Page 1

Recirculating Chiller F-100 / F-105

Operation Manual

11593840C en

Page 2

Imprint

Product Identification:

Operation Manual (Original), Recirculating Chiller F-100 / F-105

11593840C en

Publication date: 02.2016

BÜCHI Labortechnik AG

Meierseggstrasse 40

Postfach

CH-9230 Flawil 1

E-Mail: quality@buchi.com

BUCHI reserves the right to make changes to the manual as deemed necessary in the light of

experience; especially in respect to structure, illustrations and technical detail.

This manual is copyright. Information from it may not be reproduced, distributed, or used for

competitive purposes, nor made available to third parties. The manufacture of any component

with the aid of this manual without prior written agreement is also prohibited.

Page 3

Table of contents

3

F-100 / F-105 Operation Manual, Version C

Table of contents

1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 User qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Safety warnings and safety signs used in this manual . . . . . . . . . . . . . . . . . . 6

2.5 Product safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.5.1 General hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.5.2 Personal protective equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5.3 Built-in safety elements and measures . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6 General safety rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Materials used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Description of function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Functional principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 Operating controls and housing . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Preparing for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.1 Installing the hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.2 Filling the chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3 Start operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4 No BUCHI vacuum controller connected to the system . . . . . . . . . . . . . . . 21

6.5 Working with BUCHI vacuum controller . . . . . . . . . . . . . . . . . . . . . . . 22

7 Maintenance and repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2 General inspection and cleaning instructions. . . . . . . . . . . . . . . . . . . . . 24

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.1 Error message display (only F-105) . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.2 Malfunctions and their remedies. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9 Shutdown, storage, transport and disposal . . . . . . . . . . . . . . . . . . . . . . . . 26

9.1 Storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.1 Enclosed parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.2 Instrument configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10.3 Spare parts, optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Page 4

1 About this manual

4

F-100 / F-105 Operation Manual, Version C

1 About this manual

This manual describes the Chiller and provides all information required for its safe operation and to

maintain it in good working order.

It is addressed to laboratory personnel and operators in particular.

Read this manual carefully before installing and running your system and note the safety precautions

in section 2 in particular. Store the manual in the immediate vicinity of the instrument, so that it can be

consulted at any time.

No technical modifications may be made to the instrument without the prior written agreement of

BUCHI. Unauthorized modifications may affect the system safety or result in accidents. Technical data

are subject to change without notice.

NOTE

The symbols pertaining to safety (WARNINGS and ATTENTIONS) are explained in section 2.

This manual is copyright. Information from it may not be reproduced, distributed or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of

this manual without prior written agreement is also prohibited.

The German manual is the original language version and serves as basis for all translations into other

languages. If you need another language version of this manual, you can download available versions

at www.buchi.com or reorder manuals from a BUCHI representative.

Recirculating Chiller – Types

F-100 F-105

Page 5

2 Safety

5

F-100 / F-105 Operation Manual, Version C

2 Safety

This section introduces the safety concept of the instrument and contains general rules of behavior

and warnings from direct and indirect hazards concerning the use of the product.

For the users safety, all safety instructions and safety messages in the individual sections shall

be strictly observed and followed. Therefore, the manual must always be available to all persons

performing any tasks described herein.

2.1 User qualification

The instrument may only be used by laboratory personnel and other persons who on account of

training and professional experience know the potential dangers that can develop when operating the

instrument.

Untrained personnel, or persons who are currently being trained, require careful supervision by a qualified person. This Operation Manual serves as a basis for training.

2.2 Proper use

The Recirculating Chiller is conceived and built as a piece of laboratory equipment. Its regulation use is

the cooling of closed cycles (e.g. rotary evaporators, reaction vessels).

When the Recirculating Chiller is used in combination with other instruments (e.g. rotary evaporator

and extraction unit) all related manuals are to be fully observed.

The regulation use of the Recirculating Chiller also includes its care.

2.3 Improper use

Any other use than the one stated above and any application that does not comply with the technical

data is considered to be improper use. Improper use can cause hazardous situations for the operator

and / or for the instrument and might cause consequential property damage.

The operator bears the sole risk for any damages or hazards caused by improper use!

In particular, the following uses must not be permitted

• Installation or use of the instrument in rooms, which require ex-protected instruments.

• The use of spare parts or accessories other than those mentioned in these operating instructions.

• The equipment may not be operated using combustible substances.

• It is not allowed to put anything on the top of the Recirculating Chiller.

Page 6

2 Safety

6

F-100 / F-105 Operation Manual, Version C

2.4 Safety warnings and safety signs used in this manual

DANGER, WARNING, CAUTION and NOTICE are standardized signal words for identifying levels of

hazards and risks related to personal injury and property damage. All signal words, which are related

to personal injury are accompanied by the general safety sign.

For your safety it is important to read and fully understand the table below with the different signal

words and their definitions!

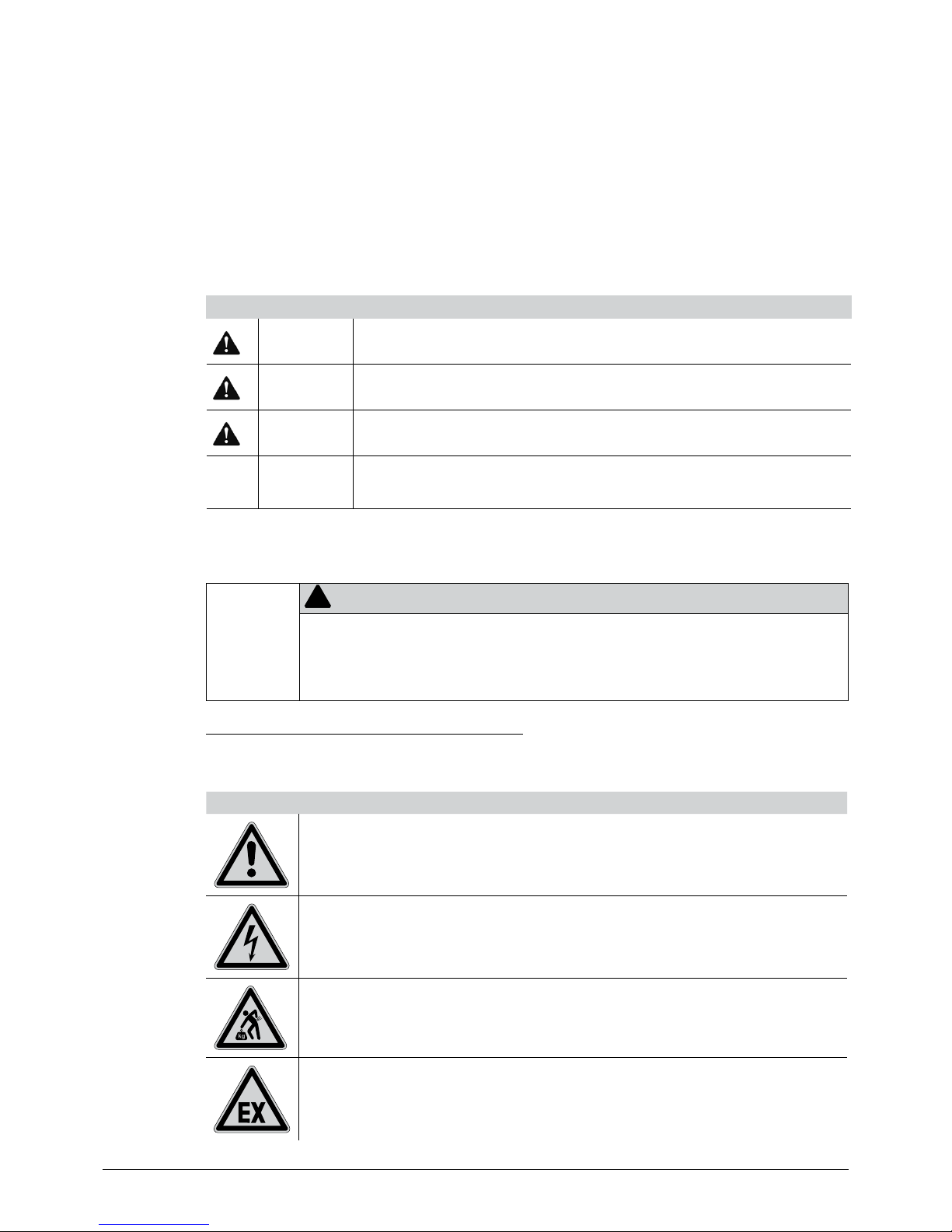

Sign Signal word Definition Risk level

DANGER

Indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

★★★★

WARNING

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

★★★☆

CAUTION

Indicates a hazardous situation which, if not avoided, may result

in minor or moderate injury.

★★☆☆

no NOTICE

Indicates possible property damage, but no

practices related to personal injury.

★☆☆☆

(property damage only)

Supplementary safety information symbols may be placed in a rectangular panel on the left to the

signal word and the supplementary text (see example below).

Space for

supplementary

safety

information

symbols.

!

SIGNAL WORD

Supplementary text, describing the kind and level of hazard/risk seriousness.

• List of measures to avoid the described hazard or hazardous situation.

• …

• …

Table of supplementary safety information symbols

The reference list below incorporates all safety information symbols used in this manual and their

meaning.

Symbol Meaning

General warning

Electrical hazard

Heavy weight, avoid overexertion

Explosive gases, explosive environment

Page 7

2 Safety

7

F-100 / F-105 Operation Manual, Version C

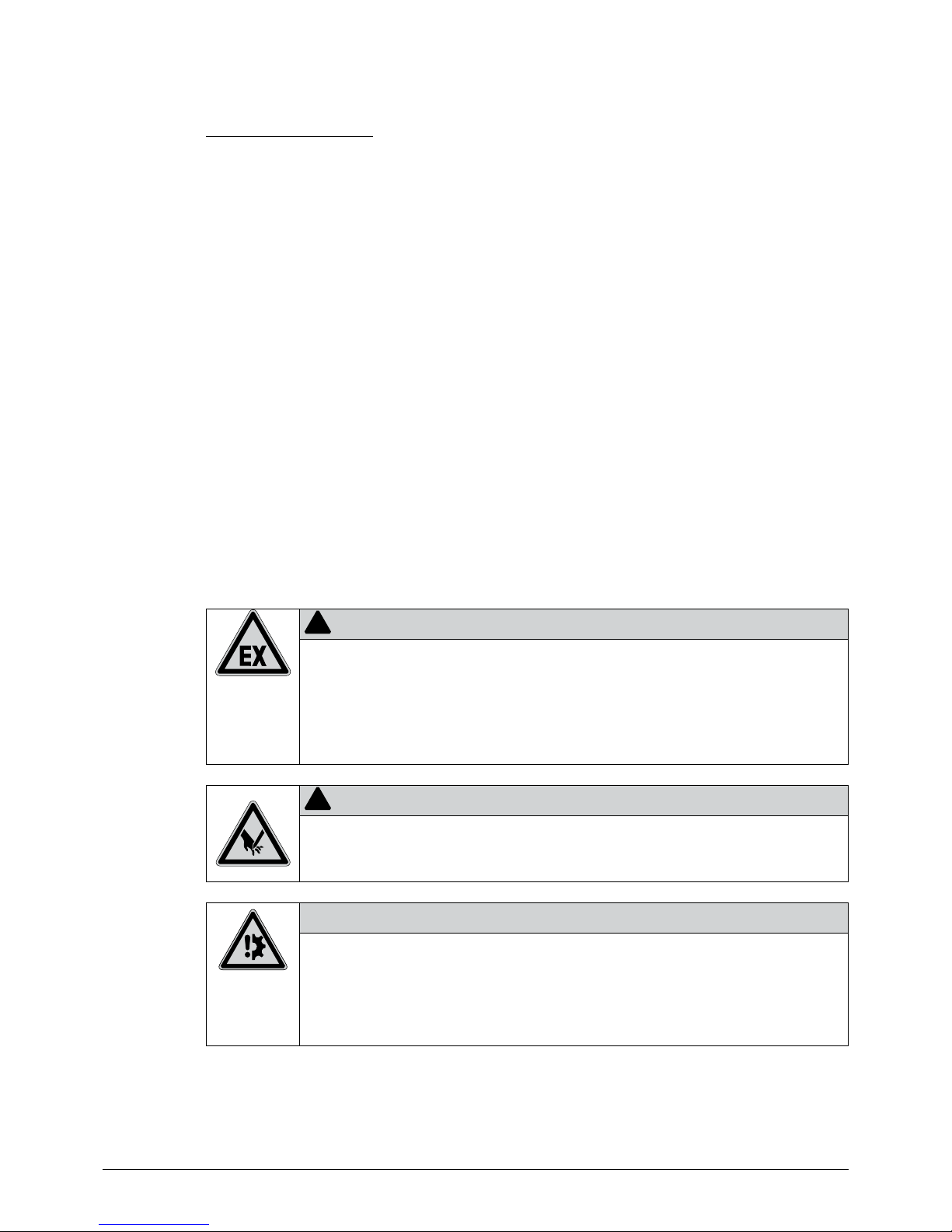

Symbol Meaning

Fire hazard

Harmful to life forms

Hot item, hot surface

Device damage

Inhalation of substances

Chemical burns by corrosives

Cuts by sharp edges

Flooding

Wear laboratory coat

Wear protective goggles

Wear protective gloves

Page 8

2 Safety

8

F-100 / F-105 Operation Manual, Version C

Additional user information

Paragraphs starting with NOTE transport helpful information for working with the device/software or its

supplementaries. NOTEs are not related to any kind of hazard or damage (see following example).

NOTE

Useful tips for the easy operation of the instrument/software.

2.5 Product safety

The Recirculating Chiller has been designed and built in accordance with current state-of-the-art technology, at the time of development. Safety warnings in this manual (as described in section 2.4) serve

to make the user alert to, and avoid hazardous situations emanating from residual dangers by giving

appropriate counter measures.

However, risks to users, property and the environment can arise when the instrument is damaged,

used carelessly or improperly.

2.5.1 General hazards

The following safety messages show hazards of general kind which may occur when handling the

instrument. The user shall observe all listed counter measures in order to achieve and maintain the

lowest possible level of hazard.

Additional warning messages can be found whenever actions and situations described in this manual

are related to situational hazards.

!

DANGER

Death or serious injuries when used in explosive environments.

• Do not store or operate the instrument in explosive environments

• Remove all sources of ammable vapors

• Do not store chemicals in the vicinity of the device

!

CAUTION

Risk of minor or moderate cuts by sharp edges.

• Do not touch defective or broken glassware with bare hands

• Do not touch thin metal edges

NOTICE

Risk of instrument damage by liquids or mechanical shocks.

• Do not spill liquids over the instrument or its components

• Do not drop the instrument or its components

• Keep external vibrations away from the instrument

Page 9

2 Safety

9

F-100 / F-105 Operation Manual, Version C

Safety messages regarding Refrigerant R134a:

!

WARNING

Danger of injury and material damage due to overheating.

• Keep at a temperature not exceeding 45°C

!

WARNING

Danger of corrosion and poisoning through inhalation of the fumes.

• In case of re and/or explosion do not breathe fumes

!

CAUTION

If R134a escapes in the event of a fault..

• Avoid contact with skin and eyes

• Always wear safety goggles

• Always wear safety gloves

2.5.2 Personal protective equipment

Always wear personal protective equipment such as protective eye goggles and protective clothing.

The personal protective equipment must meet all requirements of all data sheets for the chemicals

used. These instructions are an important part of the Recirculating Chiller and must be made available

at all times to the operating personnel at the place where the equipment is deployed.

!

WARNING

Serious chemical burns by corrosives.

• Always wear protective goggles

• Always wear protective gloves

• Always wear laboratory coat

2.5.3 Built-in safety elements and measures

The instrument is fitted with a thermal overload protection for the compressor.

Page 10

2 Safety

10

F-100 / F-105 Operation Manual, Version C

2.6 General safety rules

Responsibility of the operator

The head of the laboratory is responsible for training his/her personnel.

The operator shall inform the manufacturer without delay of any safety-related incidents which might

occur during operation of the instrument or its accessories. Legal regulations, such as local, state and

federal laws applying to the instrument or its accessories must be strictly followed.

Duty of maintenance and care

The operator is responsible for the proper condition of instrument. This includes maintenance, service

and repair jobs that are performed on schedule by authorized personnel only.

Spare parts to be used

Use only genuine consumables and spare parts for maintenance to assure good system performance,

reliability and safety. Any modifications of spare parts or assemblies are only allowed with the prior

written permission of the manufacturer.

Modifications

Modifications to the instrument are only permitted after prior consultation and with the written approval

of the manufacturer. Modifications and upgrades shall only be carried out by an authorized BUCHI

technical engineer. The manufacturer will decline any claim resulting from unauthorized modifications.

Page 11

3 Technical data

11

F-100 / F-105 Operation Manual, Version C

3 Technical data

This section introduces the reader to the Recirculating Chiller and its specifications. It contains the

technical data, requirements and performance data.

3.1 Technical data

Technical data

F-100 F-105

Dimensions (W x H x D) 280 x 500 x 420 mm 280 x 500 x 420 mm

Weight 28 kg 30 kg

Power consumption (max.) 850 W 850 W

Supply voltage 230 VAC ±10%

115 VAC ± 10 %

230 VAC ±10%

115 VAC ± 10 %

Fuse

230 V

115 V

6.3 AT

8 AT

6.3 AT

8 AT

Frequency 50/60 Hz 50/60 Hz

Environmental conditions For indoor use only

- Temperature 5–35°C 5–35°C

- Altitude up to 2000 m

- Humidity Maximum relative humidity 80% for temperatures up to 31°C

decreasing linearly to 50% relative humidity at 40°C

Temperature display No display digital, resolution 0.1°C

Overvoltage category II II

Degree of protection IP20 IP20

Pollution degree 2 2

Cooling capacity at 15°C --- 530 W

Cooling capacity at 10°C 300 W 390 W

Cooling capacity at 0°C --- 120 W

Cooling capacity at -10°C --- 10 W

Refrigerant R134a R134a

Set temperature range x +10°C –10°C … +25°C

Temperature regulation accuracy ±2°C ±1°C

Tank volume 3 L 3 L

Tubing connection 8 mm (GL14) 8 mm (GL14)

Pump ow rate 2.5 L/min 2.5 L/min

Pump pressure (max.) 0.6 bar 0.6 bar

Page 12

3 Technical data

12

F-100 / F-105 Operation Manual, Version C

3.2 Materials used

Materials used

Component Material designation Material code Hazardous substances

Stainless steel, powder-coated with

polyester-epoxide

Housing 1.4301

–

Copper Internal pipes and

coolers

CU –

Polyester Foil PES –

Glass-ber-reinforced epoxy resin Circuit board –

Polyvinyl chloride Cable PVC –

R134a Refrigerant 1,1,1,2-tetrauoro-

ethane

Check MSDS

Page 13

4 Description of function

13

F-100 / F-105 Operation Manual, Version C

4 Description of function

This section explains the basic working principle of the Recirculating Chiller. It also shows how the

instrument is structured and provides a general functional description of its assemblies.

4.1 Functional principle

The BUCHI Recirculating Chillers are a closed-circuit cooler for use with appropriate laboratory instruments. The four models are distinguished by their outputs and control. The F-100 has a fixed cooling

temperature without display. The models F-105 to F-114 are equipped with a control unit and built

in display to regulate and indicate the actual and set value of the cooling temperature. The F-100 is

optimal for cooling one BUCHI Rotavapor system. The F-114 is sufficient for cooling up to two small

to medium Rotavapor systems (e.g. R-210).

Diagram F-100

3

2

1

4

5

6

1 Circulation pump

2 Container with cooling coil

3 Capillary

4 Filter dryer

5 Heat exchanger

6 Compressor

Page 14

4 Description of function

14

F-100 / F-105 Operation Manual, Version C

Diagram F-105

3

2

1

4

5

6

7

1 Circulation pump

2 Container with cooling coil

3 Thermostatic expansion valve

4 Filter dryer

5 Heat exchanger

6 Compressor

7 In-line valve

Page 15

5 Putting into operation

15

F-100 / F-105 Operation Manual, Version C

5 Putting into operation

This section describes how the instrument has to be installed. It also gives instructions for the initial

startup.

NOTE

Inspect the instrument for damage during unpacking. If necessary, prepare a status report immediately and inform customer and your local BUCHI representative. Keep the original packaging for

future transportation.

Also adhere to all instructions concerning transport as described in section 9.1, Storage and transport.

To move the instrument use the handle (as described in section 6.1, Operating controls and housing),

slightly lift the side of the instrument with the fix anti-slip foots and pull the instrument carefully by the

rollers.

5.1 Installation site

!

DANGER

Death or serious injuries when used in explosive environments.

• Do not store or operate the instrument in explosive environments

• Remove all sources of ammable vapors

• Do not store chemicals in the vicinity of the device

Put the instrument onto a clean, stable and horizontal surface. Consider the maximum product dimensions and weight. Obtain the environmental conditions as described in section 3.1, technical data.

Installation pre-requisites and installation steps:

• Do not place any objects in front of or behind the instrument.

• The instrument must have a clearance of 40cm between itself and the wall, both in front and

behind (sufficient cooling).

• Do not place containers, chemicals or other items behind the instrument.

• Do not place anything on top of the Recirculating Chiller.

NOTE

• After transport, wait at least 2 hours before switching on the chiller! Within this time the refrigerant

gathers in the compressor, avoiding damage of the compressor.

• To ensure that the power can be cut by unplugging in case of an emergency, the mains plug must

not be blocked by the instruments or any other items!

• Depending on the environmental conditions, condensation water at the cooling tubes and all other

cold surfaces of the instruments can collect!

Page 16

5 Putting into operation

16

F-100 / F-105 Operation Manual, Version C

!

WARNING

Stumbling or falling due to improper installation of the cables and hoses.

• The length of the cables and hoses should be kept as short as possible

• Absorb condensate water from tubes and all other cold surfaces

• If possible, avoid installing cables and hoses in aisle areas

• If installation of cables and hoses in aisle areas is unavoidable, use an adequate protective

pad in order to avoid the danger of stumbling and damage

!

WARNING

Fire hazard, damage to the instrument through overheating due to inadequate air circulation.

• Do not cover the instrument

• Minimum distance from other objects must be at least 40cm

!

CAUTION

Risk of minor or moderate injury due to the heavy weight of the instrument.

• Do not drop the instrument or its transport box

• Place the instrument on a stable, even and vibration-free surface

• Keep limbs out of crushing zone

!

CAUTION

Danger from falling objects due to inadequate stability.

• Do not place other objects or instruments on the Chiller

Page 17

5 Putting into operation

17

F-100 / F-105 Operation Manual, Version C

5.2 Electrical connections

Notice

Risk of instrument damage if mains supply is incorrect.

• External mains supply must meet the voltage given on the type plate

• Check for proper grounding

• Exchange defective cabling immediately

After the installation procedure has been completed successfully, the power plug of the Recirculating

Chiller can be connected to mains.

The used mains circuit has to:

• provide the voltage that is given on the type plate of the instrument.

• be able to handle the load of the connected instruments.

• be equipped with adequate fuses and electrical safety measures, in particular proper grounding.

See also technical data of all components regarding the different minimum system requirements!

NOTE

• Additional electrical safety measures such as residual current breakers may be necessary to

meet local laws and regulations!

• External power switches (e.g. emergency stop switches) must meet IEC 60947-1 and

IEC60947-3 requirements. Such devices must be clearly labeled and accessible at any time.

• External connections and extension lines must be provided with a grounded conductor lead

(3-pole couplings, cord or plug equipment). All electrical cables used must be suitable for the

required power rating.

5.3 Factors affecting chilling capacity

The available chilling capacity is dependent on various factors. The most important aspect to be

aware of is that the chilling capacity diminishes as the chilling temperature is lowered. In the case

of the F-105 it is approx. 600W at 20 °C and only around 50W at –5°C. The ambient temperature

has an effect as well. At room temperatures above 35 °C the chiller's air cooling may, depending on

chilling capacity, no longer be sufficient and the chiller may switch off for safety reasons to protect

itself against overheating. At an ambient temperature of 30°C the F-105 still has a chilling capacity

of around 150–W. We recommended a chilling temperature setting of 10–15 °C and a room temperature that does not exceed 25 °C. Outside of those parameters, the chilling capacity is substantially

reduced.

Page 18

6 Operation

18

F-100 / F-105 Operation Manual, Version C

6 Operation

This section gives examples of typical instrument applications and instructions on how to operate the

instrument properly and safely. See also section 2.5 “Product safety” for general warnings.

6.1 Operating controls and housing

Front side

8

1

5

7

3

2

4

6

1 Opening for cooling medium

2 Handle (to pull the instrument)

3 On-/Off switch (lights green when instrument is

switched on)

4 Cooling media level indicator

5 Cooling lamella for air ow in

6 Wheels (not lockable)

7 Fix anti-slip feet

8 Operating panel with various parameter

displays (not available on the F-100)

Buttons (not for F-100)

Button Functionality

UP

Increase the desired set temperature in steps of 0.1°C.

DOWN

Decrease the desired set temperature in steps of 0.1°C.

START

Button to start or continue the cooling regulation.

Page 19

6 Operation

19

F-100 / F-105 Operation Manual, Version C

STOP

Button to stop the cooling regulation.

Display (not for F-100)

1

3

4

2

1 Set temperature of Recirculating Chiller in °C

2 Actual temperature of Recirculating Chiller in °C

3 Active cooling is indicated by the snow ake

4 If the Recirculating Chiller is connected to the

BUCHI vacuum controller the connection symbol

is displayed

Level indicator

2

3

1

1 Lower black line: minimum lling level

2 Upper black line: maximum lling level

3 Ball oat: actual ll level of coolant

Page 20

6 Operation

20

F-100 / F-105 Operation Manual, Version C

Rear side

1

8

2

7

5

6

3

4

1 Cooling medium ow in

2 Cooling medium ow out

3 Power socket

4 Communication cable socket, RS485

(not available for F-100 models)

5 Fuse

6 Slots for air ow out

7 Antistatic wheels (not lockable)

8 Drainvalve, to empty the cooling medium tank

6.2 Preparing for use

Prerequisites

• All parts must be clean and free of damage.

• Close the drainvalve.

6.2.1 Installing the hoses

!

WARNING

Stumbling or falling due to improper installation of the cables and hoses.

• The length of the cables and hoses should be kept as short as possible

• If possible, avoid installing cables and hoses in aisle areas

• If installation of cables and hoses in aisle areas is unavoidable, use an adequate protective

pad in order to avoid the danger of stumbling and damage

• Connect out flow and return flow connections of the Recirculating Chiller with the condenser of the

rotary evaporator.

NOTE

Only use hoses which can withstand min. –10°C and 2bar pressure and secure them with the usual

hose clamps.

• Connect Chiller outlet (OUT) to the second condenser installed on the pump.

• Connect the outlet of the second condenser to the Rotavapor® Condenser.

• Connect the outlet of the Rotavapor® Condenser to the inlet (IN) of the Recirculating Chiller.

Page 21

6 Operation

21

F-100 / F-105 Operation Manual, Version C

6.2.2 Filling the chiller

NOTICE

Risk of instrument damage if wrong cooling medium is used.

• Check to ensure that the cooling medium is suitable for use at the desired cooling temperature and does not freeze at the working temperature

Fill the cooling liquid in the opening to maximum filling level while the chiller is not connected to

another device. We recommend a mixture of ethylene glycol/water at least 40/60, which does not

freeze until –16°C.

6.3 Start operation

NOTE

See installation instructions (chapter 5.1) for initial startup!

!

WARNING

Danger of injury due to tipping or failure of the instrument due to vibrations.

• After being transported, the recirculating chiller must be allowed to stand for at least 2 hour

before it is switched on.

Start the Recirculating Chiller by switching on the Instrument by the main switch. Press start on the

Chiller to fill the cooling coils.

6.4 No BUCHI vacuum controller connected to the system

Preparational steps

• System must be in good working order. See final installation check, section 5.1.

• Turn on instrument.

• Check level of cooling transfer medium as described in section 6.1 Level indicator.

• Set the desired working temperature by the UP and DOWN buttons (not for F-100).

• Press the START button to start the cooling process (not for F-100).

• Check the actual temperature on the Chiller until it has reached the required temperature and start

working.

Working steps

• The cooling temperature can be adjusted during the operation process by pressing the UP and

DOWN buttons on the Chiller (not for F-100).

• If the Chiller can’t keep the required temperature, do a slower distillation, by means of decreasing

the vacuum to a slightly higher level so that less vapour is coming to the cooling coil.

Steps for end of process

• Press the STOP button on the Chiller.

➡ The cooling stops immediately.

➡ After a few seconds ventilation also stops.

Page 22

6 Operation

22

F-100 / F-105 Operation Manual, Version C

6.5 Working with BUCHI vacuum controller

The Chiller model F-105 is equipped with a communication socket. Here, a BUCHI Rotavapor setup

or other appropriate laboratory instruments equipped with a BUCHI vacuum controller (model V-850

or higher with firmware version 3.0 or higher) can be attached.

To establish communication switch on all connected devices. After bootup time the UP and DOWN

buttons of the Chillers operation panel are blocked – the Chiller can be controlled via the Vacuum

Controller buttons.

*click*

To Rotavapor /

Vacuum pump

≤ 5m

NOTE

Do not exceed max. recommended cable length (5 m). For more information about operation see

respective manual of the Vacuum Controller in use.

Communication F-105

Vacuum Controller

V-850 or V-855

Interface I-100 Interface I-300 with

Legacy box

Start or stop chiller via controller or interface Yes Yes Ye s

Display set point and current temperature Yes No Yes

Adjust set point via controller or interface Yes No Yes

Page 23

7 Maintenance and repairs

23

F-100 / F-105 Operation Manual, Version C

7 Maintenance and repairs

This section gives instructions on maintenance work to be performed in order to keep the instrument in a good and safe working condition. All maintenance and repair work requiring the opening or

removal of the instrument housing must be carried out by trained BUCHI service personnel and only

with the tools provided for this purpose.

!

WARNING

Death or serious burns by electric current.

• Switch off the instrument, disconnect the power cord and prevent unintentional restart before

touching any of the elements inside the Recirculating Chiller

• Do not spill liquids over the device

NOTICE

Risk of housing and instrument damage by liquids and detergents.

• Use only ethanol or soapy water for cleaning

NOTE

Use only genuine consumables and spare parts for any maintenance and repair work in order to

assure warranty and continued system performance. Any modifications of the Recirculating Chiller or

parts of it require the prior written permission of the manufacturer.

7.1 Customer service

Only authorized service personnel are allowed to open up the housing and /or perform repair work on

the instrument which is not described in this manual. Authorization requires a comprehensive technical

training and knowledge of possible dangers which might arise when working at the instrument. Such

training and knowledge can only be provided by BUCHI.

Addresses of official BUCHI customer service offices are given on the BUCHI website under:

www.buchi.com. If malfunctions occur on your instrument or you have technical questions or application problems, contact one of these offices.

The customer service offers the following:

• Spare part delivery

• Repairs

• Technical advice

Page 24

7 Maintenance and repairs

24

F-100 / F-105 Operation Manual, Version C

7.2 General inspection and cleaning instructions

Check the housing for visible defects (switches, plugs, enclosure etc.) and clean it regularly under

safe conditions with a damp cloth. Wipe off any splashes of aggressive chemicals immediately using

a damp cloth in order to avoid any damage being caused to the coating on the housing. Ethanol as a

cleaning agent is also possible to use.

Cleaning under safe conditions

• Switch off the Recirculating Chiller and unplug the power cord.

➡ Let the system reach ambient temperature completely!

• Perform cleaning actions with a damp cloth.

• Regularly clean lamella with a damp cloth to remove dust, at least once a year.

Hoses

• Check the hoses for wear at least every six months.

• Exchange damaged hoses.

Cooling media tank

• Check before prior use the filling level of the Recirculating Chiller

• Exchange the cooling liquid once a year by means of the drainvalve and renew.

Page 25

8 Troubleshooting

25

F-100 / F-105 Operation Manual, Version C

8 Troubleshooting

This section helps to resume operation after a problem has occurred with the instrument which does

not require special technical training. It lists possible occurrences, their probable causes and suggests

how to remedy the problem.

8.1 Error message display (only F-105)

2

1

1 For every error the triangle lights.

2 The error number is indicated on the

display.

8.2 Malfunctions and their remedies

The troubleshooting table below lists possible malfunctions and errors of the instrument. The operator

is enabled to correct some of those problems or errors by him/herself. For this, appropriate corrective

measures are listed in the column “Remedy”.

Malfunctions and their remedies

Error Code Problem Remedy

E01 Temperature fault

Temperature sensor circuit break

Switch off the unit, and restart.

Call service if the problem persists.

E04 Pressure fault of the compressor Switch off the unit, let it cool down the compressor.

Call service to check the system if the problem persists.

E05 Data fault Switch off the unit and restart.

Call service if the problem persists.

E06 Temperature fault in the electronics Switch off the unit, let it cool down, clean air inlet and restart.

Call service if the problem persists.

Problem Remedy

F-100 / F-105 does not work Switch off the unit and unplug the

power cord.

Change the fuse according to technical

data and restart.

Call service if the problem persists.

1

1 Fuse

Page 26

9 Shutdown, storage, transport and disposal

26

F-100 / F-105 Operation Manual, Version C

9 Shutdown, storage, transport and disposal

!

WARNING

Poisoning or serious injuries through contact with or incorporation of harmful substances.

• Wear safety goggles

• Wear safety gloves

• Wear a laboratory coat

• Clean the instrument and all accessories thoroughly to remove possibly dangerous substances

• Do not clean dusty parts with compressed air

• Store the instrument and its accessories in a dry place in the original packaging

This section instructs how to shut down and pack the instrument for storage or transport. Specifications for storage and shipping conditions can also be found listed here.

NOTE

See manufacturer safety data sheet (chapter 11) about the refrigerant!

9.1 Storage and transport

NOTICE

Defective instrument due to improper packaging or improper transport.

• Pack the instrument for safe transport with new, suitable packaging material

• In particular, secure the compressor for transport

• Secure the properly packaged instrument on a pallet for transport

Switch off the instrument and remove the power cord. To disassemble the Recirculating Chiller follow

the installation instructions in section 5 in reverse order. Clean the instrument thoroughly! The cooling

liquid is to be drained before storage or shipping. The instrument is to be stored in the original packaging in a dry location. Shipping is also to be done in the original packaging and in upright position

only.

NOTE

• After transport, wait at least 2 hours before switching on the chiller! Within this time the refrig-

erant gathers in the compressor, avoiding damage of the compressor.

• Completely drain off coolant fluid (tilt appliance slightly if necessary). Then turn off the drain tap.

Page 27

9 Shutdown, storage, transport and disposal

27

F-100 / F-105 Operation Manual, Version C

9.2 Disposal

!

CAUTION

Freeze-burns and eye injuries through direct contact with R134a.

• Avoid contact with skin and eyes

• Always wear safety goggles

• Always wear safety gloves

• Hoses can be additionally insulated (see optional offering for hose insulation)

Disposal of instrument

For instrument disposal in an environmentally friendly manner, a list of materials is given in section 3.2.

This helps to ensure that the components can be separated and recycled correctly by a specialist for

disposal.

You have to follow valid regional and local laws concerning disposal. For help, please contact your

local authorities!

NOTE

When returning the instrument to the manufacturer for repair work, please copy and complete the

health and safety clearance form on the following page and enclose it with the instrument.

Disposal of Refrigerant R134a

The cooling medium R134a must be destroyed in an approved facility, which is equipped to absorb

and neutralize acidic gases and other toxic processing products.

Page 28

Health and Safety Clearance

Health and Safety Clearance_20081110_KESS.doc_20081110 Version 1.0 Page 1/1

Declaration concerning safety, potential hazards and safe disposal of waste.

For the safety and health of our staff, laws and regulations regarding the handling of

dangerous goods, occupational health and safety regulations, safety at work laws and

regulations regarding safe disposal of waste (e.g. chemical waste, chemical residues

or solvents) require that this form must be completed, signed and enclosed to every

return shipment of equipment or defective parts.

Instruments or parts will not be accepted if this declaration is not present.

Equipment

Model: Part/Instrument no.:

1.A Declaration for non dangerous goods

We assure that the returned equipment:

is unused and new.

has not been exposed to toxic, corrosive, biologically active, explosive, radioactive

or other dangerous matters. No hazard emanates from the device!

is free of contamination (e.g.that chemicals, solvents or residues of pumped media

have been drained prior to shipment). No hazard emanates from the device!

1.B Declaration for dangerous goods

Exhaustive list of dangerous substances the equipment has been exposed to:

Chemical, substance Danger classification

We assure that:

all hazardous substances (e.g. toxic, corrosive, biologically active, explosive,

radioactive etc.) which have been processed or been in contact with the equipment

are listed above.

the equipment has been cleaned, decontaminated and is free of transmissible

agents such as hazardous fungi, bacteria, viruses etc. If sterilization is applicable,

all in- and outlets of the equipment have been properly sealed the process.

2. Final Declaration

We hereby declare that:

- we know all about the substances which have been in contact with the equipment

and all questions have been answered correctly.

- we have taken all measures to prevent potential risks that might emanate from the

delivered equipment.

- this document will be attached clearly visible and securely to the outside of the

transport box.

Company name or stamp:

Place, date:

Name (print), job title (print):

Signature:

Page 29

10 Spare parts

29

F-100 / F-105 Operation Manual, Version C

10 Spare parts

This section lists spare parts, accessories and options including their ordering information.

Only order spare parts and consumables from BUCHI to maintain the warranty status and to assure

best performance and reliability of the system and affected components. Any modifications to the

spare parts used are only allowed with the prior written permission of the manufacturer.

Always state the product designation, instrument serial and part numbers for warranty clearance when

ordering spare parts!

10.1 Enclosed parts

Enclosed parts matrix

F-100 F-105

Mains cables

✓ ✓

Control cable RJ45,

2m

— ✓

Hose D6/9 2m,

2×

✓ ✓

Hose nipple 8mm,

4×

✓ ✓

Screw cap GL14,

4×

✓ ✓

Hose clamp 9.9mm,

4×

✓ ✓

Operation Manual

✓ ✓

Page 30

10 Spare parts

30

F-100 / F-105 Operation Manual, Version C

10.2 Instrument configuration

Content

Instrument versions:

BUCHI Recirculating Chiller

Order no.

F-1XX 230 V

F-100 Model 300 Watt x at 10°C 11060000

F-105 Model 500 Watt controlled 11060002

F-1XX 115 V

F-100 Model 300 Watt x at 10°C 11056461

F-105 Model 500 Watt controlled 11056463

10.3 Spare parts, optional accessories

Example

Spare parts

Description Order no.

Power cable 3 pin, type CH 010010

Power cable 3 pin, type SCHUKO 010016

Power cable 3 pin, type GB 017835

Power cable 3 pin, type AU 017836

Power cable, 3 pin, type US 010020

Power cable, 3 pin, type IND 11060536

Ethernet cable, 2m, RJ45 Cat. 5e, gray 044989

Cable RJ45, 5 m 11056240

Tubing, silicone, 6/9 mm, 1m, transparent (F-100, F-105)

04133

Page 31

10 Spare parts

31

F-100 / F-105 Operation Manual, Version C

Set of hose barbs, GL14

olive bent (4 pcs), cap nut (4 pcs)

037287

Hose clamp 9.9 mm 027738

Insulation hose for silicone hose,

Kaiex, 11/23 mm, 1m, black

28696

Y piece tubing coupling, 8 mm 011043

Quick-t coupling, 12 mm

set of 2 pieces

042885

Page 32

Page 33

Page 34

Quality in your hands

BUCHI Affiliates:

We are represented by more than 100 distribution partners worldwide.

Find your local representative at: www.buchi.com

BUCHI Support Centers:

Europe

Switzerland/Austria

BÜCHI Labortechnik AG

CH – 9230 Flawil

T +41 71 394 63 63

F +41 71 394 65 65

buchi@buchi.com

www.buchi.com

Benelux

BÜCHI Labortechnik GmbH

Branch Offi ce Benelux

NL – 3342 GT Hendrik-Ido-Ambacht

T +31 78 684 94 29

F +31 78 684 94 30

benelux@buchi.com

www.buchi.be

France

BUCHI Sarl

FR – 94656 Rungis Cedex

T +33 1 56 70 62 50

F +33 1 46 86 00 31

france@buchi.com

www.buchi.fr

Germany

BÜCHI Labortechnik GmbH

DE – 45127 Essen

T +800 414 0 414 0 (Toll Free)

T +49 201 747 49 0

F +49 201 747 49 20

deutschland@buchi.com

www.buechigmbh.de

Italy

BUCHI Italia s.r.l.

IT – 20010 Cornaredo (MI)

T +39 02 824 50 11

F +39 02 575 12 855

italia@buchi.com

www.buchi.it

Russia

BUCHI Russia/CIS

Russia 127287 Moscow

T +7 495 36 36 495

F +7 495 98 10 520

russia@buchi.com

www.buchi.ru

United Kingdom

BUCHI UK Ltd.

GB – Oldham OL9 9QL

T +44 161 633 1000

F +44 161 633 1007

uk@buchi.com

www.buchi.co.uk

Germany

BÜCHI NIR-Online

DE – 69190 Walldor f

T +49 6227 73 26 60

F +49 6227 73 26 70

nir-online@buchi.com

www.nir-online.de

China

BUCHI China

CN – 200052 Shanghai

T +86 21 6280 3366

F +86 21 5230 8821

china@buchi.com

www.buchi.com.cn

India

BUCHI India Private Ltd.

IN – Mumbai 400 055

T +91 22 667 75400

F +91 22 667 18986

india@buchi.com

www.buchi.in

Indonesia

PT. BUCHI Indonesia

ID – Tangerang 15321

T +62 21 537 62 16

F +62 21 537 62 17

indonesia@buchi.com

www.buchi.co.id

Japan

Nihon BUCHI K.K.

JP – Tokyo 110-0008

T +81 3 3821 4777

F +81 3 3821 4555

nihon@buchi.com

www.nihon-buchi.jp

Korea

BUCHI Korea Inc.

KR – Seoul 153-782

T +82 2 6718 7500

F +82 2 6718 7599

korea@buchi.com

www.buchi.kr

Malaysia

BUCHI Malaysia Sdn. Bhd.

MY – 47301 Petaling Jaya,

Selangor

T +60 3 7832 0310

F +60 3 7832 0309

malaysia@buchi.com

www.buchi.com

Singapore

BUCHI Singapore Pte. Ltd.

SG – Singapore 609919

T +65 6565 1175

F +65 6566 7047

singapore@buchi.com

www.buchi.com

Thailand

BUCHI (Thailand) Ltd.

TH – Bangkok 10600

T +66 2 862 08 51

F +66 2 862 08 54

thailand@buchi.com

www.buchi.co.th

Asia

America

Brazil

BUCHI Brasil Ltda.

BR – Valinhos SP 13271-200

T +55 19 3849 1201

F +55 19 3849 2907

brasil@buchi.com

www.buchi.com

USA/Canada

BUCHI Corporation

US – New Castle, DE 19720

T +1 877 692 8244 (Toll Free)

T +1 302 652 3000

F +1 302 652 8777

us-sales@buchi.com

www.mybuchi.com

South East Asia

BUCHI (Thailand) Ltd.

TH-Bangkok 10600

T +66 2 862 08 51

F +66 2 862 08 54

bacc@buchi.com

www.buchi.com

Middle East

BÜCHI Labortechnik AG

UAE – Dubai

T +971 4 313 2860

F +971 4 313 2861

middleeast@buchi.com

www.buchi.com

Latin America

BUCHI Latinoamérica Ltda.

BR – Valinhos SP 13271-200

T +55 19 3849 1201

F +55 19 3849 2907

latinoamerica@buchi.com

www.buchi.com

Loading...

Loading...