Burnham MPC User Manual

INSTALLATION, OPERATING AND SERVICE INSTRUCTIONS FOR

Model MPC™ MULTI-PASS

COMMERCIAL CAST IRON BOILER

3050579

For service or repairs to boiler, call your heating contractor. When seeking information on boiler, provide Boiler Model Number and Serial Number as shown on Rating Label.

Boiler Model Number |

Boiler Serial Number |

Installation Date |

_ - MPC _ _ - _ _ _ _ |

|

|

|

|

|

Heating Contractor |

|

Type of Fuel |

|

|

|

Address |

|

Phone Number |

|

|

|

|

|

Commercial Boilers |

||

101786-01R5-11/10 |

www.burnhamcommercialcastiron.com |

||

|

|

Price - $5.00 |

|

EQUIPMENT CHECK LIST

NOTE: Only factory packaged and firetested units are eligible to bear the UL listing mark.

This Equipment Check List has been provided so that the Installer can determine if all parts have been provided for the boiler ordered. It covers standard equipment for Knockdown boilers, 4 thru 18 section models. Optional equipment ordered will be in addition to, or in lieu of, equipment shown below.

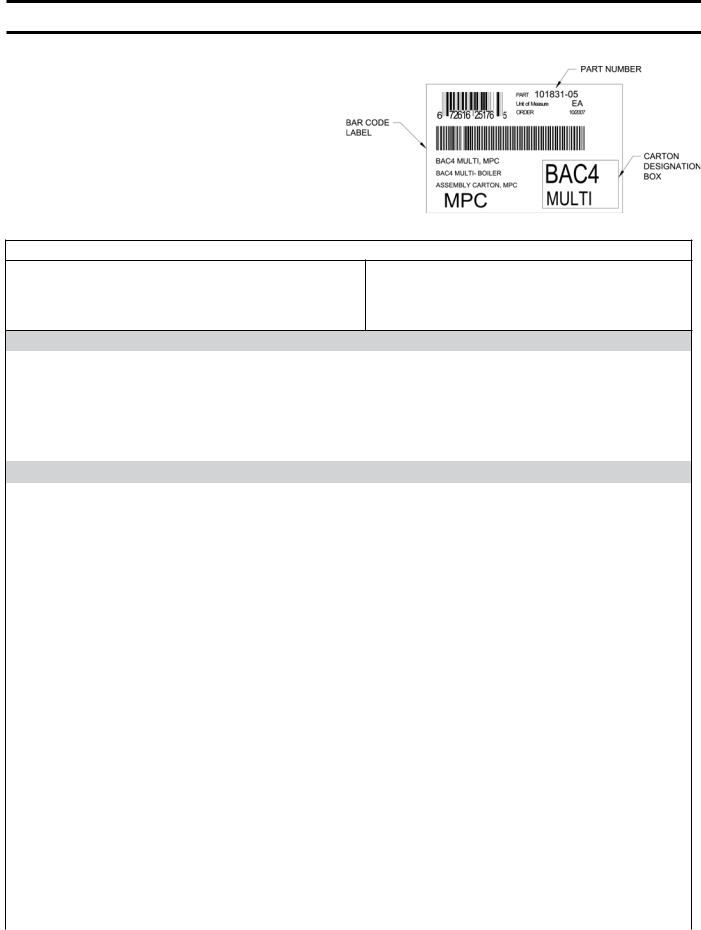

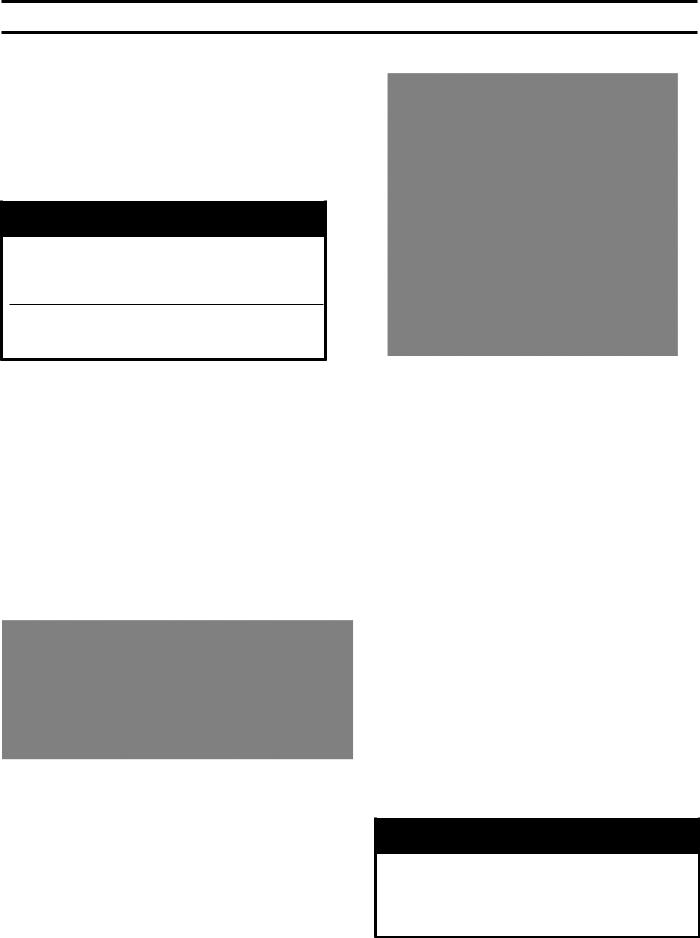

To simplify boiler assembly, instructions refer to carton |

|

designations located in box on Bar Code Labels, see Figure |

|

1a. When instructed, locate and open specified carton. |

|

Some cartons use all contents immediately and others use |

Figure 1a: Carton Identification |

parts throughout the assembly procedure until depleted. |

KNOCKDOWN BOILER - EQUIPMENT CHECK LIST

|

Carton |

|

|

Component Description |

Designation |

Part |

|

on Bar Code |

Number |

||

|

|||

|

Label |

|

|

|

|

|

Qty. Req’d. Per Boiler Size

4 Sect. |

5 Sect. |

6 Sect. |

7 Sect. |

8 Sect. |

9 Sect. |

10 Sect. |

11 Sect. |

12 Sect. |

13 Sect. |

14 Sect. |

15 Sect. |

16 Sect. |

17 Sect. |

18 Sect. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Castings (Shipped Loose - Field Assembly)

MPC Common Castings & Parts Skid |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

(Includes Front Section, Rear Section, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Burner Swing Door Assembly, |

CP-S |

101829-01 |

1 |

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|||

|

|

|

Rear Flue Collector and |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Miscellaneous Common Parts Carton) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

Center Section - Machined |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[Quantity shown shipped on separate |

MPC-C |

100657-01 |

2 |

|

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

|||

|

skid(s), Maximum 6 per skid] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Parts Cartons |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

BAC4 |

101831-01 |

1 |

|

|

|

|

1 |

1 |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

BAC5 |

101831-02 |

|

|

1 |

|

|

|

|

1 |

|

|

|

1 |

|

|

|

1 |

|

|

|

Boiler Assembly Cartons |

BAC6 |

101831-03 |

|

|

|

1 |

|

|

|

|

1 |

|

|

|

1 |

|

|

|

|

|

|

BAC7 |

101831-04 |

|

|

|

|

1 |

|

|

|

|

1 |

|

|

|

1 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

BAC4 Multi |

101831-05 |

|

|

|

|

|

1 |

|

|

|

|

1 |

1 |

1 |

1 |

|

2 |

|

|

|

|

BAC5 Multi |

101831-06 |

|

|

|

|

|

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

2 |

1 |

Supply & Return Manifold Carton |

S/RM CI |

103818-01 |

1 |

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|||

|

|

|

|

RWMT 4 RC |

102804-04 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RWMT 5 RC |

102804-05 |

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RWMT 6 RC |

102804-06 |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RWMT 7 RC |

102804-07 |

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RWMT 8 RC |

102804-08 |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RWMT 9 RC |

102804-09 |

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

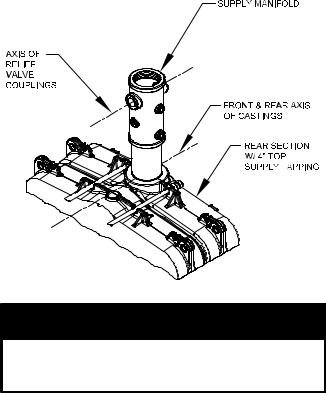

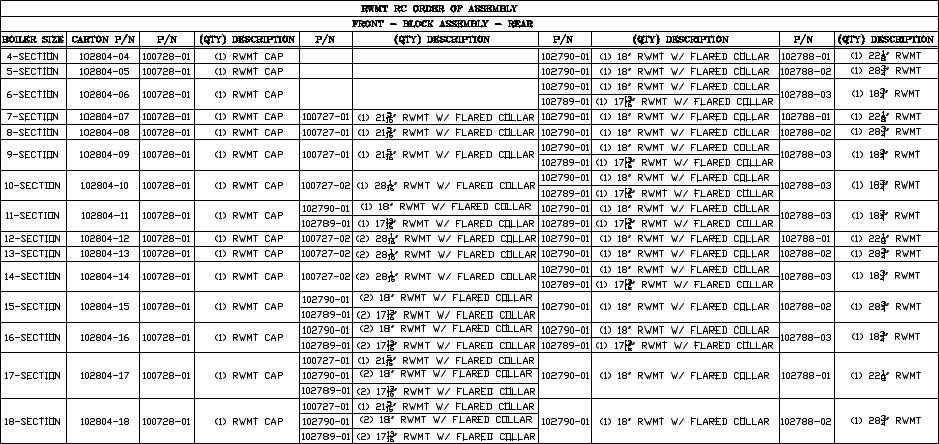

Return Water Mixing Tube Cartons |

RWMT 10 RC |

102804-10 |

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|||

RWMT 11 RC |

102804-11 |

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

||||

|

|

|

Restricted Clearance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

RWMT 12 RC |

102804-12 |

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

RWMT 13 RC |

102804-13 |

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

RWMT 14 RC |

102804-14 |

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

RWMT 15 RC |

102804-15 |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

RWMT 16 RC |

102804-16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

RWMT 17 RC |

102804-17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

RWMT 18 RC |

102804-18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

Jacket |

|

|

Jacket Frame (Front/Rear Rails) |

JF-1 |

101834-01 |

1 |

|

1 |

1 |

|

|

|

|

|

1 |

1 |

1 |

1 |

1 |

|

|

|

|

Jacket Frame |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Frame |

|

|

JF-2 |

101834-02 |

|

|

|

|

1 |

1 |

1 |

1 |

1 |

|

|

|

|

|

1 |

1 |

|

|

|

(Front/Center/Rear Rails) |

|

|

|

|

|

|

|

|

|

||||||||||

Cartons |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Jacket Frame (Center Rails) |

JF-3 |

101834-03 |

|

|

|

|

|

|

|

|

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

(Continued) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

KNOCKDOWN BOILER - EQUIPMENT CHECK LIST |

(Continued) |

|

|

|

|

|

|

||||||||||

|

Carton |

|

|

|

|

|

Qty. Req’d. Per Boiler Size |

|

|

|

|

||||||

Component Description |

Designation |

Part |

Sect.4 |

Sect.5 |

Sect.6 |

Sect.7 |

Sect.8 |

Sect.9 |

Sect.10 |

Sect.11 |

Sect.12 |

Sect.13 |

Sect.14 |

Sect.15 |

Sect.16 |

Sect.17 |

Sect.18 |

Code Label |

|

||||||||||||||||

|

on Bar |

Number |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parts Cartons (Continued)

|

Complete Heat Exchanger |

CPHW 4 |

101835-04 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CPHW 5 |

101835-05 |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Insulation Wrapper |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

CPHW 6 |

101835-06 |

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Front Heat Exchanger |

FTHW 1 |

101849-01 |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

FTHW 2 |

101849-02 |

|

|

|

|

1 |

1 |

|

|

1 |

1 |

1 |

|

|

1 |

1 |

|

Heat Exchanger |

Insulation Wrapper |

|

|

|

|

|

|

|

|

|||||||||

FTHW 3 |

101849-03 |

|

|

|

|

|

|

1 |

1 |

|

|

|

1 |

1 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

Insulation Bags |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Rear Heat Exchanger |

RRHW 1 |

101850-01 |

|

|

|

1 |

1 |

|

|

|

1 |

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

RRHW 2 |

101850-02 |

|

|

|

|

|

1 |

1 |

|

|

1 |

1 |

1 |

|

|

1 |

|

|

Insulation Wrapper |

|

|

|

|

|

|

|

|

|

||||||||

|

RRHW 3 |

101850-03 |

|

|

|

|

|

|

|

1 |

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Center Heat Exchanger |

CTHW 1 |

101851-01 |

|

|

|

|

|

|

|

|

1 |

1 |

|

|

|

1 |

1 |

|

Insulation Wrapper |

CTHW 2 |

101851-02 |

|

|

|

|

|

|

|

|

|

|

1 |

1 |

1 |

1 |

1 |

|

Jacket Common Panels |

JC-1 |

101836-01 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|

(Front and Rear) |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC2- 4 |

101837-04 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC2- 5 |

101837-05 |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC2- 6 |

101837-06 |

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC2- 7 |

101837-07 |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

JC2- 8 |

101837-08 |

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

JC2- 9 |

101837-09 |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

Jacket Uncommon Panels |

JC210 |

101837-10 |

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

(Outer Top Panels, Tie Bars, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC211 |

101837-11 |

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

Chaseway Channels & |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

JC212 |

101837-12 |

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

Internal Wiring Harness) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

JC213 |

101837-13 |

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

JC214 |

101837-14 |

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

JC215 |

101837-15 |

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

Jacket Panel |

|

JC216 |

101837-16 |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

Cartons |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC217 |

101837-17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

(4 Cartons |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

JC218 |

101837-18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

Required per |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Boiler) |

|

JC3- 4 |

101838-04 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC3- 5 |

101838-05 |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC3- 6 |

101838-06 |

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC3- 7 |

101838-07 |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

JC3- 8 |

101838-08 |

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

JC3- 9 |

101838-09 |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

Jacket Uncommon Top |

JC310 |

101838-10 |

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

JC311 |

101838-11 |

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

Panels Cartons |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

JC312 |

101838-12 |

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

JC313 |

101838-13 |

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

JC314 |

101838-14 |

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC315 |

101838-15 |

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

JC316 |

101838-16 |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

JC317 |

101838-17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC318 |

101838-18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

(Continued)

|

KNOCKDOWN BOILER - EQUIPMENT CHECK LIST |

|

(Continued) |

|

|

|

|

|

|

|

||||||||||

|

|

|

Carton |

|

|

|

|

|

Qty. Req’d. Per Boiler Size |

|

|

|

||||||||

Component Description |

|

Designation |

Part |

4 Sect. |

5 Sect. |

6 Sect. |

7 Sect. |

|

8 Sect. |

9 Sect. |

10 Sect. |

11 Sect. |

12 Sect. |

13 Sect. |

14 Sect. |

15 Sect. |

16 Sect. |

17 Sect. |

18 Sect. |

|

|

on Bar |

Number |

|

|||||||||||||||||

|

|

|

|

|||||||||||||||||

|

|

|

Code Label |

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parts Cartons (Continued) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

JC4- 4 |

101839-04 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC4- 5 |

101839-05 |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC4- 6 |

101839-06 |

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC4- 7 |

101839-07 |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JC4- 8 |

101839-08 |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

(Continued) |

|

|

JC4- 9 |

101839-09 |

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

Jacket Uncommon Side |

|

JC410 |

101839-10 |

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

JC411 |

101839-11 |

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

Jacket Panel Cartons |

Panel Cartons |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

JC412 |

101839-12 |

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

||

(4 Cartons Required |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

per Boiler) |

|

|

JC413 |

101839-13 |

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

JC414 |

101839-14 |

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

JC415 |

101839-15 |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

JC416 |

101839-16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

JC417 |

101839-17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

JC418 |

101839-18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

2FB-18 |

101840-01 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2FB-24 |

101840-02 |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2FB-31 |

101840-03 |

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Second Pass Flueway |

|

2FB-38 |

101840-04 |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2FB-45 |

101840-05 |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

Baffle Cartons |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

(Stainless Steel) |

|

2FB-51 |

101840-06 |

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

Flueway Baffle Cartons |

|

|

2FB-58 |

101840-07 |

|

|

|

|

|

|

|

1 |

1 |

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

2FB-65 |

101840-08 |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

|

|

|

|

2FB72 |

101840-09 |

|

|

|

|

|

|

|

|

|

1 |

|

|

1 |

|

|

|

|

|

|

2FB78 |

101840-10 |

|

|

|

|

|

|

|

|

|

|

1 |

1 |

|

|

|

|

|

Third Pass Flueway |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Baffle Carton |

|

3FB |

101852-01 |

1 |

1 |

1 |

1 |

|

1 |

1 |

1 |

1 |

|

|

|

|

|

|

|

|

(Cold Rolled Steel) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WT30-A |

101841-01 |

1 |

1 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 PSI Water Trim |

|

WT30-B |

101841-02 |

|

|

|

1 |

|

1 |

1 |

|

|

|

|

|

|

|

|

|

|

& Control Cartons |

|

WT30-C |

101841-03 |

|

|

|

|

|

|

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|

|

Water Trim and |

|

|

WT30-D |

101841-04 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

|

|

WT50-A |

101853-01 |

1 |

1 |

1 |

1 |

|

1 |

1 |

|

|

|

|

|

|

|

|

|

|

Control Cartons |

50 PSI Water Trim |

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

WT50-B |

101853-02 |

|

|

|

|

|

|

|

1 |

1 |

1 |

1 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

& Control Cartons |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

WT50-C |

101853-03 |

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

1 |

1 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

80 PSI Water Trim |

|

WT80-A |

101854-01 |

1 |

1 |

1 |

1 |

|

1 |

1 |

1 |

1 |

1 |

|

|

|

|

|

|

|

& Control Cartons |

|

WT80-B |

101854-02 |

|

|

|

|

|

|

|

|

|

|

1 |

1 |

1 |

1 |

1 |

1 |

Flue Outlet Damper Carton - 7” |

|

FODC7 |

102473-01 |

1 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Flue Outlet Damper Carton - 8” |

|

FODC8 |

102473-02 |

|

|

1 |

1 |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

Flue Outlet Damper Carton - 10” |

|

FODC10 |

102473-03 |

|

|

|

|

|

|

1 |

1 |

1 |

|

|

|

|

|

|

|

|

Flue Outlet Damper Carton - 12” |

|

FODC12 |

102473-04 |

|

|

|

|

|

|

|

|

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|

INSPECT SHIPMENT carefully for any signs of damage. All equipment is carefully manufactured, inspected and packed.

Our responsibility ceases upon delivery of Boiler to carrier in good condition. Any claims for damage or shortage in shipment must be filed immediately against the carrier by the consignee. No claims for variances or shortages will be allowed by Boiler Manufacturer, unless presented within thirty (30) days after receipt of equipment.

IMPORTANT INFORMATION -

READ and save these instructions for reference

All boilers must be installed in accordance with National, State and Local Plumbing, Heating and Electrical Codes and the regulations of the serving utilities. These Codes and Regulations may differ from this instruction manual. Authorities having jurisdiction should be consulted before installations are made.

In all cases, reference should be made to the following Standards:

USA BOILERS

A.Current Edition of American National Standard ANSI/NFPA 31, “Installation of Oil Burning Equipment”, for recommended installation practices.

B.Current Edition of National Fuel Gas Code, NFPA 54/ANSI Z223.1.

C.Current Edition of American National Standard ANSI/NFPA 211, “Chimneys, Fireplaces, Vents, and Solid Fuel Burning Appliances”, for venting requirements.

D.Current Edition of American Society of Mechanical Engineers ASME CSD-1, “Controls and Safety Devices forAutomatically Fired Boilers”, for assembly and operations of controls and safety devices.

E.All wiring on boilers installed in the USA shall be made in accordance with the National Electrical Code and/or Local Regulations.

CANADIAN BOILERS

A.Current Edition of Canadian Standards Association CSA B139, “Installation Code for Oil Burning Equipment”, for recommended Installation Practices.

B.The equipment shall be installed in accordance with the current Installation Code for Gas Burning Appliances and Equipment, CSA B149, and applicable Provincial Regulations for the class; which should be carefully followed in all cases.

Authorities having jurisdiction should be consulted before installations are made.

C.All wiring on boilers installed in Canada shall be made in accordance with the Canadian Electrical Code and/or Local Regulations.

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in death, serious injury or substantial property damage.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in moderate or minor injury or property damage.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death, serious injury or substantial property damage.

NOTICE

Indicates special instructions on installation, operation, or maintenance which are important but not related to personal injury hazards.

NOTICE

This boiler has a limited warranty, a copy of which is printed on the back of this manual.

It is the responsibility of the installing contractor to see that all controls are correctly installed and are operating properly when the installation is complete. The warranty for this boiler is valid only if the boiler has been installed, maintained and operated in accordance with these instructions.

DANGER

DO NOT store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal injury or loss of life. Failure to follow all instructions in the proper order can cause personal injury or death. Read and understand all instructions, including all those contained in component manufacturers manuals which are provided with the appliance before installing, starting-up, operating, maintaining or servicing this appliance. Keep this manual and literature in legible condition and posted near appliance for reference by owner and service technician.

This boiler requires regular maintenance and service to operate safely. Follow the instructions contained in this manual.

Installation,maintenance,andservicemustbeperformedonlybyanexperienced,skilledandknowledgeable installer or service agency.

All heating systems should be designed by competent contractors and only persons knowledgeable in the layout and installation of hydronic heating systems should attempt installation of any boiler.

It is the responsibility of the installing contractor to see that all controls are correctly installed and are operating properly when the installation is completed.

Installation is not complete unless a pressure relief valve is installed into the specified tapping on the supply manifold located on top and at rear of appliance - See Section III, Paragraph R, Item 3 of this manual for details.

All boiler builds, except boilers bearing the ULLabel, are suitable for installation on combustible flooring. Do not install boiler on carpeting. Do not operate on floors where heat affected material is below.

Do not tamper with or alter the boiler or controls. Retain your contractor or a competent serviceman to assure that the unit is properly adjusted and maintained.

Clean boiler at least once a year - preferably at the start of the heating season to remove soot and scale. The inside of the combustion chamber should also be cleaned and inspected at the same time.

Have Burner and Controls checked at least once a year or as may be necessitated. Do not operate unit with jumpered or absent controls or safety devices. Do not operate unit if any control, switch, component, or device has been subject to water.

This boiler is designed to operate with lower return water temperatures and avoid thermal shock and accumulation of condensate if operated per the following criteria:

•Minimum Return Water Temperature = 80°F

•Maximum Delta T Between Boiler Supply and Return = 80°F

•Minimum Supply Water Temperature = 130°F

Continued operation beyond these limitations will result in sustained condensing within the combustion chamber and potentially reduce boiler longevity and may result in premature boiler failure through thermal shock.

WARNING

Appliance materials of construction, products of combustion and the fuel contain alumina, silica, heavy metals, carbon monoxide, nitrogen oxides, aldehydes and/or other toxic or harmful substances which can cause death or serious injury and which are known to the state of California to cause cancer, birth defectsandotherreproductiveharm. Alwaysusepropersafetyclothing,respiratorsandequipmentwhen servicing or working nearby the appliance.

This boiler contains very hot water under high pressure. Do not unscrew any pipe fittings nor attempt to disconnect any components of this boiler without positively assuring the water is cool and has no pressure. Always wear protective clothing and equipment when installing, starting up or servicing this boiler to prevent scald injuries. Do not rely on the pressure and temperature gauges to determine the temperature and pressure of the boiler. This boiler contains components which become very hot when the boiler is operating. Do not touch any components unless they are cool.

This appliance must be properly vented and connected to an approved vent system in good condition. Do not operate boiler with the absence of an approved vent system.

This boiler needs fresh air for safe operation and must be installed so there are provisions for adequate combustion and ventilation air.

The interior of the venting and air intake systems must be inspected and cleaned before the start of the heating season and should be inspected periodically throughout the heating season for any obstructions. Clean and unobstructed venting and air intake systems are necessary to allow noxious fumes that could cause injury or loss of life to vent safely and will contribute toward maintaining the boiler’s efficiency.

This boiler is supplied with controls which may cause the boiler to shut down and not re-start without service. If damage due to frozen pipes is a possibility, the heating system should not be left unattended in cold weather; or appropriate safeguards and alarms should be installed on the heating system to prevent damage if the boiler is inoperative.

This boiler is designed to burn No. 2 fuel oil only. Do not use gasoline, crankcase drainings, or any oil containing gasoline. Never burn garbage or paper in this boiler. Do not convert to any solid fuel (i.e. wood, coal). Do not convert to any gaseous fuel (i.e. natural gas, LP). All flammable debris, rags, paper, wood scraps, etc., should be kept clear of the boiler at all times. Keep the boiler area clean and free of fire hazards.

Always keep the oil supply valve shut off if the burner is shut down for an extended period of time.

Probe and float type low water cutoff devices require annual inspection and maintenance. Refer to instructions in Section VI, Paragraph C for inspection and cleaning instructions.

NOTICE

Model MPC cast iron boilers are designed, built, marked and tested in accordance with the ASME Boiler and Pressure Vessel Code, Section IV, Heating Boilers. An ASME Data Label is factory applied to each MPC jacket, which indicates the boiler Maximum Allowable Working Pressure (MAWP). Each cast iron section is permanently marked with the MAWP listed on the boiler’s ASME Data Label. This value for the MPC is as follows:

MAWP, Water (USA and Canada) - 80 PSI

It is common and acceptable practice to install these boilers in lower pressure systems, below the boiler MAWP. Therefore, Burnham offers safety relief valves set at or below the MAWP of the boiler. See Page 12 for available safety relief valve set pressures.

Table of Contents |

|

SECTION I - GENERAL INFORMATION |

|

Dimensional Information.................................................................................................................. |

10 |

Ratings/Data....................................................................................................................................... |

12 |

Locating the Unit ............................................................................................................................... |

13 |

Air Supply/Venting............................................................................................................................. |

14 |

SECTION II - CAST IRON BLOCK ASSEMBLY INSTRUCTIONS (Knockdown Boiler) |

|

Knockdown Boiler w/ Factory Assembled Section......................................................................... |

17 |

Assembly of Sections, Manual Draw-up ......................................................................................... |

18 |

Assembly of Sections, Hydraulic Draw-up ..................................................................................... |

23 |

Hydrostatic Test ................................................................................................................................ |

24 |

SECTION III - BOILER ASSEMBLY INSTRUCTIONS (Knockdown Boiler) |

|

Install Common Parts to Block (Hinge Hardware, Flue Collector, Clean-out Covers, Etc.) ....... |

25 |

Install Supply and Return Manifolds ............................................................................................... |

27 |

Install Return Water Mixing Tube...................................................................................................... |

27 |

Install Jacket Support Frame to Block............................................................................................. |

30 |

Install Heat Exchanger Insulation..................................................................................................... |

37 |

Install Internal Wiring Harness Components ................................................................................. |

38 |

Install Jacket Top Corner Panels ..................................................................................................... |

43 |

Install Jacket Front and Rear Panels .............................................................................................. |

44 |

Install Jacket Top and Side Panels .................................................................................................. |

45 |

Install Burner Swing Door (BSD) ..................................................................................................... |

47 |

Install 2nd and 3rd Pass Flueway Baffles........................................................................................... |

49 |

Procedure to Close and Secure Burner Swing Door...................................................................... |

50 |

Install Burner Adapter Plate and Mount Burner (Burner Specific)................................................ |

50 |

Connecting Internal Wiring Harness to Burner Controls............................................................... |

51 |

Install Standard Water Trim and Control.......................................................................................... |

52 |

Install Optional Controls: |

|

• Probe LWCO............................................................................................................................. |

54 |

• High Limit Control w/ Manual Reset....................................................................................... |

54 |

• Low Fire Hold Control.............................................................................................................. |

54 |

• Low / High / Low Control or Modulating Control................................................................... |

55 |

Install Flue Outlet Damper Assembly............................................................................................... |

56 |

Install Optional Burner Swing Door Cover Split Jacket Panels..................................................... |

57 |

SECTION IV - INSTALLATION INSTRUCTIONS |

|

Packaged Boiler - Shipping Information.......................................................................................... |

58 |

Boiler Piping - Heating Applications................................................................................................ |

58 |

Boiler Piping - Domestic Hot Water.................................................................................................. |

64 |

Relief Valve Piping............................................................................................................................. |

64 |

Electric Wiring.................................................................................................................................... |

64 |

SECTION V - OPERATING INSTRUCTIONS |

|

Filling System..................................................................................................................................... |

65 |

Adjusting Controls............................................................................................................................. |

65 |

Adjusting Burner................................................................................................................................ |

65 |

Test Controls...................................................................................................................................... |

66 |

Initial Cleaning, Water Boilers........................................................................................................... |

66 |

Frequent Water Addition................................................................................................................... |

67 |

Oxygen Corrosion.............................................................................................................................. |

67 |

Table of Contents (continued)

SECTION VI - SERVICE INSTRUCTIONS |

|

Cleaning Boiler Heating Surfaces.................................................................................................... |

68 |

Maintenance of Low Water Cutoff Devices...................................................................................... |

69 |

Checking Burner & Controls............................................................................................................. |

70 |

Lubrication.......................................................................................................................................... |

70 |

General Maintenance Considerations.............................................................................................. |

70 |

Attention to Boiler While Not in Operation...................................................................................... |

70 |

Recommended Periodic Testing....................................................................................................... |

71 |

SECTION VII - BURNER SPECIFICATIONS |

|

Beckett Burners (Tables XIIIa and XIIIb).......................................................................................... |

73 |

Power Flame Burners (Tables XIVa, XIVb and XIVc)....................................................................... |

74 |

SECTION VIII - REPAIR PARTS |

|

Regional Office Directory.................................................................................................................. |

76 |

Cast Iron Section Assembly.............................................................................................................. |

76 |

Common Bare Boiler Components.................................................................................................. |

78 |

Front & Center Section Frame Rail Assembly................................................................................. |

82 |

Rear Section Frame Rail Assembly.................................................................................................. |

84 |

Return Water Mixing Tube Assembly............................................................................................... |

86 |

Heat Exchanger Insulation Wrapper................................................................................................ |

88 |

Internal Wiring Harness Components.............................................................................................. |

90 |

Jacket Panel Assembly...................................................................................................................... |

92 |

2nd and 3rd Pass Flueway Baffles....................................................................................................... |

96 |

Standard Water Trim and Controls................................................................................................... |

98 |

Optional Working Pressure Trim.................................................................................................... |

100 |

Optional Controls............................................................................................................................. |

102 |

APPENDIX A - LIST OF FIGURES................................................................................................................ |

104 |

APPENDIX B - LIST OF TABLES.................................................................................................................. |

107 |

WARRANTY................................................................................................................................ |

REAR COVER |

10

* Wiring harness shown in this location for illustration purposes - typically, wiring harness leads will exit jacket on same side as BSD hinges.

Figure 1b: Dimensional Information

SECTION I - GENERAL INFORMATION

Table I: Dimensional Information

|

Number |

|

* Burner Dimension B (Inches) |

Minimum Flue |

Vent (Flue Outlet |

Approx. Weight of |

Approx. |

||||

Boiler |

Dim. A |

Beckett |

Power Flame |

Baffle Installation |

Damper) |

Shipping |

|||||

of |

Sections - LBS. |

||||||||||

Model |

(Inches) |

|

|

|

|

Clearance Dim. C |

Connection Size |

Weight - LBS. |

|||

Sections |

CF |

CG |

C |

JR |

(Block Assy.) |

||||||

|

|

(Inches) |

Dim. D (Inches) |

(KD Boiler) |

|||||||

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

MPC4 |

4 |

33-3/4 |

10-1/4 |

20-3/4 |

29-5/8 |

23 |

35 |

7” |

1875 |

2370 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC5 |

5 |

40-1/2 |

12-1/4 |

21-3/4 |

29-5/8 |

23 |

35 |

7” |

2321 |

2821 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC6 |

6 |

47-1/4 |

20-1/2 |

28-1/2 |

29-5/8 |

23 |

41 |

8” |

2767 |

3272 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC7 |

7 |

54 |

20-1/2 |

28-1/2 |

29-5/8 |

23 |

48 |

8” |

3213 |

3733 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC8 |

8 |

60-3/4 |

21 |

29 |

34-5/8 |

25-3/4 |

55 |

8” |

3659 |

4194 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC9 |

9 |

67-1/2 |

21 |

29 |

34-5/8 |

25-3/4 |

61 |

10” |

4105 |

4655 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC10 |

10 |

74-1/4 |

21 |

29 |

34-5/8 |

25-3/4 |

68 |

10” |

4551 |

5116 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC11 |

11 |

81 |

22-1/2 |

29 |

34-5/8 |

25-3/4 |

68 |

10” |

4997 |

5577 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC12 |

12 |

87-7/8 |

22-1/2 |

29-3/8 |

34-5/8 |

--- |

82 |

10” |

5443 |

6073 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC13 |

13 |

94-5/8 |

22-1/2 |

29-3/8 |

34-5/8 |

--- |

88 |

12” |

5889 |

6544 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC14 |

14 |

101-3/8 |

22-1/2 |

29-3/8 |

34-5/8 |

--- |

88 |

12” |

6335 |

7015 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC15 |

15 |

108-1/8 |

22-1/2 |

29-3/8 |

39-1/2 |

--- |

82 |

12” |

6781 |

7486 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC16 |

16 |

114-7/8 |

26-3/8 |

29-3/8 |

39-1/2 |

--- |

75 |

12” |

7227 |

7957 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC17 |

17 |

121-5/8 |

26-3/8 |

29-3/8 |

39-1/2 |

--- |

75 |

12” |

7673 |

8438 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC18 |

18 |

128-3/8 |

26-3/8 |

29-3/8 |

39-1/2 |

--- |

68 |

12” |

8119 |

8919 |

|

|

|

|

|

|

|

|

|

|

|

|

|

* Burner control panel configuration may change this dimension.

11

|

|

|

|

|

|

|

TABLE II: Ratings/Data |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model MPC™ Boilers |

|

|

|

|

|

|

|

|

|

|||

|

(1) |

|

|

(3) |

|

|

(2) |

|

|

|

|

|

(4) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ModelBoiler |

HorsepowerBoiler |

(GPH)Oil |

(MBH)Oil |

(MBH)Gas |

OutputGross(MBH) |

I=B=RNetRating (MBH) |

Combustion |

|

SurfaceHeating Ft.)(Sq. |

FurnaceNetVolume Ft.)(Cu. |

inPressureFirebox Wtr.(InchesColumn) |

ContentWater (Gallons) |

WeightBoiler (LBS.)w/Water |

(FlueVentOutlet Damper)Dia. (Inches) |

|

|

%-Oil |

%-Gas |

|

|||||||||||||

|

|

|

Burner Input |

|

|

Efficiency |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC4 |

12.7 |

3.55 |

497 |

500 |

424 |

369 |

89.0 |

86.3 |

|

75.0 |

7.1 |

0.10 |

63 |

2820 |

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC5 |

19.5 |

5.50 |

770 |

773 |

652 |

567 |

88.8 |

86.1 |

|

95.3 |

9.1 |

0.19 |

78 |

3396 |

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC6 |

25.0 |

7.10 |

994 |

995 |

837 |

728 |

88.7 |

86.0 |

|

115.5 |

11.0 |

0.28 |

93 |

3972 |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC7 |

30.6 |

8.70 |

1218 |

1216 |

1023 |

890 |

88.7 |

86.0 |

|

135.8 |

12.9 |

0.34 |

108 |

4558 |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC8 |

36.1 |

10.2 |

1428 |

1438 |

1209 |

1051 |

88.6 |

85.9 |

|

156.1 |

14.8 |

0.39 |

123 |

5144 |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC9 |

41.7 |

11.8 |

1652 |

1660 |

1395 |

1213 |

88.6 |

85.9 |

|

176.4 |

16.7 |

0.45 |

137 |

5721 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC10 |

47.2 |

13.4 |

1876 |

1881 |

1580 |

1374 |

88.6 |

85.9 |

|

196.6 |

18.6 |

0.50 |

152 |

6307 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC11 |

52.8 |

15.0 |

2100 |

2103 |

1766 |

1536 |

88.5 |

85.9 |

|

216.9 |

20.6 |

0.66 |

167 |

6893 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC12 |

58.3 |

16.6 |

2324 |

2325 |

1951 |

1697 |

88.5 |

85.8 |

|

237.2 |

22.5 |

0.82 |

182 |

7489 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC13 |

63.8 |

18.2 |

2548 |

2547 |

2137 |

1858 |

88.5 |

85.8 |

|

257.5 |

24.4 |

0.98 |

196 |

8077 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC14 |

69.4 |

19.8 |

2772 |

2769 |

2322 |

2019 |

88.5 |

85.8 |

|

277.7 |

26.3 |

1.14 |

211 |

8673 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC15 |

74.9 |

21.5 |

3010 |

2991 |

2508 |

2181 |

88.4 |

85.8 |

|

298.0 |

28.2 |

1.30 |

226 |

9269 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC16 |

80.5 |

23.0 |

3220 |

3213 |

2694 |

2343 |

88.4 |

85.8 |

|

318.3 |

30.2 |

1.30 |

241 |

9865 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC17 |

86.0 |

24.5 |

3430 |

3435 |

2880 |

2504 |

88.4 |

85.8 |

|

338.6 |

32.1 |

1.40 |

256 |

10470 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPC18 |

91.6 |

26.0 |

3640 |

3657 |

3065 |

2665 |

88.4 |

85.8 |

|

358.8 |

34.0 |

1.50 |

270 |

11068 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(1)Suffix “N” indicates natural gas-fired, suffix “P” indicates LP gas-fired, “O” indicates oil-fired, “C” indicates combination natural gas/oil-fired, “D” indicates combination LP gas/oil-fired.

(2)I=B=R net ratings shown are based on 1.15 piping and pickup factor for water.

Consult manufacturer for installations having unusual piping and pickup requirements, such as intermittent system operation, extensive piping systems, etc.

(3)The I=B=R burner capacity in GPH is based on oil having a heat value of 140,000 BTU per gallon.

(4)Boiler ratings are based on 13.2% CO2 (oil) and 10.2% CO2 (natural gas) and +.10” water column pressure at boiler flue outlet.

Ratings shown above apply at altitudes up to 1000 feet on oil and 2000 feet on gas. For altitudes above those indicated, the ratings should be reduced at the rate of 4% for each 1000 feet above sea level.

Safety Relief Valve Set Pressure: Standard - 50 PSI; Optional - 30 PSI, 80 PSI

12

SECTION I - GENERAL INFORMATION (Continued)

A.INSPECT SHIPMENT carefully for any signs of damage.

1.ALL EQUIPMENT is carefully manufactured, inspected and packed. Our responsibility ceases upon delivery of crated Boiler to the carrier in good condition.

2.ANY CLAIMS for damage or shortage in shipment must be filed immediately against the carrier by the consignee. No claims for variances from,

or shortage in orders, will be allowed by the manufacturer unless presented within thirty (30) days after the receipt of goods.

B.LOCATE THE UNIT

NOTICE

Recommended clearance for service may be reduced to minimum clearance to combustible material. However, increased service and maintenance difficulty will result.

1.RECOMMENDED SERVICE CLEARANCE

-Locate the unit in the boiler room so as to provide ease of venting and adequate clearance for maintenance, serviceability, and installation of piping. Refer to Figure 1b and Table 1 for boiler dimensional data.

from Jacket Front Panel:

•Provide 54” service clearance for removal, maintenance, and servicing of burner and controls.

•Provide service clearance for removal of baffles to perform annual cleaning of

flueways, refer to Table I, Dimension “C”.

From Jacket Rear Panel:

•Provide a minimum service clearance from the boiler jacket for access to boiler supply and return piping, relief valve, drain valve, flue collector clean-out covers, vent piping and optional flue damper assembly. See

Table III.

Table III: Recommended Rear Service Clearance

Flue Outlet Size |

Combustible or Non-Combustible |

|

Surfaces |

||

|

||

|

|

|

7” Dia. |

36 |

|

8” Dia. |

36 |

|

10” Dia. |

36 |

|

12” Dia. |

36 |

From Jacket Left Side Panel:

•Provide clearance per Table I, Dimension ‘B’, for burner swing door (BSD), opened fully with burner mounted, otherwise 12” with burner removed.

•18” access clearance to service rear of boiler if right side clearance is less than 12”.

•12” minimum if right side clearance is 18” or larger to access and service rear of boiler.

From Jacket Right Side Panel:

•See Table I, Dimension ‘B’ if BSD is hinged to swing to right side with burner mounted, otherwise 12” minimum if left side clearance is 18” or larger to access and service rear of boiler.

From Jacket Top Panel:

•Provide a minimum clearance from the boiler jacket of 24”.

2.FOR MINIMUM CLEARANCES to combustible materials, See Table IV or Table V.

Table IV: Minimum Installation Clearances To

Combustible Materials (Inches) per

ANSI/NFPA 31 (Knockdown/Non-UL

Packaged Boiler)

|

|

|

C |

|

|

|

A |

B |

Chimney |

D |

E |

Boiler |

Above |

Front |

Connector |

Rear |

Sides |

|

|

|

|

|

|

MPC |

6 |

24 |

18 |

6 |

6 |

Note: See Table III for recommended service clearance to access rear of boiler.

NOTE 1: Listed clearances comply with American National Standard ANSI/NFPA 31, Installation of Oil Burning Equipment.

NOTE 2: MPC Series boilers can be installed in rooms with clearances from combustible material as listed above. Listed clearances cannot be reduced for alcove or closet installations.

NOTE 3: For reduced clearances to combustible material, protection must be provided as described in the above ANSI/NFPA 31 Standard.

13

Table V: Minimum Installation Clearances To

Combustible Materials (Inches) per

UL726 (Packaged / Firetested Boiler)

|

|

|

C |

|

|

|

|

A |

B |

Chimney |

D |

E |

F |

Boiler |

Above |

Front |

Connector |

Rear |

Sides |

Below |

|

|

|

|

|

|

|

MPC |

18 |

48 |

18 |

18 |

18 |

NC * |

* NC - Noncombustible Flooring

Note: See Table III for recommended service clearance to access rear of boiler.

NOTE 1: Listed clearances comply with UL 726, Standard for Oil-Fired Boiler Assemblies.

NOTE 2: MPC Series boilers can be installed in rooms with clearances from combustible material as listed above. Listed clearances cannot be reduced for alcove or closet installations.

3.PROVIDE ADEQUATE FOUNDATION for the unit. Refer to Figure 2.

WARNING

All boiler builds, except boilers bearing the UL Label, are suitable for installation on combustible floor. Do not install boiler on carpeting.

Floor construction should have adequate load bearing characteristics to bear the weight of the boiler filled with water (see

Table 1). A boiler foundation similar to the one shown in Figure 2 is recommended if the boiler room floor is weak or uneven or if a water condition exists.

4.PROVIDE AIR SUPPLY AND VENTILATION to accommodate proper combustion.

WARNING

Failure to supply adequate air to the boiler will result in unsafe boiler operation.

For commercial and industrial equipment, permanent facilities for supplying an ample amount of outside air shall be provided in accordance with the following.

For boiler rooms adjacent to outside walls, and where combustion air is provided by natural ventilation from the outside, there shall be a permanent air supply inlet having a total free area of not less than 1 sq. in. per 4,000 Btu per hr. (35 sq. in. per gal. per hr.) (5.5 cm2 per kw.) of total input rating of the burner or burners and in no case less than 35 sq. in. (0.425 m2).

For boiler rooms not adjacent to outside walls, the combustion air shall be supplied in a manner acceptable to the authority having jurisdiction.

Figure 2: Boiler Foundation

14

a.In the absence of local requirements, the confined space shall be provided with two permanent openings, one in or near the top of the room and one near the bottom. The openings shall communicate by means of ducts, with the outdoors or to such spaces (crawl or attic) that communicate with the outdoors.

i.Where communicating by means of vertical ducts, each opening shall have a free area of not less than 1 sq. in. per 4,000 Btuh (35 sq. in. per gph.) (5.5 cm2 per kw) of total input rating of all appliances in the enclosure.

ii.If horizontal ducts are used, each opening shall have a free area of not less than 1 sq. in. per 2,000 Btuh (70 sq. in. per gph.) (11 cm2 per kw) of total input of all appliances in the enclosure.

5.CHIMNEY OR VENT (Be sure to read below WARNINGS.)

The Model MPC™ Series boiler is designed for forced draft firing and may be used with a conventional natural draft stack (15’ minimum height) or a stub vent, sometimes called a diesel stack (see Figure 3a). See Table I for the proper vent outlet size. For low silhouette vent

terminations, see Figure 3b. Draft controls are not normally required, although they may be used on installations where a natural draft stack is used or on multiple boiler installations with a common stack. For proper operation, boiler must maintain positive pressure of 0.1” W.C. at the breech in the cast iron flue collector during burner high fire operation (see breeching pressure sensing port in Figure 1b). To obtain the above, a factory supplied MPC Flue Outlet Damper Assembly (see Page 56 for details) must be attached directly to the Rear Flue Collector Outlet.

If the venting system is designed for positive or forced draft venting, the boiler, vent connector and stack will operate under positive pressure. Gas tight vent systems designed for pressure systems must

Figure 3a: MPC with Rear Outlet Vent

be used to prevent flue by-product leakage. The vent height is usually limited to prevent negative draft, typically three (3) feet above the roof line (see Figure 3a). The damper shall be adjusted to maintain a positive pressure of 0.1” W.C. at the flue outlet during burner high fire operation.

If the venting system is designed for negative pressure (natural draft), the boiler still operates with positive pressure in the chamber and up to the fixed damper on the flue collar. However, if the venting system is larger than what is required, the stack will provide a surplus draft (or negative pressure) that may require the use of a barometric damper to maintain the positive 0.1” W.C. pressure

at the flue outlet. Multiple forced draft boiler stacks should always be designed as negative to ensure the products of combustion do not exit a boiler that is not firing.

NOTICE

When an MPC gas fired boiler is connected to a venting system that is designed so that it will operate under a negative pressure, the use of Type B, or other manufactured vent systems designed for negative pressure is acceptable.

When an MPC oil fired or combination gas/oil fired boiler is connected to a venting system that is designed so that it will operate under a negative pressure, the use of Type L or other manufactured vent systems designed for negative pressure is acceptable.

Unlined masonry chimneys are not acceptable. Lined masonry chimneys are acceptable with the appropriate vent connectors using materials described above.

MPC oil or combination gas/oil boilers should be vented using Type L vent, regardless if the vent pressure is positive or negative.

15

WARNING

Single wall Type C vent material is not approved for MPC boiler venting. When an MPC gas fired boiler is connected to a venting system that is designed so that it will operate under a negative pressure, manufactured vent systems, designed and approved for positive pressure application per UL1738, must be used (for example, Van-Packer Model CS, Protech Model FasNSeal / FasNSeal W2, Heatfab

Saf-T-Vent or equivalent).