Page 1

SPECIALISTS IN THE

MEAS UREMENT AND

CONTROL OF VISCOSITY

TEL508-946-6200

or 800-628-8139 (USA excluding MA)

BROOKFIELD ENGINEERING LABORA TORIES, INC.

11 Commerce Boulevard, Middleboro, MA 02346 USA

with offices in

:

Boston • Chicago • London • Stuttgart • Guangzhou

BROOKFIELD KF10 and KF20

Falling Ball Viscometer

Operating Instructions

Manual No. M09-352-B0411

Brookeld Engineering Labs., Inc. Page 1 Manual No. M09-352-B0411

Page 2

Table of Contents

I. INTRODUCTION ..............................................................................................................3

I.1 Components .......................................................................................................................................3

I.2 Specications .....................................................................................................................................4

I.3 Details on Viscosity Measurement Range .........................................................................................5

I.4 Description of the Equipment ............................................................................................................5

I.5 Safety Symbols and Precautions .......................................................................................................9

I.6 Cleaning .............................................................................................................................................9

II. GETTING STARTED ...................................................................................................10

II.1 Choice of Balls ...............................................................................................................................10

II.2 Filling the Sample Tube .................................................................................................................10

II.3 Temperature Control of the Sample ...............................................................................................11

II.4 Measuring the Falling Time ...........................................................................................................12

III.CALCULATIONS ..........................................................................................................13

III.1 Dynamic Viscosity ..........................................................................................................................13

III.2 Kinetmatic Viscosity .......................................................................................................................14

IV. DETERMINATION OF THE NON-NEWTONIAN BEHAVIOR ...........................15

IV.1 Thixotrophy/Rheopexy ...................................................................................................................15

IV.2 Structural Viscosity (Pseudoplasticity and Dilantancy) .................................................................15

Appendix A - Maintenance .....................................................................................................16

A.1 Exchanging the Sample Tube ............................................................................................................16

A.2 Exchanging the Water Bath Jacket .....................................................................................................16

A.3 Exchanging the Ball or the Viscometer .............................................................................................16

Appendix B - Calibration of the Ball Constants ........................................................................17

Appendix C - Warranty Repair and Service ..............................................................................18

Brookeld Engineering Labs., Inc. Page 2 Manual No. M09-352-B0411

Page 3

I. INTRODUCTION

Falling Ball Viscometer, Models KF10 and KF20, comply with the German industry standard

DIN 53015. The measuring principle, according to Höppler, is to determine the falling time of

a ball in a cylindrical glass tube lled with liquid. The working angle of the falling tube in the

KF10 is xed in the DIN 53015 position of 80° relative to horizontal. The water jacket, surrounding the falling tube, when connected to a Brookeld circulating temperature bath provides

for precise temperature control of the sample.

The user calculates the dynamic viscosity of the sample by determining the falling time of the

ball between the upper and lower ring marks displayed on the falling tube. Using data on the

ball constants, the density difference between the liquid sample and the ball, and the working

angle constant, a mathematical equation is used to convert the time measurement to a viscosity

value in centipoise.

Note: The ball constants (forwards and backwards) and ball densities are listed on the test

certicate accompanying the instrument. You must provide the density value for the

liquid that you are testing.

The six (6) balls with different diameters and densities enable the KF10 to measure a wide range

of viscosities. The ability to adjust the angle of inclination of the KF20 extends the measuring

range for low viscosity liquids.

For non-Newtonian liquids, by subjecting the same sample to repetitive measurements with the

KF20 at different angles, pseudoplastic or dilatant behavior may be determined as explained in

Section 7. Time dependent behavior (thixotropy and rheopexy) may also be noted.

The ease of operation and precise temperature control, using a Brookeld circulating temperature

bath, allows for very reproducible measuring results.

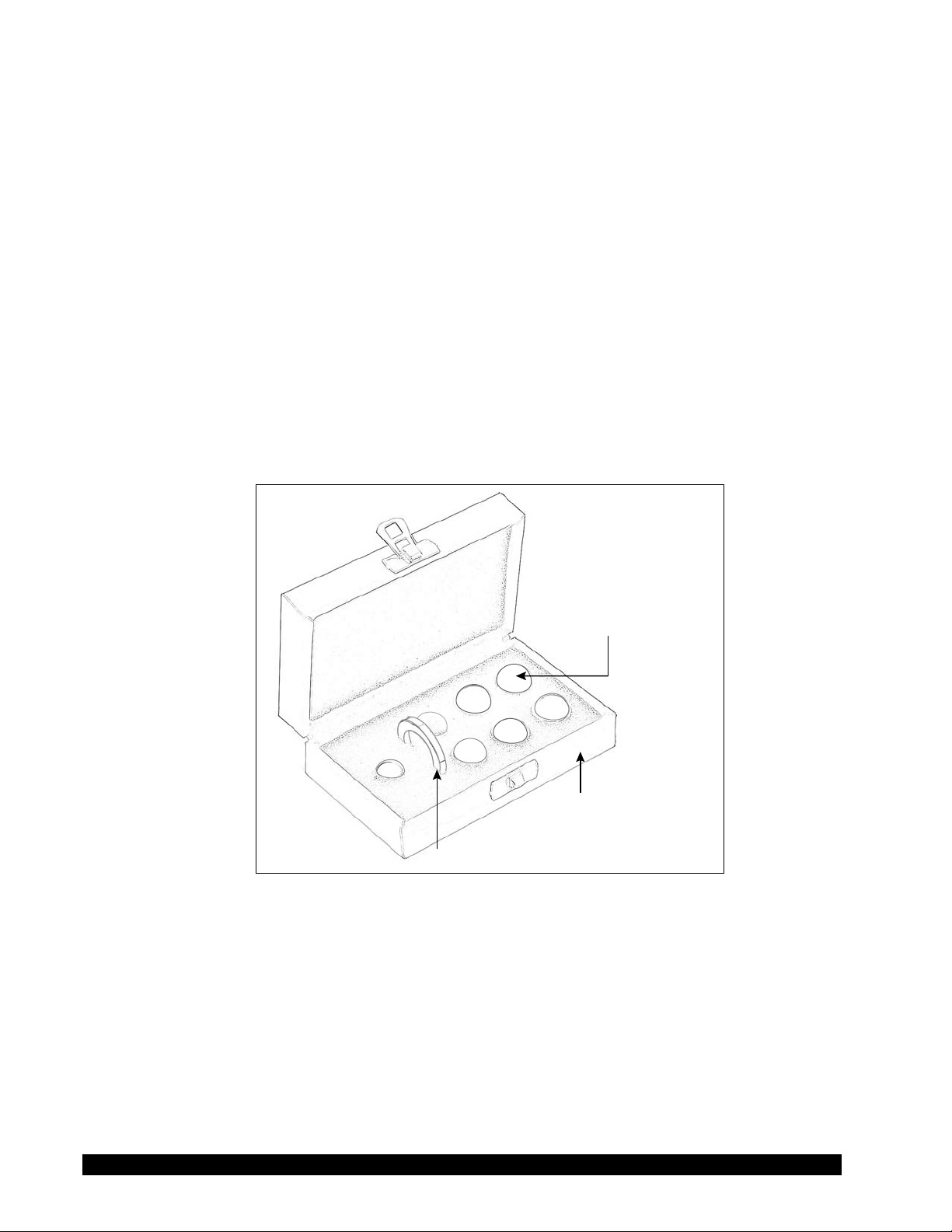

I.1 Components

Component Part No. Quantity

Falling Ball Viscometer: 1

KF10 at xed DIN position of 80° KF10 OR KF20 variable angle with position 80°, 70°, 60° 50° KF20 -

Set of (6) balls with gauge (FB68) in a carrying case (FB22) FB21C 1

Supplied w/certicate stating diameter and mass of each ball

-Ball 1 (glass) FB1 -

-Ball 2 (glass) FB2 -

-Ball 3 (nickel and iron) FB3 -

-Ball 4 (nickel and iron) FB4 -

-Ball 5 (steel) FB5 -

-Ball 6 (steel) FB6 -

Ball Tweezers FB51 1

Brookeld Engineering Labs., Inc. Page 3 Manual No. M09-352-B0411

Page 4

Wire Cleaning Brush for Sample Tube FB53 1

Brush to clean loose debris from Falling Balls FB52 1

Leather cloth for polishing Falling Balls FB70 1

Sealant ring (perbunane) A 16x20 FB31 4

Sealant ring (silicone) 10x14x2 FB32 1

Thermometer, 0°C to +100°C* TM1 1

Operator Manual M09-352 1

Instrument Case FB71 1

Latex rubber tubing, 5/16 I.D. x 1/16 wall FB69 1

Certicate of Calibration ____ 1

*Other temperature measurement options are available. Contact your Brookeld dealer for

information.

I.2 Specifications

Viscosity Range: 0.5 - 7x104 mPa•s (cP)

Falling Time-Lower Limit: 60 s for Ball No.1

30 s for Ball Nos. 2,3,4,5 and 6

Falling Time-Upper limit: 300 s

Materials with viscosity >7x104 mPa•s require running

times of over 300 s.

Measuring Distance: 100 mm (50 mm between adjacent ring marks) in both

directions

Fall Tube Inner Diameter: 15.94mm +/- 0.01mm

Set of Balls: 6 balls

Working Angle: KF10: 80° (DIN position)

KF20: 80°, 70°, 60°, 50°

Temperature Range: -60°C - +150°C

Sample Volume: 40 mL

Dimensions: 180 mm x 220 mm x 330 mm

Weight: 6.4 lbs, 2.9 kg

(empty sample tube and empty water jacket)

Brookeld Engineering Labs., Inc. Page 4 Manual No. M09-352-B0411

Page 5

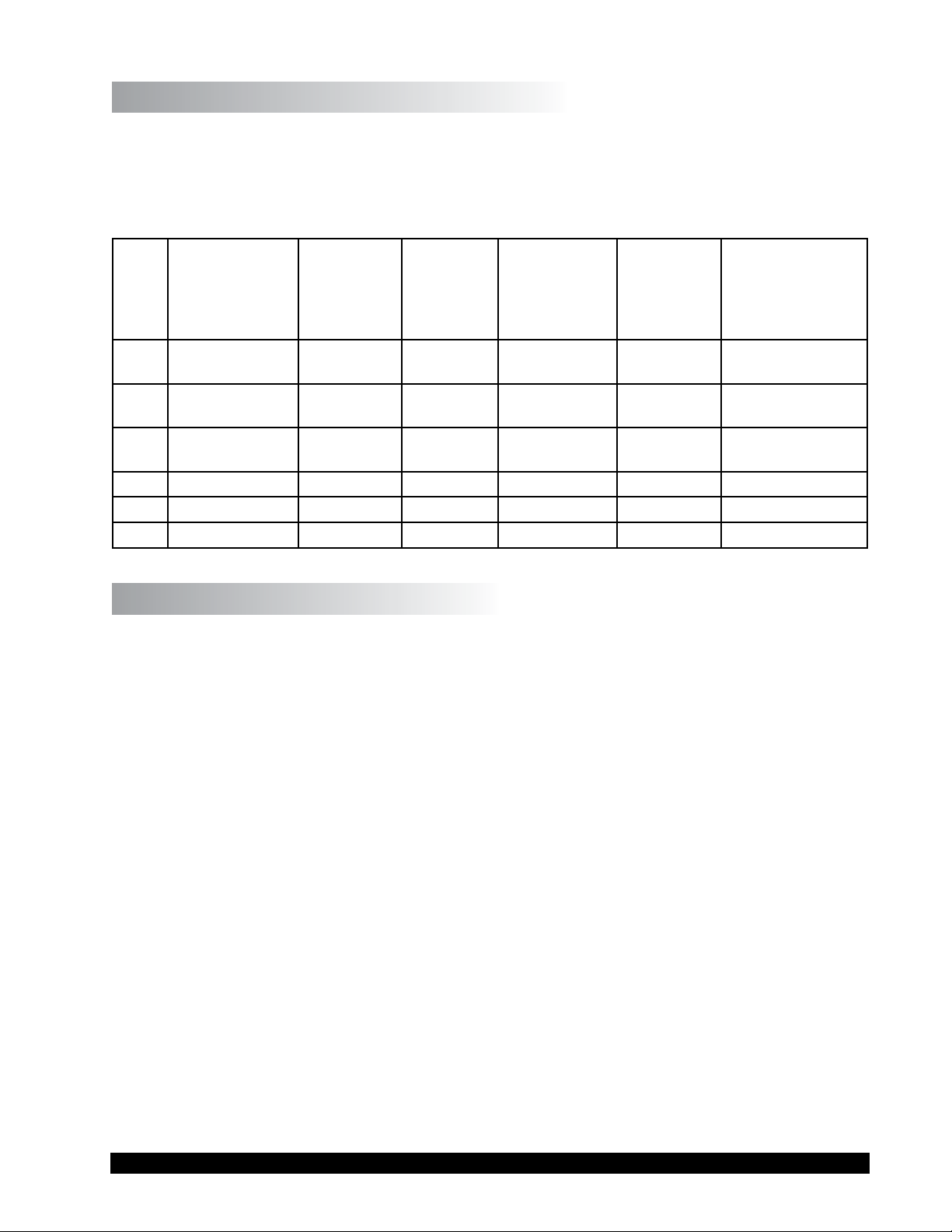

I.3 Details on Viscosity Measurement Range

Per DIN 53015, the Falling Ball method is suitable for measuring dynamic viscosities ranging

from 0.6 mPa•s to 250,000 mPa•s at temperatures from -60ºC to 150ºC. Use is made of six

balls having different diameters, each ball covering part of the range. All guideline values and

referenced parameters in the following table are per DIN 53015.

Viscosity

Ball

No.

measurement

range (guideline value)

(mPa•s)

Material

(Recommendation)

1 0.5 to 10 Borosilicate

Density

(guideline

value)

3)

(g/cm

Ball diameter

(mm)

Deviation

from

circularity

(mm)

2.4 15.81 ± .01 ± 0.0005 0.007

Calibration

constant

(guideline value)

(mPa•s•cm3/g•s)

glass

2 9 to 140 Borosilicate

2.4 15.6 ± 0.05 ± 0.0005 0.09

glass

3 40 to 700 Ni/iron 8.1 15.6 ± 0.05 ± 0.001 0.09

4 150 to 5,000 Ni/iron 8.1 15.2 ± 0.1 ± 0.001 0.7

5 1,500 to 50,000 Ni/iron 8.1 14.0 ± 0.5 ± 0.001 7

6 Above 7,500 Ni/iron 8.1 11.0 ± 1 ± 0.002 35

I.4 Description of the Equipment

Refer to Figures 1 through 4. Specic items identied on the Falling Ball Viscometer are identied by

parentheses ( ) in the following steps:

1. The Falling Ball Viscometer

must be level. The level is adjusted using the two Leveling

Screws (4) on the base. Adjust so that the bubble level on top of the Falling Ball Viscometer

is centered within the circle. Check level periodically during use.

2. a. The working angles of the KF20 are 80°, 70°, 60° and 50° relative to horizontal. The

DIN 53015 working position of 80° is the preferred position. The different working

angles are secured by a locking adjustment screw (5). To select a working angle, the

adjustment screw (5) should be loosened by turning it counter-clockwise approximately

one rotation. After the working angle is selected, the adjustment screw should then be

tightened again.

b. The working angle of the KF10 Viscometer is xed at the DIN 53015 position of 80°

relative to horizontal.

3. The two running directions of the balls can be chosen by swivelling the viscometer, which

is mounted in the stand, and is secured by a locking mechanism (14).

4. The sample tube (6) is surrounded by a water jacket which is xed between the upper plate

(7) and lower plate (8). The upper locking plug (16) with lid (20), the lower locking plug

(17) and accompanying seals (gaskets and washers) (19), and the caps (18) are designed to

perform the following functions within the sample tube:

a. keep the liquid sample tightly sealed

Brookeld Engineering Labs., Inc. Page 5 Manual No. M09-352-B0411

Page 6

b. eliminate the formation of air bubbles

Ball Gauge (p/n FB68)

Balls (set of 6)

(p/n FB1-FB6)

Case (p/n FB22)

c. avoid a build up of pressure (see Fig. 3 and 4)

5. Mounted on the lower plate are tubes (10) to which the circulating temperature bath tubing

is attached.

NOTE: Any alteration, modication or replacement of the sample tube, water jacket,

falling tube screw ttings, tension rods or balls renders the ball constants invalid

and requires the re-calibration of the viscometer. See Appendix B.

6. The thermometer fastening screw (11) and sealing washer (13) with inserted thermometer

is screwed into the screw neck (12) in the upper plate. The thermometer fastening screw

should be tightened securely to prevent uid leakage.

7. The primary function of the ball gauge is to distinguish the two glass balls (Ball No. 1 and

Ball No. 2) from each other. Ball No. 1 will not pass through the ball gauge, whereas Ball

No. 2 will pass through. The ball gauge may also be used to help identify Ball No. 2 through

4.

Figure 1

NOTES:

Ball diameters, weights, densities and ball constants (forwards and backwards) are

listed in the test certicate accompanying the viscometer.

Brookeld Engineering Labs., Inc. Page 6 Manual No. M09-352-B0411

Page 7

50°

60°

70°

DIN

1

3

5

7

4

6

9

2

14

10

15

22

8

11

12

13

Figure 2: Falling Ball Viscometer KF10

1. Stand

2. Viscometer 13. Sealing washer

3. Bubble level 14. Bearing for viscometer rotation

4. Leveling screw 15. Nuts

5. Adjustment screw for angle (KF20 only) 16. Upper locking plug

6. Sample tube 17. Lower locking plug

7. Upper plate 18. Cap

8. Lower plate 19. Seal

9. Water jacket 20. Lid

10. Tubes for connection to water bath 21. Falling tube screw tting

11. Fastening screw for thermometer

12. Screw neck

22. Stop to hold viscometer in position

Brookeld Engineering Labs., Inc. Page 7 Manual No. M09-352-B0411

Page 8

Figure 3: Sample tube screw tting (top)

Figure 4: Sample tube screw tting (bottom)

Brookeld Engineering Labs., Inc. Page 8 Manual No. M09-352-B0411

Page 9

I.5 Safety Symbols and Precautions

Safety Symbols

The following explains safety symbols which may be found in this operating manual.

Refer to the manual for specic warning or caution information to avoid personal injury

or damage to the instrument.

Precautions

If this instrument is used in a manner not specied by the manufacturer, the protection

provided by the instrument may be impaired.

This instrument is not intended for use in a potentially hazardous environment.

The user should ensure that the substances placed under test do not release poisonous,

toxic or ammable gases at the temperatures to which they are subjected to during the

testing.

I.6 Cleaning

Great care should be given to cleaning of the sample tube, the locking plugs and the balls. These

components (material: glass, Ni-iron, steel, perbunan, silicone, chromium-plated surfaces) must

not be damaged or subject to chemical action by the cleaning uid.

The cleaning procedure is to be carried out in the following sequence:

• The viscometer is pulled out of the bearing guide (14) in the stand by turning it 90° and

placed in a suitable collecting basin.

• Unscrew the caps and remove the locking plugs in such a way that the ball does not fall into

the collecting basin (possibly damaging the ball). The ball collector (Part No. FB23) is an

optional item that can be purchased on request.

• Clean the sample tube using a suitable cleaning agent for the material being measured with

the cleaning brush (Part No. FB53).

• There must not be any residue remaining in the sample tube or on the balls after they have

been cleaned and are dry. Wipe with a Kim wipe or cloth that will not leave bers, if necessary.

• When cleaning, be careful that the cleaning agent does not come into contact with the equip

ment outside of the measuring tube (potential for varnish damage).

-

II

. GETTING STARTED

Brookeld Engineering Labs., Inc. Page 9 Manual No. M09-352-B0411

Page 10

II. GETTING STARTED

II.1 Choice of Balls

The balls are chosen in such a way that the minimum falling time is not less than what is shown

in the table and the maximum falling time is not greater than 300 s. The DIN 53015 indicates

that a falling time greater than 300 s is allowed, but for practical reasons, a shorter test time

makes more sense.

Ball

No.

Diameter

[mm]

1 15.81 60 0.5 10

2 15.60 30 2.5 130

3 15.60 30 20 700

4 15.20 30 200 7800

5 14.00 30 1000 45000

6 11.00 30 5500 70000

The specications for the ball constant and the ball density are taken from the test certicate

which came with the equipment.

The exchange of balls or equipment components between different viscometers is not permitted. Otherwise, the ball constants lose their validity.

When the falling time for the ball is less than the minimum time, turbulence may occur.

II.2 Filling the Sample Tube

Minimum falling

time [s]

Lower measuring range limit

[mPa•s]

Upper

measuring range

limit [mPa•s]

To ll the sample tube:

• The sample tube is locked on the lower plate with the lower locking plug, seal, and cap.

• The liquid is lled up to approximately 25 mm beneath the top of the sample tube without

air bubbles. Use a glass lter to remove any impurities when introducing a liquid into the

tube.

• The ball is polished with the leather cloth and bres are removed with the small cleaning

brush, before being inserted into the tube with the ball tweezers. The ball must not be touched

after polishing. The ball will travel to the bottom of the tube. Possible air bubbles in the

sample, or trapped below the ball, are removed with a suitable rod, by rotating the ball.

• Insert the upper locking plug with seal into the sample tube. In so doing, the sample must

enter the inside of the upper locking plug through the opening. The upper locking plug must

not be lled more than half way with the sample in order to minimize pressure build-up due

Brookeld Engineering Labs., Inc. Page 10 Manual No. M09-352-B0411

Page 11

to the air bubbles. Due to the design of the upper locking plug, air bubbles cannot get into

the sample tube.

• The sample must be free of air bubbles between the two locking plugs. The lid of the up-

per locking plug is attached and the temperature control (desired test temperature) must be

achieved. After proper temperature control is achieved, the upper cap is screwed on.

Do not heat the sample with the upper lid attached as pressure may build in the tube.

NOTE: Gas bubbles can be removed by warming up the sample for a short time (approxi-

mately 20 degrees above the measuring temperature with the upper locking plug

removed) or by lightly tapping on the lid of the upper locking plug.

II.3 Temperature Control of the Sample

The following are suggested working uids for the circulating temperature bath:

Temperature

Range

-60 to +20°C Water (deionized) - glycol-mixture; mixed

in accordance with the manufacturer’s

instructions for the temperature range

+1°C to +90°C Distilled water Perbunan tube

+90°C to +150°C Transparent thermostatic oil Insulated Vitons tube, se-

Bath Working Fluids Tubing

Insulated Perbunan tubing,

secured with tube band clips

cured with tube band clips

The tubing from the circulating bath should be pushed tightly onto the viscometer tubes. By

pulling gently, check whether the tubing is rmly attached. Tubing and circulating bath are

available on request from your Brookeld dealer. If the water bath jacket has condensation on

the glass, rub with alcohol.

The sample tube is sealed with the upper cap after temperature set point has been achieved.

Allow 30 minutes for thermal equilibrium.

Falling ball viscometers provide precise temperature control for the sample. By measuring

your sample at multiple temperatures, you can determine the temperature viscosity curve.

Brookeld Engineering Labs., Inc. Page 11 Manual No. M09-352-B0411

Page 12

II.4 Measuring the Falling Time

Before beginning the measurement, the upper cap is loosened (unscrewed) again to let off possible pressure.

The time which the balls take to run between the top and bottom ring marks in the sample tube

is determined with a stop watch (resolution 0.01 s).

It is recommended that you record the passage of the lower ball point using the ring marks as

follows. Position your eyes at the same height as the ring marks so that these appear as a line.

A dark paper, placed behind the viscometer with its edge at the same height as the ring mark,

shows the ball periphery more distinctly.

With dark liquids, you can better observe the ball in the sample tube by looking from behind

the instrument.

Possible variations in the measuring times may be due to impurities in the sample, air bubbles or

the fact that it has not been brought to the right temperature (insufcient temperature control).

Even 0.1°C change in temperature is clearly measurable. The rst forward and return passage

of the ball can be used to achieve a thorough mixing (temperature equalization) of the sample

before running the viscosity test.

BALL

BALL BEGINS

DESCENT

START STOPWATCH WHEN

BOTTOM OF

BALL CROSSES

OVER THE

RING MARK

BALL IN

TRANSIT

AT

MIDPOINT

BALL

FINISHES

DESCENT

RING MARK

STOP STOPWATCH WHEN

BOTTOM OF

BALL CROSSES

OVER RING

MARK

Brookeld Engineering Labs., Inc. Page 12 Manual No. M09-352-B0411

Page 13

III. CALCULATIONS

III.1 Dynamic Viscosity

With Newtonian liquids absolute values of the dynamic viscosity are calculated, where as,

for non-Newtonian liquids, relative values of the dynamic viscosity (apparent viscosity) are

calculated.

The dynamic viscosity is calculated according to the following equation:

Equation 1:

η = t(ρ

where: η dynamic viscosity [mPa•s]

t travelling time of the ball [s]

ρ1 density of the ball according to the test certicate [g/cm3]

ρ2 density of the sample [g/cm3]

K ball constant according to test certicate [mPa·cm

F working angle constant

- ρ

1

)K•F

2

3

/g]

Angle of inclination a

(applied to the level)

80° (DIN) 1.0

70° 0.952

60° 0.879

50° 0.778

Working angle constant F

The density and ball constant are each stated in the test certicate.

Consideration for buoyancy of the ball in the sample is accounted for by means of (ρ1-ρ2) in

equation (1).

The density of the sample can be determined by:

• referring to the material specications from the manufacturer of the uid

• measuring with a densitometer

Note: Be sure to measure the sample density at the same temperature at which the viscosity

will be measured.

The density of the sample must be determined exactly when the amount (ρ1-ρ2) becomes small.

The use of the glass ball requires the determination of the density of the sample ρ2 to the 3rd

decimal position in g/cm3. For metal balls, the 2nd decimal position is sufcient. For glass

balls, the density of the measuring substance is determined to 0.001 g/cm3, for metal balls to

0.01 g/cm3.

Brookeld Engineering Labs., Inc. Page 13 Manual No. M09-352-B0411

Page 14

III.2 Kinetmatic Viscosity

The conversion of the dynamic viscosity into the kinematic viscosity is accomplished using the

following equation:

Equation 2:

η

ν =

ρ

2

ν Kinematic viscosity [mm2/s]

η Dynamic viscosity [mPa•s]

ρ2 Density of the sample [g/cm3]

Brookeld Engineering Labs., Inc. Page 14 Manual No. M09-352-B0411

Page 15

IV. DETERMINATION OF THE NON-NEWTONIAN BEHAVIOR

Non-Newtonian behavior can be determined when different measurement times are recorded

with repeated tests.

IV.1 Thixotrophy/Rheopexy

Thixotropy (rheopexy) is indicated if the travelling times for a ball decreases (increases) when

repeated measurements are made on the same volume of sample.

NOTE: If temperature control is not done correctly, thixotropy or rheopexy can be inferred

by mistake.

Rotational or Capillary Viscometers should be used for better determination of ow behavior.

IV.2 Structural Viscosity (Pseudoplasticity and Dilatancy)

Using the KF20 Falling Ball Viscometer at different angles may serve to determine pseudoplastic or dilatant behavior for non-Newtonian liquids. If the sample is non-Newtonian, the

travel time of the ball multiplied by the sine of the working angle for the KF20 will not remain

constant. This infers non-Newtonian ow behavior. For pseudoplasticity, the calculated value

decreases; for dilatancy, it increases.

NOTE: If temperature control is not done correctly, pseudoplasticity or dilatancy can be

inferred by mistake.

Details about the relative values for pseudoplasticity and dilatancy are related to the diameter

of the ball and the working angle.

More sophisticated equipment, like rotational viscometers/rheometers, should be used for detailed examination of non-Newtonian materials.

Brookeld Engineering Labs., Inc. Page 15 Manual No. M09-352-B0411

Page 16

Appendix A - Maintenance

A.1 Exchanging the Sample Tube

1. Loosen the two setscrews of the sample tube screw ttings (above and below).

a. Empty the water jacket and sample tube. Make sure the water jacket is clean on

2. Unscrew both of the sample tube screw ttings using a ring nut key.

3. Pull off the rubber seal (washer) on one end of the sample tube.

4. Pull the sample tube out at the other end.

5. Insert the new sample tube and also wet the sample tube gaskets and washers.

6. Assemble the sample tube in the reverse order. Observe that the ends of the sample tube

7. Re-calibrate all the ball constants according to Appendix B.

Caution Glass Components. Excessive force may result in broken glass.

the inside surface before reassembling.

project evenly from the upper and lower plates.

A.2 Exchanging the Water Bath Jacket

1. Remove the sample tube.

a. Empty the water jacket and sample tube. Make sure the water jacket is clean on

2. Unscrew the upper and lower plates on the connecting bar.

3. Unscrew the three lower nuts on the viscometer.

4. Replace rubber washers and insert the new water bath jacket.

5. Put on the upper plate and screw down the nuts evenly.

6. Fix the lower plate an the lower connecting bar.

7. Assemble the sample tube.

8. Calibrate all the ball constants according to Appendix B.

Caution Glass Components. Excessive force may result in broken glass.

the inside surface before reassembling.

A.3 Exchanging the Ball or the Viscometer

1. Exchange the balls or viscometer.

2. Re-calibrate the ball constants according to Appendix B.

Brookeld Engineering Labs., Inc. Page 16 Manual No. M09-352-B0411

Page 17

Appendix B - Calibration of the Ball Constants

Re-calibration of the ball constants is required if:

1. changes in the sample tube or water jacket were made

2. one or more balls were replaced

The calibration requires the use of a Newtonian viscosity standard.

Choice of the viscosity standard is according to the ball; the standards are provided in 100 mL

bottles and can be obtained from your Brookeld dealer.

BALL NO. 1 2 3 4 5

N44 Viscosity Fluid

(Nominal Value of 92cP @

20ºC) [mPa•s}

The calibration is made according to the method in DIN 53015 at 20°C ± .05 C. A suitably

calibrated thermometer can be obtained from your Brookeld dealer, on request.

The ball constants are determined from (5) running times, in both forward and reverse direction.

4 20 250 1000 3000

The ball constant is calculated according to the following equation:

Equation 3:

K =

η

(ρ1-ρ2)

• t

t Mean value from 5 running times [s]

η Dynamic viscosity of the calibrating uid [mPa•s] at 20°C ± .05 C

ρ1 Density of ball [g/cm3]

ρ2 Density of calibrating uid [g/cm3]

Note: Be sure to measure the sample density at the same temperature at which the viscosity

will be measured.

The expected value of the constant should be similar to the constant stated in the test certicate.

For Ball No. 6, the ball constant changes signicantly as a function of the falling tube diameter and diameter of the ball, so that the ball constant is calculated according to the following

equation:

Equation 4:

K6 = 1.4057(D-d6)

(0.75042+1.82637 )

d

D

6

D Falling tube diameter (see calibration certicate)

d6 Diameter of Ball No. 6 (see calibration certicate)

K6 Ball constant of Ball No. 6

Brookeld Engineering Labs., Inc. Page 17 Manual No. M09-352-B0411

Page 18

Appendix C - Warranty Repair and Service

Brookeld Viscometers are guaranteed for one year from date of purchase against defects in materials

and workmanship. They are certied using primary viscosity standards traceable to the National Institute

of Standards and Technology (NIST). The Viscometer must be returned to Brookeld Engineering

Laboratories, Inc. or the Brookeld dealer from whom it was purchased for no charge warranty ser-

vice. Transportation is at the purchaser’s expense. The Viscometer should be shipped in its carrying

case together with all spindles and the guardleg if originally provided with the instrument.

For repair or service in the United States call Brookeld to obtain a Return Authorization Number.

Record this number on the Repair Return Form which you can download from the Brookeld website.

A tear cut copy is at the end of the manual. Return your instrument to:

Brookeld Engineering Laboratories, Inc.

11 Commerce Boulevard

Middleboro, MA 02346 U.S.A.

Telephone: (508) 946-6200 FAX: (508) 923-5009

www.brookeldengineering.com

For repair or service outside the United States consult Brookeld Engineering Laboratories, Inc. or

the dealer from whom you purchased the instrument.

For repair or service in the United Kingdom return to:

Brookeld Viscometers Limited

1 Whitehall Estate

Flex Meadow, Pinnacles West

Harlow, Essex CM19 5TJ, United Kingdom

Telephone: (44) 27/945 1774 FAX: (44) 27/945 1775

www.brookeld.co.uk

For repair or service in Germany return to:

RheoTec Messtechnik GmbH

(A Division of Brookeld)

Schutterwaelder Strasse 23

D-01458 Ottendorf-Okrilla, Germany

Telephone: (49) (035205) 5967-0 FAX: (49) FAX: 49 (035205) 5967-30

www.rheotec.de

For repair or service in China return to:

Guangzhou Brookeld Viscometers and Texture Instruments Service Company Ltd.

Room C1, 5/F, Tianxing Building East Tower, No. 21, Zhongshan Yi Road, Yuexiu District

Guangzhou, 510600, P. R. China

Telephone: (86) 20/3760-0548 FAX: (86) 20/3760-0548

www.brookeld.com.cn

On-site service at your facility is also available from Brookeld. Please contact our Service

Department in the United States, United Kingdom, Germany or China for details.

Brookeld Engineering Labs., Inc. Page 18 Manual No. M09-352-B0411

Loading...

Loading...