select Parameters - More... - BIS.

19

Document No. 800 3476

Page 24

Datex-Ohmeda S/5 monitors

5.1 BIS service menu

5.1.1 Module service page

Check Sensor activates the sensor impedance check.

Module

Measurement indicates if BIS Engine is on: ON/OFF

Imp.Check Key indicates that the key in the module front panel works properly.

Bis Menu Key indicates that the key in the module front panel works properly.

Impedance Meas indicates the impedance measurement mode. The modes are

CYCLIC/COMBINED/GROUND/OFF

BIS Engine errors: error messages created by DSC or BIS Engine. See "Table 9" below for

detailed description of the error message

Statuses (HEX): See appendix B; How to read HEX numbers.

General Status1 indicates the general status of the module. See "Table 7" to see the detailed

description of the message

Bis_status1 indicates the BIS Engine status. See "Table 8" to see the detailed description of the

message

Msgs to BE number of data packages sent from interface board to BIS Engine

Msgs from BE number of data packages sent from BIS Engine to interface board

Mod Mon Timeouts is a cumulative number that indicates how many times the module (interface

board) has not responded to monitor’s inquiry.

Mod Mon Bad Checksum is a cumulative number that indicates how many times there has been

an error in the message from module (interface board) to monitor.

Mon Mod Bad Checksum is a cumulative number that indicates how many times there has been

an error in the message from monitor to module (interface board).

Bad Checksums from BIS is a cumulative number that indicates how many times there has been

an error in the message from the BIS Engine to module interface board.

20

Document No. 800 3476

Page 25

RAM indicates the state of the RAM memory.

ROM indicates whether the checksum at the EPROM is accordance with the one the software has

calculated.

EEPROM indicates if the values stored in permanent memory are valid.

The states in memory checks are OK, Fail or ? (module not in place or a communication error).

Measured parameters indicated:

BIS indicates BIS index ; range 0..1000 (corresponds 0..100)

SQI indicates signal quality index; range 0..1000 (corresponds 0..100)

EMG indicates EMG activity level; range 0..10000 (corresponds 0..100dB NOTE! On the display

EMG will be shown between 30..55dB on the bar graph or 30..80dB on the trend)

SR indicates supression ratio; range 0...100 (corresponds 0..100%)

General_Status1 Module general status.

Table 7 Module general status

bit 0-5 Not used

bit 6 State error

bit 7 Communication failure

bit 8 Power failure

bit 9 Clock failure

bit 10 EEPROM checksum failure

bit 11 EEPROM writing failure

bit 12 ROM failure

bit 13 RAM failure

bit 14 Test mode

bit 15 Init mode

S/5 BIS Module, M-BIS

BIS_Status1 BIS Engine status

Table 8 BIS Engine status

bit 0 Check Sensor key pressed

bit 1 BIS key pressed

bit 2 Inpedance check mode cyclic

bit 3 Impedance check mode combined

bit 4 Impedance check mode ground

bit 5 Impedance check off

bit 6 Measurement on

bit 7 EEG measurement on

bit 8 Impedance check on DSC channel 1 passed

bit 9 Impedance check on DSC channel 2 passed

bit 10 BIS Engine powerup failure

bit 11 DSC selftest failure

bit 12 DSC quick test failure

bit 13 DSC selftest on

bit 14 No data from BIS Engine

bit 15 Not used

21

Document No. 800 3476

Page 26

Datex-Ohmeda S/5 monitors

Table 9 BIS Engine and DSC error messages

Message Errors of type 1

DSC buffer overrun

Out of dynamic memory

Execution time exceeded in main

Error in algorithm processing

Invalid state in UART receive state machine UART related errors

UART initalization error

Transmit queue full

Illegal number of data bytes for packet to be transmitted

to the Host

Illegal number of channels for EEG data Misc. errors

Illegal EEG data type

Illegal EEG data rate

Illegal EEG filter coefficients

No updates from Host Communication related errors

Bad CRC - TI_SELFTEST_CODE EEPROM CRC checks

Bad CRC - TI_RUN_CODE

Bad CRC - FPGA_CONFIG

Bad CRC - REV_INFO

Illegal serial number Serial number check

DSC failed to power up DSC related errors

Serious DSC overcurrent error

DSC receiver data overrun

DSC failed repeatedly in responding to commands

DSC update failed

Serious DSC power regulation fault

General DSC failure

Sensor Negative Ground Fault Smart sensor errors

Serious Sensor Positive Ground Fault

Serious Sensor Overcurrent Fault

22

Document No. 800 3476

Page 27

Message Errors of type 2

Illegal message ID Errors for layer 3 packets

Illegal command parameter

Illegal length for layer 2 data

Disabled interrupt received UART transmitter empty interrupt

Disabled interrupt received UART modem interrupt

No status nibble received DSC related errors

DSC not connected

DSC disconnected after test failure

Illegal DSC ID

DSC power regulation fault

DSC interface fault

DSC did not respond to command

Illegal PIC ID

DSC overcurrent

DSC overrun

EEPROM Bad packet length Software update related errors

EEPROM Bad checksum

EEPROM Bad code length

EEPROM Illegal packet subtype

EEPROM physical write error

EEPROM NOT_DATA_TIMEOUT

UART related errors

S/5 BIS Module, M-BIS

23

Document No. 800 3476

Page 28

Datex-Ohmeda S/5 monitors

5.1.2 Sensor

Sensor type: indicates the type of the sensor connected

Lot code: indicates the manufacturing lot code of the sensor. The lot code contains the

manufacturing date and shift

Serial no: indicates the serial number of the sensor.

Shelf life: indicates max storage duration

Usage count: indicates how many times the sensor has been attached/detached. Not Active!!

Mains Freq.: indicates the set mains frequency; 50Hz/60 Hz

Sensor Impedances: indicates the last measured impedances

Imped. indicates the measured impedance value in Kohms.

Qualif. indicates the quality of the measured impedance; PASS/FAIL

BE powerup test: indicates the status of BIS Engine power up test: PASS/FAIL

DSC selftest ch1: indicates the DSC selftest status for channel 1: PASS/FAIL

DSC selftest ch2: indicates the DSC selftest status for channel 2: PASS/FAIL

Measured parameters indicated:

BIS indicates BIS index ; range 0..1000 (corresponds 0..100)

SQI indicates signal quality index; range 0..1000 (corresponds 0..100)

EMG indicates EMG activity level; range 0..10000 (corresponds 0..100dB

(NOTE! On the trend display EMG will be shown between 30..80dB)

SR indicates supression ratio; range 0...100 (corresponds 0..100%)

Statuses (HEX): See "APPENDIX B"How to read HEX numbers.

DSC status: indicates the DSC status for the four channels. See "Table 10" to see the detailed

description of the message.

Sensor status: indicates the Sensor status. See "Table 11" to see the detailed description of the

message.

BE powup stat: indicates the BE power up status. See "Table 12" to see the detailed description

of the message.

24

Document No. 800 3476

Page 29

Table 10 DSC status

bit 0 Noise test

bit 1 BIS key pressed

bit 2 Blocked droop test

bit 3 Unblocked gain test

bit 4 Impedance wait time out test

bit 5 Noise timeout test

bit 6 Blocked timeout test

bit 7 Unblocked timeout test

bit 8 DSC not connected test

bit 9 Not used test

bit 10 Not used test

bits 11 - 15 Not used

Table 11 Sensor status

bit 0 Quick selftest pass

bit 1 Quick selftest gain

bit 2 Quick selftest noise

bit 3 Quick selftest fail

bit 4 Quick selftest valid

bit 5 Sensor valid

bit 6 Sensor invalid

bit 7 Sensor too many uses

bit 8 Sensor expired

bit 9 Sensor validity unknown

bits 10 -15 Not used

S/5 BIS Module, M-BIS

Table 12 BE powup stat

bit 0 XRAM test

bit 1 Dma test

bit 2 Timer test

bit 3 Fpga test

bits 4 -15 Not used

25

Document No. 800 3476

Page 30

Datex-Ohmeda S/5 monitors

5.1.3 Setup

Automatic Check: A selection to define whether automatic sensor check is used ON/OFF

Test DSC indicates the status of the DSC self test; PASS/FAIL

Filters: A selection to define if filters are used

ON; disturbances are filtered from the raw EEG signal

OFF; raw EEG signal is shown

26

Document No. 800 3476

Page 31

6 SPARE PARTS

6.1 Spare part list

6.1.1 M-BIS

S/5 BIS Module, M-BIS

Figure 7 Exploded view of module box and BIS module

Item Description Order code

1 Module box (single width) 886167

2 Latch 879181

3 Spring pin 879182

4 Cross recess screw, M3×8 black 616215

5 Front panel unit 8002476

6 Membrane keypad 880101

7 Cross cylinder head screw, M3×12 628700

8 Metal frame 879184

9 Cross cylinder head screw, M3×6 61721

10 BIS interface board 8002285

11 Aspect BIS engine board 900505

12 BIS connector unit, M-BIS 8002480

27

Document No. 800 3476

Page 32

Datex-Ohmeda S/5 monitors

Item Description Order code

13 Front panel sticker, M-BIS, DA 8002855

13 Front panel sticker, M-BIS, DE 8002848

13 Front panel sticker, M-BIS, EN 8002555

13 Front panel sticker, M-BIS, ES 8002853

13 Front panel sticker, M-BIS, FI 8002847

13 Front panel sticker, M-BIS, FR 8002852

13 Front panel sticker, M-BIS, IT 8002850

13 Front panel sticker, M-BIS, JA 8003001

13 Front panel sticker, M-BIS, NO 8002849

13 Front panel sticker, M-BIS, NL 8002856

13 Front panel sticker, M-BIS, PT 8002854

13 Front panel sticker, M-BIS, SV 8002851

28

Document No. 800 3476

Page 33

7 EARLIER REVISIONS

Revision Manual slot/main manual Note

No previous revisions

S/5 BIS Module, M-BIS

29

Document No. 800 3476

Page 34

Datex-Ohmeda S/5 monitors

30

Document No. 800 3476

Page 35

APPENDIX A, Service check form, S/5 BIS Module, M-BIS

APPENDICES A, B

31

Document No. 800 3476

Page 36

Datex-Ohmeda S/5 monitors

This page intentionally left blank.

32

Document No. 800 3476

Page 37

SERVICE CHECK FORM

BIS Module, M-BIS

Customer

APPENDIX A, Service check form, S/5 BIS Module, M-BIS

Service

Service engineer Date

OK = Test OK N.A. = Test not applicable Fail = Test Failed

Service check

OK N.A. Fail OK N.A. Fail

1. Check internal parts: 2. Check external parts of

3. Check the external

parts of DSC

5. Recognition of module

6. module software

7. Recognition of DSC 8. Communication and

9. membrane keys 10. Messages from BE

M-BIS

Module type S/N

the module:

4. Installation

memories of module

11. Sensor IDSensor 12. Sensor check

13. Checks with simulator Allowed range

BIS 0…1000

SQI 0…1000

SR 0…100

EMG 0…10000

14. BIS Engine errors 15. check

A-1(2)

Document No. 800 3476

Page 38

Datex-Ohmeda S/5 monitors

OK N.A. Fail OK N.A. Fail

16. Electrical safety check 17. Functioning after

electrical safety check

18. Final cleaning

Notes

Used Spare Parts

Signature

A-2(2)

Document No. 800 3476

Page 39

APPENDIX B, How to read hex numbers, S/5 BIS Module, M-BIS

APPENDIX B, HOW TO READ HEX NUMBERS

Some statuses on BIS Module service pages are given as HEX (hexadecimal) numbers. To

understand them, please read the following:

A HEX number has a base of 16 instead of 10. This means that every character in a number can

have a value between 0 and 15. Numbers from 0 to 9 are displayed as if they were normal 10based numbers. Numbers from 10 to 15 are displayed with letters from a to f or A to F respectively.

Every character of a HEX number expands into a binary code of four 0:s (zeroes) and 1:s (ones) as

given in table 13. Four successive characters thus expand into four times four binary numbers.

Here's an example:

We have a HEX number F3A1. We expand the number into binary code so that we first take the four

binary digits that correspond to F, which are 1111. Then we write the four binaries that correspond

to 3 (0011) after the first four. We now have 11110011. And so on.

Eventually, we have a string of 16 binary numbers, so called bits. HEX number F3A1 corresponds to

a binary code of 1111 0011 1010 0001. Spaces are added here for legibility and to visualize the

fact that every group of four bits corresponds to one HEX character.

The bits in a binary number are numbered from right to left always starting from 0 as follows:

bit 15

bit 14

bit 13

bit 12

bit 11

bit 10

bit 8

bit 7

bit 6

bit 5

bit 4

bit 3

bit 2

bit 1

bit 0

bit 9

1111 0011 1010 0001

With this information and a table of status fields from section 5 “Service Menu” we can translate a

HEX status code into actual status messages. If a bit is 1 this means that the corresponding

status/error condition is valid, whereas a 0 means that it is not.

Table 13 HEX to binary conversion

HEX binary HEX binary

0 0000 8 1000

1 0001 9 1001

2 0010 A 1010

3 0011 B 1011

4 0100 C 1100

5 0101 D 1101

6 0110 E 1110

7 0111 F 1111

B-1(2)

Document No. 800 3476

Page 40

Datex-Ohmeda S/5 monitors

B-2(2)

Document No. 800 3476

Loading...

Loading...