Page 1

Operating Instructions for the

RST Rheometer

Page 2

!"#$%&'(&)'*+%*+,&

!! !"#$%&'(#)%"*+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*,!

!+-! ./01'$)"2*3$)"()45/*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*,!

!+6! 781#/9*:%";)2'$0#)%"*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*<!

"#$#%! &'()**!&+,-.,/,0!#####################################################################################################################!1!

"#$#$! &'()''(!&+,-.,/,0!####################################################################################################################!2!

"#$#3! 4,567089:!;<,.,9/6!59=!>??,66-08,6!@-0!&'()**!59=!&'()''(!##################################################!2!

"#$#A! &'()*B'!&+,-.,/,0!###################################################################################################################!C!

"#$#D! ;<,.,9/6!@-0!&'()*B'!#################################################################################################################!E!

"#$#1! *-.F7/,0!'G6/,.!#####################################################################################################################!%H!

!!! =/##)"2*7#0$#/&*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*--!

!!+-! >$0"14%$#0#)%"*0"&*?"40(@)"2*+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*--!

!!+6! 70;/#8*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*--!

""#$#%! I,9,05<!'5@,/G!J-/,6!##############################################################################################################!%%!

""#$#$! >66,.K<G!-@!L;!*--<89:!M,N8?,!###############################################################################################!%3!

!!+A! B4/$0#)"2*C"D)$%"9/"#*0"&*=/"/$05*E0"&5)"2*+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*-,!

!!+,! 7/#'4*;%$*F7>G::*0"&*F7>G77>*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*-,!

""#A#%! O,8:+/!>=P76/.,9/!&'()**!#####################################################################################################!%A!

""#A#$! O,8:+/!>=P76/.,9/!&'()''(!####################################################################################################!%A!

""#A#3! 4-79/89:!/+,!Q-0RF<5/,!&'()''(!##########################################################################################!%D!

""#A#A! ;<,?/08?5<!*-99,?/8-96!&'()**!59=!&'()''(!############################################################################!%D!

""#A#D! &'()**!59=!&'()''(!>66,.K<G!@-0!>==8/8-95<!M,N8?,6!############################################################!%D!

""#A#D#%! >66,.K<G!-@!S(L!(,.F,05/70,!*-9/0-<!M,N8?,!TQ5/,0!U5?R,/V!############################################!%1!

""#A#D#$! >66,.K<G!-@!*-9,WB<5/,!4,567089:!'G6/,.!########################################################################!%C!

""#A#1! >66,.K<G!-@!L;!*--<89:!M,N8?,!###############################################################################################!%E!

!!+<! 7/#'4*;%$*F7>G:37*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*6H!

""#D#%! &,.-N89:!'5@,:750=!&'()*B'!#################################################################################################!$H!

""#D#$! ;<,?/08?5<!*-99,?/8-96!&'()*B'!###############################################################################################!$%!

""#D#3! (,.F,05/70,!',96-0!&'()*B'!#################################################################################################!$%!

""#D#A! >*!>=5F/,0!&'()*B'!################################################################################################################!$%!

!!+I! 3$)"#/$*:%""/(#)%"*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*66!

!!+J! :%94'#/$*:%""/(#)%"*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*66!

!!+K! :5/0")"2*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*6A!

!!+L! .0)"#/"0"(/*+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*6A!

!!!! .0@)"2*./01'$/9/"#1*)"*7#0"&05%"/*.%&/*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*6,!

!!!+-! M')(@*7#0$#N**F'"*7)"25/*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*6,!

!!!+6! O0"2'02/1*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*6L!

!!!+A! >%'(P1($//"*+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*AH!

!!!+,! >P/*./"'*781#/9*%;*#P/*F7>*FP/%9/#/$*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*AH!

!!!+<! C&)#*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*A6!

"""#D#%! X98/6!######################################################################################################################################!3$!

"""#D#$! 4,567089:!'G6/,.6!################################################################################################################!33!

"""#D#3! X6,0!>7/+-08Y5/8-9!59=!4595:,.,9/!###################################################################################!31!

!!!+I! C&)#*3$%2$09*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*AJ!

"""#1#%! Z75<8/G!*-9/0-<!######################################################################################################################!A%!

"""#1#$! 45/+!######################################################################################################################################!A%!

"""#1#3! &,F-0/!####################################################################################################################################!A%!

!!!+J! CQ45%$/$*+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*,6!

Brookfield Engineering Labs., Inc. page 2 Manual No. M14-223

Page 3

!!!+K! B4#)%"1*+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*,6!

"""#C#%! (8.,!#######################################################################################################################################!A3!

"""#C#$! *-79/,0!#################################################################################################################################!A3!

"""#C#3! [,0-89:!##################################################################################################################################!A3!

"""#C#A! &'$3$!#####################################################################################################################################!A3!

"""#C#D! 4,.-0G!#################################################################################################################################!A3!

"""#C#1! ;\F-0/!]F/8-96!######################################################################################################################!AA!

"""#C#2! ',0N8?,!###################################################################################################################################!AA!

"""#C#C! X'^!B-0/!59=!&'$3$!B-0/!#######################################################################################################!AA!

"""#C#E! _59:75:,!###############################################################################################################################!AA!

"""#C#%H! ^50?-=,!###############################################################################################################################!AD!

"""#C#%%! (,.F,05/70,!#######################################################################################################################!AD!

"""#C#%$! !!>^]X(!###############################################################################################################################!AD!

!!!+L! F'"*3$%2$099*-*#%*--*++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*,<!

!R! =/"/$05*3$%(/&'$/1*;%$*B4/$0#)%"*%;*FP/%9/#/$*0"&*./01'$)"2*781#/91*+++++++++++++++++++++*,J!

!R+-! ./01'$/9/"#*781#/91*;%$*F7>G::*0"&*F7>G77>*+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*,K!

"`#%#%! 4,5670,.,9/!M80,?/<G!89!/+,!'5.F<,!####################################################################################!AE!

"`#%#$! 4,5670,.,9/!a8/+!'5.F<,!89!/+,!4,567089:!'G6/,.!##########################################################!AE!

"`#%#3! 4,5670,.,9/!a8/+!(,.F,05/70,!*-9/0-<!M,N8?,!#################################################################!DH!

"`#%#A! 4,5670,.,9/!X689:!*-9,WB<5/,!59=!B<5/,WB<5/,!4,567089:!'G6/,.!>??,66-0G!##################!DH!

"`#%#D! 4,5670,.,9/!X689:!'F,?85<!4,567089:!^-K6!#######################################################################!D%!

!R+6! ./01'$/9/"#1*?1)"2*F7>G:37*+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++*<-!

"`#$#%! 4,5670,.,9/!a8/+!45975<!I5F!>=P76/.,9/!T4I>V!############################################################!D$!

"`#$#$! 4,5670,.,9/!a8/+!45975<!I5F!>=P76/.,9/!T4I>V!############################################################!D$!

APPENDIX A: Technical Data ................................................................................................................ 53

APPENDIX B: RST-CPS Rheometer Gap Setting Procedure for Cone and Plate Spindles .................. 54

APPENDIX C: Calibration Check ............................................................................................................ 56

APPENDIX D: Symbols for Test Parameters and Units of Measurement ............................................... 58

APPENDIX E: Data Sheets for Standard Measuring Systems ............................................................... 59

APPENDIX F: RST-SST for Measuring in Brabender Units (BU) ........................................................... 63

APPENDIX G: Instrument Dimensions .................................................................................................... 64

APPENDIX H: Online Help and Additional Resources ............................................................................ 68

APPENDIX I: Warranty Repair and Service .......................................................................................... 69

Brookfield Engineering Labs., Inc. page 3 Manual No. M14-223

Page 4

I Introduction

I.1 Measuring Principle

The RST Rheometer is a rotational, controlled-stress rheometer. The measuring drive developed for this

instrument utilizes a high-precision dynamic drive system with optical encoder for absolute position

measurement of spindle geometry.

There are two basic measurement methods:

• rotational measurement under controlled shear rate (CSR)

• rotational measurement under controlled shear stress (CSS)

The RST Rheometer performs rotational tests with pre-set speed (shear rate) and measures the torque

imposed on the measuring element or in shear stress a pre-set shear stress to measure the shear

deformation of the measured substance by angular deflection of the measuring element. The RST

Rheometer can be used for shear stress tests that allow precise measurement of the yield point without

shearing the measured substance, as well as creep behavior and recovery after shearing.

Both CSR and CSS measurements can be carried out manually (without PC support) or with a

computer system and the Rheo3000 application software.

The RST Rheometer is used in quality control, product development and research.

Brookfield Engineering Labs., Inc. page 4 Manual No. M14-223

Page 5

I.2 System Configuration

RST-CC and RST-SST Rheometer:

The basic configuration for the RST Rheometer includes:

• rheometer with touch screen, electronic unit and measuring drive

• power unit (AC adapter)

Available accessories:

• printer

• coaxial cylinder measuring systems

• temperature sensor Pt100

• measuring device ME3-CP/PP for cone/plate and plate/plate measuring systems

• special measuring systems, e.g. vane spindles

• temperature control device FTK-RST for cylinder measuring systems

• KE cooling unit

• fluid circulation thermostat

• holding device for measuring bob and temperature control device

• computer system

• Rheo3000 software

The RST has the following features of performance:

• digital speed and torque control

• automatic adjustment of control parameters during testing

• direct display of measured and calculated values for speed, torque, shear rate, shear stress,

viscosity, temperature, time etc.

• internal storage of measured values

• optional output of measured values to an USB printer

• operator support through dialog control via touch screen direct on the measuring instrum ent

• built-in system interface with serial standard port (RS232 C) and USB 2.0 for direct connection of

a computer

• output of measuring results in the form of a table or graph in real time

• saving of measuring results to USB-2.0-compa tib le instruments, e.g. USB s tic k

The RST Rheometer can be operated manually via touch screen or under computer control. DC power

supply to the RST Rheometer is through an AC adapter.

Brookfield Engineering Labs., Inc. page 5 Manual No. M14-223

Page 6

I.2.1 RST-CC Rheometer

Figure I-1

Components:

1 Rheometer with touchscreen 5 Barcode reader

2 Measuring bob coupling 6 Clamp handle

3 Seat flange for sample cup 7 Stand

4 Stand base plate 8 Leveling screw

Brookfield Engineering Labs., Inc. page 6 Manual No. M14-223

Page 7

I.2.2 RST-SST Rheometer

The RST-SST Rheometer has the following additional components as shown in the figure.

Figure I-2

Components:

1 Extension bellows 5 Operating handle

2 Clamp handle 6 Fastening claw

3 Work plate 7 Thumb wheel

4 Lower seat of work plate 8 Upper seat of work plate

I.2.3 Measuring Elements and Accessories for RST-CC and RST-SST

Measuring devices are not part of the standard delivery of the RST Rheometer and must be ordered

according to your measuring requirements.

Optional measuring devices available:

• coaxial standard measuring systems for RST with or without b u ilt-in temperature sensor Pt100

• temperature control device FTKY3 fur use of cylinder measuring systems in the temperature

range of -10°C … +90°C

• KE cooling device for use of cylinder measuring systems in the temperature range of -20°C …

+180°C

• measuring device ME3-CP/PP for use of cone/plate or plate/plate measuring systems in the

temperature range of -10°C … +90°C (… +180°C with cooling device)

• special measuring bobs such as vane spindles in the temperature range of -10°C … +90°C

(… +180°C with cooling device)

•

Brookfield Engineering Labs., Inc. page 7 Manual No. M14-223

Page 8

I.2.4 RST-CPS Rheometer

The RST-CPS Rheometer system consists of:

• Rheometer head with touch screen containing electronic unit and measuring drive integrated in

one housing

• Bas ic in s tr u ment with measuring bottom plate and temperature sensor Pt100

• AC Adapter

Available Accessories:

• Measuring cones and measuring plates

• Bath/Circulator* for RST -CPS-F

• Computer system

• Rheo3000 software

*The accessories in bold print are necessary for a minimal configuration.

Available Accessories:

• Start-up A ssistance

• Instrument Training

• Rheo3000 Software Training

Instrument features include:

• Digital control of rotational speed and torque

• Automatic adjustment of control parameters during measurement

• Direct indication of measured and calculated values of speed/shear rate, torque/shear stress,

viscosity, temperature and time.

• Internal or external storage of datas (measured values)

• Data output of measured values to a printer

• User support by dialog mode at touch screen display

• Built-in system interface with serial standard interface (RS 232-C) for connection to a computer

• USB port for connection of RST-CPS to printer, computer or USB flash drive

The RST-CPS Rheometer can either be operated manually using the touch screen display or it can be

operated under computer control. The RST-CPS Rheometer is supplied with direct drive current by the AC

Adapter.

Brookfield Engineering Labs., Inc. page 8 Manual No. M14-223

Page 9

Figure I-3

Components:

1 Measuring Head 6 Touch Screen Display

2 Barcode Reader 7 Measuring Spindle Coupling

3 Spindle (Cone or Plate) 8 Lever

4 Bubble Level 9 Measuring Bottom Plate

5 Hose Connectors (RST-CPS-F) 10 Levelling Screw

I.2.5 Elements for RST-CPS

Measuring devices are not part of the standard delivery of the RST-CPS Rheometer and must be ordered

according to your measuring requirements. The following types of measuring systems are suited for use

with the RST-CPS Rheometer:

a) cone/plate measuring systems

b) plate/plate measuring systems

c) Please select a suitable measuring system in the measuring range required for your

measurements (see Appendix E).

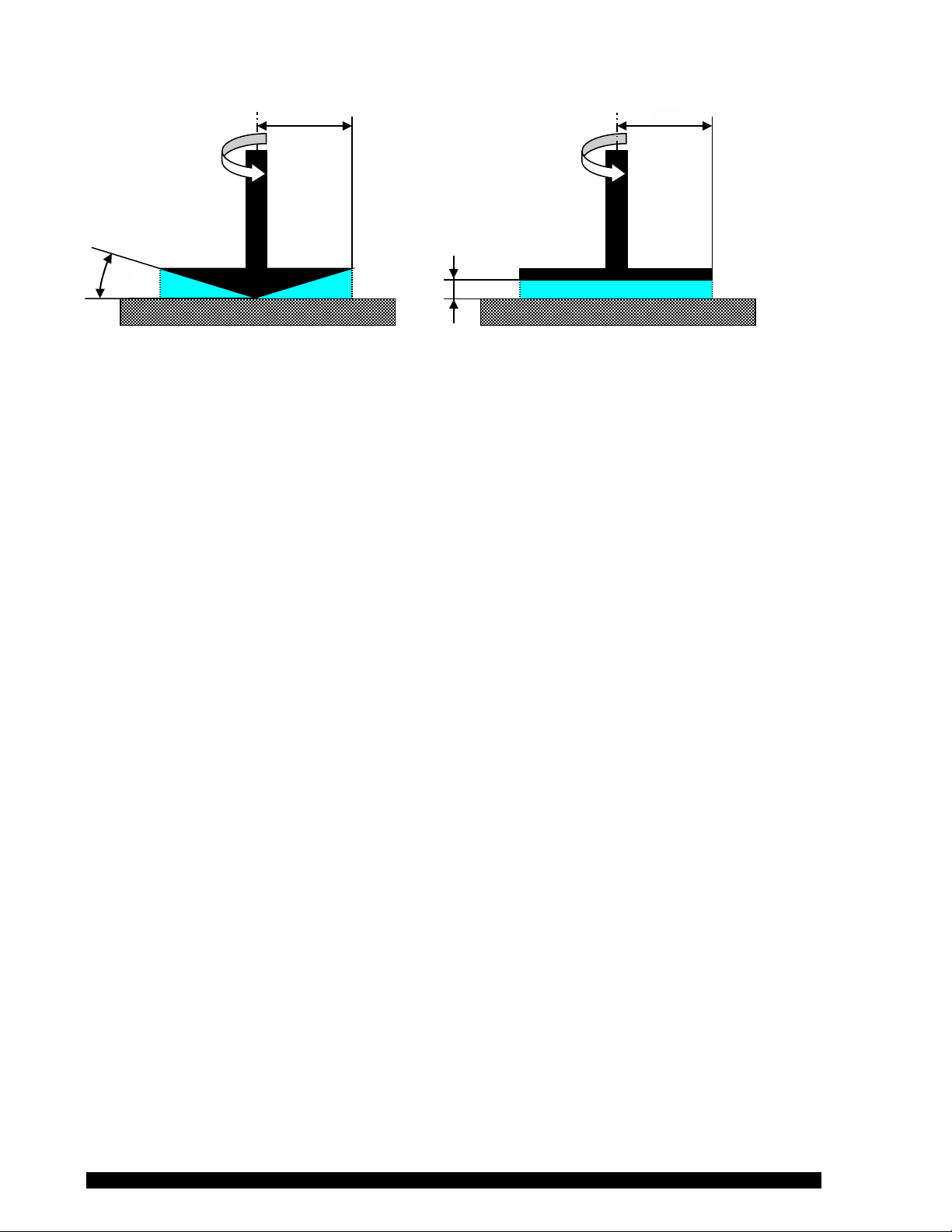

When measuring cones are used the shear rate is the same across the whole measuring gap. The

most common cone angles are =1° and !=2°. The cone is truncated 50µm (0.05 mm) in order

to avoid contact and friction with the bottom measuring plate.

Measuring plates are used when larger filling particles occur in the measured substance. Gaps

between 0.1 to 3.0 mm may be used. In this case, the shear rate in the measuring gap is a function

of the radius.

Brookfield Engineering Labs., Inc. page 9 Manual No. M14-223

Page 10

R

h

!

R

Radius

Radius

Cone Angle

Gap Setting

Cone Spindle

Plate Spindle

Figure I-4

I.2.6 Computer System

The computer system and the Rheo3000 software are optional and allow for the graphic representation of

measuring results in real time, report print-out, analysis of existing measured data and the automation of

measuring procedures. Several RST Rheometers can be controlled through several thermostats from

different manufacturers.

The computer system consists of a PC with the following minimum system requirements:

• CPU with at least 1.5 GHz clock frequency

• 1 GB RAM (primary storage)

• 2.5 GB free fixed-disk capacity

• operating system Microsoft (32bit or 64bit) Windows XP, Vista, 7 or 8

• mouse and keyboard

• VGA graphic adapter with 1024 x 768 resolution and monitor

• 2 USB ports for rheometer and temperature accessory control

• application software package Rheo3000

The application software for the RST Rheometer (Rheo3000 software package) is available separately

and not absolutely necessary for the operation of the measuring instrument. In the following cases,

however, it is highly recommended:

• extensive rheological analyses

• graphic evaluation

• evaluation using mathematical models

• automated measurements

• specific requirements (e.g. FDA Title 21 CFR Part 11)

• research and development

• continuous use

Brookfield Engineering Labs., Inc. page 10 Manual No. M14-223

Page 11

Caution!

Transportation

Danger!

Transport damage

Caution!

Moving the measuring instrument

Danger!

Location

Danger!

Type or souce

Caution!

Type or source

II Getting Starte d

II.1 Transportation and Unpacking

Transport the RST Rheometer always in its original carton.

Should you detect any transport damage when unpacking the instrument, please inform the carrier, draw

up damage records with him and contact Brookfield or your Brookfield Dealer.

Protect the original carton against bumps, shocks and falling down.

Observe the notes on ambient conditions.

Do not take the measuring instrument into service with transport damage in evidence.

Place the measuring instrument upright on a stable, level table (stand base at the bottom).

Check the measuring instrument for transport damage after unpacking.

To assemble or move the RST-CPS Rheometer, hold it nowhere but by the stand.

Never hold the measuring instrument by the Measuring Head to carry it.

Pay attention to the ambient conditions.

Do not place the instrument near the edge of a table.

II.2 Safety

This operating manual uses the following safety notes:

“Danger” indicates a situation of immediate danger which may result in death or irreversible, severe

injuries and damage to property if ignored:

”Caution!” indicates a situation of im m ediate danger which may result in reversible, slight injuries and

damage to property if ignored:

Measure(s)

Measure(s)

II.2.1 General Safety Notes

Read the operating manual through carefully. It provides important information on unpacking, assembly,

start-up and operation of this measuring instrument. If you have any further questions please contact our

service department (see Appendix I).

Brookfield Engineering Labs., Inc. page 11 Manual No. M14-223

Page 12

Danger!

Personnel and operation

Danger!

Operation

Power supply

• in case of danger.

Danger!

Service and repair

Danger!

Technical modifications

Danger!

Emergency

Danger!

Protection

Danger!

Protective Clothing

Caution!

General

Follow all instructions given in this operating manual. This is the only way to ensure the proper use of this

measuring instrument.

More particularly, observe all safety notes.

Danger!

Never operate and run the measuring instrument when the instrument or power supply

Switch the measuring instrument off and pull the mains plug for:

• service or repair

• moving the measuring instrument

• removal or attachment of components or accessories

Service and repair work must only be performed by trained and authorized specialist

Do not make any technical modifications on the instrument! Any modification will result in the

extinguishment of implied and express warranty on the measuring instrument!

Make sure that the measuring instrument is operated by

ONE instructed specialist personnel only.

components (e.g. mains cable) are damaged.

personnel

In case of emergency, turn off the instrument and then disconnect the electrical cord

If this instrument is used in a manner not specified by the manufacturer, the protection

It’s recommended to wear protective goggles, gloves and snood-type cap.

Observe all safety notes contained in this operating manual and read it through carefully.

from the wall outlet.

provided by the instrument may be impaired.

Brookfield Engineering Labs., Inc. page 12 Manual No. M14-223

Page 13

Danger!

AC Adapter

Caution!

Handling

Operating Environment

RST Rheometer is not exposed to the following:

The RST Rheometer is not intended for use in a potentially hazardous environment.

Danger!

Samples

Danger!

Temperature

Danger!

Indoor

II.2.2 Assembly of KE Cooling Device

Connect the AC adapter using a grounded plug to avoid electric shock or damage to the

system components!

Danger!

The user should ensure that the substances placed under test do not release poisonous,

If you use temperature control system do not touch any components (such as water jacket,

hoses, measurement system) under 5°C or over 40°C of your sample. Do not disconnect any

Never lift your RST Rheometer by the measuring element or its coupling.

• heavy dirt or dust,

• direct sun radiation,

• objects that emit strong heat (e.g. heating radiators),

• objects with a strong electromagnetic field (e.g. loudspeakers, motors etc.),

• liquids or corrosive chemicals.

toxic or flammable gases at the temperatures which they are subjected to during the

testing.

hoses in this temperature range.

Brookfield Engineering Labs., Inc. page 13 Manual No. M14-223

Operation only indoors.

Page 14

Caution!

Ambient conditions for operation and stoppage

Make sure that the following ambient conditons are maintained:

• relative air humidity: 20 … 80%

Environment and ambience

Make sure that the RST-CPS Rheometer is not exposed to:

• liquids or corrosive chemicals.

Caution!

Handling

II.3 Operating Environment and General Handling

Find a comfortable, convenient work place for the installation of the RST Rheometer. There should be

enough room to place the Rheometer, the measuring systems, the measuring substances and the

peripheral devices (e.g. printer, computer and bath/circulator). You need a grounded AC plug to operate

the RST Rheometer. You also need an additional plug for the connection of each peripheral device.

Your operating environment and the place where you store the RST Rheometer should not be extremely

hot, extremely cold or extremely moist. Places with strong tem perature and air humidity fluctuation should

also be avoided.

Caution!

Be careful to protect the RST Rheometer against heavy bumps or falls down. Avoid vibrations and shocks!

The Rheometer motor will automatically turn off if the maximum torque (100 mNm) is exceeded.

If the measuring torque is exceeded, e.g. by a stop of the measuring drive under full load or by a rise in

viscosity caused by hardening processes, the electronic safety devices will be activated and prevent a

defect. However, it is inevitable in such cases to abort the measurement or measuring program and to

disconnect the measuring bob from the measuring instrument.

• temperature: +10 … +40°C

• heavy dirt or dust,

• direct sun radiation,

• objects that emit strong heat (e.g. heating radiators),

• objects with a strong electromagnetic field (e.g. loudspeakers, motors etc.),

Never lift your RST Rheometer by the measuring element or its coupling. Avoid everything that

might impair the rotation of coupling (e.g. shock).

II.4 Setup for RST-CC and RST-SST

II.4.1 Height Adjustment RST-CC

To adjust the height of the stand, release the clamp handle and pull the stand to the desired height,

holding the rheometer unit by the rear bridge.

When the height is right, fasten the clamp handle finger-tight again.

II.4.2 Height Adjustment RST-SST

The RST-SST Rheometer can perform viscosity measurements in original packing containers with the test

material.

The height of the RST-SST is adjusted by loosening the clamp handle and then moving the instrument to

the desired position with the operating handle. After height adjustment the clamp handle can be fastened

finger-tight again if desired.

Brookfield Engineering Labs., Inc. page 14 Manual No. M14-223

Page 15

Caution!

Connecting the measuring instrument

II.4.3 Mounting the Workplate RST-SST

This step is required only if you intend to use the workplate of the RST-SST. To mount it, proceed as

follows:

• Place the workplate into the upper or lower seat by pushing it in laterally until it stops.

• Screw the work plate to the stand finger-tight using the two spigot nuts.

• Put the sliding blocks with the threaded rods through the slots in the work plate from below. Make

sure that the groove of the sliding block fits into the slot.

• Use the thumb wheel to screw the fastening claw down finger-tight.

• For each slot you will need 1 fastening claw, 1 sliding block with threaded rod and 1 thumb wheel.

II.4.4 Electrical Connections RST-CC and RST-SST

Connections for the electrical components of the RST Rheometer are located on the back of the

instrument.

Figure II-1

Connecting elements on the back of the instrument in Figure II-8:

1 PC (USB) 5 RS 232 port

2 LAN (network) 6 ON / OFF control light

3 USB stick or printer 7 Power unit (AC adapter)

4 ON / OFF button 8 Pt100 temperature sensor

Connect or disconnect any cables from and to the RST Rheometer only with the instrument

turned off.

II.4.5 RST-CC and RST-SST Assembly for Additional Devices

This section describes assembly and connection of the following measuring systems:

• FTK temperature-control device (water jacket) for use of cylinder measuring systems in the

temperature range of -10°C...+90°C (temperature control by liquid thermostat)

• ME3-CP/PP measuring device for cone/plate and plate/plate measuring systems in the

temperature range of -10°C...+90°C (temperature control by liquid thermostat)

• KE cooling device in connection with FTK temperature-control device (water jacket) or ME3-

CP/PP measuring device for extension of temperature range to -20°C...+180°C

Brookfield Engineering Labs., Inc. page 15 Manual No. M14-223

Page 16

Temperature control device

+90°C!

II.4.5.1 Assembly of FTK Temperature Control Device (Water Jacket)

This section describes assembly and connection of the following measuring systems:

Figure II-2

Components:

1 Threaded joint for mounting flange 4 Hose conncetion for thermal oil discharge

2 Thermostatting chamber 5 Pt100 temperature sensor

3 Threaded joint for sample cup 6 Hose connction for thermal oil inflow

Optional temperature control devices available:

• Liquid temperature control device FTK for use in cylinder measuring systems in the

temperature range of -10°C ... +90°C (temperature control by liquid thermostat).

• If the optional KE cooling device is used, the temperature control device FTK can be

operated in the temperature range of -20°C ... +180°C.

The temperature control device FTK

without KE cooling unit must not be used

Caution!

beyond the temperature range of -10°C ...

Figure II-3

Brookfield Engineering Labs., Inc. page 16 Manual No. M14-223

Page 17

Danger!

External thermostat / Cryostatic temperature regulator

Operation of the FTK

When making tests at temperatures below -10°C and above

avoid overheating of the rheometer.

FTK temperature control device (water jacket) and measuring systems in Figure II-3:

1 FTK water jacket 5 Measuring bob CC3-14

2 Sample cup for FTK-RST 6 Measuring bob CC3-25

3 Immersion type sample cup 7 Measuring bob CC3-40

Measuring bob CC3-8

4

Assembly:

• Turn the RST Rheometer off with the mains switch on the back of the instrument.

• If the cooling device KE is to be used, mount it first.

• Set the FTK from below on the mounting flange for the sample cup and tighten the thread.

• Fix the hoses for the liquid circulation thermostat (see below).

• Plug the cable “VK-MB” supplied with the FTK into the built-in Pt100 and into the “Pt100”

socket on the back panel of the RST Rheometer.

Thermostat connection to the FTK temperature control device:

• Hose connections are required to connect a liquid circulation thermostat when the RST

Rheometer is operated with the FTK temperature control device.

• The hoses from the liquid circulation thermostat are connected with the FTK temperature

control device (see Figure II-2, page 16) using the quick-fitting couplings.

• For that purpose you push the coupling sleeve slightly back, insert the hose connector

and let the coupling go. It will fasten the hose (without screwing or turning) by locking in.

Pull lightly to check if the hoses fit tightly.

Typical thermostatting liquids are:

• -10 °C ... +90 °C deionized water mixed with glycol

• -20 °C ... +180 °C thermostat oil

Suitable thermostatting liquids can be obtained from Rheotec Messtechnik Gm bH .

Caution!

Set the upper temperature limit at the liquid circulation

thermostat to 90°C if using water and to 180°C if using oil (only

with KE cooling device!).

+90°C, do not start the temperature control device FTK before

the cooling liquid flows through the KE cooling device in order to

Brookfield Engineering Labs., Inc. page 17 Manual No. M14-223

Page 18

II.4.5.2 Assembly of Cone/Plate Measuring System

Figure II-4

Components:

1 Threaded joint for mounting flange 5 Guide pin

2 Quarter-turn fastener 6 Measuring bob

3 Hose connectors for thermostatting medium 7 Measuring table

4 Adjusting screw 8 Gauge

The RST Rheometer enables you to determine viscosity using a cone/plate or plate/plate

system with the measuring device ME3-CP/PP. To install this optional measuring system,

proceed as follows:

• Turn the RST Rheometer off with the mains switch on the back of the instrument

• If the KE cooling unit is to be used, mo u n t it firs t.

• Set the ME3-CP/PP on the rheometer flange from below and tighten the thread.

• Before tightening the thread, check to see if the guide pin of the measuring plate lies

in the groove of the mounting flange of the RST.

• Connect hoses to the liquid circulation thermostat (see below).

• Plug the cable of the built-in Pt100 into the socket “Pt100” on the back panel of the

RST Rheometer.

Hose connection from thermostat to measuring device ME3-CP/PP:

• Hose connections are required to connect a liquid circulation thermostat when the

RST Rheometer is operated with the cone/plate measuring device ME3-CP/PP.

• The hoses from the liquid circulation thermostat are connected with the cone/plate

measuring device ME3-CP/PP using the quick-fitting couplings. For that purpose you

push the coupling sleeve slightly back, insert the hose connector and let the coupling

go. It will fasten the hose (without screwing or turning) by locking in. Pull lightly to

check if the hoses fit tightly .

Brookfield Engineering Labs., Inc. page 18 Manual No. M14-223

Page 19

Caution!

Measuring device ME3-CP/PP

Caution!

Cooling device

Caution!

Operation of the FTK-RST (water jacket)

External thermostat / Cryostatic temperature regulator

temperature range of -10°C ... +90°C.

Working in the temperature range of -20°C ... +180°C requires an additional

The cone/plate measuring device ME3-CP/PP may only be operated in the

cooling device KE.

When making tests at temperatures below -10°C and above +90°C, do not start

the temperature control device FTK-RST before the cooling liquid flows through

the cooling device KE-FTK-RST in order to avoid overheating of the rheometer!

Set the upper temperature limit at the external liquid circulation thermostat:

Danger!

to +90°C if using water and to +180°C if using oil (with cooling device

KE-FTK-RST).

Typical thermostatting liquids are:

• -10 °C ... +90 °C deionized water mixed with glycol

• -20 °C ... +180 °C thermostat oil

Suitable thermostatting liquids can be obtained from R heotec Messtechnik GmbH.

II.4.6 Assembly of KE Cooling Device

Figure II-5

Components:

1 Cooling device K-MK 2 Hose connections

Using the cooling device KE you can operate the temperature control device FTK-RST or

the measuring device KP adapter in the temperature range of -20°C … +180°C.

Flowing through the cooling channel of the cooling device, the cooling liquid prevents heat

transmission from the temperature-controlled measuring device to the RS T R heom eter.

Assembly:

• Turn the RST Rheometer off with the mains switch on the back of the instrument

• Slide the cooling device KE onto the RST Rheometer from below and tighten the thread.

• Fasten the hoses of the cooling circuit on the cooling device KE using the quick-fitting

hose coupling.

Cooling water connection to cooling device KE:

Brookfield Engineering Labs., Inc. page 19 Manual No. M14-223

Page 20

• The hoses of the cooling circuit are connected to the cooling device KE using the quick-

fitting couplings.

• For that purpose you push the coupling sleeve slightly back, insert the hose connector

and let the coupling go. It will fasten the hose (without screwing or turning) by locking in.

• Pull lightly to check if the hoses fit tightly.

II.5 Setup for RST-CPS

II.5.1 Removing Safeguard RST-CPS

To remove the safeguard:

• Pullout the shipping pin. See Figure II-6, page 20.

• Turn up the lever

• Remove the black foam rubber (shipping protection). See Figure II-7, page 20.

Figure II-6

Figure II-7

Brookfield Engineering Labs., Inc. page 20 Manual No. M14-223

Page 21

Connecting the measuring instrument

Danger!

AC adapter

II.5.2 Electrical Connections RST-CPS

Connections for the electrical components of the RST-CPS Rheometer are located on the back of the

instrument.

Figure II-8

Connecting elements on the back of the instrument in Figure II-8:

1 LAN (network) 4 RS 232 port

2 PC (USB) 5 USB stick or printer

3 ON / OFF button 6 ON / OFF control light

Caution!

Be sure that your USB Flash Drive is formatted in FAT32. Otherwise it doesn’t work.

Connect or disconnect any cables from and to the RST-CPS Rheometer only with the

instrument turned off.

II.5.3 Temperature Sensor RST-CPS

The temperature sensor Pt100 is inside the bottom measuring plate. The temperature is measured

continuously and is displayed in the Touch Screen Display alternately with the Date.

II.5.4 AC Adapter RST-CPS

The AC adapter is used to power the RST-CPS Rheometer. Do not use any other device to supply the

RST-CPS Rheometer with power than the AC adapter of IP class 4/2 delivered by Brookfield.

Always connect the AC adapter to a properly grounded socket. To avoid electric shock or

damage to system components, always use a properly grounded plug to connect the AC

Connecting the AC adapter:

• Insert the connecting socket of the power cord into the AC adapter until the plugs locks into place.

Brookfield Engineering Labs., Inc. page 21 Manual No. M14-223

adapter.

Page 22

Caution!

AC adapter

AC adapter

Be sure to observe the following instructions:

The AC adapter and the cables must never get into contact with liquids.

• Insert the socket of the DC cable into the “DC” connector on the back panel of the RST-CPS

stand and fasten it finger-tight.

• Plug the power cord into a grounded mains socket.

• Turn the RST-CPS Rheometer on again, if necessary.

Figure II-9

The AC adapter should not remain plugged in long when the socket of the DC cable is

disconnected from the “DC” connector on the back panel of the instrument.

• Never reach into the AC adapter or touch its contact pieces!

Danger!

• The AC adapter must lie open and not be covered.

• Position cables and AC adapter in a way to ensure that no-one will stumble over them.

•

II.6 Printer Connection

For measurements without PC support the printer

®

• DYMO LabelWriter

This printer can be connected directly to the USB Host port of the RST Rheometer. To print the measured

values during measurement you must pre-select “Printer” as output device.

Connecting the printer DYMO LabelWriter

®

:

• Turn the RST Rheometer off with the mains switch on the back of the rheometer.

• Insert the printer connecting cable into the USB socket on the back panel of the RST Rheometer.

• Turn the RST Rheometer on again.

A standard USB printer connecting cable can be used to connect the printer. The cable is normally

delivered with the printer.

The printout of measuring results can only be guaranteed for the printer mentioned above. If you use other

printers or need extensive prints (e.g. graphic) or color print you should use the Rheo3000 software.

II.7 Computer Connection

If the RST Rheometer is to be operated in REMOTE mode with PC support (Rheo3000 program

package), connect the two devices using a data transmission line delivered by Brookfield with the USB

conncetion 2.0 or with the “RS232” socket on the back panel of the RST Rheometer:

• Turn the RST Rheometer off using the mains switch on the back of the instrument.

Brookfield Engineering Labs., Inc. page 22 Manual No. M14-223

Page 23

Caution!

Data transmission line

Cleaning and Environment

Do not use chemical products such as strong solvents or strong acids to clean the housing,

express warranties!

Danger!

Service and Repair

• Turn your computer system off.

• Insert the data transmission line into the “RS232” or “PC” socket on the back panel of the RST

Rheometer.

• Connect the other end of the data transmission line with a free RS232 serial port (e.g. “COM2”) or

the USB connector of your computer.

• Turn the RST Rheometer and your computer system on again.

For information on the installation of the computer system, please refer to the operating instrutions of the

individual devices.

Use no other than the data transmission line delivered by Brookfield.

II.8 Cleaning

The paint coat of the RST Rheometer resists most solvents and weak acids. Use a dry, clean, soft and

nap-free cloth to clean the housing. Use neutral detergent liquids if necessary.

especially the Touch Screen Display.

Make sure NO liquid penetrates into the housing (e.g. through the instrument connecting

Danger!

Use the supplied cleaning cloth to clean the touchscreen and, if necessary, replace the protective foil on

the display. It is available from your Brookfield dealer.

sockets) and into the bearings of the measuring drive. This could destroy the instrument and

this would result in the destruction of the instrument and in the termination of implied and

II.9 Maintenance

The RST Rheometer system is designed for long-term operation. Should the instrument require repair,

contact Brookfield or your authorized Brookfield dealer.

Only authorized service personnel may work on the control electronics, all accessories, the

Measurement accuracy can be checked by the user at any time. We recommend that the measurements

be done with Brookfield viscosity standard fluids (mineral oils) as recommended for each individual

spindle geometry.

You must:

• Use temperature control

• Select the appropriate measuring system

• Carry out measurements at the following pre-set M (‰ torque) values: 250‰, 500‰ and 750‰

• Read viscosity values from the display on the RST Rheometer

In case of instrument failure (or severe deviation from the mineral oil viscosity value), contact Brookfield or

your authorized Brookfield dealer.

Brookfield Engineering Labs., Inc. page 23 Manual No. M14-223

measuring device, as well as the AC Adapter and all electric circuits and connections!

Page 24

III Making Measurements in Standalone Mode

The following chapter summarizes the operation and the menu system of the RST for the performance of

manual measurements without PC.

III.1 Quick Start: Run Single

The following steps describe the procedure to run a test in standalone mode:

1. Connect the power supply to the instrument and plug into the main power supply. Turn on the

instrument by pushing the POWER button on the back panel. The spindle coupling rotates in one

direction, then the opposite direction for a few seconds. The following self-test message appears on the

screen during this brief startup procedure:

Figure III-1

2. When the self-test completes, the following main screen appears:

Figure III-2

Attach the spindle. Push the Run Single button. The following screens allow the operator to input test

parameters that will execute a single step test.

The data will be reported in the default units for the RST Rheometer;

Viscosity: Pa.s

Shear Stress: Pa

Shear Rate: 1/s

Temperature: °C

Push the OK button to proceed to the next screen. Push the HOME button to return at any time to the

main screen.

Brookfield Engineering Labs., Inc. page 24 Manual No. M14-223

Page 25

3. The next screen to appear will be the confirmation for the spindle identity. The bar code on the spindle

shaft is identified by the infrared sensor built into the RST Rheometer.

Figure III-3

Push the OK button to proceed to the next screen. Push the BACK ARROW to return to the preceding

screen.

4. The next screen confirms the Measuring System Type.

Figure III-4

Choices include: Cone, Cylinder, Vane, Plate, DG (Double Gap) and Custom. Your spindle type will

automatically be recognized by your RST Rheometer. The “visible” box will have a check mark. Click this

box if you want to remove the check mark, in which case, the spindle identity will not be displayed. Push

the OK button to go to the next screen.

5. The following screen appears:

Figure III-5

This screen confirms values for K-Gamma and Tau-Prom; both are automatically recognized on the bar

code. Push OK. The following screen appears only when a cone spindle type has been recognized by

your RST Rheometer.

Brookfield Engineering Labs., Inc. page 25 Manual No. M14-223

Page 26

Figure III-6

Enter the value for the cone spindle truncation in mm on this screen. This value is listed on the data sheet

that comes with your spindle.

Set the gap for the cone spindle. See Appendix B for the procedure to set the gap.

When the gap has been set, push OK to go to the next screen.

6. If the spindle is not a cone spindle, the following screen appears and provides the sample volume

required for a viscosity test with the spindle that has been selected.

Figure III-7

Push OK to go to the next screen.

7. This screen allows you to choose the type of test that you want to run. Choices include:

Speed

Torque

Shear Stress

Shear Rate

Figure III-8

Push OK to go to the next screen.

8. Enter the START and END values for the test type that you have chosen.

Brookfield Engineering Labs., Inc. page 26 Manual No. M14-223

Page 27

Figure III-9

Push OK to go to the next screen.

9. Enter the number of measuring points and total test time on this screen.

Figure III-10

Push OK to go to the next screen.

10. Check the box “Wait for Temperature” to control the temperature setpoint of the sample material

before the viscosity test begins. Push OK to go to the next screen.

Figure III-11

Enter a value for the control temperature on this screen. Push OK to go to the next screen.

11. Input the substance information for the test material if desired. You can use up to 25 alphanumeric

characters. This is an optional screen.

Push OK and the viscosity test will automatically start.

12. During the test execution, the following screen shows the parameters that are displayed:

Brookfield Engineering Labs., Inc. page 27 Manual No. M14-223

Page 28

Figure III-12

While the test is running, the following choices are available for data display format:

a) Table format with values for time, viscosity, shear rate or speed, shear stress or torque, and

temperature.

Figure III-13

b) Graph format with time on the x-axis, viscosity on the y-1 axis, and temperature on the y-2 axis.

Figure III-14

c) Math format which shows the minimum viscosity value, the maximum viscosity value and the average

of all viscosity values. The top half of this table contains data while the bottom half remains empty

because there is only one block in this test with multiple steps. See Program Tests to understand how the

bottom half of this table is used.

If the STOP button is pushed at any time, the test will stop, and the measuring point data will be saved up

to that time.

13. At the end of the test, the operator has the following choices:

a) Repeat the test by pushing the CIRCULAR ARROW. This allows you to repeat the same test by using

a single button push.

b) Go to the Data File by pushing the FOLDER BUTTON. This allows you to review data for the test that

has just completed. This is discussed in the next Section.

c) Push OK to return to the main screen.

14. Click on the FOLDER icon. The parameters for the completed test are reviewed on the next two

screens. The first screen will review the company/user information if the USER MANAG EM E N T feature

Brookfield Engineering Labs., Inc. page 28 Manual No. M14-223

Page 29

has been turned on. If you see the following MEAS SYS SN:0 the explanation is that either the spindle

with bar code was not recognized or the spindle does not have a bar code.

Push OK to go to the next screen which gives the summary of test parameters.

Push OK to go to the next screen which shows three icons: MATH, QC, REPORT

Push OK to go to the next screen which shows test information for the first measuring point in the

completed test. Use the RIGHT ARROW to go forward from the first measuring point to the second

measuring point. Continue using the RIGHT ARROW to review all the measuring points in the test file or

the LEFT ARROW if you need to go backwards in the test.

The icons at the bottom provide choices for TABLE and GRAPH.

Click on TABLE to review the test measuring points in tabular format. The UP and DOWN arrows allow

you to review all of the measuring points in the test.

Click on GRAPH to review the graphical data for the completed test. The Y1-axis is the viscosity data, the

Y-2 axis is the temperature data and the X-axis is time. It is not possible to change the identities for each

axis.

Click on MATH to review maximum average and minimum viscosity values for the completed test.

III.2 Languages

User screens for the RST Rheometer are available in the following languages; click on SETTINGS on the

home screen (main menu), then click on LANGUAGE:

• German

• English

• Chinese

In future versions, the following language s will be implemented:

• Japanese

• French

• Polish

• Portuguese

• Russian

• Spanish

Figure III-15

Brookfield Engineering Labs., Inc. page 29 Manual No. M14-223

Page 30

Figure III-16

III.3 Touchscreen

All user input is done via touchscreen. The touchscreen doubles as both an input and output device. The

touchscreen is resistive, i.e. it responds to light pressure. You tap lightly with your finger to select the

desired option on the touchscreen. Tap and drag your finger across the touchscreen to perform a dragand-drop operation. Instead of your finger you may also use the stylus that is provided with your

instrument. Replace the protective foil on the display when damage or heavy wear is in evidence.

After turning the RST Rheometer on, you will see the main menu. Since the RST Rheometer cannot show

all main menu items at the same time, there is a second menu page to which you go with the icon “Run

4…10“ at the bottom right of the touchscreen.

Tapping at the stylized house you will always get to the first page of the main menu.

Use the arrow keys up or down to turn pages within the active menu.

The Status Bar provides information relating to the time (as configured by the user), the coupling and

various connections to the RST-CPS Rheometer:

Figure III-17

III.4 The Menu System of the RST Rheometer

This is a schematic representation of the menu sytem of the RST-CPS Rheometer on the touchscreen –

start screen / main menu:

!Edit

!Units

!Measuring Systems

!Users

Brookfield Engineering Labs., Inc. page 30 Manual No. M14-223

Page 31

!Edit Program

!Explorer

!Settings

!Time

!Counter

!Zeroing

!Barcode

!Memory

!Self Test

!Temperature

!USB

!Language

!German

!English

!Chinese

!Japanese

!Portuguese

!Spanish

!Polish

!French

!Russian

!RS232

!Service

!About

!Activation

Brookfield Engineering Labs., Inc. page 31 Manual No. M14-223

Page 32

!Run Single

!Zeroing

!Run Program 1

!Run Program 2

!Run Program 3

!Programs 4 to 11

!Display

!Export Options

!Run Program 4

!Run Program 5… to 11

III.5 Edit

Press the Edit icon in the main menu.

In this menu you can change:

• units

• measuring systems

• user management (Users)

• test programs (Edit P rog )

• view and manage measured data in “Explorer”

III.5.1 Units

Figure III-18

Press the Units icon in the Edit menu.

Brookfield Engineering Labs., Inc. page 32 Manual No. M14-223

Page 33

Figure III-19

In this menu you can change the units for:

• dynamic viscosity

• temperature

To make a change, press to highlight the radio button in front of the desired unit.

III.5.2 Measuring Systems

Press the Measuring Sys icon.

Figure III-20

In this menu you manage your choice of measuring system (spindle or bob). Measuring systems can be

• changed

• added

• deleted.

An additional feature allows yout to “Hide” measuring systems which you seldom use. Tap the check box

in front of the measuring system type you want to hide to remove the check m ark.

Press the OK icon to go to a list from which you choose the measuring system to be changed. Bear in

mind that the list of measuring systems consists of several pages. Move up or down through the list with

the arrows.

Figure III-21

Brookfield Engineering Labs., Inc. page 33 Manual No. M14-223

Page 34

Figure III-22

Figure III-23

Using the three icons in the center at the bottom of the screen, you can:

• add (Plus symbol)

• edit (Pencil)

• delete (Waste Paper Basket)

measuring systems.

Press OK to acknowledge this action and to go to the next menu:

Figure III-24

This is where you enter the name of the measuring system using the keyboard to enter up to 25 alpha

numeric characters. Push OK to confirm the name and go to the next screen where you select the

measuring system type:

Figure III-25

Brookfield Engineering Labs., Inc. page 34 Manual No. M14-223

Page 35

To select the type of measuring system, press the appropriate radio button:

• Cone

• Plate

• Vane

• Cylinder

• DG

• Custom

By selecting “Visible” you determine whether users selecting a measuring system in the measuring

program can see this measuring system.

Press OK to acknowledge your choice. On the next screen you enter the shear rate factor (K•Gamma)

and the shear stress factor (Tau Promill) using the numeric keyboard and acknowledge your entries with

OK:

Figure III-26

For cones, truncation must be entered in "m on the next screen:

Figure III-27

Acknowledge your entry with OK. Then enter the sample volume required for the measurement in

milliliters (mL) in the next mask and acknowledge with OK.

Figure III-28

Now your new or changed measuring system is durably stored in your RST-CPS Rheometer.

To correct input errors or check your entries you can always return to the previous input mask using

“Back”.

Brookfield Engineering Labs., Inc. page 35 Manual No. M14-223

Page 36

III.5.3 User Authorization and Management

When using this feature, operators are authorized to perform specific tests by a System Administrator.

For example, this feature provides the support capability to comply with the requirements of 21CFR Part

11 for the pharmaceutical industry which addfresses the controls for user access to the RST Rheometer.

Press the “Users” icon. Switch on “User Management” by putting a check mark in the box and press OK.

Figure III-29

The next screen is called “Edit User”. This is the screen used by the Administrator to add authorized

users with specific rights to perform tests.

Figure III-30

Use the three iconds at the bottom to add (Plus symbol), edit (Pencil) and delete (Waste Basket) users.

Click on the Plus symbol to add a user. The next screen allows you to enter the User’s name with up to

11 alphanumeric characters. Click OK to go to the next two screens which provide choices for user rights

which you wish to assign:

Figure III-31

The first option is “Program” which provides access to test program m anagement. By checking the “View”

box, the user is authorized to run test programs. If the box is not checked, then the user will not be able to

run any test program. Authorization to “Create”, “Edit” and “Delete” test programs is assigned by checking

the corresponding boxes.

The same approach is used for “Measuring Systems and Users”.

Brookfield Engineering Labs., Inc. page 36 Manual No. M14-223

Page 37

Figure III-32

Additional rights are shown on the above screen. Check the box to assign the user rights in each case.

Push the OK button, and the next screen allows you to assign a password with up to 10 alphanumeric

characters:

Figure III-33

This password is necessary for the user to gain access to the assigned features when using the

instrument.

Once users have been set up by the Administrator, turn off the RST Rheometer. The next time the

instrument is turned on, the first screen to appear is User Names. This occurs because the User

Management feature is active. Use the Down Arrow to see the menu of users who have been assigned to

this instrument. Choose the appropriate user name, enter the password and then push OK to go to the

main screen. The name for the current user will appear on the menu bar at the left top of the main screen.

III.6 Edit Program

This allows the user to create a multiple step test for a detailed and comprehensive evaluation of a sample

material. For example, it is possible to perform a controlled stress ramp to determine the yield stress, then

a flow curve to characterize viscosity vs. shear rate, and finally, a creep/recovery test to measure residual

flow and relaxation after the shearing action stops.

There are analysis functions that permit the use of QC limits for viscosity values during the rtest and math

models which show the minimum, maximum and average viscosity values. There is a “Reports” function

that tells how the data is to be stored after the test.

Click the “Edit” button on the main screen. Then click the “Edit Program” button on the next screen:

Brookfield Engineering Labs., Inc. page 37 Manual No. M14-223

Page 38

Figure III-34

PROG1 through PROG6 are displayed on the screen. Use the down arrow to access PROG7 through

PROG11. Each individual PROG is accessed by pressing the radio button and then pressing the OK

button.

Click on the PROG1 button. The following screen appears:

Figure III-35

You can change the program name if you wish using the keyboard to input up to 15 alphanumeric

characters, including symbols, if desired. Push OK to go to the next screen to choose your measuring

system. Use the down arrow to navigate to additional screens with more spindle choices:

Figure III-36

Figure III-37

Brookfield Engineering Labs., Inc. page 38 Manual No. M14-223

Page 39

Figure III-38

The spindles are arranged in the following order:

Cone Spindles

Coaxial Cylinder Spindles

Plate Spindles

Vane Spindles

Press the radio button for the spindle that you wish to use in this program.

To enter a spindle that is not in the list, go to the HOME screen, then go to SETTINGS and choose

BARCODE. Use this function to enter the parameters for the spindle that you will use.

Push OK to go to the next screen which allows you to choose the instrument units:

Figure III-39

There are choices for viscosity and temperature. Units for viscosity include Pascal•seconds,

milliPascal•seconds, Poise and centipoises.

Units for temperature include °C and °F.

Push OK to go to the next screen, “Edit Steps”, where you create a structured test program:

Figure III-40

Use a drag and drop technique to move each program test block that you wish to use. Choices include

Constant and Ramp. Constant allows you to maintain a constant value for the test parameter: torque,

shear stress, speed, shear rate. Ramp allows you to go from an initial value to a final value for the same

test parameters. Place program blocks in sequence to create your test. For example, you can start at a

low rotational speed and ramp to a higher speed, then maintain that speed at a constant value, then ramp

back down to your start speed.

Brookfield Engineering Labs., Inc. page 39 Manual No. M14-223

Page 40

The first block in your program test will normally be a ramp. If it is a torque or shear stress ramp, the

objective could be to determine a yield stress. If it is a speed or shear rate ramp, the objective could be to

establish a flow curve.

An alternative technique for moving the test block into the proram is to click on the test block, then click on

the empty block in the program sequence. The test block will appear in the empty space.

Click on each program block to enter values for the test parameters. The following screens provide the

choices for information that you must enter into the program test block so that you can run the test:

Figure III-41

Figure III-42

Figure III-43

Figure III-44

Brookfield Engineering Labs., Inc. page 40 Manual No. M14-223

Page 41

Figure III-45

While assembling your test blocks in the order needed to run your program, you may choose additional

functions if desired.

III.6.1 Quality Control

Drag the “QC” block to your test program. Double click on the QC block. The screen that appears allows

you to enter the target value for viscosity and the tolerance limits in ±% around the target value. For

example, if you enter 1000 cP and ±10%, the limits would be 900 cP to 1100 cP. Push OK.

The next screen allows you to control an alarm which is sounded by the RST Rheometer whenever the

viscosity is outside the QC limits that you set. The sliding scale allows you to set the amount of time that

the larm will beep for each measuring point that is outside the QC limits. The beep time can range from

0.1 seconds to 5 seconds. Your choice for beep time may depend on the time interval between

measuring points.

III.6.2 Math

Drag the “Math” block to your test program. Double click on the Math block. The screen that appears

allows you to create a summary data report which displays the minimum, maximum and average values

for shear rate, shear stress and viscosity. These values can be displayed for each step in the program

and/or for the overall test program.

III.6.3 Report

Drag the “Report” block to your test program. Double click on the Report block. A screen called “Default

Report Output” shows choices for data output:

• Output Group 1 gives you the choice to send the data to a USB-A memory stock or to a printer.

• Output Group 2 gives you the choice to send the data to a USB-B port or to a local area network,

such as Ethernet, or to an RS-232 serial port.

After selecting your data output, push OK to go to the next screen.

Choose the measuring points that you wish to include in your report by clicking the radio button that

satisfies your data requirement. If you check the “Math Model Result”, the report will include the minimum

viscosity value, the maximum viscosity value and the average viscosity value.

Push OK to go to the next screen:

Brookfield Engineering Labs., Inc. page 41 Manual No. M14-223

Page 42

Figure III-46

This shows how the test data will appear whem coming from the printer. If you wish to re-arange the data

columns, click on the parameter at the top of each column and use the drop down menu to change the

parameter.

Push OK. Enter the “Company Name” on the next screen using up to 25 alphanumeric characters. Push

OK. Check the box if you do not want to be asked for the company name again when running the

program.

Push OK. Use the “Substance” screen to enter the name of the test material. This completes the creation

of your test program. Return to the “Home” screen.

Select the test program that you have created and verify that it executes correctly.

III.7 Explorer

This feature allows you to view and manage test data. Click on the Explorer icon, and go to the next

screen. Folder icons are displayed. The first icon is the SD card.

III.8 Options

In this menu you manage and change settings for your RST Rheometer:

Figure III-47

Note that the menu has a second page:

Figure III-48

Brookfield Engineering Labs., Inc. page 42 Manual No. M14-223

Page 43

III.8.1 Time

Set the current date and the current time here and acknowledge with OK:

Figure III-49

III.8.2 Counter

This screen reports the number of tests that have been run by your RST Rheometer.

III.8.3 Zeroing

Zeroing measures the bearing friction and uses this inform ation to adjust measurements during tests.

Figure III-50

High Range Calibration is zeroing for high speeds (1…1300 rpm) and Low Range Calibration is zeroing

for low speeds (0.01…1 rpm), and very low range calibration is zeroing for 0.01 rpm. If in doubt, run High

Range Calibration for a period of approx. 20 min.

III.8.4 RS232

This screen configures the RS232 port:

Figure III-51

III.8.5 Memory

This screen tells you how much free memory is available in your RST Rheometer. When you open the

“Folder” icon, you can review data files stored in memory.

Brookfield Engineering Labs., Inc. page 43 Manual No. M14-223

Page 44

III.8.6 Export Options

The first icon is the SD card. This is for use by Brookfield service personnel.

If a USB memory stick is connected, the next icon is a folder label that will say, “USBSTICK1”. Double

click on the folder to view the data files that are stored on the memory stick.

The next icon is a folder that is called, “DATA2”, and contains the test data files from the internal memory

of your RST Rheometer. Double click “DATA2” and the data files that have been stored in the RST

Rheometer memory will be listed in reverse chronology – from the most recently completed test to the first

test. The format for each file will look like one of the following:

o Run Single_63 04/28/14 10:28:25 am

o PROG1_32 04/10/14 15:30:05 pm

Select the test that you are interested in by double clicking on the data file and reviewing the measuring

points for that test.

To transfer files from the “DATA2” folder to the USB memory stick, press on the files one time and then on

the data transfter icon in the menu bar at the bottom of the screen. The files are automatically transferred

to the memory stick.

Choices for file format when exporting data include .csv, .bin, and .txt. Numerical data can be delineated

by either a decimal point or comma. Separator designation can either be a tab or a semicolon.

III.8.7 Service

This menu item is relevant only for service work and may be requested by our service technician.

III.8.8 USB Port and RS232 Port

USB Port provides information on use of the port. Host identifides USB m emory stick when connected.

Device identifies the printer when connected.

RS232 povides sleelctions for band, Data Bits, Stop Bit and Parity.

III.8.9 Language

Select your preferred language for the RST Rheometer from this menu:

Figure III-52

Push the down arrow to see additional languages. Activate the language of choice by pressing the

preferred language icon.

Brookfield Engineering Labs., Inc. page 44 Manual No. M14-223

Page 45

III.8.10 Barcode

Barcode identification for your measuring system can be checked using this feature:

Figure III-53

III.8.11 Temperature

This menu item is relevant for service work only and may be requested by our service technician:

Figure III-54

III.8.12 ABOUT

This screen identifies firmware and hardware information for your RS T R heom eter.

III.9 Run Programm 1 to 11

The procedure and functionality of “Run Program 1” is the same as for Programs 2 through 11. Click on

the program icon for the test that you have stored in memory using the “Edit Program” feature. The test

will start up and execute automatically.

While your program is running, you will see the following measured values on the touchscreen:

Figure III-55

Brookfield Engineering Labs., Inc. page 45 Manual No. M14-223

Page 46

Click on the “Table” icon (table of measured data in real time) to see the five most recent measuring

points.

Figure III-56

Click the “Graph” icon (graphic representation of your measured data in real time) to see measured

values for viscosity and temperature vs. time.

Figure III-57

or the Math icon (mathematic evaluation of your measured data).

Brookfield Engineering Labs., Inc. page 46 Manual No. M14-223

Page 47

Caution!

Assembly / disassembly of measuring devices

Caution!

Power ON

IV General Procedures for Operation of Rheometer and Measuring

Systems

Make sure during all measurements that no sample or solvent whatsoever penetrates into the

This is the procedure to be followed for measurements in manual mode:

Measuring:

• Connect the AC adapter.

• Connect a printer, if required.

• Remove any attached spindle.

• Turn the power button ON and wait until the main menu is shown in the Touchscreen.

• Prepare the sample.

• Attach the measuring system.

• For temperature-controlled measurement, wait until the substance to be measured has reached

the desired temperature.

• Start a measuring program.

• After completion of measurement, turn off temperature control, wait until your sample has cooled

down.

• Remove and clean the measuring system.

measuring bob coupling, the measuring drive, the instrument or the electronic unit.

During Power ON process the motor encoder needs some rpm for initialization , therefore no

spindle may be attached!

When making measurements in remote mode under PC control, follow this procedure:

• Connect the AC adapter.

• Connect the cable between RST Rheometer and PC.

• Remove any attached spindle.

• Turn the power button ON and wait until the main menu is shown in the Touchscreen.

• Select the menu item Remote.

• Turn on the PC and all peripheral devices.

• Start the Rheo3000 software.

• Load a measuring program into the Rheo3000 software.

• Prepare the sample.

• Attach the measuring system.

• For temperature-controlled measurement, wait until the substance to be measured has reached

the desired temperature.

• Start the measuring program in the Rheo3000 software.

• After com pletion of the measurement, turn off temperature control and wait until your sample has

cooled down.

• Remove and clean the measuring system.

Brookfield Engineering Labs., Inc. page 47 Manual No. M14-223

Page 48

Danger!

Operation

Caution!

Threaded joint for sample sup

Caution!

Pt100 temperature sensor

IV.1 Measurement Systems for RST-CC and RST-SST

The following types of measuring systems are used with RST-CC and RST-SST:

a) standard coaxial geometry measuring systems for measurement without thermostatic control device

FTK, consisting of

• sample cup for (MB3-40...MB3-8 DIN and MB3-DG)

• sample cup buttom

• measuring bob (CCT-40...CCT-8 and CCT-DG)

• thread guard

b) standard coaxial geometry measuring systems for measurement with temperature control device FTK,

consisting of:

• sample cup (MB3-40F...MB3-8F and MB3-DGF)

• threaded joint for sample cup

• measuring bob (CCT-40...CCT-8 and CCT-DG)

• optional Pt100 temperature sensor in the sample cup bottom or in the temperature control device

c) disposable measuring systems EWS3-CC40...CC8 DIN/FTK for measurement with temperature control

device FTK, consisting of:

• sample cup seat MBA3-CC40...CC8 DIN/FTK

• disposable sample cup (aluminium ) EMB-CC40...CC8 DIN/FTK

• sample cup ejector

• measuring bob CCT-40...CCT-8 DIN or disposable measuring bob CCT-25D DIN

d) cone/plate measuring system for measurement with measuring device ME3-CP/PP consisting of:

• measuring cone (RCT-25-1...RCT-50-2) depending on the measuring system

e) plate/plate measuring system for measurement with measuring device ME3-CP/PP consisting of:

• measuring plate (RPT-25 and RPT-50 ) depending on the measuring system

To carry out measurements, please select a measuring system suited for the desired measuring range

and your rheological requirements.

Give due consideration to the following safety notes w hen carrying out measurements:

Caution when carrying out temperature-controlled tests: Check temperature before removing

Be sure to hold the measuring system with one hand when unscrewing the sample cup. Due to

the measuring system. Danger of injuries!

its weight the measuring system will fall down.

Do not immerse the Pt100 temperature sensor into the medium deeper than 2/3 of the length

Brookfield Engineering Labs., Inc. page 48 Manual No. M14-223

of the metal rod. The cable must remain outside the medium.

Page 49

Caution!

Temperature control

Figure IV-1

IV.1.1 Measurement Directly in the Sample

If necessary, remove the sample cup bottom from the measuring system and attach the thread guard.

Use caution with the Double Gap DG system:

• When using the measuring system MS3-DG, remove the packing ring from between the shell and

the inner part of the sample cup. For that purpose you open the measuring system at the bottom

and take the inner part out. Be careful not to damage or overstretch the packing ring when you

take it out. Place the inner part back inside and and screw down the measuring system.

Slide the coupling sleeve of the measuring bob coupling up (ring visible).

Insert the measuring bob into the coupling with caution. Be careful to insert the shaft of the measuring bob

into the coupling without bumping against it.

Slide the coupling sleeve of the measuring bob coupling down (ring hidden).

Fasten the sample cup to the sample cup flange seat using the threaded joint for the sample cup.

Immerse the sample cup in the substance as far as the ring mark or the conical

swelling, as the case may be, by lowering the stand.

Make sure that no sample or solvent whatsoever penetrates into the measuring

bob coupling, the measuring drive or the electronic unit.

Now the measurement can be carried out.

When the measurement is finished, first open the threaded joint of the sample

cup and remove the sample cup, then open the measuring bob coupling and

remove the measuring bob.

Clean sample cup and measuring bob carefully without using hard objects. Be sure to avoid scratches.

Store the measuring bob on a soft surface or in its original jar.