Carrier 50TC Product Data

50TC

Cooling Only/Electric Heat Packaged Rooftop

3to12.5NominalTons

Product Data

This product has been designed and manufac tured t o

meet Energy Star® criteria for energy efficiency.

However, pr oper ref rigerant charge and proper ai r f low

are critical to achieve rated capacity and efficiency.

Installation of this product should follow all

manufacturer’s refrigerant charging and air flow

instructions. Failure to confirm proper charge and

air fl ow may reduce energ y efficienc y and shorten

equipment life.

C08613

the environmentally sound refrigerant

TABLE OF CONTENTS

PAGE

PAGE

FEATURES AND BENEFITS 3....................

MODEL NUMBER NOMENCLATURE 4............

FACTORY OPTIONS & ACCESSORIES 5...........

ARI CAPACITY RATING 8.......................

SOUND PERFORMANCE 10......................

PHYSICAL DA TA 11.............................

BASE UNIT DIMENSIONS 23.....................

APPLICATION DATA 29.........................

50TC

COOLING TABLES 31...........................

STATIC PRESSURE TABLES 41...................

F AN PERFORMANCE 42.........................

OUTDOOR AIR INTAKE & EXHAUST PERF 54.....

ELECTRICAL INFO 55...........................

MCA / MOCP 59................................

TYPICAL WIRING DIAGRAM 79..................

GUIDE SPECIFICATIONS 84......................

Your Carrier rooftop unit (RTU) was designed by customers for customers. With no--strip screw collars, handled access

panels, and more we’ve made your unit easy to install, easy to maintain and easy to use.

Easy to install:

All WeatherMakert units are field--convertible to horizontal air flow; no special adapter curbs or kits are necessary.

Convertible airflow design makes it easy to adjust to unexpected job--site complications. Lighter units make easy

replacement. Carrier 3--12.5 ton 50TC rooftops fit on existing Carrier curbs dating back to 1989. Also, our large control

box gives you room to work and room to mount Carrier accessory controls.

Easy to maintain:

Easy access handles by Carrier provide quick and easy access to all normally serviced components. Our “no--strip” screw

system has superior holding power and guides screws into position while preventing the screw from stripping the unit’s

metal. Take accurate pressure readings by reading condenser pressure with panels on. Simply remove the black, composite

plug, route your gauge line(s) t hrough the hole, and connect them to the refrigeration service valve(s). Now, you can take

refrigeration system pressure readings without affecting the condenser airflow.

Easy to use:

The newly designed, master terminal board by Carrier puts all your connections and troubleshooting points in one

convenient place, standard. Most low voltage connections are made to the same board and make it easy t o find what you’re

looking for and easy to access it. Carrier rooftops have high and low pressure switches, a filter drier, and 2” (51mm) filters

standard.

2

FEATURES AND BENEFITS

S Up to 28% lighter than similar industry units. Lighter rooftops make easier replacement jobs.

S 3--12.5 ton units fit on existing Carrier rooftop curbs making the utility connections the same. This saves time and money

on replacement jobs.

S Standardized components and layout. Standardized components and c ontrols m ake service and stocking parts easier.

S Scroll compressors on all units. This makes service, stocking parts, replacement, and trouble--shooting easier.

S Field convertible airflow (3--12.5 tons). Being able to convert a unit from vertical airflow to horizontal makes it easy to

overcome job site complications.

S Easy --adjust, belt--drive motor available. Carrier provides a factory solution for most points in the fan performance table.

There’s no need for fie ld--supplied drives or motors.

S Provisions for bottom or side condensate drain.

S Capable of thru--the--base or thru--the--curb electrical routing.

S Single--point electrical connection.

S Sloped, com posite drain pan. Sloped, composite drain pan sheds water; and won’t rust.

S Standardized controls and control box layout. Standardized components and controls make stocking parts and service

easier.

S Clean, easy to use control box.

S Color --coded wiring.

S Large, laminated wiring and power wiring drawings which are affixed to unit make troubleshooting easy.

S Single, central terminal board for test and wiring connections.

S Fast--access, handled, panels for easy access to the blower and blower motor, control box, and compressors.

S “No--strip” screw system guides screws into the panel a nd captures them tightly without strippi ng the screw, the panel, or

the unit.

50TC

S Exclusive, newly-- design indoor refrigerant header for easier maintenance and replacement.

S Mechanical cooling (115_Fto25_For46_Cto--4_C) on Direct Digital Controller (DDC) (PremierLinkt or RTU--MP

controller).

S Mechanical cooling (115_Fto25_For46_Cto--4_C) on Electro--Mechanical (E/M) models, with winter start kit.

S 2” (51mm) disposable filters on all units.

S Refrigerant filter --drier on each circuit.

S High and low pressure switches. Added reliability with high pressure switch and low pressure switch.

S Factory--installed Humidi--MiZert adaptive dehumidification system.

the environmentally sound refrigerant

This product has been design ed and manufac tured t o

meet Energy Star® criteria for energy efficiency.

However, pr oper ref rigerant charge and proper ai r f low

are critical to achieve rated capacity and efficiency.

Installation of this product should follow all

manufacturer’s refrigerant charging and air flow

instructions. Failure to confirm proper charge and

air fl ow may reduce energ y efficienc y and shorten

equipment life.

3

MODEL NUMBER NOMENCLATURE

123456789101112131415161718

5 0 T C -- A 0 6 A 1 A 5 A 0 A 0 A 0

____ ____ ____

2

2

50TC

Unit Heat Type Brand / Packaging

50 = Cooling/Elec Heat RTU 0=Standard

Tier / Model

TC = Entry tier (with Puron refrigerant) Electrical Options

Heat Size C = N o n --- f u s e d d i sc

--- = N o h e a t D=Thruthebase

Refrig. System Options

A = Standard 1 ---stage cooling Service Options

B = S t a n d a r d 1 --- s ta g e c o o l i n g w / H u m i d i --- M i Z e r 0=None

D = 2 ---stg. cooling compressor w/NOVATION™ 1 = Unpowered convenience outlet

Cooling Tons

04 = 3 Ton Intake / Exhaust Options

05 = 4 Ton A=None

06 = 5 Ton B=Tempeconow/barorelief

07 = 6 Ton F = Enthalpy econo w/ baro relief

08 = 7.5 Ton K = 2 position damper

09 = 8.5 Ton

12 = 10 Ton Base Unit Controls

14 = 12.5 Ton 0 = Electromechanical

Sensor Options 2 = Open protocol DDC controller

A=None

B = RA smoke detector Design Rev

C = SA smoke detector Factory assigned

D=RA&SAsmokedetector

E=CO2sensor Voltage

F = RA smoke detector & CO

G = SA smoke detector & CO

H=RA&SAsmokedetector&CO

1=LTL

A=None

F = Non--- fused & thru the base

2 = Powered convenience outlet

1 = PremierLink DDC controller

1 = 575/3/60

3 = 208 ---230/1/60

2

5 = 208 ---230/3/60

6 = 460/3/60

Indoor Fan Options 1 --- S t a g e C o o l i n g C o i l O p t i o n s ( O u t d o o r --- I n d o o r )

1 = Standard static option A = Al/Cu --- Al/Cu

2 = Medium static option B = P r e c o a t A l / C u --- A l / C u

3 = High static option C = E c o a t A l / C u --- A l / C u

D=EcoatAl/Cu--- EcoatAl/Cu

E = Cu/C u --- Al/Cu

F = Cu/Cu --- Cu/Cu

M = A l / C u --- A l/ C u --- L o u v e r e d H a i l G u a r d s

N = P r e c o a t A l / C u --- A l / C u --- L o u v e r e d H a i l G u a r d s

P = E c o a t A l / C u --- A l / C u --- L o u v e r e d H a i l G u a r d s

Q = E c o a t A l / C u --- E c o a t A l / C u --- L o u v e r e d H a i l G u a r d s

R = C u / C u --- A l / C u --- L o u v e r e d H a i l G u a r d s

S = C u / C u --- C u / C u --- L o u v e r e d H a i l G u a r d s

2 --- S t a g e C o o l i n g C o i l O p t i o n s ( O u t d o o r --- I n d o o r )

G = Al/Al --- Al/Cu

H = Al/Al --- Cu/Cu

J = A l / A l --- E --- c o a t A l / C u

K = E --- c o a t A l/ A l --- A l / C u

L = E --- c o a t A l / A l --- E --- c o a t A l / C u

T = A l / A l --- A l / C u --- L o u v e r e d H a i l G u a r d s

U = A l / A l --- C u / C u --- L o u v e r e d H a i l G u a r d s

V = A l / A l --- E --- c o a t A l / C u --- L o u v e r e d H a i l G u a r d s

W = E --- c oa t A l/ A l --- Al / C u --- L o u v e r e d H a i l G u a r d s

X = E --- c o a t A l/ A l --- E --- c o a t A l / C u --- L o u v e r e d H a i l G u a r d s

4

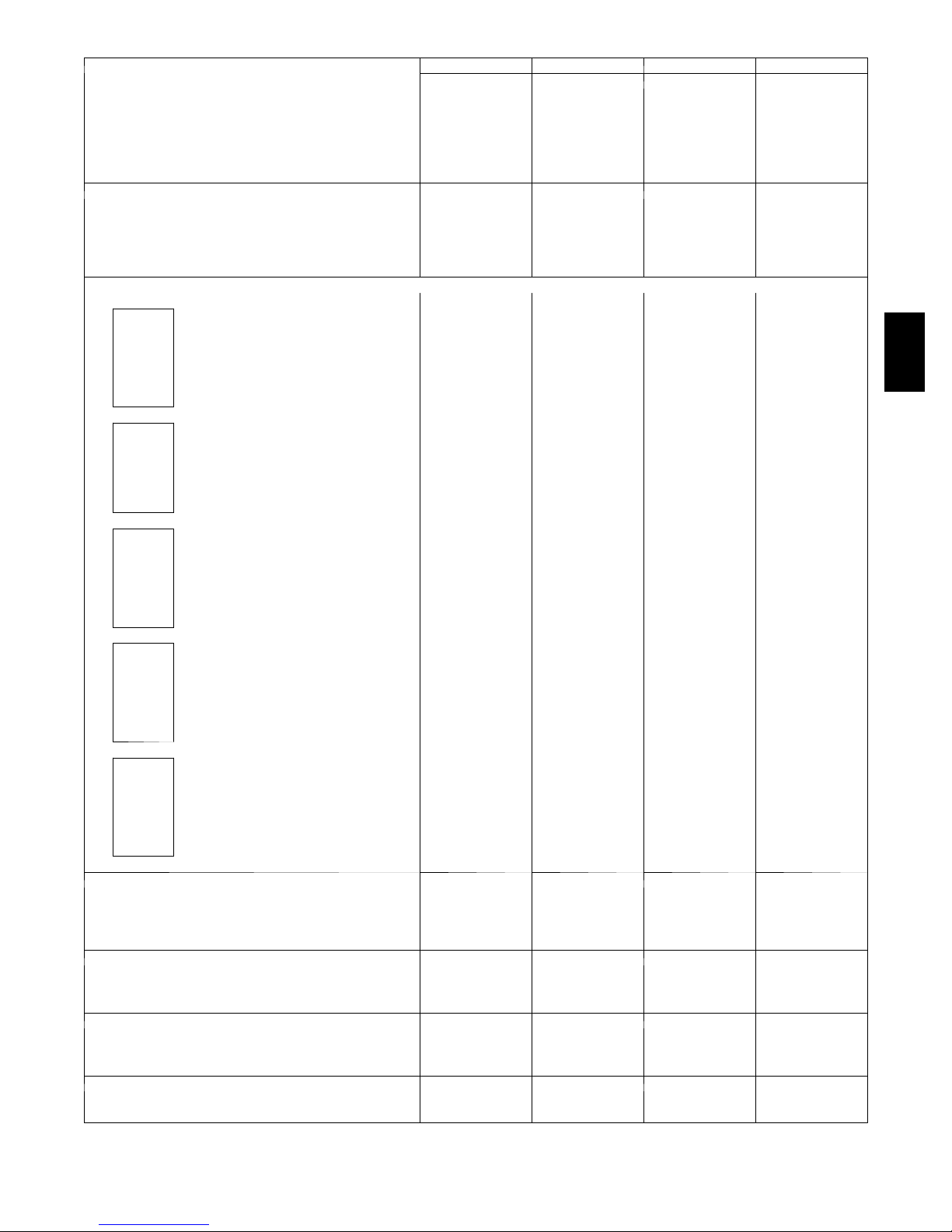

Table 1 – FACTORY--INSTALLED OPTIONS AND FIELD-- INSTALLED ACCESSORIES

FACTO RY

CATEGORY ITEM

Cabinet Thru--- the--- base electrical connections X X

1

1

Coil Options

Cu/Cu indoor and/or outdoor coils

Pre--- coated outdoor coils

1

Premium, E --- coated outdoor coils

Humidity Control Humdi ---MiZer™ Adaptive Dehumidification System X

Condenser Protection Condenser coil hail guard (louvered design) X X

Thermostats, temperature sensors, and subbases X

PremierLink DDC communicating controller X X

Controls

RTU ---MP open - -- protocol controller X

Smoke detector (supply and/or return air) X

Time Guard II compressor delay control circuit X

Phase Monitor X

EconoMi$er IV (for electro --- mechanical controlled RTUs) X X

EconoMi$er2 (for DDC controlled RTUs) X X

Economizers

& Outdoor Air

Dampers

Motorized 2 position outdoor ---air damper X X

Manual outdoor--- air damper (25% and 50%) X

Barometric relief

2

Power exhaust X

3

3

3

Economizer Sensors &

IAQ Devices

Electric Heat

Single dry bulb temperature sensors

Differential dry bulb temperature sensors

Single enthalpy sensors

Differential enthalpy sensors

3

3

CO2sensor (wall, duct, or unit mounted)

Electric Resistance Heaters X

Single Point Kit X

Indoor Motor & Drive Multiple motor and drive packages X

Low Ambient

Control

Power

Options

Roof Curbs

Winter start kit

Motormaster head pressure controller

Convenience outlet (powered) X

Convenience outlet (unpowered) X

Non -- -fused disconnect X

Roof curb 14” (356mm) X

Roof curb 24” (610mm) X

4

4

INSTALLED

OPTION

X

X

X

X X

X X

X X

X X

INSTALLED

ACCESSORY

FIELD

50TC

X

X

X

X

NOTES:

1. NOVATION™ coils (2 --- stage cooling models 08 ---14): Condenser Coil = E - -- coat, Indoor Coil = Cu/Cu or E --- coat

2. Included with economizer.

3. Sensors for optimizing economizer.

4. See application data for assistance.

5

FACTORY OPTIONS AND/OR ACCESSORIES

Economizer (dry--bulb or enthalpy)

Economizers save money. They bring in fresh, outside air

for ventilation; and provide cool, outside air to cool your

building. This is the preferred method of low--ambient

cooling. W h en coupled to CO

provide even more savings by coupling the ventilation air

to only that amount required.

Economizers are available, installed and tested by the

factory, with either enthalpy or dry--bulb temperature

inputs. There are also models for electromechanical as

well as direct digital controllers. Additional sensors are

available as accessories to optimize the economizers.

Economizers include gravity controlled, barometric relief

equalizes building pressure and ambient air pressures.

This can be a cast effective solution to prevent building

50TC

pressurization.

sensors, Economize r s can

2

CO2Sensor

Improves productivity and saves money by working with

the economizer to intake only the correct amount of

outside air for ventilation. As occupants fill your building,

the CO

CO

When the occupants leave, the CO

the sensor appropriately closes the economizer. This

intelligent control of the ventilation air, called Demand

Control Ventilation (DCV) reduces the overall load on the

rooftop, saving money.

sensor detects their presence through increasing

2

levels, and opens the economizer appropriately.

2

levels decrease, and

2

Power Exhaust with Barometric Relief.

Superior internal building pressure control. This

field--installed accessory may eliminate the need for

costly, external pressure control fans.

PremierLinkt

This CCN controller regulates your rooftop’s performance

to tighter tolerances and expanded limits, as well as

facilitates zoning systems and digital accessories. It also

unites your Carrier HVAC equipment together on one,

coherent CCN network. The PremierLink can be

factory--installed, or easily field-- installed.

RTU--MP, Multi --protocol Controller

Connect the rooftop to an existing BAS without needing

complicated translators or adapter modules using the

RTU--MP controller. This new controller speaks the 4

most common building automation system languages

(Bacnet, Modbus, N2, and Lonworks). Use this controller

when you have an existing BAS.

Time Guard II Control Circuit

This accessory protects your compressor by preventing

short--cycling in the event of some other failure, prevents

the compressor from restarting for 30 seconds after

stopping. Not required with PremierLinkr,RTU--MP,or

authorized commercial thermostats.

Filter or Fan Status Switches

Smoke Detectors

Trust the experts. Smoke detect ors make your application

safer a nd your job easier. Carrier smoke detectors

immediately shut down the rooftop unit when smoke is

detected. They are available, installed by the factory, for

supply air, return air, or both.

Louvered Hail Guards

Sleek, louvered panels protect the condenser coil from

hail damage, foreign objects, and incidental contact.

Convenience Outlet (powered or un--powered)

Reduce service and/or installation costs by including a

convenience outlet in your specification. Carrier will

install this service feature at our factory. Provides a

convenient, 15 amp, 115v GFCI receptacle with “Wet in

Use” cover. The “powered” option allows the installer to

power the outlet from the line side of the disconnect or

load side as required by code. The “unpowered” option is

to be powered from a separate 115/120v power source.

Non--fused Disconnect

This OSHA--compliant, factory--installed, safety switch

allows a service technician to locally secure power to the

rooftop.

Use these differential pressure switches to detect a filter

clog or indoor fan motor failure. When used in

conjunction with a compatible unit controller/thermostat,

the switches will activate an alarm to warn the appropriate

personnel.

Motorized 2--Position Damper

The new Carrier 2--position, motorized outdoor air damper

admits up to 100% outside air. Using reliable, gear--driven

technology, the 2--position damper opens to allow

ventilation air and closes when the rooftop stops, stopping

unwanted infiltration.

Manual OA Damper

Manual outdoor air dampers are an economical way to

bring in ventilation air. The dampers are available in 25%

and 50% versions.

Optional Humidi--MiZert Adaptive

Dehumidification System

Carrier’s Humidi--MiZer adaptive dehumidification

system is an all-- inclusive factory--installed option that can

be ordered with any WeatherMaker 50TC--04--07 rooftop

unit.

This system expands the envelope of operation of

Carrier’s WeatherMaker rooftop products to provide

6

unprecedented flexibility to meet year --round comfort

conditions.

The Humidi--MiZer adaptive dehumidification system has

the industry’s only dual dehumidification mode setting.

The Humidi--MiZer system includes two new modes of

operation.

The WeatherMaker 50TC--04--07 ooftop coupled with the

Humidi--MiZer system is capable of operating in normal

design cooling mode, subcooling mode, and hot gas reheat

mode. Normal design cooling mode is when the unit will

operate under its normal sequence of ope ration by cycling

compressors to maintain comfort conditions.

Subcooling mode will operate to satisfy part load type

conditions when the space requires combined sensible and

a higher proportion of latent load control. Hot Gas Reheat

mode will operate when outdoor temperatures diminish

and the need for latent capacity is required for sole

humidity control. Hot Gas Reheat mode will provide

neutral air for maximum dehumidification operation.

Motormaster Head Pressure Controller

The Motormaster motor controller is a low ambient, head

pressure controller kit that is designed to m aintain the

unit’s condenser head pressure during periods of low

ambient cooling operation. This device should be used as

an alternative to economizer free cooling not when

economizer usage is either not appropriate or desired. The

Motormaster will either cycle the outdoor--fan motors or

operate them at reduced speed to maintain the unit

operation, depending on the model.

Winter Start Kit

The winter start kit by Carrier extends the low ambient

limit of your rooftop to 25_F(--4_C). The kit bypasses the

low pressure switch, preventing nuisance tri pping of the

low pressure switch. Other low ambient precautions may

still be prudent.

Alternate Motors and Drives

Some applications need larger horsepower motors, some

need more airflow, and some need both. Regardless of the

case, your Carrier expert has a factory installed

combination to meet your application. A wide selection of

motors and pulleys (drives) are available , factory

installed, to handle nearly any application.

Thru--the--Base Connections

Thru--the--base connections, available as either an

accessory or as a factory option, are necessary to ensure

proper connection and seal when routing wire and piping

through the rooftop’s basepan and curb. These couplings

eliminate roof penetration and should be considered for

gas lines, main power lines, as well as control power.

Electric Heaters

Carrier offers a full--line of field-- installed accessory

heaters. The heaters are very easy to use, install and are

all pre--engineered and certified.

50TC

7

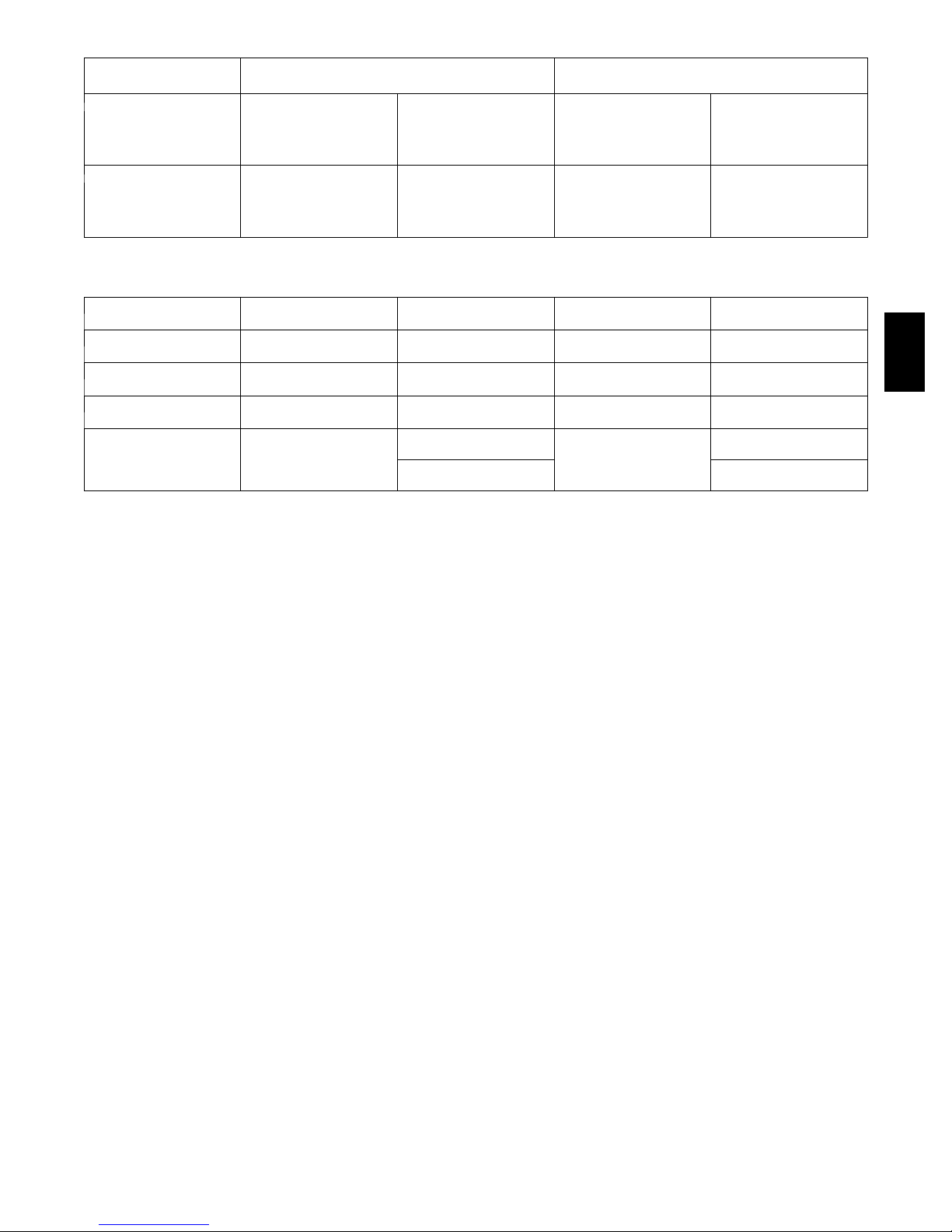

Table 2 – ARI COOLING RATING TABLES

UNIT

COOLING

STAGES

NOM.

CAPACITY

(TONS)

A04 1 3 34.6 3.1 13.00 11.00 N/A

A05 1 4 45.0 4.0 13.00 11.00 N/A

A06 1 5 59.0 5.5 13.00 10.75 N/A

A07 1 6 70.0 6.4 N/A 11.20 N/A

A08 1 7.5 88.0 8.0 N/A 11.20 N/A

A09 1 8.5 97.0 8.8 N/A 11.20 N/A

A12 1 10 117.0 10.6 N/A 11.20 N/A

NET

COOLING

CAPACITY

(MBH)

POWER (KW)

TABLE 3 – ARI COOLING RATING TABLE 2--STAGE COOLING

NET

COOLING

CAPACITY

(MBH)

POWER (KW)

50TC

UNIT

COOLING

STAGES

NOM.

CAPACITY

(TONS)

D08 2 7.5 83.0 7.4 N/A 11.20 12.0

D12 2 10 114.0 10.1 N/A 11.30 12.6

D14 2 12.5 140.0 12.7 N/A 11.00 11.7

TOTAL

TOTAL

SEER EER IPLV

SEER EER IPLV

LEGEND

ARI --- Air---Conditioning, Heating and Refrigeration

Institute

ASHRAE --- American Society of Heating, Refrigerating

and Air Conditioning, Inc.

EER --- Energy Efficiency Ratio

SEER --- Seasonal Energy Efficiency Ratio

IPLV --- Integrated Part Load Value

NOTES

1. Rated and certified under ARI Standard 210/240 --- 06 or

340/360--- 07, as appropriate.

2. Ratings are based on:

Cooling Standard: 80_F(27_C) db, 67_F(19_C) wb

indoor air temp and 95_F db outdoor air temp.

IPLV Standard:80_F(27_C) db, 67_F(19_C) wb indoor

air temp and 80_F(27_C) db outdoor air temp.

3. All 50TC units comply with ASHRAE 90.1 2001, 2004

Energy Standard for minimum SEER and EER

requirements.

4. Where appropriate, 50TC units comply with US Energy

Policy Act (2005). Refer to state and local codes or visit

the following website: http://bcap ---energy. org to

determine if compliance with this standard pertains to

your state, territory, or municipality.

This product has been design ed and manufac tured t o

meet Energy Star® criteria for energy efficiency.

However, pr oper ref rigerant charge and proper ai r f low

are critical to achieve rated capacity and efficiency.

Installation of this product should follow all

manufacturer’s refrigerant charging and air flow

instructions. Failure to confirm proper charge and

air fl ow may reduce energ y efficienc y and shorten

equipment life.

8

Table 4 – MINIMUM -- MAXIMUM AIRFLOWS ELECTRIC HEAT

UNIT

50TC**04 900 1500 900 1500

50TC**05 1200 2000 1200 2000

50TC**06 1500 2500 1500 2500

50TC**07 1800 3000 1800 3000

50TC**08 2250 3750 2250* 3750

50TC**09 2550 4250 2250* 4250

50TC**12 3000 5000 3000* 5000

50TC**14 3600 6000 3000* 6000

Minimum Maximum Minimum Maximum

* Minimum electric heat CFM exceptions :

UNIT UNIT VOLTAGE HEATER KW UNIT CONFIGURATION

50TC**12

50TC**14

50TC**12

50TC**14

50TC**12

50TC**14

50TC**08

50TC**09

50TC**12

50TC**14

208/230 42.4 Horizontal 3200

208/230 50.0 Horizontal 3200

460 50.0 Horizontal or Vertical 3200

575

COOLING ELECTRIC HEATERS

17.0

34.0 2350

REQUIRED MINIMUM

CFM

50TC

2800

Horizontal or Vertical

9

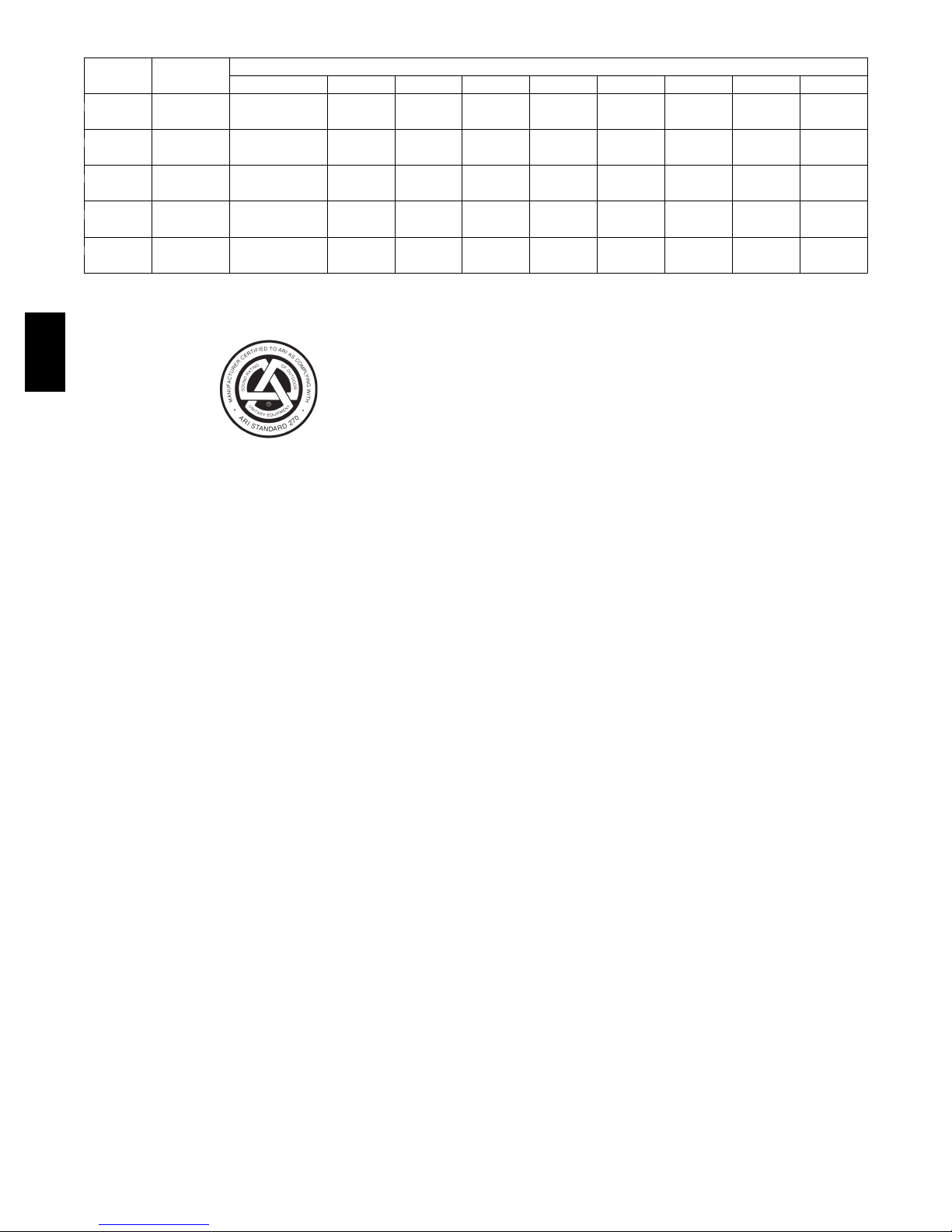

Table 5 – SOUND PERFORMANCE TABLE

UNIT

A04 1 80 90.6 80.9 80.2 76 74.6 71.3 68.5 63.9

A05 1 81 90.9 84.6 79.5 77.9 76.5 71.1 66.9 62.5

A06 1 78 84.0 82.2 76.3 74.8 72.5 68.8 65.6 61.8

A07 1 78 88.8 81.8 76.9 74.4 73.3 69.8 66.3 62.7

A08 1 82 90.1 82.6 81.0 79.4 77.0 73.0 70.4 66.7

D08 2 82 85.8 84.3 80.5 78.7 76.4 72.7 68.3 65.1

A09 1 83 91.2 86.4 81.9 81.0 78.3 73.9 71.4 67.3

A12 1 82 88.6 85.0 81.6 79.5 77.4 74.1 71.0 66.3

D12 2 82 89.0 83.1 80.5 78.5 75.5 71.6 69.6 69.3

D14 2 87 87.0 85.2 84.6 84.9 82.2 78.4 75.3 72.9

COOLING

STAGES

A --- W E I G H T E D 63 125 250 500 1000 2000 4000 8000

OUTDOOR SOUND (dB)

50TC

LEGEND

dB --- Decibel

NOTES:

1. Outdoor sound data is measure in accordance with ARI

standard 270--- 2008.

2. Measurements are expressed in terms of sound power.

Do not compare these values to sound pressure values

because sound pressure accounts for specific environmental factors which do not match individual applications. Sound power values are independent of the environment and therefore more accurate.

3. A ---weighted sound ratings filter out very high and very

low frequencies, to better approximate the response of

an “average” human ear. A--- weighted measurements for

Carrier units are taken in accordance with 270 ---2008.

10

Table 6 – PHYSICAL DATA (COOLING) 3 -- 6 TONS

50TC*A04 50TC*A05 50TC*A06 50TC*A07

Refrigeration System

#Circuits/#Comp./Type 1/1/Scroll 1/1/Scroll 1/1/Scroll 1/1/Scroll

Puronr refrig. (R--- 410A) charge per circuit A/B (lbs --- oz) 5 --- 1 0 / --- 8 --- 8 / --- 1 0 --- 1 1 / --- 1 4 --- 2 / ---

O p e r a t i n g c h a r g e ( l b s --- o z ) --- H u m id i --- M i Z e r U n i t 8 --- 1 2 14--- 13 1 6 --- 0 2 2 --- 4

Metering Device Acutrol Acutrol Acutrol Acutrol

High--- press. Trip / Reset (psig) 630 / 505 630 / 505 630 / 505 630 / 505

Low--- press. Trip / Reset (psig) 54 / 117 54 / 117 54 / 117 54 / 117

Evap. Coil

Material Cu / Al Cu / Al Cu / Al Cu / Al

Coil type 3/8” RTPF 3/8” RTPF 3/8” RTPF 3/8” RTPF

Rows / FPI 2 / 15 2/15 4/15 4/15

Total Face A r e a (ft2)5.5 5.5 5.5 7.3

Condensate Drain Conn. Size 3/4” 3/4” 3/4” 3/4”

Evap. Fan and Motor

Motor Qty / Drive Type 1/Belt

Max BHP 1.2

RPM Range 560--- 854 560--- 854 770--- 1175 ---

1phase

Standard Static

1phase

Medium Static

3phase

Standard Static

3phase

Medium Static

3phase

High Static

Motor Frame Size 48 48 48 ---

Fan Qty / Type 1/Centrifugal 1/Centrifugal 1/Centrifugal ---

Fan Diameter (in) 10 x 10 10 x 10 10 x 10 ---

Motor Qty / Drive Type 1/Belt 1/Belt 1/Belt ---

Max BHP 1.2 1.2 1.5 ---

RPM Range 770 ---1175 770--- 1175 1035 ---1466 ---

Motor Frame Size 48 48 56 ---

Fan Qty / Type 1/Centrifugal 1/Centrifugal 1/Centrifugal ---

Fan Diameter (in) 10 x 10 10 x 10 10 x 10 ---

Motor Qty / Drive Type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 1.2 1.2 1.5 2.4

RPM Range 560--- 854 560--- 854 770--- 1175 1073---1457

Motor Frame Size 48 48 48 56

Fan Qty / Type 1/Centrifugal 1/Centrifugal 1/Centrifugal 1/Centrifugal

Fan Diameter (in) 10 x 10 10 x 10 10 x 10 10 x 10

Motor Qty / Drive Type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 1.2 1.2 2.4 2.9*

RPM Range 770 ---1175 770--- 1175 1035 ---1466 1173 --- 1518

Motor Frame Size 48 48 56 56

Fan Qty / Type 1/Centrifugal 1/Centrifugal 1/Centrifugal 1/Centrifugal

Fan Diameter (in) 10 x 10 10 x 10 10 x 10 10 x 10

Motor Qty / Drive Type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 2.4 2.4 2.9 3.7

RPM Range 1035--- 1466 1035 --- 1466 1303 --- 1687 1474 ---1788

Motor Frame Size 56 56 56 56

Fan Qty / Type 1/Centrifugal 1/Centrifugal 1/Centrifugal 1/Centrifugal

Fan Diameter (in) 10 x 10 10 x 10 10 x 10 10 x 10

1/Belt 1/Belt ---

1.2 1.2 ---

50TC

Cond. Coil

Total Face A r e a (ft2) 14.6 16.5 16.5 21.3

H u m i d i --- M i Z e r C o i l

Total Face A r e a (ft2)3.9 3.9 3.9 5.2

Cond. fan / motor

Qty / Motor Drive Type 1/ Direct 1/ Direct 1/ Direct 1/ Direct

Fan diameter (in) 22 22 22 22

Filters

RA Filter # / Size (in) 2 / 16 x 25 x 2 2/16x25x2 2/16x25x2 4/16x16x2

OA inlet screen # / Size (in) 1/20x24x1 1/20x24x1 1/20x24x1 1/20x24x1

* 575V motor utilizes 3.7 BHP.

Material Cu / Al Cu / Al Cu / Al Cu / Al

Coil type 3/8” RTPF 3/8” RTPF 3/8” RTPF 3/8” RTPF

Rows / FPI 1 / 17 2/17 2/17 2/17

Material Cu / Al Cu / Al Cu / Al Cu / Al

Rows..Fins/in. 1 / 17 2/17 2/17 2/17

Motor HP / RPM 1/4 / 1100 1/4 / 1100 1/4 / 1100 1/4 / 1100

11

Table 7 – PHYSICAL DATA (COOLING) 7.5 -- 12.5 TONS

50TC*A08 50TC*D08 50TC*A09 50TC*A12 50TC*D12 50TC*D14

Refrigeration System

#Circuits/#Comp./Type 1/1/Scroll 2/2/Scroll 1/1/Scroll 1/1/Scroll 2/2/Scroll 2/2/Scroll

Puronr refrig. (R--- 410A) charge per

High--- press. Trip / Reset (psig) 630 / 505 630 / 505 630 / 505 630 / 505 630 / 505 630 / 505

Low--- press. Trip / Reset (psig) 54 / 117 54 / 117 54 / 117 54 / 117 54 / 117 54 / 117

Evap. Coil

Condensate Drain Conn. Size 3/4” 3/4” 3/4” 3/4” 3/4” 3/4”

Evap. Fan and Motor

50TC

3phase

Standard Static

3phase

Medium Static

c i r c u i t A / B ( l b s --- o z )

Total Face A r e a (ft2)8.9 8.9 11.1 11.1 11.1 11.1

Motor Qty / Drive Type 1/Belt 1/Belt 1/Belt 1/Belt 1/Belt 1/Belt

RPM Range 489--- 747 489--- 747 518--- 733 591 --- 838 591--- 838 652--- 843

Motor Frame Size 56 56 56 56 56 56

Fan Qty / Type 1/Centrifugal 1/Centrifugal 1/Centrifugal 1/Centrifugal 1/Centrifugal 1/Centrifugal

Fan Diameter (in) 15 x 15 15 x 15 15 x 15 15 x 15 15 x 15 15 x 15

Motor Qty / Drive Type 1/Belt 1/Belt 1/Belt 1/Belt 1/Belt 1/Belt

RPM Range 733--- 949 733--- 949 690--- 936 838--- 1084 838--- 1084 838--- 1084

Motor Frame Size 56 56 56 56 56 56

Fan Qty / Type 1/Centrifugal 1/Centrifugal 1/Centrifugal 1/Centrifugal 1/Centrifugal 1/Centrifugal

Fan Diameter (in) 15 x 15 15 x 15 15 x 15 15 x 15 15 x 15 15 x 15

Metering Device Acutrol Acutrol Acutrol Acutrol Acutrol Acutrol

Material Cu / Al Cu / Al Cu / Al Cu / Al Cu / Al Cu / Al

Coil type 3/8” RTPF 3/8” RTPF 3/8” RTPF 3/8” RTPF 3/8” RTPF 3/8” RTPF

Rows / FPI 3 / 15 3/15 3/15 4/15 4/15 4/15

Max BHP 1.7 1.7 1.7 2.4 2.4 2.9*

Max BHP 2.9* 2.9* 2.4 3.7 3.7 3.7

1 3 --- 1 2 / --- 4 --- 6 / 4 --- 6 1 5 --- 4 / --- 2 0 --- 0 / --- 6 --- 0 / 6 --- 0 7 --- 6 / 8 --- 0

Motor Qty / Drive Type 1/Belt 1/Belt 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 4.7 4.7 3.7 4.7 4.7 4.7

RPM Range 909 --- 1102 909--- 1102 838--- 1084 1022--- 1240 1022--- 1240 1022 ---1240

Motor Frame Size 145TY 145TY 56 145TY 145TY 145TY

3phase

High Static

Cond. Coil

Cond. fan / motor

Filters

Fan Qty / Type 1/Centrifugal 1/Centrifugal 1/Centrifugal 1/Centrifugal 1/Centrifugal 1/Centrifugal

Fan Diameter (in) 15 x 15 15 x 15 15 x 15 15 x 15 15 x 15 15 x 15

Material Cu / Al Al / Al Cu / Al Cu / Al Al / Al Al / Al

Coil type 3/8” RTPF NOVATION™ 3/8” RTPF 3/8” RTPF NOVATION™ NOVATION™

Rows / FPI 2 / 17 1/20 2/17 2/17 1/20 2/20

Total Face A r e a (ft2) 20.5 20.5 21.4 25.1 25.1 25.1

Qty / Motor Drive Type 2 / Direct 2/direct 2/Direct 2/Direct 2/direct 1/direct

Motor HP / RPM 1/4 / 1100 1/4 / 1100 1/4 / 1100 1/4 / 1100 1/4 / 1100 1 / 1175

Fan diameter (in) 22 22 22 22 22 30

RAFilter#/Size(in) 4/16x20x2 4/16x20x2 4/20x20x2 4/20x20x2 4/20x20x2 4/20x20x2

OA inlet screen # / Size (in) 1/20x24x1 1/20x24x1 1/20x24x1 1/20x24x1 1/20x24x1 1/20x24x1

* 575V motor utilizes 3.7 BHP.

12

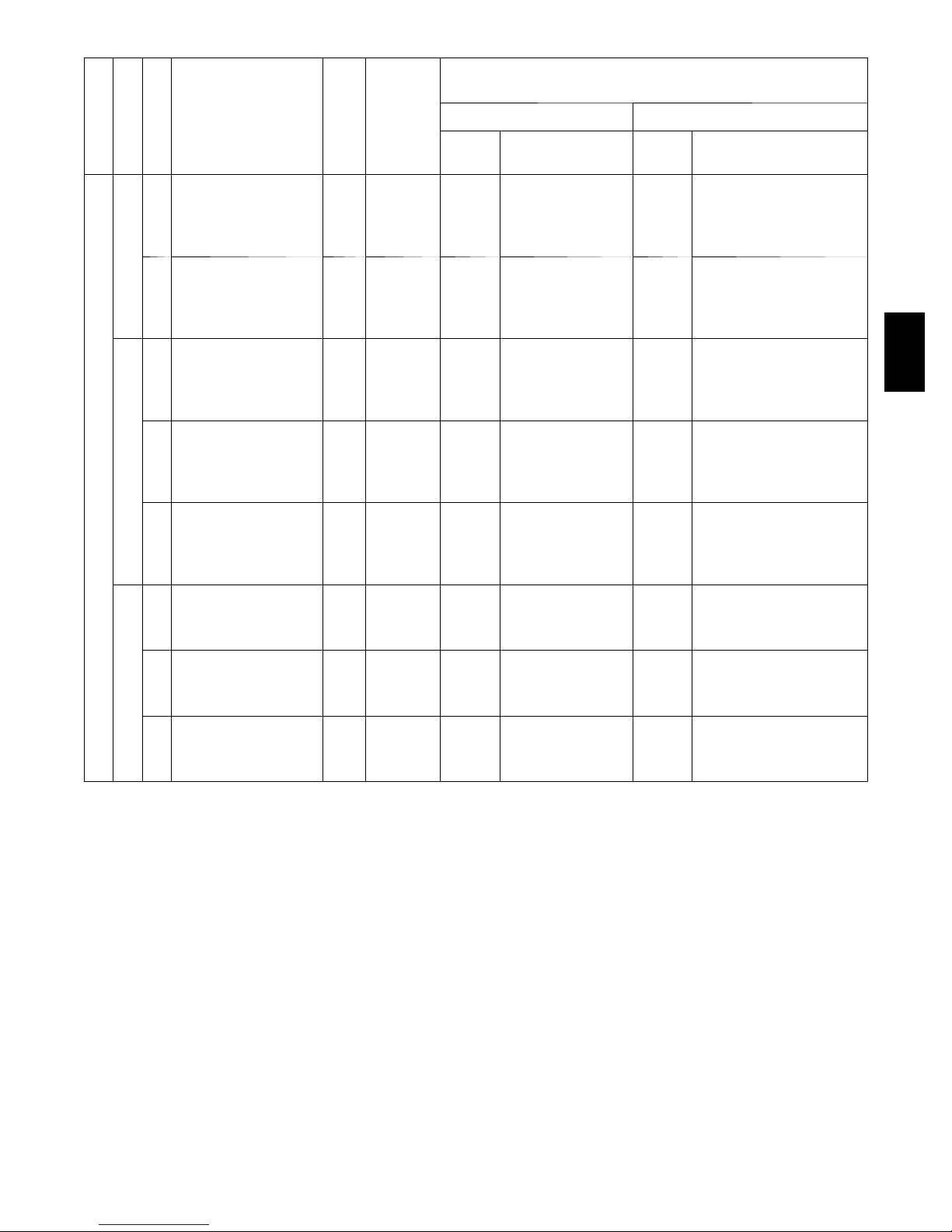

Table 8 – ELECTRIC HEAT -- ELECTRICAL DATA 3 -- 12. 5 TONS

SINGLE POINT KIT PART NUMBER

CRSINGLEXXXXXX

NO P.E.

w/P.E.

(pwrd fr/unit)

UNIT

50TC*A04

N O M . V --- P H --- H Z

208/230--- 1 --- 60

208/230--- 3 --- 60

4 6 0 --- 3 --- 6 0

ELECTRIC HEATER

PAR T NUMBE R

CRHEATERXXXXXX

IFM TYPE

101A00 4.4 3.3/4.0 --- --- --- --102A00 6.5 4.9/6.0 --- --- --- ---

STD

MED

STD

MED

HIGH

STD

MED

HIGH

103B00 8.7 6.5/8.0 --- --- --- --104B00 10.5 7.9/9.6 040A00 040A00 040A00 040A00

102A00,102A00 13 9.8/11.9 040A00 040A00 040A00 040A00

101A00 4.4 3.3/4.0 --- --- --- --102A00 6.5 4.9/6.0 --- --- --- --103B00 8.7 6.5/8.0 --- --- --- --104B00 10.5 7.9/9.6 040A00 040A00 040A00 040A00

102A00,102A00 13 9.8/11.9 040A00 040A00 040A00 040A00

101A00 4.4 3.3/4.0 --- --- --- --102A00 6.5 4.9/6.0 --- --- --- --103B00 8.7 6.5/8.0 --- --- --- --104B00 10.5 7.9/9.6 --- --- --- --105A00 16 12.0/14.7 --- --- 038A00 038A00

101A00 4.4 3.3/4.0 --- --- --- --102A00 6.5 4.9/6.0 --- --- --- --103B00 8.7 6.5/8.0 --- --- --- --104B00 10.5 7.9/9.6 --- --- --- --105A00 16 12.0/14.7 --- --- 038A00 038A00

101A00 4.4 3.3/4.0 --- --- --- --102A00 6.5 4.9/6.0 --- --- --- --103B00 8.7 6.5/8.0 --- --- --- --104B00 10.5 7.9/9.6 --- --- --- --105A00 16 12.0/14.7 --- --- 038A00 038A00

106A00 6 5.5 --- --- --- --107A00 8.8 8.1 --- --- --- --108A00 11.5 10.6 --- --- --- --109A00 14 12.9 --- --- --- --106A00 6 5.5 --- --- --- --107A00 8.8 8.1 --- --- --- --108A00 11.5 10.6 --- --- --- --109A00 14 12.9 --- --- --- --106A00 6 5.5 --- --- --- --107A00 8.8 8.1 --- --- --- --108A00 11.5 10.6 --- --- --- --109A00 14 12.9 --- --- --- ---

NOM

PWR

(kW)

APP

PWR

(kW)

NO C.O. or UNPWRD C.O. w/PWRD C.O.

NO P.E.

w/P.E.

(pwrd fr/unit)

50TC

LEGEND

APP PWR --- 208 / 230V / 460V / 575V

C.O. --- Convenient outlet

FLA --- Full load amps

IFM --- Indoor fan motor

NOM PWR -- - 240V / 480V / 600V

P.E . --- P ow e r e x h a u s t

PWRD --- Powered convenient outlet

UNPWRD -- - Unpowered convenient outlet

13

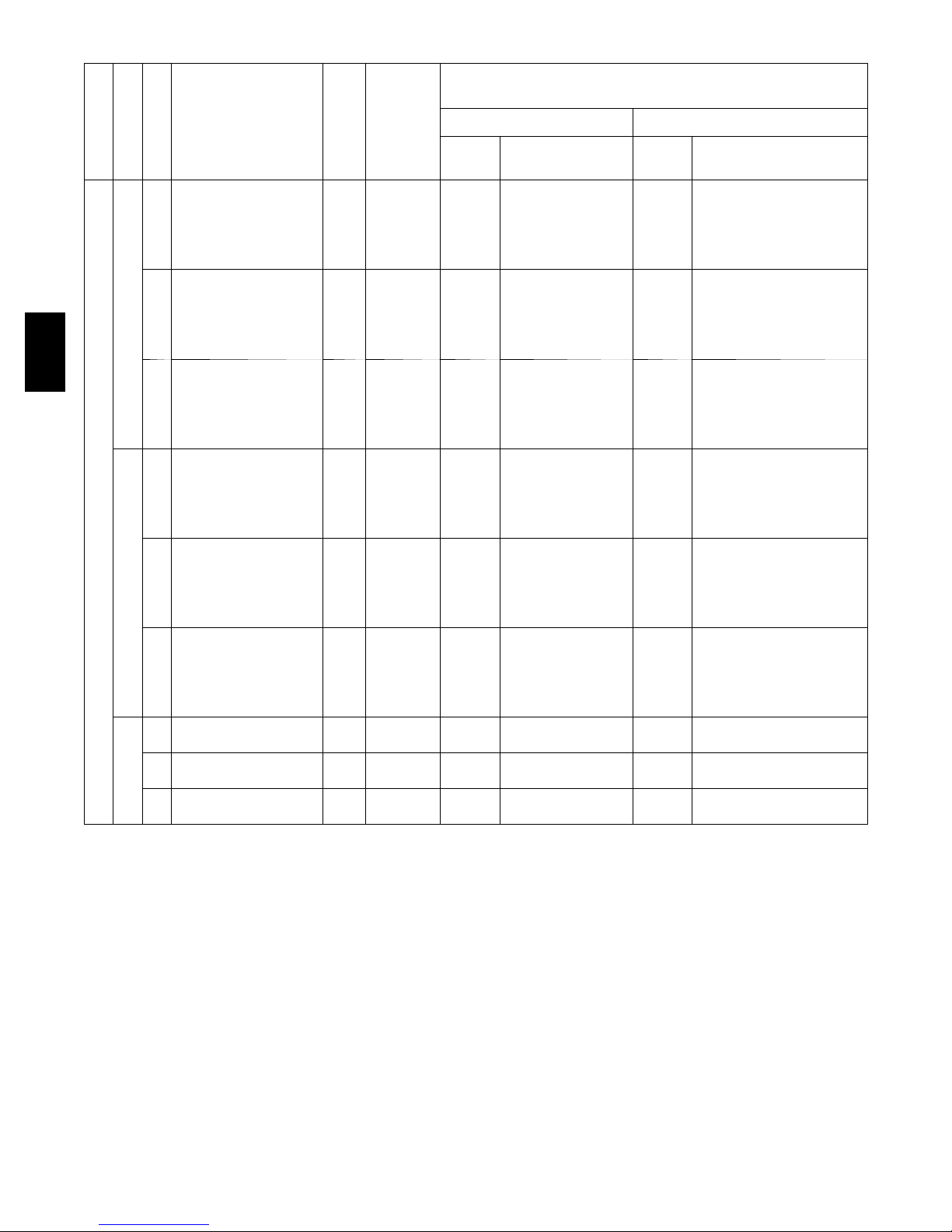

Table 8 -- (cont.) ELECTRIC HEAT -- ELECTRICAL DATA 3 -- 12. 5 TONS

SINGLE POINT KIT PART NUMBER

CRSINGLEXXXXXX

NO P.E.

w/P.E.

(pwrd fr/unit)

50TC

UNIT

50TC*A05

N O M . V --- P H --- H Z

208/230--- 1 --- 60

208/230--- 3 --- 60

4 6 0 --- 3 --- 6 0

ELECTRIC HEATER

PAR T NUMBE R

CRHEATERXXXXXX

IFM TYPE

101A00 4.4 3.3/4.0 --- --- --- --103B00 8.7 6.5/8.0 --- --- --- ---

102A00,102A00 13 9.8/11.9 040A00 040A00 040A00 040A00

STD

103B00,103B00 17.4 13.1/16.0 040A00 040A00 040A00 040A00

104B00,104B00 21 15.8/19.3 040A00 040A00 040A00 040A00

101A00 4.4 3.3/4.0 --- --- --- --103B00 8.7 6.5/8.0 --- --- --- ---

102A00,102A00 13 9.8/11.9 040A00 040A00 040A00 040A00

MED

103B00,103B00 17.4 13.1/16.0 040A00 040A00 040A00 040A00

104B00,104B00 21 15.8/19.3 040A00 040A00 040A00 040A00

102A00 6.5 4.9/6.0 --- --- --- --103B00 8.7 6.5/8.0 --- --- --- ---

STD

MED

HIGH

STD

MED

HIGH

105A00 16 12.0/14.7 --- --- 038A00 038A00

104B00,104B00 21 15.8/19.3 038A00 038A00 038A00 038A00

102A00 6.5 4.9/6.0 --- --- --- --103B00 8.7 6.5/8.0 --- --- --- --105A00 16 12.0/14.7 --- --- 038A00 038A00

104B00,104B00 21 15.8/19.3 038A00 038A00 038A00 038A00

102A00 6.5 4.9/6.0 --- --- --- --103B00 8.7 6.5/8.0 --- --- --- --105A00 16 12.0/14.7 --- --- 038A00 038A00

104B00,104B00 21 15.8/19.3 038A00 038A00 038A00 038A00

106A00 6 5.5 --- --- --- --108A00 11.5 10.6 --- --- --- --109A00 14 12.9 --- --- --- ---

108A00,108A00 23 21.1 --- --- --- ---

106A00 6 5.5 --- --- --- --108A00 11.5 10.6 --- --- --- --109A00 14 12.9 --- --- --- ---

108A00,108A00 23 21.1 --- --- --- ---

106A00 6 5.5 --- --- --- --108A00 11.5 10.6 --- --- --- --109A00 14 12.9 --- --- --- ---

108A00,108A00 23 21.1 --- --- --- ---

NOM

PWR

(kW)

APP

PWR

(kW)

NO C.O. or UNPWRD C.O. w/PWRD C.O.

NO P.E.

w/P.E.

(pwrd fr/unit)

LEGEND

APP PWR --- 208 / 230V / 460V / 575V

C.O. --- Convenient outlet

FLA --- Full load amps

IFM --- Indoor fan motor

NOM PWR -- - 240V / 480V / 600V

P.E . --- P ow e r e x h a u s t

PWRD --- Powered convenient outlet

UNPWRD -- - Unpowered convenient outlet

14

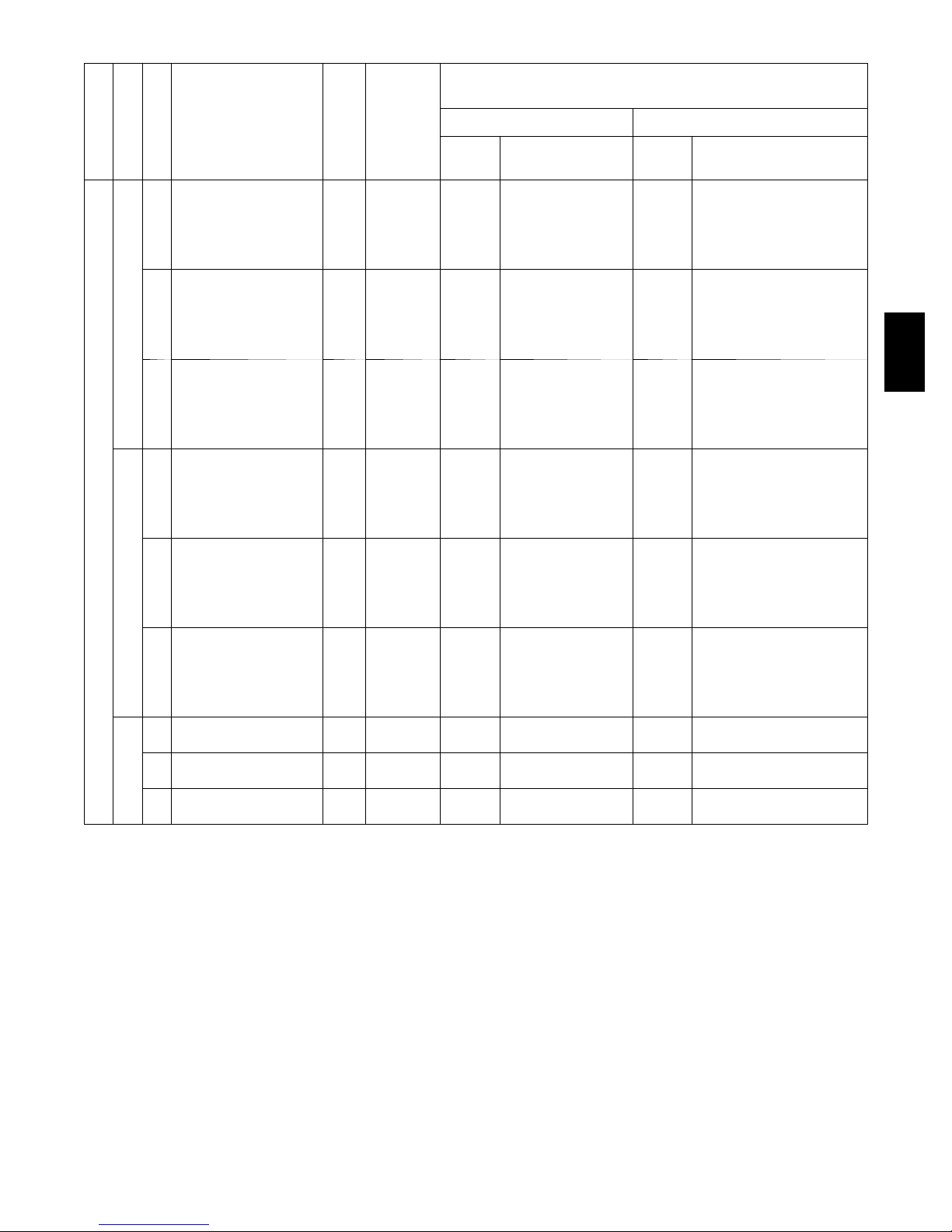

Table 8 -- (cont.) ELECTRIC HEAT -- ELECTRICAL DATA 3 -- 12. 5 TONS

SINGLE POINT KIT PART NUMBER

CRSINGLEXXXXXX

NO P.E.

w/P.E.

(pwrd fr/unit)

UNIT

50TC*A06

N O M . V --- P H --- H Z

208/230--- 1 --- 60

208/230--- 3 --- 60

4 6 0 --- 3 --- 6 0

ELECTRIC HEATER

PAR T NUMBE R

CRHEATERXXXXXX

IFM TYPE

102A00 6.5 4.9/6.0 --- --- --- --103B00 8.7 6.5/8.0 --- --- --- ---

102A00,102A00 13 9.8/11.9 040A00 040A00 040A00 040A00

STD

103B00,103B00 17.4 13.1/16.0 040A00 040A00 040A00 040A00

104B00,104B00 21 15.8/19.3 040A00 040A00 040A00 040A00

102A00 6.5 4.9/6.0 --- --- --- --103B00 8.7 6.5/8.0 --- --- 040A00 040A00

102A00,102A00 13 9.8/11.9 040A00 040A00 040A00 040A00

MED

103B00,103B00 17.4 13.1/16.0 040A00 040A00 040A00 040A00

104B00,104B00 21 15.8/19.3 040A00 040A00 040A00 040A00

102A00 6.5 4.9/6.0 --- --- --- --104B00 10.5 7.9/9.6 --- --- --- ---

STD

MED

HIGH

STD

MED

HIGH

105A00 16 12.0/14.7 --- --- 038A00 038A00

104B00,104B00 21 15.8/19.3 038A00 038A00 038A00 038A00

104B00,105A00 26.5 19.9/24.3 038A00 038A00 038A00 038A00

102A00 6.5 4.9/6.0 --- --- --- ---

104B00 10.5 7.9/9.6 --- --- --- ---

105A00 16 12.0/14.7 --- --- 038A00 038A00

104B00,104B00 21 15.8/19.3 038A00 038A00 038A00 038A00

104B00,105A00 26.5 19.9/24.3 038A00 038A00 038A00 038A00

102A00 6.5 4.9/6.0 --- --- --- ---

104B00 10.5 7.9/9.6 --- --- --- ---

105A00 16 12.0/14.7 --- --- 038A00 038A00

104B00,104B00 21 15.8/19.3 038A00 038A00 038A00 038A00

104B00,105A00 26.5 19.9/24.3 038A00 038A00 038A00 038A00

106A00 6 5.5 --- --- --- ---

108A00 11.5 10.6 --- --- --- ---

109A00 14 12.9 --- --- --- --108A00,108A00 23 21.1 --- --- --- --108A00,109A00 25.5 23.4 --- --- --- ---

106A00 6 5.5 --- --- --- ---

108A00 11.5 10.6 --- --- --- ---

109A00 14 12.9 --- --- --- --108A00,108A00 23 21.1 --- --- --- --108A00,109A00 25.5 23.4 --- --- --- ---

106A00 6 5.5 --- --- --- ---

108A00 11.5 10.6 --- --- --- ---

109A00 14 12.9 --- --- --- --108A00,108A00 23 21.1 --- --- --- --108A00,109A00 25.5 23.4 --- --- --- ---

NOM

PWR

(kW)

APP

PWR

(kW)

NO C.O. or UNPWRD C.O. w/PWRD C.O.

NO P.E.

w/P.E.

(pwrd fr/unit)

50TC

LEGEND

APP PWR --- 208 / 230V / 460V / 575V

C.O. --- Convenient outlet

FLA --- Full load amps

IFM --- Indoor fan motor

NOM PWR -- - 240V / 480V / 600V

P.E . --- P ow e r e x h a u s t

PWRD --- Powered convenient outlet

UNPWRD -- - Unpowered convenient outlet

15

Table 8 -- (cont.) ELECTRIC HEAT -- ELECTRICAL DATA 3 -- 12. 5 TONS

SINGLE POINT KIT PART NUMBER

CRSINGLEXXXXXX

NO P.E.

w/P.E.

(pwrd fr/unit)

50TC

UNIT

50TC*A07

N O M . V --- P H --- H Z

208/230--- 3 --- 60

4 6 0 --- 3 --- 6 0

ELECTRIC HEATER

PAR T NUMBE R

CRHEATERXXXXXX

IFM TYPE

102A00 6.5 4.9/6.0 --- --- --- --104B00 10.5 7.9/9.6 --- --- --- ---

STD

MED

HIGH

STD

MED

HIGH

105A00 16.0 12.0/14.7 037A00 037A00 038A00 038A00

104B00,104B00 21.0 15.8/19.3 038A00 038A00 038A00 038A00

104B00,105A00 26.5 19.9/24.3 038A00 038A00 038A00 038A00

102A00 6.5 4.9/6.0 --- --- --- ---

104B00 10.5 7.9/9.6 --- --- --- ---

105A00 16.0 12.0/14.7 037A00 037A00 038A00 038A00

104B00,104B00 21.0 15.8/19.3 038A00 038A00 038A00 038A00

104B00,105A00 26.5 19.9/24.3 038A00 038A00 038A00 038A00

102A00 6.5 4.9/6.0 --- --- --- ---

104B00 10.5 7.9/9.6 --- --- --- ---

105A00 16.0 12.0/14.7 037A00 037A00 038A00 038A00

104B00,104B00 21.0 15.8/19.3 038A00 038A00 038A00 038A00

104B00,105A00 26.5 19.9/24.3 038A00 038A00 038A00 038A00

106A00 6.0 5.5 --- --- --- ---

108A00 11.5 10.6 --- --- --- ---

109A00 14.0 12.9 --- --- --- --108A00,108A00 23.0 21.1 037A00 037A00 037A00 037A00

108A00,109A00 25.5 23.4 037A00 037A00 037A00 037A00

106A00 6.0 5.5 --- --- --- ---

108A00 11.5 10.6 --- --- --- ---

109A00 14.0 12.9 --- --- --- --108A00,108A00 23.0 21.1 037A00 037A00 037A00 037A00

108A00,109A00 25.5 23.4 037A00 037A00 037A00 037A00

106A00 6.0 5.5 --- --- --- ---

108A00 11.5 10.6 --- --- --- ---

109A00 14.0 12.9 --- --- --- --108A00,108A00 23.0 21.1 037A00 037A00 037A00 037A00

108A00,109A00 25.5 23.4 037A00 037A00 037A00 037A00

NOM

PWR

(kW)

APP

PWR

(kW)

NO C.O. or UNPWRD C.O. w/PWRD C.O.

NO P.E.

w/P.E.

(pwrd fr/unit)

LEGEND

APP PWR --- 208 / 230V / 460V / 575V

C.O. --- Convenient outlet

FLA --- Full load amps

IFM --- Indoor fan motor

NOM PWR -- - 240V / 480V / 600V

P.E . --- P ow e r e x h a u s t

PWRD --- Powered convenient outlet

UNPWRD -- - Unpowered convenient outlet

16

Table 8 -- (cont.) ELECTRIC HEAT -- ELECTRICAL DATA 3 -- 12. 5 TONS

SINGLE POINT KIT PART NUMBER

CRSINGLEXXXXXX

NO P.E.

w/P.E.

(pwrd fr/unit)

UNIT

50TC*A08

N O M . V --- P H --- H Z

208/230--- 3 --- 60

4 6 0 --- 3 --- 6 0

5 7 5 --- 3 --- 6 0

ELECTRIC HEATER

PAR T NUMBE R

CRHEATERXXXXXX

IFM TYPE

117A00 10.4 7.8/9.6 042A00 042A00 042A00 042A00

110A00 16.0 12.0/14.7 042A00 042A00 043A00 043A00

STD

MED

HIGH

STD

MED

HIGH

STD

MED

HIGH

111A00 24.8 18.6/22.8 043A00 043A00 043A00 043A00

112A00 32.0 24.0/29.4 043A00 043A00 043A00 043A00

112A00,117A00 42.4 31.8/38.9 045A00 045A00 045A00 045A00

117A00 10.4 7.8/9.6 042A00 042A00 042A00 042A00

110A00 16.0 12.0/14.7 042A00 043A00 043A00 043A00

111A00 24.8 18.6/22.8 043A00 043A00 043A00 043A00

112A00 32.0 24.0/29.4 043A00 043A00 043A00 043A00

112A00,117A00 42.4 31.8/38.9 045A00 045A00 045A00 045A00

117A00 10.4 7.8/9.6 042A00 042A00 043A00 043A00

110A00 16.0 12.0/14.7 043A00 043A00 043A00 043A00

111A00 24.8 18.6/22.8 043A00 043A00 043A00 043A00

112A00 32.0 24.0/29.4 043A00 043A00 043A00 043A00

112A00,117A00 42.4 31.8/38.9 045A00 045A00 045A00 045A00

116A00 13.9 12.8 042A00 042A00 042A00 042A00

113A00 16.5 15.2 042A00 042A00 042A00 042A00

114A00 27.8 25.5 042A00 042A00 042A00 042A00

115A00 33.0 30.3 042A00 042A00 042A00 042A00

114A00,116A00 41.7 38.3 044A00 044A00 044A00 044A00

116A00 13.9 12.8 042A00 042A00 042A00 042A00

113A00 16.5 15.2 042A00 042A00 042A00 042A00

114A00 27.8 25.5 042A00 042A00 042A00 042A00

115A00 33.0 30.3 042A00 042A00 042A00 042A00

114A00,116A00 41.7 38.3 044A00 044A00 044A00 044A00

116A00 13.9 12.8 042A00 042A00 042A00 042A00

113A00 16.5 15.2 042A00 042A00 042A00 042A00

114A00 27.8 25.5 042A00 042A00 042A00 042A00

115A00 33.0 30.3 042A00 044A00 044A00 044A00

114A00,116A00 41.7 38.3 044A00 044A00 044A00 044A00

118A00 17.0 17.0 042A00 042A00 042A00 042A00

119A00 34.0 34.0 042A00 042A00 042A00 044A00

118A00 17.0 17.0 042A00 042A00 042A00 042A00

119A00 34.0 34.0 042A00 042A00 042A00 044A00

118A00 17.0 17.0 042A00 042A00 042A00 042A00

119A00 34.0 34.0 042A00 044A00 044A00 044A00

NOM

PWR

(kW)

APP

PWR

(kW)

NO C.O. or UNPWRD C.O. w/PWRD C.O.

NO P.E.

w/P.E.

(pwrd fr/unit)

50TC

LEGEND

APP PWR --- 208 / 230V / 460V / 575V

C.O. --- Convenient outlet

FLA --- Full load amps

IFM --- Indoor fan motor

NOM PWR -- - 240V / 480V / 600V

P.E . --- P ow e r e x h a u s t

PWRD --- Powered convenient outlet

UNPWRD -- - Unpowered convenient outlet

17

Table 8 -- (cont.) ELECTRIC HEAT -- ELECTRICAL DATA 3 -- 12. 5 TONS

SINGLE POINT KIT PART NUMBER

CRSINGLEXXXXXX

NO P.E.

w/P.E.

(pwrd fr/unit)

50TC

ELECTRIC HEATER

UNIT

N O M . V --- P H --- H Z

208/230--- 3 --- 60

50TC*D08

4 6 0 --- 3 --- 6 0

5 7 5 --- 3 --- 6 0

PAR T NUMBE R

CRHEATERXXXXXX

IFM TYPE

117A00 10.4 7.8/9.6 042A00 042A00 042A00 042A00

110A00 16.0 12.0/14.7 042A00 042A00 043A00 043A00

STD

MED

HIGH

STD

MED

HIGH

STD

MED

HIGH

111A00 24.8 18.6/22.8 043A00 043A00 043A00 043A00

112A00 32.0 24.0/29.4 043A00 043A00 043A00 043A00

112A00,117A00 42.4 31.8/38.9 045A00 045A00 045A00 045A00

117A00 10.4 7.8/9.6 042A00 042A00 042A00 042A00

110A00 16.0 12.0/14.7 042A00 043A00 043A00 043A00

111A00 24.8 18.6/22.8 043A00 043A00 043A00 043A00

112A00 32.0 24.0/29.4 043A00 043A00 043A00 043A00

112A00,117A00 42.4 31.8/38.9 045A00 045A00 045A00 045A00

117A00 10.4 7.8/9.6 042A00 042A00 042A00 043A00

110A00 16.0 12.0/14.7 043A00 043A00 043A00 043A00

111A00 24.8 18.6/22.8 043A00 043A00 043A00 043A00

112A00 32.0 24.0/29.4 043A00 043A00 043A00 043A00

112A00,117A00 42.4 31.8/38.9 045A00 045A00 045A00 045A00

116A00 13.9 12.8 042A00 042A00 042A00 042A00

113A00 16.5 15.2 042A00 042A00 042A00 042A00

114A00 27.8 25.5 042A00 042A00 042A00 042A00

115A00 33.0 30.3 042A00 042A00 042A00 042A00

114A00,116A00 41.7 38.3 044A00 044A00 044A00 044A00

116A00 13.9 12.8 042A00 042A00 042A00 042A00

113A00 16.5 15.2 042A00 042A00 042A00 042A00

114A00 27.8 25.5 042A00 042A00 042A00 042A00

115A00 33.0 30.3 042A00 042A00 042A00 042A00

114A00,116A00 41.7 38.3 044A00 044A00 044A00 044A00

116A00 13.9 12.8 042A00 042A00 042A00 042A00

113A00 16.5 15.2 042A00 042A00 042A00 042A00

114A00 27.8 25.5 042A00 042A00 042A00 042A00

115A00 33.0 30.3 042A00 044A00 044A00 044A00

114A00,116A00 41.7 38.3 044A00 044A00 044A00 044A00

118A00 17.0 17.0 042A00 042A00 042A00 042A00

119A00 34.0 34.0 042A00 042A00 042A00 044A00

118A00 17.0 17.0 042A00 042A00 042A00 042A00

119A00 34.0 34.0 042A00 042A00 042A00 044A00

118A00 17.0 17.0 042A00 042A00 042A00 042A00

119A00 34.0 34.0 042A00 044A00 044A00 044A00

NOM

PWR

(kW)

APP

PWR

(kW)

NO C.O. or UNPWRD C.O. w/PWRD C.O.

NO P.E.

w/P.E.

(pwrd fr/unit)

LEGEND

APP PWR --- 208 / 230V / 460V / 575V

C.O. --- Convenient outlet

FLA --- Full load amps

IFM --- Indoor fan motor

NOM PWR -- - 240V / 480V / 600V

P.E . --- P ow e r e x h a u s t

PWRD --- Powered convenient outlet

UNPWRD -- - Unpowered convenient outlet

18

Table 8 -- (cont.) ELECTRIC HEAT -- ELECTRICAL DATA 3 -- 12. 5 TONS

SINGLE POINT KIT PART NUMBER

CRSINGLEXXXXXX

NO P.E.

w/P.E.

(pwrd fr/unit)

UNIT

50TC*A09

N O M . V --- P H --- H Z

208/230--- 3 --- 60

4 6 0 --- 3 --- 6 0

5 7 5 --- 3 --- 6 0

ELECTRIC HEATER

PAR T NUMBE R

CRHEATERXXXXXX

IFM TYPE

117A00 10.4 7.8/9.6 047A00 047A00 047A00 049A00

110A00 16.0 12.0/14.7 047A00 047A00 049A00 049A00

STD

MED

HIGH

STD

MED

HIGH

STD

MED

HIGH

111A00 24.8 18.6/22.8 049A00 049A00 049A00 049A00

112A00 32.0 24.0/29.4 049A00 049A00 049A00 049A00

112A00,117A00 42.4 31.8/38.9 051A00 051A00 051A00 051A00

117A00 10.4 7.8/9.6 047A00 047A00 047A00 049A00

110A00 16.0 12.0/14.7 047A00 047A00 049A00 049A00

111A00 24.8 18.6/22.8 049A00 049A00 049A00 049A00

112A00 32.0 24.0/29.4 049A00 049A00 049A00 049A00

112A00,117A00 42.4 31.8/38.9 051A00 051A00 051A00 051A00

117A00 10.4 7.8/9.6 047A00 049A00 049A00 049A00

110A00 16.0 12.0/14.7 049A00 049A00 049A00 049A00

111A00 24.8 18.6/22.8 049A00 049A00 049A00 049A00

112A00 32.0 24.0/29.4 049A00 049A00 049A00 049A00

112A00,117A00 42.4 31.8/38.9 051A00 051A00 051A00 051A00

116A00 13.9 12.8 047A00 047A00 047A00 047A00

113A00 16.5 15.2 047A00 047A00 047A00 047A00

114A00 27.8 25.5 047A00 047A00 047A00 047A00

115A00 33.0 30.3 047A00 047A00 047A00 047A00

114A00,116A00 41.7 38.3 050A00 050A00 050A00 050A00

116A00 13.9 12.8 047A00 047A00 047A00 047A00

113A00 16.5 15.2 047A00 047A00 047A00 047A00

114A00 27.8 25.5 047A00 047A00 047A00 047A00

115A00 33.0 30.3 047A00 047A00 047A00 047A00

114A00,116A00 41.7 38.3 050A00 050A00 050A00 050A00

116A00 13.9 12.8 047A00 047A00 047A00 047A00

113A00 16.5 15.2 047A00 047A00 047A00 047A00

114A00 27.8 25.5 047A00 047A00 047A00 047A00

115A00 33.0 30.3 047A00 047A00 047A00 050A00

114A00,116A00 41.7 38.3 050A00 050A00 050A00 050A00

118A00 17.0 17.0 047A00 047A00 047A00 047A00

119A00 34.0 34.0 047A00 047A00 047A00 050A00

118A00 17.0 17.0 047A00 047A00 047A00 047A00

119A00 34.0 34.0 047A00 047A00 047A00 050A00

118A00 17.0 17.0 047A00 047A00 047A00 047A00

119A00 34.0 34.0 047A00 047A00 047A00 050A00

NOM

PWR

(kW)

APP

PWR

(kW)

NO C.O. or UNPWRD C.O. w/PWRD C.O.

NO P.E.

w/P.E.

(pwrd fr/unit)

50TC

LEGEND

APP PWR --- 208 / 230V / 460V / 575V

C.O. --- Convenient outlet

FLA --- Full load amps

IFM --- Indoor fan motor

NOM PWR -- - 240V / 480V / 600V

P.E . --- P ow e r e x h a u s t

PWRD --- Powered convenient outlet

UNPWRD -- - Unpowered convenient outlet

19

Table 8 -- (cont.) ELECTRIC HEAT -- ELECTRICAL DATA 3 -- 12. 5 TONS

SINGLE POINT KIT PART NUMBER

CRSINGLEXXXXXX

NO P.E.

w/P.E.

(pwrd fr/unit)

50TC

UNIT

50TC*A12

N O M . V --- P H --- H Z

208/230--- 3 --- 60

4 6 0 --- 3 --- 6 0

5 7 5 --- 3 --- 6 0

ELECTRIC HEATER

PAR T NUMBE R

CRHEATERXXXXXX

IFM TYPE

117A00 10.4 7.8/9.6 047A00 047A00 047A00 049A00

110A00 16.0 12.0/14.7 047A00 047A00 049A00 049A00

STD

MED

HIGH

STD

MED

HIGH

STD

MED

HIGH

112A00 32.0 24.0/29.4 049A00 049A00 049A00 049A00

112A00,117A00 42.4 31.8/38.9 051A00 051A00 051A00 051A00

112A00,110A00 50.0 37.6/45.9 051A00 051A00 051A00 051A00

117A00 10.4 7.8/9.6 047A00 049A00 049A00 049A00

110A00 16.0 12.0/14.7 049A00 049A00 049A00 049A00

112A00 32.0 24.0/29.4 049A00 049A00 049A00 049A00

112A00,117A00 42.4 31.8/38.9 051A00 051A00 051A00 051A00

112A00,110A00 50.0 37.6/45.9 051A00 051A00 051A00 051A00

117A00 10.4 7.8/9.6 049A00 049A00 049A00 049A00

110A00 16.0 12.0/14.7 049A00 049A00 049A00 049A00

112A00 32.0 24.0/29.4 049A00 049A00 049A00 049A00

112A00,117A00 42.4 31.8/38.9 051A00 051A00 051A00 051A00

112A00,110A00 50.0 37.6/45.9 051A00 051A00 051A00 051A00

116A00 13.9 12.8 047A00 047A00 047A00 047A00

113A00 16.5 15.2 047A00 047A00 047A00 047A00

115A00 33.0 30.3 047A00 047A00 047A00 047A00

114A00,116A00 41.7 38.3 050A00 050A00 050A00 050A00

115A00,113A00 50.0 45.9 050A00 050A00 050A00 050A00

116A00 13.9 12.8 047A00 047A00 047A00 047A00

113A00 16.5 15.2 047A00 047A00 047A00 047A00

115A00 33.0 30.3 047A00 047A00 047A00 050A00

114A00,116A00 41.7 38.3 050A00 050A00 050A00 050A00

115A00,113A00 50.0 45.9 050A00 050A00 050A00 050A00

116A00 13.9 12.8 047A00 047A00 047A00 047A00

113A00 16.5 15.2 047A00 047A00 047A00 047A00

115A00 33.0 30.3 047A00 050A00 050A00 050A00

114A00,116A00 41.7 38.3 050A00 050A00 050A00 050A00

115A00,113A00 50.0 45.9 050A00 050A00 050A00 050A00

118A00 17.0 17.0 047A00 047A00 047A00 047A00

119A00 34.0 34.0 047A00 047A00 047A00 050A00

118A00,119A00 51.0 51.0 050A00 050A00 050A00 050A00

118A00 17.0 17.0 047A00 047A00 047A00 047A00

119A00 34.0 34.0 047A00 047A00 047A00 050A00

118A00,119A00 51.0 51.0 050A00 050A00 050A00 050A00

118A00 17.0 17.0 047A00 047A00 047A00 047A00

119A00 34.0 34.0 047A00 050A00 050A00 050A00

118A00,119A00 51.0 51.0 050A00 050A00 050A00 050A00

NOM

PWR

(kW)

APP

PWR

(kW)

NO C.O. or UNPWRD C.O. w/PWRD C.O.

NO P.E.

w/P.E.

(pwrd fr/unit)

LEGEND

APP PWR --- 208 / 230V / 460V / 575V

C.O. --- Convenient outlet

FLA --- Full load amps

IFM --- Indoor fan motor

NOM PWR -- - 240V / 480V / 600V

P.E . --- P ow e r e x h a u s t

PWRD --- Powered convenient outlet

UNPWRD -- - Unpowered convenient outlet

20

Table 8 -- (cont.) ELECTRIC HEAT -- ELECTRICAL DATA 3 -- 12.5 TONS

SINGLE POINT KIT PART NUMBER

ELECTRIC HEATER

UNIT

N O M . V --- P H --- H Z

208/230--- 3 --- 60

50TC*D12

4 6 0 --- 3 --- 6 0

5 7 5 --- 3 --- 6 0

PAR T NUMBE R

CRHEATERXXXXXX

IFM TYPE

117A00 10.4 7.8/9.6 047A00 047A00 047A00 047A00

110A00 16.0 12.0/14.7 047A00 047A00 049A00 049A00

STD

MED

HIGH

STD

MED

HIGH

STD

MED

HIGH

112A00 32.0 24.0/29.4 049A00 049A00 049A00 049A00

112A00,117A00 42.4 31.8/38.9 051A00 051A00 051A00 051A00

112A00,110A00 50.0 37.6/45.9 051A00 051A00 051A00 051A00

117A00 10.4 7.8/9.6 047A00 047A00 047A00 049A00

110A00 16.0 12.0/14.7 049A00 049A00 049A00 049A00

112A00 32.0 24.0/29.4 049A00 049A00 049A00 049A00

112A00,117A00 42.4 31.8/38.9 051A00 051A00 051A00 051A00

112A00,110A00 50.0 37.6/45.9 051A00 051A00 051A00 051A00

117A00 10.4 7.8/9.6 047A00 049A00 049A00 049A00

110A00 16.0 12.0/14.7 049A00 049A00 049A00 049A00

112A00 32.0 24.0/29.4 049A00 049A00 049A00 049A00

112A00,117A00 42.4 31.8/38.9 051A00 051A00 051A00 051A00

112A00,110A00 50.0 37.6/45.9 051A00 051A00 051A00 051A00

116A00 13.9 12.8 047A00 047A00 047A00 047A00

113A00 16.5 15.2 047A00 047A00 047A00 047A00

115A00 33.0 30.3 047A00 047A00 047A00 047A00

114A00,116A00 41.7 38.3 050A00 050A00 050A00 050A00

115A00,113A00 50.0 45.9 050A00 050A00 050A00 050A00

116A00 13.9 12.8 047A00 047A00 047A00 047A00

113A00 16.5 15.2 047A00 047A00 047A00 047A00

115A00 33.0 30.3 047A00 047A00 047A00 050A00

114A00,116A00 41.7 38.3 050A00 050A00 050A00 050A00

115A00,113A00 50.0 45.9 050A00 050A00 050A00 050A00

116A00 13.9 12.8 047A00 047A00 047A00 047A00

113A00 16.5 15.2 047A00 047A00 047A00 047A00

115A00 33.0 30.3 047A00 050A00 050A00 050A00

114A00,116A00 41.7 38.3 050A00 050A00 050A00 050A00

115A00,113A00 50.0 45.9 050A00 050A00 050A00 050A00

118A00 17.0 17.0 047A00 047A00 047A00 047A00

119A00 34.0 34.0 047A00 047A00 047A00 050A00

118A00,119A00 51.0 51.0 050A00 050A00 050A00 050A00

118A00 17.0 17.0 047A00 047A00 047A00 047A00

119A00 34.0 34.0 047A00 047A00 047A00 050A00

118A00,119A00 51.0 51.0 050A00 050A00 050A00 050A00

118A00 17.0 17.0 047A00 047A00 047A00 047A00

119A00 34.0 34.0 047A00 050A00 050A00 050A00

118A00,119A00 51.0 51.0 050A00 050A00 050A00 050A00

NOM

PWR

(kW)

APP

PWR

(kW)

NO C.O. or UNPWRD C.O. w/PWRD C.O.

NO P.E.

w/P.E.

(pwrd fr/unit)

CRSINGLEXXXXXX

NO P.E.

(pwrd fr/unit)

w/P.E.

50TC

LEGEND

APP PWR --- 208 / 230V / 460V / 575V

C.O. --- Convenient outlet

FLA --- Full load amps

IFM --- Indoor fan motor

NOM PWR -- - 240V / 480V / 600V

P.E . --- P ow e r e x h a u s t

PWRD --- Powered convenient outlet

UNPWRD -- - Unpowered convenient outlet

21

Table 8 -- (cont.) ELECTRIC HEAT -- ELECTRICAL DATA 3 -- 12.5 TONS

SINGLE POINT KIT PART NUMBER

CRSINGLEXXXXXX

NO P.E.

50TC

ELECTRIC HEATER

UNIT

N O M . V --- P H --- H Z

208/230--- 3 --- 60

50TC*D14

4 6 0 --- 3 --- 6 0

5 7 5 --- 3 --- 6 0

PAR T NUMBE R

CRHEATERXXXXXX

IFM TYPE

117A00 10.4 7.8/9.6 049A00 049A00 049A00 049A00

110A00 16.0 12.0/14.7 049A00 049A00 049A00 049A00

STD

MED

HIGH

STD

MED

HIGH

STD

MED

HIGH

112A00 32.0 24.0/29.4 049A00 049A00 049A00 049A00

112A00,117A00 42.4 31.8/38.9 051A00 051A00 051A00 051A00

112A00,110A00 50.0 37.6/45.9 051A00 051A00 051A00 051A00

117A00 10.4 7.8/9.6 049A00 049A00 049A00 049A00

110A00 16.0 12.0/14.7 049A00 049A00 049A00 049A00

112A00 32.0 24.0/29.4 049A00 049A00 049A00 049A00

112A00,117A00 42.4 31.8/38.9 051A00 051A00 051A00 051A00

112A00,110A00 50.0 37.6/45.9 051A00 051A00 051A00 051A00

Std Unit Without Heat --- --- --- --- --- 049A00

117A00 10.4 7.8/9.6 049A00 049A00 049A00 049A00

110A00 16.0 12.0/14.7 049A00 049A00 049A00 049A00

112A00 32.0 24.0/29.4 049A00 049A00 049A00 049A00

112A00,117A00 42.4 31.8/38.9 051A00 051A00 051A00 051A00

112A00,110A00 50.0 37.6/45.9 051A00 051A00 051A00 051A00

116A00 13.9 12.8 047A00 047A00 047A00 047A00

113A00 16.5 15.2 047A00 047A00 047A00 047A00

115A00 33.0 30.3 047A00 047A00 047A00 047A00

114A00,116A00 41.7 38.3 050A00 050A00 050A00 050A00

115A00,113A00 50.0 45.9 050A00 050A00 050A00 050A00

116A00 13.9 12.8 047A00 047A00 047A00 047A00

113A00 16.5 15.2 047A00 047A00 047A00 047A00

115A00 33.0 30.3 047A00 047A00 047A00 050A00

114A00,116A00 41.7 38.3 050A00 050A00 050A00 050A00

115A00,113A00 50.0 45.9 050A00 050A00 050A00 050A00

116A00 13.9 12.8 047A00 047A00 047A00 047A00

113A00 16.5 15.2 047A00 047A00 047A00 047A00

115A00 33.0 30.3 047A00 050A00 050A00 050A00

114A00,116A00 41.7 38.3 050A00 050A00 050A00 050A00

115A00,113A00 50.0 45.9 050A00 050A00 050A00 050A00

118A00 17.0 17.0 047A00 047A00 047A00 047A00

119A00 34.0 34.0 047A00 047A00 047A00 050A00

118A00,119A00 51.0 51.0 050A00 050A00 050A00 050A00

118A00 17.0 17.0 047A00 047A00 047A00 047A00

119A00 34.0 34.0 047A00 047A00 047A00 050A00

118A00,119A00 51.0 51.0 050A00 050A00 050A00 050A00

118A00 17.0 17.0 047A00 047A00 047A00 047A00

119A00 34.0 34.0 047A00 050A00 050A00 050A00

118A00,119A00 51.0 51.0 050A00 050A00 050A00 050A00

NOM

PWR

(kW)

APP

PWR

(kW)

NO C.O. or UNPWRD C.O. w/PWRD C.O.

NO P.E.

w/P.E.

(pwrd fr/unit)

w/P.E.

(pwrd fr/unit)

LEGEND

APP PWR --- 208 / 230V / 460V / 575V

C.O. --- Convenient outlet

FLA --- Full load amps

IFM --- Indoor fan motor

NOM PWR -- - 240V / 480V / 600V

P.E . --- P ow e r e x h a u s t

PWRD --- Powered convenient outlet

UNPWRD -- - Unpowered convenient outlet

22

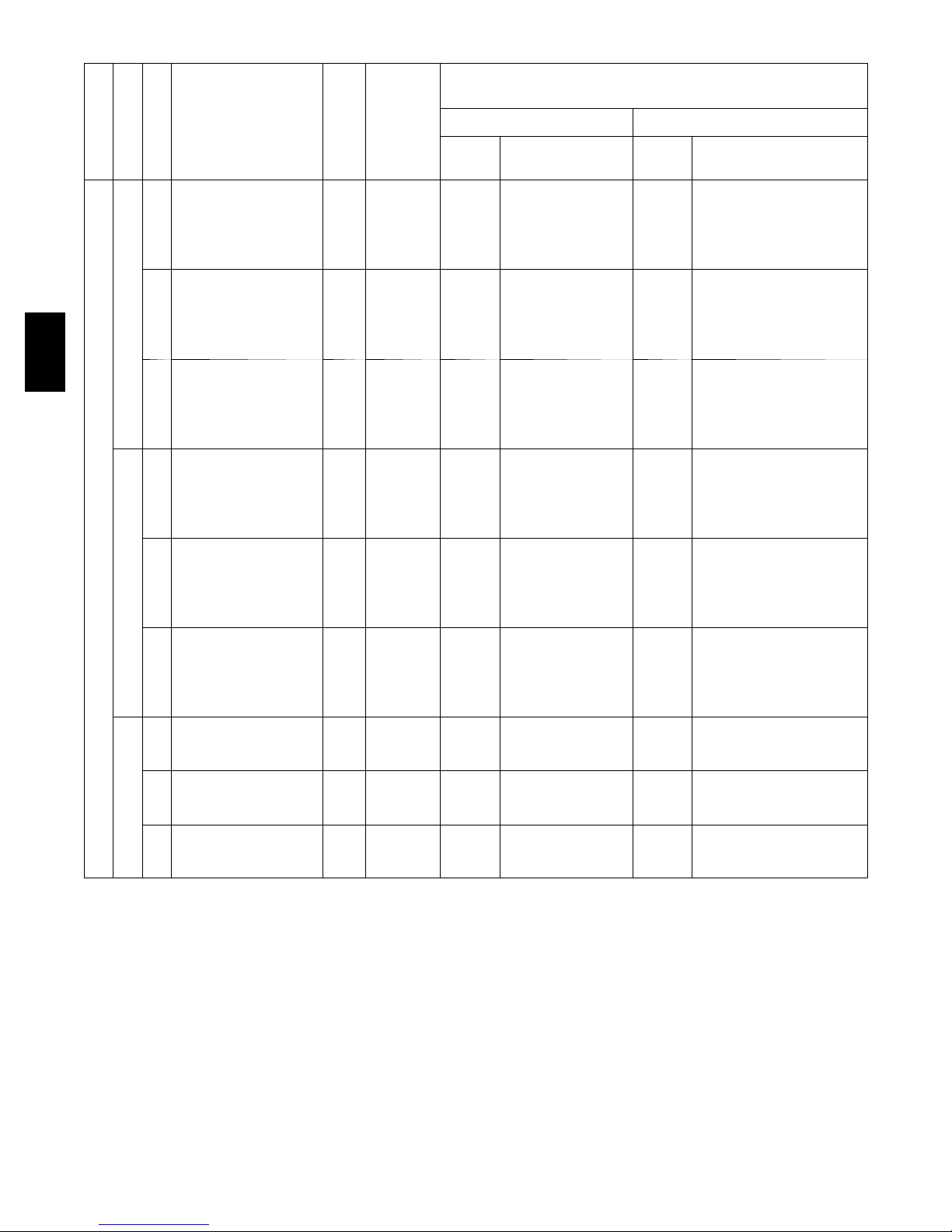

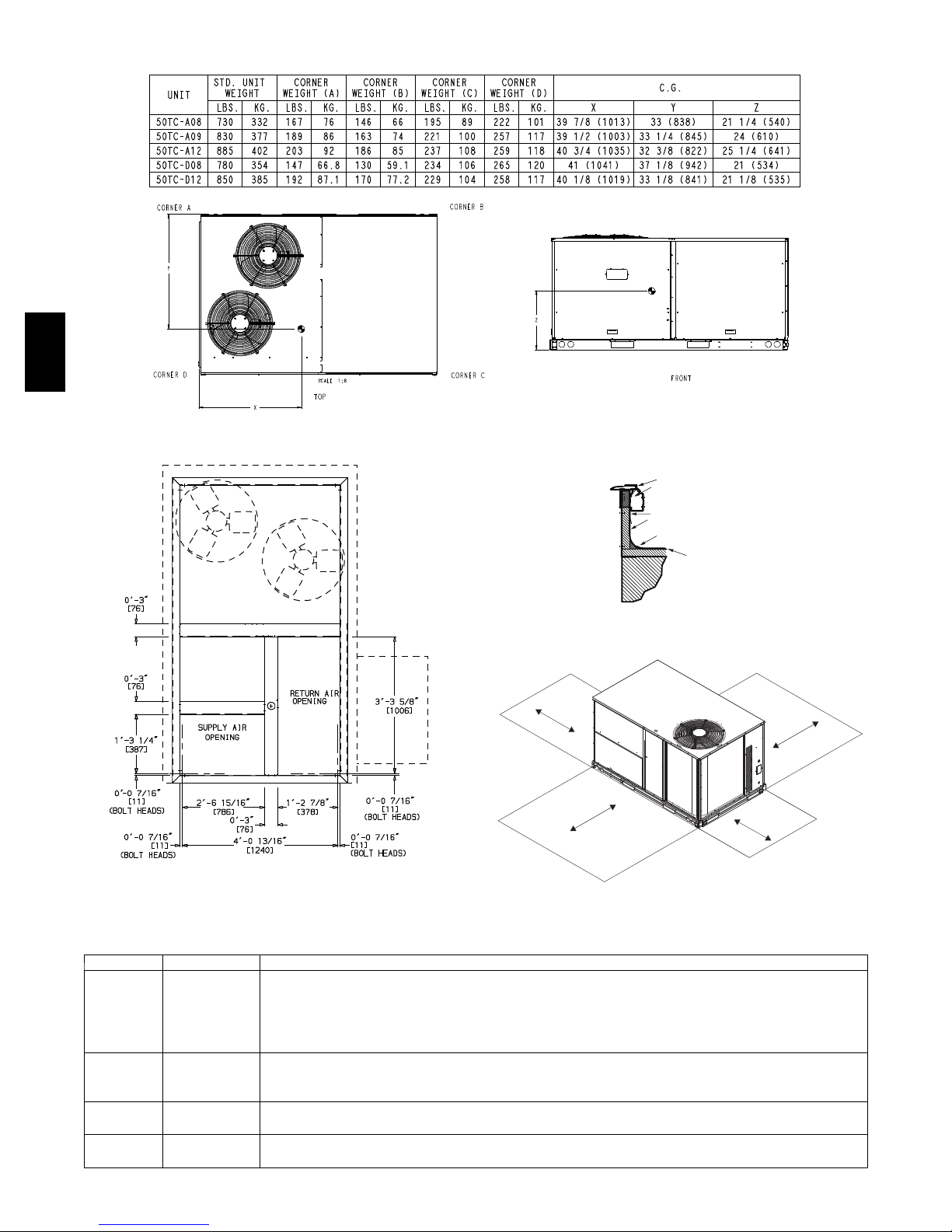

CURBS & WEIGHTS DIMENSIONS -- CHASSIS 1

50TC

C08529

Fig. 1 -- Dimensions 50TC 04-- 0 7

23

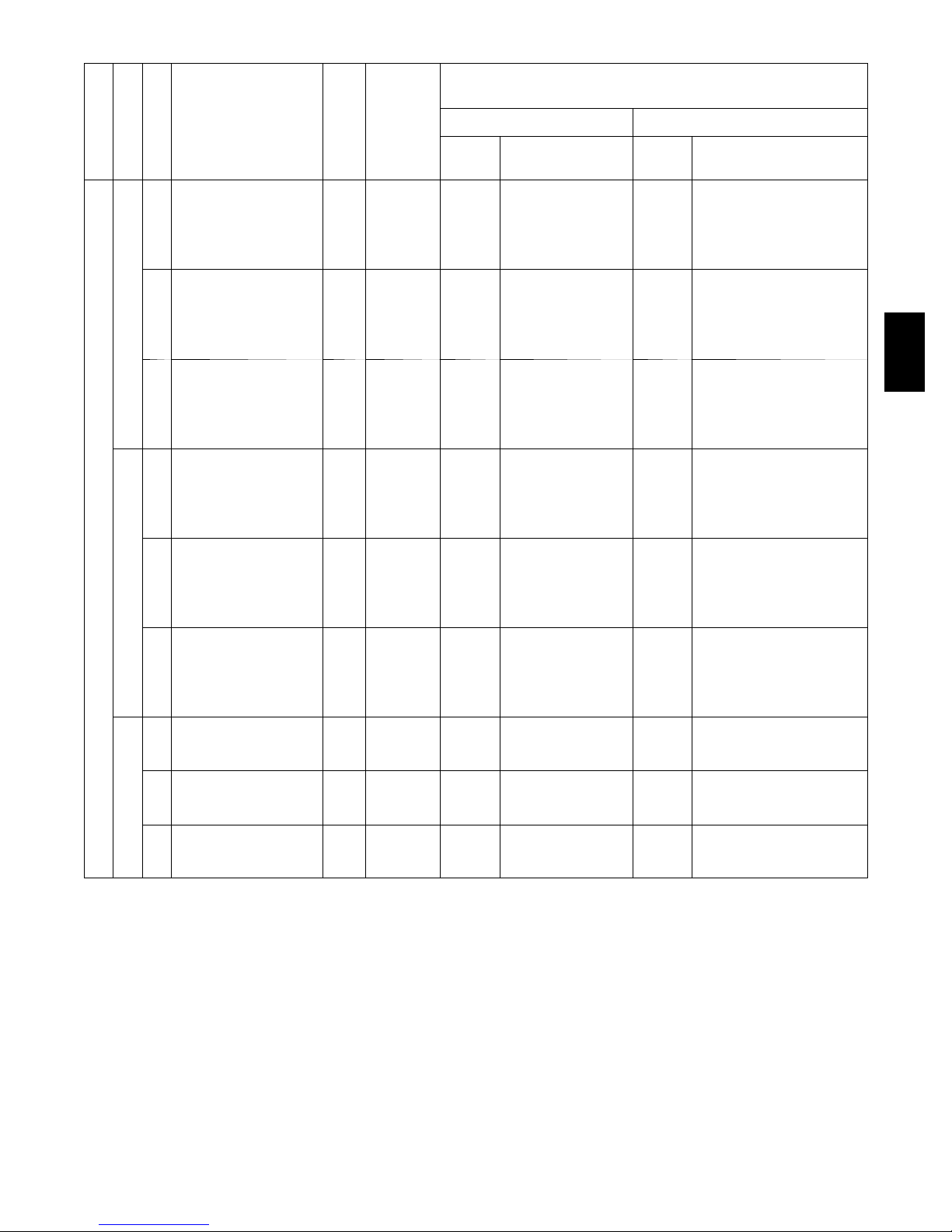

50TC

CURBS & WEIGHTS DIMENSIONS -- CHASSIS 1 (cont.)

Fig. 2 -- Dimensions 50TC 04-- 0 7

GASKET

(SUPPLIED WITH CURB)

NAIL

COUNTER FLASHING

(FIELD SUPPLIED)

ROOFING FELT

(FIELD SUPPLIED)

CANT STRIP

(FIELD SUPPLIED)

ROOFING FELT

(FIELD SUPPLIED)

C08530

C07458

Fig. 3 -- Curb Dimensions

LOC DIMENSION CONDITION

48” (1219 mm) Unit disconnect is mounted on panel

A

B

C

D

18” (457 mm) No disconnect, convenience outlet option

18” (457 mm) Recommended service clearance

12” (305 mm) Minimum clearance

42” (1067 mm) Surface behind servicer is grounded (e.g., metal, masonry wall)

36” (914 mm) Surface behind servicer is electrically non ---conductive (e.g., wood, fiberglass)

Special Check for sources of flue products within 10--- ft of unit fresh air intake hood

36” (914 mm) Side condensate drain is used

18” (457 mm) Minimum clearance

42” (1067 mm) Surface behind servicer is grounded (e.g., metal, masonry wall, another unit)

36” (914 mm) Surface behind servicer is electrically non ---conductive (e.g., wood, fiberglass)

C07457

Fig. 4 -- Curb Installation Detail (Typical)

C

D

B

A

C08337

Fig. 5 -- Service Clearance

24

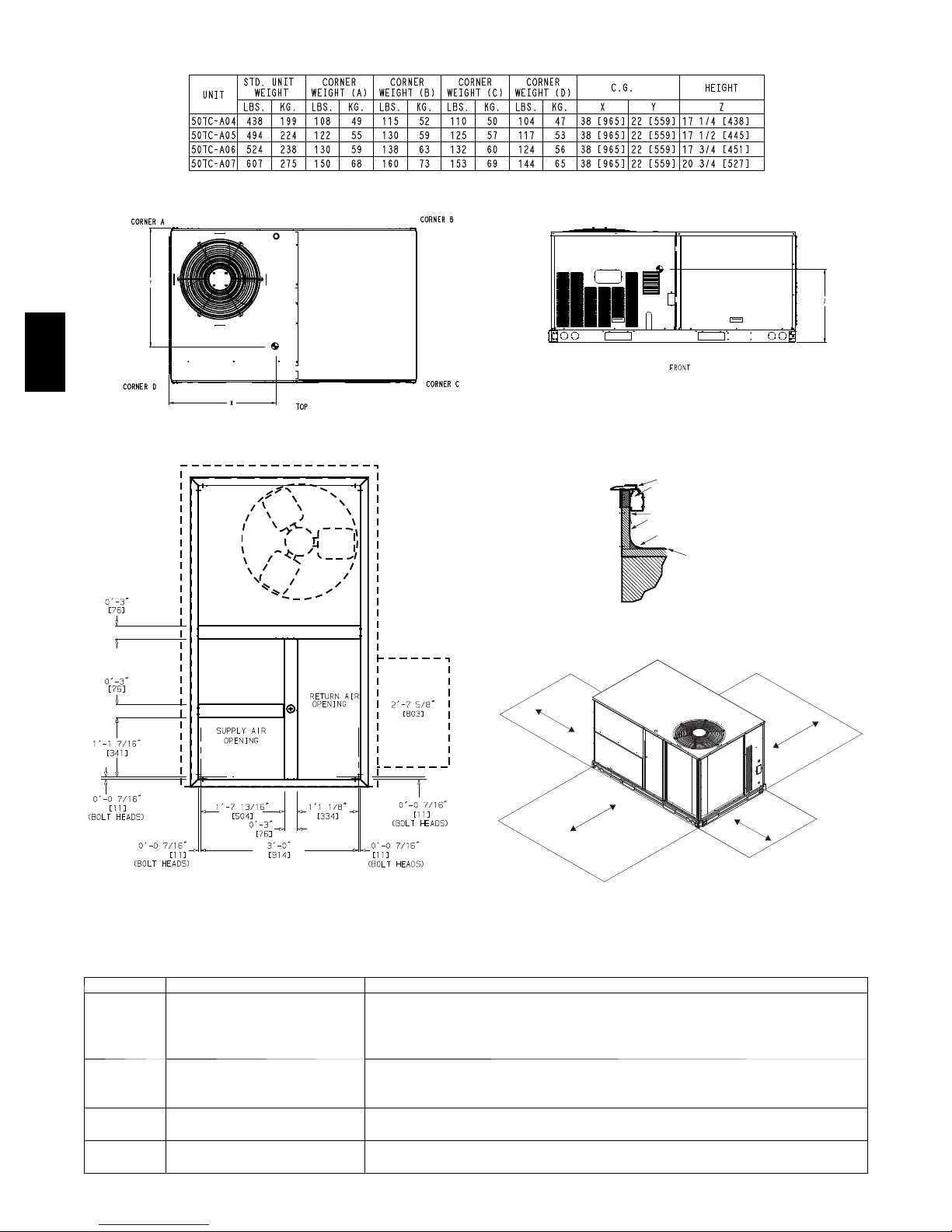

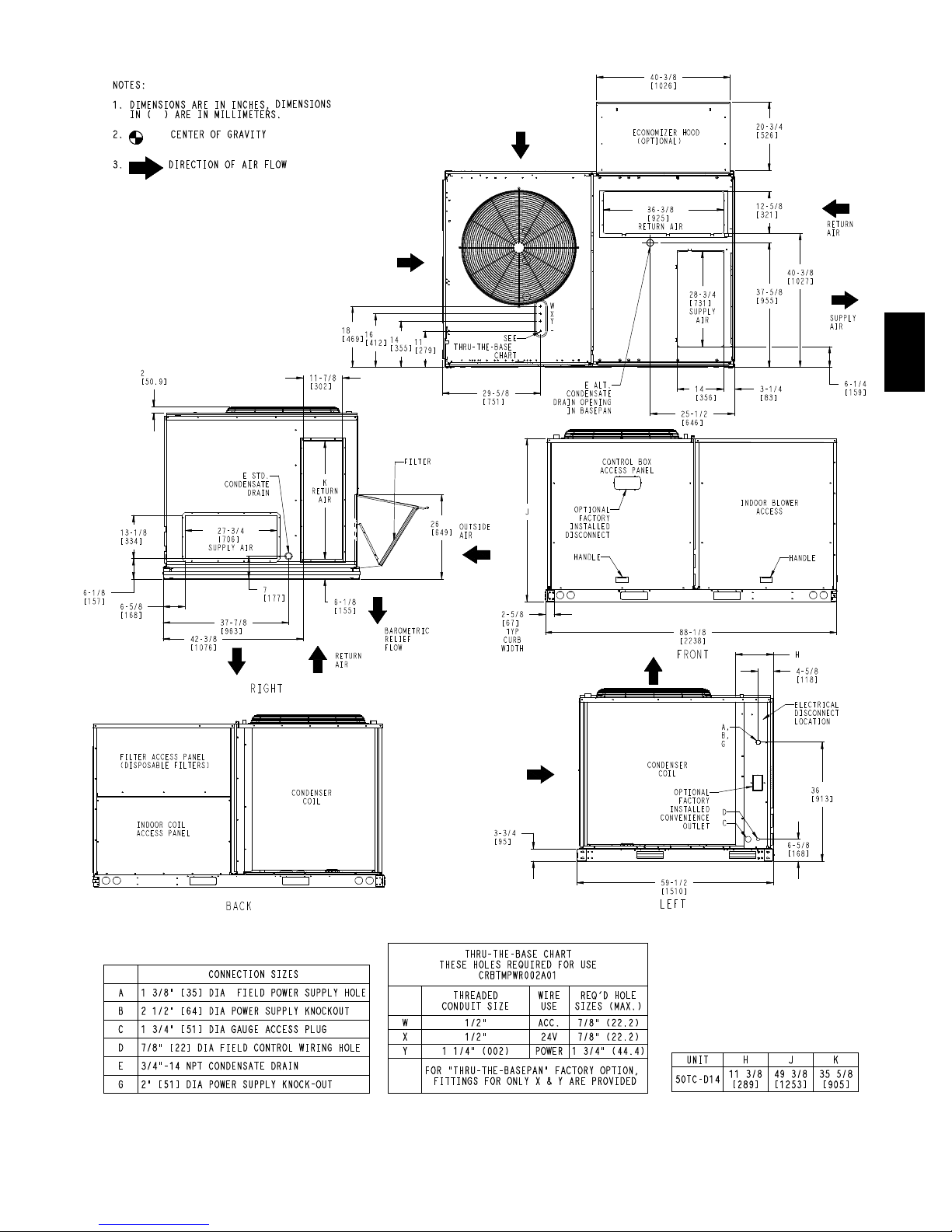

CURBS & WEIGHTS DIMENSIONS -- CHASSIS 2

50TC

C08531

Fig. 6 -- Dimensions 50TC 08-- 1 2

25

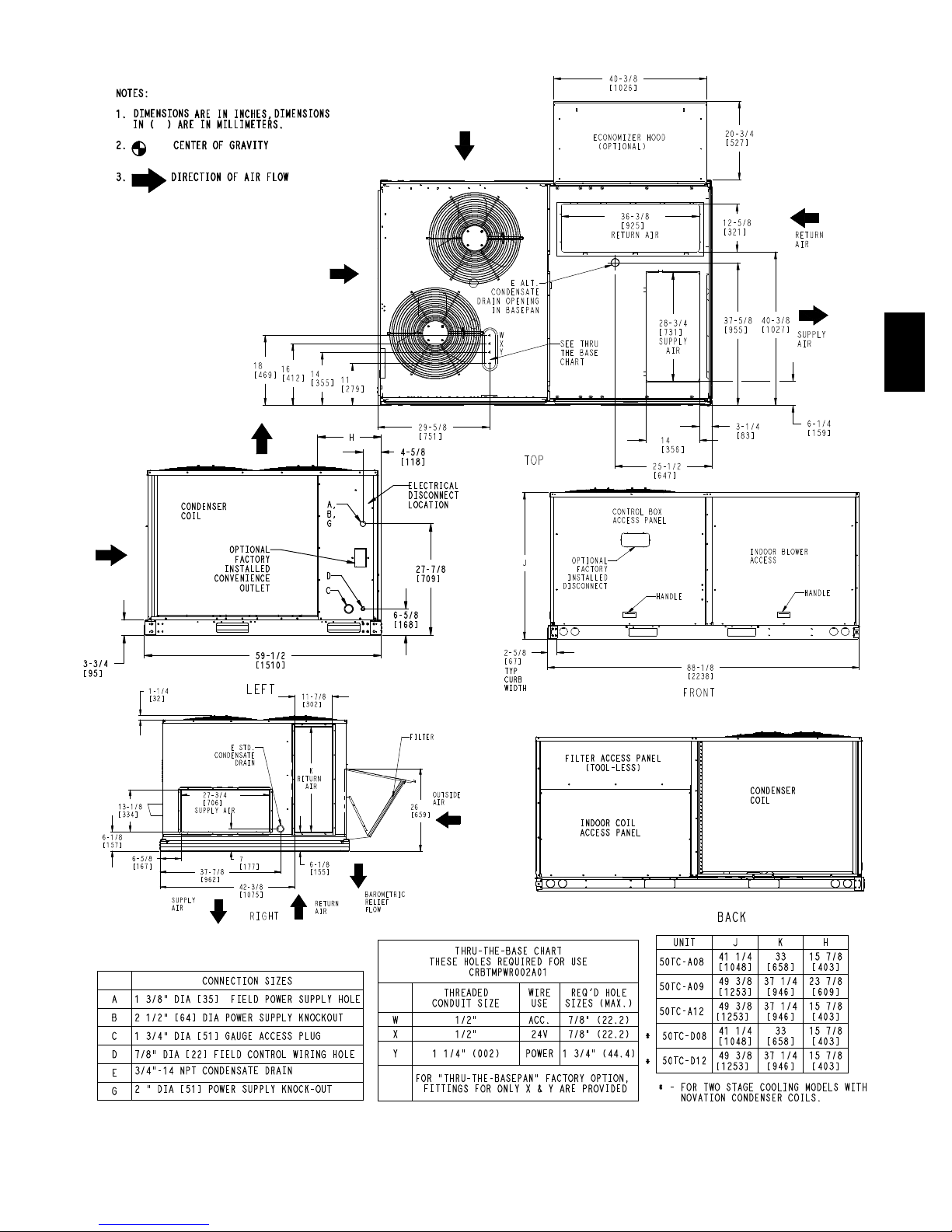

50TC

CURBS & WEIGHTS DIMENSIONS -- CHASSIS 2 (cont.)

Fig. 7 -- Dimensions 50TC 08-- 1 2

GASKET

(SUPPLIED WITH CURB)

NAIL

COUNTER FLASHING

(FIELD SUPPLIED)

ROOFING FELT

(FIELD SUPPLIED)

CANT STRIP

(FIELD SUPPLIED)

ROOFING FELT

(FIELD SUPPLIED)

C08532

Fig. 8 -- Curb Dimensions

LOC DIMENSION CONDITION

48” (1219 mm) Unit disconnect is mounted on panel

36” (914 mm) If dimension--- B is 12” (305 mm)

A

B

C

D

18” (457 mm) No disconnect, convenience outlet option

18” (457 mm) Recommended service clearance (use electric screwdriver)

12” (305 mm) Minimum clearance (use manual ratchet screwdriver)

36” (914 mm) Unit has economizer

12” (305 mm) If dimension--- A is 36” (914 mm)

Special Check for sources of flue products within 10--- ft of unit fresh air intake hood

36” (914 mm) Side condensate drain is used

18” (457 mm) Minimum clearance

42” (1067 mm) Surface behind servicer is grounded (e.g., metal, masonry wall, another unit)

36” (914 mm) Surface behind servicer is electrically non --- conductive (e.g., wood, fiberglass)

C07457

Fig. 9 -- Curb Installation Detail (Typical)

C

D

B

A

C08309

C08337

Fig. 10 -- Service Clearance

26

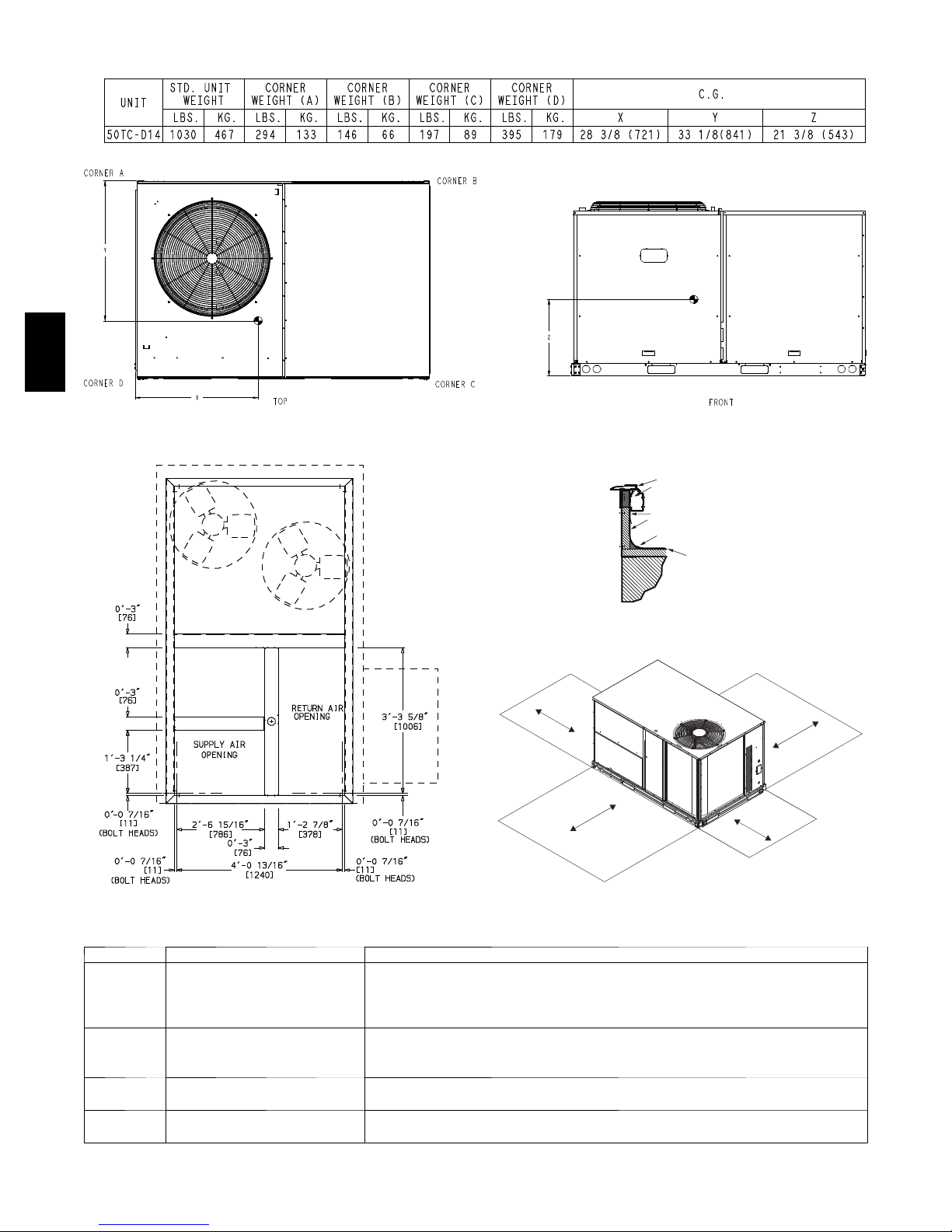

CURBS & WEIGHTS DIMENSIONS -- CHASSIS 3

50TC

C08533

Fig. 11 -- Dimensions 50TC--14

27

50TC

CURBS & WEIGHTS DIMENSIONS -- CHASSIS 3 (cont.)

Fig. 12 -- Dimensions 50TC--14

GASKET

(SUPPLIED WITH CURB)

NAIL

COUNTER FLASHING

(FIELD SUPPLIED)

ROOFING FELT

(FIELD SUPPLIED)

CANT STRIP

(FIELD SUPPLIED)

ROOFING FELT

(FIELD SUPPLIED)

C08534

C08309

Fig. 13 -- Curb Dimensions

LOC DIMENSION CONDITION

48” (1219 mm) Unit disconnect is mounted on panel

A

B

C

D

18” (457 mm) No disconnect, convenience outlet option

18” (457 mm) Recommended service clearance

12” (305 mm) Minimum clearance

42” (1067 mm) Surface behind servicer is grounded (e.g., metal, masonry wall)

36” (914 mm) Surface behind servicer is electrically non ---conductive (e.g., wood, fiberglass)

Special Check for sources of flue products within 10--- ft of unit fresh air intake hood

36” (914 mm) Side condensate drain is used

18” (457 mm) Minimum clearance

42” (1067 mm) Surface behind servicer is grounded (e.g., metal, masonry wall, another unit)

36” (914 mm) Surface behind servicer is electrically non ---conductive (e.g., wood, fiberglass)

C07457

Fig. 14 -- Curb Installation Detail (Typical)

C

D

B

A

C08337

Fig. 15 -- Service Clearance

28

APPLICATION DATA

Min operating ambient temp (cooling):

In mechanical cooling mode, your Carrier rooftop can

safely operate down to an outdoor ambient temperature of

40_F(4_C) and 25_F(--4_C), with an accessory winter

start kit. It is possible to provide cooling at lower outdoor

ambient temperatures by using less outside air,

economizers, and/or accessory low ambient kits.

Max operating ambient temp (cooling):

The maximum operating ambient temperature for cooling

mode is 115_F(46_C). While cooling operation above

115_F(46_C) may be possible, it could cause either a

reduction in performance, reliability, or a protective action

by the unit’s internal safety devices.

Min and max airflow (cooling mode):

To maintain safe and reliable operation of your rooftop,

operate within the cooling airflow limits. Operating above

the max may cause blow--off, undesired airflow noise, or

airflow related problems with the rooftop unit. Operating

below the min may cause problems with coil freeze--up.

Airflow:

All units are draw--though in cooling mode.

Outdoor air application strategies:

Economizers reduce operating expenses and compressor

run time by providing a free source of cooling and a

means of ventilation to match application changing needs.

In fact, they should be considered for most applications.

Also, consider the various economizer control methods

and their benefits, as well as sensors required to

accomplish your application goals. Please contact your

local Carrier representative for assistance.

Motor limits, break horsepower (BHP):

Sizing a rooftop

Bigger isn’t necessarily better. While an air conditioner

needs to have enough capacity to meet the load, it doesn’t

need excess capacity. In fact, having excess capacity

typically results in very poor part load performance and

humidity control.

Using higher design temperatures than ASHRAE

recommends for your locati on, adding “safety factors” to

the calculated load, and rounding up to the next largest

unit, are all signs of oversizing air conditioners.

Oversizing can cause short--cycling, and short cycling

leads to poor humidity control, reduced efficiency, higher

utility bills, drastic indoor temperature swings, excessive

noise, and increased wear and tear on the air conditioner.

Rather than oversizing an air conditioner, wise contractors

and engineers “right--size” or even slight ly undersize air

conditioners. Correctly sizing an air conditioner controls

humidity better; promotes efficiency; reduces utility bills;

extends equipment life, and maintains even, comfortable

temperatures.

Low ambient applications

When equipped with a Carrie r economizer, your rooftop

unit can cool your space by bringing in fresh, cool outside

air. In fact, when so equipped, accessory low--ambient kit

may not be necessary. In low ambient conditions, unless

the outdoor air is excessively humid or contaminated,

economizer--based “free cooling” is the preferred less

costly and energy conscious method.

In low ambient applications where outside air might not

be desired (such as contaminated or excessively humid

outdoor environments), your Carrier rooftop can operate

to ambient temperatures down to --20_F(--29_C) using t he

recommended accessory Motormaster low ambient

controller.

50TC

Due to Carrier’s internal unit design, air path, and

specially designed motors, the full horsepower (maximum

continuous BHP) band, as listed in Table 5, can be used

with the utmost confidence. There is no need for extra

safety factors, as Carrier’s motors are designed and

rigorously tested to use the entire, listed BHP range

without either nuisance tripping or premature motor

failure.

Winter start

Carrier’s winter start kit extends the low ambient limit of

your rooftop to 25_F(--4_C). The kit bypasses the low

pressure switch, preventing nuisance tripping of the low

pressure switch. Other low ambient precautions may still

be prudent.

29

SELECTION PROCEDURE (WITH 50TC*A07 EXAMPLE)

I. Determine cooling and heating loads.

Given:

Mixed Air Drybulb 80_F(27_C)

Mixed Air Wetbulb 67_F(19_C)

Ambient Drybulb 95_F(35_C)

TC

Load

SHC

Load

Vertical Supply Air 2100 CFM

External Static Pressure 0.66 in.wg

Electrical Characteristics 230--3--60

II. Make an initial guess at cooling tons.

Refrig. tons = TC

Refrig. tons = 69.0 / 12 = 5.75 tons

In this case, start by looking at the 50TC*A07.

50TC

III. Look up the rooftop’s TC and SHC.

Table 12 shows that, at the application’s supply air

CFM, mixed air and ambient temperatures, the

50TC*A07 supplies:

TC

SHC

= 73.7 MBH

Load

Load

= 54.4 MBH.

IV. Calculate the building Latent Heat Load.

LC

LC

=TC

Load

Load

Load

= 69.0 MBH -- 51.0 MBH = 18.0 MBH

/ 12 MBH per ton

Load

-- S H C

Load

69.0 MBH

51.0 MBH

V. Calculate RTU Latent Heat Capacity

LC = TC -- SHC

LC = 73.7 MBH -- 54.4 MBH = 19.3 MBH

VI. Compare RTU capaciti es to loads.

2,3

Compare the rooftop’s SHC and LC to the building’s

Sensible and Latent Heat Loads.

VII. Select factory options (FIOP)

Local code requires an economizer for any unit with

TC larger than 65.0 MBH.

VIII. Calculate the total static pressure.

External static pressure 0.66 in. wg

Sum of FIOP/Accessory static +0.14 in.

Total Static Pressure 0.80 in. wg

IX. Look up the Indoor Fan RPM & BHP.

Table 33 shows, at 2100 CFM & ESP= 0.8,

RPM = 1268 & BHP = 1.52

X. Determine electrical requirements

Table 52 shows the MCA and MOCP of a

50TC*A07 (without convenience outlet) as:

MCA = 30.5 amps & MOCP = 45 amps

Min. Disconnect Size: FLA = 30 & LRA = 157.

wg

LEGEND

BHP — Break horsepower

FLA — Full load amps

LC — Latent capacity

LRA — Lock rotor amp

MBH — (1,000) BTUH

MCA — Min. circuit ampacity

MOCP — Max. over --- current protection

RPM — Revolutions per minute

RTU — Rooftop unit

SHC — Sensible heat capacity

TC — Total capacity

NOTES:

1. Selection software by Carrier saves time by performing

many of the steps above. Contact your Carrier sales representative for assistance.

2. Selecting a unit with a SHC slightly lower than the

SHC

SHC’s will help control indoor humidity, and prevent temperature swings.

3. If the rooftop’s capacity meets the Sensible Heat Load,

butnottheLatentHeatLoad.

4. Indoor Fan Motor efficiency is available in Table 46. Use

the decimal form in the equation eg. 80% =.8.

is often better than oversizing. Slightly lower

Load

30

Loading...

Loading...