Page 1

Operation Manual

Extraction Unit

E�812/816 SOX

093169

en

Page 2

Page 3

Table of contents

Table of contents

1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1 Reference documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1 User qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Safety warnings and safety signs used in this manual . . . . . . . . . . . . . . . . . . 7

2.5 Product safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5.1 General hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5.2 Warning labels on housing and assemblies . . . . . . . . . . . . . . . . . . . . . . 10

2.5.3 Personal protective equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5.4 Safety elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6 General safety rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.1 Standard instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.2 Standard accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.3 Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 Technical data overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Materials used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 Description of function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1 Overview over the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 Functional principle of a Soxhlet extraction . . . . . . . . . . . . . . . . . . . . . . 19

4.2.1 Step 1 - extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.2 Step 2 - rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.3 Step 3 - drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.4 Solvent collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Controls of the Extraction Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 Putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1 Installation site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3 Condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4 Soxhlet extractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5 Water supply connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.6 Cooling water connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.7 Cooling medium connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.7.1 Recirculating Chiller B-740/41 or equivalent model . . . . . . . . . . . . . . . . . . 25

5.7.2 Recirculating Chiller F-1xx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.8 Solvent hose connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3 E-812/816 Soxhlet Operation Manual, Version B

Page 4

Table of contents

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1 Main screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

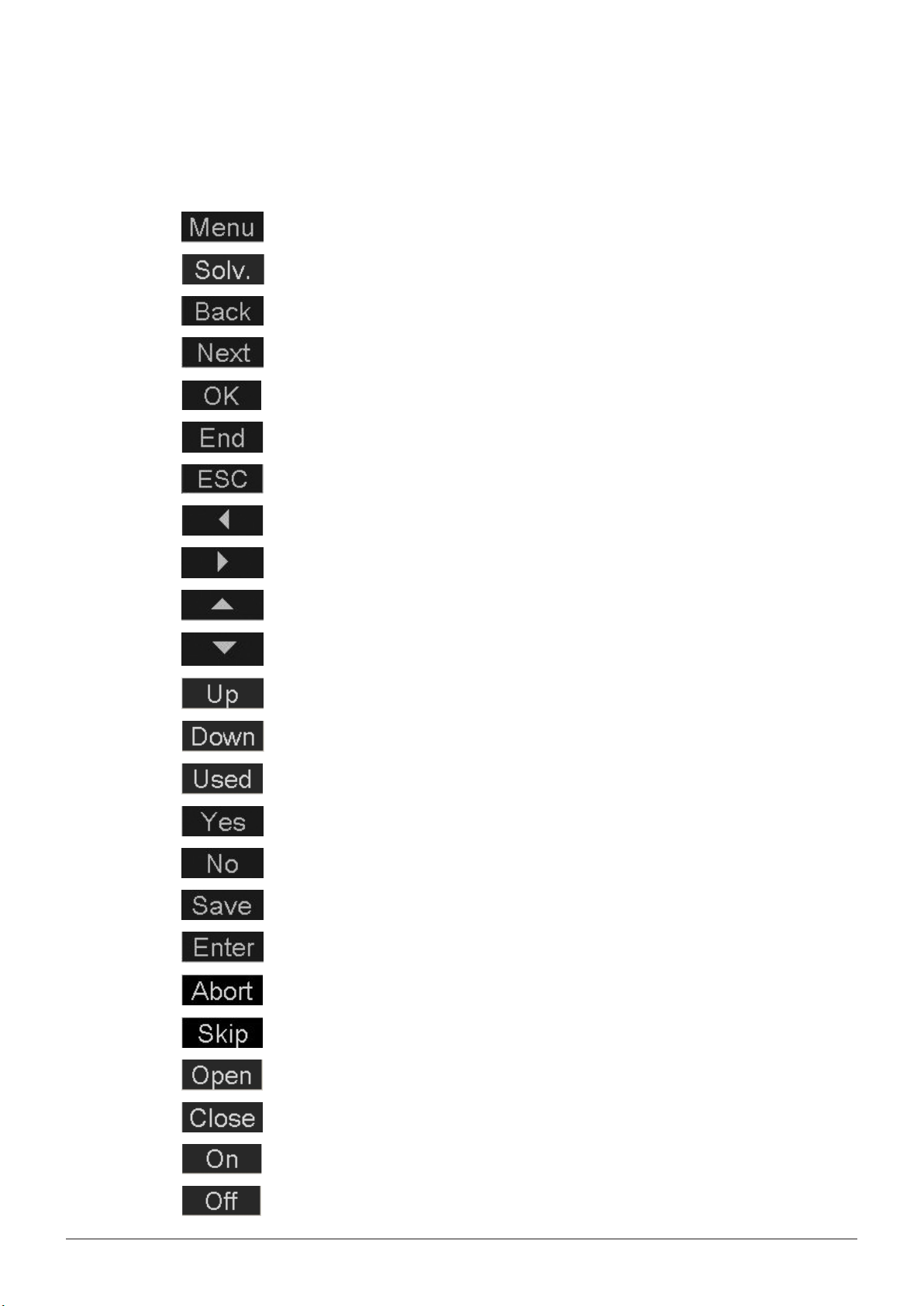

6.2 General information on buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3 Description of the menu functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.1 Starting up the instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.2 Instrument settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.3 Occupying the positions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3.4 Defining a method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3.5 Saving a method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3.6 Opening a method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.7 Deleting a method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3.8 Abort function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3.9 Skip function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.10 Service functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4 Example of an extraction process . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.4.1 Material and equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.4.2 Preparing an extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.4.3 After the extraction process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4.4 Emptying the solvent tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4.5 Reusing the solvent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1 Daily maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.1 Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.2 Hoses and hose connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.3 Glass parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.4 Solvent tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.2 Weekly maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2.1 Heating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.3 Monthly maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.3.1 Cleaning the seals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.3.2 Replacing the seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.3.3 Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3.4 Flushing the tank valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.4 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.1 Malfunctions and their remedy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.2 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.3 Too high/too low results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9 Shutdown, storage, transport and disposal . . . . . . . . . . . . . . . . . . . . . . . . 49

9.1 Preparing the instrument for storage and transport . . . . . . . . . . . . . . . . . . 49

9.2 Storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.3 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11 Declarations and requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

11.1 FCC requirements (for USA and Canada) . . . . . . . . . . . . . . . . . . . . . . . 52

11.2 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4 E-812/816 Soxhlet Operation Manual, Version B

Page 5

1 About this manual

This manual describes the Extraction Unit E-812/816 SOX and provides all information required for its

safe operation and to maintain it in good working order.

It is addressed to laboratory personnel and operators in particular.

Read this manual carefully before installing and running your system and note the safety precautions

in section 2 in particular. Store the manual in the immediate vicinity of the instrument, so that it can be

consulted at any time.

No technical modifications may be made to the instrument without the prior written agreement of

BUCHI. Unauthorized modifications may affect the system safety or result in accidents. Technical data

are subject to change without notice.

NOTE

The symbols pertaining to safety are explained in section 2.

1 About this manual

This manual is copyright. Information from it may not be reproduced, distributed or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of

this manual without prior written agreement is also prohibited.

The English manual is the original language version and serves as basis for all translations into

other languages. If you need another language version of this manual, you can download available

versions at www.buchi.com.

1.1 Reference documents

For information on the Extraction Unit E-812/816 Hot Extraction, please refer to the corresponding

manuals as PDF on CD available in English, German, French, Italian and Spanish

• Extraction Unit E-812/816 Hot Extraction, Operation Manual number 93164 - 93168

1.2 Abbreviations

FEP: Fluorinated Ethylene Propylene

FPM: Fluorpolymer rubber

PMMA: Polymethyl methacrylate

PP: Polypropylene

PTFE: Ethylenetetrafluoroethylene

PVDF: Polyvinylidene difluoride

5 E-812/816 Soxhlet Operation Manual, Version B

Page 6

2 Safety

This chapter points out the safety concept of the instrument and contains general rules of behavior

and warnings from hazards concerning the use of the product.

The safety of users and personnel can only be ensured if these safety instructions and the safetyrelated warnings in the individual chapters are strictly observed and followed. Therefore, the manual

must always be available to all persons performing the tasks described herein.

2.1 User qualification

The instrument may only be used by laboratory personnel and other persons who on account of

training or professional experience have an overview of the dangers which can develop when

operating the instrument.

Personnel without this training or persons who are currently being trained require careful instruction.

The present Operation Manual serves as the basis for this.

2 Safety

2.2 Proper use

The instrument has been designed and built for laboratories. It serves for activities associated with fat

extraction.

It is used for:

• Soxhlet extraction with diethyl ether, hexane, petroleum ether and chloroform.

2.3 Improper use

Applications not mentioned above are improper. Also, applications, which do not comply with the

technical data, are considered improper. The operator bears the sole risk for any damages caused by

such improper use.

The following uses are expressly forbidden:

• Use of the instrument in rooms which require ex-protected instruments.

• Determination of samples, which can explode or inflame (example: explosives, etc.) due to shock,

friction, heat or spark formation.

• Use in overpressure situations.

• Use with other glassware than the original from BUCHI.

• Use with other solvents than diethyl ether, hexane, petroleum ether or chloroform.

• Use with more than the allowed maximum solvent amount (max. 150 ml).

• Use with samples that react with solvent.

6 E-812/816 Soxhlet Operation Manual, Version B

Page 7

2.4 Safety warnings and safety signs used in this manual

DANGER, WARNING, CAUTION and NOTICE are standardized signal words for identifying levels of

hazard seriousness of risks related to personal injury and property damage. All signal words, which are

related to personal injury are accompanied by the general safety sign.

For your safety it is important to read and fully understand the table below with the different signal

words and their definitions!

Sign Signal word Definition Risk level

!

DANGER

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

2 Safety

★★★★

WARNING

!

CAUTION

!

NOTICE

no

Supplementary safety information symbols may be placed in a rectangular panel on the left to the

signal word and the supplementary text (see below example).

Space for

supplementary

safety

information

symbols.

Table of supplementary safety information symbols

The reference list below incorporates all safety information symbols used in this manual and their

meaning.

Indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Indicates a hazardous situation which, if not avoided, may result

in minor or moderate injury.

Indicates possible property damage, but no

practices related to personal injury.

!

SIGNAL WORD

Supplementary text, describing the kind and level of hazard / risk seriousness.

• List of measures to avoid the herein described, hazard or hazardous situation.

• ...

• ...

(property damage only)

★★★☆

★★☆☆

★☆☆☆

Symbol Meaning

General warning

Electrical hazard

Heavy weight, avoid overexertion

7 E-812/816 Soxhlet Operation Manual, Version B

Page 8

Symbol Meaning

Harmful to life-forms

Pinch point, mechanical hazards

Fire hazard

Hot item, hot surface

2 Safety

Device damage

Inhalation of substances

Chemical burns by corrosives

Wear laboratory coat

Wear protective goggles

Wear protective gloves

Heavy weight, lifting requires more than one person

Additional user information

Paragraphs starting with Note transport helpful information for working with the device / software or its

supplementaries. Notes are not related to any kind of hazard or damage (see following example).

8 E-812/816 Soxhlet Operation Manual, Version B

Page 9

NOTE

Useful tips for the easy operation of the instrument / software.

2.5 Product safety

The Extraction Unit is designed and built in accordance with state-of-the-art technology. Nevertheless, risks to users, property, and the environment can arise when the instrument is used carelessly or

improperly.

The manufacturer has determined residual dangers emanating from the instrument

• if the instrument is operated by insufficiently trained personnel.

• if the instrument is not operated according to its proper use.

Appropriate warnings in this manual serve to make the user alert to these residual dangers.

2.5.1 General hazards

Pay attention to the following safety notices:

!

WARNING

Death or serious injuries by formation of explosive atmospheres inside the instrument.

• Before operation, check all tube connections for correct installation

• Check for proper system tightness

2 Safety

!

DANGER

Death or serious injuries by use in explosive environments.

• Do not store or operate the instrument in explosive environments

• Provide sufficient ventilation and make sure to directly withdraw fumes

!

WARNING

Death or serious burns by flammable vapors.

• Remove all sources of flammable vapors

• Do not store flammable chemicals in the vicinity of the device

!

CAUTION

Risk of burns by hot heating glass plate (up to 250°C).

• Do not touch hot parts or surfaces

• Let the system and inserted extraction cells cool down safely

• Do not move the instrument or parts of it when hot

Risk of instrument damage by liquids or mechanical shocks.

• Do not spill liquids over the instrument or its components

• Do not move the instrument when it is loaded with sample liquid

• Do not drop the instrument or its components

• Keep external vibrations away from the instrument

• Safely attach the instrument to the bench in earthquake prone regions

• Do not operate the instrument without the safety shield installed

NOTICE

9 E-812/816 Soxhlet Operation Manual, Version B

Page 10

2 Safety

Risk of instrument damage by wrong mains supply.

• External mains supply must meet the voltage given on the type plate

• Check for sufficient grounding

2.5.2 Warning labels on housing and assemblies

The following warning sticker(s) can be found on the housing or assemblies of the instrument:

Symbol Meaning Location

Hot item, hot surface Sticker / label, located at the heating block

2.5.3 Personal protective equipment

Always wear personal protective equipment such as protective eye goggles, protective clothing and

gloves. The personal protective equipment must meet all requirements of the supplementary data

sheets for the chemicals used.

NOTICE

!

WARNING

Serious chemical burns by corrosives.

• Observe supplementary data sheets of all used chemicals.

• Handle corrosives in well ventilated environments only.

• Always wear protective goggles.

• Always wear protective gloves.

• Always wear protective clothes.

• Do not use damaged glassware.

10 E-812/816 Soxhlet Operation Manual, Version B

Page 11

2.5.4 Safety elements

Electronics

• The heating element is equipped with an electronic over-temperature protection.

• If no cooling water is detected at the cooling water output (for example, due to a leak in the

condenser), the electronic over-protection will stop all processes.

• To start a program at least one extraction position must be activated in the software.

• Safety shield: The protective shield protects operators from broken glass, solvent splashes and

prevents burns from the hot plates.

• Safety shield sensor: To start an extraction the protective shield must be closed.

Optional

• The protective shield (optional accessory) for the condenser protects operators from broken glass

in case of an accident or explosion.

2.6 General safety rules

2 Safety

Responsibility of the operator

The head of laboratory is responsible for training his personnel.

The operator shall inform the manufacturer without delay of any safety-related incidents which might

occur during operation of the instrument. Legal regulations, such as local, state and federal laws

applying to the instrument must be strictly followed.

Duty of maintenance and care

The operator is responsible for ensuring that the instrument is operated in proper condition only, and

that maintenance, service, and repair jobs are performed with care and on schedule, and by authorized personnel only.

Spare parts to be used

Use only genuine consumables and genuine spare parts for maintenance to assure good system

performance and reliability. Any modifications to the spare parts used are only allowed with the prior

written permission of the manufacturer.

Modifications

Modifications to the instrument are only permitted after prior consultation with and with the written

approval of the manufacturer. Modifications and upgrades shall only be carried out by an authorized

BUCHI technical engineer. The manufacturer will decline any claim resulting from unauthorized modifications.

11 E-812/816 Soxhlet Operation Manual, Version B

Page 12

3 Technical data

This chapter introduces the reader to the instrument specifications. It contains the scope of delivery,

technical data, requirements and performance data.

3.1 Scope of delivery

Check the scope of delivery according to the order number.

NOTE

For detailed information on the listed products, see www.buchi.com or contact your local dealer.

3.1.1 Standard instrument

3 Technical data

Table 3-1: Standard instrument

Product Order number

Extraction Unit E-816 Soxhlet

(6 place; 100 - 120 VAC / 200 - 240 VAC;

50/60 Hz; 1950/1200 W)

Extraction Unit E-812 Soxhlet

(2 place; 100 - 120 VAC / 200 - 240 VAC;

50/60 Hz; 700/1200 W)

47581

49111

12 E-812/816 Soxhlet Operation Manual, Version B

Page 13

3.1.2 Standard accessories

2

3

3 Technical data

Table 3-2: Standard accessories

1

E-812 E-816 Product Order number

1 1 Beaker pliers, 50 mm a 02004

1 1 Pliers for glass sample tubes with frit

4

b

47609

1 1 Turix wrench c 44349

5 5 Hose clamp, Ø 10.1 mm d 28737

- 1 Holder for 6 beakers (for E-816) 47643

1 3 Set of glass sample tubes, 2 pieces 49430

1 1 Set of holders for glass sample tubes

49432

with frits, set of 6 pieces

1 3 Set of beakers Soxhlet, 2 pieces 49427

1 3 Set of Soxhlet glass chamber, 2 pieces 49452

13 E-812/816 Soxhlet Operation Manual, Version B

Page 14

3 Technical data

Table 3-2: Standard accessories (cont.)

E-812 E-816 Product Order number

2 2 Paper thimbles 25 x 100 mm,

41882

set of 6 pieces

2 2 Paper thimbles 33 x 94 mm,

41883

set of 6 pieces

1 1 Set of holders for paper thimbles

49428

25 x 100 mm, 6 pieces

1 1 Set of holders for paper thimbles

49429

33 x 94 mm, 6 pieces

1 1 Boiling stones, 10 g 42864

1 1 Plastic funnel 51167

1 1 Hose adapter for cooling media input 49151

1 1 Cooling water hose complete,

37780

G3/4”, G1/2”, L = 1.5 m

1 1 Solvent hose, Tygon SE 200, 1 m a 49450

1 1 PTFE hose, 500 mm b 25315

2

1

14 E-812/816 Soxhlet Operation Manual, Version B

Page 15

3 Technical data

Table 3-2: Standard accessories (cont.)

E-812 E-816 Product Order number

3

1

5

2 2 Knurled screw (for solvent hose) a 43237

2 2 Clamping ring (for solvent hose) a 43238

4

2

5 5 Hose clamp, Ø 9.6 mm b 27738

2 2 Hose, silicone, Ø 6/9

43940

L = 1.5 m c

2 2 Condenser connection hose, silicone,

49161

L = 0.35 m, mounted

1 5 Condenser hose, silicone, L = 0.20 m

49163

d

2 2 Hose coupling (wide and small) e 43565

2 6 Set of seals, Viton, 2 pieces 49431

2 6 Seal PVDF holder 47610

1 1 Set of seals PTFE 49433

1 1 Sound absorber 15641

2 6 Glass valve unit complete 47590

1 1 Power cable

Type CH 10010

Type Schuko 10016

Type GB 17835

Type USA 10020

Type AUS 17836

1 1 Operation Manual E-812/816 SOX

English 93169

German 93170

French 93171

Italian 93172

Spanish 93173

15 E-812/816 Soxhlet Operation Manual, Version B

Page 16

3.1.3 Optional accessories

3 Technical data

Table 3-3: Optional accessories

Product Order number

Holder for glass sample tubes, microwavable (6 positions), PTFE

Holder for glass sample tubes,

(4 positions), PP

Condenser complete, including connector,

straight

49424

37462

47604

Protective shield E-816 SOX 51923

Protective shield E-812 SOX 51968

Expansion element 51957

16 E-812/816 Soxhlet Operation Manual, Version B

Page 17

3.2 Technical data overview

Table 3-4: Technical data

Dimensions (L x H x D) 275 x 776 x 456 mm 635 x 776 x 456 mm

Connection voltage 100 - 120 VAC / 200 - 240 VAC

Power consumption max. 700/1200 W max. 1950/1200 W

Weight 21 kg 36 kg

Overvoltage category II II

Pollution degree 2 2

Environmental conditions

Temperature

Altitude

Humidity

3 Technical data

Extraction Unit E-812 Soxhlet Extraction Unit E-816 Soxhlet

100 - 120 VAC / 200 - 240 VAC

± 10%, 50/60 Hz

for indoor use only

5 – 40 °C

up to 2000 m above sea level

maximum relative humidity 80% for

temperatures up to 31 °C, and then

linearly decreasing to 50% at 40 °C

± 10%, 50/60 Hz

for indoor use only

5 – 40 °C

up to 2000 m above sea level

maximum relative humidity 80% for

temperatures up to 31 °C, and then

linearly decreasing to 50% at 40 °C

3.3 Materials used

Table 3-5: Materials used

Component Material designation Material code

Housing Stainless steel

Glass parts Borosilicate glass 3.3

Axial seal FPM 80-Shore A 170-A

Solvent hose inside instrument FEP DN 3.18/2.18; FEP DN 8/6

Solvent hose Tygon with FEP veneer

Solvent tank Borosilicate glass 3.3

Solvent valve and valve piston Body: Al Mg Si Sn Bi (Stanal-32)

Cooling media hoses Silicone

Condenser holder PVDF

Heating plate Ceran-Hightrans

Protective shield PMMA transparent green 777

Membrane glass valve Fluorez

Surface: Ematal, plane, high corrosive-compressed

®

17 E-812/816 Soxhlet Operation Manual, Version B

Page 18

4 Description of function

This chapter explains the basic principle of the instrument, shows how it is structured and gives a

functional description of the assemblies.

4.1 Overview over the instrument

4 Description of function

1

a Condensers

b Protective shield

c Soxhlet extraction chambers with sample tube

Fig. 4.1: Overview over the instrument

2

3

4

5

6

d Beaker

e Heating plate

f Operating panel

18 E-812/816 Soxhlet Operation Manual, Version B

Page 19

4.2 Functional principle of a Soxhlet extraction

The Extraction Unit E-812/816 Soxhlet is designed to extract fat quickly and product-friendly from

food and feed. Thereby the sample is extracted in running cycles. The extraction process consists of 3

steps decribed in the following.

1

1

2

3

4 Description of function

4

6

a Cooling water

b Receiving funnel

c Solvent tank connection

Fig. 4.2: Schematic overview over an extraction position

4.2.1 Step 1 - extraction

The solvent evaporates and the vapor rises up to the condenser. From there the condensed solvent

flows into the 10 ml receiving funnel. When the receiver is full, the solvent flows back into the sample

through the 5 holes of the receiving funnel.

The tank valve and the glass valve are closed.

The solvent level increases up to the optical sensor. The sample is extracted.

The optical sensor detects the solvent level and opens the glass valve. The solvent containing the

extract flows back into the solvent beaker.

When the programmed number of cycles is reached and /or if the extraction time is over the system

goes to the next step.

5

7

d Optical sensor

e Soxhlet extraction chamber with glass sample tube

f Magnetic glass valve

g Beaker

19 E-812/816 Soxhlet Operation Manual, Version B

Page 20

4.2.2 Step 2 - rinsing

The glass valve is open. The condensed solvent flows into the receiving funnel, drops down into the

extraction chamber and flows back into the beaker.

When the programmed rinsing time is over, the system goes to the next step.

4.2.3 Step 3 - drying

The tank valve is open and removes the solvent. In the end the extract is dried as much as possible.

The glass valve is still open.

4.2.4 Solvent collection

After the extraction is finished, all solvent is collected in the tank.

4.3 Controls of the Extraction Unit

1

2

2 2

3

4

2

4 Description of function

a Display

b Functional buttons

c START button

d STOP button

5

e Selection knob

Fig. 4.3: Controls of the Extraction Unit

20 E-812/816 Soxhlet Operation Manual, Version B

Page 21

5 Putting into operation

This chapter describes how the instrument is installed and gives instructions on initial startup.

NOTE

Inspect the instrument for damages during unpacking. If necessary, prepare a status report immediately to inform the postal company, railway company or transportation company.

Keep the original packaging for future transportation.

5.1 Installation site

Put the instrument on a stable, horizontal surface. Consider the maximum product dimensions and

weight. Conform to the environmental conditions as described in section 3.2, technical data.

Installation prerequisites:

• Do not place any objects on top or below the instrument.

• The instrument must be installed with 5 cm clearance from any other objects or walls to allow

sufficient cooling.

• Do not store containers, chemicals or other items behind the instrument.

5 Putting into operation

!

WARNING

Death or serious injuries by use in explosive environments.

• Do not operate the instrument in explosive environments

• Do not operate the instrument with explosive gas mixtures

• Before operation, check all gas connections for correct installation

• Directly withdraw released gases and gaseous substances by sufficient ventilation

CAUTION

!

Risk of minor or moderate injury by heavy weight of the instrument.

• Consult three further persons to transport the instrument

• Do not drop the instrument

• Place the instrument on a stable, even and vibration-free surface

• Keep limbs out of crushing zone

Risk of instrument damage by liquids or mechanical shocks.

• Do not spill liquids over the instrument or its components

• Do not move the instrument when it is loaded with sample liquid

• Do not drop the instrument or its components

• Keep external vibrations away from the instrument

• Safely attach the instrument to the bench in earthquake prone regions

• Do not operate the instrument without the protection cover installed at the front

NOTICE

21 E-812/816 Soxhlet Operation Manual, Version B

Page 22

5.2 Electrical connections

NOTE

External connections and extension lines must be provided with a grounded conductor lead (3-pole

couplings, cord or plug equipment). All used power cords must meet the input power requirements.

5 Putting into operation

5.3 Condensers

To install the glass condensers proceed as follows:

• Dip your fingertip into distilled water and run over the black O-ring of the receiving funnel. Make

sure that no water drops remain in the funnel.

• Carefully put the condenser into the receiving funnel.

Risk of instrument damage by wrong mains supply.

• External mains supply must meet the voltage given on the type plate

• Check for sufficient grounding

NOTICE

Fig. 5.1: Installing the glass components

22 E-812/816 Soxhlet Operation Manual, Version B

Page 23

5.4 Soxhlet extractor

a

b

Fig. 5.2: Adjusting the Soxhlet chambers

To adjust the Soxhlet chambers, proceed as follows:

1. Move the rack up.

2. Pull the tray out.

3. Remove the safety shield by loosing the screws on the side of the instrument.

4. Remove the sealing holder from the extraction chambers.

5. Fix the magnet valve at the glass valve of the extraction chamber (b).

6. Connect the magnetic valve cable to the instrument (a).

7. Place the extraction chamber in position (d) and fix it with the sealing holder (e). Make sure that

the PTFE sealing ring is in correct position.

8. Adjust the optical sensor (c). It detects the solvent level. The solvent must cover the sample

during the extraction process. To achieve the optimum extraction efficiency adjust the optical

sensor directly above the sample.

9. Fix the safety shield after having fixed all extraction chambers.

5 Putting into operation

e

d

c

5.5 Water supply connections

The condensers have to be connected in series.

• Condensers connected in

series.

First connect the cooling water hoses (two longer hoses) to the rear panel. Put a hose clamp over the

cooling water hose. Take a pincer to fix the hose clamp. Begin with the left condenser position. Screw

it into the collection vessel (see chapter 5.3 Condensers) and connect the cooling water hoses (hose

clamp and GL-14 plug). To connect them among each other use the short hoses.

NOTE

Do not forget the grommet otherwise cooling water may leak.

• For safety reasons, secure the hoses with pivoting clamps.

• To save cooling water use a chiller.

• Fixing the clamp. • Hose with pivoting connec-

tion and clamp.

23 E-812/816 Soxhlet Operation Manual, Version B

Page 24

5.6 Cooling water connection

Connect the cooling water to the cooling water input a. The cooling water hose has to be secured

on both the instrument and the water connection side by means of hose clamps. The water pressure

should have a maximum of 4 bar. The built in valve reduces the water flow to 1.2 liters per minute.

The flanged screw coupling for the water connection has a standard screw thread of G 3/4“.

2

5 Putting into operation

a Cooling water input

b Cooling water output

1

Fig. 5.3: Cooling water connection

Fix the silicon hose to the cooling water output b. The drain hose for the cooling water should be

placed directly into the drain. For this purpose, shorten the silicone hose to the optimal length. The

drain hose should not show any kinks, sharp bends and/or siphoning effect. Prevent flooding inside

and outside the instrument by securing the drain hose.

Check the cooling water hoses for bends.

To save water the instrument switches off the flow 5 minutes after the extraction has ended.

NOTE

The condensers can be filled with cooling medium in the Service mode. In this case, proceed as

follows:

• Change to the service mode (click Menu, go to Mode and change from Extraction to Service, then

confirm with OK).

• Open the cooling medium valve (click Menu, go to Service functions, then to Valve testing, select

Cooling water and press Open).

• Open the cooling medium flow (open the water tap).

• After all condensers are filled with cooling medium, close the valve again and set the instrument

back to the Extraction mode (click Menu, go to Mode and change from Service to Extraction, then

confirm with OK).

NOTE

The temperature of the cooling water must be at least 25 °C below the boiling point of the organic

solvent used. If this is not possible use a chiller.

24 E-812/816 Soxhlet Operation Manual, Version B

Page 25

5.7 Cooling medium connection

5.7.1 Recirculating Chiller B-740/41 or equivalent model

When you operate with a BUCHI Recirculating Chiller B-740/41 or an equivalent model of another

manufacturer, use the adapter (see figure below) to connect the water input to the chiller output. Make

sure, that the axial seal is inserted.

A temperature of 10 °C is recommended.

• Adapter • Axial seal within the adapter

5 Putting into operation

5.7.2 Recirculating Chiller F-1xx

To connect the chiller models F-1xx to the extraction unit use the chiller connection set (article no.

11058415).

NOTE

F-100: to be used with one E-812, F-108: to be used with one E-816 or two E-812, F-114: to be

used with two E-816.

Fig. 5.3: Cooling water connection with mounted chiller connection set

Before starting an extraction make a test start to fill the condensers as the flow control unit for

cooling water gets no signal until all condensers are filled. Fill the condensers with cooling medium as

described in the chapter “Cooling water connection”.

25 E-812/816 Soxhlet Operation Manual, Version B

Page 26

5.8 Solvent hose connection

Fix the solvent hose to the solvent connection on the left of the instrument by pushing it on the

connector and tightening the knurled screw.

Fig. 5.6: Solvent hose connection

The solvent hose consists of two parts, a transparent Tygon hose (with FEP veneer) and a white PTFE

hose. The PTFE hose is solvent resistant, thus it has to be inserted into the Tygon hose.

5 Putting into operation

NOTE

Only the PTFE hose must come into contact with solvent, see picture below.

The solvent container should be placed in a

lower position than the instrument.

Fig. 5.7: PTFE hose in the solvent container

26 E-812/816 Soxhlet Operation Manual, Version B

Page 27

6 Operation

This chapter gives examples of typical instrument applications and instructions on how to operate the

instrument properly and safely.

6.1 Main screen

6 Operation

11

9

12

10

8

1

Fig. 6.1: Display elements on the main screen

2

a Functional button to open the solvent tank valve

b Functional button to open the main menu

c Functional button to move the rack down

d Symbol for the heating (on or off)

e Symbol for the solvent tank valve (open/close)

f Symbol for cooling medium valve (open/close)

g Symbol for cooling medium running (on/off)

h Current beaker situation (Extraction, Rinsing,

7

6

5

4

Drying, Beaker active, Beaker inactive Error,

Abort) with position number

i Remaining time for the running method

j Extraction step / status

k Selected solvent / operation mode

l Method name

3

27 E-812/816 Soxhlet Operation Manual, Version B

Page 28

6.2 General information on buttons

The following control buttons are available in the software for navigation and input confirmation:

Open the main menu

Open the solvent valve and thus emptying the solvent tank

Get back to the previous screen

Get on to the next screen

Confirm and save a setting and get back to the main / previous screen

Leave the current screen and get back to the main screen

Get back to the start screen without saving possible settings

6 Operation

Backward button to move backward within in the submenu structure

Forward button to move forward within in the submenu structure

Move up within the entries of a screen

Move down within the entries of a screen

Move rack up

Move rack down

When entering a name for a method the names of already existing methods can be found when

pressing the button

Affirm a screen message

Negate a screen message

Save a program under the entered name

Confirm the entry of a character when naming a program

Abort a single position during an extraction process

Skip the process to the next step

Open a valve for test purposes

Close a valve for test purposes

Switch the pump on for test purposes / switch the sound off

Switch the pump off for test purposes / switch the sound off

28 E-812/816 Soxhlet Operation Manual, Version B

Page 29

6.3 Description of the menu functions

6.3.1 Starting up the instrument

Make sure, that the instrument is correctly connected to the mains supply and the cooling water. Then

switch on the instrument at the main switch. The main screen appears:

6 Operation

Fig. 6.1: Main screen

6.3.2 Instrument settings

To define the instrument settings, press the Menu button. The following screen opens:

Fig. 6.2: Menu

Select instrument settings and press the forward button.

Fig. 6.3: Instrument settings

29 E-812/816 Soxhlet Operation Manual, Version B

Page 30

You can now change the settings by turning the selection knob and pressing OK to confirm. Press the

move up or move down button to switch between the settings. When the Beep key function is on, a

beep sound is audible whenever a key is pressed. When the Beep end function is on a beep sound is

audible when the extraction process is finished.

Max. cycle time: If a cycle is not reached after this time, an error message apears.

Standard setting: 30 min.

Press the backward button to get back to the main menu.

6.3.3 Occupying the positions

To occupy the positions, press the Menu button. The following screen opens:

6 Operation

Fig. 6.4: Menu

Select Occupied positions and press the forward button. The software will now ask you whether you

want to occupy all positions or not. To occupy all positions, press Yes. You will then get back to the

main menu and the positions 1 to 6 are occupied and ready for use.

If you do not want to occupy all but only some manually defined positions, press No. The following

screen appears:

Fig. 6.5: Occupied positions

You can now switch individual positions by turning the selection knob and pressing OK. Press the

backward button to get back to the main menu.

30 E-812/816 Soxhlet Operation Manual, Version B

Page 31

6.3.4 Defining a method

In the main menu select Program. The following screen opens:

Fig. 6.6: Extraction solvent

You can now select the desired solvent by turning the selection knob.

6 Operation

NOTE

The Extraction Unit is only tested with the solvents petroleum ether, diethyl ether, chloroform and

hexane. The use of other solvents can be done by choosing “Custom” but is on the risk of the user.

Please check chemical resistance of all parts in contact with the solvent prior to use.

Press OK to confirm and then Next to proceed with the Extraction step.

Fig. 6.7: Extraction step

Set the extraction time and/or the number of cycles by means of the selection knob and press OK to

confirm it.

NOTE

If the extraction time and the number of cycles are programmed, both criteria need to be fulfilled to

go to the next step.

Positions that have fulfilled the criteria will be heated until the last position has fulfills the criteria as

well.

If you have to change the default heater setting, you can regulate it between 50 - 110%. Use the

default setting for general extraction purposes.

Press Next to proceed with the Rinse step.

31 E-812/816 Soxhlet Operation Manual, Version B

Page 32

6 Operation

Fig. 6.8: Rinse step

Set the rinse time by means of the selection knob and press OK to confirm it.

NOTE

We recommend to use the default heater setting of 100% for general extraction purposes.

Press Next to continue with the drying step.

Fig. 6.9: Drying step

Set the drying time by means of the selection knob and press OK to confirm it.

NOTE

We recommend to use the default heater setting of 100% for general extraction purposes.

Your method is now created. Press End to get back to the menu.

32 E-812/816 Soxhlet Operation Manual, Version B

Page 33

6.3.5 Saving a method

Define a method according to the chapter “Defining a method” and save it as follows:

In the main menu select File.

Fig. 6.10: Main screen

Press the forward button to get to the submenu File.

6 Operation

Fig. 6.11: File

Press the forward button to enter a name for your new method.

Fig. 6.12: Enter name

Use the selection knob to select the letters for the name and press Enter each time. To delete a letter,

select BACKSPACE and then Enter.

When you have finished, press Save to save the name. You will get back to the submenu File.

33 E-812/816 Soxhlet Operation Manual, Version B

Page 34

NOTE

To overwrite an existing method, select Used and press OK. To carry out minor changes in the

method name, select Used, select the name you want to change, carry out the changes and press

OK.

6.3.6 Opening a method

In the File submenu go to Open.

6 Operation

Fig. 6.13: File

Select the method you want to open with the selection knob and press OK. The method now appears

on the main screen ready for carrying out a corresponding extraction process.

Fig. 6.14: Main screen with selected program

34 E-812/816 Soxhlet Operation Manual, Version B

Page 35

6.3.7 Deleting a method

In the File submenu go to Delete.

Fig. 6.15: File

Select the method you want to open with the selection knob and press OK. A message appears

asking you whether you really want to delete this program. Press Yes to confirm and the backward

button to get back to the main menu.

6 Operation

6.3.8 Abort function

It is possible to abort a specific position during an extraction process. For all other positions the

extraction is continued. For this purpose, press Abort. The first defined beaker symbol starts flashing.

Select the position you want to abort by means of the selection knob and press Abort.

Fig. 6.16: Abort

35 E-812/816 Soxhlet Operation Manual, Version B

Page 36

6.3.9 Skip function

During the extraction process it is possible to skip one step and go directly to the next step, e.g. from

the extraction step to the rinse step. For this purpose, press Skip and confirm the appearing message

by pressing Yes.

Fig. 6.17: Skip

6 Operation

6.3.10 Service functions

In the main menu the submenu Service functions is available. Here you have an overview over all

sensors, functional efficiency of the valves, heating elements, information on the extraction unit and

the operating hours. Part of this information (all testing functions) is only available in the Service mode.

To change to the Service mode proceed as follows:

In the main menu select Mode, turn the selection knob to Service and press OK.

Fig. 6.18: Go to the Service Mode

Now go to the Service functions with the move up button and press the forward button. The following

screen appears:

36 E-812/816 Soxhlet Operation Manual, Version B

Page 37

Fig. 6.19: Service functions

Heater testing

Select Heater temperatures.

6 Operation

Fig. 6.20: Heater temperatures

Here you get an overview over the current temperatures at the individual heating positions.

NOTE

The indicated temperature is the temperature within the heating element, not on top of the heating

plate.

To get back to the Service functions press the backward button.

37 E-812/816 Soxhlet Operation Manual, Version B

Page 38

6 Operation

Valve testing

Select Valve testing. The following screen opens:

Fig. 6.21: Valve testing

You can now test the functioning of the three valves by changing their status. For this purpose, select

a valve and press Open or Close. You will hear a corresponding sound and see a corresponding reaction, depending on your setup.

NOTE

Close all valves before you leave this submenu, otherwise it is not possible to start an extraction.

NOTE

The tank valve may overheat if it is open for more than 10 s, the valve therefore closes after 10 s and

cannot be reopened for another 20 s afterwards.

To get back to the Service functions press the backward button.

Sensor testing

Select sensor testing. The following screen opens:

Fig. 6.23: Sensor testing

The “X” behind the sensor name signalizes that the sensor is activated. This is the case when:

• the solvent tank is completely full (Solvent)

• the cooling water is flowing (Flow)

• the protective shield is down (Shield)

For the rack, the “X” has a special meaning:

• Pos. up: [X] Pos. down [X]: Rack is up

38 E-812/816 Soxhlet Operation Manual, Version B

Page 39

• Pos. up: [ ] Pos. down [ ]: Rack is down

• Pos. up: [ ] Pos. down [X]: Rack is in between

To get back to the Service functions press the backward button.

Operating hours

Select operating hours. The following screen opens:

6 Operation

Fig. 6.24: Operating hours - 1

Here you see the operating hours of each heating position. To see the second page press Next. The

following screen appears:

Fig. 6.25: Operating hours - 2

Here you can see for how many hours the instrument was switched on, how many extractions were

carried out already and what extraction time was needed up to now.

To get back to the Service functions press the backward button.

39 E-812/816 Soxhlet Operation Manual, Version B

Page 40

Unit information

Select unit information. The following screen opens:

Fig. 6.26: Unit information

Here you get a short overview over technical instrument data.

6 Operation

6.4 Example of an extraction process

6.4.1 Material and equipment

Before starting an extraction process all necessary materials and chemicals must be present:

• Fume hood (only when working with diethyl ether or chloroform)

• Cooling water connection

• Analytical balance (± 0.1 mg; minimal weight 200 g)

• Spatula

• Funnel

• Desiccator

• Solvent

• 2 or 6 beakers

• 2 or 6 glass sample tubes or thimbles

• Waste container for organic solvents

• Depending on the application: Silica sand, celite, glass wool and paper thimbles

NOTE

The holders for the glass sample tubes and the paper thimbles are not microwavable.

6.4.2 Preparing an extraction

To prepare the instrument for extraction, proceed as follows:

1. Dry the clean solvent beakers with three boiling stones each in the drying oven for 30 minutes, let

the beakers cool down to ambient temperature in the desiccator and weigh them.

2. Prepare the sample as required in the glass sample tubes with frits or in the paper thimbles, e.g.

hydrolysis and/or drying.

3. Place the prepared glass sample tube or paper thimble with the corresponding holder in the

extraction chamber.

4. Adjust the optical sensor above sample level.

5. Fill the organic solvent directly into the beakers.

40 E-812/816 Soxhlet Operation Manual, Version B

Page 41

6. Place the beakers on the corresponding positions directly on the heating plate.

7. Lower the rack.

8. Activate the occupied positions.

9. Select a previous program or enter a new one.

10. Open the cooling water flow or switch on the connected chiller.

11. Start the extraction process.

6.4.3 After the extraction process

The end of an extraction process is indicated on the display and audible by a beep sound (if selected

in the instrument settings).

After an extraction process is finished, proceed as follows:

• Confirm the message on the screen by pressing the backward button.

• Empty the solvent tank.

• Move up the rack.

• Carefully remove the glass tubes or thimbles from the beakers by means of the pliers.

• Place the glass sample tubes or thimbles on a tissue and let them dry under the fume hood.

• Dry the beakers in a drying oven at 100 °C or in a vacuum oven at 200 mbar and 70 °C until they

have a constant weight.

• Let the beakers cool down to ambient temperature in a desiccator.

• Weigh the beakers and calculate the resulting fat content.

6 Operation

6.4.4 Emptying the solvent tank

• To empty the solvent tank put the solvent outlet hose into the waste container.

• Press Solv. and confirm the appearing message by pressing Yes.

NOTE

Make sure to empty the solvent tank after each extraction.

6.4.5 Reusing the solvent

• The solvent can be reused directly or after being distilled in a rotary evaporator.

When the instrument was used for the first time:

• Waste the solvent

When a different solvent was used before

• Waste the solvent

After incorrect procedure:

• Clean the glass assembly

• Clean the solvent tank

• Waste the solvent

NOTE

When working with petroleum ether from 40 - 60 °C: Renew the whole solvent after 10 extractions

to achieve a reproducible extraction behaviour. The mixture changes within time because the light

fraction evaporates and the heavy fraction accumulates.

41 E-812/816 Soxhlet Operation Manual, Version B

Page 42

7 Maintenance

This chapter gives instructions on all maintenance work to be performed in order to keep the instrument in good working condition.

7 Maintenance and repairs

WARNING

!

Death or serious burns by electric current at cleaning.

• Switch off the instrument

• Disconnect the power cord and prevent unintentional restart

• Wait until the instrument is completely dry before reconneting to mains

Risk of housing and instrument damage by liquids and detergents.

• Do not spill liquids over the instrument or parts of it

• Wipe off any liquids instantly

• Use ethanol or soapy water as detergent only

NOTICE

7.1 Daily maintenance

7.1.1 Housing

Check the housing for defects (switches, plugs) and clean it regularly with a damp cloth.

7.1.2 Hoses and hose connections

Check the hoses and hose connections for defects (cracks, brittle areas) and replace damaged hoses

immediately.

7.1.3 Glass parts

Visually inspect all glass parts for defects (cracks, stars, and splintering) regularly.

Beakers

After extraction, rinse the beakers with hot water and dish washing liquid and use a brush to clean

them thoroughly. Subsequently wash them in a laboratory dish washer.

Sample tubes

Empty the sample tubes into a waste and rinse them with water. They can be washed in a dish

washer as well. Make sure that they do not get in contact with the metal cones.

All glass parts, except for the condenser spiral, must be clean and dry before they are used again. The

glass parts can be dried in a drying oven at 100 °C for 30 minutes or in a vacuum oven at 70 °C for 20

minutes. Afterwards let the glass parts cool down slowly before reusing them, as they are under too

high tension when they are warm/hot.

42 E-812/816 Soxhlet Operation Manual, Version B

Page 43

7.1.4 Solvent tank

Empty the solvent tank after each extraction process. The solvent in the tank can be reused when

the extraction process was normal. In case of an incident during the extraction, the solvent can be

cleaned e.g. in a rotary evaporator.

NOTE

In case you empty the tank after you have already filled in the solvent for the next extraction, be

aware that the 10 ml of solvent in the receiving funnel are withdrawn as well, because the tank valve

has to be opened to empty the solvent tank.

In case it is not possible to empty the solvent tank automatically because of a software breakdown,

the instrument has to be opened manually by the emergency opening. For this purpose, proceed as

follows:

7 Maintenance and repairs

• Unscrew all screws on the back side of the

instrument and remove the back cover.

Fig. 7.1: Emptying the solvent tank manually

• Loosen the outer left screw cap (solvent feed

from the collection valve to the tank) and lift it

a little as to provide air to the system.

• Provide a vessel to collect the outflowing

solvent.

• Remove the solvent screw on the left bottom

side by means of a hexagonal socket or a flat

pincer.

43 E-812/816 Soxhlet Operation Manual, Version B

Page 44

7.2 Weekly maintenance

7.2.1 Heating elements

The ceramic heating plates should be cleaned regularly after they have cooled down. Remove dirt

adhering to the plate with e.g. ethanol. Then clean the plate with a moist cloth and dry it.

7.3 Monthly maintenance

7.3.1 Cleaning the seals

NOTE

When replacing the seals, take care not to damage them. To avoid damaging the seals, never apply

grease and never touch them with sharp objects.

To prolong the lifetime of the seals, rinse them regularly with distilled water. Afterwards, dry them with

a soft cloth.

7 Maintenance and repairs

7.3.2 Replacing the seals

Seals are subject to wear and tear, thus you should check them regularly and replace them, if necessary.

To replace the seals on the extraction chambers, proceed as follows:

• Remove the protective shield.

• Slide the rack forward, so that you have free access to the extraction chambers.

• Remove the extraction chamber for which you want to replace the seal.

• Now proceed as shown in the figures below:

Fig. 7.2: Replacing the seals on the extraction chambers

• Now refix the extraction chamber, slide back the rack and remount the protective shield.

To replace the seals on the beakers, proceed as shown in the figures belows:

44 E-812/816 Soxhlet Operation Manual, Version B

Page 45

Fig. 7.3: Replacing the seals on the beakers

7.3.3 Condenser

Unscrew the condenser connections, remove the condenser and place it in a laboratory dish washer

for cleaning with a conventional agent.

Use an appropriate cleaner to remove possible contaminations adhering to the condenser spiral, e.g.

algae. Let the spiral soak for a while.

7 Maintenance and repairs

NOTE

To remove the condensers moisten the seal with water.

7.3.4 Flushing the tank valve

The tank valve has to be flushed in regular intervals to prevent clogging.

For this purpose, we recommend to carry out an extraction process with fresh solvent at least every

six months (or earlier, denpending on your extraction processes and frequency).

7.4 Customer service

Only authorised service personnel are allowed to perform repair work on the instrument. These

persons have a comprehensive technical training and knowledge of possible dangers which might

arise from the instrument.

Addresses of official BUCHI customer service offices are given on the BUCHI website under:

www.buchi.com. If malfunctions occur on your instrument or you have technical questions or application problems, contact one of these offices.

The customer service offers the following:

• Spare part delivery

• Repairs

• Technical advice

45 E-812/816 Soxhlet Operation Manual, Version B

Page 46

8 Troubleshooting

This chapter helps to resume operation after a minor problem has occurred with the instrument. It lists

possible occurrences, their probable cause and suggests how to remedy the problem.

The troubleshooting table below lists possible malfunctions and errors of the instrument. The operator

is enabled to correct some of those problems or errors by him/herself. For this, appropriate corrective

measures are listed in the column “Corrective measure”.

The elimination of more complicated malfunctions or errors is usually performed by a BUCHI technical

engineer who has access to the official service manuals. In this case, please refer to your local BUCHI

customer service agent.

8.1 Malfunctions and their remedy

Table 8-1: General malfunctions and their remedy

Malfunction Possible cause Corrective measure

Instrument does not work Incorrect or no mains connection Connect the instrument correctly to the mains

Instrument not switched on Switch on the instrument

Method cannot be started Service mode active Change to Extraction mode

Rack is in upper position Lower the rack

Solvent tank is full Empty the tank

Protective shield is open Close the protective shield

Software does not show the main

screen

Method stops Cooling water flow is too low Check the cooling water connection and all

Cooling water sensor is defective (may be the feeding water is

contaminated with algae, lime, etc.)

Evaporation of extraction

solvent

Boiling retardation Incorrect positioning of the beaker Place the beaker directly onto the heating plate

No boiling Incorrect positioning of the beaker Place the beaker directly onto the heating plate

Seals wrong, deformed or

damaged

Spring deflection downwards Contact the BUCHI customer service

Incorrect positioning of the beaker/

glassware and seals

No anti-bumping granules were

used

Beaker position is not active

8 Troubleshooting

supply

Go back to the main screen

hoses for bends and remove them, if necessary

Contact the BUCHI customer service

Exchange the seals

Contact the BUCHI customer service

Put anti-bumping granules into the beakers

Activate the beaker position

Heater power is set too low

Elution of celite Too much organic solvent for

extraction

Sand/celite layers mixed up Clean the extraction chambers

46 E-812/816 Soxhlet Operation Manual, Version B

Use 100% for general purpose

Choose correct solvent

Stick to the standard application parameters

Page 47

Table 8-1: General malfunctions and their remedy (cont.)

Malfunction Possible cause Corrective measure

Empty solvent tank not

possible

8.2 Error messages

NOTE

In the following table X refers to the position in the instrument starting from left to right.

Table 8-2: Error messages

Error number Display information Possible cause Corrective measure

0001 No cooling water flow detected.

Please verify if a proper flow is

possible

0002 Please close safety shield

completely

0003 The Line Voltage is too low Voltage is out of the range Make sure the power supply is

0004 The Line Voltage is too high Voltage is out of the range Make sure the power supply is

0005 Rack not in rear position The rack is not properly

0006 Heating malfunction. Please

contact service

0010 to

0015

0020 Error during extraction process:

0021 to

0026

0051 Error during rack positioning.

0053 to

0058

0077 to

0082

0083 Solvent tank is full. Please empty

any other - Technical errors Contact the BUCHI customer service

Extraction stopped on position

X. Soxhlet cycle has not been

completed

All tasks stopped

Overtemperature Heater X:

Heater was turned off

Motor was shut off

Transfer valve at position X is not

connected

Malfunction of heater at position X

occurred. Please check heater

tank and restart again.

8 Troubleshooting

Software breakdown Retry to empty the solvent tank. If this does not

work, manually empty the tank by opening the

emergency opening

No cooling water started or

Open the cooling water flow

connected

Safety shield is open Close safety shield correctly

stable and start again

stable and start again

Bring rack in upper position and

pushed back to rear

push it back to rear position

position

Heating defective Contact the BUCHI customer service

Maximum cycle time is

exceeded

Check for possible leakages and add

solvent

Error during process Start again

Overtemperature on

respective position

Cool down the heating and start

again

Motor error Contact the BUCHI customer service

Transfer valve not

connected

Check plug connection at the instrument

Heater defective Contact the BUCHI customer service

Solvent tank was not

cleared. There is too much

Empty solvent tank by pressing the

button “Solv.”

solvent in the tank

47 E-812/816 Soxhlet Operation Manual, Version B

Page 48

8.3 Too high/too low results

There are many reasons for too high or too low results even though the extraction process ran without

problems. The most important reasons are listed in the following:

Results too high

• Work with clean and dry hands and material (weighing and sample preparation).

• Dry the beakers completely after extraction until a constant weight is reached.

• Use clean and pure solvent.

• Make sure that the components in contact with solvent are out of solvent resistant material (solvent

resistant funnel, dispensette organic, for example).

Results too low

• Insufficient sample homogenisation

• Sample was wet before extraction.

• Fat is combusted during drying due to high temperature in the drying oven.

• Use clean and pure solvent.

Problems during hydrolysis with B-411/E-416

• If the hydrolysing temperature is too high fat of sample can combust or the sample solution can

boil over.

• If the hydrolysing time is too long sample fat might be destroyed.

• If the hydrolysing time is too short the fat is not unhinged completely of the matrix.

• If the temperature of the rinsing water (hydrolysis) is too hot, fat is washed out.

• If the celite content is too small the sample fat can not be bounded sufficiently.

• Fat can combust during too hot drying (too high temperature/power in microwave, drying oven or

vacuum drying oven).

8 Troubleshooting

48 E-812/816 Soxhlet Operation Manual, Version B

Page 49

9 Shutdown, storage, transport and disposal

9 Shutdown, storage, transport and disposal

This chapter instructs how to shut down the instrument, how to pack it for storage or transport, and

specifies the storage and shipping conditions.

9.1 Preparing the instrument for storage and transport

To prepare the instrument for storage and transport, lower the rack, unplug the power cord, remove

the cooling water, and remove all glass parts from the instrument.

Emptying the condenser

Place the cooling water out hose into a drain. Disconnect the silicon hose (cooling water in) at the rear

of the instrument and place it into a waste container. Loosen the upper condenser screws by half a

turn.

Dismantling the condenser

Moisten the connection between condenser and holder before removing the condenser.

By doing so, turn it a little.

Emptying the solvent tank

Make sure, that the solvent tank is empty before transporting the instrument.

9.2 Storage and transport

Store the instrument at a dry place. Store and transport the instrument in its original packaging.

!

Death or serious poisoning by contact or incorporation of harmful substances.

• Wear safety goggles

• Wear safety gloves

• Wear a laboratory coat

• Flush the instrument and clean all accessories thoroughly to remove possibly dangerous

substances

• Do not clean dusty parts with compressed air

• Store the instrument and its accessories at a dry place in its original packaging

WARNING

49 E-812/816 Soxhlet Operation Manual, Version B

Page 50

9.3 Disposal

To dispose of the instrument in an environmentally friendly manner, a list of materials is given in

chapter 3. This helps to ensure that the components are separated and recycled correctly.

Please follow valid regional and local laws concerning disposal.

9 Shutdown, storage, transport and disposal

CAUTION

!

Risk of minor or moderate injury by heavy weight of the instrument.

• Consult three further persons to transport the instrument

• Do not drop the instrument or its transport box

• Place the instrument on a stable, even and vibration-free surface

• Keep limbs out of crushing zone

50 E-812/816 Soxhlet Operation Manual, Version B

Page 51

10 Spare parts

This chapter lists spare parts, accessories, and options including their ordering information.

Order the spare parts from BUCHI. Always state the product designation and the part number when

ordering spare parts.

Use only genuine BUCHI consumables and genuine spare parts for maintenance and repair to assure

good system performance and reliability. Any modifications to the spare parts used are only allowed

with the prior written permission of the manufacturer.

Table 10-1: Spare parts

Product Order number

Plastic funnel 51167

Beaker pliers, 50 mm 02004

Turix wrench 44349

Pliers for glass sample tubes with frit 47609

Hose adapter for cooling media input 49151

Hose coupling (wide and small) 43565

Hose clamp 28737

Cooling water hose complete, G3/4”, G1/2”, L = 1.5 m 37780

Hose, silicone Ø 6/9, L = 1.5 m 43940

Solvent hose, Tygon SE 200 49450

PTFE hose 500 mm 25315

Knurled screw (for solvent hose) 43237

Clamping ring (for solvent hose) 43238

Condenser connection hose, silicone, L = 0.35 m 49161

Condenser hose, silicone, L = 0.20 m 49163

Set of holders for glass sample tubes with frits, set of 6 pieces 49432

Set of holders for paper thimbles, 25 x 100 mm, 6 pieces 49428

Set of holders for paper thimbles, 33 x 94 mm, 6 pieces 49429

Holder for 6 beakers (for E-816) 47643

Set of beakers Soxhlet, 2 pieces 49427

Set of beakers Soxhlet, 12 pieces 45675

Condenser complete, including connector, straight 47604

Protective shield E-816 SOX 51923

Protective shield E-812 SOX 51968

Set of seals, Viton, 2 pieces 49431

Set of sealing ring PTFE SOX, 6 pieces 49433

Holder for glass sample tubes, micro-wavable, 6 positions, PTFE 49424

Solvent hose Soxhlet, including coupling 49164

Set of Soxhlet glass chamber, 2 pieces 49452

Glass valve unit, complete 47590

Sound absorber 15641

Membrane with anchor for glass valve 37534

Chiller connection set 11058415

IQ/OQ-set E-812/816 SOX 45657

10 Spare parts

51 E-812/816 Soxhlet Operation Manual, Version B

Page 52

11 Declarations and requirements

11.1 FCC requirements (for USA and Canada)

English:

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to both Part 15 of the FCC Rules and the radio interference regulations of the Canadian

Department of Communications. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Français:

Cet appareil a été testé et s'est avéré conforme aux limites prévues pour les appareils numériques

de classe A et à la partie 15 des réglementations FCC ainsi qu’à la réglementation des interférences

radio du Canadian Department of Communications. Ces limites sont destinées à fournir une protection adéquate contre les interférences néfastes lorsque l’appareil est utilisé dans un environnement

commercial.

Cet appareil génère, utilise et peut irradier une énergie à fréquence radioélectrique, il est en outre

susceptible d’engendrer des interférences avec les communications radio, s’il n’est pas installé et

utilisé conformément aux instructions du mode d’emploi. L’utilisation de cet appareil dans les zones

résidentielles peut causer des interférences néfastes, auquel cas l’exploitant sera amené à prendre les

dispositions utiles pour palier aux interférences à ses propres frais.

11 Declarations and requirements

52 E-812/816 Soxhlet Operation Manual, Version B

Page 53

11.2 Declaration of conformity

11 Declarations and requirements

53 E-812/816 Soxhlet Operation Manual, Version B

Page 54

Page 55

Page 56

BÜCHI Labortechnik AG

CH-9230 Flawil 1 / S witzerlan d

T +41 71 394 63 63

F +41 71 394 65 65

www.buchi.com Quality in your hands

Loading...

Loading...