Burnham 20-PV-I User Manual

Price - $3.00

INSTALLATION, OPERATING

AND

SERVICE INSTRUCTIONS

SERIES 2PV

GAS BOILER

For service or repairs to boiler, call your heating contractor. When seeking information on boiler, provide Boiler Model Number and Serial Number as shown on Rating Label.

Boiler Model Number |

Boiler Serial Number |

Installation Date |

20_PV_I-_ _ _ _ |

6_ _ _ _ _ _ _ |

Heating Contractor |

Phone Number |

Address

8141775R9-11/99 |

1 |

|

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels, or to important information concerning product life.

DANGER

Indicates an imminently hazardous situation wh ic h, if n ot avoide d, will re sult in de at h, serious injury or substantial property damage.

CAUTION

Indicate s a po tentia lly hazardous s ituat ion w hich, if n ot avoided, may re sult in

mod erate o r minor in jury or prope rty damage .

WARNING

In dic at es a pot ent ia lly ha za rdo us situ ation which, if not avoide d, could result in death, serious injury or substantial property damage.

NOTICE

Indicates spec ial ins tru ctions on

ins tallatio n, opera tion, or maintenanc e whi ch are importan t but not re late d to persona l injury ha zards .

Table of Contents

I. |

Pre-Installation ..................................... |

4 |

II. |

Unpack Boiler ....................................... |

5 |

III. |

Water Piping ......................................... |

6 |

IV. |

Gas Piping ............................................ |

8 |

V. |

Venting ................................................. |

9 |

VI. |

Electrical ............................................. |

12 |

VII. |

System Start-up .................................. |

13 |

VIII. |

Service Instructions ............................ |

20 |

IX. |

Repair Parts ........................................ |

23 |

2

NOTICE

USA boilers built for installation at altitudes greater than 2,000 feet above sea level have been specially orificed to reduce gas input rate 4 percent per 1,000 feet above sea level per the National Fuel Gas Code, NFPA 54/ANSI Z223.1, Section 8.1.2 and Appendix F. Canadian boilers’ orifice sizing is indicated on the rating label. High altitude boiler models are identifiable by the second digit in the model number suffix on the rating label:

20_PV_I-__2: Less than 2000 ft. elevation

20_PV_I-__4: 2000 ft. and higher elevation, Canada 20_PV_I-__5: 2000 ft. and higher elevation, USA

Figure 1: Elevation Views

Boiler Model |

|

Dimensions [in inches] |

|

Water Content |

Approx. Shipping |

||

A |

B |

|

C |

D |

[Gallons] |

Weight (lb.) |

|

|

|

||||||

|

|

|

|

|

|

|

|

203PV |

20‰ |

14‰ |

|

10-1/16 |

15-5/8 |

3.2 |

265 |

|

|

|

|

|

|

|

|

204PV |

23 |

17 |

|

11 |

15-5/8 |

4 |

309 |

|

|

|

|

|

|

|

|

205PV |

27 |

21 |

|

13‰ |

15… |

4.7 |

357 |

|

|

|

|

|

|

|

|

206PV |

30… |

24… |

|

15-1/8 |

15… |

5.5 |

419 |

|

|

|

|

|

|

|

|

3

I. Pre-Installation

WARNING

Carefully read all instructions before installing boiler. Failure to follow all instructions in proper order can cause personal injury or death.

A. Inspect shipment carefully for any signs of damage. All equipment is carefully manufactured, inspected and packed. Our responsibility ceases upon delivery of boiler to carrier in good condition. Any claim for damage or shortage in shipment must be filed immediately against carrier by consignee. No claims for variances or shortages will be allowed by Boiler Manufacturer, unless presented within sixty (60) days after receipt of equipment.

B.Installation must conform to the requirements of the authority having jurisdiction. In the absence of such requirements, installation must conform to National Fuel Gas Code, NFPA 54/ANSI Z223.1, and/or CAN/ CGA B149 Installation Codes. Where required by the authority having jurisdiction, the installation must conform to the Standard for Controls and Safety Devices for Automatically Fired Boilers, ANSI/ASME CSD-1.

C.Appliance is design certified for installation on combustible flooring. The boiler must not be installed on carpeting.

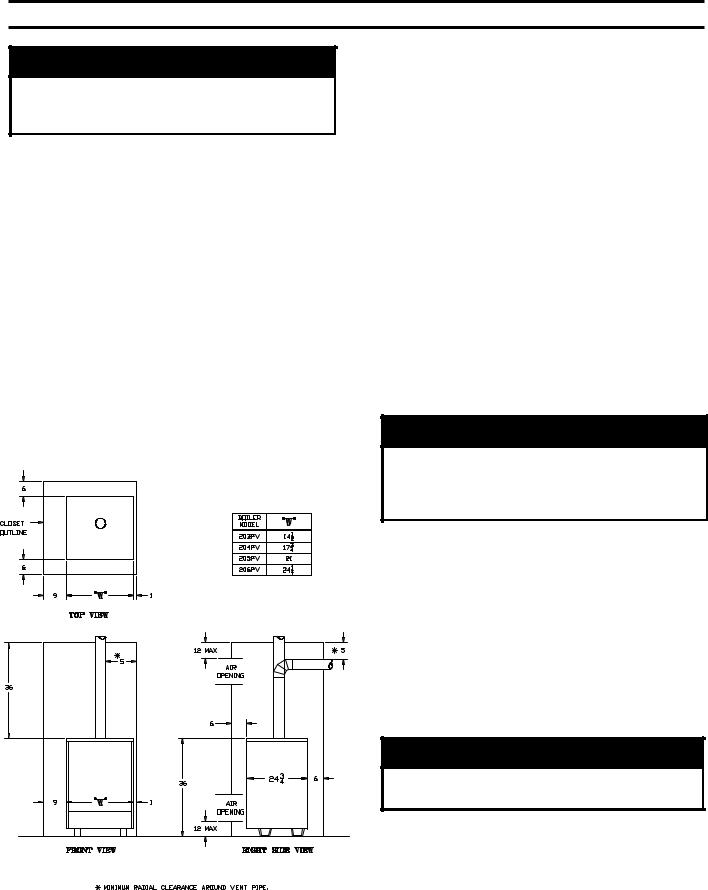

D.Provide clearance between boiler jacket and combustible material in accordance with local fire ordinance. See Figure 2 for minimum clearance from combustible material for closet installation. For alcove installation provide top clearance of 27 inches and right side clearance of 6 inches. Recommended service clearance is 24 inches from left side, right side and front. Service clearances may be reduced to minimum clearances to combustible materials.

E.Install on level floor. For basement installation provide solid base, such as concrete, if floor is not level or if water may be encountered on floor around boiler.

F.Install near outside wall for through wall venting. Refer to Section V: Venting. Certified for minimum vent length of 2 feet with one (1) elbow and maximum vent length of 15 feet with one (1) or two (2) elbows.

WARNING

Certified as Category III appliance. Install vent system in accordance with Section V: Venting. Do not vent using masonry chimney, Type B gas vent, or other Category I venting system.

G.Protect gas ignition system components from water (dripping, spraying, rain, etc.) during boiler operation and service (circulator replacement, condensate trap, control replacement, etc.).

H.Provide combustion and ventilation air in accordance with applicable provisions of local building codes, or National Fuel Gas Code, NFPA 54/ANSI Z223.1, Section 5.3, Air for Combustion and Ventilation, or Sections 7.2, 7.3 or 7.4 of CAN/CGA B149 Installation Codes.

Figure 2: Minimum Clearances to Combustible Construction for Closet Installation

WARNING

Adequate combustion and ventilation air must be provided to assure proper combustion.

The following guideline is based on the National Fuel Gas Code, NFPA 54/ANSI Z223.1.

1.Determine volume of space (boiler room). Rooms communicating directly with space (through openings not furnished with doors) are considered part of space.

4 |

Volume [ft³] = Length [ft] x Width [ft] x Height [ft] |

|

freely communicating with the outdoors. Locate one |

I. Do not install boiler where gasoline or other |

|

flammable vapors or liquids, or sources of |

|

|

opening within 12 inches of top of space. Locate |

|

|

hydrocarbons (i.e. bleaches, cleaners, chemicals, |

|

|

remaining opening within 12 inches of bottom of |

|

|

sprays, paint removers, fabric softeners, etc.) are used |

|

|

space. Minimum dimension of air opening is 3 |

|

|

or stored. |

|

|

inches. Size each opening per following: |

|

2. |

Determine Total Input of all appliances in space. |

a. Direct communication with outdoors. Minimum |

|

Round result to nearest 1,000 Btu per hour (Btuh). |

free area of 1 square inch per 4,000 Btu per hour |

3. Determine type of space. Divide Volume by Total |

input of all equipment in space. |

|

|

Input. |

b. Vertical ducts. Minimum free area of 1 square |

|

a. If result is greater than or equal to 50 ft³ per |

inch per 4,000 Btu per hour input of all |

|

1,000 Btuh, space is considered an unconfined |

equipment in space. Duct cross-sectional area |

|

space. |

shall be same as opening free area. |

|

b. If result is less than 50 ft³ per 1,000 Btuh, space |

c. Horizontal ducts. Minimum free area of 1 |

|

is considered a confined space. |

square inch per 2,000 Btu per hour input of all |

|

Determine building type. A building of unusually |

equipment in space. Duct cross-sectional area |

4. |

shall be same as opening free area. |

|

|

tight construction has the following characteristics: |

Alternate method for boiler located within confined |

|

a. Walls and ceiling exposed to outside atmosphere |

space. Use indoor air if two permanent openings |

|

have a continuous water vapor retarder with a |

communicate directly with additional space(s) of |

|

rating of 1 perm or less with openings gasketed |

sufficient volume such that combined volume of all |

|

and sealed, and; |

spaces meet criteria for unconfined space. Size each |

|

b. Weather-stripping has been added on openable |

opening for minimum free area of 1 square inch per |

|

windows and doors, and; |

1,000 Btu per hour input of all equipment in |

|

c. Caulking or sealants applied in joints around |

spaces, but not less than 100 square inches. |

|

window and door frames, between sole plates |

7. Ventilation Duct Louvers and Grilles. Equip |

|

and floors, between wall-ceiling joints, between |

outside openings with louvers to prevent entrance |

|

wall panels, at plumbing and electrical |

of rain and snow, and screens to prevent entrance of |

|

penetrations, and at other openings. |

insects and rodents. Louvers and grilles must be |

|

For boiler located in an unconfined space in a |

fixed in open position or interlocked with |

5. |

equipment to open automatically before burner |

|

|

building of other than unusually tight construction, |

operation. Screens must not be smaller than ¼ inch |

|

adequate combustion and ventilation air is normally |

mesh. |

|

provided by fresh air infiltration through cracks |

Consider the blocking effect of louvers, grilles and |

|

around windows and doors. |

screens when calculating the opening size to |

6. |

For boiler located within unconfined space in |

provide the required free area. If free area of louver |

|

building of unusually tight construction or within |

or grille is not known, assume wood louvers have |

|

confined space, provide outdoor air through two |

20-25 percent free area and metal louvers and |

|

permanent openings which communicate directly or |

grilles have 60-75 percent free area. |

|

by duct with the outdoors or spaces (crawl or attic) |

|

II. Unpack Boiler

CAUTION

Do not drop boiler. Do not bump boiler jacket against floor.

A.Move boiler to approximate installed position.

B.Remove all crate fasteners.

C.Lift outside container and remove with all other inside protective spacers and bracing. Save two of the wooden slats from the container sleeve for use in Steps E and F.

D.Remove all boiler hold-down fasteners.

E.Tilt the boiler to one side and slide a wooden slat under the two raised feet.

F.Tilt the boiler to the other side and slide another wooden slat under the two raised feet.

G.Slide the boiler forward or backward off the skid using the two wooden slats as runners.

H. Move boiler to its permanent location.

5

III. Water Piping and Trim

CAUTION

Failure to properly pipe boiler may result in improper operation and damage to boiler or building.

A.Design and install boiler and system piping to prevent oxygen contamination of boiler water.

CAUTION

Oxygen contamination of boiler water will cause corrosion of iron and steel boiler components, and can lead to boiler failure. Burnham’s standard warranty does not cover problems caused by oxygen contamination of boiler water.

Oxygen contamination sources are system leaks requiring addition of makeup water, fittings, and oxygen permeable materials in distribution system. Eliminate oxygen contamination by repairing system leaks, repairing fittings, and using nonpermeable materials in distribution system.

B.Connectsystemsupplyandreturnpiping to boiler. See Figure 3. Also consult I=B=R Installation and Piping Guides. Maintain minimum ½ inch clearance from hot water piping to combustible materials.

C.Install Circulator with flanges, gaskets and bolts provided. Five foot circulator harness allows circulator to be mounted on supply or return. Connect harness to circulator and secure any excess conduit.

D.Install Safety Relief Valve. See Figure 3. Safety Relief Valve must be installed with spindle in vertical position. Installation of the relief valve must be consistant with the ANSI/ASME Boiler and Pressure Vessel Code, SectionIV.

WARNING

Safety relief valve discharge piping must be piped near floor to eliminate potential of severe burns. Do not pipe in any area where freezing could occur. Do not install any shut-off valves.

E.Install Drain Valve in ¾" NPT connection in tee provided. See Figure 1.

F.SpaceheatinganddomesticwaterheatingwithAlliance water heater. Install Alliance water heater as a separate heating zone. Refer to Alliance Installation, Operating and Service Instructions for additional information.

G.Ifboilerisusedinconnectionwithrefrigerationsystems, boiler must be installed with chilled medium piped in parallel with the heating boiler using appropriate valves to prevent chilled medium from entering boiler, see Figure 4. Also consult I=B=R Installation and Piping Guides.

H.If boiler is connected to heating coils located in air handling units where they may be exposed to refrigerated air, boiler piping must be equipped with flow control valves to prevent gravity circulation of boiler water during operation of cooling system.

I.Use a boiler bypass if the boiler is to be operated in a system which has a large volume or excessive radiation where low boiler water temperatures may be encountered (i.e. converted gravity circulation system, etc.).

Install pipe tee between circulator and boiler return along with second tee in supply piping as shown in Figure 5. Bypass should be same size as the supply and return lines with valves located in bypass and supply outlet as illustrated in Figure 5 in order to regulate water flow to maintain higher boiler water temperatures.

After the boiler is operational (reference Section VII. System Start-Up) set by-pass and boiler supply valves to half throttle position to start. Operate boiler until system water temperature reaches normal operating range. Adjust valves to provide 180° to 200°F supply water temperature. Opening the boiler supply valve will raise system temperature, while opening the by-pass valve will lower system supply temperature.

J.Ahotwaterboilerinstalledaboveradiationlevelmustbe provided with a low water cutoff device as part of installation.

K.Oil,grease,andotherforeignmaterialswhich accumulate in new hot water boilers and a new or reworked system should be boiled out, and then thoroughly flushed. A qualified water treatment chemical specialist should be consulted for recommendations regarding appropriate chemical compounds and concentrations which are compatible with local environmental regulations.

L.Aftertheboilerandsystemhavebeencleanedand flushed, and before refilling the entire system add appropriate water treatment chemicals, if necessary, to bring the pH between 7 and 11.

6

Figure 3: Recommended Boiler Piping For Series - Loop Hot Water Heating Systems

Figure 4: Recommended Piping for Combination |

Figure 5: Recommended Bypass Piping |

Heating & Cooling (Refrigeration) Systems |

7

IV. Gas Piping

A.Size gas piping. Design system to provide adequate gas supply to boiler. Consider these factors:

1.Allowable pressure drop from point of delivery to boiler. Maximum allowable system pressure is ½ psig. Actual point of delivery pressure may be less; contact gas supplier for additional information. Minimum gas valve inlet pressure is listed on rating label.

2.Maximum gas demand. Table 1 lists boiler input rate. Also consider existing and expected future gas utilization equipment (i.e. water heater, cooking equipment).

Table 1: Rated Input

Boiler |

Input Rate |

Gas |

||

[cubic feet per hour] |

||||

Model |

Connection |

|||

|

|

|||

Number |

Natural Gas |

LP/Propane |

Size |

|

|

|

|||

|

|

|

|

|

203PV |

62 |

24 |

‰ |

|

|

|

|

|

|

204PV |

96 |

38‰ |

‰ |

|

|

|

|

|

|

205PV |

130 |

52 |

‰ |

|

|

|

|

|

|

206PV |

164 |

65 |

‰ |

|

|

|

|

|

|

3.Length of piping and number of fittings. Refer to Table 2 for maximum capacity of Schedule 40 pipe. Table 3 lists equivalent pipe length for standard fittings.

4.Specific gravity of gas. Gas piping systems for gas with a specific gravity of 0.70 or less can be sized directly from Table 2, unless authority having jurisdiction specifies a gravity factor be applied. For specific gravity greater than 0.70, apply gravity factor from Table 4. If exact specific gravity is not shown choose next higher value.

For materials or conditions other than those listed above, refer to National Fuel Gas Code, NFPA 54/ ANSI Z223.1, or size system using standard engineering methods acceptable to authority having jurisdiction.

B.Connect boiler gas valve to gas supply system.

1.Use methods and materials in accordance with local plumbing codes and requirements of gas supplier. In absence of such requirements, follow National Fuel Gas Code, NFPA 54/ANSI Z223.1 and/or CAN/CGA B149 Installation Codes.

2.Use thread (joint) compounds (pipe dope) resistant to action of liquefied petroleum gas.

3.Install sediment trap, ground-joint union and manual shut-off valve upstream of boiler gas control valve and outside jacket. See Figure 6.

4.All above ground gas piping upstream from manual shut-off valve must be electrically continuous and bonded to a grounding electrode. Do not use gas piping as grounding electrode. Refer to National Electrical Code, ANSI/NFPA 70 and/or CSA C22 Electrical Code.

C.Pressure test. The boiler and its gas connection must be leak tested before placing boiler in operation.

1.Protect boiler gas control valve. For all testing over ½ psig, boiler and its individual shutoff valve must be disconnected from gas supply piping. For testing at ½ psig or less, isolate boiler from gas supply piping by closing boiler's individual manual shutoff valve.

2.Locate leaks using approved combustible gas detector, soap and water, or similar nonflammable solution. Do not use matches, candles, open flames, or other ignition source.

Figure 6: Recommended Gas Piping

8

Table 2: Maximum Capacity of Schedule 40 Pipe in CFH For Gas Pressures of 0.5 psig or Less

Length |

|

0.3 inch w.c. Pressure Drop |

|

|

0.5 inch w.c. Pressure Drop |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

[Feet] |

‰ |

|

|

1 |

|

1… |

‰ |

|

|

1 |

|

1… |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

132 |

|

278 |

520 |

|

1,050 |

175 |

|

360 |

680 |

|

1,400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

92 |

|

190 |

350 |

|

730 |

120 |

|

250 |

465 |

|

950 |

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

73 |

|

152 |

285 |

|

590 |

97 |

|

200 |

375 |

|

770 |

|

|

|

|

|

|

|

|

|

|

|

|

|

40 |

63 |

|

130 |

245 |

|

500 |

82 |

|

170 |

320 |

|

660 |

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

56 |

|

115 |

215 |

|

440 |

73 |

|

151 |

285 |

|

580 |

|

|

|

|

|

|

|

|

|

|

|

|

|

60 |

50 |

|

105 |

195 |

|

400 |

66 |

|

138 |

260 |

|

530 |

|

|

|

|

|

|

|

|

|

|

|

|

|

70 |

46 |

|

96 |

180 |

|

370 |

61 |

|

125 |

240 |

|

490 |

|

|

|

|

|

|

|

|

|

|

|

|

|

80 |

43 |

|

90 |

170 |

|

350 |

57 |

|

118 |

220 |

|

460 |

|

|

|

|

|

|

|

|

|

|

|

|

|

90 |

40 |

|

84 |

160 |

|

320 |

53 |

|

110 |

205 |

|

430 |

|

|

|

|

|

|

|

|

|

|

|

|

|

100 |

38 |

|

79 |

150 |

|

305 |

50 |

|

103 |

195 |

|

400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 3: Fitting Equivalent Lengths

Fitting |

|

Nominal Pipe Size |

|

||||

|

|

|

|

|

|

||

‰ |

|

|

1 |

|

1… |

||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

45 |

Ell |

0.7 |

|

1 |

1.2 |

|

1.6 |

|

|

|

|

|

|

|

|

90 |

Ell |

1.6 |

|

2.1 |

2.6 |

|

3.5 |

|

|

|

|

|

|

|

|

Tee (As Elbow) |

3.1 |

|

4.1 |

5.2 |

|

6.9 |

|

|

|

|

|

|

|

|

|

Table 4: Specific Gravity Correction Factors

Specific |

Correction |

Specific |

Correction |

Gravity |

Factor |

Gravity |

Factor |

|

|

|

|

0.50 |

1.10 |

1.30 |

1.07 |

|

|

|

|

0.55 |

1.04 |

1.40 |

1.04 |

|

|

|

|

0.60 |

1.00 |

1.50 |

1.00 |

|

|

|

|

0.65 |

0.96 |

1.6 |

0.97 |

|

|

|

|

0.7 |

0.93 |

1.7 |

0.94 |

|

|

|

|

0.75 |

0.9 |

|

|

|

|

|

|

0.8 |

0.87 |

|

|

|

|

|

|

V. Venting

A.General Guidelines.

1.Vent system installation must be in accordance with

National Fuel Gas Code, NFPA 54/ANSI Z221.3, Part 7, Venting of Equipment; and/or CAN/CGA B149 Installation Codes, Section 7, Venting Systems and Air Supply for Appliances; or applicable provisions of local building codes. Contact local building or fire officials about restrictions and installation inspection in your area.

2.This appliance requires a Special Gas Vent. Use Vent Connector and Vent Terminal in Vent Accessory Carton provided with boiler (See Repair Parts, Key No. 8). The product is designed to use Burnham supplied AL 29-4C® Stainless Steel vent system components. The following manufacturers offer similar AL 29-4C® components and are approved for use with this product: Heat-Fab Inc. -

Saf-T-Vent,Flex-LInternationalInc.,-Star-34, Protech Systems, Inc. - FasNSeal™, and Z-Flex U. S., Inc. - Z-Vent. The use of these alternate manufacturer's venting systems will require adapters to connect to the Burnham supplied vent connector and vent terminal. These adapters are not supplied with this unit and should be obtained from the supplier of the alternate manufacturer's venting system. See Table 5 for complete list of Burnham Vent System Components.

WARNING

Do not use this appliance with nonmetallic vent systems such as Hart & Cooley Ultravent, Plexco Plexvent, or Selkirk-Metalbestos Sel-Vent.

9

Table 5: Burnham Vent System Components

|

|

|

Burnham |

Burnham |

Vent System |

*Cartoned |

Component |

||

Component |

Part |

Part |

||

|

|

|

Number |

Number |

|

|

|

|

|

3" Dia. Pipe x 1 |

Ft |

611 60112 |

8116135 |

|

|

|

|

|

|

3" Dia. Pipe x 3 |

Ft |

61160101 |

8116058 |

|

|

|

|

|

|

3" Dia. Pipe x 4 |

Ft |

** |

8116176 |

|

|

|

|

|

|

3" Dia. Pipe x 5 |

Ft |

6116 0111 |

8116059 |

|

|

|

|

|

|

3" Dia . 90 |

Elbow |

61160121 |

8116060 |

|

|

|

|

|

|

3" Dia . 45 |

Elbow |

61160131 |

8116061 |

|

|

|

|

|

|

*Complete with Locking Band(s)

** 61160 33 Contains (4 ) 4 ft. l engths 61160 40 Contains (2 ) 4 ft. l engths

3.Minimum vent length requirement is 2 feet of pipe and one (1) elbow. Maximum vent length is 15 feet with one (1) or two (2) elbows.

4.Do not install venting system components on the exterior of the building except as specifically required by these instructions.

B.Removal of Existing Boiler. For installations not involving the replacement of an existing boiler, proceed to Step C.

When an existing boiler is removed from a common venting system, the common venting system is likely to be too large for proper venting of the remaining appliances. At the time of removal of an existing boiler, the following steps shall be followed with each appliance remaining connected to the common venting system placed in operation, while the other appliances remaining connected to the common venting system are not in operation:

(a)Seal any unused openings in the common venting system.

(b)Visually inspect the venting system for proper size and horizontal pitch and determine there is no blockage or restriction, leakage, corrosion, and other deficiencies which could cause an unsafe condition.

(c)Insofar as is practical, close all building doors and windows and all doors between the space in which the appliances remaining connected to the common venting system are located and other spaces of the building. Turn on clothes dryers and any appliance not connected to the common venting system. Turn on any exhaust fans, such as range-hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate a summer exhaust fan. Close fireplace dampers.

(d)Place in operation the appliance being inspected. Follow the Lighting (or Operating) Instructions. Adjust thermostat so appliance will operate

continuously.

(e)Test for spillage at the drafthood relief opening after 5 minutes of main burner operation. Use the flame of a match or candle, or smoke from a cigarette, cigar or pipe.

(f)After it has been determined that each appliance remaining connected to the common venting system properly vents when tested as outlined above, return doors, windows, exhaust fans, fireplace dampers and any other gas burning appliance to their previous conditions of use.

(g)Any improper operation of the common venting system should be corrected so the installation conforms with the National Fuel Gas Code, NFPA 54/ANSI Z223.1. When resizing any portion of the common venting system, the common venting system should be resized to approach the minimum size as determined using the appropriate tables in Part II in the National Fuel Gas Code, NFPA 54/ ANSI Z223.1.

C.Install Vent Connector.

1. Remove vent connector from vent accessory carton.

2. Remove gaskets, orifice plate and hardware from blower outlet flange.

3. Assemble orifice plate gaskets, orifice plate, and vent connector. See Figure 7.

4. Secure vent connector with washers and locknuts.

Figure 7: Vent Connector Installation

10

Loading...

Loading...