Burnham ALP105, ALP080, ALP285, ALP210, ALP150 User Manual

...

101602-01R2-9/08

Price - $5.00

DNAGNITAREPO,NOITALLATSNI

ROFSNOITCURTSNIECIVRES

™ENIPLA

YCNEICIFFEHGIHGNISNEDNOC

TNEVTCERID

RELIOBRETAWTOHDERIF-SAG

As an ENERGY STAR

®

Partner, Burnham Hydronics has determined that the Alpine™ Series meets the ENERGY

STAR

®

guidelines for energy efciency established by the United States Environmental Protection Agency (EPA).

WaRning: Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury, or loss of life. For assistance or additional information, consult a qualied installer, service agency or the

gas supplier. This boiler requires a special venting system. Read these instructions carefully before installing.

2

IMPORTANT INFORMATION - READ CAREFULLY

NOTE: The equipment shall be installed in accordance with those installation regulations enforced in the area where the

installation is to be made. These regulations shall be carefully followed in all cases. Authorities having jurisdiction

shall be consulted before installations are made.

All wiring on boilers installed in the USA shall be made in accordance with the National Electrical Code and/or local regulations.

All wiring on boilers installed in Canada shall be made in accordance with the Canadian Electrical Code and/or local regulations.

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels,

or to important information concerning product life.

The City of New York requires a Licensed Master Plumber supervise the installation of this product.

The Massachusetts Board of Plumbers and Gas Fitters has approved the Alpine™ Series boiler. See the Massachusetts Board of

Plumbers and Gas Fitters website, http://license.reg.state.ma.us/pubLic/pb_pre_form.asp for the latest Approval Code or ask

your local Sales Representative.

The Commonwealth of Massachusetts requires this product to be installed by a Licensed Plumber or Gas Fitter.

DangER

indicates an imminently hazardous situation

which, if not avoided, will result in death, serious

injury or substantial property damage.

CaUTiOn

indicates a potentially hazardous situation which,

if not avoided, may result in moderate or minor

injury or property damage.

WaRning

indicates a potentially hazardous situation which,

if not avoided, could result in death, serious injury

or substantial property damage.

nOTiCE

indicates special instructions on installation,

operation, or maintenance which are important

but not related to personal injury hazards.

DangER

DO NOT store or use gasoline or other ammable vapors or liquids in the vicinity of this or any other

appliance.

if you smell gas vapors, nO nOT try to operate any appliance - DO nOT touch any electrical switch or use

any phone in the building. immediately, call the gas supplier from a remotely located phone. Follow the gas

supplier’s instructions or if the supplier is unavailable, contact the re department.

3

WaRning

This boiler requires regular maintenance and service to operate safely. Follow the instructions contained

in this manual.

improper installation, adjustment, alteration, service or maintenance can cause property damage, personal

injury or loss of life. Read and understand the entire manual before attempting installation, start-up

operation,

or service. installation and service must be performed only by an experienced, skilled, and

knowledgeable installer or service agency

This boiler must be properly vented.

This boiler needs fresh air for safe operation and must be installed so there are provisions for adequate

combustion and ventilation air.

The interior of the venting system must be inspected and cleaned before the start of the heating season

and

should be inspected periodically throughout the heating season for any obstructions. a clean and

unobstructed venting system is necessary to allow noxious fumes that could cause injury or loss of life

to vent safely and will contribute toward maintaining the boiler’s efciency.

installation is not complete unless a pressure relief valve is installed into the tapping located on left side

of appliance. - See the Water Piping and Trim Section of this manual for details.

This boiler is supplied with safety devices which may cause the boiler to shut down and not re-start

without

service. if damage due to frozen pipes is a possibility, the heating system should not be left

unattended in cold weather; or appropriate safeguards and alarms should be installed on the heating

system to prevent damage if the boiler is inoperative.

This boiler contains very hot water under high pressure. Do not unscrew any pipe ttings nor attempt

to disconnect any components of this boiler without positively assuring the water is cool and has no

pressure. Always wear protective clothing and equipment when installing, starting up or servicing this

boiler to prevent scald injuries. Do not rely on the pressure and temperature gauges to determine the

temperature and pressure of the boiler. This boiler contains components which become very hot when

the boiler is operating. Do not touch any components unless they are cool.

Boiler materials of construction, products of combustion and the fuel contain alumina, silica, heavy metals,

carbon monoxide, nitrogen oxides, aldehydes and/or other toxic or harmful substances which can cause

death or serious injury and which are known to the state of California to cause cancer, birth defects and

other reproductive harm. Always use proper safety clothing, respirators and equipment when servicing

or working nearby the appliance.

Failure to follow all instructions in the proper order can cause personal injury or death. Read all instruc-

tions, including all those contained in component manufacturers manuals which are provided with the

boiler before installing, starting up, operating, maintaining or servicing.

Keep boiler area clear and free from combustible materials, gasoline and other ammable vapors or

liquids.

a

ll cover plates, enclosures and guards must be in place at all times.

nOTiCE

This boiler has a limited warranty, a copy of which is printed on the back of this manual. it is the responsibility

of the installing contractor to see that all controls are correctly installed and are operating properly when the

installation is complete.

4

Table of Contents

I. Product Description, Specifications

and Dimensional Data....................4

II. Pre-Installation ...............................8

III. Unpacking Boiler ...........................9

IV. Venting ......................................... 10

V. Condensate Disposal .................... 29

VI. Water Piping and Trim .................31

VII. Gas Piping ....................................46

VIII. Electrical .......................................49

IX. Boiler Stacking ............................. 56

X. Modular Installation ....................58

XI. System Start-up ............................66

XII. Operation .....................................72

XIII. Service and Maintenance .............. 84

XIV. Troubleshooting ...........................88

XV. Repair Parts ..................................91

I. Product Description, Specications and Dimensional Data

Alpine™ Series boilers are condensing high efciency

gas-red direct vent hot water boilers designed for use

in forced hot water space or space heating with indirect

domestic hot water heating systems, where supply water

temperature does not exceed 210°F. These boilers have

special coil type stainless steel heat exchangers, constructed,

tested and stamped per Section IV ‘Heating Boilers’ of

ASME Boiler and Pressure Vessel Code, which provide a

maximum heat transfer and simultaneous protection against

ue gas product corrosion. These boilers are not designed

for use in gravity hot water space heating systems or

systems containing signicant amount of dissolved oxygen

(swimming pool water heating, direct domestic hot water

heating, etc.).

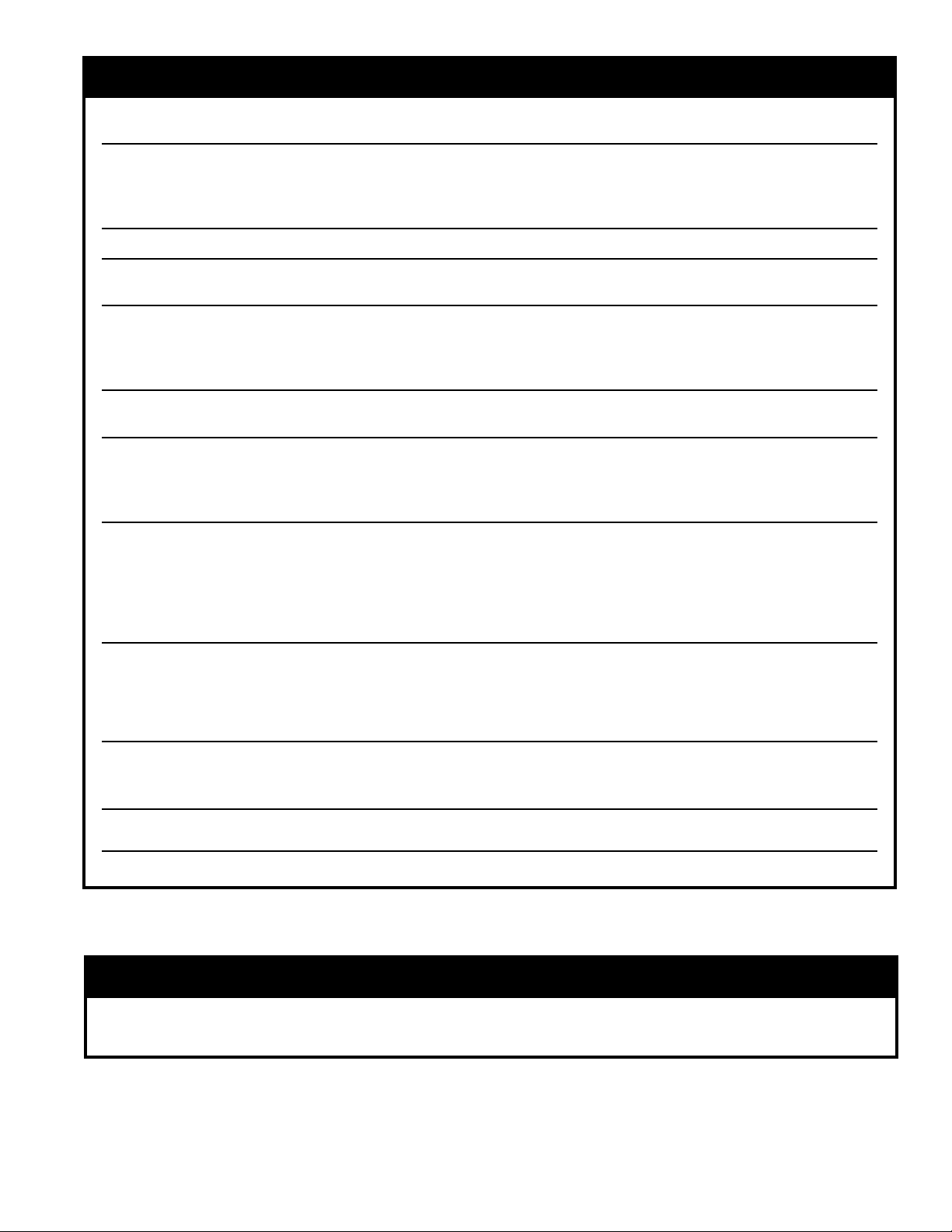

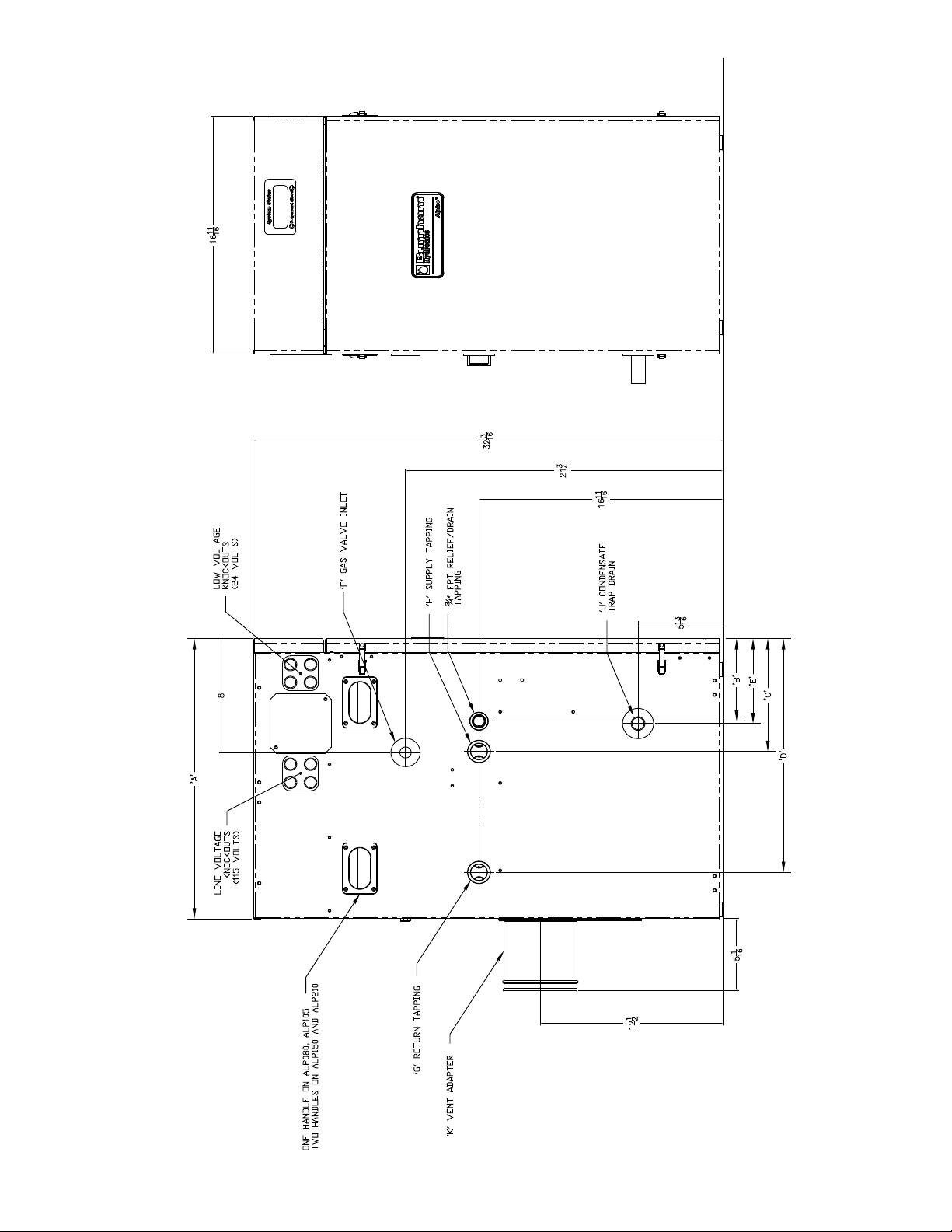

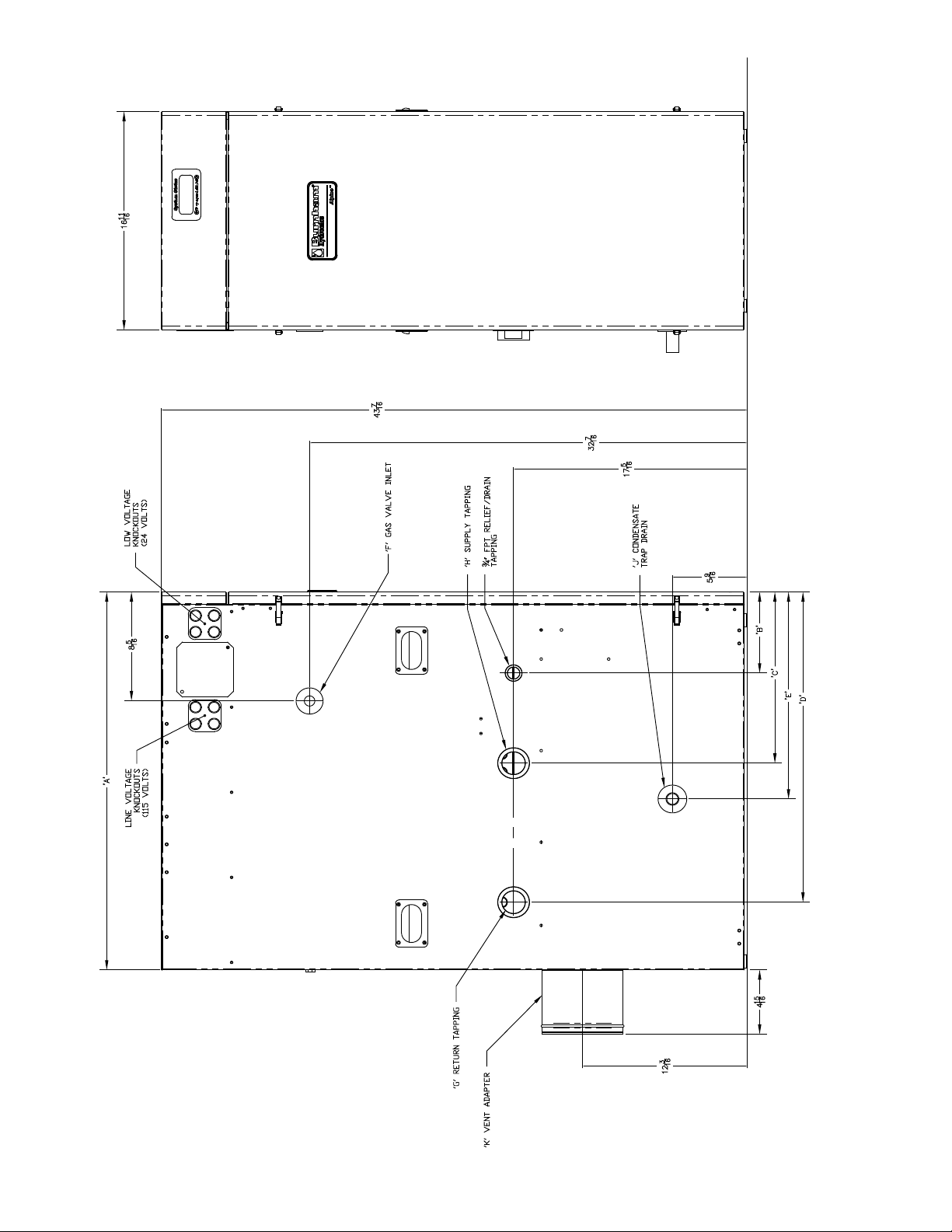

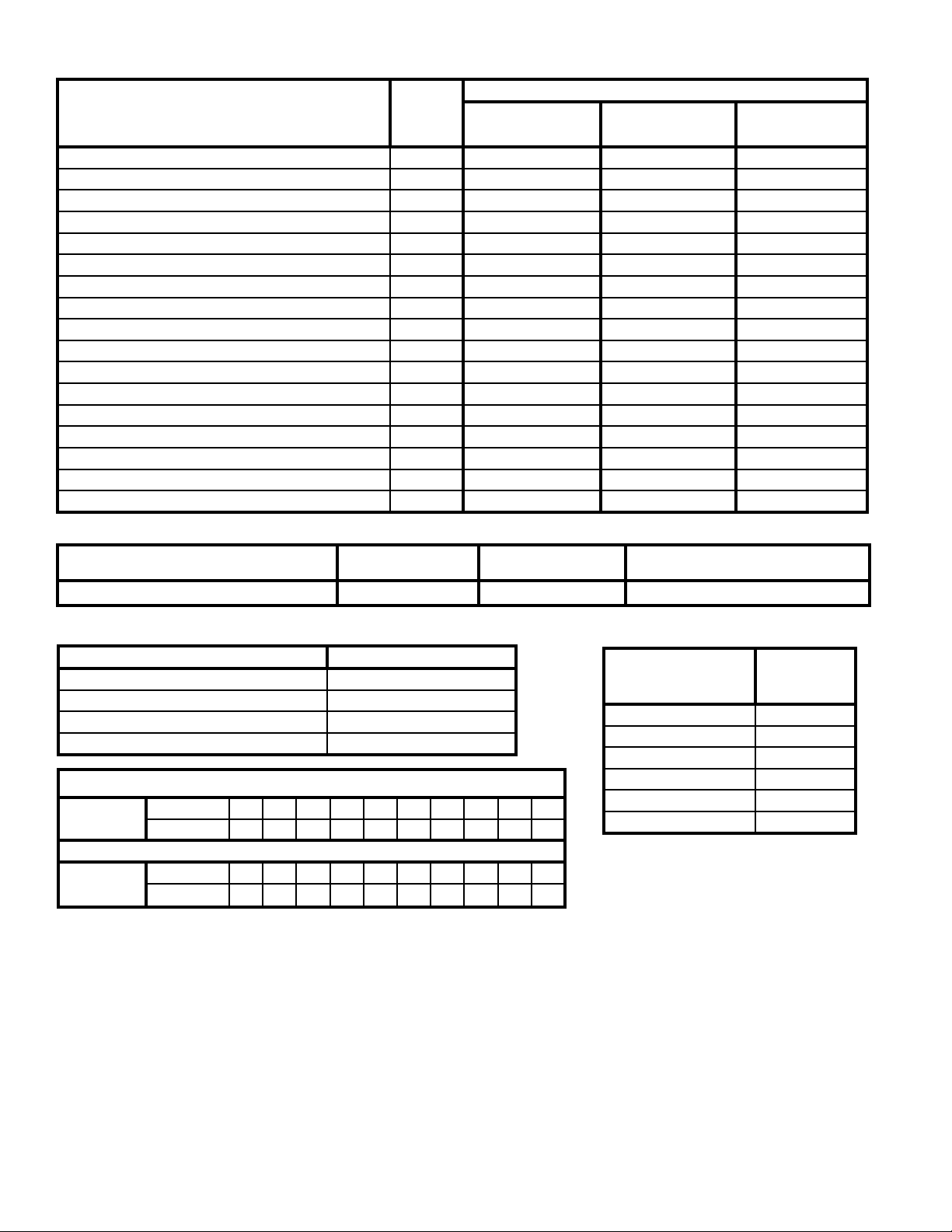

Dimension

Boiler Model

ALP080 ALP105 ALP150 ALP210 ALP285 ALP399

A - Inch

(mm)

12-9/16

(320)

14

(356)

19-11/16

(500)

23-15/16

(608)

21-13/16

(554)

28-7/8

(734)

B - Inch

(mm)

5-5/8

(142)

5-13/16

(147)

7-5/16

(185)

6-3/16

(157)

C - Inch

(mm)

7-5/16

(186)

14-1/8

(358)

13-1/16

(332)

D - Inch

(mm)

9-5/16

(237)

10-3/4

(273)

16-7/16

(417)

17-1/8

(435)

18

(456)

23-3/4

(602)

E - Inch

(mm)

5-15/16

(151)

12-1/4

(312)

15-13/16

(402)

Gas Inlet F

(FPT)

1/2” 3/4” 1”

Return G

(FPT)

1” 1-1/4” 1-1/2”

Supply H

(FPT)

1” 1-1/4” 1-1/2”

Condensate Drain J *

* Factory Provided Socket End Compression Pipe Joining Clamp

for 3/4” Schedule 40 PVC Pipe

Boiler Two Pipe

CPVC/PVC Vent Connector

- Inch

3 x 3 3 x 4 4 x 4

Approx. Shipping Weight

(LBS)

137 155 182 206 256 304

Table 1: Dimensional Data (See Figures 1a & 1B)

5

Figure 1a: alpine™ - Models aLP080 thru aLP210

6

Figure 1B: alpine™ - Models aLP285 thru aLP399

7

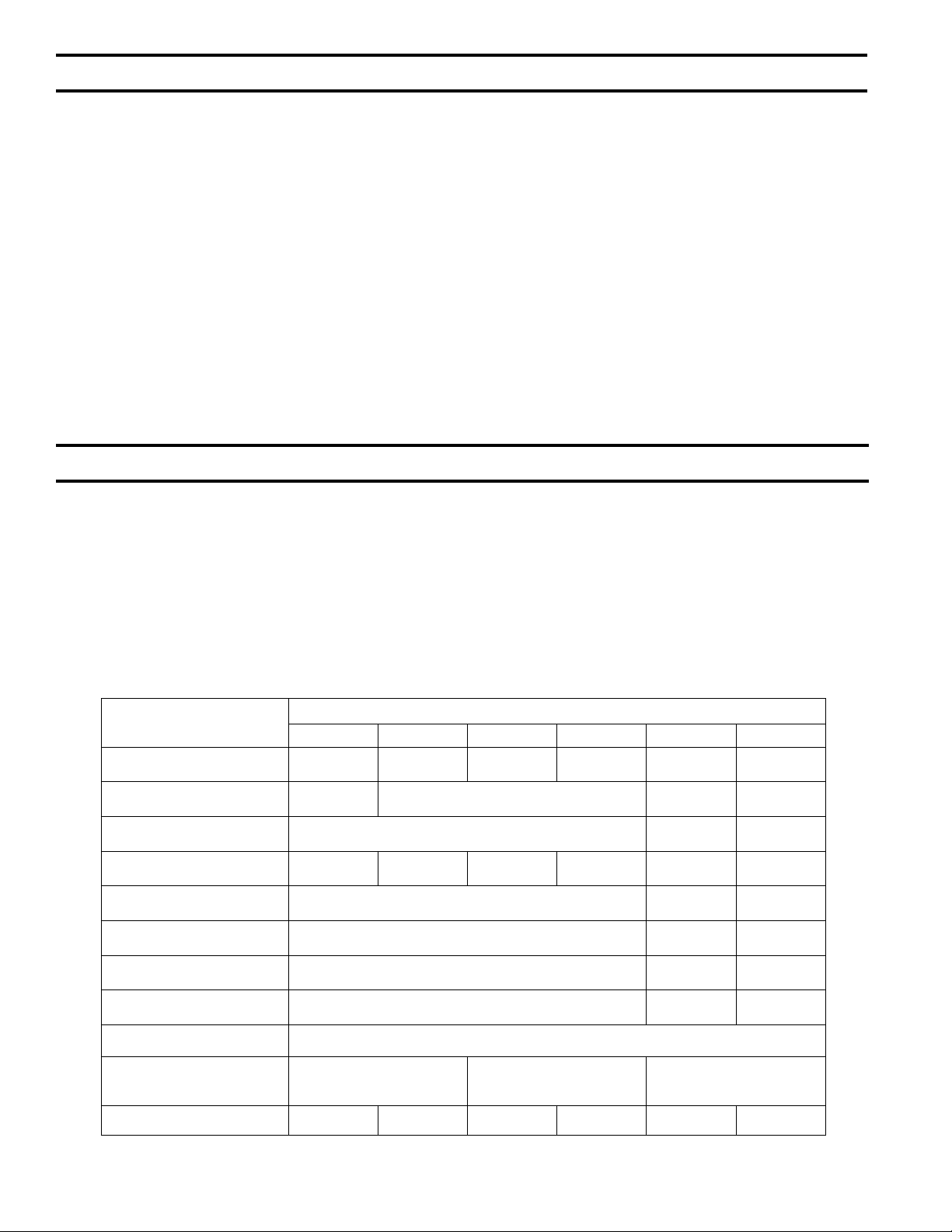

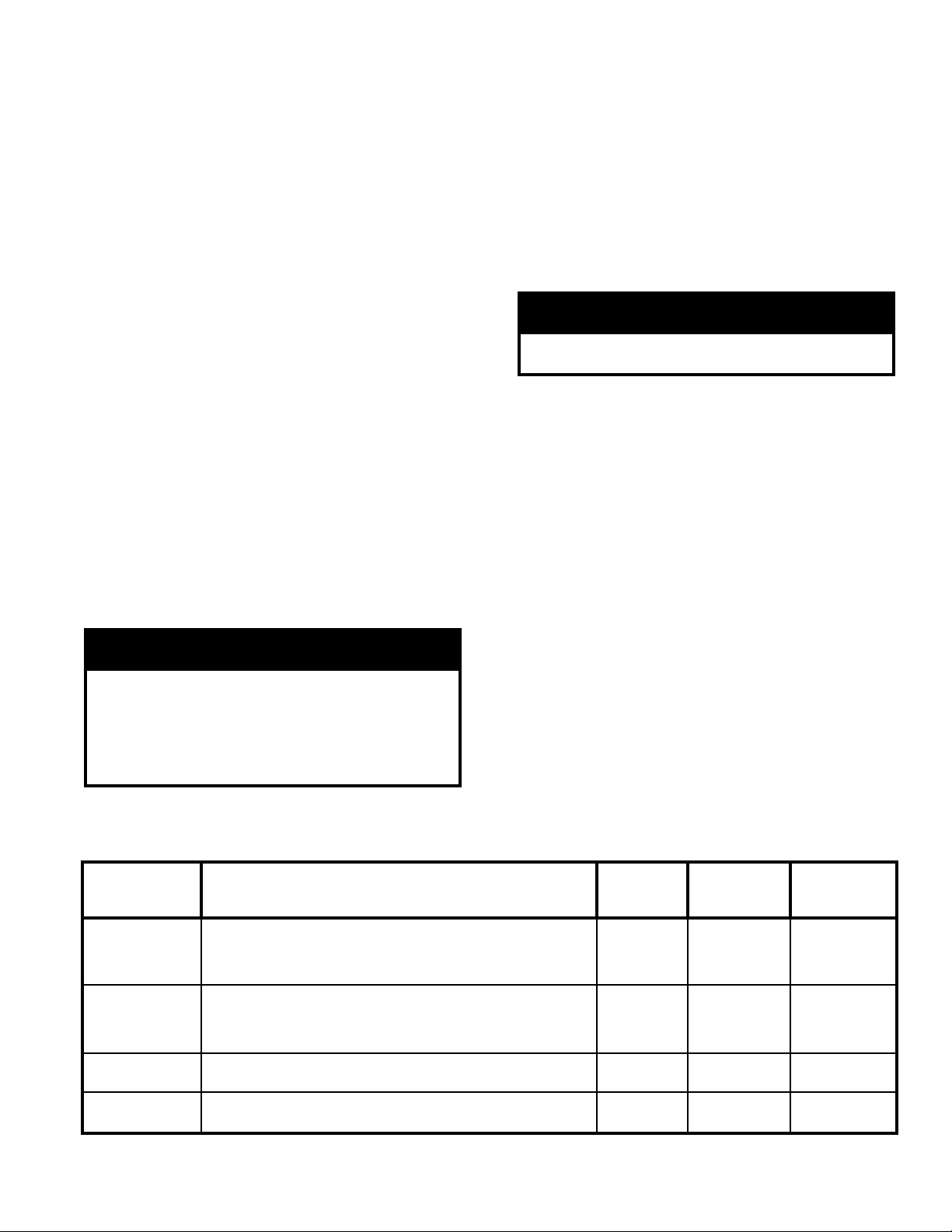

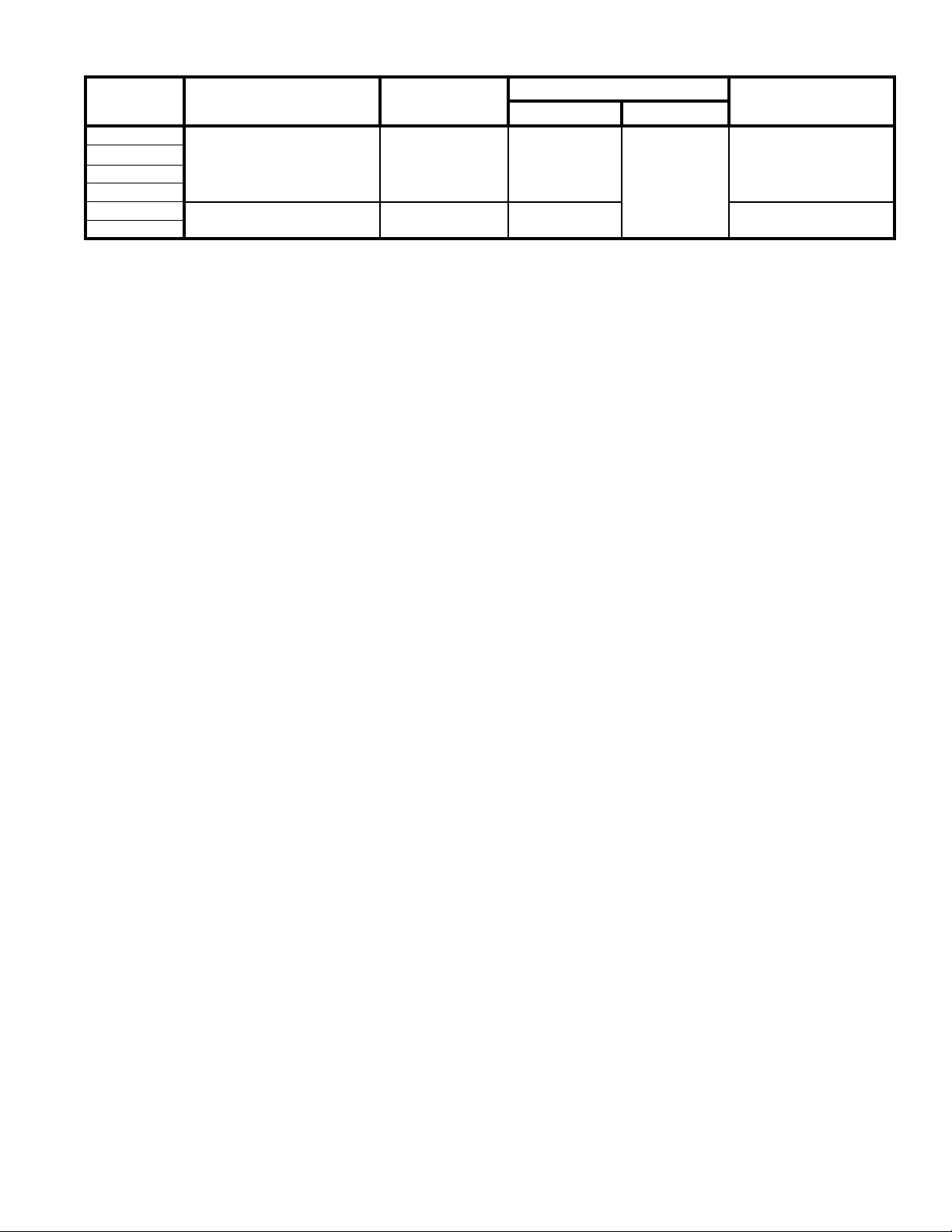

Table 2a: Rating Data - Models aLP080 thru aLP399 (0 to 2000 Feet Elevation above Sea Level)

Table 2B: Rating Data - Models aLP080 thru aLP399 (2001 to 7000 Feet Elevation above Sea Level)

alpine Series gas-Fired Boilers

Model

Number *

Input

(MBH)

** Output

(MBH)

Net I=B=R

Ratings

Water (MBH)

AFUE

%

Thermal

Efciency

(%)

Combustion

Efciency (%)

Boiler Water

Volume

(Gal.)

Heat Transfer

Area (Sq. Ft.)

Min. Max.

ALP080 27 80 73 63 95 0.6 7.3

ALP105 35 105 96 83 95 0.7 9.1

ALP150 50 150 138 120 95 1.3 16.4

ALP210 70 210 194 169 95 1.7 21.8

ALP285 57 285 265 230 95 2.4 29.1

ALP399 80 399 377 328 94.1 94.5 3.4 41.8

* Add Sufx “N” for Natural Gas or Sufx “P” for LP Gas Models.

notes: ** DOE Heating Capacity (ALP080 thru ALP285); Gross Output (ALP399)

Maximum Working Pressure, Water - 30 PSI Shipped from Factory (std.); 50 PSI - Optional

Maximum Allowable Temperature, Water - 210°F

Boilers are factory shipped as Natural Gas builds and have to be eld adjusted for LP gas application. Refer to ‘System Start-

Up Section of this manual for detailed procedure.

For elevations above 2000 Feet, ratings should be reduced at the rate of four percent (4%) for each 1000 Feet above sea level.

alpine Series gas-Fired Boilers

* Model

Number

Input

(MBH)

** Output

(MBH)

Net I=B=R

Ratings

Water (MBH)

AFUE

%

Thermal

Efciency

(%)

Combustion

Efciency (%)

Boiler Water

Volume

(Gal.)

Heat Transfer

Area

(Sq. Ft.)

Min. Max.

ALP080 16 80 73 63 95 0.6 7.3

ALP105 21 105 96 83 95 0.7 9.1

ALP150 30 150 138 120 95 1.3 16.4

ALP210 42 210 194 169 95 1.7 21.8

ALP285 57 285 265 230 95 2.4 29.1

ALP399 80 399 377 328 94.1 94.5 3.4 41.8

* Add Sufx “N” for Natural Gas or Sufx “P” for LP Gas Models.

notes: ** DOE Heating Capacity (ALP080 thru ALP285); Gross Output (ALP399)

Maximum Working Pressure, Water - 30 PSI Shipped from Factory (std.); 50 PSI - Optional (ALP080 thru ALP285)

Maximum Working Pressure, Water - 50 PSI Shipped from Factory (std.); (ALP399)

Maximum Allowable Temperature, Water - 210°F

Boilers are factory shipped as Natural Gas builds and have to be eld adjusted for LP gas application. Refer to ‘System Start-

Up Section of this manual for detailed procedure.

Ratings shown are for installations at sea level and elevations up to 2000 Feet. For elevations above 2000 Feet, ratings should be

reduced at the rate of four percent (4%) for each 1000 Feet above sea level.

8

WaRning

if you do not follow these instructions exactly,

a re or explosion may result causing property

damage or personal injury.

DangER

Do not install boiler where gasoline or other

ammable vapors or liquids, or sources of

hydrocarbons (i.e. bleaches, cleaners, chemicals,

sprays, paint removers, fabric softeners, etc.) are

used or stored.

nOTiCE

Due to the low water content of the boiler, mis-

sizing of the boiler with regard to the heating

system load will result in excessive boiler cycling

and accelerated component failure. Burnham

DOES nOT warrant failures caused by mis-sized

boiler applications. DO nOT oversize the boiler to

the system. Modular boiler installations greatly

reduce the likelihood of boiler oversizing.

A. Installation must conform to the requirements of the

authority having jurisdiction. In the absence of such

requirements, installation must conform to the National

Fuel Gas Code, NFPA 54/ANSI Z223.1, and/or CAN/

CSA B149.1 Installation Codes.

B. Appliance is design certied for installation on

combustible ooring. Do not install boiler on

carpeting.

C. Provide clearance between boiler jacket and

combustible material in accordance with local re

ordinance. Refer to Figure 2 for minimum listed

clearances from combustible material. Recommended

service clearance is 24 inches from left side, front, top

and rear of the boiler. Recommended front clearance

may be reduced to the combustible material clearance

providing:

1. Access to boiler front is provided through a door or

removable front access panel.

ii. Pre-installation

2. Access is provided to the condensate trap located

underneath the heat exchanger.

D. Install on level oor. For basement installation provide

a solid base such as concrete, if oor is not level or if

water may be encountered on oor around boiler. Floor

must be able to support weight of boiler, water and all

additional system components.

E. Protect gas ignition system components from water

(dripping, spraying, rain, etc.) during boiler operation

and service (circulator replacement, condensate trap,

control replacement, etc.).

F. Provide combustion and ventilation air in accordance

with applicable provisions of local building codes,

or: USA - National Fuel Gas Code, NFPA 54/ANSI

Z223.1, Air for Combustion and Ventilation;

Canada - Natural Gas and Propane Installation Code,

CAN/CSA-B149.1, Venting Systems and Air Supply for

Appliances.

WaRning

Adequate combustion and ventilation air must

be provided to assure proper combustion.

G. The boiler should be located so as to minimize the

length of the vent system. The PVC combustion

air piping, or the optional concentric vent piping,

containing integral combustion air inlet piping, must

terminate where outdoor air is available for combustion

and away from areas that may contaminate combustion

air. In particular, avoid areas near chemical products

containing chlorines, chloro/uorocarbons, paint

removers, cleaning solvents and detergents. Avoid

areas containing saw dust, loose insulation bers, dry

wall dust etc.

CaUTiOn

avoid operating this boiler in an environment

where saw dust, loose insulation bers, dry wall

dust, etc. are present. if boiler is operated under

these conditions, the burner interior and ports

must be cleaned and inspected daily to insure

proper operation.

9

iii. Unpacking Boiler

CaUTiOn

Do not drop boiler.

A. Move boiler to approximate installed position.

B. Remove all crate fasteners.

C. Lift and remove outside container.

D. Remove boiler from cardboard positioning sleeve on

shipping skid.

WaRning

installation of this boiler should be undertaken

only by trained and skilled personnel from a

qualied service agency.

E. Move boiler to its permanent location.

Figure 2: Clearances To Combustible and non-combustible Material

10

iV. Venting

WaRning

Failure to vent this boiler in accordance with these instructions could cause products of combustion to

enter the building resulting in severe property damage, personal injury or death.

Do not interchange vent systems or materials unless otherwise specied.

The use of thermal insulation covering pipe and ttings is prohibited.

Do not use a barometric damper, draft hood or vent damper with this boiler.

The use of CPVC is required when venting in chase ways and through interior wall penetrations.

Do not locate vent termination where exposed to prevailing winds. Moisture and ice may form on

surface around vent termination. To prevent deterioration, surface must be in good repair (sealed,

painted, etc.).

Do not locate vent termination where chlorines, chloro/uorocarbons (CFC’s), petroleum distillates,

detergents, volatile vapors or other chemicals are present. Severe boiler corrosion and failure will

result.

The use of cellular core PVC (

aSTM F891) is prohibited.

Do not locate vent termination under a deck.

Do not reduce size of vent/combustion air pipe diameter.

When installing vent pipe through chimney, no other appliance can be vented into the chimney.

Do not allow low spots in the vent where condensate may pool.

A. Vent Guidelines Due to Removal of an Existing

Boiler

For installations not involving the replacement of an

existing boiler, proceed to Step B.

When an existing boiler is removed from a common

venting system, the common venting system is likely

to be too large for proper venting of the remaining

appliances. At the time of removal of an existing

boiler, the following steps shall be followed with each

appliance remaining connected to the common venting

system placed in operation, while the other appliances

remaining connected to the common venting system are

not in operation:

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper

size and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion, and other

deciencies which could cause an unsafe condition.

3. Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on clothes dryers and any appliance

not connected to the common venting system.

Turn on any exhaust fans, such as range-hoods and

bathroom exhausts, so they will operate at maximum

speed. Do not operate a summer exhaust fan. Close

replace dampers.

4. Place in operation the appliance being inspected.

Follow the Lighting (or Operating) Instructions.

Adjust therm

ostat so appliance will operate

continuously.

5. Test for spillage at the draft hood relief opening

after ve (5) minutes of main burner operation. Use

the ame of a match or candle, or smoke from a

cigarette, cigar or pipe.

6. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, replace dampers and

any other gas burning appliance to their previous

conditions of use.

7. Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code, NFPA

54/ANSI Z223.1. When resizing any portion of the

common venting system, the common venting

system should be resized to approach the minimum

size as determined using the appropriate tables in

Part II in the National Fuel Gas Code, NFPA 54/

ANSI Z223.1.

B. General Guidelines

1. Vent system installation must be in accordance

with National Fuel Gas Code, NFPA 54/ANSI

Z221.3 or applicable provisions of local building

codes. Contact local building or re ofcials about

restrictions and installation inspection in your area.

11

2. The Alpine™ is designed to be installed as a Direct

Vent boiler. The air for combustion is supplied

directly to the burner enclosure from outdoors and

ue gases are vented directly outdoors (through wall

or roof).

3. The following combustion air/vent system options

are approved for use with the Alpine™ boilers:

i. Two-Pipe CPVC/PVC Gas Vent/Combustion

Air System (factory standard) - separate

CPVC/PVC pipe serves to expel products of

combustion and separate PVC pipe delivers fresh

outdoor combustion air. Refer to Paragraph C

through F for specic details.

ii. Combination Concentric Gas Vent/

Combustion Air Inlet (optional) - the assembly

consists of inner re resistant polypropylene

vent pipe and outer steel pipe casing. The inner

pipe serves as conduit to expel products of

combustion, while outdoor fresh combustion air

is drawn through the space between the inner and

outer pipes. Refer to Paragraphs G through P for

specic details.

4. Refer to Table 3 and the appropriate drawings to

determine the proper conguration of either factory

standard or optional venting/combustion air system

details.

C. The following information is applicable for Two-

Pipe CPVC/PVC Gas Vent/Combustion Air System

(factory standard).

WaRning

all CPVC vent components (supplied with boiler)

must be used for near-boiler vent piping before

transitioning to Schedule 40 PVC pipe (aSTM

2665) components for remainder of vent system.

CPVC vent components must be used prior to

exit of any closet or conned space.

See

Table 6 for complete list of Burnham Vent

System Components. Use single wall thimble

[Burnham Part No. 102180-01 (3”), 102181-01 (4”)]

when penetrating a combustible wall for vent only.

1.

Horizontal vent pipe must maintain a minimum ¼

inch per foot slope down towards boiler.

2. Use noncombustible ¾ inch pipe strap to support

horizontal runs and maintain vent location and slope

while preventing sags in pipe. Maximum support

spacing is four (4) feet. Avoid low spots where

condensate may pool. Do not penetrate any part of

the vent system with fasteners.

WaRning

all condensate that forms in the vent must be

able to drain back to the boiler.

3.

Vent length restrictions are based on equivalent

length of vent/combustion air pipe (total length

of straight pipe plus equivalent length of ttings).

Maximum vent/combustion air lengths are listed in

Table 7. Do not exceed maximum vent/combustion

air lengths. Table 6 lists equivalent lengths for

ttings. Do not include vent/combustion air

terminals in equivalent feet calculations. See

“Combustion Air/Vent, Equivalent Length Work

Sheet”.

4. Provide minimum service clearance between boiler

back and concentric vent exiting through outside

wall, for concentric vent installation/replacement

and/or ue temperature sensor service/replacement.

5. Do not install venting system components on

the exterior of the building except as specically

required by these instructions. The vent termination

location is restricted as follows (refer to Figures 6

and 9):

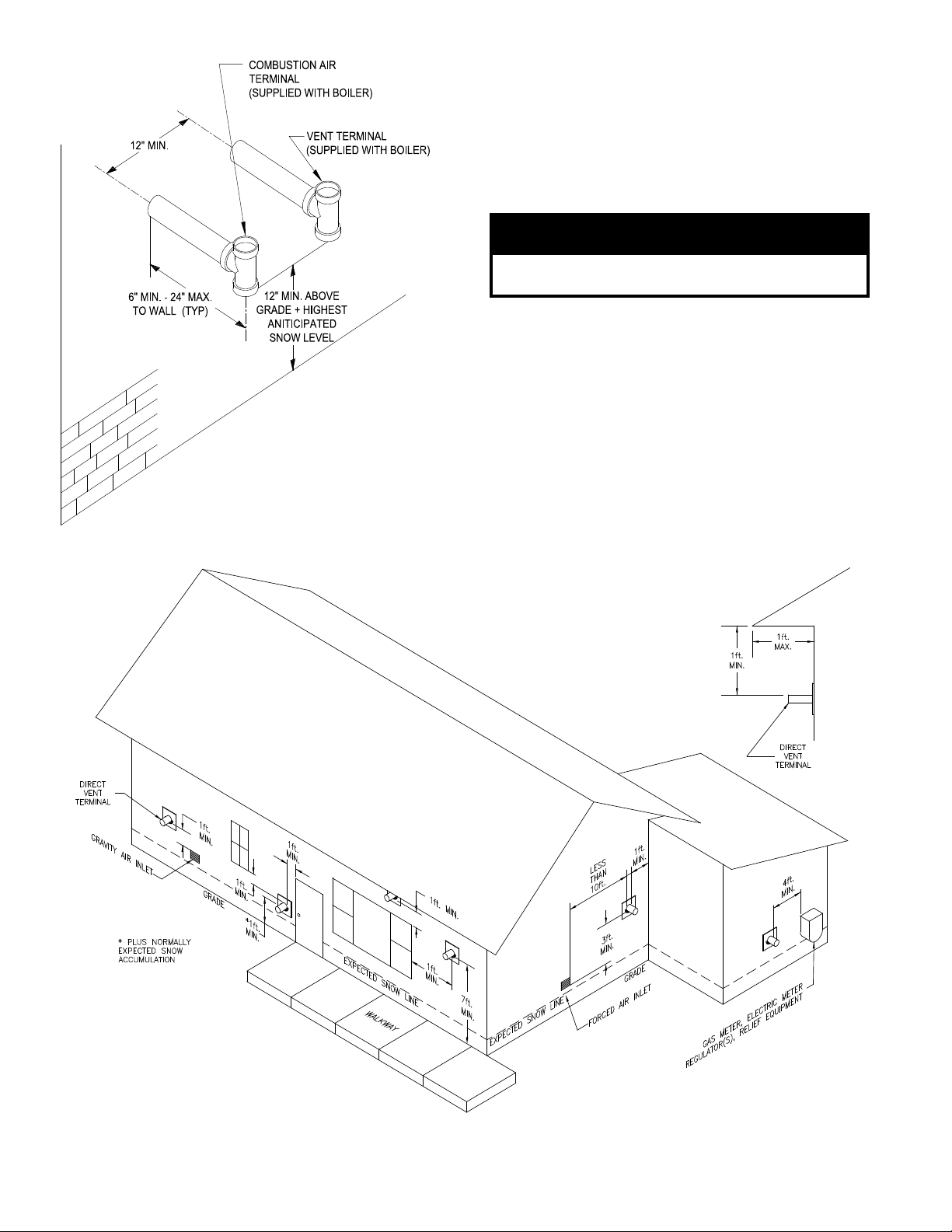

a.

Minimum twelve (12) inches above grade plus

normally expected snow accumulation level, or

seven (7) feet above grade, if located adjacent

Option Description

additional

Vent Kit

Required

Components

included with

Boiler

installation

Drawing and

Specication

TWO-PiPE

CPVC/PVC

HORizOnTaL

Direct Vent (sealed combustion) with both the vent pipe and

combustion air pipe terminating horizontally (through a sidewall)

with individual penetrations for the vent and combustion air

piping and terminals.

no See Table 4 See Figure 6

TWO-PiPE

CPVC/PVC

V

ERTiCaL

Direct Vent (sealed combustion) with both the vent pipe and

combustion air pipe terminating vertically (through the roof) with

individual penetrations for the vent and combustion air piping

and terminals.

no See Table 4

See Figures

9 and 10

COnCEnTRiC

HORizOnTaL

Direct Vent (sealed combustion) the concentric vent pipe

terminates horizontally (through a sidewall).

n

o See Table 9 See Figure 13

COnCEnTRiC

VERTiCaL

Direct Vent (sealed combustion) the concentric vent pipe

terminates vertically (through the roof).

Yes See Table 9 See Figure 19

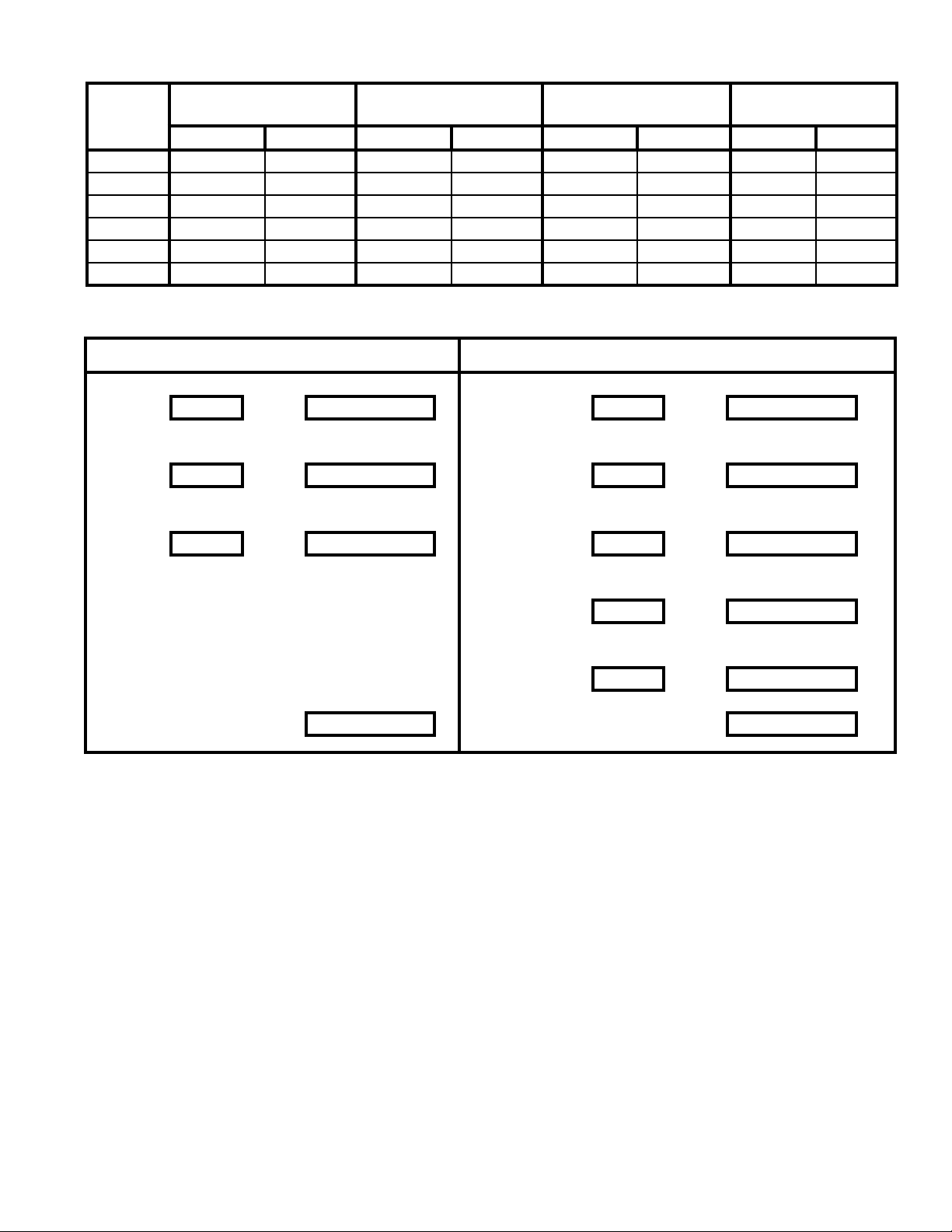

Table 3: Combustion air/Vent System Options

12

Vent Pipe Pipe Direction Enclosure

Minimum Clearance To

Combustible Material, Inches

CPVC/PVC Venting Vertical or Horizontal Enclosed at all Sides 1” Vent/0” Combustion Air

Table 5: Clearances from Vent Piping to Combustible Material

Vent System Components

Part

Number

Quantity

ALP080 & ALP105

(P/N 102189-01)

ALP150 & ALP210

(P/N 102189-02)

ALP285 & ALP399

(P/N 102189-03)

3” Schedule 40 PVC Tee Combustion Air/Vent Terminal 102190-01 2 1 ---

4” Schedule 40 PVC Tee Combustion Air/Vent Terminal 102190-02 --- 1 2

3” Stainless Steel Rodent Screens 102191-01 2 1 ---

4” Stainless Steel Rodent Screens 102191-02 --- 1 2

3” x 30” Schedule 40 CPVC Pipe 102193-01 1 1 ---

4” x 30” Schedule 40 CPVC Pipe 102193-02 --- --- 1

3” Schedule 80 CPVC 90° Elbow 102192-01 1 1 ---

4” Schedule 80 CPVC 90° Elbow 102192-02 --- --- 1

8 oz. Bottle of Transition Cement 102195-01 1 1 1

8 oz. Bottle of Primer 102194-01 1 1 1

Burnham Vent Supplement Manual 102188-01 1 1 1

Two Pipe Vent System Connector for CPVC/PVC 102183-01 1 --- ---

Two Pipe Vent System Connector for CPVC/PVC 102183-02 --- 1 ---

Two Pipe Vent System Connector for CPVC/PVC 102183-03 --- --- 1

Two Pipe Vent System Connector for CPVC/PVC Gasket 102185-01 1 1 ---

Two Pipe Vent System Connector for CPVC/PVC Gasket 102185-02 --- --- 1

Silicone Vent Sensor Cap 102153-01 1 1 1

Table 4: Vent System Components included with Boiler

Table 6: Burnham Vent System and Combustion air System Components

Vent System Component Equivalent Length (Ft.)

3” Schedule 40 CPVC Pipe x 30 Inches 2.5

4” Schedule 40 CPVC Pipe x 30 Inches 2.5

3” Schedule 80 CPVC 90° Elbow 5

4” Schedule 80 CPVC 90° Elbow 5

Combustion Air

System Component

(Parts by Others)

Equivalent

Feet of Pipe*

3” or 4” ID Pipe x 1 Ft. 1

3” or 4” ID Pipe x 2 Ft. 2

3” or 4” ID Pipe x 4 Ft. 4

3” or 4” ID Pipe x 5 Ft. 5

3” or 4” 90° Elbow 5

3” or 4” 45° Elbow 5

*Equivalent Feet of Pipe Based on

Standard 4” PVC Design

Maximum Number of 90’s and Straight Pipe

Vent Pipe

# of 90’s 1 2 3 4 5 6 7 8 9 10

Feet of Pipe 55 50 45 40 35 30 25 20 15 10

Combustion

Air Pipe

# of 90’s 1 2 3 4 5 6 7 8 9 10

Feet of Pipe 55 50 45 40 35 30 25 20 15 10

to public walkway. Do not install over public

walkway where local experience indicates

appliance ue gas vapor or condensate creates a

nuisance or hazard.

b. Minimum three (3) feet above any forced

combustion air located within ten (10) feet.

c. Direct Vent - Minimum one (1) foot below, one

(1) foot horizontally from, or one (1) foot above

any door, window, or gravity air inlet.

d. Minimum four (4) feet horizontally from electric

meters, gas meters, regulators, and relief valves.

This distance may be reduced if equipment is

protected from damage due to condensation or

vapor by enclosure, overhangs, etc.

e. Minimum twelve (12) inches from overhang or

corner of building.

6. Enclose vent passing through occupied or

unoccupied spaces above the boiler with material

having a re resistance rating of at least equal to the

rating of the adjoining oor or ceiling. Maintain

minimum clearances to combustible materials. See

Figure 2 and Table 5 for details.

13

Boiler

Model

3” Combustion Air Pipe

(Equivalent Length)

4” Combustion Air Pipe

(Equivalent Length)

3” Vent Pipe

(Equivalent Length)

4” Vent Pipe

(Equivalent Length)

Min. Max. Min. Max. Min. Max. Min. Max.

ALP080 21-7/8 In. 60 Ft. --- --- 21-7/8 In. 60 Ft. --- ---

ALP105 21-7/8 In. 60 Ft. --- --- 21-7/8 In. 60 Ft. --- ---

ALP150 --- --- 21-7/8 In. 60 Ft. 21-7/8 In. 60 Ft. --- ---

ALP210 --- --- 21-7/8 In. 60 Ft. 21-7/8 In. 60 Ft. --- ---

ALP285 --- --- 32 In. 60 Ft. --- --- 32 In. 60 Ft.

ALP399 --- --- 32 In. 60 Ft. --- --- 32 In. 60 Ft.

Table 7: Vent/Combustion air Pipe Length

Combustion air Vent

90° elbow(s) PVC Supplied 30” straight CPVC

Quantity = x 5’ = equiv. ft. a. Length ft. = 2.5 x 1 = 2.5 equiv. ft. a.

45° elbow(s) PVC Supplied 90° elbow CPVC

Quantity = x 2.5’ = equiv. ft. b. Quantity = 1 x 5’ = 5 equiv. ft. b.

Straight pipe PVC 90° elbow(s) PVC

Length ft. = x 1 = equiv. ft. c. Quantity = x 5’ = equiv. ft. c.

45° elbow(s) PVC

Quantity = x 2.5’ = equiv. ft. d.

Straight pipe PVC

Length ft. = x 1 = equiv. ft. e.

Total* a.+b.+c. = equiv. ft. Total* a.+b.+c.+d.+e.= equiv. ft.

* Total cannot exceed 60 equiv. ft. length.

Vent and combustion air terminals do not count towards total equiv. ft.

Combustion Air/Vent, Equivalent Length Work Sheet

This sheet is supplied to assist in vent/combustion air, equivalent length calculating

Note: For one or two family dwellings, re

resistance rating requirement may not need to be

met, but is recommended.

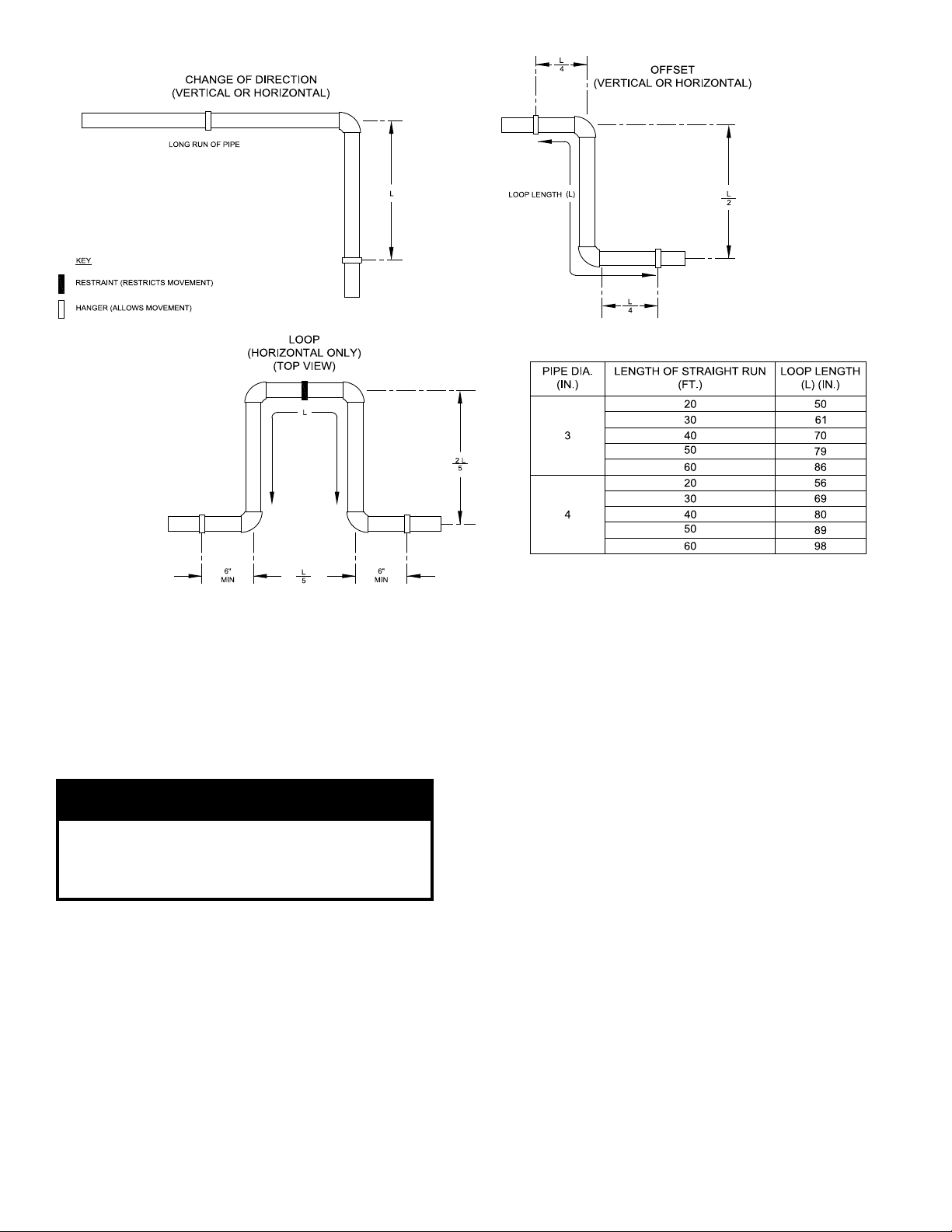

7. Plan venting system to avoid possible contact with

plumbing or electrical wires. Start at vent connector

at rear of boiler and work towards vent termination.

8. Design the Vent System to allow a 3/8” of thermal

expansion per 10 feet of CPVC/PVC pipe. Runs of

20 ft. or longer that are restrained at both ends must

use an offset or expansion loop. Refer to Figure 3.

9. Follow all manufacturer instructions and warnings

when preparing pipe ends for joining and using the

primer and the cement.

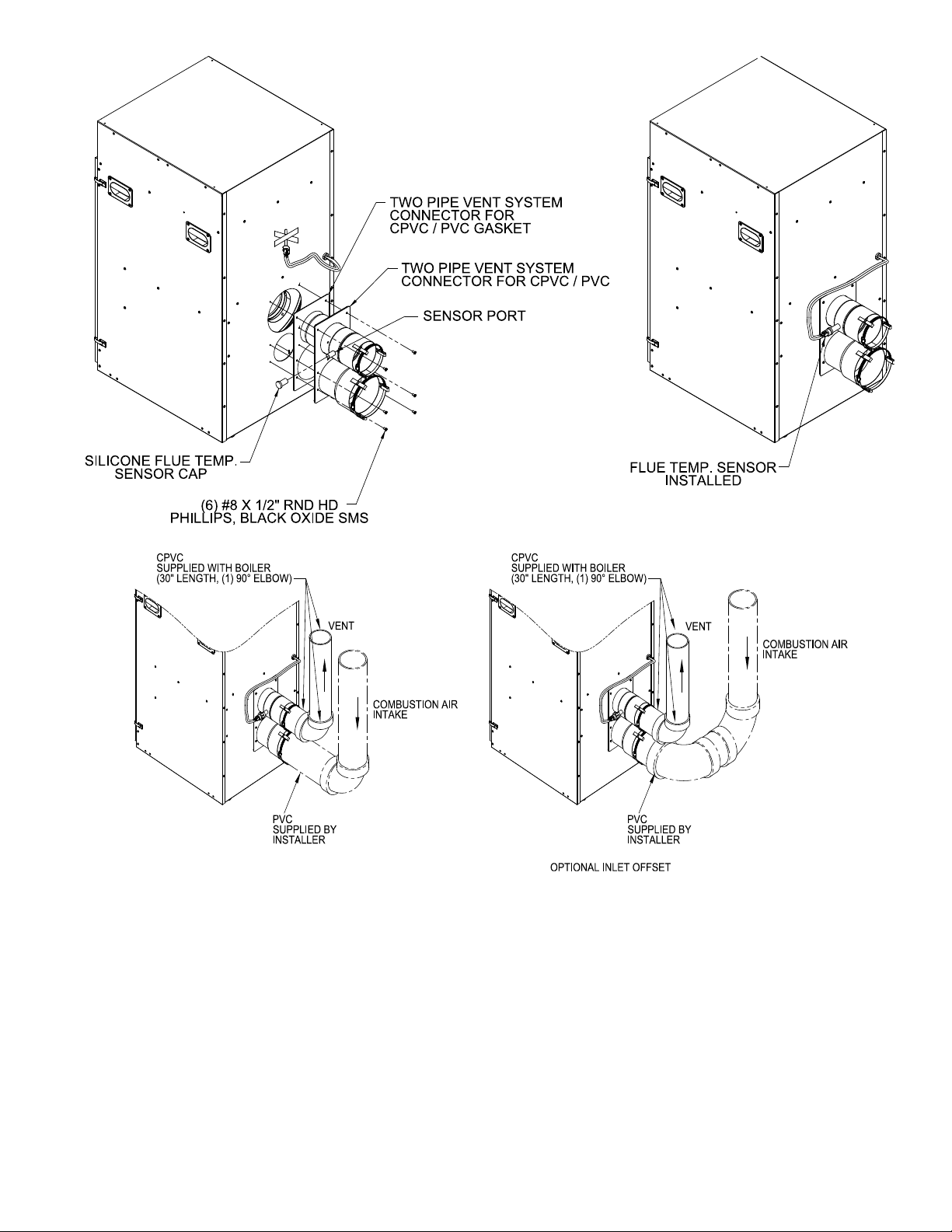

D. Installation of Two-Pipe CPVC/PVC Gas Vent/

Combustion Air System Connector

The boiler two pipe vent system connector for CPVC/

PVC and gasket are shipped inside the vent carton. The

vent connector mounting hardware - six (6) #8 x ½”

black oxide round head Phillips sheet metal screws - are

shipped inside Miscellaneous Part Carton.

1. Remove the vent connector and gasket from the vent

carton.

2. Locate six mounting screws.

3. Position the vent connector and gasket onto jacket

combination rear/bottom panel and insert vent

connector inner stainless steel vent pipe into the heat

exchanger vent outlet.

4. Align vent connector plate and gasket clearance

holes with rear/bottom panel engagement holes; then

secure the collar and gasket to rear/bottom panel

with six mounting screws. See Figure 4.

5. Flue temperature sensor, factory attached to the

boiler wiring harness, is secured to the boiler rear/

bottom panel with tape.

14

6. Remove the Silicone ue sensor cap from the vent

carton and press onto the two pipe vent system

connector for CPVC/PVC sensor port. Remove

the tape holding the ue sensor and insert the ue

temperature sensor into the ue sensor plug until it

is rmly engaged. See Figure 4.

7. Near-Boiler Vent Piping (see Figure 5):

WaRning

all CPVC vent components (supplied with boiler)

must be used for near-boiler vent piping before

transitioning to Schedule 40 PVC pipe (aSTM

2665) components for remainder of vent system.

a. All CPVC vent components (supplied with

boiler), 30” straight and 90° elbow, must be

used for near-boiler piping before transitioning

to Schedule 40 PVC (ASTM 2665) pipe

components for remainder of vent system.

The CPVC 30” straight section may be cut to

accommodate desired vent conguration for

near-boiler piping, provided both pieces are used

in conjunction with the CPVC 90° elbow, before

any PVC components are used. Ensure that the

CPVC elbow is the rst elbow used in the vent

system as it exits the boiler.

b.

Clean all vent and combustion air pipe joints

with primer and secure with transition cement,

(8 oz. bottle of primer and 8 oz. bottle of

transition cement supplied with boiler). Follow

the instructions provided on the primer and

cement.

E. CPVC/PVC Horizontal Venting System

See Figures 3 thru 8.

Vent Piping - Horizontal

1. See Paragraph D for instructions on attaching the

vent system connector to the boiler.

2. Do not exceed maximum vent length. Refer to

Table 7 for pipe diameters and allowable lengths.

3. Horizontal vent pipe must maintain a minimum ¼

inch per foot slope down towards boiler.

4. Use appropriately designed thimbles when passing

through combustible walls (thimble use is optional

for noncombustible walls). Insert thimble through

wall from outside. Secure outside ange to wall

with nails or screws, and seal ID, OD and vent holes

with sealant material. Install inside ange to inside

wall, secure with nails or screws, and seal with

sealant material.

5. For noncombustible wall application when thimble

is not used, size opening such that a minimal

clearance is obtained.

Figure 3: Expansion Loop and Offset

15

6. Install Rodent Screen and Vent Terminal (supplied

with boiler), see Figure 8 for appropriate

conguration.

7. Apply sealant between vent pipe and opening/

thimble to provide weather-tight seal. Sealant

should not restrain the expansion of the vent pipe.

Combustion Air Piping - Horizontal

1. See Paragraph D for instructions on attaching the

vent system connector to the boiler.

2. Do not exceed maximum combustion air length.

Refer to Table 7 for pipe diameters and allowable

lengths.

3. Horizontal combustion air pipe must maintain a

minimum ¼ inch per foot slope down towards

terminal, when possible. If not, slope toward boiler.

4.

It is strongly recommended to locate the combustion

air terminal on the same wall as the vent termination

to prevent nuisance boiler shutdowns. Combustion

air terminal can be installed closer to wall than vent.

5. Start at vent connector (rear boiler jacket) and work

towards the combustion air terminal.

6. Size combustion air wall penetration to allow easy

insertion of combustion air piping.

Figure 4: Field installation of Two Pipe Vent System Connector for CPVC/PVC

Figure 5: near-Boiler Vent/Combustion air Piping

16

7. Install Rodent Screen and Combustion Air Terminal

(supplied with boiler), see Figure 8 for appropriate

conguration.

8. Apply sealant between vent pipe and opening to

provide weather-tight seal

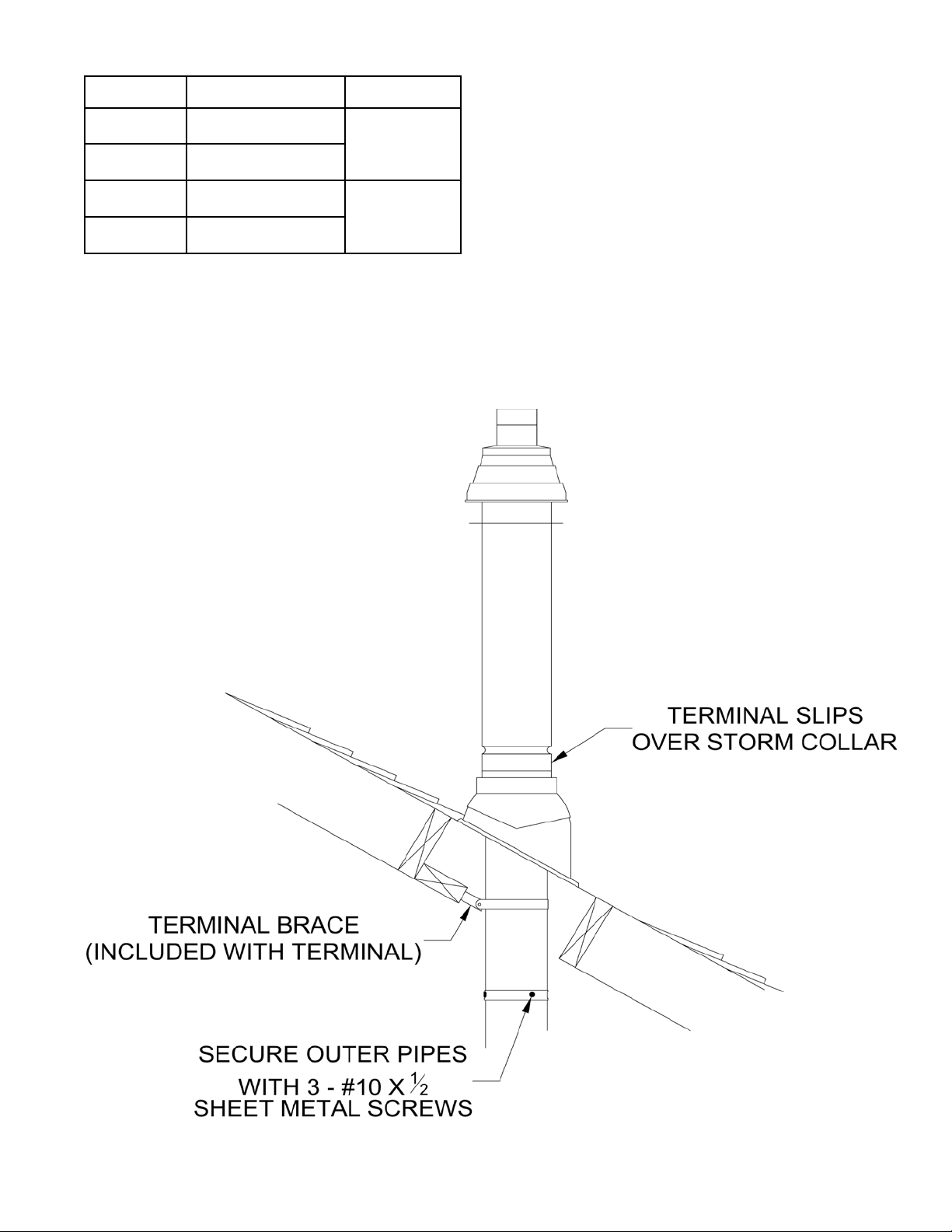

F. CPVC/PVC Vertical Venting System

Refer to Figures 3, 4, 5, 8, 9 & 10.

nOTiCE

Roof penetrations require the use of roof ashing

and storm collar that are not supplied with boiler.

Vent Piping - Vertical

1. See Paragraph D for instructions on attaching the

vent system connector to the boiler.

2. Do not exceed maximum vent length. Refer to

Table 7 for pipe diameters and allowable lengths.

3. Horizontal vent pipe must maintain a minimum ¼

inch per foot slope down towards boiler.

4. Install re stops where vent passes through oors,

ceilings or framed walls. The re stop must close

the opening between the vent pipe and the structure.

5. Whenever possible, install vent straight through the

roof. Refer to Figures 9 and 10.

Figure 6 : Direct Vent - Side Wall Terminations

Figure 7: Location of Vent Terminal Relative to Windows, Doors, grades,

Overhangs, Meters and Forced air inlets (Combustion air Terminal not shown)

17

a. Size roof opening to maintain minimum

clearance of 1 inch from combustible materials.

b. Extend vent pipe to maintain minimum vertical

and horizontal distance of twelve (12) inches

from roof surface. Allow additional vertical

distance for expected snow accumulation.

Provide brace as required.

CaUTiOn

Vertical venting requires the use of roof ashing

and a storm collar to prevent moisture from

entering the structure.

c. Install storm collar on vent pipe immediately

above ashing. Apply Dow Corning Silastic 732

RTV Sealant between vent pipe and storm collar

to provide weather-tight seal.

6.

Install Rodent Screen and Vent Terminal (supplied

with boiler), see Figure 8 for appropriate

conguration.

Figure 8: Rodent Screen

installation

Figure 9: Direct Vent - Vertical Terminations

Figure 10: Direct Vent - Vertical Terminations with Sloped Roof

Extend vent/combustion air piping to maintain minimum vertical (‘X’) and minimum horizontal (‘Y’) distance of

twelve (12) inches (18 inches Canada) from roof surface. a

llow additional vertical (‘X’) distance for expected

snow accumulation.

18

7. Brace exterior piping if required.

Combustion Air Piping - Vertical

1. See Paragraph D for instructions on attaching the

vent system connector to the boiler.

2. Do not exceed maximum combustion air length.

Refer to Table 7 for pipe diameters and allowable

lengths.

3. Horizontal combustion air pipe must maintain a

minimum ¼ inch per foot slope down towards

boiler.

4. Locate combustion air termination on the same roof

location as the vent termination to prevent nuisance

boiler shutdowns. Combustion air terminal can be

installed closer to roof than vent.

5. Start at vent connector on burner enclosure (rear

boiler jacket) and work towards the combustion air

terminal.

6. Size roof opening to allow easy insertion of

combustion air piping and allow proper installation

of ashing and storm collar to prevent moisture

from entering the structure.

a. Use appropriately designed vent ashing

when passing through roofs. Follow ashing

manufacturers’ instructions for installation

procedures.

b. Extend combustion air pipe to maintain

minimum vertical and horizontal distance of

twelve (12) inches from roof surface. Allow

additional vertical distance for expected snow

accumulation. Provide brace as required.

c. Install storm collar on combustion air pipe

immediately above ashing. Apply Dow

Corning Silastic 732 RTV Sealant between

combustion air pipe and storm collar to provide

weather-tight seal.

7. Install Rodent Screen and Combustion Air Terminal

(supplied with boiler), see Figure 8 for appropriate

conguration.

8. Brace exterior piping if required.

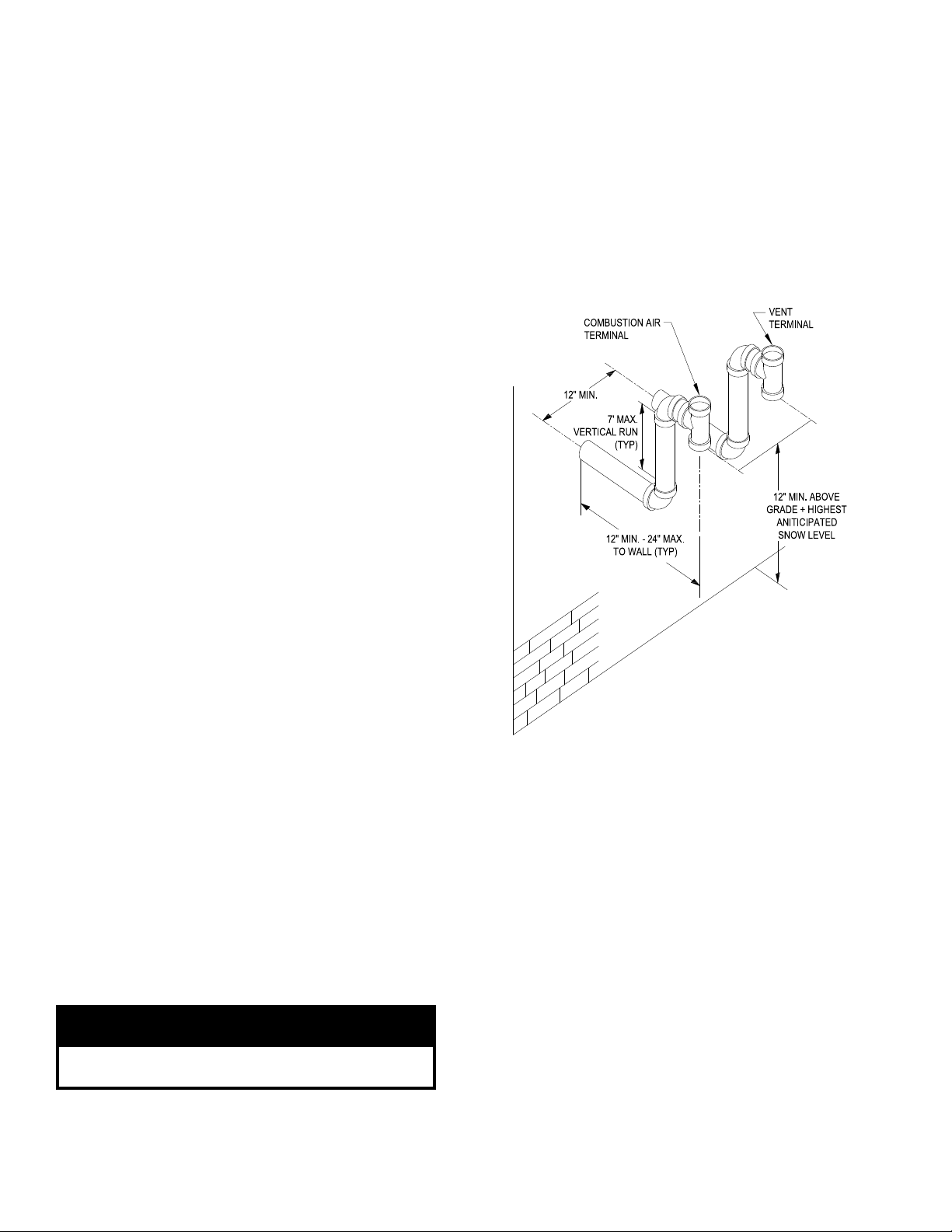

G. Optional Snorkel CPVC/PVC Horizontal Vent

System

Refer to Figures 3, 4, 5, 7, 8 and 11.

This installation will allow a maximum of seven (7) feet

vertical exterior run of the vent/combustion air piping

to be installed on the CPVC/PVC horizontal venting

application (Section E).

nOTiCE

Exterior run to be included in equivalent vent/

combustion air lengths.

Vent Piping - Snorkel

1. See Paragraph D for instructions on attaching the

vent system connector to the boiler.

2. Do not exceed maximum vent length. Refer to

Table 7 for pipe diameters and allowable lengths.

3. Horizontal vent pipe must maintain a minimum ¼

inch per foot slope down towards boiler

4. After penetrating wall/thimble, install a Schedule

40 PVC 90° elbow so that the elbow leg is in the up

direction.

5. Install maximum vertical run of seven (7) feet of

Schedule 40 PVC vent pipe. See Figure 11.

Figure 11: Direct Vent - Optional Side Wall

Snorkel Terminations

6. At top of vent pipe length install another PVC 90°

elbow so that elbow leg is opposite the building’s

exterior surface.

7. Install Rodent Screen and Vent Terminal (supplied

with boiler), see Figure 8 for appropriate

conguration.

8. Brace exterior piping if required.

Combustion Air Piping - Snorkel

1. See Paragraph D for instructions on attaching the

vent system connector to the boiler.

2. Do not exceed maximum combustion air length.

Refer to Table 7 for pipe diameters and allowable

lengths.

3. Horizontal combustion air pipe must maintain a

minimum ¼ inch per foot slope down towards

terminal, when possible. If not, slope toward boiler.

4. After penetrating wall, install a Schedule 40 PVC

90

o

elbow so that elbow leg is in the up direction.

19

5. Install maximum vertical run of seven (7) feet of

Schedule 40 PVC vent pipe. See Figure 11.

6. At top of vent pipe length install another PVC 90°

elbow so that elbow leg is opposite the building’s

exterior surface.

7. Install Rodent Screen and Combustion Air Terminal

(supplied with boiler), see Figure 8 for appropriate

conguration.

8. Brace exterior piping if required.

H. The following information is applicable for

Combination Concentric Gas Vent/Combustion air

System (optional).

I. Field Installation of Boiler Concentric Vent Collar

The Boiler Concentric Vent Collar is shipped inside the

boiler in plastic bag. The Collar mounting hardware

- six (6) #8 x ½” black oxide round head Phillips sheet

metal screws - are shipped inside Miscellaneous Part

Carton.

1.

Release four side draw latches and remove boiler

lower front door assembly to gain access to the Vent

Collar.

2.

Remove the collar from the bag and set aside.

3. Locate and remove six mounting screws.

4. Position the Collar onto jacket combination rear/

bottom panel and insert collar inner stainless steel

vent pipe into the heat exchanger vent outlet.

5.

Align collar plate clearance holes with rear/bottom

panel engagement holes; then secure the collar to

rear/bottom panel with six mounting screws. See

Figure 12.

6. Flue temperature sensor, factory attached to the

boiler wiring harness, is secured to the boiler rear/

bottom panel with tape.

7. Remove the tape and push the sensor rubber plug

into Concentric Vent Collar sensor port until the

plug is securely engaged. See Figure 12.

The installation of the Concentric Vent Collar is now

completed.

J. General Guidelines - Concentric Venting

1. Vent system installation must be in accordance

with National Fuel Gas Code, NFPA 54/ANSI

Z221.3 or applicable provisions of local building

Table 8: Concentric Vent Components

Part Number Component Description Size

Component

Equivalent Vent

Length, Ft

Comments

101493-01 90° Elbow – Long Radius 80/125 mm 5.5

101491-01 45° Elbow - Long Radius 80/125 mm 3.0

101163-01 Cut -To-Length Extension, 500 mm (19-1/2”) 80/125 mm 1.63 **Can be cut

101162-01 Cut -To-Length Extension, 1000 mm (39”) 80/125 mm 3.25 **Can be cut

101485-01 Fixed Extension, 2000 mm (78”) 80/125 mm 3.25 ***Must not be cut

101808-01 Horizontal (Wall) Terminal 80/125 mm *NA Supplied with boiler

101495-01 Vertical Roof Terminal 80/125 mm *NA See Note 1

101496-01 Flat Roof Flashing 80/125 mm

101497-01 Sloped Roof Flashing 80/125 mm See Note 2

101492-01 Support Elbow with Chimney Chase Bracket 80/125 mm 8.5 See Note 3

101498-01 Hanger Wall Bracket 80/125 mm

101548-01 90° Elbow – Long Radius 100/150 mm 8.0

101549-01 45° Elbow - Long Radius 100/150 mm 3.0

101550-01 1 Cut -To-Length Extension, 500 mm (19-1/2”) 100/150 mm 1.63 ** Can be cut

101551-01 Cut -To-Length Extension, 1000 mm (39”) 100/150 mm 3.25 ** Can be cut

101553-01 Fixed Extension, 2000 mm (78”) 100/150 mm 6.5 *** Must not be cut

101809-01 Horizontal (Wall) Terminal 100/150 mm * NA Supplied with boiler

101557-01 Vertical (Roof) Terminal 100/150 mm * NA See Note 1

101558-01 Flat Roof Flashing 100/150 mm

101559-01 Sloped Roof Flashing 100/150 mm See Note 2

101560-01 Support Elbow with Chimney Chase Bracket 100/150 mm 10.0 See Note 3

101561-01 Hanger Wall Bracket 100/150 mm

n

otes:

* NA – do not include vent terminal into total vent length calculations.

** These sections have plain male end and beaded female end. See Figure 11 for details.

*** These sections have beaded male end and beaded female end. See Figure 12 for details.

1. Vertical terminal can be used with either of the roof ashings listed beneath it.

2. Sloped roof ashing suitable for roof angles between 25° and 45°.

3. Used at base of vertical run inside unused masonry chimney.

20

Figure 12: Field installation of Boiler Concentric Vent Collar

codes. Contact local building or re ofcials about

restrictions and installation inspection in your area.

2.

Horizontal vent pipe must maintain a minimum ¼

inch per foot slope towards the boiler.

3. Use noncombustible ¾ inch pipe strap to support

horizontal runs and maintain vent location and

slope while preventing sags in pipe. Do not restrict

thermal expansion or movement of vent system.

Maximum support spacing is ve (5) feet. Do not

penetrate any part of the vent system with fasteners.

4. Vent length restrictions are based on equivalent

length of vent pipe i.e. total length of straight pipe

plus equivalent length of ttings. See Table 11

for specied vent length details. Do not exceed

maximum vent length. Table 8 lists available

concentric vent components and includes equivalent

vent length for ttings. Do not include vent terminal

into total vent length calculations.

5. Provide and maintain vent pipe minimum clearances

to combustible material. See Figure 2 and Table 10

for details.

6. Provide minimum service clearance between boiler

back and concentric vent exiting through outside

wall, for concentric vent installation/replacement

and/or ue temperature sensor service/replacement,

as follows:

a. For horizontal venting where supplied

Concentric Vent Terminal is attached directly to

installed Boiler Concentric Vent Collar - 6 inches

b. For vertical venting where optional Concentric

Vent 90° long radius elbow is attached to

installed Boiler Concentric Vent Collar - 18

inches

7. Do not install venting system components on the

exterior wall of the building except as specically

required by these instructions. Refer to Figure 7.

Table 9: Vent System Components included with Boiler

Vent System Components Part Number

80/125mm Horizontal (Wall) Terminal (ALP080 thru ALP210) 101808-01

100/150mm Horizontal (Wall) Terminal (ALP285 thru ALP399) 101809-01

Vent Pipe Pipe Direction Enclosure

Minimum Clearance To

Combustible Material, Inches

CPVC/PVC Venting Vertical Or Horizontal Enclosed at All Sides 1” Vent/0” Combustion Air

Table 10: Clearances from Vent Piping to Combustible Material

21

The direct vent termination location is restricted as

follows:

a. Minimum twelve (12) inches above grade plus

normally expected snow accumulation level, or

minimum seven (7) feet above grade, if direct

vent terminal is located adjacent to public

walkway. Do not install the terminal over public

walkway where local experience indicates that

appliance ue gas vapor or condensate creates a

nuisance or hazard.

b. Minimum three (3) feet above any forced air

inlet located within ten (10) feet.

c. Minimum four (4) feet horizontally from electric

meters, gas meters, regulators and relief valves.

This distance may be reduced if equipment is

protected from damage due to ue gas vapor or

condensation by enclosure, overhang, etc.

d. Minimum twelve (12) inches below, above or

horizontally from any air opening into a building

(window, door or gravity air inlet).

e. Minimum twelve (36) inches horizontally from a

building corner.

f. Minimum twelve (12) inches vertically from any

roof overhang twelve (12) inches or less wide.

If a roof overhang width exceeds twelve (12)

inches the terminal vertical clearance must be

increased to avoid ue vapor condensation.

8. Enclose vent passing through occupied or

unoccupied spaces above the boiler with material

having a re resistance rating of at least equal to the

rating of the adjoining oor or ceiling. Maintain

minimum clearances to combustible materials. See

Figure 2.

Note: For one or two family dwellings, re

resistance rating requirement may not need to be

met, but is recommended.

9. Plan venting system to avoid possible contact with

plumbing or electrical wires. Start at vent connector

on top of boiler and work towards vent terminal.

Concentric Venting - Horizontal Venting

1. Permitted terminals for horizontal venting:

Horizontal (Wall) Terminal, either 80/125 mm (P/N

101808-01) or 100/150 mm (P/N 101809-01) - see

Table 8.

2. Concentric Vent components supplied with the boiler

are packed inside boiler carton and include the

following:

a. 80/125 mm Horizontal (Wall) Terminal, Part

Number 101808-01

• Horizontal (Wall) Terminal consists of

Straight section having plain male end with

locking band clamp installed; Terminal

Assembly with offset vent termination,

and Outside Wall Plate, both riveted

on the opposite end; overall length is

approximately 28-1/8”.

• Separate Inside Wall Plate

• Two Hardware Bags (each bag contains

four screws and four anchors) to attach vent

terminal Outside Wall Plate to exterior wall

and Inside Wall Plate to interior wall.

b. 100/150 mm Horizontal (Wall) Terminal, Part

Number 101809-01

• Horizontal Concentric Vent Terminal, which

consists of Straight section having plain

male end with locking band clamp installed;

Terminal Assembly with offset vent

termination, and Outside Wall Plate, both

riveted on the opposite end); overall length

is approximately 31-1/8”.

• Separate Inside Wall Plate.

• Two Hardware Bags (each bag contains

four screws and four anchors) to attach vent

terminal Outside Wall Plate to exterior wall

and Inside Wall Plate to interior wall.

14. Installation of the Boiler Concentric Vent Collar is

covered in Section I above. See Figure 12.

15. For horizontal (side wall) installation, the Horizontal

(Wall) Terminal will extend past outer wall surface

either by 4-1/4” (80/125 mm), or, 5-1/2” (100/150

mm). See Figure 13 “Horizontal (Wall) Terminal

Installation”.

17. For horizontal venting, to install the Horizontal

(Wall) Terminal:

a. Cut a 5-1/2” diameter hole through the exterior

wall opening (for 80/125 mm concentric vent) or

6-1/2” diameter hole (for 100/150 mm concentric

vent) at the planned location of the horizontal

terminal.

Table 11: Concentric Vent Length

Boiler Model Concentric Vent

Inner/Outer Pipe

Dia., mm

Vent Length

Wall Opening Diameter

Minimum * Maximum

ALP080

Factory Supplied

Horizontal (Wall) Terminal

80/125 mm 21-7/8 in

Total of 60

Equivalent ft.

5-1/2 in

ALP105

ALP150

ALP210

ALP285

Factory Supplied

Horizontal (Wall) Terminal

100/150 mm 32 in 6-1/2 in

ALP399

n

ote: * With optional concentric vent components. See Table 10 for details.

22

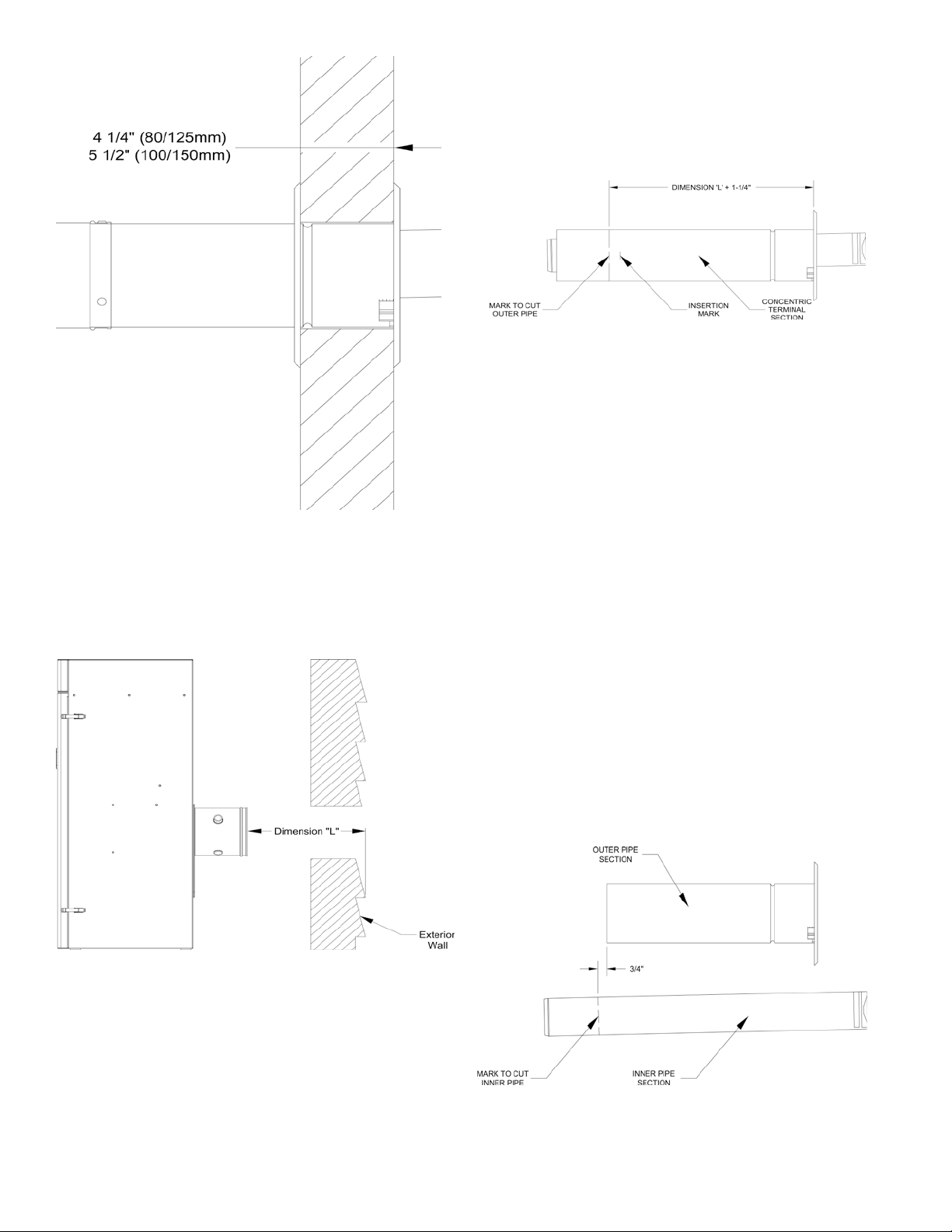

b. Measure dimension “L” from exterior wall outer

surface to the end of the last tting (or end of

installed Boiler Concentric Vent Collar). See

Figure 14 ‘Dimension “L”’.

several marks around the outer pipe to establish a

cut line. See Figure 15 ‘ Cutting Outer Pipe’.

d. Carefully cut the outer pipe at the marked line

using aviation shears, a hacksaw etc. Ensure the

pipe is cut square and cut end is deburred.

Figure 13: Horizontal (Wall) Terminal installation

Figure 14: Dimension “L”

Figure 15: Cutting Outer Pipe

c.

When factory supplied Horizontal (Wall)

Terminal needs to be shortened, measure

dimension “L” plus 1-¼” from inside of the

attached Outside Wall Plate and mark the

Horizontal (Wall) Terminal outer pipe. To

achieve a square cut of the outer pipe, place

e.

Mark the end of the Horizontal (Wall) Terminal

inner polypropylene vent pipe to extend ¾” past

the cut end of the outer pipe. To achieve a square

cut of the inner pipe, place several marks around

the inner pipe to establish a cut line.

f.

Cut off the marked end of inner polypropylene

vent pipe with a ne tooth blade hacksaw etc.

and deburr. See Figure 16 “Cutting Inner Pipe.

g. Place a mark around the outer pipe, 1” from cut

edge, towards the attached Outside Wall Plate, to

establish visual insertion line as shown in Figure

16 “Cutting Inner Pipe”.

h. Pass the shortened Horizontal Concentric Vent

from outside, thru earlier cut exterior wall

opening and push in until the attached Outside

Wall Plate is tight against exterior wall surface.

Insure the proper position of the Horizontal

Concentric Vent before securing the Outside Wall

Plate to the wall with provided fasteners. Seal

plate edges with exterior grade sealant to prevent

moisture penetration.

Figure 16: Cutting

inner Pipe

23

i. Install the supplied Inside Wall Plate onto the

shortened Horizontal (Wall) Terminal interior

end and move the plate to cover interior wall

cut opening. Secure the plate with provided

fasteners, then, apply the sealant around plate

sides to seal it to interior wall.

j. Lubricate the brown gasket inside boiler

concentric vent collar or the last section of the

vent pipe with small amount of water.

k. Ensure that inner pipe of the terminal is evenly

engaged into the gasket all around, then push the

termination male end inside boiler concentric

vent collar or the last section of the vent pipe,

until the mark (see Step g) is no longer visible.

l. Re-install locking band clamp onto the joint

to secure the terminal to the collar or the last

section of the vent pipe.

Figure 17: Horizontal (Wall) Terminal Detail

WaRning

The terminal vent portion is offset towards the top

inside the outer pipe of the Horizontal Concentric

Vent Terminal to provide vent pipe pitch towards

the boiler for condensate removal.

See Figure 17 ‘Horizontal (Wall) Terminal Detail’.

it is imperative to properly mount the vent

terminal.

The terminal orientation label is located on the

inside of the terminal Outside Wall Plate. insure

the vent terminal is positioned as shown in

Figure 18 before securing the Outside Wall Plate

to exterior wall.

CaUTiOn

Exterior wall surface must be reasonably at to

attach the Outside Wall Plate. When exterior wall

surface is not at (covered with vinyl or wood

shingle siding etc.) the siding must be removed,

and a at surface build up ash or above siding

exterior surface to secure/seal the terminal

Outside Wall Plate.

Figure 18: Completing Horizontal (Wall)

T

erminal installation

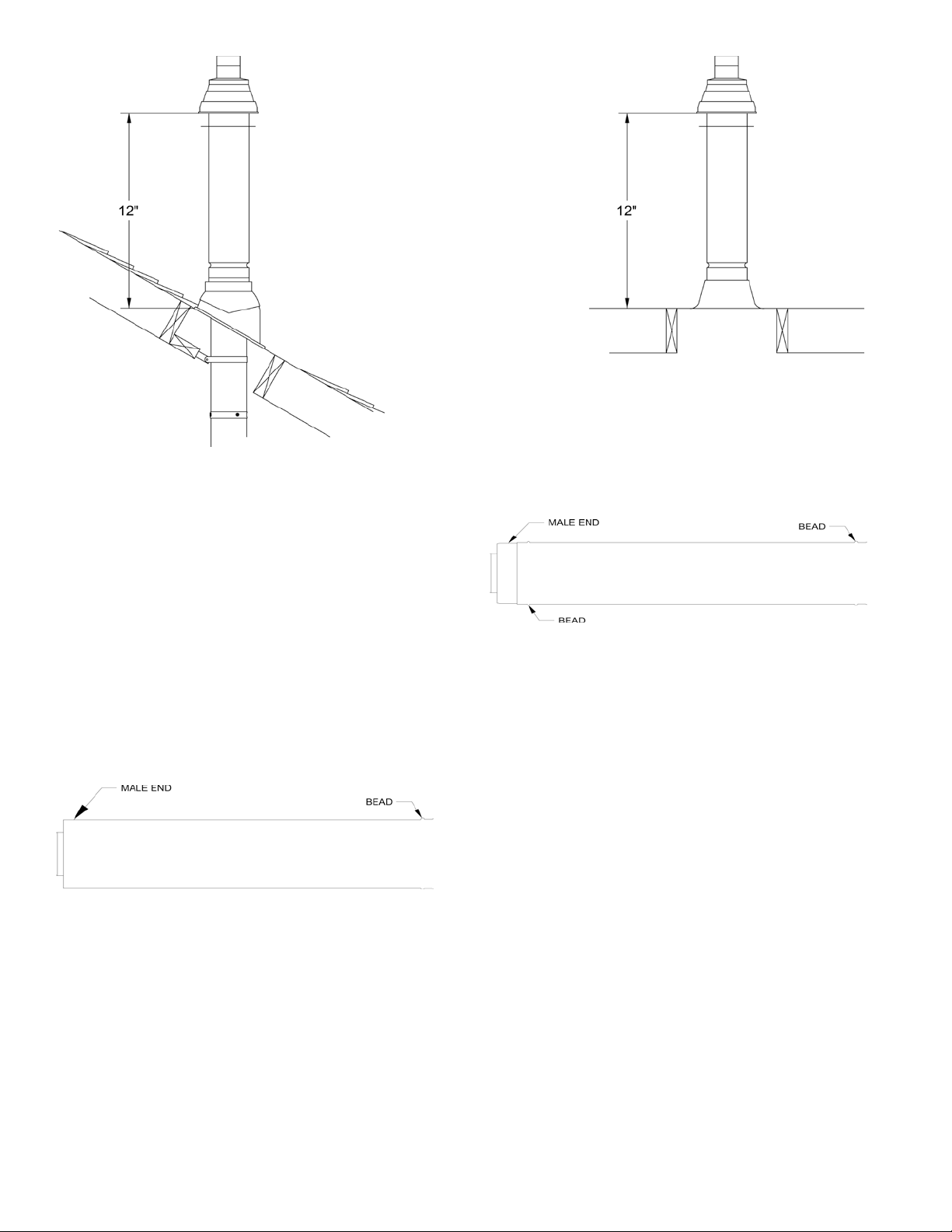

Concentric Venting - Vertical Venting

For vertical (through the roof) venting, extend

Vertical (Roof) Terminal to maintain minimum 12

inches vertical and horizontal distance from building

roof surface. Allow additional vertical distance

for expected snow accumulation. Provide brace as

required. See Figure 19 ‘Vertical Concentric Vent

Installation’.

1. For vertical venting, where optional Concentric Vent

90° degree long radius elbow is attached to installed

Boiler Concentric Vent Collar, to install elbow:

a. Remove locking band clamp off the terminal and

set aside.

b. Lubricate the brown gasket inside boiler

concentric vent collar with small amount of

water.

c. Ensure that male end of the elbow inner plastic

pipe is evenly engaged into the gasket all around,

then, push the elbow male end inside boiler

concentric vent collar until the bead on male end

of elbow outer pipe bottoms out inside boiler

vent collar.

d. Re-install locking band clamp onto the joint to

secure the elbow to the collar.

e.

Continue installing additional concentric vent

cuttable or non-cuttable piping as required.

2. Additionally, secure elbow to boiler vent collar with

three evenly spaced #8 x ½” sheet metal screws.

Use collar rivets as reference attachment points.

Mark (center punch) each screw location off each

rivet centerline 5/8” towards collar-beaded end. See

Figure 18 ‘Completing Horizontal (Wall) Terminal

Installation’ for details. Drill 1/8” hole thru both

24

Figure 19: Vertical Concentric Vent installation

outer pipes to start the screw. Use a drill stop or

other means to ensure that the drill bit does not

penetrate more than 3/8” into the outer pipe. Do

not use sheet metal screws longer than ½”.

When Additional Concentric Vent Piping is

needed

1. If additional concentric vent piping is needed:

a. Concentric Vent Cut-To-Length Extension pipes,

identied in Tables 8 and 10 CAN BE CUT

to required length when used as an extension.

These pipes have plain male end and beaded

female end. Always cut the pipe from plain

male end. See Figure 20 ‘Cut-To-Length

Extension (Cuttable)”.

b. The remaining Concentric Vent Fixed Extensions

shown in Table 8 CANNOT BE CUT. These

pipes have beaded male and beaded female ends.

See Figure 21 ‘Fixed Extension (Non-Cuttable)’.

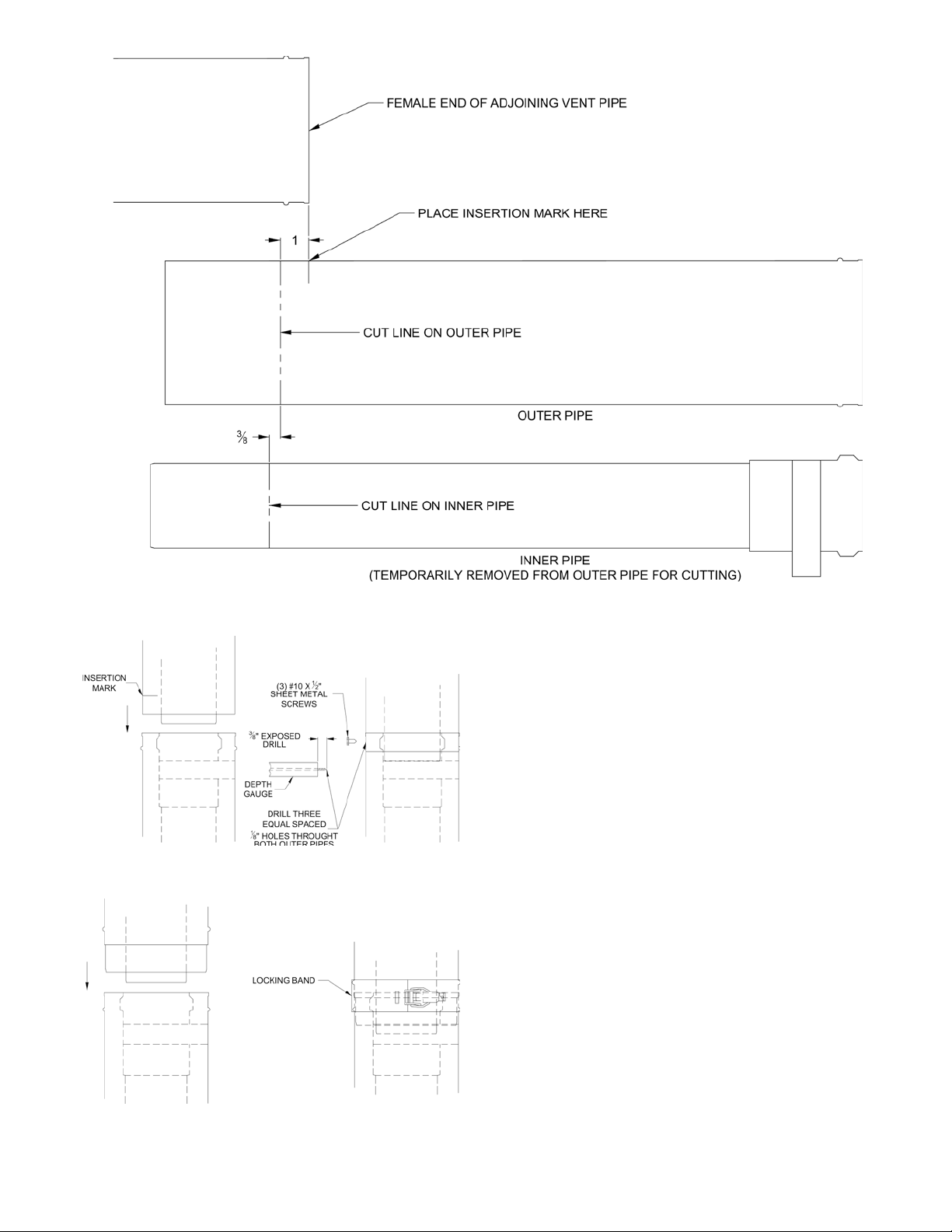

2. To cut the Concentric Vent Straight pipe to required

length refer to Figure 22 “Cutting Straight Pipe” and

follow the procedure below:

a. Determine the required length of the outer pipe.

When doing this allow an additional 1” of length

for insertion into the female end of the adjoining

pipe. Mark the cut line on the outer pipe.

Figure 21: Fixed Extension (non-Cuttable)

Figure 20: Cut-To-Length Extension (Cuttable)

b.

Remove the plastic inner pipe by pulling it out

from the female end.

c.

Cut the OUTER PIPE ONLY at the point

marked in Step (a) using aviation shears, a

hacksaw, or an abrasive wheel cutter. Be careful

to cut the pipe square. Deburr the cut end with a

le or emery cloth.

d. Make an insertion mark 1” from the male end of

the outer pipe.

e. Cut the plastic inner pipe so that it will protrude

3/8” beyond the male end of the outer pipe when

reinstalled in the outer pipe. Use a ne tooth

hacksaw or a PvC saw to cut the plastic pipe and

be careful to cut the pipe square. Deburr the cut

edge of the plastic pipe with a le, razor blade or

ne sandpaper.

f. Reinstall the inner pipe.

3. To join Concentric Vent Pipe refer to Figure 23

“Joining Cuttable Pipe” and Figure 24 “Joining

Non-Cuttable Pipe” and follow the procedure below:

a. Start assembly of the vent system at the boiler.

Lubricate the brown gasket in the boiler vent

collar with a few drops of water.

25

Figure 22: Cutting Straight Pipe

Figure 23: Joining Cuttable Pipe

Figure 24: Joining non-Cuttable Pipe

b. Push the male end of the rst tting into the

boiler collar until it bottoms out. The male end

of cuttable sections should go 1” into the collar

until the insertion mark (made in Step 2d above)

is covered. On other ttings, the bead on the

male pipe will be bottom out on the collar (see

Figure 24).

c.

The male end of cuttable ttings must be held to

the collar with three (3) #10 x 1/2” sheet metal

screws. Drill a 1/8 hole through both outer pipes

to start this screw. Use a drill stop or other

means to ensure that the drill bit does not

penetrate more than 3/8” into the outer pipe.

Do not use a sheet metal screw longer than

1/2” (see Figure 23).

d. Use locking bands (provided with all ttings) to

secure non-cuttable pipe, as well as ttings, to

the boiler collar (see Figure 24).

e. Use the same method to join all remaining vent

components except for the terminal.

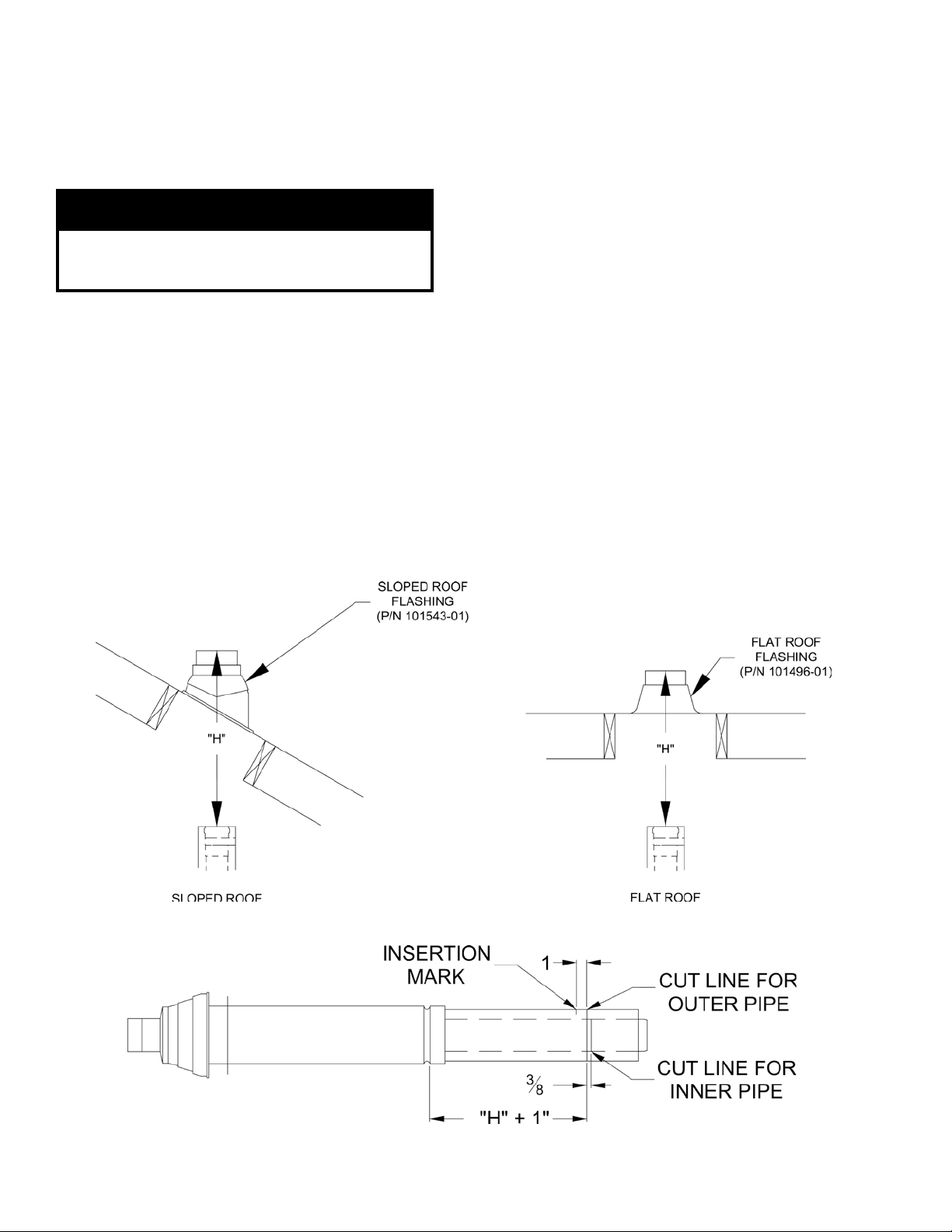

Vertical (Roof Terminal Installation

1. Vertical (Roof) Terminal Installation. Refer to

Figures 26, 27 and 28.

In addition to the vertical terminal, either a Flat

Roof Flashing or Sloped Roof Flashing is required

for this installation. Refer to Table 8 ‘Concentric

Vent Components’ for details.

26

Figure 26: Cutting Vertical Terminal

a. Determine the centerline of the terminal location

on the roof. For at roof, cut either 5-1/2”

diameter hole (80/125 mm concentric vent size)

or 6-1/2” diameter hole (100/150 mm concentric

vent size) for the terminal. For sloped roof, cut a

hole in the roof large enough for the terminal to

pass through the roof while remaining plumb.

CaUTiOn

if the boiler is located directly under the hole,

cover it while cutting the hole to prevent debris

from falling onto boiler.

b. Install the roof ashing using standard practice

on the roong system of the structure.

c.

If not already done, assemble the venting system

inside the building. The last section of pipe needs

to be on the same center line as the terminal

and within 19-1/4” of the top edge of the roof

ashing.

d.

Measure distance “H” from the top edge of the

storm collar to the end of the last tting as shown

in Figure 25.

e. Add 1” to distance “H”. Carefully mark this

length on the pipe as shown in Figure 26.

f. Cut the outer pipe only at the point marked in

Step (e) using aviation shears, a hacksaw, or an

abrasive wheel cutter. Be careful to cut the pipe

square. De-burr the cut end with a le or emery

cloth.

g.

Place a mark on the plastic inner pipe 3/8”

beyond the end of the outer pipe (Figure 26).

Use a ne tooth hacksaw to cut the plastic pipe

and be careful to cut the pipe square. De-burr the

cut edge of the plastic pipe with a le or emery

cloth.

h. Make a mark on the terminal section 1” from the

cut end of the outer pipe as shown in Figure 26.

i. Slip the terminal section through the roof from

the outside. Push into the last section of vent

pipe until the mark made in Step (h) is not

longer visible. Secure the terminal to the last

piece of pipe with three #10 x 1/2” sheet metal

screws. Drill a 1/8” hole through both outer

pipes to start these screws. Use a drill stop or

other means to ensure that the drill bit does

not penetrate more than 3/8” into the outer

pipe. Do not use a sheet metal screw longer

than 1/2”.

j. Secure the terminal section to the inside of

the roof structure using the mounting bracket

provided with the terminal (Figure 27).

Figure 25: Dimension "H"

27

Table 10: Cut-To-Length Extensions (Cuttable)

Part No. Component Description Size

101163-01

Cut-To-Length Extension,

500 mm (19-1/2”)

80/125 mm

101162-01

Cut-To-Length Extension,

1000 mm (39”)

101550-01

Cut-To-Length Extension,

500 mm (19-1/2”)

100/150 mm

101551-01

Cut-To-Length Extension,

1000 mm (39”)

Figure 27: Completing Vertical Terminal installation

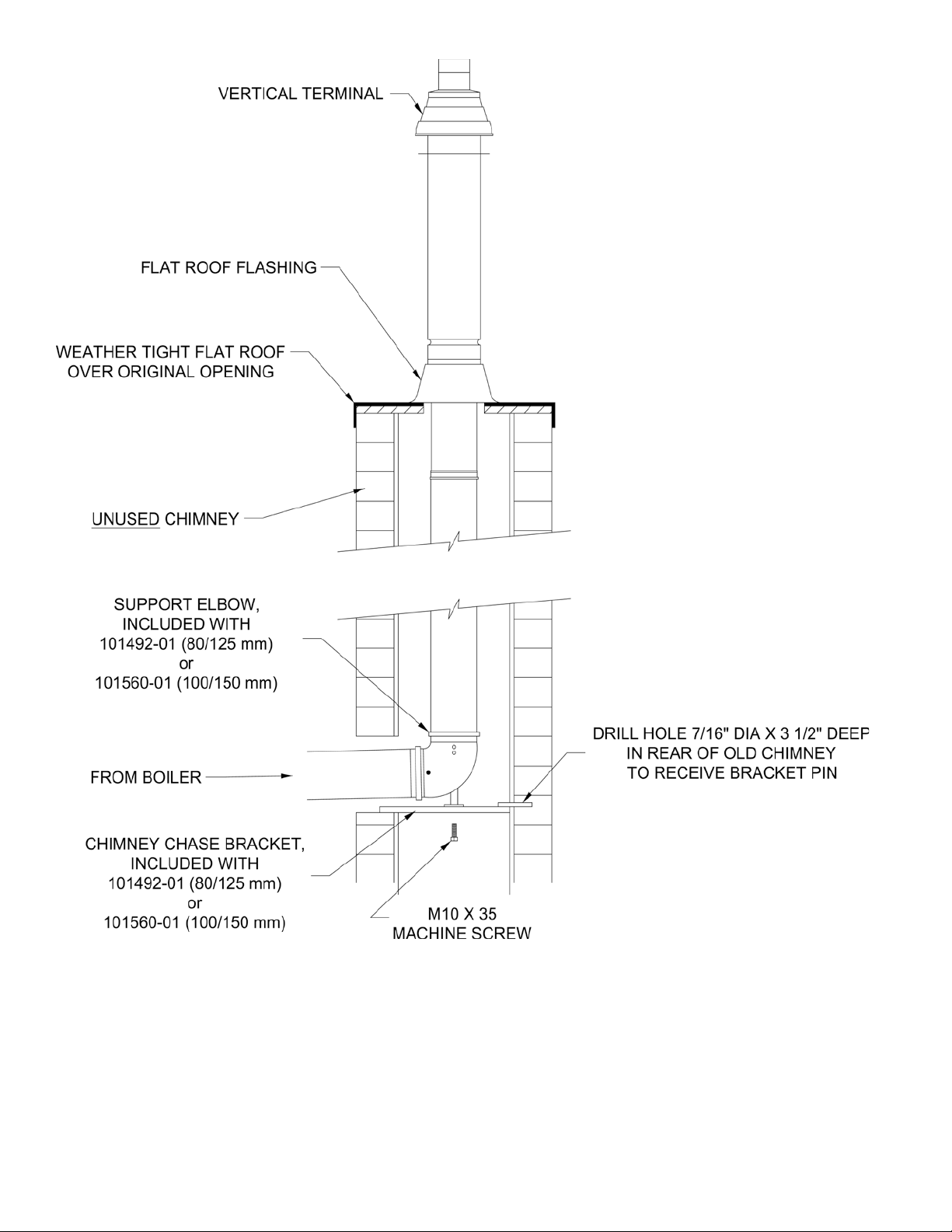

Chimney Chase Installation.

A vertical concentric vent system, either 80/125 mm

or 100/150 mm can be installed in an UNUSED

masonry chimney. Refer to Figure 28.

a. The Chimney chase Support Elbow with

attached Mounting Bracket is used at the base

of the chimney. Refer to Table 8 ‘Concentric

Vent Components’ for details. Slip the elbow

over the M10 x 35 screw in the support bracket.

Determine the desired vertical location of the

support elbow in the chimney and mark the

location of the pin, positioned on the back of

the support bracket, onto the chimney rear wall.

Drill a 7/16” diameter x 3-1/2” deep hole in the

marked location, then, insert the back bracket pin

into the hole. The front of the elbow mounting

bracket should be supported either by bottom of

the opening into chimney or installer supplied

spacer.

b.

Construct a weather-tight at roof to cover

the top of the old chimney. Install the vertical

terminal through this roof using the at roof

ashing.

28

Figure 28: Chimney Chase installation

29

V. Condensate Disposal

A. Condensate Trap and Drain Line.

1. All condensate, which forms in the boiler or vent

system, collects in the sump under heat exchanger

and leaves the boiler through factory installed

condensate trap.

2. The trap allows condensate to drain from sump

while retaining ue gases in the boiler. The trap

has factory installed overow switch, which shuts

down the boiler in the event the drain line becomes

obstructed, preventing proper condensate removal.

Refer to Section XIII “Service and Maintenance”

for condensate trap and condensate overow switch

removal and replacement procedure, if required.

3. Note the following when disposing of the

condensate:

a. Condensate is slightly acidic, typical pH around

3.5 - 4.5. Do not use metallic pipe or ttings in

the condensate drain line. Do not route the drain

line through areas that could be damaged by

leaking condensate.

b.

Do not route or terminate the condensate drain

line in arrears subject to freezing temperatures.

c. If the point of condensate disposal is above the

trap, a condensate pump is required to move

the condensate to the drain. Select a condensate

pump approved for use with condensing

furnaces. If overow from the pump would

result in property damage, select a pump with an

overow switch. Wire this switch in series with

installer provided external high limit, to shut off

the boiler, and, if desired, in series with installer-

supplied alarm, to trigger an alarm in the event

of overow.

d. Do not attempt to substitute another trap for one

provided with the boiler.

e. In order for boiler to work properly, the boiler

must be leveled during installation.

4. The condensate trap stub is located at boiler left

side, below inlet and outlet water pipe connections.

Refer to Figures 1A and 1B.

5. Condensate trap must be lled up with water,

prior to boiler start-up and before connecting any

condensate line to the boiler, to insure combustion

products cannot escape from operating boiler. To ll

the trap, inject water in the amount of 1 cup (8 uid

ounces) through condensate trap stub opening. Do

not overll the trap.

6. If any additional condensate drain line is needed,

construct the extension from PVC or CPVC

Schedule 40 pipe. The factory supplied ¾” x 5-5/8”

long PVC coupling, located in the Part Carton, must

be used to connect drain line to the condensate trap

stub. Do not over tighten coupling compression nuts

when connecting drain line and condensate trap

stub.

WaRning

Failure to install the condensate trap and

condensate drain in accordance with the above

instructions could cause ue gas to enter the

building, resulting in personal injury or death.

CaUTiOn

Boiler condensate is corrosive. Route

condensate drain line in a manner such

that any condensate leakage will not cause

property damage.

Some jurisdictions may require that

condensate be neutralized prior to disposal.

nOTiCE

Use materials approved by the authority having

jurisdiction.

B. Condensate Neutralizer Installation

1. Some jurisdictions may require that the condensate

be neutralized before being disposed of. Follow

local codes pertaining to condensate disposal.

2. A Condensate Neutralizer Kit (P/N 101867-01)

is available as optional equipment. Follow local

codes and instructions enclosed with the kit for

Condensate Neutralizer installation.

3. Limestone chips will get coated by neutral salts

(product of chemical reaction between limestone

and acidic condensate) and lose neutralizing

effectiveness over time. Therefore, periodic

condensate neutralizer maintenance and limestone

chip replacement must be performed. A pH test or

acid test kits are available from HVAC/plumbing

distributors and should be used to measure

condensate acidity before/after neutralizer thus

indicating a need for service and chip replacement.

30

Figure 29: Condensate Trap and Drain Line

Loading...

Loading...