Came ZT6, ZT6C Manual

Control panel for BK220T, CBYT, CBXT

ZT6-ZT6C

INSTALLATION MANUAL

ENGLISH |

1 Symbols legend |

This symbol denotes notes to communicate to the user. |

|

|

This symbol denotes parts that require special attention. |

|

This symbol denotes parts that concern safety. |

2Limits of use and intended use

2.1Limits of use

The ZT6-ZT6C electrical switchboards, in the version with control and safety block buttons incorporated into the panel, were designed to control BK2200T automations, for moving CBXT and CBYT sliding gates and for controlling drop-curtain doors and sliding and swing gate systems.

Any use, other than the ones described above, and installations in methods other than those shown in this technical manual are considered prohibited.

Any use, other than the ones described above, and installations in methods other than those shown in this technical manual are considered prohibited.

WARNING - incorrect installation could cause serious injury. Follow the installation instructions carefully.

2.2 Intended uses

This manual was written specifically for a professional installer or other specifically trained person.

This manual was written specifically for a professional installer or other specifically trained person.

3 Reference standards

The product in question is subject to the following reference standards: EN 12978, UNI EN 954-1, CEI EN 60335-1, UNI EN

2453.

4Description

4.1Three phase/single-phase electrical switchboard

Electrical switchboard for gearmotors with single-phase 230V power supply or three-phase 230/400V power supply; frequency 50÷60 Hz. Fully designed and built by CAME Cancelli Automatici S.p.A. Box equipped with an air recirculation outlet. Guaranteed for 24 months if not tampered with.

4.2 Technical information

Electrical switchboard |

Protection level: IP54 |

|

Supply voltage: 230V / 400V - 60 Hz |

solation category: II |

|

Power rating: 750W |

||

Material: ABS |

||

Absorption at rest: 50 MA |

||

|

||

Maximum power accessories, 24V : 20 W |

Operating temperature: |

|

Maximum power accessories, 230V : 85 W |

|

|

|

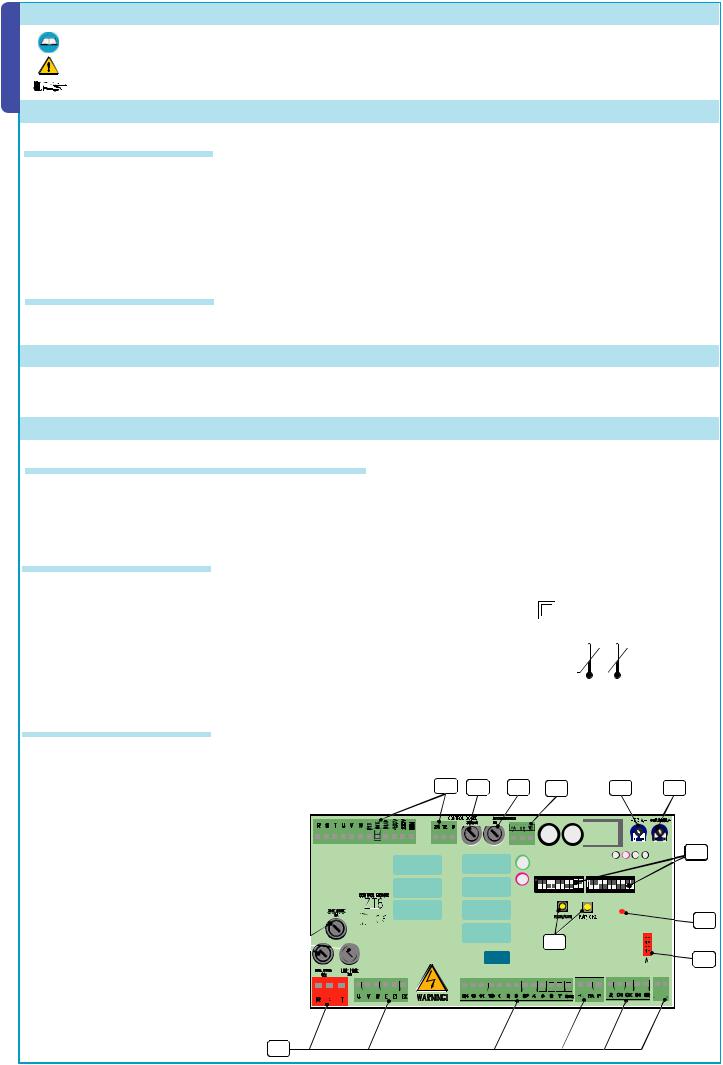

4.3 Primary components

1 |

“Functions selection” Dip switch |

|

|

2 |

2A |

F Accessories fuse |

|

3 |

315mA Control unit fuse |

|

|

4 |

8A |

F Line fuse |

T. |

5Radio frequency card connector (see table) point 5.10

6 Radio code signal LED

7 Connecting terminal boards

8Connecting terminal boards transformer

9 Radio code memorizing buttons

10 TCA Trimmer: automatic closure time adju-

10 TCA Trimmer: automatic closure time adju-

stment 11 Par. Op. trimmer: partial opening adjustment

All the data and information contained herein is considered subject to change at any time and at our discretion.

2

5 Installation

5 .1 Preliminary checks

.1 Preliminary checks

Before proceeding with installation, it is necessary to:

Before proceeding with installation, it is necessary to:

• Check that the point of attachment of the control panel is protected from shocks, the fastening surfaces are solid, and appropriate components (screws, plugs, etc) are used for fastening to the surface.

• Provide for an appropriate omni-polar disconnection device with a distance of more than 3 mm between the contacts, to shunt the power supply

Check that the connections inside the case executed for continuity of the protection circuit are allowed, provided they have supplementary isolation with respect to the other internal conducting parts.

Check that the connections inside the case executed for continuity of the protection circuit are allowed, provided they have supplementary isolation with respect to the other internal conducting parts.

discretion.ourat |

• Prepare adequate cable troughs and hoses for the electrical wires, to ensure protection against mechanical damage. |

|

time and |

5.2 Equipment and materials |

|

Be sure to have all the instruments and materials necessary to execute installation in utmost safety, in accordance with prevai- |

||

any |

||

ling standards. Here are a few examples. |

||

considered subject to change at |

||

5.3 Size and distances of fastening holes |

||

is |

|

|

informationandcontained herein |

||

|

t is best to use a fillister head Phillips screws, maximum diameter of 6 mm. |

|

All the data |

|

Holes are 20/21 mm.

Holes are 20/21 mm.

2 |

1 |

5 |

|

||

|

|

295

ENGLISH

3

ENGLISH

5.4 Minimum thickness and wires

Connections |

Cable type |

Cable length |

Cable length |

Cable length |

||||

<10 M |

0<20 M |

20<30 M |

||||||

|

|

|||||||

Power supply line, 230/400V 3F |

|

4G |

1,5mm |

4G |

2,5mm |

4G |

4mm |

|

Power supply line, 230V 2F |

|

3G |

1,5mm |

3G |

2,5mm |

3G |

4mm |

|

Motors, 230/400V 2F/3F |

|

4G |

1mm |

4G |

1,5mm |

4G |

2,5mm |

|

Motor, 24V |

|

2 x 1mm |

2 x 1,5mm |

2 x 2,5mm |

||||

Flashing lamp 230V |

|

2 x 0,5mm |

2 x 1mm |

2 x 1,5mm |

||||

Flashing lamp 24V |

|

2 x 0,5mm |

2 x 1mm |

2 x 1,5mm |

||||

Cycle/courtesy lights 230V |

|

3G |

0,5mm |

3G |

1mm |

3G |

1,5mm |

|

Power supply accessories 24V |

FROR CEI 20-22 |

2 x 0,5mm |

2 x 0,5mm |

2 x 1mm |

||||

Warning light 24V |

CEI EN 50267-2-1 |

2 x 0,5mm |

2 x 0,5mm |

2 x 1mm |

||||

Output 24V “in motion” |

|

2 x 0,5mm |

2 x 0,5mm |

2 x 1mm |

||||

Safety contacts |

|

2 x 0,5mm |

2 x 0,5mm |

2 x 0,5mm |

||||

N.O./N.C. control buttons |

|

2 x 0,5mm |

2 x 0,5mm |

2 x 0,5mm |

||||

End stop |

|

3 x 0,5mm |

3 x 1mm |

3 x 1,5mm |

||||

2nd motor control |

|

x 0,5mm |

x 0,5mm |

x 1mm |

||||

Antenna connection (max 50m) |

|

|

|

|

RG58 |

|

|

|

Encoder connection (max 30m) |

|

|

nsulated cable 2402C 22AWG |

|||||

N.B.: The cross section of cables with lengths other than those listed in the table must be evaluated based on the actual absorption of the devices connected, in accordance with the recommendations of the CEI EN 60204-1 standard.

For connections that require several loads on the same line (sequential), the sizes listed in the table must be reconsidered based on the actual absorption and distances.

All the data and information contained herein is considered subject to change at any time and at our discretion.

4

All the data and information contained herein is considered subject to change at any time and at our discretion.

5.5 ZT6 Electrical connections

ENGLISH

E4 10 11 TS 1 2 3 3P 4 5 6 7 2Mot |

FC |

FA |

F |

2 |

C1 CX B1 B2 |

|

|

R  S

S

R  S

S  T

T

U  W

W

V

V

E

EX

EX

E

E1

E1

Power supply: 230V (AC) single-phase (220-COM)

Power supply: 400V (AC) three-phase (380-COM) and 230V (AC) three-phase (220-COM)

Single-phase/three-phase motor 230/400V (AC) max.750 W

Cycle or courtesy lamp (230V) (Cycle lamp Dip 16 OFF Dip 17 ON)-(Courtesy light Dip 16 ON Dip 17 OFF) max 60 W.

Output 230V (AC) in motion (e.g. flashing lamp - max. 25W)

10  11

11

10  E4

E4

Power supply accessories 24V (AC

Output 24V (AC)

in motion

} |

2 |

Radio contact and/or control button |

|

(see dip-switch 2-3 sel.functions) |

|||

2 |

|||

|

7 |

|

|

|

Max.20 W totali |

Contact (N.C.) «Re-closing during |

|

|

|

||

|

CX |

opening»*Dip 8 OFF and Dip 9 OFF) |

|

|

Contact (N.C.) partial stop (Dip 8 OFF Dip 9 ON |

5 |

Warning light (24V-3W max.) |

|

11 |

“gate open” |

|

|

||

6 |

Warning light (24V-3W max.) |

|

11 |

||

“gate closed” |

||

|

||

1 |

Stop button (N.C.) |

|

2 |

||

|

||

2 |

|

|

3 |

Open button (N.O.) |

|

|

2 |

Contact (N.C.) of «Re-opening during |

|

C1 |

closure |

|

|

||

F |

End stop connection closes |

|

FC |

||

|

||

F |

|

|

FA |

End stop connection opens |

|

B1 |

Contact outlet (N.O.) Contact capacity: 5A |

|

B2 |

at 24V (DC) |

2 |

|

|

Connection of antenna |

|

3P |

Button for partial opening (N.O.) |

|

||

|

|

|||

2 |

Closure button (N.O.) |

2MOT |

Output for control of 2 coupled motors |

|

4 |

||||

|

||||

|

|

|

||

|

Position the exposed control buttons, located 1.5 m from the ground and distant from mobile parts of the automation |

|||

5

Loading...

Loading...